2023 Vol. 40, No. 9

2023, 40(9): 4863-4879.

doi: 10.13801/j.cnki.fhclxb.20230509.002

Abstract:

Electrochromic materials are a kind of materials whose optical characteristics can be regulated with voltage reversibly. It is widely used in smart windows, displays, electrochromic sunroof, smart thermal management, military camouflage, and other fields. In recent years, electrochromic materials based on metal oxide nanocrystals have attracted extensive attention of researchers due to their excellent performance and cost advantages. In this paper, we first introduce the principle of electrochemically controlled localized surface plasmon resonance (LSPR) of nanocrystals. Then, we review the latest research progress of metal oxide nanocrystals and their compo-sites in traditional electrochromic and novel electrochromic fields based on electrochemically regulated LSPR. Finally, we put forward the existing problems and solutions of electrochromic materials based on metal oxide nanocrystals and their development prospects are prospected.

Electrochromic materials are a kind of materials whose optical characteristics can be regulated with voltage reversibly. It is widely used in smart windows, displays, electrochromic sunroof, smart thermal management, military camouflage, and other fields. In recent years, electrochromic materials based on metal oxide nanocrystals have attracted extensive attention of researchers due to their excellent performance and cost advantages. In this paper, we first introduce the principle of electrochemically controlled localized surface plasmon resonance (LSPR) of nanocrystals. Then, we review the latest research progress of metal oxide nanocrystals and their compo-sites in traditional electrochromic and novel electrochromic fields based on electrochemically regulated LSPR. Finally, we put forward the existing problems and solutions of electrochromic materials based on metal oxide nanocrystals and their development prospects are prospected.

2023, 40(9): 4880-4892.

doi: 10.13801/j.cnki.fhclxb.20230428.001

Abstract:

In order to prevent the increasingly serious electromagnetic interference problem, the research and development of microwave absorbing materials has attracted more and more attention. As a microwave absorbing material with excellent dielectric properties, SiC also has the advantages of excellent stability, high strength and corrosion resistance. But it also has the disadvantages of poor impedance matching and single microwave absorbing mechanism. Compounding SiC with other materials is an important means to further improve the microwave absorbing properties of SiC materials. The structure, microwave absorbing mechanism and influencing factors of SiC were briefly introduced in the paper. Then the microwave absorbing properties of SiC composites with different dimensions were summarized in detail, including SiC nanoparticles, SiC nanowires, three-dimensional SiC materials with different kinds of materials such as metallic materials, carbon materials, ceramic materials, and polymer materials. Compared with a single SiC material, the composite materials can improve their dielectric properties, enrich the absorption mechanism, optimize the impedance matching, and then improve the microwave absorption ability. Finally, the development direction of SiC based composite microwave absorbing materials was prospected.

In order to prevent the increasingly serious electromagnetic interference problem, the research and development of microwave absorbing materials has attracted more and more attention. As a microwave absorbing material with excellent dielectric properties, SiC also has the advantages of excellent stability, high strength and corrosion resistance. But it also has the disadvantages of poor impedance matching and single microwave absorbing mechanism. Compounding SiC with other materials is an important means to further improve the microwave absorbing properties of SiC materials. The structure, microwave absorbing mechanism and influencing factors of SiC were briefly introduced in the paper. Then the microwave absorbing properties of SiC composites with different dimensions were summarized in detail, including SiC nanoparticles, SiC nanowires, three-dimensional SiC materials with different kinds of materials such as metallic materials, carbon materials, ceramic materials, and polymer materials. Compared with a single SiC material, the composite materials can improve their dielectric properties, enrich the absorption mechanism, optimize the impedance matching, and then improve the microwave absorption ability. Finally, the development direction of SiC based composite microwave absorbing materials was prospected.

2023, 40(9): 4893-4916.

doi: 10.13801/j.cnki.fhclxb.20230425.003

Abstract:

Hydrogels have hydrophilic three-dimensional network structure, which are widely used in biomedicine and other fields because of its similar structure and function to biological tissue. Silk fibroin (SF) has become one of potential hydrogel substrates due to its abundant resources, good biodegradability and biocompatibility. However, due to the dissolution and destruction of the natural hierarchical structure of silk fibers in the process of preparing silk fibroin, the natural advantage of high mechanical strength of silk fibers is lost, and the poor mechanical properties become one of the main reasons limiting the wide application of silk fibroin-based hydrogels. Therefore, researchers are constantly seeking strategies to prepare silk fibroin-based high strength hydrogels (SF-HSHs). This review first introduced the basic structure of SF. Then the preparation methods and gelation mechanisms of SF hydrogel were described. Furthermore, physical cross-linking, dual cross-linking, dual network and composite SF-HSHs were discussed in detail. Finally, the biological applications, prospects and challenges of SF-HSHs were briefly analyzed.

Hydrogels have hydrophilic three-dimensional network structure, which are widely used in biomedicine and other fields because of its similar structure and function to biological tissue. Silk fibroin (SF) has become one of potential hydrogel substrates due to its abundant resources, good biodegradability and biocompatibility. However, due to the dissolution and destruction of the natural hierarchical structure of silk fibers in the process of preparing silk fibroin, the natural advantage of high mechanical strength of silk fibers is lost, and the poor mechanical properties become one of the main reasons limiting the wide application of silk fibroin-based hydrogels. Therefore, researchers are constantly seeking strategies to prepare silk fibroin-based high strength hydrogels (SF-HSHs). This review first introduced the basic structure of SF. Then the preparation methods and gelation mechanisms of SF hydrogel were described. Furthermore, physical cross-linking, dual cross-linking, dual network and composite SF-HSHs were discussed in detail. Finally, the biological applications, prospects and challenges of SF-HSHs were briefly analyzed.

2023, 40(9): 4917-4931.

doi: 10.13801/j.cnki.fhclxb.20230418.002

Abstract:

Electrocatalysis is the key technology of new energy storage and conversion in the future, which is mainly used in hydrogen energy industries such as hydrogen production by water electrolysis and fuel cells. MXene is a general term for two-dimensional layered transition metal carbides, nitrides and carbonitrides. It has high conductivity, large specific surface area, good charge transfer ability as well as rich and controllable surface functional groups, which has been widely used in the field of electrochemical catalysis in recent years. In this paper, the multiple structures of two-dimensional MXene are described firstly, and then the advantages of MXene based electrocatalytic materials in hydrophilicity, conductivity, ion transport and surface defects are summarized, with emphasis on the application and progress of MXene based materials in hydrogen evolution reaction (HER), oxygen evolution reaction (OER), oxygen reduction reaction (ORR) and other catalytic reactions in recent years, The relationship between MXene structure and performance is revealed. Finally, the future development prospect is summarized and prospected.

Electrocatalysis is the key technology of new energy storage and conversion in the future, which is mainly used in hydrogen energy industries such as hydrogen production by water electrolysis and fuel cells. MXene is a general term for two-dimensional layered transition metal carbides, nitrides and carbonitrides. It has high conductivity, large specific surface area, good charge transfer ability as well as rich and controllable surface functional groups, which has been widely used in the field of electrochemical catalysis in recent years. In this paper, the multiple structures of two-dimensional MXene are described firstly, and then the advantages of MXene based electrocatalytic materials in hydrophilicity, conductivity, ion transport and surface defects are summarized, with emphasis on the application and progress of MXene based materials in hydrogen evolution reaction (HER), oxygen evolution reaction (OER), oxygen reduction reaction (ORR) and other catalytic reactions in recent years, The relationship between MXene structure and performance is revealed. Finally, the future development prospect is summarized and prospected.

2023, 40(9): 4932-4942.

doi: 10.13801/j.cnki.fhclxb.20230504.002

Abstract:

Solar evaporation technology is considered to be a green and sustainable technology to alleviate water shortage. The substrate, as an important component of the solar evaporator, is a key factor affecting the evaporation efficiency. Hydrogels have become one of the research hotspots due to their wide source and easy preparation. In this paper, the research progress of the hydrogels in solar evaporators is reviewed. Hydrogel substrate materials, such as polyvinyl alcohol, chitosan, sodium alginate and cellulose are mainly introduced. The characteristics and applications of solar evaporators composed of different hydrogels and photothermal materials are analyzed. The corresponding suggestions for the hydrogel as the substrate of solar evaporator are given. It indicates that the fabrication of hydrogel substrate with more efficient contact area, the improvement of salt-resistant, antifouling and antibacterial properties and self-healing ability are important directions for the development of hydrogel-based solar evaporators.

Solar evaporation technology is considered to be a green and sustainable technology to alleviate water shortage. The substrate, as an important component of the solar evaporator, is a key factor affecting the evaporation efficiency. Hydrogels have become one of the research hotspots due to their wide source and easy preparation. In this paper, the research progress of the hydrogels in solar evaporators is reviewed. Hydrogel substrate materials, such as polyvinyl alcohol, chitosan, sodium alginate and cellulose are mainly introduced. The characteristics and applications of solar evaporators composed of different hydrogels and photothermal materials are analyzed. The corresponding suggestions for the hydrogel as the substrate of solar evaporator are given. It indicates that the fabrication of hydrogel substrate with more efficient contact area, the improvement of salt-resistant, antifouling and antibacterial properties and self-healing ability are important directions for the development of hydrogel-based solar evaporators.

2023, 40(9): 4943-4957.

doi: 10.13801/j.cnki.fhclxb.20230509.001

Abstract:

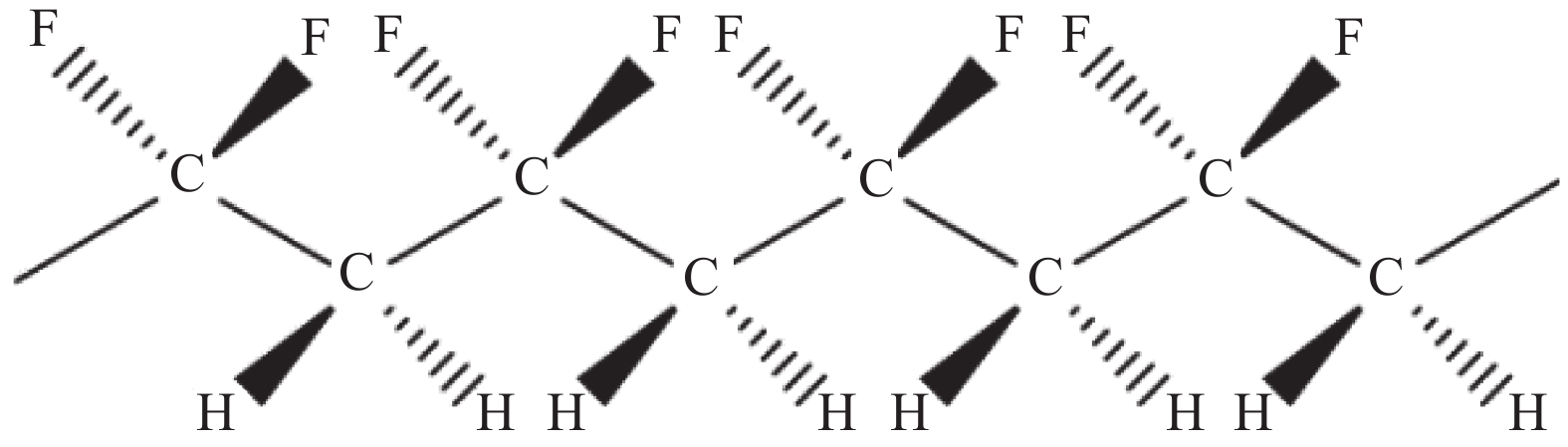

With the back ground of "double carbon" strategy in China, the development of energy storage devices with 'three high, one long, one low and one protection' (i.e. high energy density, high power density, high security, long cycle stability, low cost and environmental protection) is of great significance. Polyvinylidene fluoride (PVDF)-based fluoropolymers has been widely used as binder, separator and electrolyte materials for energy storage devices of batteries and supercapacitors due to their good mechanical property, electrical and chemical stability. With the rapid development of energy storage devices, functionalization of PVDF-based fluoropolymers to meet the needs of energy storage devices with 'three high, one long, one low and one protection' for energy storage device has gain increasing number of research interests. This paper comprehensively introduces the application of PVDF-based polymer nanocomposites as binder, electrolyte and separator materials in energy storage devices. The mechanism of different functional composite modifications to improve the performance of PVDF-based materials are compared and highlighted. The outlook of the PVDF-based materials applied in the field of energy storage is also discussed.

With the back ground of "double carbon" strategy in China, the development of energy storage devices with 'three high, one long, one low and one protection' (i.e. high energy density, high power density, high security, long cycle stability, low cost and environmental protection) is of great significance. Polyvinylidene fluoride (PVDF)-based fluoropolymers has been widely used as binder, separator and electrolyte materials for energy storage devices of batteries and supercapacitors due to their good mechanical property, electrical and chemical stability. With the rapid development of energy storage devices, functionalization of PVDF-based fluoropolymers to meet the needs of energy storage devices with 'three high, one long, one low and one protection' for energy storage device has gain increasing number of research interests. This paper comprehensively introduces the application of PVDF-based polymer nanocomposites as binder, electrolyte and separator materials in energy storage devices. The mechanism of different functional composite modifications to improve the performance of PVDF-based materials are compared and highlighted. The outlook of the PVDF-based materials applied in the field of energy storage is also discussed.

2023, 40(9): 4958-4971.

doi: 10.13801/j.cnki.fhclxb.20230420.001

Abstract:

With the rapid development of society, latent fire hazards have a great threat to social security. Fire prevention and control can be effectively carried out by using fire insulation materials. Aerogels have the characteristics of low density, low thermal conductivity, high porosity, and exhibit excellent fire insulation properties. SiO2 aerogel is the typical representative of aerogel materials and widely used in many industries. However, SiO2 aerogel still has the bottleneck problem of poor mechanical properties at present, resulting in greatly limits for the engineering application. Therefore, it is necessary to introduce reinforcements to make SiO2 aerogel maintain its own excellent characteristics and enhance its mechanical properties. In this paper, the current research status of reinforced SiO2 materials is briefly described, then the methods of improving mechanical properties by optimizing the process and adding nanomaterials, fibers, compacts in the preparation of silica aerogels are discussed and analyzed. Finally, this paper proposed the future research direction and development suggestions of SiO2 aerogels .

With the rapid development of society, latent fire hazards have a great threat to social security. Fire prevention and control can be effectively carried out by using fire insulation materials. Aerogels have the characteristics of low density, low thermal conductivity, high porosity, and exhibit excellent fire insulation properties. SiO2 aerogel is the typical representative of aerogel materials and widely used in many industries. However, SiO2 aerogel still has the bottleneck problem of poor mechanical properties at present, resulting in greatly limits for the engineering application. Therefore, it is necessary to introduce reinforcements to make SiO2 aerogel maintain its own excellent characteristics and enhance its mechanical properties. In this paper, the current research status of reinforced SiO2 materials is briefly described, then the methods of improving mechanical properties by optimizing the process and adding nanomaterials, fibers, compacts in the preparation of silica aerogels are discussed and analyzed. Finally, this paper proposed the future research direction and development suggestions of SiO2 aerogels .

2023, 40(9): 4972-4984.

doi: 10.13801/j.cnki.fhclxb.20230512.003

Abstract:

Infections caused by pathogenic microorganisms have long been a threat to human health around the world. The development of antibacterial biomaterials can be regarded as a substitute for antibiotics in some cases, among which antibacterial hydrogels are an important class of macromolecular antibacterial agents. Bio-based antibacterial hydrogels can be divided into chitosan, cellulose, starch, sodium alginate and protein-based antibacterial hydrogels according to different matrix types. These substrates have high abundance, good biocompatibility and biodegradability in nature, and are ideal materials for preparing antibacterial hydrogels. In this paper, the development status and application fields of bio-based antibacterial hydrogels in recent years were reviewed, mainly from the types, preparation and application of bio-based antibacterial hydrogels. Finally, the challenges faced by bio-based antibacterial hydrogels and the future development trend were summarized and prospeced.

Infections caused by pathogenic microorganisms have long been a threat to human health around the world. The development of antibacterial biomaterials can be regarded as a substitute for antibiotics in some cases, among which antibacterial hydrogels are an important class of macromolecular antibacterial agents. Bio-based antibacterial hydrogels can be divided into chitosan, cellulose, starch, sodium alginate and protein-based antibacterial hydrogels according to different matrix types. These substrates have high abundance, good biocompatibility and biodegradability in nature, and are ideal materials for preparing antibacterial hydrogels. In this paper, the development status and application fields of bio-based antibacterial hydrogels in recent years were reviewed, mainly from the types, preparation and application of bio-based antibacterial hydrogels. Finally, the challenges faced by bio-based antibacterial hydrogels and the future development trend were summarized and prospeced.

2023, 40(9): 4985-5001.

doi: 10.13801/j.cnki.fhclxb.20230331.001

Abstract:

Compared to traditional nanocatalysts, single-atom catalysts (SACs) with advantages of unique structure, remarkable performance and maximum atom utilization efficiency have emerged as a new research focus in catalysis field. Metal-organic frameworks (MOFs) is recognized as one of ideal precursors for constructing SACs, due to the unique features of MOFs including atomically dispersed of metal ion nodes, clear coordination environment and tailorable structure. Recently, a large number of studies reported SACs with excellent performance derived from pyrolysis of MOFs. In this review, five major construction strategies of MOFs-derived SACs, including direct pyrolysis of MOFs, mixed-metal strategy, mixed-ligand strategy, spatial confinement strategy and other strategies, as well as the application of these SACs for hydrogen evolution through electrocatalysis, photocatalysis and hydrogen storage small molecule catalysis are summarized. Finally, the future development directions of MOFs-derived SACs are pointed out.

Compared to traditional nanocatalysts, single-atom catalysts (SACs) with advantages of unique structure, remarkable performance and maximum atom utilization efficiency have emerged as a new research focus in catalysis field. Metal-organic frameworks (MOFs) is recognized as one of ideal precursors for constructing SACs, due to the unique features of MOFs including atomically dispersed of metal ion nodes, clear coordination environment and tailorable structure. Recently, a large number of studies reported SACs with excellent performance derived from pyrolysis of MOFs. In this review, five major construction strategies of MOFs-derived SACs, including direct pyrolysis of MOFs, mixed-metal strategy, mixed-ligand strategy, spatial confinement strategy and other strategies, as well as the application of these SACs for hydrogen evolution through electrocatalysis, photocatalysis and hydrogen storage small molecule catalysis are summarized. Finally, the future development directions of MOFs-derived SACs are pointed out.

2023, 40(9): 5002-5010.

doi: 10.13801/j.cnki.fhclxb.20221219.001

Abstract:

Quartz fiber (QF) reinforced poly(silica-containing arylacetylene) (PSA) composite is a new type of highly promising new wave-transparent materials with highly heat-resistance. However, the brittleness and low molecular polarity of PSA resins, combined with the smooth surface of quartz fibers, results in a weak interfacial adhesion, and low interlaminar shear strength (ILSS) of the composites. In this paper, silicon-containing arylacetylene resin was modified by copolymerizing with styrene (ST). As a consequence, the crosslinking density was decreased, the crosslinking network got homogenized, and the crack resistance of the resin against load was improved. Finally, the ILSS of Quartz fiber reinforced PSA composites was improved. The properties of the resin and composites were characterized with differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), dynamic mechanical analysis (DMA), mechanical property testing, dielectric property testing, rheological property testing. The results showed that the addition of ST didn’t affect the curing process of the resin. With the increase of ST content, the heat resistance of modified PSA resin decreased to some extent, but its mass loss 5wt% temperature Td5 was still close to 500℃, which was much higher than the expected application temperature of 350℃. The modified composite also maintained the good dielectric properties with dielectric constant of 3.09 and loss factor tanδ of 0.002. The results also showed that the addition of ST significantly improved ILSS. For instance, the ILSS of QF/PSA-15ST increased by 53.0% at room temperature and 98.3% at 350℃. Compared with that at room temperature, the retention rate of interlaminar shear strength at 350℃ was 78.3%, which was much higher than that before modification (60.4% ).

Quartz fiber (QF) reinforced poly(silica-containing arylacetylene) (PSA) composite is a new type of highly promising new wave-transparent materials with highly heat-resistance. However, the brittleness and low molecular polarity of PSA resins, combined with the smooth surface of quartz fibers, results in a weak interfacial adhesion, and low interlaminar shear strength (ILSS) of the composites. In this paper, silicon-containing arylacetylene resin was modified by copolymerizing with styrene (ST). As a consequence, the crosslinking density was decreased, the crosslinking network got homogenized, and the crack resistance of the resin against load was improved. Finally, the ILSS of Quartz fiber reinforced PSA composites was improved. The properties of the resin and composites were characterized with differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), dynamic mechanical analysis (DMA), mechanical property testing, dielectric property testing, rheological property testing. The results showed that the addition of ST didn’t affect the curing process of the resin. With the increase of ST content, the heat resistance of modified PSA resin decreased to some extent, but its mass loss 5wt% temperature Td5 was still close to 500℃, which was much higher than the expected application temperature of 350℃. The modified composite also maintained the good dielectric properties with dielectric constant of 3.09 and loss factor tanδ of 0.002. The results also showed that the addition of ST significantly improved ILSS. For instance, the ILSS of QF/PSA-15ST increased by 53.0% at room temperature and 98.3% at 350℃. Compared with that at room temperature, the retention rate of interlaminar shear strength at 350℃ was 78.3%, which was much higher than that before modification (60.4% ).

2023, 40(9): 5011-5025.

doi: 10.13801/j.cnki.fhclxb.20230110.003

Abstract:

Carbon fiber-epoxy resin composites have excellent properties such as high strength and high modulus, corrosion and fatigue resistances, and are widely used as structural materials in civil engineering. Nylon 6 has advantages of great fracture toughness, self-lubrication, friction and wear reduction, etc. Its incorporation as a filler in short-cut carbon fiber-epoxy composites is expected to significantly improve mechanical and frictional wear properties. In this paper, a high performance composite with excellent mechanical properties, high temperature resistance, low coefficient of friction and wear rate was prepared through using short-cut carbon fiber-epoxy resin composites modified with nylon 6 based on the resin selection method. The effect of the addition of nylon 6 on the thermal, mechanical and frictional wear properties of composite was investigated, and the mechanism of nylon 6 on its performance enhancement was revealed by combining microscopic morphology and structural analysis. It was found that the tensile fracture toughness of the modified composites increased by 199% with the addition of 7.5wt% nylon 6, and the fracture damage mode changed from brittle fracture to ductile fracture, the tensile fracture morphology changed from "plain" to "gully" and the glass transition temperature increased by 15.2℃. The addition of 10wt% nylon 6 significantly reduced the frictional coefficient (~80%), wear rate (~53%), scratch width (~22%) and line roughness (~15%) of the composites. The improvement mechanism can be attributed to the fact that nylon 6 assisted in the formation of a uniform and dense lubricant isolation film on the scratch surface, which changed the wear type of the composites from the severe fatigue wear to the slight adhesive wear or abrasive wear.

Carbon fiber-epoxy resin composites have excellent properties such as high strength and high modulus, corrosion and fatigue resistances, and are widely used as structural materials in civil engineering. Nylon 6 has advantages of great fracture toughness, self-lubrication, friction and wear reduction, etc. Its incorporation as a filler in short-cut carbon fiber-epoxy composites is expected to significantly improve mechanical and frictional wear properties. In this paper, a high performance composite with excellent mechanical properties, high temperature resistance, low coefficient of friction and wear rate was prepared through using short-cut carbon fiber-epoxy resin composites modified with nylon 6 based on the resin selection method. The effect of the addition of nylon 6 on the thermal, mechanical and frictional wear properties of composite was investigated, and the mechanism of nylon 6 on its performance enhancement was revealed by combining microscopic morphology and structural analysis. It was found that the tensile fracture toughness of the modified composites increased by 199% with the addition of 7.5wt% nylon 6, and the fracture damage mode changed from brittle fracture to ductile fracture, the tensile fracture morphology changed from "plain" to "gully" and the glass transition temperature increased by 15.2℃. The addition of 10wt% nylon 6 significantly reduced the frictional coefficient (~80%), wear rate (~53%), scratch width (~22%) and line roughness (~15%) of the composites. The improvement mechanism can be attributed to the fact that nylon 6 assisted in the formation of a uniform and dense lubricant isolation film on the scratch surface, which changed the wear type of the composites from the severe fatigue wear to the slight adhesive wear or abrasive wear.

2023, 40(9): 5026-5034.

doi: 10.13801/j.cnki.fhclxb.20221111.001

Abstract:

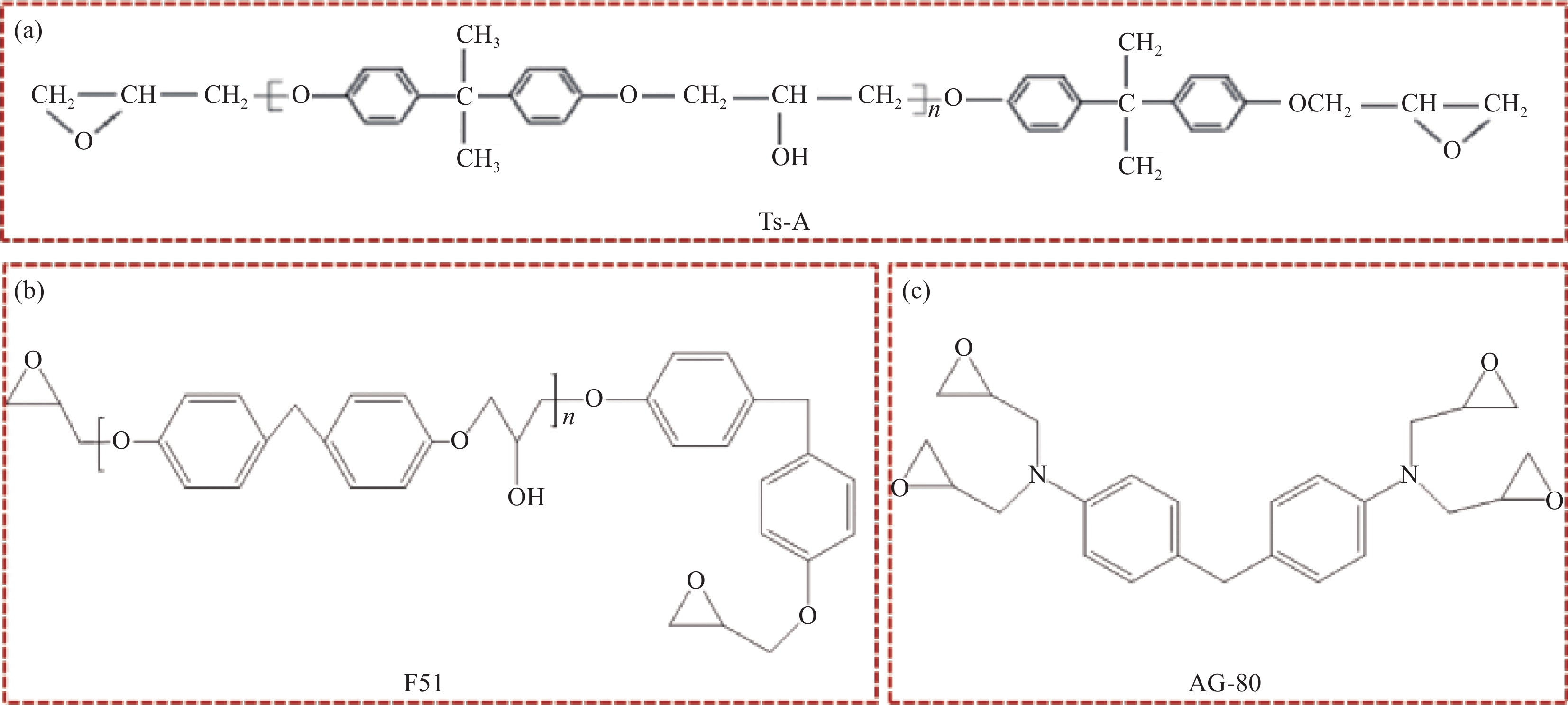

With the wide application of epoxy resin-based carbon fiber composites, the recycling of their waste products had become an important issue for low-carbon development. The resin degradation mechanism of epoxy resin-based carbon fiber composites containing ester bonds and the effect of degradation process on the structure and properties of recycled carbon fibers were studied by GC-MS, FTIR, XPS, SEM and other characterization methods. The results show that the optimal degradation time is 1 h under the conditions of benzyl alcohol dosage of 120 mL, mass ratio W (NaOH)∶W (ZnCl2)=1∶1 and degradation temperature of 190℃, and the optimal dosages of NaOH and resin are both 1 g. The degradation products are separated by standing stratification, and the content of benzyl alcohol in the supernatant is 99%. The degradation mechanism of the resin is as follows: Firstly, benzyl alcohol is ionized to generate benzyloxy group in an alkaline environment, and the benzyloxy groups attack ester bonds in the resin, and transesterification reaction occures to break the ester bond to achieve degradation. Benzyl alcohol ester and alcohol anion are produced by transesterification reaction. Next, the benzyl alcohol ester undergoes saponification reaction in alkaline environment to regenerate benzyl alcohol. The transesterification reaction and the saponification reaction are repeated until the final degradation is completed. The surface O/C and surface smoothness of the recycled carbon fibers and the original carbon fibers are at the same level, and the strength retention rate of the recycled carbon fibers reaches 97%.

With the wide application of epoxy resin-based carbon fiber composites, the recycling of their waste products had become an important issue for low-carbon development. The resin degradation mechanism of epoxy resin-based carbon fiber composites containing ester bonds and the effect of degradation process on the structure and properties of recycled carbon fibers were studied by GC-MS, FTIR, XPS, SEM and other characterization methods. The results show that the optimal degradation time is 1 h under the conditions of benzyl alcohol dosage of 120 mL, mass ratio W (NaOH)∶W (ZnCl2)=1∶1 and degradation temperature of 190℃, and the optimal dosages of NaOH and resin are both 1 g. The degradation products are separated by standing stratification, and the content of benzyl alcohol in the supernatant is 99%. The degradation mechanism of the resin is as follows: Firstly, benzyl alcohol is ionized to generate benzyloxy group in an alkaline environment, and the benzyloxy groups attack ester bonds in the resin, and transesterification reaction occures to break the ester bond to achieve degradation. Benzyl alcohol ester and alcohol anion are produced by transesterification reaction. Next, the benzyl alcohol ester undergoes saponification reaction in alkaline environment to regenerate benzyl alcohol. The transesterification reaction and the saponification reaction are repeated until the final degradation is completed. The surface O/C and surface smoothness of the recycled carbon fibers and the original carbon fibers are at the same level, and the strength retention rate of the recycled carbon fibers reaches 97%.

2023, 40(9): 5035-5045.

doi: 10.13801/j.cnki.fhclxb.20221117.001

Abstract:

Nonlinear conductivity dielectric is widely used today to solve high energy discharge problems in many fields (such as spacecraft charging and motor insulation). In this paper, we optimize the nonlinear conductivity properties and other electrical properties of the composites by continuing the addition of zero- or one-dimensional ZnO to the micro-nano composite systems containing micron SiC and montmorillonite (MMT). The layer spacing before and after the organic modification of MMT was characterized by X-ray diffractometry. The dispersion of each filler inside the composite and the interfacial state were characterized by scanning electron microscopy. Conductivity, breakdown, and dielectric spectroscopy tests were performed on the composites to investigate the pattern of influence of the dimensionality of the nanofillers on the electrical properties. The experimental results showed that the addition of one-dimensional four-needle zincoxide (T-ZnOw) was more effective than zero-dimensional granular ZnO in the MMT-SiC/EP composite system. Thus, the same content of T-ZnOw can increase the interfacial recombination rate in the composite system and constitute the conductive pathway more effectively. Improved nonlinear conductivity properties of the composite. Moreover, T-ZnOw also ensures stable breakdown field strength of the composite material and reduces the relative permittivity and dielectric loss angle tangent values.

Nonlinear conductivity dielectric is widely used today to solve high energy discharge problems in many fields (such as spacecraft charging and motor insulation). In this paper, we optimize the nonlinear conductivity properties and other electrical properties of the composites by continuing the addition of zero- or one-dimensional ZnO to the micro-nano composite systems containing micron SiC and montmorillonite (MMT). The layer spacing before and after the organic modification of MMT was characterized by X-ray diffractometry. The dispersion of each filler inside the composite and the interfacial state were characterized by scanning electron microscopy. Conductivity, breakdown, and dielectric spectroscopy tests were performed on the composites to investigate the pattern of influence of the dimensionality of the nanofillers on the electrical properties. The experimental results showed that the addition of one-dimensional four-needle zincoxide (T-ZnOw) was more effective than zero-dimensional granular ZnO in the MMT-SiC/EP composite system. Thus, the same content of T-ZnOw can increase the interfacial recombination rate in the composite system and constitute the conductive pathway more effectively. Improved nonlinear conductivity properties of the composite. Moreover, T-ZnOw also ensures stable breakdown field strength of the composite material and reduces the relative permittivity and dielectric loss angle tangent values.

2023, 40(9): 5046-5056.

doi: 10.13801/j.cnki.fhclxb.20221213.004

Abstract:

In order to obtain nanomaterials with better dispersal, filling and barrier properties, which were used as fillers to enhance the protection of the epoxy coatings for cement mortar, the polydopamine (PDA), which was prepared by self-polymerization of dopamine hydrochloride (DA) and silane coupling agent (KH550), was utilized to modify nano hexagonal boron nitride (hBN) and nano silicon dioxide (SiO2), respectively, to obtain two nanomaterials polydopamine hexagonal boron nitride (PDABN) and functionalised SiO2 (fSiO2) by polymerization reactions. A new nanomaterial, polydopamine hexagonal boron nitride-functionalised silicon dioxide (PDABN-fSiO2), was synthesized, and it was mixed with epoxy to prepare a modified coating. The coating was covered on the surface of cement mortar to enhance its carbonation resistance. The microscopic characteristics of nano materials were observed by FTIR, SEM-EDS and XPS. The modified effect of epoxy coating by nano PDABN-fSiO2 was analyzed by carbonation experiments and permeability tests. Results indicate that the prepared nano PDABN-fSiO2 has a layer-particle structure and better dispersion in coating, which can effectively slow down the penetration of CO2 in the coating. Compared with the blank coating, the carbonation depth of the cement mortar coated with nano PDABN-fSiO2/epoxy coating is decreased by 68.7%, 72.9% and 64.8% at 7, 14 and 28 days of carbonation, respectively, and the permeability of its coating is decreased by 34.7% at 48 hours. Thus, the epoxy coating with nano PDABN-fSiO2 can significantly improve the carbonation resistance of cement mortar and reduce its permeability.

In order to obtain nanomaterials with better dispersal, filling and barrier properties, which were used as fillers to enhance the protection of the epoxy coatings for cement mortar, the polydopamine (PDA), which was prepared by self-polymerization of dopamine hydrochloride (DA) and silane coupling agent (KH550), was utilized to modify nano hexagonal boron nitride (hBN) and nano silicon dioxide (SiO2), respectively, to obtain two nanomaterials polydopamine hexagonal boron nitride (PDABN) and functionalised SiO2 (fSiO2) by polymerization reactions. A new nanomaterial, polydopamine hexagonal boron nitride-functionalised silicon dioxide (PDABN-fSiO2), was synthesized, and it was mixed with epoxy to prepare a modified coating. The coating was covered on the surface of cement mortar to enhance its carbonation resistance. The microscopic characteristics of nano materials were observed by FTIR, SEM-EDS and XPS. The modified effect of epoxy coating by nano PDABN-fSiO2 was analyzed by carbonation experiments and permeability tests. Results indicate that the prepared nano PDABN-fSiO2 has a layer-particle structure and better dispersion in coating, which can effectively slow down the penetration of CO2 in the coating. Compared with the blank coating, the carbonation depth of the cement mortar coated with nano PDABN-fSiO2/epoxy coating is decreased by 68.7%, 72.9% and 64.8% at 7, 14 and 28 days of carbonation, respectively, and the permeability of its coating is decreased by 34.7% at 48 hours. Thus, the epoxy coating with nano PDABN-fSiO2 can significantly improve the carbonation resistance of cement mortar and reduce its permeability.

2023, 40(9): 5057-5069.

doi: 10.13801/j.cnki.fhclxb.20221129.003

Abstract:

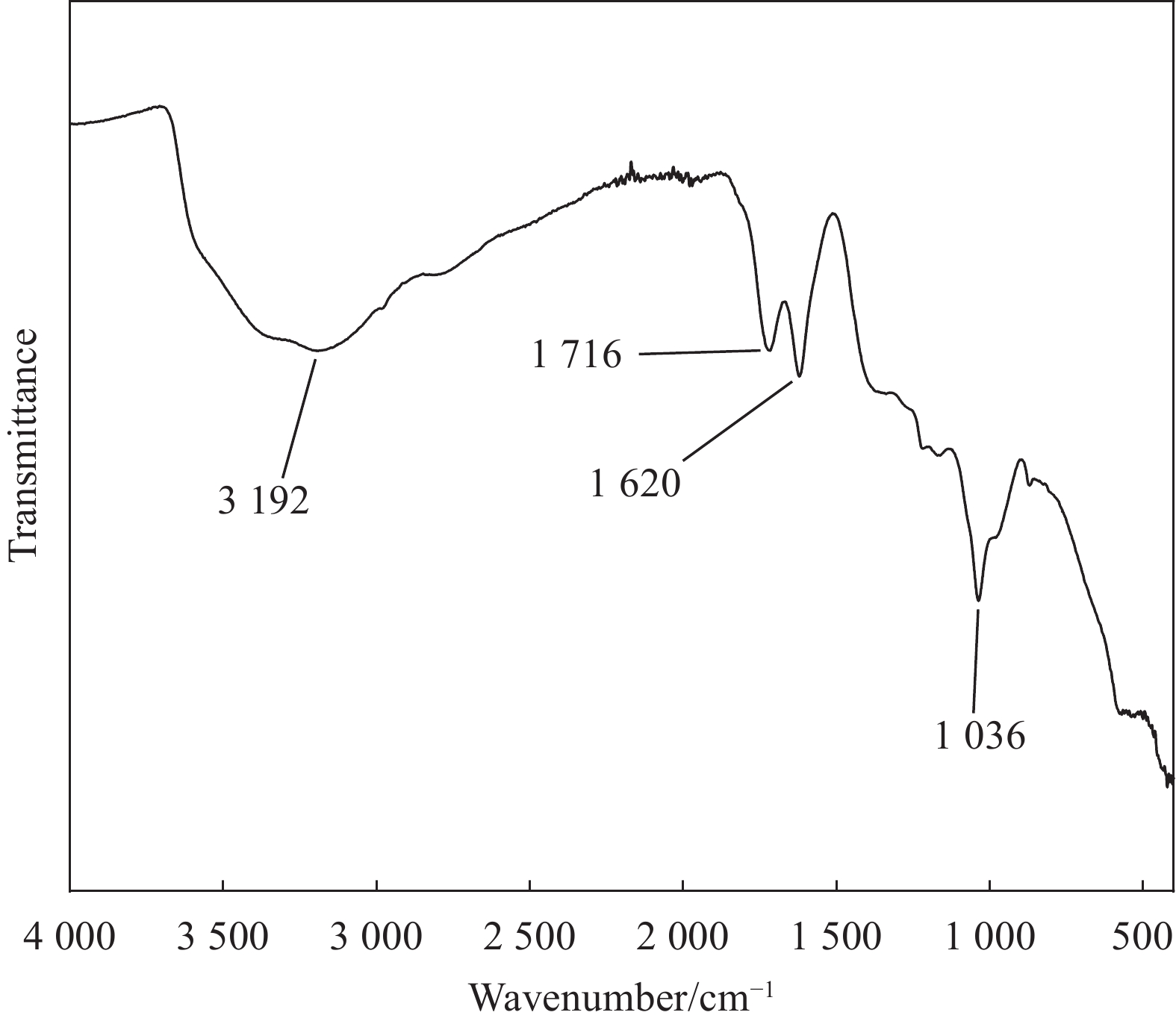

The service life of steel deck pavement is far shorter than that of bridge structure due to the failure of waterproof adhesive layer. In order to prolong the service life of steel bridge deck pavement and improve the bonding condition between layers, a durable polymer waterproof bonding layer was prepared. A series of poly(butyl acrylate)-dodecafluoroheptyl methacrylate-methyl methacrylate-styrene block copolymers with different fluorine contents were synthesized by free radical solution polymerization. Five kinds of self-stratified waterproof coatings were obtained by physical blending of the above copolymers with bisphenol A epoxy resin E-51, and then they were coated on the surface of steel bridge deck to get a waterproof bonding layer after standing and drying. The self-stratification behavior of coatings in curing stage was studied by Fourier transform infrared spectroscopy, static contact angle test and scanning electron microscope. The self-stratification behavior was theoretically verified by surface energy theory. Finally, the high and low temperature properties, mechanical properties, impermeability, bonding strength and ultraviolet aging durability of the bonding layers with different fluorine contents were studied. The results show that when the fluorine content is 20wt%, the tensile strength and elongation at break reach the maximum, reaching 7.04 MPa and 128.9% respectively. At the same time, it shows the best bonding strength and ultraviolet aging durability, and the comprehensive performance reaches the best.

The service life of steel deck pavement is far shorter than that of bridge structure due to the failure of waterproof adhesive layer. In order to prolong the service life of steel bridge deck pavement and improve the bonding condition between layers, a durable polymer waterproof bonding layer was prepared. A series of poly(butyl acrylate)-dodecafluoroheptyl methacrylate-methyl methacrylate-styrene block copolymers with different fluorine contents were synthesized by free radical solution polymerization. Five kinds of self-stratified waterproof coatings were obtained by physical blending of the above copolymers with bisphenol A epoxy resin E-51, and then they were coated on the surface of steel bridge deck to get a waterproof bonding layer after standing and drying. The self-stratification behavior of coatings in curing stage was studied by Fourier transform infrared spectroscopy, static contact angle test and scanning electron microscope. The self-stratification behavior was theoretically verified by surface energy theory. Finally, the high and low temperature properties, mechanical properties, impermeability, bonding strength and ultraviolet aging durability of the bonding layers with different fluorine contents were studied. The results show that when the fluorine content is 20wt%, the tensile strength and elongation at break reach the maximum, reaching 7.04 MPa and 128.9% respectively. At the same time, it shows the best bonding strength and ultraviolet aging durability, and the comprehensive performance reaches the best.

2023, 40(9): 5070-5084.

doi: 10.13801/j.cnki.fhclxb.20221215.002

Abstract:

High thermal performance thermoplastic, poly(ether ketone ketone) (PEKK), was used as the matrix for in-situ impregnation 3D printing with continuous carbon fiber (CCF) to prepare continuous carbon fiber/poly(ether ketone ketone) composites (CCF/PEKK). The effects of layer thickness, flow ratio, print temperature and build orientation in 3D printing process parameters on the internal structure, matrix crystallization, surface quality and mechanical properties of the composites were systematically investigated. The microstructure of 3D printed CCF/PEKK was observed by scanning electron microscopy, the crystallization properties of the matrix were analyzed by X-ray diffraction, the surface morphologies of 3D printed CCF/PEKK was observed and analyzed by ultra-deep field microscopy, and the flexural properties and interlaminar shear strength of CCF/PEKK were also tested. The results shows that with the layer thickness of 0.2 mm, the flow ratio of 85%, the printing temperature of 395°C, and the build orientation of flat, the performance of 3D printed CCF/PEKK is optimal, including the flexural strength of 302.0 MPa and the interlaminar shear strength of 24.1 MPa. The flexural strength of CCF/PEKK is improved by 194% compared with 3D printed pure PEKK, and the interlaminar shear strength is improved by 113% after process optimization. It indicates that 3D printed CCF/PEKK has the potential to manufacture complex structural engineering parts without using any additional optimization.

High thermal performance thermoplastic, poly(ether ketone ketone) (PEKK), was used as the matrix for in-situ impregnation 3D printing with continuous carbon fiber (CCF) to prepare continuous carbon fiber/poly(ether ketone ketone) composites (CCF/PEKK). The effects of layer thickness, flow ratio, print temperature and build orientation in 3D printing process parameters on the internal structure, matrix crystallization, surface quality and mechanical properties of the composites were systematically investigated. The microstructure of 3D printed CCF/PEKK was observed by scanning electron microscopy, the crystallization properties of the matrix were analyzed by X-ray diffraction, the surface morphologies of 3D printed CCF/PEKK was observed and analyzed by ultra-deep field microscopy, and the flexural properties and interlaminar shear strength of CCF/PEKK were also tested. The results shows that with the layer thickness of 0.2 mm, the flow ratio of 85%, the printing temperature of 395°C, and the build orientation of flat, the performance of 3D printed CCF/PEKK is optimal, including the flexural strength of 302.0 MPa and the interlaminar shear strength of 24.1 MPa. The flexural strength of CCF/PEKK is improved by 194% compared with 3D printed pure PEKK, and the interlaminar shear strength is improved by 113% after process optimization. It indicates that 3D printed CCF/PEKK has the potential to manufacture complex structural engineering parts without using any additional optimization.

2023, 40(9): 5085-5094.

doi: 10.13801/j.cnki.fhclxb.20221128.002

Abstract:

The functional material (called shield powder) was formed by mixing functional additives with ordinary carbon steel slag under the work of ultra-fine vertical mill, and replaced the flame retardant filler aluminum hydroxide to form shield powder/rubber composite material. In order to reveal the flame retardant mechanism of shield powder in the rubber system, the paper tested vulcanization properties, mechanical properties and combustion properties and analyzed the gas phase and solid phase residues in the combustion process of shield powder/rubber composite material. The results show that, the shield powder prepared from steel slag could promote the vulcanization process of rubber system, shorten vulcanization time and increase vulcanization rate index. What is more, it can replace aluminum hydroxide as flame retardant filler of rubber system and has little effect on mechanical pro-perties. Besides in the combustion process of shield powder/rubber flame retardant composite material, there are Al2O3, MgO, SiO2, Fe2O3 and other substances in shield powder to form a synergistic flame retardant-smoke extinguishing system. Furthermore, the main mineral composition of carbon slag of shield powder/rubber flame retardant composite material is ZnS and FeS2 and is closely related to the proportion of shield powder replacing alumina hydroxide. With the increase of substitution ratio, there are SiO2 and MnP newly in carbon slag.

The functional material (called shield powder) was formed by mixing functional additives with ordinary carbon steel slag under the work of ultra-fine vertical mill, and replaced the flame retardant filler aluminum hydroxide to form shield powder/rubber composite material. In order to reveal the flame retardant mechanism of shield powder in the rubber system, the paper tested vulcanization properties, mechanical properties and combustion properties and analyzed the gas phase and solid phase residues in the combustion process of shield powder/rubber composite material. The results show that, the shield powder prepared from steel slag could promote the vulcanization process of rubber system, shorten vulcanization time and increase vulcanization rate index. What is more, it can replace aluminum hydroxide as flame retardant filler of rubber system and has little effect on mechanical pro-perties. Besides in the combustion process of shield powder/rubber flame retardant composite material, there are Al2O3, MgO, SiO2, Fe2O3 and other substances in shield powder to form a synergistic flame retardant-smoke extinguishing system. Furthermore, the main mineral composition of carbon slag of shield powder/rubber flame retardant composite material is ZnS and FeS2 and is closely related to the proportion of shield powder replacing alumina hydroxide. With the increase of substitution ratio, there are SiO2 and MnP newly in carbon slag.

2023, 40(9): 5095-5106.

doi: 10.13801/j.cnki.fhclxb.20221201.001

Abstract:

The combination of polypyrrole (PPy) with a unique doping structure and graphene (GE) aerogel with a rich porous structure can realize the complementary advantages of the two materials. Triphenyl blue (TB) doped GE/PPy composite aerogel was prepared by one-step hydrothermal method. The SEM, FTIR, XRD, Raman spectroscopy and XPS were used to characterize the morphological structure, chemical structure, and doping structure of the composite electrode material. The results showed that TB doped GE/PPy composite aerogel provided three porous network structure. Conductive PPy can be successfully polymerized as graphene oxide (GO) was reduced in the composite hydrogel. Due to the introduction of TB, the doping level of the composite hydrogel has been increased. The electrochemical tests demonstrated that the prepared TB-5/PPy-GO (TB concentration of 5 mmol·L−1) aerogel exhibited superior specific capacitance of 392 F·g−1 at 1 A·g−1. The capacitance retention rate can reach 85% after 10 000 cycles. The hybrid device, which was assembled with TB-5/PPy-GO and active carbon as positive and negative electrode, respectively, demonstrated maximum energy of 35.89 W·h·kg−1 at 400 W·kg−1, suggesting its good supercapacitive performances.

The combination of polypyrrole (PPy) with a unique doping structure and graphene (GE) aerogel with a rich porous structure can realize the complementary advantages of the two materials. Triphenyl blue (TB) doped GE/PPy composite aerogel was prepared by one-step hydrothermal method. The SEM, FTIR, XRD, Raman spectroscopy and XPS were used to characterize the morphological structure, chemical structure, and doping structure of the composite electrode material. The results showed that TB doped GE/PPy composite aerogel provided three porous network structure. Conductive PPy can be successfully polymerized as graphene oxide (GO) was reduced in the composite hydrogel. Due to the introduction of TB, the doping level of the composite hydrogel has been increased. The electrochemical tests demonstrated that the prepared TB-5/PPy-GO (TB concentration of 5 mmol·L−1) aerogel exhibited superior specific capacitance of 392 F·g−1 at 1 A·g−1. The capacitance retention rate can reach 85% after 10 000 cycles. The hybrid device, which was assembled with TB-5/PPy-GO and active carbon as positive and negative electrode, respectively, demonstrated maximum energy of 35.89 W·h·kg−1 at 400 W·kg−1, suggesting its good supercapacitive performances.

2023, 40(9): 5107-5123.

doi: 10.13801/j.cnki.fhclxb.20221124.002

Abstract:

Lithium ion sieve formation technology for Li+ recovery industrial production and application from brine is very important. Polyvinyl chloride (PVC)-Li1.6Mn1.6O4 lithium ion sieve precursor membrane was prepared by blend of Li1.6Mn1.6O4 with PVC, polymethyl methacrylate (PMMA) and polyvinylpyrrolidone (PVPk30). After the precursor membrane was treated with HCl solution it can uptake lithium. A series of experiments for examining its adsorption and cyclic performance were carried out. The adsorption isotherm model and the adsorption kinetics of PVC lithium ion sieve membrane were analyzed. The results showed that the adsorption capacity of PVC lithium ion sieve membrane was 1336.30 mg/m2 when the concentration of PVC was 10wt%, the content of PMMA was 6wt%, the content of PVPk30 was 2wt%, and the amount of loading of Li1.6Mn1.6O4 was 20wt%. After treated with 0.1 mol·L−1 HCl for 2 h, the lithium extraction reached equilibrium and the dissolution loss rate of Mn2+ was about 0.56%. After 10 cycles of adsorption and desorption in brine, the Li+ adsorption capacity was lost only 3.0% (from 1336.30 mg/m2 to 1294.16 mg/m2). The PVC lithium ion sieve membrane showed great selectivity for Li+ in brine containing a variety of complex ions such as Na+, K+, Mg2+ and Ca2+. The PVC lithium ion sieve membrane has stable structure and excellent recycling performance, which is conducive to its industrial application. The PVC lithium ion sieve membrane accords with the pseudo second order kinetic equation and Langmuir adsorption isotherm model, indicating a monolayer chemisorption. It is potential to be used in enrichment and recovery of lithium from salt lake brine and other liquid lithium sources.

Lithium ion sieve formation technology for Li+ recovery industrial production and application from brine is very important. Polyvinyl chloride (PVC)-Li1.6Mn1.6O4 lithium ion sieve precursor membrane was prepared by blend of Li1.6Mn1.6O4 with PVC, polymethyl methacrylate (PMMA) and polyvinylpyrrolidone (PVPk30). After the precursor membrane was treated with HCl solution it can uptake lithium. A series of experiments for examining its adsorption and cyclic performance were carried out. The adsorption isotherm model and the adsorption kinetics of PVC lithium ion sieve membrane were analyzed. The results showed that the adsorption capacity of PVC lithium ion sieve membrane was 1336.30 mg/m2 when the concentration of PVC was 10wt%, the content of PMMA was 6wt%, the content of PVPk30 was 2wt%, and the amount of loading of Li1.6Mn1.6O4 was 20wt%. After treated with 0.1 mol·L−1 HCl for 2 h, the lithium extraction reached equilibrium and the dissolution loss rate of Mn2+ was about 0.56%. After 10 cycles of adsorption and desorption in brine, the Li+ adsorption capacity was lost only 3.0% (from 1336.30 mg/m2 to 1294.16 mg/m2). The PVC lithium ion sieve membrane showed great selectivity for Li+ in brine containing a variety of complex ions such as Na+, K+, Mg2+ and Ca2+. The PVC lithium ion sieve membrane has stable structure and excellent recycling performance, which is conducive to its industrial application. The PVC lithium ion sieve membrane accords with the pseudo second order kinetic equation and Langmuir adsorption isotherm model, indicating a monolayer chemisorption. It is potential to be used in enrichment and recovery of lithium from salt lake brine and other liquid lithium sources.

2023, 40(9): 5124-5133.

doi: 10.13801/j.cnki.fhclxb.20221201.002

Abstract:

The massive generation of industrial oily wastewater and the frequent occurrence of oil spills have caused efficient treatment of oily wastewater to emerge as a global challenge. A superhydrophilic/ underwater superoleophobic stainless mesh (PDA-HNTs/SSM) was conveniently fabricated by in-situ immersion of polydopamine (PDA) and halloysite nanotubes (HNTs) and used for oil-water spearation. The surface morphology, chemical composition and wettability of the modified SSM were analyzed by SEM, EDS, FTIR, XRD, XPS and contact Angle instrument. The results showed that the wettability and surface micro-nano hierarchical structure of PDA-HNTs/SSM can be controlled by immersion times of PDA-HNTs. PDA-HNTs/SSM obtained by immersion for 10 times had the best wetting performance, the contact angle underwater of dichloromethane was 157°, and the sliding Angle is less than 5°. Dimetylbenzene, cyclohexane, n-hexane, petroleum ether and dichloromethane were used for oil-water separation test. The separation efficiency of PDA-HNTs/SSM was more than 99%, and still maintained above 95.5% after 50 cycles. Moreover, after standing in 1 mol/L HCl, NaOH and NaCl solution for 7 days or rubbing with sandpaper for 10 m, PDA-HNTs/SSM still maintained stable underwater superhydrophobility and good oil-water separation ability.

The massive generation of industrial oily wastewater and the frequent occurrence of oil spills have caused efficient treatment of oily wastewater to emerge as a global challenge. A superhydrophilic/ underwater superoleophobic stainless mesh (PDA-HNTs/SSM) was conveniently fabricated by in-situ immersion of polydopamine (PDA) and halloysite nanotubes (HNTs) and used for oil-water spearation. The surface morphology, chemical composition and wettability of the modified SSM were analyzed by SEM, EDS, FTIR, XRD, XPS and contact Angle instrument. The results showed that the wettability and surface micro-nano hierarchical structure of PDA-HNTs/SSM can be controlled by immersion times of PDA-HNTs. PDA-HNTs/SSM obtained by immersion for 10 times had the best wetting performance, the contact angle underwater of dichloromethane was 157°, and the sliding Angle is less than 5°. Dimetylbenzene, cyclohexane, n-hexane, petroleum ether and dichloromethane were used for oil-water separation test. The separation efficiency of PDA-HNTs/SSM was more than 99%, and still maintained above 95.5% after 50 cycles. Moreover, after standing in 1 mol/L HCl, NaOH and NaCl solution for 7 days or rubbing with sandpaper for 10 m, PDA-HNTs/SSM still maintained stable underwater superhydrophobility and good oil-water separation ability.

2023, 40(9): 5134-5144.

doi: 10.13801/j.cnki.fhclxb.20221209.002

Abstract:

N doped carbon nitride (N-C3N4)/BiOClxI1−x S-type heterojunctions were prepared by a facile one-step hydrothermal method. The crystal form, morphology, structure, elemental composition, surface functional groups and optical properties of the samples were characterized by XRD, XPS, SEM, TEM, FTIR and UV-Vis. The photocatalytic activity of N-C3N4/BiOClxI1−x oxidation of organic pollutants and reduction of Cr(VI) was investigated. The results show that N-C3N4/BiOClxI1−x sample exhibits the effective enhancement in light absorption. The charge carriers were generated by the transfer of the photoinduced electron from N-C3N4 to BiOClxI1−x across the interface under irradiation, which inhibited the recombination of electron-hole pairs. Under visible light irradiation, 20%N-BiOCl0.5I0.5 exhibited high activity, the degradation rate of phenol reached 98.53% with 2.5 h of visible light irradiation. Meanwhile, the reduction rate of Cr(VI) of 20%N-BiOCl0.5I0.5 reached to 99.11% with 1 h of visible light irradiation. 20%N-BiOCl0.5I0.5 showed good stability after five cycles. The total organic carbon (TOC) removal rate of degradation phenol by 20%N-BiOCl0.5I0.5 within 3 h was 80.21%. Combined with capture experiment, ESR and DFT calculation, the improvement activity of N-C3N4/BiOClxI1−x was attributed to the formation of S-type heterojunction, the internal electric field based on different Fermi levels between N-C3N4 and BiOClxI1−x, as well as band bending and Coulomb force, which together accelerated spatial separation of photogenerated carriers and orderly electron flow.

N doped carbon nitride (N-C3N4)/BiOClxI1−x S-type heterojunctions were prepared by a facile one-step hydrothermal method. The crystal form, morphology, structure, elemental composition, surface functional groups and optical properties of the samples were characterized by XRD, XPS, SEM, TEM, FTIR and UV-Vis. The photocatalytic activity of N-C3N4/BiOClxI1−x oxidation of organic pollutants and reduction of Cr(VI) was investigated. The results show that N-C3N4/BiOClxI1−x sample exhibits the effective enhancement in light absorption. The charge carriers were generated by the transfer of the photoinduced electron from N-C3N4 to BiOClxI1−x across the interface under irradiation, which inhibited the recombination of electron-hole pairs. Under visible light irradiation, 20%N-BiOCl0.5I0.5 exhibited high activity, the degradation rate of phenol reached 98.53% with 2.5 h of visible light irradiation. Meanwhile, the reduction rate of Cr(VI) of 20%N-BiOCl0.5I0.5 reached to 99.11% with 1 h of visible light irradiation. 20%N-BiOCl0.5I0.5 showed good stability after five cycles. The total organic carbon (TOC) removal rate of degradation phenol by 20%N-BiOCl0.5I0.5 within 3 h was 80.21%. Combined with capture experiment, ESR and DFT calculation, the improvement activity of N-C3N4/BiOClxI1−x was attributed to the formation of S-type heterojunction, the internal electric field based on different Fermi levels between N-C3N4 and BiOClxI1−x, as well as band bending and Coulomb force, which together accelerated spatial separation of photogenerated carriers and orderly electron flow.

2023, 40(9): 5145-5157.

doi: 10.13801/j.cnki.fhclxb.20230109.002

Abstract:

Exploring electromagnetic wave (EMW) absorbing materials with excellent performance is the main method to solve electromagnetic pollution. However, it remains a challenge to meet the high performance and practical application requirements of materials simultaneously. Conductive carbon black (CCB)@nano Fe3O4/natural rubber (NR) absorbing films with excellent mechanical and EMW absorption properties were prepared by sol-gel method, plasticizing, blending and vulcanization, and the mechanical and EMW absorbing properties of the films were controlled by adjusting the addition amount of CCB@Fe3O4. The introduction of the CCB@Fe3O4 composites greatly ameliorates the interfacial loss and polarization loss of the films, in which the CCB can enhance the mechanical properties while improving the dielectric constant and conductivity of the materials. The film achieves the minimum reflection loss (RL) of -40.5 dB and maximum effective absorption bandwidth (EAB) of 2.4 GHz with the thickness of 5.0 mm when the CCB@Fe3O4 was added at 29wt%, and exhibited the optimal tensile strength, hardness and wear properties. The remarkable EMW absorbing properties of the material originate from impedance matching, strong EMW attenuation and high conduction loss caused by the synergistic effect of dielectric-magnetic loss. This work provides a new mentality for the structure design and practical application of natural rubber-based absorbing films.

Exploring electromagnetic wave (EMW) absorbing materials with excellent performance is the main method to solve electromagnetic pollution. However, it remains a challenge to meet the high performance and practical application requirements of materials simultaneously. Conductive carbon black (CCB)@nano Fe3O4/natural rubber (NR) absorbing films with excellent mechanical and EMW absorption properties were prepared by sol-gel method, plasticizing, blending and vulcanization, and the mechanical and EMW absorbing properties of the films were controlled by adjusting the addition amount of CCB@Fe3O4. The introduction of the CCB@Fe3O4 composites greatly ameliorates the interfacial loss and polarization loss of the films, in which the CCB can enhance the mechanical properties while improving the dielectric constant and conductivity of the materials. The film achieves the minimum reflection loss (RL) of -40.5 dB and maximum effective absorption bandwidth (EAB) of 2.4 GHz with the thickness of 5.0 mm when the CCB@Fe3O4 was added at 29wt%, and exhibited the optimal tensile strength, hardness and wear properties. The remarkable EMW absorbing properties of the material originate from impedance matching, strong EMW attenuation and high conduction loss caused by the synergistic effect of dielectric-magnetic loss. This work provides a new mentality for the structure design and practical application of natural rubber-based absorbing films.

2023, 40(9): 5158-5169.

doi: 10.13801/j.cnki.fhclxb.20221128.001

Abstract:

The conversion of CO2 into carbon-based fuels through artificial photosynthesis technology based on semiconductor photocatalytic reduction has been identified as an ideal strategy to alleviate energy shortage and environmental crisis. However, due to insufficient utilization of solar energy and rapid recombination of photogenerated charges for the reported photocatalysts, the energy conversion efficiency of CO2 photoreduction is still low. Amorphous CoOx/WO3-x composite photocatalysts were synthesized by a hydrothermal method combining with surface impregnation process for the first time. Crystal phase composition, microstructure, optical absorption properties and oxygen vacancy defects of the prepared catalysts were systematically characterized by XRD, TEM, XPS, EPR and UV-Vis-NIR DRS. The results of CO2 photoreduction experiments show that only 3.2 μmol·g−1 CH4 can be detected when using WO3-x as a catalyst after Vis-NIR light irradiation for 3 h, whereas introducing CoOx can significantly boost the CO2 photocatalytic reduction performance of WO3-x. Under the same experimental conditions, the yield of CO and CH4 on 2.5wt%CoOx/WO3-x catalyst can reach 78.2 and 19.7 μmol·g−1 respectively. Introducing oxygen vacancies can form a new intermediate energy level in the band structure of WO3-x, which enhances NIR absorption and causes local temperature rise of the catalysts surface. Incorporating CoOx contributes to enhance the separation and migration of photogenerated charges, and meanwhile can regulate the conduction-band potential of WO3-x. The synergistic effect of photothermal effect and CoOx cocatalyst is the primary reason for the promoted performance of CO2 photocatalytic conversion. Additionally, the composite photocatalysts CoOx/WO3-x shows excellent long-term catalytic and structural stability.

The conversion of CO2 into carbon-based fuels through artificial photosynthesis technology based on semiconductor photocatalytic reduction has been identified as an ideal strategy to alleviate energy shortage and environmental crisis. However, due to insufficient utilization of solar energy and rapid recombination of photogenerated charges for the reported photocatalysts, the energy conversion efficiency of CO2 photoreduction is still low. Amorphous CoOx/WO3-x composite photocatalysts were synthesized by a hydrothermal method combining with surface impregnation process for the first time. Crystal phase composition, microstructure, optical absorption properties and oxygen vacancy defects of the prepared catalysts were systematically characterized by XRD, TEM, XPS, EPR and UV-Vis-NIR DRS. The results of CO2 photoreduction experiments show that only 3.2 μmol·g−1 CH4 can be detected when using WO3-x as a catalyst after Vis-NIR light irradiation for 3 h, whereas introducing CoOx can significantly boost the CO2 photocatalytic reduction performance of WO3-x. Under the same experimental conditions, the yield of CO and CH4 on 2.5wt%CoOx/WO3-x catalyst can reach 78.2 and 19.7 μmol·g−1 respectively. Introducing oxygen vacancies can form a new intermediate energy level in the band structure of WO3-x, which enhances NIR absorption and causes local temperature rise of the catalysts surface. Incorporating CoOx contributes to enhance the separation and migration of photogenerated charges, and meanwhile can regulate the conduction-band potential of WO3-x. The synergistic effect of photothermal effect and CoOx cocatalyst is the primary reason for the promoted performance of CO2 photocatalytic conversion. Additionally, the composite photocatalysts CoOx/WO3-x shows excellent long-term catalytic and structural stability.

2023, 40(9): 5170-5180.

doi: 10.13801/j.cnki.fhclxb.20221109.003

Abstract:

In order to improve the flame retardant and smoke suppression properties of thermoplastic polyurethane elastomer (TPU), ZIF-8-CES hybrid was synthesized by using waste chicken eggshell (CES) as raw material and modified by zeolitic imidazolate framework-8 (ZIF-8). Compared with pure TPU, when 20wt% intumescent flame retardant (IFR) and 5wt% ZIF-8-CES are added to TPU, the peak heat release rate (pHRR) and peak smoke release rate (pSPR) of TPU composites are reduced to 242 kW·m−2 and 0.151 m2·s−1, respectively. The limiting oxygen index (LOI) value reached 31.5%, and the vertical combustion (UL-94) reached V-0 level. ZIF-8-CES and IFR have good synergistic flame retardant effect in TPU. This is mainly because ZIF-8-CES and IFR generate zinc oxide, calcium phosphate and calcium phosphite at high temperatures, which play a role in catalyzing carbon formation and enhancing the carbon layer, thereby improving the flame retardant and smoke suppression properties of TPU composites.

In order to improve the flame retardant and smoke suppression properties of thermoplastic polyurethane elastomer (TPU), ZIF-8-CES hybrid was synthesized by using waste chicken eggshell (CES) as raw material and modified by zeolitic imidazolate framework-8 (ZIF-8). Compared with pure TPU, when 20wt% intumescent flame retardant (IFR) and 5wt% ZIF-8-CES are added to TPU, the peak heat release rate (pHRR) and peak smoke release rate (pSPR) of TPU composites are reduced to 242 kW·m−2 and 0.151 m2·s−1, respectively. The limiting oxygen index (LOI) value reached 31.5%, and the vertical combustion (UL-94) reached V-0 level. ZIF-8-CES and IFR have good synergistic flame retardant effect in TPU. This is mainly because ZIF-8-CES and IFR generate zinc oxide, calcium phosphate and calcium phosphite at high temperatures, which play a role in catalyzing carbon formation and enhancing the carbon layer, thereby improving the flame retardant and smoke suppression properties of TPU composites.

2023, 40(9): 5181-5188.

doi: 10.13801/j.cnki.fhclxb.20230112.005

Abstract:

In order to study the reinforcing mechanism of carbon nanotubes (CNT) on the mechanical and thermal stability of nitrile rubber (NBR) O-ring, 1%CNT/NBR (mass ratio of CNT) and 2%CNT/NBR composite O-ring were prepared by mechanical blending and hot pressing. The mechanical properties of CNT/NBR composite O-ring were tested on the basis of SEM, EDS and FTIR. The results show that with the increase of CNT content, the elastic modulus and rigidity of CNT/NBR composite O-ring increase. The tensile strength of 1%CNT/NBR O-ring reaches 12.6 MPa due to the formation of C—O bond. The increase of CNT content in NBR matrix can improve the thermal stability of CNT/NBR composite O-ring, and the phase transition temperature of 2%CNT/NBR reaches 297℃. The excellent aging resistance of 1%CNT/NBR composites is attributed to the fact that CNT makes NBR matrix produce C≡N triple bond functional groups. High-performance CNT/NBR composite O-ring has certain application value in the field of aviation seals.

In order to study the reinforcing mechanism of carbon nanotubes (CNT) on the mechanical and thermal stability of nitrile rubber (NBR) O-ring, 1%CNT/NBR (mass ratio of CNT) and 2%CNT/NBR composite O-ring were prepared by mechanical blending and hot pressing. The mechanical properties of CNT/NBR composite O-ring were tested on the basis of SEM, EDS and FTIR. The results show that with the increase of CNT content, the elastic modulus and rigidity of CNT/NBR composite O-ring increase. The tensile strength of 1%CNT/NBR O-ring reaches 12.6 MPa due to the formation of C—O bond. The increase of CNT content in NBR matrix can improve the thermal stability of CNT/NBR composite O-ring, and the phase transition temperature of 2%CNT/NBR reaches 297℃. The excellent aging resistance of 1%CNT/NBR composites is attributed to the fact that CNT makes NBR matrix produce C≡N triple bond functional groups. High-performance CNT/NBR composite O-ring has certain application value in the field of aviation seals.

2023, 40(9): 5189-5200.

doi: 10.13801/j.cnki.fhclxb.20221117.002

Abstract:

The oxidation behaviors of the homemade high thermal conductive mesophase-pitch-based carbon fiber (CFMP) at different time and temperature were investigated using the polyacrylonitrile-based carbon fiber (M55J) as the control group. The results show that CFMP exhibits a fold radiation structure in the outer part and onion skin structure in the inner part. The CFMP has a well-developed graphite crystallite and a high degree of orientation. Oxygen atoms preferentially diffuse in the microcracks and micropores in the fold radiation carbon textures of CFMP and react with them resulting in radial cracks and localized pits. In the low temperature oxidation stage, the oxidation behaviors of the fibers are controlled by the carbon-oxygen chemical reaction. Because the active site concentration in graphite crystallite of CFMP is lower, its initial reaction temperature is higher than that of M55J, and its oxidation mass loss rate is relative lower. In the high temperature oxidation stage, the oxidation behaviors of the fibers are controlled by oxygen diffusion. The oxidation mass loss rate of CFMP is higher than that of M55J because there are more oxygen diffusion paths in the CFMP. Moreover, because there are more and larger microstructural defects in CFMP after oxidation, the strength retention rate of the CFMP is only 78%, which is lower than that of M55J (85%). This study provides certain technical and theoretical references for the structural design and actual service of high thermal conductive C/C composites.

The oxidation behaviors of the homemade high thermal conductive mesophase-pitch-based carbon fiber (CFMP) at different time and temperature were investigated using the polyacrylonitrile-based carbon fiber (M55J) as the control group. The results show that CFMP exhibits a fold radiation structure in the outer part and onion skin structure in the inner part. The CFMP has a well-developed graphite crystallite and a high degree of orientation. Oxygen atoms preferentially diffuse in the microcracks and micropores in the fold radiation carbon textures of CFMP and react with them resulting in radial cracks and localized pits. In the low temperature oxidation stage, the oxidation behaviors of the fibers are controlled by the carbon-oxygen chemical reaction. Because the active site concentration in graphite crystallite of CFMP is lower, its initial reaction temperature is higher than that of M55J, and its oxidation mass loss rate is relative lower. In the high temperature oxidation stage, the oxidation behaviors of the fibers are controlled by oxygen diffusion. The oxidation mass loss rate of CFMP is higher than that of M55J because there are more oxygen diffusion paths in the CFMP. Moreover, because there are more and larger microstructural defects in CFMP after oxidation, the strength retention rate of the CFMP is only 78%, which is lower than that of M55J (85%). This study provides certain technical and theoretical references for the structural design and actual service of high thermal conductive C/C composites.

2023, 40(9): 5201-5211.

doi: 10.13801/j.cnki.fhclxb.20221129.001

Abstract:

Graphene oxide (GO) has a large specific surface area, and there are a large number of oxygen-containing groups in the chemical structure, which makes it have excellent hydrophilic properties and dispersing properties in cement-based materials. GO can effectively improve the microstructure of cement-based materials and enhance its mechanical properties. In this paper, based on the Dinger-Funk model, the mix ratio design of 3D printing cement-based materials was carried out, and the effect of different dosages of GO on the properties was studied. The results show that: The addition of 0.03wt%-0.05wt%GO accelerates the cement hydration process, which is beneficial to the enhancement of the mechanical properties of 3D printed cement-based materials in all directions. Compared with the group without GO, after adding 0.03wt%GO, the 28 days compressive strength of the 3D printed specimens in the X, Y, and Z directions increase by 12.07%, 11.93%, and 17.42%, respectively, and the 28 days flexural strength increase by 30.61%, 21.13%, and 13.70%, respectively. The pores of the 3D printed specimen are re-latively concentrated at the interface between layers, showing an irregular shape, resulting in anisotropic behavior of the mechanical properties of the 3D printed specimens. The anisotropy of the compressive strength of the 3D printed specimen is not obvious, while the anisotropic behavior of the flexural strength is significant.

Graphene oxide (GO) has a large specific surface area, and there are a large number of oxygen-containing groups in the chemical structure, which makes it have excellent hydrophilic properties and dispersing properties in cement-based materials. GO can effectively improve the microstructure of cement-based materials and enhance its mechanical properties. In this paper, based on the Dinger-Funk model, the mix ratio design of 3D printing cement-based materials was carried out, and the effect of different dosages of GO on the properties was studied. The results show that: The addition of 0.03wt%-0.05wt%GO accelerates the cement hydration process, which is beneficial to the enhancement of the mechanical properties of 3D printed cement-based materials in all directions. Compared with the group without GO, after adding 0.03wt%GO, the 28 days compressive strength of the 3D printed specimens in the X, Y, and Z directions increase by 12.07%, 11.93%, and 17.42%, respectively, and the 28 days flexural strength increase by 30.61%, 21.13%, and 13.70%, respectively. The pores of the 3D printed specimen are re-latively concentrated at the interface between layers, showing an irregular shape, resulting in anisotropic behavior of the mechanical properties of the 3D printed specimens. The anisotropy of the compressive strength of the 3D printed specimen is not obvious, while the anisotropic behavior of the flexural strength is significant.

2023, 40(9): 5212-5224.

doi: 10.13801/j.cnki.fhclxb.20230103.004

Abstract:

To study the effect of fiber reinforced plastic (FRP) grid-engineered cementitious composite (ECC) matrix strengthened method on the deflection of reinforced concrete (RC) beams, flexural performance test was carried out on 10 RC beams. Each test variable which does effect on the deflection of RC beams strengthened with FRP grid-ECC matrix composite was analyzed, and a model for calculating the deflection of reinforced beams was derived. The test results show that the FRP grid-ECC matrix strengthened method can significantly improve the ultimate bearing capacity and flexural stiffness of the test beams, in which the ultimate load carrying capacity of the reinforced beam increases from 27.9% to 67.4%, the mid-span deflection decreases from 30.7% to 43.7%, and the reinforced beams occur suitable reinforcement damage with obvious ductile characteristics. The FRP grid has a strong influence on flexural performance of reinforced beams, and its grid thickness is proportional to the strengthening effection. The thickness, matching ratio and interface treatment method of ECC reinforcement layer have little effect on the flexural performance of the reinforced beam, and the sanding treatment improves the interface bonding performance of the reinforcement layer better than other interface treatment methods. The deflection calculation model of reinforced beams is derived based on the specification, and its calculating values agree well with the testing values, so the model is a reference for the deflection calculation of RC beams strengthened with FRP grid-ECC matrix composite.

To study the effect of fiber reinforced plastic (FRP) grid-engineered cementitious composite (ECC) matrix strengthened method on the deflection of reinforced concrete (RC) beams, flexural performance test was carried out on 10 RC beams. Each test variable which does effect on the deflection of RC beams strengthened with FRP grid-ECC matrix composite was analyzed, and a model for calculating the deflection of reinforced beams was derived. The test results show that the FRP grid-ECC matrix strengthened method can significantly improve the ultimate bearing capacity and flexural stiffness of the test beams, in which the ultimate load carrying capacity of the reinforced beam increases from 27.9% to 67.4%, the mid-span deflection decreases from 30.7% to 43.7%, and the reinforced beams occur suitable reinforcement damage with obvious ductile characteristics. The FRP grid has a strong influence on flexural performance of reinforced beams, and its grid thickness is proportional to the strengthening effection. The thickness, matching ratio and interface treatment method of ECC reinforcement layer have little effect on the flexural performance of the reinforced beam, and the sanding treatment improves the interface bonding performance of the reinforcement layer better than other interface treatment methods. The deflection calculation model of reinforced beams is derived based on the specification, and its calculating values agree well with the testing values, so the model is a reference for the deflection calculation of RC beams strengthened with FRP grid-ECC matrix composite.

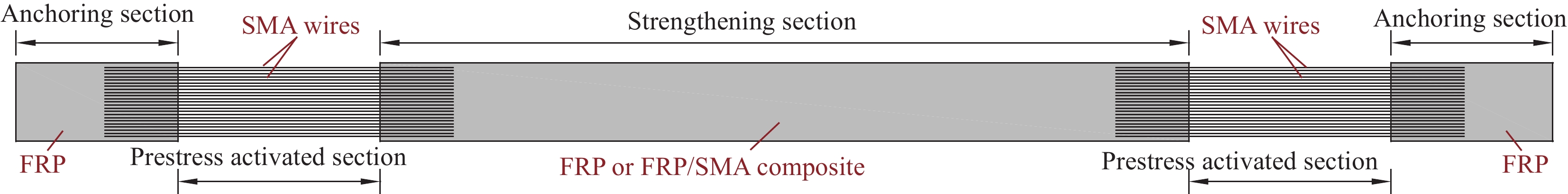

2023, 40(9): 5225-5240.

doi: 10.13801/j.cnki.fhclxb.20221223.001