2023 Vol. 40, No. 10

2023, 40(10): 5447-5465.

doi: 10.13801/j.cnki.fhclxb.20230607.001

Abstract:

In recent years, all-inorganic perovskite solar cells have become a hot topic in the photovoltaic field due to their excellent optoelectronic properties and outstanding thermal stability. This type of cell has achieved a photovoltaic conversion efficiency (PCE) of 21.15%, and further improvements are expected. However, the effective area of currently efficient all-inorganic perovskite cells is relatively small, mostly around 0.1 cm2, and the PCE of large-area all-inorganic perovskite solar cells will decrease significantly with an increase in effective area. The preparation of large-area cells is crucial for the commercial application of all-inorganic perovskite solar cells. In order to make all-inorganic perovskite materials better apply in the photovoltaic field, it is the simplest and most effective method to construct a multi-component composite structure and adjust the preparation process of all-inorganic perovskite. This article provides a systematic review of the progress in large-area all-inorganic perovskite solar cells, summarizing the achievements of all-inorganic perovskite solar cells with larger area. An analysis of the current status of large-area all-inorganic perovskite solar cells is also presented, and systematic summaries are given for the process of preparing large-area perovskite solar cells and strategies for optimizing cell performance. Finally, the future development trends in this field are discussed.

In recent years, all-inorganic perovskite solar cells have become a hot topic in the photovoltaic field due to their excellent optoelectronic properties and outstanding thermal stability. This type of cell has achieved a photovoltaic conversion efficiency (PCE) of 21.15%, and further improvements are expected. However, the effective area of currently efficient all-inorganic perovskite cells is relatively small, mostly around 0.1 cm2, and the PCE of large-area all-inorganic perovskite solar cells will decrease significantly with an increase in effective area. The preparation of large-area cells is crucial for the commercial application of all-inorganic perovskite solar cells. In order to make all-inorganic perovskite materials better apply in the photovoltaic field, it is the simplest and most effective method to construct a multi-component composite structure and adjust the preparation process of all-inorganic perovskite. This article provides a systematic review of the progress in large-area all-inorganic perovskite solar cells, summarizing the achievements of all-inorganic perovskite solar cells with larger area. An analysis of the current status of large-area all-inorganic perovskite solar cells is also presented, and systematic summaries are given for the process of preparing large-area perovskite solar cells and strategies for optimizing cell performance. Finally, the future development trends in this field are discussed.

2023, 40(10): 5466-5485.

doi: 10.13801/j.cnki.fhclxb.20230427.001

Abstract:

Reliable numerical simulation results depend on the use of accurate numerical models. Micro-computed tomography (Micro-CT) technology is capable of non-destructively imaging the internal structure of composite materials, hence, numerical models reconstructed from it are more representative than the idealized ones. Here, a review is presented for constructing mesoscopic models of composite materials based on Micro-CT images and its application in virtual testing. A novel concept, Micro-CT aided numerical simulation, is proposed. First, the principle of Micro-CT imaging, the characteristics of equipment, and the difficulties with scanning fabric-reinforced composites are discussed. Second, the characteristics of existing Micro-CT aided modeling techniques are analyzed and compared. The models are divided into three types including indirect, voxel, and digital material twin ones. The theoretical basis and technical approaches for constructing each type of model are highlighted, and the advantages and limitations of each are analyzed. Then recent applications of Micro-CT aided numerical simulation in composite molding process and mechanical property prediction of fabric reinforced composites are summarized, showing the potential and importance of the technology. Finally, the future of Micro-CT aided numerical simulation technology is anticipated.

Reliable numerical simulation results depend on the use of accurate numerical models. Micro-computed tomography (Micro-CT) technology is capable of non-destructively imaging the internal structure of composite materials, hence, numerical models reconstructed from it are more representative than the idealized ones. Here, a review is presented for constructing mesoscopic models of composite materials based on Micro-CT images and its application in virtual testing. A novel concept, Micro-CT aided numerical simulation, is proposed. First, the principle of Micro-CT imaging, the characteristics of equipment, and the difficulties with scanning fabric-reinforced composites are discussed. Second, the characteristics of existing Micro-CT aided modeling techniques are analyzed and compared. The models are divided into three types including indirect, voxel, and digital material twin ones. The theoretical basis and technical approaches for constructing each type of model are highlighted, and the advantages and limitations of each are analyzed. Then recent applications of Micro-CT aided numerical simulation in composite molding process and mechanical property prediction of fabric reinforced composites are summarized, showing the potential and importance of the technology. Finally, the future of Micro-CT aided numerical simulation technology is anticipated.

2023, 40(10): 5486-5501.

doi: 10.13801/j.cnki.fhclxb.20230423.002

Abstract:

Photonic crystal (PC) is a structure formed by the periodic arrangement of dielectric materials. Due to its distinct photoregulatory features, it has drawn significant attention in the realm of optics and photonics. From the structure, mechanism, material, and functional application, people have carried out in-depth research and continuous development. Because of their large specific surface area and customizable three-dimensional structure, photonic crystal fibers (PCFs) in particular provide new opportunities for the development of detecting sensing, smart wearables, photoelectric transmission, and other sectors. In this paper, the structure and color mechanism of PC, basic materials, preparation methods, and applications of PCFs are reviewed. The contribution of electrostatic spinning technology in the field of PCFs is highlighted, as are the functional applications of PCFs in textile printing and dyeing, intelligent response, sensing detection, and hydrophobic regulation are discussed. Finally, the problems in macro preparation and practical production application of PCFs are pointed out, and the possible research focus and direction in the future have prospected.

Photonic crystal (PC) is a structure formed by the periodic arrangement of dielectric materials. Due to its distinct photoregulatory features, it has drawn significant attention in the realm of optics and photonics. From the structure, mechanism, material, and functional application, people have carried out in-depth research and continuous development. Because of their large specific surface area and customizable three-dimensional structure, photonic crystal fibers (PCFs) in particular provide new opportunities for the development of detecting sensing, smart wearables, photoelectric transmission, and other sectors. In this paper, the structure and color mechanism of PC, basic materials, preparation methods, and applications of PCFs are reviewed. The contribution of electrostatic spinning technology in the field of PCFs is highlighted, as are the functional applications of PCFs in textile printing and dyeing, intelligent response, sensing detection, and hydrophobic regulation are discussed. Finally, the problems in macro preparation and practical production application of PCFs are pointed out, and the possible research focus and direction in the future have prospected.

2023, 40(10): 5502-5517.

doi: 10.13801/j.cnki.fhclxb.20230607.003

Abstract:

Biomimetic superhydrophobic surfaces have been widely used in critical areas such as healthcare, environment, and energy. First, this work briefly reviewed bioinspired design and preparation technology, which combined with theoretical basis on superhydrophobicity. Second, due to the significant biological effects for high water/blood-repellency, biological/blood compatibility, anticoagulation/thrombosis, anti-bacteria, low bio-adhesion, etc., superhydrophobic surfaces have attracted much attention in biomedical applications. The present work mainly focused on summarizing representative applications of bioinspired superhydrophobic surfaces in wound healing (hemostatic dressings), anti-coagulation/anti-thrombotic (blood-contact medical devices), antibacterial surfaces, drug release, motion monitoring, biochips, anticorrosion of magnesium alloy, biomedical detection and so on in recent years. Finally, combining with our own research experience, we deeply analyzed the existing issues and challenges of bioinspired superhydrophobic surfaces in practical biomedical applications, mainly involving mechanical durability, chemical corrosion, biofouling, interfacial construction, and biomedical applications. Therefore, focusing on practical functions and high performance, conceptual design of superhydrophobic surfaces will be moved toward industrial applications.

Biomimetic superhydrophobic surfaces have been widely used in critical areas such as healthcare, environment, and energy. First, this work briefly reviewed bioinspired design and preparation technology, which combined with theoretical basis on superhydrophobicity. Second, due to the significant biological effects for high water/blood-repellency, biological/blood compatibility, anticoagulation/thrombosis, anti-bacteria, low bio-adhesion, etc., superhydrophobic surfaces have attracted much attention in biomedical applications. The present work mainly focused on summarizing representative applications of bioinspired superhydrophobic surfaces in wound healing (hemostatic dressings), anti-coagulation/anti-thrombotic (blood-contact medical devices), antibacterial surfaces, drug release, motion monitoring, biochips, anticorrosion of magnesium alloy, biomedical detection and so on in recent years. Finally, combining with our own research experience, we deeply analyzed the existing issues and challenges of bioinspired superhydrophobic surfaces in practical biomedical applications, mainly involving mechanical durability, chemical corrosion, biofouling, interfacial construction, and biomedical applications. Therefore, focusing on practical functions and high performance, conceptual design of superhydrophobic surfaces will be moved toward industrial applications.

2023, 40(10): 5518-5528.

doi: 10.13801/j.cnki.fhclxb.20230310.002

Abstract:

Secondary particle assembed with radial oriented primary grains can inhibit the formation of microcracks and provide a good Li+ diffusion path, and it is an ideal morphology for high-end polycrystalline Ni-rich cathode materials. In recent years, some researchers have obtained nickel-rich cathode materials assembed with grains with large length-width ratio by regulating precursor precipitation crystallization and high temperature lithium crystallization. However, the regulation method and formation mechanism of the radially oriented structure of Ni-rich cathode, especially the regulation method of the radially oriented hydroxide precursor and the influence of the key parameters on the radially oriented structure, have not been elaborated. In this paper, the necessity of regulating the radially oriented structure of polycrystalline Ni-rich cathode and the mechanism on enhancing electrochemical performance are introduced. Secondly, the regulation method and formation mechanism of the radially oriented polycrystalline Ni-rich cathode are introduced, including the influence of the key parameters of precipitation crystallization process (pH, ammonia concentration and solid content) on the radially oriented precursor, and the influence of temperature and doping elements induced in calcination process on the maintenance of the oriented structure of precursor. Finally, the challenges facing for the regulation of radially oriented Ni-rich cathode are discussed.

Secondary particle assembed with radial oriented primary grains can inhibit the formation of microcracks and provide a good Li+ diffusion path, and it is an ideal morphology for high-end polycrystalline Ni-rich cathode materials. In recent years, some researchers have obtained nickel-rich cathode materials assembed with grains with large length-width ratio by regulating precursor precipitation crystallization and high temperature lithium crystallization. However, the regulation method and formation mechanism of the radially oriented structure of Ni-rich cathode, especially the regulation method of the radially oriented hydroxide precursor and the influence of the key parameters on the radially oriented structure, have not been elaborated. In this paper, the necessity of regulating the radially oriented structure of polycrystalline Ni-rich cathode and the mechanism on enhancing electrochemical performance are introduced. Secondly, the regulation method and formation mechanism of the radially oriented polycrystalline Ni-rich cathode are introduced, including the influence of the key parameters of precipitation crystallization process (pH, ammonia concentration and solid content) on the radially oriented precursor, and the influence of temperature and doping elements induced in calcination process on the maintenance of the oriented structure of precursor. Finally, the challenges facing for the regulation of radially oriented Ni-rich cathode are discussed.

2023, 40(10): 5529-5541.

doi: 10.13801/j.cnki.fhclxb.20230413.001

Abstract:

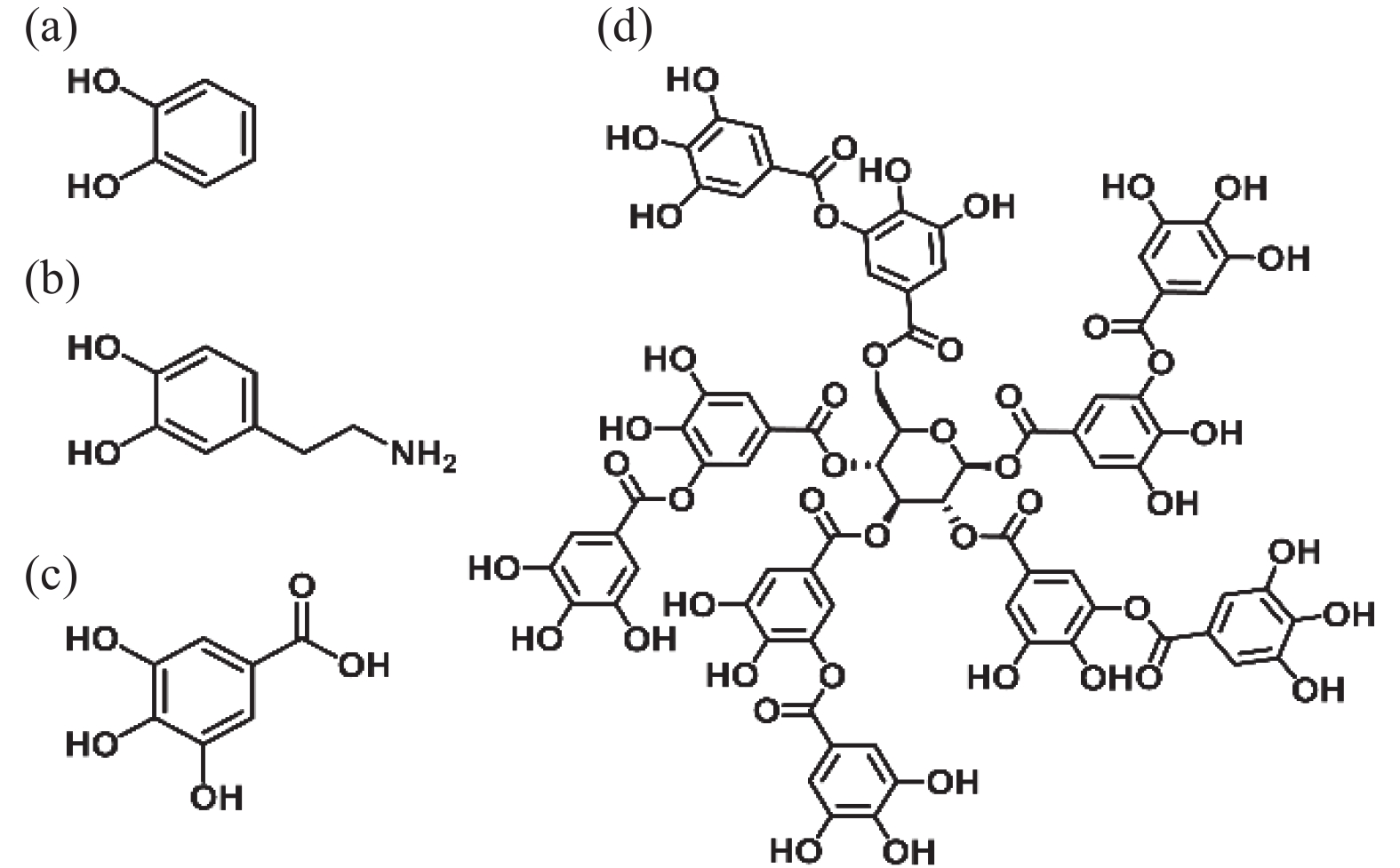

Polyphenols are compounds with abundant phenolic hydroxyl groups which can be widely found in natural plants. Polyphenols can interact with the various materials to form hydrogen bonds, metal coordination and π-π interactions. Over the past few years, polyphenols have been widely applied in material functional modifications. In this paper, the structures and properties of polyphenols, including dopamine, catechol, gallic acid and tannic acid were reviewed. Meanwhile, the modification methods of fiber surface and the applications of fiber reinforced polymer composites were introduced. Finally, a prospective analysis on the future research direction and focus of polyphenol modification studies were provided.

Polyphenols are compounds with abundant phenolic hydroxyl groups which can be widely found in natural plants. Polyphenols can interact with the various materials to form hydrogen bonds, metal coordination and π-π interactions. Over the past few years, polyphenols have been widely applied in material functional modifications. In this paper, the structures and properties of polyphenols, including dopamine, catechol, gallic acid and tannic acid were reviewed. Meanwhile, the modification methods of fiber surface and the applications of fiber reinforced polymer composites were introduced. Finally, a prospective analysis on the future research direction and focus of polyphenol modification studies were provided.

2023, 40(10): 5542-5553.

doi: 10.13801/j.cnki.fhclxb.20230523.003

Abstract:

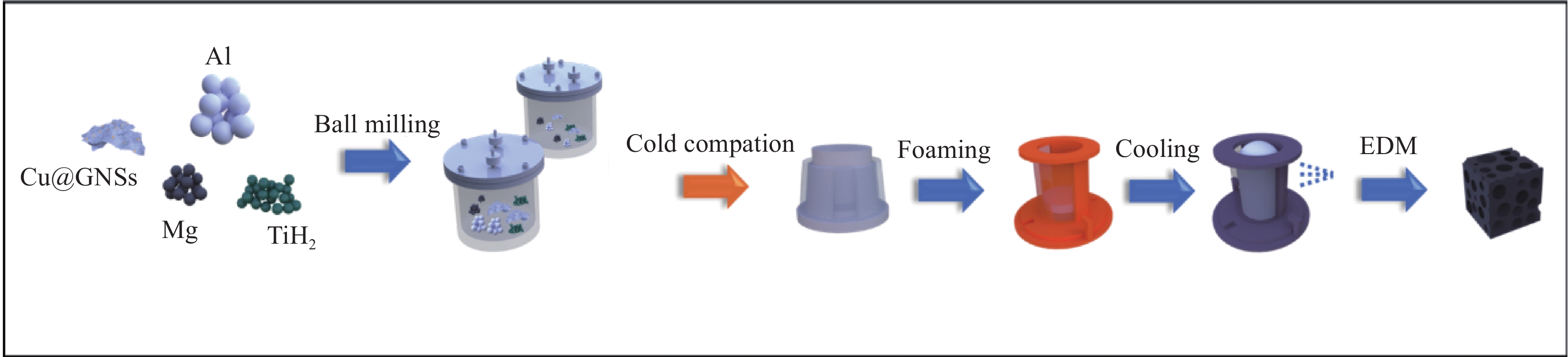

Copper and copper alloys are widely used in electrical contact materials, electronic packaging materials, heat exchange materials and other fields because of their high electrical conductivity, thermal conductivity, easy machinability and corrosion resistance. However, the contradiction between strength, electrical conductivity and thermal conductivity in copper alloys limits its development. Copper matrix composites can improve the strength of materials by strengthening phase, avoid serious lattice distortion to copper matrix, and maximize the conductivity of materials, thus obtaining materials with excellent strength-resistance ratio. Therefore, copper matrix composites are an important development direction of high performance copper materials. In this paper, the main preparation methods of high performance copper matrix composites are summarized, and the reinforcing phase of composites, its characteristics and development direction are summarized. The main research progress and its application status in rail transit, electrics and electronics, military industry are described, and the future development direction of this material is prospected, which provides reference for the research and application of high performance copper matrix composites.

Copper and copper alloys are widely used in electrical contact materials, electronic packaging materials, heat exchange materials and other fields because of their high electrical conductivity, thermal conductivity, easy machinability and corrosion resistance. However, the contradiction between strength, electrical conductivity and thermal conductivity in copper alloys limits its development. Copper matrix composites can improve the strength of materials by strengthening phase, avoid serious lattice distortion to copper matrix, and maximize the conductivity of materials, thus obtaining materials with excellent strength-resistance ratio. Therefore, copper matrix composites are an important development direction of high performance copper materials. In this paper, the main preparation methods of high performance copper matrix composites are summarized, and the reinforcing phase of composites, its characteristics and development direction are summarized. The main research progress and its application status in rail transit, electrics and electronics, military industry are described, and the future development direction of this material is prospected, which provides reference for the research and application of high performance copper matrix composites.

2023, 40(10): 5554-5566.

doi: 10.13801/j.cnki.fhclxb.20230302.001

Abstract:

To clarity the preparation of anti-overburden/de-icing coating and improve its properties on composite materials, the anti-overburden/de-icing mechanisms were systematically introduced in this article, including the structure, properties and influencing factors of superhydrophobic, super lubricating and composite coating finishing process. From the technical characteristics of textile composite coating finishing, the latest research anti-icing/de-icing functional finishing of textile composites was summarized. Finally, considering the weak weather resistance, poor shape plasticity and hard disassemble of present materials, the views that couple the advantages of different coating finishing technology to develop flexible type, composite synergy proof anti-overburden/de-icing functional textile materials were put forward. The review article may promote the development and research of anti-icing/deicing function textile composite materials.

To clarity the preparation of anti-overburden/de-icing coating and improve its properties on composite materials, the anti-overburden/de-icing mechanisms were systematically introduced in this article, including the structure, properties and influencing factors of superhydrophobic, super lubricating and composite coating finishing process. From the technical characteristics of textile composite coating finishing, the latest research anti-icing/de-icing functional finishing of textile composites was summarized. Finally, considering the weak weather resistance, poor shape plasticity and hard disassemble of present materials, the views that couple the advantages of different coating finishing technology to develop flexible type, composite synergy proof anti-overburden/de-icing functional textile materials were put forward. The review article may promote the development and research of anti-icing/deicing function textile composite materials.

2023, 40(10): 5567-5576.

doi: 10.13801/j.cnki.fhclxb.20230512.001

Abstract:

In recent years, environmentally friendly green solvents have become an important research direction in green chemistry. As a new type of green solvent with certain degradability, good biocompatibility and relatively environmental protection, the deep eutectic solvent has preliminarily shown its strong development potential in the preparation and functional modification of nanocellulose. This paper mainly reviews the basic properties and formation mechanism of the deep eutectic solvent, and introduces the application of different deep eutectic solvent in the preparation and functional modification of nanocellulose, so as to achieve efficient preparation and modification of nanocellulose. In the future, the designability of the deep eutectic solvent can be brought into full play through the combination of experiment and computational simulation technology and reveal the law of its dissolution, degradation and functionalization in the preparation of nanocellulose, so as to provide references for the preparation and modification of the pretreatment of the deep eutectic solvent and promote its large-scale application in biomass pretreatment.

In recent years, environmentally friendly green solvents have become an important research direction in green chemistry. As a new type of green solvent with certain degradability, good biocompatibility and relatively environmental protection, the deep eutectic solvent has preliminarily shown its strong development potential in the preparation and functional modification of nanocellulose. This paper mainly reviews the basic properties and formation mechanism of the deep eutectic solvent, and introduces the application of different deep eutectic solvent in the preparation and functional modification of nanocellulose, so as to achieve efficient preparation and modification of nanocellulose. In the future, the designability of the deep eutectic solvent can be brought into full play through the combination of experiment and computational simulation technology and reveal the law of its dissolution, degradation and functionalization in the preparation of nanocellulose, so as to provide references for the preparation and modification of the pretreatment of the deep eutectic solvent and promote its large-scale application in biomass pretreatment.

2023, 40(10): 5577-5587.

doi: 10.13801/j.cnki.fhclxb.20230221.001

Abstract:

Magnesium (Mg) alloy is the lightest metal material in practical application, and its structural parts are expected to be widely used in aerospace, rail transit, automobile, electronics and other lightweight fields. However, Mg alloy has the disadvantage of corrosion resistance, which seriously limits its wide application in the field of lightweight. Coating Mg alloy with good corrosion resistance aluminum (Al) alloy to form Mg-Al laminate can not only protect Mg alloy, but also play the advantages of high specific strength and specific stiffness of Mg alloy, good shock absorption and electromagnetic shielding performance. In this paper, the preparation methods and characteristics of Mg-Al laminates are reviewed, the microstructure evolution of component plates and layer interfaces in Mg-Al laminates and their influence on mechanical properties of the laminates are analyzed, and the innovative research results of our research group on stamping forming and deformation microscopic mechanism of Mg-Al laminates are introduced. How to prepare wider and thinner Mg-Al laminates with intermetallic compounds controllable at the interface is the focus of future research.

Magnesium (Mg) alloy is the lightest metal material in practical application, and its structural parts are expected to be widely used in aerospace, rail transit, automobile, electronics and other lightweight fields. However, Mg alloy has the disadvantage of corrosion resistance, which seriously limits its wide application in the field of lightweight. Coating Mg alloy with good corrosion resistance aluminum (Al) alloy to form Mg-Al laminate can not only protect Mg alloy, but also play the advantages of high specific strength and specific stiffness of Mg alloy, good shock absorption and electromagnetic shielding performance. In this paper, the preparation methods and characteristics of Mg-Al laminates are reviewed, the microstructure evolution of component plates and layer interfaces in Mg-Al laminates and their influence on mechanical properties of the laminates are analyzed, and the innovative research results of our research group on stamping forming and deformation microscopic mechanism of Mg-Al laminates are introduced. How to prepare wider and thinner Mg-Al laminates with intermetallic compounds controllable at the interface is the focus of future research.

2023, 40(10): 5588-5600.

doi: 10.13801/j.cnki.fhclxb.20230105.002

Abstract:

Three-dimensional (3D) braided glass fiber/epoxy resin composite thin-walled tubes with three braiding angles of 15°, 25°, and 35° were prepared by 3D braiding molding technology and resin transfer molding process (RTM). The quasi-static compression performance test of 3D braided composite thin-walled tubes was carried out at low temperature (−100℃, −50℃), normal temperature (20℃) and high temperature field (80°C, 110°C, 140°C and 170°C). The effects of temperature and braiding angle on compression properties and compression failure pattern of 3D braided composite thin-walled tubes were studied based on X-ray micro-computer tomography (Micro-CT). The results show that the quasi-static compression behavior of 3D braided composite thin-walled tubes has a significant temperature effect. As the temperature increases, the failure mode of the braided composite thin-walled tubes changes from local shear failure to large-area debonding of the fiber tows-matrix interface. The braiding angle has different effects on the compressive strength, compressive modulus and specific energy absorption of 3D braided composite thin-walled tubes. The braided composite thin-walled tubes with small braiding angle have a higher orientation along the braided yarn direction which can withstand greater axial compounding, so the compression performance is better.

Three-dimensional (3D) braided glass fiber/epoxy resin composite thin-walled tubes with three braiding angles of 15°, 25°, and 35° were prepared by 3D braiding molding technology and resin transfer molding process (RTM). The quasi-static compression performance test of 3D braided composite thin-walled tubes was carried out at low temperature (−100℃, −50℃), normal temperature (20℃) and high temperature field (80°C, 110°C, 140°C and 170°C). The effects of temperature and braiding angle on compression properties and compression failure pattern of 3D braided composite thin-walled tubes were studied based on X-ray micro-computer tomography (Micro-CT). The results show that the quasi-static compression behavior of 3D braided composite thin-walled tubes has a significant temperature effect. As the temperature increases, the failure mode of the braided composite thin-walled tubes changes from local shear failure to large-area debonding of the fiber tows-matrix interface. The braiding angle has different effects on the compressive strength, compressive modulus and specific energy absorption of 3D braided composite thin-walled tubes. The braided composite thin-walled tubes with small braiding angle have a higher orientation along the braided yarn direction which can withstand greater axial compounding, so the compression performance is better.

2023, 40(10): 5601-5610.

doi: 10.13801/j.cnki.fhclxb.20221221.001

Abstract:

With the rapid development of China's domestic space engineering, the harsher requirements are put forward for lightweight, dimensional stability, thermal protection efficiency and long service capability of the thermal protection system. Rigid nanoporous phenolic resin-based RMI/PR composites are prepared via a sol-gel polymerization and ambient-pressure gradient drying using rigid mullite ceramic tile (RMI) as the reinforcement and hybrid phenolic resin (PR) as matrix. The effects of resin concentration on the microstructure, mechanical properties, thermal insulation properties and ablative properties of the composites are systematically studied. The results show that RMI has obvious transverse isotropy, and the room-temperature thermal conductivity in the Z direction is 0.036 W/(m∙K). With the increase of the resin concentration from 15wt% to 45wt%, the density of RMI/PR increases from 0.52 g/cm3 to 0.85 g/cm3, and the most probable pore size of the resin matrix decreases sharply from 2081 nm to 32 nm. With the increase of resin concentration, the room-temperature thermal conductivity of RMI/PR increases slowly and all of them are less than 0.07 W/(m∙K), but its mechanical properties are significantly enhanced and the maximum compressive strength in the Z direction of composites is up to 20.8 MPa. After static heat insulation test at 1000℃ for 300 s, the backside temperature of composites decreases from 277℃ to 240℃. Under the oxy-acetylene ablation at 2000℃ for 30 s, the linear ablation rate of the composites is reduced from 0.200 mm/s to 0.081 mm/s, indicating that the increase of resin concentration can significantly improve the high-temperature thermal insulation properties and ablation resistance of the composites.

With the rapid development of China's domestic space engineering, the harsher requirements are put forward for lightweight, dimensional stability, thermal protection efficiency and long service capability of the thermal protection system. Rigid nanoporous phenolic resin-based RMI/PR composites are prepared via a sol-gel polymerization and ambient-pressure gradient drying using rigid mullite ceramic tile (RMI) as the reinforcement and hybrid phenolic resin (PR) as matrix. The effects of resin concentration on the microstructure, mechanical properties, thermal insulation properties and ablative properties of the composites are systematically studied. The results show that RMI has obvious transverse isotropy, and the room-temperature thermal conductivity in the Z direction is 0.036 W/(m∙K). With the increase of the resin concentration from 15wt% to 45wt%, the density of RMI/PR increases from 0.52 g/cm3 to 0.85 g/cm3, and the most probable pore size of the resin matrix decreases sharply from 2081 nm to 32 nm. With the increase of resin concentration, the room-temperature thermal conductivity of RMI/PR increases slowly and all of them are less than 0.07 W/(m∙K), but its mechanical properties are significantly enhanced and the maximum compressive strength in the Z direction of composites is up to 20.8 MPa. After static heat insulation test at 1000℃ for 300 s, the backside temperature of composites decreases from 277℃ to 240℃. Under the oxy-acetylene ablation at 2000℃ for 30 s, the linear ablation rate of the composites is reduced from 0.200 mm/s to 0.081 mm/s, indicating that the increase of resin concentration can significantly improve the high-temperature thermal insulation properties and ablation resistance of the composites.

2023, 40(10): 5611-5620.

doi: 10.13801/j.cnki.fhclxb.20221228.002

Abstract:

Carbon fiber reinforced polymer (CFRP) composites are widely used because of their excellent properties such as high specific strength and high specific modulus, but their mechanical properties along the thickness are poor due to the laminar structure characteristics and the intrinsic brittleness of epoxy resin, and they are prone to delamination under out-of-plane impact and in-plane compression loads, which in turn reduce the strength of the composites. Therefore it is especially important to improve the interlaminar fracture toughness of the composites. In this paper, we attempt to improve the interlaminar fracture toughness of the composite by introducing highly oriented carbon nanotube (CNT) fiber veils in the interlaminar region. To ensure that the fiber veils are well infiltrated by the resin, they are first immersed in an epoxy resin solution diluted with acetone. After the acetone evaporated, it is inserted into the interlayer region of the homemade carbon fiber prepreg and subsequently cured by a hot pressing process. The mode I and mode II interlaminar fracture toughness of the toughened samples are evaluated via ASTM testing standards. Combined with the optical microscopic observation of the cross-section and scanning electron microscopy analysis of the fracture surface, the crack propagation paths are clearly shown and the interlaminar toughening mechanisms of CNT fiber veils are revealed. The results show that the mode I and mode II interlaminar fracture toughness of CNT veil toughened samples are improved by 37.4% and 41.8%, respectively. The toughening mechanisms mainly include matrix toughening, strengthening carbon fiber bridging and crack deflection.

Carbon fiber reinforced polymer (CFRP) composites are widely used because of their excellent properties such as high specific strength and high specific modulus, but their mechanical properties along the thickness are poor due to the laminar structure characteristics and the intrinsic brittleness of epoxy resin, and they are prone to delamination under out-of-plane impact and in-plane compression loads, which in turn reduce the strength of the composites. Therefore it is especially important to improve the interlaminar fracture toughness of the composites. In this paper, we attempt to improve the interlaminar fracture toughness of the composite by introducing highly oriented carbon nanotube (CNT) fiber veils in the interlaminar region. To ensure that the fiber veils are well infiltrated by the resin, they are first immersed in an epoxy resin solution diluted with acetone. After the acetone evaporated, it is inserted into the interlayer region of the homemade carbon fiber prepreg and subsequently cured by a hot pressing process. The mode I and mode II interlaminar fracture toughness of the toughened samples are evaluated via ASTM testing standards. Combined with the optical microscopic observation of the cross-section and scanning electron microscopy analysis of the fracture surface, the crack propagation paths are clearly shown and the interlaminar toughening mechanisms of CNT fiber veils are revealed. The results show that the mode I and mode II interlaminar fracture toughness of CNT veil toughened samples are improved by 37.4% and 41.8%, respectively. The toughening mechanisms mainly include matrix toughening, strengthening carbon fiber bridging and crack deflection.

2023, 40(10): 5621-5629.

doi: 10.13801/j.cnki.fhclxb.20230104.002

Abstract:

Due to the high strength and lightweight, epoxy-based composites have high application value in the fields of aerospace and automotive. However, the brittle nature of epoxy resins significantly hinder theirapplication in real engineering, and it is still a great challenge to improve the strength and toughness of the epoxy-based composites. Herein, we develop an epoxy-based composite lattice composing of strengthening zones and toughening zones, which are rationally assembled into a layered structure through direct ink writing technique. The physical and chemical properties of the epoxy-based composite inks and printed filaments were characterized by rotational rheometer and optical microscope, and a universal testing machine was used to evaluate the mechanical properties of the epoxy-based composite lattice with various structural parameters. It is found that the specific strength, toughness and fracture toughness of the epoxy-based composite lattice increase by 95%, 630% and 19.1% compared to the solid composite, respectively. Based on the fracture surfaces and finite element analysis, it can be concluded that the strengthening zones ensure the structural strength, while the toughening zones are capable of effectively sharing the external deformation and preventing the crack propagation. The current research provides new ideas and theoretical basis for the design, manufacturing, and applications of structural nanocomposites with high strength and toughness.

Due to the high strength and lightweight, epoxy-based composites have high application value in the fields of aerospace and automotive. However, the brittle nature of epoxy resins significantly hinder theirapplication in real engineering, and it is still a great challenge to improve the strength and toughness of the epoxy-based composites. Herein, we develop an epoxy-based composite lattice composing of strengthening zones and toughening zones, which are rationally assembled into a layered structure through direct ink writing technique. The physical and chemical properties of the epoxy-based composite inks and printed filaments were characterized by rotational rheometer and optical microscope, and a universal testing machine was used to evaluate the mechanical properties of the epoxy-based composite lattice with various structural parameters. It is found that the specific strength, toughness and fracture toughness of the epoxy-based composite lattice increase by 95%, 630% and 19.1% compared to the solid composite, respectively. Based on the fracture surfaces and finite element analysis, it can be concluded that the strengthening zones ensure the structural strength, while the toughening zones are capable of effectively sharing the external deformation and preventing the crack propagation. The current research provides new ideas and theoretical basis for the design, manufacturing, and applications of structural nanocomposites with high strength and toughness.

2023, 40(10): 5630-5640.

doi: 10.13801/j.cnki.fhclxb.20230110.001

Abstract:

By compounding rice straw with phenolic resin (PF) foam, to improve the shortcomings of PF foam itself, such as high brittleness and poor mechanical strength, and to investigate the effects of length (8 cm, 12 cm and 16 cm) and form (cross-cutting straw, slope-cutting straw and grinding straw fiber) of rice straw on the physical properties, mechanical and combustion properties of the composite material. The results show that the inner and outer surfaces of rice straw have an obvious mechanical engagement with PF foam. The bending strength, compressive strength and tensile strength perpendicular to the board surface of rice straw/PF foam composites are better than PF foam. The bending strength of 16 cm long slope-cutting rice straw/PF foam composite reaches 1.18 MPa, which is 195% higher than PF foam. The compressive stress at 10% strain and tensile strength perpendicular to the plate surface of 16 cm long grinding rice straw/PF foam composite are 251.30 kPa and 121.26 kPa, respectively, which are 112.1% and 20.7% higher than PF foam. The vertical combustion and limited oxygen index (LOI) results show that PF foam has better wrapping effect on straw, the thermal stability of the composite is almost the same as that of PF foam, with almost no change in LOI value. The flammability test results of both rice straw/PF foam composites and PF foam meet the requirements of B1 class building materials, which show an excellent fire resistance. To sum up, 8 cm slope-cutting rice straw reinforced PF foam composite has an optimal integrated mechanical property.

By compounding rice straw with phenolic resin (PF) foam, to improve the shortcomings of PF foam itself, such as high brittleness and poor mechanical strength, and to investigate the effects of length (8 cm, 12 cm and 16 cm) and form (cross-cutting straw, slope-cutting straw and grinding straw fiber) of rice straw on the physical properties, mechanical and combustion properties of the composite material. The results show that the inner and outer surfaces of rice straw have an obvious mechanical engagement with PF foam. The bending strength, compressive strength and tensile strength perpendicular to the board surface of rice straw/PF foam composites are better than PF foam. The bending strength of 16 cm long slope-cutting rice straw/PF foam composite reaches 1.18 MPa, which is 195% higher than PF foam. The compressive stress at 10% strain and tensile strength perpendicular to the plate surface of 16 cm long grinding rice straw/PF foam composite are 251.30 kPa and 121.26 kPa, respectively, which are 112.1% and 20.7% higher than PF foam. The vertical combustion and limited oxygen index (LOI) results show that PF foam has better wrapping effect on straw, the thermal stability of the composite is almost the same as that of PF foam, with almost no change in LOI value. The flammability test results of both rice straw/PF foam composites and PF foam meet the requirements of B1 class building materials, which show an excellent fire resistance. To sum up, 8 cm slope-cutting rice straw reinforced PF foam composite has an optimal integrated mechanical property.

2023, 40(10): 5641-5653.

doi: 10.13801/j.cnki.fhclxb.20221228.003

Abstract:

Carbon fiber reinforced poly aryl ether ketone (SCF35/PAEK) thermoplastic composites were prepared using two different melt viscosities of domestic high performance poly aryl ether ketone resins (PAEK-L and PAEK-H) and domestic T300 grade carbon fibers (SCF35), and the effects of resin matrix viscosity and impact energy and impact energy on the impact properties of the composites were investigated. In addition, the internal morphology of quasi-static indentation specimens was characterized by Micro-CT to study the impact damage mechanism of the composites. The results show that PAEK-L resin matrix composite with lower fluidity has higher impact resistance than PAEK-H resin matrix composite with higher fluidity. The impact energy loss of the SCF35/PAEK-L composite system is ~7% lower than that of the SCF35/PAEK-H composite system, its damage area is ~90% smaller, and its compression strength after impact reaches ~307 MPa at an impact energy of 6.67 J/mm, which is ~50% higher than that of SCF35/PAEK-H composite system (205 MPa). The depth of surface dent in SCF35/PAEK-L composites tends to increase with the increase of impact energy, and the compression strength after impact tends to decrease with the increase of impact energy, and the compression strength after impact is ~268 MPa when the depth of surface dent of the composites reaches about 1.0 mm, i.e., when the threshold value of barely visible impact damage (BVID) is reached. In addition, the results of quasi-static indentation tests show that the surface dent of SCF35/PAEK-L composite after impact is mainly caused by plastic deformation of the resin matrix and fiber flexure, the cracks around the surface dent are caused by compressive stress, the fiber on the back side of the specimen is fractured under the action of tensile stress during the impact process, the fiber on the bottom layer of the specimen sprouts interlayer cracks under the action of shear force, with the increase of flexural deformation of the specimen, the degree of fiber fracture increases and the interlayer cracks gradually expand.

Carbon fiber reinforced poly aryl ether ketone (SCF35/PAEK) thermoplastic composites were prepared using two different melt viscosities of domestic high performance poly aryl ether ketone resins (PAEK-L and PAEK-H) and domestic T300 grade carbon fibers (SCF35), and the effects of resin matrix viscosity and impact energy and impact energy on the impact properties of the composites were investigated. In addition, the internal morphology of quasi-static indentation specimens was characterized by Micro-CT to study the impact damage mechanism of the composites. The results show that PAEK-L resin matrix composite with lower fluidity has higher impact resistance than PAEK-H resin matrix composite with higher fluidity. The impact energy loss of the SCF35/PAEK-L composite system is ~7% lower than that of the SCF35/PAEK-H composite system, its damage area is ~90% smaller, and its compression strength after impact reaches ~307 MPa at an impact energy of 6.67 J/mm, which is ~50% higher than that of SCF35/PAEK-H composite system (205 MPa). The depth of surface dent in SCF35/PAEK-L composites tends to increase with the increase of impact energy, and the compression strength after impact tends to decrease with the increase of impact energy, and the compression strength after impact is ~268 MPa when the depth of surface dent of the composites reaches about 1.0 mm, i.e., when the threshold value of barely visible impact damage (BVID) is reached. In addition, the results of quasi-static indentation tests show that the surface dent of SCF35/PAEK-L composite after impact is mainly caused by plastic deformation of the resin matrix and fiber flexure, the cracks around the surface dent are caused by compressive stress, the fiber on the back side of the specimen is fractured under the action of tensile stress during the impact process, the fiber on the bottom layer of the specimen sprouts interlayer cracks under the action of shear force, with the increase of flexural deformation of the specimen, the degree of fiber fracture increases and the interlayer cracks gradually expand.

2023, 40(10): 5654-5665.

doi: 10.13801/j.cnki.fhclxb.20230213.003

Abstract:

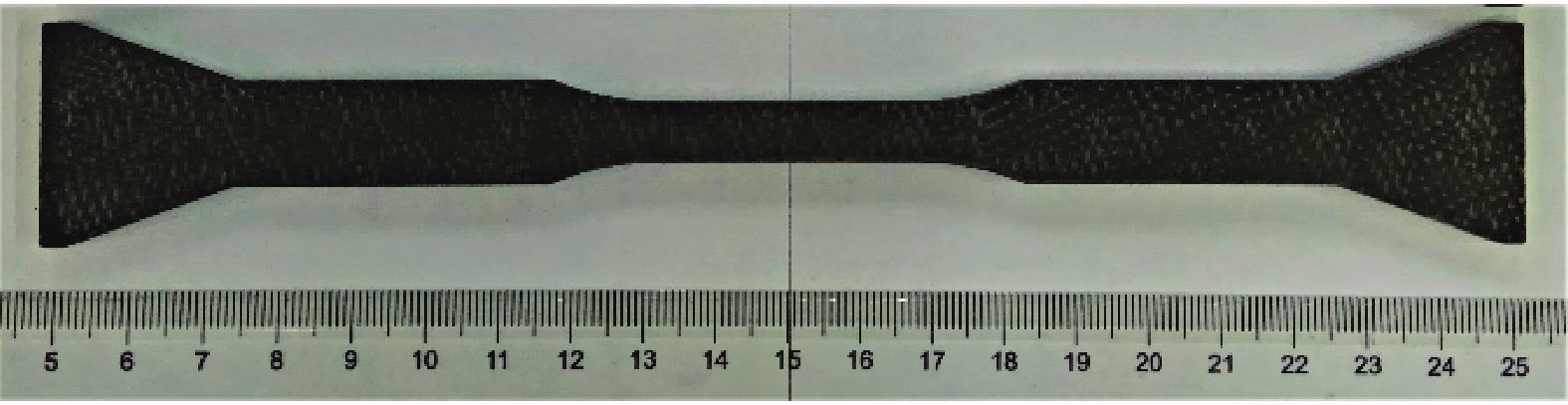

To reduce the porosity of 3D printing continuous fiber reinforced polymer (CFRP) composites and improve the degree of resin impregnation on fibers, it is of great necessity to conduct research on the preparation and 3D printing performance of melt-impregnated continuous fiber prepreg filaments, as well as develop integrated fiber prepreg equipment. With glass fiber (GF) and carbon fiber (CF) as reinforcement, and polycarbonate (PC) as matrix, this study aims to develop a melt-impregnated prepreg wire preparation process and study the influence of the impregnation process on prepreg wire properties. Besides, using prepreg yarn as the raw material, this study is aimed at studying the effect of 3D printing forming process parameters on the fiber content, porosity and mechanical properties as well. The results indicate that when the tensile strength of continuous glass fiber reinforced polycarbonate (CGF/PC) prepreg filament is 627.8 MPa, the printing temperature is 260℃, the layering thickness is 0.10 mm, the scan spacing is 1.0 mm, the fiber content of continuous carbon fiber reinforced polycarbonate (CCF/PC) composite is 28.66vol%, the tensile strength and modulus are respectively 644.8 MPa and 85.6 GPa, and the optimized porosity is 3.87%. When the printing temperature is 280℃, the layering thickness is 0.14 mm, and the scan spacing is 1.2 mm, the fiber content of continuous glass fiber reinforced polycarbonate (CGF/PC) composite turn out to be 51.35vol%, the tensile strength and modulus are respectively 381.4 MPa and 23.6 GPa, and the optimized porosity is 4.41%.

To reduce the porosity of 3D printing continuous fiber reinforced polymer (CFRP) composites and improve the degree of resin impregnation on fibers, it is of great necessity to conduct research on the preparation and 3D printing performance of melt-impregnated continuous fiber prepreg filaments, as well as develop integrated fiber prepreg equipment. With glass fiber (GF) and carbon fiber (CF) as reinforcement, and polycarbonate (PC) as matrix, this study aims to develop a melt-impregnated prepreg wire preparation process and study the influence of the impregnation process on prepreg wire properties. Besides, using prepreg yarn as the raw material, this study is aimed at studying the effect of 3D printing forming process parameters on the fiber content, porosity and mechanical properties as well. The results indicate that when the tensile strength of continuous glass fiber reinforced polycarbonate (CGF/PC) prepreg filament is 627.8 MPa, the printing temperature is 260℃, the layering thickness is 0.10 mm, the scan spacing is 1.0 mm, the fiber content of continuous carbon fiber reinforced polycarbonate (CCF/PC) composite is 28.66vol%, the tensile strength and modulus are respectively 644.8 MPa and 85.6 GPa, and the optimized porosity is 3.87%. When the printing temperature is 280℃, the layering thickness is 0.14 mm, and the scan spacing is 1.2 mm, the fiber content of continuous glass fiber reinforced polycarbonate (CGF/PC) composite turn out to be 51.35vol%, the tensile strength and modulus are respectively 381.4 MPa and 23.6 GPa, and the optimized porosity is 4.41%.

2023, 40(10): 5666-5677.

doi: 10.13801/j.cnki.fhclxb.20221227.001

Abstract:

The preparation of polymeric materials with good mechanical properties and efficient self-healing properties at room temperature has been a difficult challenge. Herein, a lignin-reinforced self-healing polyurea elastomer (T-L-PUA) was prepared by a two-step process (polyurea reaction and Schiff base reaction) using natural aromatic-based lignin as the reinforcing phase. The effects of lignin addition on the thermal, UV-blocking and mechanical properties of T-L-PUA were investigated and the self-healing property and recyclability based on dynamic reversible imine bonding (C=N) of T-L-PUA were analyzed. The results show that the thermal stability of T-L-PUA is significantly enhanced with the increase of lignin ratio, where the maximum increase of residual carbon is 16.6% compared with the sample without lignin. The low transmittance of T-L-PUA in the UV region (280-400 nm) helps to realize the UV-blocking function. Compared with the average transmittance of self-healing polyurea composite elastomer (T-PUA) (41.6%), the average transmittance of all T-L-PUAs is around 0.2%. The best mechanical property appears at 20% of lignin addition, and the corresponding tensile strength of T-L-PUA is 12.44 MPa, which is 937% higher than that of pure polyurea elastomer. T-L-PUA exhibits good self-healing properties. When T-L-PUA is repaired at room temperature for 48 h, the recovery efficiencies of tensile strength and elongation at break is above 91% and 92%, respectively. In addition, the T-L-PUA can also be recovered by the hot-pressing and solvent dissolution processes, and the mechanical properties remain largely unchanged after remolding.

The preparation of polymeric materials with good mechanical properties and efficient self-healing properties at room temperature has been a difficult challenge. Herein, a lignin-reinforced self-healing polyurea elastomer (T-L-PUA) was prepared by a two-step process (polyurea reaction and Schiff base reaction) using natural aromatic-based lignin as the reinforcing phase. The effects of lignin addition on the thermal, UV-blocking and mechanical properties of T-L-PUA were investigated and the self-healing property and recyclability based on dynamic reversible imine bonding (C=N) of T-L-PUA were analyzed. The results show that the thermal stability of T-L-PUA is significantly enhanced with the increase of lignin ratio, where the maximum increase of residual carbon is 16.6% compared with the sample without lignin. The low transmittance of T-L-PUA in the UV region (280-400 nm) helps to realize the UV-blocking function. Compared with the average transmittance of self-healing polyurea composite elastomer (T-PUA) (41.6%), the average transmittance of all T-L-PUAs is around 0.2%. The best mechanical property appears at 20% of lignin addition, and the corresponding tensile strength of T-L-PUA is 12.44 MPa, which is 937% higher than that of pure polyurea elastomer. T-L-PUA exhibits good self-healing properties. When T-L-PUA is repaired at room temperature for 48 h, the recovery efficiencies of tensile strength and elongation at break is above 91% and 92%, respectively. In addition, the T-L-PUA can also be recovered by the hot-pressing and solvent dissolution processes, and the mechanical properties remain largely unchanged after remolding.

2023, 40(10): 5678-5691.

doi: 10.13801/j.cnki.fhclxb.20221222.001

Abstract:

Ti3CNTx/TMAOH was prepared when tetramethylammonium hydroxide (TMAOH) was selected as the intercalating agent. Adsorption performance of Ti3CNTx/TMAOH on Sr2+ in simulated radioactive wastewater was evaluated. The synthesized Ti3CNTx/TMAOH was characterized by SEM-EDS, XRD, BET and FTIR. In the batch experiment, the effects of the dosage of adsorbent Ti3CNTx/TMAOH, time, pH and competitive ions on Sr2+ removal were investigated. The results show that the removal rate of Sr2+ is 99.28% when the dosage is 1.0 g·L−1, pH is 6, and the time is 10 min. The inhibition order of competitive ions is Ca2+\begin{document}$ \text{ > > } $\end{document} \begin{document}$ \text{ > } $\end{document} \begin{document}$ \text{ > } $\end{document} \begin{document}$ \text{ > } $\end{document}

Ti3CNTx/TMAOH was prepared when tetramethylammonium hydroxide (TMAOH) was selected as the intercalating agent. Adsorption performance of Ti3CNTx/TMAOH on Sr2+ in simulated radioactive wastewater was evaluated. The synthesized Ti3CNTx/TMAOH was characterized by SEM-EDS, XRD, BET and FTIR. In the batch experiment, the effects of the dosage of adsorbent Ti3CNTx/TMAOH, time, pH and competitive ions on Sr2+ removal were investigated. The results show that the removal rate of Sr2+ is 99.28% when the dosage is 1.0 g·L−1, pH is 6, and the time is 10 min. The inhibition order of competitive ions is Ca2+

2023, 40(10): 5692-5705.

doi: 10.13801/j.cnki.fhclxb.20221223.004

Abstract:

To explore a simple method to prepare a epoxy resin (EP)-silicone sealant-SiO2 superhydrophobic composite coating with self-repairing property and capable of being applied to the surface of a structure like concrete, which can be self-repairing in the case of chemical and mechanical damage, The EP-silicone sealant-SiO2 superhydrophobic composite coating with self-repairing property was prepared on the surface of concrete by one-step method. The specific steps were to dissolve the EP, silicone adhesive and nano-SiO2 in anhydrous ethanol solution, and the compound solution would be obtained after 8 h magnetic stirring and 20 min ultrasonic dispersion. Then the superhydrophobic coating with self-repairing performance would be successfully prepared on the surface of concrete by spraying compound solution. When the content of epoxy resin is 2wt%, the content of silicone adhesive is 3wt% and the content of nano-SiO2 is 3wt%, the coating could exhibit optimal superhydrophobic performance. The average contact angle (CA) of the coating is 156°±1.2° and the average slid angle (SA) is 6°±0.8°. After 8 m of abrasion length at a pressure of 2.66 kPa (Sandpaper: 1.7 µm) or 8 h of immerse time in saline (2 mol/L NaCl solution) or acidic environments (pH=3, acetic acid), the coating still maintain superhydrophobicity. The contact angle of the coating remains above 150° after 8 cycles of alkaline damage and self-repair (pH=12, NaOH solution) or 4 cycles of mechanical damage and self-repair. Moreover, the coating also displays excellent self-cleaning and waterproof performance according to the self-cleaning test and waterproof test. The experiments of mechanical and environmental corrosion damage show that the similar structure of the coating can ensure that the micro-nano rough structure of the lower layer maintain superhydrophobicity after the upper layer being damaged. The damage and self-repair experiments show that the coating can be repaired when the coating is heated. This is because the flow of silicone adhesive can promote the migration of low surface energy molecules and nano-SiO2 particles in the coating during the heating process. The simple preparation method, good mechanical wear resistance and excellent self-healing properties of this coating offer the possibility of practical application of superhydrophobic coatings.

To explore a simple method to prepare a epoxy resin (EP)-silicone sealant-SiO2 superhydrophobic composite coating with self-repairing property and capable of being applied to the surface of a structure like concrete, which can be self-repairing in the case of chemical and mechanical damage, The EP-silicone sealant-SiO2 superhydrophobic composite coating with self-repairing property was prepared on the surface of concrete by one-step method. The specific steps were to dissolve the EP, silicone adhesive and nano-SiO2 in anhydrous ethanol solution, and the compound solution would be obtained after 8 h magnetic stirring and 20 min ultrasonic dispersion. Then the superhydrophobic coating with self-repairing performance would be successfully prepared on the surface of concrete by spraying compound solution. When the content of epoxy resin is 2wt%, the content of silicone adhesive is 3wt% and the content of nano-SiO2 is 3wt%, the coating could exhibit optimal superhydrophobic performance. The average contact angle (CA) of the coating is 156°±1.2° and the average slid angle (SA) is 6°±0.8°. After 8 m of abrasion length at a pressure of 2.66 kPa (Sandpaper: 1.7 µm) or 8 h of immerse time in saline (2 mol/L NaCl solution) or acidic environments (pH=3, acetic acid), the coating still maintain superhydrophobicity. The contact angle of the coating remains above 150° after 8 cycles of alkaline damage and self-repair (pH=12, NaOH solution) or 4 cycles of mechanical damage and self-repair. Moreover, the coating also displays excellent self-cleaning and waterproof performance according to the self-cleaning test and waterproof test. The experiments of mechanical and environmental corrosion damage show that the similar structure of the coating can ensure that the micro-nano rough structure of the lower layer maintain superhydrophobicity after the upper layer being damaged. The damage and self-repair experiments show that the coating can be repaired when the coating is heated. This is because the flow of silicone adhesive can promote the migration of low surface energy molecules and nano-SiO2 particles in the coating during the heating process. The simple preparation method, good mechanical wear resistance and excellent self-healing properties of this coating offer the possibility of practical application of superhydrophobic coatings.

2023, 40(10): 5707-5716.

doi: 10.13801/j.cnki.fhclxb.20221228.001

Abstract:

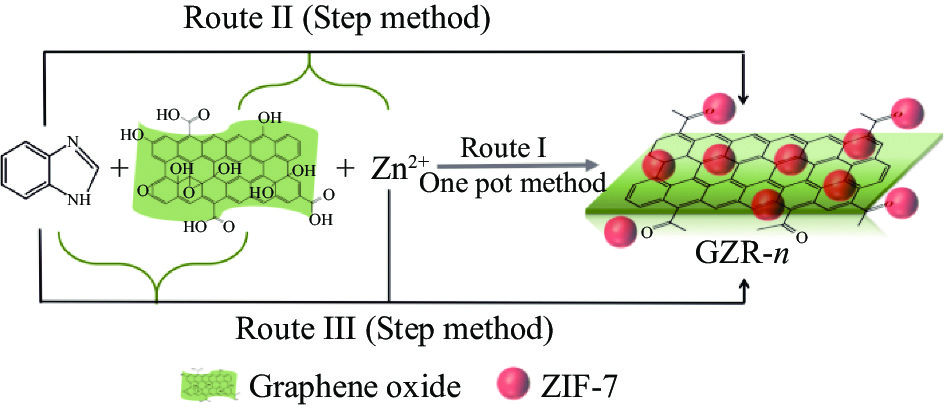

ZIF-7 crystals were in situ grown on graphene oxide (GO) by three synthetic routes, and the resulting graphene oxide/ZIF-7 composites (GZR-n) were characterized by PXRD, FTIR, SEM, TEM, and N2 isothermal adsorption-desorption. The effects of the synthetic routes on the growth, crystallinity, microscopic morphology and pore size of ZIF-7 crystals on GO were investigated. ZIF-7 crystals were grown on the surface and sheet of GO by three synthetic routes. The crystallinity of ZIF-7 crystals on GZR-n was significantly enhanced and some were wrapped by GO. The shape and size of ZIF-7 crystals growing on GZR-n were modulated by the synthesis routes. In particular, the ZIF-7 crystals are spherical particle with a diameter of 50 nm in GZR-II. For GZR-I and GZR-III, the ZIF-7 crystals are regular polyhedron with a size of 200 nm. Additional, their dispersion properties in solvents, adsorption properties and kinetic simulations for organic dyes were explored. GZR-n show good dispersion in methanol and chloroform. Compared with ZIF-7 crystals, the adsorption capacities of GZR-I, GZR-II and GZR-III for methylene blue are increased by 226%, 302% and 278%, respectively. The kinetic simulations indicate that the adsorption of GZR-II and GZR-III for methylene blue are chemisorption and that of GZR-I is physical adsorption.

ZIF-7 crystals were in situ grown on graphene oxide (GO) by three synthetic routes, and the resulting graphene oxide/ZIF-7 composites (GZR-n) were characterized by PXRD, FTIR, SEM, TEM, and N2 isothermal adsorption-desorption. The effects of the synthetic routes on the growth, crystallinity, microscopic morphology and pore size of ZIF-7 crystals on GO were investigated. ZIF-7 crystals were grown on the surface and sheet of GO by three synthetic routes. The crystallinity of ZIF-7 crystals on GZR-n was significantly enhanced and some were wrapped by GO. The shape and size of ZIF-7 crystals growing on GZR-n were modulated by the synthesis routes. In particular, the ZIF-7 crystals are spherical particle with a diameter of 50 nm in GZR-II. For GZR-I and GZR-III, the ZIF-7 crystals are regular polyhedron with a size of 200 nm. Additional, their dispersion properties in solvents, adsorption properties and kinetic simulations for organic dyes were explored. GZR-n show good dispersion in methanol and chloroform. Compared with ZIF-7 crystals, the adsorption capacities of GZR-I, GZR-II and GZR-III for methylene blue are increased by 226%, 302% and 278%, respectively. The kinetic simulations indicate that the adsorption of GZR-II and GZR-III for methylene blue are chemisorption and that of GZR-I is physical adsorption.

2023, 40(10): 5716-5725.

doi: 10.13801/j.cnki.fhclxb.20230202.001

Abstract:

In recent years, flexible pressure sensors with three-dimensional mesh structure show high reversible compressibility and good sensitivity, and their complex network shape is also conducive to the construction of stable conductive network, which is widely used in human health monitoring, wearable devices, medical diagnosis and other fields. In this study, a carbonized wood sponge (CWS)/thermoplastic polyurethane elastomers (TPU) composite pressure sensor with three-dimensional layered structure based on natural balsa wood was designed to construct a stable three-dimensional conductive network and optimize the sensing performance. The catalytic treatment, carbonization process, sensing performance and human applicability of the sensor were characterized. The results show that the carbon yield of the light wood-based CWS/TPU sensor by catalytic treatment and high temperature carbonization can reach 20.15%, the compressive strain can reach at 60%, and the maximum pressure sensing sensitivity can reach 12.87 kPa−1 in the pressure range of 0-4 kPa. Moreover, the sensor still has good sensing stability and environmental stability even after 5000 compression/release cycles, showing good sensing performance. The sensor is successfully used to monitor hand movement, walking and pulse in real time, which shows the potential application value of the sensor in motion and health monitoring.

In recent years, flexible pressure sensors with three-dimensional mesh structure show high reversible compressibility and good sensitivity, and their complex network shape is also conducive to the construction of stable conductive network, which is widely used in human health monitoring, wearable devices, medical diagnosis and other fields. In this study, a carbonized wood sponge (CWS)/thermoplastic polyurethane elastomers (TPU) composite pressure sensor with three-dimensional layered structure based on natural balsa wood was designed to construct a stable three-dimensional conductive network and optimize the sensing performance. The catalytic treatment, carbonization process, sensing performance and human applicability of the sensor were characterized. The results show that the carbon yield of the light wood-based CWS/TPU sensor by catalytic treatment and high temperature carbonization can reach 20.15%, the compressive strain can reach at 60%, and the maximum pressure sensing sensitivity can reach 12.87 kPa−1 in the pressure range of 0-4 kPa. Moreover, the sensor still has good sensing stability and environmental stability even after 5000 compression/release cycles, showing good sensing performance. The sensor is successfully used to monitor hand movement, walking and pulse in real time, which shows the potential application value of the sensor in motion and health monitoring.

2023, 40(10): 5726-5735.

doi: 10.13801/j.cnki.fhclxb.20230310.003

Abstract:

The desalination evaporator based on the solar interface water evaporation technology can realize the desalination and purification of seawater, but the evaporation rate of the evaporator is low at present. In this work, the composite aerogel of polyvinyl alcohol and sodium alginate was prepared by directional freezing. At the same time, carbon nanotubes were used as light absorbing material. The effects of the composition, proportion and content of light absorbing material of the composite aerogel on the evaporation performance of evaporator water were explored. The results show that the composite aerogel evaporator has a light absorption rate of up to 97% and excellent seawater desalination performance. The water evaporation rate under a sun light can reach 2.7 kg·m−2·h−1.In the long-term alternating process of light and darkness, the salt crystals accumulated on the surface of the evaporator will automatically melt and disappear, playing a self-cleaning effect, and can achieve long-term sustainable evaporation. It has broad application prospects in the field of seawater desalination.

The desalination evaporator based on the solar interface water evaporation technology can realize the desalination and purification of seawater, but the evaporation rate of the evaporator is low at present. In this work, the composite aerogel of polyvinyl alcohol and sodium alginate was prepared by directional freezing. At the same time, carbon nanotubes were used as light absorbing material. The effects of the composition, proportion and content of light absorbing material of the composite aerogel on the evaporation performance of evaporator water were explored. The results show that the composite aerogel evaporator has a light absorption rate of up to 97% and excellent seawater desalination performance. The water evaporation rate under a sun light can reach 2.7 kg·m−2·h−1.In the long-term alternating process of light and darkness, the salt crystals accumulated on the surface of the evaporator will automatically melt and disappear, playing a self-cleaning effect, and can achieve long-term sustainable evaporation. It has broad application prospects in the field of seawater desalination.

2023, 40(10): 5736-5749.

doi: 10.13801/j.cnki.fhclxb.20230117.001

Abstract:

The development of renewable, low-cost and environmentally friendly electrode materials with fast ion/electron transfer rate and adjustable surface chemistry is an urgent need for the development of current energy storage devices. In recent years, biomass carbon materials have attracted much attention because of their low cost, renewable and good cycling performance, but their low specific capacitance and energy density affect their practical applications. Here, the biomass waste was transformed into carbon materials with good chemical properties, and the transition metal oxide Fe2O3 was composite by heteroatom-doped biomass carbon materials, taking advantage of the complementary strengths of Fe2O3 and nitrogen doped carbon was used to prepare Fe2O3/nitrogen-doped biomass carbon (NBCs) composite materials by one-step carbonization, showing excellent electrochemical performance. The results show that the specific capacitance of Fe2O3/NBCs as the negative electrode material is 575 F·g−1 at a current density of 1 A·g−1. At the same time, Fe2O3/NBCs-700℃ and NiCoFe-P were used as cathode and cathode materials respectively to assemble asymmetric supercapacitors, achieves an energy density of 33.3 W·h·kg−1 at a power density of 800 W·kg−1. The assembled asymmetric supercapacitors also exhibit excellent cycling stability, maintaining 82.4% capacitance after 3500 cycles. Therefore, Fe2O3/NBCs is a promising electrode material for supercapacitors as negative electrode materials.

The development of renewable, low-cost and environmentally friendly electrode materials with fast ion/electron transfer rate and adjustable surface chemistry is an urgent need for the development of current energy storage devices. In recent years, biomass carbon materials have attracted much attention because of their low cost, renewable and good cycling performance, but their low specific capacitance and energy density affect their practical applications. Here, the biomass waste was transformed into carbon materials with good chemical properties, and the transition metal oxide Fe2O3 was composite by heteroatom-doped biomass carbon materials, taking advantage of the complementary strengths of Fe2O3 and nitrogen doped carbon was used to prepare Fe2O3/nitrogen-doped biomass carbon (NBCs) composite materials by one-step carbonization, showing excellent electrochemical performance. The results show that the specific capacitance of Fe2O3/NBCs as the negative electrode material is 575 F·g−1 at a current density of 1 A·g−1. At the same time, Fe2O3/NBCs-700℃ and NiCoFe-P were used as cathode and cathode materials respectively to assemble asymmetric supercapacitors, achieves an energy density of 33.3 W·h·kg−1 at a power density of 800 W·kg−1. The assembled asymmetric supercapacitors also exhibit excellent cycling stability, maintaining 82.4% capacitance after 3500 cycles. Therefore, Fe2O3/NBCs is a promising electrode material for supercapacitors as negative electrode materials.

2023, 40(10): 5750-5759.

doi: 10.13801/j.cnki.fhclxb.20230117.006

Abstract:

The organic piezoelectric sensor prepared by electrospinning is better flexibility, light weight and breathability than the traditional pressure sensor, which has attracted much attention in the field of wearable sensor research. In this paper, a method of preparing BiCl3/poly(vinylidene fluoride-trifluoroethylene) (P(VDF-TrFE)) composite film by electrospinning was proposed, and the flexible piezoelectric sensor was designed and prepared with the composite film as the functional layer. After a certain amount of BiCl3 is added, the scanning electron microscope analysis shows that the average diameter of the fiber increases from 619 nm to 1158 nm, and the surface becomes smoother. The X-ray diffraction pattern confirms that β phase content of the composite film has been significantly improved. The piezoelectric response testing results show that the open circuit peak-to-peak voltage (Voc) and short-circuit current (Isc) of P(VDF-TrFE) composite films with 2wt%BiCl3 are 16.8 V and 164 nA. Compared with pure P(VDF-TrFE) piezoelectric film, it is obviously improved 2.15 and 2.24 times. The pressure sensing testing results show that the piezoelectric film is good linear output characteristics under the pressure of 1.28 N. A flexible wearable force sensing keyboard was designed with this film, which could collect fingers pressing force and duration time. And it provides a reference solution on smart fabrics such as flexible keyboard applications.

The organic piezoelectric sensor prepared by electrospinning is better flexibility, light weight and breathability than the traditional pressure sensor, which has attracted much attention in the field of wearable sensor research. In this paper, a method of preparing BiCl3/poly(vinylidene fluoride-trifluoroethylene) (P(VDF-TrFE)) composite film by electrospinning was proposed, and the flexible piezoelectric sensor was designed and prepared with the composite film as the functional layer. After a certain amount of BiCl3 is added, the scanning electron microscope analysis shows that the average diameter of the fiber increases from 619 nm to 1158 nm, and the surface becomes smoother. The X-ray diffraction pattern confirms that β phase content of the composite film has been significantly improved. The piezoelectric response testing results show that the open circuit peak-to-peak voltage (Voc) and short-circuit current (Isc) of P(VDF-TrFE) composite films with 2wt%BiCl3 are 16.8 V and 164 nA. Compared with pure P(VDF-TrFE) piezoelectric film, it is obviously improved 2.15 and 2.24 times. The pressure sensing testing results show that the piezoelectric film is good linear output characteristics under the pressure of 1.28 N. A flexible wearable force sensing keyboard was designed with this film, which could collect fingers pressing force and duration time. And it provides a reference solution on smart fabrics such as flexible keyboard applications.

2023, 40(10): 5760-5771.

doi: 10.13801/j.cnki.fhclxb.20230104.001

Abstract:

In recent years, serious industrial pollution has led to the growth of various types of bacteria, and pathogenic bacterial infections can be spread rapidly by various means, posing a great risk of infection. Therefore, it is important to develop high-performance antibacterial materials and study their antibacterial mechanisms for application. To address this issue, this work designed a novel nanocomposite bacteriostatic material UiO-66-NHCl by modifying zirconium-based metal-organic backbone material UiO-66-NH2 via sodium chlorite solution, and characterized the structure and chemical composition of metal-organic framework (MOF) composites by using XRD, FTIR, SEM, TEM, EDS and XPS, and the effects of different loading processes on the chlorine loading were also explored, and the antibacterial properties and skin irritation experiments of UiO-66-NHCl composites were investigated. The results show that the active chlorine is introduced on UiO-66-NH2 by impregnation bonding, and the chlorine loading can be increased by changing the chlorine loading ratio (mass ratios m(UiO-66-NH2)∶m(NaClO2)) and chlorination time of UiO-66-NH2 in NaClO2 solution, and the highest chlorine loading is achieved when the chlorine loading ratio is 1∶5 and the chlorination time is 4 h. Under the conditions of high temperature, high humidity and high temperature, it can still maintain 80% of its original chlorine loading and has good stability. The inhibition activity show that the UiO-66-NHCl composites inhibit both Staphylococcus aureus and Escherichia coli compared to the original UiO-66-NH2 material, and the samples with higher chlorine content show higher inhibition effect and no irritation.

In recent years, serious industrial pollution has led to the growth of various types of bacteria, and pathogenic bacterial infections can be spread rapidly by various means, posing a great risk of infection. Therefore, it is important to develop high-performance antibacterial materials and study their antibacterial mechanisms for application. To address this issue, this work designed a novel nanocomposite bacteriostatic material UiO-66-NHCl by modifying zirconium-based metal-organic backbone material UiO-66-NH2 via sodium chlorite solution, and characterized the structure and chemical composition of metal-organic framework (MOF) composites by using XRD, FTIR, SEM, TEM, EDS and XPS, and the effects of different loading processes on the chlorine loading were also explored, and the antibacterial properties and skin irritation experiments of UiO-66-NHCl composites were investigated. The results show that the active chlorine is introduced on UiO-66-NH2 by impregnation bonding, and the chlorine loading can be increased by changing the chlorine loading ratio (mass ratios m(UiO-66-NH2)∶m(NaClO2)) and chlorination time of UiO-66-NH2 in NaClO2 solution, and the highest chlorine loading is achieved when the chlorine loading ratio is 1∶5 and the chlorination time is 4 h. Under the conditions of high temperature, high humidity and high temperature, it can still maintain 80% of its original chlorine loading and has good stability. The inhibition activity show that the UiO-66-NHCl composites inhibit both Staphylococcus aureus and Escherichia coli compared to the original UiO-66-NH2 material, and the samples with higher chlorine content show higher inhibition effect and no irritation.

2023, 40(10): 5772-5781.

doi: 10.13801/j.cnki.fhclxb.20230110.002

Abstract:

The polylactic acid (PLA) has great potential in the preparation of environmentally friendly dielectric materials due to its biodegradability and high strength, but low dielectric constant limits its wide application in this field. The carboxylic multi-walled carbon nanotubes (MWCNTs—COOH), epoxy-based chain extender (ADR) and poly(butylene adipate-co-terephthalate) (PBAT) were introduced into PLA by melt blending to prepare MWCNTs—COOH-ADR-PBAT/PLA composites. The effects of MWCNTs—COOH on the inter-molecular chain interactions, processing, crystallization, dynamic mechanical, mechanical and dielectric properties of the PBAT/PLA reactive compatibilization system were studied by FTIR, Torque rheometer, DSC, DMA, electron universal testing machine, SEM and LCR dielectric measuring instrument, etc. The results show that the carboxyl group in MWCNTs—COOH preferentially reacts with the reactive compatibilizer during the blending process, which reduces the catalytic compatibilization efficiency of the reactive compatibilizer on the interface between PLA and PBAT. At the same time, MWCNTs—COOH preferentially disperse at the two-phase interface under the drive of dynamics and thermodynamics, giving the material a better rigid toughness balance, while significantly improving the dielectric properties of the material. When the MWCNTs—COOH content is 4wt%, the dielectric constant and dielectric loss of MWCNTs—COOH-ADR-PBAT/PLA composite at 100 Hz were 5.35 and 0.06 respectively, and the material had good comprehensive properties.

The polylactic acid (PLA) has great potential in the preparation of environmentally friendly dielectric materials due to its biodegradability and high strength, but low dielectric constant limits its wide application in this field. The carboxylic multi-walled carbon nanotubes (MWCNTs—COOH), epoxy-based chain extender (ADR) and poly(butylene adipate-co-terephthalate) (PBAT) were introduced into PLA by melt blending to prepare MWCNTs—COOH-ADR-PBAT/PLA composites. The effects of MWCNTs—COOH on the inter-molecular chain interactions, processing, crystallization, dynamic mechanical, mechanical and dielectric properties of the PBAT/PLA reactive compatibilization system were studied by FTIR, Torque rheometer, DSC, DMA, electron universal testing machine, SEM and LCR dielectric measuring instrument, etc. The results show that the carboxyl group in MWCNTs—COOH preferentially reacts with the reactive compatibilizer during the blending process, which reduces the catalytic compatibilization efficiency of the reactive compatibilizer on the interface between PLA and PBAT. At the same time, MWCNTs—COOH preferentially disperse at the two-phase interface under the drive of dynamics and thermodynamics, giving the material a better rigid toughness balance, while significantly improving the dielectric properties of the material. When the MWCNTs—COOH content is 4wt%, the dielectric constant and dielectric loss of MWCNTs—COOH-ADR-PBAT/PLA composite at 100 Hz were 5.35 and 0.06 respectively, and the material had good comprehensive properties.

2023, 40(10): 5782-5791.

doi: 10.13801/j.cnki.fhclxb.20230117.004

Abstract: