2021 Vol. 38, No. 9

2021, 38(9): 3008-3015.

doi: 10.13801/j.cnki.fhclxb.20201112.001

Abstract:

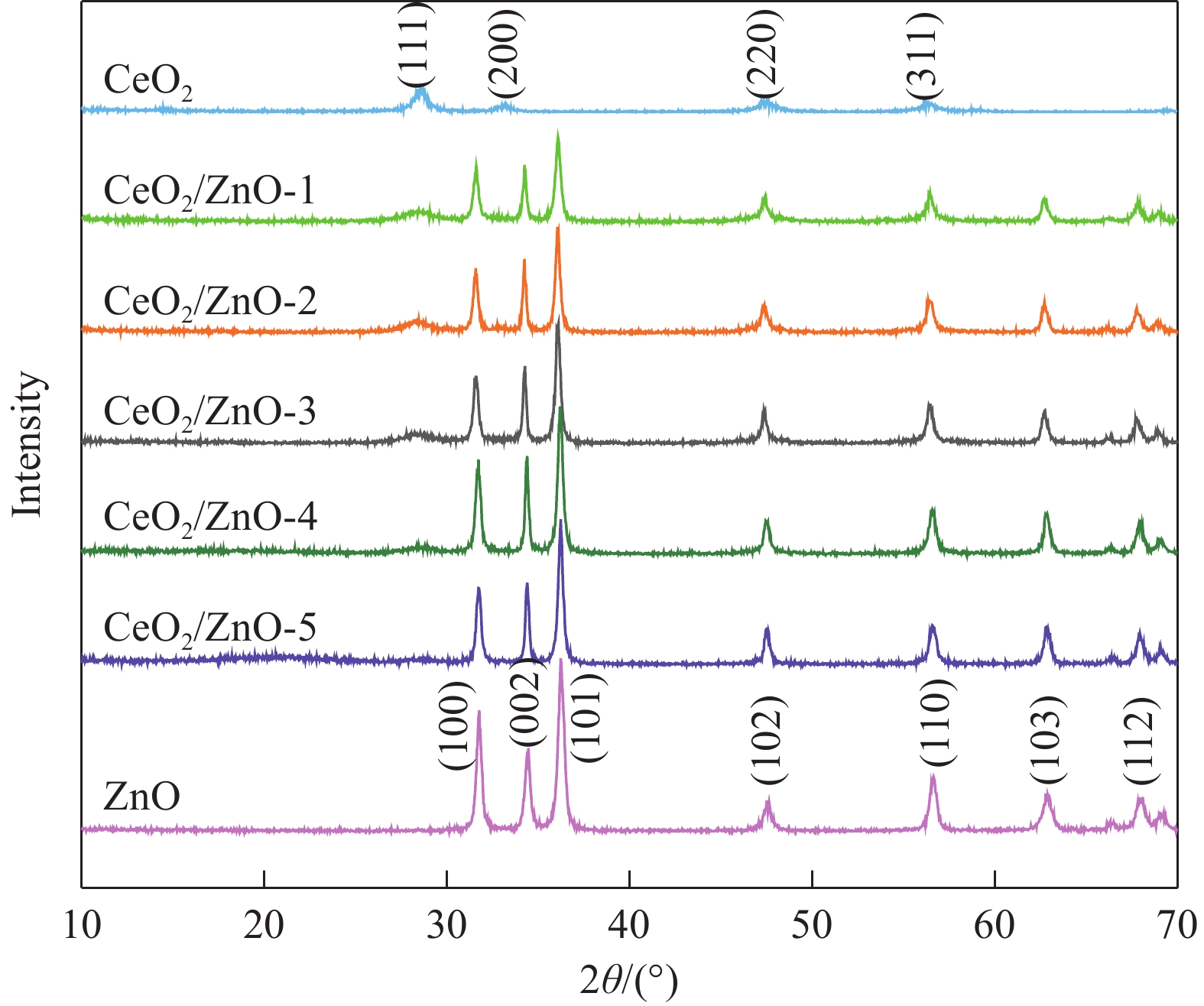

CeO2/ZnO composite photocatalysts were prepared via in-situ precipitation of CeO2 nanoparticles on ZnO substrate by ultrasonic microwave method and were characterized by XRD, SEM, TEM, PL, UV-Vis DRS and other techniques. The photocatalytic properties of the samples were investigated by degrading acid fuchsin (AF). The results show that ZnO has flower-shaped spherical structure assembled by ZnO nanoflskes, and its surfaces are evenly attached with CeO2 nanoparticles. CeO2/ZnO composite photocatalyst showed good photocatalytic activity with visible light irradiation. When the molar ratio of ZnO and CeO2 was 20∶1, the photodegradation rate of AF reached 96.44% after 90 min of illumination, which was significantly higher than those of pure phase ZnO and CeO2. CeO2/ZnO indicated high stability, as the degradation rate retained 93.53% after repeated use of the same photocatalyst for 6 times. The photdegradation mechanism study shows that superoxide radical (·O2−) was the main active substance in photdegrading AF.

CeO2/ZnO composite photocatalysts were prepared via in-situ precipitation of CeO2 nanoparticles on ZnO substrate by ultrasonic microwave method and were characterized by XRD, SEM, TEM, PL, UV-Vis DRS and other techniques. The photocatalytic properties of the samples were investigated by degrading acid fuchsin (AF). The results show that ZnO has flower-shaped spherical structure assembled by ZnO nanoflskes, and its surfaces are evenly attached with CeO2 nanoparticles. CeO2/ZnO composite photocatalyst showed good photocatalytic activity with visible light irradiation. When the molar ratio of ZnO and CeO2 was 20∶1, the photodegradation rate of AF reached 96.44% after 90 min of illumination, which was significantly higher than those of pure phase ZnO and CeO2. CeO2/ZnO indicated high stability, as the degradation rate retained 93.53% after repeated use of the same photocatalyst for 6 times. The photdegradation mechanism study shows that superoxide radical (·O2−) was the main active substance in photdegrading AF.

2021, 38(9): 3016-3025.

doi: 10.13801/j.cnki.fhclxb.20201214.002

Abstract:

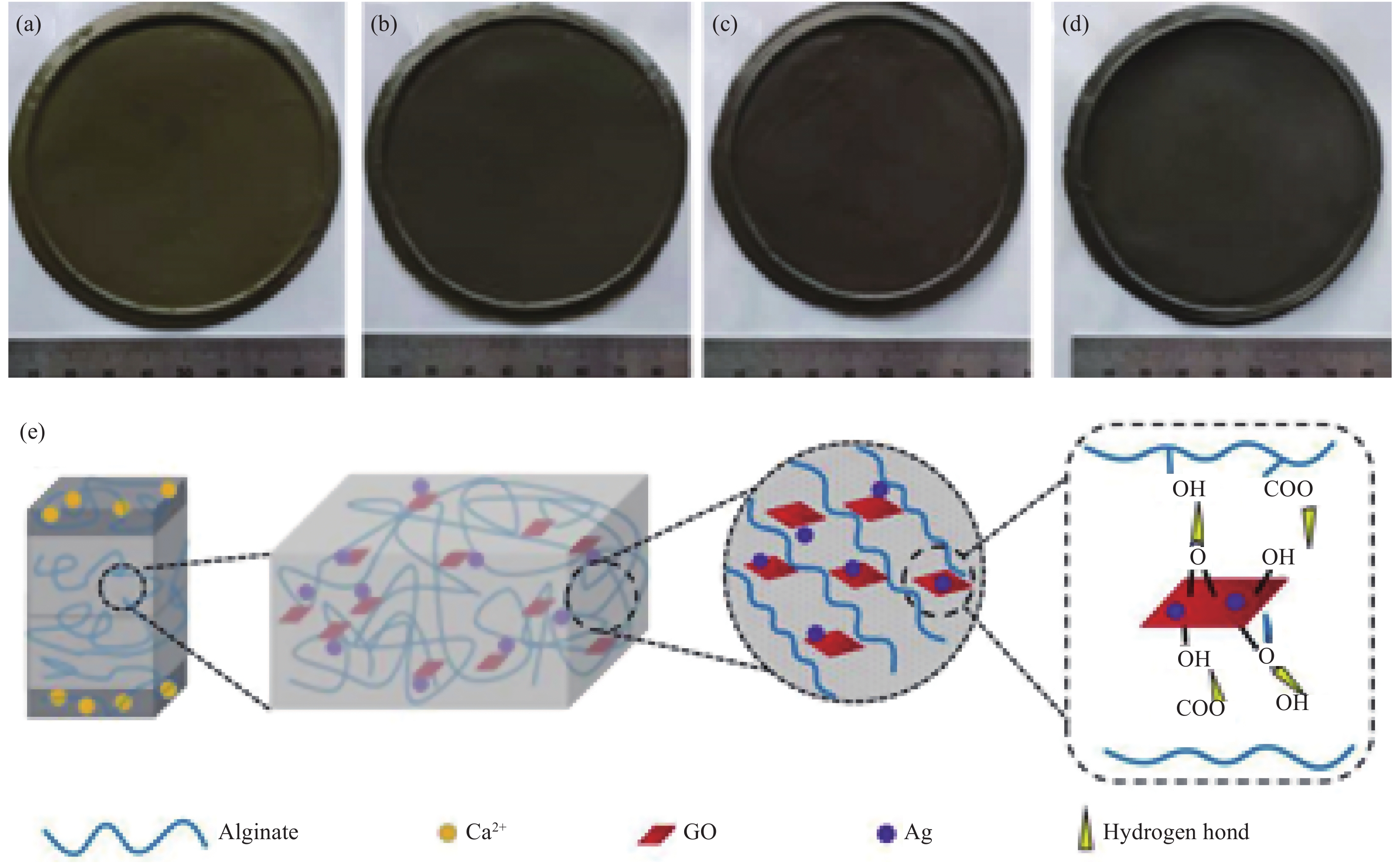

Sodium alginate (SA) is a natural polymer material that has been widely studied and used in the biomedical field. Nano-silver (Ag) has been proven to present good antibacterial properties, but its application is limited due to its easy agglomeration. In this paper, a series of Ag-graphene composites (Ag-GO) were prepared and characterized by loading Ag nanoparticles on the surface of graphene oxide (GO) sheets. Ag-GO was then added into SA, and a double-layered SA hydrogel film (Ag-GO/SA) carrying Ag-GO was prepared by sol-gel process. FTIR, XRD and SEM characterizations were used to determine the chemical structure and micromorphology of Ag-GO/SA. In addition, swelling ability, mechanical and antibacterial properties, as well as in-vitro cytotoxicity and in-vivo wound healing ability of Ag-GO/SA samples were also evaluated. The results show that the prepared Ag-GO/SA has good swelling property, sufficient mechanical strength, excellent wound healing and antibacterial properties. Specially, the optimum hydrogel of Ag-GO/SA can promote wound healing in SD rats, with a wound healing rate of up to 98%, presenting great application potential as a new type of wound dressing.

Sodium alginate (SA) is a natural polymer material that has been widely studied and used in the biomedical field. Nano-silver (Ag) has been proven to present good antibacterial properties, but its application is limited due to its easy agglomeration. In this paper, a series of Ag-graphene composites (Ag-GO) were prepared and characterized by loading Ag nanoparticles on the surface of graphene oxide (GO) sheets. Ag-GO was then added into SA, and a double-layered SA hydrogel film (Ag-GO/SA) carrying Ag-GO was prepared by sol-gel process. FTIR, XRD and SEM characterizations were used to determine the chemical structure and micromorphology of Ag-GO/SA. In addition, swelling ability, mechanical and antibacterial properties, as well as in-vitro cytotoxicity and in-vivo wound healing ability of Ag-GO/SA samples were also evaluated. The results show that the prepared Ag-GO/SA has good swelling property, sufficient mechanical strength, excellent wound healing and antibacterial properties. Specially, the optimum hydrogel of Ag-GO/SA can promote wound healing in SD rats, with a wound healing rate of up to 98%, presenting great application potential as a new type of wound dressing.

2021, 38(9): 3026-3034.

doi: 10.13801/j.cnki.fhclxb.20201123.001

Abstract:

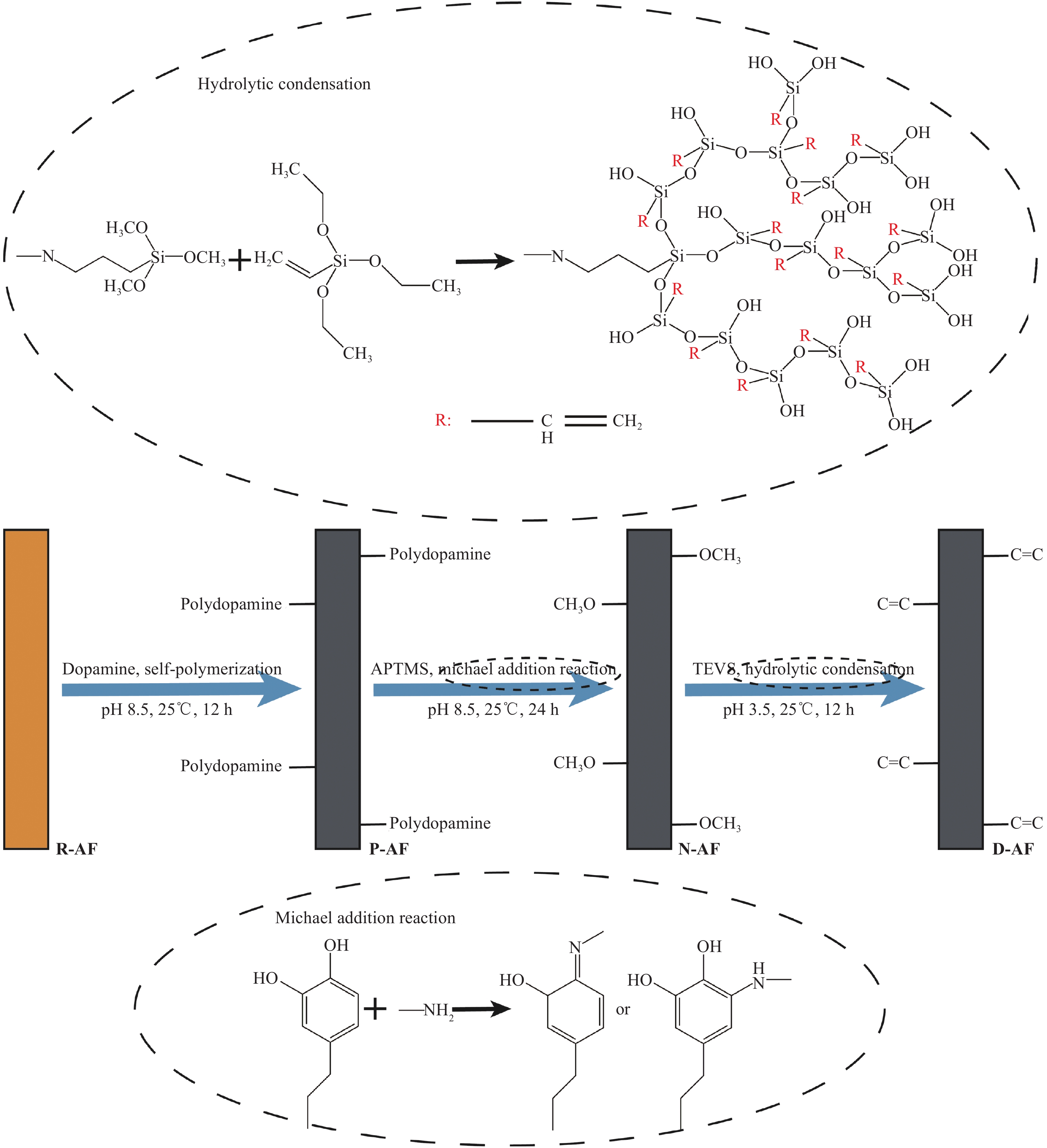

To improve the interfacial performance between aramid fiber and rubber matrix, this paper developed a strategy of in-situ growth of hyperbranched polysiloxane with double bonds onto the surface of aramid fiber. At first, the initial layer on the surface of fiber was established by the biomimetic modification of dopamine, and then, the middle layer was created by the graft of amino silane coupling agent via Michael addition reaction. Finally, the in-situ growth of hyperbranched polysiloxane was realized through the dehydration condensation reaction. The surface morphology and chemical structures of aramid fibers before and after modification were investigated by scanning electron microscope, Fourier transform infrared spectroscopy, X-ray photoelectron spectroscopy and thermogravimetric analysis. It can be obtained from the results of H pull-out tests of aramid fiber/rubber that the method proposed in this paper can increase the interfacial bonding strength by 66.4%, which can be ascribed to the improvement of surface roughness and the co-vulcanization between fibers and rubber. Furthermore, the graft of polydopamine initial layer makes this modification method have high universality and industrial application potential.

To improve the interfacial performance between aramid fiber and rubber matrix, this paper developed a strategy of in-situ growth of hyperbranched polysiloxane with double bonds onto the surface of aramid fiber. At first, the initial layer on the surface of fiber was established by the biomimetic modification of dopamine, and then, the middle layer was created by the graft of amino silane coupling agent via Michael addition reaction. Finally, the in-situ growth of hyperbranched polysiloxane was realized through the dehydration condensation reaction. The surface morphology and chemical structures of aramid fibers before and after modification were investigated by scanning electron microscope, Fourier transform infrared spectroscopy, X-ray photoelectron spectroscopy and thermogravimetric analysis. It can be obtained from the results of H pull-out tests of aramid fiber/rubber that the method proposed in this paper can increase the interfacial bonding strength by 66.4%, which can be ascribed to the improvement of surface roughness and the co-vulcanization between fibers and rubber. Furthermore, the graft of polydopamine initial layer makes this modification method have high universality and industrial application potential.

2021, 38(9): 3035-3043.

doi: 10.13801/j.cnki.fhclxb.20201210.005

Abstract:

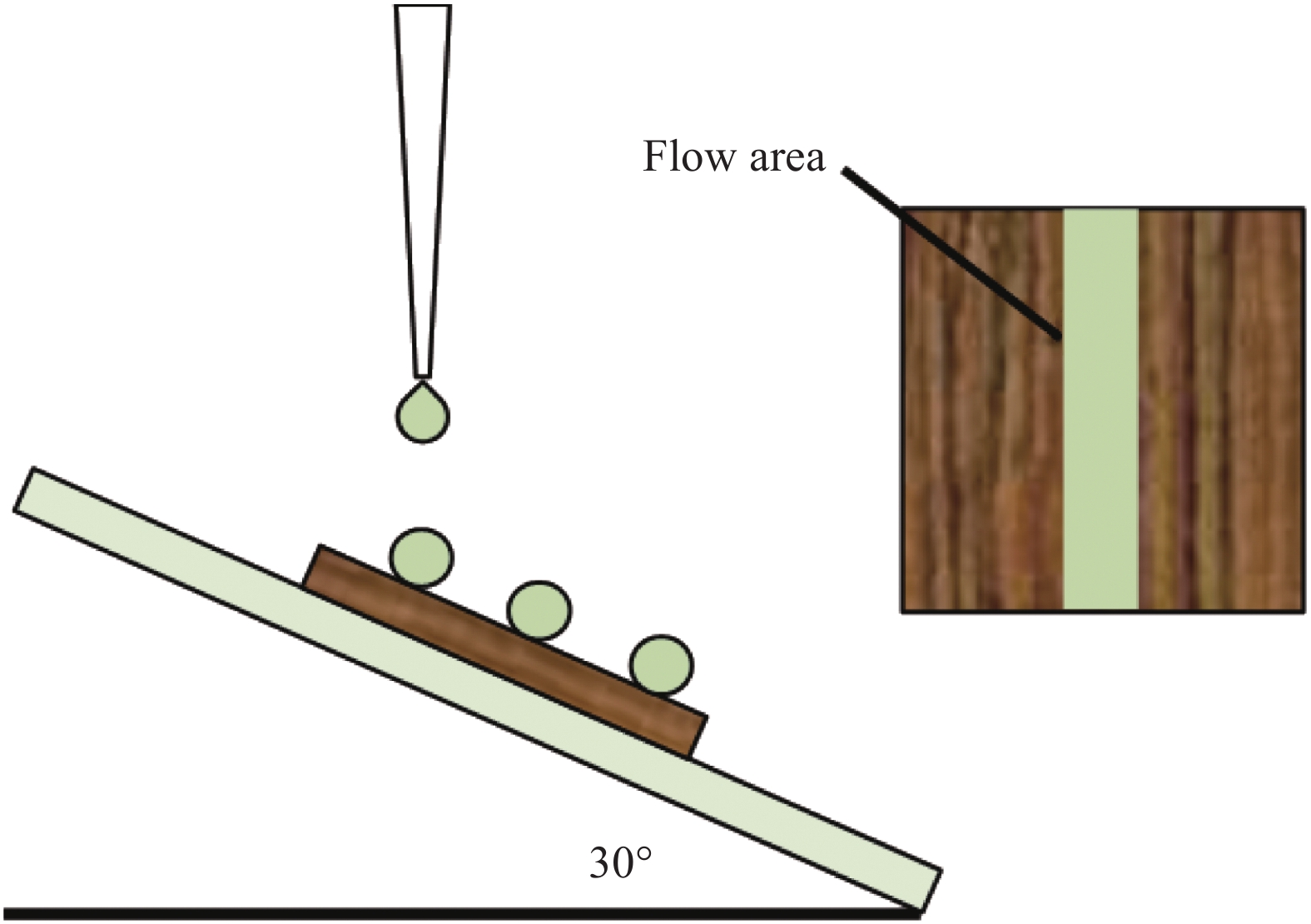

Superhydrophobic treatment of wood surface is of great significance for overcoming the hydrophilic problem of wood and expanding its application fields. In this paper, based on the adhesion and deprotonation characteristics of polydopamine (PDA) coating, sodium methylsilicate (SMS) was used to etch the PDA coating. Furthermore, octadecyltrichlorosilane (OTS) was used as a low surface free energy agent to prepare stable superhydrophobic wood (Wood@PDA-SMS-OTS). The samples were characterized by contact angle (CA) meter, SEM and XPS respectively. The results show that the maximum static CA of water on the surface of Wood@PDA-SMS-OTS samples is 157.4° and the sliding angle (SA) is 4.3°. SEM images show that SMS successfully etch the PDA coating and hydrolyze to generate hydrophobic oligomeric or semi-polymerized methylsiloxane on the surface of the PDA coating, forming an obvious micro-nano rough structure. XPS analysis shows that PDA forms a uniform coating on the surface of wood. While SMS etchs the PDA coating, its polymer formed by hydrolysis is successfully loaded on the surface of PDA. OTS containing long chain structure is grafted on the surface of wood, which makes the wood realize superhydrophobic. The surface of superhydrophobic wood still has stable superhydrophobicity after 24 h of water scouring, ultrasonic vibration, acid-base corrosion and organic solvent treatment.

Superhydrophobic treatment of wood surface is of great significance for overcoming the hydrophilic problem of wood and expanding its application fields. In this paper, based on the adhesion and deprotonation characteristics of polydopamine (PDA) coating, sodium methylsilicate (SMS) was used to etch the PDA coating. Furthermore, octadecyltrichlorosilane (OTS) was used as a low surface free energy agent to prepare stable superhydrophobic wood (Wood@PDA-SMS-OTS). The samples were characterized by contact angle (CA) meter, SEM and XPS respectively. The results show that the maximum static CA of water on the surface of Wood@PDA-SMS-OTS samples is 157.4° and the sliding angle (SA) is 4.3°. SEM images show that SMS successfully etch the PDA coating and hydrolyze to generate hydrophobic oligomeric or semi-polymerized methylsiloxane on the surface of the PDA coating, forming an obvious micro-nano rough structure. XPS analysis shows that PDA forms a uniform coating on the surface of wood. While SMS etchs the PDA coating, its polymer formed by hydrolysis is successfully loaded on the surface of PDA. OTS containing long chain structure is grafted on the surface of wood, which makes the wood realize superhydrophobic. The surface of superhydrophobic wood still has stable superhydrophobicity after 24 h of water scouring, ultrasonic vibration, acid-base corrosion and organic solvent treatment.

2021, 38(9): 3044-3052.

doi: 10.13801/j.cnki.fhclxb.20201130.002

Abstract:

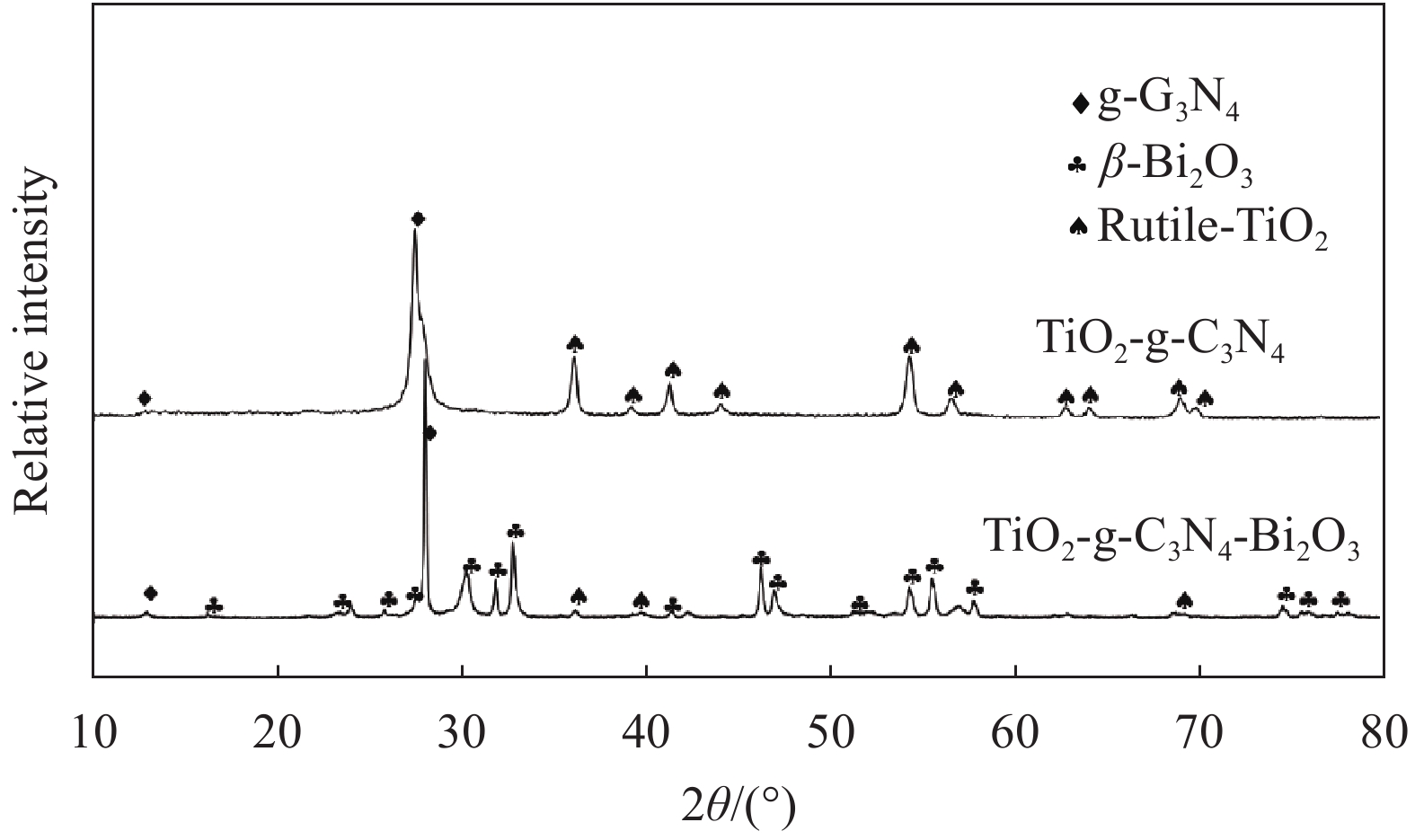

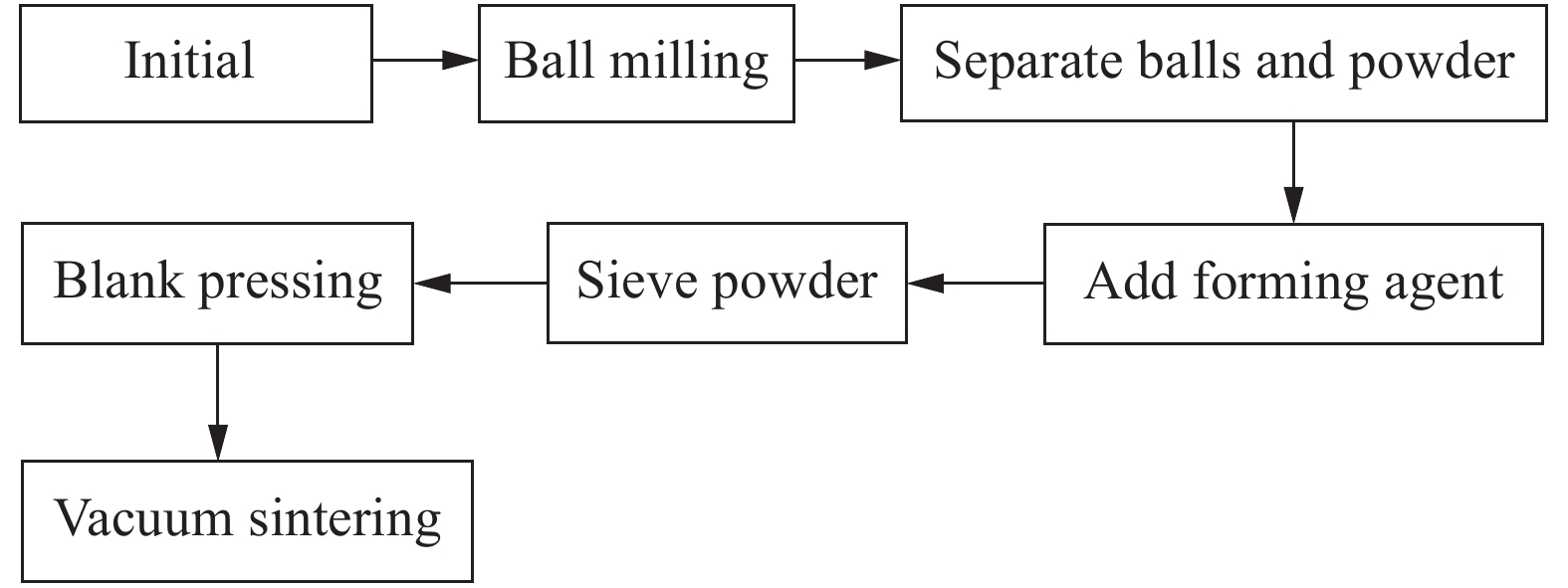

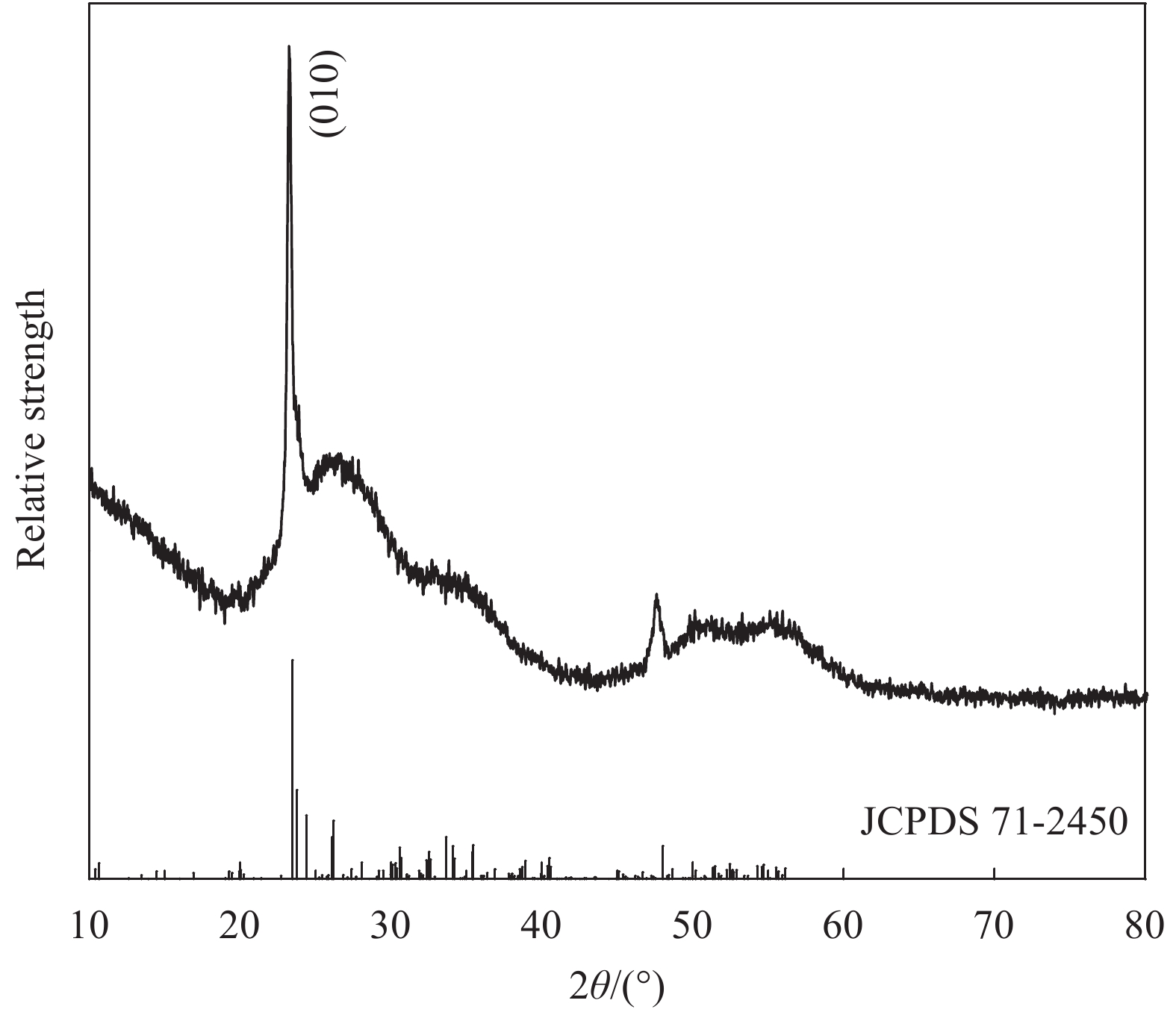

Heterojunction photocatalytic materials show excellent ability in degrading toxic and harmful pollutants. In this study, we prepared TiO2-g-C3N4 and TiO2-g-C3N4-Bi2O3 heterostructure photocatalytic materials by ball milling. The photocatalytic performance of TiO2-g-C3N4 and TiO2-g-C3N4-Bi2O3 towards phenol organic wastewater were investigated under different light source, as well as the effects of light source on the degradation performance. Under the single visible light or ultraviolet light, the ternary TiO2-g-C3N4-Bi2O3 shows higher photocatalytic activity than TiO2-g-C3N4. And under visible light conditions, the degradation performance of TiO2-g-C3N4-Bi2O3 is much better than TiO2-g-C3N4. Under the simultaneous irradiation of visible light and ultraviolet light, the degradation efficiency of TiO2-g-C3N4-Bi2O3 and TiO2-g-C3N4 on phenol wastewater reached 99.44% and 96.67%, respectively. The characterization results show that the doping of Bi2O3 remarkably enhances the absorption of light by the catalyst in the full spectrum, and the construction of the ternary system promotes the separation of photogenerated electrons and holes. The research results show that the ternary TiO2-g-C3N4-Bi2O3 can be achieved through a feasible ball method of milling-microwave heating-calcination process, and confirms the promising prospects of TiO2-g-C3N4-Bi2O3 in organic wastewater treatment.

Heterojunction photocatalytic materials show excellent ability in degrading toxic and harmful pollutants. In this study, we prepared TiO2-g-C3N4 and TiO2-g-C3N4-Bi2O3 heterostructure photocatalytic materials by ball milling. The photocatalytic performance of TiO2-g-C3N4 and TiO2-g-C3N4-Bi2O3 towards phenol organic wastewater were investigated under different light source, as well as the effects of light source on the degradation performance. Under the single visible light or ultraviolet light, the ternary TiO2-g-C3N4-Bi2O3 shows higher photocatalytic activity than TiO2-g-C3N4. And under visible light conditions, the degradation performance of TiO2-g-C3N4-Bi2O3 is much better than TiO2-g-C3N4. Under the simultaneous irradiation of visible light and ultraviolet light, the degradation efficiency of TiO2-g-C3N4-Bi2O3 and TiO2-g-C3N4 on phenol wastewater reached 99.44% and 96.67%, respectively. The characterization results show that the doping of Bi2O3 remarkably enhances the absorption of light by the catalyst in the full spectrum, and the construction of the ternary system promotes the separation of photogenerated electrons and holes. The research results show that the ternary TiO2-g-C3N4-Bi2O3 can be achieved through a feasible ball method of milling-microwave heating-calcination process, and confirms the promising prospects of TiO2-g-C3N4-Bi2O3 in organic wastewater treatment.

2021, 38(9): 3053-3063.

doi: 10.13801/j.cnki.fhclxb.20210108.002

Abstract:

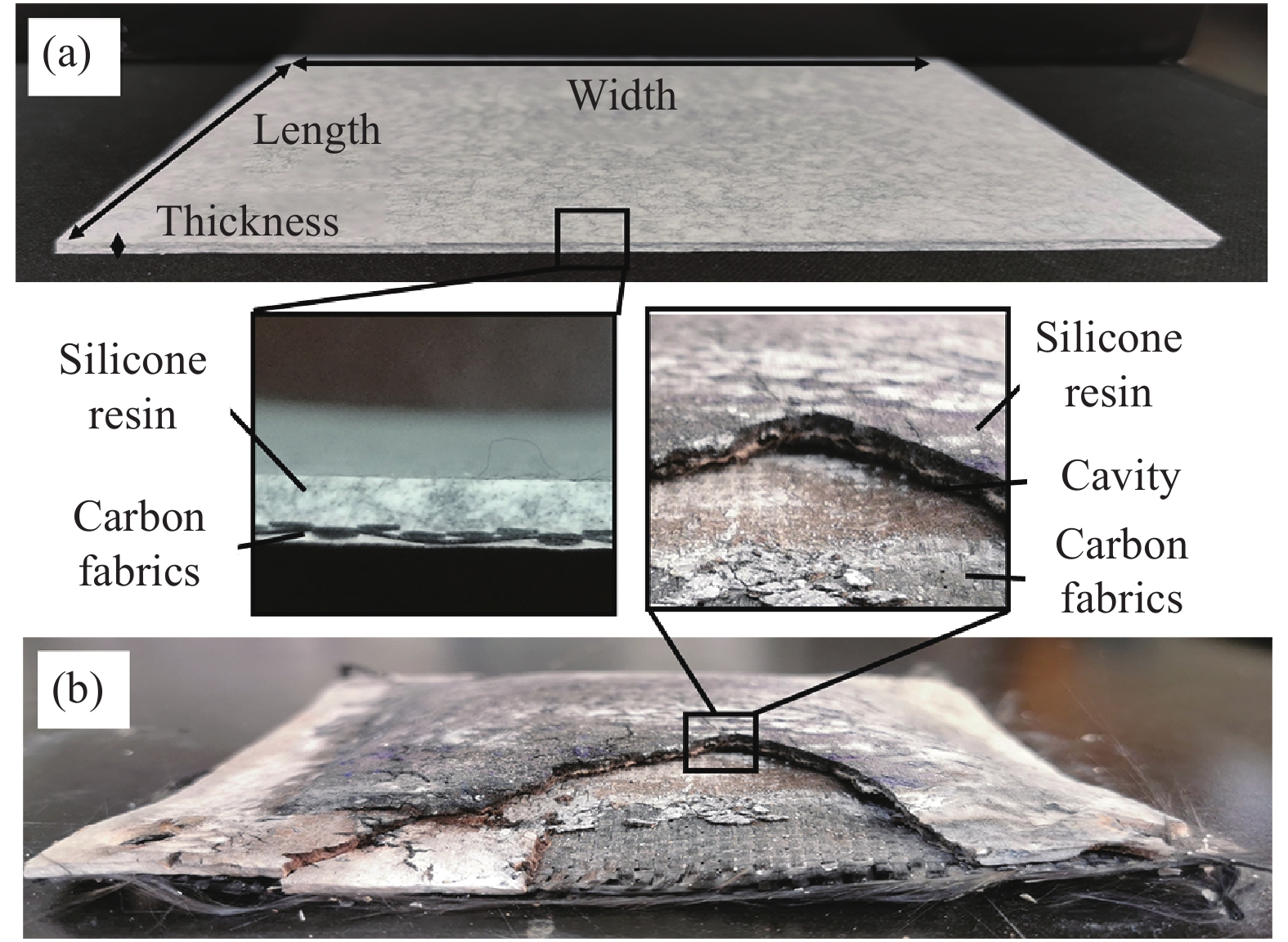

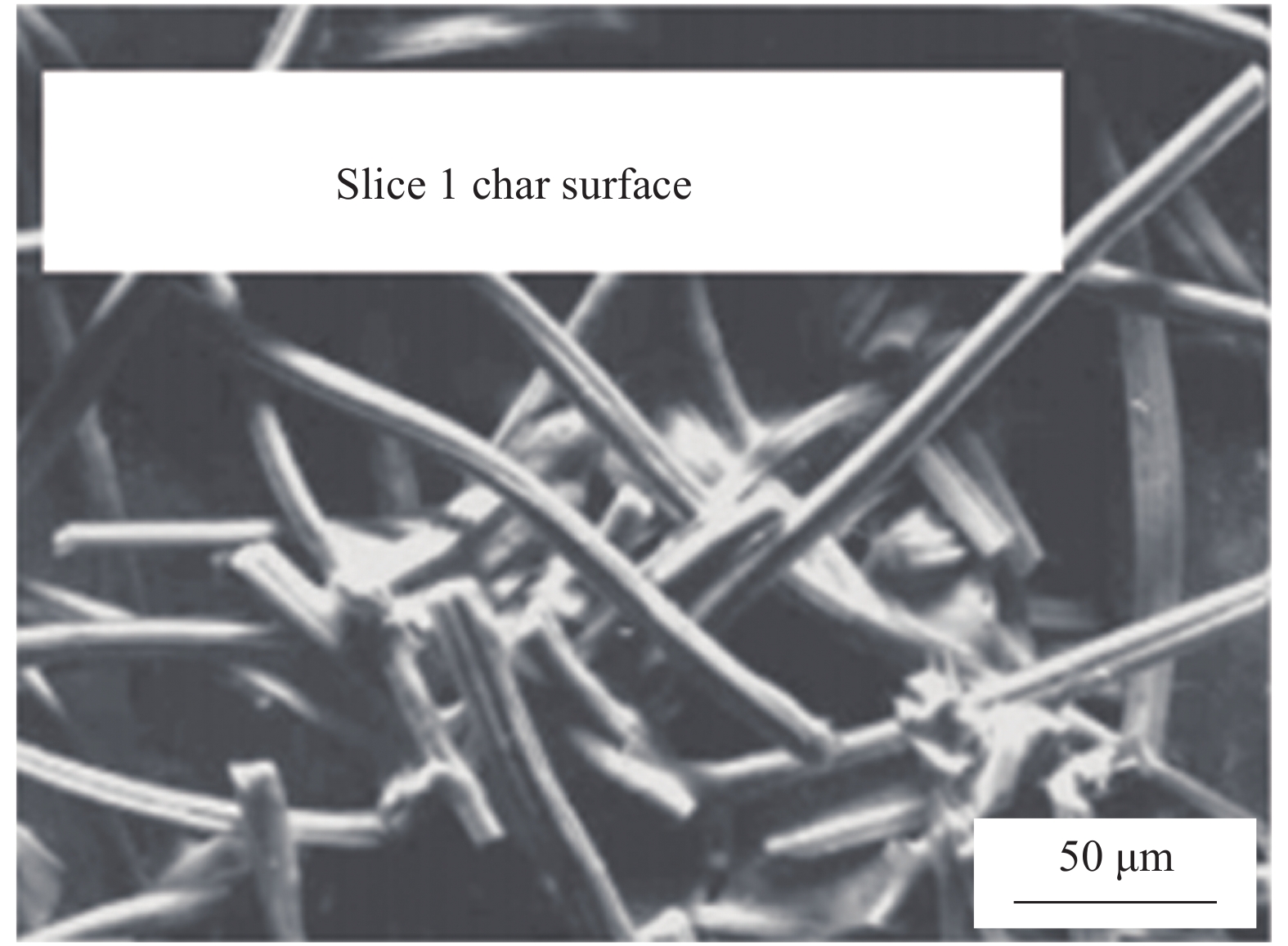

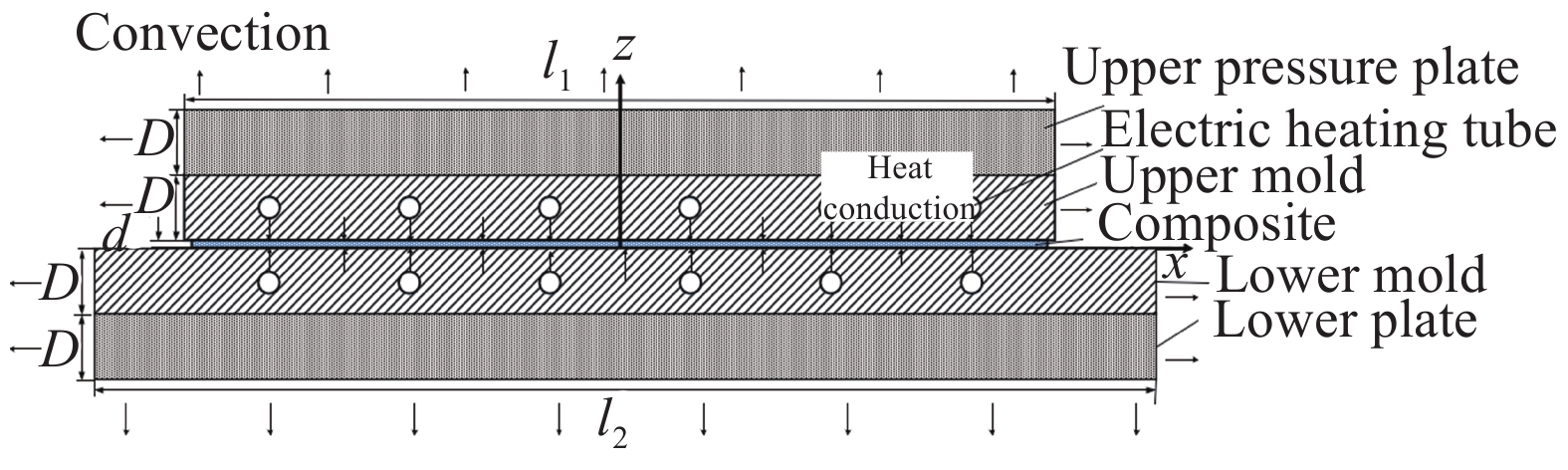

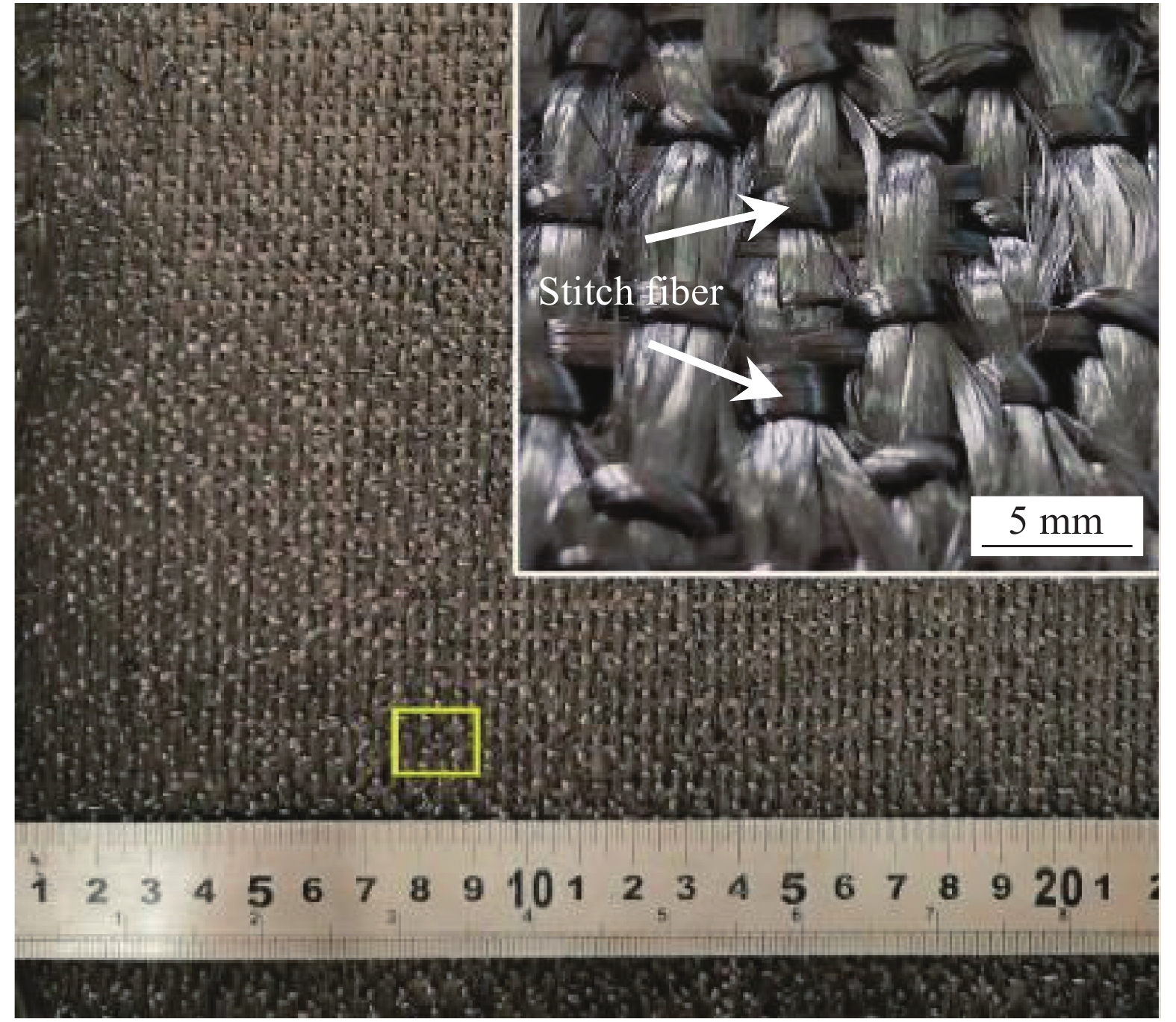

To evaluate the contribution of the thermal blocking effect to the heat protection of silicone resin-carbon fiber fabrics composites, a mathematical model of the thermal response process was established based on the ablation and thermal degradation behavior of silicone resin. The temperature of the back side of the silicone resin-carbon fiber fabrics composite and thermo-physical parameters of the silicone resin have been predicted by this model. The analysis of the thermal blocking effect on the thermal performance of silicone resin-carbon fiber fabrics composite was mainly focused on. The results show that when the silicone resin-coated carbon fiber fabrics are ablated under 400 kW/m2 heat flow, most of the thermal blocking effect comes from the ejection gas generated by the decomposition of the silicone resin in 40 s, and it completely comes from the ejection generated by carbon combustion after 40 s. The blocking factor reaches the minimum at 10 s, which blocks 121.6 kW/m2 heat flow into silicone resin. During the entire ablation process, the thermal blocking effect reduces 4.1% percent of the total heat entering the silicone resin. Among the thermophysical parameters, the thermal blocking effect has the greater influence on the density of the silicone resin than its thermal conductivity and specific heat capacity. Compared with increasing the mass flow rate of the pyrolysis gas of the silicone resin, prolonging the time for the silicone resin to escape the gas can significantly improve the thermal blocking effect and achieve a better heat protection effect.

To evaluate the contribution of the thermal blocking effect to the heat protection of silicone resin-carbon fiber fabrics composites, a mathematical model of the thermal response process was established based on the ablation and thermal degradation behavior of silicone resin. The temperature of the back side of the silicone resin-carbon fiber fabrics composite and thermo-physical parameters of the silicone resin have been predicted by this model. The analysis of the thermal blocking effect on the thermal performance of silicone resin-carbon fiber fabrics composite was mainly focused on. The results show that when the silicone resin-coated carbon fiber fabrics are ablated under 400 kW/m2 heat flow, most of the thermal blocking effect comes from the ejection gas generated by the decomposition of the silicone resin in 40 s, and it completely comes from the ejection generated by carbon combustion after 40 s. The blocking factor reaches the minimum at 10 s, which blocks 121.6 kW/m2 heat flow into silicone resin. During the entire ablation process, the thermal blocking effect reduces 4.1% percent of the total heat entering the silicone resin. Among the thermophysical parameters, the thermal blocking effect has the greater influence on the density of the silicone resin than its thermal conductivity and specific heat capacity. Compared with increasing the mass flow rate of the pyrolysis gas of the silicone resin, prolonging the time for the silicone resin to escape the gas can significantly improve the thermal blocking effect and achieve a better heat protection effect.

2021, 38(9): 3064-3072.

doi: 10.13801/j.cnki.fhclxb.20201207.001

Abstract:

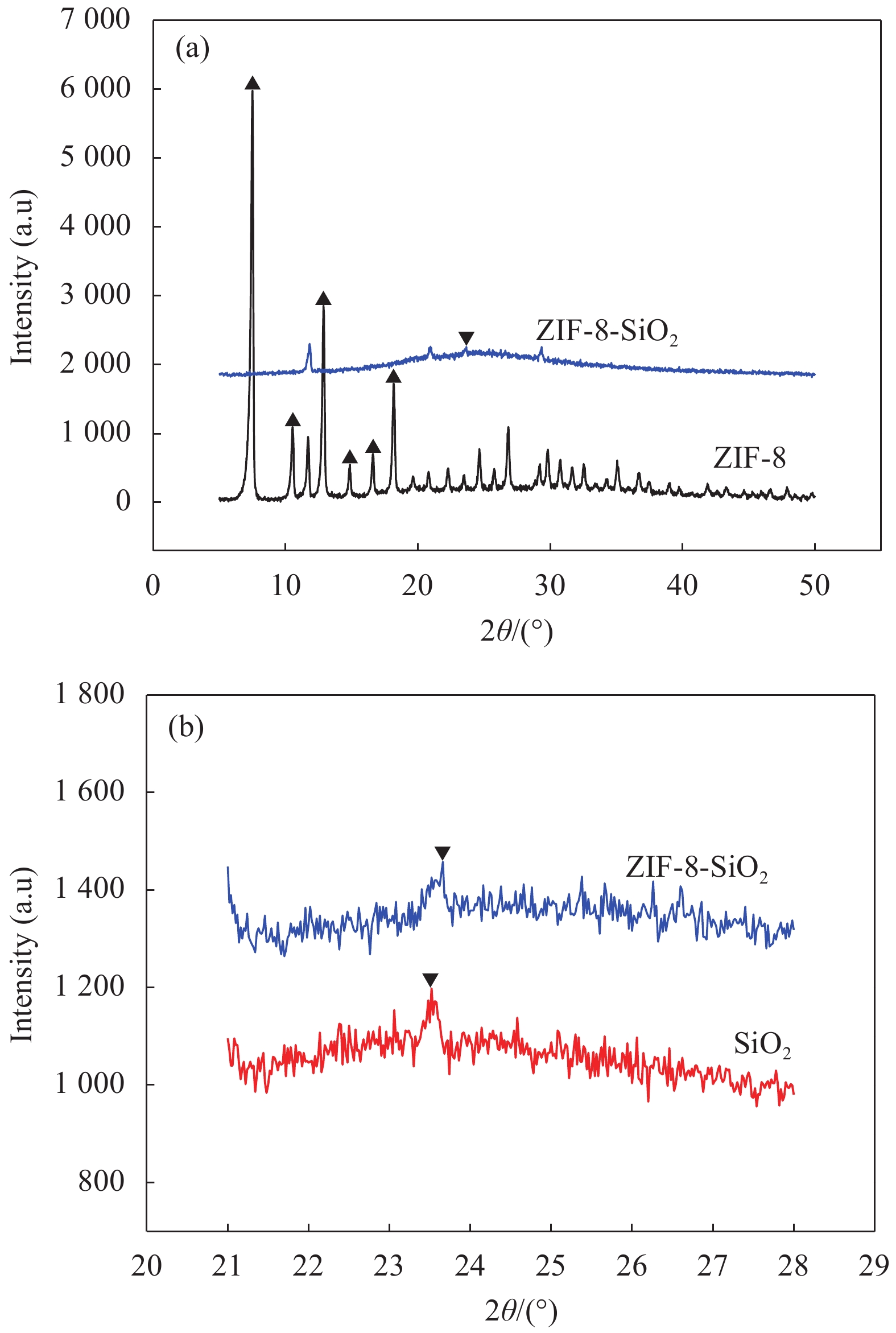

Zeolite imidazole ester framework structure material ZIF-8 and TEOS were used to prepare ZIF-8-SiO2 composite, the structure of ZIF-8-SiO2 and the morphology before and after adsorption of U(VI) were characterized by XRD, SEM, EDS. And the results show that ZIF-8-SiO2 is successfully prepared and has a good adsorption effect on U(VI). The effects of pH value, time, temperature, initial uranium concentration and salt concentration on the adsorption performance of ZIF-8-SiO2 were investigated by static adsorption experiments. According to the experimental results, when the initial concentration is 80 mg·g−1, the maximum actual adsorption capacity of ZIF-8-SiO2 on U(VI) at 25℃ is 498 mg·g−1, and according to the analysis of Langmuir model fitting results, the theoretical adsorption capacity of the material on U(VI) is up to 678.5 mg·g−1. And in the range of 200~500 MPa, the higher the pressure, the better the adsorption. FTIR and XPS were used to characterize the structure of the material before and after uranylion adsorption, to explore the possible adsorption mechanism during the adsorption process.

Zeolite imidazole ester framework structure material ZIF-8 and TEOS were used to prepare ZIF-8-SiO2 composite, the structure of ZIF-8-SiO2 and the morphology before and after adsorption of U(VI) were characterized by XRD, SEM, EDS. And the results show that ZIF-8-SiO2 is successfully prepared and has a good adsorption effect on U(VI). The effects of pH value, time, temperature, initial uranium concentration and salt concentration on the adsorption performance of ZIF-8-SiO2 were investigated by static adsorption experiments. According to the experimental results, when the initial concentration is 80 mg·g−1, the maximum actual adsorption capacity of ZIF-8-SiO2 on U(VI) at 25℃ is 498 mg·g−1, and according to the analysis of Langmuir model fitting results, the theoretical adsorption capacity of the material on U(VI) is up to 678.5 mg·g−1. And in the range of 200~500 MPa, the higher the pressure, the better the adsorption. FTIR and XPS were used to characterize the structure of the material before and after uranylion adsorption, to explore the possible adsorption mechanism during the adsorption process.

2021, 38(9): 3073-3083.

doi: 10.13801/j.cnki.fhclxb.20201112.002

Abstract:

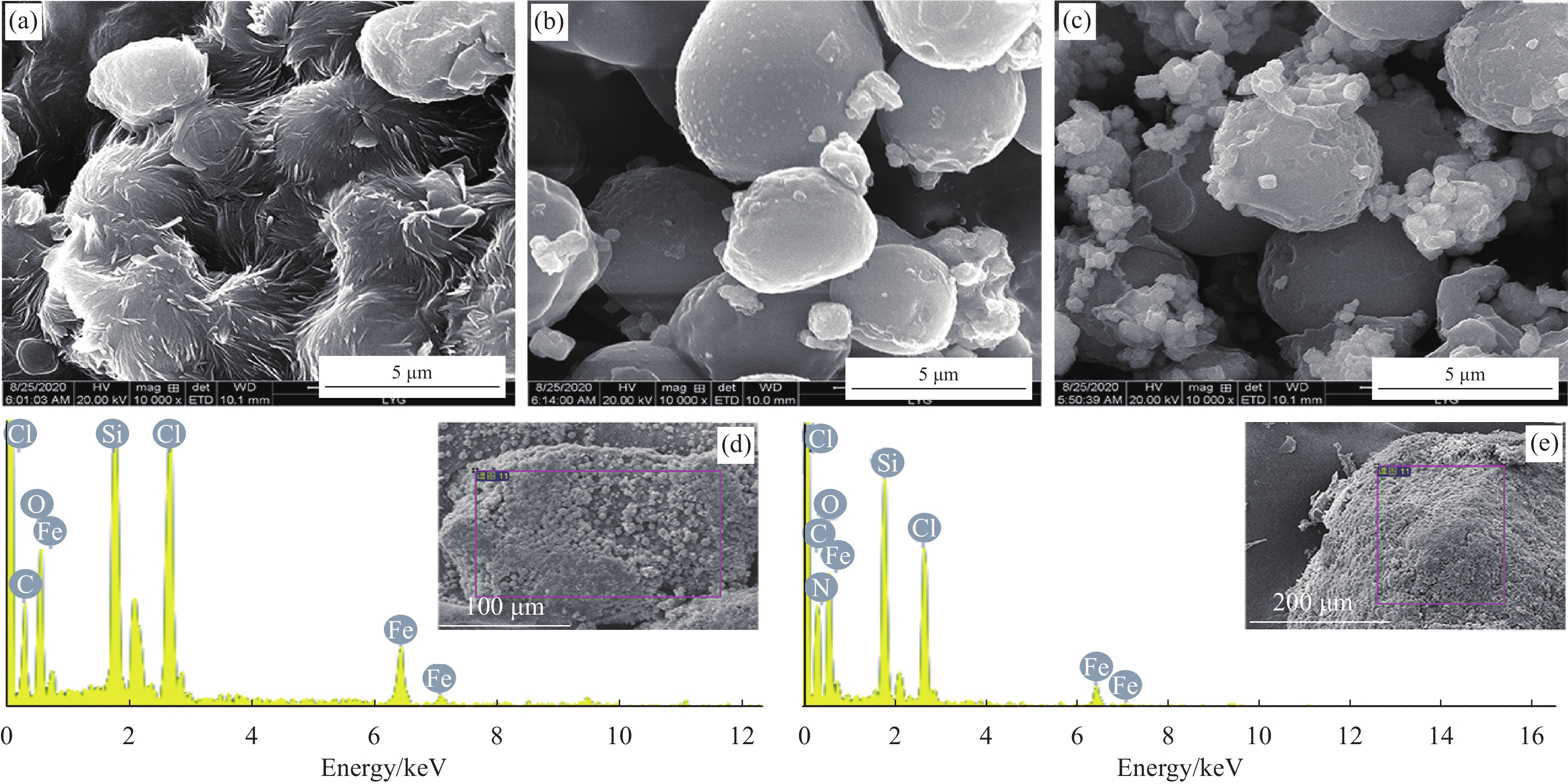

In order to efficiently and conveniently treat radioactive wastewater, polyethyleneimine (PEI) modified magnetic yeast(MY) composite biological material(MY@SiO2-PEI) was prepared and used for the removal of uranium (VI).The material was characterized by SEM, FTIR, Zeta potential and XPS, the U(VI) morphology distribution under different conditions was simulated by Visual MINTEQ, the different solution pH, temperature, reaction time, ionic strength, anion interference(CO32−, PO43−) and different U(VI) in terms of initial mass solubility were analyzed. In addition, the influence of different factors on the adsorption performance of MY@SiO2-PEI on U(VI) was investigated, and the recycling capacity of MY@SiO2-PEI was studied. The results show that the adsorption of U(VI) by MY@SiO2-PEI shows a strong pH dependence, and the ionic strength does not significantly interfere with the adsorption effect, indicating that the reaction is mainly controlled by surface complexation. FTIR, XPS and Zeta potential analysis found that the main factor that promotes the adsorption of U(VI) is the complexation and electrostatic attraction of different functional groups (N=C, NH(NH2), C—N=C) and U(VI) on the surface of the material. The maximum adsorption capacity of MY@SiO2-PEI can reach 173.99 mg/g, and the adsorption equilibrium can be reached within 20 minutes. Quasi-second-order kinetics and Langmuir isotherm equation can fit this adsorption process well, and thermodynamics show that the adsorption process is a spontaneous endothermic process. MY@SiO2-PEI material has simple synthesis method, good removal effect and good reproducibility. It is a promising adsorbent for radionuclides in environmental pollution control.

In order to efficiently and conveniently treat radioactive wastewater, polyethyleneimine (PEI) modified magnetic yeast(MY) composite biological material(MY@SiO2-PEI) was prepared and used for the removal of uranium (VI).The material was characterized by SEM, FTIR, Zeta potential and XPS, the U(VI) morphology distribution under different conditions was simulated by Visual MINTEQ, the different solution pH, temperature, reaction time, ionic strength, anion interference(CO32−, PO43−) and different U(VI) in terms of initial mass solubility were analyzed. In addition, the influence of different factors on the adsorption performance of MY@SiO2-PEI on U(VI) was investigated, and the recycling capacity of MY@SiO2-PEI was studied. The results show that the adsorption of U(VI) by MY@SiO2-PEI shows a strong pH dependence, and the ionic strength does not significantly interfere with the adsorption effect, indicating that the reaction is mainly controlled by surface complexation. FTIR, XPS and Zeta potential analysis found that the main factor that promotes the adsorption of U(VI) is the complexation and electrostatic attraction of different functional groups (N=C, NH(NH2), C—N=C) and U(VI) on the surface of the material. The maximum adsorption capacity of MY@SiO2-PEI can reach 173.99 mg/g, and the adsorption equilibrium can be reached within 20 minutes. Quasi-second-order kinetics and Langmuir isotherm equation can fit this adsorption process well, and thermodynamics show that the adsorption process is a spontaneous endothermic process. MY@SiO2-PEI material has simple synthesis method, good removal effect and good reproducibility. It is a promising adsorbent for radionuclides in environmental pollution control.

2021, 38(9): 3084-3093.

doi: 10.13801/j.cnki.fhclxb.20201117.001

Abstract:

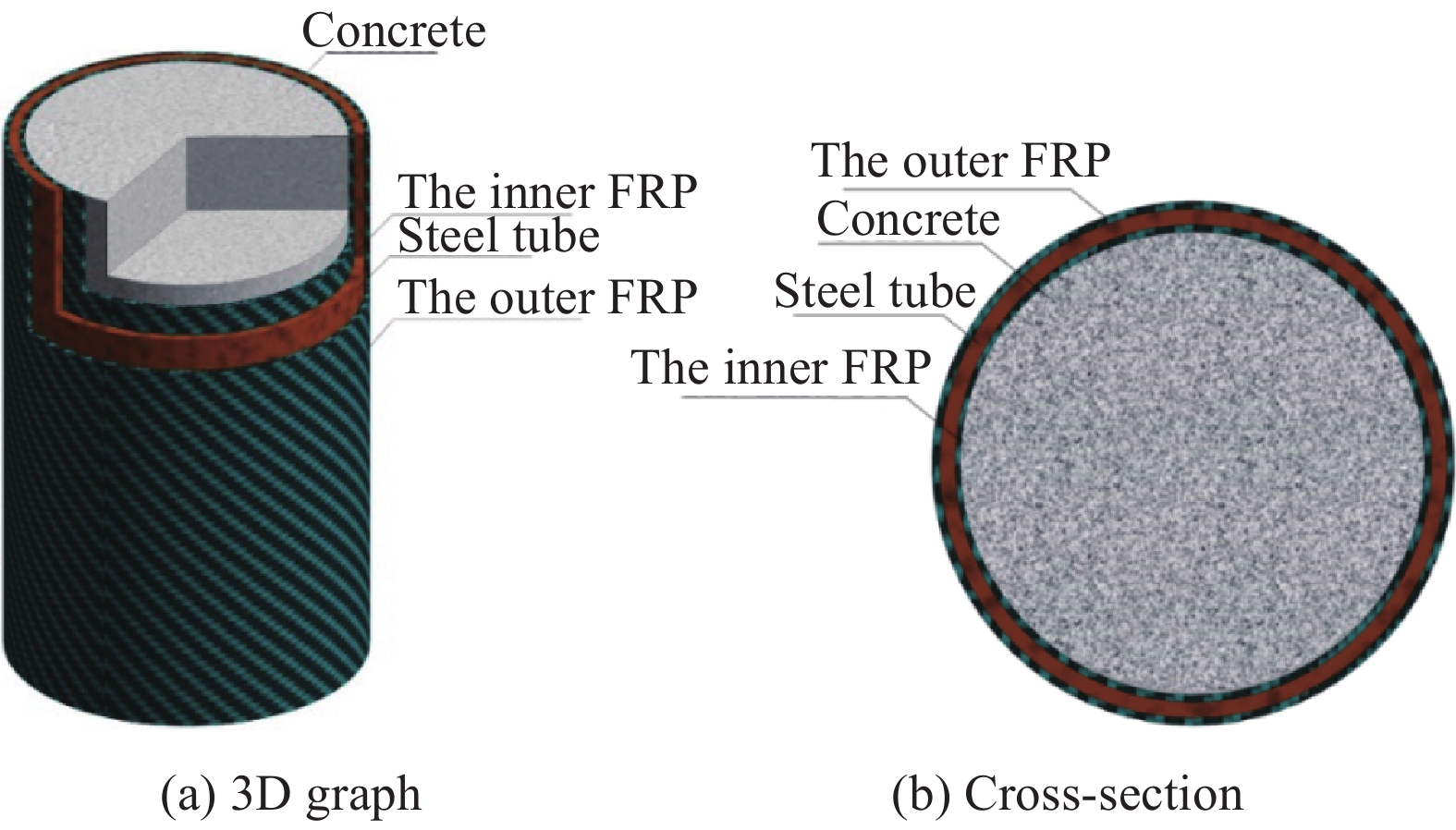

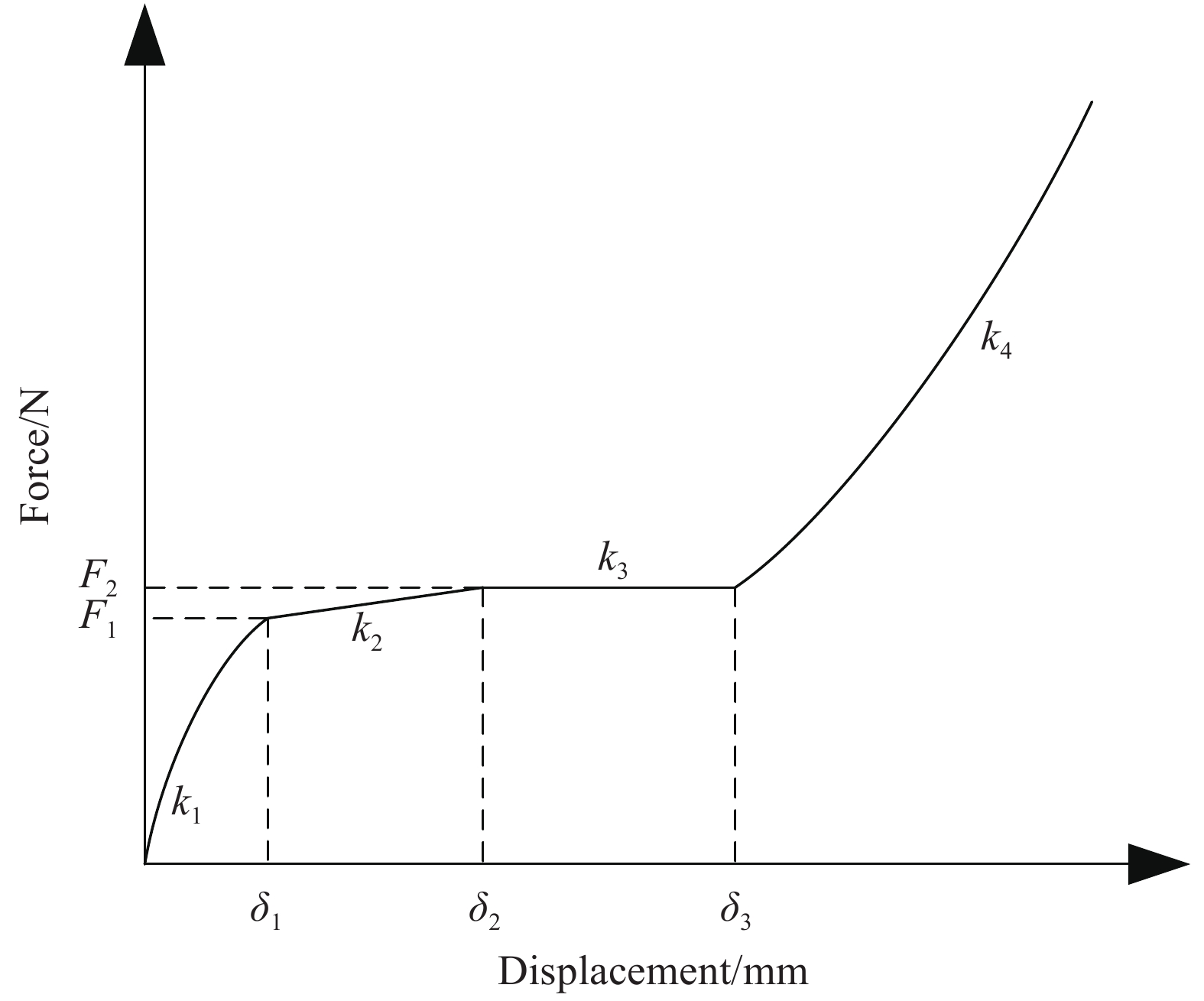

In order to study the feasibility of applying the original seawater and sea sand concrete directly to the concrete filled composite tube, a new structure of seawater and sea sand concrete filled carbon fiber reinforced polymer (CFRP) -steel composite tube composed of internal and external fiber reinforced polymer (FRP) and sandwich steel tube was proposed. Twelve new seawater and sea sand concrete filled circular CFRP-steel composite tube columns were tested under axial compression, and the influence of the number of CFRP layers and the strength grade of core concrete on the axial compression performance was studied. The test results show that the wrapping of inner and outer CFRP can effectively improve the bearing capacity and deformation capacity of the structure. The failure mode of common strength seawater and sea sand concrete filled circular CFRP-steel composite tube columns is concrete crushing, while that of high strength seawater and sea sand concrete filled circular CFRP-steel composite tube columns is shear failure. The ultimate stress of the structure is positively correlated with the number of CFRP layers and the strength of concrete. However, the ultimate strain only increases with the number of CFRP layers, but decreases with the strength of concrete. The contribution of core concrete and steel tube to the ultimate stress almost does not change with the increase of the number of layers of CFRP, and the contribution of CFRP to the ultimate stress of specimens is dominant when two or more layers of CFRP are wrapped.

In order to study the feasibility of applying the original seawater and sea sand concrete directly to the concrete filled composite tube, a new structure of seawater and sea sand concrete filled carbon fiber reinforced polymer (CFRP) -steel composite tube composed of internal and external fiber reinforced polymer (FRP) and sandwich steel tube was proposed. Twelve new seawater and sea sand concrete filled circular CFRP-steel composite tube columns were tested under axial compression, and the influence of the number of CFRP layers and the strength grade of core concrete on the axial compression performance was studied. The test results show that the wrapping of inner and outer CFRP can effectively improve the bearing capacity and deformation capacity of the structure. The failure mode of common strength seawater and sea sand concrete filled circular CFRP-steel composite tube columns is concrete crushing, while that of high strength seawater and sea sand concrete filled circular CFRP-steel composite tube columns is shear failure. The ultimate stress of the structure is positively correlated with the number of CFRP layers and the strength of concrete. However, the ultimate strain only increases with the number of CFRP layers, but decreases with the strength of concrete. The contribution of core concrete and steel tube to the ultimate stress almost does not change with the increase of the number of layers of CFRP, and the contribution of CFRP to the ultimate stress of specimens is dominant when two or more layers of CFRP are wrapped.

2021, 38(9): 3094-3108.

doi: 10.13801/j.cnki.fhclxb.20201204.001

Abstract:

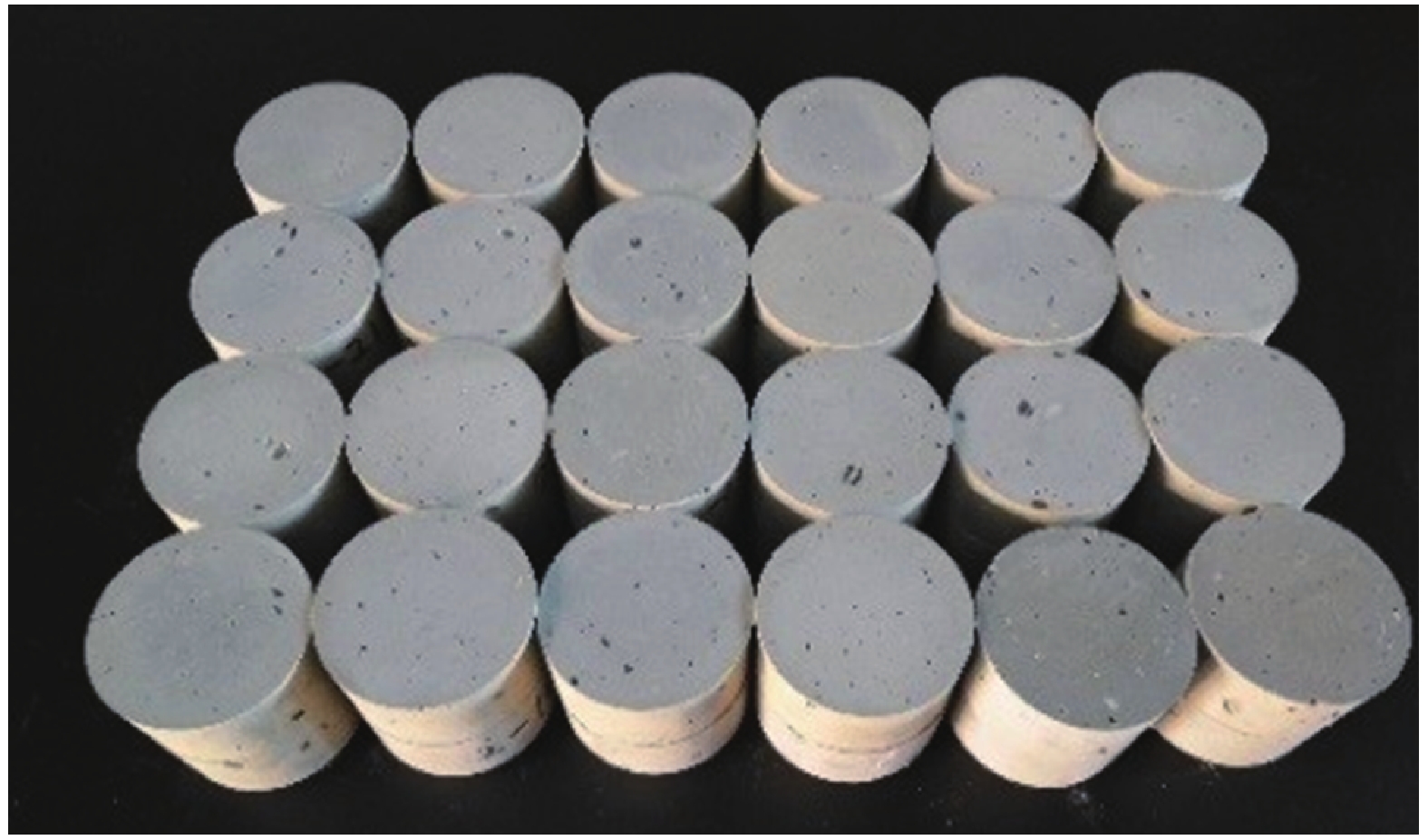

In order to explore the dynamic constitutive relationship of ultra-high toughness cementitious composites (UHTCC) and the influence of fiber volume fraction on dynamic mechanical properties of polyvinyl alcohol (PVA) reinforced cementitious composites (PVAFRCC), the compressive impact tests were carried out on PVAFRCC specimens with different fiber volume fractions (0vol%, 0.5vol%, 1vol%, 1.5vol%, 2vol%) by using Φ80 mm split Hopkinson pressure bar (SHPB) system, through which the stress-strain curves of various types of materials at different strain rates were obtained. The results show that: compared with the matrix without fiber added (PVAFRCC-0), the incorporation of PVA fiber has a significant effect on the dynamic increase factor (\begin{document}$ {\mu }_{\rm{DIF}} $\end{document} ![]()

![]()

\begin{document}$ {\rm{s}}^{-1} $\end{document} ![]()

![]()

\begin{document}$ {\mu }_{\rm{DIF}} $\end{document} ![]()

![]()

In order to explore the dynamic constitutive relationship of ultra-high toughness cementitious composites (UHTCC) and the influence of fiber volume fraction on dynamic mechanical properties of polyvinyl alcohol (PVA) reinforced cementitious composites (PVAFRCC), the compressive impact tests were carried out on PVAFRCC specimens with different fiber volume fractions (0vol%, 0.5vol%, 1vol%, 1.5vol%, 2vol%) by using Φ80 mm split Hopkinson pressure bar (SHPB) system, through which the stress-strain curves of various types of materials at different strain rates were obtained. The results show that: compared with the matrix without fiber added (PVAFRCC-0), the incorporation of PVA fiber has a significant effect on the dynamic increase factor (

2021, 38(9): 3109-3117.

doi: 10.13801/j.cnki.fhclxb.20201124.002

Abstract:

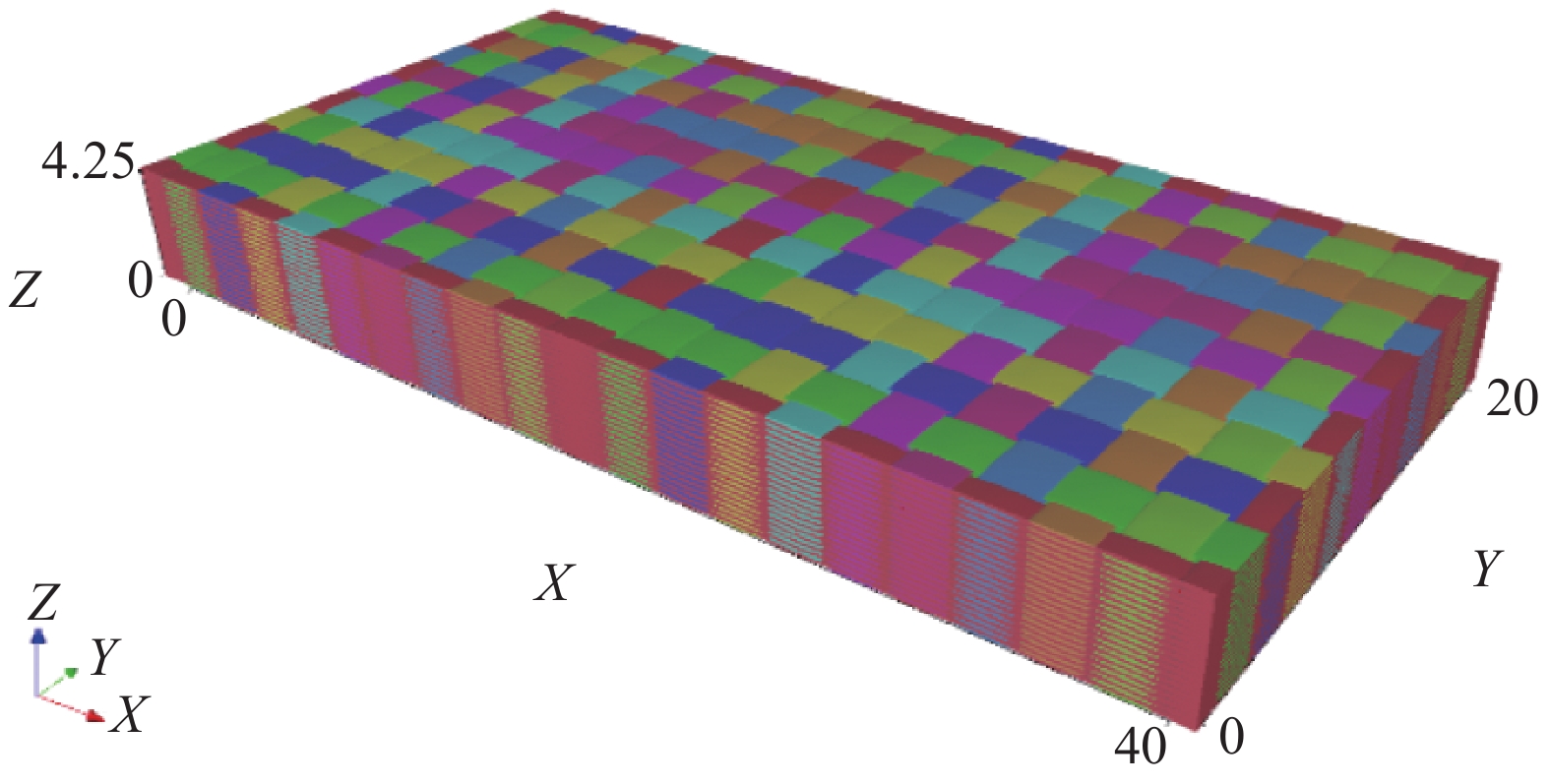

According to the 3D integral preform which is used for multidirectional heteromorphic shaped composite parts, the preform sample with typical pulling in and adding in yarn structure was designed and prepared based on the 2.5D woven with warp-stuffer preform. Computed tomography (Micro-CT) was used to observe the morphological changes of the yarn cross-section and the distribution of yarn orientation in each system. The squeezed state of the pulled out and added in yarn changes along the thickness direction of the preform, and the cross-section shape of the pulled out and added in yarn are changed from an ellipse to a trapezoid, and then to a triangle. When the warp yarns are pulled out and added in, the cross-section of the weft yarns in contact with them change. Combining the practical loading condition of the composite parts, 5 kinds of composites with pulling out-adding in yarns were tested by three-point bending in warp direction. The results show that the retention rates of bending strength and modulus of the composites reach 82.6%-95.7% and 89.1%-97.9%, respectively. So, to meet the mechanical performance requirements of the composites, developing the 3D integral shaped braided technology of preforms is the effective approach for realizing the material/structure integrated manufacturing of complex shaped composite parts.

According to the 3D integral preform which is used for multidirectional heteromorphic shaped composite parts, the preform sample with typical pulling in and adding in yarn structure was designed and prepared based on the 2.5D woven with warp-stuffer preform. Computed tomography (Micro-CT) was used to observe the morphological changes of the yarn cross-section and the distribution of yarn orientation in each system. The squeezed state of the pulled out and added in yarn changes along the thickness direction of the preform, and the cross-section shape of the pulled out and added in yarn are changed from an ellipse to a trapezoid, and then to a triangle. When the warp yarns are pulled out and added in, the cross-section of the weft yarns in contact with them change. Combining the practical loading condition of the composite parts, 5 kinds of composites with pulling out-adding in yarns were tested by three-point bending in warp direction. The results show that the retention rates of bending strength and modulus of the composites reach 82.6%-95.7% and 89.1%-97.9%, respectively. So, to meet the mechanical performance requirements of the composites, developing the 3D integral shaped braided technology of preforms is the effective approach for realizing the material/structure integrated manufacturing of complex shaped composite parts.

2021, 38(9): 3118-3130.

doi: 10.13801/j.cnki.fhclxb.20201127.001

Abstract:

In order to reveal the chemical shrinkage characteristics of graphene oxide cement composite paste (GO/C), the chemical shrinkage of cement composite paste with different water-cement ratio (0.3, 0.4, 0.5) and different mass fractions of graphene oxide (GO) (0wt%, 0.01wt%, 0.02wt%, 0.03wt%, 0.04wt% and 0.05wt%). The results show that the chemical shrinkage of GO/C is significantly increased with an increase in water-cement ratio. At the same water-cement ratio, the early chemical shrinkage of GO/C is lower than that of ordinary cement paste, and when the mass fraction of GO is 0.04wt%, the shrinkage value reaches the minimum. However, the growth rate of chemical shrinkage of GO/C specimens is obviously faster than that of ordinary cement paste in later hydration process. The analysis shows that the influence of GO on the chemical shrinkage of cement paste is mainly attributed to the regulation of GO on the pore structure of cement paste and the bonding behavior of GO with calcium hydroxide crystal. Furthermore, based on the comparison results of existing shrinkage models, it is found that the chemical shrinkage models of ordinary cement cannot accurately predict the chemical shrinkage of GO/C. Therefore, in order to consider the effect of GO,\begin{document}$K(\xi , t)$\end{document} ![]()

![]()

In order to reveal the chemical shrinkage characteristics of graphene oxide cement composite paste (GO/C), the chemical shrinkage of cement composite paste with different water-cement ratio (0.3, 0.4, 0.5) and different mass fractions of graphene oxide (GO) (0wt%, 0.01wt%, 0.02wt%, 0.03wt%, 0.04wt% and 0.05wt%). The results show that the chemical shrinkage of GO/C is significantly increased with an increase in water-cement ratio. At the same water-cement ratio, the early chemical shrinkage of GO/C is lower than that of ordinary cement paste, and when the mass fraction of GO is 0.04wt%, the shrinkage value reaches the minimum. However, the growth rate of chemical shrinkage of GO/C specimens is obviously faster than that of ordinary cement paste in later hydration process. The analysis shows that the influence of GO on the chemical shrinkage of cement paste is mainly attributed to the regulation of GO on the pore structure of cement paste and the bonding behavior of GO with calcium hydroxide crystal. Furthermore, based on the comparison results of existing shrinkage models, it is found that the chemical shrinkage models of ordinary cement cannot accurately predict the chemical shrinkage of GO/C. Therefore, in order to consider the effect of GO,

2021, 38(9): 3131-3140.

doi: 10.13801/j.cnki.fhclxb.20201231.001

Abstract:

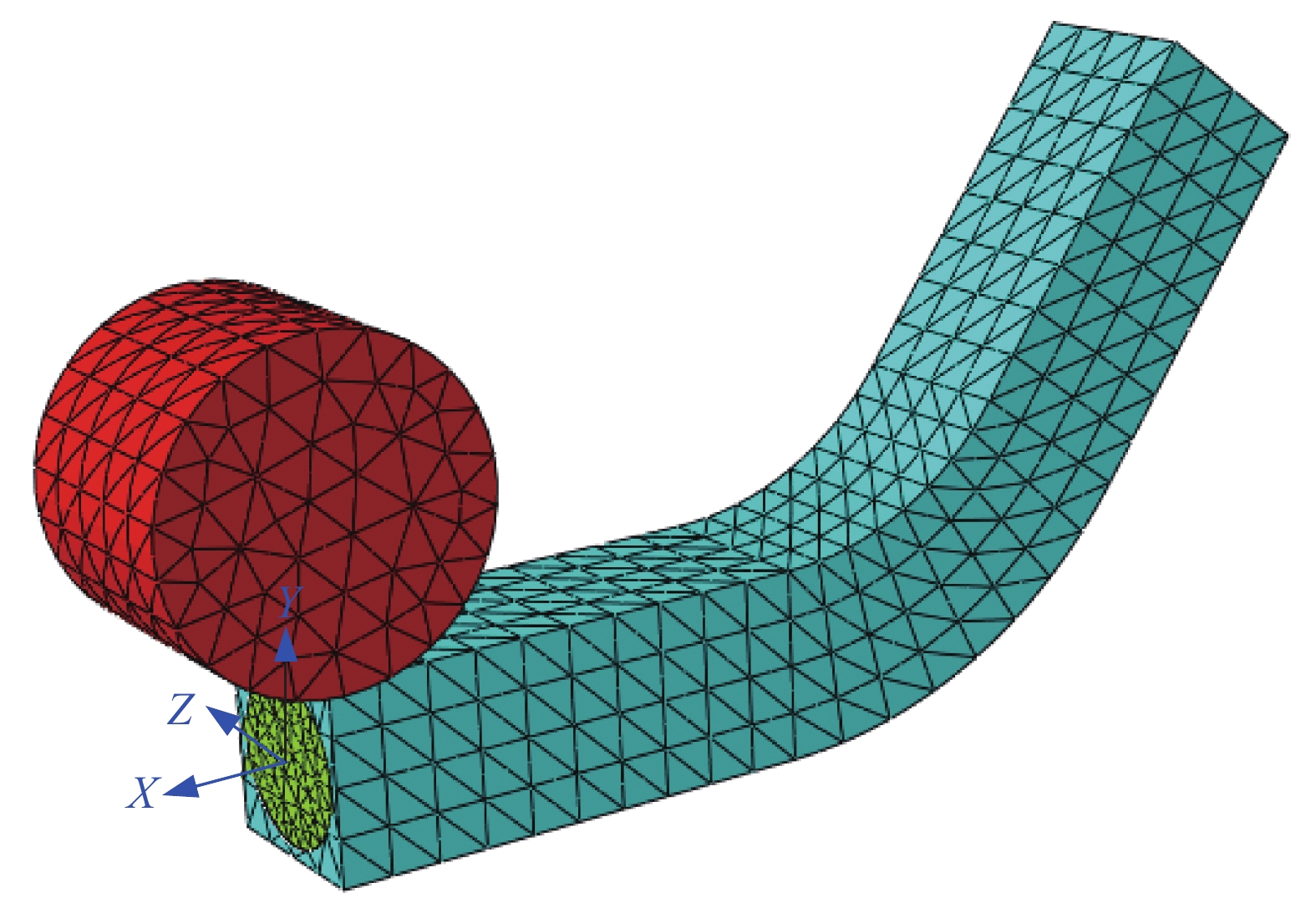

The deformation, fracture, and fragmentation of fiber fabric happened in the process of hypervelocity impact have been widely researched. However, the analysis of the contact between yarns during the impact has not been reported. Considering the contact behavior between fabric fibers, a unit cell model for fiber fabric was established, based on the FEM-SPH coupling algorithm. The model can be used to analyze the damage behavior such as the perforation, fracture, fragmentation, and cloud propagation, as well as provide the mechanical information of the interaction process between yarns during the hypervelocity impact between fiber fabric and space debris. The analysis results obtained by the model are in good agreement with experimental measurements.

The deformation, fracture, and fragmentation of fiber fabric happened in the process of hypervelocity impact have been widely researched. However, the analysis of the contact between yarns during the impact has not been reported. Considering the contact behavior between fabric fibers, a unit cell model for fiber fabric was established, based on the FEM-SPH coupling algorithm. The model can be used to analyze the damage behavior such as the perforation, fracture, fragmentation, and cloud propagation, as well as provide the mechanical information of the interaction process between yarns during the hypervelocity impact between fiber fabric and space debris. The analysis results obtained by the model are in good agreement with experimental measurements.

2021, 38(9): 2767-2775.

doi: 10.13801/j.cnki.fhclxb.20210215.003

Abstract:

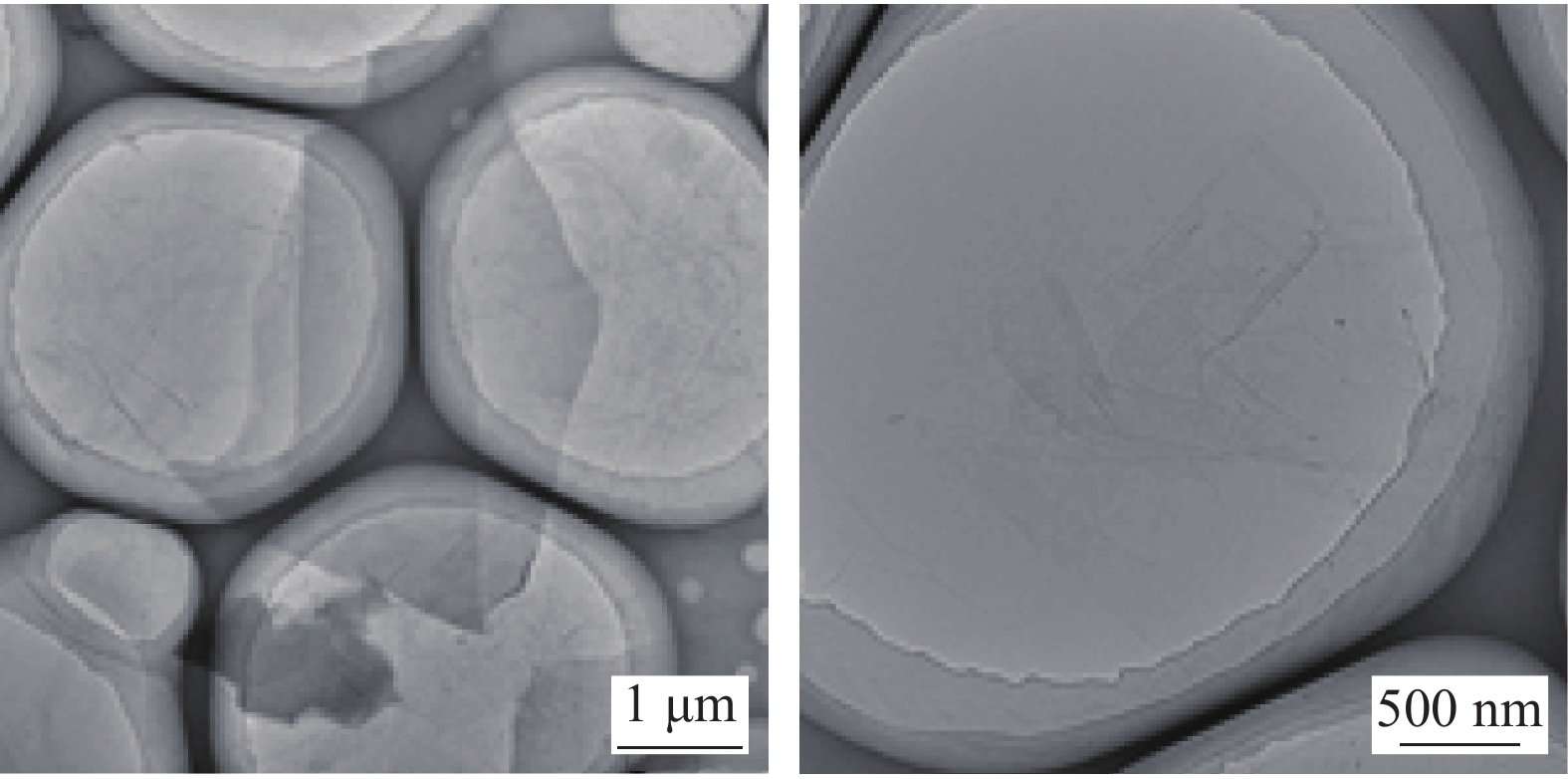

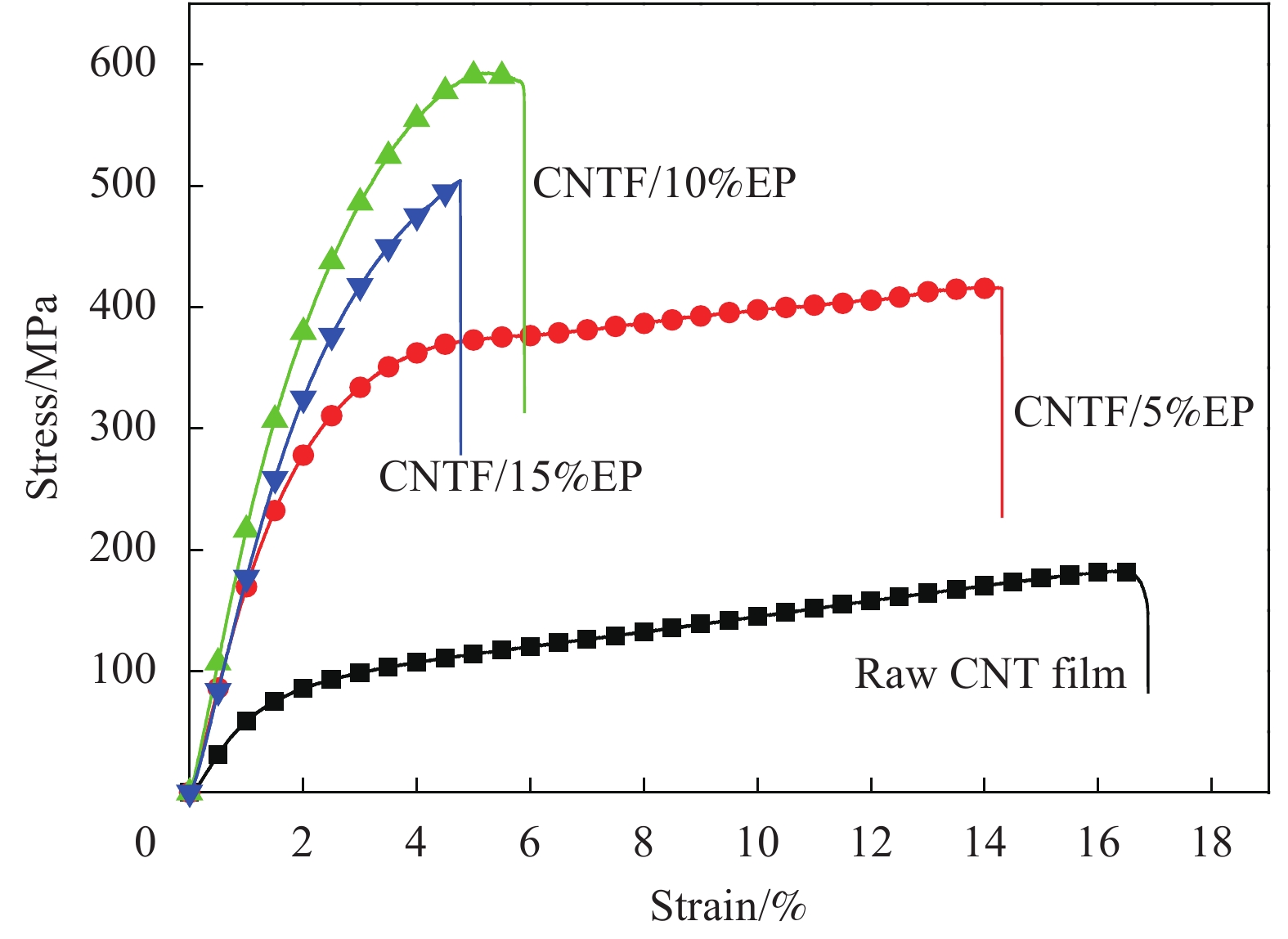

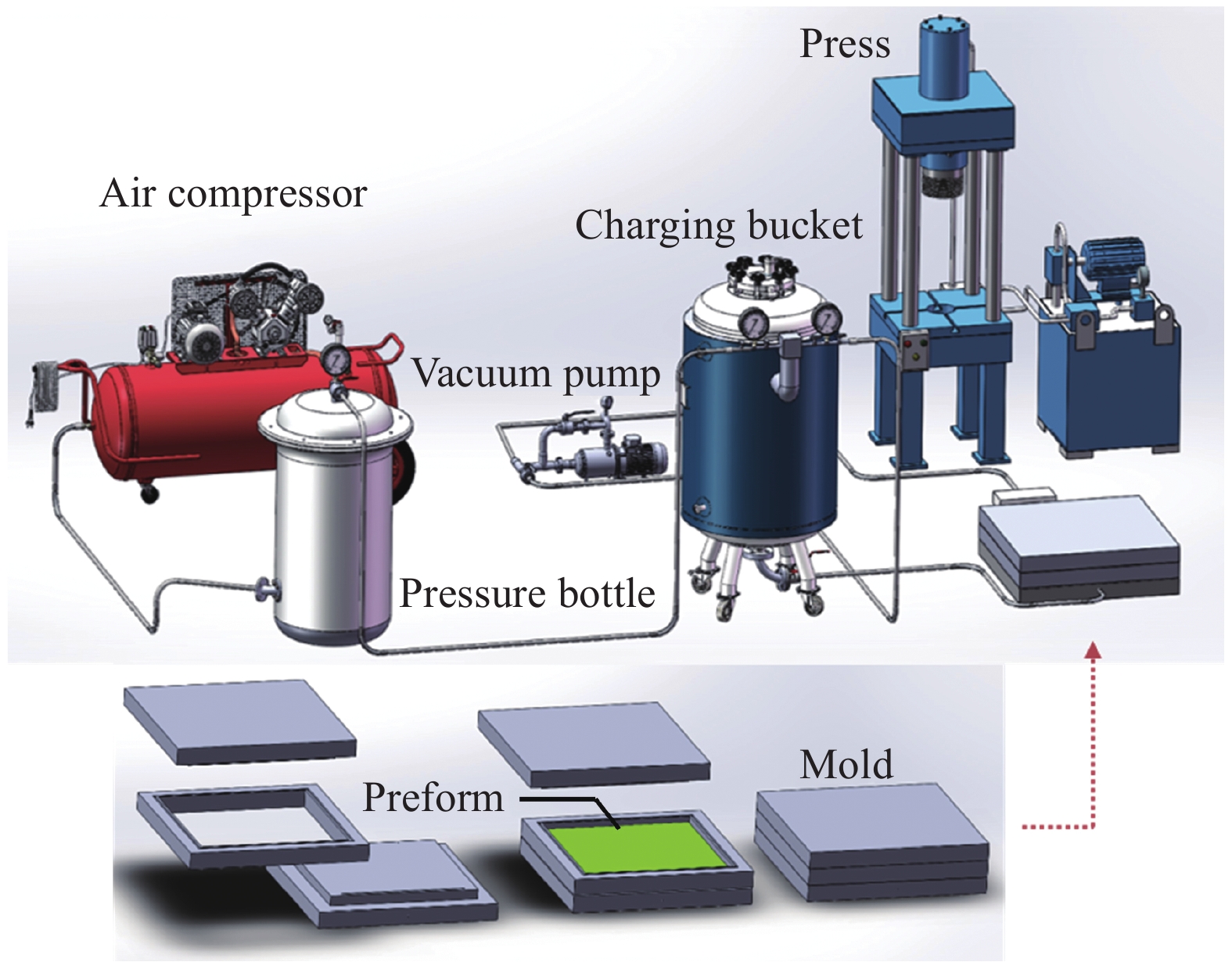

In carbon nanotube (CNT)/epoxy resin (EP) nanocomposites, the resin content and distribution, CNT orientation and CNT-resin interfacial strength are the key factors to fibrate the high-performance composites. In order to study the relationship between the resin distribution and the CNT/EP composite properties, CNT films prepared by floating catalytic chemical vapor deposition were impregnated by using EP and then stretched, washed and hot-press cured. The focus ion beam and scanning electron microscope were used to characterize the distribution of resin in the CNT/EP composites. The results show that, with the increase of resin content, the amount of resin on the composite surface is increasing and the average tensile strength and tensile modulus of CNT/EP composite with CNT content of 66.14wt% can be up to 1405 MPa and 46.7 GPa, respectively.

In carbon nanotube (CNT)/epoxy resin (EP) nanocomposites, the resin content and distribution, CNT orientation and CNT-resin interfacial strength are the key factors to fibrate the high-performance composites. In order to study the relationship between the resin distribution and the CNT/EP composite properties, CNT films prepared by floating catalytic chemical vapor deposition were impregnated by using EP and then stretched, washed and hot-press cured. The focus ion beam and scanning electron microscope were used to characterize the distribution of resin in the CNT/EP composites. The results show that, with the increase of resin content, the amount of resin on the composite surface is increasing and the average tensile strength and tensile modulus of CNT/EP composite with CNT content of 66.14wt% can be up to 1405 MPa and 46.7 GPa, respectively.

2021, 38(9): 2776-2786.

doi: 10.13801/j.cnki.fhclxb.20210104.003

Abstract:

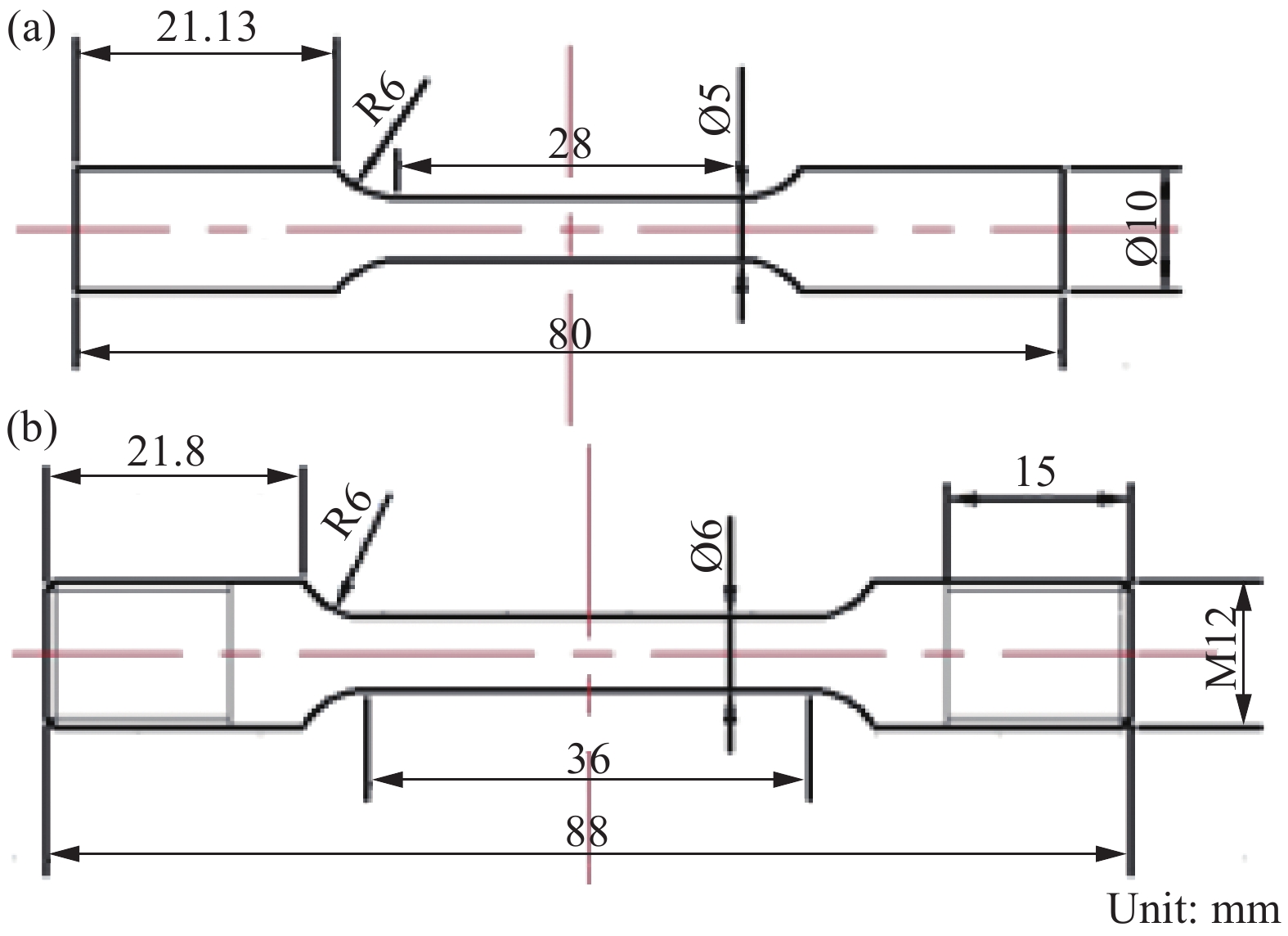

Bamboo fiber/vinyl ester resin (BF/VE) composites were prepared via vacuum-assisted resin transfer molding (VARTM). Nano-SiO2 modified by coupling agent KH602 was used to modify BF and VE resin, the surface physical and chemical properties of modified fibers and resin were characterized by scanning electron microscope (SEM) and Fourier transform infrared spectroscopy (FTIR). Analysis of SEM and FTIR results show that nano-SiO2 is successfully grafted onto the BF surface and dispersed into the resin matrix; Nano-SiO2 is more evenly dispersed in BF1/VE0.5 (1.0wt% modified nano-SiO2 was used to modify BF and 0.5wt% modified nano-SiO2 was used to modify resin) composites. The mechanical properties, fracture and surface morphologies of BV/VE composites were analyzed by mechanical testing machine and SEM. Effects of the modified nano-SiO2 addition content on the mechanical properties and interfacial properties of BF/VE composites were investigated and analyzed. Through mechanical tests, the tensile, flexural and impact strengths of the BF1/VE0.5 composites reach to the maximum value of 49.0 MPa, 70.6 MPa, and 150.4 J/m, which are increased by 18.9%, 26.1% and 70.7% respectively compared with the untreated composites. Besides, the interface enhancement mechanism of modified nano-SiO2 was preliminarily discussed.

Bamboo fiber/vinyl ester resin (BF/VE) composites were prepared via vacuum-assisted resin transfer molding (VARTM). Nano-SiO2 modified by coupling agent KH602 was used to modify BF and VE resin, the surface physical and chemical properties of modified fibers and resin were characterized by scanning electron microscope (SEM) and Fourier transform infrared spectroscopy (FTIR). Analysis of SEM and FTIR results show that nano-SiO2 is successfully grafted onto the BF surface and dispersed into the resin matrix; Nano-SiO2 is more evenly dispersed in BF1/VE0.5 (1.0wt% modified nano-SiO2 was used to modify BF and 0.5wt% modified nano-SiO2 was used to modify resin) composites. The mechanical properties, fracture and surface morphologies of BV/VE composites were analyzed by mechanical testing machine and SEM. Effects of the modified nano-SiO2 addition content on the mechanical properties and interfacial properties of BF/VE composites were investigated and analyzed. Through mechanical tests, the tensile, flexural and impact strengths of the BF1/VE0.5 composites reach to the maximum value of 49.0 MPa, 70.6 MPa, and 150.4 J/m, which are increased by 18.9%, 26.1% and 70.7% respectively compared with the untreated composites. Besides, the interface enhancement mechanism of modified nano-SiO2 was preliminarily discussed.

2021, 38(9): 2786-2794.

doi: 10.13801/j.cnki.fhclxb.20201116.004

Abstract:

Lactic acid oligomer was prepared by direct condensation method and used as modifier of nano-calcium carbonate (CaCO3) to developed modified nano-calcium carbonate (g-CaCO3). g-CaCO3 was blended with polylactic acid (PLA) by solution blending to prepare g-CaCO3/PLA composites. The g-CaCO3 was characterized by FTIR and oil absorption value etc. SEM, DSC, universal testing machine, rheometer, water vapor transmission tester and UV-Vis-AIR spectrophotometer were used to study the g-CaCO3 on the structure and performances of the PLA. The results show that the modification of lactic acid oligomer reduces the absorption value of CaCO3, promotes compatibility between CaCO3 and PLA and improves the dispersion of CaCO3 in PLA matrix. At the same time, the g-CaCO3 acts as nucleating agent in PLA matrix, improving the crystallization ability of the PLA. The tensile strength and strain at break of the g-CaCO3/PLA composites first rise and then fall as the g-CaCO3 content increasing. When the g-CaCO3 content is 5wt%, the tensile strength is 50% higher than that of 5%CaCO3/PLA composite. When the addition amount of g-CaCO3 reaches 10wt%, the tensile strength is still 13% higher than that of pure PLA. The storage modulus and complex viscosity of the composites are improved by adding g-CaCO3. In addition, the addition of g-CaCO3 enhances the barrier property of PLA to ultraviolet visible light and water vapor.

Lactic acid oligomer was prepared by direct condensation method and used as modifier of nano-calcium carbonate (CaCO3) to developed modified nano-calcium carbonate (g-CaCO3). g-CaCO3 was blended with polylactic acid (PLA) by solution blending to prepare g-CaCO3/PLA composites. The g-CaCO3 was characterized by FTIR and oil absorption value etc. SEM, DSC, universal testing machine, rheometer, water vapor transmission tester and UV-Vis-AIR spectrophotometer were used to study the g-CaCO3 on the structure and performances of the PLA. The results show that the modification of lactic acid oligomer reduces the absorption value of CaCO3, promotes compatibility between CaCO3 and PLA and improves the dispersion of CaCO3 in PLA matrix. At the same time, the g-CaCO3 acts as nucleating agent in PLA matrix, improving the crystallization ability of the PLA. The tensile strength and strain at break of the g-CaCO3/PLA composites first rise and then fall as the g-CaCO3 content increasing. When the g-CaCO3 content is 5wt%, the tensile strength is 50% higher than that of 5%CaCO3/PLA composite. When the addition amount of g-CaCO3 reaches 10wt%, the tensile strength is still 13% higher than that of pure PLA. The storage modulus and complex viscosity of the composites are improved by adding g-CaCO3. In addition, the addition of g-CaCO3 enhances the barrier property of PLA to ultraviolet visible light and water vapor.

2021, 38(9): 2795-2802.

doi: 10.13801/j.cnki.fhclxb.20201203.002

Abstract:

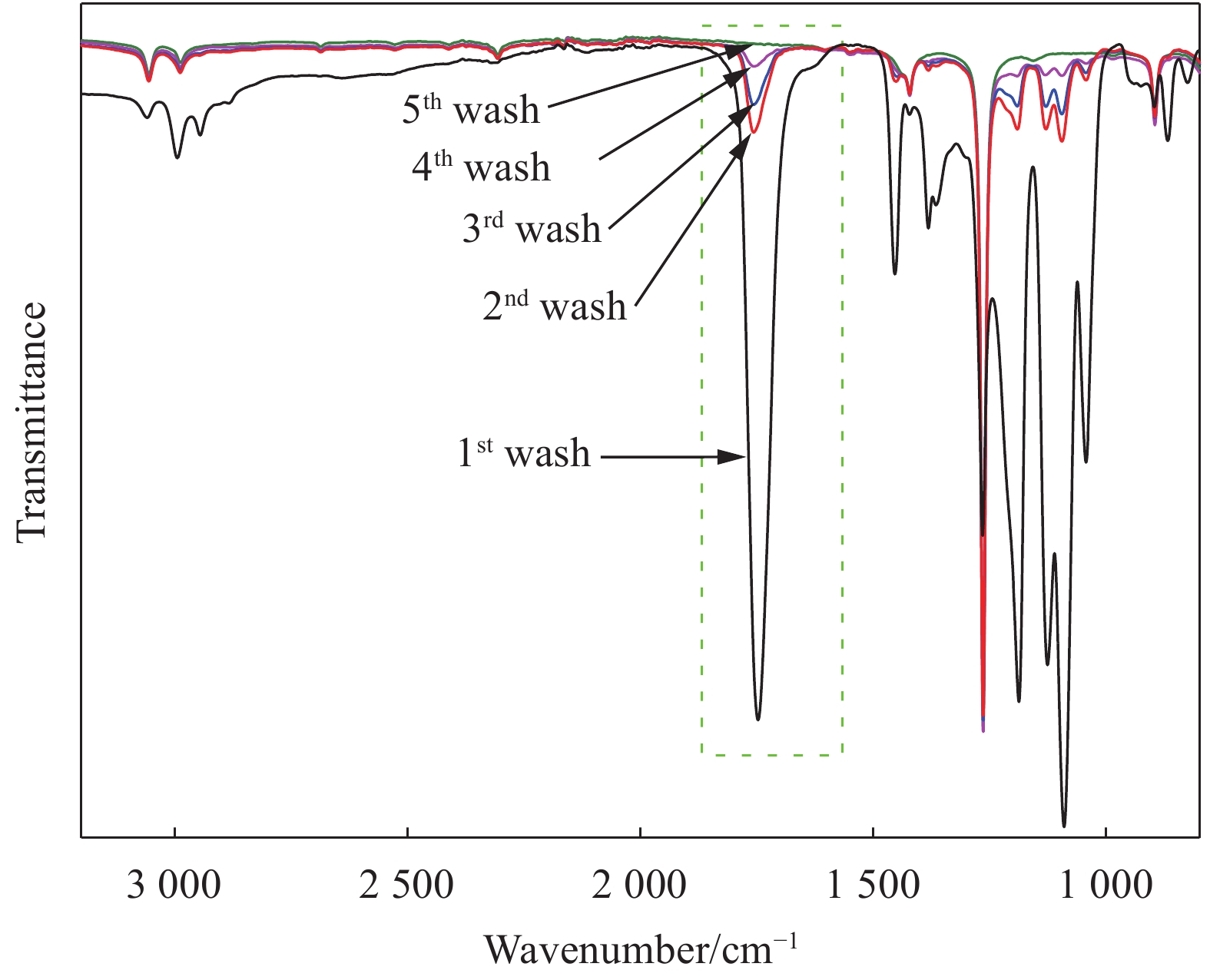

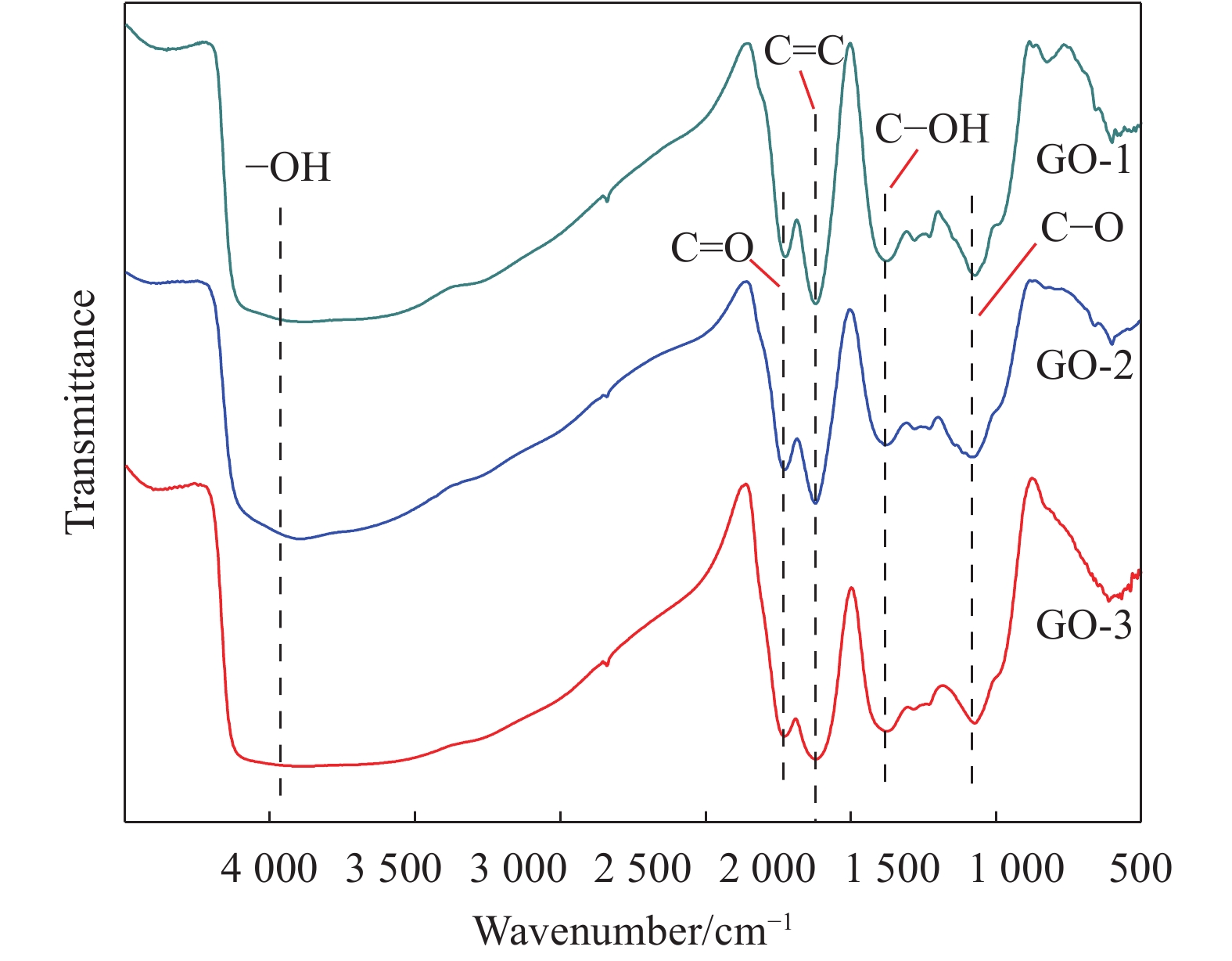

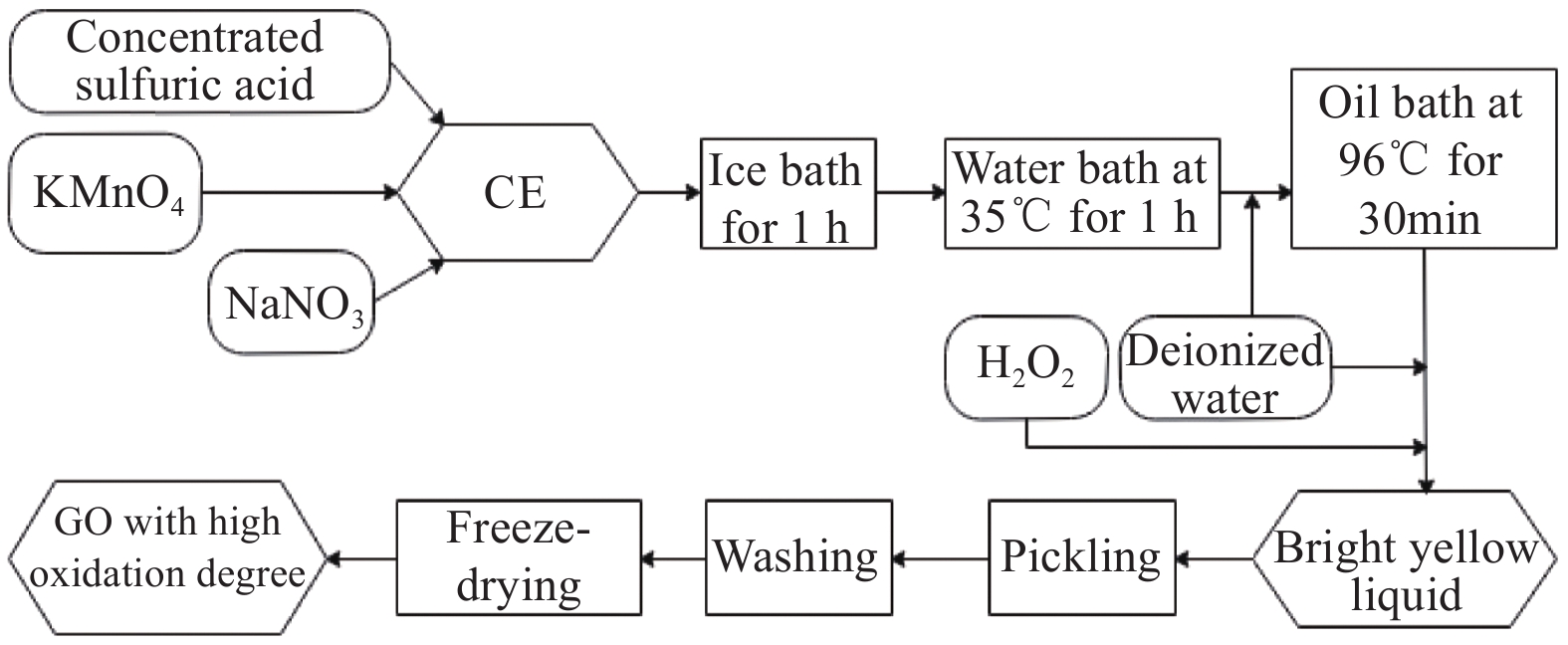

Graphene oxide (GO) has excellent adsorption performance for dyes in water, but the effect of its oxidation degree on the adsorption performance and mechanism of composite materials has not been fully studied. Three kinds of graphene oxide (GO) with different oxidation degrees were synthesized by the Hummers and then compounded with polyvinyl alcohol (PVA) to synthesize three kinds of GO/PVA aerogels. The oxidation degree of GO was characterized by infrared spectroscopy (FTIR), elemental analysis (EA) and thermogravimetric analysis (TG). Using methylene blue (MB) as a simulated pollutant, the effect of GO oxidation degree of GO/PVA aerogels on MB adsorption performance under different solution pH, adsorption time and initial concentration was investigated through static adsorption experiments. The absorption mechanism of GO/PVA aerogels had been explored by adsorption kinetics model, model of adsorption isotherm and adsorption thermodynamic model. The results show that the adsorption behavior of GO/PVA aerogels on MB is slightly affected by pH. Increasing the oxidation degree of GO can significantly improve the adsorption capacity and adsorption speed of GO/PVA aerogels. And the adsorption sites on aerogel can be increase by improving the oxidation degree of GO , which is conducive to adsorption. In addition, the degree of GO oxidation has no obvious effect on the adsorption mechanism of GO/PVA aerogels.

Graphene oxide (GO) has excellent adsorption performance for dyes in water, but the effect of its oxidation degree on the adsorption performance and mechanism of composite materials has not been fully studied. Three kinds of graphene oxide (GO) with different oxidation degrees were synthesized by the Hummers and then compounded with polyvinyl alcohol (PVA) to synthesize three kinds of GO/PVA aerogels. The oxidation degree of GO was characterized by infrared spectroscopy (FTIR), elemental analysis (EA) and thermogravimetric analysis (TG). Using methylene blue (MB) as a simulated pollutant, the effect of GO oxidation degree of GO/PVA aerogels on MB adsorption performance under different solution pH, adsorption time and initial concentration was investigated through static adsorption experiments. The absorption mechanism of GO/PVA aerogels had been explored by adsorption kinetics model, model of adsorption isotherm and adsorption thermodynamic model. The results show that the adsorption behavior of GO/PVA aerogels on MB is slightly affected by pH. Increasing the oxidation degree of GO can significantly improve the adsorption capacity and adsorption speed of GO/PVA aerogels. And the adsorption sites on aerogel can be increase by improving the oxidation degree of GO , which is conducive to adsorption. In addition, the degree of GO oxidation has no obvious effect on the adsorption mechanism of GO/PVA aerogels.

2021, 38(9): 2803-2813.

doi: 10.13801/j.cnki.fhclxb.20201116.001

Abstract:

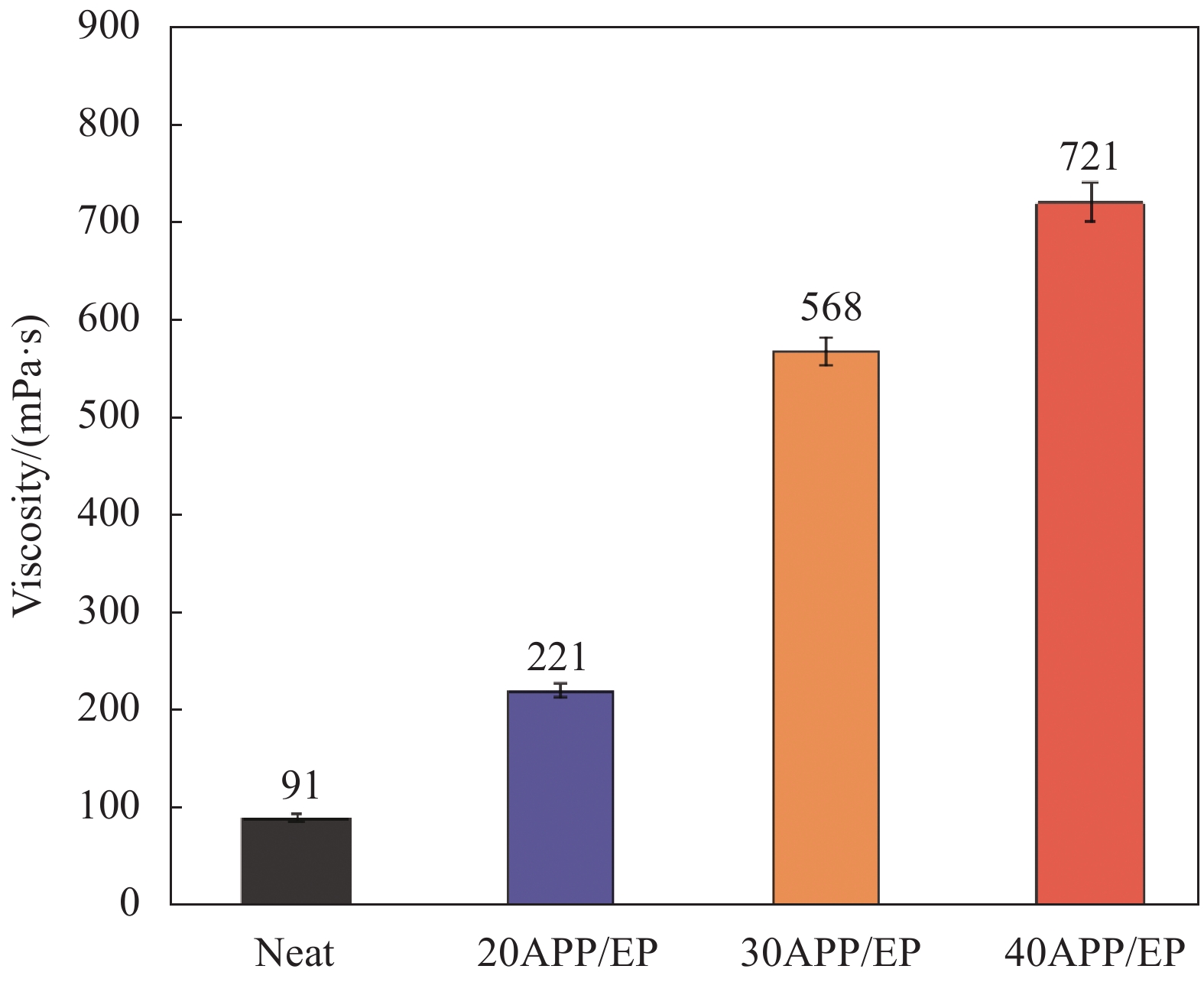

Epoxy resins were modified by ammonium polyphosphate (APP) and its combination with different contents of melamine (MA) and triazine carbon-forming agent (CFA). The effects of flame retardants with different proportions(total content of 40wt%) on the rheological, curing, thermomechanical, mechanical and flame-retardant properties of epoxy resins were investigated systematically. The optimized flameretardant epoxy resin was used to fabricate glass fiber reinforced epoxy composite (GFRC), and the mechanical as well as flame retardancy of the resulting GFRC were studied. The results show that the epoxy resins modified by APP-MA and APP-CFA combinations do not show apparent synergistic flame retardancy effects, but the ternary APP-MA-CFA system (30wt%APP-5wt% MA-5wt%CFA) demonstrates superior synergistic flame retardancy effects. Compared with the unmodified epoxy resin, the epoxy resin modified by APP-MA-CFA exhibits an increase in limit oxygen index (LOI) from 18% to 50.2%, a 84% decrease in peak heat release rate (PHRR) and a 78% decrease in total hear release (THR). With the addition of flame retardants in the epoxy matrix, the GFRC shows deteriorative mechanical properties, especially for interlaminar shear strength. Again, the GFRC based on the epoxy matrix modified by APP-MA-CFA presents the best flame-retardant performance. Compared with the unmodified GFRC, the modified GFRC shows an increased LOI (from 22.8% to 66.0%), a decreased PHRR (from 354 kW/m2 to 93 kW/m2) and a decreased THR (from 49.3 MJ/m2 to 22.8 MJ/m2).

Epoxy resins were modified by ammonium polyphosphate (APP) and its combination with different contents of melamine (MA) and triazine carbon-forming agent (CFA). The effects of flame retardants with different proportions(total content of 40wt%) on the rheological, curing, thermomechanical, mechanical and flame-retardant properties of epoxy resins were investigated systematically. The optimized flameretardant epoxy resin was used to fabricate glass fiber reinforced epoxy composite (GFRC), and the mechanical as well as flame retardancy of the resulting GFRC were studied. The results show that the epoxy resins modified by APP-MA and APP-CFA combinations do not show apparent synergistic flame retardancy effects, but the ternary APP-MA-CFA system (30wt%APP-5wt% MA-5wt%CFA) demonstrates superior synergistic flame retardancy effects. Compared with the unmodified epoxy resin, the epoxy resin modified by APP-MA-CFA exhibits an increase in limit oxygen index (LOI) from 18% to 50.2%, a 84% decrease in peak heat release rate (PHRR) and a 78% decrease in total hear release (THR). With the addition of flame retardants in the epoxy matrix, the GFRC shows deteriorative mechanical properties, especially for interlaminar shear strength. Again, the GFRC based on the epoxy matrix modified by APP-MA-CFA presents the best flame-retardant performance. Compared with the unmodified GFRC, the modified GFRC shows an increased LOI (from 22.8% to 66.0%), a decreased PHRR (from 354 kW/m2 to 93 kW/m2) and a decreased THR (from 49.3 MJ/m2 to 22.8 MJ/m2).

2021, 38(9): 2814-2820.

doi: 10.13801/j.cnki.fhclxb.20201030.007

Abstract:

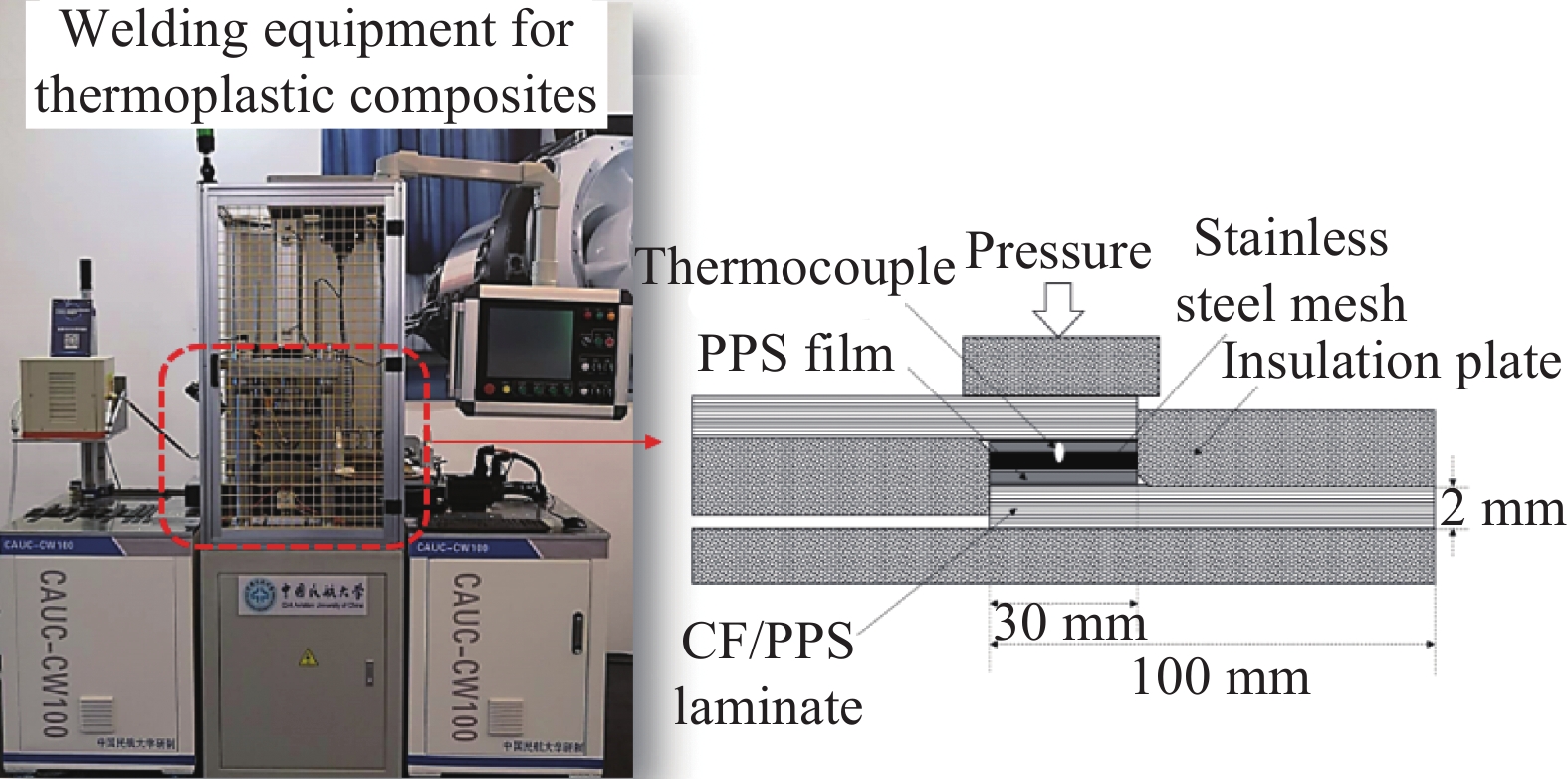

The carbon fiber reinforced polyphenylene sulfide (CF/PPS) composite laminate was taken as the research object, and the induction welding method was used to weld the CF/PPS laminate. It was focused on the effect of hygrothermal on the welded joint performance of the CF/PPS laminate. The experimental results show that the PPS resin does not undergo chemical changes before and after moisture absorption. At room temperature, the shear strengths of the welded joints gradually decrease with the increase of moisture absorption time, and compared with the dry welded joints, they are reduced by 15%, 18%, 23%, 32%, and 38%, respectively. The wet stress increases at the interface of the stainless steel mesh, resin matrix and carbon fiber, which weakens the bonding performance of the welded joint interface, and affects the failure mode of the welded joint. Under the environment of 120℃, the shear strength values of the welded joints with different moisture absorption times decrease by 12%, 15%, 22%, 37% and 44%, respectively. High temperature and high humidity make the thermal stress and wet stress at the interface of the stainless steel mesh, resin matrix and carbon fiber greater, which aggravates the damage of interface bonding performance. Interface debonding is the main failure form of the welded joints.

The carbon fiber reinforced polyphenylene sulfide (CF/PPS) composite laminate was taken as the research object, and the induction welding method was used to weld the CF/PPS laminate. It was focused on the effect of hygrothermal on the welded joint performance of the CF/PPS laminate. The experimental results show that the PPS resin does not undergo chemical changes before and after moisture absorption. At room temperature, the shear strengths of the welded joints gradually decrease with the increase of moisture absorption time, and compared with the dry welded joints, they are reduced by 15%, 18%, 23%, 32%, and 38%, respectively. The wet stress increases at the interface of the stainless steel mesh, resin matrix and carbon fiber, which weakens the bonding performance of the welded joint interface, and affects the failure mode of the welded joint. Under the environment of 120℃, the shear strength values of the welded joints with different moisture absorption times decrease by 12%, 15%, 22%, 37% and 44%, respectively. High temperature and high humidity make the thermal stress and wet stress at the interface of the stainless steel mesh, resin matrix and carbon fiber greater, which aggravates the damage of interface bonding performance. Interface debonding is the main failure form of the welded joints.

2021, 38(9): 2821-2828.

doi: 10.13801/j.cnki.fhclxb.20201210.001

Abstract:

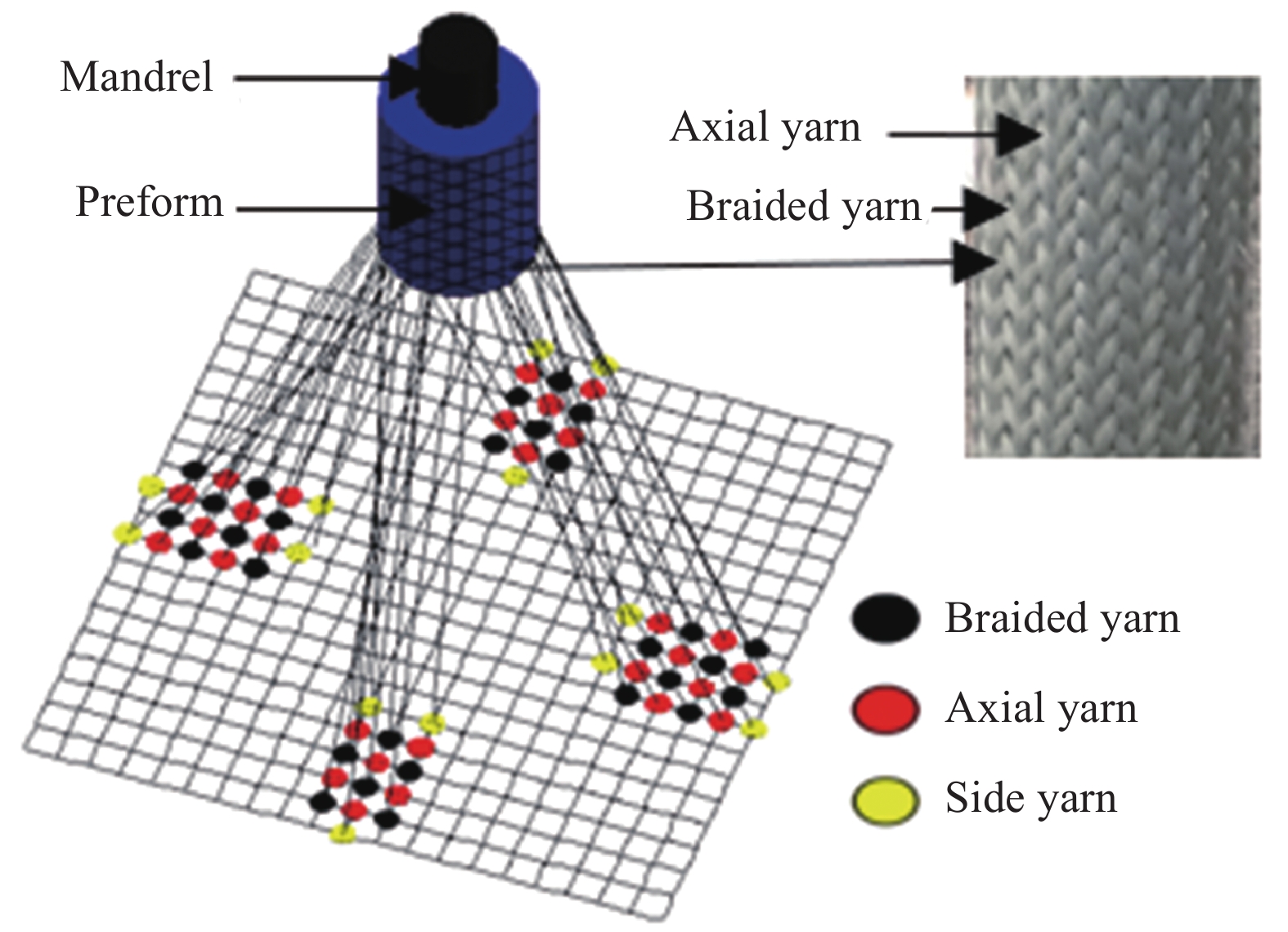

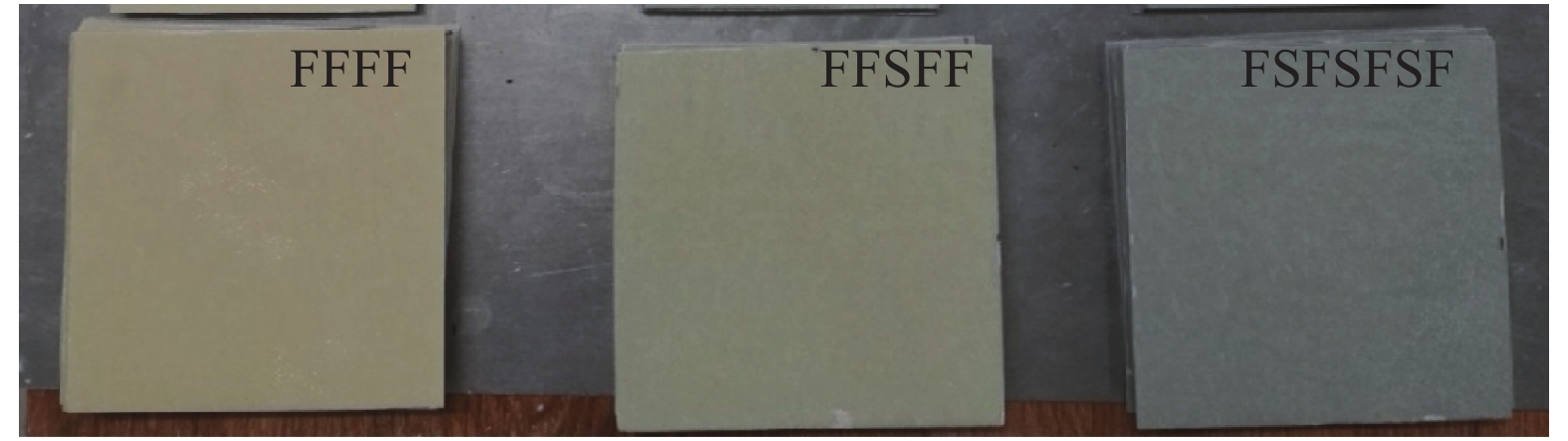

Based on 3D braiding and vacuum assisted resin transfer molding, three types of epoxy (EP) matrix three-dimensional braided composite thin-walled circular tubes with different hybrid modes (braided yarn/axial yarn: carbon fiber-carbon fiber (CF-CF), carbon fiber-glass fiber (CF-GF), glass fiber-carbon fiber (GF-CF)) were prepared. Through quasi-static axial crushing and detailed observation of failure section, the influence of fiber hybrid mode of thin-walled tube on energy absorption performance and failure mode was studied. The results show that: the specific energy absorption values of CF-CF/EP samples are 36% and 12% higher than those of GF-CF/EP and CF-GF/EP, respectively. When the braided yarns are made of carbon fiber (CF-CF/EP and CF-GF/EP), the failure mode of circular tube is folding failure mode. Carbon fiber is used in braided yarn to effectively restrain the axial expansion of central crack, and more tiny micro damage occurs in the 3D structure of folding deformation. However, when the braided yarn is made of glass fiber (GF-CF/EP), and the failure mode is flowering and bending inside and outside, the central crack is produced, and the 3D structure presents delamination and bends to the inside and outside of circular tube.

Based on 3D braiding and vacuum assisted resin transfer molding, three types of epoxy (EP) matrix three-dimensional braided composite thin-walled circular tubes with different hybrid modes (braided yarn/axial yarn: carbon fiber-carbon fiber (CF-CF), carbon fiber-glass fiber (CF-GF), glass fiber-carbon fiber (GF-CF)) were prepared. Through quasi-static axial crushing and detailed observation of failure section, the influence of fiber hybrid mode of thin-walled tube on energy absorption performance and failure mode was studied. The results show that: the specific energy absorption values of CF-CF/EP samples are 36% and 12% higher than those of GF-CF/EP and CF-GF/EP, respectively. When the braided yarns are made of carbon fiber (CF-CF/EP and CF-GF/EP), the failure mode of circular tube is folding failure mode. Carbon fiber is used in braided yarn to effectively restrain the axial expansion of central crack, and more tiny micro damage occurs in the 3D structure of folding deformation. However, when the braided yarn is made of glass fiber (GF-CF/EP), and the failure mode is flowering and bending inside and outside, the central crack is produced, and the 3D structure presents delamination and bends to the inside and outside of circular tube.

2021, 38(9): 2829-2838.

doi: 10.13801/j.cnki.fhclxb.20201210.003

Abstract:

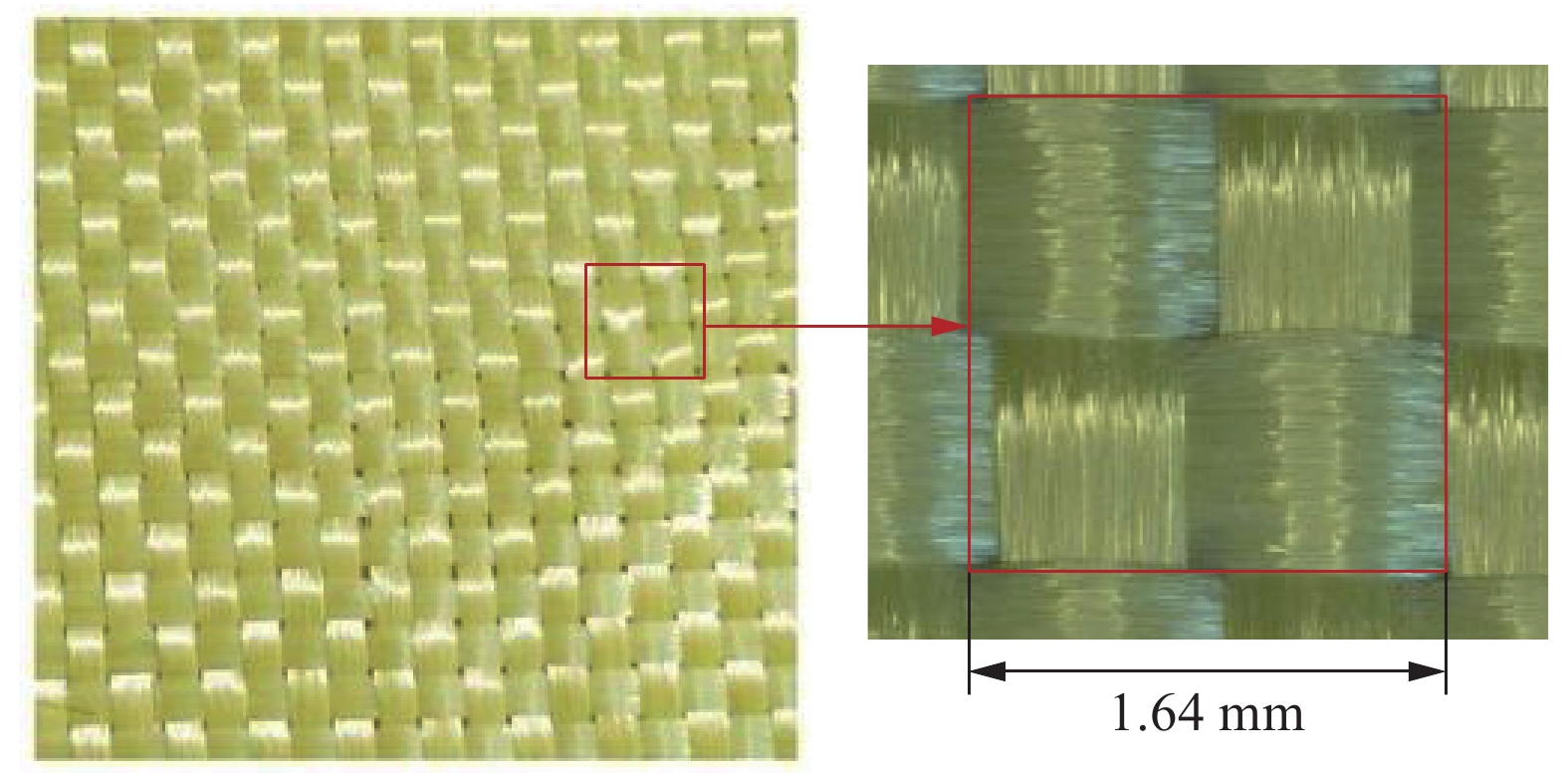

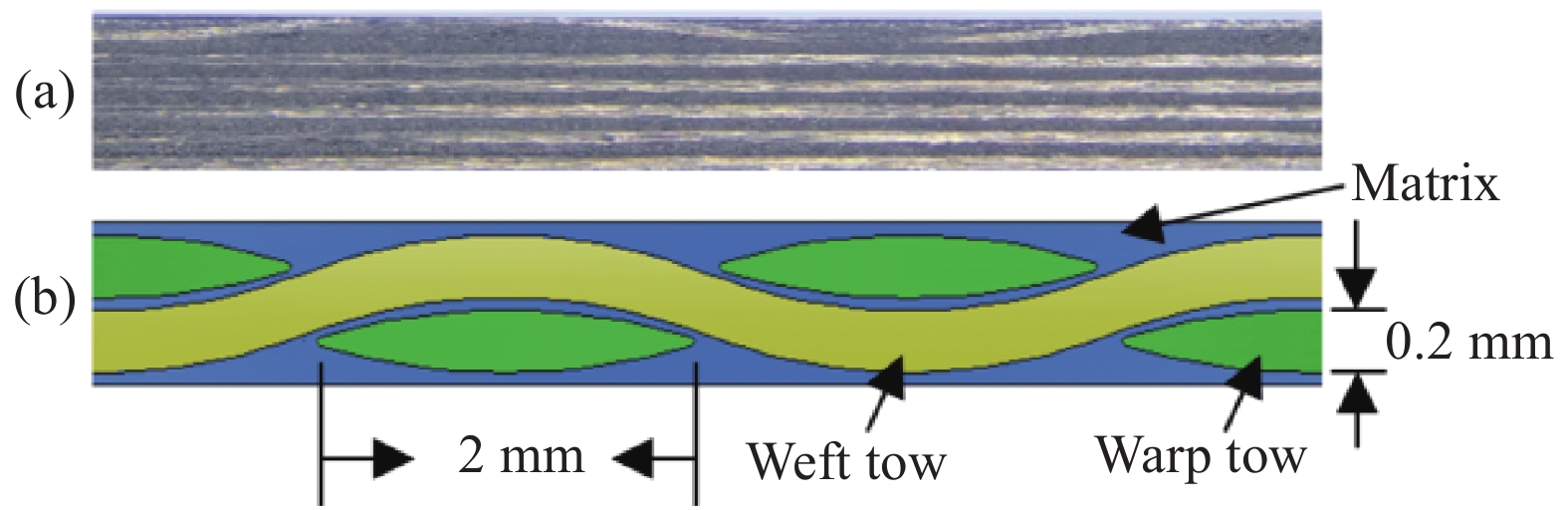

Due to its non-contact, no coupling agent, fast and high resolution nature, laser ultrasonic technology has great potential in the detection of defects of anisotropic carbon fiber braided composites. In this paper, the finite element method was used to analyze the effect of the excitation position and braided structure on the ultrasonic signal excited by the laser point source, also the propagation law and energy distribution characteristics of the elastic wave inside the material were obtained. A non-contact laser ultrasonic C-scan imaging system was built based on a 1 MHz air-coupled transducer, and the experiments of near-surface micro structure and internal defect detection in plain and satin carbon fiber braided composites were carried out. The experimental results have shown that the spatial distribution characteristics of the near-surface resin capsule, carbon fiber bundle shape, orientation, size and internal defects and so on in the carbon fiber braided composites can be observed with high resolution by employing the laser air-coupled ultrasonic imaging technique. It provides an effective method of the micro structure characterization and defect detection for the aerospace composites.

Due to its non-contact, no coupling agent, fast and high resolution nature, laser ultrasonic technology has great potential in the detection of defects of anisotropic carbon fiber braided composites. In this paper, the finite element method was used to analyze the effect of the excitation position and braided structure on the ultrasonic signal excited by the laser point source, also the propagation law and energy distribution characteristics of the elastic wave inside the material were obtained. A non-contact laser ultrasonic C-scan imaging system was built based on a 1 MHz air-coupled transducer, and the experiments of near-surface micro structure and internal defect detection in plain and satin carbon fiber braided composites were carried out. The experimental results have shown that the spatial distribution characteristics of the near-surface resin capsule, carbon fiber bundle shape, orientation, size and internal defects and so on in the carbon fiber braided composites can be observed with high resolution by employing the laser air-coupled ultrasonic imaging technique. It provides an effective method of the micro structure characterization and defect detection for the aerospace composites.

2021, 38(9): 2839-2847.

doi: 10.13801/j.cnki.fhclxb.20201229.001

Abstract:

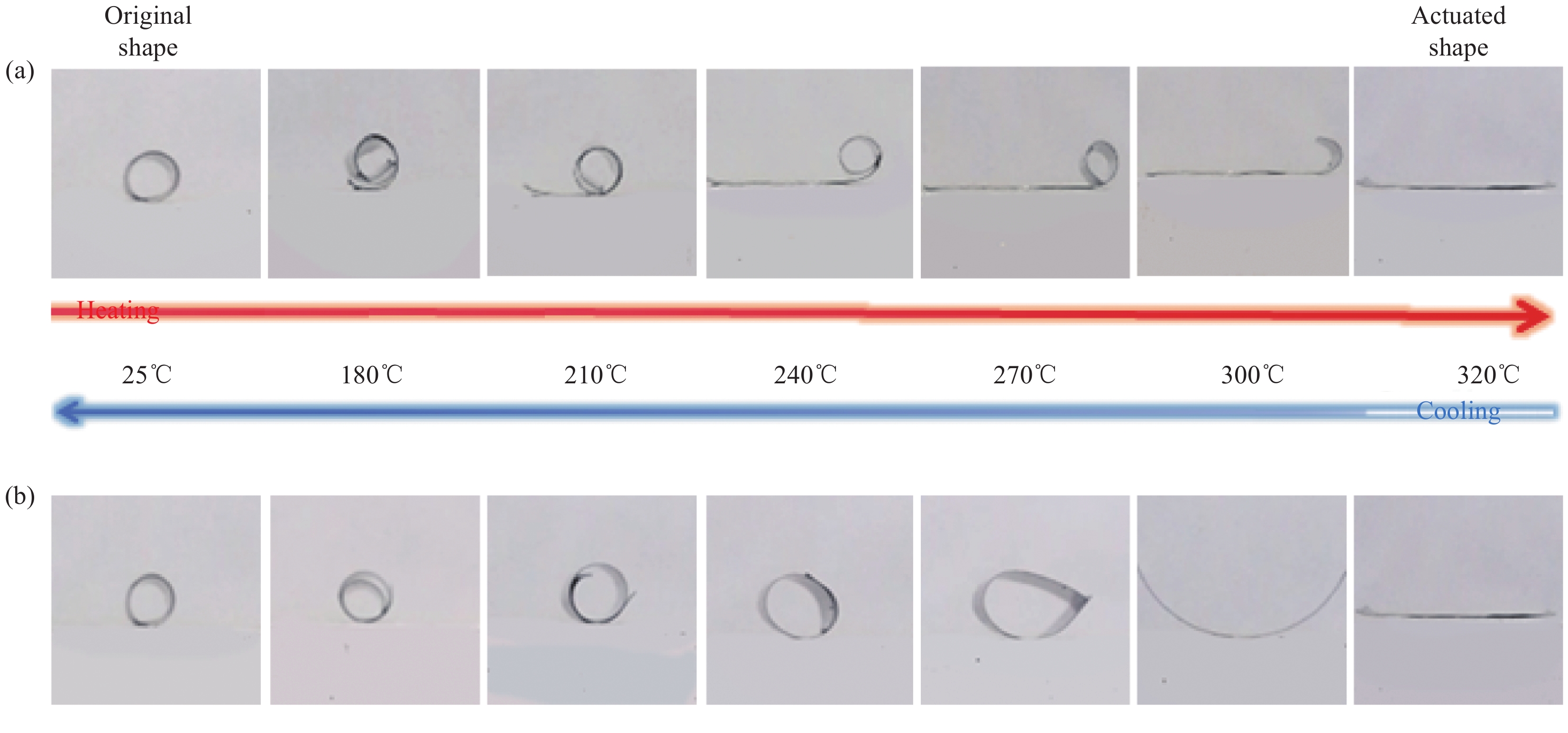

In order to improve the application of shape memory polymers in extreme harsh environments, the ultrathin carbon fibers reinforced polyether-ether-ketone (CF/PEEK) composite with 0.036 mm thickness was fabricated by overlapping and hot-pressing technologies, and the shape memory behaviors of the composite under the action of thermal stress were investigated. The results show the shape recovery rate of CF/PEEK composite ultrathin laminate is approximately 100%, and still has above 90% reversion rate after 100 times tests of thermal cycling action at 320℃. The stress-driving deformation mechanism of CF/PEEK composite is explained based on the relationship between temperature and stress-strain. The CF/PEEK composites with variable thickness were designed to simulate the deformation and recovery of complex shapes, containing deep-sea coral, cube and pitcher plant. Using mechanical clamping force during the deformation of CF/PEEK composite, the grasping coin experiment was carried out, which verifies the application feasibility for the active deformed structure of CF/PEEK composite.

In order to improve the application of shape memory polymers in extreme harsh environments, the ultrathin carbon fibers reinforced polyether-ether-ketone (CF/PEEK) composite with 0.036 mm thickness was fabricated by overlapping and hot-pressing technologies, and the shape memory behaviors of the composite under the action of thermal stress were investigated. The results show the shape recovery rate of CF/PEEK composite ultrathin laminate is approximately 100%, and still has above 90% reversion rate after 100 times tests of thermal cycling action at 320℃. The stress-driving deformation mechanism of CF/PEEK composite is explained based on the relationship between temperature and stress-strain. The CF/PEEK composites with variable thickness were designed to simulate the deformation and recovery of complex shapes, containing deep-sea coral, cube and pitcher plant. Using mechanical clamping force during the deformation of CF/PEEK composite, the grasping coin experiment was carried out, which verifies the application feasibility for the active deformed structure of CF/PEEK composite.

2021, 38(9): 2848-2861.

doi: 10.13801/j.cnki.fhclxb.20201124.003

Abstract:

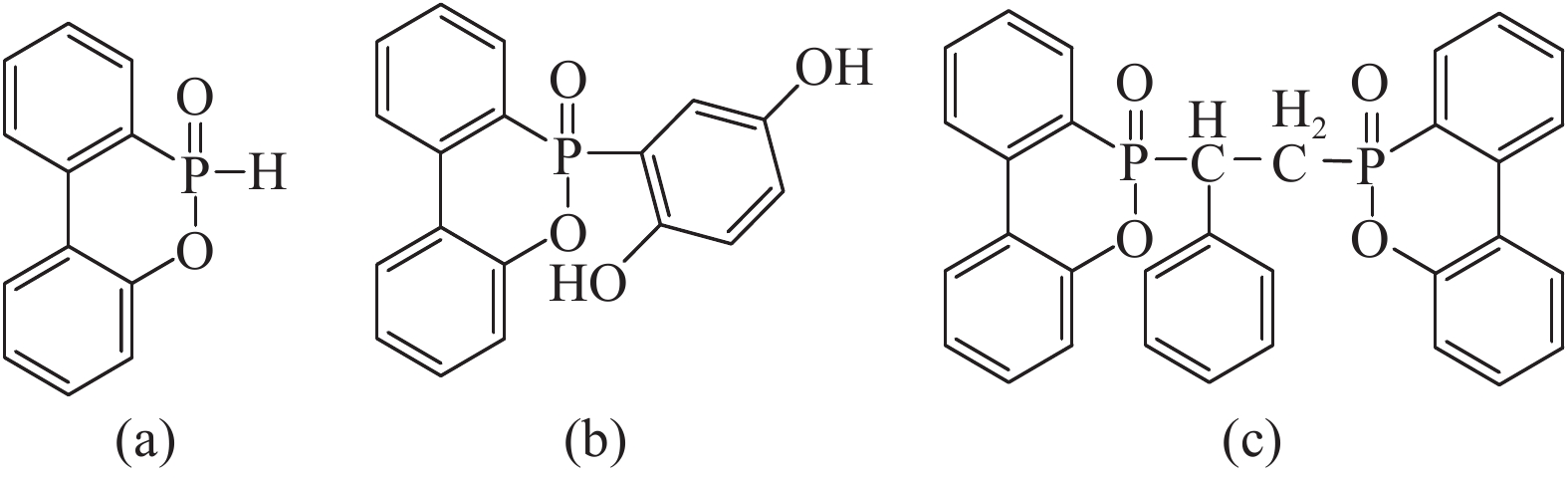

The thermal decomposition behaviors of three kinds of derivatives, including 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide(DOPO), 10-(2, 5-dihydroxyphenyl)-10-hydro-9-oxa-10-phosphaphenanthrene-10-oxide(DOPO-HQ), 6H-dibenz[c, e][1, 2]oxaphosphorin, 6’6-(1, 2-phenethyl)bis-, 6’6-dioxide (DiDOPO), were studied. And effects of these DOPO derivatives on the thermal degradation behavior, flame retardancy and mechanical properties of poly(lactic acid) (PLA) were comparatively studied. TG results show that the initial decomposition temperature (T5%) of DOPO is 154℃, and an increased T5% of DOPO-HQ of 342℃ is displayed. In addition, T5% of DiDOPO reaches to as high as 363℃, which is higher than that of DOPO and DOPO-HQ. As for PLA composites, T5% reveals an increase trend as follow: T5%(DOPO/PLA, 273.5℃) <T5%(DOPO-HQ/PLA, 321.5℃) <T5%(DiDOPO/PLA, 333.8℃). T5% shows an progressively increase trend with the increased thermal stability of flame retardants. Furthermore, the thermal degradation kinetics results indicate that the thermal degradation activation energy of the composites material is improved. The thermal degradation of DOPO derivatives/PLA composites was investigated by thermogravimetric-infrared spectroscopy analysis (TG-IR) and pyrolysis-gas chromatography/mass spectrometry (PY-GC/MS). It shows that the three flame retardants mainly exert their gas phase flame retardant effect by generating phosphorus oxygen free radicals, and the characteristic groups of DOPO-HQ and DiDOPO may play a role in the condensation phase. All the three systems have attained the V-0 rating (UL-94), what’s more DOPO/PLA dripping is the most serious, on the contrary the dripping of DiDOPO/PLA is suppressed. Furthermore, the mechanical test results indicate that the tensile strength of DOPO/PLA decreases by 83.1% compared with pure PLA, while DOPO-HQ/PLA and DiDOPO/PLA only drops by 14.2% and 15.6%, respectively.

The thermal decomposition behaviors of three kinds of derivatives, including 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide(DOPO), 10-(2, 5-dihydroxyphenyl)-10-hydro-9-oxa-10-phosphaphenanthrene-10-oxide(DOPO-HQ), 6H-dibenz[c, e][1, 2]oxaphosphorin, 6’6-(1, 2-phenethyl)bis-, 6’6-dioxide (DiDOPO), were studied. And effects of these DOPO derivatives on the thermal degradation behavior, flame retardancy and mechanical properties of poly(lactic acid) (PLA) were comparatively studied. TG results show that the initial decomposition temperature (T5%) of DOPO is 154℃, and an increased T5% of DOPO-HQ of 342℃ is displayed. In addition, T5% of DiDOPO reaches to as high as 363℃, which is higher than that of DOPO and DOPO-HQ. As for PLA composites, T5% reveals an increase trend as follow: T5%(DOPO/PLA, 273.5℃) <T5%(DOPO-HQ/PLA, 321.5℃) <T5%(DiDOPO/PLA, 333.8℃). T5% shows an progressively increase trend with the increased thermal stability of flame retardants. Furthermore, the thermal degradation kinetics results indicate that the thermal degradation activation energy of the composites material is improved. The thermal degradation of DOPO derivatives/PLA composites was investigated by thermogravimetric-infrared spectroscopy analysis (TG-IR) and pyrolysis-gas chromatography/mass spectrometry (PY-GC/MS). It shows that the three flame retardants mainly exert their gas phase flame retardant effect by generating phosphorus oxygen free radicals, and the characteristic groups of DOPO-HQ and DiDOPO may play a role in the condensation phase. All the three systems have attained the V-0 rating (UL-94), what’s more DOPO/PLA dripping is the most serious, on the contrary the dripping of DiDOPO/PLA is suppressed. Furthermore, the mechanical test results indicate that the tensile strength of DOPO/PLA decreases by 83.1% compared with pure PLA, while DOPO-HQ/PLA and DiDOPO/PLA only drops by 14.2% and 15.6%, respectively.

2021, 38(9): 2862-2868.

doi: 10.13801/j.cnki.fhclxb.20201116.005

Abstract:

Graphite oxide (GO) was prepared by using a modified layer of graphite powder as the raw material, and pseudoboehmite (AlOOH) nanoparticles were grown on the surface of GO by a sol-gel method to obtain pseudo-boehmite stone-coated graphene oxide (GO@AlOOH). The matrix (E51-BCE) was synthesized from epoxy resin (E51) and bisphenol A cyanate (BCE), and GO@AlOOH as reinforcement to prepare the GO@AlOOH modified epoxy resin-cyanate composites (GO@AlOOH/E51-BCE) composites. Infrared analysis and X-ray characterization of GO coating materials shows that AlOOH and GO particles have a particular interaction, and there are certain hydroxyl groups on the surface of the material after coating. The composite samples were characterized by SEM showing that the addition of GO@AlOOH significantly changes the fracture surface of the resin and improves the performance. When the doping amount is 0.6wt%, the bending strength, bending modulus and impact strength of the composite material reach the maximum, which are 158.23 MPa, 2.37 GPa and 46.96 kJ/m2, respectively. The composite material has excellent mechanical properties and specific development potential.

Graphite oxide (GO) was prepared by using a modified layer of graphite powder as the raw material, and pseudoboehmite (AlOOH) nanoparticles were grown on the surface of GO by a sol-gel method to obtain pseudo-boehmite stone-coated graphene oxide (GO@AlOOH). The matrix (E51-BCE) was synthesized from epoxy resin (E51) and bisphenol A cyanate (BCE), and GO@AlOOH as reinforcement to prepare the GO@AlOOH modified epoxy resin-cyanate composites (GO@AlOOH/E51-BCE) composites. Infrared analysis and X-ray characterization of GO coating materials shows that AlOOH and GO particles have a particular interaction, and there are certain hydroxyl groups on the surface of the material after coating. The composite samples were characterized by SEM showing that the addition of GO@AlOOH significantly changes the fracture surface of the resin and improves the performance. When the doping amount is 0.6wt%, the bending strength, bending modulus and impact strength of the composite material reach the maximum, which are 158.23 MPa, 2.37 GPa and 46.96 kJ/m2, respectively. The composite material has excellent mechanical properties and specific development potential.

2021, 38(9): 2869-2881.

doi: 10.13801/j.cnki.fhclxb.20210406.001

Abstract:

In order to study the damage characteristics of glass fiber-stainless steel mesh hybrid laminates under high-speed oblique impact, the impact experiments with an angle of 30° were carried out on glass fiber reinforced epoxy laminates with 2 mm thickness and glass fiber-stainless steel mesh hybrid reinforced epoxy laminates with one or three layers of 304 stainless steel mesh by using a one-stage air gun. The effects of 304 stainless steel mesh on the ballistic limit and energy absorption of laminated plates were revealed, and the damage characteristics and mechanism of laminated plates were analyzed. Based on the experiments, it is found that the ballistic limit of the laminates with three layers of stainless steel mesh is the highest, while the ballistic limit velocity of the laminate without stainless steel mesh is close to that of the laminate with one stainless steel mesh. The energy absorbed by the laminate firstly increases with the increase of projectile velocity, and then becomes stable, and increases rapidly finally. The failure modes of laminates are matrix crack, matrix fracture, delamination, tensile fracture and shear fracture of fiber and stainless steel wire tensile fracture. The delamination damage area of laminated plates increases firstly and then decreases with the increase of the velocity of projectile, and finally tends to be stable. When the velocity of the projectile is low, the laminate fiber mainly produces tensile fracture, matrix cracking and delamination damage. With the increase of the velocity of the projectile, compression shear fracture of the front fiber of the laminate gradually occurs, the matrix is broken, and the back fiber has serious tensile tear.

In order to study the damage characteristics of glass fiber-stainless steel mesh hybrid laminates under high-speed oblique impact, the impact experiments with an angle of 30° were carried out on glass fiber reinforced epoxy laminates with 2 mm thickness and glass fiber-stainless steel mesh hybrid reinforced epoxy laminates with one or three layers of 304 stainless steel mesh by using a one-stage air gun. The effects of 304 stainless steel mesh on the ballistic limit and energy absorption of laminated plates were revealed, and the damage characteristics and mechanism of laminated plates were analyzed. Based on the experiments, it is found that the ballistic limit of the laminates with three layers of stainless steel mesh is the highest, while the ballistic limit velocity of the laminate without stainless steel mesh is close to that of the laminate with one stainless steel mesh. The energy absorbed by the laminate firstly increases with the increase of projectile velocity, and then becomes stable, and increases rapidly finally. The failure modes of laminates are matrix crack, matrix fracture, delamination, tensile fracture and shear fracture of fiber and stainless steel wire tensile fracture. The delamination damage area of laminated plates increases firstly and then decreases with the increase of the velocity of projectile, and finally tends to be stable. When the velocity of the projectile is low, the laminate fiber mainly produces tensile fracture, matrix cracking and delamination damage. With the increase of the velocity of the projectile, compression shear fracture of the front fiber of the laminate gradually occurs, the matrix is broken, and the back fiber has serious tensile tear.

2021, 38(9): 2882-2893.

doi: 10.13801/j.cnki.fhclxb.20201202.001

Abstract:

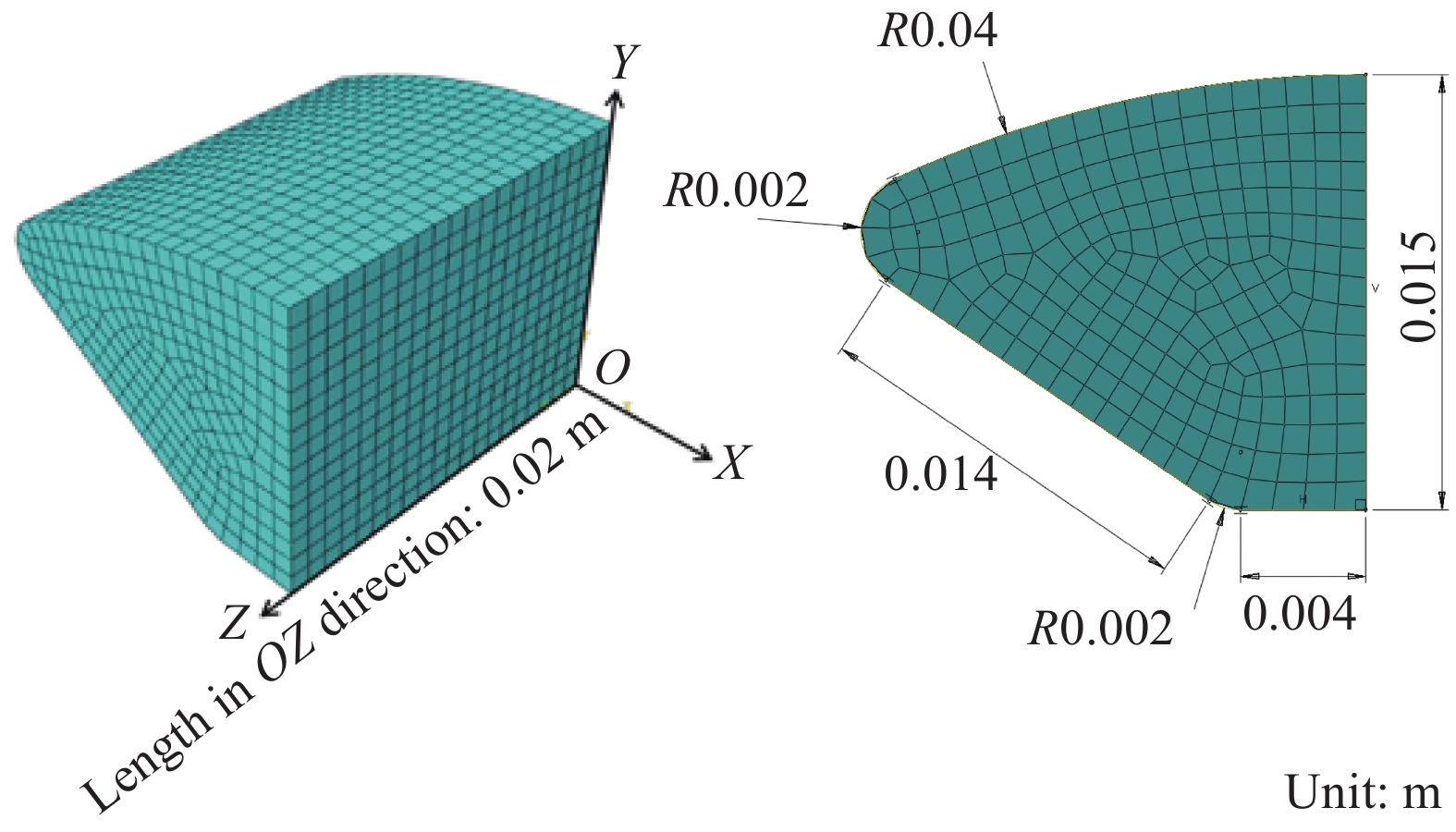

The deformation of fiber under the action of thermal mechanical parameters is caused by the differences of thermal expansion coefficient between the epoxy resin matrix and carbon fiber, and the stress concentration at the contact of fiber and matrix. Thermal residual stress is experienced in the product material during the laying process of carbon fiber/epoxy resin prepreg composites. Due to the structural characteristics of the carbon fiber/epoxy resin prepreg composite, the micro representative volume element (RVE) finite element model of the carbon fiber/epoxy resin prepreg composite with interface phase was established by using ABAQUS finite element software. The distribution rule and influence mechanism of the residual stress of the prepreg caused by temperature and pressure parameters were investigated by use of theoretical research and finite element simulation analysis. First, the temperature and pressure models of the prepreg were established to study the distribution of the residual stress of the products under different temperatures and pressure parameters. Second, the indirect coupling temperature reduction method was applied to simulate the change of residual stress of carbon fiber/epoxy resin prepreg with fiber volume content. Pressure, temperature and the microstructure of the product were analyzed by electron microscopy scanning. The basic influence rules of each factor on the residual stress of the products were thus obtained through analysis and comparison of the simulation results. In conclusion, the influences of different underlying parameters such as temperature and pressure on the residual stress of the prepreg were then tested.

The deformation of fiber under the action of thermal mechanical parameters is caused by the differences of thermal expansion coefficient between the epoxy resin matrix and carbon fiber, and the stress concentration at the contact of fiber and matrix. Thermal residual stress is experienced in the product material during the laying process of carbon fiber/epoxy resin prepreg composites. Due to the structural characteristics of the carbon fiber/epoxy resin prepreg composite, the micro representative volume element (RVE) finite element model of the carbon fiber/epoxy resin prepreg composite with interface phase was established by using ABAQUS finite element software. The distribution rule and influence mechanism of the residual stress of the prepreg caused by temperature and pressure parameters were investigated by use of theoretical research and finite element simulation analysis. First, the temperature and pressure models of the prepreg were established to study the distribution of the residual stress of the products under different temperatures and pressure parameters. Second, the indirect coupling temperature reduction method was applied to simulate the change of residual stress of carbon fiber/epoxy resin prepreg with fiber volume content. Pressure, temperature and the microstructure of the product were analyzed by electron microscopy scanning. The basic influence rules of each factor on the residual stress of the products were thus obtained through analysis and comparison of the simulation results. In conclusion, the influences of different underlying parameters such as temperature and pressure on the residual stress of the prepreg were then tested.

2021, 38(9): 2894-2903.

doi: 10.13801/j.cnki.fhclxb.20201201.003

Abstract:

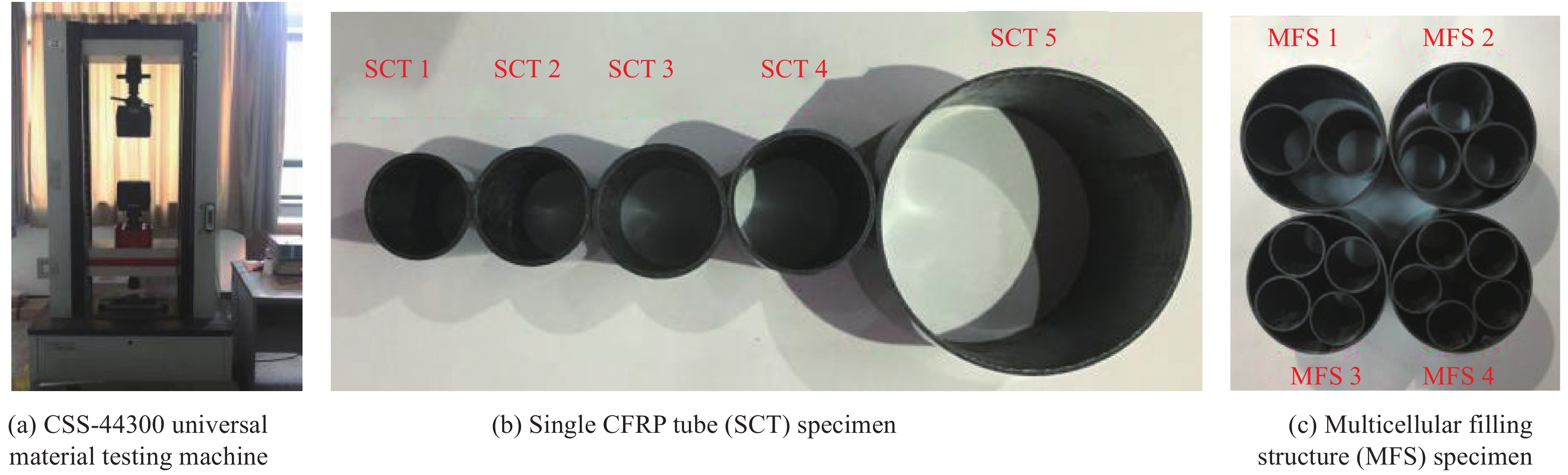

In view of the deficiency of the existing research on the energy absorption characteristics of composite multi-cell structures, a kind of multicellular filling structure (MFS) was proposed, which was filled by some single small-size CFRP tubes (SCT) into large-size CFRP tubes. The quasi-static compression tests of SCT and MFS were carried out, which included full stroke compression and multi-staged compression, then the failure mode and energy absorption characteristics were analyzed. The results show that the failure mode of the outermost CFRP tube of MFS is similar to SCTs, and there is no obvious difference between full stroke compression and multi-staged compression, but the radial deformation of the outermost tube is obvious due to the compression of the inner tube and debris. Compared with the full stroke compression process, the total energy absorption of SCT and MFS is more when they are multi-staged compressed. In this study, the maximum specific energy absorption (SEA) of SCT is 86.0 J/g and the minimum SEA is 59.3 J/g. While, due to the low SEA of the outermost tube of filled structures, the SEA of the MFS is between 69.8 J/g and 75.9 J/g, which is less than the maximum SEA of SCT. The SEA of the MFS is higher than that of SCT with appropriate external constraint and internal carbon tube number by further research.

In view of the deficiency of the existing research on the energy absorption characteristics of composite multi-cell structures, a kind of multicellular filling structure (MFS) was proposed, which was filled by some single small-size CFRP tubes (SCT) into large-size CFRP tubes. The quasi-static compression tests of SCT and MFS were carried out, which included full stroke compression and multi-staged compression, then the failure mode and energy absorption characteristics were analyzed. The results show that the failure mode of the outermost CFRP tube of MFS is similar to SCTs, and there is no obvious difference between full stroke compression and multi-staged compression, but the radial deformation of the outermost tube is obvious due to the compression of the inner tube and debris. Compared with the full stroke compression process, the total energy absorption of SCT and MFS is more when they are multi-staged compressed. In this study, the maximum specific energy absorption (SEA) of SCT is 86.0 J/g and the minimum SEA is 59.3 J/g. While, due to the low SEA of the outermost tube of filled structures, the SEA of the MFS is between 69.8 J/g and 75.9 J/g, which is less than the maximum SEA of SCT. The SEA of the MFS is higher than that of SCT with appropriate external constraint and internal carbon tube number by further research.

2021, 38(9): 2904-2913.

doi: 10.13801/j.cnki.fhclxb.20210312.004

Abstract:

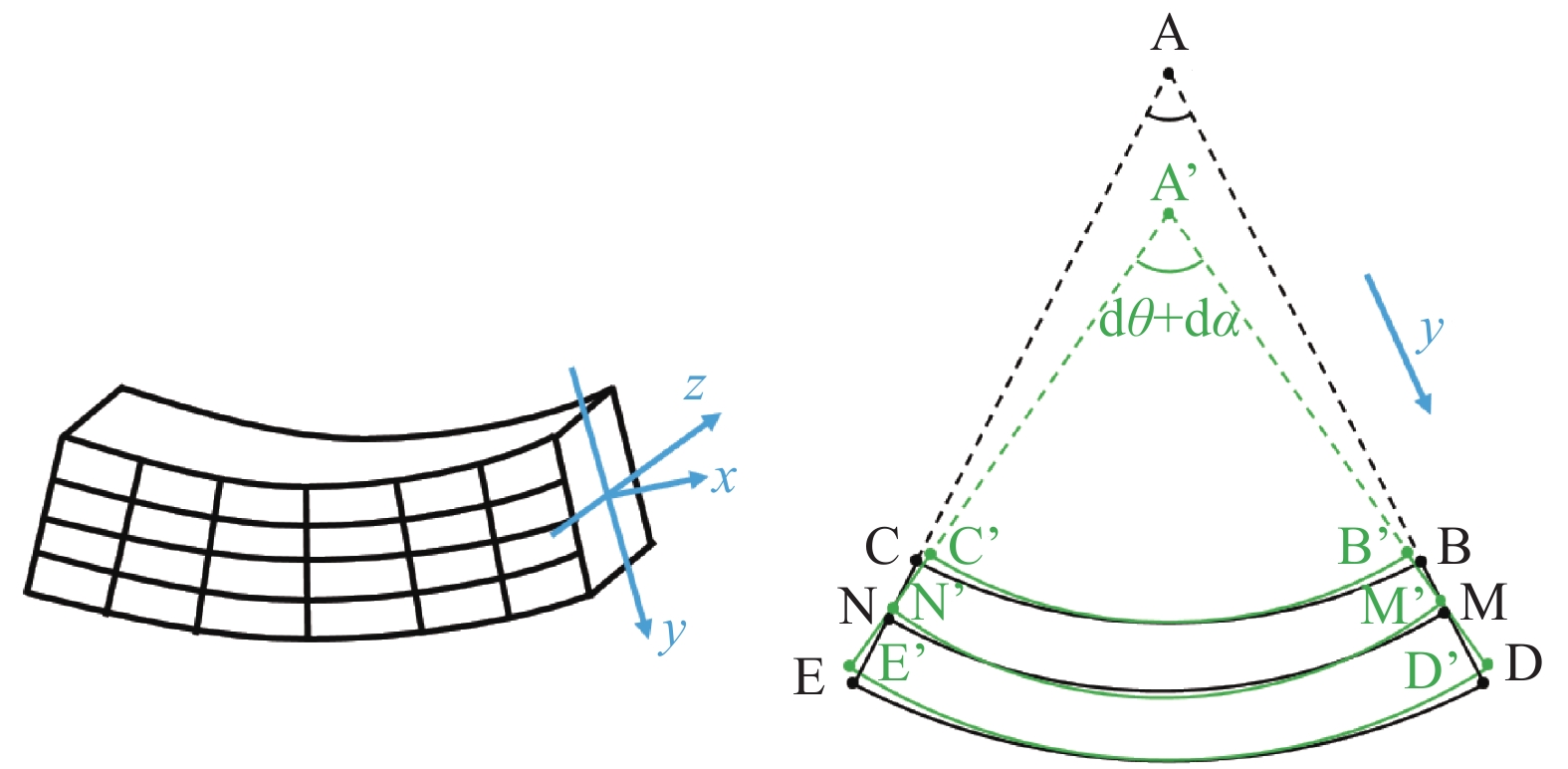

The test method for mode I delamination toughness of composite layers was the double cantilever beam (DCB) test with end notched flexure (ENF) specimen of unidirectional fiber-reinforced resin composites. In order to obtain the mode I delamination toughness of composite structures with curvature, the DCB test was used on the Arc-ENF specimen. The formulas of compliance and GIC for Arc-ENF specimen were derived by using beam bending theory and Irwin-Kies formula, and the numerical simulation of the DCB test was finished with ABAQUS. Finally, The formulas of compliance and GIC are proved to be reasonable and effective by comparing the results of theory formulas, numerical simulation and the DCB test, which have reference value for the test and analysis of mode I delamination toughness of DCB specimens with any curvature.

The test method for mode I delamination toughness of composite layers was the double cantilever beam (DCB) test with end notched flexure (ENF) specimen of unidirectional fiber-reinforced resin composites. In order to obtain the mode I delamination toughness of composite structures with curvature, the DCB test was used on the Arc-ENF specimen. The formulas of compliance and GIC for Arc-ENF specimen were derived by using beam bending theory and Irwin-Kies formula, and the numerical simulation of the DCB test was finished with ABAQUS. Finally, The formulas of compliance and GIC are proved to be reasonable and effective by comparing the results of theory formulas, numerical simulation and the DCB test, which have reference value for the test and analysis of mode I delamination toughness of DCB specimens with any curvature.

2021, 38(9): 2914-2924.

doi: 10.13801/j.cnki.fhclxb.20200922.001

Abstract:

This paper aims at optimizing the cure cycle of specific encapsulation structures composed of E51 resin from room temperature cure cycle to medium-high “two-phase” cure cycle by means of combination of numerical simulation and experimental testing on the basis of experimentally obtained parameters of cure kinetics and mechanical properties for E51 epoxy resin. The numerical method was firstly adopted to simulate the effects of temperature magnitude and curing time in the first and second dwelling phase to internal temperature, degree of cure and strain of structure during curing to optimize the process parameter. Then the internal temperature and strain of the structure were real-time recorded using Fiber Bragg Grating (FBG) monitoring technique, and the corresponding results reveal the validity of numerical simulation, which demonstrates the reliability of the approach of optimizing the cure cycle using numerical simulation. Lastly, the properties of the casting body specimens of E51 resin manufactured with optimized and original cure cycle were compared, and the results show that the tensile strength, compressive yield strength, flexural strength and impact strength for the specimens manufactured with optimized cure cycle increase by 3.9%, 1.5%, 14.5% and 16.2% compared with the specimens manufactured with original cure cycle, respectively.

This paper aims at optimizing the cure cycle of specific encapsulation structures composed of E51 resin from room temperature cure cycle to medium-high “two-phase” cure cycle by means of combination of numerical simulation and experimental testing on the basis of experimentally obtained parameters of cure kinetics and mechanical properties for E51 epoxy resin. The numerical method was firstly adopted to simulate the effects of temperature magnitude and curing time in the first and second dwelling phase to internal temperature, degree of cure and strain of structure during curing to optimize the process parameter. Then the internal temperature and strain of the structure were real-time recorded using Fiber Bragg Grating (FBG) monitoring technique, and the corresponding results reveal the validity of numerical simulation, which demonstrates the reliability of the approach of optimizing the cure cycle using numerical simulation. Lastly, the properties of the casting body specimens of E51 resin manufactured with optimized and original cure cycle were compared, and the results show that the tensile strength, compressive yield strength, flexural strength and impact strength for the specimens manufactured with optimized cure cycle increase by 3.9%, 1.5%, 14.5% and 16.2% compared with the specimens manufactured with original cure cycle, respectively.

2021, 38(9): 2925-2933.

doi: 10.13801/j.cnki.fhclxb.20201230.001

Abstract: