Damage monitoring model of shape memory alloy composites based on strain transfer

-

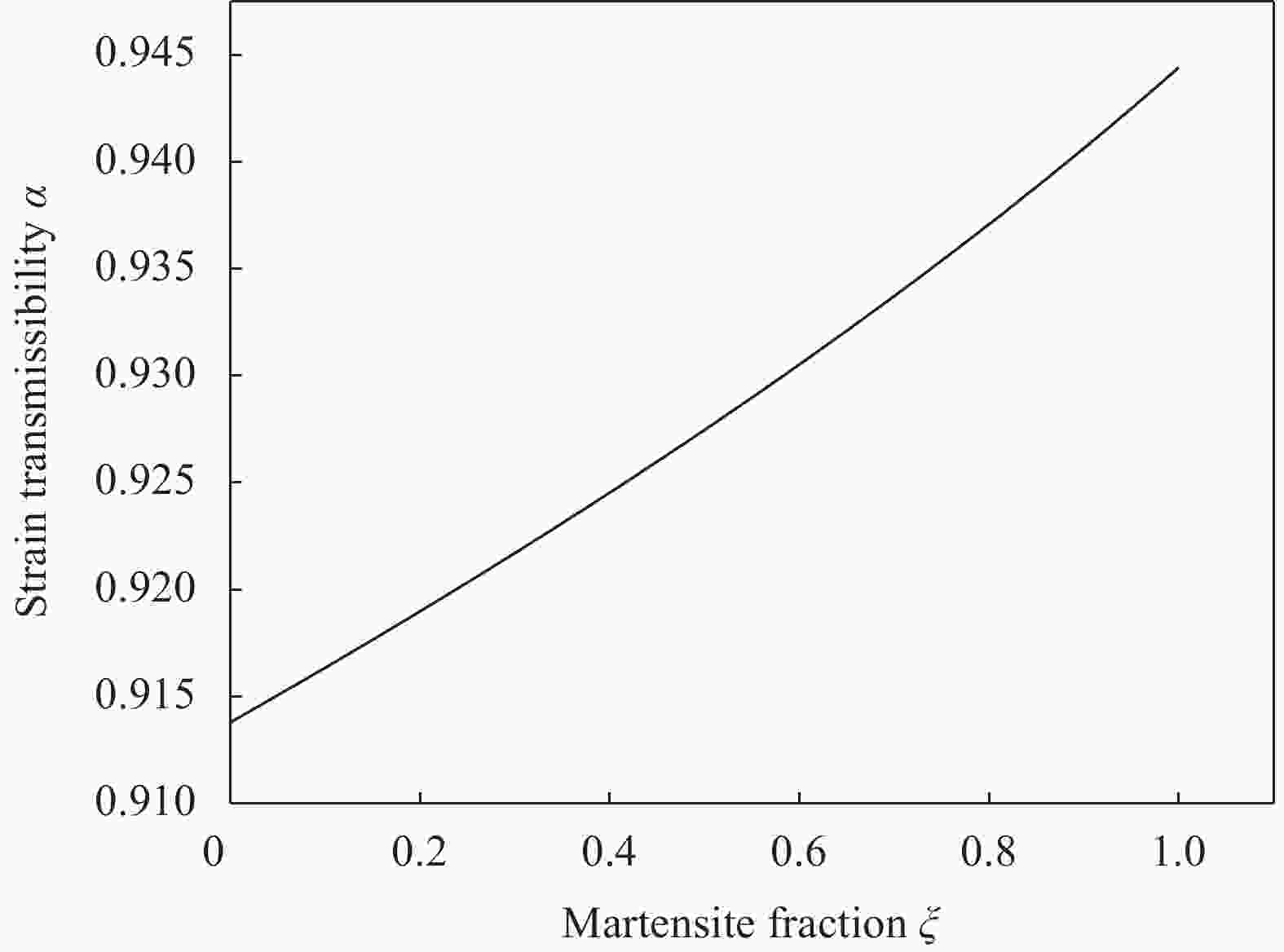

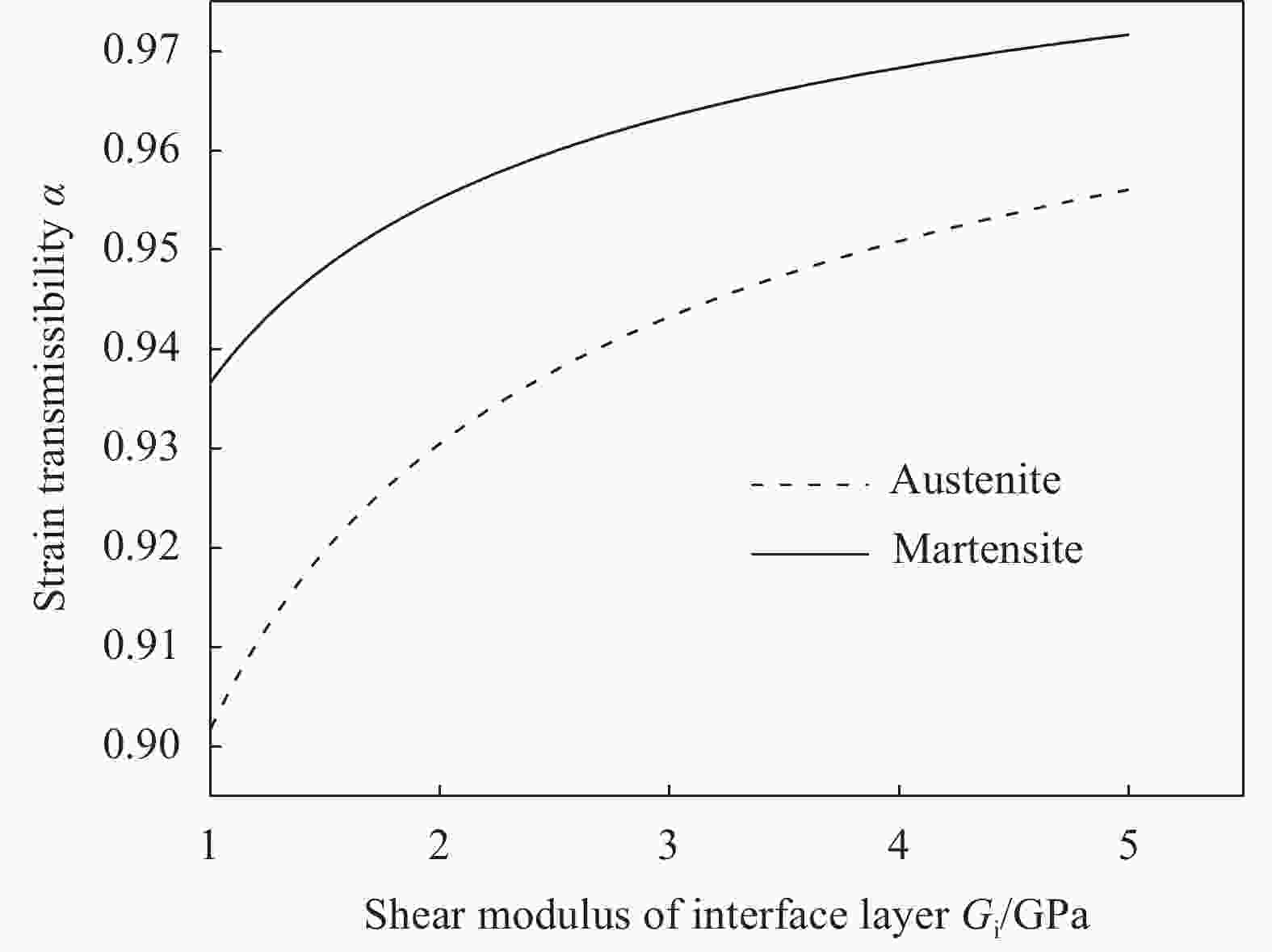

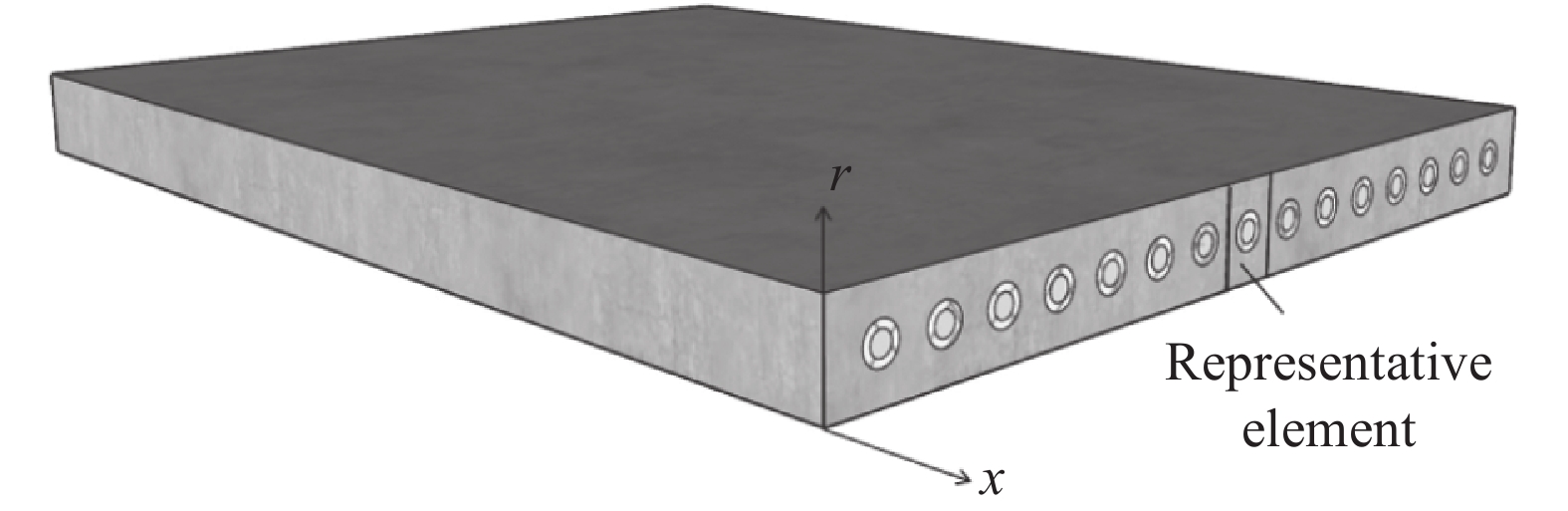

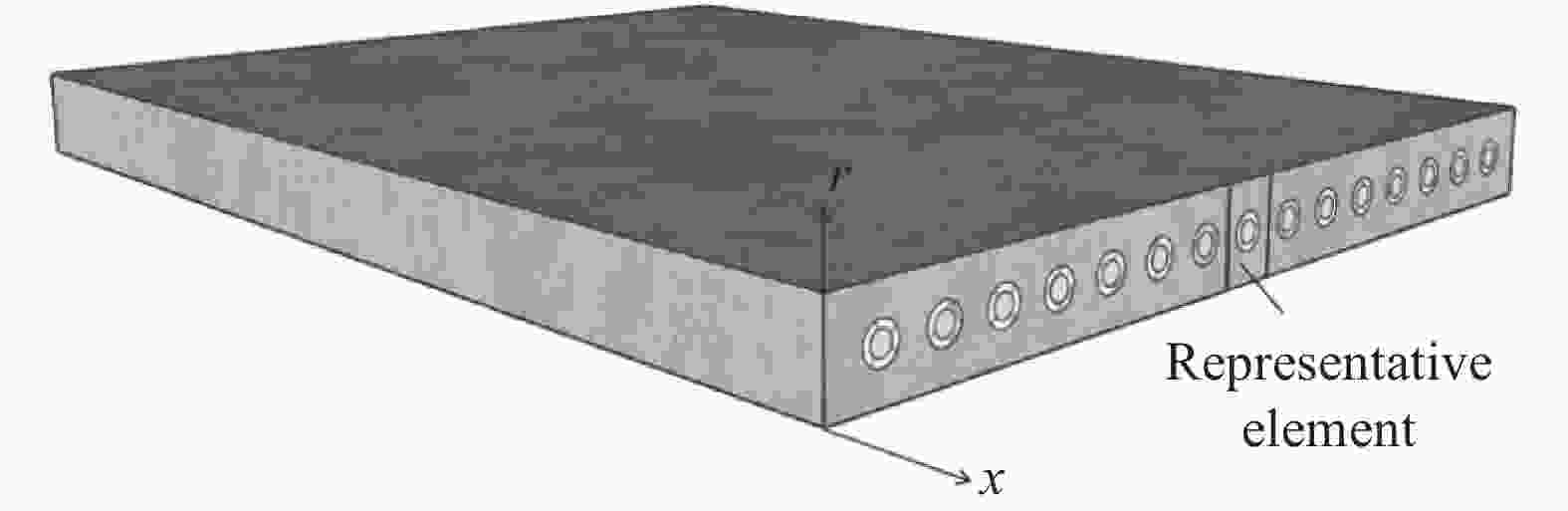

摘要: 复合材料由于其优异的性能已被广泛地应用于建筑、医学、航空航天等各个领域中,然而其损伤监测一直是国内外专家和学者关注的难点问题之一。本文将形状记忆合金(SMA)埋入到复合材料中,考虑了界面层的应变传递作用,利用SMA的电阻传感特性建立了基于应变传递的SMA复合材料塑性损伤监测模型,实现复合材料塑性损伤应变的实时监测。基于该监测模型讨论了不同材料参数条件对SMA和复合材料间平均应变传递率的影响,并讨论了SMA在不同初始状态和温度条件下损伤监测行为。研究结果表明:减小界面层厚度、增加界面层剪切模量及增加SMA的埋入长度均增加界面平均应变传递率,SMA电阻变化和复合材料塑性损伤应变呈分段线性关系。本文可为SMA复合材料损伤监测的进一步优化设计和应用提供理论基础。Abstract: Composite materials have been widely used in architecture, medicine, aerospace and other fields because of their excellent properties, however, the damage monitoring of composite materials has always been one of the difficult problems concerned by experts and scholars at home and abroad. In this paper, shape memory alloy (SMA) was embedded in the composite, and the strain transfer effect of the interface layer was considered. Using the resistance sensing characteristics of SMA, a plastic damage monitoring model of SMA composite based on strain transfer was established, which realizes the real-time monitoring of plastic damage strain of composite materials. Based on the monitoring model, the effects of different material parameters on the average strain transfer rate between SMA and composite were discussed, and the damage monitoring behaviors of SMA under different initial states and temperature conditions were discussed. The results show that decreasing the thickness of the interface layer, increasing the shear modulus of the interface layer and increasing the embedded length of SMA all increase the average strain transfer rate of the interface. The change of SMA resistance and the plastic damage strain of the composite are piecewise linear. This study can provide a theoretical basis for further optimization design and application of SMA composite damage monitoring.

-

Key words:

- shape memory alloy /

- damage monitoring /

- strain transfer /

- interface /

- composite materials

-

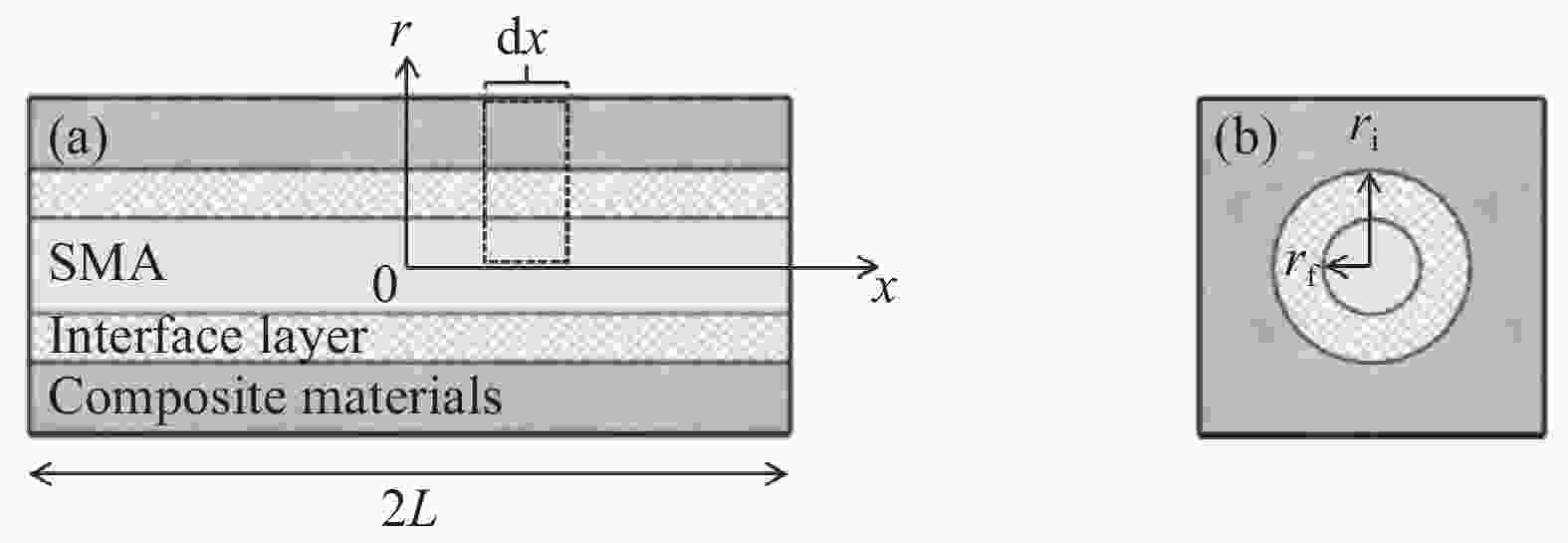

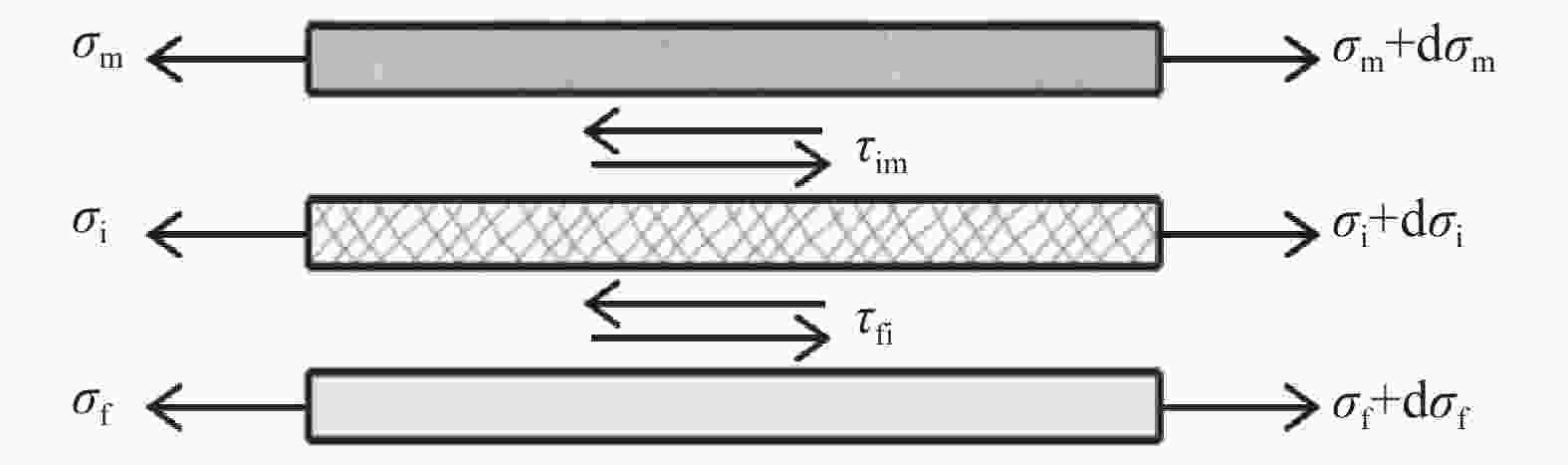

图 3 dx微元段SMA复合材料应力分布

Figure 3. Stress distribution of dx microelement SMA composite

$ {\sigma _{\rm{m}}} $—Composite axial stress; $ {\sigma _{\rm{i}}} $—Interface layer axial stress; $ {\sigma _{\rm{f}}} $—SMA fiber axial stress;$ {\tau _{{\text{im}}}} $—Shear stress between interface layer and composite;$ {\tau _{{\text{fi}}}} $—Shear stress between SMA fiber and interface layer

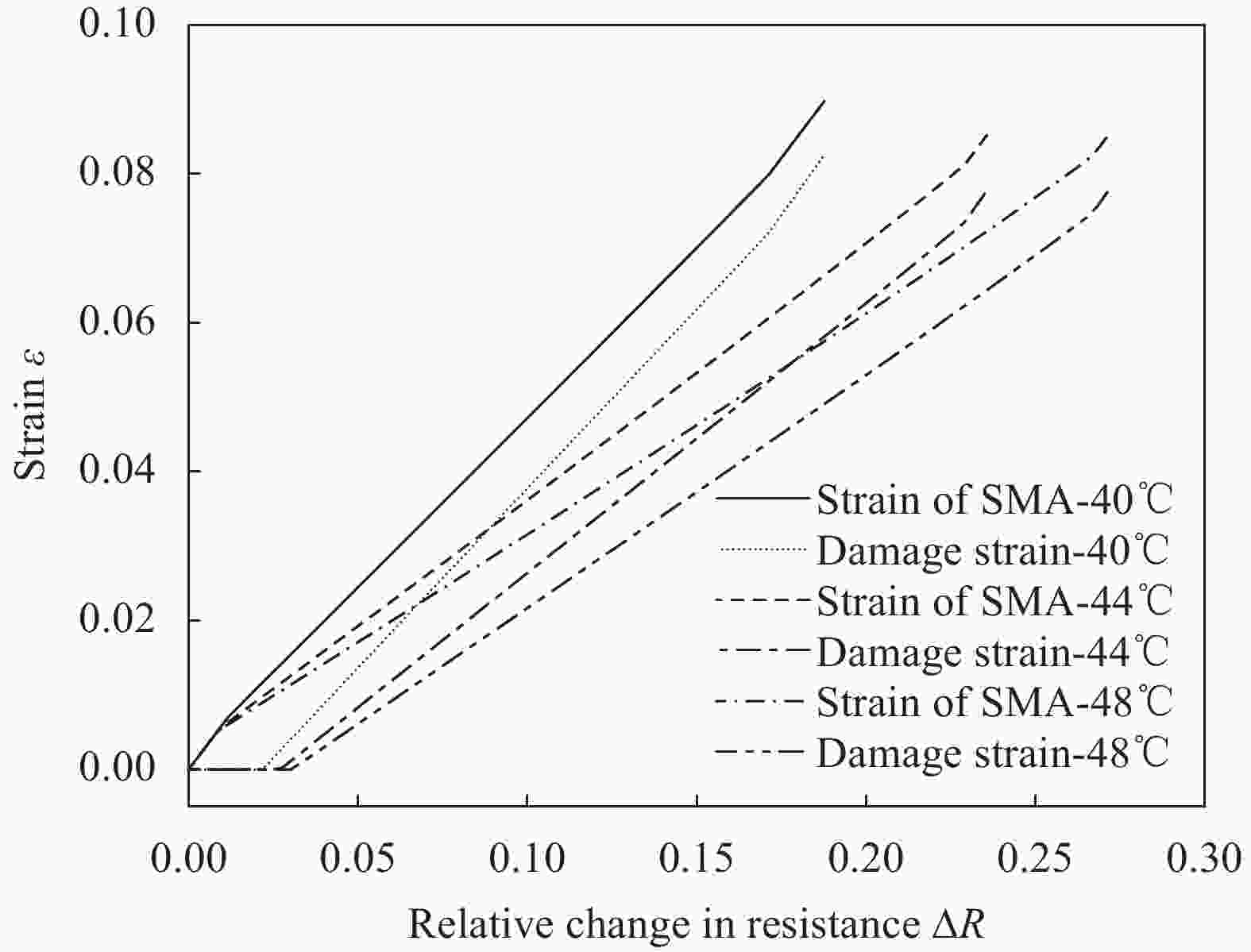

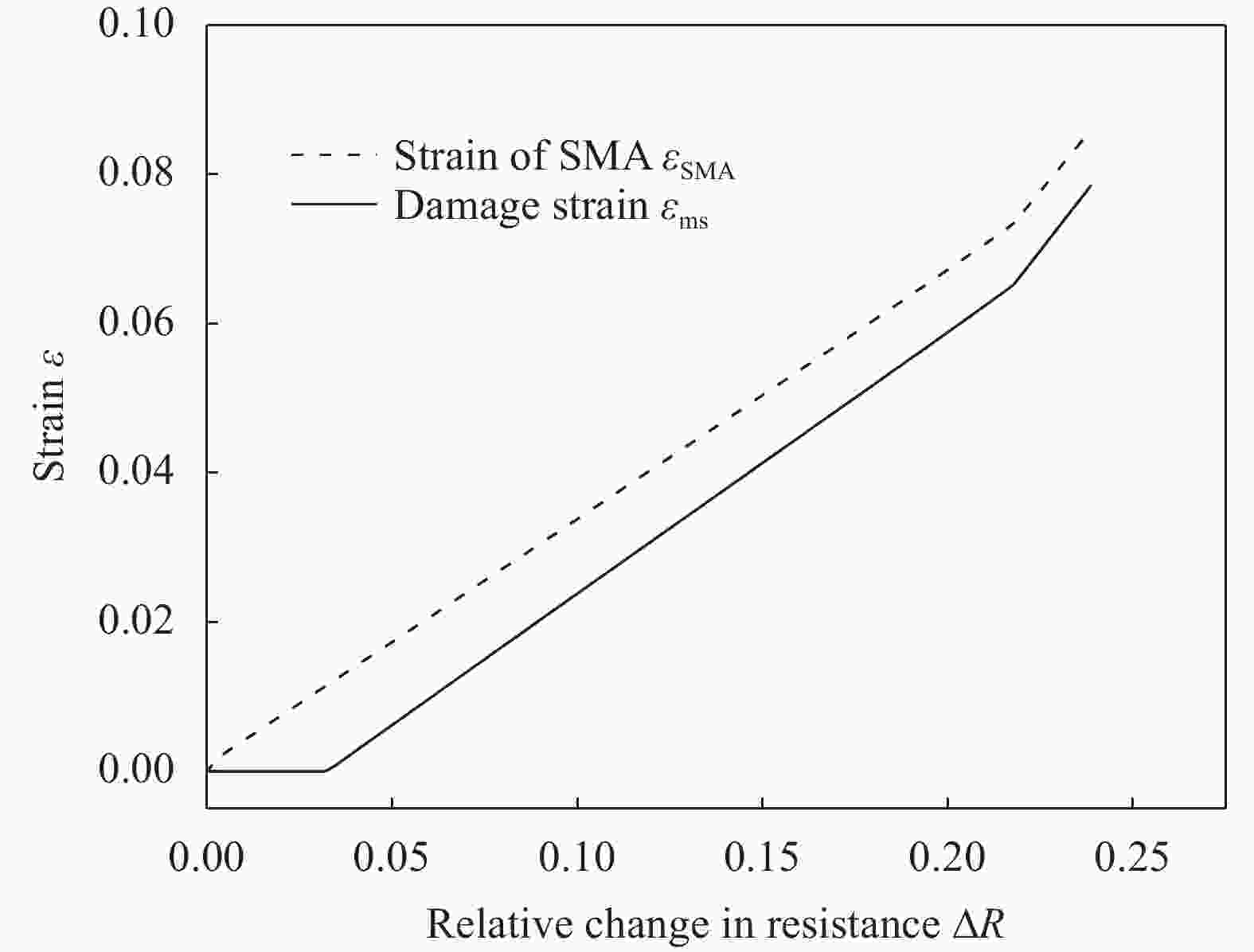

图 9 奥氏体相变开始温度($ {{{A}}_{\rm{s}}} $)<$ {{T}} $<奥氏体相变结束温度($ {{{A}}_{\rm{f}}} $)时SMA电阻相对变化和应变的关系

Figure 9. Relationship between SMA resistance relative change and strain at starts temperature of austenite trasformation ($ {{{A}}_{\rm{s}}} $)<$ {{T}} $<ends temperature of austenite trasformation ($ {{{A}}_{\rm{f}}} $)

表 1 SMA纤维材料参数

Table 1. SMA fiber material parameters

$ {{{E}}_{\rm{A}}} $/MPa $ {{{E}}_{\rm{M}}} $/MPa $ {{{M}}_{\rm{f}}} $/℃ $ {{{M}}_{\rm{s}}} $/℃ $ {{{A}}_{\rm{s}}} $/℃ $ {{{A}}_{\rm{f}}} $/℃ $ \theta $/(MPa·℃−1) 67×103 26.3×103 9 18.4 34.5 49 0.55 $ \sigma _{\rm{s}}^{{\rm{cr}}} $/MPa $ \sigma _{\rm{f}}^{{\rm{cr}}} $/MPa $ {{{C}}_{\rm{M}}} $/(MPa·℃−1) $ {{{C}}_{\rm{A}}} $/(MPa·℃−1) $ {\varepsilon _{\rm{L}}} $ $ {{v}} $ $ {{{r}}_{\rm{f}}} $/m 100 170 8 13.8 0.067 0.33 0.001 $ {{{C}}_{{\rm{M1}}}} $/(Ω·m·℃−1) $ {{{C}}_{{\rm{M2}}}} $/(Ω·m) $ {{{C}}_{{\rm{A1}}}} $/(Ω·m·℃−1) $ {{{C}}_{{\rm{A2}}}} $/(Ω·m) $ {{{L}}_{\rm{f}}} $/m 7×10−10 0.87×10−6 8×10−10 0.72×10−6 0.1 Notes: $ {{{E}}_{\rm{A}}} $ and $ {{{E}}_{\rm{M}}} $—Elastic modulus of SMA austenite and martensite; $ {{{M}}_{\rm{s}}} $ and $ {{{M}}_{\rm{f}}} $—Starts and ends temperature of martensitic transformation; $ {{{A}}_{\rm{s}}} $ and $ {{{A}}_{\rm{f}}} $—Starts and ends temperature of austenite transformation; $ \theta $—Thermal elastic modulus of SMA; $ \sigma _{\rm{s}}^{{\rm{cr}}} $ and $ \sigma _{\rm{f}}^{{\rm{cr}}} $—SMA reorientation starts and ends critical stress; $ {{{C}}_{\rm{M}}} $ and $ {{{C}}_{\rm{A}}} $—Stress influence coefficient of martensite and austenite; $ {\varepsilon _{\rm{L}}} $—Maximum residual strain of SMA; $ {{v}} $—Poisson's ratio of SMA; $ {{{C}}_{{\rm{M1}}}} $, $ {{{C}}_{{\rm{M2}}}} $, $ {{{C}}_{{\rm{A1}}}} $ and $ {{{C}}_{{\rm{A2}}}} $—Material parameters related to resistivity; $ {{{r}}_{\rm{f}}} $—Fiber radius of SMA; $ {{{L}}_{\rm{f}}} $—Axial length of SMA fiber. 表 2 碳纳米纤维/环氧树脂基复合材料和环氧树脂材料参数[21]

Table 2. Carbon nanofibers/epoxy composites and epoxy resin material parameters[21]

$ {{{L}}_{\rm{m}}} $/m $ {\varepsilon _{{\rm{mt}}}} $ $ {{{G}}_{\rm{i}}} $/GPa $ {{{r}}_{\rm{i}}} $/m $ {{{E}}_{\rm{i}}} $/GPa 0.1 0.0125 1.3 0.002 2.3 Notes: $ {{{L}}_{\rm{m}}} $—Axial length of composite; $ {\varepsilon _{{\rm{mt}}}} $—Maximum elastic strain of composite; $ {{{G}}_{\rm{i}}} $—Shear modulus of epoxy resin; $ {{{r}}_{\rm{i}}} $—Radius of epoxy resin; $ {{{E}}_{\rm{i}}} $—Elastic modulus of epoxy resin. -

[1] CHANDARANA N, MATTHIEU G, SOUTIS C. Damage detection and monitoring in composite pipes using piezoelectric sensors[C]//9th European Workshop on Structural Health Monitoring. Manchester: NDT. net, 2018: 1-9. [2] BENAZZO F, RIGAMONTI D, BETTINI P, et al. Interlaminar fracture of structural fibre/epoxy composites integrating damage sensing and healing[J]. Composites Part B: Engineering,2022,244:110137. doi: 10.1016/j.compositesb.2022.110137 [3] SENTHILKUMAR M, SREEKANTH T G, MANIKANTA REDDY S. Nondestructive health monitoring techniques for composite materials: A review[J]. Polymers and Polymer Composites,2021,29(5):528-540. doi: 10.1177/0967391120921701 [4] EL-SABBAGH A, STEUERNAGEL L, ZIEGMANN G. Characterisation of flax polypropylene composites using ultrasonic longitudinal sound wave technique[J]. Compo-sites Part B: Engineering,2013,45(1):1164-1172. doi: 10.1016/j.compositesb.2012.06.010 [5] FREEMANTLE R J, HANKINSON N, BROTHERHOOD C J. Rapid phased array ultrasonic imaging of large area composite aerospace structures[J]. Insight,2005,47(3):129-132. doi: 10.1784/insi.47.3.129.61315 [6] RYU C H, PARK S H, KIM D H, et al. Nondestructive evaluation of hidden multi-delamination in a glass-fiber-reinforced plastic composite using terahertz spectroscopy[J]. Composite Structures,2016,156:338-347. doi: 10.1016/j.compstruct.2015.09.055 [7] HOSOI A, YAMAGUCHI Y, JU Y, et al. Detection and quantitative evaluation of defects in glass fiber reinforced plastic laminates by microwaves[J]. Composite Structures,2015,128:134-144. doi: 10.1016/j.compstruct.2015.03.050 [8] KALYANAVALLI V, ABILASHA RAMADHAS T K, SASTIKUMAR D. Long pulse thermography investigations of basalt fiber reinforced composite[J]. NDT & E International,2018,100:84-91. [9] 邱自学, 姚兴田. 结构中埋入TiNi超弹性丝传感网络的实验研究[J]. 传感器技术, 2001, 20(11):11-13.QIU Zixue, YAO Xingtian. Experimental research on sensor network embedded TiNi super-elastic wire in structures[J]. Journal of Transducer Technology,2001,20(11):11-13(in Chinese). [10] LYNCH B. Modeling of the stress-strain-resistance behaviour of Ni-Ti and Ni-Ti-Cu shape memory alloys for use in sensorless actuator position control[D]. Ontario: Carleton University, 2013. [11] 马奎. NiTi形状记忆合金棒的受限回复与加热试验及分析[D]. 广州: 华南理工大学, 2013.MA Kui. Tests and analyses of NiTi shape memory alloy bars' restrained recovery and heating[D]. Guangzhou: South China University of Technology, 2013(in Chinese). [12] 崔迪. 形状记忆合金及其智能混凝土结构研究[D]. 大连: 大连理工大学, 2007.CUI Di. Research on shape memory alloy and shape memory alloy restrained intelligent concrete structure[D]. Dalian: Dalian University of Technology, 2007(in Chinese). [13] 狄生奎, 韩全治, 李慧, 等. SMA在结构健康监测中的应用研究[J]. 低温建筑技术, 2008, 30(4):58-60. doi: 10.3969/j.issn.1001-6864.2008.04.027DI Shengkui, HAN Quanzhi, LI Hui, et al. Research on the shape memory alloy applied in structural health monitoring[J]. Low Temperature Architecture Technology,2008, 30(4):58-60(in Chinese). doi: 10.3969/j.issn.1001-6864.2008.04.027 [14] 狄生奎, 花尉攀, 汲生伟, 等. 约束态SMA混凝土梁的裂缝监测及自修复[J]. 建筑材料学报, 2010, 13(2):237-242. doi: 10.3969/j.issn.1007-9629.2010.02.021DI Shengkui, HUA Weipan, JI Shengwei, et al. Self-monitoring and self-repairing of crack in concrete beam with constraint super-elastic SMA[J]. Journal of Building Materials,2010,13(2):237-242(in Chinese). doi: 10.3969/j.issn.1007-9629.2010.02.021 [15] LIU B F, WANG Q F, YIN K, et al. An analytical model for crack monitoring of the shape memory alloy intelligent concrete[J]. Journal of Intelligent Material Systems and Structures,2020,31(1):100-116. doi: 10.1177/1045389X19880010 [16] 张亚楠, 刘亚冬, 刘兵飞. 形状记忆合金在复合材料损伤监测中的应用[J]. 复合材料学报, 2021, 38(4):1177-1191.ZHANG Yanan, LIU Yadong, LIU Bingfei. Application of shape memory alloy in damage monitoring of composite materials[J]. Acta Materiae Compositae Sinica,2021,38(4):1177-1191(in Chinese). [17] BRINSON L C. One-dimensional constitutive behavior of shape memory alloys: Thermomechanical derivation with non-constant material functions and redefined martensite internal variable[J]. Journal of Intelligent Material Systems and Structures,1993,4(2):229-242. doi: 10.1177/1045389X9300400213 [18] IKUTA K, TSUKAMOTO M, HIROSE S. Mathematical model and experimental verification of shape memory alloy for designing micro actuator[C]//[1991] Proceedings. IEEE Micro Electro Mechanical Systems. New York: IEEE, 1991: 103-108. [19] 王花平. 损伤状态下光纤应变传递及其在多层路面的应用[D]. 大连: 大连理工大学, 2015.WANG Huaping. Strain transfer of optical fiber under damage conditions and its application in mutil-layered pavements[D]. Dalian: Dalian University of Technology, 2015(in Chinese). [20] 杨博恒. 形状记忆合金超细丝电阻传感特性试验及理论研究[D]. 哈尔滨: 哈尔滨工业大学, 2020.YANG Boheng. Research on characteristic modeling and resistance sensing control of shape memory alloy actuators[D]. Harbin: Harbin Institute of Technology, 2020(in Chinese). [21] WANG Y L, WANG Y S, WAN B L, et al. Strain and damage self-sensing of basalt fiber reinforced polymer laminates fabricated with carbon nanofibers/epoxy composites under tension[J]. Composites Part A: Applied Science and Manufacturing,2018,113:40-52. doi: 10.1016/j.compositesa.2018.07.017 -

下载:

下载: