2023 Vol. 40, No. 7

2023, 40(7): 3703-3721.

doi: 10.13801/j.cnki.fhclxb.20230224.001

Abstract:

Compared with metal, ceramic or other structural materials, continuous fiber-reinforced polymer composites can offer significant advantage for their excellent design tailorability, mechanical properties, fracture toughness, good resistance to corrosion and fatigue, and are widely used in aerospace, transportation, energy, machinery and other fields. The organic combination of continuous fiber-reinforced polymer composites and additive manufacturing technology has the potential to promote new revolution for weight saving and structure-function integrated manufacturing of high-end equipment. This paper reviewed the recent research progress of extrusion and impregnation methods, printing temperature, auxiliary process, printing speed, printing spacing and geometric construction methods in additive manufacturing of continuous fiber composites. The influence of various process parameters on properties of the formed parts was emphatically discussed. Finally, the present challenges and future development directions have been prospected for reference.

Compared with metal, ceramic or other structural materials, continuous fiber-reinforced polymer composites can offer significant advantage for their excellent design tailorability, mechanical properties, fracture toughness, good resistance to corrosion and fatigue, and are widely used in aerospace, transportation, energy, machinery and other fields. The organic combination of continuous fiber-reinforced polymer composites and additive manufacturing technology has the potential to promote new revolution for weight saving and structure-function integrated manufacturing of high-end equipment. This paper reviewed the recent research progress of extrusion and impregnation methods, printing temperature, auxiliary process, printing speed, printing spacing and geometric construction methods in additive manufacturing of continuous fiber composites. The influence of various process parameters on properties of the formed parts was emphatically discussed. Finally, the present challenges and future development directions have been prospected for reference.

2023, 40(7): 3722-3737.

doi: 10.13801/j.cnki.fhclxb.20230225.001

Abstract:

With the rapid development of flexible pressure sensors in the fields of health detection, electronic skin and wearable electronic devices, the research on fabrication of high-performance flexible piezoresistive sensors has become prevalent. The performance of flexible pressure sensors can be optimized by nanomaterials because of their surface and interface effects, small size effects and macroscopic quantum tunneling effects. Nanomaterials based pressure sensor has the advantages of small size, wide detection range and high sensitivity. In this paper, the latest research progress of nanomaterials in flexible pressure sensors in recent years is reviewed.

With the rapid development of flexible pressure sensors in the fields of health detection, electronic skin and wearable electronic devices, the research on fabrication of high-performance flexible piezoresistive sensors has become prevalent. The performance of flexible pressure sensors can be optimized by nanomaterials because of their surface and interface effects, small size effects and macroscopic quantum tunneling effects. Nanomaterials based pressure sensor has the advantages of small size, wide detection range and high sensitivity. In this paper, the latest research progress of nanomaterials in flexible pressure sensors in recent years is reviewed.

2023, 40(7): 3738-3755.

doi: 10.13801/j.cnki.fhclxb.20230306.001

Abstract:

Antimicrobials are indispensable drugs to inhibit bacterial infection. The overuse of conventional antibacterial (antibiotics) leads to the gradual enhancement of antimicrobial resistance of bacteria, which poses a serious threat to human health. As a new type of nano antibacterial material, carbon dots have the advantages of high anti antibacterial ability, wide range of raw materials, low cytotoxicity and good biocompatibility. Novel nano composite materials constructed by combining carbon dots with traditional antibacterial agents show great application prospects in the antibacterial field. This paper reviews the research progress on antibacterial mechanisms and applications of carbon dots and their composites. Firstly, the main factors affecting on the antibacterial performance of carbon dots are systematically analyzed by summarizing their antibacterial mechanisms. Secondly, the new nano composite materials combining carbon dots with traditional antibacterial agents and their applications in the antibacterial field are introduced. Finally, problems in the antibacterial application research of carbon dots and their composites are summarized and prospects are put forward, so as to provide reference experience for the design and synthesis of carbon dot composites with efficient and long-time antibacterial properties.

Antimicrobials are indispensable drugs to inhibit bacterial infection. The overuse of conventional antibacterial (antibiotics) leads to the gradual enhancement of antimicrobial resistance of bacteria, which poses a serious threat to human health. As a new type of nano antibacterial material, carbon dots have the advantages of high anti antibacterial ability, wide range of raw materials, low cytotoxicity and good biocompatibility. Novel nano composite materials constructed by combining carbon dots with traditional antibacterial agents show great application prospects in the antibacterial field. This paper reviews the research progress on antibacterial mechanisms and applications of carbon dots and their composites. Firstly, the main factors affecting on the antibacterial performance of carbon dots are systematically analyzed by summarizing their antibacterial mechanisms. Secondly, the new nano composite materials combining carbon dots with traditional antibacterial agents and their applications in the antibacterial field are introduced. Finally, problems in the antibacterial application research of carbon dots and their composites are summarized and prospects are put forward, so as to provide reference experience for the design and synthesis of carbon dot composites with efficient and long-time antibacterial properties.

2023, 40(7): 3756-3770.

doi: 10.13801/j.cnki.fhclxb.20221206.001

Abstract:

As a newly developed energy storage system, aqueous magnesium ion battery takes its edge by lower cost, more abundant source of raw materials, higher theoretical energy storage capacity. However, the problems brought by aqueous electrolytes and magnesium themselves greatly limit the further development of aqueous magnesium ion batteries. Here, the influence of the type and concentration of anions in aqueous electrolyte and electrolyte additives on the battery performance is described, and the research of some electrode materials, including new materials and new theories, is introduced. Finally, some efficient characterization and analysis methods are summarized.

As a newly developed energy storage system, aqueous magnesium ion battery takes its edge by lower cost, more abundant source of raw materials, higher theoretical energy storage capacity. However, the problems brought by aqueous electrolytes and magnesium themselves greatly limit the further development of aqueous magnesium ion batteries. Here, the influence of the type and concentration of anions in aqueous electrolyte and electrolyte additives on the battery performance is described, and the research of some electrode materials, including new materials and new theories, is introduced. Finally, some efficient characterization and analysis methods are summarized.

2023, 40(7): 3771-3784.

doi: 10.13801/j.cnki.fhclxb.20221123.002

Abstract:

Bolted joint is the weak link of composite structures, and determines the load-carrying capacity of the entire structures. The reinforcement design of composite bolted joints can significantly improve the application efficiency of composites. For this reason, researchers at home and abroad have developed design methods for the overall or local improvement of composite bolted joints, and evaluated the strengthening effects of these methods by using experimental and numerical simulation methods. Some of the reinforcement design methods have been applied in the design of advanced aerospace vehicles abroad. In this paper, the existing reinforcement design methods of composite bolted joints are classified and summarized in detail, and the evaluation methods for the strengthening effect are analyzed. Finally, the existing problems are summarized, and the future development direction is proposed.

Bolted joint is the weak link of composite structures, and determines the load-carrying capacity of the entire structures. The reinforcement design of composite bolted joints can significantly improve the application efficiency of composites. For this reason, researchers at home and abroad have developed design methods for the overall or local improvement of composite bolted joints, and evaluated the strengthening effects of these methods by using experimental and numerical simulation methods. Some of the reinforcement design methods have been applied in the design of advanced aerospace vehicles abroad. In this paper, the existing reinforcement design methods of composite bolted joints are classified and summarized in detail, and the evaluation methods for the strengthening effect are analyzed. Finally, the existing problems are summarized, and the future development direction is proposed.

2023, 40(7): 3785-3794.

doi: 10.13801/j.cnki.fhclxb.20230119.002

Abstract:

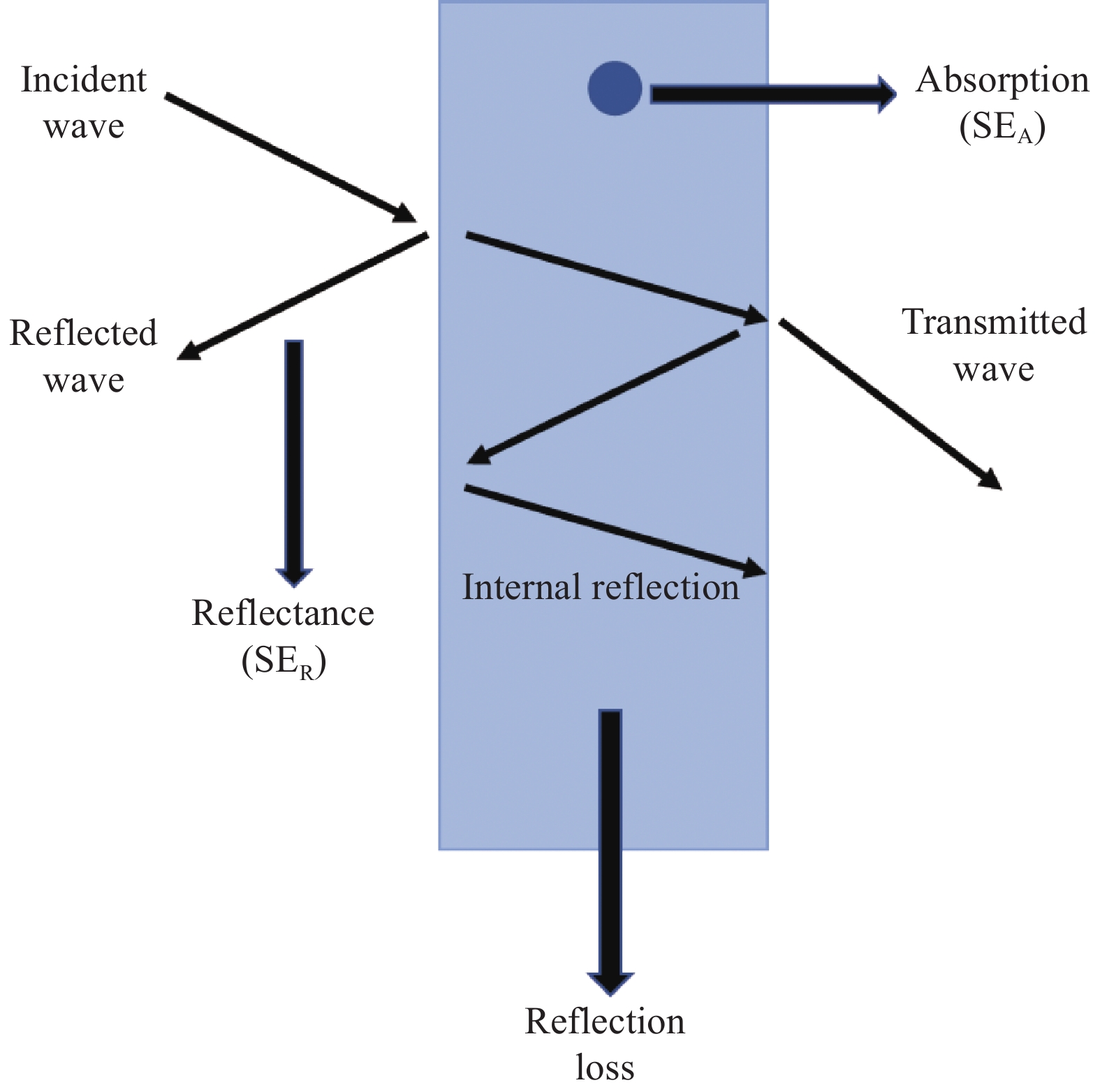

With the continuous progress of science and technology, the rapid popularization of 5G technology and the rapid development of wearable devices, life is becoming more and more convenient. Meanwhile, electromagnetic interference poses a threat to the health of people and the operation of precision electronic devices. Nowadays, traditional electromagnetic interference shielding materials can no longer meet the daily needs of people's life, lightweight polymer-based electromagnetic interference shielding materials have attracted more and more attention. This study summarized the electromagnetic interference shielding mechanism, and the influence of polymer structures on electromagnetic interference shielding performance, reviewed the preparation methods, electromagnetic shielding properties, and related mechanisms of advanced carbon/polymer materials, metal/polymer materials, and novel MXene/polymer materials, discussed their advantages and limitations, and prospected the key challenges, potential applications and development prospects of lightweight polymer-based electromagnetic shielding materials in the future.

With the continuous progress of science and technology, the rapid popularization of 5G technology and the rapid development of wearable devices, life is becoming more and more convenient. Meanwhile, electromagnetic interference poses a threat to the health of people and the operation of precision electronic devices. Nowadays, traditional electromagnetic interference shielding materials can no longer meet the daily needs of people's life, lightweight polymer-based electromagnetic interference shielding materials have attracted more and more attention. This study summarized the electromagnetic interference shielding mechanism, and the influence of polymer structures on electromagnetic interference shielding performance, reviewed the preparation methods, electromagnetic shielding properties, and related mechanisms of advanced carbon/polymer materials, metal/polymer materials, and novel MXene/polymer materials, discussed their advantages and limitations, and prospected the key challenges, potential applications and development prospects of lightweight polymer-based electromagnetic shielding materials in the future.

2023, 40(7): 3795-3811.

doi: 10.13801/j.cnki.fhclxb.20221024.001

Abstract:

To meet the demand for thermal management of lithium-ion batteries in electric vehicle, the cooling method with phase change materials (PCM) on battery modules has gradually become a research hotspot. Based on the poor physical properties of organic PCM, the preparation and improvement directions of composite organic PCM for battery thermal management (BTM) are summarized, including adding multi-dimensional materials such as carbon materials, nano-metals and metal foams to enhance the heat transfer, and adding copolymer such as polyethylene and thermoplastic elastomer to improve the flexibilities. Additionally, flame retardants such as red phosphorus and ammonium polyphosphate are used to improve the flame retardance for better practicabilities. Among them, expanded graphite, styrene-ethylene-butadiene-styrene, and the composite of red phosphorus and ammonium polyphosphate significantly improve the thermal conductivity, flexibility and flame retardancy respectively. Subsequently, the heat transfer enhancement effects of the system after coupling organic PCM with heat pipe, liquid cooling or air cooling are evaluated, indicating that various arrangements of heat pipe and appropriate flow channels of air and liquid should be considered. Then the optimal operating conditions of organic PCM used in BTM system is determined with numerical calculation. Finally, the progress and shortcomings of organic PCM used in BTM are summarized. It is pointed out that the difficulties of composite organic PCM used in BTM are still accounted for the improvement of flammability and conductivity and the insufficient flexibility of flexible organic PCM at room temperature. Furthermore, the reliability and cycle feasibility of PCM and traditional heat dissipation system in the process of vehicle use are still lack of verification. Totally, several suggestions are put forward for the application of organic PCM in BTM in the future.

To meet the demand for thermal management of lithium-ion batteries in electric vehicle, the cooling method with phase change materials (PCM) on battery modules has gradually become a research hotspot. Based on the poor physical properties of organic PCM, the preparation and improvement directions of composite organic PCM for battery thermal management (BTM) are summarized, including adding multi-dimensional materials such as carbon materials, nano-metals and metal foams to enhance the heat transfer, and adding copolymer such as polyethylene and thermoplastic elastomer to improve the flexibilities. Additionally, flame retardants such as red phosphorus and ammonium polyphosphate are used to improve the flame retardance for better practicabilities. Among them, expanded graphite, styrene-ethylene-butadiene-styrene, and the composite of red phosphorus and ammonium polyphosphate significantly improve the thermal conductivity, flexibility and flame retardancy respectively. Subsequently, the heat transfer enhancement effects of the system after coupling organic PCM with heat pipe, liquid cooling or air cooling are evaluated, indicating that various arrangements of heat pipe and appropriate flow channels of air and liquid should be considered. Then the optimal operating conditions of organic PCM used in BTM system is determined with numerical calculation. Finally, the progress and shortcomings of organic PCM used in BTM are summarized. It is pointed out that the difficulties of composite organic PCM used in BTM are still accounted for the improvement of flammability and conductivity and the insufficient flexibility of flexible organic PCM at room temperature. Furthermore, the reliability and cycle feasibility of PCM and traditional heat dissipation system in the process of vehicle use are still lack of verification. Totally, several suggestions are put forward for the application of organic PCM in BTM in the future.

2023, 40(7): 3812-3823.

doi: 10.13801/j.cnki.fhclxb.20221109.001

Abstract:

Based on the problems of energy crisis and environmental pollution, it is very important to develop new high-performance energy storage devices. Supercapacitors are favored by researchers because of their high specific energy and good stability. Biomass carbon is obtained by pre-carbonization and activation of biomass materials, with developed pore size, high active specific surface area, and rich resources, which has good application prospects as a supercapacitor material. In order to meet the high specific capacity and high cycle stability of supercapacitors, the current effective method is to combine biomass carbon materials with pseudo capacitor materials. Transition metal oxide MnO2 has become the most promising pseudocapacitor material due to its high theoretical specific capacitance, wide potential window, low cost and environmental friendliness. The research shows that the specific capacitance and energy density of the supercapacitor made of the composite material of biomass carbon and transition metal oxide are significantly improved. This paper mainly introduces the source, characteristics and preparation methods of biomass carbon, also introduces the composite methods of biomass carbon and MnO2 and the research progress of biomass carbon@MnO2 composite materials, and finally looks forward to the development trend of biomass carbon@MnO2 based supercapacitors.

Based on the problems of energy crisis and environmental pollution, it is very important to develop new high-performance energy storage devices. Supercapacitors are favored by researchers because of their high specific energy and good stability. Biomass carbon is obtained by pre-carbonization and activation of biomass materials, with developed pore size, high active specific surface area, and rich resources, which has good application prospects as a supercapacitor material. In order to meet the high specific capacity and high cycle stability of supercapacitors, the current effective method is to combine biomass carbon materials with pseudo capacitor materials. Transition metal oxide MnO2 has become the most promising pseudocapacitor material due to its high theoretical specific capacitance, wide potential window, low cost and environmental friendliness. The research shows that the specific capacitance and energy density of the supercapacitor made of the composite material of biomass carbon and transition metal oxide are significantly improved. This paper mainly introduces the source, characteristics and preparation methods of biomass carbon, also introduces the composite methods of biomass carbon and MnO2 and the research progress of biomass carbon@MnO2 composite materials, and finally looks forward to the development trend of biomass carbon@MnO2 based supercapacitors.

2023, 40(7): 3824-3836.

doi: 10.13801/j.cnki.fhclxb.20230103.003

Abstract:

Water stimulus responsive materials can undergo reversible color or fluorescence emission change process under the external stimulus of water. Because of its low cost, non-toxic, compatibility with existing inkjet printing technology and other advantages, it is an ideal choice to achieve rewritable. Meanwhile, it shows great application potential in information storage, security and anti-counterfeiting. In this review, the research progress of water responsive compound material based on organic small molecules in the past five years is systematically reviewed. Inductive materials are classified from the viewpoints of water induced proton transfer, water induced configuration change, water induced proton transfer combined with configuration change sensing principle. The achievements and technologies in design principles, optical physical properties and information storage applications are summarized. It is hoped to provide ideas for further developing the application of water responsive composites in the field of green writing and anti-counterfeiting, promoting the development of related industries.

Water stimulus responsive materials can undergo reversible color or fluorescence emission change process under the external stimulus of water. Because of its low cost, non-toxic, compatibility with existing inkjet printing technology and other advantages, it is an ideal choice to achieve rewritable. Meanwhile, it shows great application potential in information storage, security and anti-counterfeiting. In this review, the research progress of water responsive compound material based on organic small molecules in the past five years is systematically reviewed. Inductive materials are classified from the viewpoints of water induced proton transfer, water induced configuration change, water induced proton transfer combined with configuration change sensing principle. The achievements and technologies in design principles, optical physical properties and information storage applications are summarized. It is hoped to provide ideas for further developing the application of water responsive composites in the field of green writing and anti-counterfeiting, promoting the development of related industries.

2023, 40(7): 3837-3851.

doi: 10.13801/j.cnki.fhclxb.20230222.001

Abstract:

A flexible strain sensor is a device that converts changes in external stress into electrical signals. It overcomes the shortcomings of traditional rigid sensors such as high hardness and poor human adaptability. As a wearable device, it has great development prospects in the field of human motion monitoring. However, in harsh conditions or extreme environments, there are still risks such as signal output distortion and easy corrosion. The superhydrophobic flexible strain sensor combines the water repellency, surface self-cleaning, anti-corrosion and anti-fouling of the superhydrophobic coating with the high ductility and high sensitivity of the flexible strain sensor, which enhances the performance of the sensor and broadens the applications in human motion monitoring. This paper reviews the basic performance parameters of superhydrophobic flexible strain sensors, the commonly used construction materials and construction methods as well as their functions and applications in human motion monitoring, and provides perspectives on this field.

A flexible strain sensor is a device that converts changes in external stress into electrical signals. It overcomes the shortcomings of traditional rigid sensors such as high hardness and poor human adaptability. As a wearable device, it has great development prospects in the field of human motion monitoring. However, in harsh conditions or extreme environments, there are still risks such as signal output distortion and easy corrosion. The superhydrophobic flexible strain sensor combines the water repellency, surface self-cleaning, anti-corrosion and anti-fouling of the superhydrophobic coating with the high ductility and high sensitivity of the flexible strain sensor, which enhances the performance of the sensor and broadens the applications in human motion monitoring. This paper reviews the basic performance parameters of superhydrophobic flexible strain sensors, the commonly used construction materials and construction methods as well as their functions and applications in human motion monitoring, and provides perspectives on this field.

2023, 40(7): 3852-3861.

doi: 10.13801/j.cnki.fhclxb.20220922.005

Abstract:

With the rapid development of nuclear science and technology, there has been an increasing application of high-energy rays in medicine, industry and other fields, which puts forward higher requirements on the performance of shielding materials, and developing new protective materials to effectively reduce radiation harm has thus become an important goal in the field of radiation protection. Here, an advanced wearable protective composites with excellent shielding performance for low- and medium-energy X-rays which using natural leather (NL) as the substrate and CsI as the high Z elements (Z elements refer to the elements with the plateau subral number) source was constructed via “impregnation-desolvation” strategy. The results indicate that the CsI is stably loaded and well dispersed into the hierarchical structure of NL. A 4.5 mm thickness CsI2.0/NL displays excellent attenuation efficiency of higher than 95% for the low-energy X-ray (16-48 keV) and higher than 85% for the medium-energy X-ray (65 keV), which is comparative or superior than that of 0.25 mm Pb plate, and its density is only 8.6% of Pb plate. In addition, the mechanical strength and water vapor permeability of the prepared material not only meet the requirements of national standard for protective clothing but also exceed those of the commercial lead apron. This work shows promising potential of CsIx/NL to be an ideal wearable X-ray shielding composites which features light weight, convenient and high X-rays shielding capabilities.

With the rapid development of nuclear science and technology, there has been an increasing application of high-energy rays in medicine, industry and other fields, which puts forward higher requirements on the performance of shielding materials, and developing new protective materials to effectively reduce radiation harm has thus become an important goal in the field of radiation protection. Here, an advanced wearable protective composites with excellent shielding performance for low- and medium-energy X-rays which using natural leather (NL) as the substrate and CsI as the high Z elements (Z elements refer to the elements with the plateau subral number) source was constructed via “impregnation-desolvation” strategy. The results indicate that the CsI is stably loaded and well dispersed into the hierarchical structure of NL. A 4.5 mm thickness CsI2.0/NL displays excellent attenuation efficiency of higher than 95% for the low-energy X-ray (16-48 keV) and higher than 85% for the medium-energy X-ray (65 keV), which is comparative or superior than that of 0.25 mm Pb plate, and its density is only 8.6% of Pb plate. In addition, the mechanical strength and water vapor permeability of the prepared material not only meet the requirements of national standard for protective clothing but also exceed those of the commercial lead apron. This work shows promising potential of CsIx/NL to be an ideal wearable X-ray shielding composites which features light weight, convenient and high X-rays shielding capabilities.

2023, 40(7): 3862-3873.

doi: 10.13801/j.cnki.fhclxb.20221027.003

Abstract:

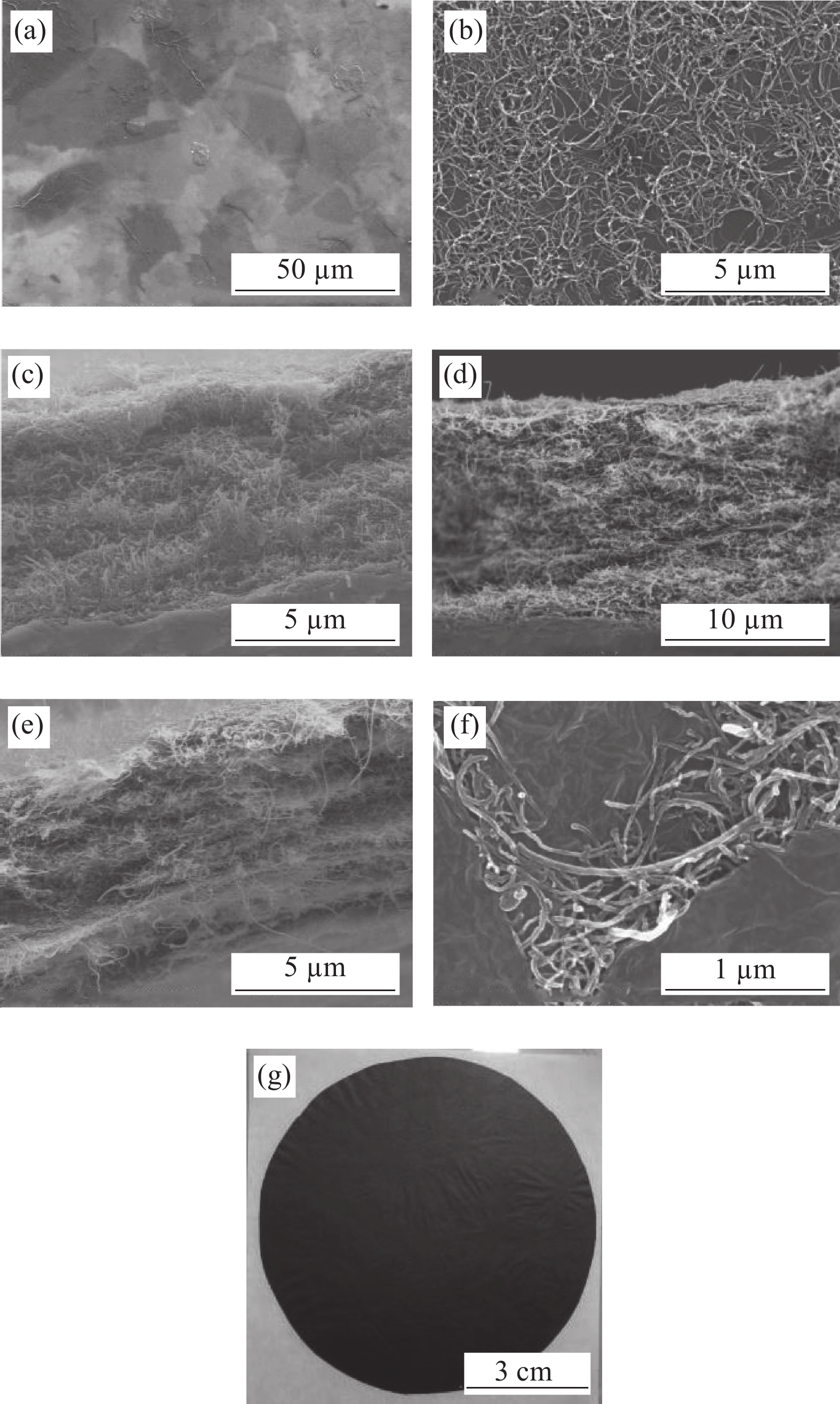

The interlayer properties of carbon fiber reinforced resin matrix composites are always the weakness of composites. A composite film was designed and fabricated using graphene oxide (GO) and carbon nanotubes (CNT), which exhibited good permeability and resin wettability. A hybrid carbon fiber/epoxy (CF/EP) composite was prepared using the composite GO-CNT film by interlayer toughening method. The interlaminar toughness of the GO-CNT-CF/EP composites was investigated by open type interlaminar fracture toughness (GIC) and slip type interlaminar fracture toughness (GIIC). The interlayer toughening effect and toughening mechanism of the GO-CNT composite film on the GO-CN-CF/EP composites were analyzed based on the damage micro-morphology and damage/destruction characteristics of the composites. The results show that the composite GO-CNT film prepared with a mass ratio of GO to CNT of 3∶7 has good film-forming processability and resin wettability.The contact angle between EP and GO-CNT composite film is much lower than that between EP and pure GO film. Moreover, GO and oxygen-containing groups such as hydroxyl, carboxyl, and epoxy group in CNT increase their physical affinity and chemical interaction with EP, which is conducive to the toughening of GO-CNT/EP microzone structure between layers of composite materials. The GO-CNT composite film has no enhancement effect on the GIC of the composite. The GIC value of the GO-CNT-CF/EP composite even dropped slightly compared to the CF/EP composites. However, the GO-CNT composite film has a good effect on improving the GIIC of the GO-CNT-CF/EP composite. The GIIC of the composite increased from 1855 J/m2 for the CF/EP composite to 2720 J/m2 for the GO-CNT-CF/EP composite, which has an increase of 47%. This is attributed to the interpenetrating and overlapping network structure formed between the GO-CNT composite film and the resin, which inhibits the propagation of interlayer microcracks caused by slip-type loading. The glass transition temperature of GO-CNT/EP composites is similar to that of CF/EP composites.

The interlayer properties of carbon fiber reinforced resin matrix composites are always the weakness of composites. A composite film was designed and fabricated using graphene oxide (GO) and carbon nanotubes (CNT), which exhibited good permeability and resin wettability. A hybrid carbon fiber/epoxy (CF/EP) composite was prepared using the composite GO-CNT film by interlayer toughening method. The interlaminar toughness of the GO-CNT-CF/EP composites was investigated by open type interlaminar fracture toughness (GIC) and slip type interlaminar fracture toughness (GIIC). The interlayer toughening effect and toughening mechanism of the GO-CNT composite film on the GO-CN-CF/EP composites were analyzed based on the damage micro-morphology and damage/destruction characteristics of the composites. The results show that the composite GO-CNT film prepared with a mass ratio of GO to CNT of 3∶7 has good film-forming processability and resin wettability.The contact angle between EP and GO-CNT composite film is much lower than that between EP and pure GO film. Moreover, GO and oxygen-containing groups such as hydroxyl, carboxyl, and epoxy group in CNT increase their physical affinity and chemical interaction with EP, which is conducive to the toughening of GO-CNT/EP microzone structure between layers of composite materials. The GO-CNT composite film has no enhancement effect on the GIC of the composite. The GIC value of the GO-CNT-CF/EP composite even dropped slightly compared to the CF/EP composites. However, the GO-CNT composite film has a good effect on improving the GIIC of the GO-CNT-CF/EP composite. The GIIC of the composite increased from 1855 J/m2 for the CF/EP composite to 2720 J/m2 for the GO-CNT-CF/EP composite, which has an increase of 47%. This is attributed to the interpenetrating and overlapping network structure formed between the GO-CNT composite film and the resin, which inhibits the propagation of interlayer microcracks caused by slip-type loading. The glass transition temperature of GO-CNT/EP composites is similar to that of CF/EP composites.

2023, 40(7): 3874-3880.

doi: 10.13801/j.cnki.fhclxb.20220930.003

Abstract:

Glass bead buoyancy material is a two-phase composite material made of hollow glass bead (HGB) and epoxy resin. Glass bead has been widely used in building materials, navigation, aerospace and other fields because of its low density, high strength and low water absorption. Its static mechanical properties have been fully studied, but its dynamic mechanical properties are less studied, which are not enough to meet the needs of engineering applications. The compression, splitting and pseudo-triaxial compression experiments of HGB/epoxy resin composites under quasi-static/dynamic loading were carried out by INSTRON electronic universal testing machine and split Hopkinson pressure bar (SHPB). The results show that HGB/epoxy composite has strong strain rate sensitivity. The compressive strength and splitting resistance increase with the increase of strain rate, showing strain rate enhancement effect. The failure mode is also rate sensitive, and its brittleness increases with the increase of strain rate. Comparing uniaxial compression with pseudo triaxial compression, it is found that the compressive strength of the material under pseudo triaxial compression is higher than that under uniaxial compression.

Glass bead buoyancy material is a two-phase composite material made of hollow glass bead (HGB) and epoxy resin. Glass bead has been widely used in building materials, navigation, aerospace and other fields because of its low density, high strength and low water absorption. Its static mechanical properties have been fully studied, but its dynamic mechanical properties are less studied, which are not enough to meet the needs of engineering applications. The compression, splitting and pseudo-triaxial compression experiments of HGB/epoxy resin composites under quasi-static/dynamic loading were carried out by INSTRON electronic universal testing machine and split Hopkinson pressure bar (SHPB). The results show that HGB/epoxy composite has strong strain rate sensitivity. The compressive strength and splitting resistance increase with the increase of strain rate, showing strain rate enhancement effect. The failure mode is also rate sensitive, and its brittleness increases with the increase of strain rate. Comparing uniaxial compression with pseudo triaxial compression, it is found that the compressive strength of the material under pseudo triaxial compression is higher than that under uniaxial compression.

2023, 40(7): 3881-3891.

doi: 10.13801/j.cnki.fhclxb.20220917.001

Abstract:

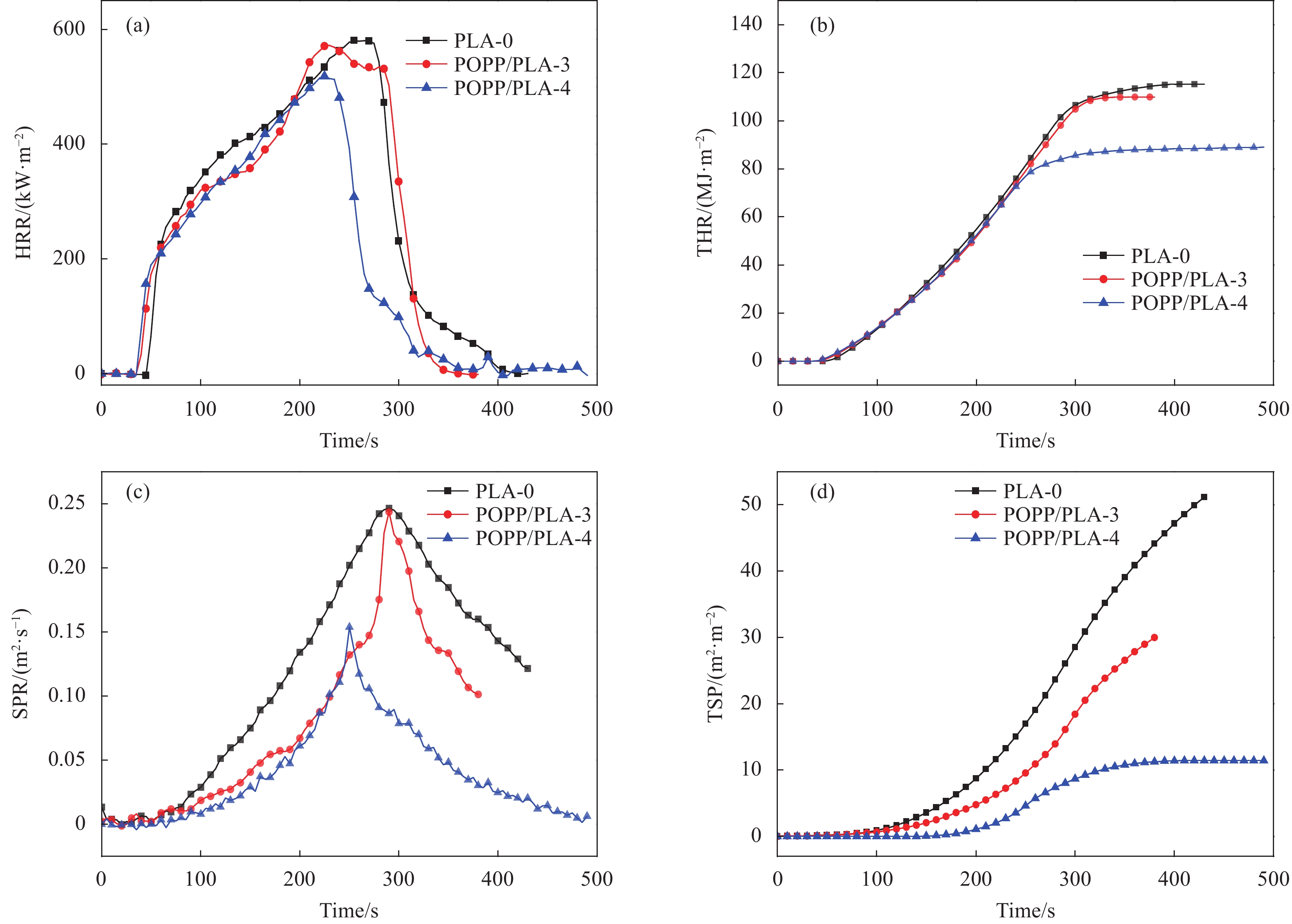

Due to poly(lactic acid) (PLA) was easy to burn and accompanied by serious droplet phenomenon, its application in many fields such as packaging, automotive, electrical and electronic industries were seriously limited. And in order to solve this problem, PLA was used as matrix and poly(2-10-hydrogen-9-oxa-phosphaphenanthrene hydroquinone phenyl phosphate) (POPP) was used as flame retardant. PLA composites with different contents were prepared via melting blending and hot-compression method. The flame retardant properties and smoke suppression of PLA composites were investigated by means of limited oxygen index (LOI), vertical burning test (UL-94), thermogravimetric analysis (TG) and cone calorimetric test etc. The results show that the LOI of PLA composite with 4wt% POPP is 34.8%, and it reaches a UL-94 V-0 rating. Comparing with pure PLA, the smoke production rate and total smoke production of POPP/PLA-4 are respectively reduced by 85.83% and 77.65%, which dramatically improve the smoke suppression performance of PLA materials. Moreover, the results of microstructure of char residues after cone calorimeter and thermal degradation behavior analysis reveal that the excellent flame-retardant performance of PLA composites are followed a flame-retardant mechanism of gaseous phase at superiority. This is attributed to •PO and •PO2 decomposed by POPP quenching •H and •OH. Otherwise, by promoting the intermolecular crosslinking of PLA, a continuous and dense carbon layer on the surface is formed, which improve flame retardancy of PLA composites.

Due to poly(lactic acid) (PLA) was easy to burn and accompanied by serious droplet phenomenon, its application in many fields such as packaging, automotive, electrical and electronic industries were seriously limited. And in order to solve this problem, PLA was used as matrix and poly(2-10-hydrogen-9-oxa-phosphaphenanthrene hydroquinone phenyl phosphate) (POPP) was used as flame retardant. PLA composites with different contents were prepared via melting blending and hot-compression method. The flame retardant properties and smoke suppression of PLA composites were investigated by means of limited oxygen index (LOI), vertical burning test (UL-94), thermogravimetric analysis (TG) and cone calorimetric test etc. The results show that the LOI of PLA composite with 4wt% POPP is 34.8%, and it reaches a UL-94 V-0 rating. Comparing with pure PLA, the smoke production rate and total smoke production of POPP/PLA-4 are respectively reduced by 85.83% and 77.65%, which dramatically improve the smoke suppression performance of PLA materials. Moreover, the results of microstructure of char residues after cone calorimeter and thermal degradation behavior analysis reveal that the excellent flame-retardant performance of PLA composites are followed a flame-retardant mechanism of gaseous phase at superiority. This is attributed to •PO and •PO2 decomposed by POPP quenching •H and •OH. Otherwise, by promoting the intermolecular crosslinking of PLA, a continuous and dense carbon layer on the surface is formed, which improve flame retardancy of PLA composites.

2023, 40(7): 3892-3899.

doi: 10.13801/j.cnki.fhclxb.20221012.002

Abstract:

During the operation of the conveyor belt used in the food industry, the plastic particles on the surface layer may fall off and adhere to the food, resulting in unqualified food quality and a negative impact on human health. Therefore, it is of great importance to research the modification of surface layer materials that can be detected by X-rays. In this study, BaSO4/thermoplastic polyurethane (TPU) nanocomposites were prepared by the melt blending method. The phase morphology, thermal stability, and tensile property of BaSO4/TPU nanocomposites were systematically characterized by scanning electron microscopy (SEM), Fourier transform infrared spectroscopy (FTIR), thermal gravimetric analysis (TGA), hardness, and tensile property tests. In particular, the X ray developing properties of the composites were characterized by X ray fluoroscopy tests. SEM shows that BaSO4/TPU nanocomposites are the best. The tensile strength, elongation at break and work of fracture improve by 10.19%, 30.09% and 31.92% compared to unmodified TPU. The TGA test results show that the high-temperature thermal stability of BaSO4/TPU nanocomposites is improved. In addition, by adding BaSO4, the X ray developing properties of the composites are also improved, thus realizing the application in the surface layer of conveyor belts.

During the operation of the conveyor belt used in the food industry, the plastic particles on the surface layer may fall off and adhere to the food, resulting in unqualified food quality and a negative impact on human health. Therefore, it is of great importance to research the modification of surface layer materials that can be detected by X-rays. In this study, BaSO4/thermoplastic polyurethane (TPU) nanocomposites were prepared by the melt blending method. The phase morphology, thermal stability, and tensile property of BaSO4/TPU nanocomposites were systematically characterized by scanning electron microscopy (SEM), Fourier transform infrared spectroscopy (FTIR), thermal gravimetric analysis (TGA), hardness, and tensile property tests. In particular, the X ray developing properties of the composites were characterized by X ray fluoroscopy tests. SEM shows that BaSO4/TPU nanocomposites are the best. The tensile strength, elongation at break and work of fracture improve by 10.19%, 30.09% and 31.92% compared to unmodified TPU. The TGA test results show that the high-temperature thermal stability of BaSO4/TPU nanocomposites is improved. In addition, by adding BaSO4, the X ray developing properties of the composites are also improved, thus realizing the application in the surface layer of conveyor belts.

2023, 40(7): 3900-3911.

doi: 10.13801/j.cnki.fhclxb.20220922.004

Abstract:

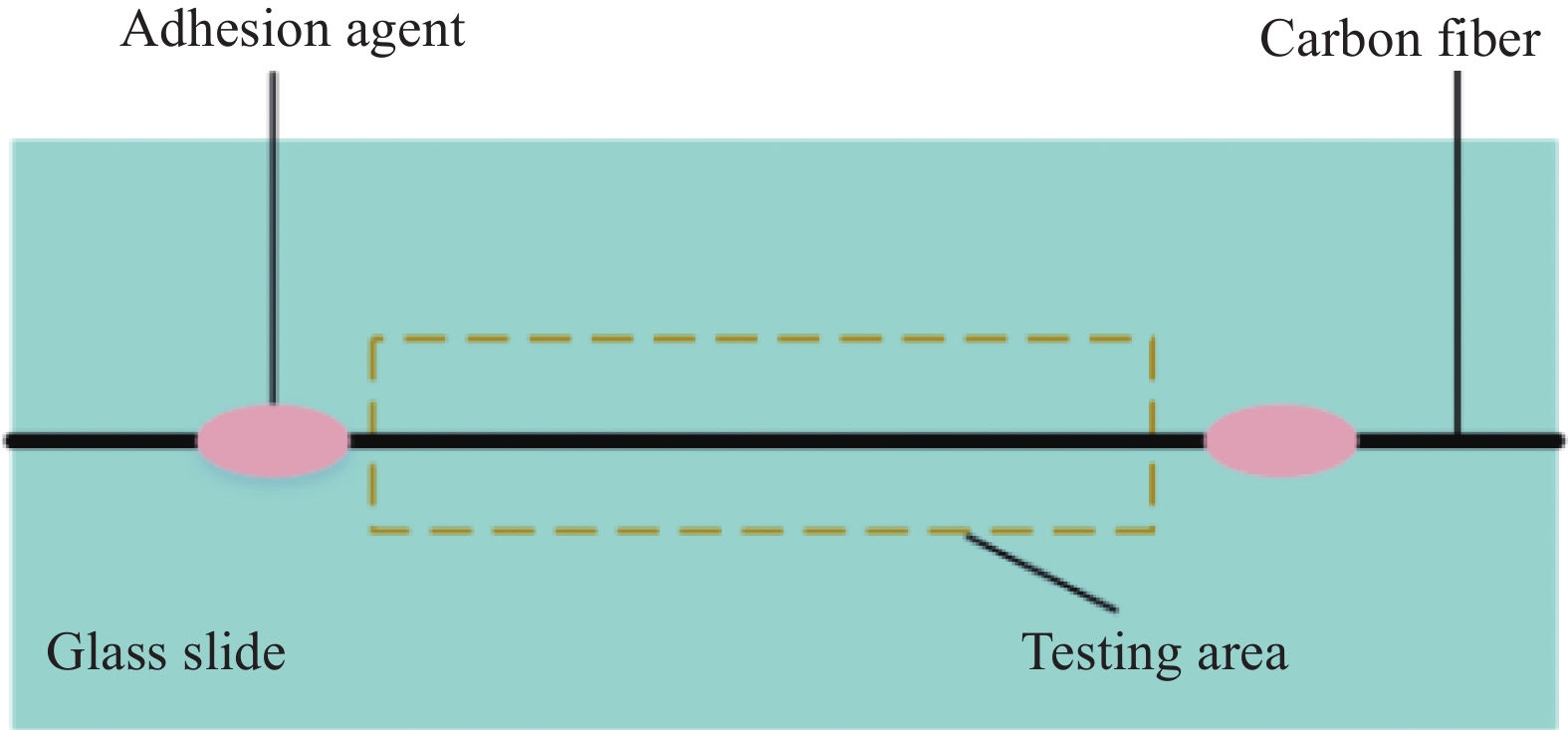

For carbon fiber reinforced polymer matrix composites (CFRP), the in-situ electron beam (E-Beam) curing meets the requirements of integrated manufacturing of shape and performance, which is low-cost according with the "carbon peak and carbon neutralization" strategy. But the E-Beam technology has not yet been industrialized due to the poor interface quality of cured components. Addressing the weak interface of E-Beam cured CFRP, the mechanism and technology of an efficient and high industrial feasibility strengthening technology by microwave short-time radiation were explored in this study. The evolution of physical morphology, roughness and chemical composition of carbon fiber surface under different microwave radiation process parameters was described, showing that the surface roughness, surface area and the O/C atomic ratio of CFs increased from 4.41 nm,7.5 nm2, 0.2578 at 0 s irradiation to 21.7 nm, 26.4 nm2, and 0.3278 respectively after 180 s microwave irradiation. Furthermore, a molecular dynamics model of the interface was constructed to refine and deepen the nature of the carboxyl and hydroxyl enhanced interface from the molecular level, and then their effects on the interface structure and interface energy. The experimental results show that the interfacial shear strength of carbon fiber/resin is improved by 20.47% under the combined effect of physical and chemical modification of microwave radiation (90 s). This research provides the foundation and support for green forming manufacturing of high-performance E-Beam cured CFRP, and has important scientific significance.

For carbon fiber reinforced polymer matrix composites (CFRP), the in-situ electron beam (E-Beam) curing meets the requirements of integrated manufacturing of shape and performance, which is low-cost according with the "carbon peak and carbon neutralization" strategy. But the E-Beam technology has not yet been industrialized due to the poor interface quality of cured components. Addressing the weak interface of E-Beam cured CFRP, the mechanism and technology of an efficient and high industrial feasibility strengthening technology by microwave short-time radiation were explored in this study. The evolution of physical morphology, roughness and chemical composition of carbon fiber surface under different microwave radiation process parameters was described, showing that the surface roughness, surface area and the O/C atomic ratio of CFs increased from 4.41 nm,7.5 nm2, 0.2578 at 0 s irradiation to 21.7 nm, 26.4 nm2, and 0.3278 respectively after 180 s microwave irradiation. Furthermore, a molecular dynamics model of the interface was constructed to refine and deepen the nature of the carboxyl and hydroxyl enhanced interface from the molecular level, and then their effects on the interface structure and interface energy. The experimental results show that the interfacial shear strength of carbon fiber/resin is improved by 20.47% under the combined effect of physical and chemical modification of microwave radiation (90 s). This research provides the foundation and support for green forming manufacturing of high-performance E-Beam cured CFRP, and has important scientific significance.

2023, 40(7): 3912-3920.

doi: 10.13801/j.cnki.fhclxb.20220915.006

Abstract:

In order to analyze the influence of layer structure of composite material on bending-twisting coupling behavior of wind turbine blade, the carbon/glass biaxial warp knitting fabric with hybrid layer ratio 4∶4 and 2∶6 were selected as reinforcement to fabricate blade. A 2 kW wind turbine blade samples model was established and the strain deform behavior of blade samples was experimental studied by combining classical laminate theory and nodal displacement method. The bending-twisting coupling behavior was also analyzed. The results show that when the carbon/glass hybrid ratio is same and the fiber off-axis angle is 25°, the optimal value of equivalent bending-twisting coupling coefficient of blade samples is 0.186. With same fiber off-axis angle, carbon/glass hybrid ratio 4∶4 blade samples has higher equivalent bending-twisting coupling coefficient than carbon/glass hybrid ratio 2∶6 blade samples. The strain measurement experiment shows that the principal strains decreases gradually along with blade length, and bending-twisting coupling behavior have a good effect on perfecting the principal strain at the blade root.

In order to analyze the influence of layer structure of composite material on bending-twisting coupling behavior of wind turbine blade, the carbon/glass biaxial warp knitting fabric with hybrid layer ratio 4∶4 and 2∶6 were selected as reinforcement to fabricate blade. A 2 kW wind turbine blade samples model was established and the strain deform behavior of blade samples was experimental studied by combining classical laminate theory and nodal displacement method. The bending-twisting coupling behavior was also analyzed. The results show that when the carbon/glass hybrid ratio is same and the fiber off-axis angle is 25°, the optimal value of equivalent bending-twisting coupling coefficient of blade samples is 0.186. With same fiber off-axis angle, carbon/glass hybrid ratio 4∶4 blade samples has higher equivalent bending-twisting coupling coefficient than carbon/glass hybrid ratio 2∶6 blade samples. The strain measurement experiment shows that the principal strains decreases gradually along with blade length, and bending-twisting coupling behavior have a good effect on perfecting the principal strain at the blade root.

2023, 40(7): 3921-3927.

doi: 10.13801/j.cnki.fhclxb.20221009.002

Abstract:

Aiming at the deficiency of high back-face signature (BFS) of ultra-high molecular weight polyethylene (UHMWPE) fiber-reinforced ballistic composites, a series of polyimide (PI) and UHMWPE fiber hybrid composites were prepared by making full use of the advantages of high temperature resistance and high modulus of PI fibers in this study. The effects of layer structure and mixing ratio on the specific energy absorption (SEA) and BFS values of the hybrid composites and the protective mechanism were investigated. The results show that the use of PI fibers can effectively limit the BFS without affecting the SEA value. The bipolar layer structure (H3, UHMWPE/PI) and the sandwich layer structure (H4, PI/UHMWPE/PI) exhibit positive mixed effect. SEA and BFS values of the two structures can reach 193.2 J·m2/kg, 17.40 mm and 208.9 J·m2/kg, 17.77 mm, respectively, demonstrated excellent bulletproof performance.

Aiming at the deficiency of high back-face signature (BFS) of ultra-high molecular weight polyethylene (UHMWPE) fiber-reinforced ballistic composites, a series of polyimide (PI) and UHMWPE fiber hybrid composites were prepared by making full use of the advantages of high temperature resistance and high modulus of PI fibers in this study. The effects of layer structure and mixing ratio on the specific energy absorption (SEA) and BFS values of the hybrid composites and the protective mechanism were investigated. The results show that the use of PI fibers can effectively limit the BFS without affecting the SEA value. The bipolar layer structure (H3, UHMWPE/PI) and the sandwich layer structure (H4, PI/UHMWPE/PI) exhibit positive mixed effect. SEA and BFS values of the two structures can reach 193.2 J·m2/kg, 17.40 mm and 208.9 J·m2/kg, 17.77 mm, respectively, demonstrated excellent bulletproof performance.

2023, 40(7): 3928-3938.

doi: 10.13801/j.cnki.fhclxb.20220919.002

Abstract:

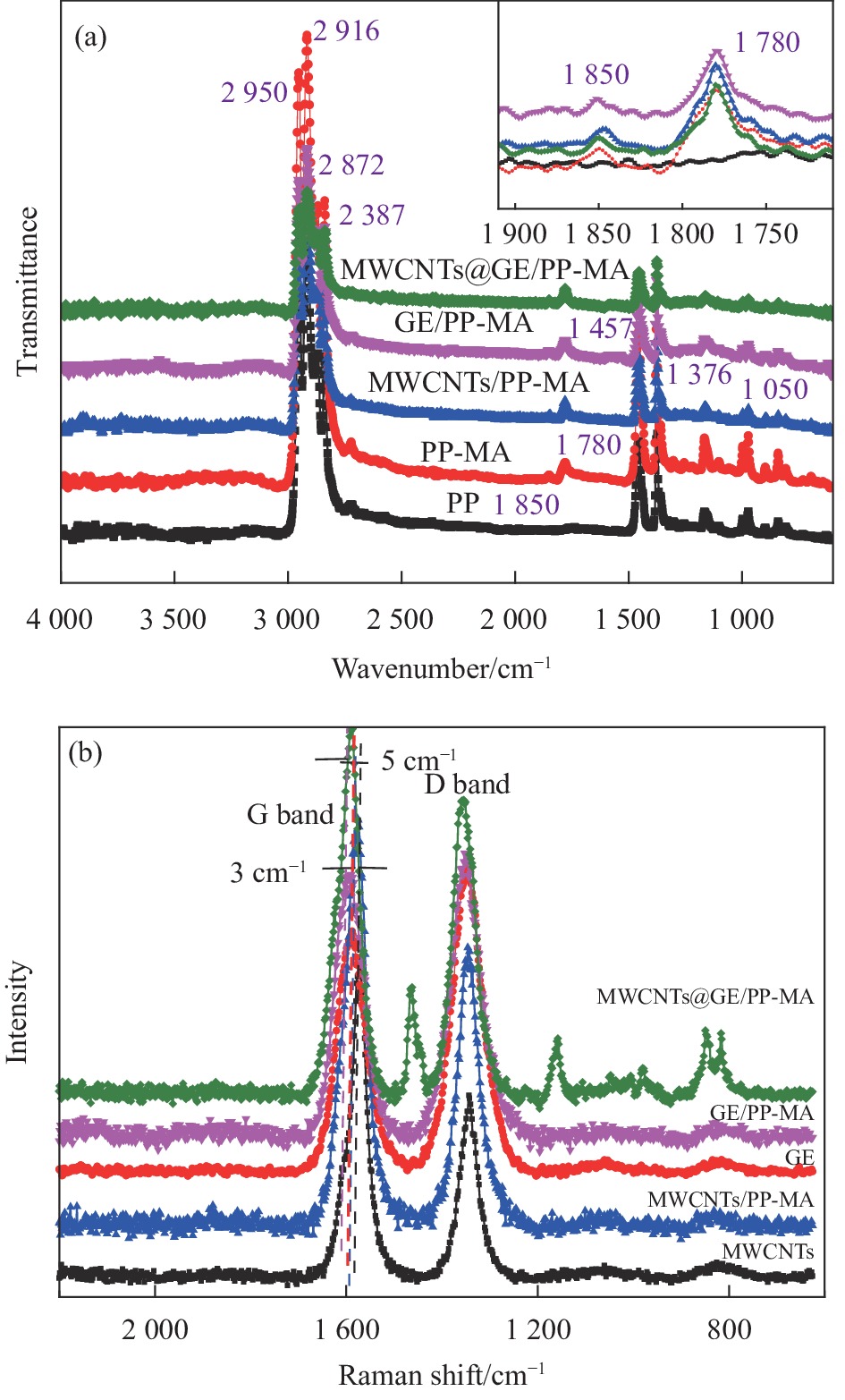

This work mainly used the synergistic effect of one- and two-dimensional fillers (Multi-walled carbon nanotubes (MWCNTs)@graphene (GE)) to improve the thermoelectric and mechanical properties of thermoplastic vulcanizate (TPV). MWCNTs@GE/polypropylene-maleic anhydride (PP-MA) masterbatch were first prepared by melt-graft blending. The structure, crystallinity and microstructure of MWCNTs@GE/PP-MA masterbatch were characterized. Then MWCNTs@GE/TPV composites with unique network structure were prepared by dynamic vulcanization method. The effects of the amount of MWCNTs@GE on the phase structure, electrical conductivity, thermal conductivity and mechanical properties of MWCNTs@GE/TPV composites were studied. The results show that the combination of MWCNTs and GE has a synergistic effect and can be used as nucleating agent to improve crystallization peak temperature (Tc) and crystallinity of PP (Xc) and reduce crystal size of the PP crystal plane (LCrystallite) in the crystallization process, compared with the masterbatch prepared with single filler. In the MWCNTs@GE/PP-MA masterbatch, MWCNTs and GE are uniformly dispersed in PP-MA and have strong bonding force with the matrix. The MWCNTs@GE/TPV composites show an obvious "island" structure, and the cross-linked butyl rubber (IIR) rubber is dispersed in the PP-MA phase as micron size particles. MWCNTs and GE are uniformly dispersed in the continuous phase PP-MA, and the distance between MWCNTs and GE is less than 1 µm, forming the MWCNTs@GE network structure. When the content of MWCNTs@GE in MWCNTs@GE/TPV composites reaches 3wt%, the alternating current (AC) electrical conductivity, thermal conductivity, elongation at break and tensile strength reach the best value.

This work mainly used the synergistic effect of one- and two-dimensional fillers (Multi-walled carbon nanotubes (MWCNTs)@graphene (GE)) to improve the thermoelectric and mechanical properties of thermoplastic vulcanizate (TPV). MWCNTs@GE/polypropylene-maleic anhydride (PP-MA) masterbatch were first prepared by melt-graft blending. The structure, crystallinity and microstructure of MWCNTs@GE/PP-MA masterbatch were characterized. Then MWCNTs@GE/TPV composites with unique network structure were prepared by dynamic vulcanization method. The effects of the amount of MWCNTs@GE on the phase structure, electrical conductivity, thermal conductivity and mechanical properties of MWCNTs@GE/TPV composites were studied. The results show that the combination of MWCNTs and GE has a synergistic effect and can be used as nucleating agent to improve crystallization peak temperature (Tc) and crystallinity of PP (Xc) and reduce crystal size of the PP crystal plane (LCrystallite) in the crystallization process, compared with the masterbatch prepared with single filler. In the MWCNTs@GE/PP-MA masterbatch, MWCNTs and GE are uniformly dispersed in PP-MA and have strong bonding force with the matrix. The MWCNTs@GE/TPV composites show an obvious "island" structure, and the cross-linked butyl rubber (IIR) rubber is dispersed in the PP-MA phase as micron size particles. MWCNTs and GE are uniformly dispersed in the continuous phase PP-MA, and the distance between MWCNTs and GE is less than 1 µm, forming the MWCNTs@GE network structure. When the content of MWCNTs@GE in MWCNTs@GE/TPV composites reaches 3wt%, the alternating current (AC) electrical conductivity, thermal conductivity, elongation at break and tensile strength reach the best value.

2023, 40(7): 3939-3949.

doi: 10.13801/j.cnki.fhclxb.20220907.005

Abstract:

MXenes show unique advantages in electromagnetic shielding materials due to their high electrical conductivity, abundant active sites (such as —OH, —F, —O), electrochemical behavior, and excellent hydrophilicity. However, hydrogels with both excellent mechanical strength and high electromagnetic shielding efficiency remain to be further studied. Meanwhile, transparent hydrogels often lack the ability to filter ultraviolet light, which greatly limits the application of hydrogel materials. In this work, PAAm-PHEMA/PAA-Fe3+-MXene hydrogels with double shielding mechanism were prepared by using acrylamide (AAm) copolymer hydroxyethyl methacrylate (HEMA) chemical cross-linking as the first network, and polyacrylic acid (PAA)-Fe3+ metal ion complexation as the second network, and two-dimensional MXene as conductive nanofillers. The presence of MXene and Fe3+ makes the hydrogel possess both electromagnetic and UV shielding properties. The structure and three-dimensional network of the composite hydrogel were confirmed by FTIR, SEM and EDS. The as-prepared double-network hydrogel exhibits high mechanical strength (320.1 kPa), high stretchability (1786%), and good electrical conductivity (3.8 S/m). In addition, the composite hydrogel also exhibits excellent UV shielding ability, with transmittances of 0% and 79.2% at characteristic wavelengths of 365 and 550 nm, respectively. At the same time, the composite hydrogel can obtain excellent electromagnetic-interference (EMI) shielding effect of more than 36 dB in the X-band, strong adhesion to various substrates, rapid self-healing performance and high shape adaptability. This work provides a flexible and highly tunable dual-shielding mechanism hydrogel network design and large-scale facile fabrication of new ideas, showing great application prospects in flexible wearable materials.

MXenes show unique advantages in electromagnetic shielding materials due to their high electrical conductivity, abundant active sites (such as —OH, —F, —O), electrochemical behavior, and excellent hydrophilicity. However, hydrogels with both excellent mechanical strength and high electromagnetic shielding efficiency remain to be further studied. Meanwhile, transparent hydrogels often lack the ability to filter ultraviolet light, which greatly limits the application of hydrogel materials. In this work, PAAm-PHEMA/PAA-Fe3+-MXene hydrogels with double shielding mechanism were prepared by using acrylamide (AAm) copolymer hydroxyethyl methacrylate (HEMA) chemical cross-linking as the first network, and polyacrylic acid (PAA)-Fe3+ metal ion complexation as the second network, and two-dimensional MXene as conductive nanofillers. The presence of MXene and Fe3+ makes the hydrogel possess both electromagnetic and UV shielding properties. The structure and three-dimensional network of the composite hydrogel were confirmed by FTIR, SEM and EDS. The as-prepared double-network hydrogel exhibits high mechanical strength (320.1 kPa), high stretchability (1786%), and good electrical conductivity (3.8 S/m). In addition, the composite hydrogel also exhibits excellent UV shielding ability, with transmittances of 0% and 79.2% at characteristic wavelengths of 365 and 550 nm, respectively. At the same time, the composite hydrogel can obtain excellent electromagnetic-interference (EMI) shielding effect of more than 36 dB in the X-band, strong adhesion to various substrates, rapid self-healing performance and high shape adaptability. This work provides a flexible and highly tunable dual-shielding mechanism hydrogel network design and large-scale facile fabrication of new ideas, showing great application prospects in flexible wearable materials.

2023, 40(7): 3950-3963.

doi: 10.13801/j.cnki.fhclxb.20220913.004

Abstract:

Thin film capacitors have important applications in the fields of electrical engineering and electronic devices such as high voltage transmission converter stations, new energy vehicle electric drive controllers, electromagnetic weapon pulse power supply and so on. At present, thin-film capacitors are developing towards the technical direction of high energy density, voltage resistance, high temperature resistance and so on, which put forward higher requirements for the electrical performance of capacitor films. In this study, ferroelectric polyvinylidene fluoride (PVDF) and polymethyl methacrylate (PMMA) blends were selected as the energy storage polymer matrix, and BaTiO3 nanoparticles with high dielectric constant and organic molecular semiconductor [6, 6]-phenyl C61 methyl butyrate (PCBM) with high electron affinity were used as the doping phase. The high dielectric properties of BaTiO3 and the ability of PCBM to capture charge are comprehensively utilized to improve the polarization strength and breakdown field strength of the composite medium and significantly improve the energy storage performance. The results show that when the doping content is 3wt%, the composite media has the best comprehensive performance. On this basis, with the increase of PCBM doping content, its energy storage density and charge-discharge efficiency improved significantly. When PCBM doping content is 2wt%, PMMA/PVDF composite medium containing 3wt% BaTiO3 has excellent energy storage performance. When the electric field is 579.67 kV/mm, the discharge energy density reaches 15.60 J/cm3 and the charge-discharge efficiency is 75.30%. First proposed in this paper, based on a small amount of inorganic high dielectric organic molecules together semiconductor filler modified polymer film energy storage performance of the function, by adding a small amount of BaTiO3 particles, avoids insulation performance degradation caused by the high content of BaTiO3, and ensures the BaTiO3 particle on the properties of composite dielectric permittivity and polarization. At the same time, in order to further improve due to the low dielectric constant substrate with high dielectric constant BaTiO3 particles between the electric field distortion caused by the breakdown strength degradation, consider joining a certain amount of PCBM in a composite medium, use PCBM electron affinity ability, strong in composite medium build deep traps to capture and carrier, inhibit the transfer of carrier.The breakdown field strength of the composite medium is improved, so as to comprehensively improve the energy storage performance of the composite medium, which provides a new idea for the development of polymer composite medium with excellent energy storage performance.

Thin film capacitors have important applications in the fields of electrical engineering and electronic devices such as high voltage transmission converter stations, new energy vehicle electric drive controllers, electromagnetic weapon pulse power supply and so on. At present, thin-film capacitors are developing towards the technical direction of high energy density, voltage resistance, high temperature resistance and so on, which put forward higher requirements for the electrical performance of capacitor films. In this study, ferroelectric polyvinylidene fluoride (PVDF) and polymethyl methacrylate (PMMA) blends were selected as the energy storage polymer matrix, and BaTiO3 nanoparticles with high dielectric constant and organic molecular semiconductor [6, 6]-phenyl C61 methyl butyrate (PCBM) with high electron affinity were used as the doping phase. The high dielectric properties of BaTiO3 and the ability of PCBM to capture charge are comprehensively utilized to improve the polarization strength and breakdown field strength of the composite medium and significantly improve the energy storage performance. The results show that when the doping content is 3wt%, the composite media has the best comprehensive performance. On this basis, with the increase of PCBM doping content, its energy storage density and charge-discharge efficiency improved significantly. When PCBM doping content is 2wt%, PMMA/PVDF composite medium containing 3wt% BaTiO3 has excellent energy storage performance. When the electric field is 579.67 kV/mm, the discharge energy density reaches 15.60 J/cm3 and the charge-discharge efficiency is 75.30%. First proposed in this paper, based on a small amount of inorganic high dielectric organic molecules together semiconductor filler modified polymer film energy storage performance of the function, by adding a small amount of BaTiO3 particles, avoids insulation performance degradation caused by the high content of BaTiO3, and ensures the BaTiO3 particle on the properties of composite dielectric permittivity and polarization. At the same time, in order to further improve due to the low dielectric constant substrate with high dielectric constant BaTiO3 particles between the electric field distortion caused by the breakdown strength degradation, consider joining a certain amount of PCBM in a composite medium, use PCBM electron affinity ability, strong in composite medium build deep traps to capture and carrier, inhibit the transfer of carrier.The breakdown field strength of the composite medium is improved, so as to comprehensively improve the energy storage performance of the composite medium, which provides a new idea for the development of polymer composite medium with excellent energy storage performance.

2023, 40(7): 3964-3972.

doi: 10.13801/j.cnki.fhclxb.20220909.004

Abstract:

Due to the shortcomings of strontium titanate (SrTiO3) with large band gap and low separation rate of photogenerating carriers, its photoelectrochemical cathodic protection performance is limited. And in order to solve this problem, SrTiO3 can be modified with the supporting cocatalyst Ti3C2. Firstly, SrTiO3 was prepared by hydrothermal method and Ti3C2 was obtained by etching. Then, Ti3C2/SrTiO3 composites were prepared by mechanical mixing. XRD, XPS, SEM, UV-vis DRS, and PL had characterized the phase structure, chemical state, microscopic morphology, and light absorption performance of the samples. Finally, the photoelectrochemical cathodic protection performance of Ti3C2/SrTiO3 composites to 304 stainless steel (304SS) was analyzed. The results show that Ti3C2/SrTiO3 composites are broadened to absorb visible light. Among them, the photogenerated carrier separation rate of the 15%-Ti3C2/SrTiO3 composite with a mass fraction of 15wt% of Ti3C2 has a higher separation rate and an optical current density of 2.5 μA·cm−2. In the 3.5wt% NaCl solution, after the coupling of 304SS to the composite, its photomotive potential drops by 200 mV under light conditions, which can effectively protect 304SS. After four open and closed light cycle tests, the performance of Ti3C2/SrTiO3 composites are stable.

Due to the shortcomings of strontium titanate (SrTiO3) with large band gap and low separation rate of photogenerating carriers, its photoelectrochemical cathodic protection performance is limited. And in order to solve this problem, SrTiO3 can be modified with the supporting cocatalyst Ti3C2. Firstly, SrTiO3 was prepared by hydrothermal method and Ti3C2 was obtained by etching. Then, Ti3C2/SrTiO3 composites were prepared by mechanical mixing. XRD, XPS, SEM, UV-vis DRS, and PL had characterized the phase structure, chemical state, microscopic morphology, and light absorption performance of the samples. Finally, the photoelectrochemical cathodic protection performance of Ti3C2/SrTiO3 composites to 304 stainless steel (304SS) was analyzed. The results show that Ti3C2/SrTiO3 composites are broadened to absorb visible light. Among them, the photogenerated carrier separation rate of the 15%-Ti3C2/SrTiO3 composite with a mass fraction of 15wt% of Ti3C2 has a higher separation rate and an optical current density of 2.5 μA·cm−2. In the 3.5wt% NaCl solution, after the coupling of 304SS to the composite, its photomotive potential drops by 200 mV under light conditions, which can effectively protect 304SS. After four open and closed light cycle tests, the performance of Ti3C2/SrTiO3 composites are stable.

2023, 40(7): 3973-3985.

doi: 10.13801/j.cnki.fhclxb.20220909.002

Abstract:

The construction of surface plasmon resonance (SPR), oxygen vacancies, and heterojunctions is one of the effective ways to enhance the catalytic activity of semiconductor photocatalysts. In this paper, Bi-Bi2O3-BiOBr ternary heterojunction composites with SPR effect and oxygen vacancies were synthesized by a one-step solvothermal method by changing the molar ratio of Bi(NO3)3 to KBr. Used XRD, electron paramagnetic resonance (EPR), XPS, SEM, TEM, UV-vis and other means to characterize and analyze the crystal phase, elemental composition and microscopic morphology of the obtained product, and investigate the effect of the molar ratio of Bi(NO3)3 to KBr on the visible light-driven photocatalytic degradation of methylene blue (MB) activity of the ternary complex. The results show that the catalytic activity of Bi-Bi2O3-BiOBr depends on the molar ratio of Bi(NO3)3 to KBr, but is higher than that of pure Bi2O3 and BiOBr. The 2∶1-Bi-Bi2O3-BiOBr prepared with a molar ratio of Bi(NO3)3 to KBr of 2∶1 exhibited the best photocatalytic activity towards MB. 2∶1-Bi-Bi2O3-BiOBr was irradiated with visible light for 240 min. The removal rate of MB on Bi-Bi2O3-BiOBr is 95.07%, and the degradation kinetics conform to pseudo-first-order kinetics. The degradation rate constant is 2.90 h−1, which is 5 and 6 times that of pure Bi2O3 and BiOBr, respectively. After 4 cycles of experiments, 2∶1-Bi-Bi2O3-BiOBr composite does't significantly reduce the removal efficiency of MB. The excellent visible-light photocatalytic activity of this material can be attributed to the three synergistic effects of SPR effect, semiconductor heterojunction structure and oxygen vacancies. The method for synthesizing photocatalysts with special structures in this paper can be extended to other catalytic materials.

The construction of surface plasmon resonance (SPR), oxygen vacancies, and heterojunctions is one of the effective ways to enhance the catalytic activity of semiconductor photocatalysts. In this paper, Bi-Bi2O3-BiOBr ternary heterojunction composites with SPR effect and oxygen vacancies were synthesized by a one-step solvothermal method by changing the molar ratio of Bi(NO3)3 to KBr. Used XRD, electron paramagnetic resonance (EPR), XPS, SEM, TEM, UV-vis and other means to characterize and analyze the crystal phase, elemental composition and microscopic morphology of the obtained product, and investigate the effect of the molar ratio of Bi(NO3)3 to KBr on the visible light-driven photocatalytic degradation of methylene blue (MB) activity of the ternary complex. The results show that the catalytic activity of Bi-Bi2O3-BiOBr depends on the molar ratio of Bi(NO3)3 to KBr, but is higher than that of pure Bi2O3 and BiOBr. The 2∶1-Bi-Bi2O3-BiOBr prepared with a molar ratio of Bi(NO3)3 to KBr of 2∶1 exhibited the best photocatalytic activity towards MB. 2∶1-Bi-Bi2O3-BiOBr was irradiated with visible light for 240 min. The removal rate of MB on Bi-Bi2O3-BiOBr is 95.07%, and the degradation kinetics conform to pseudo-first-order kinetics. The degradation rate constant is 2.90 h−1, which is 5 and 6 times that of pure Bi2O3 and BiOBr, respectively. After 4 cycles of experiments, 2∶1-Bi-Bi2O3-BiOBr composite does't significantly reduce the removal efficiency of MB. The excellent visible-light photocatalytic activity of this material can be attributed to the three synergistic effects of SPR effect, semiconductor heterojunction structure and oxygen vacancies. The method for synthesizing photocatalysts with special structures in this paper can be extended to other catalytic materials.

2023, 40(7): 3986-3997.

doi: 10.13801/j.cnki.fhclxb.20221031.001

Abstract:

Using electrospinning technology to compound antibacterial active ingredients with matrix fibers is seen as an effective means to develop new antibacterial materials. To develop new microbial deterioration control materials for grotto cultural heritage, composite polyacrylonitrile (PAN)-nano silver (AgNPs) electrospun fiber membrane was developed by electrospinning technology. The antibacterial effects of the fiber were further evaluated. Spinning stock solution containing silver particles was prepared by PAN mixing with dimethylformamide, adding silver nitrate and tea polyphenols. Then, the nano fiber membrane containing silver particles was prepared by electrostatic spinning technology. By changing the concentration and reaction temperature of PAN, the physical and chemical properties of electrospun fiber membrane, screening the optimal preparation process of electrospun fiber membrane suitable for the prevention and control of grotto cultural heritage microbial deterioration, the antibacterial effect of fibers was verified in the laboratory and outdoors respectively. The results show that the composite fiber membrane prepared with 12wt% PAN content at 80℃ has the advantages of good fiber mechanical properties and high concentration of silver particles, which is the optimal preparation condition of composite PAN-AgNPs electrospun fiber membrane screened in this study. Silver composite nanofiber material has antibacterial effect on Aspergillus niger and Penicillium ap., two microorganisms related to the deterioration of grotto cultural heritage. Significant antibacterial effect under outdoor rock surface conditions has been detected. These results indicate that the composite PAN-AgNPs electrospun fiber membrane prepared in this study has application value for the control of grotto cultural heritage deterioration.

Using electrospinning technology to compound antibacterial active ingredients with matrix fibers is seen as an effective means to develop new antibacterial materials. To develop new microbial deterioration control materials for grotto cultural heritage, composite polyacrylonitrile (PAN)-nano silver (AgNPs) electrospun fiber membrane was developed by electrospinning technology. The antibacterial effects of the fiber were further evaluated. Spinning stock solution containing silver particles was prepared by PAN mixing with dimethylformamide, adding silver nitrate and tea polyphenols. Then, the nano fiber membrane containing silver particles was prepared by electrostatic spinning technology. By changing the concentration and reaction temperature of PAN, the physical and chemical properties of electrospun fiber membrane, screening the optimal preparation process of electrospun fiber membrane suitable for the prevention and control of grotto cultural heritage microbial deterioration, the antibacterial effect of fibers was verified in the laboratory and outdoors respectively. The results show that the composite fiber membrane prepared with 12wt% PAN content at 80℃ has the advantages of good fiber mechanical properties and high concentration of silver particles, which is the optimal preparation condition of composite PAN-AgNPs electrospun fiber membrane screened in this study. Silver composite nanofiber material has antibacterial effect on Aspergillus niger and Penicillium ap., two microorganisms related to the deterioration of grotto cultural heritage. Significant antibacterial effect under outdoor rock surface conditions has been detected. These results indicate that the composite PAN-AgNPs electrospun fiber membrane prepared in this study has application value for the control of grotto cultural heritage deterioration.

2023, 40(7): 3998-4007.

doi: 10.13801/j.cnki.fhclxb.20221102.002

Abstract:

Noise pollution greatly affects human mental and physical health. Porous sound absorption materials usually perform well in middle and high frequency bands, but improvement still needs in low frequency bands. In this work, hollow sphere foam matrix were prepared with fly-ash hollow sphere and sodium silicate as the raw materials firstly. Subsequently, flexible polyvinyl alcohol-carbon black (PVA-C) composite was introduced into the porous matrix through vacuum impregnation and ordinary heat drying or freeze drying process to obtain PVA-C/hollow sphere foam composites. The results show that the compressive strength of the obtained porous composite is more than 1.65 MPa. The sound absorption performance is improved by 35.2% in the range of 100-1000 Hz, compared with the hollow sphere foam matrix. The noise reduction coefficient reaches 0.523, which is increased by 10.1%. The results of the study provide a basis for the improvement of sound absorption performance and practical application of porous sound absorbing materials.

Noise pollution greatly affects human mental and physical health. Porous sound absorption materials usually perform well in middle and high frequency bands, but improvement still needs in low frequency bands. In this work, hollow sphere foam matrix were prepared with fly-ash hollow sphere and sodium silicate as the raw materials firstly. Subsequently, flexible polyvinyl alcohol-carbon black (PVA-C) composite was introduced into the porous matrix through vacuum impregnation and ordinary heat drying or freeze drying process to obtain PVA-C/hollow sphere foam composites. The results show that the compressive strength of the obtained porous composite is more than 1.65 MPa. The sound absorption performance is improved by 35.2% in the range of 100-1000 Hz, compared with the hollow sphere foam matrix. The noise reduction coefficient reaches 0.523, which is increased by 10.1%. The results of the study provide a basis for the improvement of sound absorption performance and practical application of porous sound absorbing materials.

2023, 40(7): 4008-4021.

doi: 10.13801/j.cnki.fhclxb.20221116.001

Abstract:

Aluminum matrix syntactic foams are a novel class of cellular materials synthesized by hollow particles and aluminum matrix, which exhibit lightweight and high energy-absorbing capacity. In this study, the glass microspheres/aluminum matrix syntactic foams were prepared by the spark plasma sintering (SPS) method. The effects of the content and size of microspheres on the quasi-static compressive deformation behavior and energy absorption properties of the syntactic foams were analyzed by optical microscope (OM), SEM, quasi-static compression in situ observation, and digital image correlation (DIC) characterization. The results show that the microspheres of aluminum matrix syntactic foams prepared by two-step heating SPS sintering are uniformly embedded in the aluminum matrix, while the aluminum matrix is completely fused with high densification. With the increase of the microsphere content, the compressive stress of the syntactic foam decreases as a whole, meanwhile, the yield plateau expands and changes from smooth to zigzag. In addition, the compressive deformation behavior gradually develops from a relatively uniform drum-shaped deformation to brittle shear. The energy absorption capacity of the syntactic foam with the volume fraction of 50vol% is 23.6 J·cm−3, which is higher than that with the volume fraction of 30vol% and 70vol%. There is an optimal correspondence between the energy absorption capacity and the microsphere content of the syntactic foam. Small-sized microspheres have better compressive resistance. With the increase of the small-sized microsphere proportion, the syntactic foams can withstand higher stress and strain concentration on the microscopic level, as a result, the compressive strain of shear deformation increases on the macro level. In this study, the peak stress and energy absorption capacity of the syntactic foam with small-sized microspheres are 89.4 MPa and 29.0 J·cm−3, which are 23.5% and 22.9% higher than those of the syntactic foam with large-sized microsphere, respectively.

Aluminum matrix syntactic foams are a novel class of cellular materials synthesized by hollow particles and aluminum matrix, which exhibit lightweight and high energy-absorbing capacity. In this study, the glass microspheres/aluminum matrix syntactic foams were prepared by the spark plasma sintering (SPS) method. The effects of the content and size of microspheres on the quasi-static compressive deformation behavior and energy absorption properties of the syntactic foams were analyzed by optical microscope (OM), SEM, quasi-static compression in situ observation, and digital image correlation (DIC) characterization. The results show that the microspheres of aluminum matrix syntactic foams prepared by two-step heating SPS sintering are uniformly embedded in the aluminum matrix, while the aluminum matrix is completely fused with high densification. With the increase of the microsphere content, the compressive stress of the syntactic foam decreases as a whole, meanwhile, the yield plateau expands and changes from smooth to zigzag. In addition, the compressive deformation behavior gradually develops from a relatively uniform drum-shaped deformation to brittle shear. The energy absorption capacity of the syntactic foam with the volume fraction of 50vol% is 23.6 J·cm−3, which is higher than that with the volume fraction of 30vol% and 70vol%. There is an optimal correspondence between the energy absorption capacity and the microsphere content of the syntactic foam. Small-sized microspheres have better compressive resistance. With the increase of the small-sized microsphere proportion, the syntactic foams can withstand higher stress and strain concentration on the microscopic level, as a result, the compressive strain of shear deformation increases on the macro level. In this study, the peak stress and energy absorption capacity of the syntactic foam with small-sized microspheres are 89.4 MPa and 29.0 J·cm−3, which are 23.5% and 22.9% higher than those of the syntactic foam with large-sized microsphere, respectively.

2023, 40(7): 4022-4029.

doi: 10.13801/j.cnki.fhclxb.20220915.007

Abstract:

Piezoelectric nanogenerators and friction nanogenerators can convert irregular mechanical energy into electrical energy which have the potential to provide independent and continuous power supply for low-power wearable electronic devices. Combining two kinds nanogenerators can integrate the advantages of their electrical output characteristics and improve the performance of nanogenerators. In this paper, polyvinyl fluoride (PVDF) and styrene butadiene styrene block copolymer (SBS) were selected as positive and negative friction materials, respectively. The PVDF/SBS composite fiber films were prepared by electrospinning and were employed to build a piezoelectric/triboelectric nanogenerator. The results show that when the amount of PVDF is 20wt%, the maximum open circuit voltage and short circuit current of the PVDF/SBS piezoelectric/triboelectric nanogenerator can reach 108 V and 0.34 μA, which are 5 and 6 times that of neat SBS sample, respectively. When the devices were fixed on the palm and sole of the shoe, output voltage signal with different amplitude can be obtained by collecting the mechanical energy of human motion, including clapping, walking and running. 64 commercial blue LED beads were lit up when the device were beaten by palm. The device can also detect the instantaneous pressure and the maximum sensitivity can reach 3.685 V·N−1. The experimental results show that PVDF/SBS piezoelectric/triboelectric nanogenerator exhibits a good application prospect in the fields of sensor monitoring and self-energy supply of electronic devices.

Piezoelectric nanogenerators and friction nanogenerators can convert irregular mechanical energy into electrical energy which have the potential to provide independent and continuous power supply for low-power wearable electronic devices. Combining two kinds nanogenerators can integrate the advantages of their electrical output characteristics and improve the performance of nanogenerators. In this paper, polyvinyl fluoride (PVDF) and styrene butadiene styrene block copolymer (SBS) were selected as positive and negative friction materials, respectively. The PVDF/SBS composite fiber films were prepared by electrospinning and were employed to build a piezoelectric/triboelectric nanogenerator. The results show that when the amount of PVDF is 20wt%, the maximum open circuit voltage and short circuit current of the PVDF/SBS piezoelectric/triboelectric nanogenerator can reach 108 V and 0.34 μA, which are 5 and 6 times that of neat SBS sample, respectively. When the devices were fixed on the palm and sole of the shoe, output voltage signal with different amplitude can be obtained by collecting the mechanical energy of human motion, including clapping, walking and running. 64 commercial blue LED beads were lit up when the device were beaten by palm. The device can also detect the instantaneous pressure and the maximum sensitivity can reach 3.685 V·N−1. The experimental results show that PVDF/SBS piezoelectric/triboelectric nanogenerator exhibits a good application prospect in the fields of sensor monitoring and self-energy supply of electronic devices.