Interfacial properties of polyurethane/nano-SiO2 modified carbon fiber epoxy resin composites

-

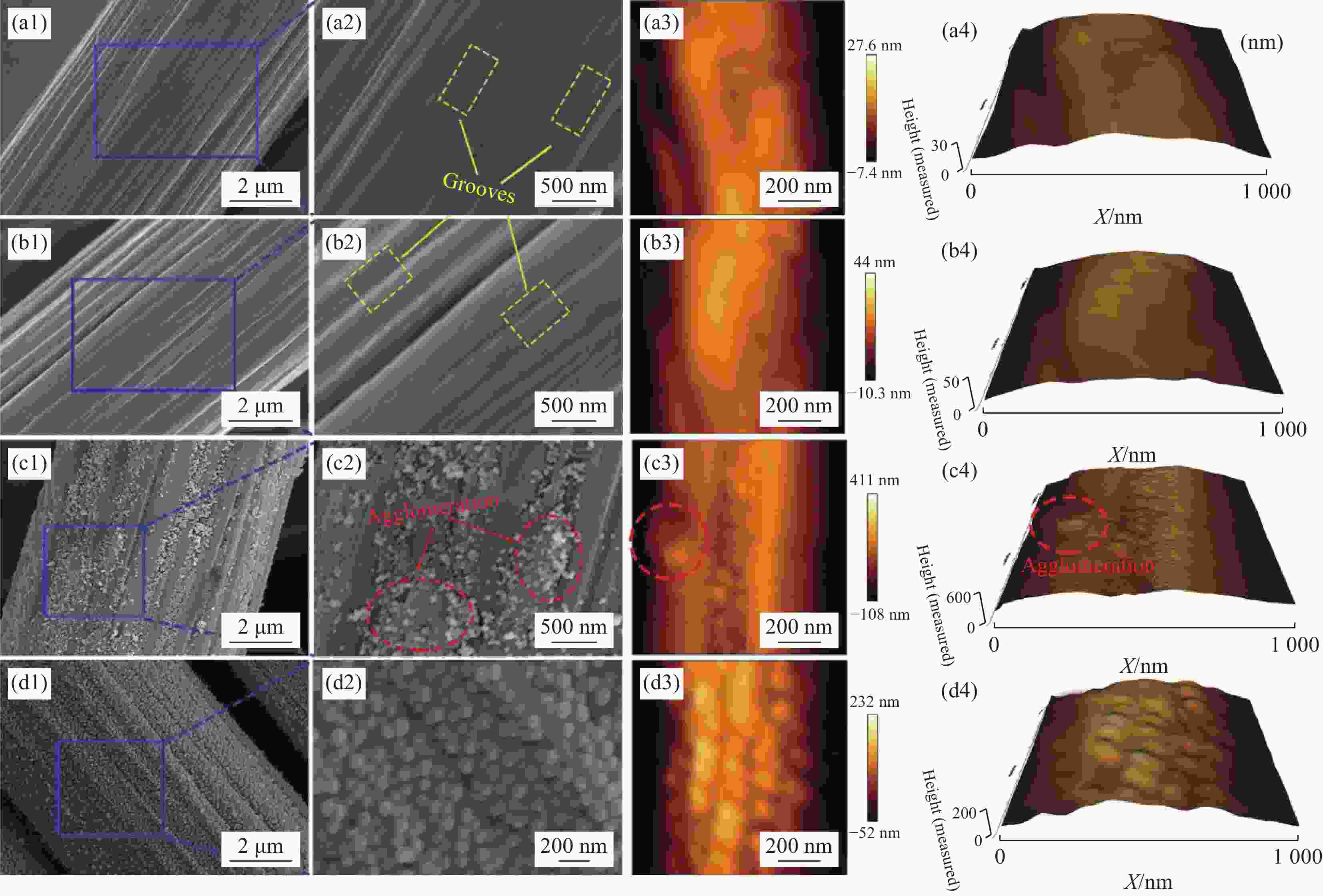

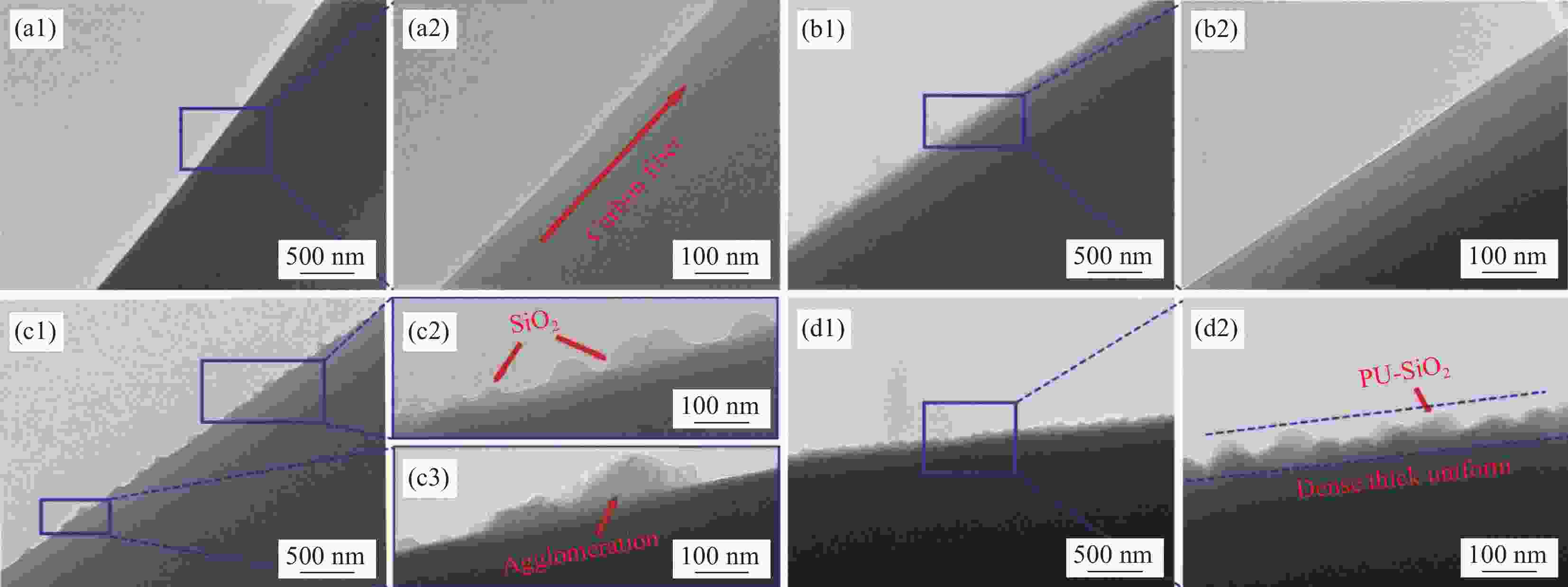

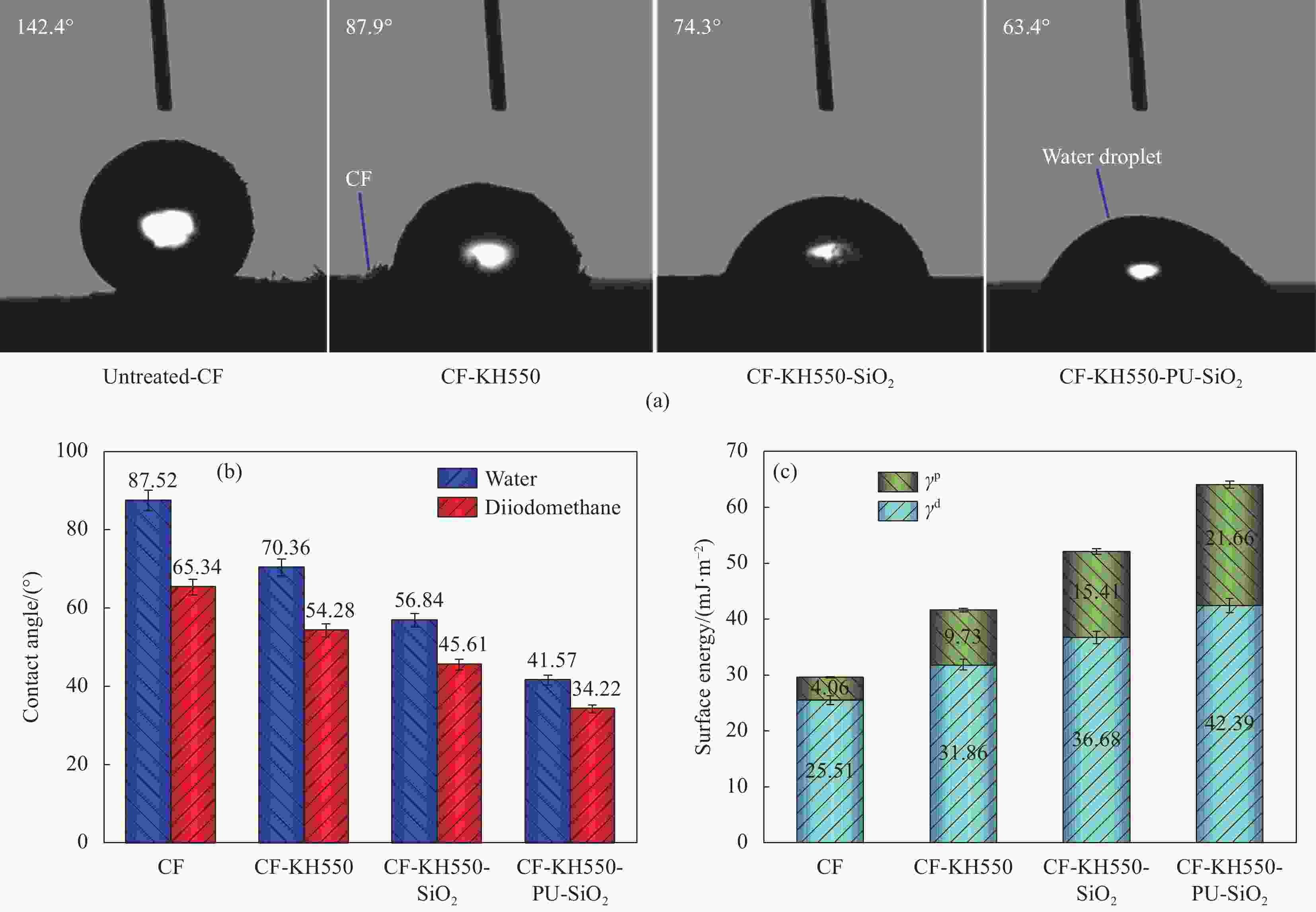

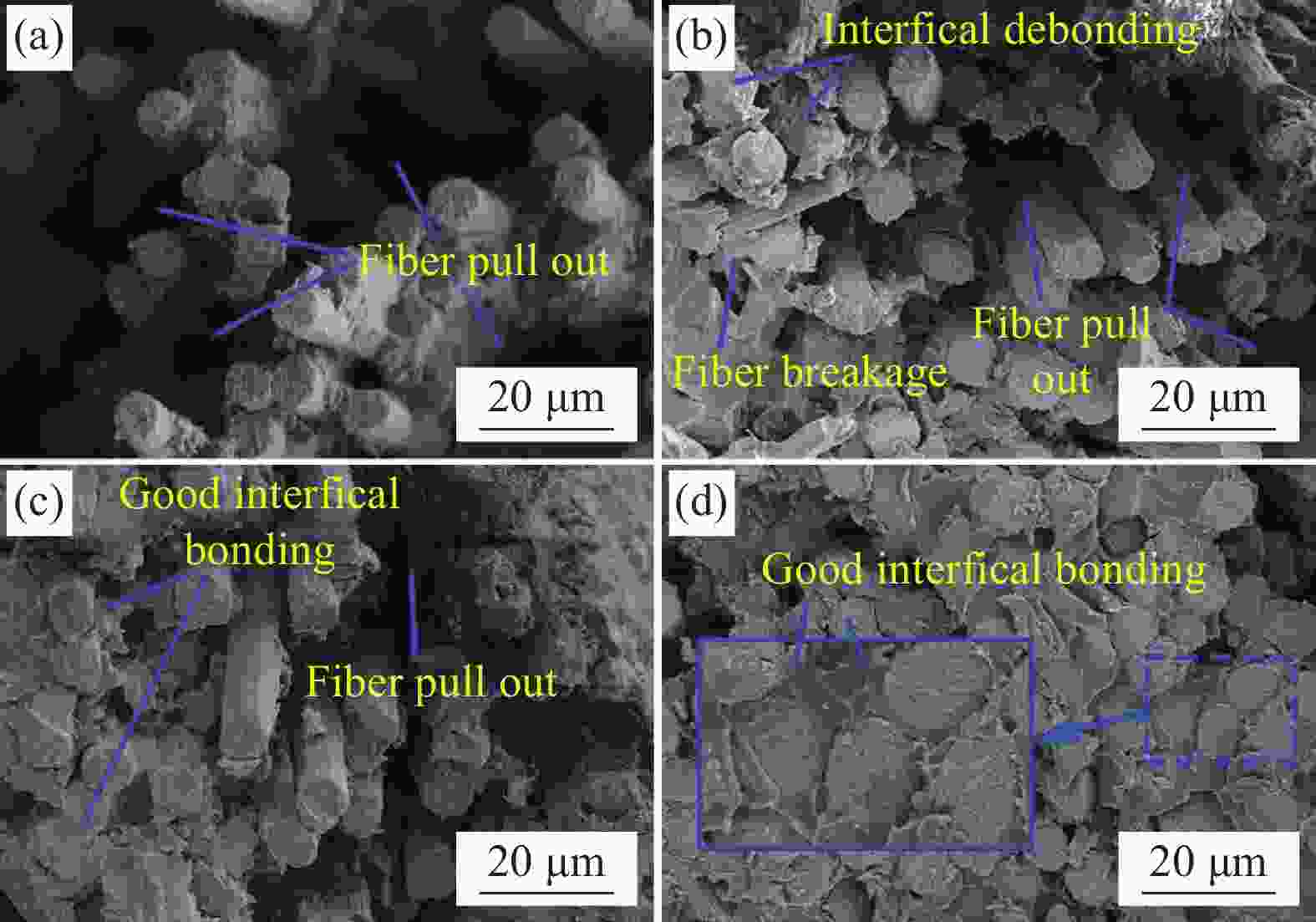

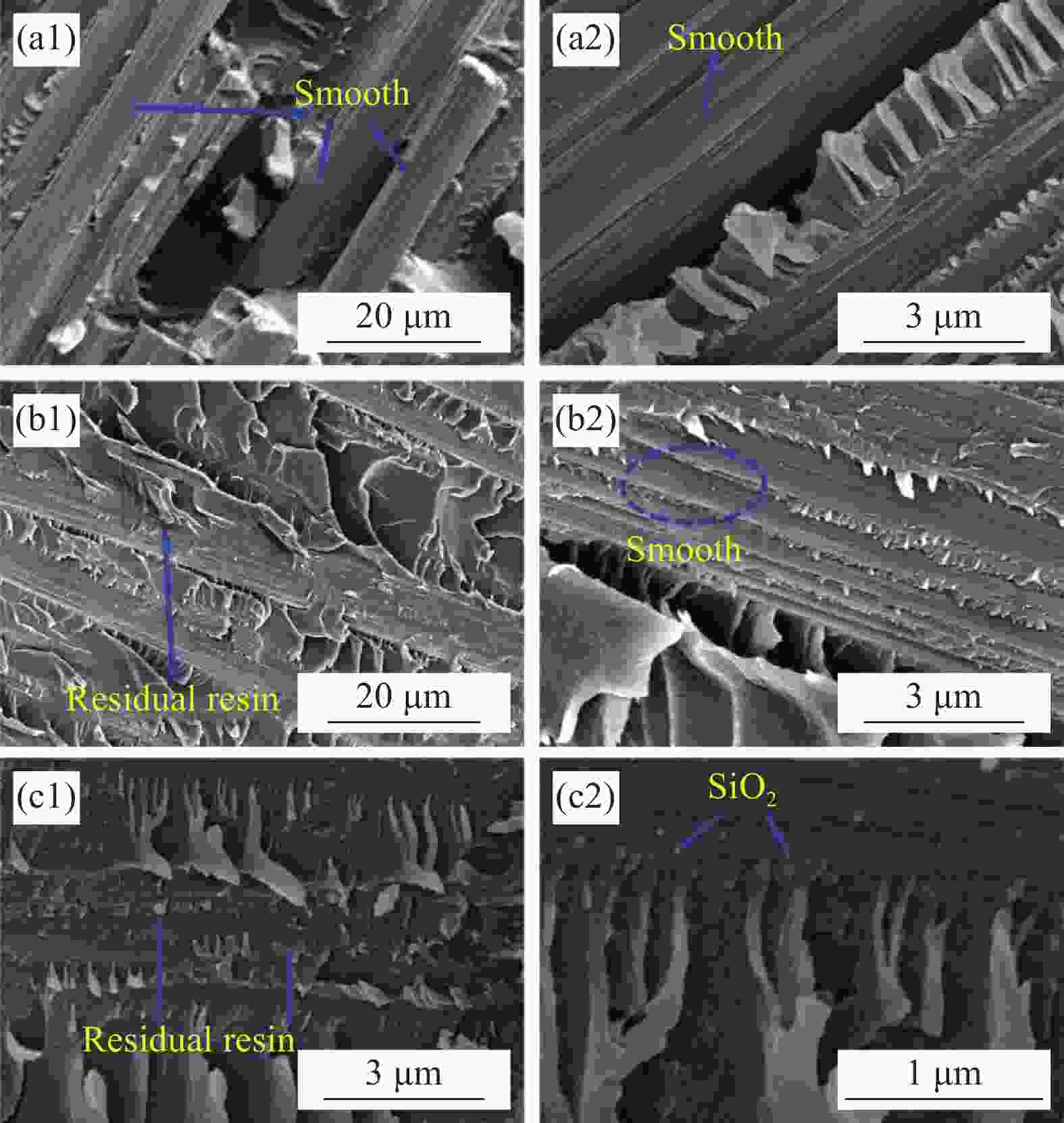

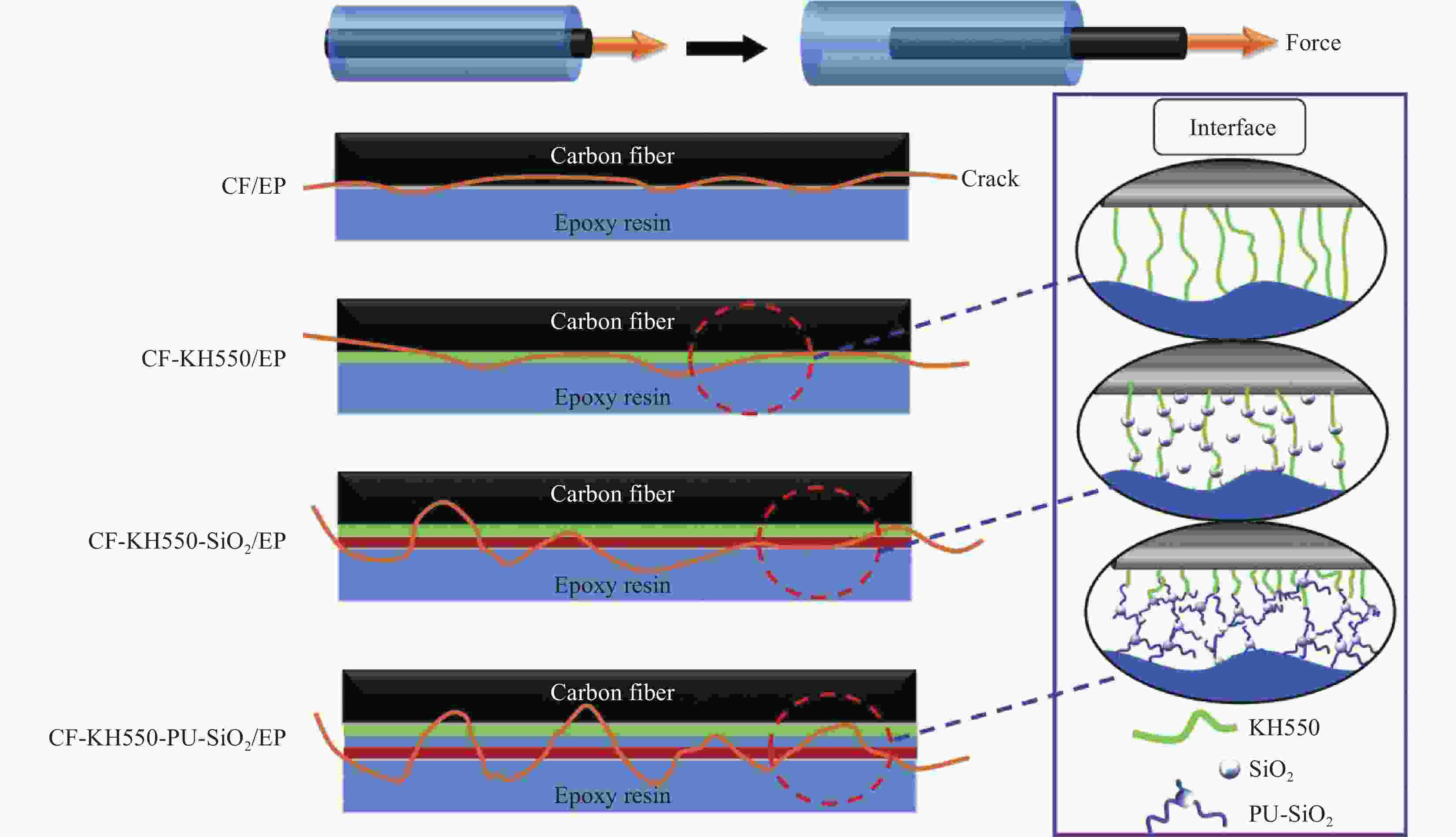

摘要: 聚合物与纤维之间的界面性能对提升复合材料力学性能尤为重要。本文采用异氰酸根(—NCO)封端的聚氨酯(PU)分子对纳米SiO2表面进行改性,同时采用KH550对碳纤维(CF)进行表面改性,利用—NH2与—NCO较高的反应活性,在CF和纳米SiO2粒子间通过PU分子链形成共价键连接。结果显示:PU极性分子链的引入,提高了CF的表面能,使其表面润湿性显著提高。相较于KH550直接接枝纳米粒子的碳纤维(CF-KH550-SiO2),通过PU分子链接枝纳米粒子的碳纤维(CF-KH550-PU-SiO2),其表面能提升23.0%,表面纳米SiO2粒子的接枝率和分散均匀性也明显提升。CF-KH550-PU-SiO2/环氧树脂(EP)的界面剪切强度(IFSS)和层间剪切强度(ILSS)相比未改性CF/EP分别提高72.9%和47.9%,相比CF-KH550-SiO2/EP分别提高17.3%和11.2%。

-

关键词:

- 碳纤维增强环氧树脂复合材料 /

- 界面性能 /

- 纳米二氧化硅 /

- 聚氨酯 /

- 碳纤维表面改性

Abstract: The interfacial properties between polymer and fiber are particularly important for improving the mechanical properties of composites. In this paper, the surface of nano-SiO2 was modified by polyurethane (PU) capped by isocyanate (—NCO), and the surface of carbon fiber (CF) was modified by KH550. Because of the high reactivity of —NH2 and —NCO, the covalent bond was formed between CF and nano-SiO2 particles through PU molecular chain. The results showed that the introduction of PU polar molecular chain improved the surface energy and wettability of CF. Compared with the CF directly grafted with nano particles by KH550(CF-KH550-SiO2), the surface energy of the CF with nano particles linked by PU (CF-KH550-PU-SiO2) molecules increased by 23.0%, and the grafting rate and dispersion uniformity of surface nano SiO2 particles also improved significantly. Compared with the untreaed CF/epoxy resin (EP) composites, the interfacial strength (IFSS) and the interlaminar shear strength (ILSS) of CF-KH550-PU-SiO2/EP composites increased by 72.9% and 47.9% respectively. Compared with the CF-KH550-SiO2/EP composites, IFSS and ILSS of CF-KH550-PU-SiO2/EP composites increased by 17.3% and 11.2%, respectively.-

Key words:

- CF/EP composite /

- interface property /

- nano-SiO2 /

- polyurethane /

- surface modification of carbon fibers

-

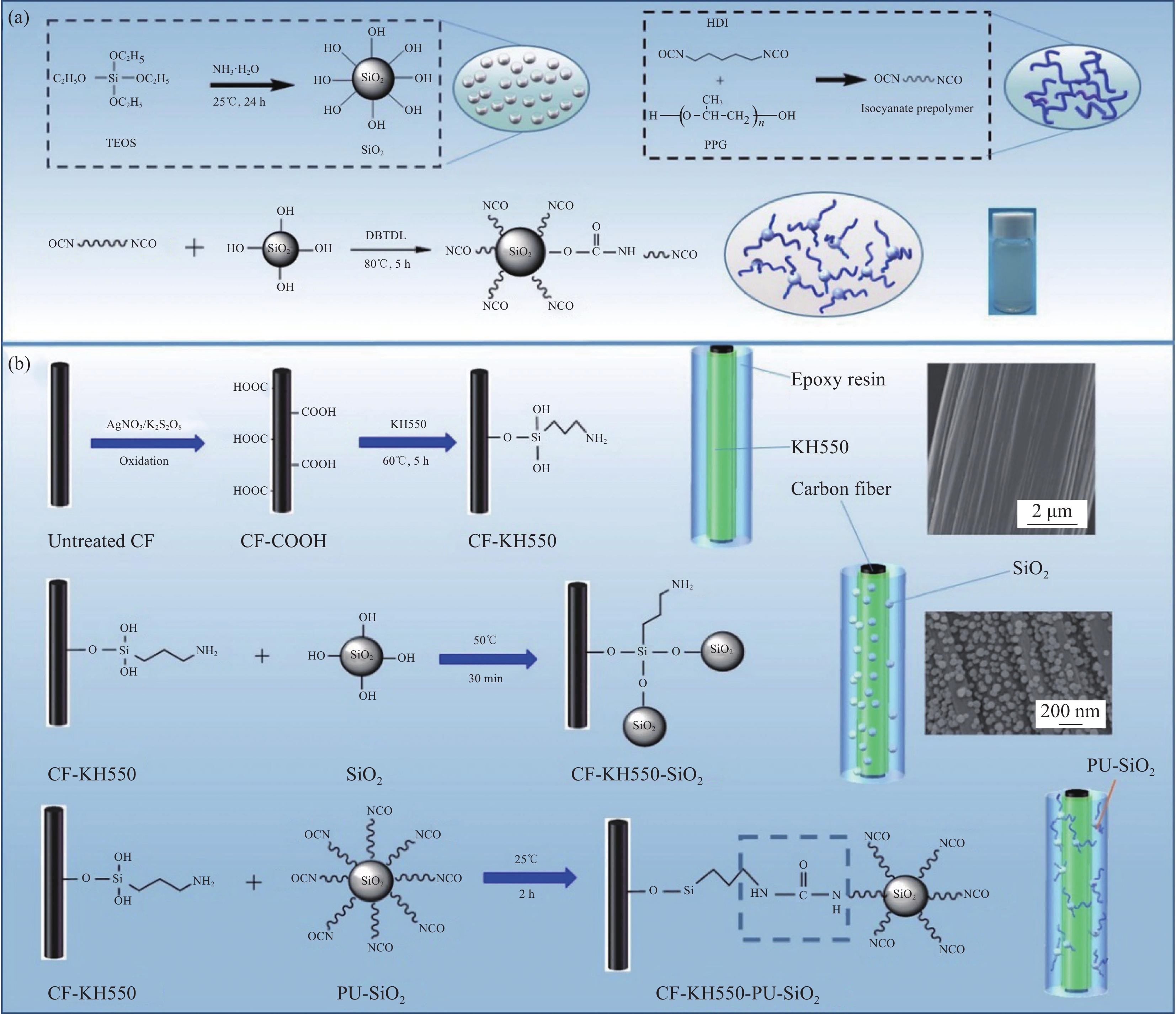

图 1 (a)纳米SiO2表面接枝聚氨酯(PU)反应过程;(b)碳纤维(CF)表面多层结构制备示意图

TEOS—Ethyl orthosilicate; HDI—Hexamethylene diisocyanate; PPG—Polypropylene glycol; DBTDL—Dibutyl tin dilaurate; KH550—3-aminopropyl triethoxysilane

Figure 1. (a) Reaction process of grafting polyurethane (PU) on nano-SiO2 surface; (b) Schematic illustration of multilayer structure grafted on carbon fiber (CF)

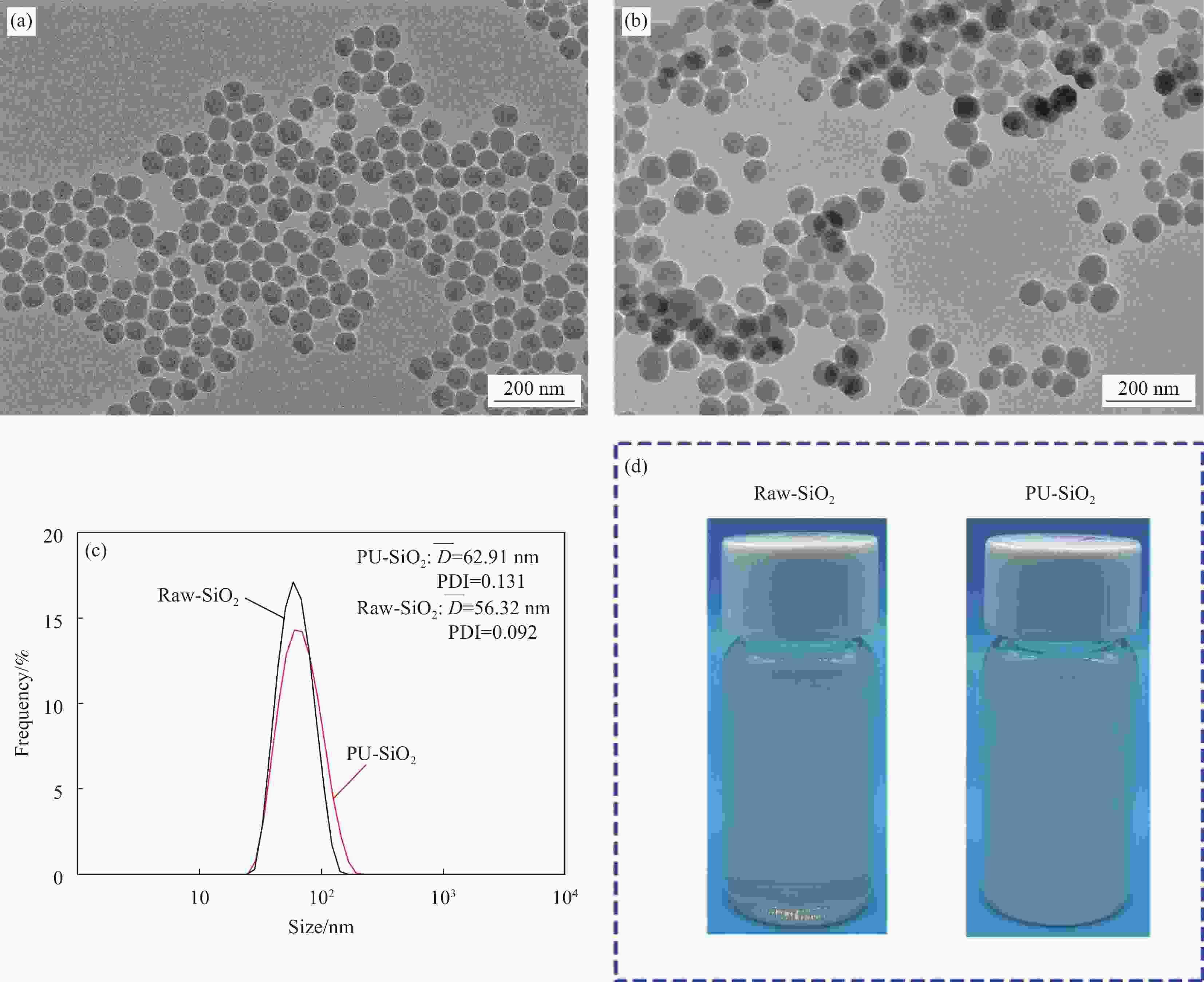

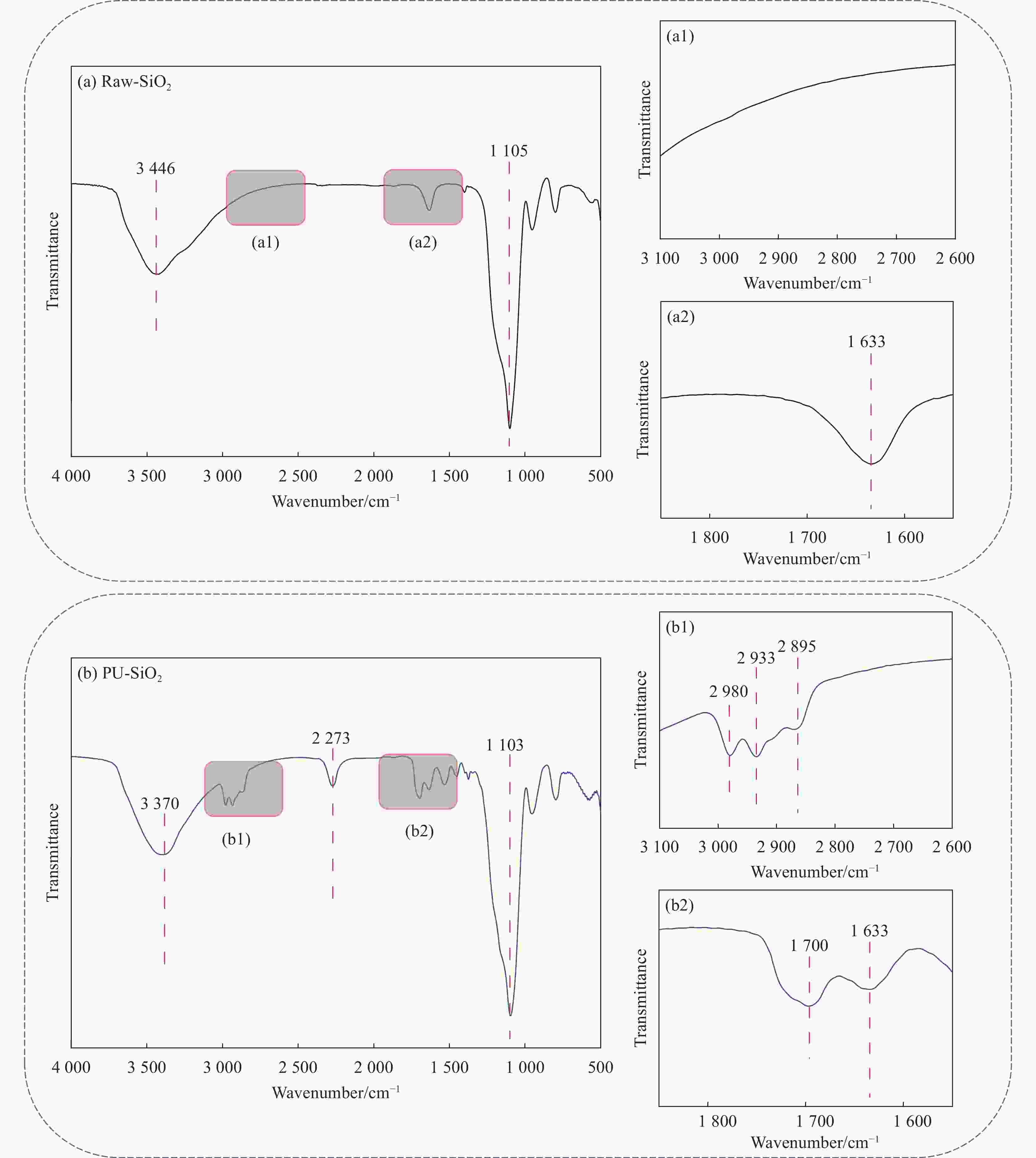

图 3 未改性纳米SiO2 (a)及PU-SiO2 (b)的TEM图像、两种粒子的动态光散射(DLS)粒径曲线(c)及未改性纳米SiO2和PU-SiO2的分散液(d)

$\overline{D} $—Average particle size of particles; PDI—Polydispersity index

Figure 3. TEM images of raw SiO2 (a) and PU-SiO2 (b), dynamic light scattering (DLS) curves of the synthesized SiO2 (c) and photograph of the particle disperdion (d)

表 1 测试液的极性分量$ {\gamma }_{{\rm{l}}}^{{\rm{p}}} $、色散分量$ {\gamma }_{{\rm{l}}}^{{\rm{d}}} $及表面能$ {\gamma }_{\rm{{l}}} $

Table 1. Polar component$ {\gamma }_{{\rm{l}}}^{{\rm{p}}} $, dispersive component $ {\gamma }_{{\rm{l}}}^{{\rm{d}}} $ and surface free energy $ {\gamma }_{{\rm{l}}} $ of the testing liquids

(mJ·m−2) Testing liquid $ {\gamma }_{{\rm{l}}}^{{\rm{p}}} $ $ {\gamma }_{{\rm{l}}}^{{\rm{d}}} $ $ {\gamma }_{{\rm{l}}} $ Water 51 21.8 72.8 CH₂I₂ 0 50.8 50.8 表 2 CF表面元素含量变化

Table 2. Changes in surface element content of CF

Sample Element/wt% C1s O1s N1s Si2p CF 81.33 16.01 2.33 0.33 CF-KH550 70.53 22.64 4.74 2.09 CF-KH550-SiO2 51.36 30.42 3.48 15.74 CF-KH550-PU-SiO2 29.09 42.80 6.43 21.68 -

[1] 郑安呐, 胡福增. 树脂基复合材料界面结合的研究I: 界面分析及界面剪切强度的研究方法[J]. 玻璃钢/复合材料, 2004(5):12-15, 23. doi: 10.3969/j.issn.1003-0999.2004.05.004ZHENG An'na, HU Fuzeng. Study on interfacial bonding of resin matrix composites I: Research methods of interface analysis and interface shear strength[J]. FRP/Composite,2004(5):12-15, 23(in Chinese). doi: 10.3969/j.issn.1003-0999.2004.05.004 [2] 胡福增. 材料表面与界面[M]. 上海: 华东理工大学出版社, 2007: 13-26.HU Fuzeng. Material surface and interface[M]. Shanghai: East China University of Science and Technology Press, 2007: 13-26(in Chinese). [3] 罗冬梅, 谢永东, 朱文亮. 含脱粘界面纤维增强复合材料应力传递的理论分析[J]. 纤维复合材料, 2010, 27(4):12-16. doi: 10.3969/j.issn.1003-6423.2010.04.003LUO Dongmei, XIE Yongdong, ZHU Wenliang. The theoretical analysis on the stress transfer for fiber teinforced composites with debonding interface[J]. Fiber Composites,2010,27(4):12-16(in Chinese). doi: 10.3969/j.issn.1003-6423.2010.04.003 [4] ZHANG T, XU Y, LI H F, et al. Interfacial adhesion between carbon fibers and nylon 6: Effect of fiber surface chemistry and grafting of nano-SiO2[J]. Composites Part A: Applied Science and Manufacturing,2019,121:157-168. doi: 10.1016/j.compositesa.2019.03.029 [5] WU Q, WAN Q Q, LIU Q L, et al. Synergistic strengthening and toughening the interphase of composites by constructing alternating "rigid-and-soft" structure on carbon fiber surface[J]. Advanced Materials Interfaces,2019,6(21):132-141. [6] 陆瑶, 赵玉芬, 田荟霞, 等. 聚丙烯腈纳米纤维膜对聚对苯撑苯并双噁唑织物增强复合材料层间剪切性能的影响[J]. 复合材料学报, 2022, 39(12):6130-6138.LU Yao, ZHAO Yufen, TIAN Huixia, et al. Effect of polyacrylonitrile nanofiber membrane on interlaminar shear properties of poly-p-phenylene benzobisoxazole fabric reinforced composites[J]. Acta Materiae Compositae Sinica,2022,39(12):6130-6138(in Chinese). [7] HE Y X, LI Q, KUILA T, et al. Micro-crack behavior of carbon fiber reinforced thermoplastic modified epoxy composites for cryogenic applications[J]. Composites Part B: Engineering,2013,44(1):533-539. doi: 10.1016/j.compositesb.2012.03.014 [8] 胡丹. 碳纤维增强复合材料界面裂纹扩展及损伤研究[D]. 北京: 北京化工大学, 2016.HU Dan. Study on the interfacial cracking and damage of the carbon reinforced composite material[D]. Beijing: Beijing University of Chemical Technology, 2016(in Chinese). [9] 黄云刚, 黄维龙, 洪浩群, 等. 界面改性对聚丙烯-玻璃纤维复合材料力学性能影响[J]. 复合材料学报, 2022, 39(7):3156-3166.HUANG Yungang, HUANG Weilong, HONG Haoqun, et al. Effect of interface modification on mechanical properties of polypropylene-glass fiber composites[J]. Acta Materiae Compositae Sinica,2022,39(7):3156-3166(in Chinese). [10] 许培俊, 吴帆, 朱真, 等. 基于聚醚砜/氰酸酯半互穿树脂体系的碳纤维复合材料性能研究[J]. 复合材料学报, 2022, 39(6):2639-2648.XU Peijun, WU Fan, ZHU Zhen, et al. Research on carbon fiber composite properties based on (polyether sulfone)/cyanate ester semi-interpenetrating resin system[J]. Acta Materiae Compositae Sinica,2022,39(6):2639-2648(in Chinese). [11] 苏峰. 碳纤维环氧树脂界面性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2013.SU Feng. Study on the interface properties between carbon fibers and epoxy resin[D]. Harbin: Harbin Institute of Technology, 2013(in Chinese). [12] DRESCHER P, THOMAS M, BORRIS J, et al. Strengthening fibre/matrix interphase by fibre surface modification and nanoparticle incorporation into the matrix[J]. Compo-sites Science and Technology,2013,74:60-66. doi: 10.1016/j.compscitech.2012.10.004 [13] ZHANG J X, DU Z J, ZOU W, et al. MgO nanoparticles-decorated carbon fibers hybrid for improving thermal conductive and electrical insulating properties of nylon 6 composite[J]. Composites Science and Technology,2017,148:1-8. doi: 10.1016/j.compscitech.2017.05.008 [14] MA Y Y, YAN C, XU H B, et al. Enhanced interfacial properties of carbon fiber reinforced polyamide 6 composites by grafting graphene oxide onto fiber surface[J]. Applied Surface Science,2018,452:286-298. doi: 10.1016/j.apsusc.2018.04.274 [15] ZHANG T, SONG Y X, ZHAO Y Q, et al. Effect of hybrid sizing with nano-SiO2 on the interfacial adhesion of carbon fibers/nylon 6 composites[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2018,553:125-133. [16] 李娜, 李晓屿, 刘丽, 等. 电泳沉积氧化石墨烯的碳纤维表面改性及其增强环氧树脂复合材料界面性能[J]. 复合材料学报, 2020, 37(7):1571-1580. doi: 10.13801/j.cnki.fhclxb.20191120.001LI Na, LI Xiaoyu, LIU Li, et al. Surface modification of carbon fiber (CF) deposited graphene oxide (GO) by electrophorestic deposition and interfacial properties of GO-CF/epoxy composites[J]. Acta Materiae Compositae Sinica,2020,37(7):1571-1580(in Chinese). doi: 10.13801/j.cnki.fhclxb.20191120.001 [17] SHI L L, SONG G J, LI P Y, et al. Enhancing interfacial performance of epoxy resin composites via in-situ nucleophilic addition polymerization modification of carbon fibers with hyperbranched polyimidazole[J]. Composites Science and Technology,2021,201:108522. doi: 10.1016/j.compscitech.2020.108522 [18] LI N, CHENG S, WANG B, et al. Chemical grafting of graphene onto carbon fiber to produce composites with improved interfacial properties via sizing process: A step closer to industrial production[J]. Composites Science and Technology,2023,231:109822. doi: 10.1016/j.compscitech.2022.109822 [19] YU J L, MENG L H, FAN D P, et al. The oxidation of carbon fibers through K2S2O8/AgNO3 system that preserves fiber tensile strength[J]. Composites Part B: Engineering,2014,60:261-267. doi: 10.1016/j.compositesb.2013.12.037 [20] QIAN H, BISMARCK A, GREENHALGH E, et al. Hierarchical composites reinforced with carbon nanotube grafted fibers: The potential assessed at the single fiber level[J]. Chemistry of Materials,2008,20(5):1862-1869. doi: 10.1021/cm702782j [21] WANG Y W, MENG L H, FAN L Q, et al. Carboxyl functionalization of carbon fibers via aryl diazonium reaction in molten urea to enhance interfacial shear strength[J]. Applied Surface Science,2016,362:341-347. doi: 10.1016/j.apsusc.2015.11.232 [22] JIANG D W, XING L X, LIU L, et al. Enhanced mechanical properties and anti-hydrothermal ageing behaviors of unsaturated polyester composites by carbon fibers interfaced with POSS[J]. Composites Science and Technology,2015,117:168-175. doi: 10.1016/j.compscitech.2015.05.011 [23] MA L C, LI N, WU G S, et al. Interfacial enhancement of carbon fiber composites by growing TiO2 nanowires onto amine-based functionalized carbon fiber surface in supercritical water[J]. Applied Surface Science,2018,433:560-567. doi: 10.1016/j.apsusc.2017.10.036 [24] 中国国家标准化管理委员会. 单向纤维增强塑料层间剪切强度试验方法: JC/T 773—1982(96)[S]. 北京: 中国标准出版社, 1982.Standardization Administration of the People's Republic of China. Test method for interlaminar shear strength of unidirectional fiber reinforced plastics: JC/T 773—1982(1996)[S]. Beijing: China Standards Press, 1982(in Chinese). [25] 赵立强, 南泉, 金花子. 单分散纳米二氧化硅的可控制备及高浓度正硅酸乙酯条件下的反应机理[J]. 化学工程师, 2016, 30(7):1-5.ZHAO Liqiang, NAN Quan, JIN Huazi. Controllable preparation of monodisperse silica and the formation mechanism under the condition of high concentration of tetra-ethyl-orthosilicate[J]. Chemical Engineer,2016,30(7):1-5(in Chinese). [26] 胡泊昭, 袁玉环, 马继文, 等. 改性纳米SiO2/环氧树脂热膨胀系数及冲击强度表征[J]. 航空制造技术, 2020, 63(18):74-81.HU Bozhao, YUAN Yuhuan, MA Jiwen, et al. Characterizations of coefficient of thermal expansion and impact strength of modified nano-SiO2/epoxy resin[J]. Aviation Manufacturing Technology,2020,63(18):74-81(in Chinese). [27] LIU L, YAN F, LI M, et al. A novel thermoplastic sizing containing graphene oxide functionalized with structural analogs of matrix for improving interfacial adhesion of CF/PES composites[J]. Composites Part A: Applied Science and Manufacturing,2018,114:418-428. doi: 10.1016/j.compositesa.2018.09.004 [28] JIANG D, XING L, LIU L, et al. Interfacially reinforced unsaturated polyester composites by chemically grafting different functional POSS onto carbon fibers[J]. Journal of Materials Chemistry A,2014,2(43):18293-18303. doi: 10.1039/C4TA04055D [29] 舒鹏. CF/改性环氧复合材料低温界面性能及液氧相容性研究[D]. 哈尔滨: 哈尔滨工业大学, 2013.SHU Peng. Cryogenic interfacial properties and liquid oxygen compatibility of CF/modified epoxy resin[D]. Harbin: Harbin Institute of Technology, 2013(in Chinese). [30] STANKOVICH S, DIKIN D A, PINER R D, et al. Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide[J]. Carbon,2007,45(7):1558-1565. doi: 10.1016/j.carbon.2007.02.034 [31] 韩萍. 碳纤维表面多尺度结构调控及其环氧树脂复合材料界面性能研究[D]. 青岛: 青岛大学, 2019.HAN Ping. Study on multi-scale structure control of carbon fiber surface and interfacial properties of epoxy resin composites[D]. Qingdao: Qingdao University, 2019(in Chinese). -

下载:

下载: