Latest Accepted Articles

, Available online

Abstract:

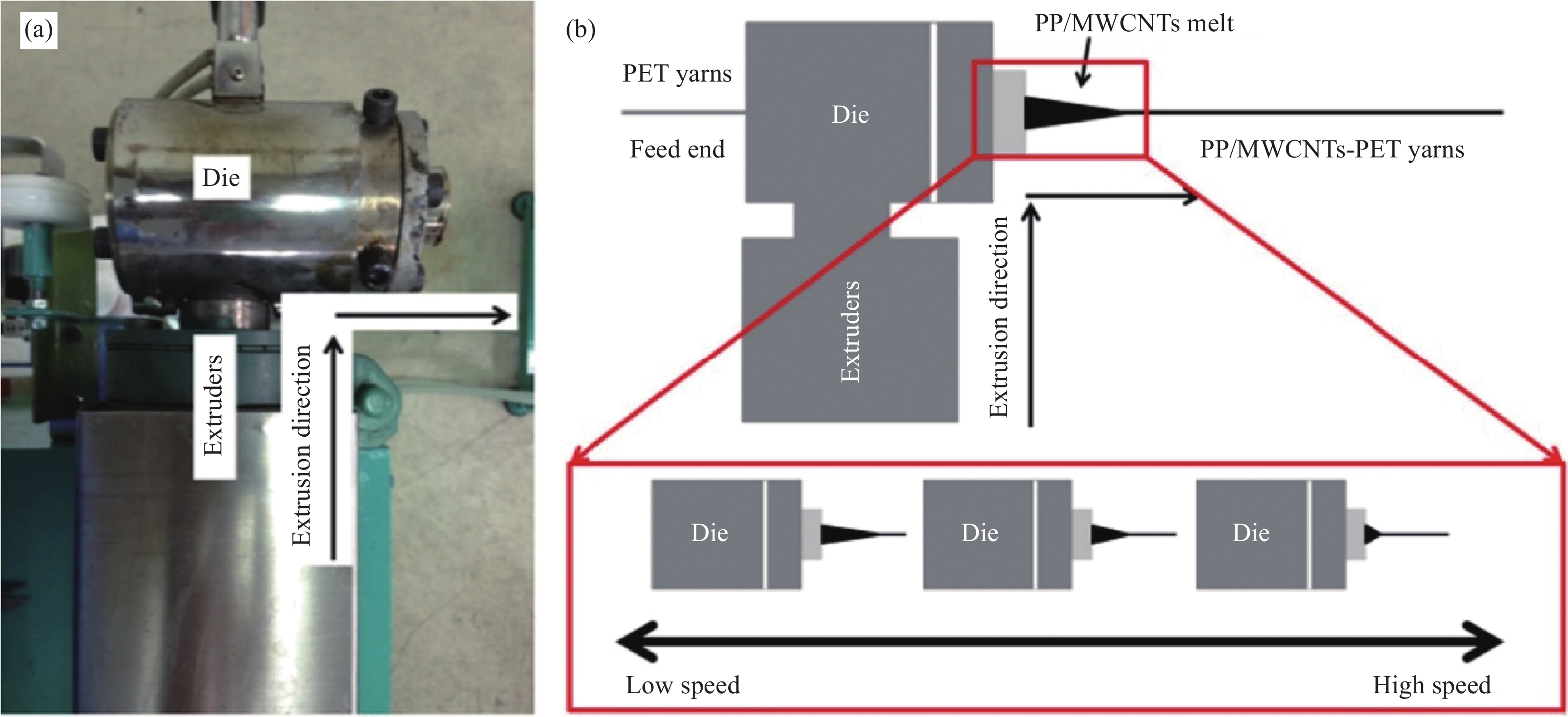

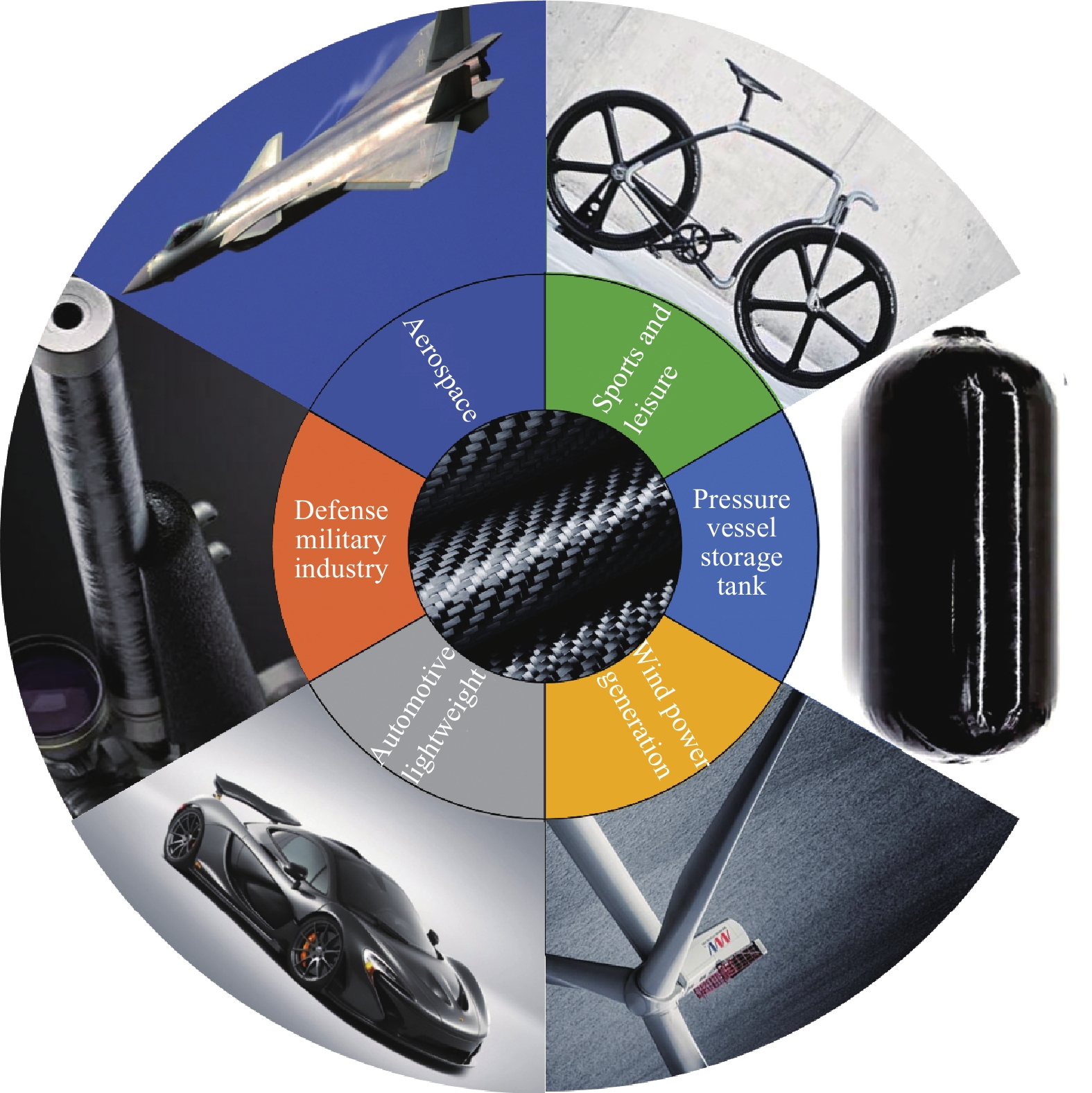

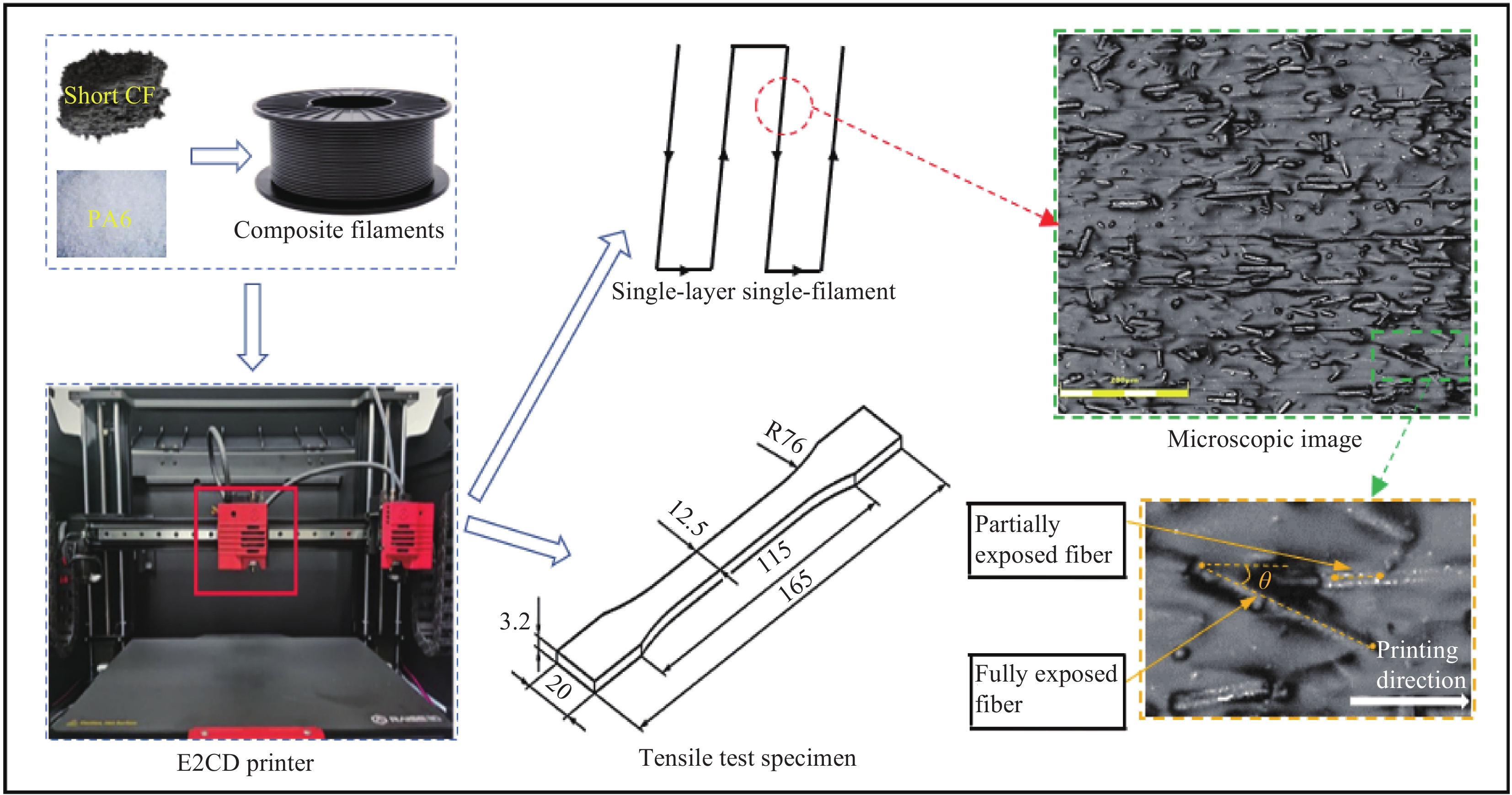

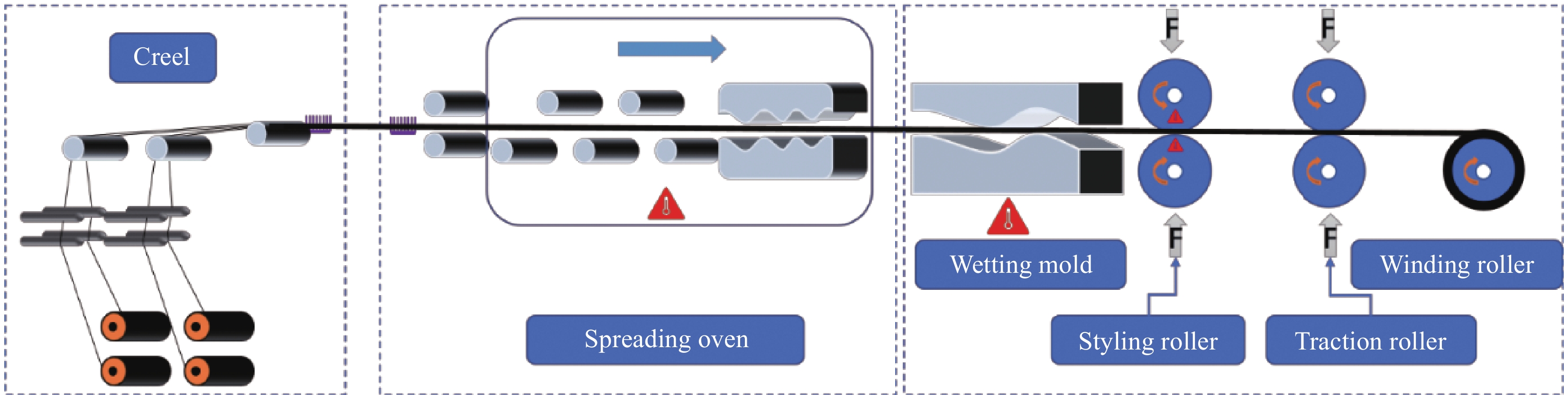

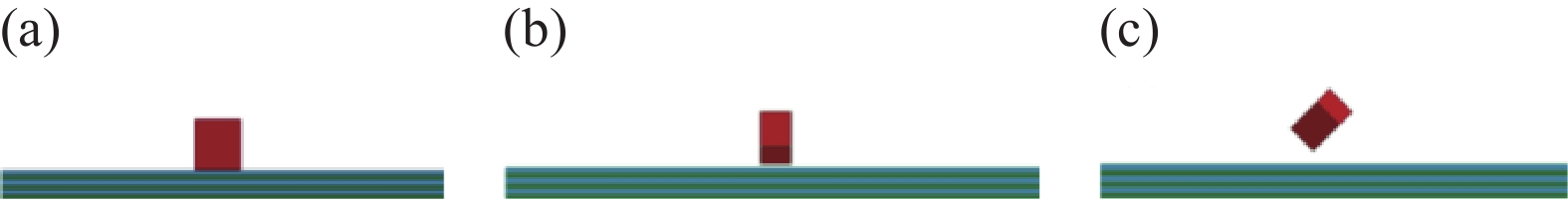

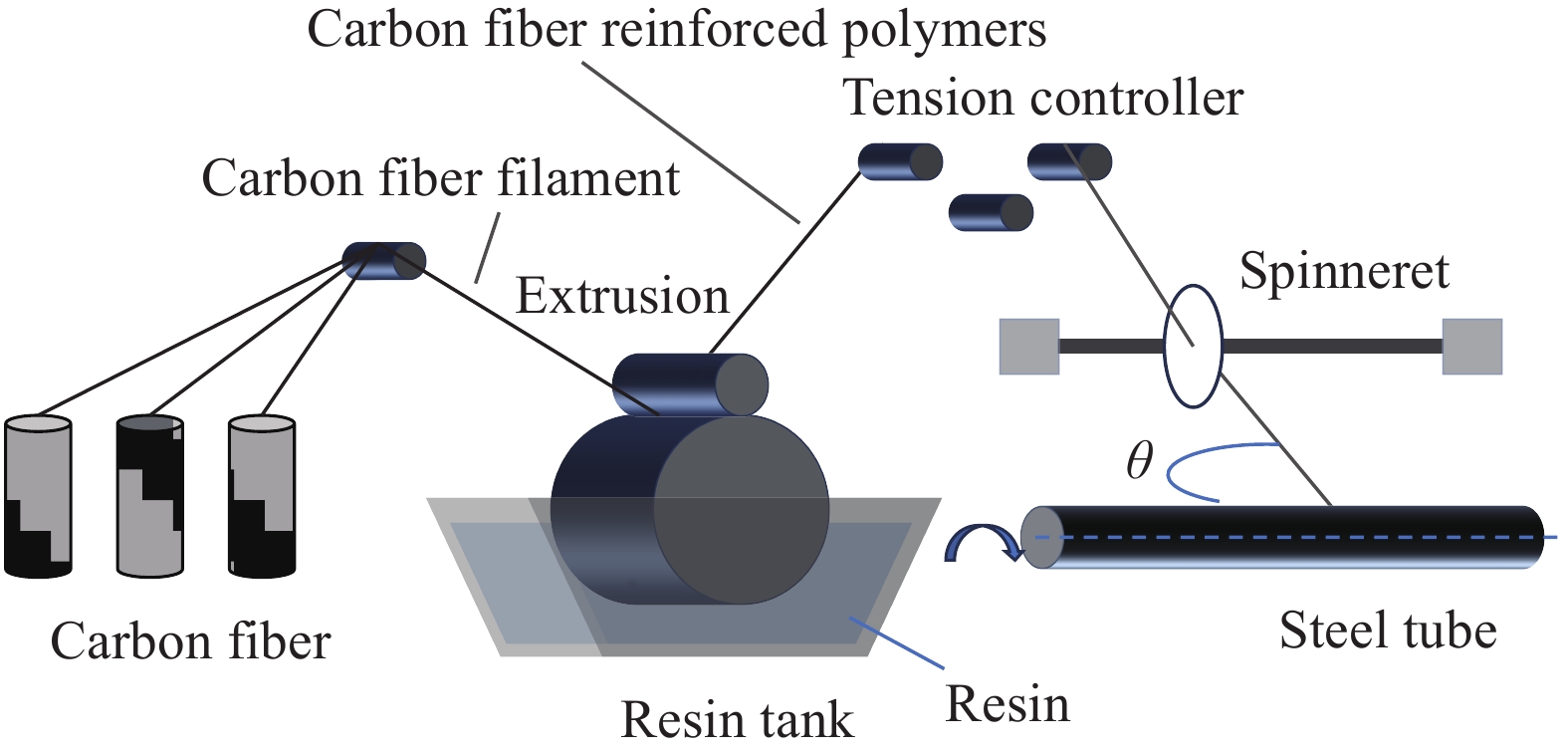

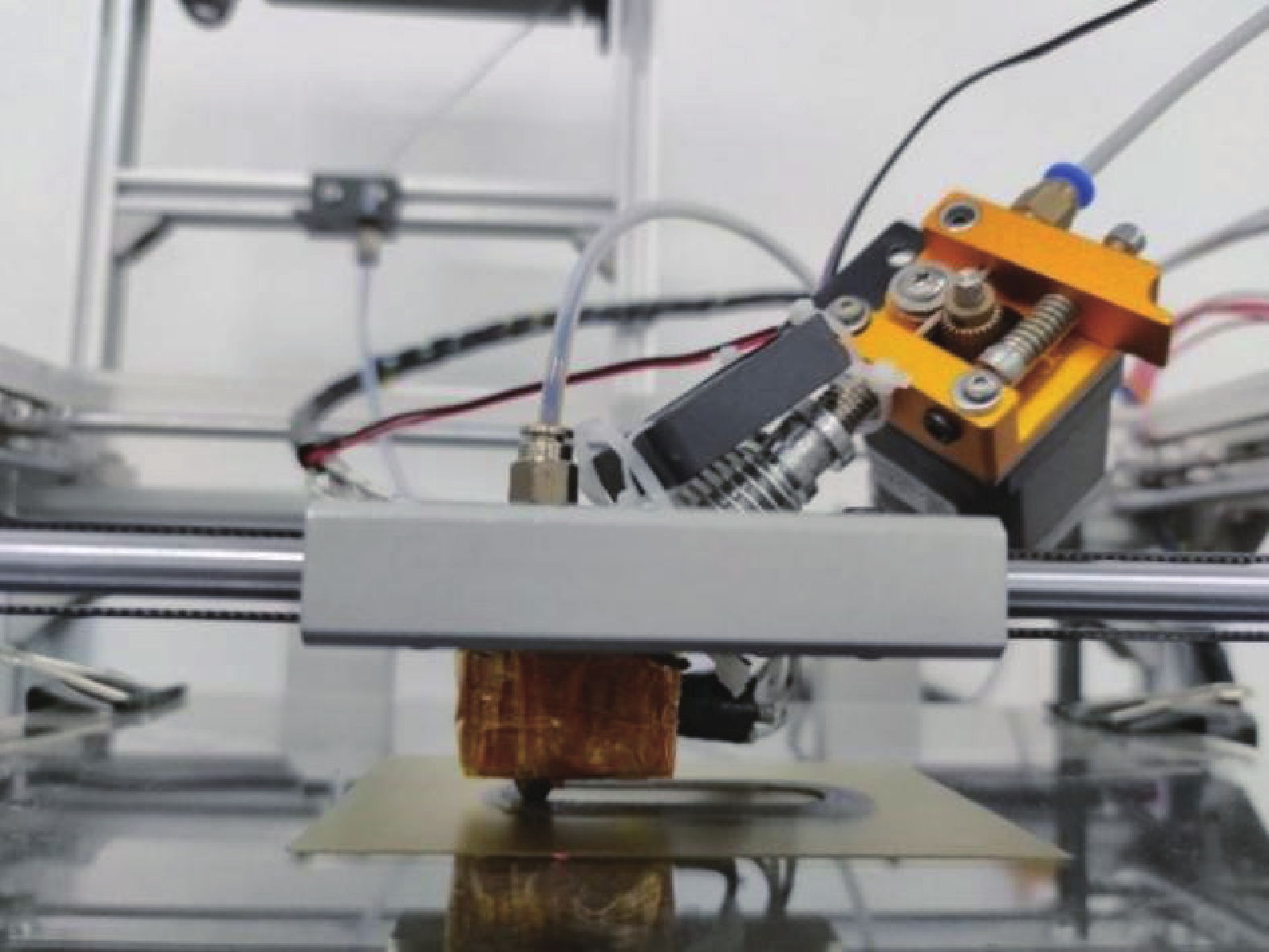

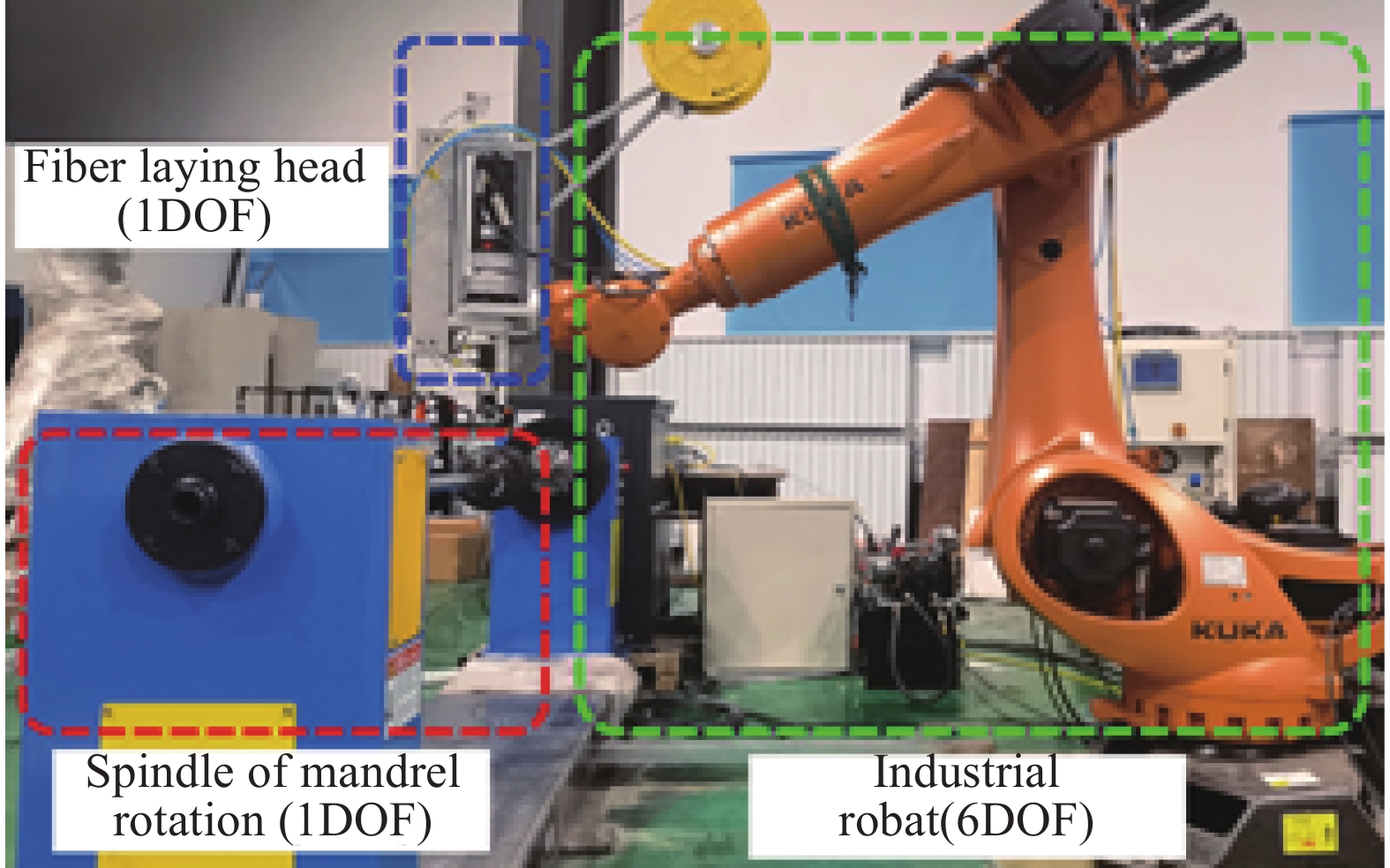

Continuous fiber-reinforced thermoplastic composites offer exceptional mechanical and chemical properties, attracting widespread attention in both academia and industry. To meet the automation requirements for high-performance complex structural components, additive manufacturing technologies for continuous fiber-reinforced thermoplastic composites have garnered significant interest. These manufacturing methods include Fused Deposition Modeling (FDM) and Automated Fiber Placement (AFP). The additive manufacturing process involves multi-scale physical phenomena, presenting a complex interplay that is not yet fully understood. The inherent properties of thermoplastic polymers, such as their high melting points and viscosities, further complicate processing, posing substantial challenges in the control of manufacturing processes. Addressing the intricate mechanical challenges within the manufacturing process can be facilitated through the application of multi-scale process mechanics simulations. The integration of these simulations with theoretical and empirical research aids in forging a clear correlation between manufacturing process parameters and the quality of the final product. This provides theoretical support for optimizing process parameters and equipment module design. However, the implementation of multi-scale process simulation requires in-depth comprehension and precise description of physical phenomena. It also involves the design of sophisticated algorithms and the construction of intricate models, thereby increasing the difficulty and challenge of the simulation. This paper reviews recent studies employing various numerical modeling approaches to investigate the processing mechanisms of continuous fiber reinforced thermoplastic composites during the AFP and FDM processes. It also outlines potential promising directions in the field.

Continuous fiber-reinforced thermoplastic composites offer exceptional mechanical and chemical properties, attracting widespread attention in both academia and industry. To meet the automation requirements for high-performance complex structural components, additive manufacturing technologies for continuous fiber-reinforced thermoplastic composites have garnered significant interest. These manufacturing methods include Fused Deposition Modeling (FDM) and Automated Fiber Placement (AFP). The additive manufacturing process involves multi-scale physical phenomena, presenting a complex interplay that is not yet fully understood. The inherent properties of thermoplastic polymers, such as their high melting points and viscosities, further complicate processing, posing substantial challenges in the control of manufacturing processes. Addressing the intricate mechanical challenges within the manufacturing process can be facilitated through the application of multi-scale process mechanics simulations. The integration of these simulations with theoretical and empirical research aids in forging a clear correlation between manufacturing process parameters and the quality of the final product. This provides theoretical support for optimizing process parameters and equipment module design. However, the implementation of multi-scale process simulation requires in-depth comprehension and precise description of physical phenomena. It also involves the design of sophisticated algorithms and the construction of intricate models, thereby increasing the difficulty and challenge of the simulation. This paper reviews recent studies employing various numerical modeling approaches to investigate the processing mechanisms of continuous fiber reinforced thermoplastic composites during the AFP and FDM processes. It also outlines potential promising directions in the field.

, Available online

Abstract:

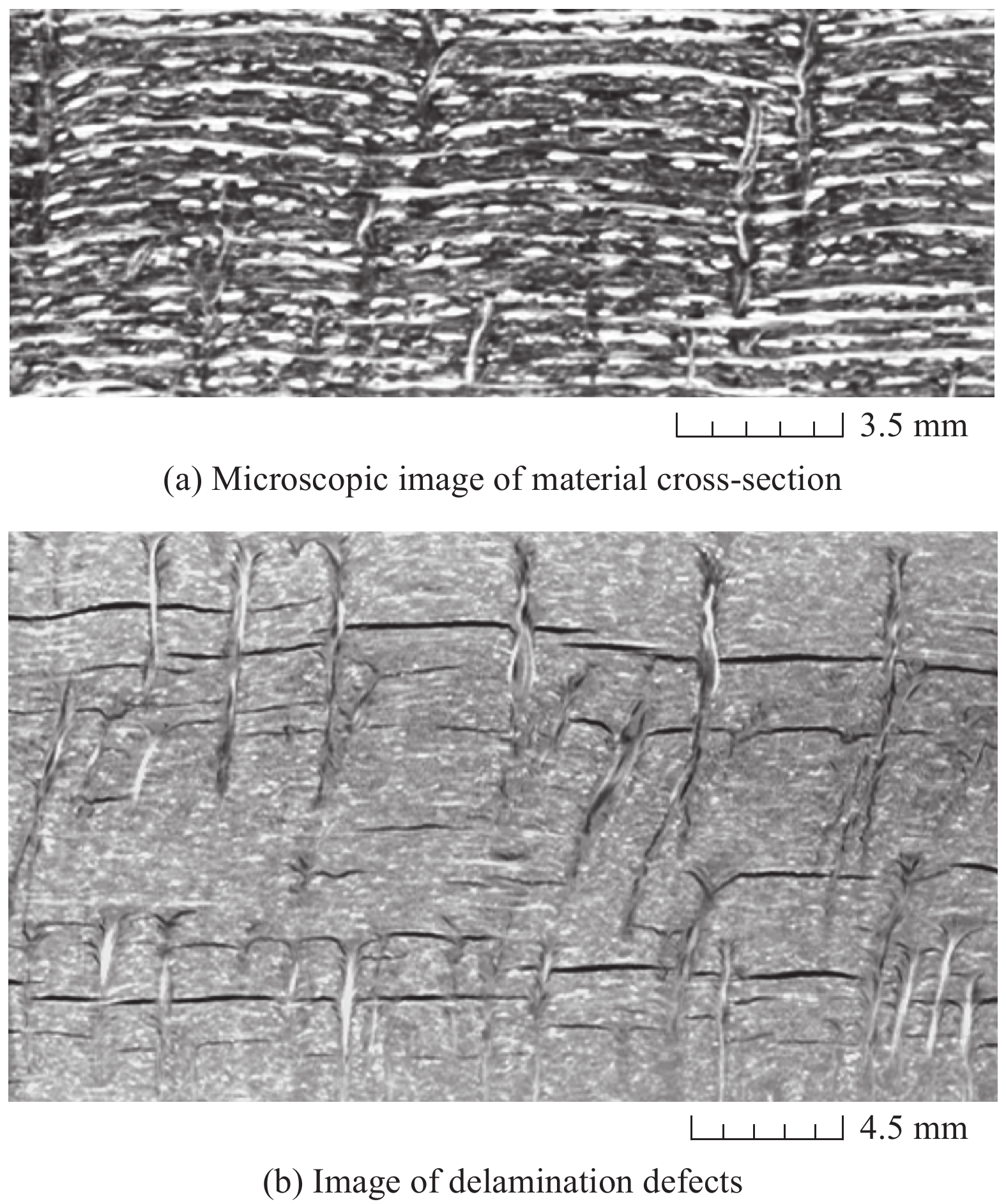

Voids have significant influence on the shear properties of carbon fiber/epoxy resin composites. In this paper, carbon fiber/epoxy resin composite laminates with varies porosity were produced by hygroscopic saturation and stepping down the autoclave pressures. Short beam shear (SBS) tests were performed to establish the influence curve of different porosity on SBS strength. The evolution of shear damage induced by voids and the degradation mechanism of SBS strength were both studied by ultrasonic imaging and metallographic observation. The result shows that when the porosity is less than 1.0%, the SBS strength retention rate is about 88.4%~90.8%; when the porosity increases to 1.0%~1.5%, the SBS strength retention rate is about 74.9%~80.6%; when the porosity increases to 1.5-2.0%, the SBS strength retention rate is about 66.3%-71.9%; When the porosity increases to 2.0~3.0%, the SBS strength decreases sharply, and the SBS strength retention rate drops below 50%. The SBS shear failure mode is very sensitive to voids. Shear failure mainly occurs close to void and the surrounding stress concentration. The higher the porosity, the more obvious the promotion effect of voids on crack initiation and propagation, yielding the higher crack density, the earlier crack occurrence time, and the faster propagation speed.

Voids have significant influence on the shear properties of carbon fiber/epoxy resin composites. In this paper, carbon fiber/epoxy resin composite laminates with varies porosity were produced by hygroscopic saturation and stepping down the autoclave pressures. Short beam shear (SBS) tests were performed to establish the influence curve of different porosity on SBS strength. The evolution of shear damage induced by voids and the degradation mechanism of SBS strength were both studied by ultrasonic imaging and metallographic observation. The result shows that when the porosity is less than 1.0%, the SBS strength retention rate is about 88.4%~90.8%; when the porosity increases to 1.0%~1.5%, the SBS strength retention rate is about 74.9%~80.6%; when the porosity increases to 1.5-2.0%, the SBS strength retention rate is about 66.3%-71.9%; When the porosity increases to 2.0~3.0%, the SBS strength decreases sharply, and the SBS strength retention rate drops below 50%. The SBS shear failure mode is very sensitive to voids. Shear failure mainly occurs close to void and the surrounding stress concentration. The higher the porosity, the more obvious the promotion effect of voids on crack initiation and propagation, yielding the higher crack density, the earlier crack occurrence time, and the faster propagation speed.

, Available online

Abstract:

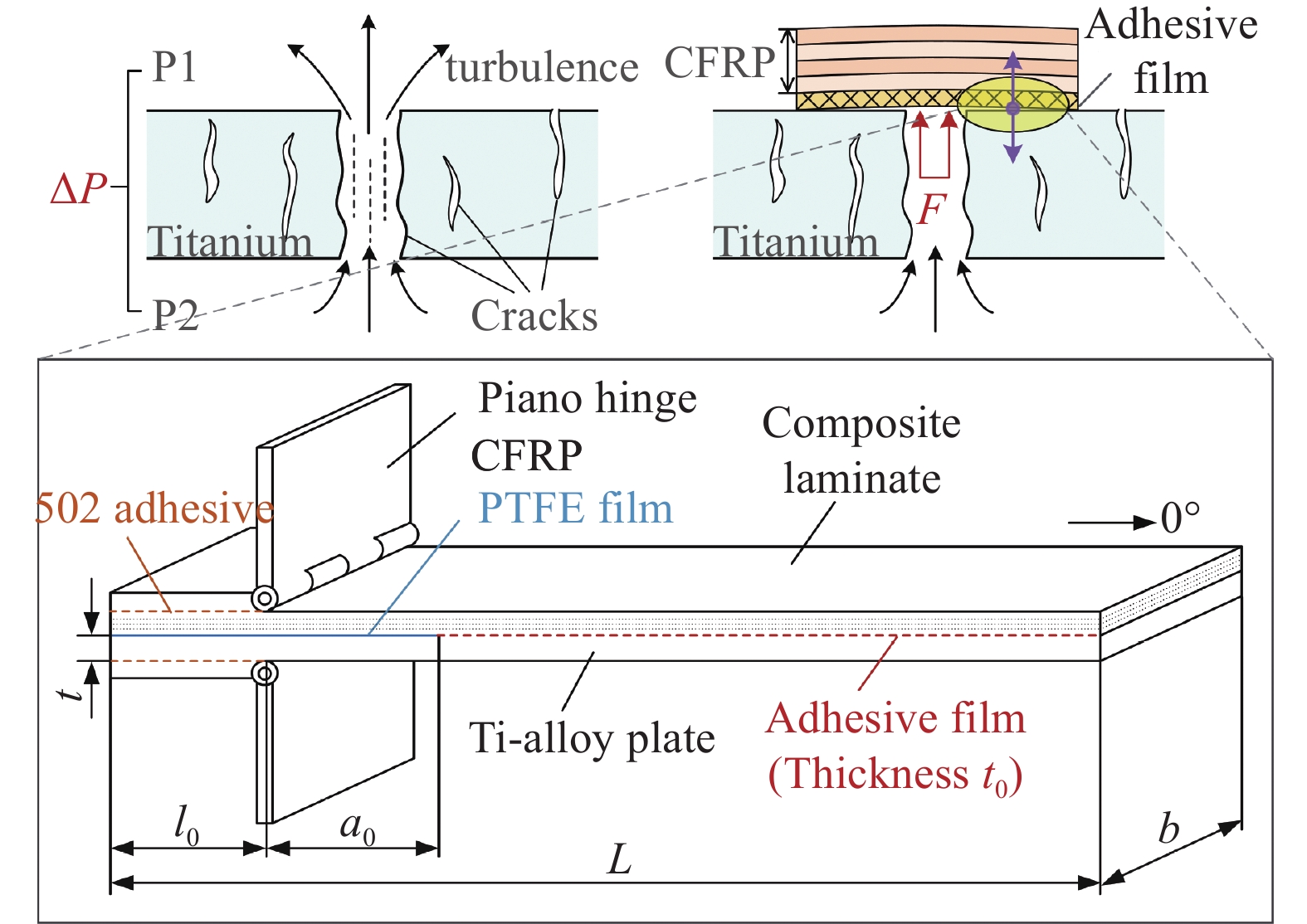

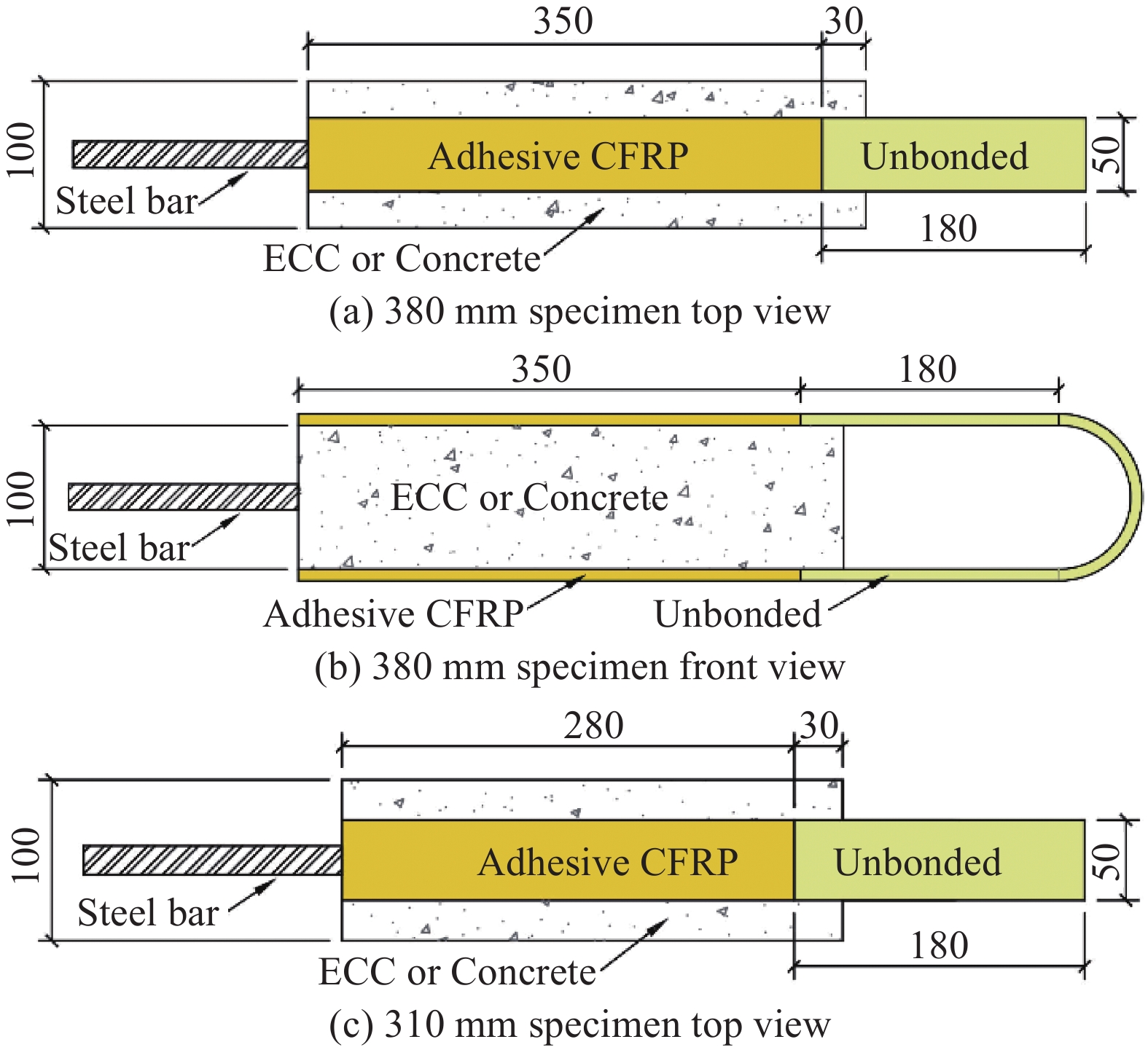

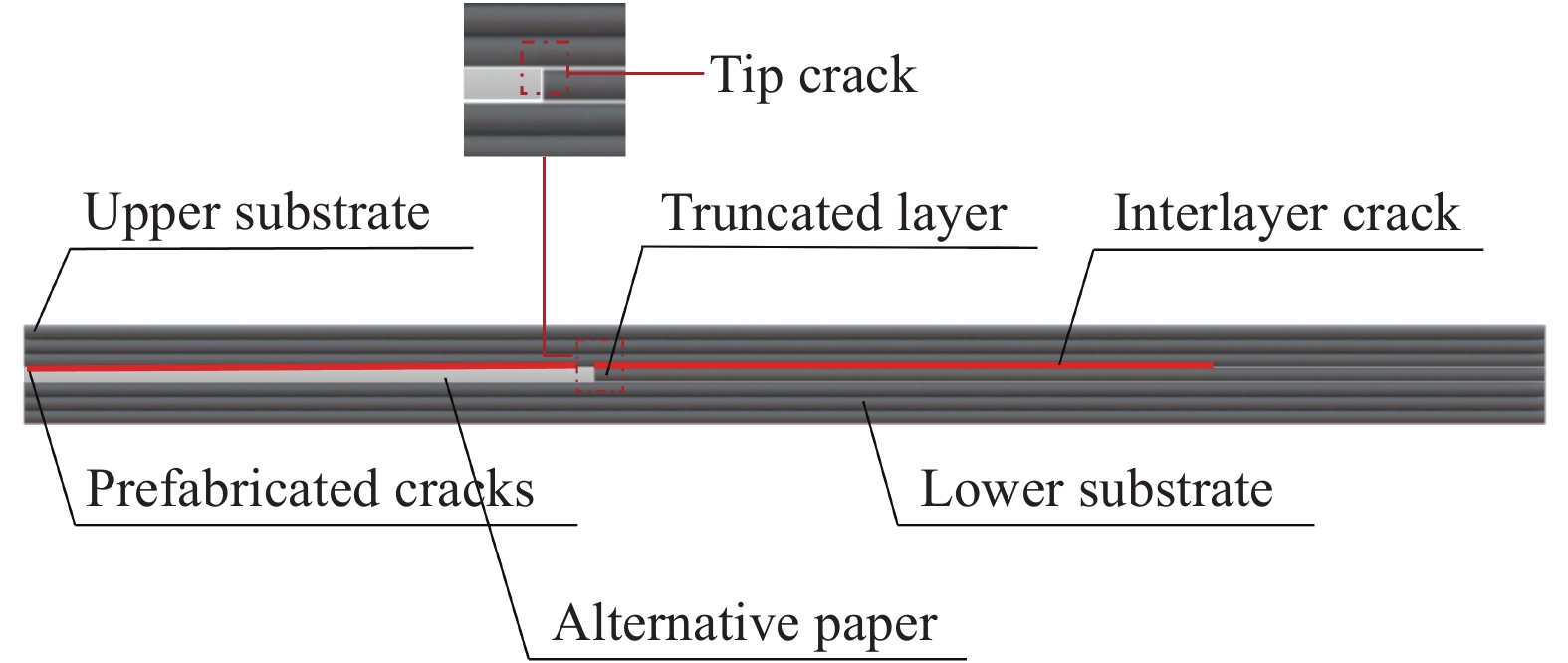

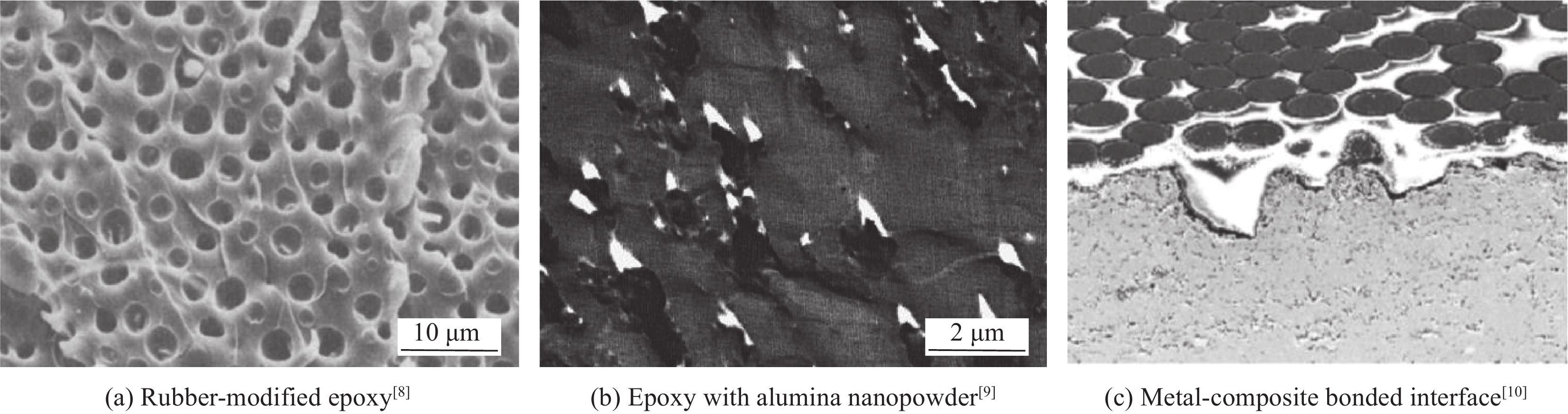

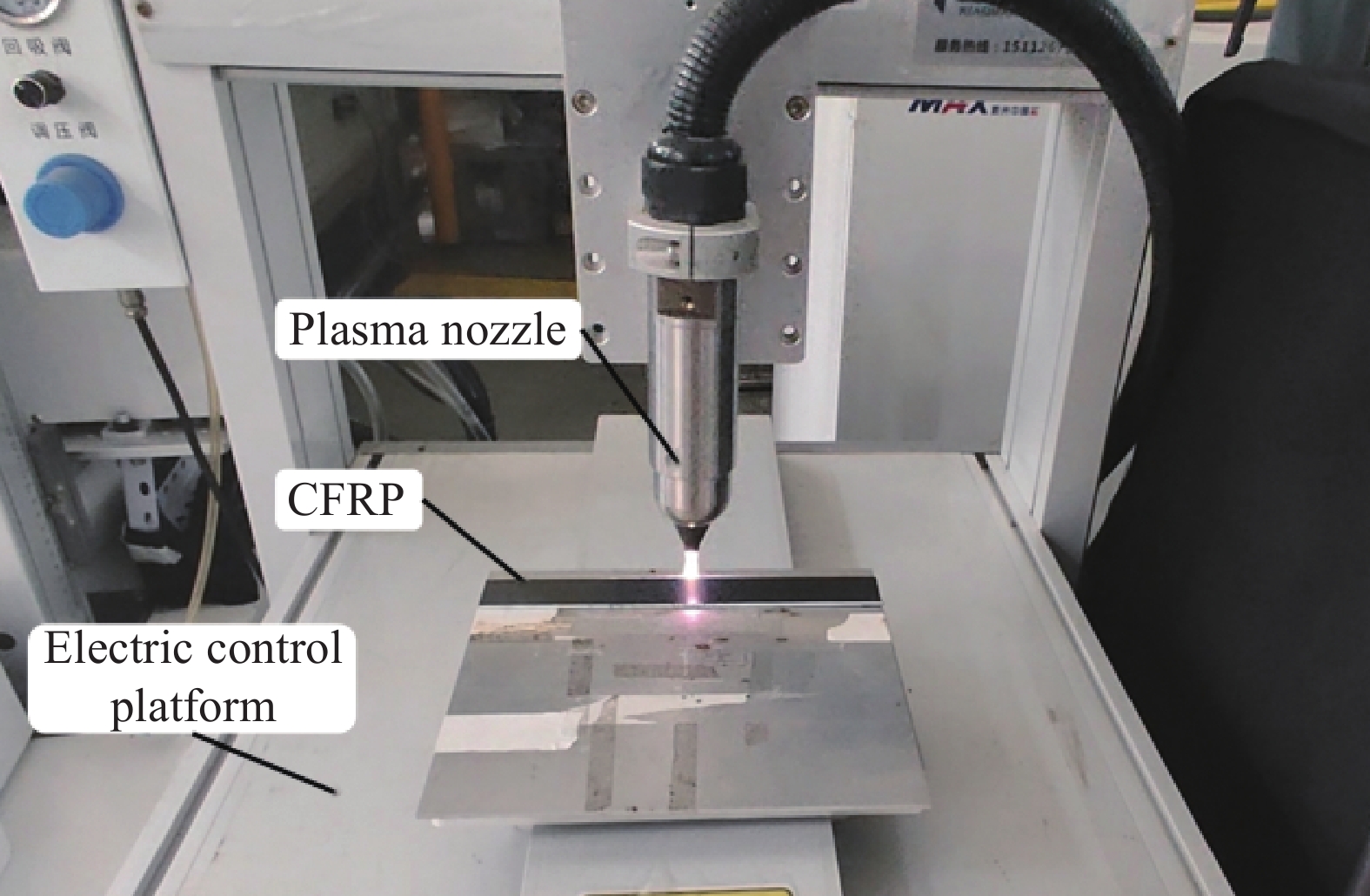

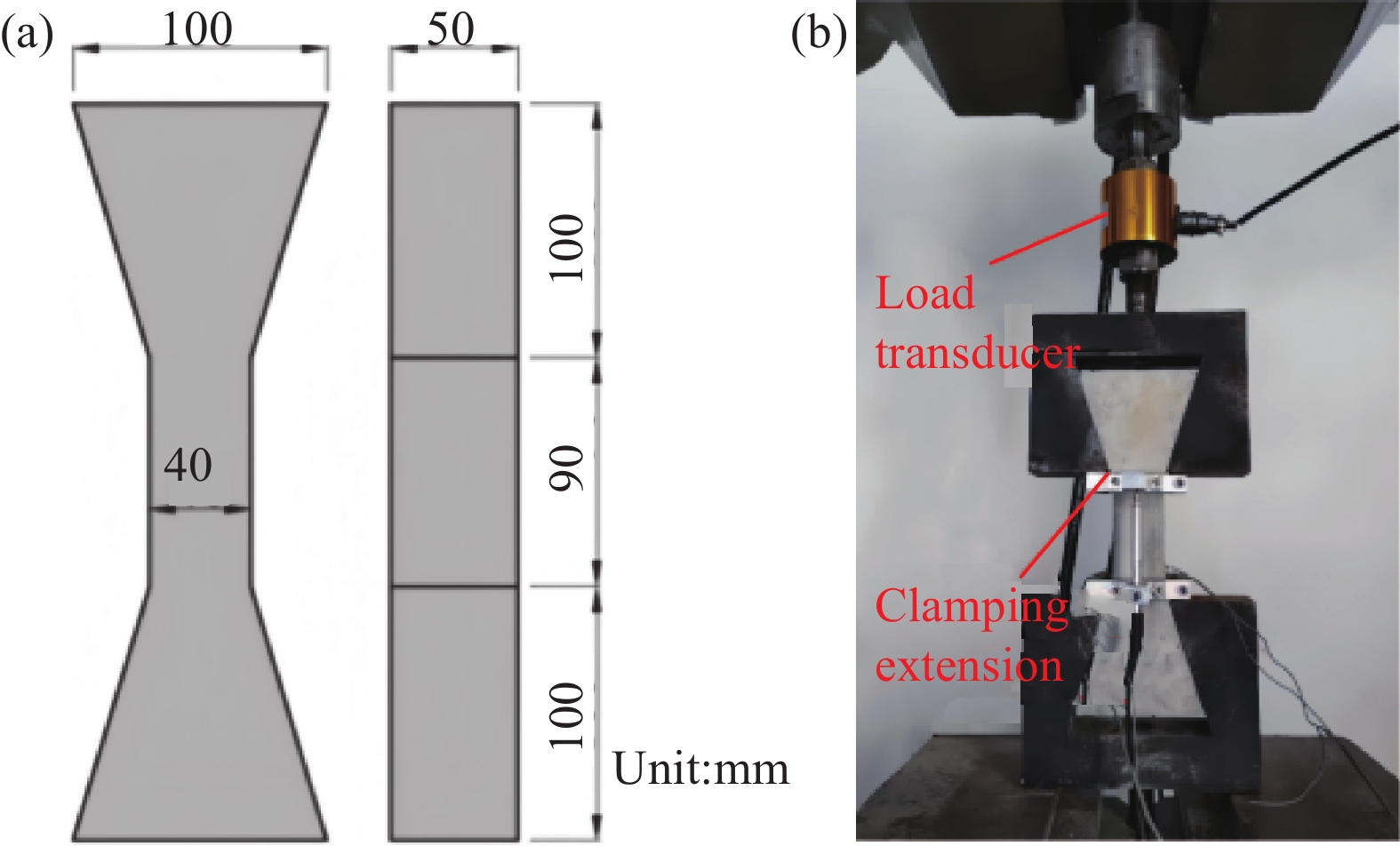

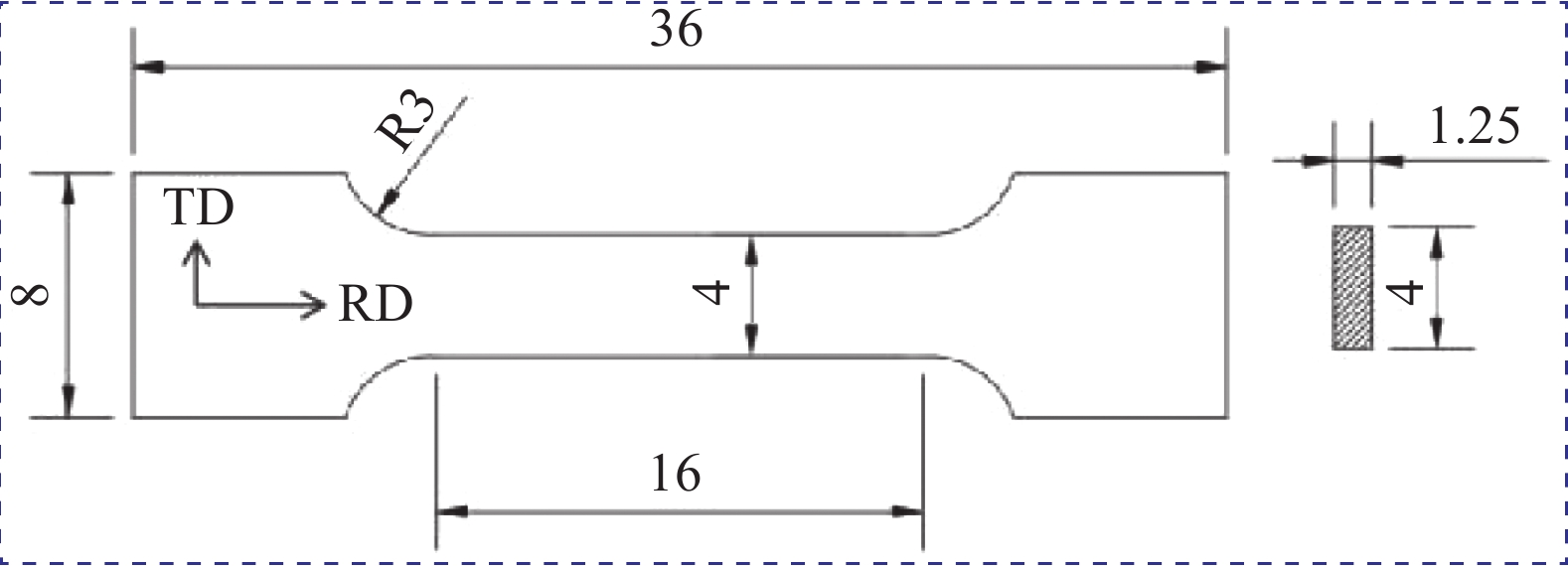

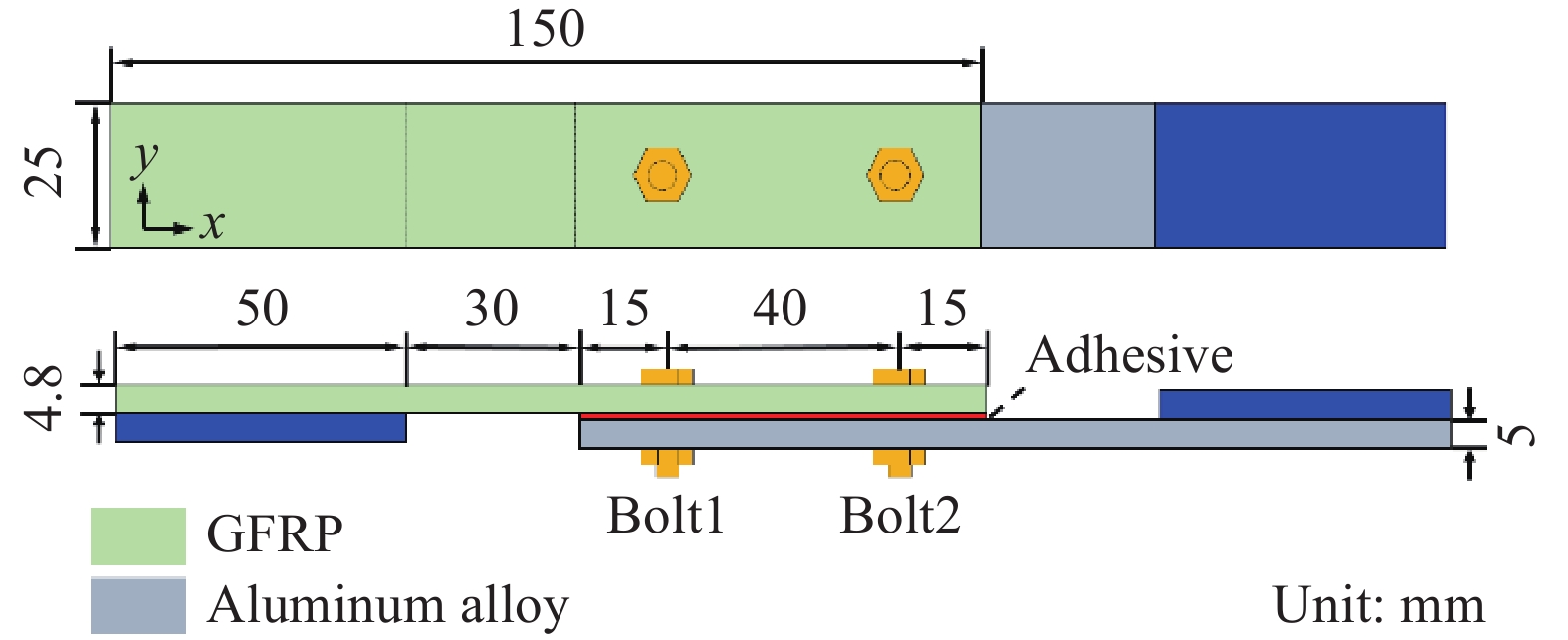

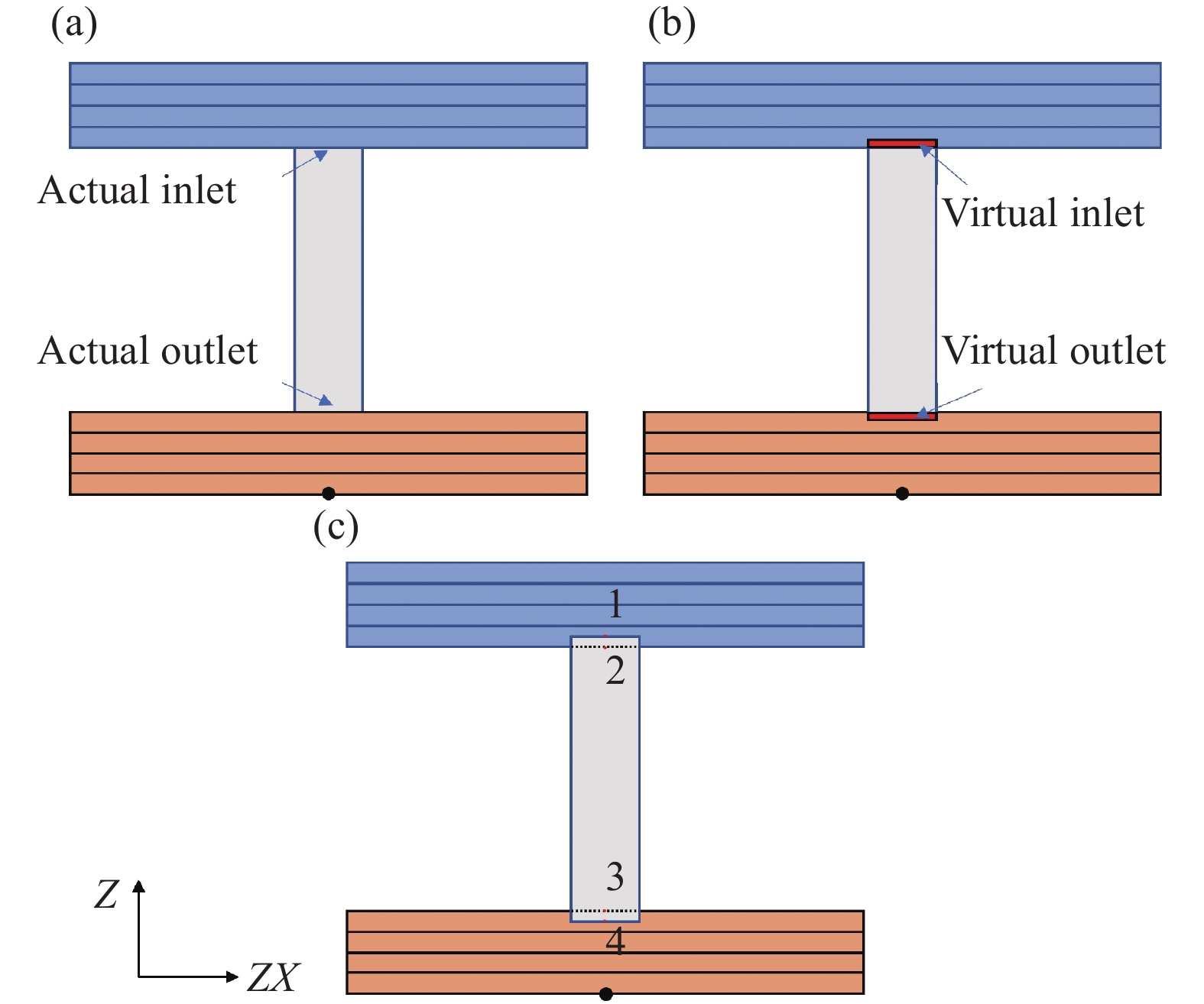

To investigate the mechanical response and fracture characteristics of adhesively bonded titanium alloy structures under mode I loading conditions, this study employed a co-curing method to fabricate repair specimens with single-sided carbon fiber reinforced polymer (CFRP) patches bonded to titanium alloy substrates. The effects of patch thickness, ply orientation, and surface treatment on mode I interfacial fracture mechanics were systematically examined using double cantilever beam (DCB) tests. Peak load and interlaminar fracture toughness were utilized as quantitative metrics to evaluate the overall repair performance. Furthermore, failure modes and fracture surface morphologies at both macroscopic and microscopic scales were analyzed to elucidate the underlying failure mechanisms of mode I static delamination in the titanium alloy/CFRP repaired specimens. The results reveal that increasing the thickness of the patch leads to a rising trend in both the bending stiffness of the specimen and the extent of fiber bridging. The mode I fracture performance of the repair interface improves significantly, with failure modes consistently evolving from adhesive failure of the glue film and cohesive damage to failure at the CRFP interface. For multidirectional laminates, the 0° ply at the bottom of the patch exhibits the strongest constraint on delamination paths, while the 45° ply effectively induces inter-ply crack migration, enhancing the toughening effect. Notably, the two-dimensional woven patch demonstrates the best repair performance. For surface-treated specimens, cohesive failure of the adhesive film is the predominant failure mode. Specifically, sulfuric acid anodization provides the most significant toughening effect, increasing fracture toughness by 3.8% and 1.9% compared to quartz sandblasting and 400# sandpaper abrasion, respectively, and by 19.2% compared to untreated specimens. These conclusions provide references for the optimized design and practical application of damage repair processes under mode I loading conditions for titanium alloy components.

To investigate the mechanical response and fracture characteristics of adhesively bonded titanium alloy structures under mode I loading conditions, this study employed a co-curing method to fabricate repair specimens with single-sided carbon fiber reinforced polymer (CFRP) patches bonded to titanium alloy substrates. The effects of patch thickness, ply orientation, and surface treatment on mode I interfacial fracture mechanics were systematically examined using double cantilever beam (DCB) tests. Peak load and interlaminar fracture toughness were utilized as quantitative metrics to evaluate the overall repair performance. Furthermore, failure modes and fracture surface morphologies at both macroscopic and microscopic scales were analyzed to elucidate the underlying failure mechanisms of mode I static delamination in the titanium alloy/CFRP repaired specimens. The results reveal that increasing the thickness of the patch leads to a rising trend in both the bending stiffness of the specimen and the extent of fiber bridging. The mode I fracture performance of the repair interface improves significantly, with failure modes consistently evolving from adhesive failure of the glue film and cohesive damage to failure at the CRFP interface. For multidirectional laminates, the 0° ply at the bottom of the patch exhibits the strongest constraint on delamination paths, while the 45° ply effectively induces inter-ply crack migration, enhancing the toughening effect. Notably, the two-dimensional woven patch demonstrates the best repair performance. For surface-treated specimens, cohesive failure of the adhesive film is the predominant failure mode. Specifically, sulfuric acid anodization provides the most significant toughening effect, increasing fracture toughness by 3.8% and 1.9% compared to quartz sandblasting and 400# sandpaper abrasion, respectively, and by 19.2% compared to untreated specimens. These conclusions provide references for the optimized design and practical application of damage repair processes under mode I loading conditions for titanium alloy components.

, Available online

Abstract:

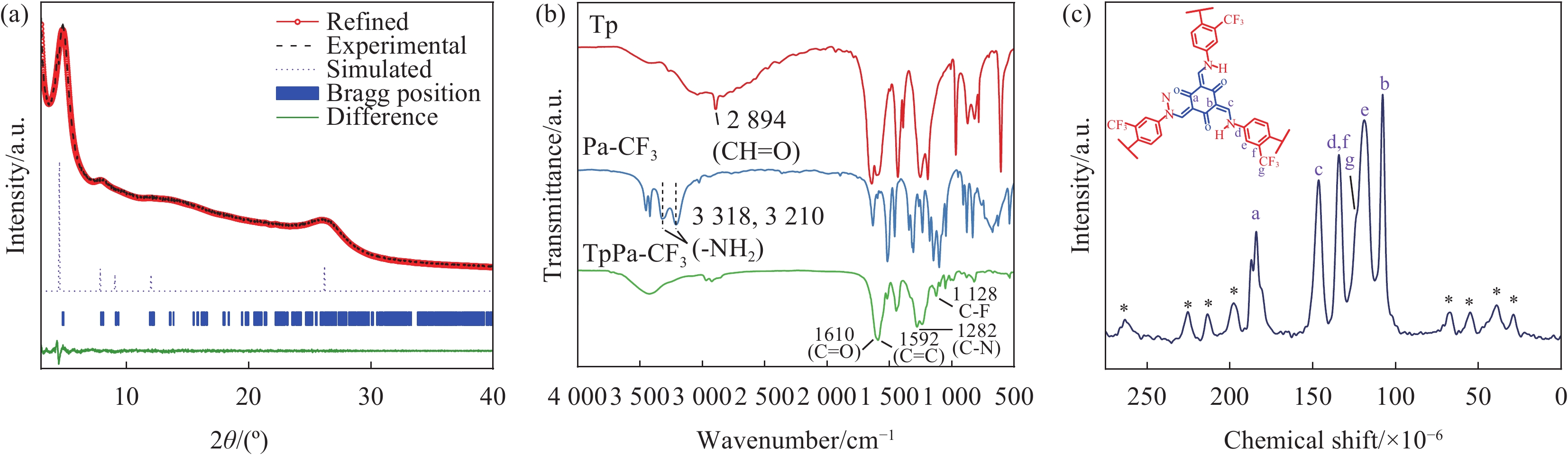

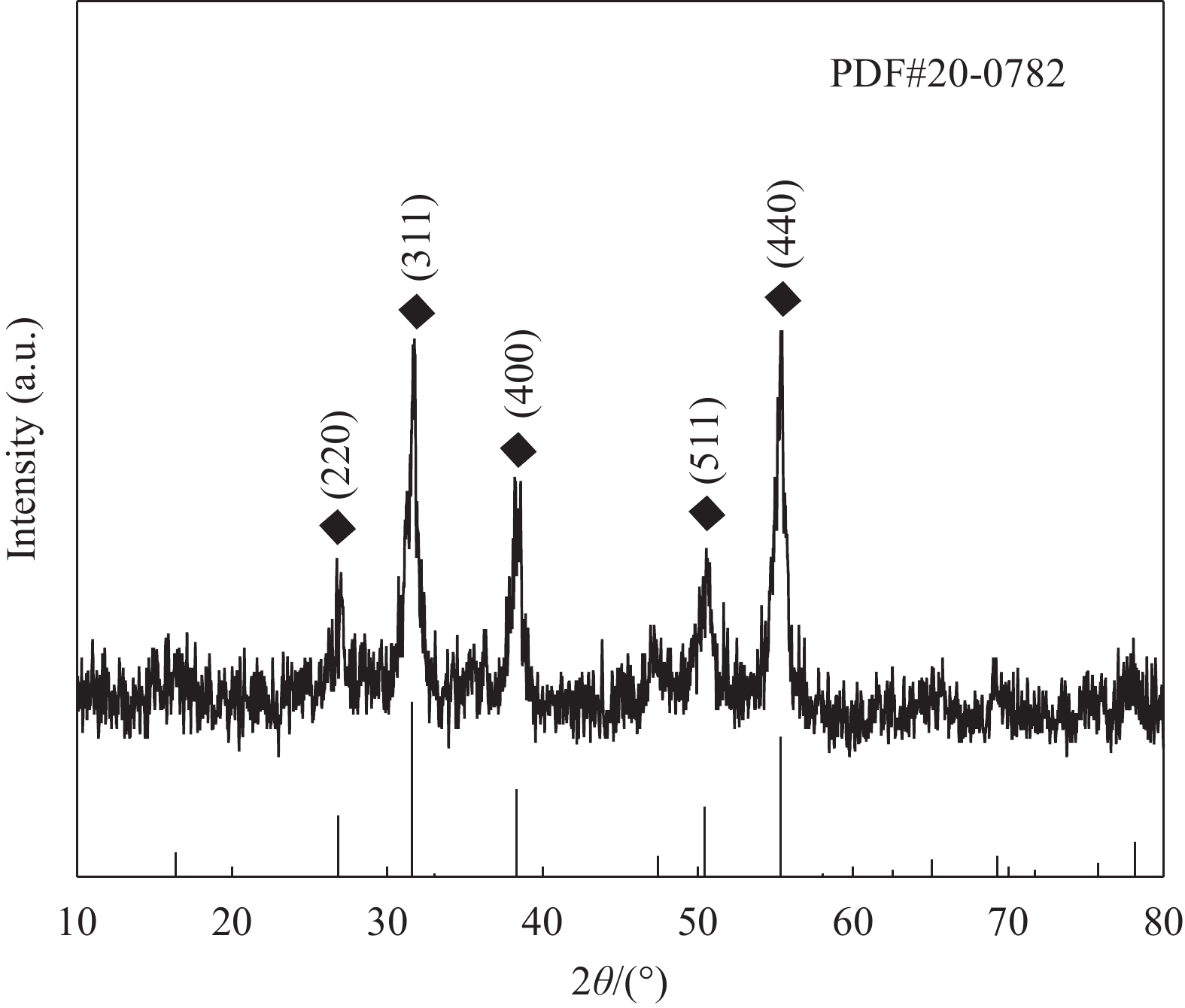

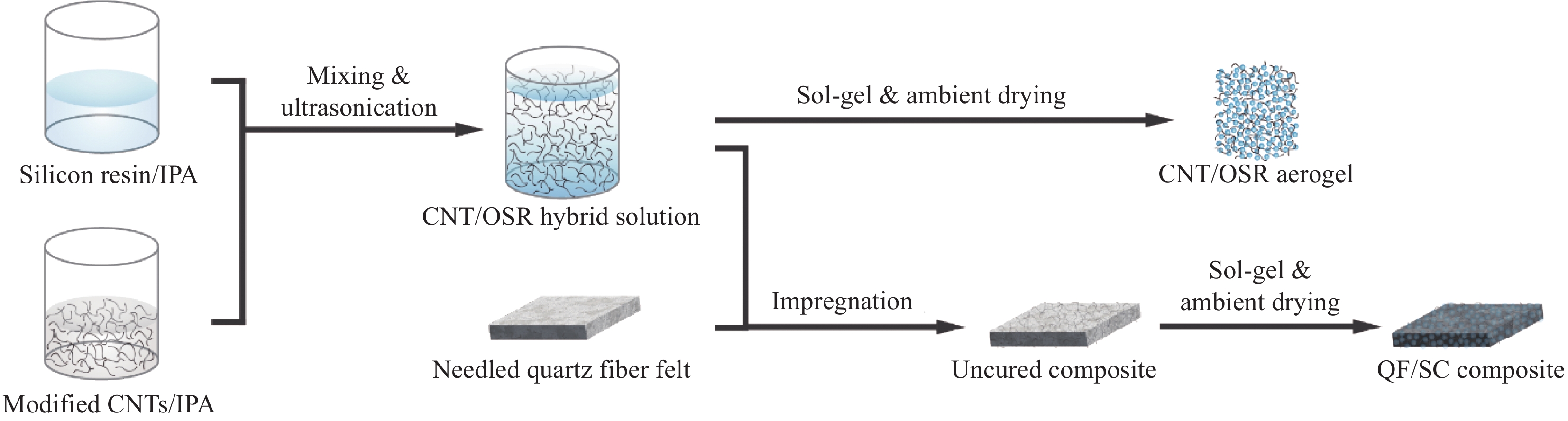

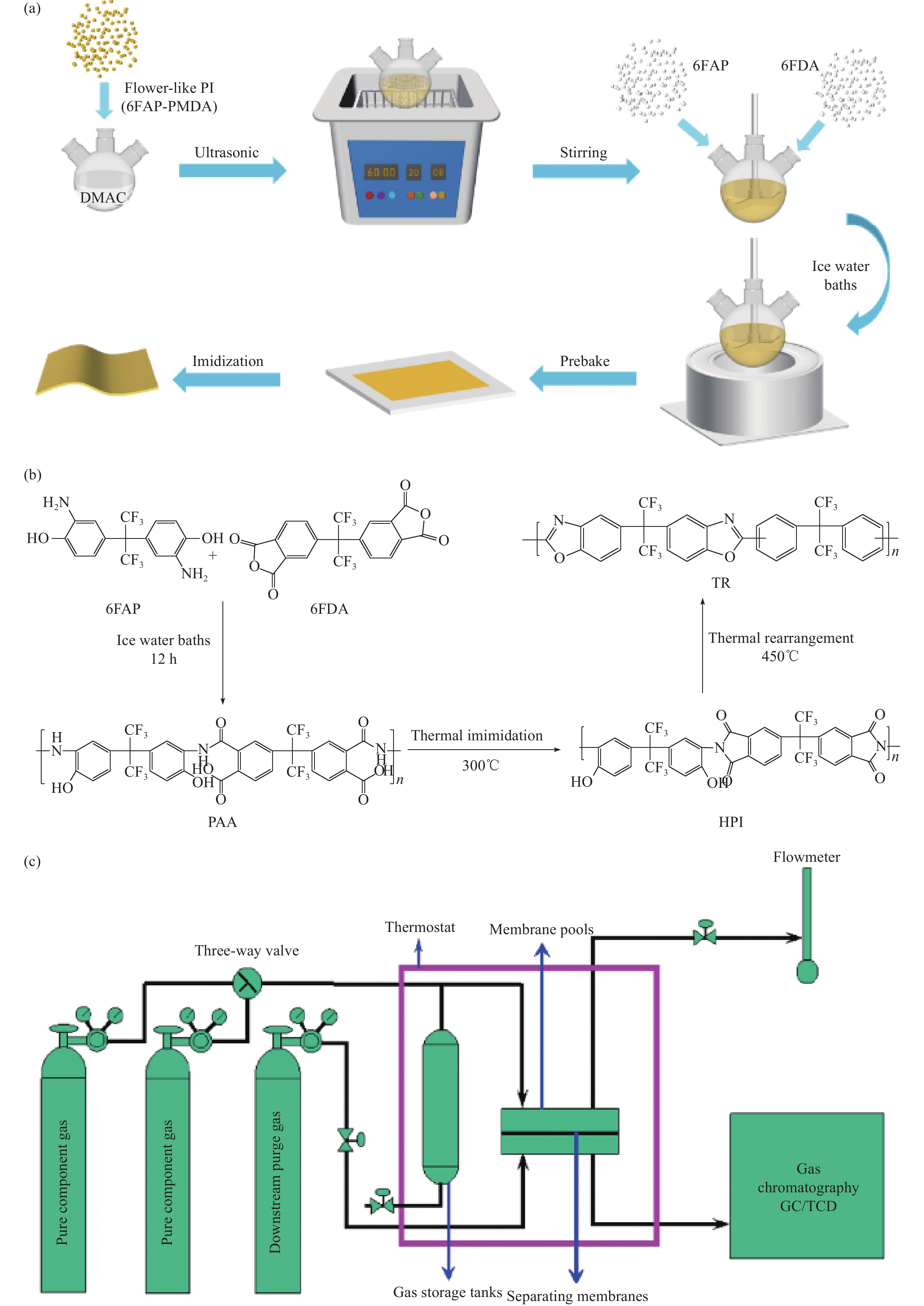

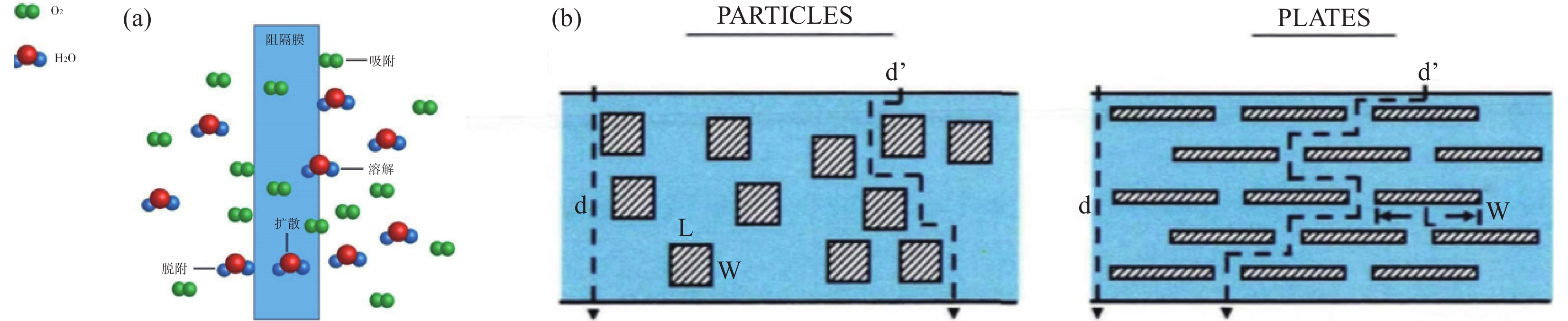

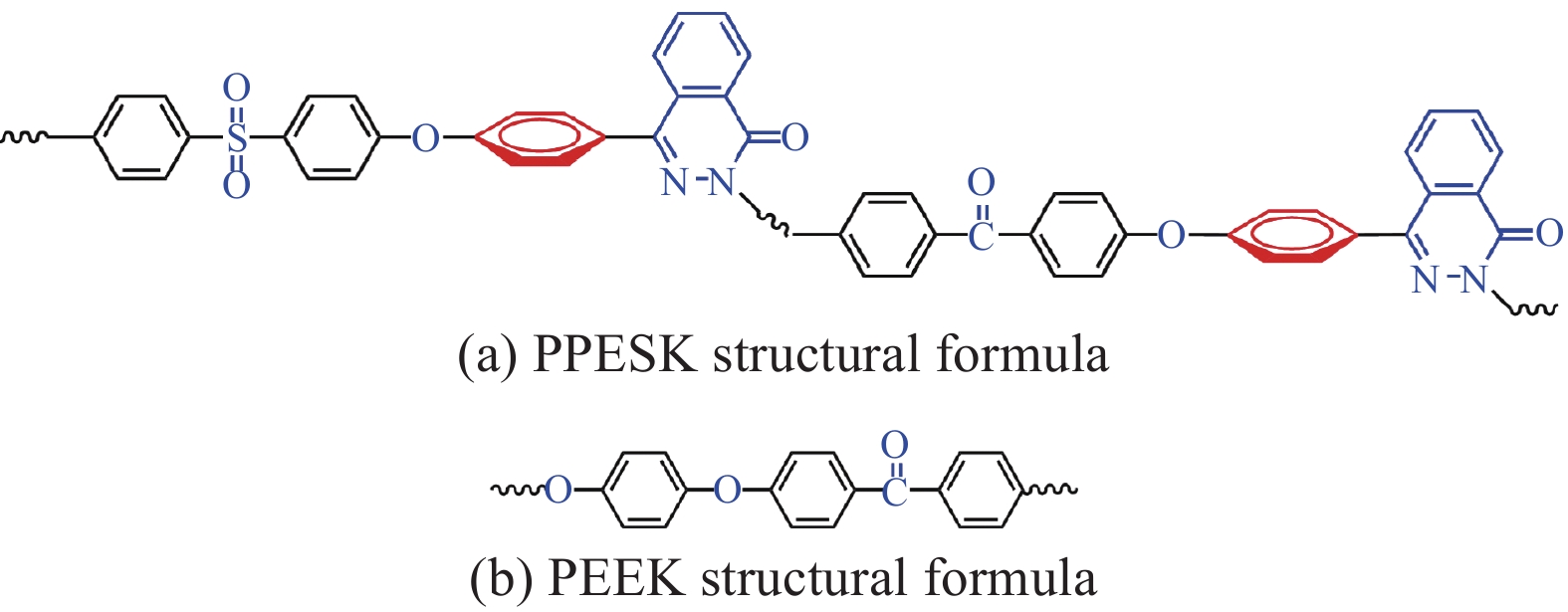

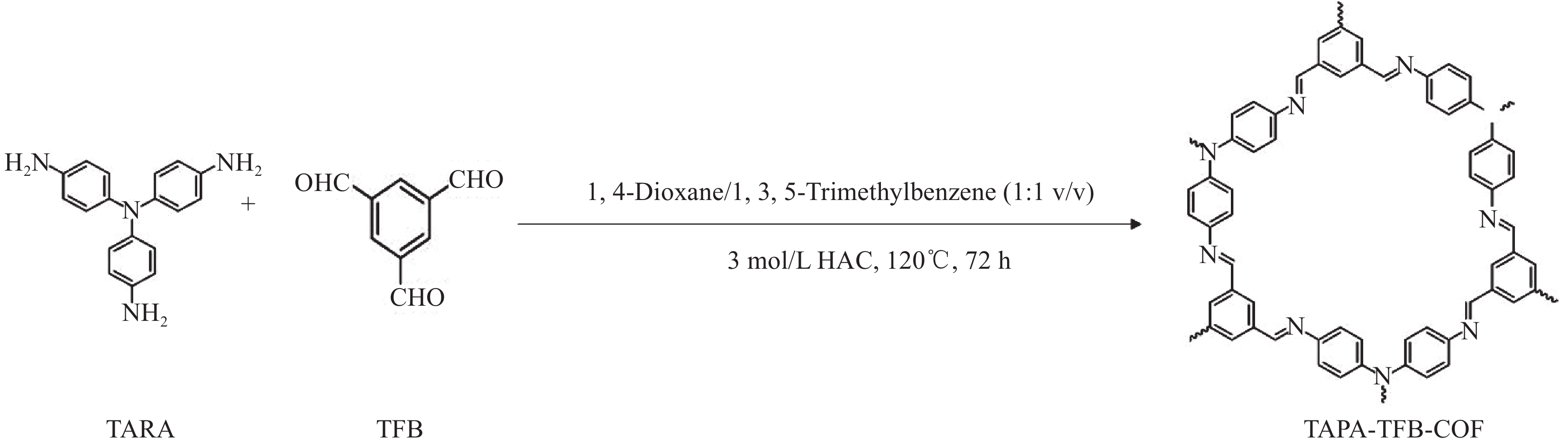

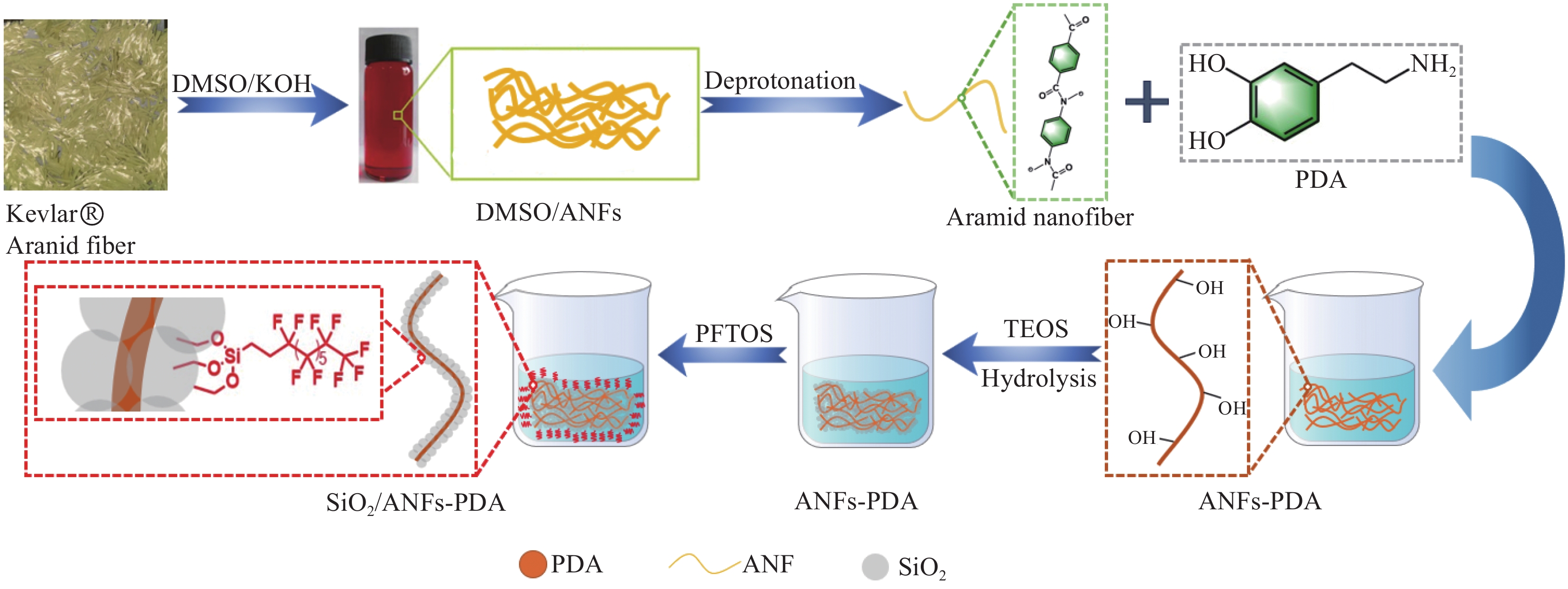

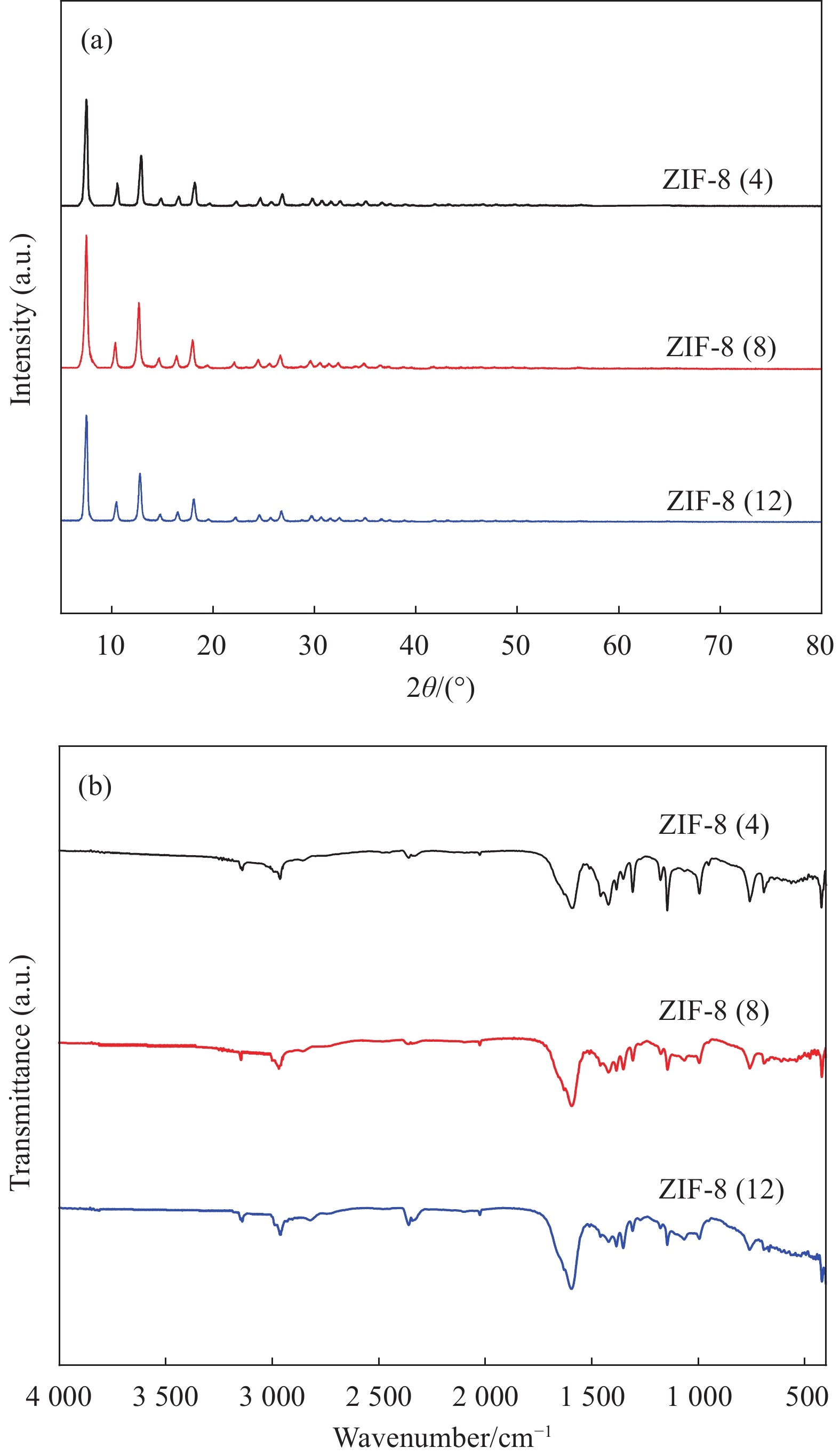

Mixed matrix membranes, which combine the flexibility of polymer membranes with the gas separation properties of porous fillers, have attracted much attention in the field of gas separation in recent years. Covalent organic framework materials (COFs) are distinguished by a high specific surface area, high porosity, and facile functionalization. Their all-organic structure exhibits favorable compatibility with polymers, which is regarded as an optimal filler for mixed matrix membranes. Accordingly, in this study, the fluorinated covalent organic framework material TpPa-CF3 was synthesized via a solvothermal method, and TpPa-CF3/6FDA-ODA mixed matrix membranes were prepared through a blending method utilizing TpPa-CF3 as a filler and polyimide 6FDA-ODA as a matrix. The structure and properties of TpPa-CF3 and its mixed matrix membranes were investigated through a series of analytical techniques, including FT-IR, XRD, TGA, SEM, and gas permeability tests. The results showed that the homogeneous pores of TpPa-CF3 provided fast channels for gas molecule transport, the microporous structure of the framework enhanced the interaction of gas molecules with functional groups on the pore walls, and the dipole-quadrupole interactions of C—F bonds with CO2 elevated the interactions of the framework with CO2. At a loading of 5 wt% of TpPa-CF3, the CO₂ and O₂ permeability exhibited an improvement of 149% and 138%, respectively, in comparison to the 6FDA-ODA matrix membrane. Additionally, the CO₂/N₂ and O₂/N₂ separation factors were elevated to 24.4 and 4.8, respectively.

Mixed matrix membranes, which combine the flexibility of polymer membranes with the gas separation properties of porous fillers, have attracted much attention in the field of gas separation in recent years. Covalent organic framework materials (COFs) are distinguished by a high specific surface area, high porosity, and facile functionalization. Their all-organic structure exhibits favorable compatibility with polymers, which is regarded as an optimal filler for mixed matrix membranes. Accordingly, in this study, the fluorinated covalent organic framework material TpPa-CF3 was synthesized via a solvothermal method, and TpPa-CF3/6FDA-ODA mixed matrix membranes were prepared through a blending method utilizing TpPa-CF3 as a filler and polyimide 6FDA-ODA as a matrix. The structure and properties of TpPa-CF3 and its mixed matrix membranes were investigated through a series of analytical techniques, including FT-IR, XRD, TGA, SEM, and gas permeability tests. The results showed that the homogeneous pores of TpPa-CF3 provided fast channels for gas molecule transport, the microporous structure of the framework enhanced the interaction of gas molecules with functional groups on the pore walls, and the dipole-quadrupole interactions of C—F bonds with CO2 elevated the interactions of the framework with CO2. At a loading of 5 wt% of TpPa-CF3, the CO₂ and O₂ permeability exhibited an improvement of 149% and 138%, respectively, in comparison to the 6FDA-ODA matrix membrane. Additionally, the CO₂/N₂ and O₂/N₂ separation factors were elevated to 24.4 and 4.8, respectively.

, Available online

Abstract:

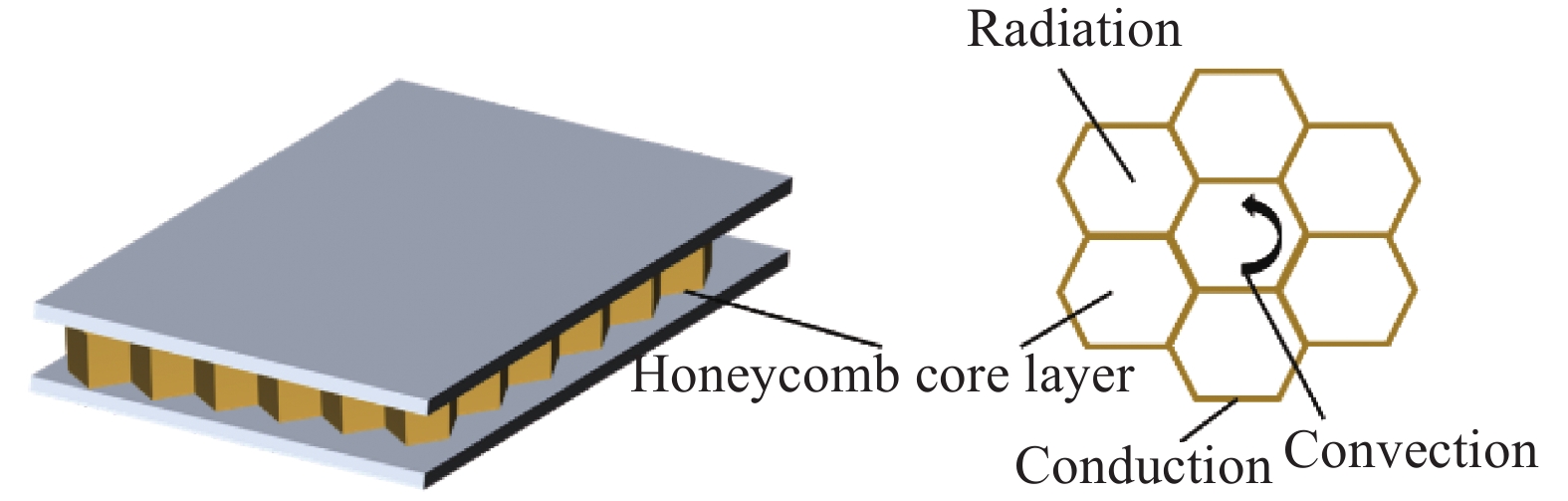

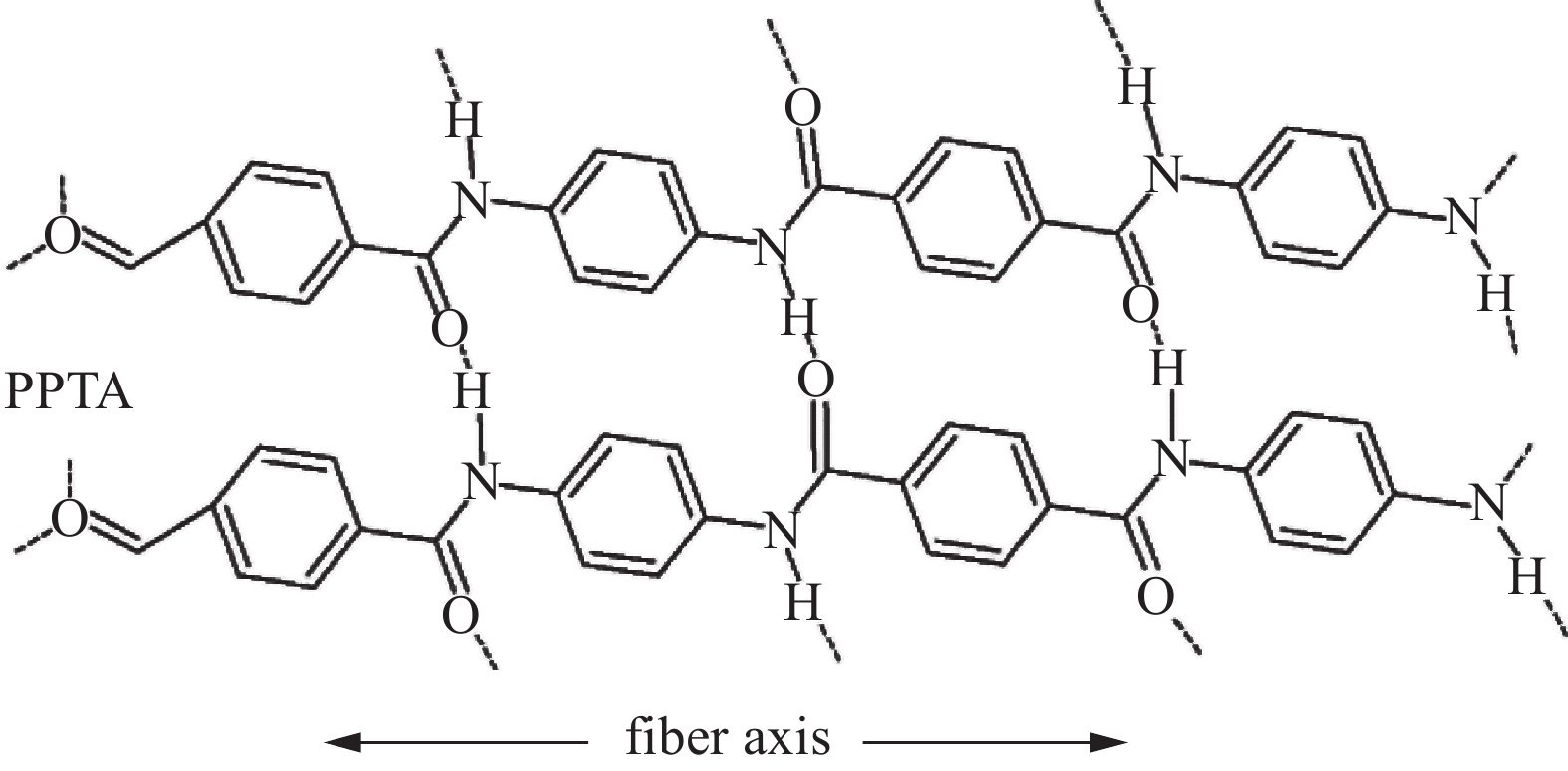

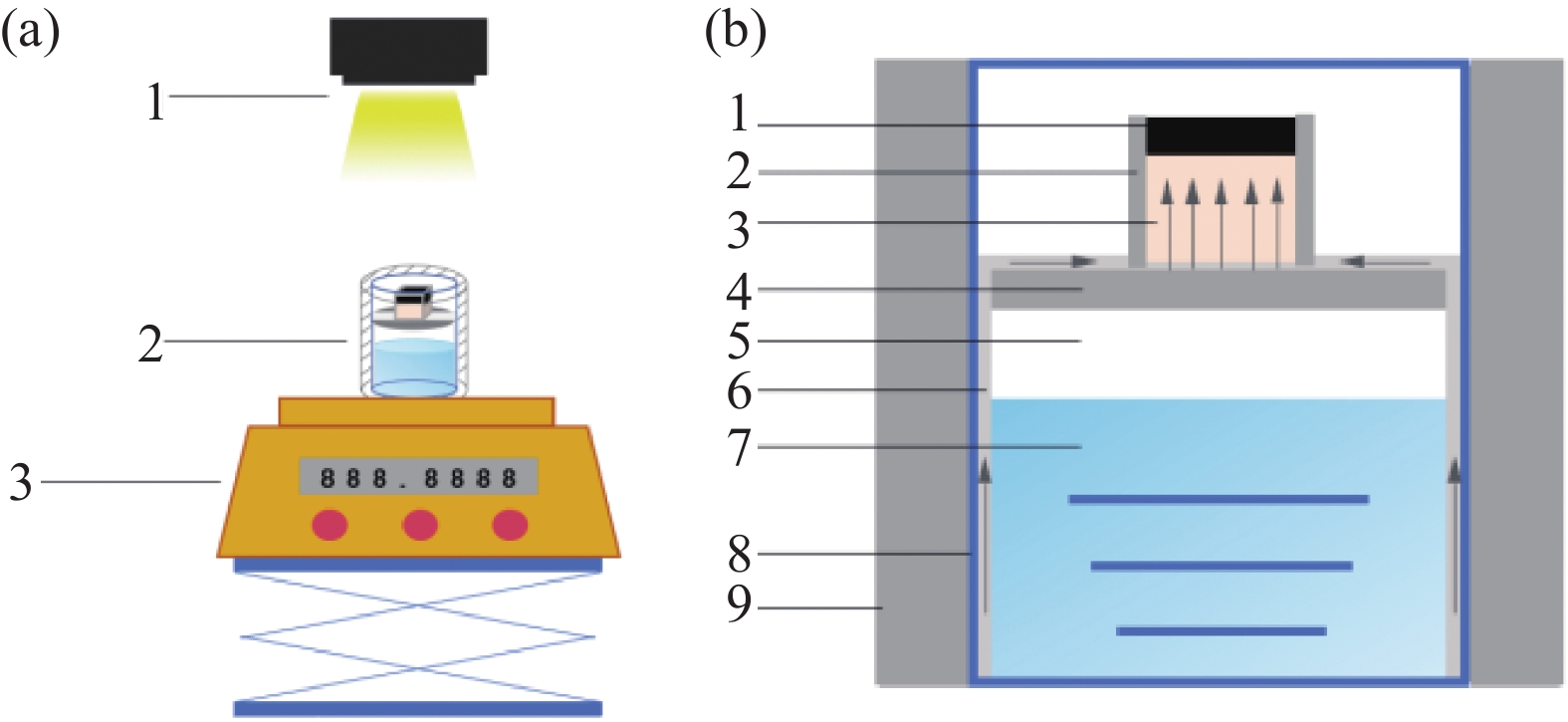

Fiberglass/epoxy honeycomb sandwich composites have become the main materials for interior wall panels of civil aircraft due to their light weight and excellent flame retardant properties. These materials are fire hazardous at high temperatures, so the study of their thermal conductivity is of great significance for aircraft fire protection. Nine kinds of honeycomb sandwich materials with different thicknesses were prepared from glass fiber/epoxy resin prepreg and aramid paper honeycomb core to carry out the thermal conductivity study. Based on Fourier's law and the semi-empirical formula of Swan-Pittman, a theoretical model of heat transfer of fiber-reinforced resin matrix composites was established, and the theoretical value of thermal conductivity of honeycomb sandwich materials was calculated based on the data obtained from the simulation of Finite Element Software. Based on the data obtained from the finite element software simulation, the theoretical value of thermal conductivity of the honeycomb sandwich is calculated. The thermal conductivity tester is used to carry out experiments on the thermal conductivity of honeycomb sandwich materials and compare the experimental and theoretical values. The results show that the theoretical values of the thermal conductivity of honeycomb sandwich materials with different thicknesses at room temperature are in good agreement with the average values of the experiments, and the theoretical model is applicable to the fiber-reinforced resin matrix composites with honeycomb sandwich structure; compared with the thickness of the panels, the honeycomb core is the main factor affecting the thermal conductivity of honeycomb sandwich materials. The porosity of the honeycomb sandwich material is inversely related to the thermal conductivity, and the specific surface area is positively related to the thermal conductivity; with the increase of the height of the honeycomb core, the thermal radiation replaces the thermal conduction to become the main way of heat transfer inside the honeycomb core gradually.

Fiberglass/epoxy honeycomb sandwich composites have become the main materials for interior wall panels of civil aircraft due to their light weight and excellent flame retardant properties. These materials are fire hazardous at high temperatures, so the study of their thermal conductivity is of great significance for aircraft fire protection. Nine kinds of honeycomb sandwich materials with different thicknesses were prepared from glass fiber/epoxy resin prepreg and aramid paper honeycomb core to carry out the thermal conductivity study. Based on Fourier's law and the semi-empirical formula of Swan-Pittman, a theoretical model of heat transfer of fiber-reinforced resin matrix composites was established, and the theoretical value of thermal conductivity of honeycomb sandwich materials was calculated based on the data obtained from the simulation of Finite Element Software. Based on the data obtained from the finite element software simulation, the theoretical value of thermal conductivity of the honeycomb sandwich is calculated. The thermal conductivity tester is used to carry out experiments on the thermal conductivity of honeycomb sandwich materials and compare the experimental and theoretical values. The results show that the theoretical values of the thermal conductivity of honeycomb sandwich materials with different thicknesses at room temperature are in good agreement with the average values of the experiments, and the theoretical model is applicable to the fiber-reinforced resin matrix composites with honeycomb sandwich structure; compared with the thickness of the panels, the honeycomb core is the main factor affecting the thermal conductivity of honeycomb sandwich materials. The porosity of the honeycomb sandwich material is inversely related to the thermal conductivity, and the specific surface area is positively related to the thermal conductivity; with the increase of the height of the honeycomb core, the thermal radiation replaces the thermal conduction to become the main way of heat transfer inside the honeycomb core gradually.

, Available online

Abstract:

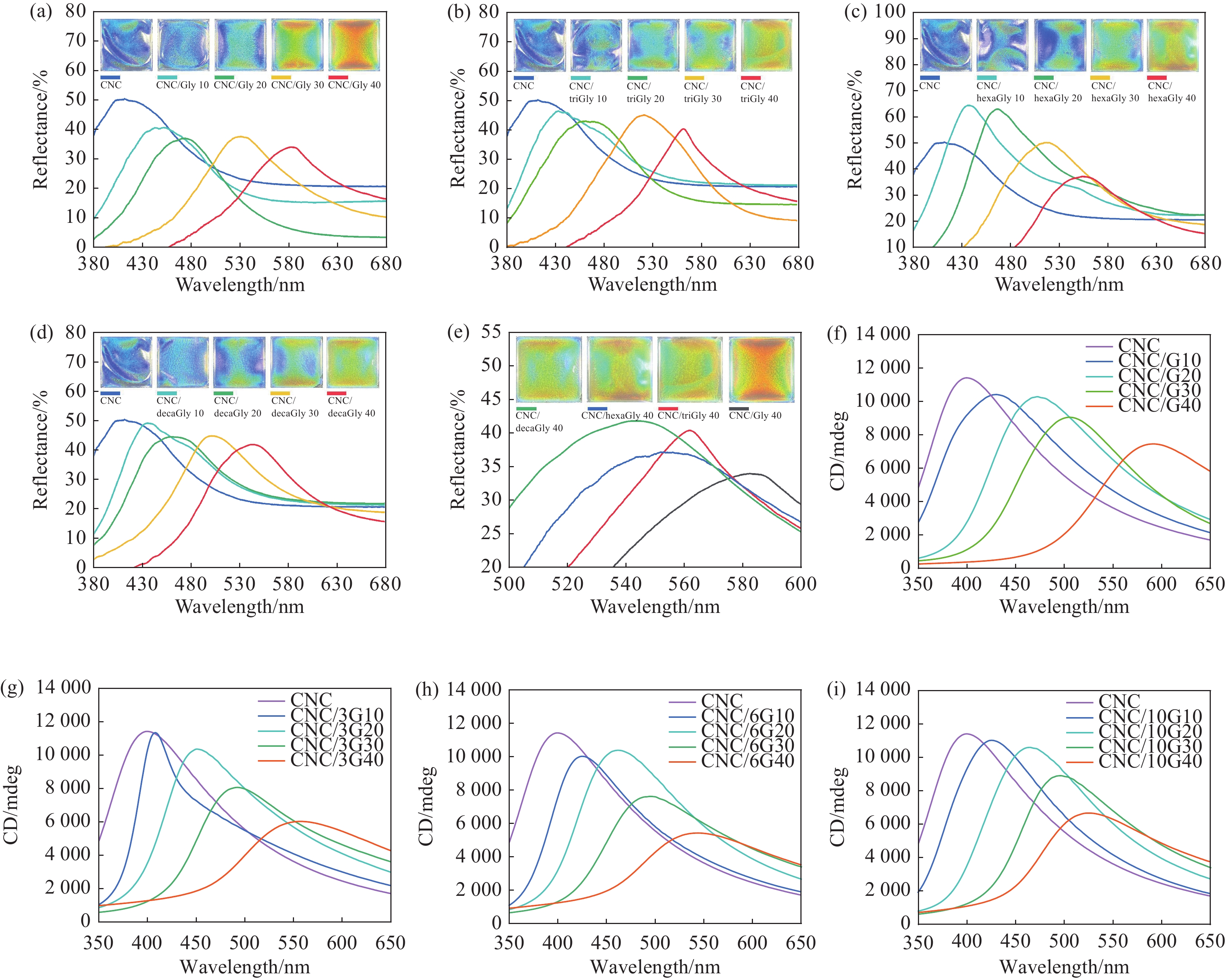

Radiative cooling lowers its own temperature by emitting heat into outer space and is a green, low-carbon and sustainable cooling strategy. Most radiative cooling materials have monotonous color appearance, mostly white or transparent, and the addition of traditional colorants will cause the materials to absorb heat and reduce the radiative cooling performance. Cellulose nanocrystal/polyethylene glycol (CNC/PEG) composite radiative cooling films with tunable structural colors were prepared by self-assembly method. And the composite films were combined with cellulose acetate (CA) films with porous structure to obtain structure-colored radiation-cooled bilayer composite films. The results show that the cellulose nanocrystalline composite films have bright structural colors with obvious birefringence phenomenon. With the increase of PEG content, the pitch of the composite film structure increases, and the color changes from blue-green to red. the CNC/PEG structural color composite film has the highest reflectance up to 68.5% in the visible light band, and the emissivity in the atmospheric window band is up to 93%, with an ambient cooling effect of about 3.4 ℃. the CNC/PEG-CA bilayer composite film has the highest reflectance in the visible light band up to 91.8%, and the emissivity in the atmospheric window band is up to 32.2%. Compared with the composite film, the bilayer composite film has better cooling performance, with a temperature difference of about 14.3 ℃ compared with the ambient temperature.In outdoor tests, compared with the ambient temperature, the composite film can achieve a cooling effect of about 2 ℃, and the bilayer composite film can achieve a cooling effect of about 6 ℃.

Radiative cooling lowers its own temperature by emitting heat into outer space and is a green, low-carbon and sustainable cooling strategy. Most radiative cooling materials have monotonous color appearance, mostly white or transparent, and the addition of traditional colorants will cause the materials to absorb heat and reduce the radiative cooling performance. Cellulose nanocrystal/polyethylene glycol (CNC/PEG) composite radiative cooling films with tunable structural colors were prepared by self-assembly method. And the composite films were combined with cellulose acetate (CA) films with porous structure to obtain structure-colored radiation-cooled bilayer composite films. The results show that the cellulose nanocrystalline composite films have bright structural colors with obvious birefringence phenomenon. With the increase of PEG content, the pitch of the composite film structure increases, and the color changes from blue-green to red. the CNC/PEG structural color composite film has the highest reflectance up to 68.5% in the visible light band, and the emissivity in the atmospheric window band is up to 93%, with an ambient cooling effect of about 3.4 ℃. the CNC/PEG-CA bilayer composite film has the highest reflectance in the visible light band up to 91.8%, and the emissivity in the atmospheric window band is up to 32.2%. Compared with the composite film, the bilayer composite film has better cooling performance, with a temperature difference of about 14.3 ℃ compared with the ambient temperature.In outdoor tests, compared with the ambient temperature, the composite film can achieve a cooling effect of about 2 ℃, and the bilayer composite film can achieve a cooling effect of about 6 ℃.

, Available online

Abstract:

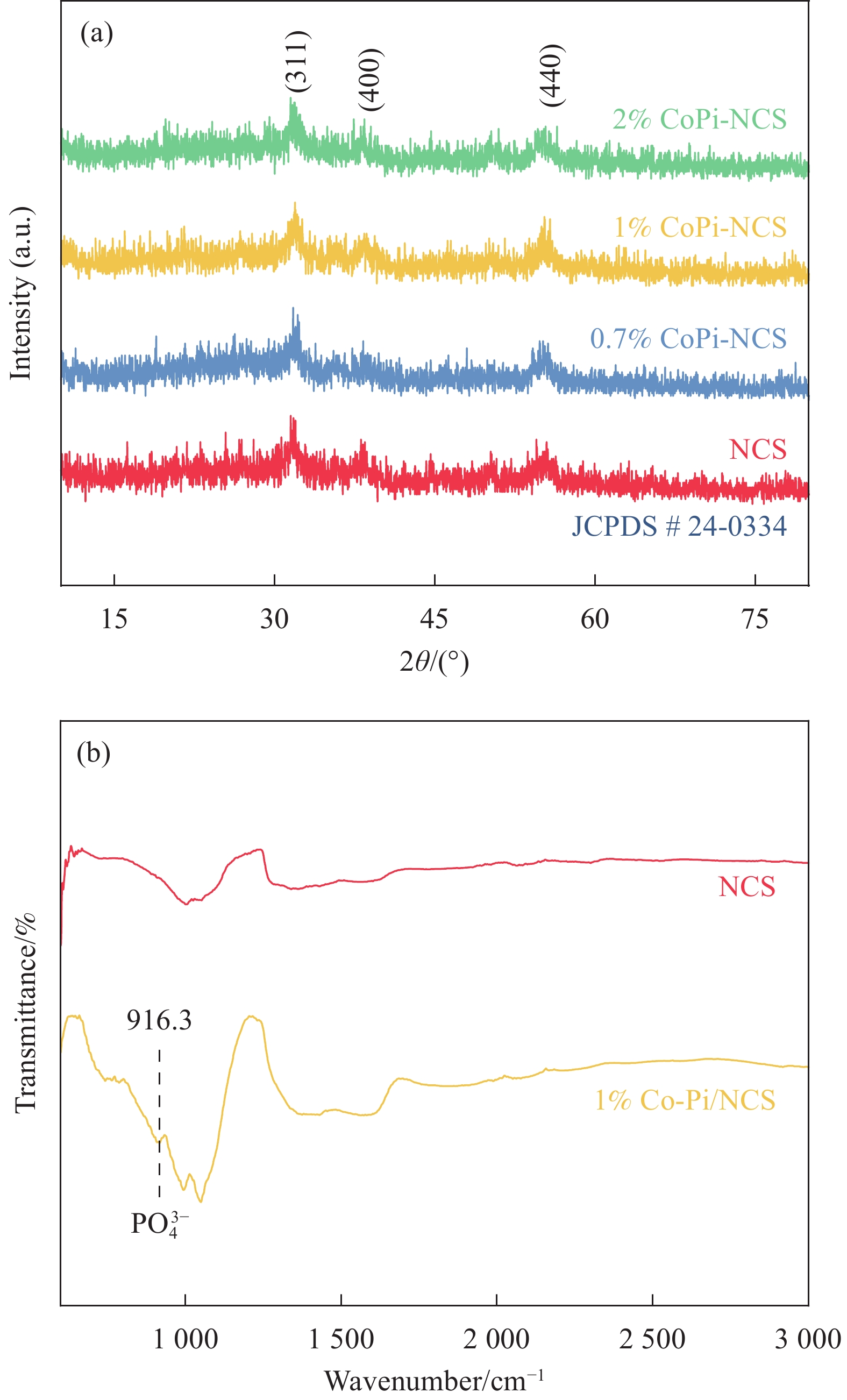

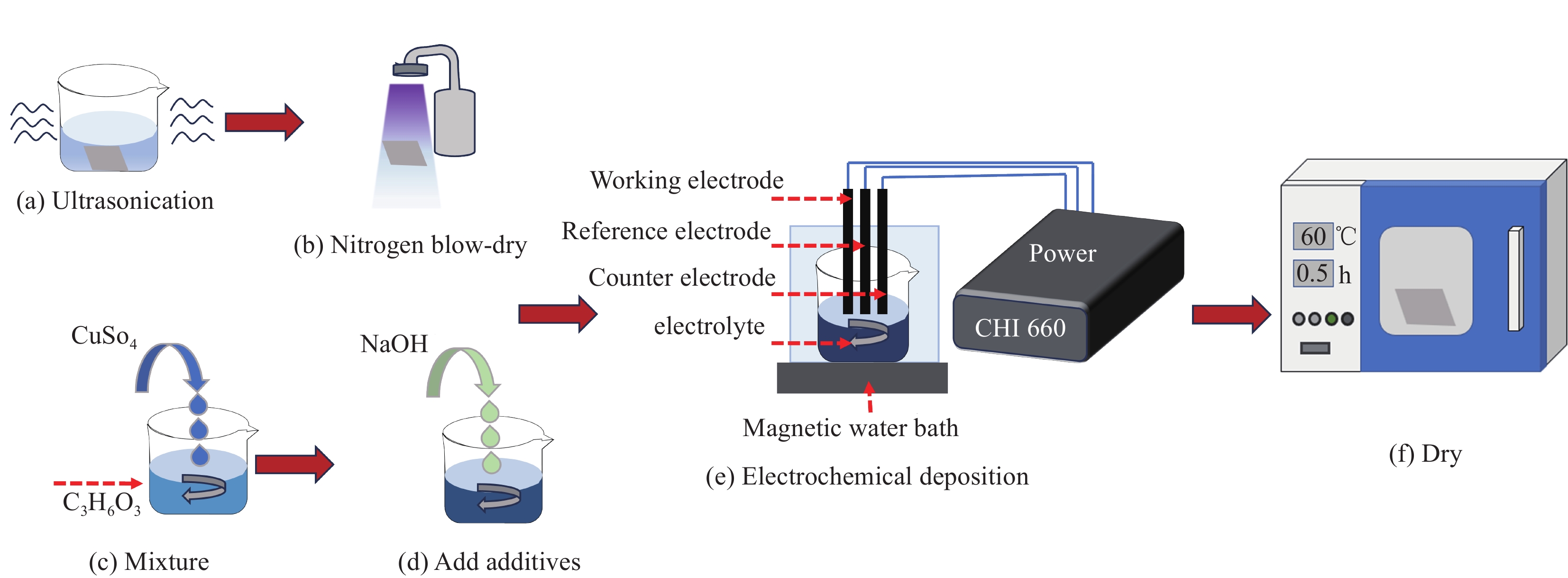

Exploring non-precious metal oxygen evolution reaction (OER) electrocatalysts with high activity and stability is pivotal for electrolytic hydrogen production. Herein, we employ a photo-reduction deposition technique to load amorphous cobalt hydrogen phosphate (CoxHyPO4, denoted as Co-Pi) onto the surface of porous NiCo2S4 (NCS) yolk-shell microspheres, successfully fabricating Co-Pi/NCS composite material. Through the integration of density functional theory (DFT) calculations with experimental investigations, the influence of Co-Pi introduction on the electronic structure and electrocatalytic performance of NCS is probed. The formation of heterogeneous interfaces and reconstruction of chemical bonds enhance the conductivity of Co-Pi/NCS, and modulate charge transfer between the catalyst and reaction intermediates, thereby altering adsorption strength and Gibbs free energy of the reaction, ultimately optimizing OER catalytic activity. Consequently, Co-Pi/NCS demonstrates commendable activity and durability, exhibiting low overpotential of 335 mV at current density of 10 mA·cm−2 and maintaining prolonged stability for 14 hours in 1 mol/L KOH solution. This work holds promise for advancing the utilization of transition metal sulfides in electrochemical oxygen production processes.

Exploring non-precious metal oxygen evolution reaction (OER) electrocatalysts with high activity and stability is pivotal for electrolytic hydrogen production. Herein, we employ a photo-reduction deposition technique to load amorphous cobalt hydrogen phosphate (CoxHyPO4, denoted as Co-Pi) onto the surface of porous NiCo2S4 (NCS) yolk-shell microspheres, successfully fabricating Co-Pi/NCS composite material. Through the integration of density functional theory (DFT) calculations with experimental investigations, the influence of Co-Pi introduction on the electronic structure and electrocatalytic performance of NCS is probed. The formation of heterogeneous interfaces and reconstruction of chemical bonds enhance the conductivity of Co-Pi/NCS, and modulate charge transfer between the catalyst and reaction intermediates, thereby altering adsorption strength and Gibbs free energy of the reaction, ultimately optimizing OER catalytic activity. Consequently, Co-Pi/NCS demonstrates commendable activity and durability, exhibiting low overpotential of 335 mV at current density of 10 mA·cm−2 and maintaining prolonged stability for 14 hours in 1 mol/L KOH solution. This work holds promise for advancing the utilization of transition metal sulfides in electrochemical oxygen production processes.

, Available online

Abstract:

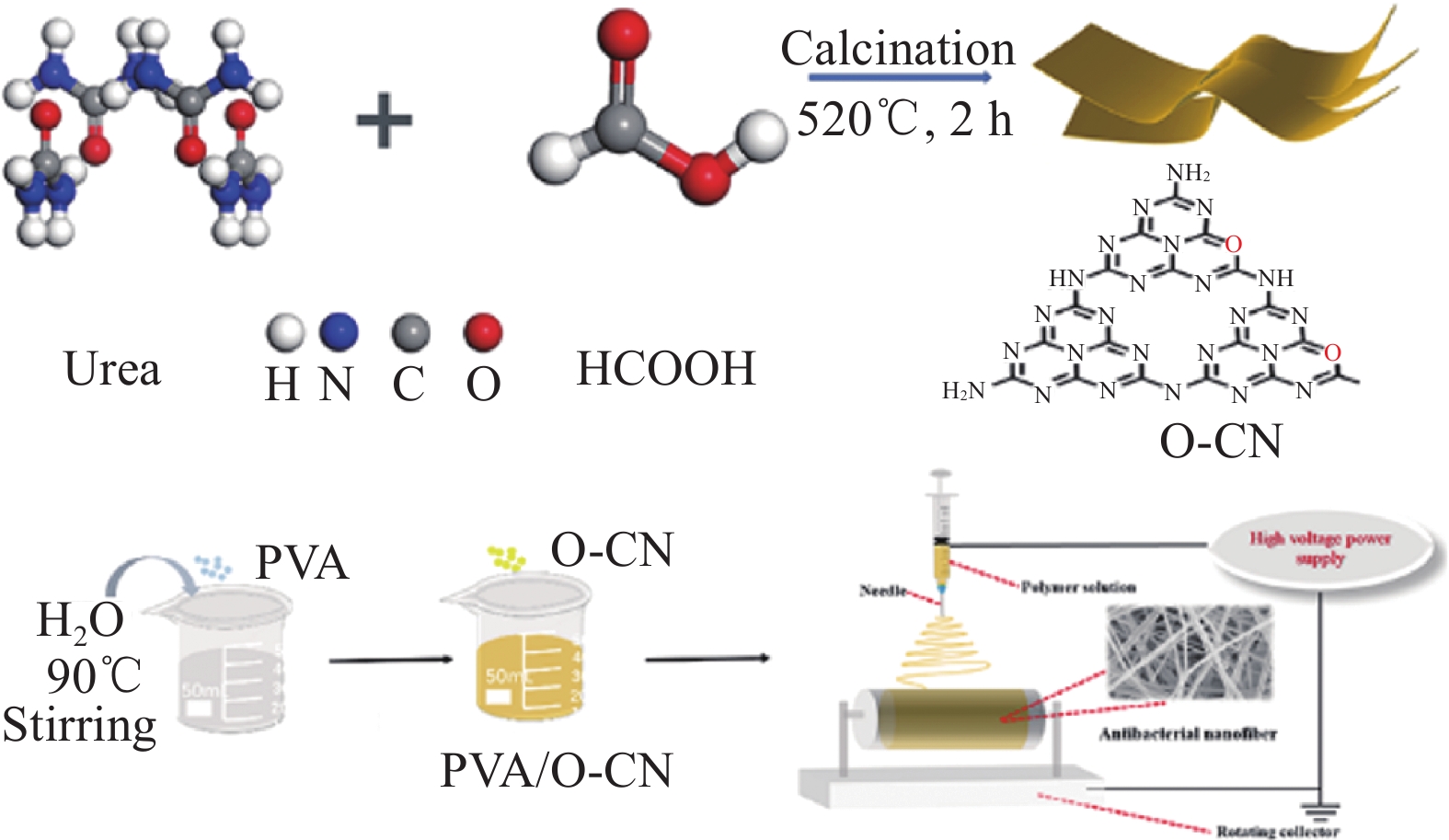

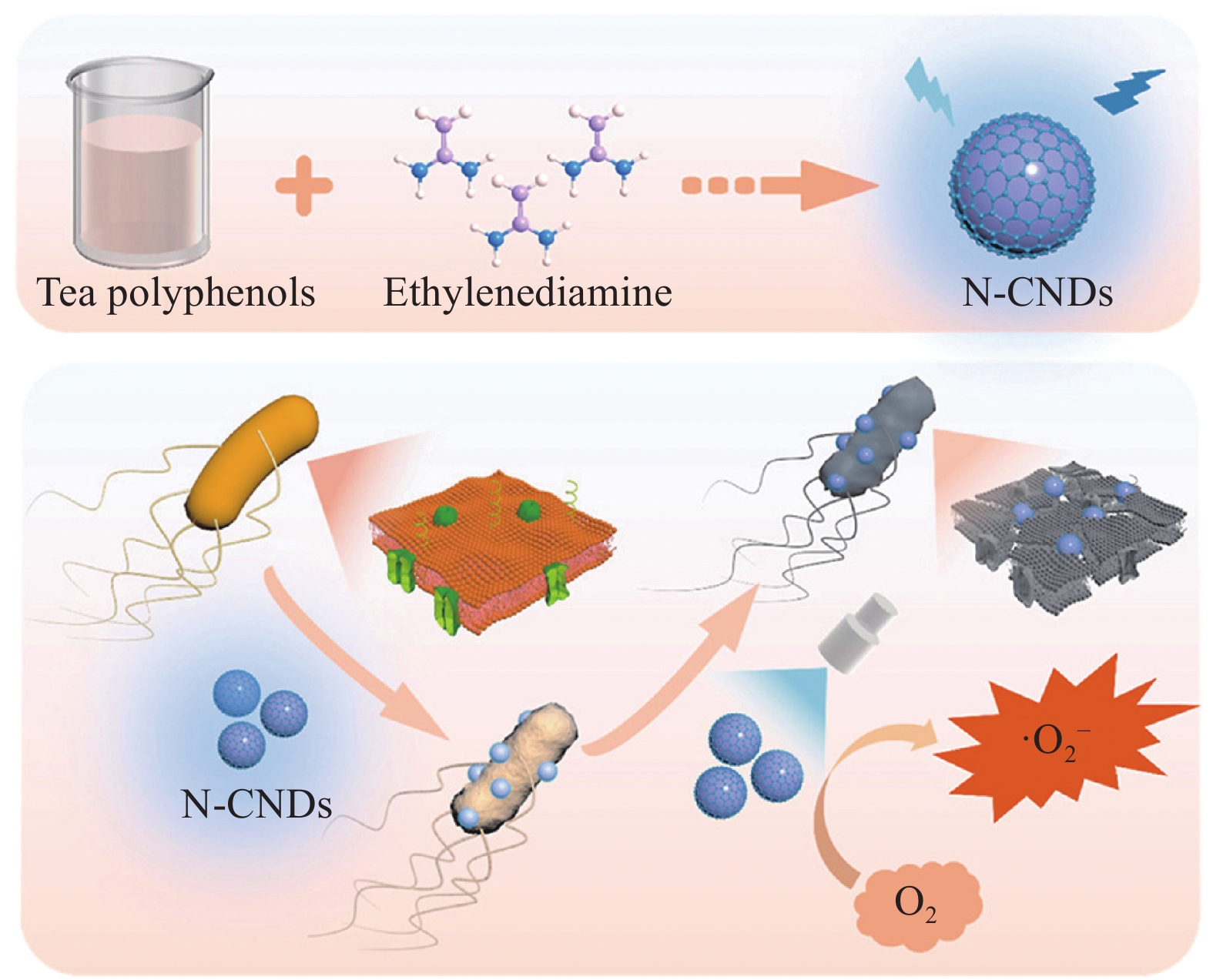

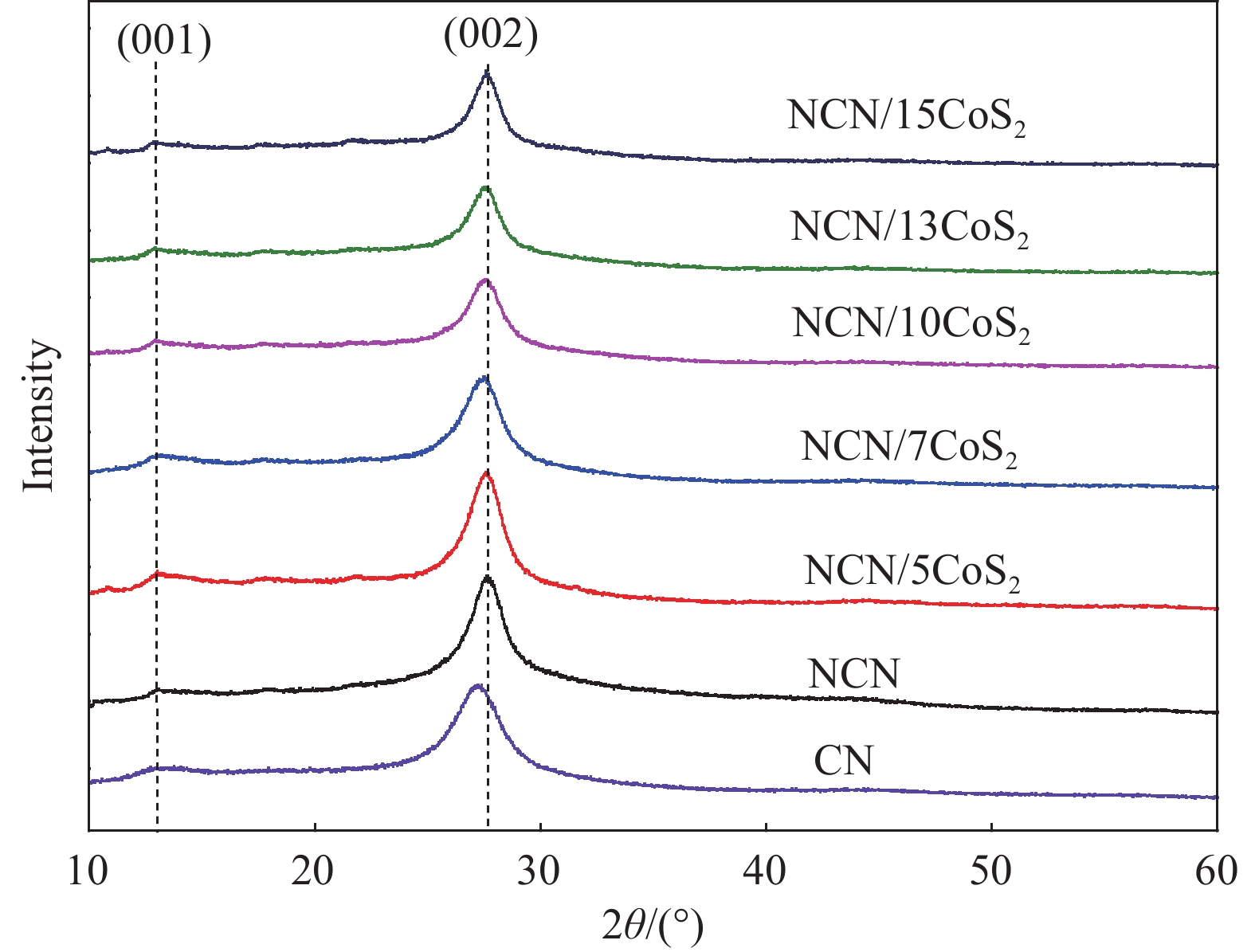

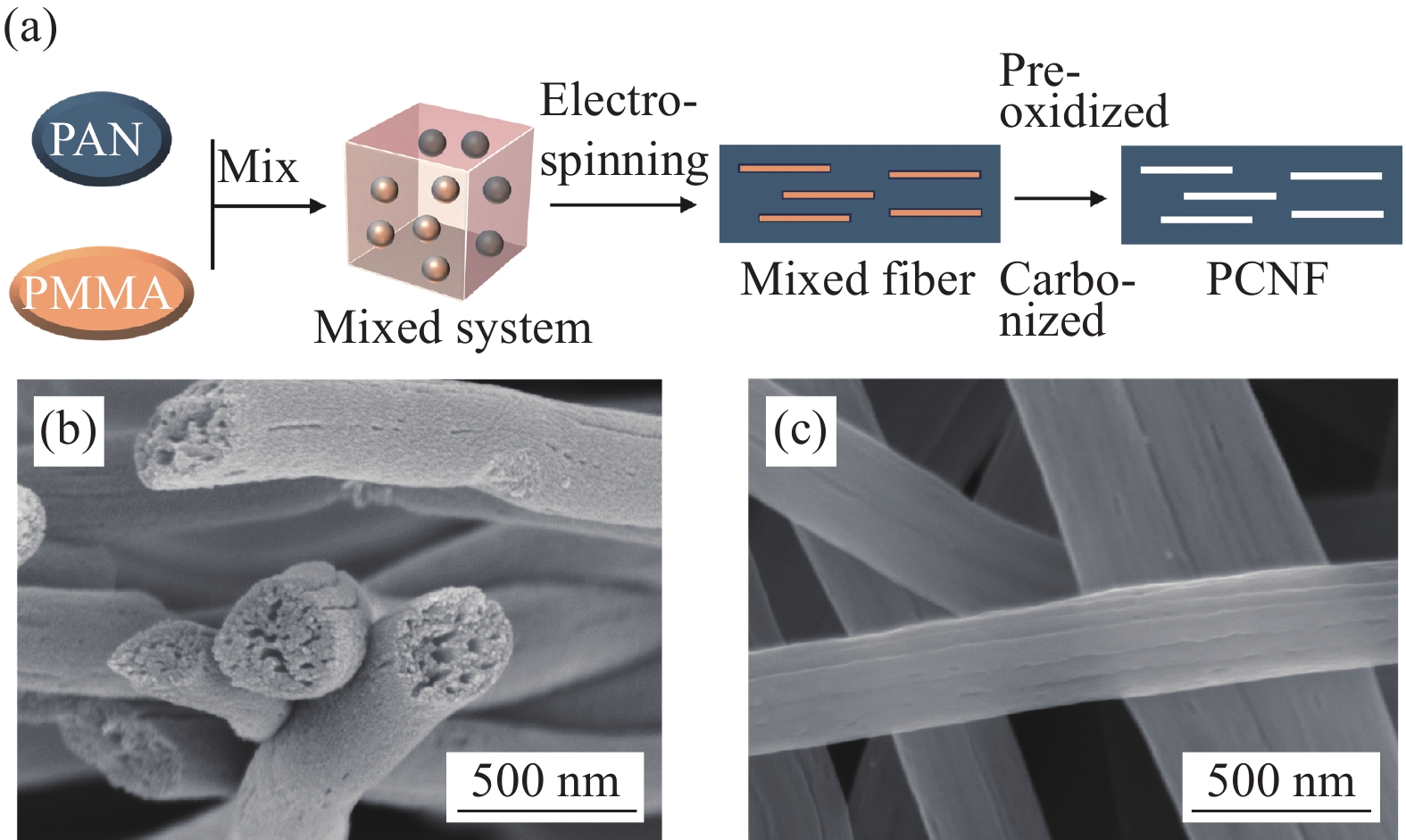

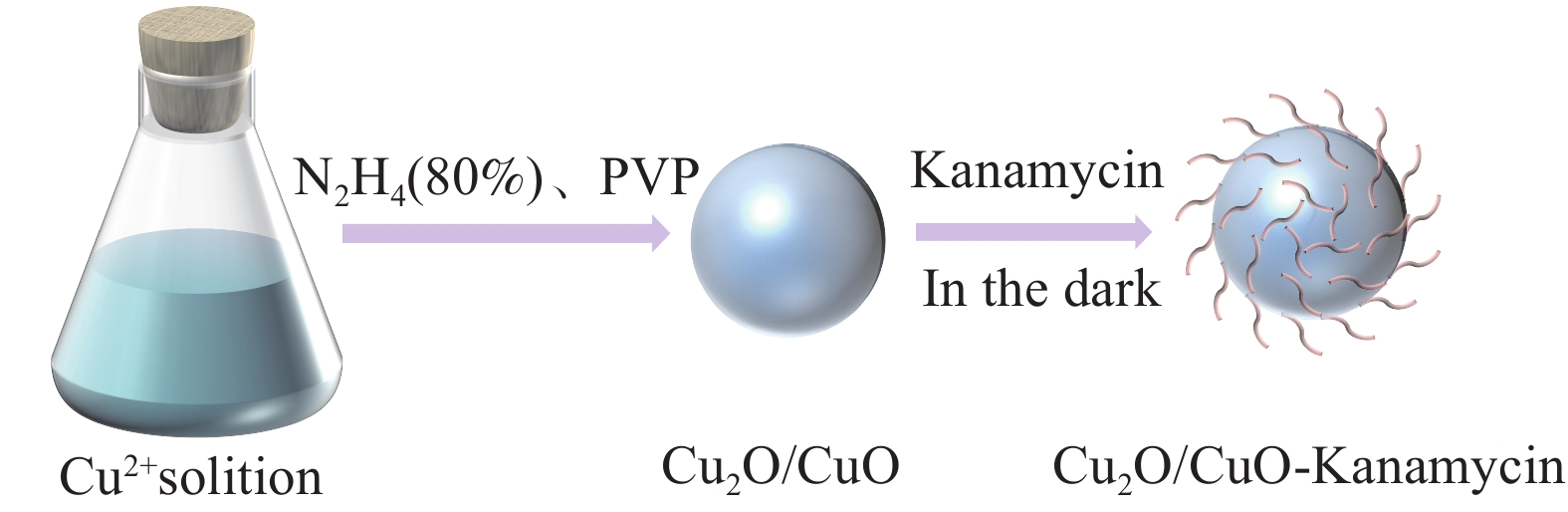

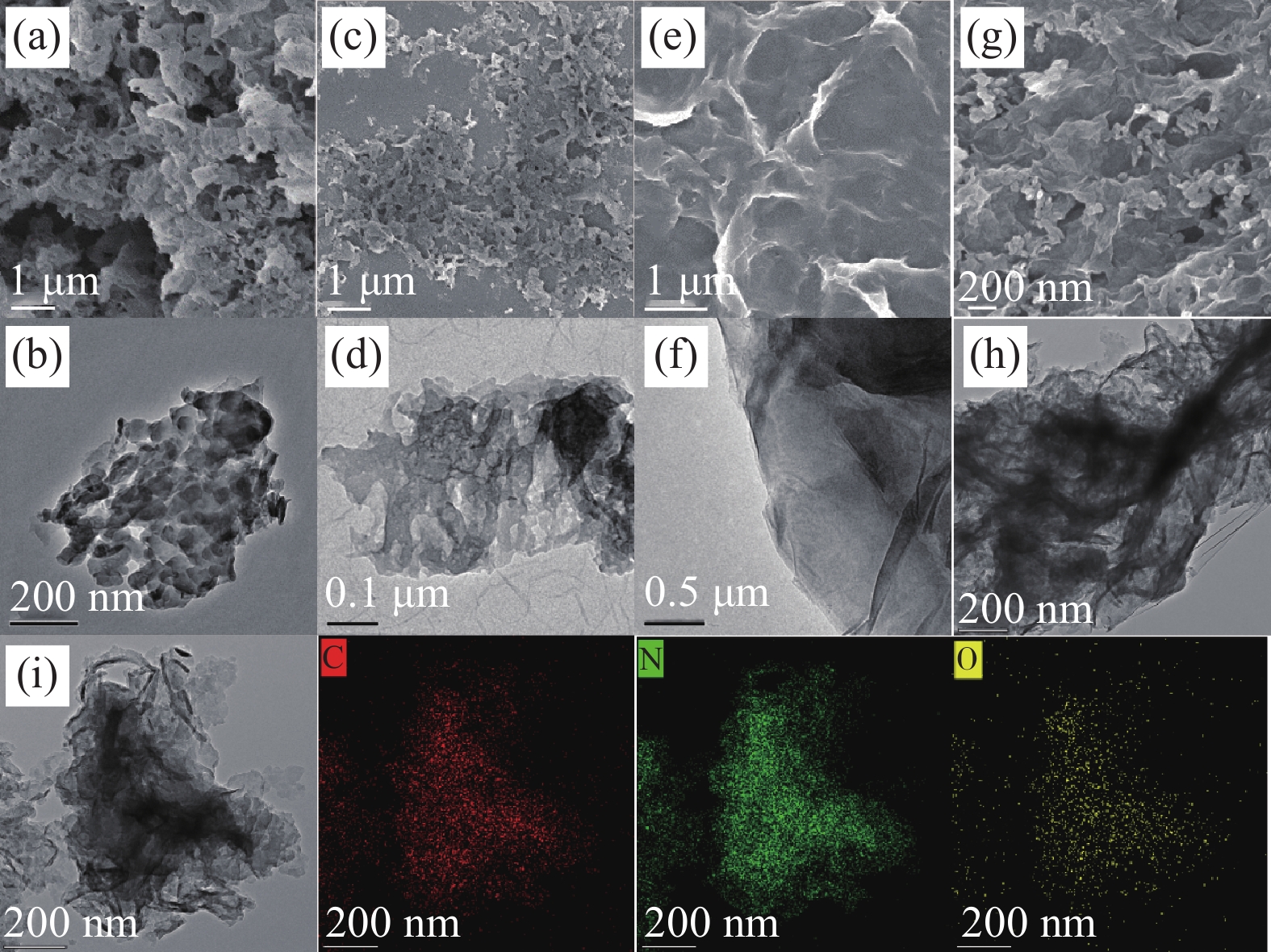

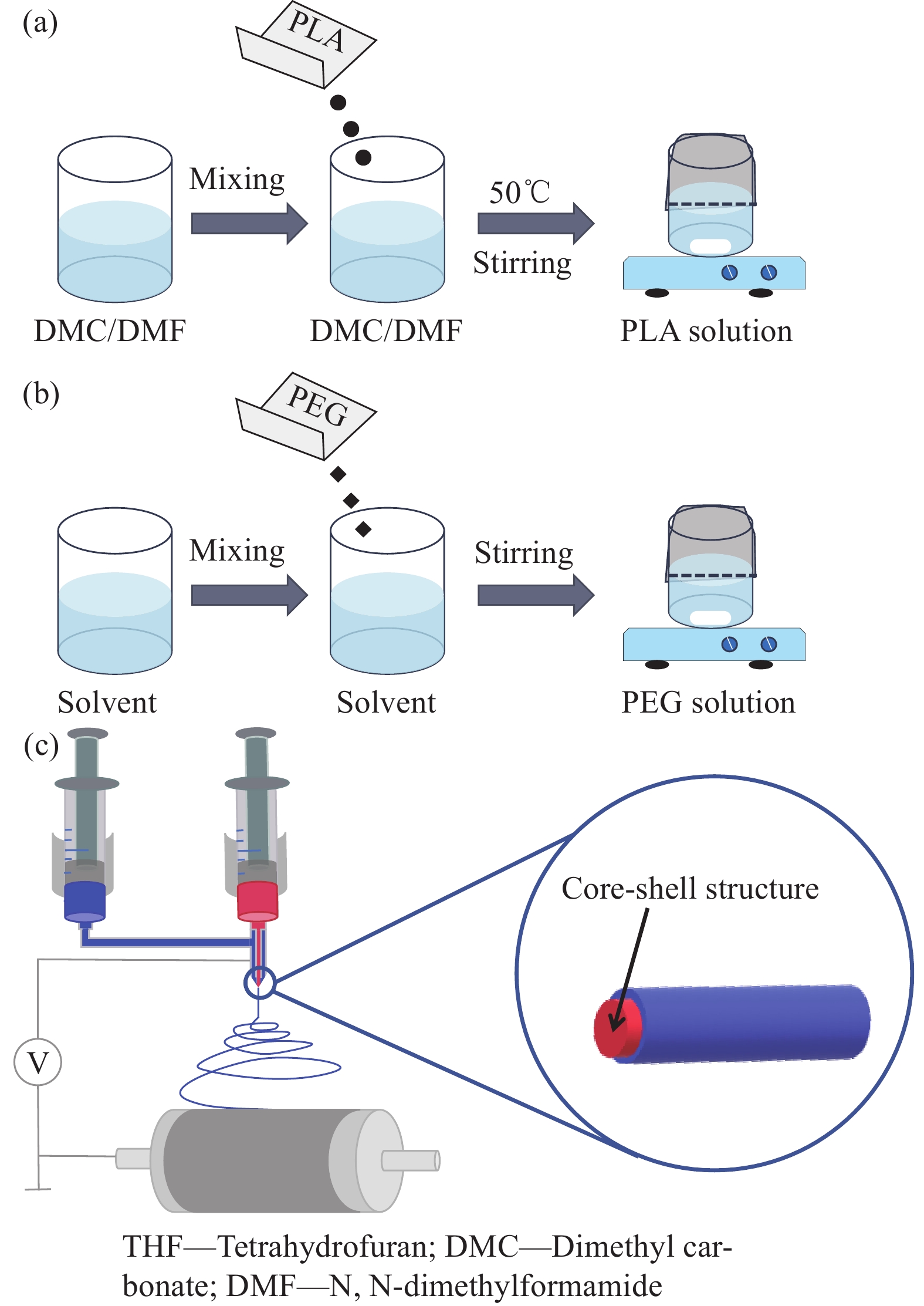

A large number of organic pollutants caused serious pollution to the water cycle, and drug-resistant bacteria posed a serious threat to human health. Photocatalytic nanomaterials have become a research hotspot in the field of antibacteria. In this paper, oxygen-doped carbon nitride (O-CN) was prepared by hot polymerization with Urea and formic acid. The optimal proportion of O-CN was mixed with polyvinyl alcohol (PVA) solution, and the polyvinyl alcohol/oxygen-doped carbon nitride (PVA/O-CN) composite nanofiber film was successfully prepared by electrospinning technology. The micro-morphology, structure, photocatalytic bacteriostatic properties and organic pollutant removal properties of O-CN and PVA/O-CN composite films were studied. The results showed that O atom could replace the N position in the triazine ring structure of CN, and the light absorption capacity and the separation rate of electron-hole improved compared with that of CN. PVA/O-CN-0.6 composite nanofiber membrane had the best inhibition effect on E.coli and S.aureus, and the inhibition rates were 96% and 93.7%, respectively. In addition, PVA/O-CN-0.6 composite nanofiber membrane had a good performance in dye removal, and the removal rate of methylene blue (MB) by PVA/O-CN-0.6 reached 97.7% within 4 h. Moreover, the film with excellent mechanical properties, has great application potential in many fields.

A large number of organic pollutants caused serious pollution to the water cycle, and drug-resistant bacteria posed a serious threat to human health. Photocatalytic nanomaterials have become a research hotspot in the field of antibacteria. In this paper, oxygen-doped carbon nitride (O-CN) was prepared by hot polymerization with Urea and formic acid. The optimal proportion of O-CN was mixed with polyvinyl alcohol (PVA) solution, and the polyvinyl alcohol/oxygen-doped carbon nitride (PVA/O-CN) composite nanofiber film was successfully prepared by electrospinning technology. The micro-morphology, structure, photocatalytic bacteriostatic properties and organic pollutant removal properties of O-CN and PVA/O-CN composite films were studied. The results showed that O atom could replace the N position in the triazine ring structure of CN, and the light absorption capacity and the separation rate of electron-hole improved compared with that of CN. PVA/O-CN-0.6 composite nanofiber membrane had the best inhibition effect on E.coli and S.aureus, and the inhibition rates were 96% and 93.7%, respectively. In addition, PVA/O-CN-0.6 composite nanofiber membrane had a good performance in dye removal, and the removal rate of methylene blue (MB) by PVA/O-CN-0.6 reached 97.7% within 4 h. Moreover, the film with excellent mechanical properties, has great application potential in many fields.

, Available online

Abstract:

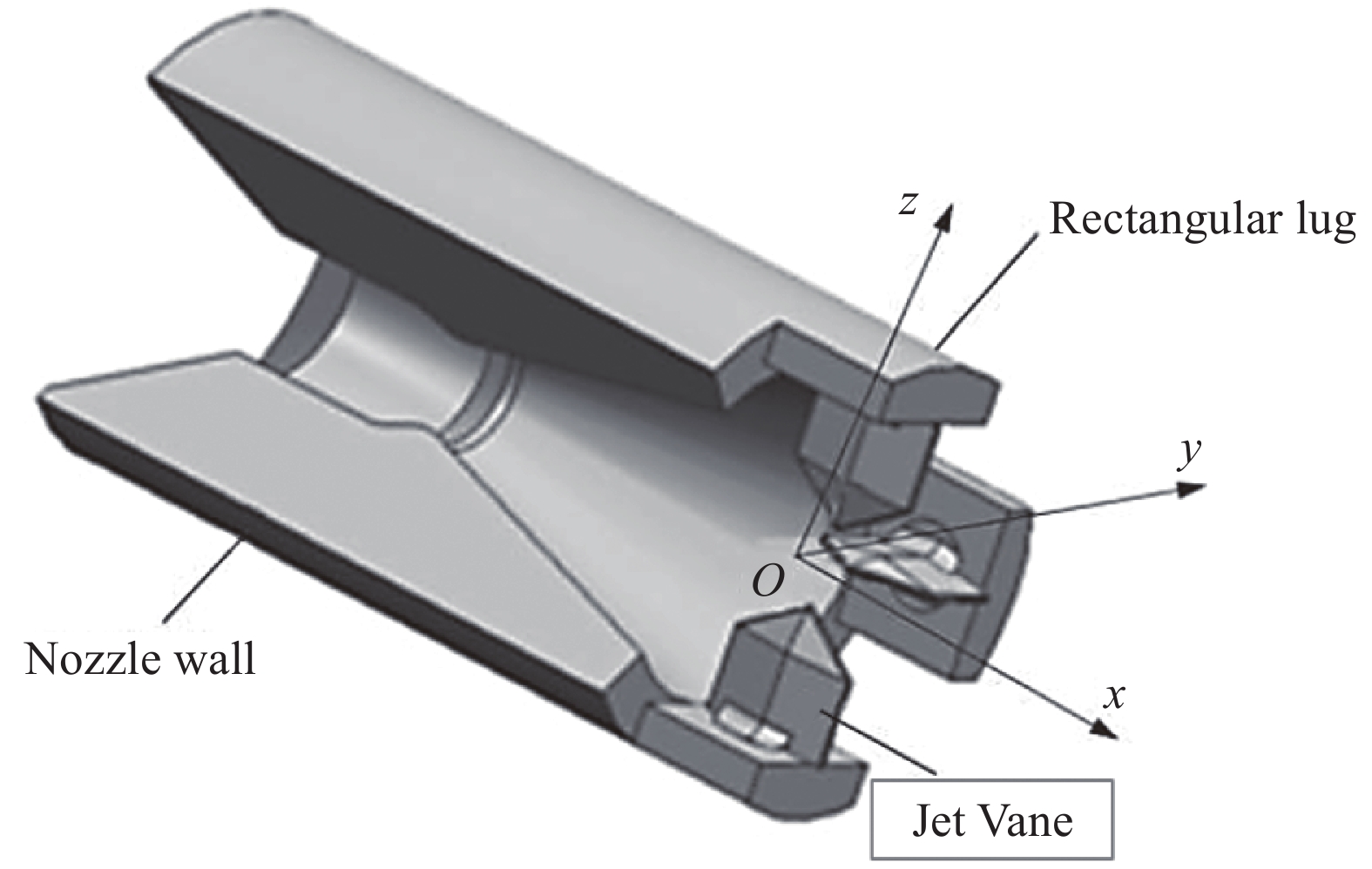

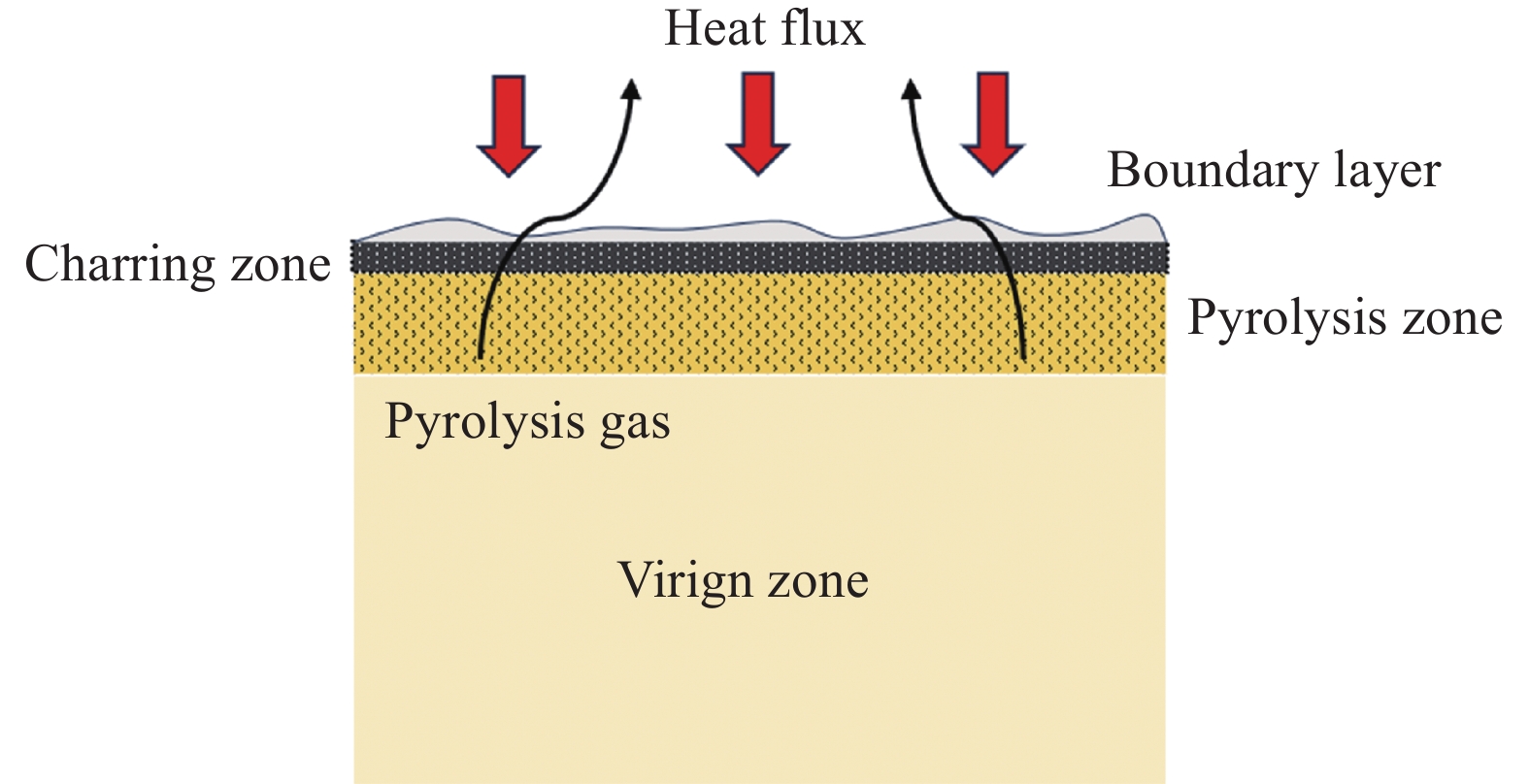

Jet vane has been widely studied and applied because of its fast response and large attitude Angle rotation. However, the ablation and denudation of jet vane surface seriously restricts its development. In this paper, the typical research progress of jet vane is reviewed, including the flow performance of jet vane, the surface thermal chemical ablation and mechanical erosion of metal and composite materials jet vane structure. In addition, in view of the light composite jet vane is an inevitable trend in the future development, the paper also discusses the ablative and denudation of other relevant composite structures for reference. Based on this, the paper finally puts forward the future development focus of composite jet vane, in order to provide reference for the research, application and development of composite jet vane in China.

Jet vane has been widely studied and applied because of its fast response and large attitude Angle rotation. However, the ablation and denudation of jet vane surface seriously restricts its development. In this paper, the typical research progress of jet vane is reviewed, including the flow performance of jet vane, the surface thermal chemical ablation and mechanical erosion of metal and composite materials jet vane structure. In addition, in view of the light composite jet vane is an inevitable trend in the future development, the paper also discusses the ablative and denudation of other relevant composite structures for reference. Based on this, the paper finally puts forward the future development focus of composite jet vane, in order to provide reference for the research, application and development of composite jet vane in China.

, Available online

Abstract:

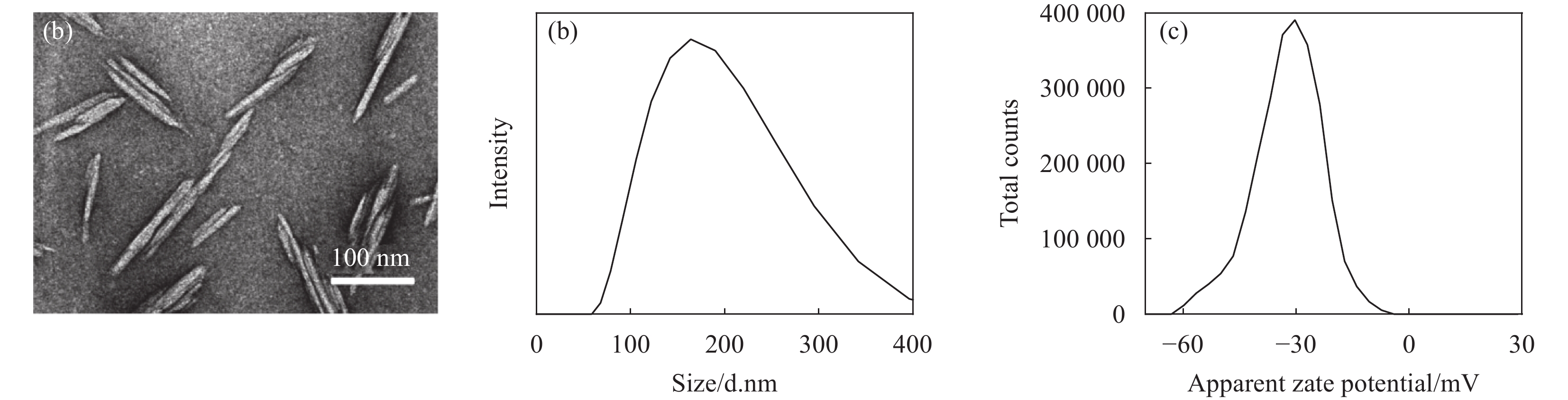

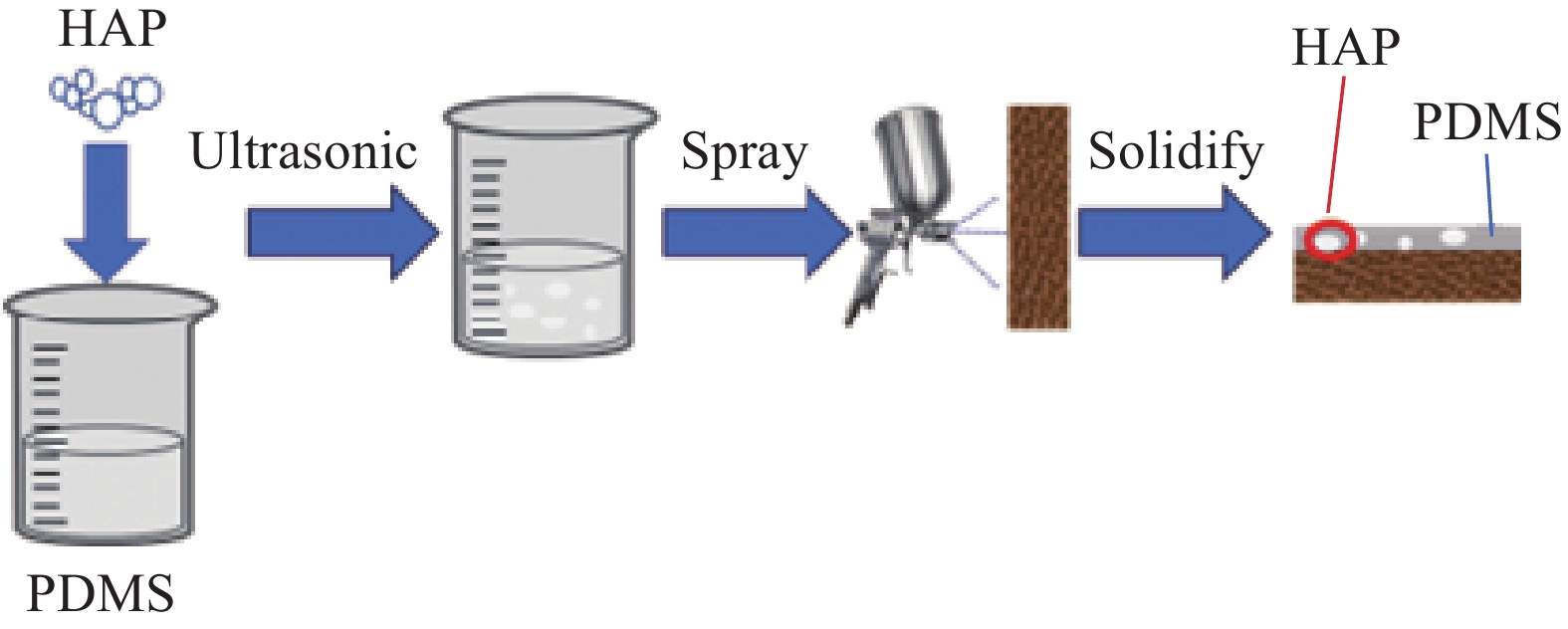

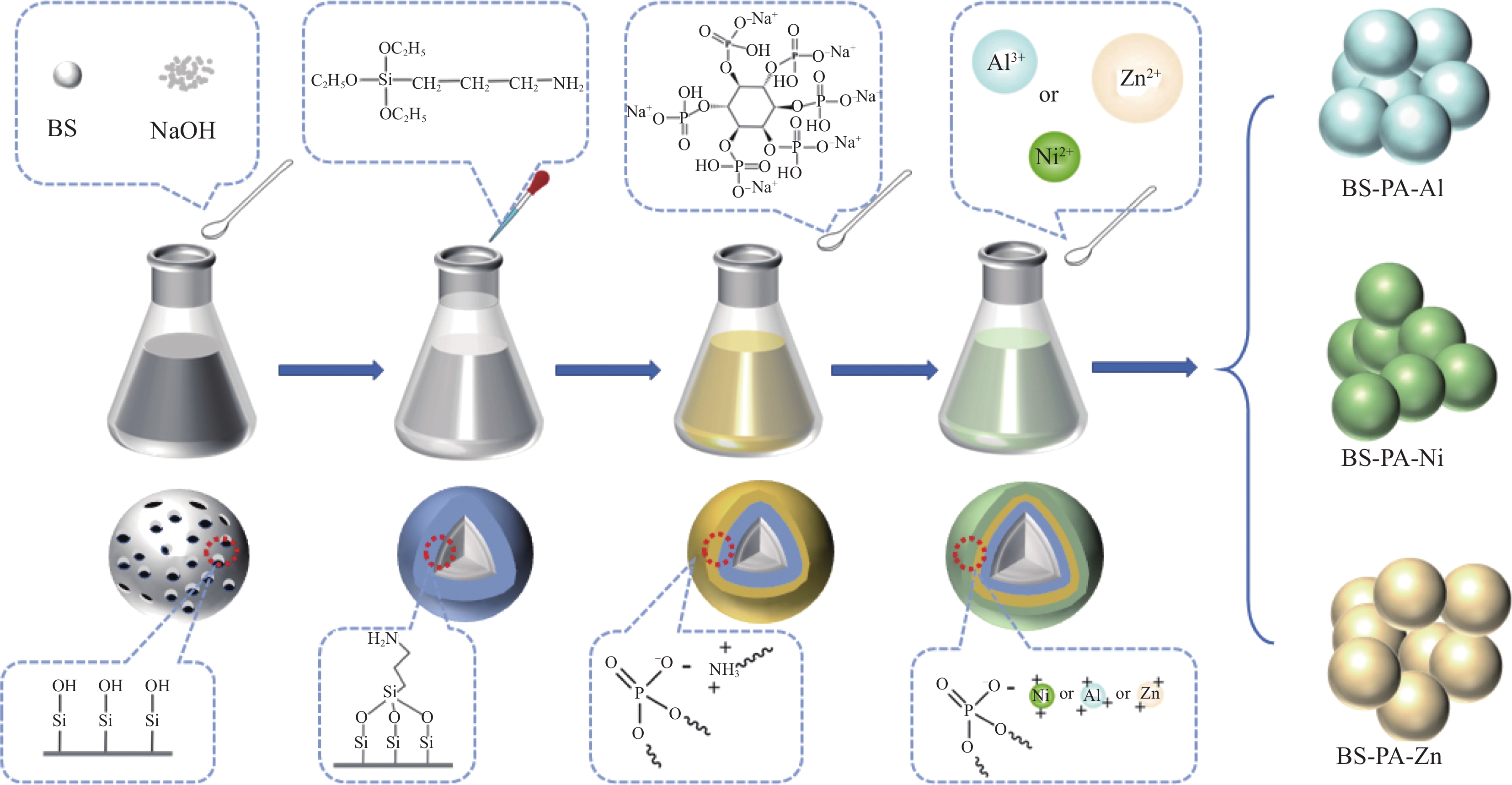

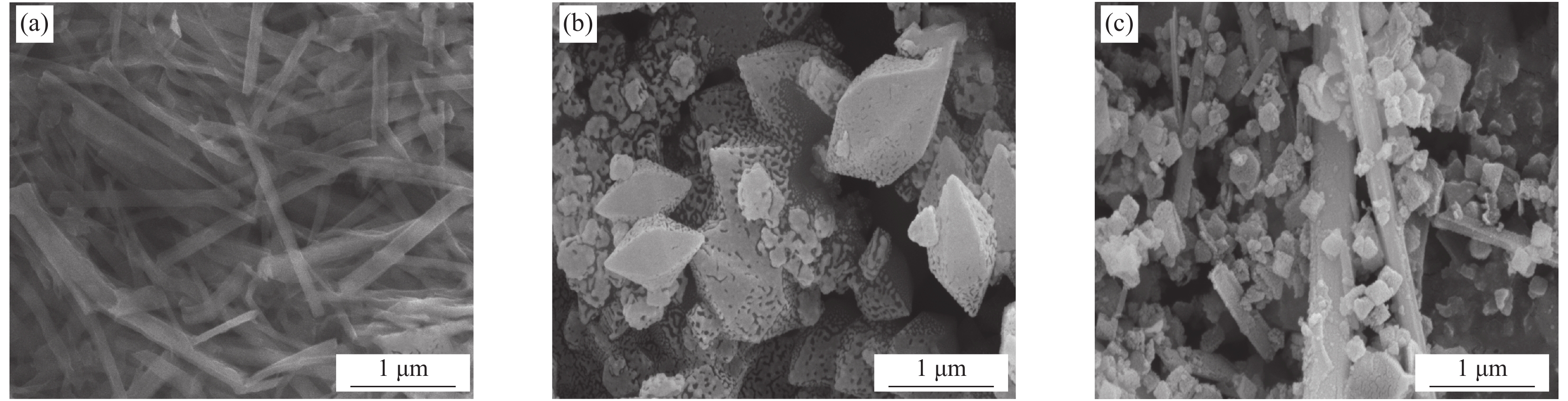

Superhydrophobic modification of wood surfaces can effectively limit the shrinkage and swelling of wood, thereby extending the service life of wood products. However, the practical application of superhydrophobic modification of wood surfaces is limited due to the poor stability of the superhydrophobic coating. The stability of the superhydrophobic coating is affected by the microscopic morphology of inorganic nanoparticles in the wood superhydrophobic layer. However, few research has systematically discussed this issue. In this paper, three types of hydroxyapatite nanomaterials (nanospheres, nanorods and nanowires), were used as raw materials for the superhydrophobic modification of wood surfaces by compounding with polydimethylsiloxane and spraying onto the wood surface. The effect of hydroxyapatite morphology on the stability of the superhydrophobic layer on wood was investigated through sandpaper wear, tape stripping, and chemical corrosion tests. The results demonstrate that hydroxyapatite nanospheres with smaller aspect ratios and sizes can efficiently penetrate the cellular walls and cavities of wood. As a result, the superhydrophobic layer prepared from these nanospheres exhibit better hydrophobicity and stability, and the obtained coatings can maintain superhydrophobicity after 15 cycles of sandpaper wearing and tape peeling. These findings provide a theoretical foundation for the development of high-performance and stable wood superhydrophobic coatings.

Superhydrophobic modification of wood surfaces can effectively limit the shrinkage and swelling of wood, thereby extending the service life of wood products. However, the practical application of superhydrophobic modification of wood surfaces is limited due to the poor stability of the superhydrophobic coating. The stability of the superhydrophobic coating is affected by the microscopic morphology of inorganic nanoparticles in the wood superhydrophobic layer. However, few research has systematically discussed this issue. In this paper, three types of hydroxyapatite nanomaterials (nanospheres, nanorods and nanowires), were used as raw materials for the superhydrophobic modification of wood surfaces by compounding with polydimethylsiloxane and spraying onto the wood surface. The effect of hydroxyapatite morphology on the stability of the superhydrophobic layer on wood was investigated through sandpaper wear, tape stripping, and chemical corrosion tests. The results demonstrate that hydroxyapatite nanospheres with smaller aspect ratios and sizes can efficiently penetrate the cellular walls and cavities of wood. As a result, the superhydrophobic layer prepared from these nanospheres exhibit better hydrophobicity and stability, and the obtained coatings can maintain superhydrophobicity after 15 cycles of sandpaper wearing and tape peeling. These findings provide a theoretical foundation for the development of high-performance and stable wood superhydrophobic coatings.

, Available online

Abstract:

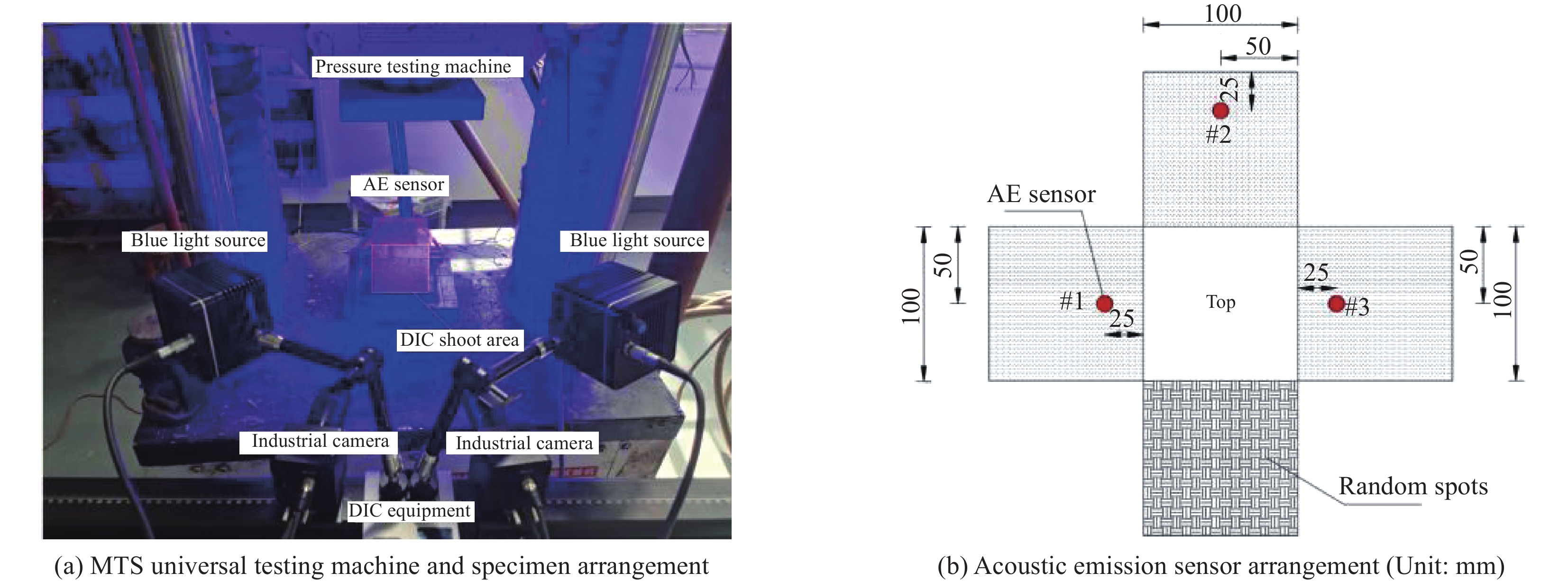

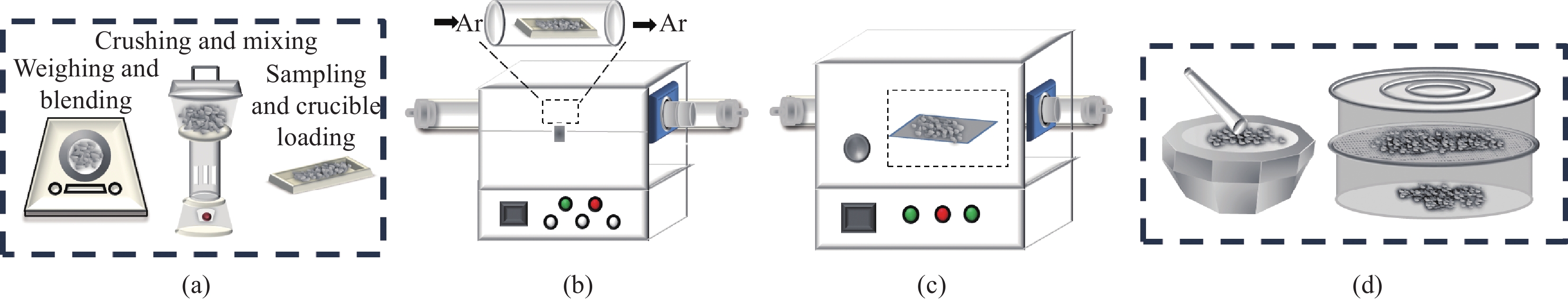

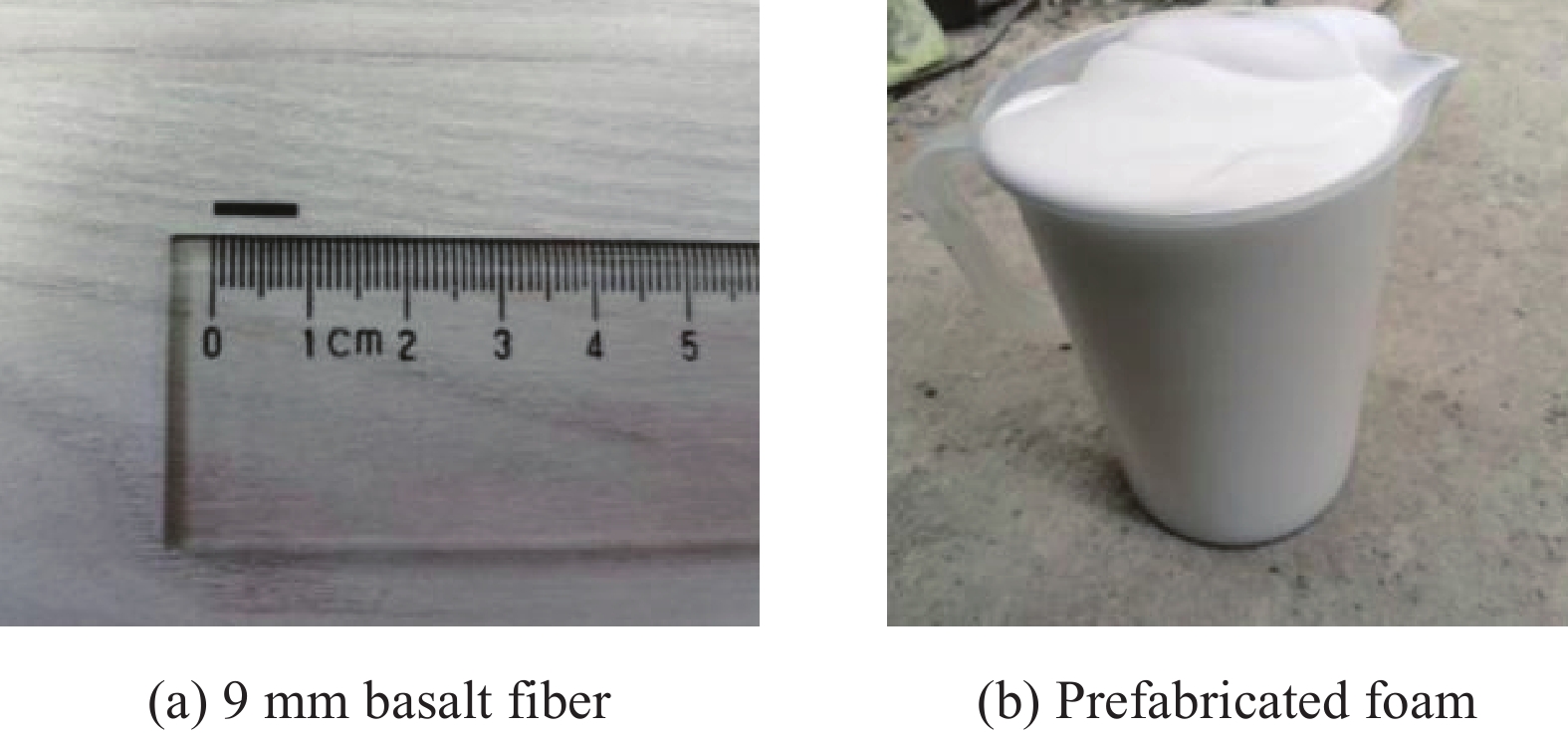

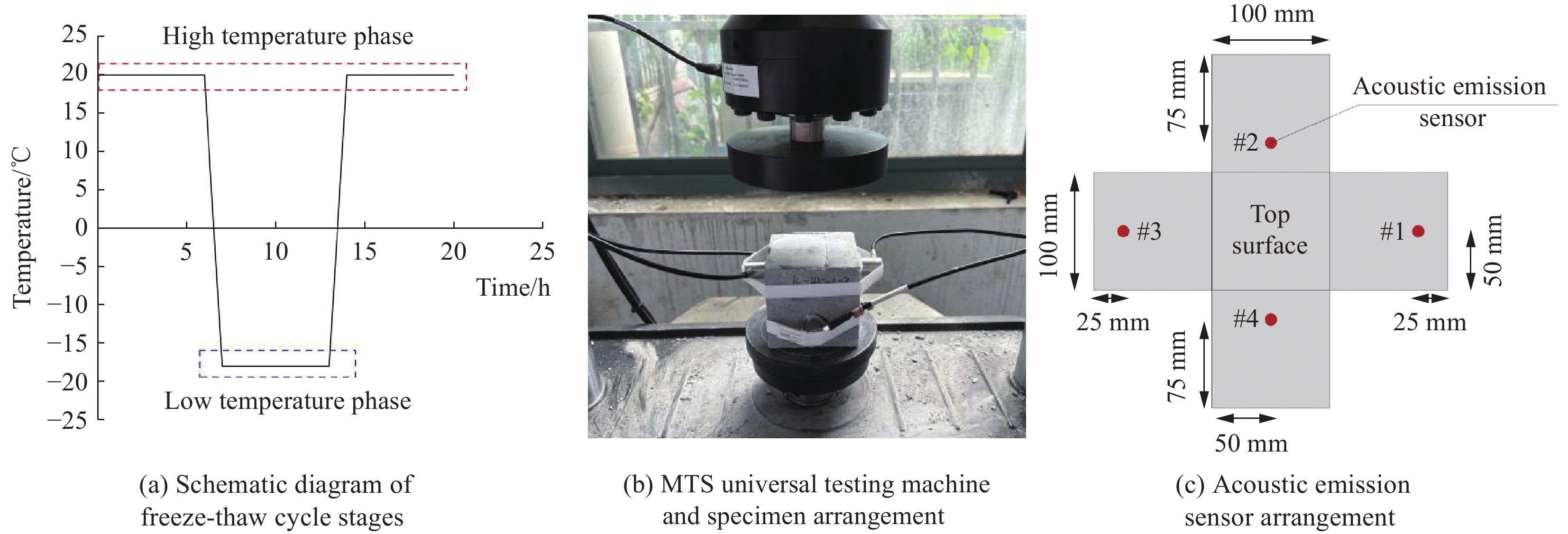

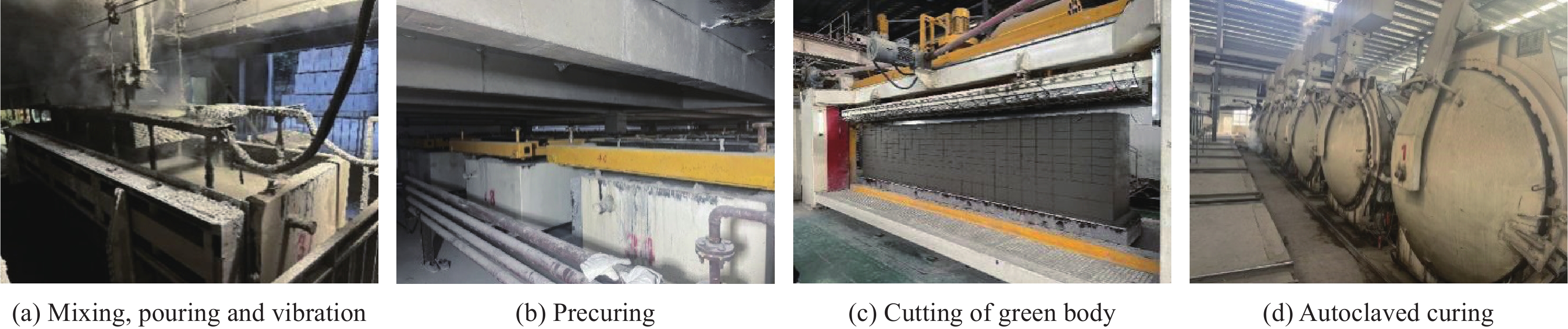

To study the compression damage characteristics and damage evolution law of foam concrete under a freeze-thaw environment, a joint test combining uniaxial compression, acoustic emission (AE), and digital image correlation (DIC) technology was carried out on foam concrete with a density of 800 kg/m3. The strain evolution cloud diagram and acoustic emission parameter change characteristics of the foam concrete during the loading process were obtained. The results show that the compression damage process curve of foam concrete presents an obvious staged effect. The more freeze-thaw cycles the specimen experiences, the more pronounced the ductile damage characteristics become. With the increase in the number of freeze-thaw cycles, the area of the strain concentration zone of the specimen monitored by the DIC gradually increases, while the average value of the strain field gradually decreases. Meanwhile, the morphology of surface cracks in the specimen evolves from initial vertical single cracks to tilted shear-type multi-fractures. The proportion of shear cracks in the final damage of foam concrete specimens with 0, 20, 40, 60, and 80 freeze-thaw cycles are 52.5%, 57.8%, 59.2%, 65.3%, and 69.2%, respectively. The stages of decreasing acoustic emission b-value appear in 92.3%, 89.1%, 88.5%, 76.5%, and 72.3% of the loading process, respectively. The freeze-thaw environment can promote the transition from tensile to shear damage in foam concrete, exacerbates the internal damage of foam concrete, and thus induces large-scale rupture phenomena within the material. The results of AE and DIC complement each other, and their combination contributes to a comprehensive understanding of the developmental pattern of microcracks and damage mechanisms in foam concrete.

To study the compression damage characteristics and damage evolution law of foam concrete under a freeze-thaw environment, a joint test combining uniaxial compression, acoustic emission (AE), and digital image correlation (DIC) technology was carried out on foam concrete with a density of 800 kg/m3. The strain evolution cloud diagram and acoustic emission parameter change characteristics of the foam concrete during the loading process were obtained. The results show that the compression damage process curve of foam concrete presents an obvious staged effect. The more freeze-thaw cycles the specimen experiences, the more pronounced the ductile damage characteristics become. With the increase in the number of freeze-thaw cycles, the area of the strain concentration zone of the specimen monitored by the DIC gradually increases, while the average value of the strain field gradually decreases. Meanwhile, the morphology of surface cracks in the specimen evolves from initial vertical single cracks to tilted shear-type multi-fractures. The proportion of shear cracks in the final damage of foam concrete specimens with 0, 20, 40, 60, and 80 freeze-thaw cycles are 52.5%, 57.8%, 59.2%, 65.3%, and 69.2%, respectively. The stages of decreasing acoustic emission b-value appear in 92.3%, 89.1%, 88.5%, 76.5%, and 72.3% of the loading process, respectively. The freeze-thaw environment can promote the transition from tensile to shear damage in foam concrete, exacerbates the internal damage of foam concrete, and thus induces large-scale rupture phenomena within the material. The results of AE and DIC complement each other, and their combination contributes to a comprehensive understanding of the developmental pattern of microcracks and damage mechanisms in foam concrete.

, Available online

Abstract:

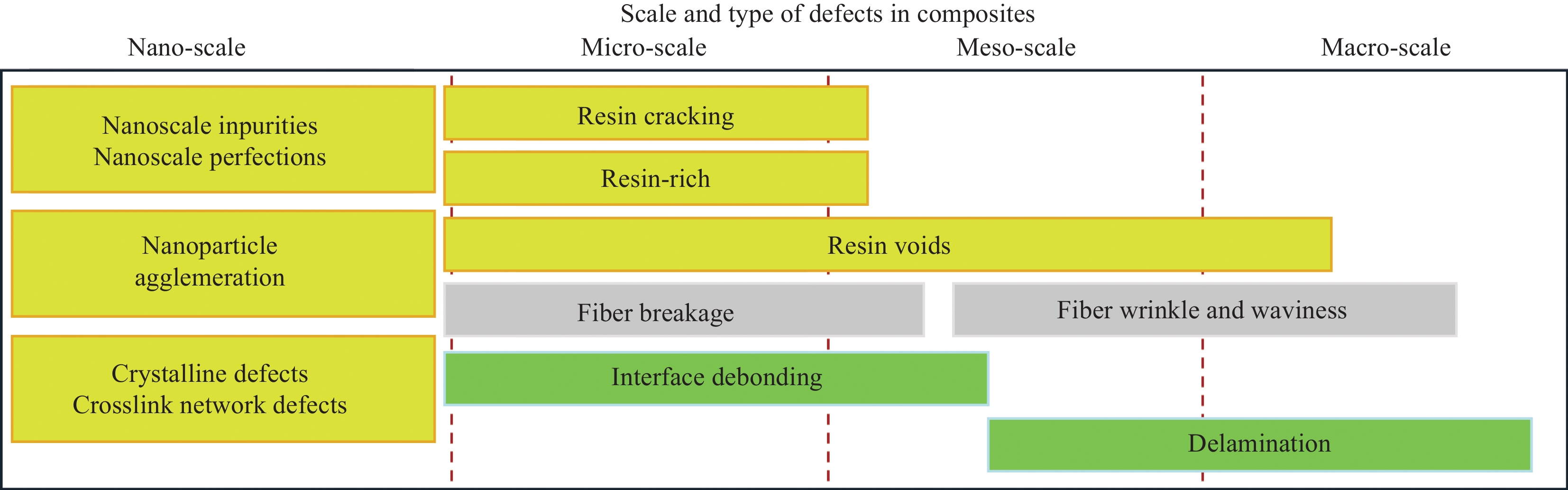

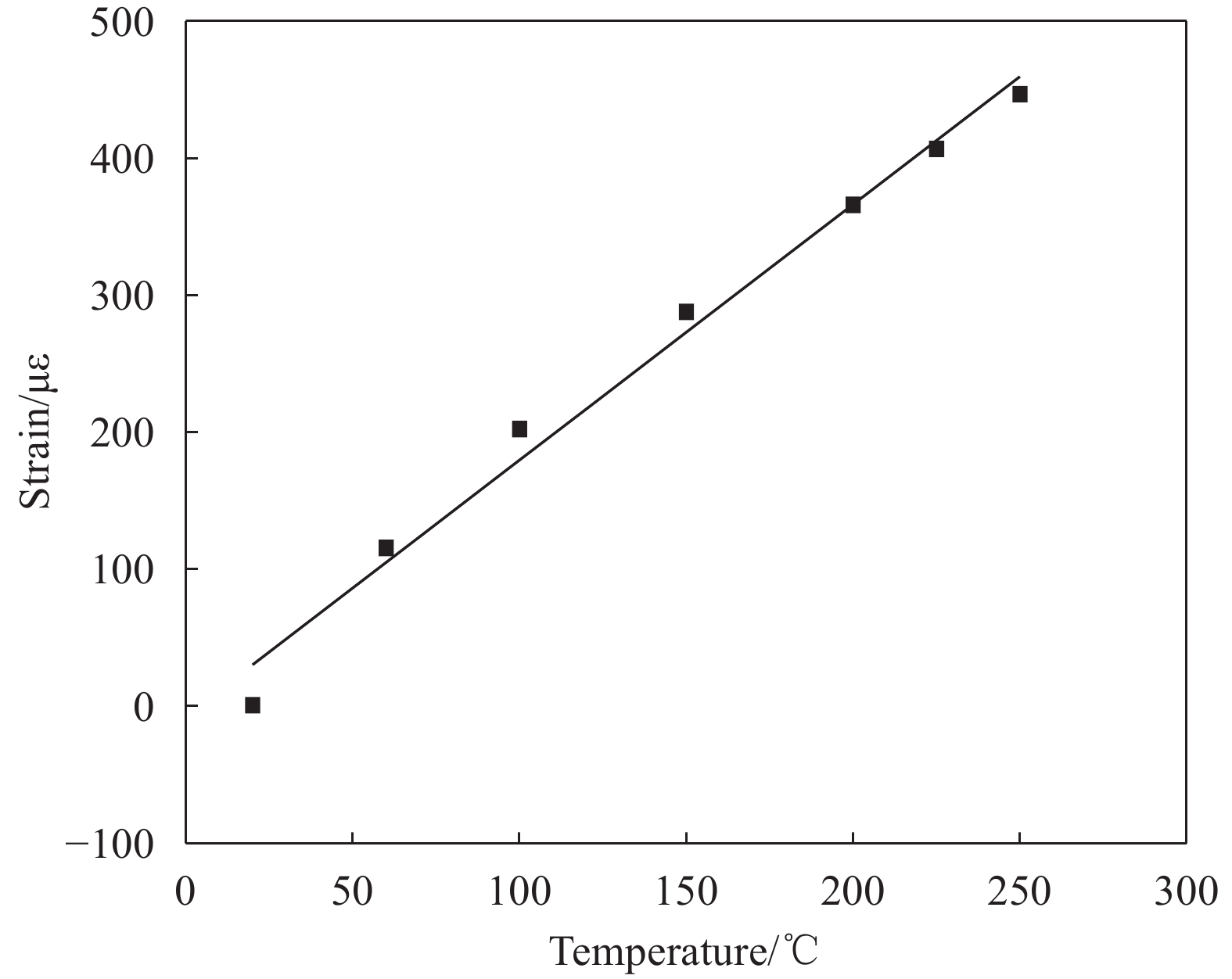

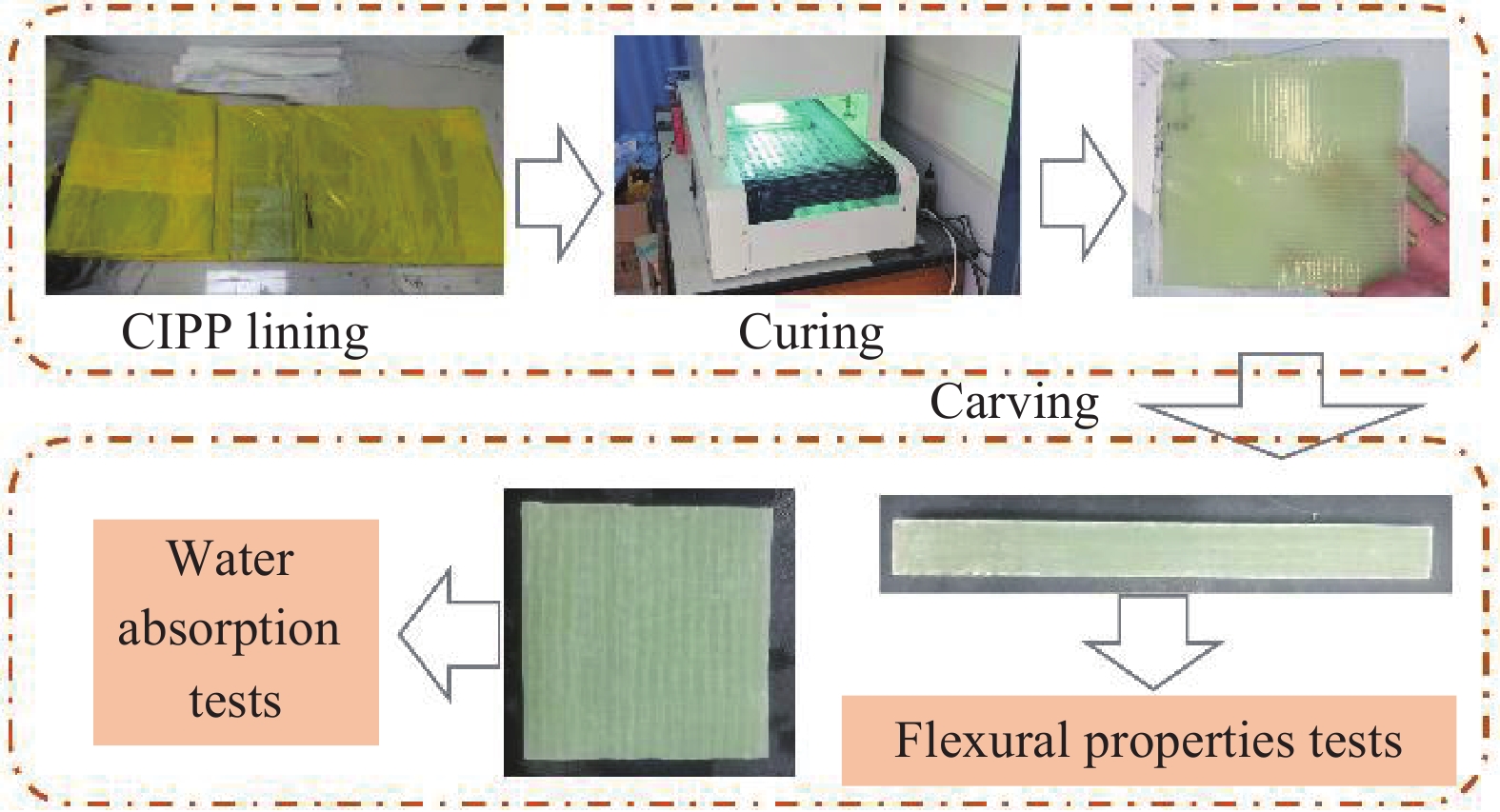

Fiber-reinforced resin matrix composites (FRC) are extensively utilized in sectors such as aerospace, rail transportation, and wind energy due to their exceptional properties, including high specific strength, corrosion resistance, and cost-effectiveness. However, during the molding process, these composites undergo complex physical and chemical transformations that inevitably lead to the formation of internal defects. Notably, the rapid thermal cycling associated with additive manufacturing (AM) processes further escalates the likelihood of defect formation. Consequently, research into manufacturing defects and online monitoring is crucial for enhancing the quality of FRC produced through additive manufacturing. This study provides an in-depth summary of the mechanisms behind the formation of defects within the resin matrix of composites, including residual stress, porosity, resin-rich areas, and interfacial defects. It analyzes the impact of these defects on the macroscopic mechanical properties of the composites and elucidates the micro-level origins of each defect type. Subsequently, the paper consolidates online detection techniques based on Fiber Bragg Grating (FBG) sensors, strain and displacement sensors, acoustic emission technology, and thermodynamic monitoring. It discusses the technical characteristics, application scenarios, and limitations of these techniques, aiming to offer insights and references for scientific research in this field.

Fiber-reinforced resin matrix composites (FRC) are extensively utilized in sectors such as aerospace, rail transportation, and wind energy due to their exceptional properties, including high specific strength, corrosion resistance, and cost-effectiveness. However, during the molding process, these composites undergo complex physical and chemical transformations that inevitably lead to the formation of internal defects. Notably, the rapid thermal cycling associated with additive manufacturing (AM) processes further escalates the likelihood of defect formation. Consequently, research into manufacturing defects and online monitoring is crucial for enhancing the quality of FRC produced through additive manufacturing. This study provides an in-depth summary of the mechanisms behind the formation of defects within the resin matrix of composites, including residual stress, porosity, resin-rich areas, and interfacial defects. It analyzes the impact of these defects on the macroscopic mechanical properties of the composites and elucidates the micro-level origins of each defect type. Subsequently, the paper consolidates online detection techniques based on Fiber Bragg Grating (FBG) sensors, strain and displacement sensors, acoustic emission technology, and thermodynamic monitoring. It discusses the technical characteristics, application scenarios, and limitations of these techniques, aiming to offer insights and references for scientific research in this field.

, Available online

Abstract:

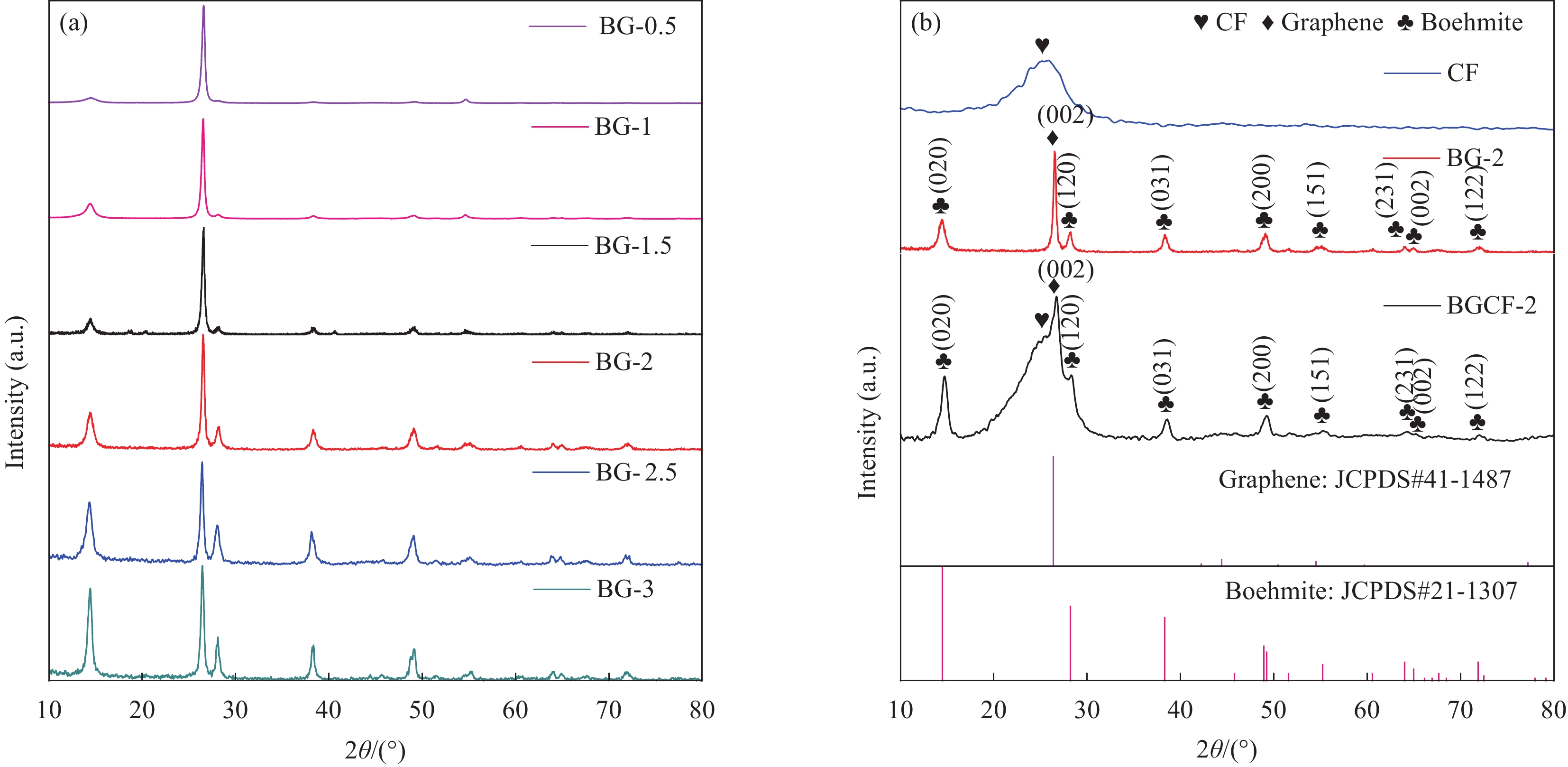

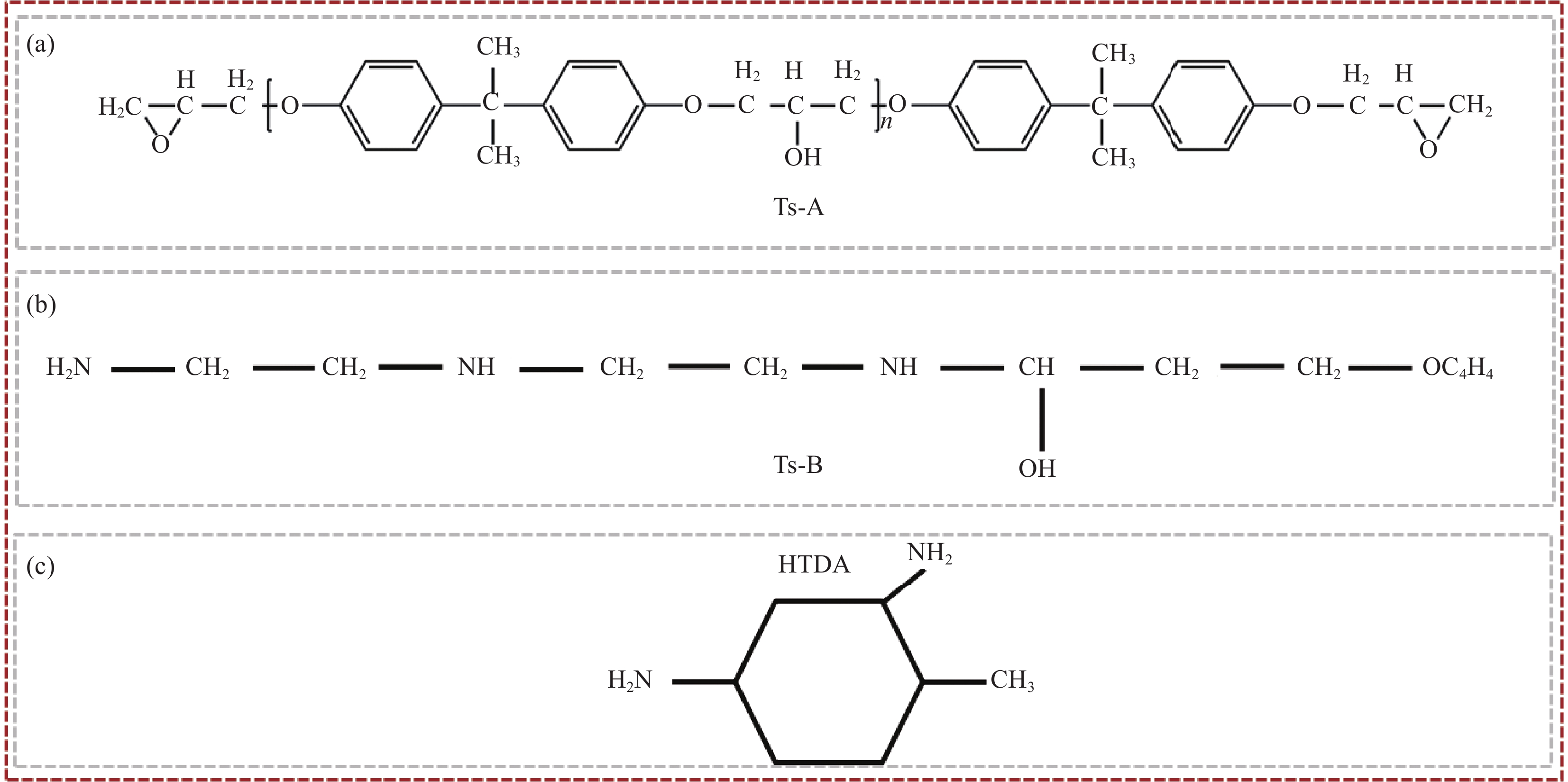

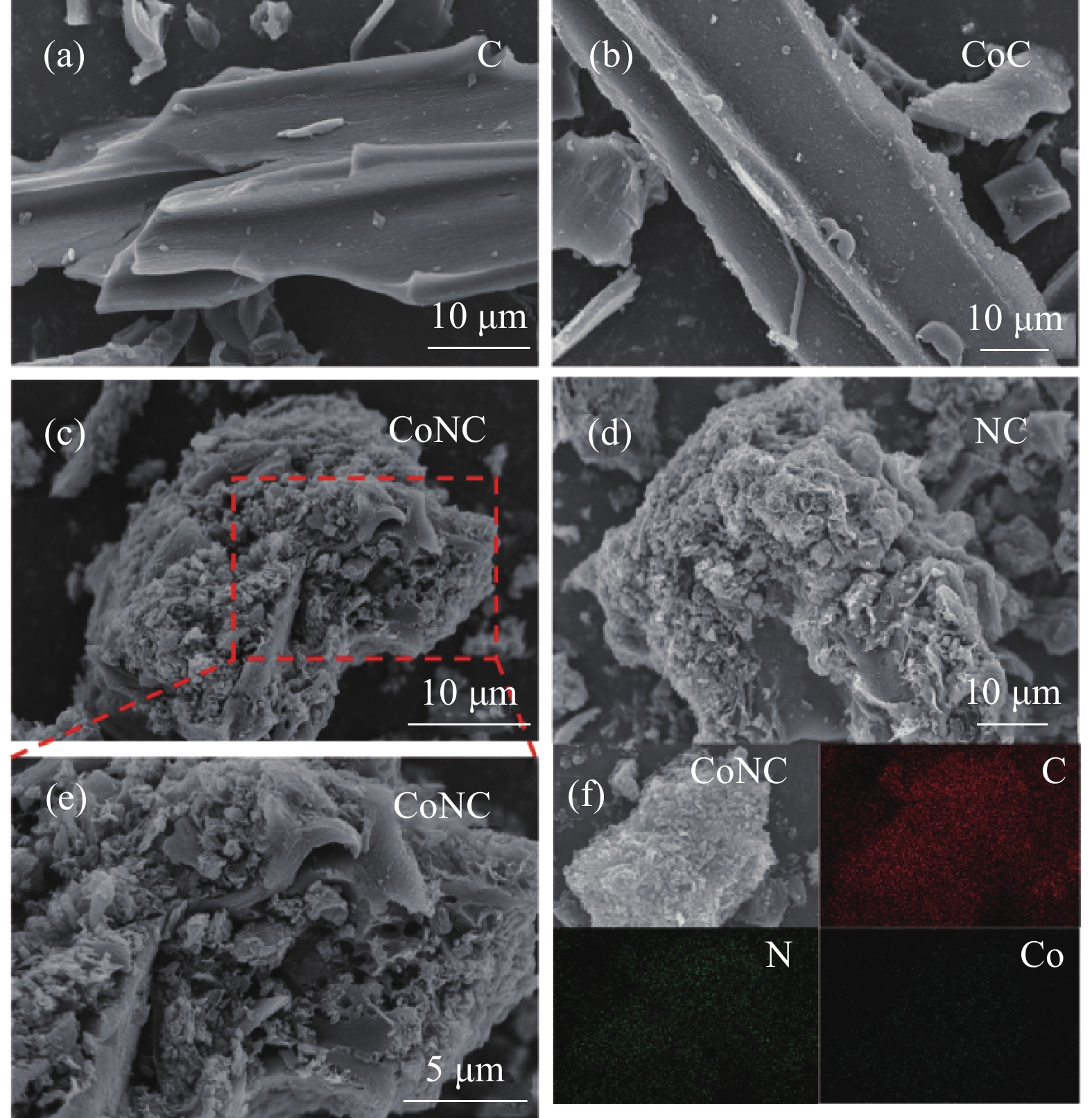

The weak interface strength between carbon fiber (CF) and polymer matrix severely limits their practical application in fields such as automotive lightweighting. To address this issue, a series of boehmite/graphene with different content were prepared by hydrothermal method and successfully introduced to the surface of CF via self-assembly method to modify the interface of carbon fiber/epoxy resin composites (CF/EPs). A series of tests were conducted to investigate the mechanical properties of the composites before and after modification and the results showed that the best performance was achieved when the boehmite/graphene mass ratio was 1∶2 (BG-2). Compared with CF/EP, the modified BGCF/EP-2 showed significant enhancements in IFSS (116.1%), ILSS (56.0%), tensile strength (61.1%), and flexural strength (30.4%). Finally, the schematic diagrams of the possible multiscale interfacial modification mechanism in the CF/EPs were further analyzed based on the results of SEM images and contact angle tests.

The weak interface strength between carbon fiber (CF) and polymer matrix severely limits their practical application in fields such as automotive lightweighting. To address this issue, a series of boehmite/graphene with different content were prepared by hydrothermal method and successfully introduced to the surface of CF via self-assembly method to modify the interface of carbon fiber/epoxy resin composites (CF/EPs). A series of tests were conducted to investigate the mechanical properties of the composites before and after modification and the results showed that the best performance was achieved when the boehmite/graphene mass ratio was 1∶2 (BG-2). Compared with CF/EP, the modified BGCF/EP-2 showed significant enhancements in IFSS (116.1%), ILSS (56.0%), tensile strength (61.1%), and flexural strength (30.4%). Finally, the schematic diagrams of the possible multiscale interfacial modification mechanism in the CF/EPs were further analyzed based on the results of SEM images and contact angle tests.

, Available online

Abstract:

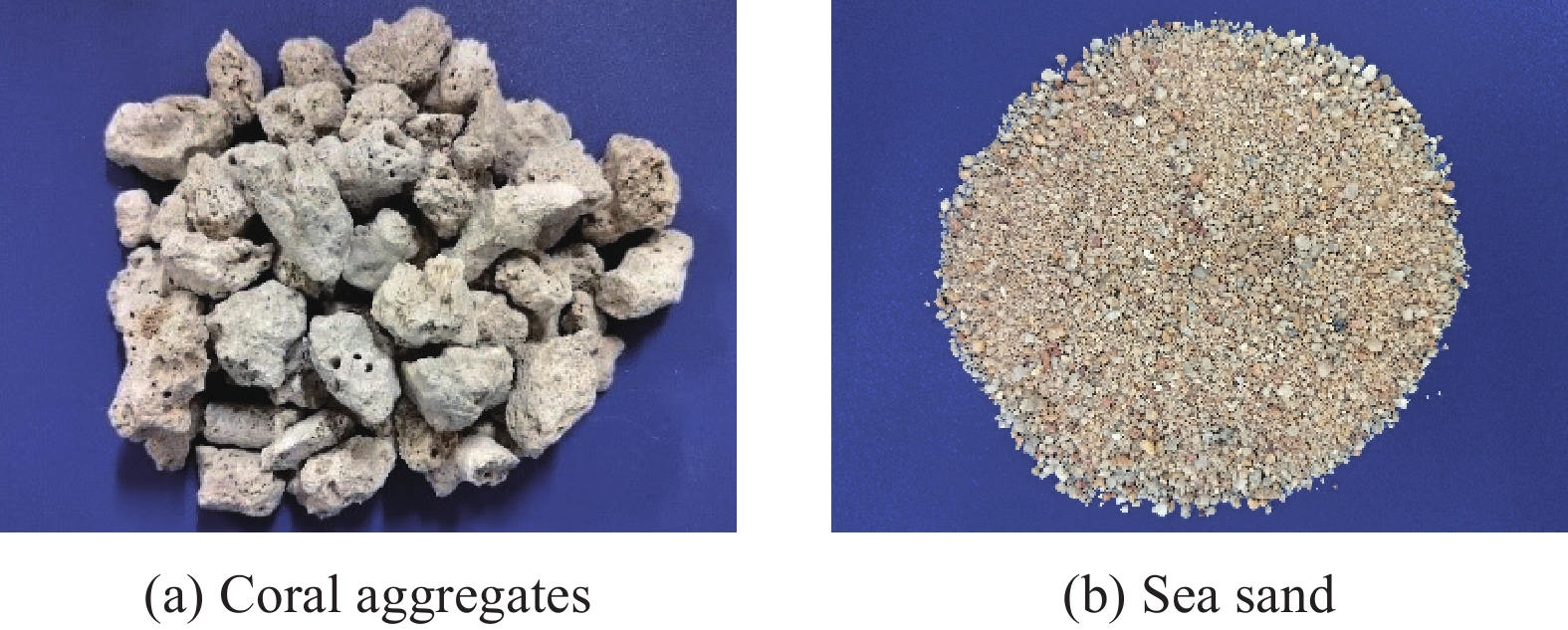

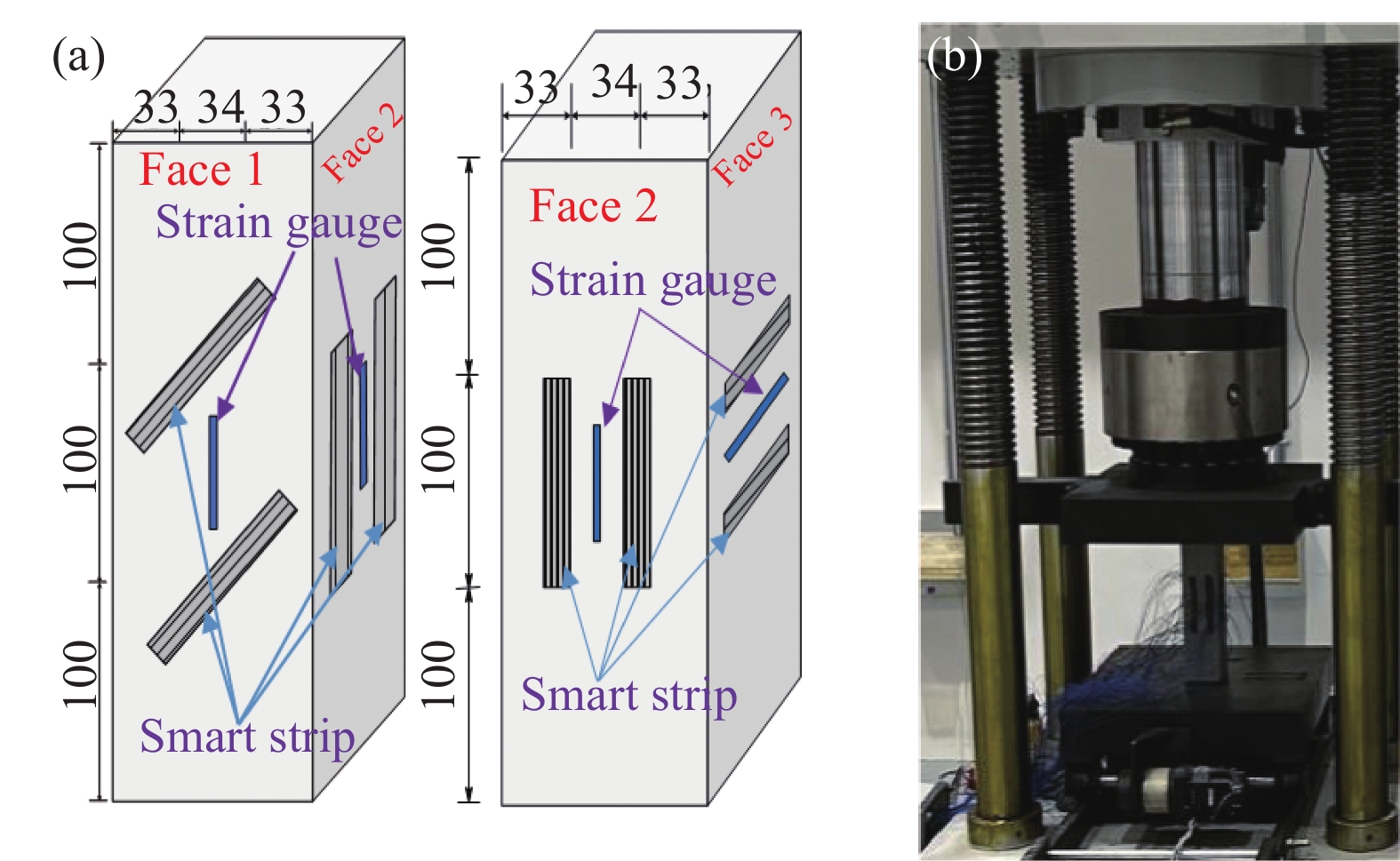

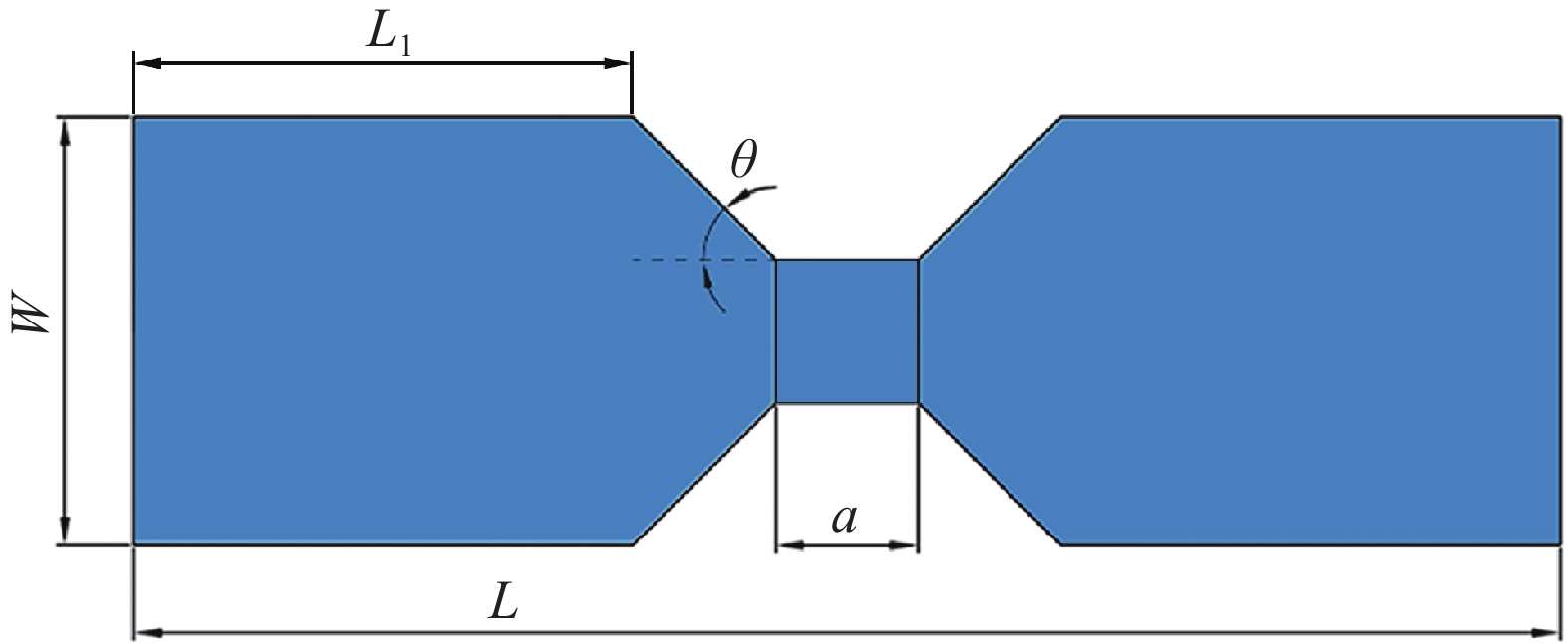

In order to study the mechanical properties of coral seawater and sea sand concrete (CSSC) under the combined action of compression and shear, 21 coral seawater and sea sand concrete specimens were designed and manufactured with the compressive stress ratio as the variable parameter. The failure modes of the specimens under the combined action of compression and shear were observed. The influence of compressive stress ratio on the shear strength of CSSC was analyzed in depth, and the shear strength calculation formula and failure criterion were proposed. The results show that with the increase of compressive stress ratio k, the shear strength of CSSC increases approximately in a power function, and the brittle failure characteristics of the specimen gradually weaken. When k increases from 0 to 0.5 with an increment of 0.1, the shear strength increases by 1.53, 2.81, 3.60, 4.32 and 4.67 times, respectively. The shear strength of coral seawater and sea sand concrete is mainly composed of cohesive strength, aggregate interlocking strength and interfacial friction strength, which account for 10%~22%,19%~30% and 50%~69% of the shear strength, respectively. With the increase of the compressive stress ratio, the cohesive strength first increases and then decreases, the aggregate occlusion strength generally shows an upward trend, and the interface friction strength increases approximately linearly. According to the experimental data, the calculation formula of CSSC shear strength is proposed, and the calculated value is in good agreement with the experimental value. Different failure criteria are used to analyze the test data, and it is found that the failure criteria based on the principal stress space are in good agreement with the test results.

In order to study the mechanical properties of coral seawater and sea sand concrete (CSSC) under the combined action of compression and shear, 21 coral seawater and sea sand concrete specimens were designed and manufactured with the compressive stress ratio as the variable parameter. The failure modes of the specimens under the combined action of compression and shear were observed. The influence of compressive stress ratio on the shear strength of CSSC was analyzed in depth, and the shear strength calculation formula and failure criterion were proposed. The results show that with the increase of compressive stress ratio k, the shear strength of CSSC increases approximately in a power function, and the brittle failure characteristics of the specimen gradually weaken. When k increases from 0 to 0.5 with an increment of 0.1, the shear strength increases by 1.53, 2.81, 3.60, 4.32 and 4.67 times, respectively. The shear strength of coral seawater and sea sand concrete is mainly composed of cohesive strength, aggregate interlocking strength and interfacial friction strength, which account for 10%~22%,19%~30% and 50%~69% of the shear strength, respectively. With the increase of the compressive stress ratio, the cohesive strength first increases and then decreases, the aggregate occlusion strength generally shows an upward trend, and the interface friction strength increases approximately linearly. According to the experimental data, the calculation formula of CSSC shear strength is proposed, and the calculated value is in good agreement with the experimental value. Different failure criteria are used to analyze the test data, and it is found that the failure criteria based on the principal stress space are in good agreement with the test results.

, Available online

Abstract:

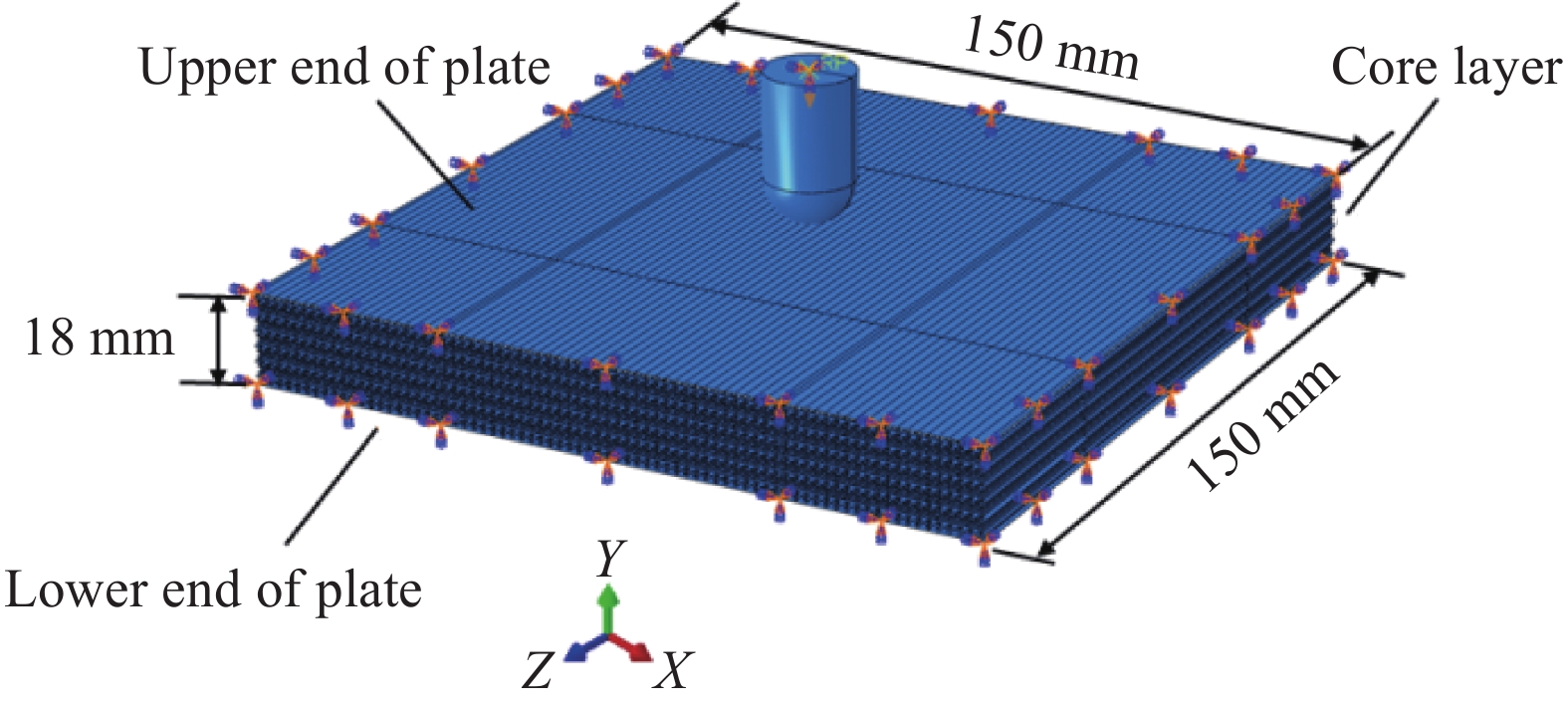

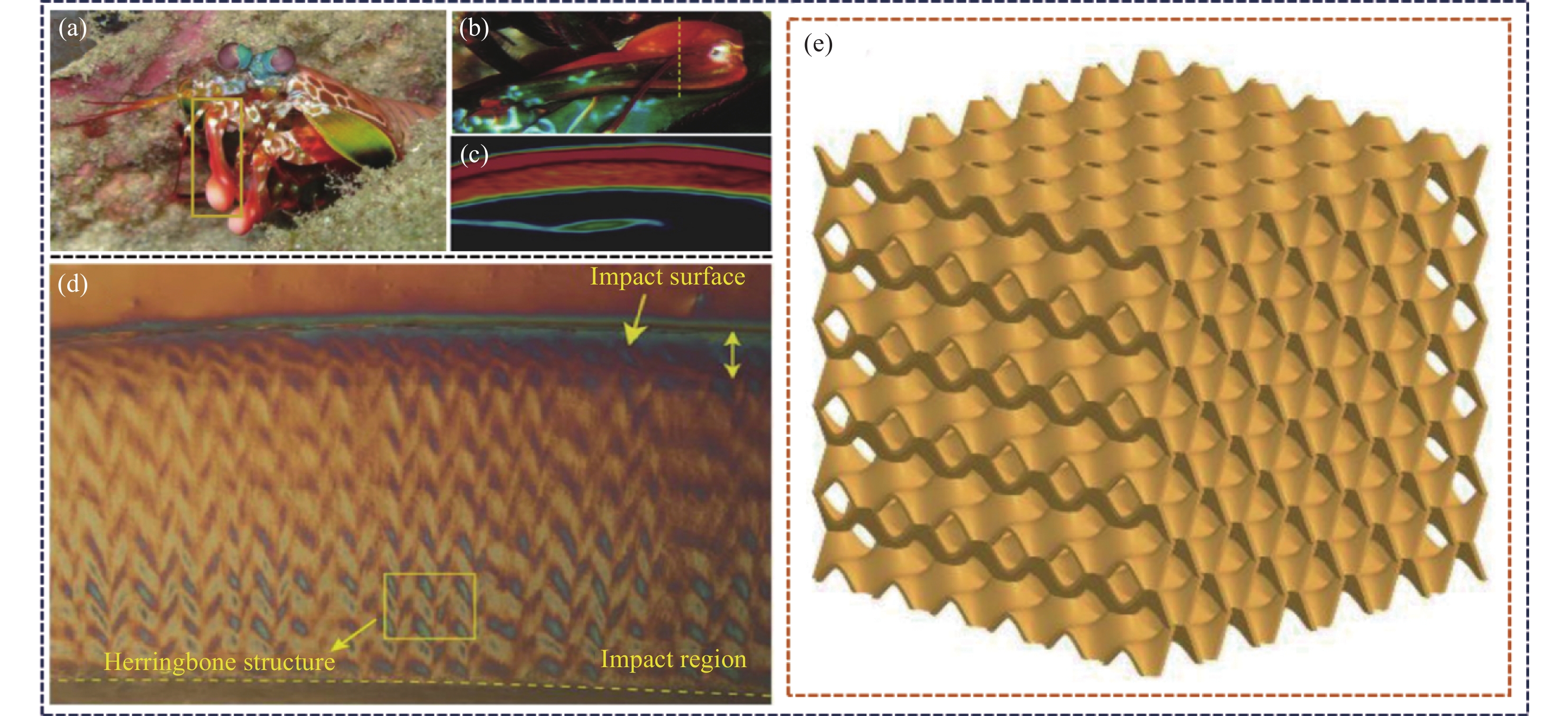

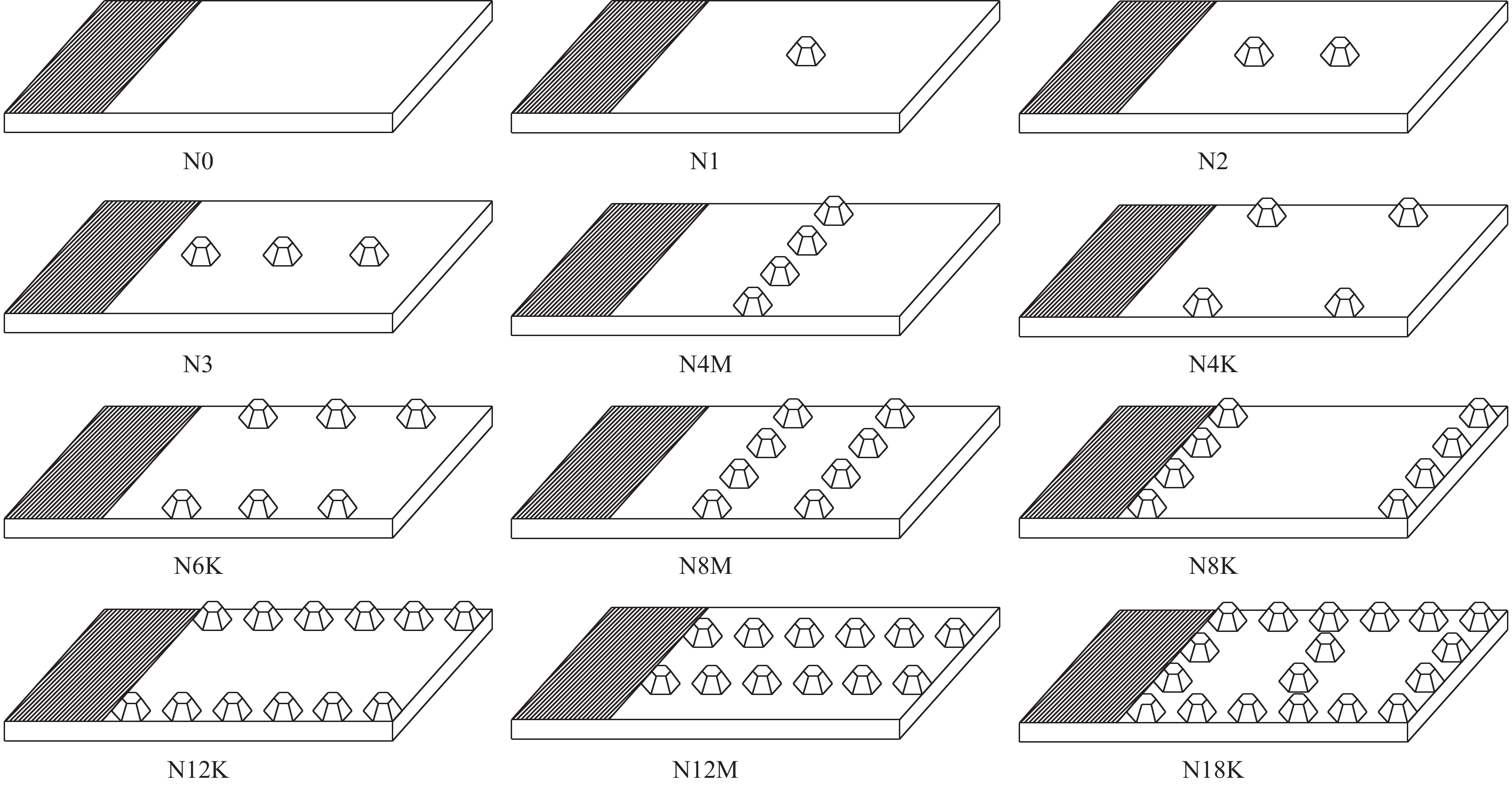

The sandwich panel structure, known for its lightweight nature, high bending stiffness, and exceptional impact resistance, can be tailored with a core layer of negative Poisson's ratio materials. This design approach yields protective structures with outstanding dynamic characteristics. In this paper, a negative Poisson's ratio biomaterial cellular sandwich plate with positive gradient, negative gradient, symmetric positive gradient and symmetric negative gradient was constructed by changing the vertical and horizontal materials in the cell based on the proposed curved edge concave negative Poisson's ratio biomaterial cell. The comparison between experimental results and simulation results demonstrates the feasibility of the numerical method proposed in this paper. The effects of punch impact velocity and gradient arrangement on the failure mode of sandwich plate, punch contact force and energy absorption were investigated. The results show that the impact failure mode and impact dynamic performance of the sandwich panels are significantly affected by the arrangement mode of core layers. This design can significantly enhance the energy absorption effect of sandwich panels.

The sandwich panel structure, known for its lightweight nature, high bending stiffness, and exceptional impact resistance, can be tailored with a core layer of negative Poisson's ratio materials. This design approach yields protective structures with outstanding dynamic characteristics. In this paper, a negative Poisson's ratio biomaterial cellular sandwich plate with positive gradient, negative gradient, symmetric positive gradient and symmetric negative gradient was constructed by changing the vertical and horizontal materials in the cell based on the proposed curved edge concave negative Poisson's ratio biomaterial cell. The comparison between experimental results and simulation results demonstrates the feasibility of the numerical method proposed in this paper. The effects of punch impact velocity and gradient arrangement on the failure mode of sandwich plate, punch contact force and energy absorption were investigated. The results show that the impact failure mode and impact dynamic performance of the sandwich panels are significantly affected by the arrangement mode of core layers. This design can significantly enhance the energy absorption effect of sandwich panels.

, Available online

Abstract:

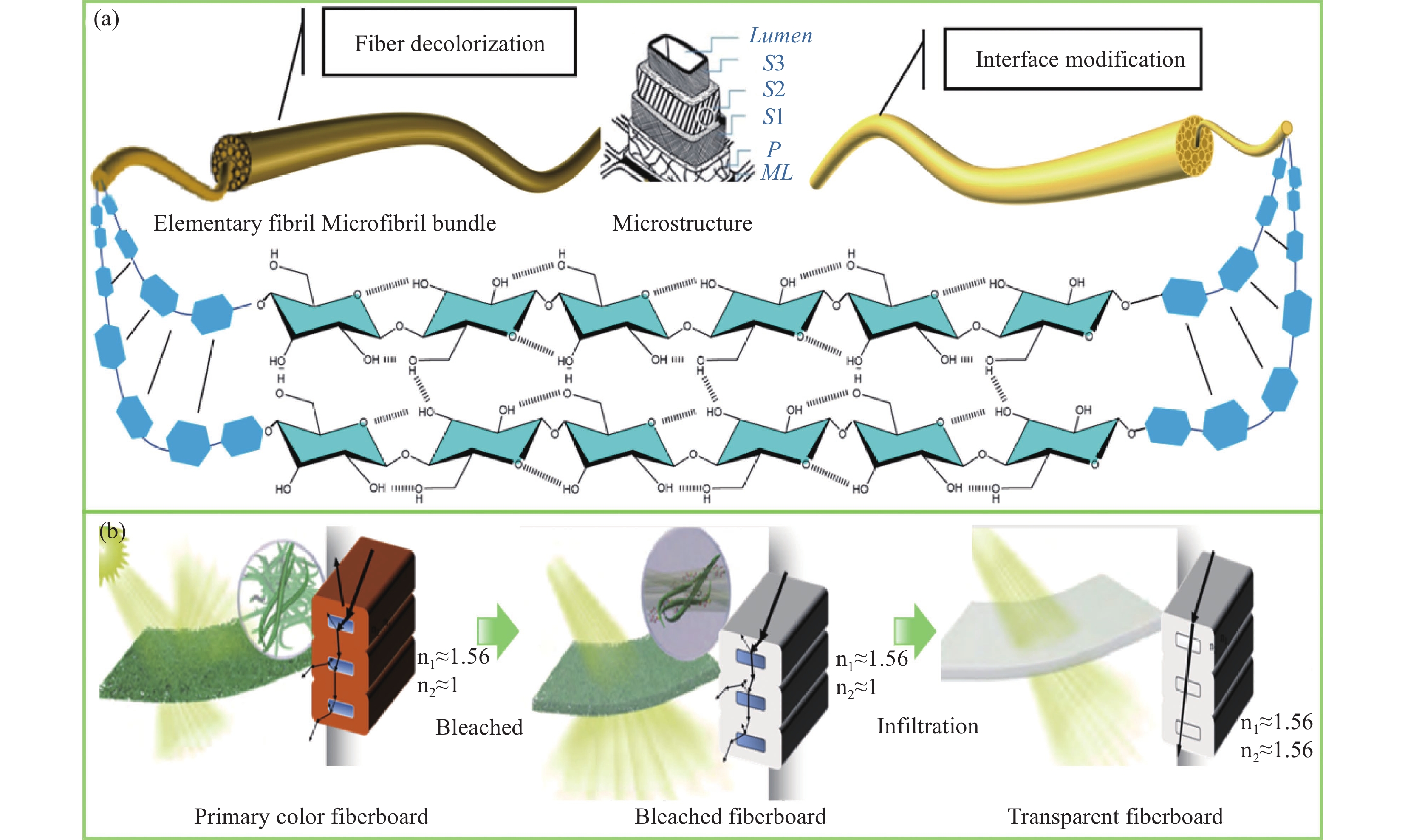

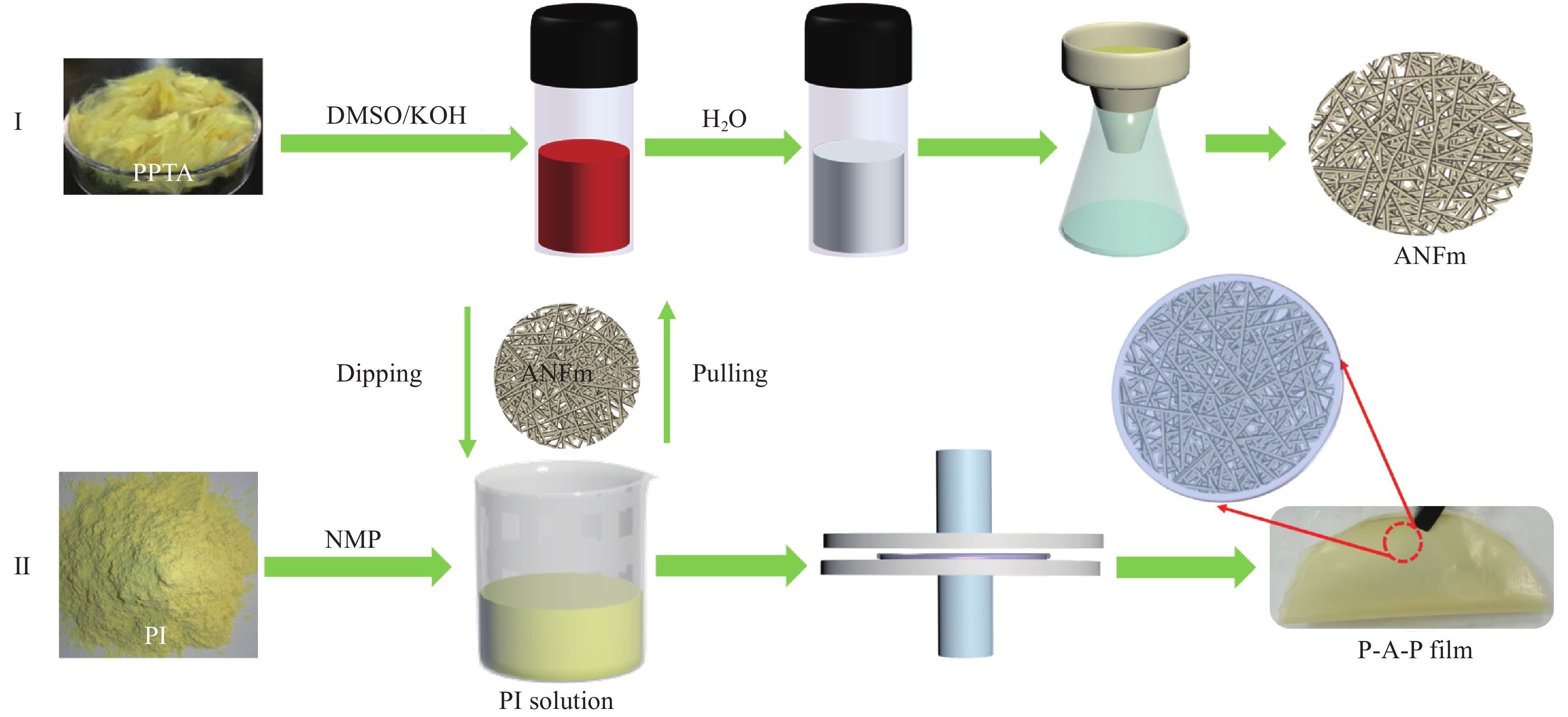

The plant fiber, as a natural renewable, biodegradable green and eco-friendly material, has a wide range of sources and abundant reserves, such as forestry wood, bamboo, and crop straw resources. It is widely used in the manufacturing of composite materials, such as fiber-reinforced resins/silicates, with a huge market and broad prospects. The development of transparent functional materials based on plant fibers has scientific significance and research value in breaking through the technical bottleneck of optical opacity for the traditional engineering materials (such as fiberboard and wood plastic composites) and expanding the application range of agricultural and forestry biomass products. The article provides a detailed overview of the latest research progress on fiber-based transparent materials. It systematically summarizes the mechanisms of green bleaching and transparency of plant fiber materials, as well as the characteristics and key difficulties of for the preparation techniques. It has been demonstrated that transparent materials treated with preliminary decolorization and transparency can optimize the process, and achieve the multifunctionality while retaining the characteristics of plant fibers. This article focuses on the mechanics, transparency, haze, flame retardancy, and thermal insulation of plant fiber based transparent materials, and explores the application prospects of fiber transparent materials in energy-saving buildings, optoelectronic devices, and energy storage materials. There is still a lot of systematic research to be promoted in the utilization of plant fiber transparent materials. With the continuous improvement of preparation technology and modification methods, its performance will be further improved, promoting its application in fields such as architecture, optoelectronics, and energy storage.

The plant fiber, as a natural renewable, biodegradable green and eco-friendly material, has a wide range of sources and abundant reserves, such as forestry wood, bamboo, and crop straw resources. It is widely used in the manufacturing of composite materials, such as fiber-reinforced resins/silicates, with a huge market and broad prospects. The development of transparent functional materials based on plant fibers has scientific significance and research value in breaking through the technical bottleneck of optical opacity for the traditional engineering materials (such as fiberboard and wood plastic composites) and expanding the application range of agricultural and forestry biomass products. The article provides a detailed overview of the latest research progress on fiber-based transparent materials. It systematically summarizes the mechanisms of green bleaching and transparency of plant fiber materials, as well as the characteristics and key difficulties of for the preparation techniques. It has been demonstrated that transparent materials treated with preliminary decolorization and transparency can optimize the process, and achieve the multifunctionality while retaining the characteristics of plant fibers. This article focuses on the mechanics, transparency, haze, flame retardancy, and thermal insulation of plant fiber based transparent materials, and explores the application prospects of fiber transparent materials in energy-saving buildings, optoelectronic devices, and energy storage materials. There is still a lot of systematic research to be promoted in the utilization of plant fiber transparent materials. With the continuous improvement of preparation technology and modification methods, its performance will be further improved, promoting its application in fields such as architecture, optoelectronics, and energy storage.

, Available online

Abstract:

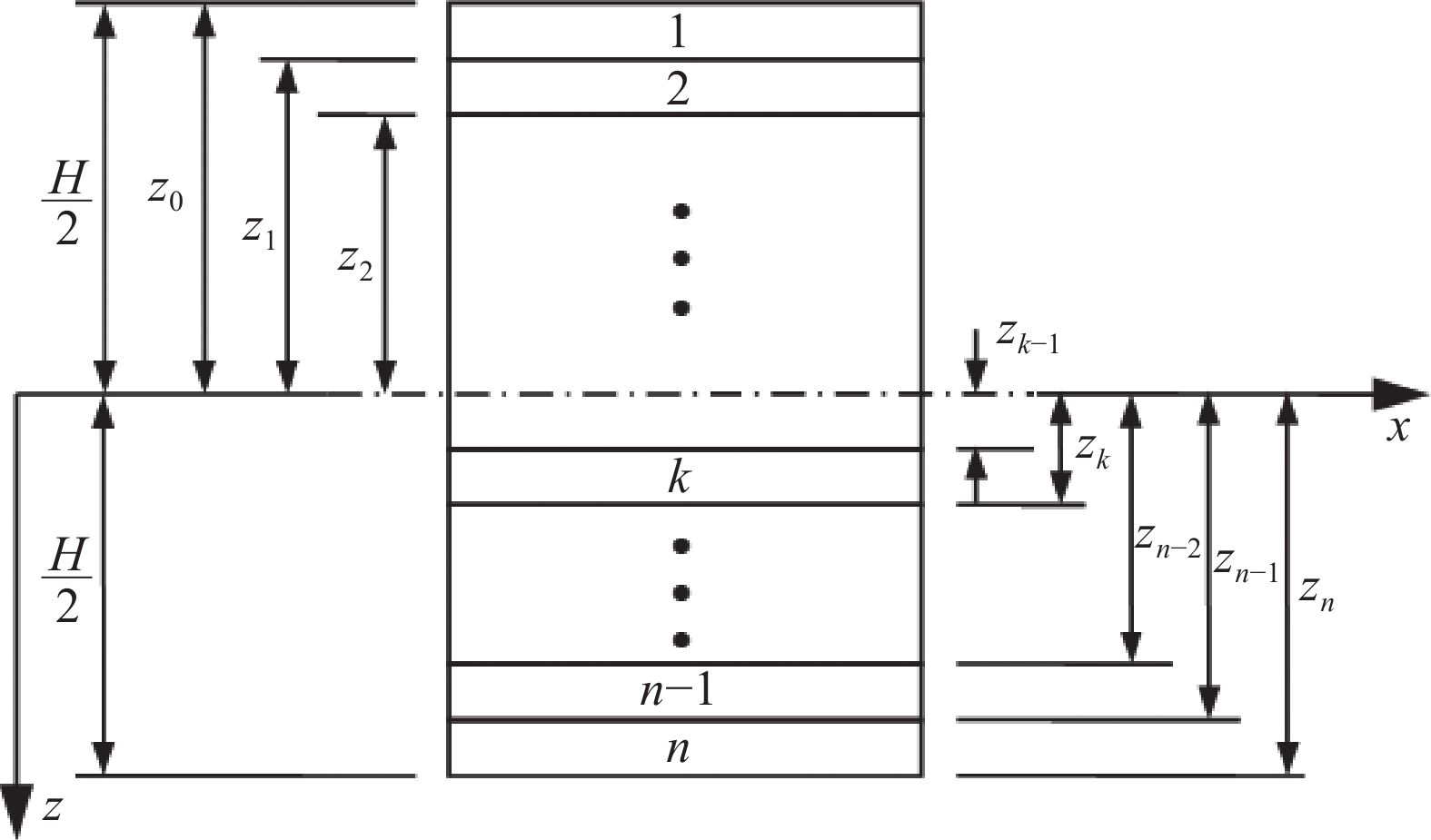

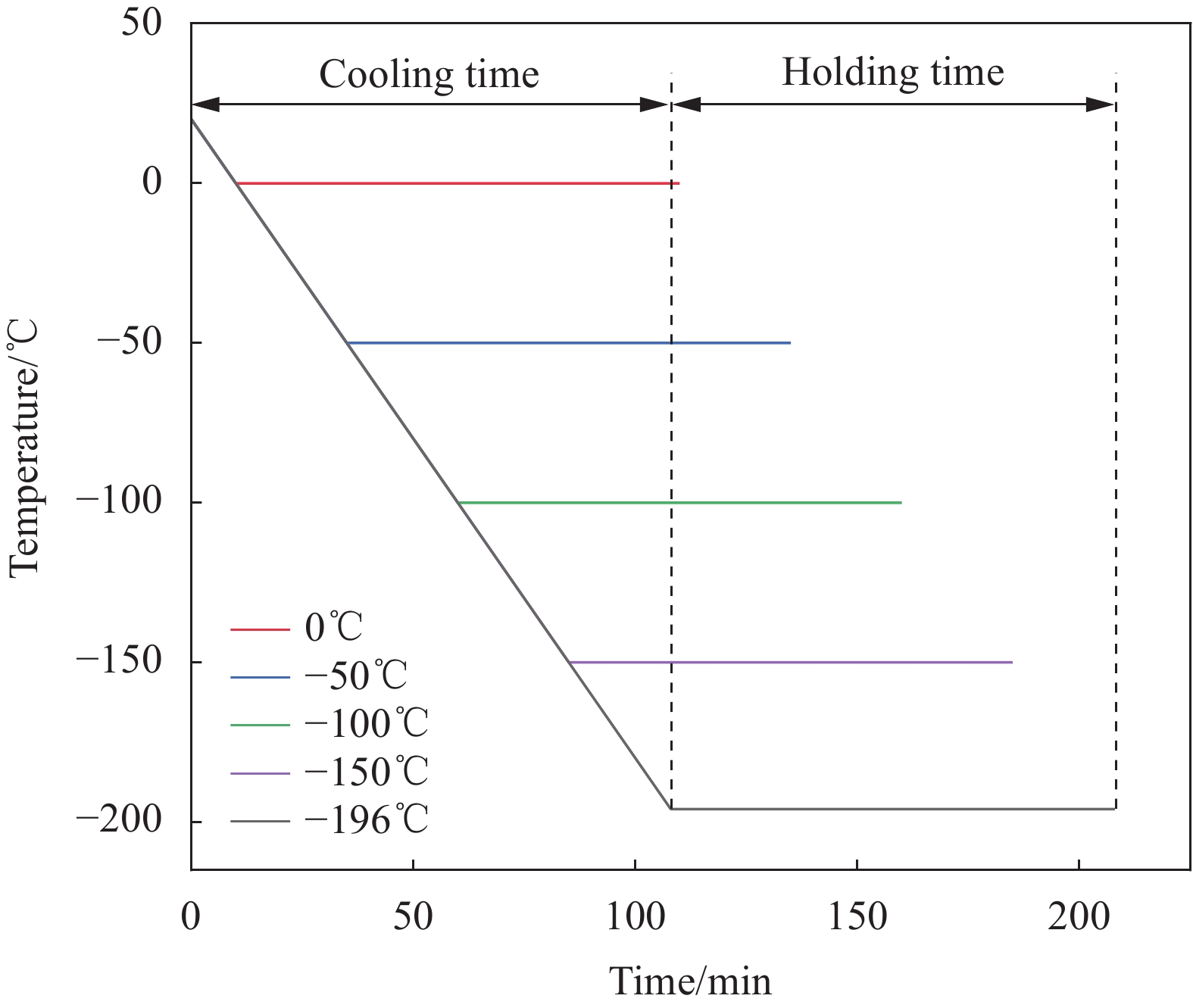

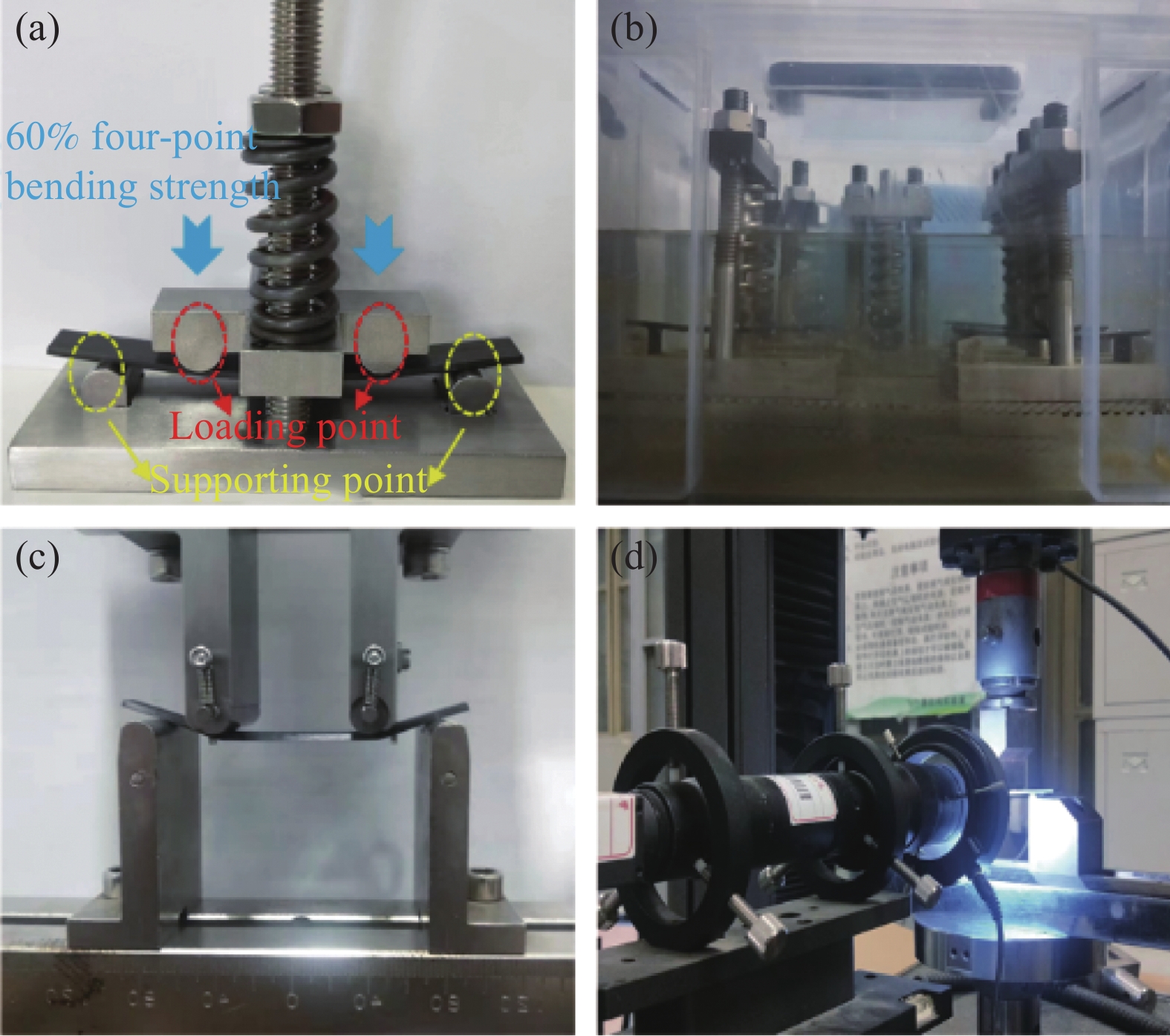

The use of composite materials in low-temperature fuel tanks is an effective approach to achieve weight reduction and enhance carrying capacity for launch vehicle structures. However, as the tank is subjected to both ultra-low temperature cycling and mechanical loads during service, it is prone to internal microcrack formation in composite materials, posing a threat to structural safety. In this study, a simple pre-stressing device was used to conduct ultra-low temperature cycling tests on carbon fiber/epoxy orthotropic laminates. The research focused on the initiation and evolution of microcracks in composite laminates under the combined action of pre-stress and ultra-low temperature cycling. The results indicate that the microcrack density at the edge layers of the laminate is generally higher than that in the inner layers, but the central two 90° stacked layers exhibits the maximum microcrack density. Compared to conditions of only low-temperature cycling, the pre-stress results in a higher microcrack density in the laminate under the same number of low-temperature cycles, with a faster growth rate. With an increase in the number of cycles, the growth rate of microcrack density initially accelerates and then slows down, eventually reaching saturation. As the pre-stress level increases, the initiation and propagation rates of microcracks in the laminate are further intensified. This study provides a preliminary insight into the mechanism of microcrack initiation and evolution in composite materials under the coupled action of load and ultra-low temperature cycling, offering meaningful references for the development and application of low-temperature composite material tanks.

The use of composite materials in low-temperature fuel tanks is an effective approach to achieve weight reduction and enhance carrying capacity for launch vehicle structures. However, as the tank is subjected to both ultra-low temperature cycling and mechanical loads during service, it is prone to internal microcrack formation in composite materials, posing a threat to structural safety. In this study, a simple pre-stressing device was used to conduct ultra-low temperature cycling tests on carbon fiber/epoxy orthotropic laminates. The research focused on the initiation and evolution of microcracks in composite laminates under the combined action of pre-stress and ultra-low temperature cycling. The results indicate that the microcrack density at the edge layers of the laminate is generally higher than that in the inner layers, but the central two 90° stacked layers exhibits the maximum microcrack density. Compared to conditions of only low-temperature cycling, the pre-stress results in a higher microcrack density in the laminate under the same number of low-temperature cycles, with a faster growth rate. With an increase in the number of cycles, the growth rate of microcrack density initially accelerates and then slows down, eventually reaching saturation. As the pre-stress level increases, the initiation and propagation rates of microcracks in the laminate are further intensified. This study provides a preliminary insight into the mechanism of microcrack initiation and evolution in composite materials under the coupled action of load and ultra-low temperature cycling, offering meaningful references for the development and application of low-temperature composite material tanks.

, Available online

Abstract:

Carbon fiber reinforced composites (CFRP) have the advantages of light weight, high strength, corrosion resistance, fatigue resistance and wear resistance, and have become a new advanced structural materials for marine engineering. In this paper, the effects of hygrothermal aging on the thermal/mechanical (tensile, flexural and short-beam shear properties) and frictional wear properties of CFRP were investigated. Combined with the analysis of micro-morphology and structure, the degradation mechanisms of mechanical and frictional wear properties of CFRP immersed in the distilled water at 60℃ for up to 90 days were revealed. It was found that the maximum degradation amplitudes of CFRP tensile, flexural and short-beam shear strengths were 5.8%, 13.0%, and 20.9%, due to the destruction of hydrogen bonds and partial covalent bonds of polymer resin chains by water molecules during the hygrothermal aging process, which resulted in the defect creation and the lateral restraint loss of the fiber bundles within the CFRP, ultimately leading to the de-bonding of fiber/resin interfaces. In addition, the thermodynamic and viscoelastic behavior of CFRP in the hygrothermal environment exhibited a nonlinear change, attributing to the coupling effects of positive resin post-curing and negative hygrothermal aging. Compared with those before immersion, the average COFs of CFRP aged for 15, 30, 60, and 90 days decreased by 23.8%, 35.0%, 43.7% and 53.8%, respectively, which was attributed to the friction lubrication of water molecules inside the diffused CFRP acting as friction lubricants during friction, alleviating the wear of the CFRP/abrasive ball interface. The Ws and WSW of CFRP aged for 90 days increased by 254.6% and 114.9% compared with that before aging, which was attributed to the fact that the water molecules forming new hydrogen bonds with the resin matrix were in the bonded water state, reducing inter-chain force between resin molecules and the continuous growth of their internal micro-cracks, resulting in severe fatigue wear.

Carbon fiber reinforced composites (CFRP) have the advantages of light weight, high strength, corrosion resistance, fatigue resistance and wear resistance, and have become a new advanced structural materials for marine engineering. In this paper, the effects of hygrothermal aging on the thermal/mechanical (tensile, flexural and short-beam shear properties) and frictional wear properties of CFRP were investigated. Combined with the analysis of micro-morphology and structure, the degradation mechanisms of mechanical and frictional wear properties of CFRP immersed in the distilled water at 60℃ for up to 90 days were revealed. It was found that the maximum degradation amplitudes of CFRP tensile, flexural and short-beam shear strengths were 5.8%, 13.0%, and 20.9%, due to the destruction of hydrogen bonds and partial covalent bonds of polymer resin chains by water molecules during the hygrothermal aging process, which resulted in the defect creation and the lateral restraint loss of the fiber bundles within the CFRP, ultimately leading to the de-bonding of fiber/resin interfaces. In addition, the thermodynamic and viscoelastic behavior of CFRP in the hygrothermal environment exhibited a nonlinear change, attributing to the coupling effects of positive resin post-curing and negative hygrothermal aging. Compared with those before immersion, the average COFs of CFRP aged for 15, 30, 60, and 90 days decreased by 23.8%, 35.0%, 43.7% and 53.8%, respectively, which was attributed to the friction lubrication of water molecules inside the diffused CFRP acting as friction lubricants during friction, alleviating the wear of the CFRP/abrasive ball interface. The Ws and WSW of CFRP aged for 90 days increased by 254.6% and 114.9% compared with that before aging, which was attributed to the fact that the water molecules forming new hydrogen bonds with the resin matrix were in the bonded water state, reducing inter-chain force between resin molecules and the continuous growth of their internal micro-cracks, resulting in severe fatigue wear.

, Available online

Abstract:

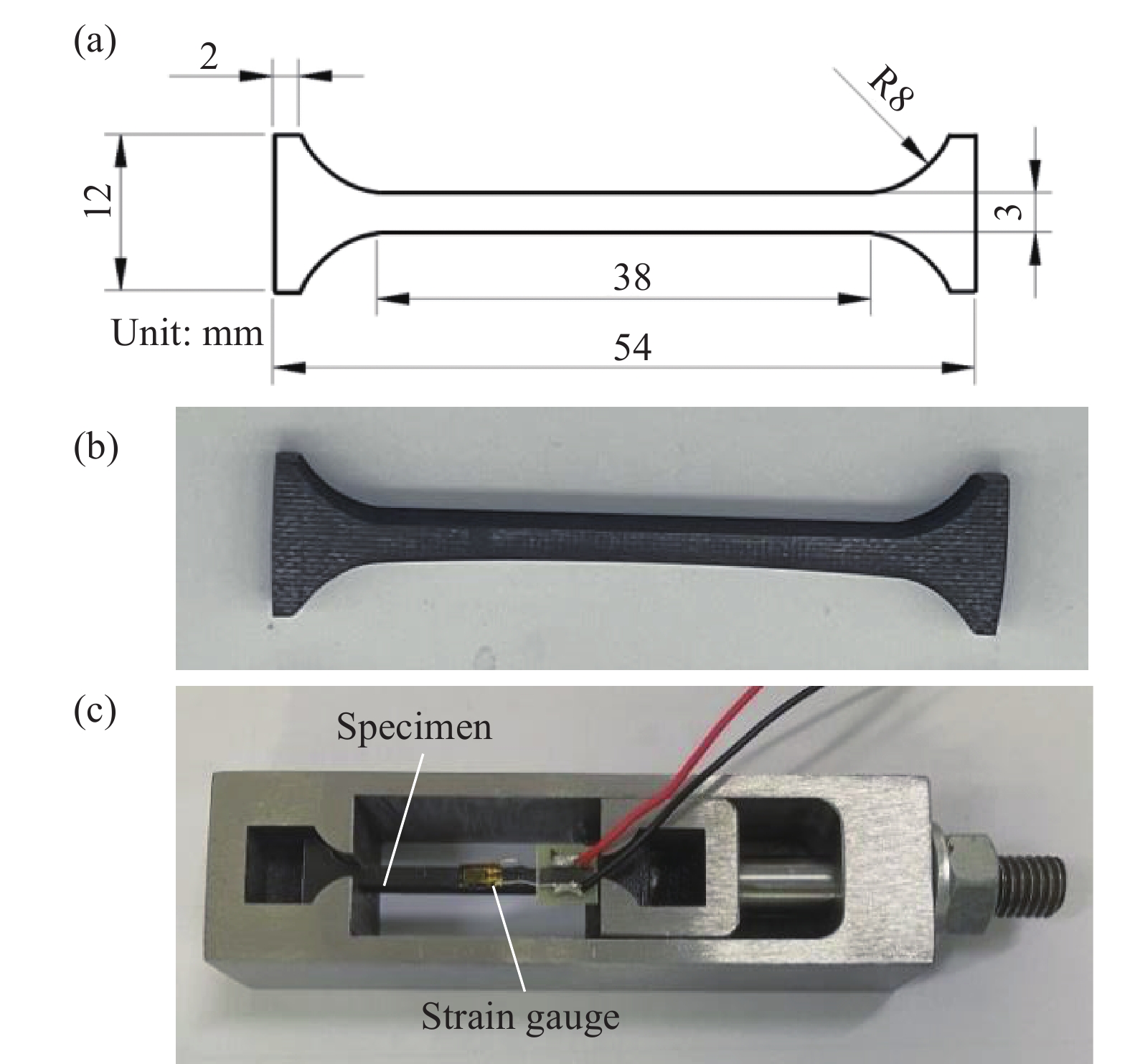

In order to reveal the mechanism of hygro-thermal stability and solve the problem of insufficient coupling effect, the design and experimental verification of carbon fiber/epoxy resin (CF/EP) multi-coupled laminates with extension-twisting coupling effect were carried out. The geometric factors of the laminates were introduced, and the conditions for hygro-thermal stability of the multi-coupled laminates with extension-twisting coupling effect were deduced. Based on these conditions, the optimal design model of multi-coupled laminates with extension-twisting coupling effect was established. Genetic algorithm-sequential quadratic program (GA-SQP) hybrid optimization algorithm was used to optimize the stacking sequence of the laminates with the maximum extension-twisting coupling effect. Based on three-dimension digital image correlation (3D-DIC), the extension-twisting coupling effect of the laminates was measured. The numerical simulation and experimental results show that the multi-coupled laminates with extension-twisting effect will not undergo curing deformation when the stacking sequences meet the conditions of hygro-thermal stability. The introduction of multi-coupling effects can significantly improve the extension-twisting coupling effect of laminates and maximum increase is over 30%.

In order to reveal the mechanism of hygro-thermal stability and solve the problem of insufficient coupling effect, the design and experimental verification of carbon fiber/epoxy resin (CF/EP) multi-coupled laminates with extension-twisting coupling effect were carried out. The geometric factors of the laminates were introduced, and the conditions for hygro-thermal stability of the multi-coupled laminates with extension-twisting coupling effect were deduced. Based on these conditions, the optimal design model of multi-coupled laminates with extension-twisting coupling effect was established. Genetic algorithm-sequential quadratic program (GA-SQP) hybrid optimization algorithm was used to optimize the stacking sequence of the laminates with the maximum extension-twisting coupling effect. Based on three-dimension digital image correlation (3D-DIC), the extension-twisting coupling effect of the laminates was measured. The numerical simulation and experimental results show that the multi-coupled laminates with extension-twisting effect will not undergo curing deformation when the stacking sequences meet the conditions of hygro-thermal stability. The introduction of multi-coupling effects can significantly improve the extension-twisting coupling effect of laminates and maximum increase is over 30%.

, Available online

Abstract:

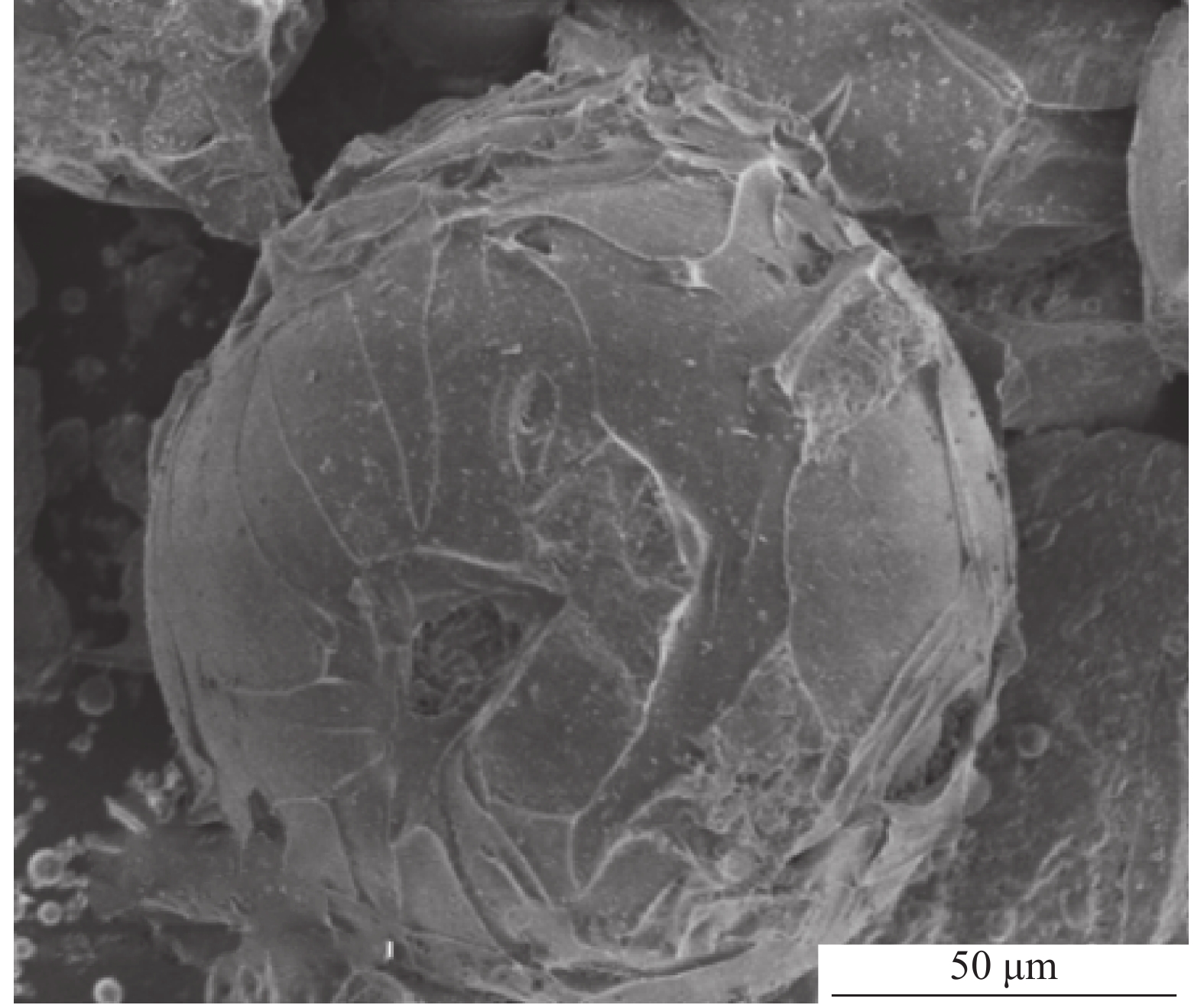

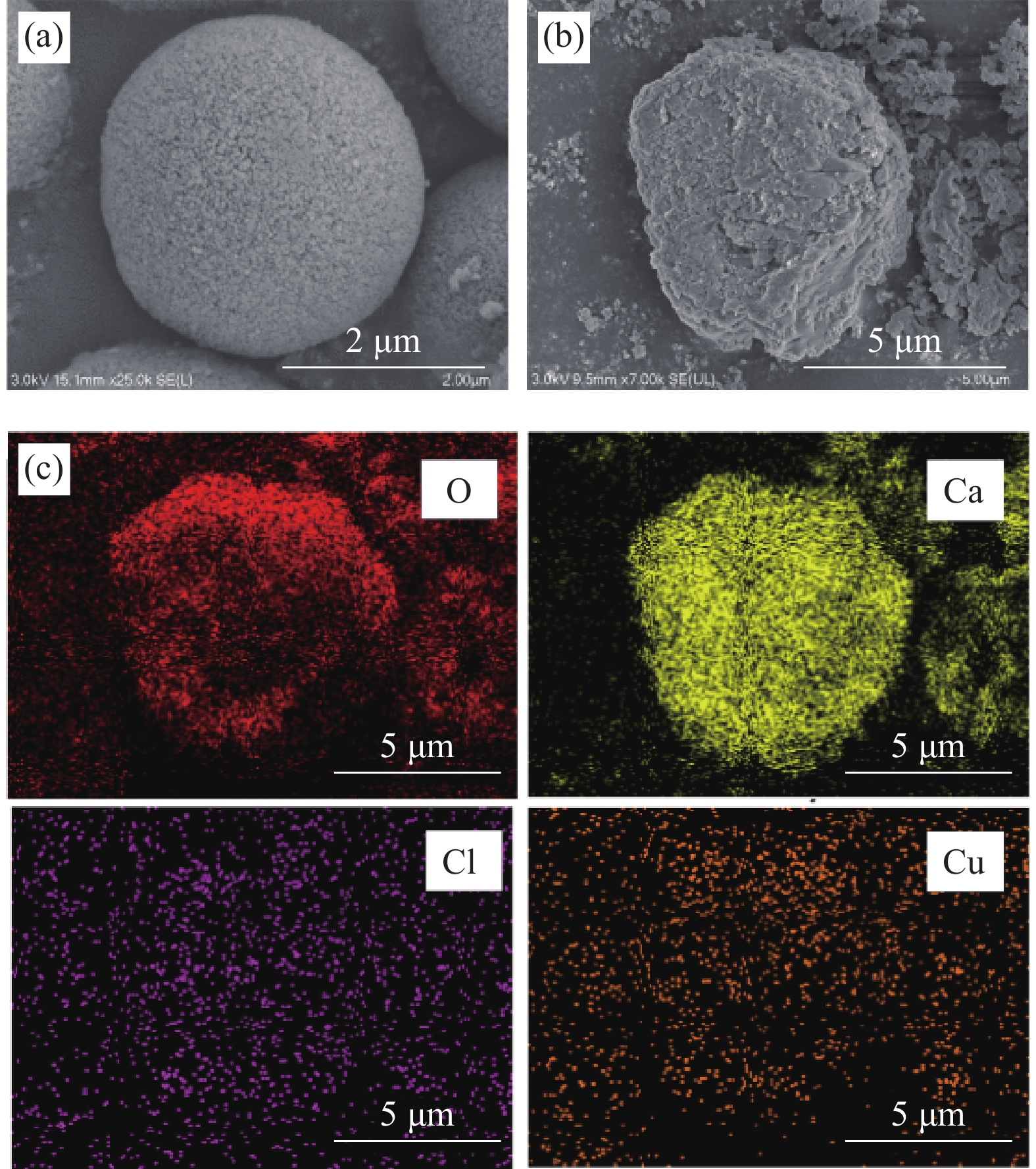

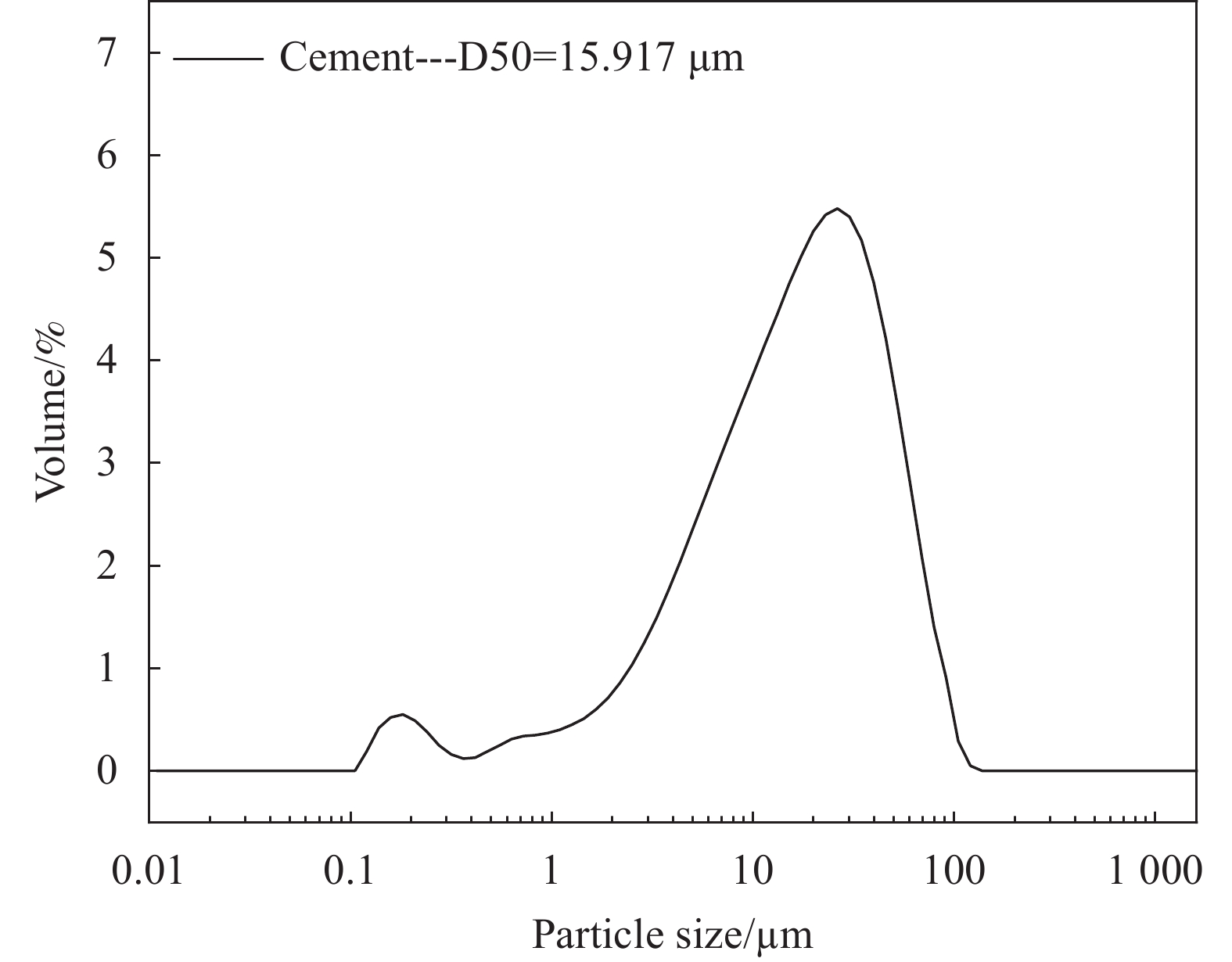

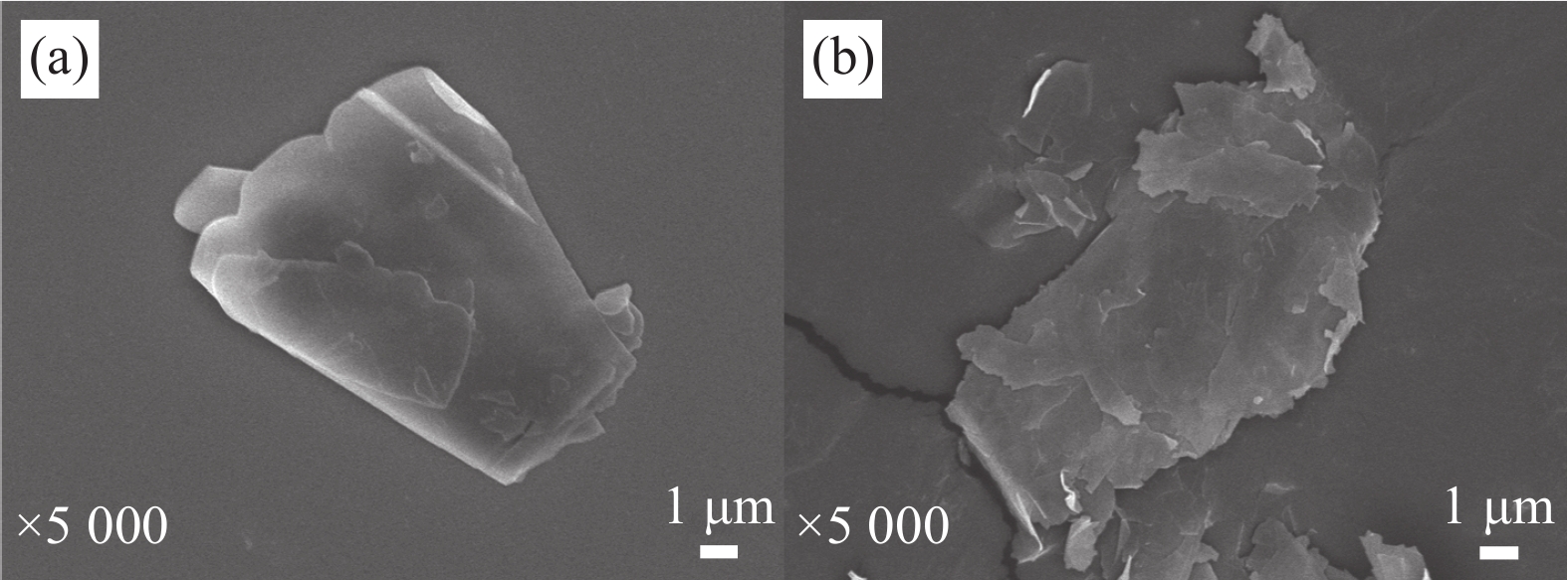

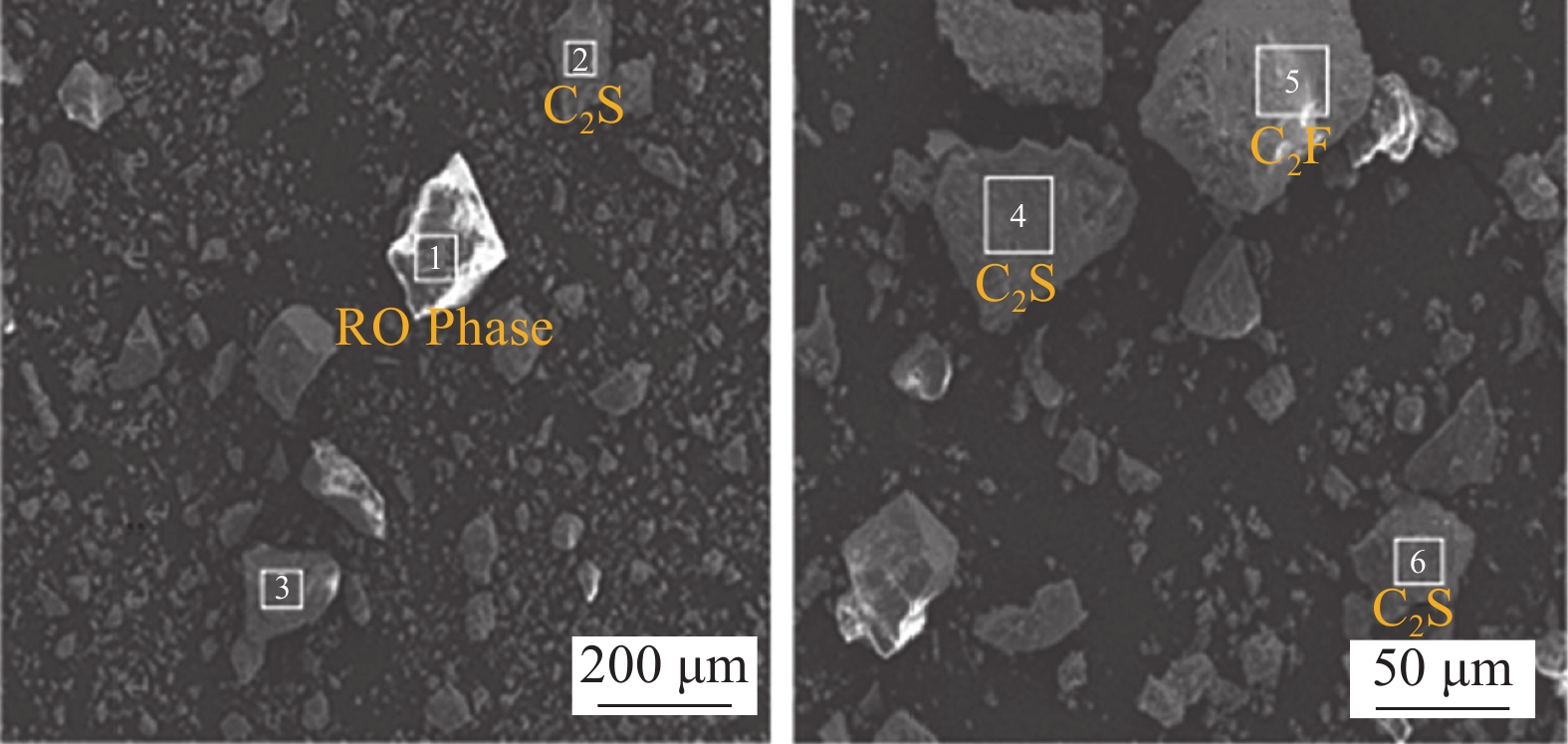

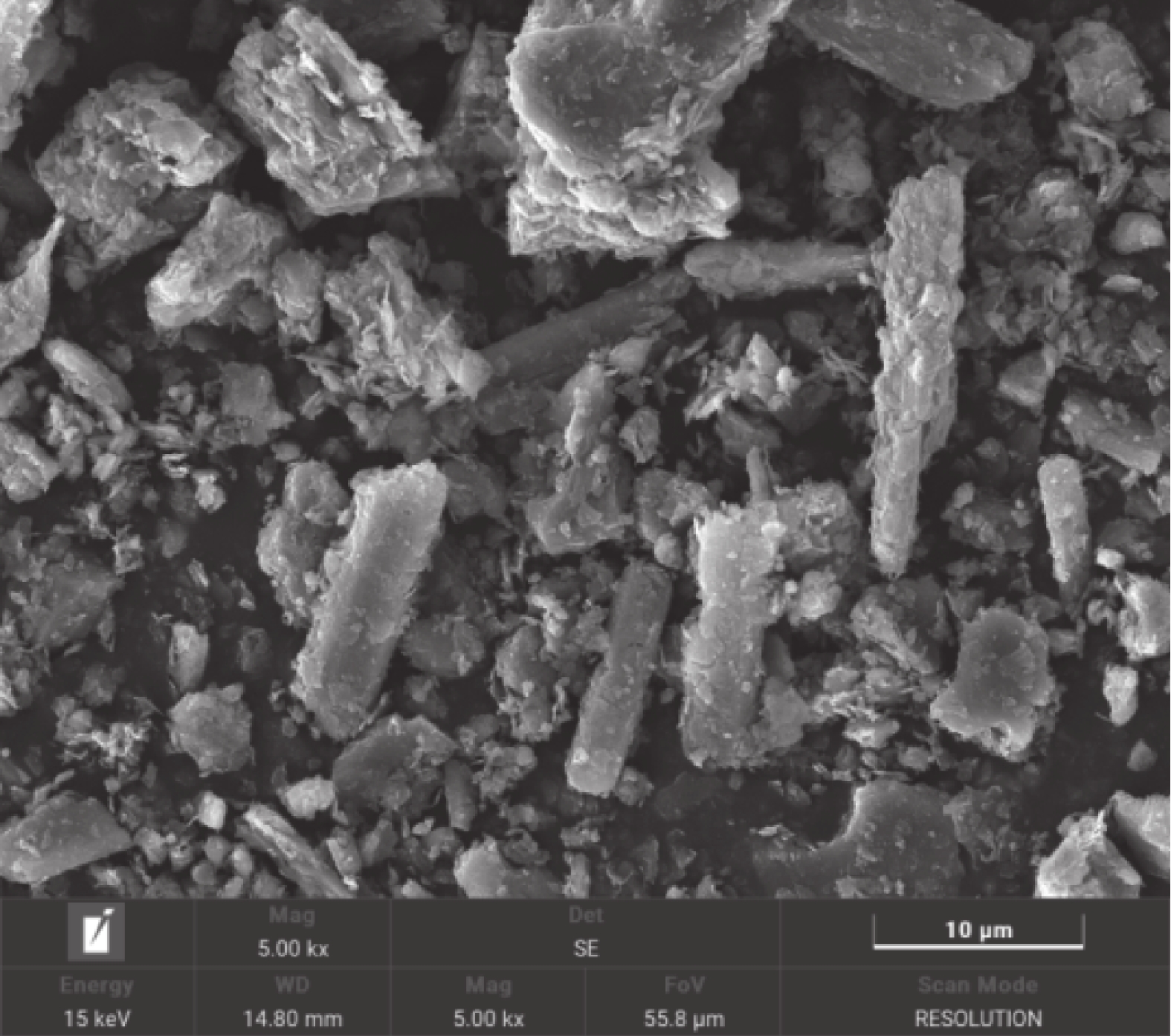

Utilizing fly ash cenosphere, which is a coal-based waste, as a substitute for cement to prepare concrete can effectively mitigate its negative environmental effect. A surface etching process for fly ash cenosphere was proposed in this paper, and nano-silica was also adopted to coordinatively reinforce concrete performance. The microstructure morphology and phase composition of the cenosphere before and after surface etching were compared using scanning electron microscopy and X-ray diffraction and the influence of the surface etched cenosphere on the hydration properties was characterized by thermogravimetric testing to determine the effectiveness of the proposed etching procedure. The effects of surface etched cenosphere and nano silica were studied using compression and split-tensile tests and scanning electron microscopy-energy dispersive spectroscopy. Results show that the etching procedure proposed in this paper accelerates the release of Si and Al elements inside fly ash cenosphere. The etched micro-pores provide effective paths for water migration, enabling fly ash cenosphere to have internal curing effect and increased pozzolanic activity. Thus, cement hydration and mechanical properties of concrete are significantly improved. However, when the dosage of fly ash cenosphere increases to 40%, the negative impact of the hollow structure of fly ash cenosphere is more significant, resulting in decreased concrete strengths. Furthermore, the synergistic enhancing effect of surface etched cenosphere and nano silica is significant with increased Si/Ca and Al/Ca ratios at the interface, which improves the composition of hydration products and optimizes the interfacial transition zone and thus benefits the microstructure and strength development of concrete.

Utilizing fly ash cenosphere, which is a coal-based waste, as a substitute for cement to prepare concrete can effectively mitigate its negative environmental effect. A surface etching process for fly ash cenosphere was proposed in this paper, and nano-silica was also adopted to coordinatively reinforce concrete performance. The microstructure morphology and phase composition of the cenosphere before and after surface etching were compared using scanning electron microscopy and X-ray diffraction and the influence of the surface etched cenosphere on the hydration properties was characterized by thermogravimetric testing to determine the effectiveness of the proposed etching procedure. The effects of surface etched cenosphere and nano silica were studied using compression and split-tensile tests and scanning electron microscopy-energy dispersive spectroscopy. Results show that the etching procedure proposed in this paper accelerates the release of Si and Al elements inside fly ash cenosphere. The etched micro-pores provide effective paths for water migration, enabling fly ash cenosphere to have internal curing effect and increased pozzolanic activity. Thus, cement hydration and mechanical properties of concrete are significantly improved. However, when the dosage of fly ash cenosphere increases to 40%, the negative impact of the hollow structure of fly ash cenosphere is more significant, resulting in decreased concrete strengths. Furthermore, the synergistic enhancing effect of surface etched cenosphere and nano silica is significant with increased Si/Ca and Al/Ca ratios at the interface, which improves the composition of hydration products and optimizes the interfacial transition zone and thus benefits the microstructure and strength development of concrete.

, Available online

Abstract:

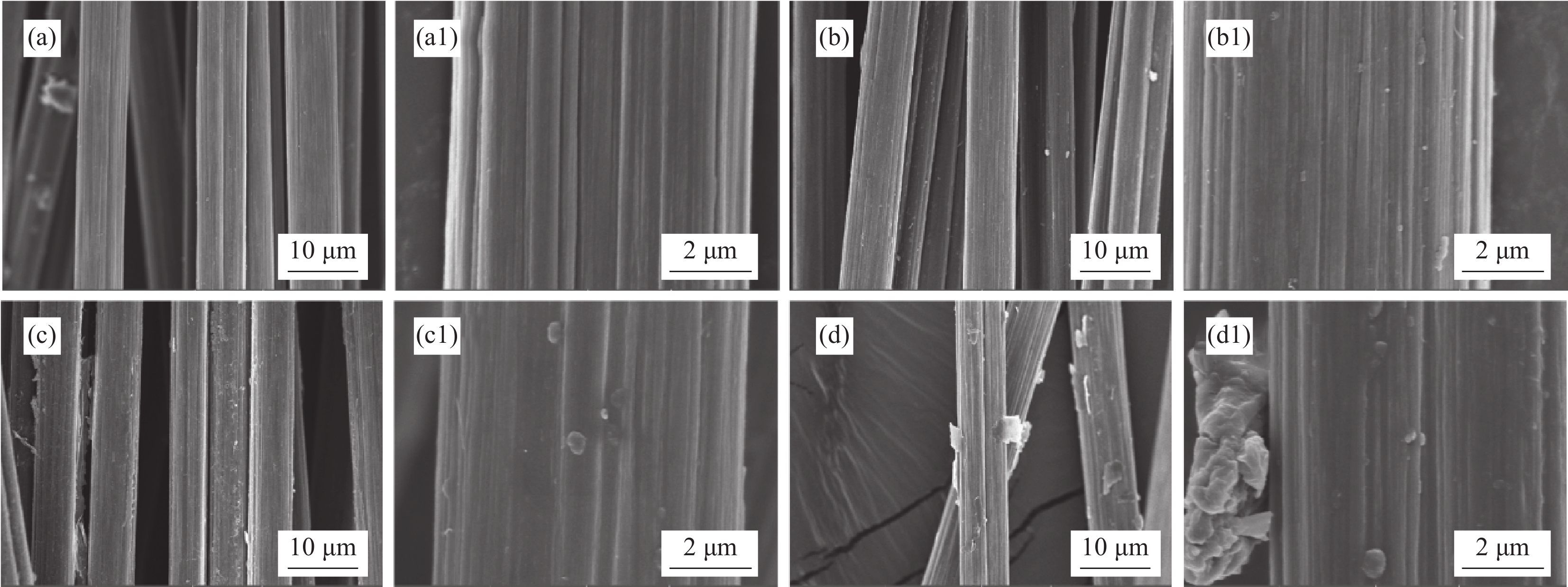

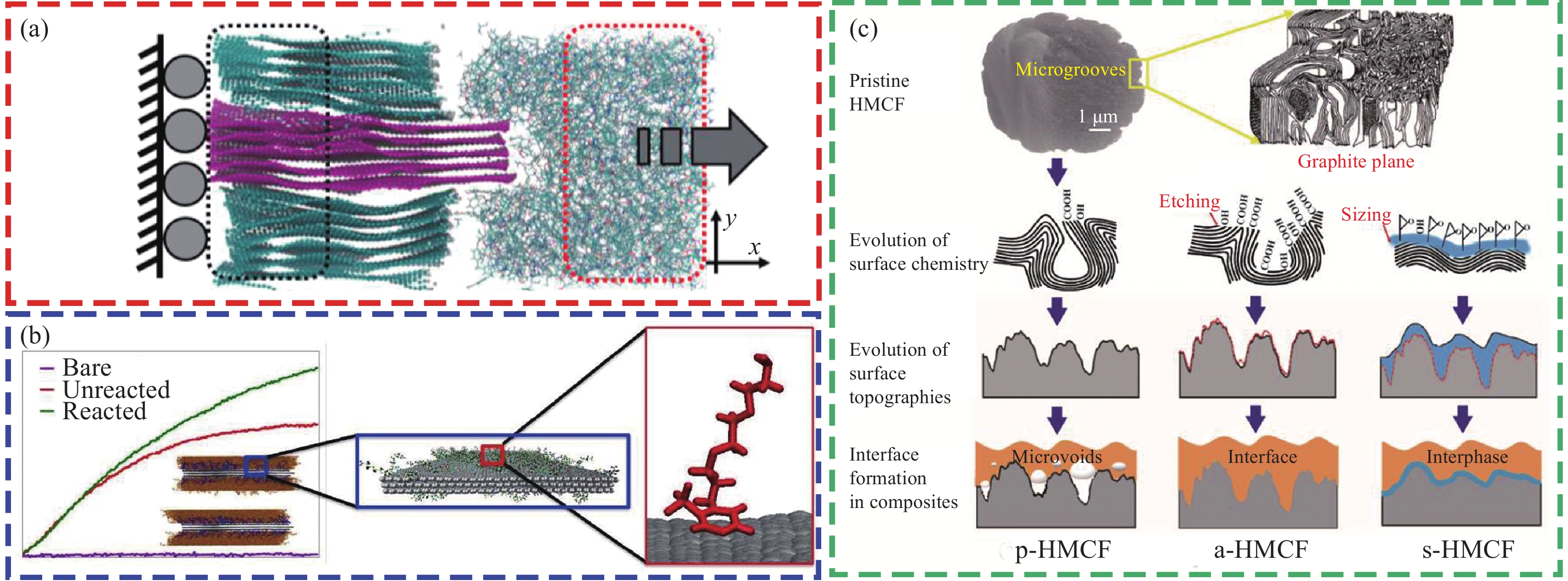

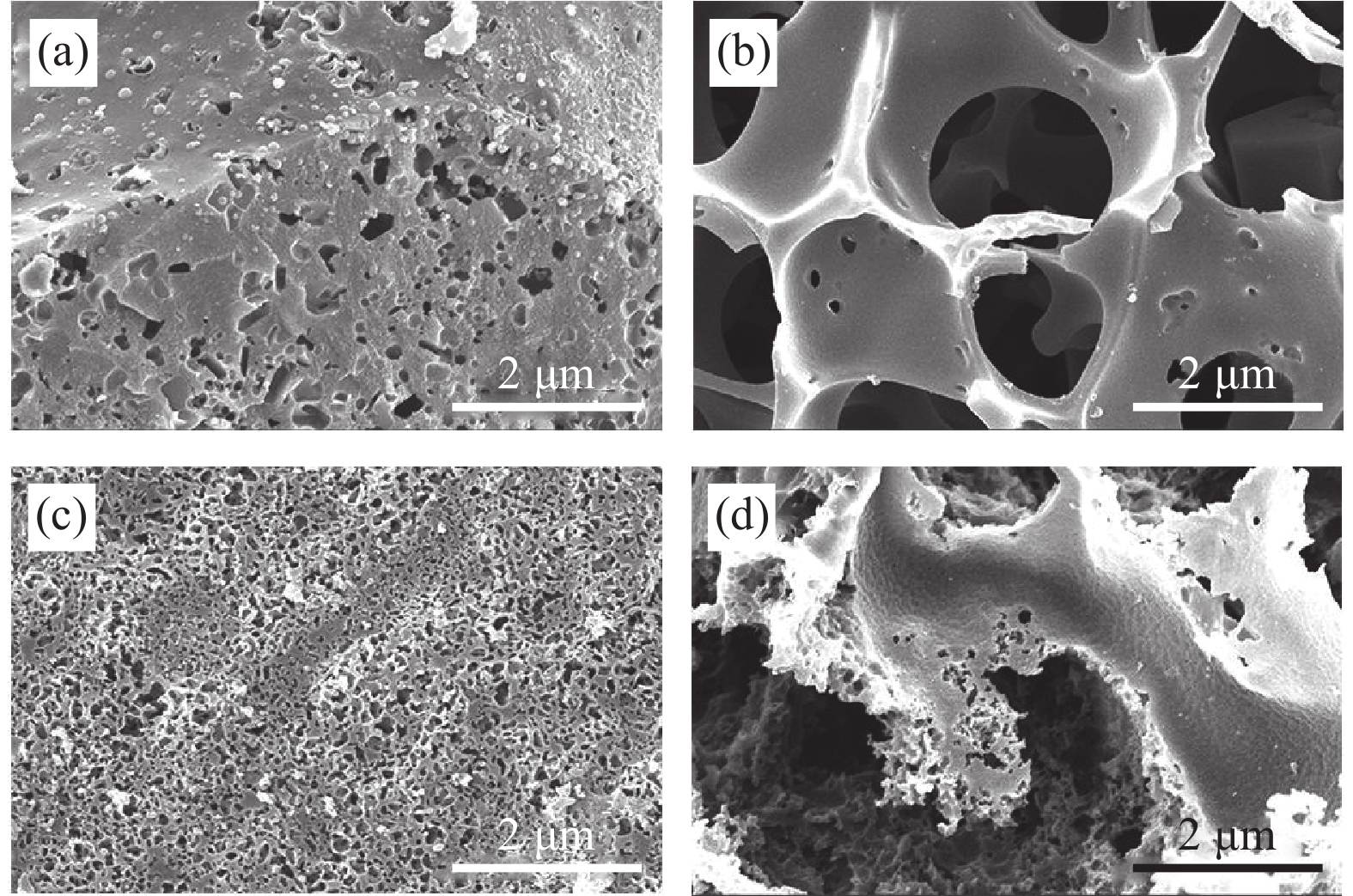

The interfacial properties of high-modulus carbon fiber (HMCF) composites have always been the key to their applications, and surface modification of HMCF is one of the important ways to improve the interfacial properties. Graphene nanosheets (GNP) were introduced into the surface of HMCF by electrophoretic deposition, and the surface morphology and surface chemical state of HMCF before and after modification were characterized by scanning electron microscopy (SEM) and X-ray photoelectron spectroscopy (XPS), and the interlaminar shear strength (ILSS) and moisture absorption rate of HMCF reinforced epoxy resin composites before and after modification were tested. The results show that the surface electrophoretic deposition of GNP by HMCF can not only improve the interfacial properties of the reinforced epoxy resin composites, but also reduce the moisture absorption rate of the composites. When the GNP concentration was 0.5 mg/mL and the electrophoretic deposition voltage was 10 V, the interlaminar shear performance of the composites increased by 8.8% to 75.6 MPa, and the moisture absorption rate was reduced by 9.5% compared with the unmodified sample after 30 days of storage at 90°C and 80 RH%, and the interlayer shear performance remained at 67.8 MPa after 60 days of storage. Both interfacial and hygrothermal properties of the modified HMCF comosites have been improved.

The interfacial properties of high-modulus carbon fiber (HMCF) composites have always been the key to their applications, and surface modification of HMCF is one of the important ways to improve the interfacial properties. Graphene nanosheets (GNP) were introduced into the surface of HMCF by electrophoretic deposition, and the surface morphology and surface chemical state of HMCF before and after modification were characterized by scanning electron microscopy (SEM) and X-ray photoelectron spectroscopy (XPS), and the interlaminar shear strength (ILSS) and moisture absorption rate of HMCF reinforced epoxy resin composites before and after modification were tested. The results show that the surface electrophoretic deposition of GNP by HMCF can not only improve the interfacial properties of the reinforced epoxy resin composites, but also reduce the moisture absorption rate of the composites. When the GNP concentration was 0.5 mg/mL and the electrophoretic deposition voltage was 10 V, the interlaminar shear performance of the composites increased by 8.8% to 75.6 MPa, and the moisture absorption rate was reduced by 9.5% compared with the unmodified sample after 30 days of storage at 90°C and 80 RH%, and the interlayer shear performance remained at 67.8 MPa after 60 days of storage. Both interfacial and hygrothermal properties of the modified HMCF comosites have been improved.

, Available online

Abstract:

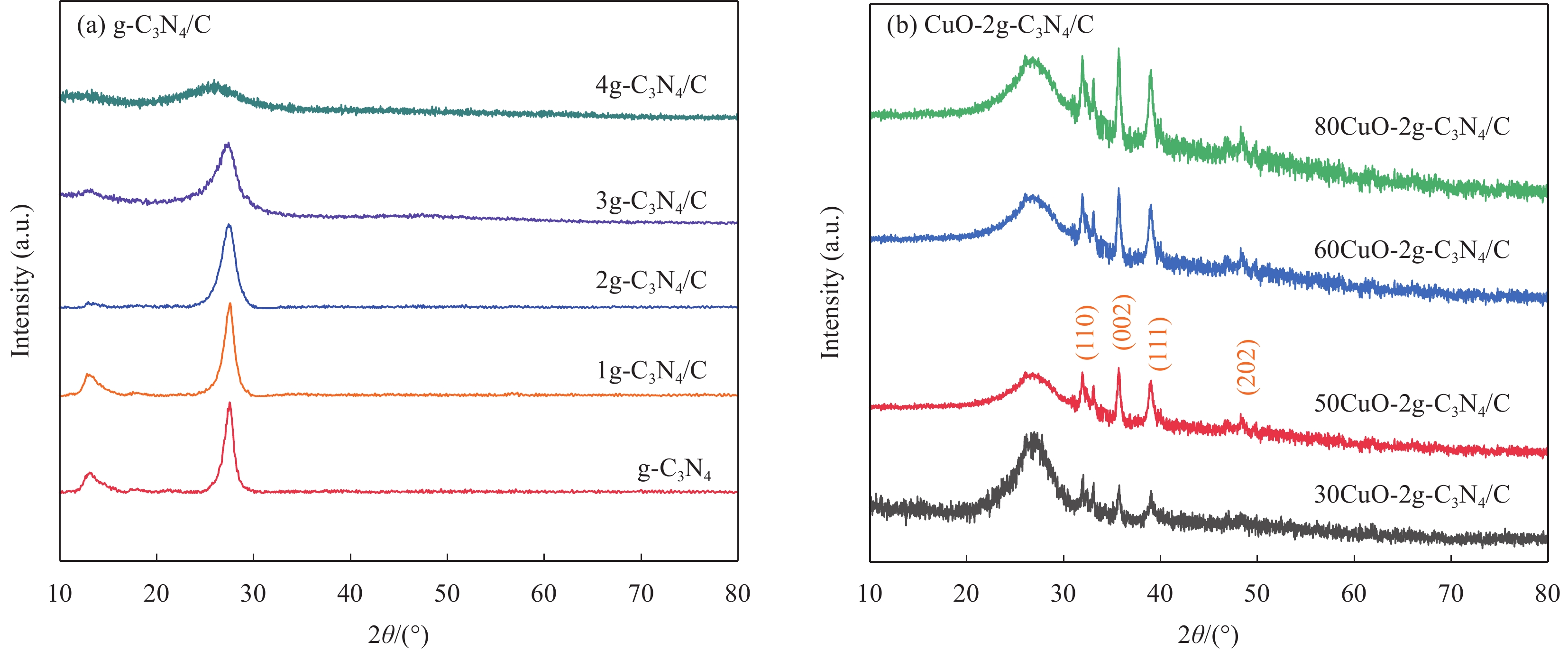

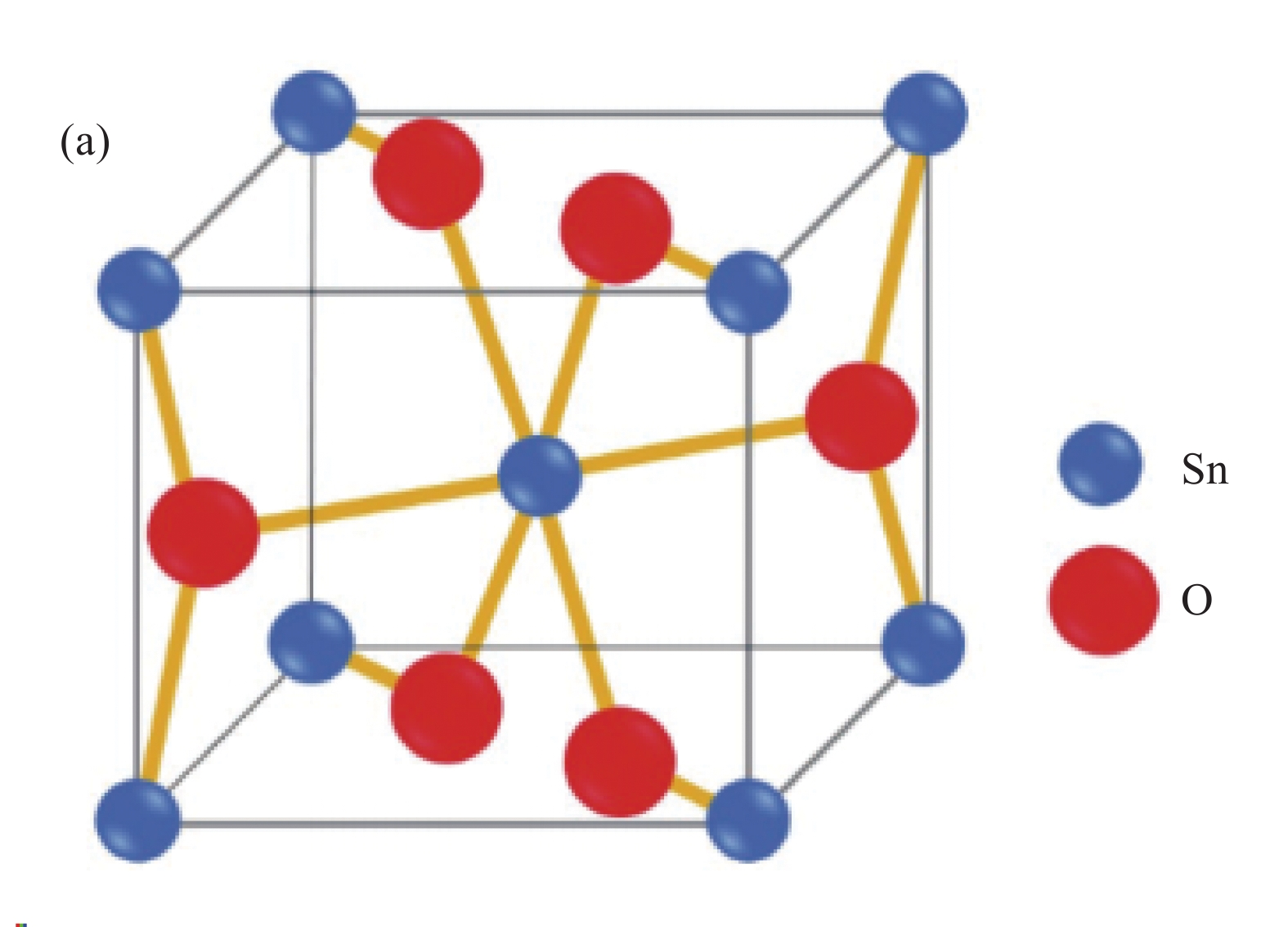

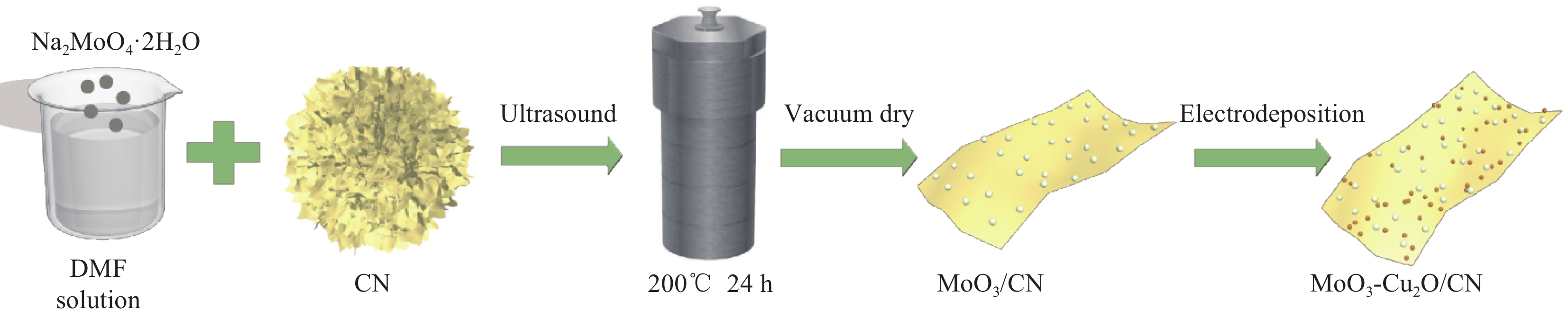

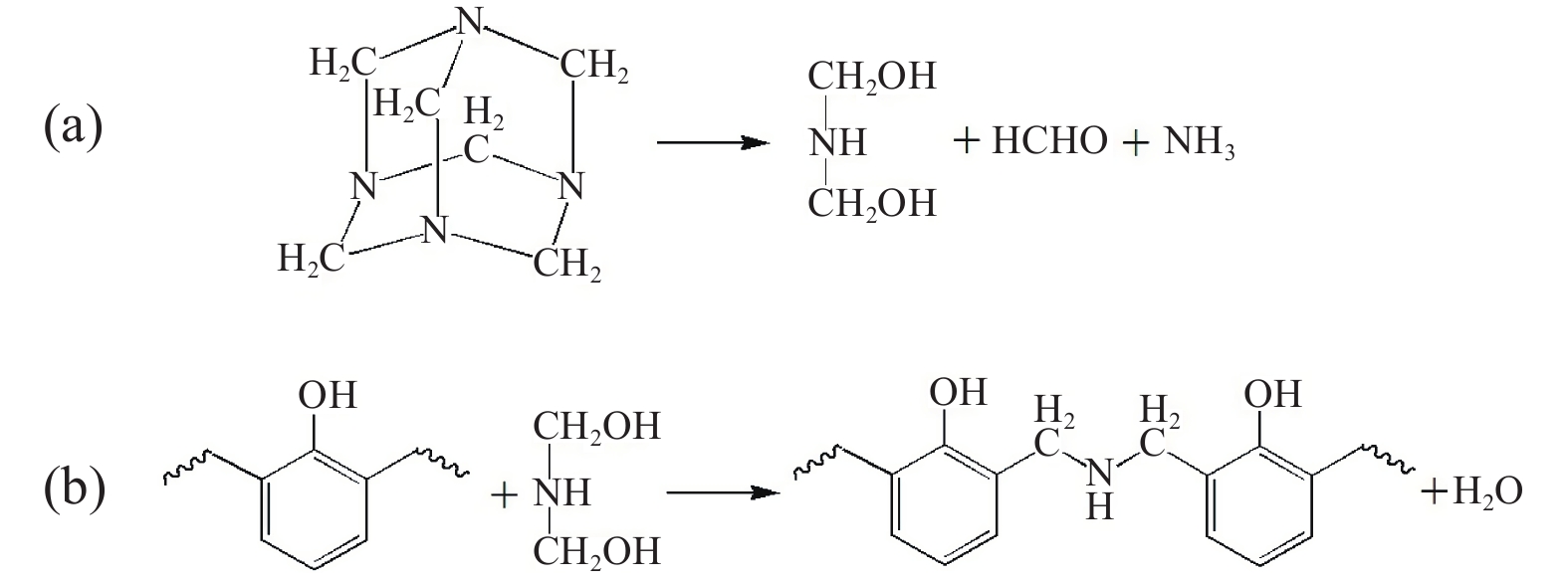

The theoretical specific capacity of polyvalent copper-based oxides is considerable, but their conductivity and stability are inadequate. Graphite phase carbon nitride (g-C3N4) exhibits good stability, high nitrogen content and simple synthesis method; however, its capacitance performance is poor. Biochar possesses a substantial specific surface area, relatively good electrical conductivity and rigid structure. To fully leverage the advantages of single phase and compensate for their respective shortcomings, a two-phase compound g-C3N4/C with porous structure was synthesized. Urea was served as the precursor of g-C3N4, and pleurorus eryngii was selected as the template. Subsequently, CuO was uniformly anchored on the surface and pores of g-C3N4/C through hydrothermal method, resulting in three-phase CuO-g-C3N4/C. Electrochemical testing reveals that the maximum specific capacitance of CuO-g-C3N4/C reaches 262.8F/g, with a capacitance retention rate of 97% after 2000 constant current charge-discharge cycles. CuO-g-C3N4/C consistently exhibits excellent charge and discharge performance across different current densities, showcasing superior capacitance and stability of CuO-g-C3N4/C. This highlights that the combination of CuO and g-C3N4/C in a three-phase structure not only enhances the conductivity of CuO, but also enhances the capacitive performance of g-C3N4, thereby improving the energy storage performance, electrical conductivity and stability of the overall material.

The theoretical specific capacity of polyvalent copper-based oxides is considerable, but their conductivity and stability are inadequate. Graphite phase carbon nitride (g-C3N4) exhibits good stability, high nitrogen content and simple synthesis method; however, its capacitance performance is poor. Biochar possesses a substantial specific surface area, relatively good electrical conductivity and rigid structure. To fully leverage the advantages of single phase and compensate for their respective shortcomings, a two-phase compound g-C3N4/C with porous structure was synthesized. Urea was served as the precursor of g-C3N4, and pleurorus eryngii was selected as the template. Subsequently, CuO was uniformly anchored on the surface and pores of g-C3N4/C through hydrothermal method, resulting in three-phase CuO-g-C3N4/C. Electrochemical testing reveals that the maximum specific capacitance of CuO-g-C3N4/C reaches 262.8F/g, with a capacitance retention rate of 97% after 2000 constant current charge-discharge cycles. CuO-g-C3N4/C consistently exhibits excellent charge and discharge performance across different current densities, showcasing superior capacitance and stability of CuO-g-C3N4/C. This highlights that the combination of CuO and g-C3N4/C in a three-phase structure not only enhances the conductivity of CuO, but also enhances the capacitive performance of g-C3N4, thereby improving the energy storage performance, electrical conductivity and stability of the overall material.

, Available online

Abstract:

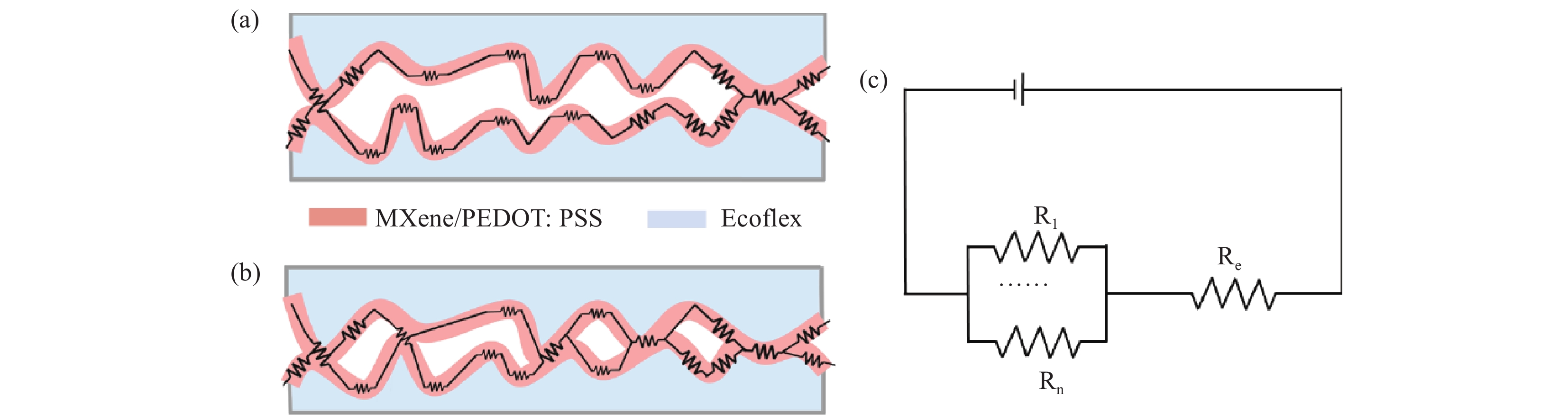

As a one-dimensional sensor, yarn-based flexible strain sensor has good flexibility, braidability and stretchability, which makes it have great application advantages in human motion monitoring. The preparation methods of yarn-based flexible strain sensors mainly include filature method, spinning method, finishing method and composite method, and the preparation process and research progress of various yarn-based flexible strain sensors are expounded from the preparation method, and the characteristics, advantages and disadvantages of various preparation methods are summarized, and finally the future research direction of yarn-based flexible strain sensors is proposed, which provides a reference for further preparation and research of such sensors.

As a one-dimensional sensor, yarn-based flexible strain sensor has good flexibility, braidability and stretchability, which makes it have great application advantages in human motion monitoring. The preparation methods of yarn-based flexible strain sensors mainly include filature method, spinning method, finishing method and composite method, and the preparation process and research progress of various yarn-based flexible strain sensors are expounded from the preparation method, and the characteristics, advantages and disadvantages of various preparation methods are summarized, and finally the future research direction of yarn-based flexible strain sensors is proposed, which provides a reference for further preparation and research of such sensors.

, Available online

Abstract:

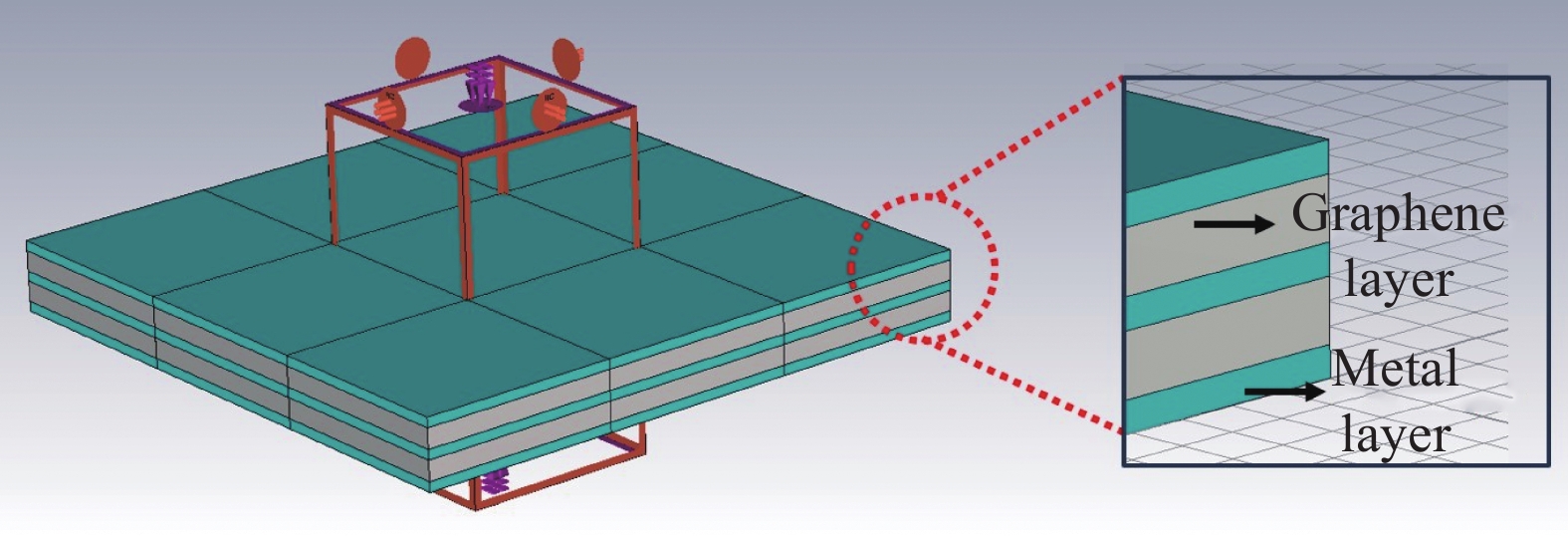

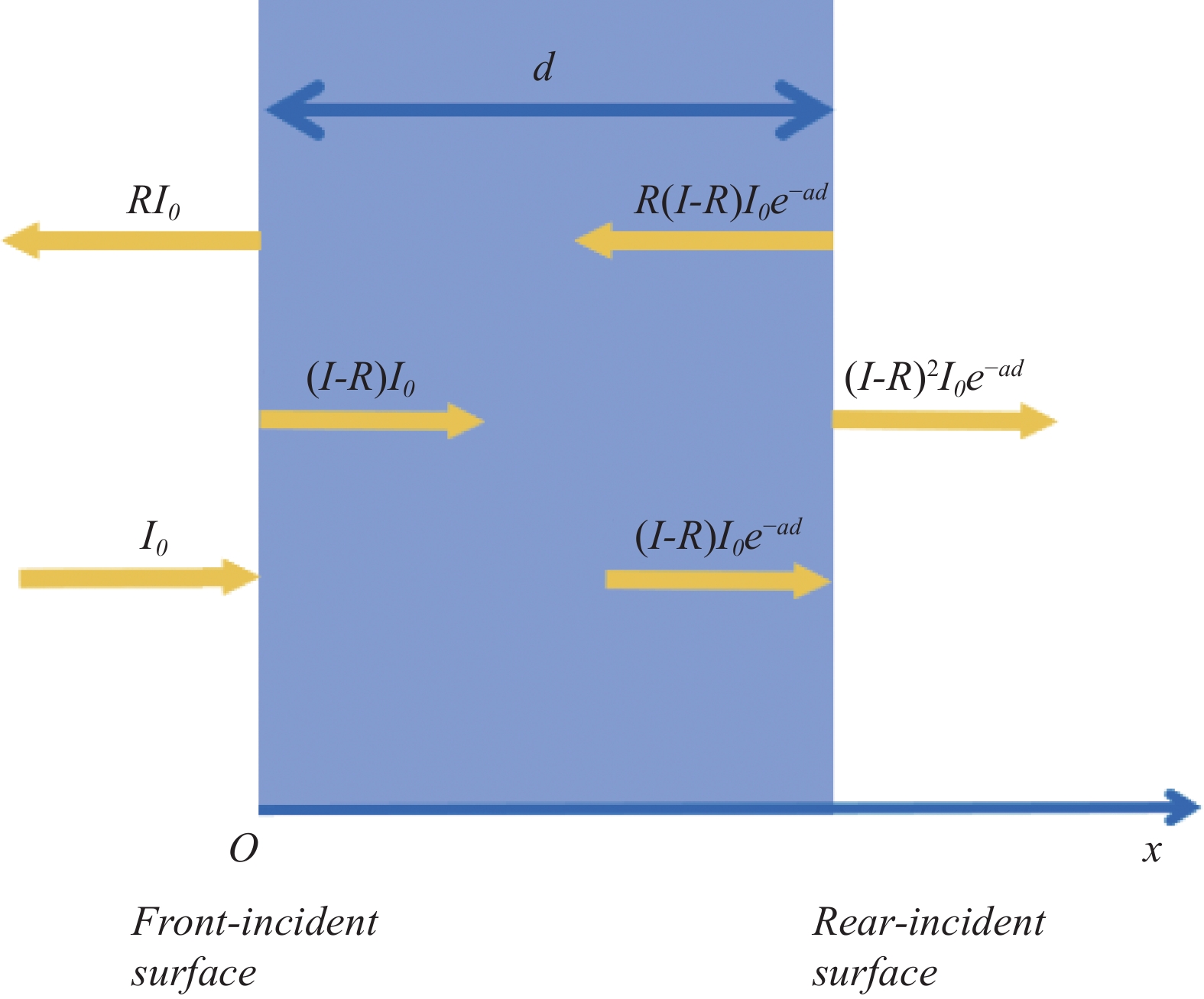

Graphene film has been widely studied in the field of electromagnetic interference (EMI) shielding due to its unique layered structure, high conductivity, and good flexibility. However, graphene film has a large skin depth, which makes it difficult to balance high shielding effectiveness (SE) and thin thickness. To solve the above problems, the surface modification of graphene film and the design of multi-layer impedance mismatch interface were carried out based on the transmission line theory. The model of metal-graphene multilayer heterostructure was established for electromagnetic simulation. The influence of structural parameters on the EMI shielding performance was studied. According to the simulation model, Ag-graphene-Ag sandwich composite films (A-G-A CF) were fabricated by magnetron sputtering, and their EMI shielding performance and mechanism were investigated. After depositing Ag on graphene film, the conductivity increases by nearly two orders of magnitude, making the skin depth significantly decrease and the SE in 4~18 GHz increase from 24 dB to 44 dB. Moreover, the sandwich structure enhances the electromagnetic loss of the film and further improves the SE to 51 dB. With the increase of metal coating thickness, the SE of A-G-A CF gradually increases. The SE of A-G-A CF with a metal coating thickness of about 580 nm is as high as 65 dB, which can shield more than 99.9999% of electromagnetic wave energy.

Graphene film has been widely studied in the field of electromagnetic interference (EMI) shielding due to its unique layered structure, high conductivity, and good flexibility. However, graphene film has a large skin depth, which makes it difficult to balance high shielding effectiveness (SE) and thin thickness. To solve the above problems, the surface modification of graphene film and the design of multi-layer impedance mismatch interface were carried out based on the transmission line theory. The model of metal-graphene multilayer heterostructure was established for electromagnetic simulation. The influence of structural parameters on the EMI shielding performance was studied. According to the simulation model, Ag-graphene-Ag sandwich composite films (A-G-A CF) were fabricated by magnetron sputtering, and their EMI shielding performance and mechanism were investigated. After depositing Ag on graphene film, the conductivity increases by nearly two orders of magnitude, making the skin depth significantly decrease and the SE in 4~18 GHz increase from 24 dB to 44 dB. Moreover, the sandwich structure enhances the electromagnetic loss of the film and further improves the SE to 51 dB. With the increase of metal coating thickness, the SE of A-G-A CF gradually increases. The SE of A-G-A CF with a metal coating thickness of about 580 nm is as high as 65 dB, which can shield more than 99.9999% of electromagnetic wave energy.

, Available online

Abstract:

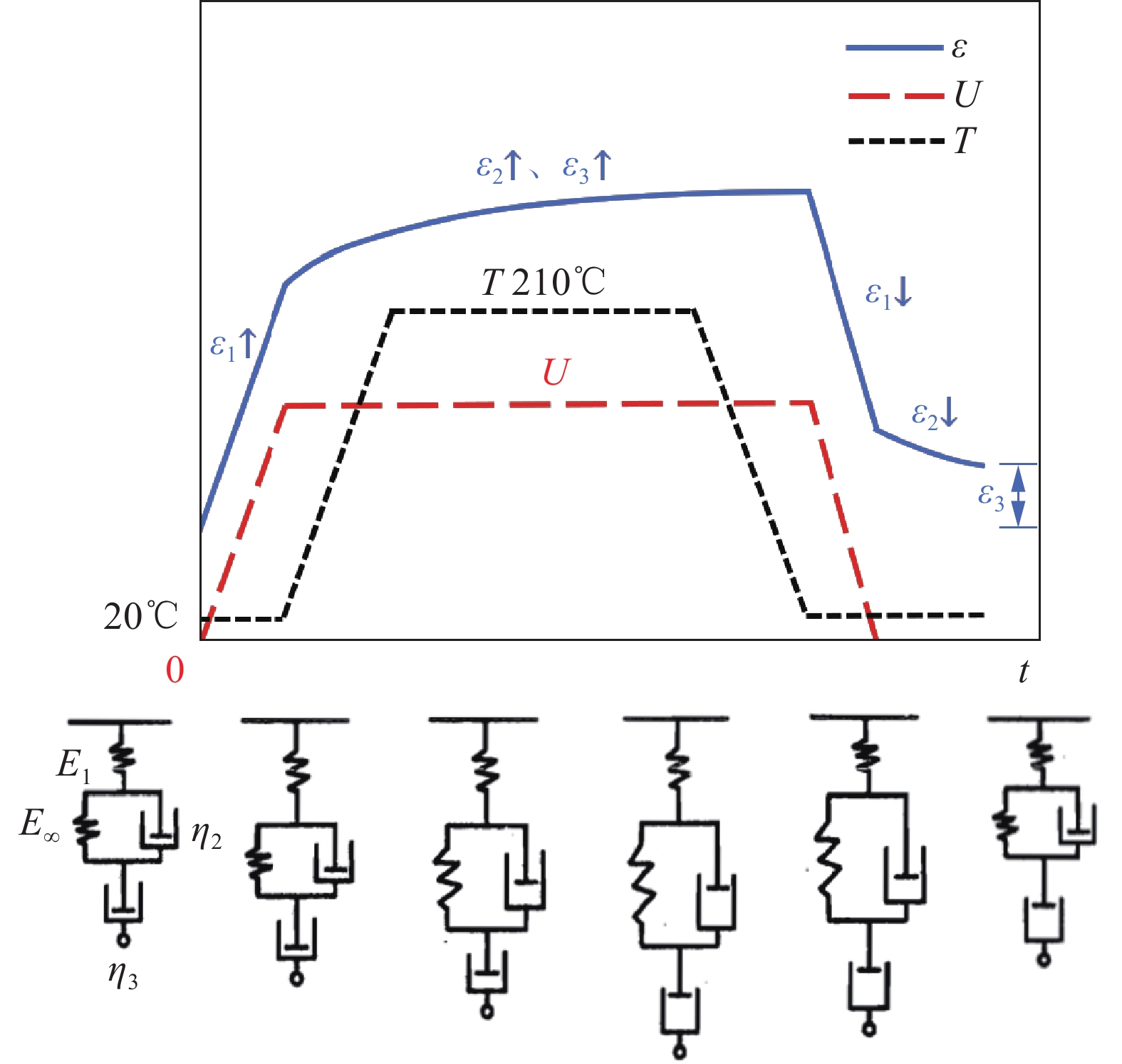

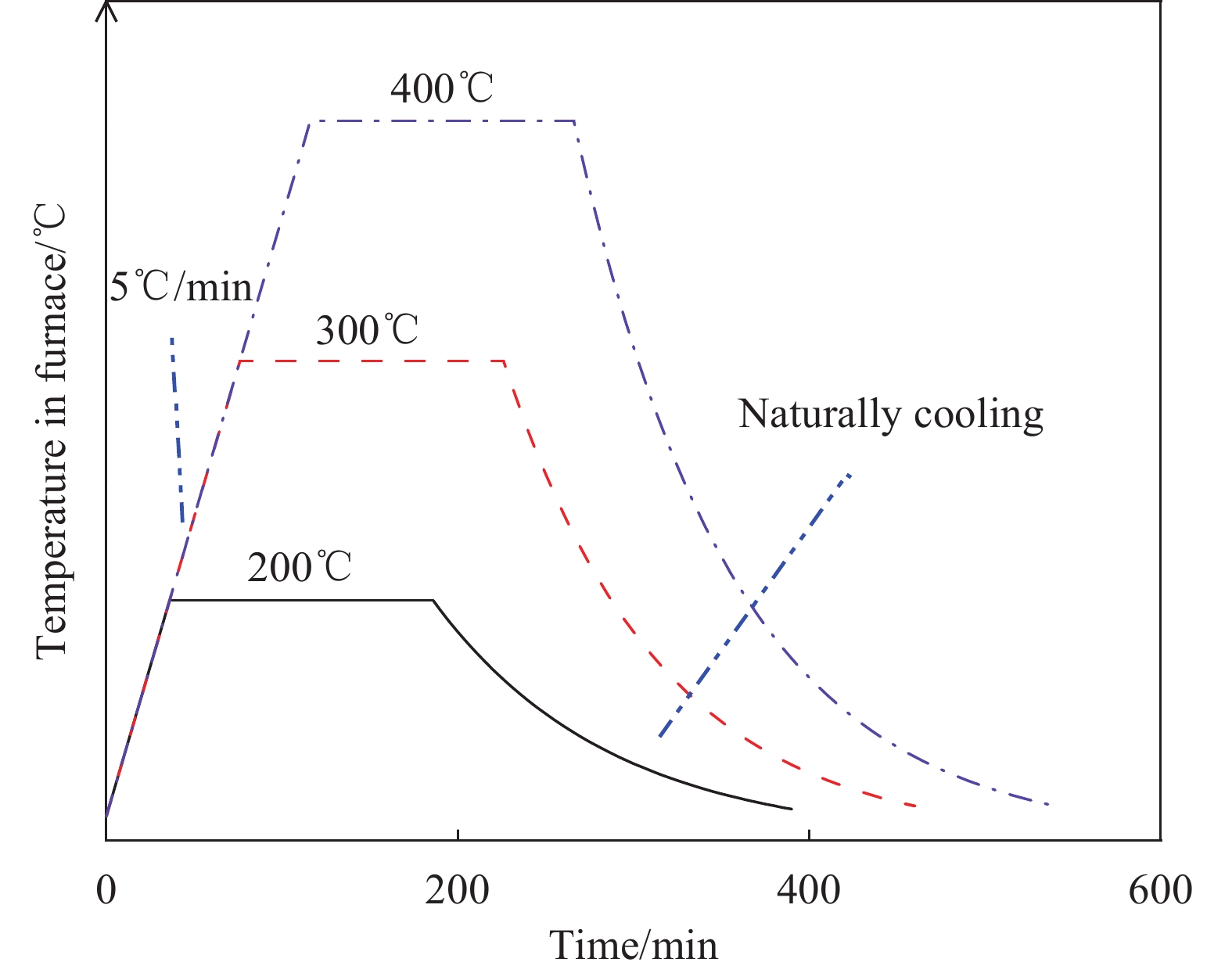

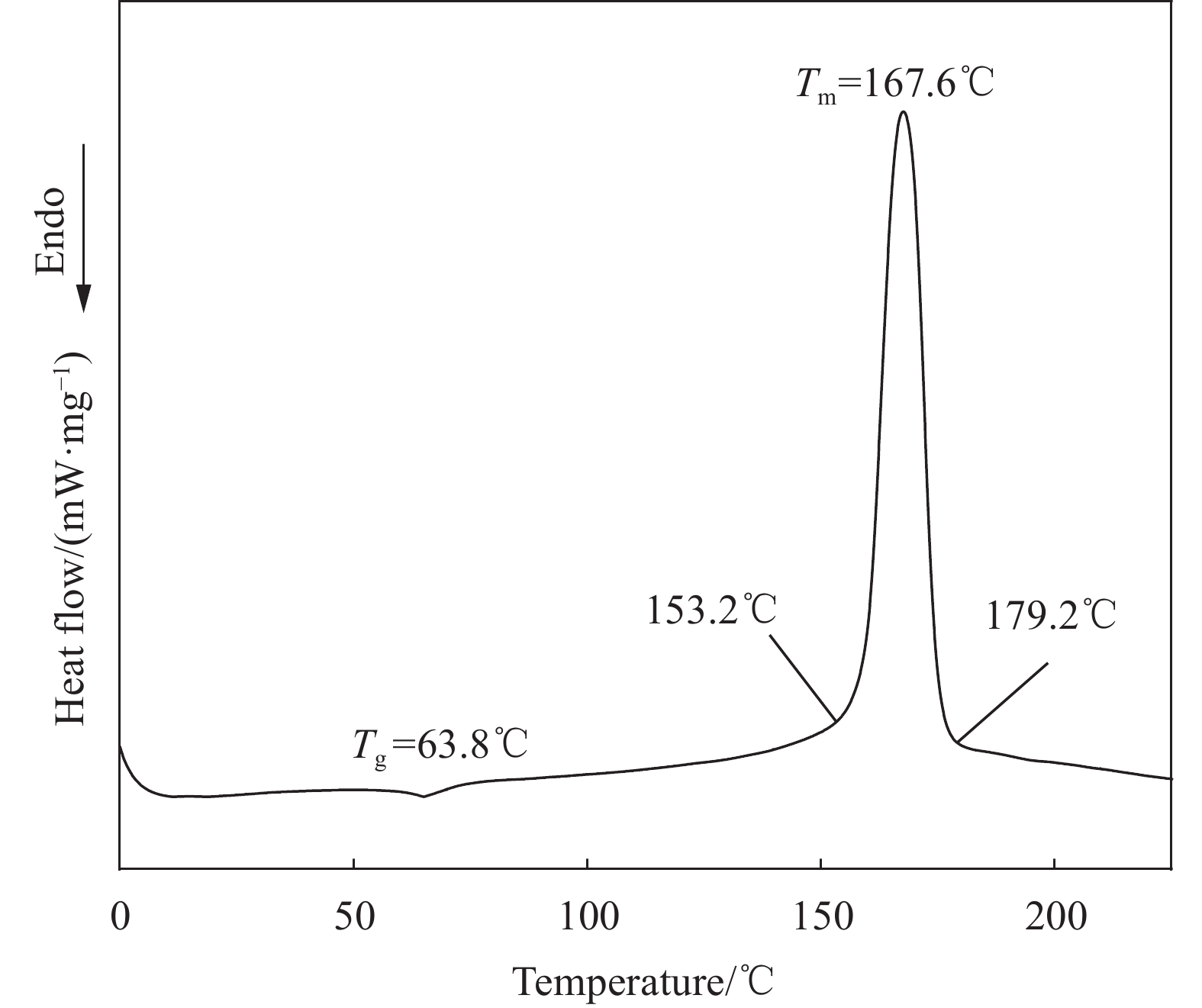

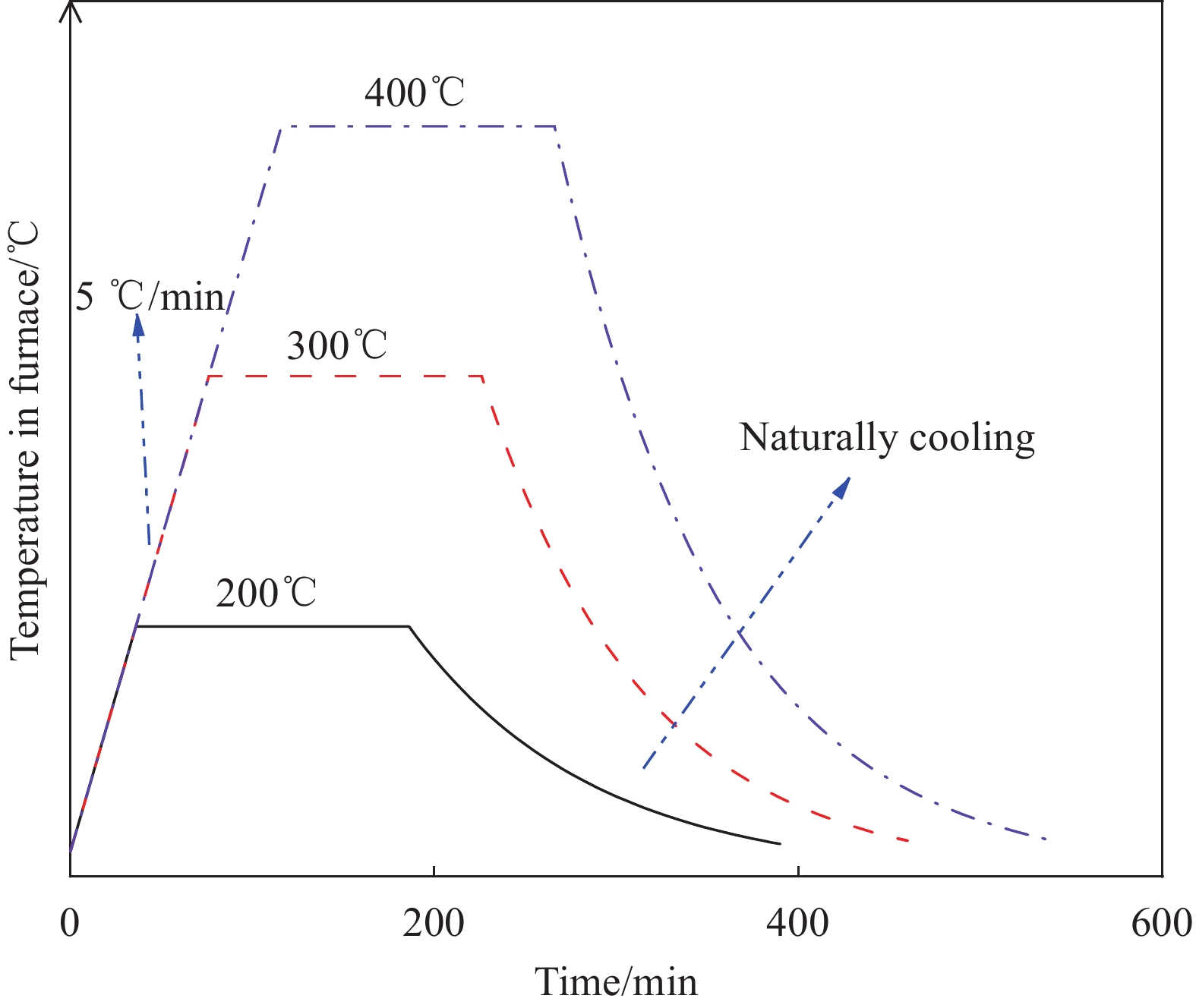

The composite cylindrical grid structures exhibit quite a few features and complex structural characteristics, and its precision in manufacturing is restricted due to the curing deformation. Based on the viscoelasticity of the bismaleimide resin, high temperature creep tensile testing of the aerospace 802 bismaleimide resin was performed, confirming the existence of unrecoverable viscous flow strain after the unloading of the bismaleimide resin creep. The micro component material mechanism was revealed to reduce the process curing deformation of large composite grid structures through hot sizing. The deformation energy increment theory for composite grid structures was derived and established. The process of hot sizing load application, relaxation, and rebound of composite grid structures was simulated. The correction rebound profile of grid structures was determined, comparing with experimental results to verify the effectiveness of the deformation energy increment theory. The failure of internal stress, number of correction points and process conditions based on time temperature equivalence of hot sizing composite grid structure was analyzed. A complete process for the deformation simulation method of hot sizing deformation control for composite grid structures formed.

The composite cylindrical grid structures exhibit quite a few features and complex structural characteristics, and its precision in manufacturing is restricted due to the curing deformation. Based on the viscoelasticity of the bismaleimide resin, high temperature creep tensile testing of the aerospace 802 bismaleimide resin was performed, confirming the existence of unrecoverable viscous flow strain after the unloading of the bismaleimide resin creep. The micro component material mechanism was revealed to reduce the process curing deformation of large composite grid structures through hot sizing. The deformation energy increment theory for composite grid structures was derived and established. The process of hot sizing load application, relaxation, and rebound of composite grid structures was simulated. The correction rebound profile of grid structures was determined, comparing with experimental results to verify the effectiveness of the deformation energy increment theory. The failure of internal stress, number of correction points and process conditions based on time temperature equivalence of hot sizing composite grid structure was analyzed. A complete process for the deformation simulation method of hot sizing deformation control for composite grid structures formed.

, Available online

Abstract:

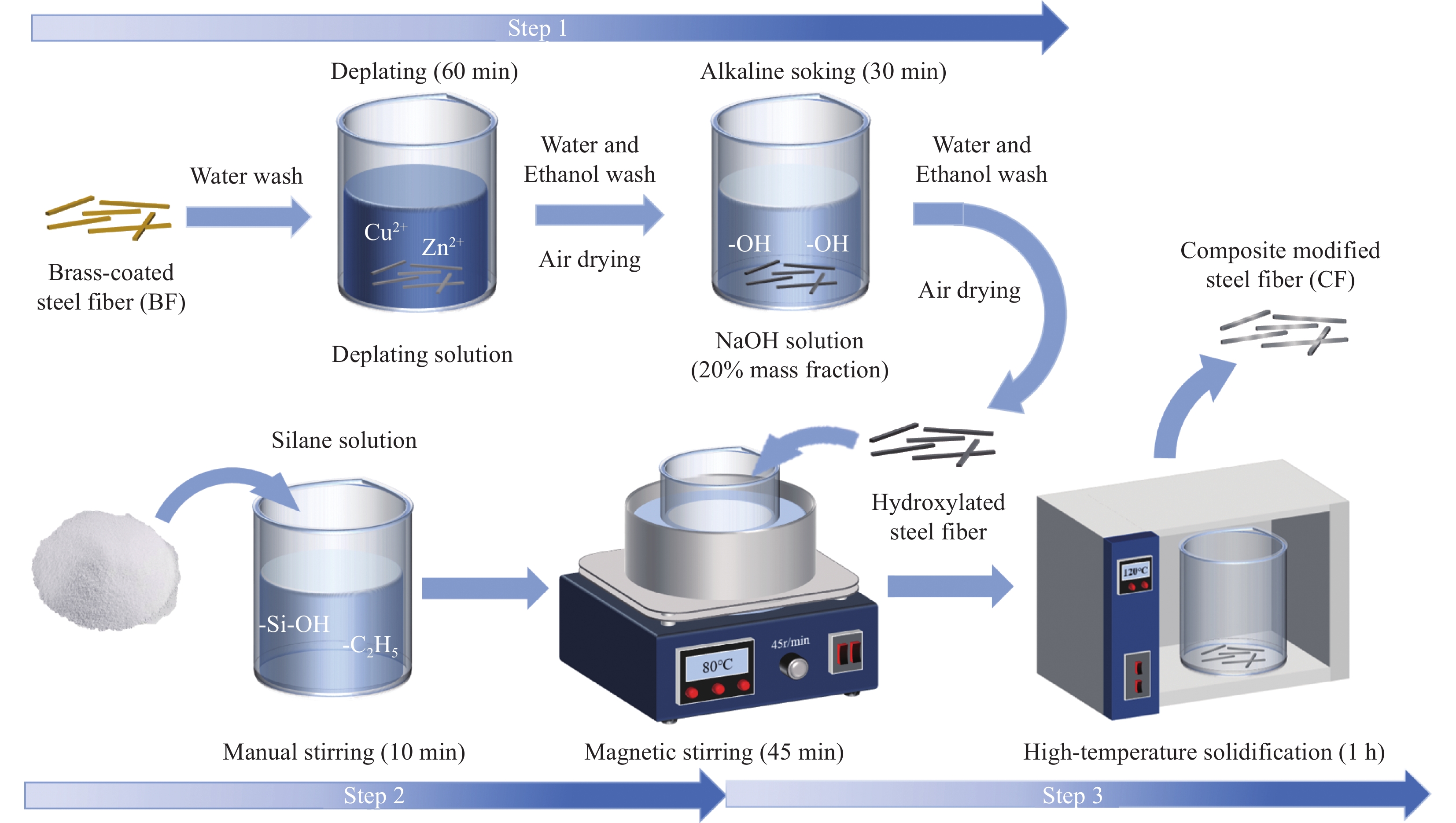

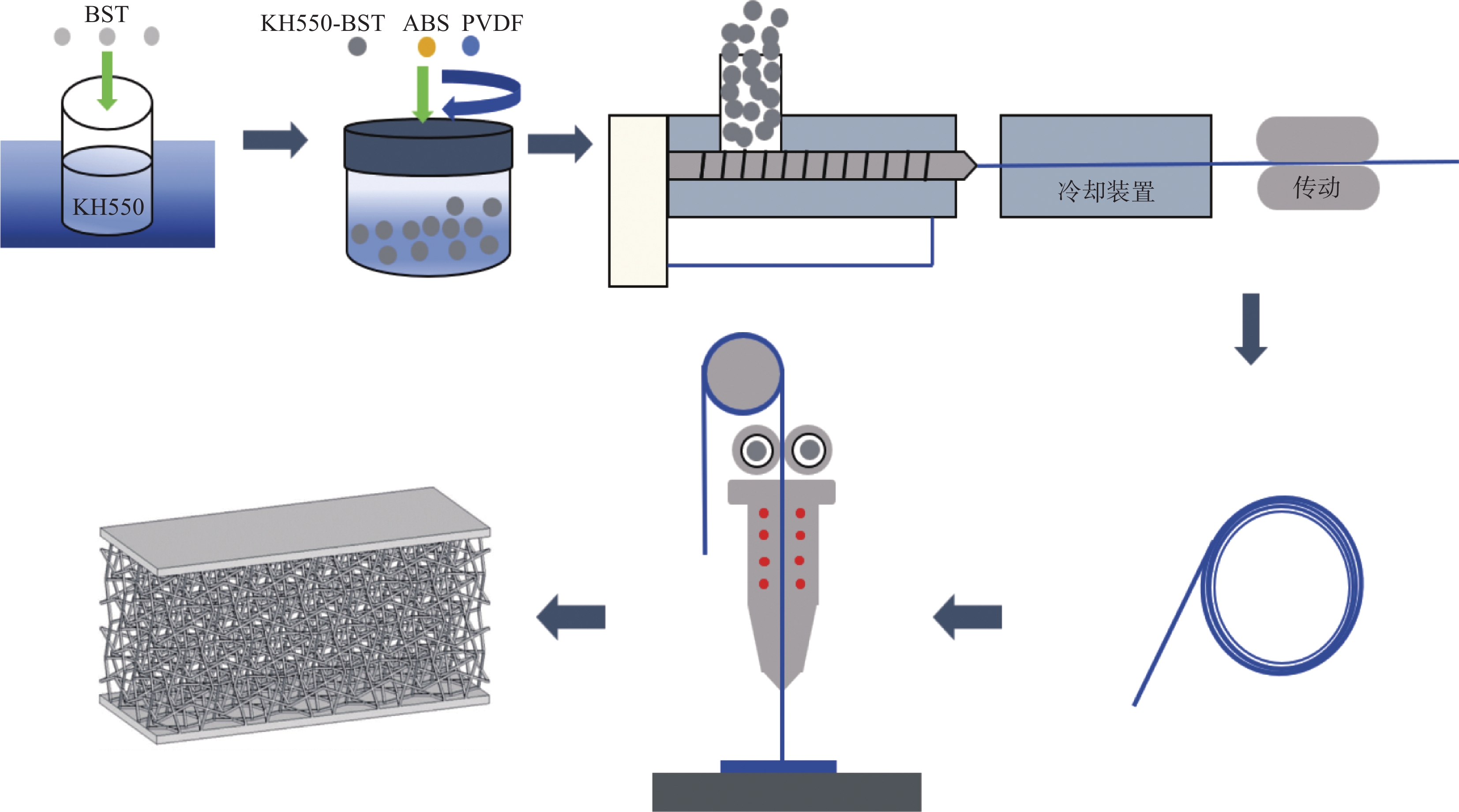

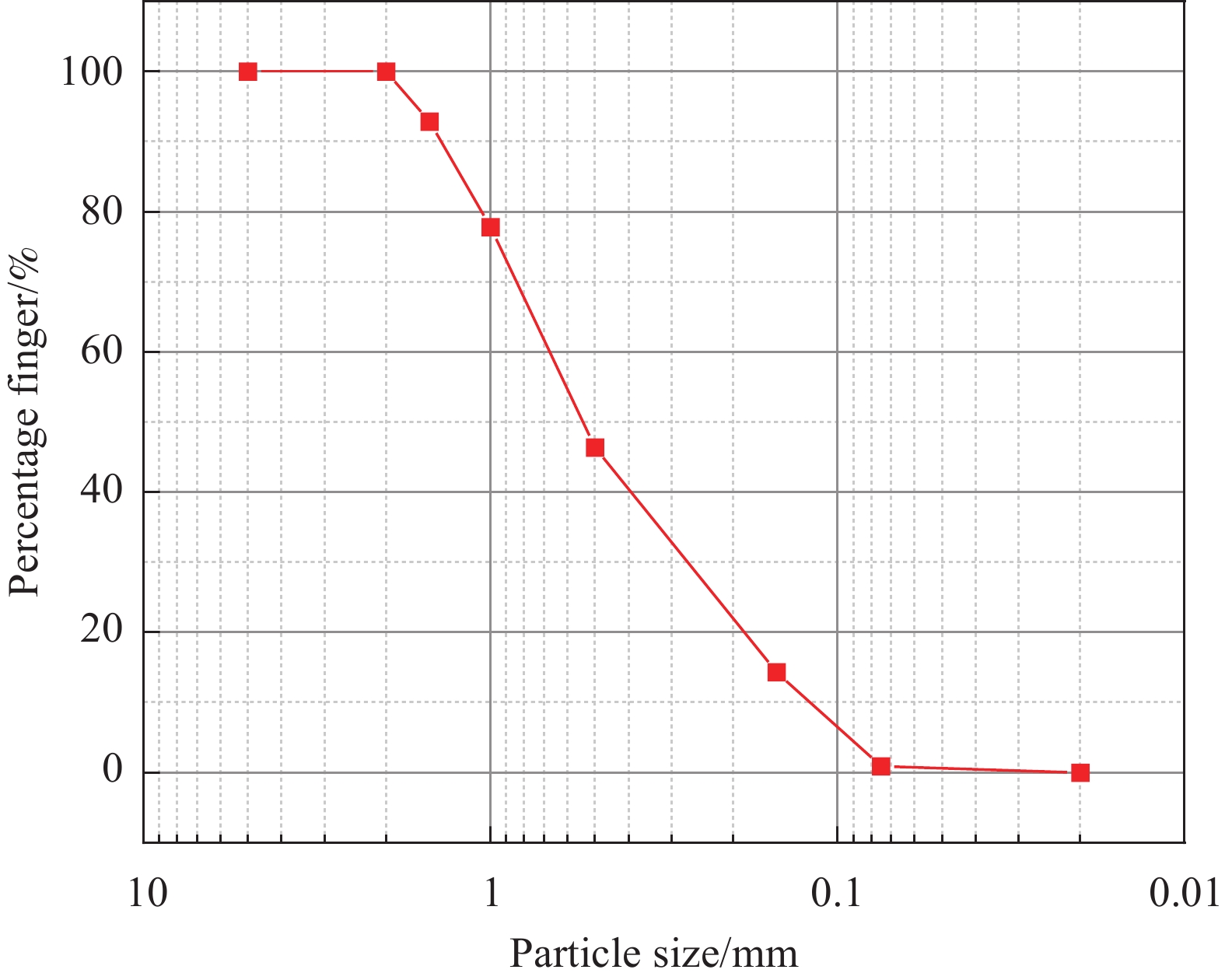

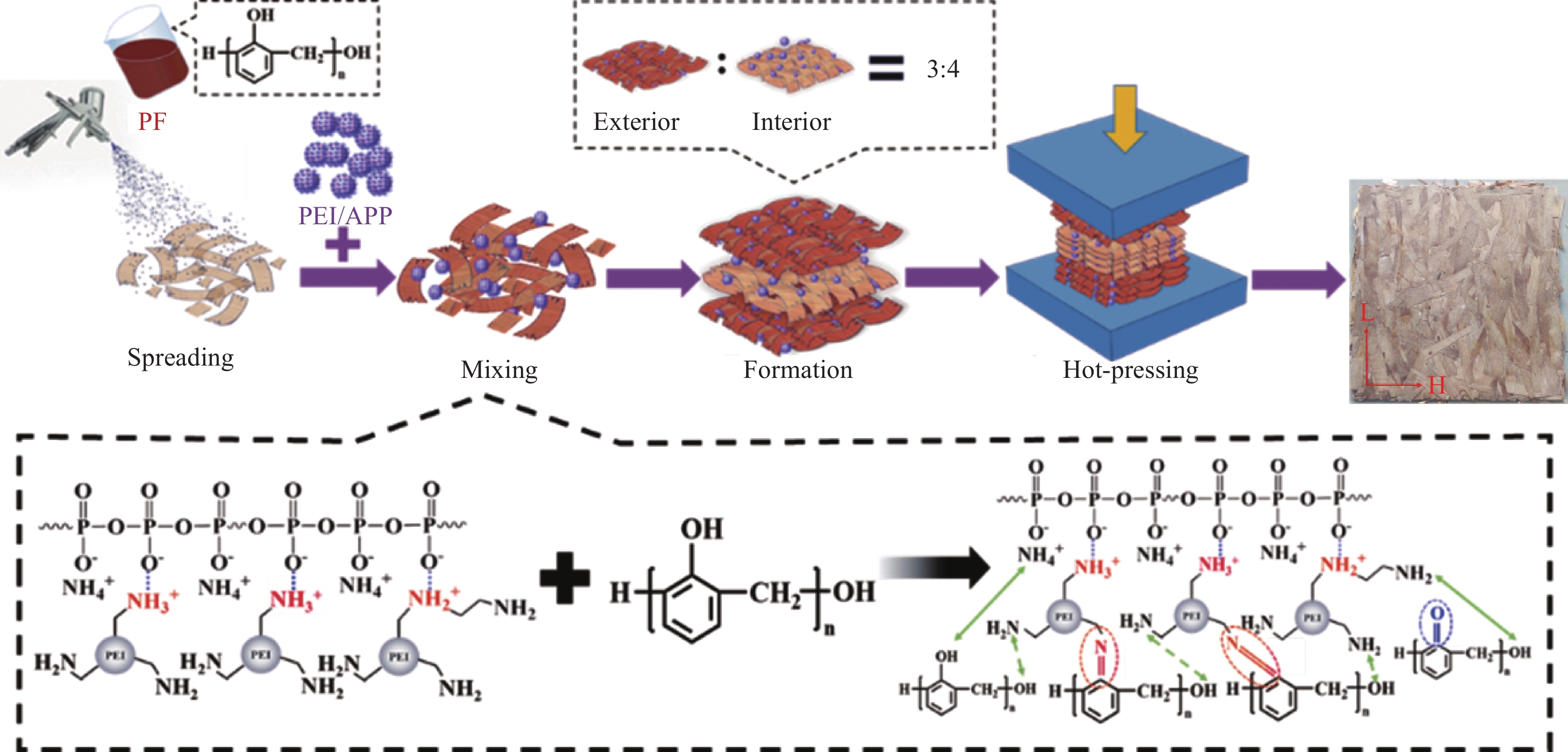

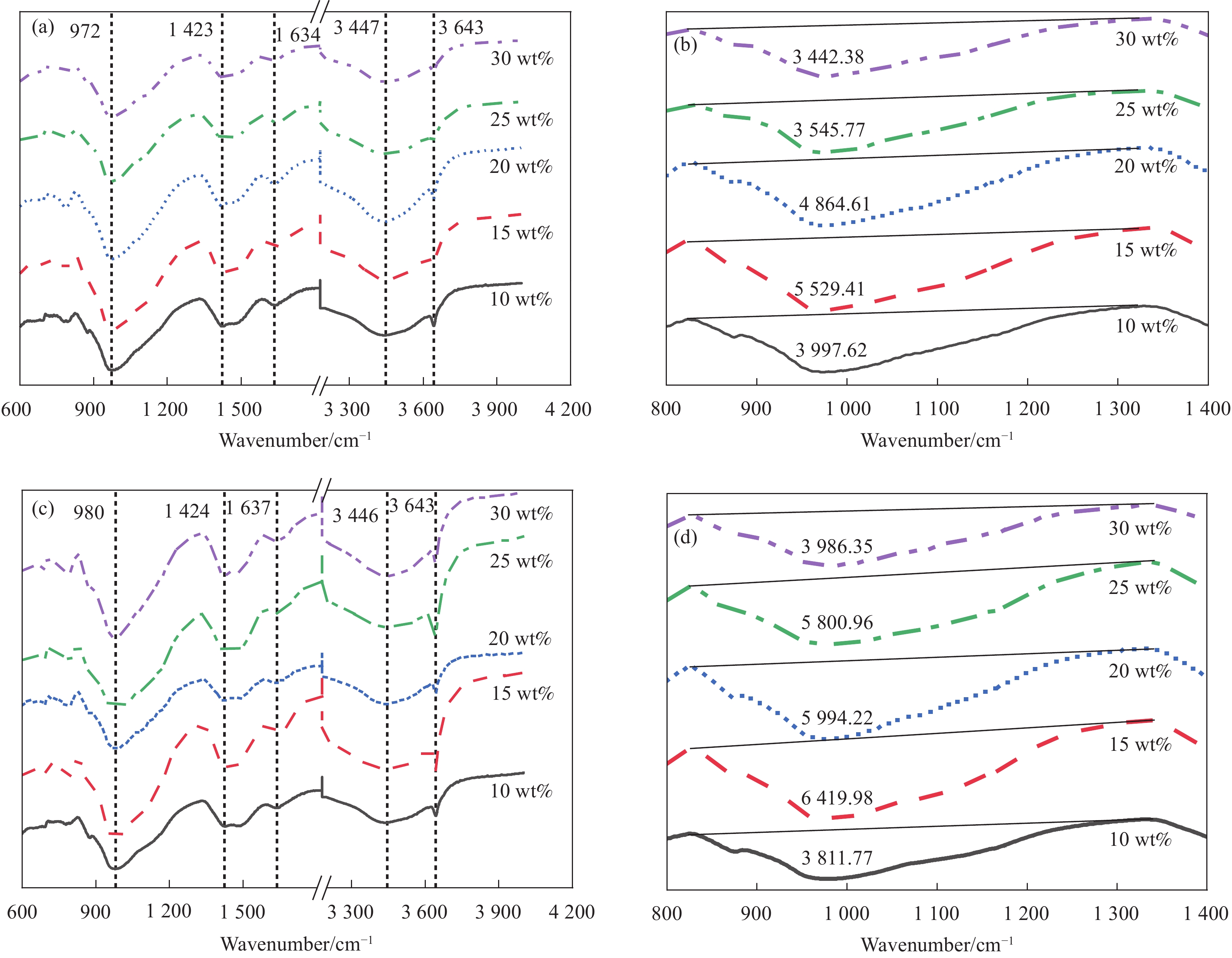

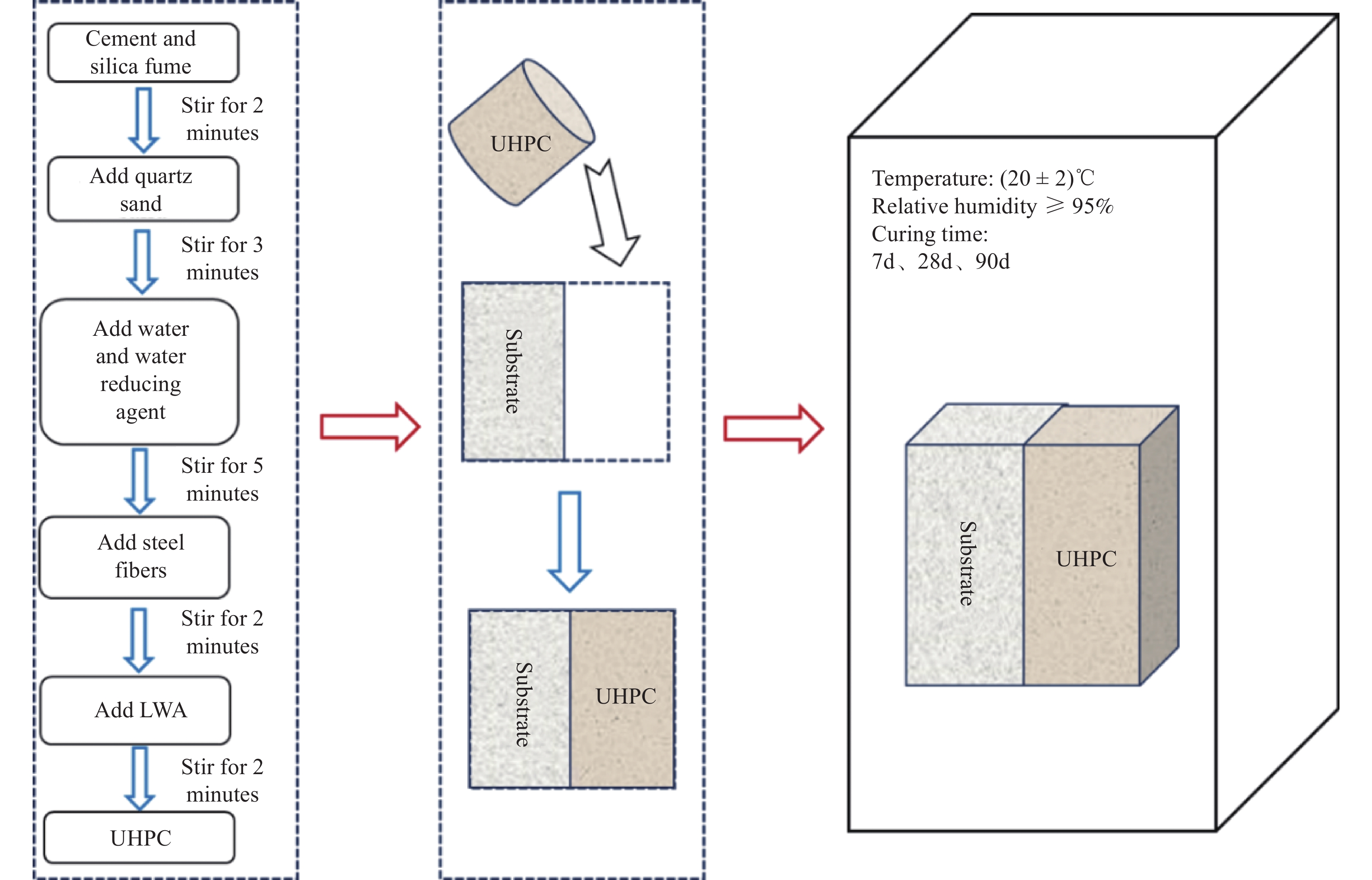

To improve the mechanical properties of steel fiber reinforced ultra-high performance concrete (UHPFRC), a new composite modification method of steel fiber surfaces was proposed using silane coupling agent KH550 and nano-SiO2 particles. Four parameters, including the mass ratio of ethanol to water (We:Wd), the content of KH550 (wt%), the content of nano-SiO2 (wt%), and the water bath temperature (Twb), were considered for the orthogonal design of proportions (L9(34)). Firstly, four mixtures with good solution stability were selected for fiber surface modification. The FTIR and SEM were then used to analyze the composition and morphology of the coatings. Finally, the optimal modification process parameters were determined based on the bending and compressive strength of UHPFRC specimens at 28 days. The results show that: (1) the ratio of We:Wd is the main factor affecting the stability of the solution, and the optimal modification parameters are: We:Wd = 3, KH550 (wt%) = 10%, Nano-SiO2 (wt%) = 0.5%, and Twb = 80℃ ; (2) the FTIR results exhibit characteristic peaks of Fe-O-Si, indicating successful bonding of KH550 and Nano-SiO2 on the steel fiber surfaces; (3) the SEM results indicate uniform distributions of composite coatings without aggregation of Nano-SiO2 particles on the fiber surfaces modified by the optimal parameters; (4) for the fiber volume fractions of 1%, 1.5%, and 2%, the bending strength (28MPa, 30.5MPa and 37MPa) and compressive strength (133.3MPa, 151.7MPa and 163.9MPa) of UHPFRC specimens with optimally-modified fibers are increased by 40.4%, 28.5%, 32.7%, and 7.5%, 8.3%, 13%, respectively, compared to the specimens with untreated fibers; (5) the composite modification technique significantly improves the fiber-matrix interfaces, as demonstrated by more tortuous and complex crack morphologies in the specimens with fiber volume fractions of 1.5% and 2%.