Enhancement of flame retardancy in polyurea composites facilitated by a trinity intumescent flame retardant

-

摘要:

聚合物材料存在易燃、易被氧化的缺点,以及传统膨胀型阻燃体系存在吸湿性大、阻燃效率较低、与基体相容性差等缺陷。结合气相阻燃、凝聚相阻燃的设计理念,制备出三位一体膨胀型阻燃剂(PTA-PA)。研究不同含量的PTA-PA对聚脲(PUA)的阻燃性能及力学的影响,分析材料在燃烧、热解过程中气相和凝聚相产物,探究PTA-PA阻燃剂的阻燃机制,建立膨胀型阻燃剂与复合材料热稳定性、阻燃性能和火灾安全性之间的关系。结果表明:和纯PUA相比,添加20.0wt% PTA-PA 的PUA复合材料(PUA-4)具有较高的热稳定性,800℃下残炭量为21.9%;PUA-4复合材料的垂直燃烧等级从V-2级提高到V-0级,极限氧指数(LOI)分别从22.2%提高到28.4%,线烧蚀率、热释放速率峰值和总热释放量分别降低19.8%、71.7%和18.3%。本文为高性能阻燃聚合物复合材料的制备提供理论基础和事实依据。

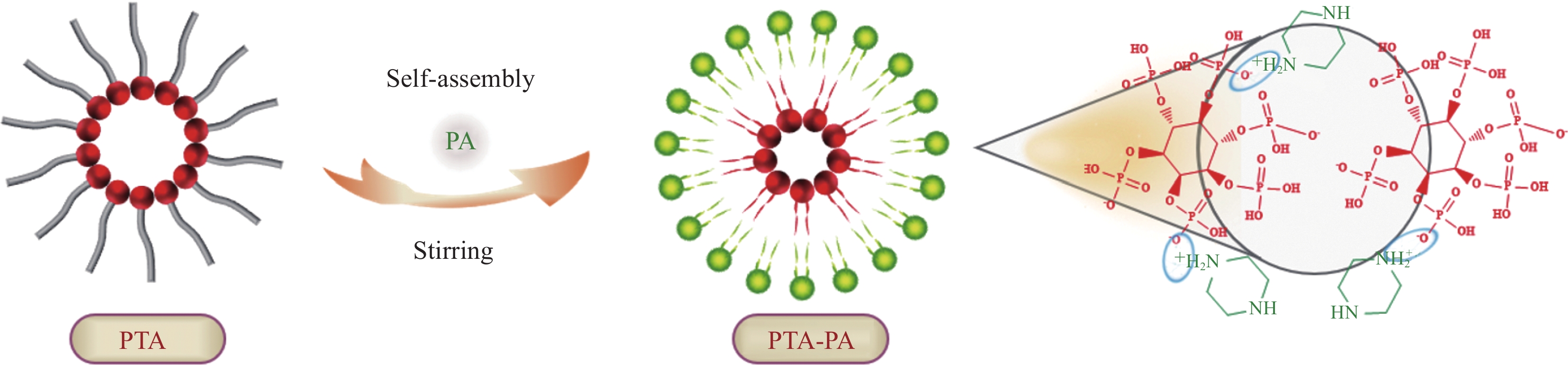

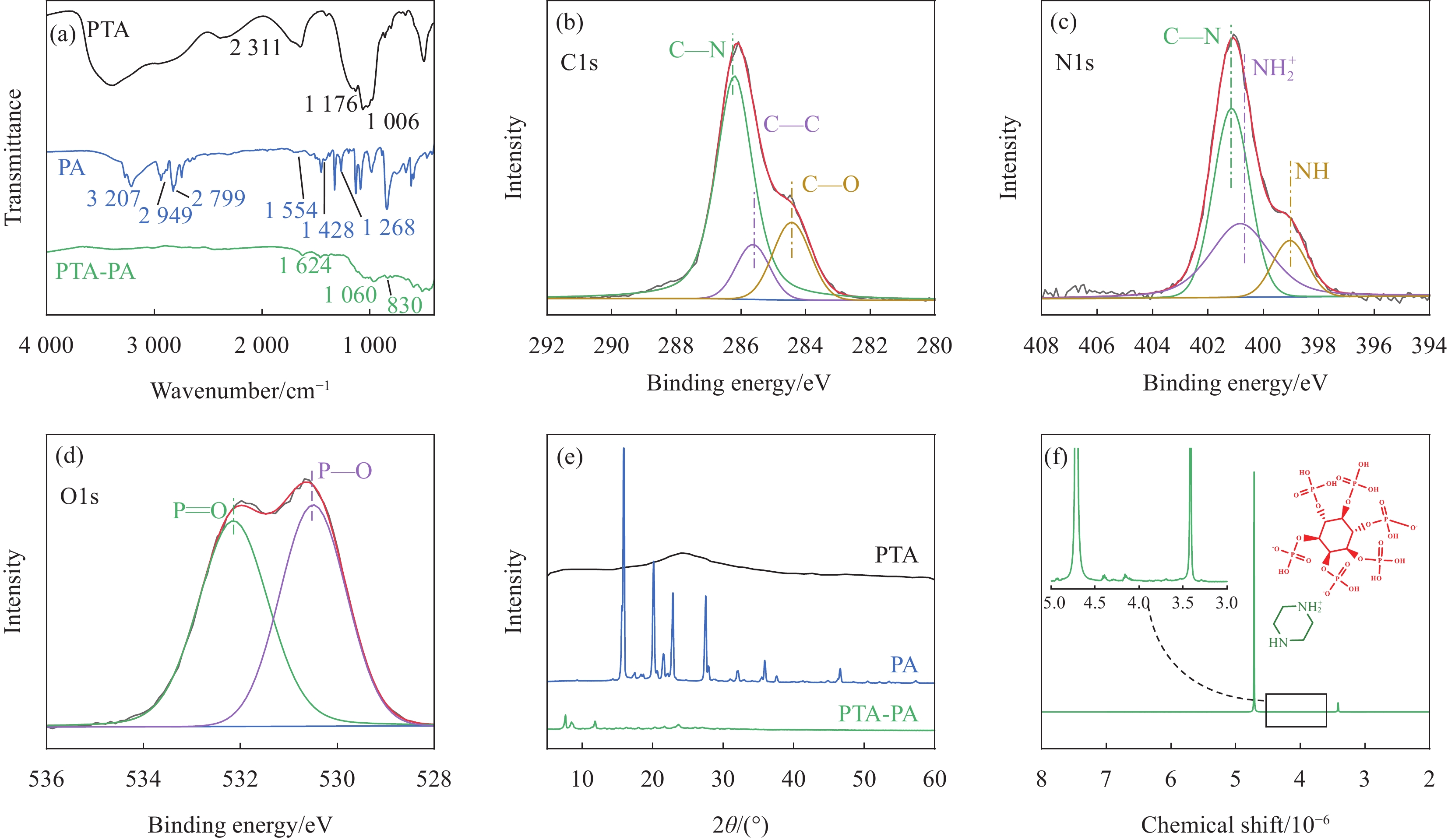

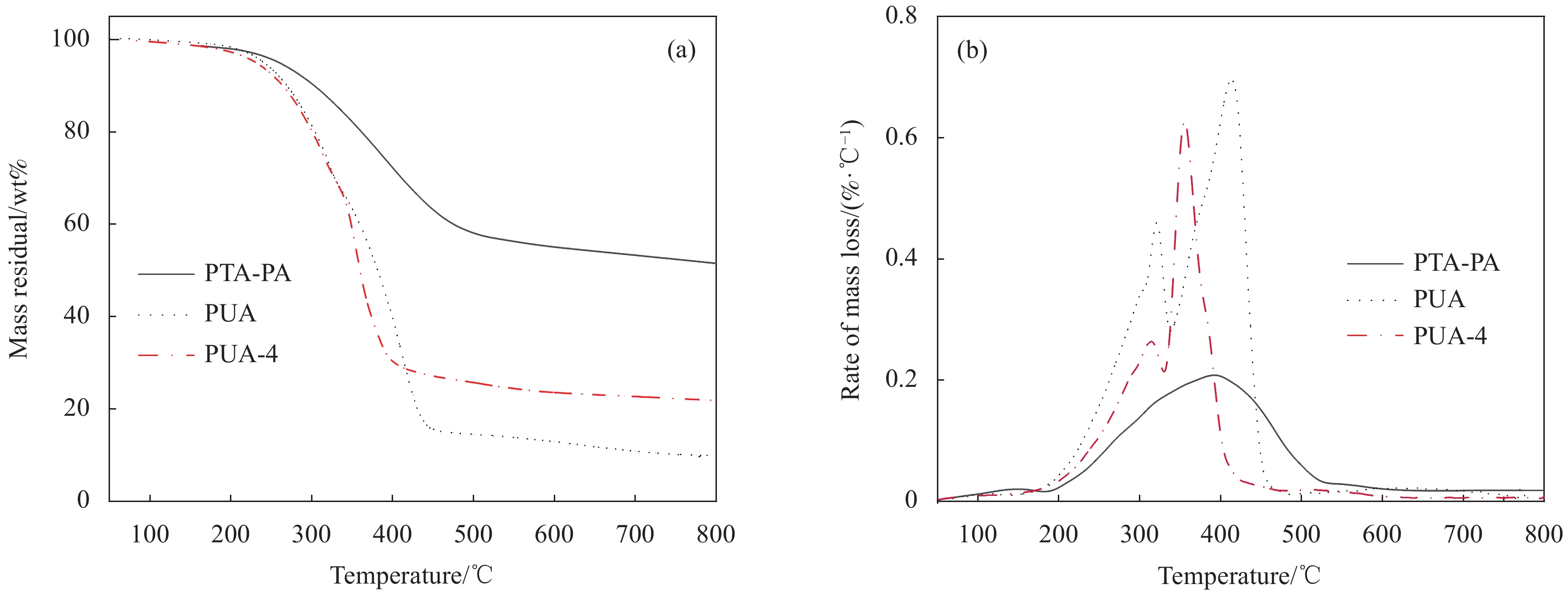

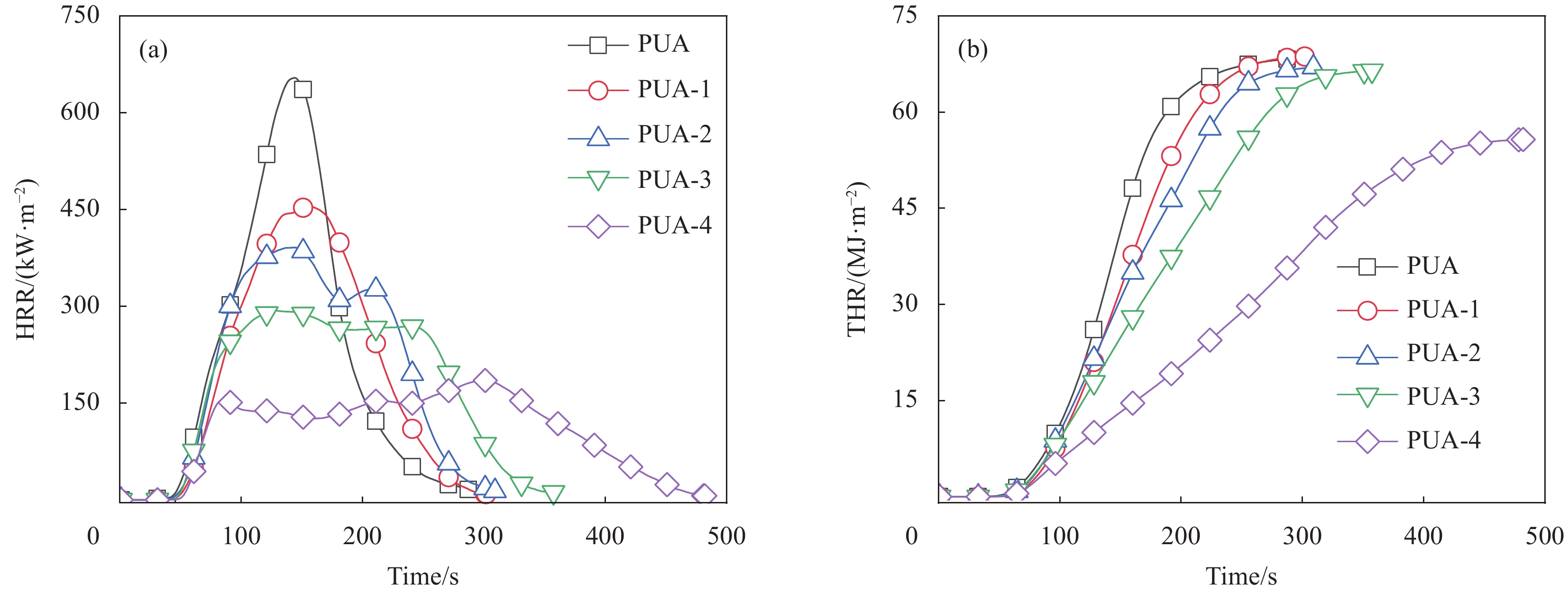

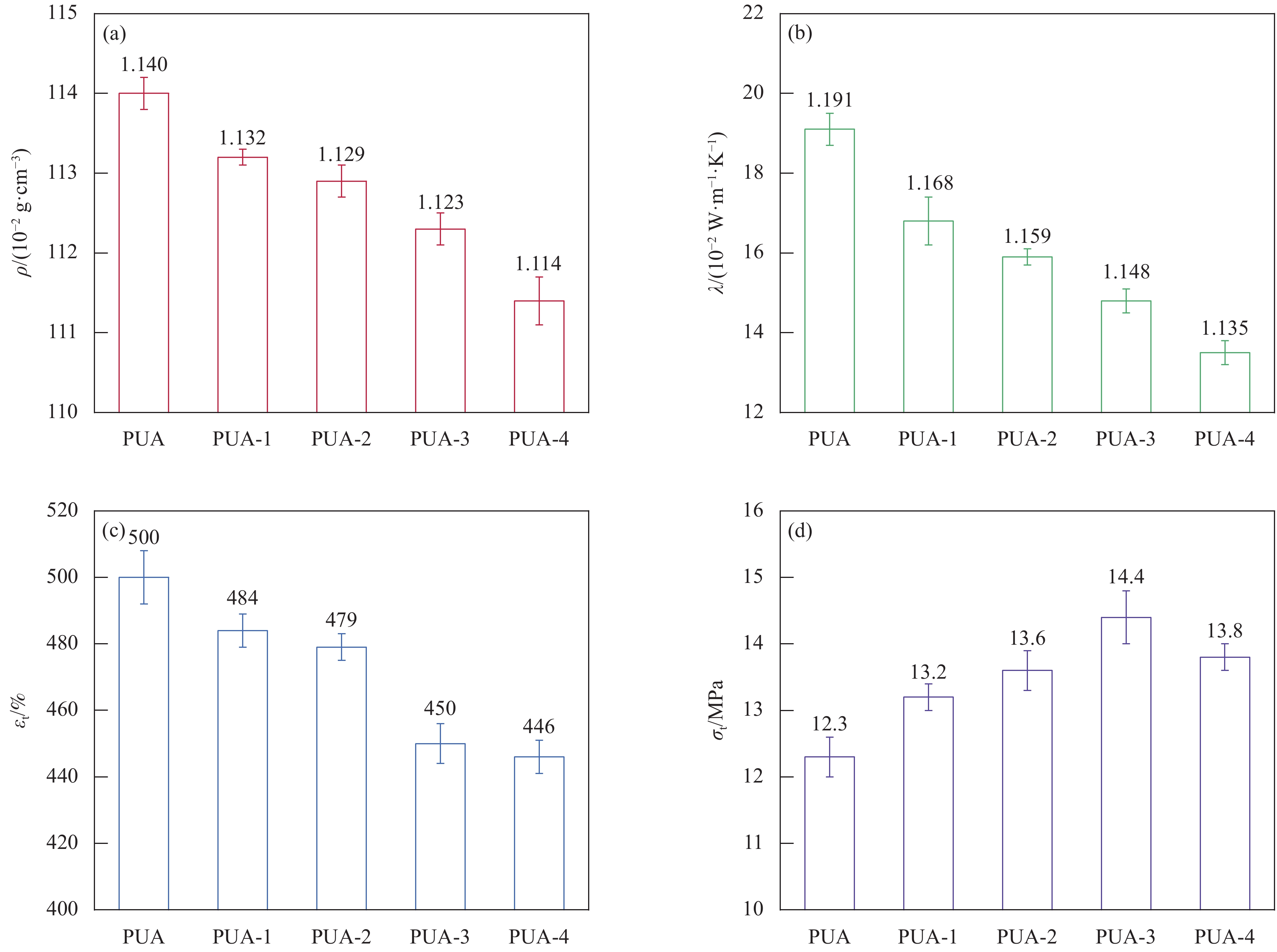

Abstract:Polymeric materials are inherently flammable and prone to oxidation. Traditional intumescent flame retardants exhibit drawbacks, including significant moisture absorption, limited flame-retardant efficacy, and suboptimal matrix compatibility. To address these challenges, a trinity intumescent flame retardant (PTA-PA) was synthesized, integrating the principles of gas-phase and condensed-phase flame retardation. This study examined the influence of varying PTA-PA concentrations on the flame resistance and mechanical properties of polyurea (PUA). It entailed analyzing combustion and pyrolysis byproducts to elucidate the mechanism of flame retardance provided by these novel agents. Additionally, the study correlated the introduction of PTA-PA with enhancements in thermal stability, flame retardance, and overall fire safety of the composites. The findings indicate that the PUA composite with a 20.0wt% loading of PTA-PA (PUA-4) exhibits increased thermal stability, evidenced by a residual carbon content of 21.9% at 800℃. Notably, the vertical burn rating of PUA-4 improved from V-2 to V-0, the limiting oxygen index (LOI) rose from 22.2% to 28.4%, and the rates of line ablation, peak heat release, and total heat release diminished by 19.8%, 71.7% and 18.3%, respectively. This investigation provides a theoretical and empirical foundation for developing advanced flame-retardant polymeric composites.

-

金属与环境接触时,金属表面与周围环境中的活性物质(如O2、H2O、Cl−等)之间会自然发生反应,生成化学性质更稳定的化合物,导致材料性能的恶化,即腐蚀[1]。金属的腐蚀基本上是一个电化学过程。当金属接触水和溶解的氧气时,表面金属原子开始发生氧化反应,其中金属离子(如Fe2+)在高电位的阳极形成,随着电子通过金属转移到阴极而流入周围环境,从而产生腐蚀电流以促进氧化反应。腐蚀作为一种自然现象,给许多行业带来了严重有害影响。据研究,过去50年,腐蚀造成的经济损失相当于各国GDP的3%~4%,全球腐蚀成本估计为2.5万亿美元,占全球GDP的3.4%[2]。金属发生腐蚀时不仅会影响经济发展,还会引起危害人民群众生命安全的事件。例如,地下地上输油输气管道因腐蚀而造成的破损导致介质的泄露;船舶由于腐蚀而发生沉船;建筑物由于腐蚀而发生坍塌[3]。因此,开发具有优良防腐蚀性能和低渗透性能的先进防护技术至关重要。

在各种腐蚀防护策略中,防腐涂层是最常用、最经济和最有效的方法。聚合物涂层可以在金属表面形成一层外壳,以阻止包括O2、H2O、Cl−在内的外部物质的渗透,起到屏障保护的作用。事实上,聚合物的微裂纹及孔洞、腐蚀性物质(如O2、H2O、Cl−等)的固有渗透性和涂层的降解会导致涂层的阻隔水平降低,使聚合物涂层的保护性能随着暴露在环境中时间的延长而丧失[4]。例如,在化学侵蚀和机械应力的共同作用下,聚合物涂层很可能产生应力腐蚀开裂,使腐蚀物质可以轻松穿过涂层腐蚀钢体。传统的聚合物涂层也容易发生表面磨损和裂缝,这会加速腐蚀介质的迁移,导致涂层过早失效[5]。因此,提高常规聚合物涂料的耐腐蚀性能以满足苛刻的防腐应用要求是至关重要的。

在聚合物中,环氧树脂作为阻隔材料具有特殊的优势:(1) 分子结构致密,具有很强的内聚力,力学性能好;(2) 分子链上具有多个吸附位点和官能团,对物质具有优越的黏附性;(3) 固化收缩率和线胀系数很小,固化后体积变化不大;(4) 重复单元主要由亚甲基组成,使其具有良好的疏水性[6]。因此,在聚合物中环氧树脂是防腐涂层基体最好的选择。二维纳米材料具有高直径/厚度比、良好的阻水阻氧性能、离子不渗透性和化学稳定性等优点[7]。将其引入到环氧树脂基体中形成二维纳米材料/环氧树脂复合材料可以结合两种材料的优点,能够实现环氧树脂重防腐的目标。常用二维纳米材料有:石墨烯及其衍生物、氮化硼和二硫化钼等。本文系统地介绍了二维纳米材料在环氧树脂防腐涂料中的屏障保护作用、抑制保护作用和牺牲保护作用,然后阐述了常见二维纳米材料在环氧树脂防腐涂料中的应用。此外,还总结了解决二维纳米材料团聚问题、调控二维纳米材料取向、提高涂层和钢体附着力的方法。最后,综述了二维纳米材料在环氧树脂防腐涂层中应用的现状,描述了其存在的挑战和应用前景。

1. 防腐机制

二维纳米材料/环氧树脂复合涂层防腐能力的显著增强主要是由于具有不同功能的各组分的协同作用,其机制可归结为以下几个方面。

1.1 抑制腐蚀介质的渗透

从本质上讲环氧树脂防腐涂层是一种复合涂层,由各种离散的固体功能添加剂和环氧树脂组成的体系。在该体系中,环氧树脂作为黏合剂占大部分成分,可以提供一个物理屏障,防止钢体直接暴露于腐蚀介质中[8]。二维纳米材料作为功能填料加入到环氧树脂中,容易填充涂层的微孔和裂纹,增强涂层的阻隔效应[9]。此外,二维纳米填料因其大的比表面积和良好的长宽比可以使腐蚀物质的扩散路径曲折延长,增强涂层的迷宫效应(图1)。因此,二维纳米材料在环氧树脂涂层中从两方面协同阻碍腐蚀介质的渗透[10]。

1.2 负载缓蚀剂并控制其释放

缓蚀剂的添加赋予了涂层主动防护的性能,能够在涂层被动防护性能失效时仍可实现对金属基体的防护。然而将缓蚀剂直接添加到涂层中,会导致缓蚀剂中的活性基团与涂层中的活性成分发生相互作用,破坏涂层的稳定性和完整性[11]。而且还可能由于缓蚀剂的不可控释放过早的响应,造成主动防护性能的快速消失,无法实现长期稳定的有效防护。把缓蚀剂负载在二维纳米材料上,利用二维纳米材料的光热效应、磁热效应和电热效应有效地放大和增强外界刺激的特点,来实现对缓蚀剂的可控释放,从而在涂层屏障作用失效时抑制钢体腐蚀的发生[12]。

1.3 阴极保护和绝缘保护

抑制电化学腐蚀速度要从电化学本质入手,改变钢体的腐蚀电位,形成阴极保护。具有导电性的二维纳米材料在阴极保护涂层中发挥重要作用,增强涂层的保护性能。在阴极保护涂层中,通常加入活性金属锌,与钢体形成电偶腐蚀,牺牲阳极保护钢体。但是,只有锌颗粒的负载高于80wt%时才可以相互接触并与钢体形成通路[13]。然而,高含量的锌颗粒会导致环氧涂层出现裂纹并且降低与钢体的附着力。导电二维纳米材料加入到富锌涂层中可以将孤立的锌颗粒连接起来,并将锌颗粒的负载量降低到20wt%以下,显著提高富锌涂层的防腐效果[14]。当界面部分的锌颗粒被消耗时,由于导电二维纳米材料的电子转移作用,涂层远端部分的锌颗粒可以被进一步消耗,提高了锌的利用率,增加了涂层的阴极保护效果[15]。

但是,在不含锌颗粒的环氧树脂涂层中填料很难构成通路,局部导电会加速腐蚀速率。因此,科研人员提出绝缘保护,从根本上阻止电子的迁移,抑制电化学腐蚀[16]。环氧树脂涂层的绝缘保护,即在环氧树脂中添加绝缘填料。腐蚀介质穿越涂层接触钢体时,通过电子的迁移发生一系列的化学反应,使钢体发生腐蚀。环氧树脂防腐涂层内部为绝缘体时,致使电子不能在腐蚀介质和钢体间迁移,从而阻止腐蚀的扩展。绝缘填料分为两种类型:一是对导电二维纳米材料进行改性使其导电性能降低;二是使用新型绝缘二维纳米材料代替导电填料。

2. 常见二维材料在环氧树脂涂层中的应用

二维材料由于其具有独特的片层结构和大的比表面积,在提高环氧树脂涂层的耐腐蚀性方面起着至关重要的作用。传统的二维材料(如玻璃鳞片和黏土片)因其厚度较大严重降低了环氧树脂涂层与钢体的附着力,大大限制了腐蚀防护性能的提高[17]。因此,新型二维纳米材料在腐蚀防护领域受到了大量研究,如石墨烯及其衍生物、氮化硼、二硫化钼。上述三种二维纳米材料生产工艺成熟,在工业生产上具有一定的应用价值。与传统二维材料相比具有单原子厚度,使得钢体与环氧树脂涂层之间具有良好的附着力,并且表面的相互作用主要由弱范德华力控制,从而形成惰性表面,化学性质稳定[18]。与其他二维纳米材料相比,石墨烯及其衍生物、氮化硼和二硫化钼具有紧凑六边形晶格,几乎所有原子和分子都难以穿透,具有良好的物理屏蔽作用[19]。下面重点介绍石墨烯及其衍生物、氮化硼和二硫化钼作为填料在环氧树脂防腐涂层中的应用。

2.1 石墨烯及其衍生物

石墨烯及其衍生物(氧化石墨烯、氟化石墨烯)具有独特的单层结构,由sp2杂化碳原子组成的二维蜂窝状晶格,可以与环氧树脂具有更大的接触区域,有利于延长腐蚀介质的扩散途径,从而抑制腐蚀介质的渗透[20]。此外,π-π共轭碳网络中密集的离域电子云可以堵塞芳香环内的间隙,形成活性分子排斥场[21],导致氧气(16.34 eV)和水分子(42.8 eV)穿过石墨烯及其衍生物的膜需要很高的势能[22-23]。因此,石墨烯及其衍生物有利于提高环氧树脂涂层的物理屏蔽作用。Rajitha等[24]报道,在环氧树脂中加入0.2wt%石墨烯纳米片,涂层电阻从1270 Ω·cm2增长到101700 Ω·cm2,防腐蚀性能显著增强。Wang等[25]利用原位聚合的方法制备磺化聚苯胺/氧化石墨烯纳米复合材料,并将其添加到水性环氧树脂涂层中,氧化石墨烯和磺化聚苯胺协同发挥物理屏蔽作用,使得添加磺化聚苯胺/氧化石墨烯纳米复合材料的水性环氧树脂复合涂层具有长期耐腐蚀性能。含有0.5wt%填料的水性环氧树脂复合涂层在腐蚀介质中浸泡168 h后,具有良好的防腐性能,保护效率高达97.43%。窦宝捷等[26]将氟化石墨烯作为填料加入到环氧树脂中制备防腐涂层。结果表明,氟化石墨烯/环氧树脂涂层的电阻在3000 h的浸泡过程中始终维持在1011 Ω·cm2以上,表现出对腐蚀介质优良的长期屏蔽性能,涂层的长期防护性能显著提升。

此外,石墨烯的导电性是决定石墨烯/环氧涂层耐腐蚀性能的另一个因素。石墨烯的每个碳原子在最外层有四个未配对电子,其中三个在一个二维平面内通过σ键连接到相邻的碳原子上,第四个电子在三维空间中可以自由获得,用于电子传导[27]。这种独特的结构使石墨烯载流子具有超高的本征迁移率,从而使石墨烯具有优异的导电性。在传统的富锌环氧树脂涂料中,锌颗粒首先起到牺牲阳极的作用来保护金属基体。其次,锌颗粒的腐蚀产物会堵塞涂层的孔隙,阻碍电解液的扩散起到防腐保护的作用。当石墨烯被添加到富锌涂层中时,在初始阶段会起到屏障的作用,延长电解质的扩散路径。当锌颗粒被腐蚀时,石墨烯可以传递电子,将孤立的锌粒子连接起来形成电子传递通道,更有效地将锌氧化失去的电子传递到金属衬底表面。因此,石墨烯加入到环氧树脂涂层中降低了富锌涂层中电子传递的难度,增强了富锌涂层对钢体的阴极保护作用(图2)[28]。Hayatdavoudi等[29]研究表明,0.4wt%石墨烯为锌颗粒提供了更均匀的活化,提高锌颗粒的利用率。因此,添加一定量的石墨烯纳米片可以作为提高富锌环氧树脂涂层保护性能的有效策略。然而,也有报道称,石墨烯可能对涂层缺陷处的腐蚀保护产生巨大的负面影响。Zhou等[30]报道石墨烯表现出腐蚀增强效应,这是由于涂层缺陷处石墨烯具有高导电性,有利于铜的电化学腐蚀。此外,Schriver等[31]发现,石墨烯只能提供短期的腐蚀保护,在一定时间内,它甚至促进了更广泛的腐蚀。Dipak等[32]指出,石墨烯与金属之间将形成导电网络,从而加速腐蚀。环氧树脂中加入石墨烯,因其负载量不同既可以抑制腐蚀又可以促进腐蚀。当石墨烯的负载量可以把孤立的锌颗粒和钢体形成通路时,表现为抑制腐蚀。当石墨烯的负载量不能使它们形成通路,在缺陷处表现为促进腐蚀。因此,为了避免腐蚀增强现象,必须控制环氧树脂中石墨烯的负载量。

![]() 图 2 石墨烯/水性环氧含锌涂层防腐机制示意图: (a) 复合涂层物理屏蔽作用; (b) 石墨烯片的阻隔作用; (c) 锌颗粒的阴极保护作用; (d) 腐蚀锌颗粒[28]Figure 2. Schematic diagram of anti-corrosion mechanism of graphene/waterborne epoxy zinc-containing coating: (a) Physical shielding effect of composite coating; (b) Barrier effect of graphene sheets; (c) Cathodic protection of zinc particles; (d) Corrosive zinc particles[28]

图 2 石墨烯/水性环氧含锌涂层防腐机制示意图: (a) 复合涂层物理屏蔽作用; (b) 石墨烯片的阻隔作用; (c) 锌颗粒的阴极保护作用; (d) 腐蚀锌颗粒[28]Figure 2. Schematic diagram of anti-corrosion mechanism of graphene/waterborne epoxy zinc-containing coating: (a) Physical shielding effect of composite coating; (b) Barrier effect of graphene sheets; (c) Cathodic protection of zinc particles; (d) Corrosive zinc particles[28]此外,部分研究人员表示降低石墨烯导电性,是提高石墨烯/环氧树脂防腐涂层防护性能的重要手段[16]。根据文献报道,石墨烯经氧化或氟化处理后得到的氧化石墨烯或氟化石墨烯,其导电率由103 S/cm降低至10−9 S/cm,导电性能显著下降,从根本上解决了石墨烯在缺陷处促进腐蚀的现象[33]。Liu等[34]将钛(Ti)修饰的氧化石墨烯加入到环氧树脂中制备防腐涂层,通过EIS分析发现,氧化石墨烯-钛/环氧树脂 (GO-Ti/EP) 防腐涂层相比于纯环氧树脂 (EP) 防腐涂层在阻抗的衰减上更加稳定,且GO-Ti/EP涂层在低频阻抗模值(|Z|0.01 Hz)的阻抗模量是纯EP的26.5倍。Sadak等[33]研究表明,氟化石墨烯在环氧树脂涂层中具有较好的分散稳定性,氟化石墨烯添加使环氧树脂涂层的接触角由95.3°提高至110.9°,提高了涂层的疏水性,降低了腐蚀介质与涂层表面的接触面积。在浸泡初期,纯环氧树脂涂层和氟化石墨烯/环氧树脂涂层的|Z|0.01 Hz均在1011 Ω·cm2左右。随浸泡时间的延长,环氧树脂涂层的|Z|0.01 Hz快速下降至109 Ω·cm2,而氟化石墨烯/环氧树脂涂层在3000 h浸泡过程中始终维持在1011 Ω·cm2以上。涂层电阻也表现出相似的变化规律。氟化石墨烯的添加提高了环氧树脂涂层的屏蔽性能,增强了涂层长期防护的稳定性,解决了石墨烯/环氧树脂涂层不能长时间稳定防腐蚀的问题。

2.2 氮化硼(h-BN)

氮化硼的晶格结构类似于石墨烯,硼原子和氮原子交替排列成六角形晶格,其片层结构对腐蚀介质具有类似的抗渗透性[35]。氮化硼还具有较高的热稳定性和化学稳定性,单层氮化硼在空气环境中可以稳定到850℃,而单层石墨烯只能稳定到450℃。实验证明,单层氮化硼涂层能够有效隔离空气环境中铜基体与氧气的相互作用,并起到的高温保护作用,有望成为抗氧化涂料的较好选择[36]。

氮化硼的带隙为5.97 eV,电场破坏强度达到7.94 MV/cm,是一种优良的电绝缘体。作为环氧树脂防腐涂层中的填料,氮化硼具有出色的抗渗透能力,阻止腐蚀介质侵蚀基体,又具有良好的绝缘性,从本质上阻隔了电化学腐蚀,显著增强环氧树脂涂层的防腐性能。即使腐蚀介质能够通过缺陷扩散到氮化硼/环氧树脂防腐涂层下面金属的表面,在很长一段时间内,也只能在缺陷附近发生局部氧化[37]。氮化硼/环氧树脂防腐涂层的绝缘特性阻断了电子从金属到氧的传递,从而阻止了电化学腐蚀,并长期表现出优良的耐腐蚀性能。因此,如果实际应用需要较长的保护时间,氮化硼/环氧树脂防腐涂层是首选。Husain等[38]报道了在海洋环境下,不锈钢表面涂有氮化硼/环氧树脂防腐涂层,具有较低的腐蚀电流密度和腐蚀速率。Wu等[17]在块状氮化硼材料剥离过程中,加入γ-氨丙基三乙氧基硅烷 (APTES) 材料,制备APTES改性的h-BN,命名为Fh-BN,并将层状Fh-BN加入含有磷酸锶锌(SZP)的环氧树脂涂层中进行腐蚀防护测试(图3)。发现,Fh-BN可以获得优异的长期防腐效果。

2.3 二硫化钼(MoS2)

二硫化钼由3个原子层组成,具有蜂窝状六边形排列的钼层夹在2个具有六边形排列的硫层之间,硫原子、钼原子通过共价键相连,原子间孔径很小,具有优越的抗渗透性。同时,二硫化钼具有比表面积大、 疏水性能好、 化学稳定性高等特点,在防腐填料方面具有强大的潜力[39]。二硫化钼拥有1.8 eV的能带隙,为半导体材料,可以用铁、钴和镍粒子对二硫化钼纳米片进行掺杂,使二硫化钼的活性位点数目增加,可发挥阴极保护机制[40]。Arunkumar等[41]研究了铁、钴和镍粒子掺杂的二硫化钼在侵蚀性氯化物环境中对低碳钢的腐蚀防护性能,结果显示铁、钴和镍粒子的加入使二硫化钼的耐腐蚀性能显著提高,其中铁显示出最高的保护效率,具有较低的电流密度 (Icorr) 和较高的腐蚀电位 (Ecorr) 值。也可以用聚合物改性二硫化钼增大能带隙,使其成为绝缘体,并且增强在环氧树脂中的分散性。Xia等[42]将聚多巴胺(PDA)改性二硫化钼 (MoS2@PDA) 引入到环氧树脂体系中,制备了一种新型环氧树脂防腐涂料 (MoS2@PDA/EP)。与未改性环氧树脂涂层相比,MoS2@PDA/EP涂层的耐腐蚀性提高了近3个数量级,结合强度提高了近3 MPa。Jing等[43]制备了富含缺陷部位的二硫化钼,并通过环氧基团进一步官能化,γ-(2, 3-环氧丙氧基)丙基三甲氧基硅烷 (KH560) 成功地对其进行了改性。结果表明,KH560-MoS2的环氧涂层在增强防腐性能方面具有显著优势。在进一步研究中,Jing等[44]通过二硫化钼的两步化学改性获得了KH560-PDA-MoS2杂化材料。在环氧树脂中加入KH560-PDA-MoS2后,发现纳米填料复合涂层的截面更粗糙,涂层具有一定的断裂韧性,并且复合涂层的耐腐蚀性比纯环氧涂层和KH560-MoS2的环氧涂层有所提高,KH560-PDA-MoS2的制备流程和防腐机制如图4所示。

石墨烯及其衍生物可以利用多种防腐机制协同作用抑制腐蚀。因其独特的二维片层结构,可以延长腐蚀介质的渗透路径,提高环氧树脂涂层的防腐蚀性能。还可以负载缓蚀剂并控制其释放,当涂层的屏蔽功能失效时也能够有效抑制钢体的腐蚀。此外,石墨烯还具有阴极保护作用,在富锌涂层中加入石墨烯,作为桥梁可以把孤立的锌颗粒和钢体连接起来,对钢体形成阴极保护。但是,石墨烯的负载量影响其作用效果,当负载量不可以把孤立的锌颗粒和钢体连成通路时,就会促进缺陷处钢体腐蚀[45]。为解决这个问题,可以对石墨烯进行改性。例如把石墨烯进行氧化或氟化处理,使其表面缺陷和官能团数量显著增加,导致导电性能显著下降,使得涂层具有长期稳定的防腐蚀性能[46];也可以使用氮化硼、二硫化钼等绝缘二维纳米材料代替石墨烯作为防腐涂层的填料。氮化硼作为绝缘二维纳米材料从根本上解决了导电性加速腐蚀的问题。即使氧和水能够通过缺陷扩散到氮化硼/环氧树脂涂层下面金属的表面,在很长一段时间内,也只能在缺陷附近发生局部氧化[37]。氮化硼还具有较高的热稳定性和化学稳定性,对腐蚀介质具有良好的抗渗透性。因此,氮化硼/环氧树脂涂料是长效防腐的首选。二硫化钼拥有1.8 eV的能带隙,为半导体材料,可以利用导电离子掺杂的方法,使其导电性能提高,发挥阴极保护机制[40];也可以用聚合物改性二硫化钼,增大能带隙,使其成为绝缘体,并且增强在环氧树脂中的分散性,提高环氧树脂防腐涂层的物理屏蔽效应。

在上述概述的基础上,表1列出环氧树脂基体中用于在3.5wt%NaCl腐蚀环境中保护金属基底的几种典型纳米填料的简要总结。综述了相同环境下的腐蚀电流密度 (Icorr)、腐蚀电位 (Ecorr)。表1还列出了这些二维纳米材料/环氧树脂涂层的其他重要特征,如稳定性、附着力、疏水性等。

表 1 二维层状材料在涂层中的防腐效果Table 1. Anticorrosion effect of two-dimensional layered materials in coatingsTwo-dimensional

nanomaterial/Epoxy

anticorrosive coatingCorrosion

environmentMass

fraction ω/wt%Preservative effect Key character Ref. Graphene/Epoxy 3.5wt%NaCl 0.5 Icorr:2.617×10−8 A·cm−2

Ecorr:−0.094 VGood adhesion and excellent corrosion resistance [24] Graphene oxide/Epoxy 3.5wt%NaCl 0.5 Icorr:3.061×10−7 A·cm−2

Ecorr:−0.690 VLow viscosity and good adhesion with steel surface [25] Fluorographene/Epoxy 3.5wt%NaCl 0.5 Icorr:6.199×10−7 A·cm−2

Ecorr:−0.696 VHigh hydrophobicity and good impermeability [26] Hexagonal boron nitride/Epoxy 3.5wt%NaCl 0.5 Icorr:4.960×10−8 A·cm−2

Ecorr:−0.608 VHigh thermal stability and excellent corrosion resistance [17] Molybdenum disulfide/Epoxy resin 3.5wt%NaCl 0.5 Icorr:7.474×10−9 A·cm−2

Ecorr:−0.0928 VGood physical shielding performance and long-term

stable corrosion resistance[42] Notes: Icorr—Corrosion current density; Ecorr—Corrosion potential. 3. 存在问题和解决方法

由于二维纳米材料的疏水性及片层之间的范德华力,在环氧树脂基体中容易团聚,分布杂乱无规则,降低了涂层的屏蔽性能。有机涂层和金属基体的界面通过物理吸附结合,涂层与金属之间的附着力较差。因此,从如何解决二维纳米材料的分散性、如何促进二维纳米材料在环氧树脂中有序排列、如何增强涂层与金属界面的附着力等三个方面来优化二维纳米材料作为填料在防腐涂料中的应用。

3.1 解决二维纳米材料团聚问题

二维纳米材料的表面积非常大,在粒子间的静电力、范德华力、化学键作用下,纳米粒子有使表面积减小的趋势,发生团聚现象[43]。环氧树脂中的二维纳米材料的团聚现象会降低环氧树脂的交联度,导致环氧树脂出现微裂纹、孔洞等缺陷,为腐蚀介质侵蚀基体提供途径(图5)[45],给环氧树脂涂层的物理性屏蔽能带来负面影响,大大降低环氧树脂涂层的耐腐蚀性能。

通过非共价改性,可以保留二维纳米材料的整体结构,利用共轭π-π相互作用、氢键相互作用对其进行表面修饰,抑制其在环氧树脂涂料中的团聚现象。Song等[46]将芘分子连接到石墨烯上,通过π-π键增强石墨烯片和环氧树脂界面之间的相互作用,从而提高其在环氧树脂中的分散性。氧化石墨烯含有大量的含氧极性官能团,使其表面可以通过氢键作用力进行修饰。Zhang等[47]首次尝试利用聚乙烯吡咯烷酮通过氢键改性氧化石墨烯,并将改性后的氧化石墨烯分散在环氧树脂中,结果表明改性氧化石墨烯在环氧树脂涂层中的分散更加均匀。Cui等[48]合成聚2-丁基苯胺,并使用其在液相中剥离氮化硼,叠层的氮化硼可以剥离成少量原子层,并且聚2-丁基苯胺对氮化硼进行表面改性,提高氮化硼在环氧树脂中的分散性,延缓金属腐蚀。

通过在二维纳米填料表面接枝官能团进行共价键改性,也可以抑制其在环氧树脂涂料中的团聚现象[49]。按接枝官能团的种类可分为有机官能团接枝改性、无机纳米粒子接枝改性、聚合物链接枝改性等。Pourhashem等[50]采用原位修饰的方法,通过在石墨烯表面封装纳米SiO2颗粒,促进石墨烯在环氧树脂中均匀分散,并且充当绝缘隔离物来抑制腐蚀。Di等[51]也采用相同的方式,以Fe3O4纳米材料原位修饰氧化石墨烯或氟化石墨烯,提高其在环氧树脂涂层中的分散性。Zhang等[52]利用聚多巴胺对有机和无机基质具有普遍黏附能力的特点来表面改性氮化硼,在氮化硼表面引发多巴胺的自氧化,随后用KH560接枝,h-BN@PDA-KH560在环氧树脂涂层中具有良好的分散性,使其显示出良好的防腐性能。

3.2 调控二维纳米材料的取向

与目前对纳米填料的分散性和相容性的大量研究相比,纳米填料的取向研究较少。同时,二维纳米材料在涂层基体中的排列和取向需要精确控制,尤其是二维纳米材料的宽高比和高各向异性,使得层状结构在提高涂层性能方面至关重要。尽管部分二维纳米材料由于具有磁性响应效应,但需要超高磁场 (9~16 T) 来排列二维纳米材料[53]。另一种简单的方法是赋予二维纳米材料磁性,即在其置于外部磁场之前,在其表面沉积磁性材料。这种修饰过的二维纳米材料可以在水平磁场作用下水平排列在环氧树脂中[7]。Ding等[54]利用表面接枝改性的方法,用Fe3O4改性石墨烯使其具有磁性,在外加磁场的作用下,调控其在环氧树脂中的取向。平行分级排列的磁性石墨烯显著增加了腐蚀介质的扩散阻力,提高了涂层的耐蚀性。这种调控取向的方法也适用于其他二维纳米材料,如氧化石墨烯、氟化石墨烯、氮化硼、二硫化钼等,以寻求更加优异的耐腐蚀性。

除了外加磁场,二维纳米材料也可以通过自组装的方法实现其在环氧树脂涂层中有序排列。例如,Li等[55]通过自组装方法发现,磺化石墨烯在水和水性环氧乳液中可以稳定。此外,在磺化石墨烯浓度为1.0wt%时,可以自发平行排列而不结块,显著提高了涂层的耐腐蚀性能。在Yousefi等[56]的研究中,水性环氧树脂中大面积氧化石墨烯的原位还原和自对齐 (平均面积191 μm2) 使还原氧化石墨烯纳米片自对齐成层状结构。这种密集堆积的层状结构具有较强的结合强度和耐腐蚀性。

3.3 提高复合涂层与钢体的附着力

涂层对钢体防护效果的好坏,除了涂层本身的防腐蚀性能,还取决于涂层与钢体之间的附着力,即它们之间的物理或化学作用力。一般认为化学附着更为牢固。二维纳米材料可以负载一些极性基团,与基材表面的极性基团发生化学作用,提高环氧树脂涂层的附着力。近些年来对附着力促进剂进行了大量研究,其中对硅烷偶联剂研究得较多。

硅烷偶联剂分子链两端一般都带有活性基团, 其结构为YRa-Si-Xb。其中:Y是一种活性基团,如氨基、环氧基等,可以与涂料体系中的活性基团反应;X是烷氧基团,通常可以水解成极性的硅羟基,吸附于钢体表面并与之反应[57]。这样硅烷偶联剂就能够在涂层和钢体之间形成一种连接纽带,大幅度提升涂层与钢体的附着力。在这个反应中,由于石墨烯表面官能团很少,一般将石墨烯部分转化为氧化石墨烯,使其表面含有可以与硅烷偶联剂反应的含氧基团。Parhizkar等[58]在N, N-二甲基甲酰胺溶液中加入氧化石墨烯和γ-氨丙基三乙氧基硅烷 (KH550),并在85℃下获得功能性氧化石墨烯(FGO)。采用FGO溶液对钢板进行处理,干燥后涂敷环氧树脂涂层,涂层的附着力和阻隔性能得到了显著改善(图6)。

4. 结论和展望

本文综述了石墨烯及其衍生物、氮化硼、二硫化钼在环氧树脂防腐涂料中的应用、作用机制及遇到的问题。二维材料具有类似的平面结构,由于其原子间的作用力,原子间孔径很小,且由于π-π相互作用,腐蚀介质通过需要克服很大的能垒,因此二维纳米材料具有很好的物理屏蔽性能。根据二维纳米材料在防腐涂料中的作用机制,阐述了其在环氧树脂防腐涂料的屏障保护作用、抑制保护作用和牺牲保护作用。最后,从二维材料在环氧树脂涂层的均匀分散、取向调控及提升环氧树脂涂层和钢体之间的附着力三个方面提出了解决方案。纵观二维纳米材料在环氧树脂防腐涂层中应用的研究现状,还存在以下问题亟需解决:

(1) 二维纳米材料与环氧树脂涂层基体之间较弱的相互作用和相容性严重限制其耐腐蚀能力,界面作用力较弱,腐蚀介质可以轻松穿过涂层腐蚀基体,如何提高二维纳米填料与树脂基体的相容性对于涂层防腐十分重要;

(2) 提高导电二维纳米材料增强阴极保护涂层是一项艰巨的任务。具体而言,通过优化成分含量 (导电二维纳米材料/锌含量比) 和涂层内部结构来同时促进电子转移和屏蔽保护尚不明确;

(3) 二维层状材料作为一类环保的纳米填料,可取代涂料中的防腐有机物和金属微粒,但有关其防腐机制的研究并不透彻,因此在对二维层状材料防腐过程深入表征的基础上,结合分子动力学模拟,对其防腐机制进行更加深入的研究;

(4) 任何一种二维纳米材料改善涂层防腐蚀性能的效果都是有限的,因此寻求多种二维纳米材料的优化组合,发挥其在涂层防腐中的协同作用是未来应该着力研究的一个重要方向。

-

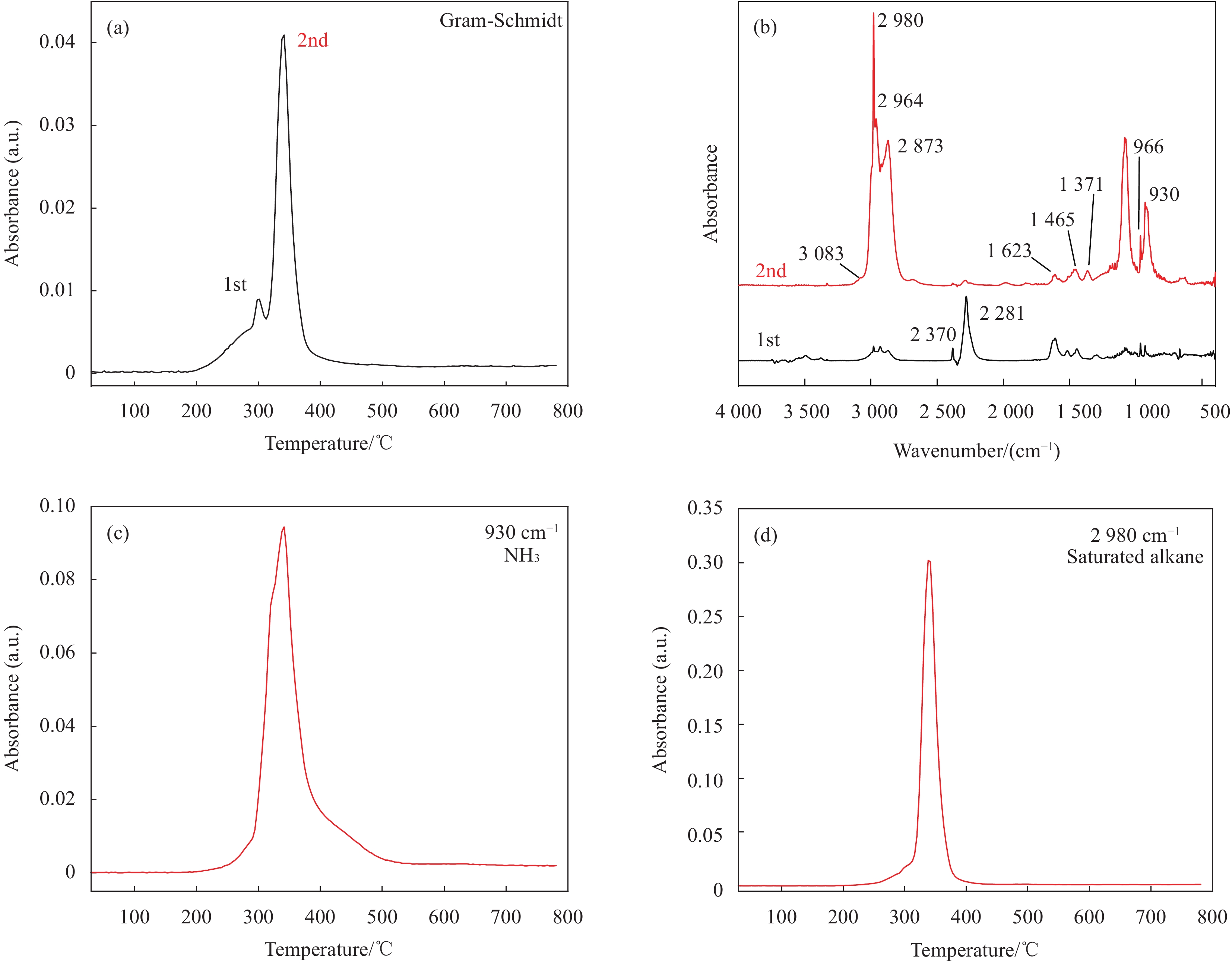

图 7 样品PUA-4的TG-IR分析:(a) Gram-Schmidt曲线;(b) Gram-Schmidt曲线峰值下FTIR光谱;(c)全过程NH3吸收光谱;(d)全过程饱和烷烃吸收光谱

Figure 7. TG-IR of PUA-4: (a) Gram-Schmidt curve; (b) FTIR of sample at the peaks of Gram-Schmidt curves; (c) Whole process absorption spectrum of NH3; (d) Whole process absorption spectrum of saturated alkane

表 1 喷涂耐烧蚀绝热材料配方

Table 1 Formulation of sprayed ablation resistant material

Sample Component A/

wt%Component B/

wt%PTA-PA/wt% PUA 66.7 33.3 – PUA-1 63.3 31.7 5.0 PUA-2 60.0 30.0 10.0 PUA-3 56.7 28.3 15.0 PUA-4 53.3 26.7 20.0 Note: PUA−Neat polyurea. 表 2 PUA复合材料极限氧指数(LOI)、UL-94、氧乙炔烧蚀和锥形量热仪测试数据

Table 2 Results of limiting oxygen index (LOI), UL-94, oxyacetylene ablation (OTA) and cone calorimeter tests for PUA composites

Sample UL-94 LOI/

%LAR/

(mm·s−1)PHRR/

(kW·m−2)TPHRR/

sTHR/

(MJ·m−2)FPI/

(m2·s·kW−1)FGI/

(kW·(m2·s)−1)TTI/

sDripping Rating PUA Y V-2 22.2 0.853 654 158 68.3 0.032 4.139 21 PUA-1 Y V-2 24.1 0.774 454 168 68.0 0.042 2.702 19 PUA-2 Y V-2 26.5 0.701 326 227 66.9 0.055 1.436 18 PUA-3 N V-0 27.0 0.695 268 264 66.0 0.063 1.015 17 PUA-4 N V-0 28.4 0.684 185 329 55.8 0.092 0.562 17 Notes: N—No; Y—Yes; LOI—Limiting oxygen index; LAR—Linear ablation rate; PHRR—Peak heat release rate; TPHRR—Peak time corresponding to the heat release rate; THR—Total heat release; FPI—Fire performance index (FPI=TTI/PHRR); FGI—Fire growth index (FGI=PHRR/TPHRR); TTI—Ignition time. -

[1] 张帅, 张隐, 潘明珠. 阻燃预警智能涂层的研究进展[J]. 复合材料学报, 2021, 38(1): 55-66. ZHANG Shuai, ZHANG Yin, PAN Mingzhu. Research progress of intelligent flame retardant coating with fire-warning capabilities[J]. Acta Materiae Compositae Sinica, 2021, 38(1): 55-66(in Chinese).

[2] YUAN B H, SUN Y R, CHEN X F, et al. Poorly-/well-dispersed graphene: Abnormal influence on flammability and fire behavior of intumescent flame retardant[J]. Composites Part A: Applied Science and Manufacturing, 2018, 109: 345-354. DOI: 10.1016/j.compositesa.2018.03.022

[3] SUN Y R, YUAN B H, SHANG S, et al. Surface modification of ammonium polyphosphate by supramolecular assembly for enhancing fire safety properties of polypropylene[J]. Composites Part B: Engineering, 2020, 181: 107588. DOI: 10.1016/j.compositesb.2019.107588

[4] 程鹏飞, 徐文总, 程传明, 等. 改性鸡蛋壳协效膨胀型阻燃剂对热塑性聚氨酯弹性体阻燃抑烟性能的影响[J]. 复合材料学报, 2023, 40(9): 5170-5180. CHENG Pengfei, XU Wenzong, CHENG Chuanming, et al. Effect of modified chicken eggshell and intumescent flame retardant on flame retardancy and smoke suppression of thermoplastic polyurethane elastomer[J]. Acta Materiae Compositae Sinica, 2023, 40(9): 5170-5180(in Chinese).

[5] 李茁实, 程文华, 董春, 等. 微胶囊化膨胀型阻燃剂与有机蒙脱土协效阻燃乙烯-醋酸乙烯共聚物性能[J]. 复合材料学报, 2021, 38(8): 2546-2553. LI Zhuoshi, CHENG Wenhua, DONG Chun, et al. Synergistic properties of microencapsulated intumescent flame retardant-organically modified montmorillonite/ethylene-vinyl acetate copolymer composites[J]. Acta Materiae Compositae Sinica, 2021, 38(8): 2546-2553(in Chinese).

[6] SUN Y R, YU B, LIU Y, et al. Novel bio-based nanosheets: Improving the fire safety, electromagnetic shielding and mechanical properties of polylactic acid[J]. Composites Part A: Applied Science and Manufacturing, 2024, 179: 108044. DOI: 10.1016/j.compositesa.2024.108044

[7] MNGOMEZULU M E, JOHN M J, JACOBS V, et al. Review on flammability of biofibres and biocomposites[J]. Carbohydrate Polymers, 2014, 111(20): 149-182.

[8] CHEN H D, WANG J H, NI A Q, et al. Effect of novel intumescent flame retardant on mechanical and flame retardant properties of continuous glass fibre reinforced polypropylene composites[J]. Composite Structures, 2018, 203: 894-902. DOI: 10.1016/j.compstruct.2018.07.071

[9] SUN Y R, YU B, LIU Y, et al. Design of 2D charring-foaming agent for highly efficient intumescent flame retardant polylactic acid composites[J]. Composites Communications, 2023, 43: 101720. DOI: 10.1016/j.coco.2023.101720

[10] ZHAN Y Y, WU X J, WANG S S, et al. Synthesis of a bio-based flame retardant via a facile strategy and its synergistic effect with ammonium polyphosphate on the flame retardancy of polylactic acid[J]. Polymer Degradation and Stability, 2021, 191: 109684. DOI: 10.1016/j.polymdegradstab.2021.109684

[11] WU Q, CUI X Y, MU C Z, et al. Toward a new approach to synchronously improve the fire performance and toughness of polylactic acid by the incorporation of facilely synthesized ammonium polyphosphate derivatives[J]. Composites Part A: Applied Science and Manufacturing, 2021, 150: 106595. DOI: 10.1016/j.compositesa.2021.106595

[12] JIN X D, GU X Y, CHEN C, et al. The fire performance of polylactic acid containing a novel intumescent flame retardant and intercalated layered double hydroxides[J]. Journal of Materials Science, 2017, 52(20): 12235-12250.

[13] TAWIAH B, ZHOU Y Y, YUEN R K K, et al. Microporous boron based intumescent macrocycle flame retardant for poly (lactic acid) with excellent UV protection[J]. Chemical Engineering Journal, 2020, 402: 126209. DOI: 10.1016/j.cej.2020.126209

[14] 解维闵, 梁晓正, 赵晓光, 等. 黏土矿物基纳米复合阻燃材料的研究进展[J]. 材料导报, 2021, 35(23): 23192-23204. DOI: 10.11896/cldb.20110151 XIE Weimin, LIANG Xiaozheng, ZHAO Xiaoguang, et al. Research progress of clay mineral-based nanocomposite flame retardants[J]. Materials Reports, 2021, 35(23): 23192-23204(in Chinese). DOI: 10.11896/cldb.20110151

[15] 贾锡宁, 王严, 石慧, 等. 兼具阻燃和导热性能的环氧树脂复合材料: 石墨烯纳米片杂化三聚氰胺磷酸盐的作用[J]. 复合材料学报, 2023, 40(3): 1395-1405. JIA Xining, WANG Yan, SHI Hui, et al. Epoxy resin composites with flame retardancy and thermal conductivity: Effect of graphene nanoplatelets hybridized with melamine phosphate[J]. Acta Materiae Compositae Sinica, 2023, 40(3): 1395-1405(in Chinese).

[16] SUN Y R, YU B, LIU Y, et al. Bio-inspired surface manipulation of halloysite nanotubes for high-performance flame retardant polylactic acid nanocomposites[J]. Nano Research, 2024, 17(3): 1595-1606. DOI: 10.1007/s12274-023-6050-y

[17] GAO Y Y, DENG C, DU Y Y, et al. A novel bio-based flame retardant for polypropylene from phytic acid[J]. Polymer Degradation and Stability, 2019, 161: 298-308. DOI: 10.1016/j.polymdegradstab.2019.02.005

[18] HUANG Z, WANG Z. Synthesis of a bio-based piperazine phytate flame retardant for epoxy resin with improved flame retardancy and smoke suppression[J]. Polymers for Advanced Technologies, 2021, 32(11): 4282-4295. DOI: 10.1002/pat.5429

[19] International Organization for Standardization. Cellular plastics and rubbers—Determination of apparent density: ISO 845[S]. Geneva: International Organization for Standardization, 2006.

[20] 国防科学技术工业委员会. 烧蚀材料烧蚀试验方法: GJB 323A—1996[S]. 北京: 国防科学技术出版社, 1996. State Science and Technology Commission of National Defense. Test methods for ablation of ablators: GJB 323A—1996[S]. Beijing: National Defense Science and Technology Press, 1996(in Chinese).

[21] American Society for Testing and Materials. Standard test method for measuring the minimum oxygen concentration to support candle-like combustion of plastics (oxygen index): ASTM D2863-97[S]. West Conshohocken, PA: ASTM International, 2023.

[22] International Organization for Standardization. Reaction to fire tests—Heat release, smoke production and mass loss rate: Part 1: Heat release rate (cone calorimeter method) and smoke production rate (dynamic measurement): ISO 5660-1[S]. Geneva: International Organization for Standardization, 2015.

[23] American Society for Testing and Materials. Standard test method for measuring the comparative burning characteristics of solid plastics in a vertical position: ASTM D3801[S]. West Conshohocken, PA: ASTM International, 2020.

[24] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶 拉伸应力应变性能的测定: GB/T 528—2009[S]. 北京: 中国标准出版社, 2009. General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Rubber, vulcanized or thermoplastic—Determination of tensile stress-strain properties: GB/T 528—2009[S]. Beijing: Standards Press of China, 2009(in Chinese).

[25] GUNASEKARAN S, ANITA B. Spectral investigation and normal coordinate analysis of piperazine[J]. Indian Journal of Pure and Applied Physics, 2008, 46(12): 833-838.

[26] SUN Y R, LIU Y, ZOU Y Y, et al. Poorly-/well-dispersed Fe3O4: Abnormal influence on electromagnetic wave absorption behavior of high-mechanical performance polyurea[J]. Chemical Engineering Journal, 2024, 493: 152833.

[27] XU M J, XIA S Y, LIU C, et al. Preparation of poly(phosphoric acid piperazine) and its application as an effective flame retardant for epoxy resin[J]. Chinese Journal of Polymer Science, 2018, 36(5): 655-664. DOI: 10.1007/s10118-018-2036-8

[28] XIAO X, HU S, ZHAI J G, et al. Thermal properties and combustion behaviors of flame-retarded glass fiber-reinforced polyamide 6 with piperazine pyrophosphate and aluminum hypophosphite[J]. Journal of Thermal Analysis and Calorimetry, 2016, 125(1): 175-185. DOI: 10.1007/s10973-016-5391-0

[29] WANG X G, WANG S H, WANG W J, et al. The flammability and mechanical properties of poly (lactic acid) composites containing Ni-MOF nanosheets with polyhydroxy groups[J]. Composites Part B: Engineering, 2020, 183: 107568. DOI: 10.1016/j.compositesb.2019.107568

[30] PAN N, JIN Y D, WANG X Q, et al. A self-assembled supramolecular material containing phosphoric acid for ultrafast and efficient capture of uranium from acidic solutions[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(1): 950-960. DOI: 10.1021/acssuschemeng.8b04596

[31] LECOUVET B, SCLAVONS M, BAILLY C, et al. A comprehensive study of the synergistic flame retardant mechanisms of halloysite in intumescent polypropylene[J]. Polymer Degradation and Stability, 2013, 98(11): 2268-2281. DOI: 10.1016/j.polymdegradstab.2013.08.024

[32] SHAO Z B, DENG C, TAN Y, et al. An efficient mono-component polymeric intumescent flame retardant for polypropylene: Preparation and application[J]. ACS Applied Materials & Interfaces, 2014, 6(10): 7363-7370. DOI: 10.1021/am500789q

[33] DENG C L, DU S L, ZHAO J, et al. An intumescent flame retardant polypropylene system with simultaneously improved flame retardancy and water resistance[J]. Polymer Degradation and Stability, 2014, 108: 97-107. DOI: 10.1016/j.polymdegradstab.2014.06.008

[34] YUAN B H, FAN A, YANG M, et al. The effects of graphene on the flammability and fire behavior of intumescent flame retardant polypropylene composites at different flame scenarios[J]. Polymer Degradation and Stability, 2017, 143: 42-56. DOI: 10.1016/j.polymdegradstab.2017.06.015

[35] SCHARTEL B, HULL T R. Development of fire-retarded material—Interpretation of cone calorimeter data[J]. Fire and Materials, 2010, 31(5): 327-354.

[36] 程博, 安晓航, 李定华, 等. ATH/ADP 配比对EVA阻燃性能及机理转变的影响[J]. 无机材料学报, 2024, 39(5): 509-516. DOI: 10.15541/jim20230502 CHENG Bo, AN Xiaohang, LI Dinghua, et al. Flame-retardant properties and transformation of flame-retardant mechanisms of EVA: Effect of ATH/ADP ratio[J]. Journal of Inorganic Materials, 2024, 39(5): 509-516 (in Chinese). DOI: 10.15541/jim20230502

[37] LIU L, HU J, ZHUO J L, et al. Synergistic flame retardant effects between hollow glass microspheres and magnesium hydroxide in ethylene-vinyl acetate composites[J]. Polymer Degradation and Stability, 2014, 104(1): 87-94.

[38] WANG X, XING W Y, FENG X, et al. Functionalization of graphene with grafted polyphosphamide for flame retardant epoxy composites: Synthesis, flammability and mechanism[J]. Polymer Chemistry, 2014, 5(4): 1145-1154. DOI: 10.1039/C3PY00963G

[39] 汤连东, 吴袁泊, 袁利萍, 等. 磷钨酸插层ZnAl层状双金属氢氧化物协同膨胀阻燃剂对环氧-聚酰胺树脂的阻燃作用[J]. 复合材料学报, 2020, 37(9): 2125-2136. TANG Liandong, WU Yuanbo, YUAN Liping, et al. Flame retardant effect of phosphotungstic acid intercalated ZnAl layered double hydroxides and intumescent flame retardant on epoxy-polyamide resin[J]. Acta Materiae Compositae Sinica, 2020, 37(9): 2125-2136(in Chinese).

[40] PENG H Q, ZHOU Q, WANG D Y, et al. A novel charring agent containing caged bicyclic phosphate and its application in intumescent flame retardant polypropylene systems[J]. Journal of Industrial and Engineering Chemistry, 2008, 14(5): 589-595. DOI: 10.1016/j.jiec.2008.05.011

[41] 马静, 刘美哲, 朱明轩, 等. 聚焦磷酸哌嗪-埃洛石纳米管-三聚氰胺氰尿酸盐协效阻燃环氧树脂[J]. 材料工程, 2023, 51(6): 177-185. DOI: 10.11868/j.issn.1001-4381.2022.000243 MA Jing, LIU Meizhe, ZHU Mingxuan, et al. Piperazine polypyrophosphat-halloysite nanotubes-melamine cyanurate synergistic flame retardant epoxy resin[J]. Journal of Materials Engineering, 2023, 51(6): 177-185(in Chinese). DOI: 10.11868/j.issn.1001-4381.2022.000243

[42] 刘超, 陈雨鑫, 尹付琳, 等. 双DOPO悬垂型阻燃剂化学修饰水性聚氨酯的性能[J]. 复合材料学报, 2023, 40(5): 2653-2669. LIU Chao, CHEN Yuxin, YIN Fulin, et al. Chemical modification of waterborne polyurethane with double DOPO pendant flame retardant[J]. Acta Materiae Compositae Sinica, 2023, 40(5): 2653-2669(in Chinese).

-

期刊类型引用(16)

1. 杨小刚,孔明洁,赵家玉,李斌. 硫酸二次掺杂聚苯胺/石墨烯/碳纳米管复合材料制备及其防腐性能. 复合材料学报. 2025(02): 924-936 .  本站查看

本站查看

2. 戴丽艳. 复合催化剂Ag-Ti/碳纤维的制备及光催化降解罗丹明B. 化学工程师. 2024(03): 11-13+18 .  百度学术

百度学术

3. 方媛,闫嘉琪,孙景齐,韩鹏辉,赵顺强,曾立军,杨杰,朱建锋. Ti_3C_2T_x改性环氧树脂涂层的制备及其在人工海水环境下的摩擦学性能研究. 陕西科技大学学报. 2024(03): 135-143 .  百度学术

百度学术

4. 陈明锴,陈磊,马彦军,张定军,周惠娣,陈建敏. 润滑耐磨耐蚀功能一体化有机黏结涂层的研究进展. 高分子材料科学与工程. 2024(04): 182-190 .  百度学术

百度学术

5. 查向浩,安旭霞,李飞星,李有文,张玉才. 二维纳米材料的研究进展. 化工新型材料. 2024(09): 31-35+42 .  百度学术

百度学术

6. 闫圣刚,周宇,许豪,宋光磊,于良民. 基于Ce-MOF@MXene复合材料涂层的防腐性能研究. 材料科学与工艺. 2024(06): 76-86 .  百度学术

百度学术

7. 谢煜彬,胡国梁,张笑晴,雷彩红. 磷杂菲-厚朴酚基环氧低聚物的合成及其固化树脂阻燃性能. 复合材料学报. 2024(12): 6545-6558 .  本站查看

本站查看

8. 董邯海,程勇,程庆利,杨珂,周日峰,毕伟扬. 六亚甲基二异氰酸酯微胶囊的制备及其在自修复涂料中的应用. 表面技术. 2023(04): 272-284 .  百度学术

百度学术

9. 何阳,李思盈,李传强,袁小亚,郑旭煦. 热还原氧化石墨烯/环氧树脂复合涂层的防腐性能. 化工进展. 2023(04): 1983-1994 .  百度学术

百度学术

10. 李翊,刘杰,刘长沙,邹阳,蒋俊,孙敬庭. 基于阴极电位保护的覆土式储罐化学稳定性与耐腐蚀试验. 粘接. 2023(05): 126-129 .  百度学术

百度学术

11. 苏新悦,孔存辉,庆达,赵英娜,王建省. Ti_3C_2/SrTiO_3复合材料的制备及其光电化学阴极保护性能. 复合材料学报. 2023(07): 3964-3972 .  本站查看

本站查看

12. 田经纬,白艳博,李承高,咸贵军. 尼龙6填料对碳纤维-环氧树脂复合材料力学与摩擦磨损性能的提升机制. 复合材料学报. 2023(09): 5011-5025 .  本站查看

本站查看

13. 刘嘉源,张宏亮,左晓宝,邹欲晓. 纳米聚多巴胺六方氮化硼–二氧化硅/环氧树脂涂层对水泥砂浆抗碳化能力的影响. 复合材料学报. 2023(09): 5046-5056 .  本站查看

本站查看

14. 张泽旭,王睿,白旭秋,郑峻,袁才登. 氧化石墨烯改性EP/PU防腐涂料的制备及性能. 塑料. 2023(05): 6-10+15 .  百度学术

百度学术

15. 栗洋,牛永平,杨康,杜三明,杨璐璐. 二硫化钼/硫化铜纳米杂化材料改性环氧树脂摩擦学性能研究. 化工新型材料. 2023(12): 133-137+142 .  百度学术

百度学术

16. 郑天麒. 碳纤维改性环氧树脂基复合材料的制备及性能研究. 功能材料. 2022(12): 12147-12151 .  百度学术

百度学术

其他类型引用(12)

-

目的

本研究旨在解决聚合物材料的易燃性问题,同时克服传统膨胀型阻燃体系存在的吸湿性大、阻燃效率低和与基体相容性差等缺陷。通过结合气相和凝聚相的阻燃设计理念,致力于设计一种三位一体膨胀型阻燃剂(PTA-PA),建立PTA-PA与PUA复合材料热稳定性、阻燃性能和力学性能之间的关系,以期提高聚脲(PUA)材料的阻燃性能和力学性能。。

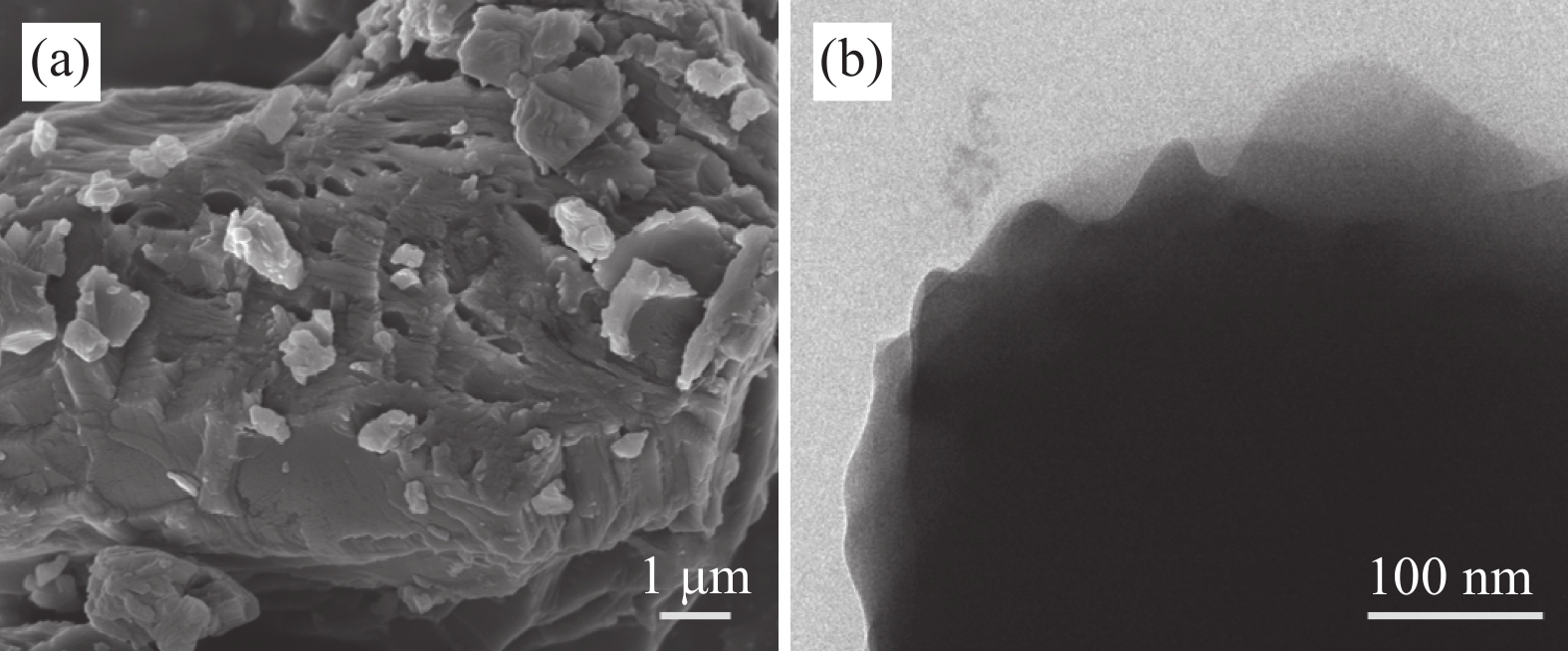

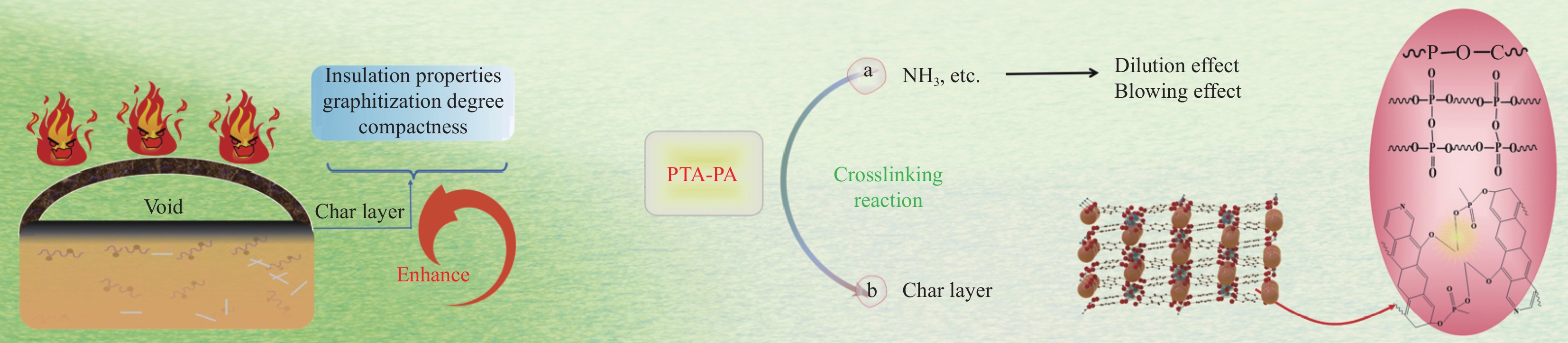

方法基于超分子自组装技术,通过精确控制反应条件,制备出集酸源、碳源和气源特性为一体的PTA-PA阻燃剂。将不同含量的PTA-PA与PUA基体混合,采用机械搅拌和热处理工艺制备出一系列PTA-PA基PUA复合材料。对PTA-PA基PUA复合材料开展热稳定性、UL-94垂直燃烧、极限氧指数(LOI)、氧乙炔烧蚀、锥形量热仪及力学性能测试。获得UL-94垂直燃烧等级、LOI值、线烧蚀率(LAR)、热释放速率峰值(PHRR)和总热释放量(THR)等阻燃测试参数。采用热重-红外联用(TG-IR)检测技术,分析PUA复合材料在热降解过程中产生的气相产物;使用SEM、XPS、拉曼光谱等测试手段表征经锥形量热仪测试后的凝聚相产物。基于气相及凝胶相产物分析结果,结合热分析数据,总结PTA-PA的阻燃机制。

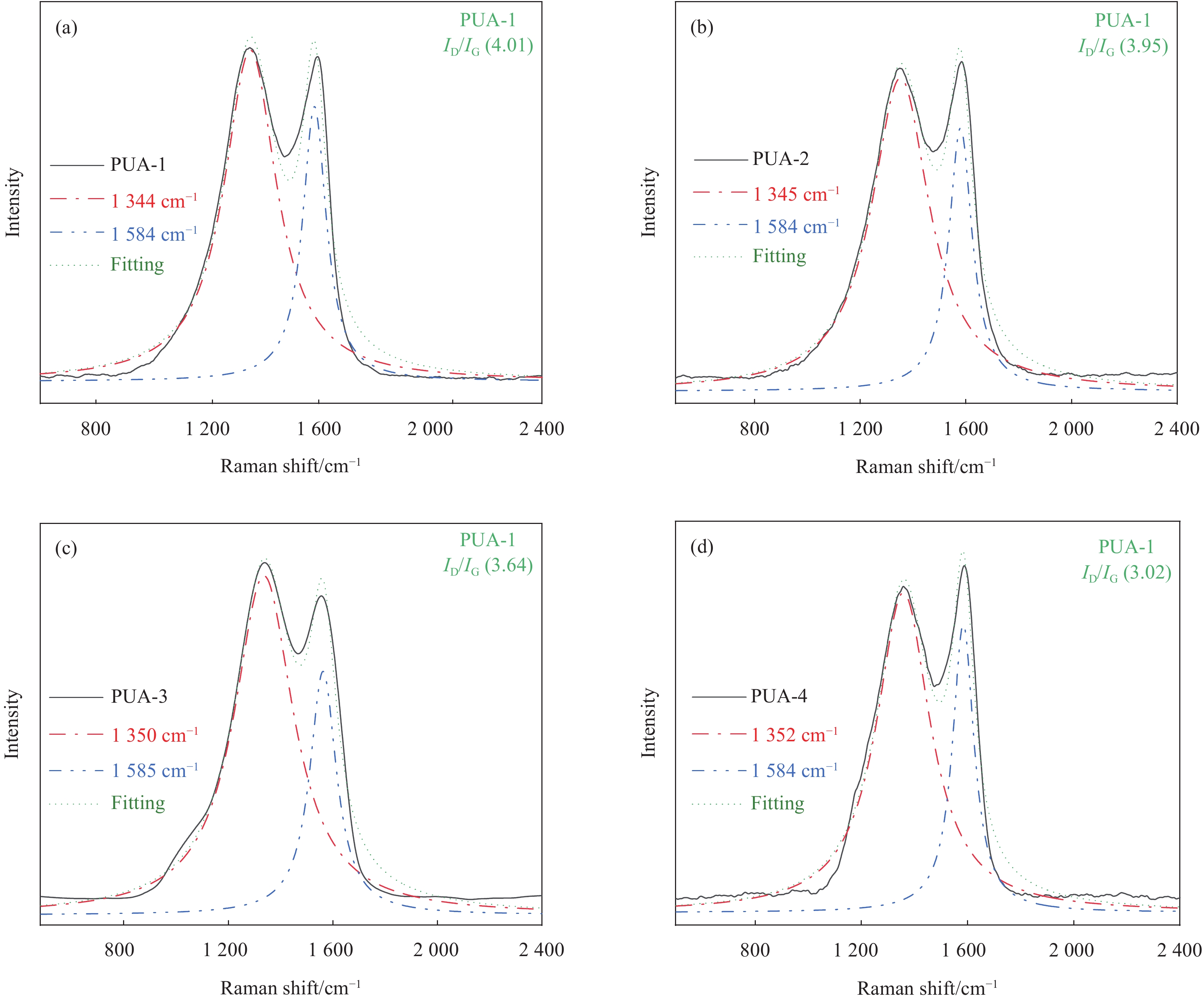

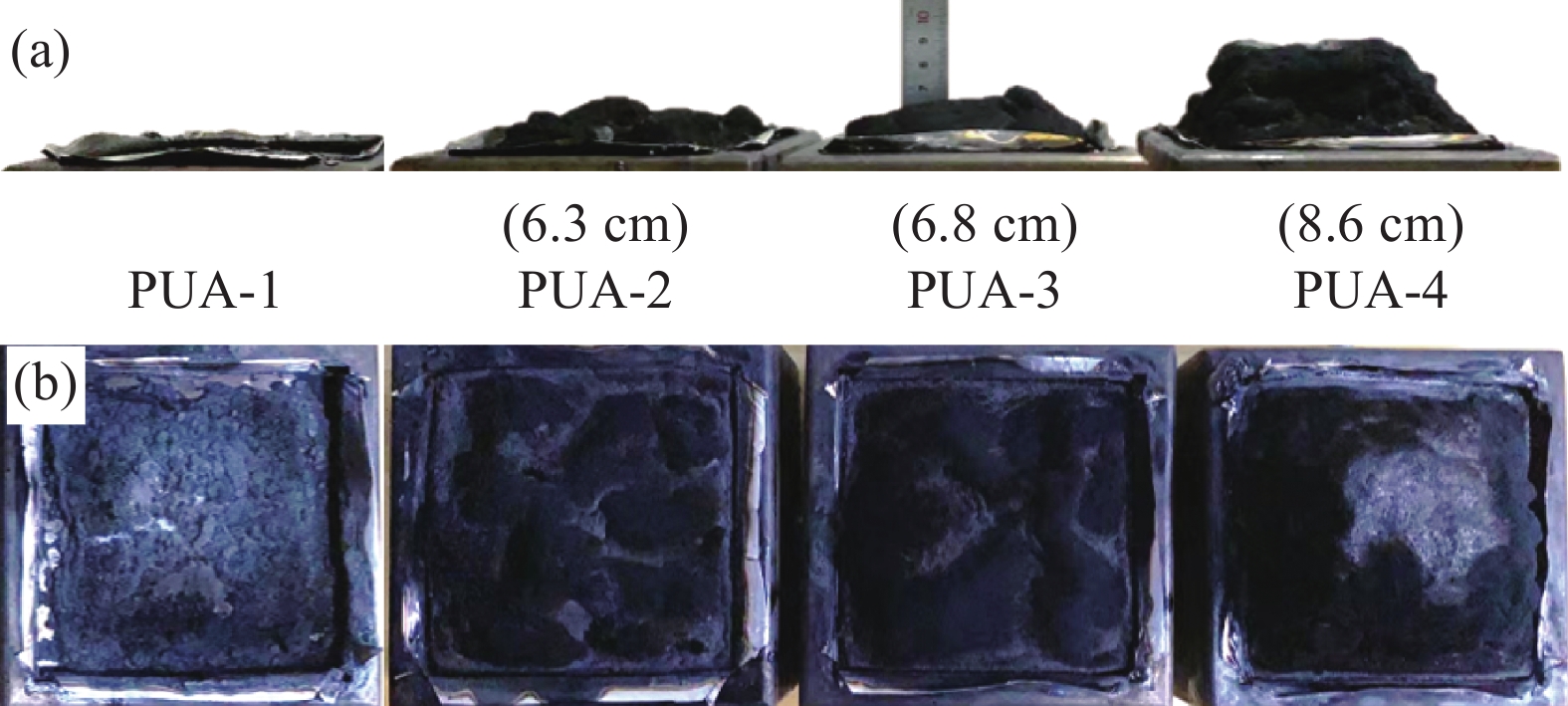

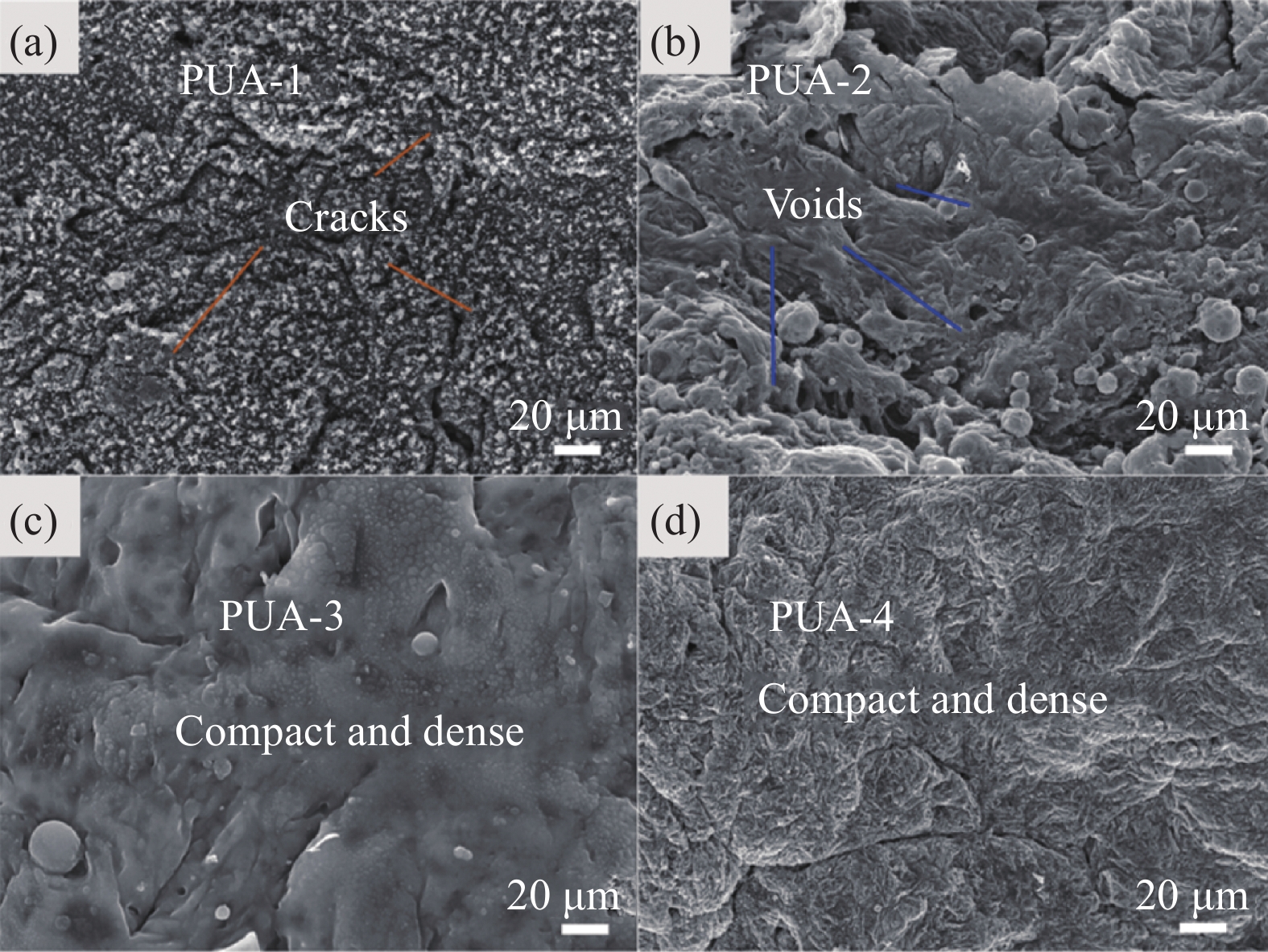

结果TGA热稳定实验数据显示,添加20.0 wt% PTA-PA的PUA复合材料(PUA-4)在800 ℃时的残炭量为21.9%,相较于未添加PTA-PA的PUA,其热稳定性得到显著提升。UL-94垂直燃烧测试结果表明,PUA-4的燃烧顺利通过UL-94 V-0级测试,这反映了PTA-PA对PUA材料阻燃性能的显著改善。LOI测试结果显示,PUA-4的LOI值从22.2%提升至28.4%,这一变化进一步证实了PTA-PA在增强材料阻燃性能方面的有效性。PUA-4的LAR较纯PUA降低了19.8%。在锥形量热仪测试中,相比于纯样PUA,PUA-4的PHRR和THR值分别降低了71.7%和18.3%。通TG-IR检测发现,PUA-4复合材料在热解过程中会释放出CO、NH和HO等不可燃气体。这些不可燃气体可稀释燃烧反应区可燃产物和氧气。凝聚相产物表明,PTA-PA的添加促进了含磷和含氮化合物的形成,这些化合物有助于形成稳定的炭层,从而提高材料的阻燃性能。力学性能测试结果表明,PUA复合材料的断裂伸长率随PTA-PA的增加而降低,断裂强度则呈现先增加后降低的趋势。

结论本研究成功合成了三位一体膨胀型阻燃剂PTA-PA,并通过一系列实验方法,系统评估了其对PUA材料阻燃性能和力学性能的影响。实验结果表明,PTA-PA的添加显著提高了PUA-4复合材料的热稳定性和阻燃性能,同时对材料的力学性能有一定影响。通过产物分析和机理探究,本研究揭示了PTA-PA在提高材料阻燃性能方面的潜在机制,为高性能阻燃聚合物复合材料的开发提供了实验依据和理论支持。这些发现有望推动无卤阻燃剂在高分子材料中的应用发展,为提高材料的火灾安全性提供了解决方案。

下载:

下载: