Figures of the Article

-

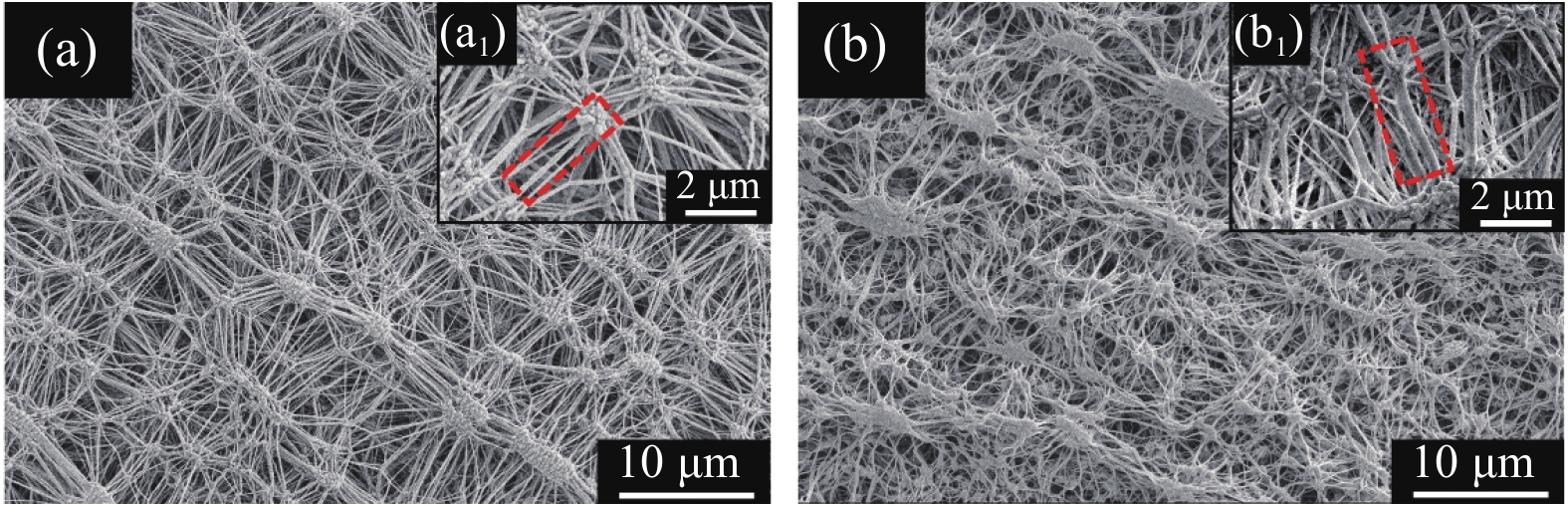

![]() FE-SEM images of PTFE fiber membrane:(a) before soaking (b) after soaking

FE-SEM images of PTFE fiber membrane:(a) before soaking (b) after soaking

-

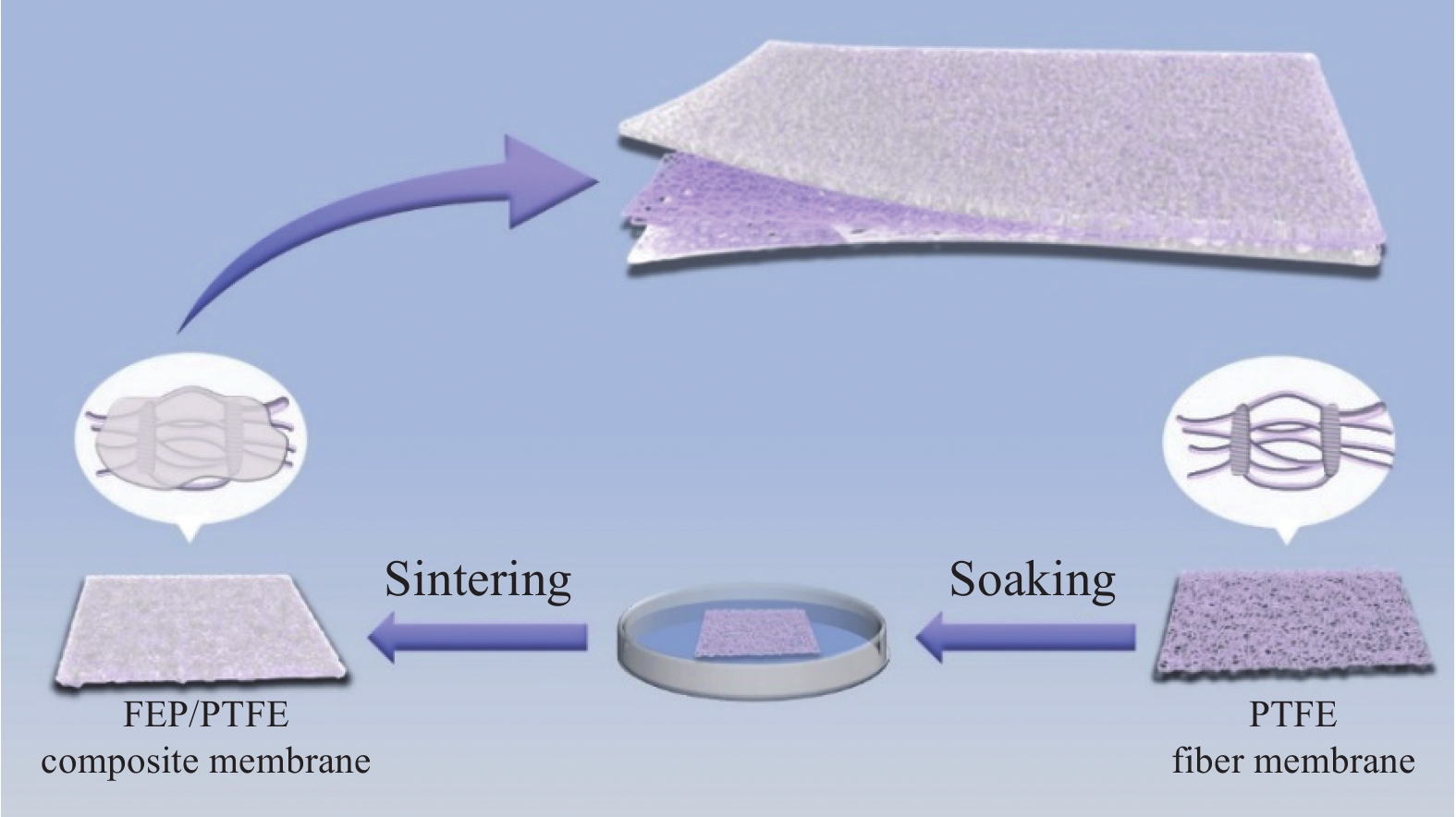

![]() Schematic diagram of FEP post-finishing PTFE

Schematic diagram of FEP post-finishing PTFE

-

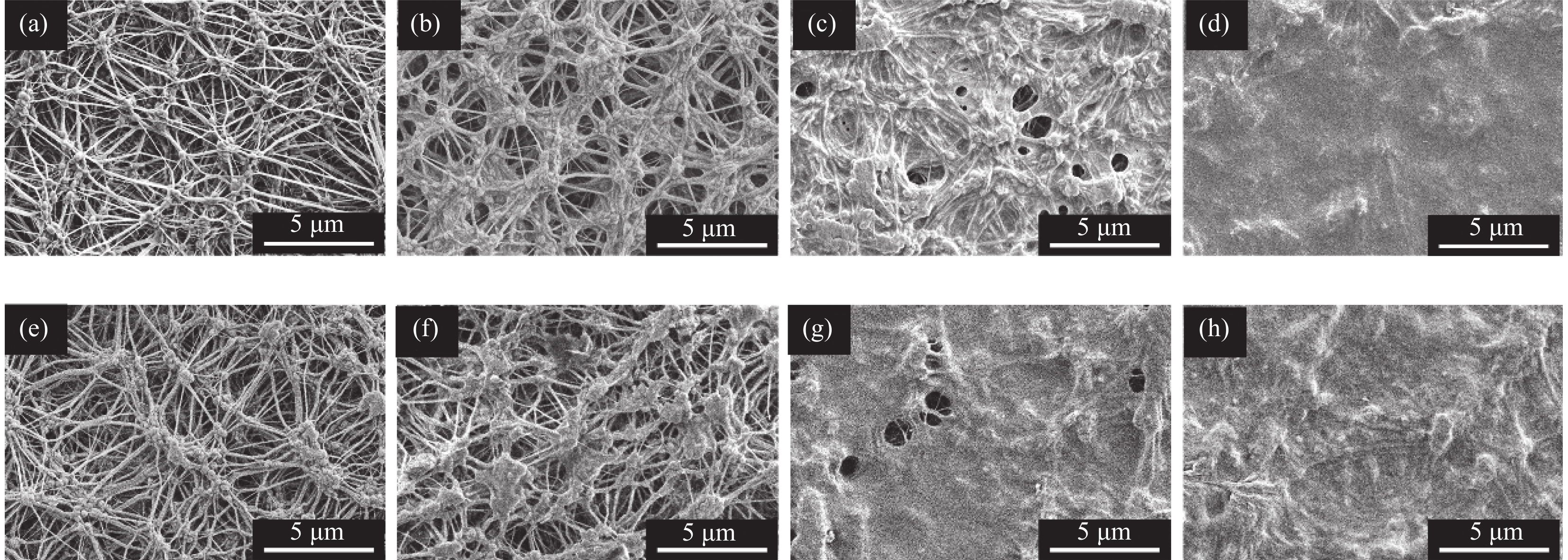

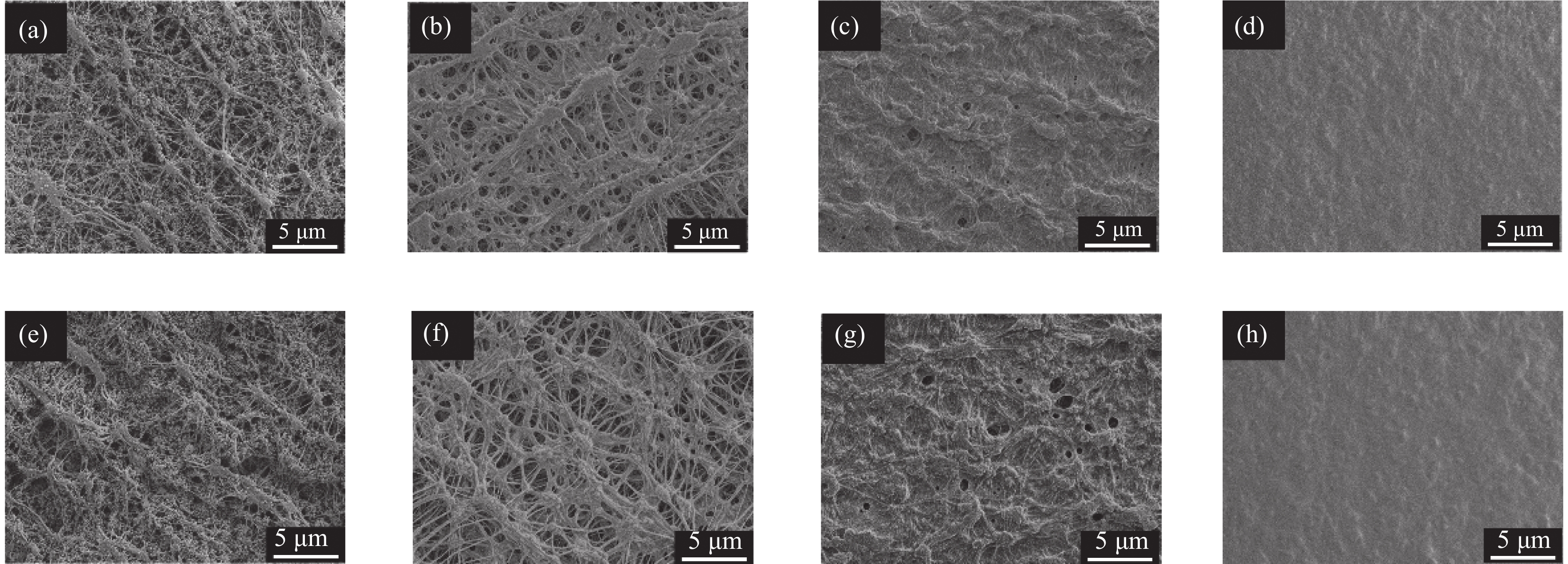

![]() FE-SEM images of composite membranes prepared with different mass fractions of FEP dispersions: (a-d): (1wt%-4wt%) FEP/PTFE; (e-h):(1wt%-4wt%) FEP/PTFE-7 d

FE-SEM images of composite membranes prepared with different mass fractions of FEP dispersions: (a-d): (1wt%-4wt%) FEP/PTFE; (e-h):(1wt%-4wt%) FEP/PTFE-7 d

-

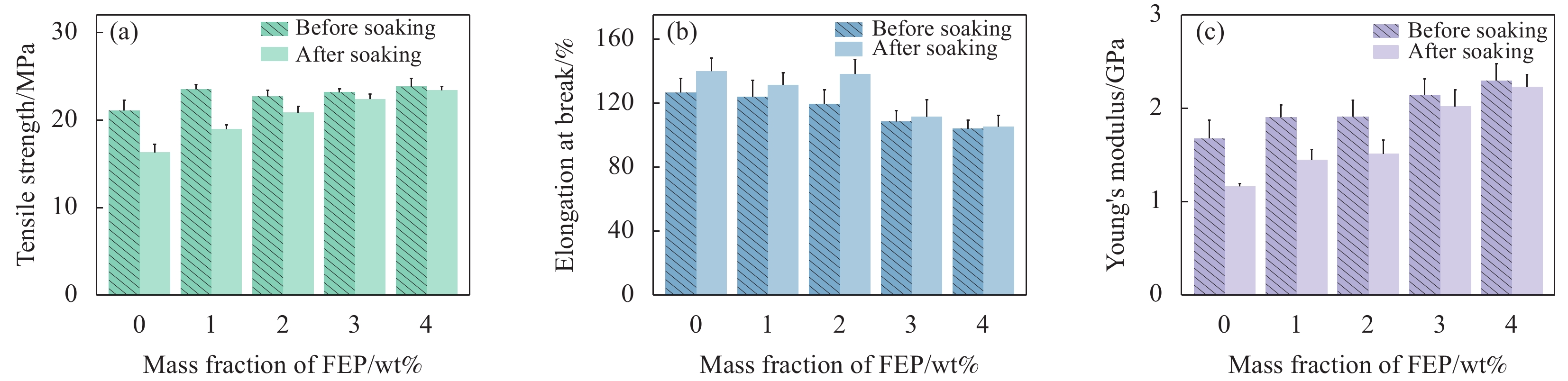

![]() Mechanical properties analysis of membrane samples with different FEP mass fractions

Mechanical properties analysis of membrane samples with different FEP mass fractions

-

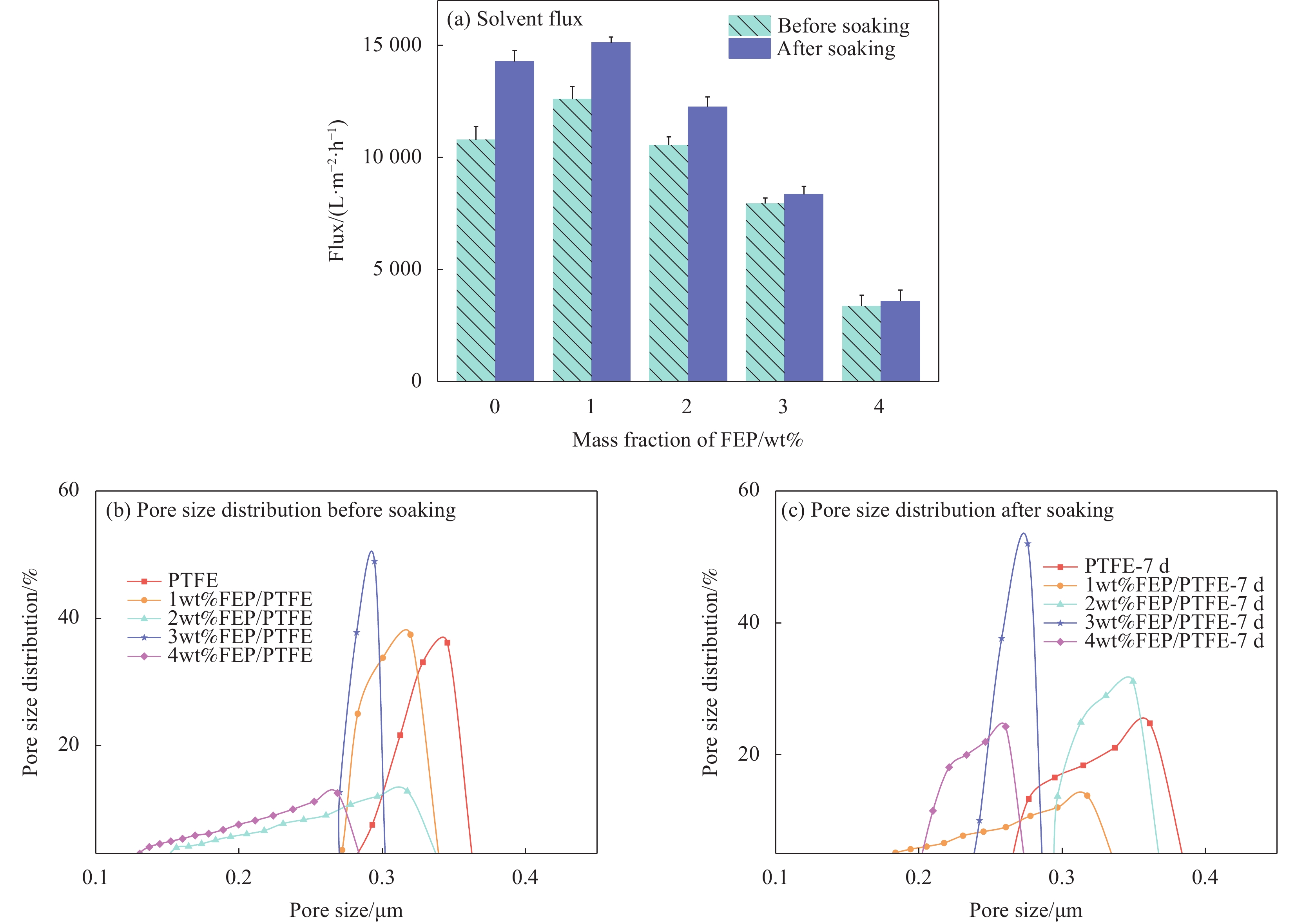

![]() Performance analysis of membrane samples with different FEP mass fractions

Performance analysis of membrane samples with different FEP mass fractions

-

![]() FE-SEM images of composite membranes at different sintering temperatures: (a-d):3wt%FEP/PTFE-(25℃-360℃);(e-h):3wt%FEP/PTFE-(25℃-360℃)-7 d

FE-SEM images of composite membranes at different sintering temperatures: (a-d):3wt%FEP/PTFE-(25℃-360℃);(e-h):3wt%FEP/PTFE-(25℃-360℃)-7 d

-

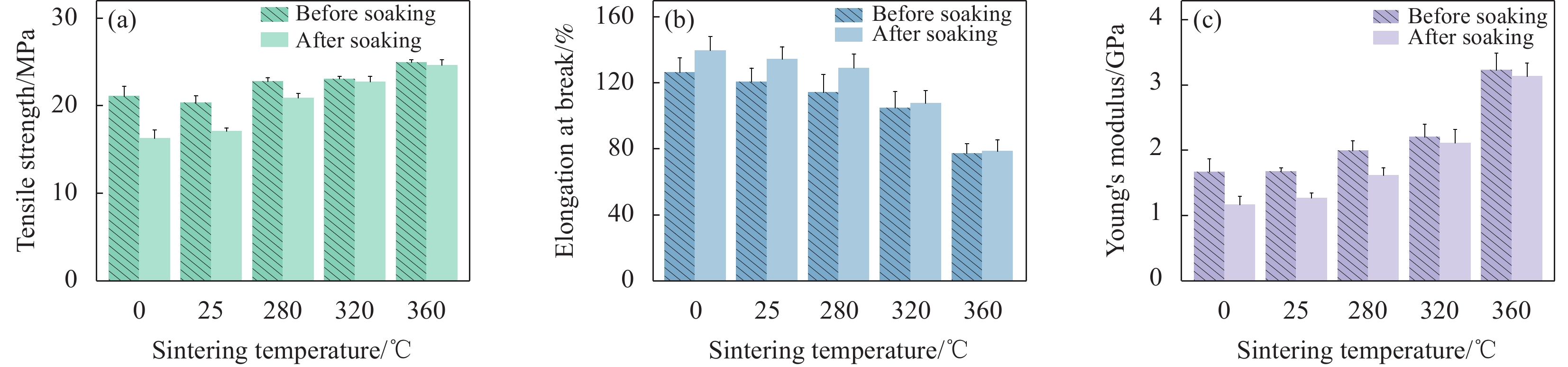

![]() Mechanical properties analysis of membrane samples at different sintering temperatures

Mechanical properties analysis of membrane samples at different sintering temperatures

-

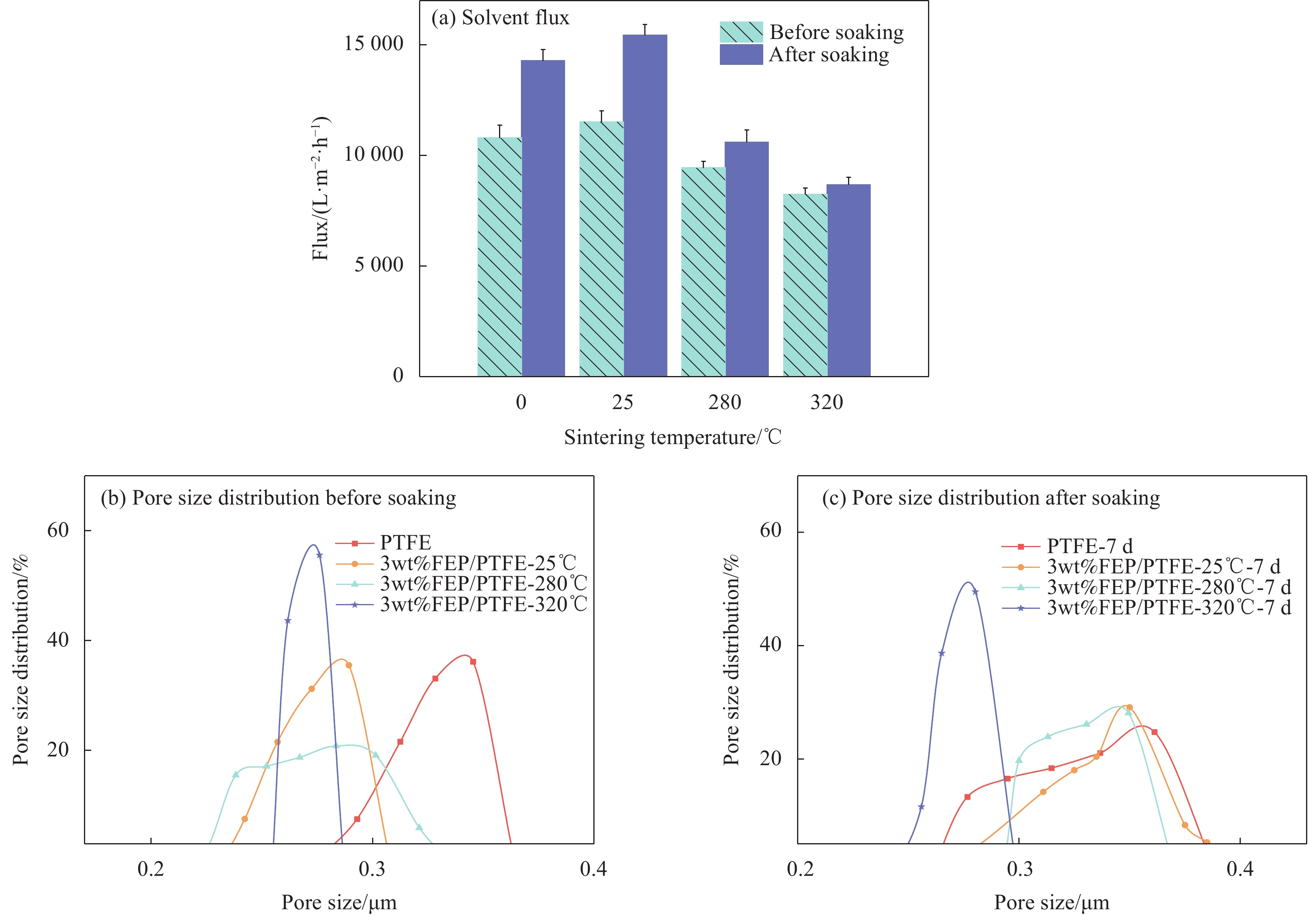

![]() Performance analysis of membrane samples at different sintering temperatures

Performance analysis of membrane samples at different sintering temperatures

-

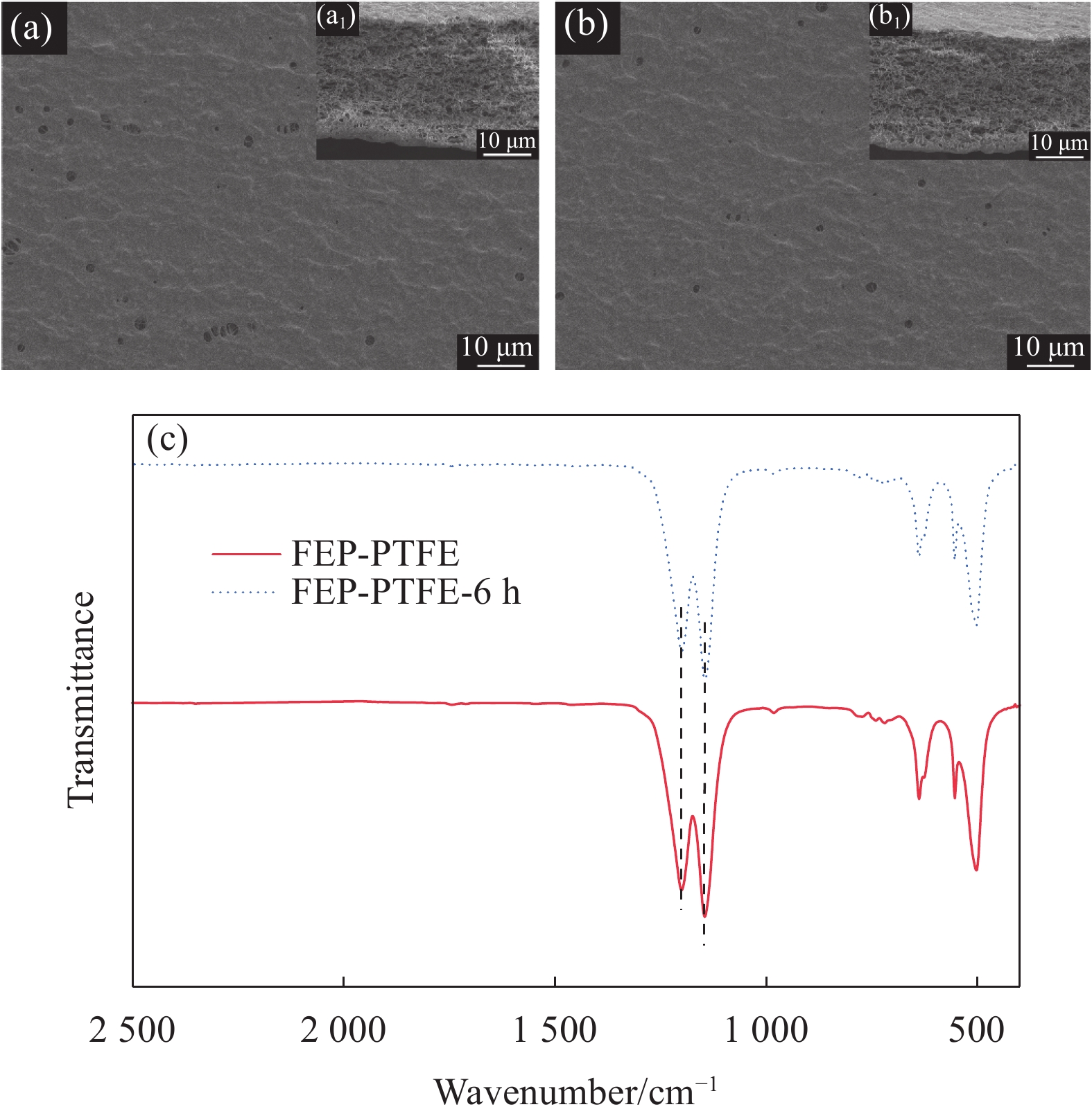

![]() Binding fastness test of FEP/PTFE composite membranes before and after ultrasonic testing (a) FE-SEM images of the primary membrane, (b) FE-SEM images of the membrane after 6 h of ultrasound, (a1、b1) FE-SEM images of Membrane cross-section,(c)Infrared spectrograms

Binding fastness test of FEP/PTFE composite membranes before and after ultrasonic testing (a) FE-SEM images of the primary membrane, (b) FE-SEM images of the membrane after 6 h of ultrasound, (a1、b1) FE-SEM images of Membrane cross-section,(c)Infrared spectrograms

-

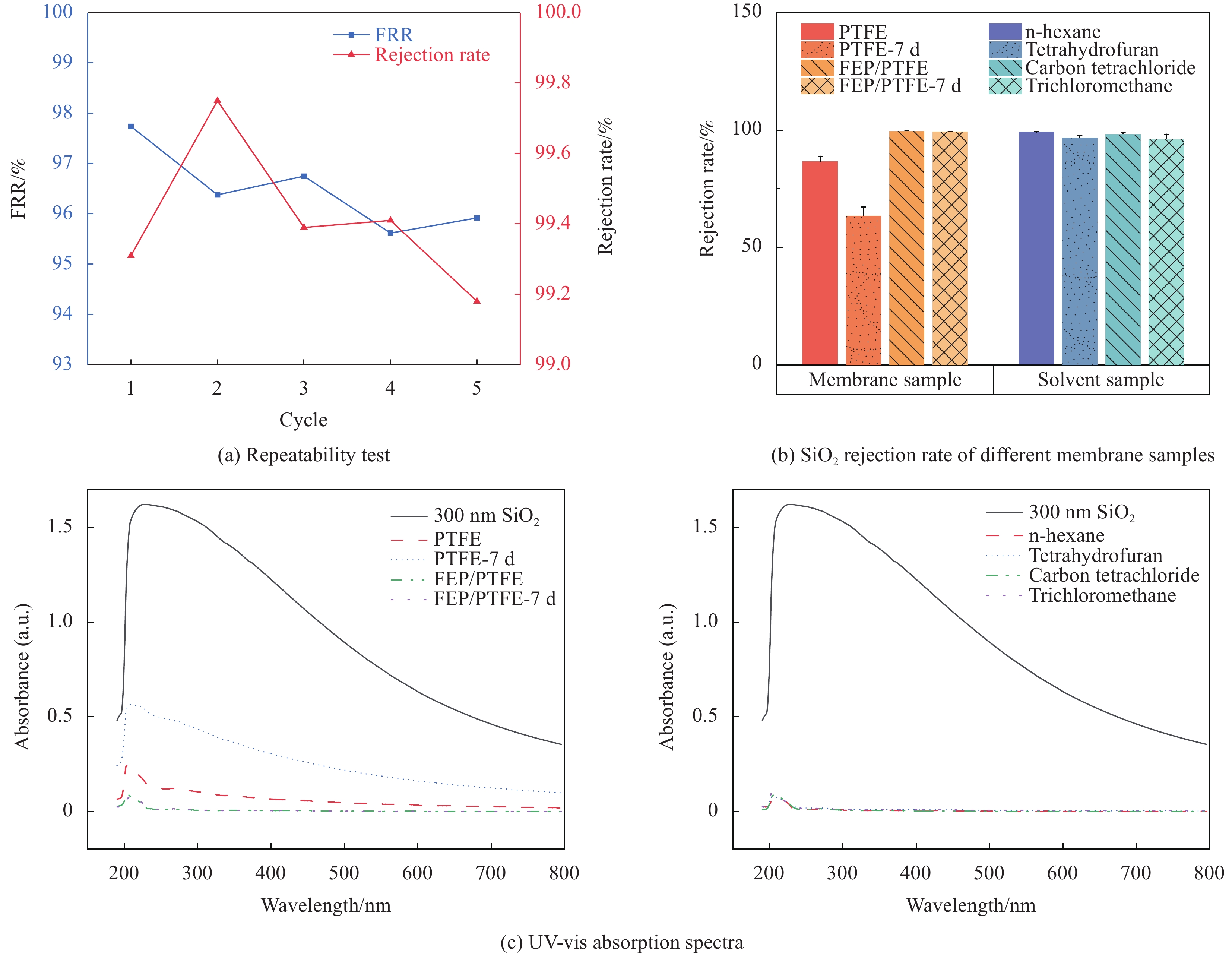

![]() Separation performance of FEP/PTFE composite membrane

Separation performance of FEP/PTFE composite membrane

Related articles

-

-

2024, 41(2): 898-910. DOI: 10.13801/j.cnki.fhclxb.20230531.004

-

2022, 39(11): 5386-5402. DOI: 10.13801/j.cnki.fhclxb.20211221.002

-

2022, 39(7): 3415-3427. DOI: 10.13801/j.cnki.fhclxb.20210804.003

-

2022, 39(5): 2356-2368. DOI: 10.13801/j.cnki.fhclxb.20210622.002

-

2022, 39(5): 2299-2307. DOI: 10.13801/j.cnki.fhclxb.20210804.002

-

2021, 38(7): 2359-2369. DOI: 10.13801/j.cnki.fhclxb.20200916.001

-

2018, 35(12): 3508-3516. DOI: 10.13801/j.cnki.fhclxb.20180211.002

-

2018, 35(8): 2222-2234. DOI: 10.13801/j.cnki.fhclxb.20171109.001

-

1993, 10(2): 17-24.

Download:

Download: