2023 Vol. 40, No. 8

2023, 40(8): 4295-4317.

doi: 10.13801/j.cnki.fhclxb.20230318.001

Abstract:

Carbon fiber composites are widely used in aerospace and automotive industries due to the characteris-tics of low density, high elasticity, and better toughness. Due to the complexity and instability of the manufacturing process of carbon fiber composites and their vulnerability to environmental impact during service, it is likely to generate delamination, porosity, fiber wrinkle, and other types of damage. In this paper, the principles and characteristics of C-scan, phased array, air-coupled, optical fiber-ultrasound, and laser-ultrasonic testing based on body or guided waves, as well as the research status of these technologies for damage detection of carbon fiber compo-sites, are introduced respectively. The most representative imaging algorithms for damage diagnosis are shown, including total-focus imaging, 3D visualization imaging, tomography, reverse time migration imaging, and probability imaging method, these imaging methods can effectively realize various types of damage morphology in carbon fiber composites. The prospect is made from the following aspects: The establishment of an array acoustic field model of carbon fiber composite laminates, the optimization of damage imaging method, the construction of intelligent/efficient/real-time structural health monitoring imaging system, the establishment of damage quantitative evaluation criteria, and combination of machine learning and digital twin technology for damage diagnosis assessment and life prediction.

Carbon fiber composites are widely used in aerospace and automotive industries due to the characteris-tics of low density, high elasticity, and better toughness. Due to the complexity and instability of the manufacturing process of carbon fiber composites and their vulnerability to environmental impact during service, it is likely to generate delamination, porosity, fiber wrinkle, and other types of damage. In this paper, the principles and characteristics of C-scan, phased array, air-coupled, optical fiber-ultrasound, and laser-ultrasonic testing based on body or guided waves, as well as the research status of these technologies for damage detection of carbon fiber compo-sites, are introduced respectively. The most representative imaging algorithms for damage diagnosis are shown, including total-focus imaging, 3D visualization imaging, tomography, reverse time migration imaging, and probability imaging method, these imaging methods can effectively realize various types of damage morphology in carbon fiber composites. The prospect is made from the following aspects: The establishment of an array acoustic field model of carbon fiber composite laminates, the optimization of damage imaging method, the construction of intelligent/efficient/real-time structural health monitoring imaging system, the establishment of damage quantitative evaluation criteria, and combination of machine learning and digital twin technology for damage diagnosis assessment and life prediction.

2023, 40(8): 4318-4326.

doi: 10.13801/j.cnki.fhclxb.20230228.001

Abstract:

The ongoing surge in demand for energy and the increasing environmental crisis makes the high-performance energy storage device become a research hotspot in recent years. Based on the power and energy density, energy storage devices can be divided into electrochemical capacitors, secondary batteries, and fuel cells, etc. Electrode materials play an important role in the preparation of energy storage with green environment protection and high performance. Nanocellulose has great application potential and development prospect in the preparation and performance improvement of energy storage materials due to their natural abundance, environmental sustainability, high specific surface area, excellent mechanical properties and biocompatibility. In this paper, the classification, preparation, modification of nanocellulose and nanocellulose composites were summarized, the application and research progress of the mixing of nanocellulose with electroactive substances and the preparation of hydrogel, aerogel, paper/film composites based on nanocellulose and as carbon precursors in electrode materials were mainly introduced.

The ongoing surge in demand for energy and the increasing environmental crisis makes the high-performance energy storage device become a research hotspot in recent years. Based on the power and energy density, energy storage devices can be divided into electrochemical capacitors, secondary batteries, and fuel cells, etc. Electrode materials play an important role in the preparation of energy storage with green environment protection and high performance. Nanocellulose has great application potential and development prospect in the preparation and performance improvement of energy storage materials due to their natural abundance, environmental sustainability, high specific surface area, excellent mechanical properties and biocompatibility. In this paper, the classification, preparation, modification of nanocellulose and nanocellulose composites were summarized, the application and research progress of the mixing of nanocellulose with electroactive substances and the preparation of hydrogel, aerogel, paper/film composites based on nanocellulose and as carbon precursors in electrode materials were mainly introduced.

2023, 40(8): 4327-4341.

doi: 10.13801/j.cnki.fhclxb.20230227.002

Abstract:

Copper nanowires not only have excellent electrical conductivity comparable to silver, but also have good light transmittance and flexural resistance due to the size effect at the nanoscale. In addition, it is far cheaper than gold and silver, hence it is an ideal electrode material for preparing flexible electronic devices. The synthesis methods of copper nanowires were systematically reviewed, such as template method, vapor deposition method, electrospinning technology, and chemical liquid phase method. Purification technologies based on water-hydrophobic organic solvent system and acid treatment for copper nanowires were introduced. Various cladding materials with core-shell structure and corresponding cladding technologies used to improve the oxidation resistance and stability of copper nanowires were listed, including inert metals, carbon-based materials, and organic polymer materials. The application status of flexible electronic devices integrating high-quality copper nanowires (or their composites) with flexible substrates (paper-based, polyurethane, and polyethylene terephthalate, etc.) in the fields of flexible transparent electrodes, energy storage/conversion, and flexible sensors were concluded. Finally, the challenges faced in practical application were prospected.

Copper nanowires not only have excellent electrical conductivity comparable to silver, but also have good light transmittance and flexural resistance due to the size effect at the nanoscale. In addition, it is far cheaper than gold and silver, hence it is an ideal electrode material for preparing flexible electronic devices. The synthesis methods of copper nanowires were systematically reviewed, such as template method, vapor deposition method, electrospinning technology, and chemical liquid phase method. Purification technologies based on water-hydrophobic organic solvent system and acid treatment for copper nanowires were introduced. Various cladding materials with core-shell structure and corresponding cladding technologies used to improve the oxidation resistance and stability of copper nanowires were listed, including inert metals, carbon-based materials, and organic polymer materials. The application status of flexible electronic devices integrating high-quality copper nanowires (or their composites) with flexible substrates (paper-based, polyurethane, and polyethylene terephthalate, etc.) in the fields of flexible transparent electrodes, energy storage/conversion, and flexible sensors were concluded. Finally, the challenges faced in practical application were prospected.

2023, 40(8): 4342-4354.

doi: 10.13801/j.cnki.fhclxb.20230330.003

Abstract:

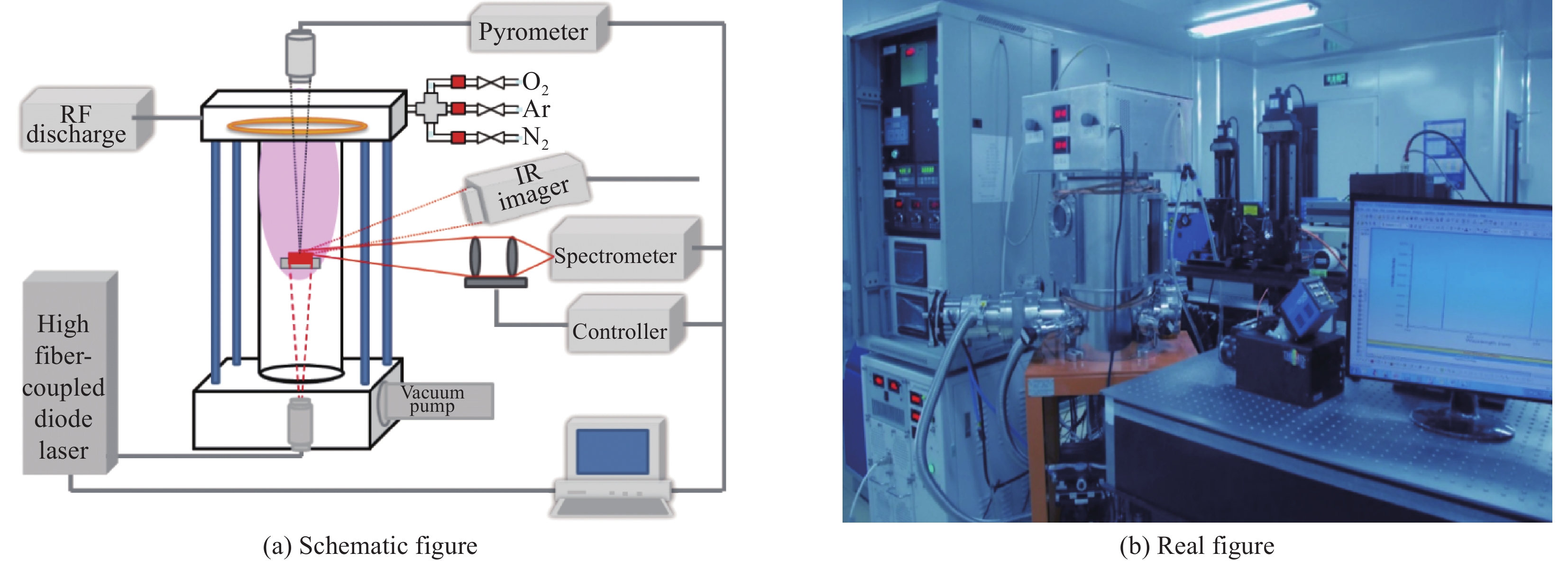

With the further improvement of aero-engine performance, it's urgent to develop new lightweight, high-temperature-resistant and long-life ceramic matrix composite guide vanes to solve the problem that the superalloy materials have reached their service temperature limit. This paper systematically reviews the current research progress of SiCf/SiC guide vanes from the service environment characteristics, material characteristics, manufacturing process, assessment method, and nondestructive testing technology, in order to provide a certain reference for the domestic relevant research work of ceramic matrix composite guide blades in the field of aeroengine.

With the further improvement of aero-engine performance, it's urgent to develop new lightweight, high-temperature-resistant and long-life ceramic matrix composite guide vanes to solve the problem that the superalloy materials have reached their service temperature limit. This paper systematically reviews the current research progress of SiCf/SiC guide vanes from the service environment characteristics, material characteristics, manufacturing process, assessment method, and nondestructive testing technology, in order to provide a certain reference for the domestic relevant research work of ceramic matrix composite guide blades in the field of aeroengine.

2023, 40(8): 4355-4373.

doi: 10.13801/j.cnki.fhclxb.20221222.002

Abstract:

In the synthesis of polymers and polymer composites, it is still a challenge to observe the real-time and dynamic evolution of material structure and provide implications for property prediction. As one of the methods to characterize the microscopic and submicroscopic structures of substances, small angle X-ray Scattering (SAXS) technology can reflect unique microscopic conformational information, and can systematically study the morphological characteristics and formation process of chain-like, network-like, and layered polymers. The analysis of the formation mechanism of the aggregated structure of molecular materials, and their macroscopic performance prediction are very important. In this paper, three common methods for SAXS applications in current polymer materials research were presented, i.e., the peak observation, the model fitting, and the annular integration. Based on the above three methods, this paper introduced the practical functions of SAXS in studying different polymer materials, such as dynamic observation of the microstructural evolution process, and obtaining large-scale and statistically significant microstructural parameters. After comparing and evaluating the application methods and influences of SAXS in different polymer materials, it was concluded that SAXS plays a comprehensive role that is difficult to replicate in the study of complex polymer materials. It was hoped that this paper could serve as a primer to attract researchers' attention to understand SAXS technology, provide alternative research methods for the investigation of complex polymers, and expand the application of SAXS in wider fields to solve more problems.

In the synthesis of polymers and polymer composites, it is still a challenge to observe the real-time and dynamic evolution of material structure and provide implications for property prediction. As one of the methods to characterize the microscopic and submicroscopic structures of substances, small angle X-ray Scattering (SAXS) technology can reflect unique microscopic conformational information, and can systematically study the morphological characteristics and formation process of chain-like, network-like, and layered polymers. The analysis of the formation mechanism of the aggregated structure of molecular materials, and their macroscopic performance prediction are very important. In this paper, three common methods for SAXS applications in current polymer materials research were presented, i.e., the peak observation, the model fitting, and the annular integration. Based on the above three methods, this paper introduced the practical functions of SAXS in studying different polymer materials, such as dynamic observation of the microstructural evolution process, and obtaining large-scale and statistically significant microstructural parameters. After comparing and evaluating the application methods and influences of SAXS in different polymer materials, it was concluded that SAXS plays a comprehensive role that is difficult to replicate in the study of complex polymer materials. It was hoped that this paper could serve as a primer to attract researchers' attention to understand SAXS technology, provide alternative research methods for the investigation of complex polymers, and expand the application of SAXS in wider fields to solve more problems.

2023, 40(8): 4374-4389.

doi: 10.13801/j.cnki.fhclxb.20230328.001

Abstract:

Hydrogen energy is considered as the most ideal alternative renewable energy of fossil energy in the future. Electrochemical water splitting is the most effective approach to produce hydrogen. Design and development of high-efficient, stable and low-cost electrocatalyst is of significant urgence and importance to realize the large-scale production of hydrogen and oxygen from water splitting. Transition metal chalcogenides have become ideal electrocatalysts for water splitting due to their intrinsic electrocatalytic activities and abundant chemical phase compositions, among which CoSe2 with layered structure is the most representative transition metal selenides. Metal organic frameworks (MOFs) possess highly-ordered porous structures and large specific surface area. The MOF-derived CoSe2 electrocatalysts can inherit the structural advantages of their MOF precursors. These kinds of MOF-derived synthetic methods are the most effective method to further improve the electrocatalytic activity of water splitting. This review summarizes the recent significant advances of MOF derived CoSe2-based electrocatalysts for overall water splitting. The crystal structure and phase transformation of CoSe2 are briefly introduced, and the synthetic methods of MOF derived CoSe2-based electrocatalysts are described. Furthermore, the effective ways to enhance the performance of hydrogen evolution reaction and oxygen evolution reaction of MOF derived CoSe2-based electrocatalysts are emphatically elucidated. Finally, future research perspectives of MOF derived CoSe2-based electrocatalysts in the field of water splitting are prospected.

Hydrogen energy is considered as the most ideal alternative renewable energy of fossil energy in the future. Electrochemical water splitting is the most effective approach to produce hydrogen. Design and development of high-efficient, stable and low-cost electrocatalyst is of significant urgence and importance to realize the large-scale production of hydrogen and oxygen from water splitting. Transition metal chalcogenides have become ideal electrocatalysts for water splitting due to their intrinsic electrocatalytic activities and abundant chemical phase compositions, among which CoSe2 with layered structure is the most representative transition metal selenides. Metal organic frameworks (MOFs) possess highly-ordered porous structures and large specific surface area. The MOF-derived CoSe2 electrocatalysts can inherit the structural advantages of their MOF precursors. These kinds of MOF-derived synthetic methods are the most effective method to further improve the electrocatalytic activity of water splitting. This review summarizes the recent significant advances of MOF derived CoSe2-based electrocatalysts for overall water splitting. The crystal structure and phase transformation of CoSe2 are briefly introduced, and the synthetic methods of MOF derived CoSe2-based electrocatalysts are described. Furthermore, the effective ways to enhance the performance of hydrogen evolution reaction and oxygen evolution reaction of MOF derived CoSe2-based electrocatalysts are emphatically elucidated. Finally, future research perspectives of MOF derived CoSe2-based electrocatalysts in the field of water splitting are prospected.

2023, 40(8): 4390-4415.

doi: 10.13801/j.cnki.fhclxb.20230403.001

Abstract:

Due to the large volume variation of silicon and the poor conductivity, it is difficult to commercialize this anode material with a capacity of up to 4200 mA·h·g−1. The silicon/carbon anode of the yolk-shell structure is currently a hot spot in the research of silicon/carbon anode materials for lithium-ion batteries, which can well alleviate a series of problems caused by volume expansion of silicon anode during the charging and discharging process, so as to obtain superior lithium storage performance. In this paper, the carbon source, structure type and preparation process of the silicon/carbon anode of the yolk-shell structure are classified and summarized, and some important structural parameters are elaborated, and the development direction of the silicon/carbon anode of the yolk-shell structure is prospected in the future.

Due to the large volume variation of silicon and the poor conductivity, it is difficult to commercialize this anode material with a capacity of up to 4200 mA·h·g−1. The silicon/carbon anode of the yolk-shell structure is currently a hot spot in the research of silicon/carbon anode materials for lithium-ion batteries, which can well alleviate a series of problems caused by volume expansion of silicon anode during the charging and discharging process, so as to obtain superior lithium storage performance. In this paper, the carbon source, structure type and preparation process of the silicon/carbon anode of the yolk-shell structure are classified and summarized, and some important structural parameters are elaborated, and the development direction of the silicon/carbon anode of the yolk-shell structure is prospected in the future.

2023, 40(8): 4416-4439.

doi: 10.13801/j.cnki.fhclxb.20230227.003

Abstract:

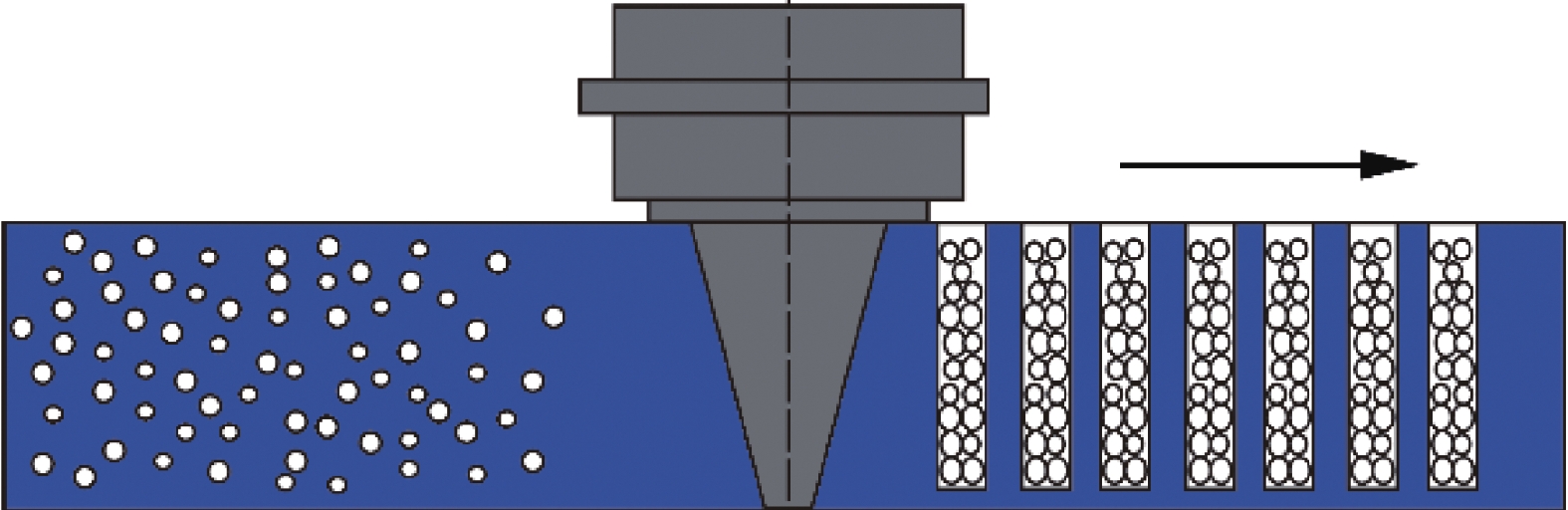

The research on the generated cutting heat and cooling strategies plays a crucial role in the optimization of process parameters and the control of hole's surface quality in drilling of fiber reinforced composite (FRC). In this paper, the review and prospect on the drilling heat during drilling FRC is systematically analyzed and summarized from three aspects: The theoretical research of drilling heat, research on the influence of drilling heat on machining quality, influencing factors and control strategies of drilling heat during drilling. Firstly, the theoretical research of drilling heat formation mechanism, heat conduction and heat damage prediction, and numerical simulation of cutting heat in FRC drilling process were summarized. Then, the main measurement methods of FRC drilling heat and the effect of cutting heat on the quality of hole machining were introduced. Meanwhile, the influencing factors of cutting heat and its auxiliary processing methods to control FRC drilling heat were discussed. Finally, the current existing problems and key points on the next study of FRC drilling heat were summarized.

The research on the generated cutting heat and cooling strategies plays a crucial role in the optimization of process parameters and the control of hole's surface quality in drilling of fiber reinforced composite (FRC). In this paper, the review and prospect on the drilling heat during drilling FRC is systematically analyzed and summarized from three aspects: The theoretical research of drilling heat, research on the influence of drilling heat on machining quality, influencing factors and control strategies of drilling heat during drilling. Firstly, the theoretical research of drilling heat formation mechanism, heat conduction and heat damage prediction, and numerical simulation of cutting heat in FRC drilling process were summarized. Then, the main measurement methods of FRC drilling heat and the effect of cutting heat on the quality of hole machining were introduced. Meanwhile, the influencing factors of cutting heat and its auxiliary processing methods to control FRC drilling heat were discussed. Finally, the current existing problems and key points on the next study of FRC drilling heat were summarized.

2023, 40(8): 4440-4459.

doi: 10.13801/j.cnki.fhclxb.20230119.005

Abstract:

With the rapid development of aerospace, military, and electronic technologies, packaging methods and packaging materials have become important constraints for electronic devices to further achieve miniaturization, lightweight, and high performance. Phased array radar T/R module packaging materials have experienced from the first generation of Kovar alloy to the second generation of copper-tungsten alloy, and the emergence of the third generation of lightweight materials with aluminum as the matrix in recent years-silicon carbide particle reinforced aluminum matrix composite material and high silicon aluminum alloy, and the problems in the preparation and processing technology of the two have become an important bottleneck restricting the comprehensive promotion and application of the third generation of materials. In this paper, the preparation methods, machining properties, welding processes, and surface treatment of the new generation of packaging materials are reviewed, and the research technology status of the processing and application of the new generation of phased array radar T/R module packaging composites is introduced in detail, and its development trend prospects.

With the rapid development of aerospace, military, and electronic technologies, packaging methods and packaging materials have become important constraints for electronic devices to further achieve miniaturization, lightweight, and high performance. Phased array radar T/R module packaging materials have experienced from the first generation of Kovar alloy to the second generation of copper-tungsten alloy, and the emergence of the third generation of lightweight materials with aluminum as the matrix in recent years-silicon carbide particle reinforced aluminum matrix composite material and high silicon aluminum alloy, and the problems in the preparation and processing technology of the two have become an important bottleneck restricting the comprehensive promotion and application of the third generation of materials. In this paper, the preparation methods, machining properties, welding processes, and surface treatment of the new generation of packaging materials are reviewed, and the research technology status of the processing and application of the new generation of phased array radar T/R module packaging composites is introduced in detail, and its development trend prospects.

2023, 40(8): 4460-4470.

doi: 10.13801/j.cnki.fhclxb.20221014.005

Abstract:

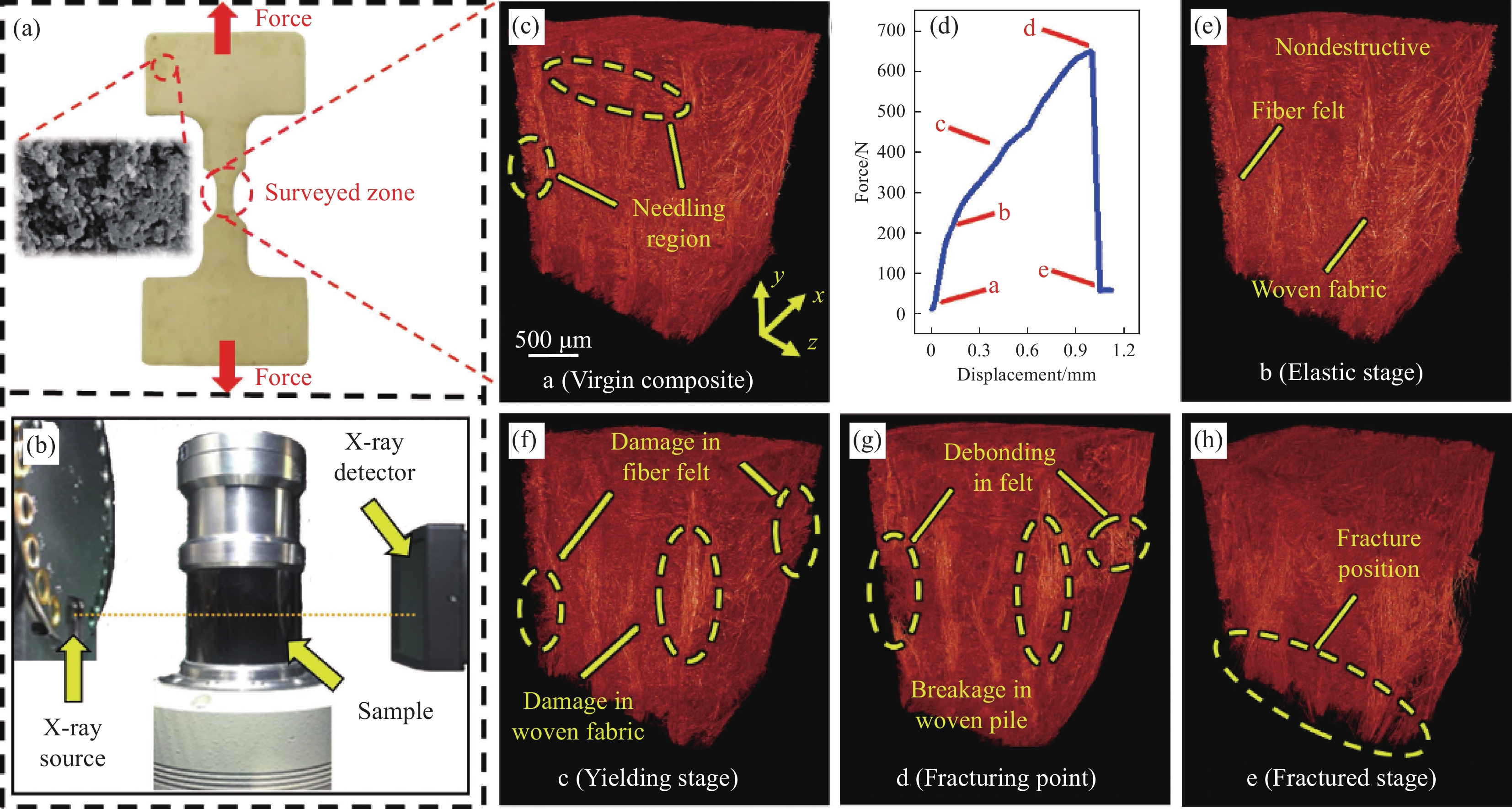

Alternately stacking needling technology is a straight forward way to prepare three-dimensional (3D) fabrics, but randomly needling process will bring great challenges to the damage evolution, mechanical analysis and property prediction. In this paper, the damage evolution of nanoporous phenolic composites reinforced by alternately stacking fiber felt and woven fabric was revealed by in-situ X-ray Micro-CT device. And the angle deflections of fiber were described quantitatively under the loading of axial tensile by automatic tracing of microtubule centerlines. Finally, based on the 3D reconstructed structure, a high-precision finite element analysis model was established, and the axial tension mechanical behavior analysis was carried out. The results show that the damage in composite starts from the outmost layer where the microcracks in the fiber felt mainly originate from the resin-rich zone in the needling area, while the microcracks in the woven fabric are among filaments in fiber bundle. Besides, the woven fabric can improve the toughness of composite by preventing the microcrack expanding into the inner. The fibers in composite will consistently deflect to the outside, showing the property of negative Poisson's ratio, avoiding the "neck contraction" phenomenon at the fracture. The finite element analysis agrees with the results of experiments. The methods and results in this paper can provide a precious reference for microscopic fracture analysis, property prediction and structural optimization of complex 3D composite.

Alternately stacking needling technology is a straight forward way to prepare three-dimensional (3D) fabrics, but randomly needling process will bring great challenges to the damage evolution, mechanical analysis and property prediction. In this paper, the damage evolution of nanoporous phenolic composites reinforced by alternately stacking fiber felt and woven fabric was revealed by in-situ X-ray Micro-CT device. And the angle deflections of fiber were described quantitatively under the loading of axial tensile by automatic tracing of microtubule centerlines. Finally, based on the 3D reconstructed structure, a high-precision finite element analysis model was established, and the axial tension mechanical behavior analysis was carried out. The results show that the damage in composite starts from the outmost layer where the microcracks in the fiber felt mainly originate from the resin-rich zone in the needling area, while the microcracks in the woven fabric are among filaments in fiber bundle. Besides, the woven fabric can improve the toughness of composite by preventing the microcrack expanding into the inner. The fibers in composite will consistently deflect to the outside, showing the property of negative Poisson's ratio, avoiding the "neck contraction" phenomenon at the fracture. The finite element analysis agrees with the results of experiments. The methods and results in this paper can provide a precious reference for microscopic fracture analysis, property prediction and structural optimization of complex 3D composite.

2023, 40(8): 4471-4480.

doi: 10.13801/j.cnki.fhclxb.20221102.001

Abstract:

Introducing viscoelastic damping layer into composites is an effective method to improve the composite structural vibration characteristics. The vacuum assisted resin transfer molding (VARTM) process of sandwich composites with perforated silicone rubber was investigated by experiment and simulation. Firstly, the equivalent permeability of fiber reinforced materials and its combination with the flow medium were tested under constant pressure injection conditions. Then, the VARTM platform was set up to observe mold filling experiment in the laboratory. The resin filling model was established based on the RTM-Worx software. The validity of the simulation model was verified by comparing the experimental resin flow diagram and the filling area with simulated results at different time. Finally, the effects of the parameters such as the spacing between columns, the row spacing, the diameter of the holes in the damping layer and the "edge effect" on the resin filling time and the filling process were discussed. The results show that the simulation model can better predict the resin flow behavior, and unreasonable parameters of damping layer can affect the resin flow and even lead to defects.

Introducing viscoelastic damping layer into composites is an effective method to improve the composite structural vibration characteristics. The vacuum assisted resin transfer molding (VARTM) process of sandwich composites with perforated silicone rubber was investigated by experiment and simulation. Firstly, the equivalent permeability of fiber reinforced materials and its combination with the flow medium were tested under constant pressure injection conditions. Then, the VARTM platform was set up to observe mold filling experiment in the laboratory. The resin filling model was established based on the RTM-Worx software. The validity of the simulation model was verified by comparing the experimental resin flow diagram and the filling area with simulated results at different time. Finally, the effects of the parameters such as the spacing between columns, the row spacing, the diameter of the holes in the damping layer and the "edge effect" on the resin filling time and the filling process were discussed. The results show that the simulation model can better predict the resin flow behavior, and unreasonable parameters of damping layer can affect the resin flow and even lead to defects.

2023, 40(8): 4481-4490.

doi: 10.13801/j.cnki.fhclxb.20221111.002

Abstract:

The interfacial strength between PAEK resin matrix and domestic T300 grade carbon fiber (SCF35) carbon fiber was studied by microsphere debonding method for domestic high performance poly aryl ether ketone (PAEK-L, PAEK-H) resins with different characteristics. The composites were prepared by using domestic carbon fiber reinforced poly aryl ether ketone (SCF35/PAEK) thermoplastic prepreg, and the effects of resin matrix on 90° tensile properties, short beam shear properties, type I fracture toughness and type II fracture toughness of the composites were studied. The results show that the interfacial properties of SCF35/PAEK composites are influenced by the fluidity of the resin matrix, and PAEK-H resin with higher fluidity can form a better interfacial bond with the fibers and higher interfacial strength. In the SCF35/PAEK-H composite, the resin-fiber contact angle is ~34.4°, the interfacial shear strength is ~79 MPa, the 90° tensile strength of the composite is ~76 MPa, the modulus is ~9.7 GPa, and the short-beam shear strength is ~92 MPa. While in the lower-fluidity PAEK-L resin and SCF35 carbon fiber composite, the resin-fiber contact angle of ~35.8°, interfacial shear strength of ~64 MPa, composite 90° tensile strength of ~55 MPa, modulus of ~8.6 GPa, and short-beam shear strength of ~86 MPa. The interlaminar properties of SCF35/PAEK composites are influenced by the plastic deformation ability of the resin matrix. PAEK-L, which has a stronger plastic deformation ability of the matrix, has a higher fracture toughness than PAEK-H. The type I fracture toughness of SCF35/PAEK-L is ~938 J/m2 and the type II fracture toughness is ~2232 J/m2, and the type I fracture toughness of SCF35/PAEK-H is ~638 J/m2 and the type II fracture toughness is ~1702 J/m2.

The interfacial strength between PAEK resin matrix and domestic T300 grade carbon fiber (SCF35) carbon fiber was studied by microsphere debonding method for domestic high performance poly aryl ether ketone (PAEK-L, PAEK-H) resins with different characteristics. The composites were prepared by using domestic carbon fiber reinforced poly aryl ether ketone (SCF35/PAEK) thermoplastic prepreg, and the effects of resin matrix on 90° tensile properties, short beam shear properties, type I fracture toughness and type II fracture toughness of the composites were studied. The results show that the interfacial properties of SCF35/PAEK composites are influenced by the fluidity of the resin matrix, and PAEK-H resin with higher fluidity can form a better interfacial bond with the fibers and higher interfacial strength. In the SCF35/PAEK-H composite, the resin-fiber contact angle is ~34.4°, the interfacial shear strength is ~79 MPa, the 90° tensile strength of the composite is ~76 MPa, the modulus is ~9.7 GPa, and the short-beam shear strength is ~92 MPa. While in the lower-fluidity PAEK-L resin and SCF35 carbon fiber composite, the resin-fiber contact angle of ~35.8°, interfacial shear strength of ~64 MPa, composite 90° tensile strength of ~55 MPa, modulus of ~8.6 GPa, and short-beam shear strength of ~86 MPa. The interlaminar properties of SCF35/PAEK composites are influenced by the plastic deformation ability of the resin matrix. PAEK-L, which has a stronger plastic deformation ability of the matrix, has a higher fracture toughness than PAEK-H. The type I fracture toughness of SCF35/PAEK-L is ~938 J/m2 and the type II fracture toughness is ~2232 J/m2, and the type I fracture toughness of SCF35/PAEK-H is ~638 J/m2 and the type II fracture toughness is ~1702 J/m2.

2023, 40(8): 4491-4505.

doi: 10.13801/j.cnki.fhclxb.20220927.002

Abstract:

Polylactide (PLA) cross-shaped ribbed plates and Voronoi-based closed-cell foam structures were prepared using 3D printing technology. A rib-reinforced foam partition-filled thin-walled tube structure (RFFT) was proposed and the crushing performance of RFFT under quasi-static lateral compression was investigated. The results show that the failure sequence of the constituent elements within RFFT structure as well as the interaction between the elements changes with the location of the lateral load. Typically, for RFFT structures, the force-displacement responses and the crushing performance (i.e., the peak force, the mean crush force, the specific energy absorption, and the crush force efficiency) exhibit anisotropic characteristics. For two typical loading scenarios (i.e., lateral loads acting on the foam-filled and -unfilled zones of RFFT structure), the specific energy absorption of RFFT structure is increased by 125.16% and 129.22%, respectively, compared to the empty tube structure, whereas the peak force is found to be reduced by 5.54% and 31.28% compared to the fully foam-filled structure. Moreover, the finite element model was adopted to analyze the influence of design parameters and reveal the energy absorption mechanism of the partition foam-filled structure. Finally, the complex proportional assessment method was introduced to comprehensively evaluate the crashworthiness of RFFT structure with multiple indicators.

Polylactide (PLA) cross-shaped ribbed plates and Voronoi-based closed-cell foam structures were prepared using 3D printing technology. A rib-reinforced foam partition-filled thin-walled tube structure (RFFT) was proposed and the crushing performance of RFFT under quasi-static lateral compression was investigated. The results show that the failure sequence of the constituent elements within RFFT structure as well as the interaction between the elements changes with the location of the lateral load. Typically, for RFFT structures, the force-displacement responses and the crushing performance (i.e., the peak force, the mean crush force, the specific energy absorption, and the crush force efficiency) exhibit anisotropic characteristics. For two typical loading scenarios (i.e., lateral loads acting on the foam-filled and -unfilled zones of RFFT structure), the specific energy absorption of RFFT structure is increased by 125.16% and 129.22%, respectively, compared to the empty tube structure, whereas the peak force is found to be reduced by 5.54% and 31.28% compared to the fully foam-filled structure. Moreover, the finite element model was adopted to analyze the influence of design parameters and reveal the energy absorption mechanism of the partition foam-filled structure. Finally, the complex proportional assessment method was introduced to comprehensively evaluate the crashworthiness of RFFT structure with multiple indicators.

2023, 40(8): 4506-4516.

doi: 10.13801/j.cnki.fhclxb.20221104.001

Abstract:

Biaxial warp-knitted glass fabric and quadriaxial warp-knitted glass fabric were used as reinforcement, respectively. The flat and curved structure samples were prepared by applying the vacuum assisted resin transfer molding process. The bending behavior and quasi-static indentation characteristics of composite specimen were experimentally tested, and the influence of the reinforcement structure on the bending behavior of the composite in 0° and 90° directions was analyzed. On this basis, the influences of the reinforcement structure and the radius of curvature of the sample on the quasi-static indentation characteristics were also analyzed. Results show that the equivalent bending strength of the composite reinforced with biaxial warp-knitted fabric in 0° and 90° directions increase by 94.74% and 98.37%, respectively in comparison with that of the quadriaxial warp-knitted fabric, and the maximum fracture strain of the quadriaxial warp-knitted fabric in 0° and 90° directions are 1.9 times and 2.4 times than that of the biaxial warp-knitted fabric. When the curvature radius of biaxial composite is 260 mm and the curvature radius of quadriaxial composite is 150 mm, the bending strength of the two materials are optimal. When the curvature radius of biaxial composite is 150 mm and the curvature radius of quadriaxial composite is 80 mm, the fracture strain of the two composites are optimal. The experimental results will provide guidance for application of curved structure composite in various large outdoor building domes.

Biaxial warp-knitted glass fabric and quadriaxial warp-knitted glass fabric were used as reinforcement, respectively. The flat and curved structure samples were prepared by applying the vacuum assisted resin transfer molding process. The bending behavior and quasi-static indentation characteristics of composite specimen were experimentally tested, and the influence of the reinforcement structure on the bending behavior of the composite in 0° and 90° directions was analyzed. On this basis, the influences of the reinforcement structure and the radius of curvature of the sample on the quasi-static indentation characteristics were also analyzed. Results show that the equivalent bending strength of the composite reinforced with biaxial warp-knitted fabric in 0° and 90° directions increase by 94.74% and 98.37%, respectively in comparison with that of the quadriaxial warp-knitted fabric, and the maximum fracture strain of the quadriaxial warp-knitted fabric in 0° and 90° directions are 1.9 times and 2.4 times than that of the biaxial warp-knitted fabric. When the curvature radius of biaxial composite is 260 mm and the curvature radius of quadriaxial composite is 150 mm, the bending strength of the two materials are optimal. When the curvature radius of biaxial composite is 150 mm and the curvature radius of quadriaxial composite is 80 mm, the fracture strain of the two composites are optimal. The experimental results will provide guidance for application of curved structure composite in various large outdoor building domes.

2023, 40(8): 4517-4530.

doi: 10.13801/j.cnki.fhclxb.20221110.003

Abstract:

There are great potential and application space of carbon fibre reinforced plastics (CFRP) in lightweight vehicle body manufacturing, and realizing effective connection of the material is still a great challenge. The connection process between CFRP and aluminum alloy plate was explored using self-piercing riveting (SPR) technology, and the effects of rivet type, punching speed and riveting die dimension on joint structural parameters were summarized, then the forming mechanism of undercut structure in the riveting process was analyzed, the strength performance and failure mode of joints with various plate thicknesses were also investigated. It is found that the undercut value of SPR joint is affected by both the penetration depth of the rivet shank into the lower plate and the local moment on the rivet toe, and increases with the rise of the effective rivet length, the punching speed and the depth of the die. Through process optimization, SPR joints between CFRP and aluminum plates with good forming structure can be obtained, and the mechanical internal locking strength can reach 89% of that of aluminum alloy plates joint. However, compared with aluminum alloy joint with the same plate thickness, the outstanding weakness of CFRP joint is the ability of its CFRP upper plate to resist concentrated stress damage.

There are great potential and application space of carbon fibre reinforced plastics (CFRP) in lightweight vehicle body manufacturing, and realizing effective connection of the material is still a great challenge. The connection process between CFRP and aluminum alloy plate was explored using self-piercing riveting (SPR) technology, and the effects of rivet type, punching speed and riveting die dimension on joint structural parameters were summarized, then the forming mechanism of undercut structure in the riveting process was analyzed, the strength performance and failure mode of joints with various plate thicknesses were also investigated. It is found that the undercut value of SPR joint is affected by both the penetration depth of the rivet shank into the lower plate and the local moment on the rivet toe, and increases with the rise of the effective rivet length, the punching speed and the depth of the die. Through process optimization, SPR joints between CFRP and aluminum plates with good forming structure can be obtained, and the mechanical internal locking strength can reach 89% of that of aluminum alloy plates joint. However, compared with aluminum alloy joint with the same plate thickness, the outstanding weakness of CFRP joint is the ability of its CFRP upper plate to resist concentrated stress damage.

2023, 40(8): 4531-4538.

doi: 10.13801/j.cnki.fhclxb.20221115.001

Abstract:

Self-passivating W alloys exhibit excellent high temperature oxidation resistance and are expected to be used in key components in high temperature environments. In order to reveal the relationship between the microstructure and high temperature oxidation resistance of the alloy, a self-passivating W-Si alloy was prepared by mechanical alloying method combined with spark plasma sintering. The effect of different mechanical alloying time on the microstructure of the alloy was studied. And the high temperature oxidation resistance of the alloys was investigated. The results show that the alloys are composed of W, W5Si3 and SiOx phases. When the ball milling time increases from 4 h to 20 h, the content of SiOx in the alloys increases from 16.2% to 23.6%, while the content of W5Si3 decreases from 57.8% to 43.6%, and the grain sizes of W and W5Si3 are both reduced. The grain refinement contri-butes to the improvement of the microhardness of the alloys. After oxidized at 1000 ℃ for 10 h, the mass gain of the alloy prepared by ball milling for 4 h is 37.4 mg, while that of the alloy prepared by ball milling for 20 h reaches 141.6 mg, and their oxide layer thicknesses are about 167.0 μm and 415.7 μm, respectively. The alloy prepared with short ball milling time has better oxidation resistance, because the W5Si3 in this alloy is a continuous phase. The WO3/SiO2 composite oxide formed by in situ oxidation of W5Si3 is also a continuous phase, forming a protective oxide layer and effectively inhibiting the internal oxidation of the alloy.

Self-passivating W alloys exhibit excellent high temperature oxidation resistance and are expected to be used in key components in high temperature environments. In order to reveal the relationship between the microstructure and high temperature oxidation resistance of the alloy, a self-passivating W-Si alloy was prepared by mechanical alloying method combined with spark plasma sintering. The effect of different mechanical alloying time on the microstructure of the alloy was studied. And the high temperature oxidation resistance of the alloys was investigated. The results show that the alloys are composed of W, W5Si3 and SiOx phases. When the ball milling time increases from 4 h to 20 h, the content of SiOx in the alloys increases from 16.2% to 23.6%, while the content of W5Si3 decreases from 57.8% to 43.6%, and the grain sizes of W and W5Si3 are both reduced. The grain refinement contri-butes to the improvement of the microhardness of the alloys. After oxidized at 1000 ℃ for 10 h, the mass gain of the alloy prepared by ball milling for 4 h is 37.4 mg, while that of the alloy prepared by ball milling for 20 h reaches 141.6 mg, and their oxide layer thicknesses are about 167.0 μm and 415.7 μm, respectively. The alloy prepared with short ball milling time has better oxidation resistance, because the W5Si3 in this alloy is a continuous phase. The WO3/SiO2 composite oxide formed by in situ oxidation of W5Si3 is also a continuous phase, forming a protective oxide layer and effectively inhibiting the internal oxidation of the alloy.

2023, 40(8): 4539-4548.

doi: 10.13801/j.cnki.fhclxb.20221205.003

Abstract:

CO emission from iron and steel sintering flue gas has been paid more and more attention. However, there is a lack of efficient and practical CO removal technology for large flow flue gas. A series of coated catalysts were prepared by coating powder catalyst on cordierite honeycomb ceramic supports. The physicochemical properties of the coated catalysts were analyzed based on a series of characterization techniques, and the catalytic performance of CO was evaluated under actual sintering flue gas conditions. The results show that 1wt‰ polyvinyl alcohol content of slurry and 300℃ calcination could promote the uniformity of powder catalyst distribution on the surface of the support, and improve the ratio of Mn4+/Mn3+and Oads/Olatt. The coating shedding rate of the optimized coated catalyst is 1.25% after 60 min ultrasonic vibration. The catalytic efficiency of 99%CO can be achieved at 7500 h−1 space speed, 1%CO, 8% water vapour content and 110℃, and remains stable within 72 h. Based on the actual desulfurization of sintering flue gas in a steel plant, the efficiency can be stable above 82% after 720 h. The study can provide reference for the application of CO removal technology for industrial flue gas.

CO emission from iron and steel sintering flue gas has been paid more and more attention. However, there is a lack of efficient and practical CO removal technology for large flow flue gas. A series of coated catalysts were prepared by coating powder catalyst on cordierite honeycomb ceramic supports. The physicochemical properties of the coated catalysts were analyzed based on a series of characterization techniques, and the catalytic performance of CO was evaluated under actual sintering flue gas conditions. The results show that 1wt‰ polyvinyl alcohol content of slurry and 300℃ calcination could promote the uniformity of powder catalyst distribution on the surface of the support, and improve the ratio of Mn4+/Mn3+and Oads/Olatt. The coating shedding rate of the optimized coated catalyst is 1.25% after 60 min ultrasonic vibration. The catalytic efficiency of 99%CO can be achieved at 7500 h−1 space speed, 1%CO, 8% water vapour content and 110℃, and remains stable within 72 h. Based on the actual desulfurization of sintering flue gas in a steel plant, the efficiency can be stable above 82% after 720 h. The study can provide reference for the application of CO removal technology for industrial flue gas.

2023, 40(8): 4549-4557.

doi: 10.13801/j.cnki.fhclxb.20221209.001

Abstract:

In order to effectively monitor isobutylene gas, Cr2O3 and W-doped Cr2O3 (W/Cr2O3) films were successfully synthesized via aerosol-assisted chemical vapor deposition (AACVD) technique on the surface of alumina substrate. The microstructure, crystal structure, and elemental binding valence of Cr2O3 and W/Cr2O3 films were analyzed by SEM, TEM, XRD and XPS. The results show that Cr2O3 film is composed of nanoparticles with the particle size of about 50 nm, a thickness of about 20 μm, and its structure is relatively loose. However, the thin film obtained by W doping Cr2O3 has a compact structure, and the size of nanoparticles is about 15 nm, which is remarkably reduced due to the introduction of W into the Cr2O3 crystal lattice. Both Cr2O3 and W/Cr2O3 films have a single hexagonal crystalline structure. The gas sensitivity test results show that the sensitivity of the gas sensor based on W/Cr2O3 film towards 2×10–5 isobutene increases from 1.11 to 3.55 compared with the Cr2O3 gas sensor at 400℃, and W/Cr2O3 gas sensor exhibits good stability, moisture resistance and gas selectivity.

In order to effectively monitor isobutylene gas, Cr2O3 and W-doped Cr2O3 (W/Cr2O3) films were successfully synthesized via aerosol-assisted chemical vapor deposition (AACVD) technique on the surface of alumina substrate. The microstructure, crystal structure, and elemental binding valence of Cr2O3 and W/Cr2O3 films were analyzed by SEM, TEM, XRD and XPS. The results show that Cr2O3 film is composed of nanoparticles with the particle size of about 50 nm, a thickness of about 20 μm, and its structure is relatively loose. However, the thin film obtained by W doping Cr2O3 has a compact structure, and the size of nanoparticles is about 15 nm, which is remarkably reduced due to the introduction of W into the Cr2O3 crystal lattice. Both Cr2O3 and W/Cr2O3 films have a single hexagonal crystalline structure. The gas sensitivity test results show that the sensitivity of the gas sensor based on W/Cr2O3 film towards 2×10–5 isobutene increases from 1.11 to 3.55 compared with the Cr2O3 gas sensor at 400℃, and W/Cr2O3 gas sensor exhibits good stability, moisture resistance and gas selectivity.

2023, 40(8): 4558-4567.

doi: 10.13801/j.cnki.fhclxb.20221103.001

Abstract:

Polymers such as polyvinylidene fluoride (PVDF) are limited by their low thermal conductivity, and it is important to enhance the thermal conductivity of polymer-based composites by adding thermally conductive fillers. In this paper, Al2O3-BNNS/PVDF composites with enhanced thermal conductivity were prepared by hot-compaction process using hexagonal boron nitride nanosheets (BNNS) and spherical alumina (Al2O3) as thermally conductive fillers. Firstly, BNNS nanofillers with thickness of 3-5 nm and diameter of 1-5 μm were prepared by exfoliation in green solvents consisting of choline chloride (ChCl) and aqueous phytic acid (PA). Then, based on the synergistic effect of BNNS and Al2O3 hybrid fillers, the thermally conductive composites with a pea pod-like structure were fabricated by solution blending-hot pressing, and a good three-dimensional heat conduction network was constructed. When 30wt%Al2O3 and 20wt%BNNS were added, the in-plane thermal conductivity of the composite was as high as 11.54 W/(m·K) and the vertical thermal conductivity was 5.70 W/(m·K). The thermal conductivity of the composite was greatly improved, showing excellent thermal performance.

Polymers such as polyvinylidene fluoride (PVDF) are limited by their low thermal conductivity, and it is important to enhance the thermal conductivity of polymer-based composites by adding thermally conductive fillers. In this paper, Al2O3-BNNS/PVDF composites with enhanced thermal conductivity were prepared by hot-compaction process using hexagonal boron nitride nanosheets (BNNS) and spherical alumina (Al2O3) as thermally conductive fillers. Firstly, BNNS nanofillers with thickness of 3-5 nm and diameter of 1-5 μm were prepared by exfoliation in green solvents consisting of choline chloride (ChCl) and aqueous phytic acid (PA). Then, based on the synergistic effect of BNNS and Al2O3 hybrid fillers, the thermally conductive composites with a pea pod-like structure were fabricated by solution blending-hot pressing, and a good three-dimensional heat conduction network was constructed. When 30wt%Al2O3 and 20wt%BNNS were added, the in-plane thermal conductivity of the composite was as high as 11.54 W/(m·K) and the vertical thermal conductivity was 5.70 W/(m·K). The thermal conductivity of the composite was greatly improved, showing excellent thermal performance.

2023, 40(8): 4568-4576.

doi: 10.13801/j.cnki.fhclxb.20221129.002

Abstract:

Reversible solid oxide cell (RSOC) is a clean and efficient electrochemical conversion and storage devices. Due to the Sr segregation in the now available perovskite oxygen electrodes, new requirements are put forward for the durability of oxygen electrodes. Y0.08Zr0.92O2-δ/Er0.4Bi1.6O3 (YSZ/ESB) composite electrolyte and Ca3Co4O9+δ (CCO) oxygen electrode were prepared by solution impregnation method in this paper. The polarization resistance of CCO oxygen electrode at 800°C was 0.45 Ω·cm2. The oxygen electrode showed superior durability in the process of alternating anodic and cathodic polarization for 100 h. Anodic and cathodic polarization displayed opposite influence mechanisms on the electrode performance. The degradation induced in the electrolysis mode can be eliminated by reversibly cycling between electrolysis and fuel-cell modes. The Ni-YSZ/YSZ/ESB/CCO single cell obtained a maximum power density of 722 mW·cm−2 at 800℃. The electrolysis current density at 1.5 V was 1204 mA·cm−2, which corresponded to the hydrogen production rate of 503.3 mL·cm−2·h−1. Results showed that CCO with good reversible polarization performance and long-term stability achieved a high energy conversion rate.

Reversible solid oxide cell (RSOC) is a clean and efficient electrochemical conversion and storage devices. Due to the Sr segregation in the now available perovskite oxygen electrodes, new requirements are put forward for the durability of oxygen electrodes. Y0.08Zr0.92O2-δ/Er0.4Bi1.6O3 (YSZ/ESB) composite electrolyte and Ca3Co4O9+δ (CCO) oxygen electrode were prepared by solution impregnation method in this paper. The polarization resistance of CCO oxygen electrode at 800°C was 0.45 Ω·cm2. The oxygen electrode showed superior durability in the process of alternating anodic and cathodic polarization for 100 h. Anodic and cathodic polarization displayed opposite influence mechanisms on the electrode performance. The degradation induced in the electrolysis mode can be eliminated by reversibly cycling between electrolysis and fuel-cell modes. The Ni-YSZ/YSZ/ESB/CCO single cell obtained a maximum power density of 722 mW·cm−2 at 800℃. The electrolysis current density at 1.5 V was 1204 mA·cm−2, which corresponded to the hydrogen production rate of 503.3 mL·cm−2·h−1. Results showed that CCO with good reversible polarization performance and long-term stability achieved a high energy conversion rate.

2023, 40(8): 4577-4586.

doi: 10.13801/j.cnki.fhclxb.20221121.001

Abstract:

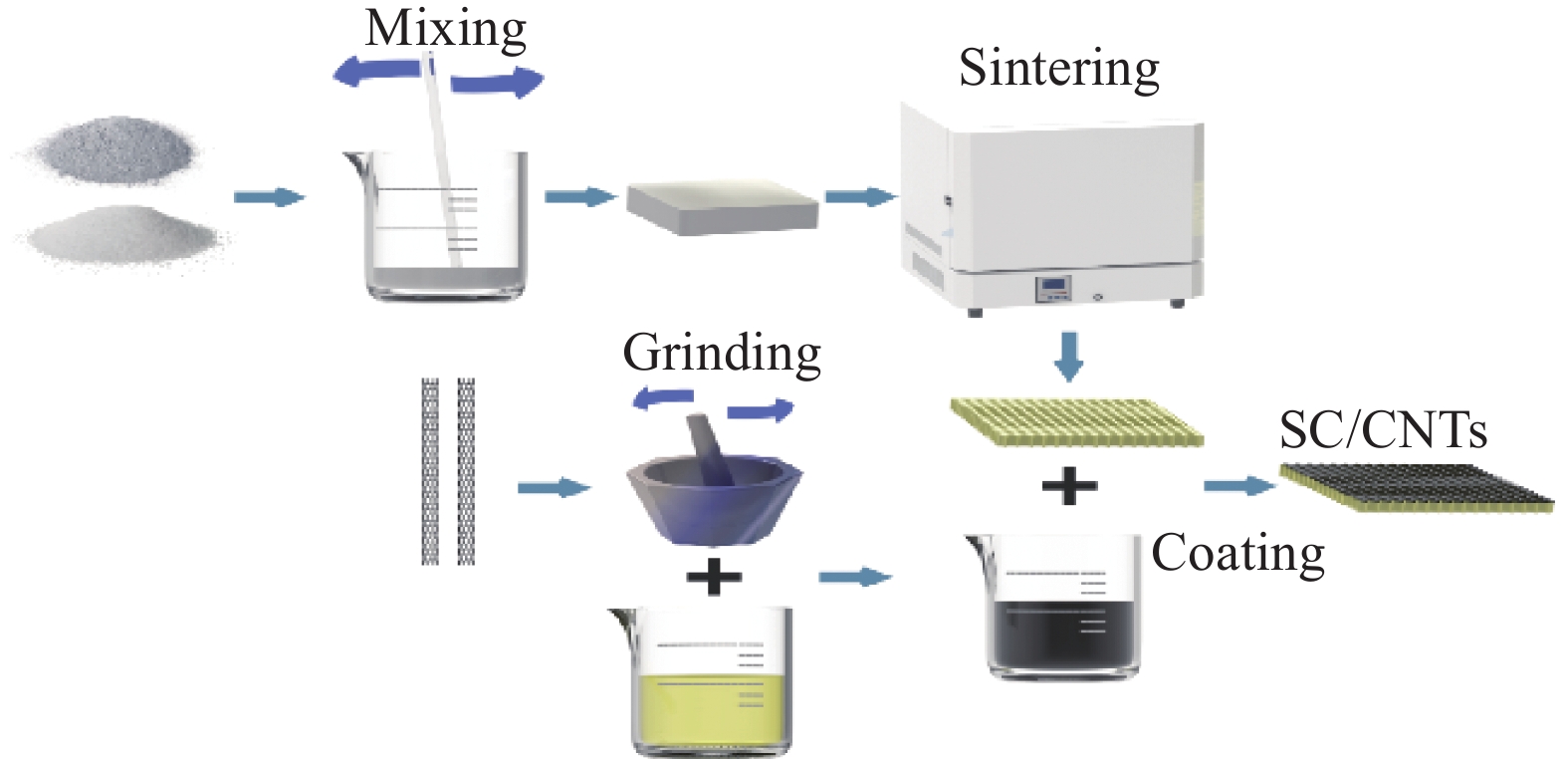

Interface solar steam generation technology provides an efficient and sustainable strategy for extracting fresh water from seawater and wastewater, which can effectively solve the current water crisis. In present work, diatomite based porous ceramics were prepared by grouting molding process by using natural diatomite as the main raw material and CaCO3 as the pore forming agent. Then, carbon nanotube/diatomite based porous ceramic composites were prepared successfully by surface modification of the diatomite based porous ceramics coating with the multi walled carbon nanotubes and sodium alginate mixed gel. Characterizations confirm that the diatomite based porous ceramics have a three-dimensional connected porous structure, and the pore size is mainly 10-30 µm. When the mass fraction of CaCO3 is 50wt%, the porosity can reach 73.2%. Owing to the multiple scattering effect and hydrophilicity of the porous structure and the excellent photothermal conversion ability of carbon nanotubes, the evaporator show excellent properties. Under one solar intensity, the evaporation rate and energy conversion efficiency of the evaporator are up to 2.07 kg·m−2·h−1 and 95.6%, respectively and maintains good cycle stability. Additionally, the ion rejection rate of seawater and wastewater for the evaporator can achieve nearly 100%. It shows broad application potential in the field of seawater desalination.

Interface solar steam generation technology provides an efficient and sustainable strategy for extracting fresh water from seawater and wastewater, which can effectively solve the current water crisis. In present work, diatomite based porous ceramics were prepared by grouting molding process by using natural diatomite as the main raw material and CaCO3 as the pore forming agent. Then, carbon nanotube/diatomite based porous ceramic composites were prepared successfully by surface modification of the diatomite based porous ceramics coating with the multi walled carbon nanotubes and sodium alginate mixed gel. Characterizations confirm that the diatomite based porous ceramics have a three-dimensional connected porous structure, and the pore size is mainly 10-30 µm. When the mass fraction of CaCO3 is 50wt%, the porosity can reach 73.2%. Owing to the multiple scattering effect and hydrophilicity of the porous structure and the excellent photothermal conversion ability of carbon nanotubes, the evaporator show excellent properties. Under one solar intensity, the evaporation rate and energy conversion efficiency of the evaporator are up to 2.07 kg·m−2·h−1 and 95.6%, respectively and maintains good cycle stability. Additionally, the ion rejection rate of seawater and wastewater for the evaporator can achieve nearly 100%. It shows broad application potential in the field of seawater desalination.

2023, 40(8): 4587-4600.

doi: 10.13801/j.cnki.fhclxb.20221102.004

Abstract:

Vanadium dioxide (VO2) can change infrared transmittance in response to external temperature changes, and has become the preferred material for thermochromic smart windows. The facile ball milling method is simple, easy to operate, short reaction time, less pollution, suitable for industrial production. However, there are still some problems with vanadium dioxide that may hinder large scale production and practical applications, such as poor stability and easily agglomeration. Here we report on the preparation of thermochromic coating based on VO2@polymethyl methacrylate (PMMA) microcapsule synthesized through in-situ polymerized method. Uniform VO2@PMMA microcapsules was obtained by in situ polymerization of double bonds on the surface of VO2 and methyl methacrylate (MMA) monomer. The space barrier effect of in-situ polymerized PMMA is used to prevent VO2 agglomeration. With good compactness PMMA prevent air and moisture from contacting VO2, which improve VO2 stability. VO2@PMMA films prepared by a roll coating method not only has good acid resistance and oxidation resistance, but also has excellent optical properties with the solar modulation efficiency (ΔTsol) 10.12% at 77.89% visible light transmittance (Tlum), which meets the application requirements of smart windows.

Vanadium dioxide (VO2) can change infrared transmittance in response to external temperature changes, and has become the preferred material for thermochromic smart windows. The facile ball milling method is simple, easy to operate, short reaction time, less pollution, suitable for industrial production. However, there are still some problems with vanadium dioxide that may hinder large scale production and practical applications, such as poor stability and easily agglomeration. Here we report on the preparation of thermochromic coating based on VO2@polymethyl methacrylate (PMMA) microcapsule synthesized through in-situ polymerized method. Uniform VO2@PMMA microcapsules was obtained by in situ polymerization of double bonds on the surface of VO2 and methyl methacrylate (MMA) monomer. The space barrier effect of in-situ polymerized PMMA is used to prevent VO2 agglomeration. With good compactness PMMA prevent air and moisture from contacting VO2, which improve VO2 stability. VO2@PMMA films prepared by a roll coating method not only has good acid resistance and oxidation resistance, but also has excellent optical properties with the solar modulation efficiency (ΔTsol) 10.12% at 77.89% visible light transmittance (Tlum), which meets the application requirements of smart windows.

2023, 40(8): 4601-4612.

doi: 10.13801/j.cnki.fhclxb.20221025.001

Abstract:

Fenton-like technology is one of the most promising water treatment technologies to remove refractory organic pollutants, and it is the key to construction Fenton-like catalysts with high activity and stability. In this work, a series of alkali-activated montmorillonite (Alk-MMT) with different structure and acidity were prepared via Ca-MMT treated with 5 mol/L NaOH solution at different treatment temperature. Fenton-like system composed with Alk-MMT supported iron catalyst (Fe/Alk-MMT) and H2O2 was used to remove methylene blue (MB). The material was systematically characterized by XRD, NH3-Temperature programmed desorption (TPD), XPS, SEM, FTIR, and N2 adsorption-desorption at low temperature techniques. The results show that the structure and acidity of Alk-MMT are significantly changed compared with Ca-MMT, which is dependent on the alkali treatment temperature. The structure and acidity of Alk-MMT obviously affect the removal performance of MB in Fenton-like system. The Fenton-like system using Fe/Alk-MMT-100 as catalyst exhibits higher removal efficiency of MB (> 98.7%) under the condition of 50℃, the catalyst dosage of 1.25 g/L, the H2O2 concentration of 0.85 mmol/L, and a wide pH (3.0-9.0) range for reacting 300 min. Meanwhile, the activity of the catalyst does not decrease after repeated use for 6 times, which exhibiting a good stability.

Fenton-like technology is one of the most promising water treatment technologies to remove refractory organic pollutants, and it is the key to construction Fenton-like catalysts with high activity and stability. In this work, a series of alkali-activated montmorillonite (Alk-MMT) with different structure and acidity were prepared via Ca-MMT treated with 5 mol/L NaOH solution at different treatment temperature. Fenton-like system composed with Alk-MMT supported iron catalyst (Fe/Alk-MMT) and H2O2 was used to remove methylene blue (MB). The material was systematically characterized by XRD, NH3-Temperature programmed desorption (TPD), XPS, SEM, FTIR, and N2 adsorption-desorption at low temperature techniques. The results show that the structure and acidity of Alk-MMT are significantly changed compared with Ca-MMT, which is dependent on the alkali treatment temperature. The structure and acidity of Alk-MMT obviously affect the removal performance of MB in Fenton-like system. The Fenton-like system using Fe/Alk-MMT-100 as catalyst exhibits higher removal efficiency of MB (> 98.7%) under the condition of 50℃, the catalyst dosage of 1.25 g/L, the H2O2 concentration of 0.85 mmol/L, and a wide pH (3.0-9.0) range for reacting 300 min. Meanwhile, the activity of the catalyst does not decrease after repeated use for 6 times, which exhibiting a good stability.

2023, 40(8): 4613-4624.

doi: 10.13801/j.cnki.fhclxb.20221009.001

Abstract:

In order to remove Cu(II) from the liquid phase efficiently, the amine-modified silica aerogel (NG) was prepared by co-condensation method using tetraethyl orthosilicate as raw material and 3-aminopropyltriethoxysilane as amino agent. The effects of pH, ionic strength, time, temperature and other factors on the removal of Cu(II) by NG were systematically investigated. The adsorption mechanism of Cu(II) on the NG was analyzed by combining adsorption kinetics model, adsorption isotherm model, adsorption thermodynamics and site energy distribution theory. The results demonstrate that the adsorption capacity of Cu(II) increase with pH value from 3.00-6.00, and the adsorption is inhibited by the addition of ionic strength at the range of 0-0.08 mol/L. The outer-sphere complexes formed by Cu(II) and NG are confirmed by using FTIR analysis. Furthermore, the adsorption equilibrium is achieved within 8 h, and the adsorption process mainly go through boundary layer diffusion, intra-particle diffusion and chemisorption. The adsorption process is best fitted with the pseudo-second-order model and Freundlich model. The increase of temperature is beneficial to promote the adsorption reaction of Cu(II), and the maximum adsorption capacity reaches to 130.45 mg/g. The adsorption process is endothermic and entropy increasing spontaneous reaction. The energy distribution show that Cu(II) is preferentially adsorbed on the high-energy adsorption sites on NG and then occupied low-energy adsorption sites. Overall, the adsorption mechanism is mainly attributed to the electrostatic interaction and the outer-sphere complexation.

In order to remove Cu(II) from the liquid phase efficiently, the amine-modified silica aerogel (NG) was prepared by co-condensation method using tetraethyl orthosilicate as raw material and 3-aminopropyltriethoxysilane as amino agent. The effects of pH, ionic strength, time, temperature and other factors on the removal of Cu(II) by NG were systematically investigated. The adsorption mechanism of Cu(II) on the NG was analyzed by combining adsorption kinetics model, adsorption isotherm model, adsorption thermodynamics and site energy distribution theory. The results demonstrate that the adsorption capacity of Cu(II) increase with pH value from 3.00-6.00, and the adsorption is inhibited by the addition of ionic strength at the range of 0-0.08 mol/L. The outer-sphere complexes formed by Cu(II) and NG are confirmed by using FTIR analysis. Furthermore, the adsorption equilibrium is achieved within 8 h, and the adsorption process mainly go through boundary layer diffusion, intra-particle diffusion and chemisorption. The adsorption process is best fitted with the pseudo-second-order model and Freundlich model. The increase of temperature is beneficial to promote the adsorption reaction of Cu(II), and the maximum adsorption capacity reaches to 130.45 mg/g. The adsorption process is endothermic and entropy increasing spontaneous reaction. The energy distribution show that Cu(II) is preferentially adsorbed on the high-energy adsorption sites on NG and then occupied low-energy adsorption sites. Overall, the adsorption mechanism is mainly attributed to the electrostatic interaction and the outer-sphere complexation.

Preparation, characterization, adsorption performance and mechanism of Fe3O4@PANI-PG boron adsorbent

2023, 40(8): 4625-4636.

doi: 10.13801/j.cnki.fhclxb.20221109.002

Abstract:

In this paper, the traditional difficult problem of separation between adsorbent and water phase was effectively solved by a kind of magnetic polyols boron adsorbent, which were designed and prepared based on the principle of magnetic separation. Firstly, the polyaniline compound Fe3O4 (Fe3O4@PANI) composites with core-shell structure were prepared by the in-situ polymerization reaction at the presence of aniline and Fe3O4 nanoparticles, which were prepared by ourselves. Then propylene glycol modified polyaniline compound Fe3O4 (Fe3O4@PANI-PG) boron adsorbent was successfully prepared by the ring-opening reaction between polyaniline terminal active —NH2 and glycidyl. After that, the micro-structure, composition and functional groups were analyzed by the SEM, TEM, EDS, XRD, XPS and FTIR, respectively. The adsorption time, initial concentration of boric acid, pH and other factors of Fe3O4@PANI-PG were investigated by the single factor experiment. On this basis, the optimal adsorption conditions (time t=10 h, initial concentration C0=1309 mg/L, pH=9.93) were obtained by response surface method, and the corresponding optimal adsorption capacity up to Qe=0.1181 mmol/g. In addition, it was found that the adsorption process was in accordance with the quasi-second-order adsorption kinetics and Langmuir adsorption isotherm based on the adsorption kinetics and adsorption isotherm fitting. Finally, the adsorption mechanism of Fe3O4@PANI-PG was explored and the results indicating the complex reaction between the hydroxyl group at the end of the adsorbent and B(OH)4− in the aqueous phase formed a stable five-membered ring chelate.

In this paper, the traditional difficult problem of separation between adsorbent and water phase was effectively solved by a kind of magnetic polyols boron adsorbent, which were designed and prepared based on the principle of magnetic separation. Firstly, the polyaniline compound Fe3O4 (Fe3O4@PANI) composites with core-shell structure were prepared by the in-situ polymerization reaction at the presence of aniline and Fe3O4 nanoparticles, which were prepared by ourselves. Then propylene glycol modified polyaniline compound Fe3O4 (Fe3O4@PANI-PG) boron adsorbent was successfully prepared by the ring-opening reaction between polyaniline terminal active —NH2 and glycidyl. After that, the micro-structure, composition and functional groups were analyzed by the SEM, TEM, EDS, XRD, XPS and FTIR, respectively. The adsorption time, initial concentration of boric acid, pH and other factors of Fe3O4@PANI-PG were investigated by the single factor experiment. On this basis, the optimal adsorption conditions (time t=10 h, initial concentration C0=1309 mg/L, pH=9.93) were obtained by response surface method, and the corresponding optimal adsorption capacity up to Qe=0.1181 mmol/g. In addition, it was found that the adsorption process was in accordance with the quasi-second-order adsorption kinetics and Langmuir adsorption isotherm based on the adsorption kinetics and adsorption isotherm fitting. Finally, the adsorption mechanism of Fe3O4@PANI-PG was explored and the results indicating the complex reaction between the hydroxyl group at the end of the adsorbent and B(OH)4− in the aqueous phase formed a stable five-membered ring chelate.

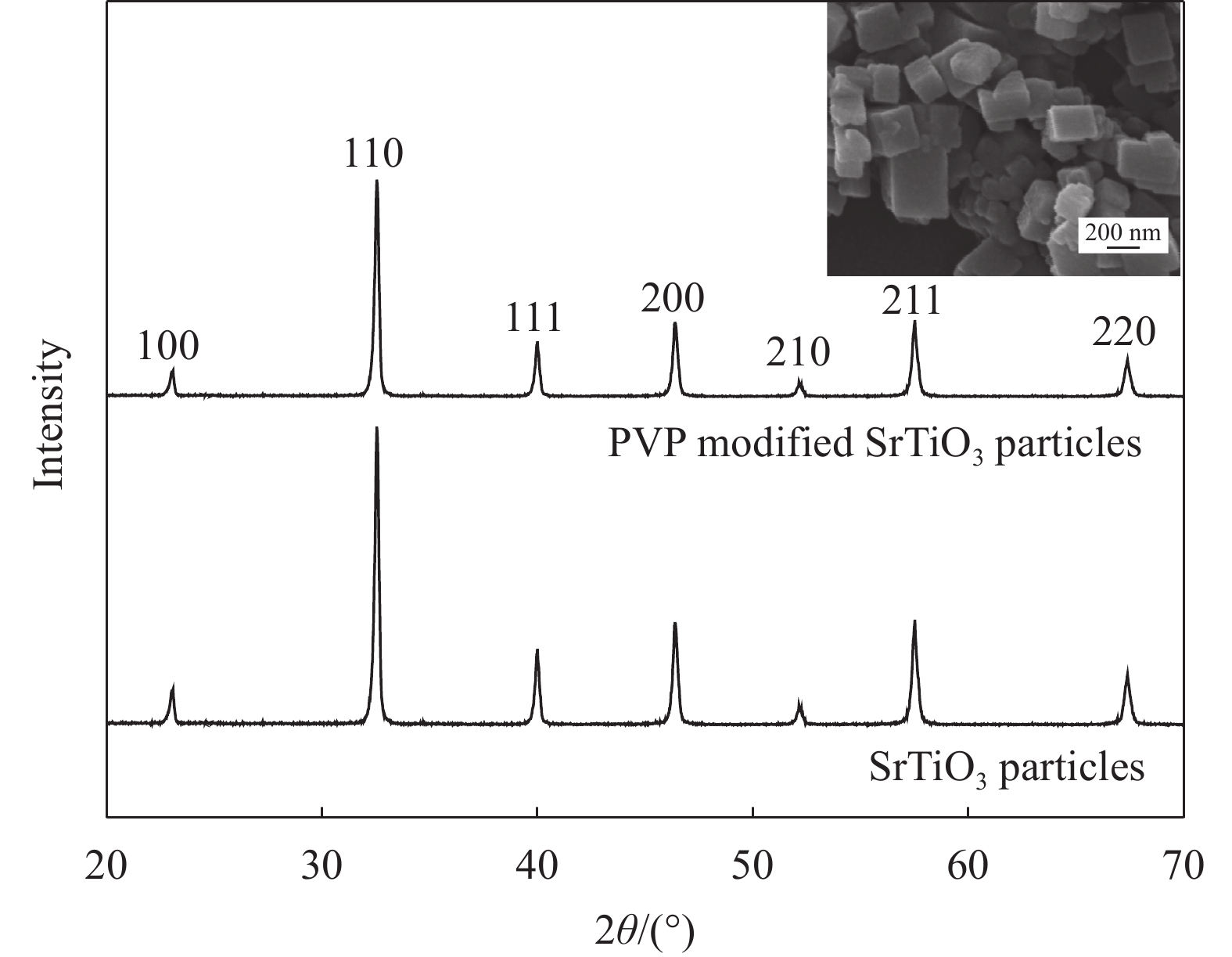

Energy storage performance of cubic SrTiO3 powder/polyvinylidene fluoride dielectric composite films

2023, 40(8): 4637-4647.

doi: 10.13801/j.cnki.fhclxb.20221108.001

Abstract:

Dielectric energy storage materials with high working field strength and high energy storage efficiency have an important impact on improving the performance of power equipment and reducing the volume of power equipment. The cubic SrTiO3 powder was prepared as ceramic filler by the mixed alkali method, and the surface of the cubic SrTiO3 particles was treated by polyvinylpyrrolidone (PVP) surface modification. The uniform polyvinylidene fluoride (PVDF) flexibility composite was prepared by the casting method. The effect of surface PVP modified cubic SrTiO3 filler on the dielectric properties and energy storage density of PVDF dielectric composites was systematically studied. The results show that the morphology of the SrTiO3 powder is cubic and the size is 200-400 nm. The particle size distribution is relatively uniform. The PVP coating layer formed on the surface of the cubic SrTiO3 filler can effectively prevent the agglomeration of the cubic SrTiO3 filler in the PVDF composites. At the same time, the PVP coating layer can improve the dispersion and bonding of the cubic SrTiO3 filler in the PVDF polymer. PVDF dielectric composite has excellent dielectric properties and breakdown strength. The dielectric constant of PVDF composites increases with the increase of the filling amount. When the filling amount of cubic SrTiO3 filler is 40vol%, the dielectric constant of the composite is 34.9. The energy storage density of PVDF dielectric composite increases first and then decreases with the increase of the filling volume. When the filling volume of the cubic SrTiO3 filler modified by the surface PVP is 5vol%, the energy storage density of the composite reaches 5.3 J/cm3.

Dielectric energy storage materials with high working field strength and high energy storage efficiency have an important impact on improving the performance of power equipment and reducing the volume of power equipment. The cubic SrTiO3 powder was prepared as ceramic filler by the mixed alkali method, and the surface of the cubic SrTiO3 particles was treated by polyvinylpyrrolidone (PVP) surface modification. The uniform polyvinylidene fluoride (PVDF) flexibility composite was prepared by the casting method. The effect of surface PVP modified cubic SrTiO3 filler on the dielectric properties and energy storage density of PVDF dielectric composites was systematically studied. The results show that the morphology of the SrTiO3 powder is cubic and the size is 200-400 nm. The particle size distribution is relatively uniform. The PVP coating layer formed on the surface of the cubic SrTiO3 filler can effectively prevent the agglomeration of the cubic SrTiO3 filler in the PVDF composites. At the same time, the PVP coating layer can improve the dispersion and bonding of the cubic SrTiO3 filler in the PVDF polymer. PVDF dielectric composite has excellent dielectric properties and breakdown strength. The dielectric constant of PVDF composites increases with the increase of the filling amount. When the filling amount of cubic SrTiO3 filler is 40vol%, the dielectric constant of the composite is 34.9. The energy storage density of PVDF dielectric composite increases first and then decreases with the increase of the filling volume. When the filling volume of the cubic SrTiO3 filler modified by the surface PVP is 5vol%, the energy storage density of the composite reaches 5.3 J/cm3.

2023, 40(8): 4648-4658.

doi: 10.13801/j.cnki.fhclxb.20221017.001

Abstract:

A unique hydrangea viburnum-like cobalt sulfide (HVCS) with multiple electrochemically active sites was successfully fabricated by a simple solvent thermal method. Polyaniline (PANI) was assembled onto the surface of HVCS through in situ polymerization and finally PANI were further carbonized to obtain hydrangea viburnum-like cobalt sulfide@nitrogen-rich carbon composite (HVCS@NC). Benefiting from the unique microstructure design and synergistic effect produced through the complementary properties of the two components, the fabricated HVCS@NC electrode demonstrates ideal electrochemical performance for supercapacitors through electrochemical analysis. The material exhibits an outstanding capacitive performance of 622 F·g−1 at a current density of 1 A·g−1 and the assembled asymmetric supercapacitor with HVCS@NC and active carbon (AC) as positive and negative electrodes, respectively, achieves a high specific energy of 19.9 W·h·kg−1 at a specific power of 1912.3 W·kg−1. All results show that high-performance supercapacitor electrode materials can be obtained by assembling conductive polymers on the surface of novel cobalt sulfide with special microscopic morphology and structure and then carbonizing. The plasticity and nitrogen-rich properties after carbonization of polyaniline have great advantages for improving the electrochemical performance of transition metal sulfide. This structural design strategy can be potentially extended to the improvement of electrochemical properties of other transition metal sulfide based electrode materials.

A unique hydrangea viburnum-like cobalt sulfide (HVCS) with multiple electrochemically active sites was successfully fabricated by a simple solvent thermal method. Polyaniline (PANI) was assembled onto the surface of HVCS through in situ polymerization and finally PANI were further carbonized to obtain hydrangea viburnum-like cobalt sulfide@nitrogen-rich carbon composite (HVCS@NC). Benefiting from the unique microstructure design and synergistic effect produced through the complementary properties of the two components, the fabricated HVCS@NC electrode demonstrates ideal electrochemical performance for supercapacitors through electrochemical analysis. The material exhibits an outstanding capacitive performance of 622 F·g−1 at a current density of 1 A·g−1 and the assembled asymmetric supercapacitor with HVCS@NC and active carbon (AC) as positive and negative electrodes, respectively, achieves a high specific energy of 19.9 W·h·kg−1 at a specific power of 1912.3 W·kg−1. All results show that high-performance supercapacitor electrode materials can be obtained by assembling conductive polymers on the surface of novel cobalt sulfide with special microscopic morphology and structure and then carbonizing. The plasticity and nitrogen-rich properties after carbonization of polyaniline have great advantages for improving the electrochemical performance of transition metal sulfide. This structural design strategy can be potentially extended to the improvement of electrochemical properties of other transition metal sulfide based electrode materials.

2023, 40(8): 4659-4669.

doi: 10.13801/j.cnki.fhclxb.20221123.001

Abstract:

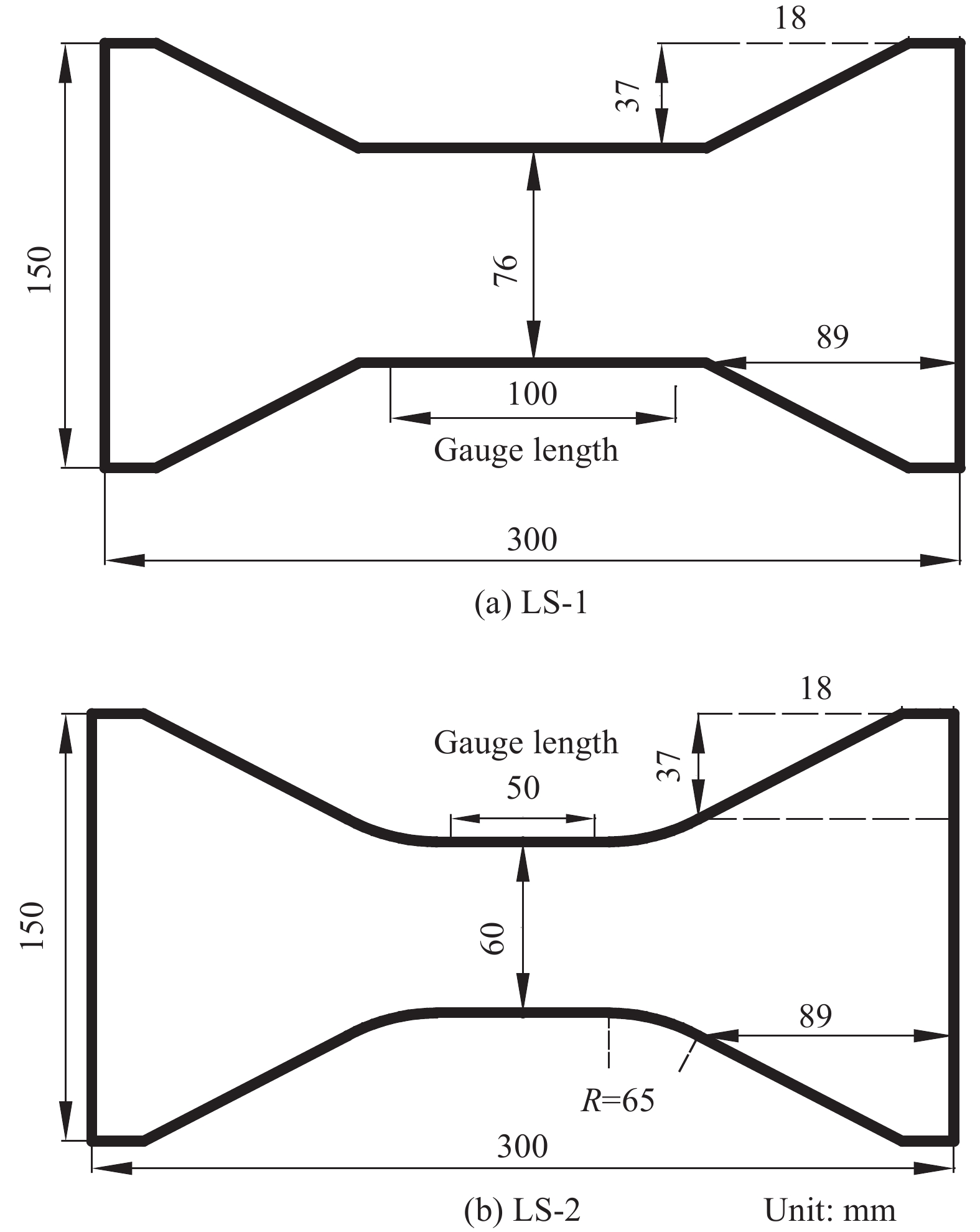

The steel bridge deck pavement materials are susceptible to damage caused by temperature, among which tensile damage is the most common. Modified polyurethane concrete is a new type of steel bridge deck pavement material. In order to study the effect of temperature on its tensile properties, uniaxial tensile experiments were carried out at −10°C, 0°C, 15°C, 40°C and 60°C. In order to ensure the success of the experiment, two kinds of experimental specimens (dumbbell-shaped specimen and dumbbell-shaped specimen with circular arc edge) were first designed. Meanwhile, a novel tensile testing fixture used to match the specimen was designed, and the experiment comparison of the two specimens was carried out. Through the uniaxial tensile experiment, the stress-strain curves were obtained and the tensile performance indexes were calculated according to the curve. The results show that using the dumbbell-shaped specimen with circular arc edge and the new tensile testing fixture has better effect. The new fixture can restrain the deformation of the fixture by adding bolts, so as to effectively reduce the stress concentration in the loading process. With the increase of temperature, the tensile strength and tensile elastic modulus of modified polyurethane concrete decrease. The peak strain, fracture energy density and tension-compression ratio all increase. The temperature related expressions of the tensile performance indexes are proposed. The uniaxial tensile constitutive relation of modified polyurethane concrete is constructed, and the calculation is in good agreement with the experimental results. The results can serve as basic references for the future engineering application of this material.