Crushing energy absorption mechanisms of the composite-metal-foam hybrid tubes under axial and oblique loads

-

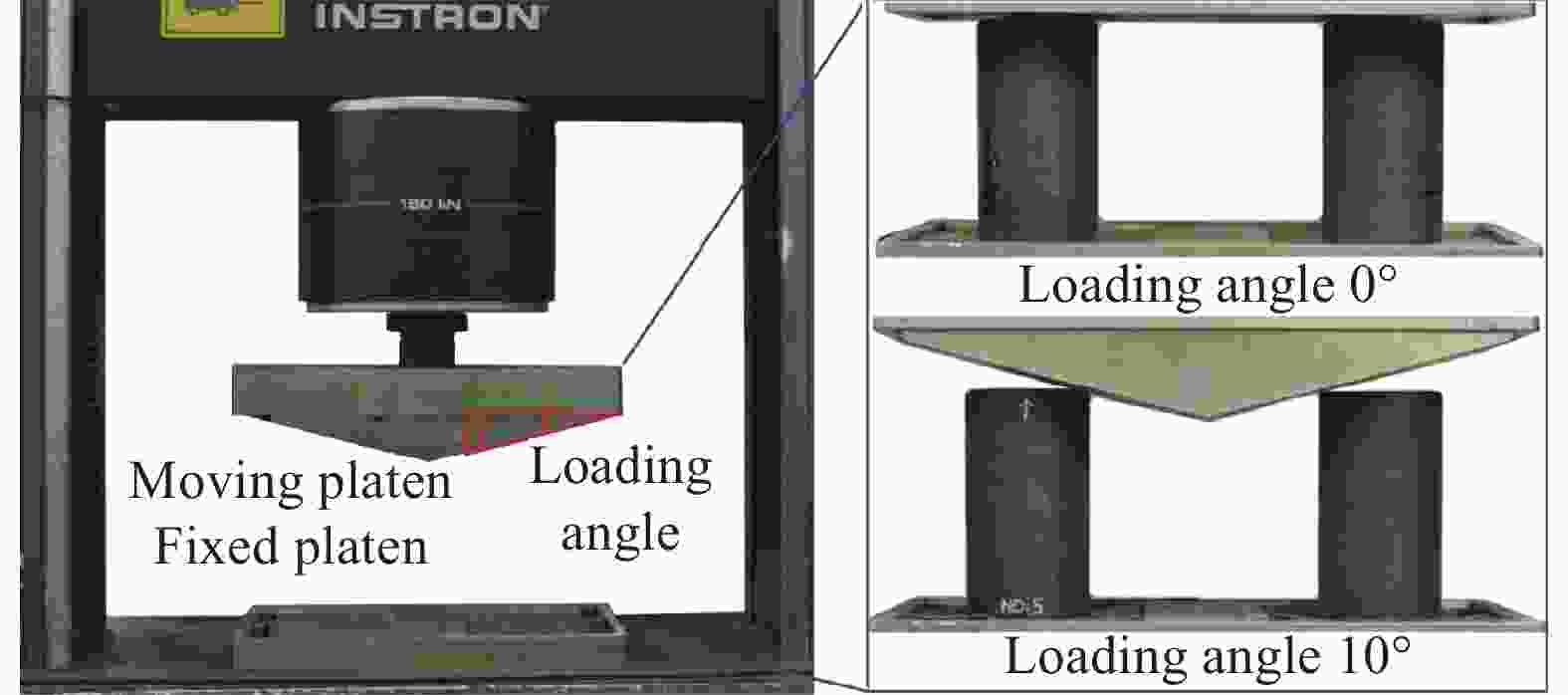

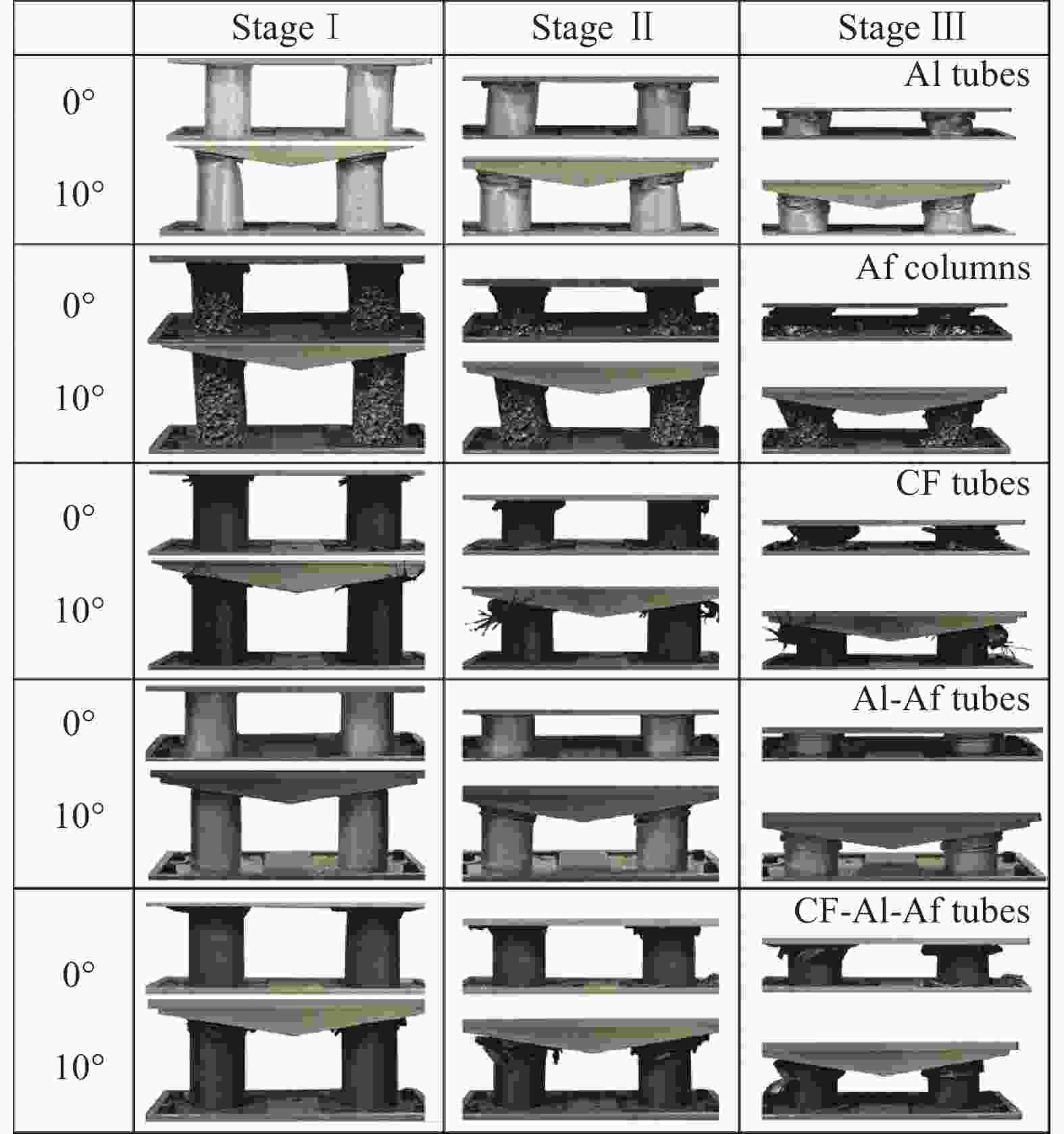

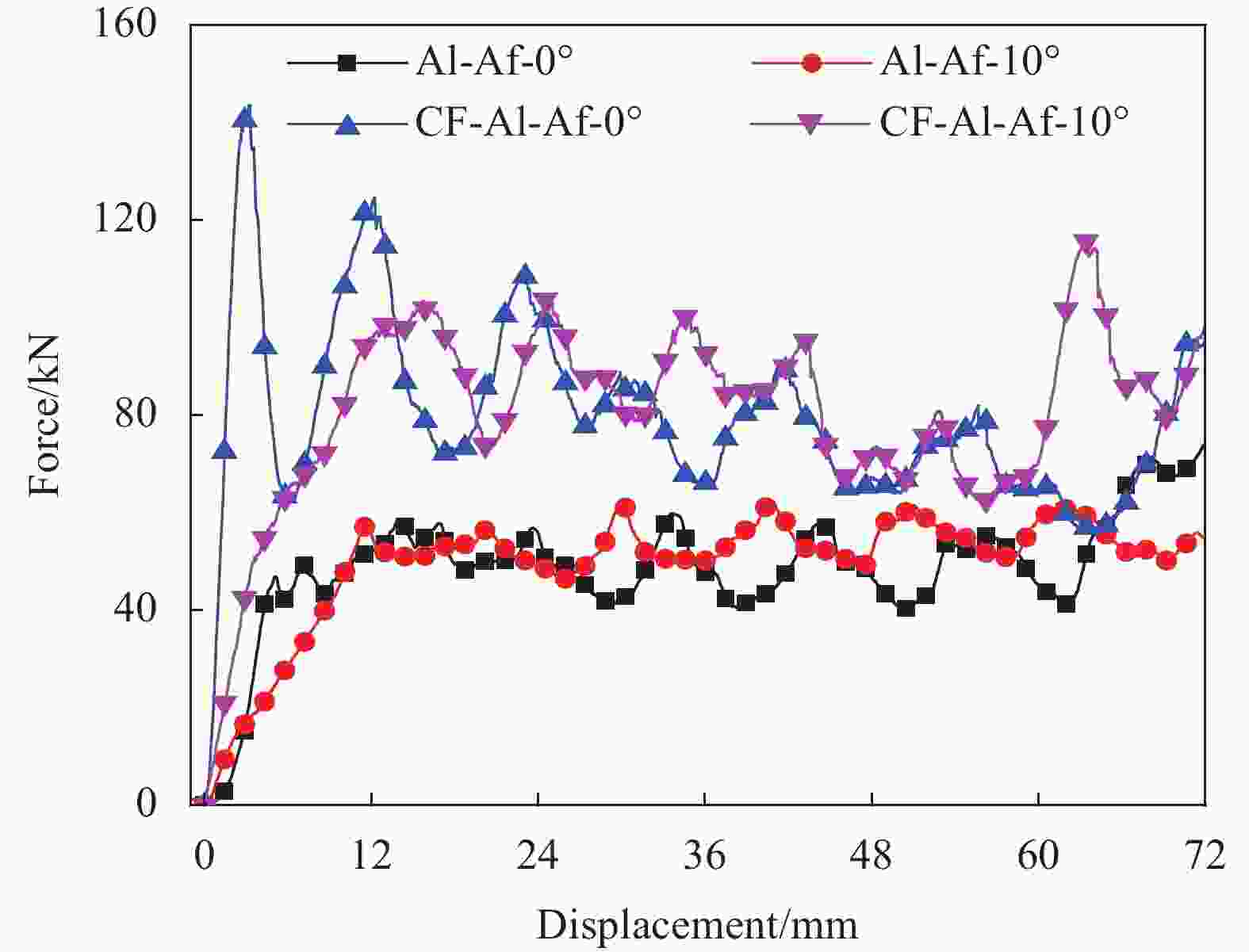

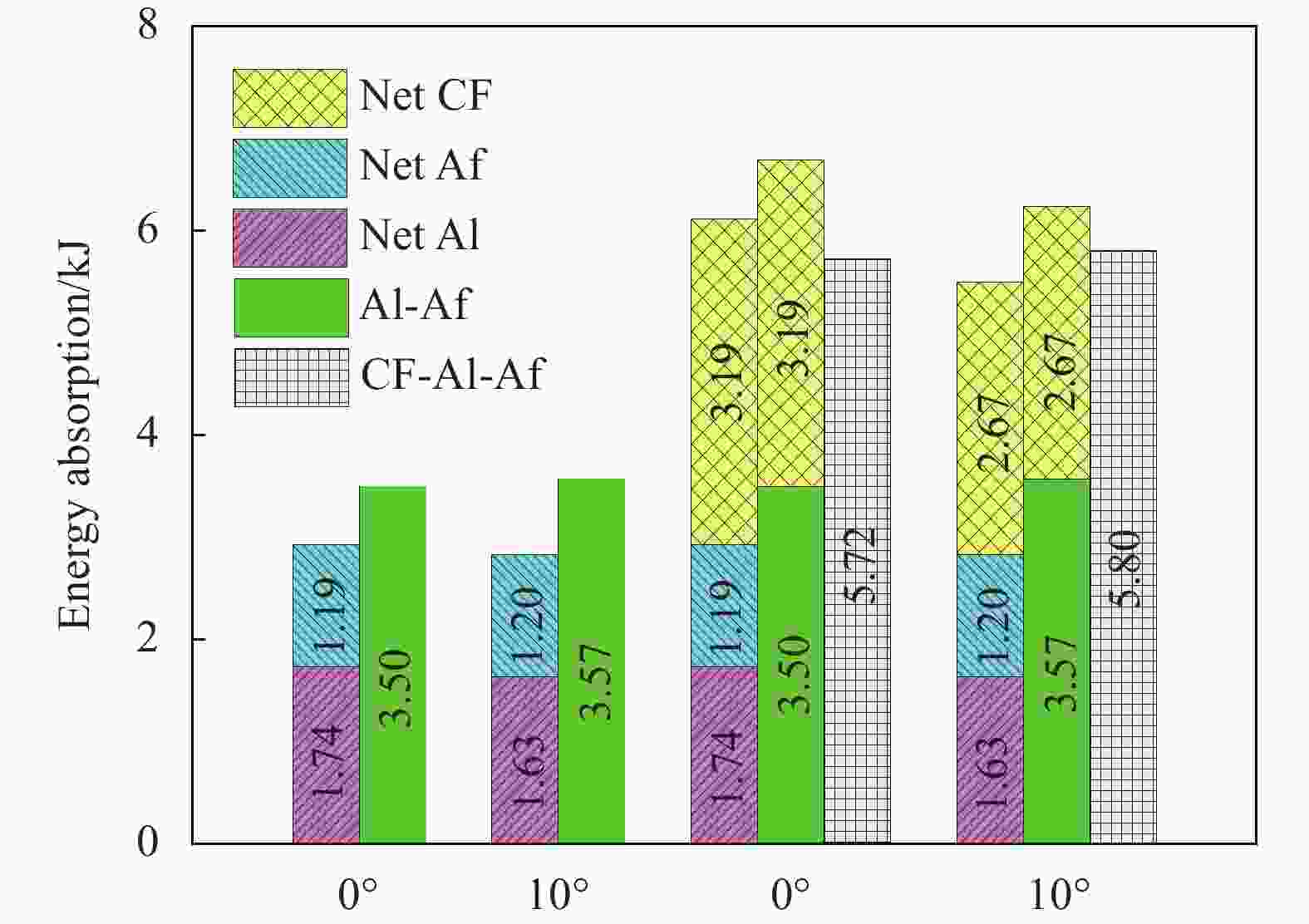

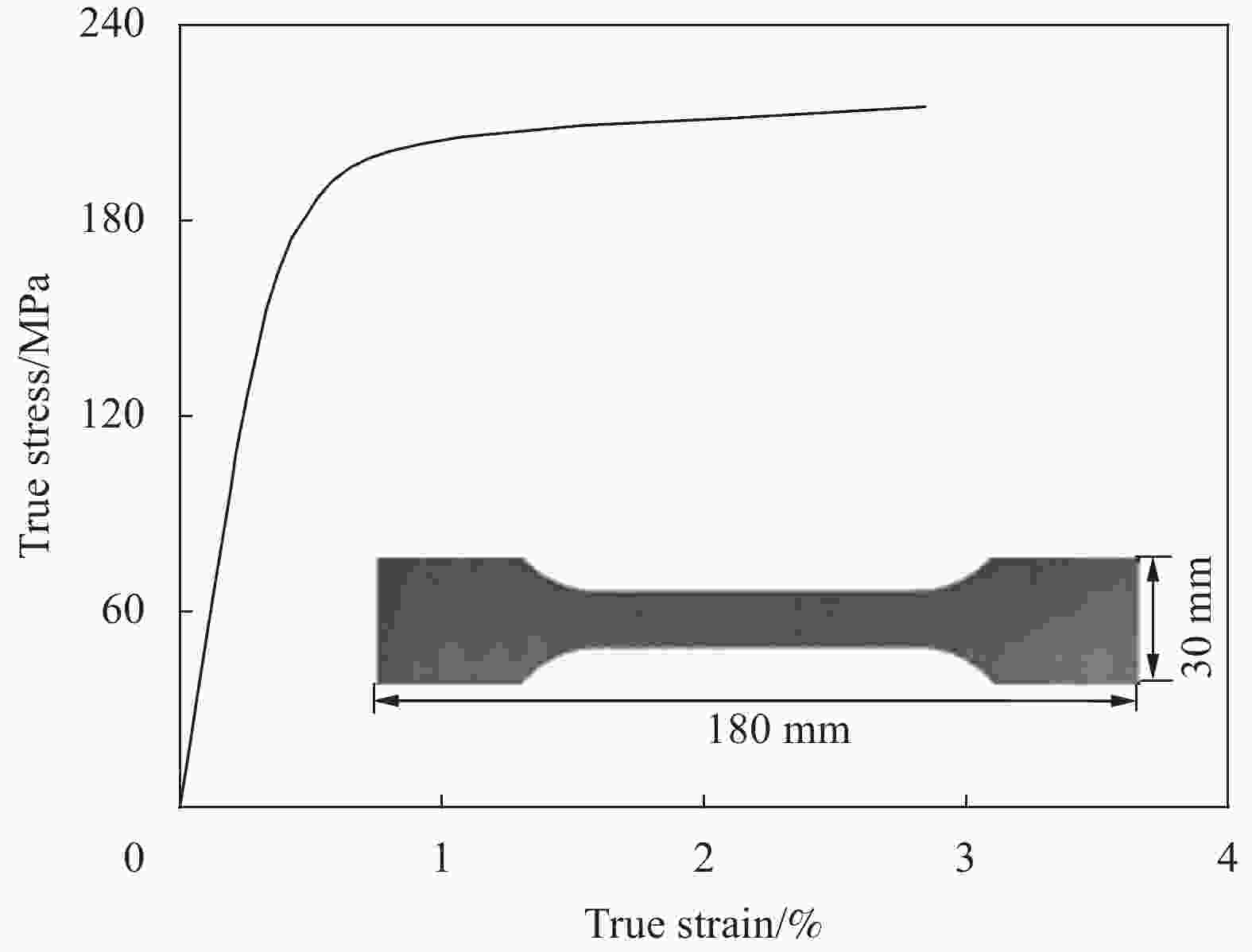

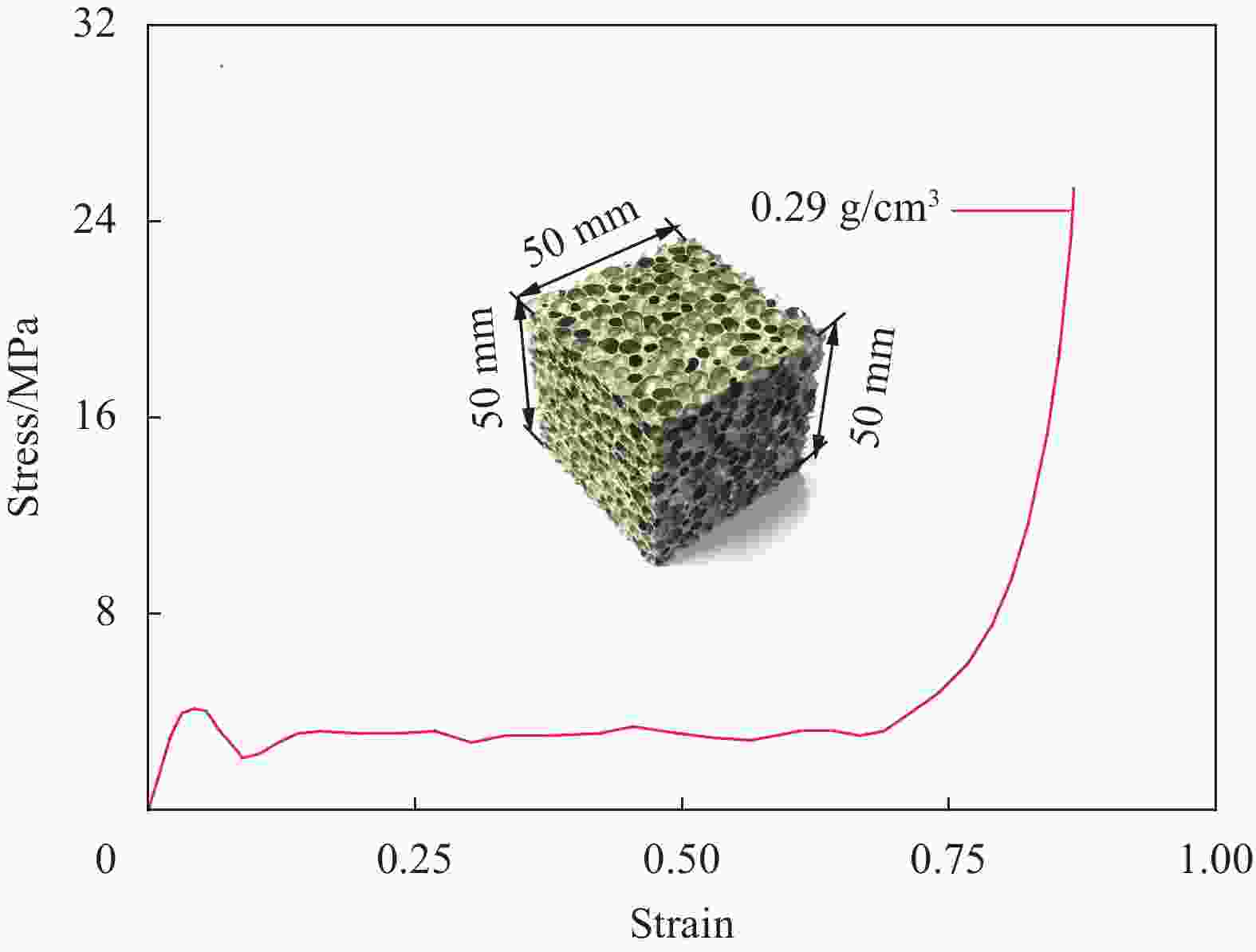

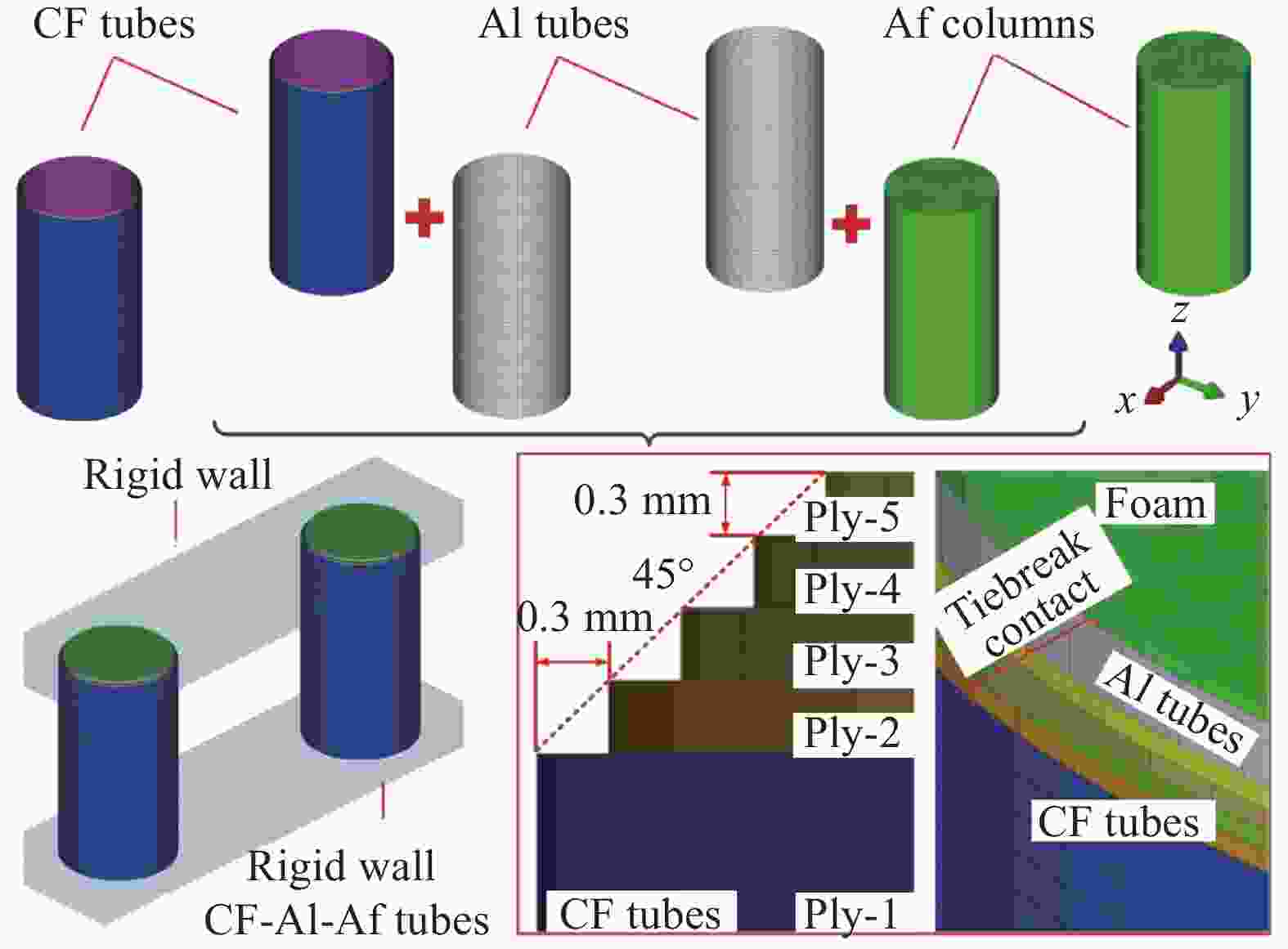

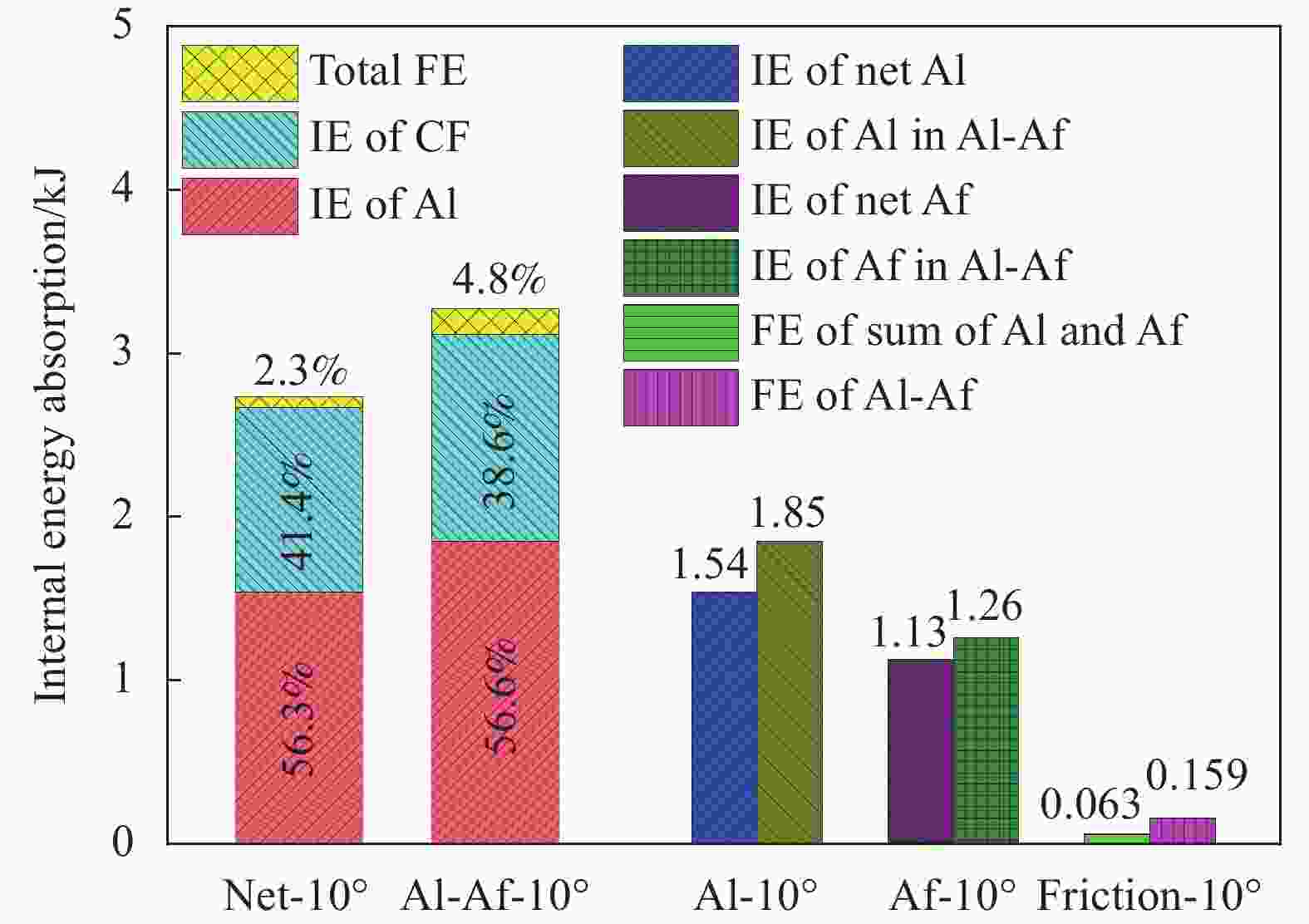

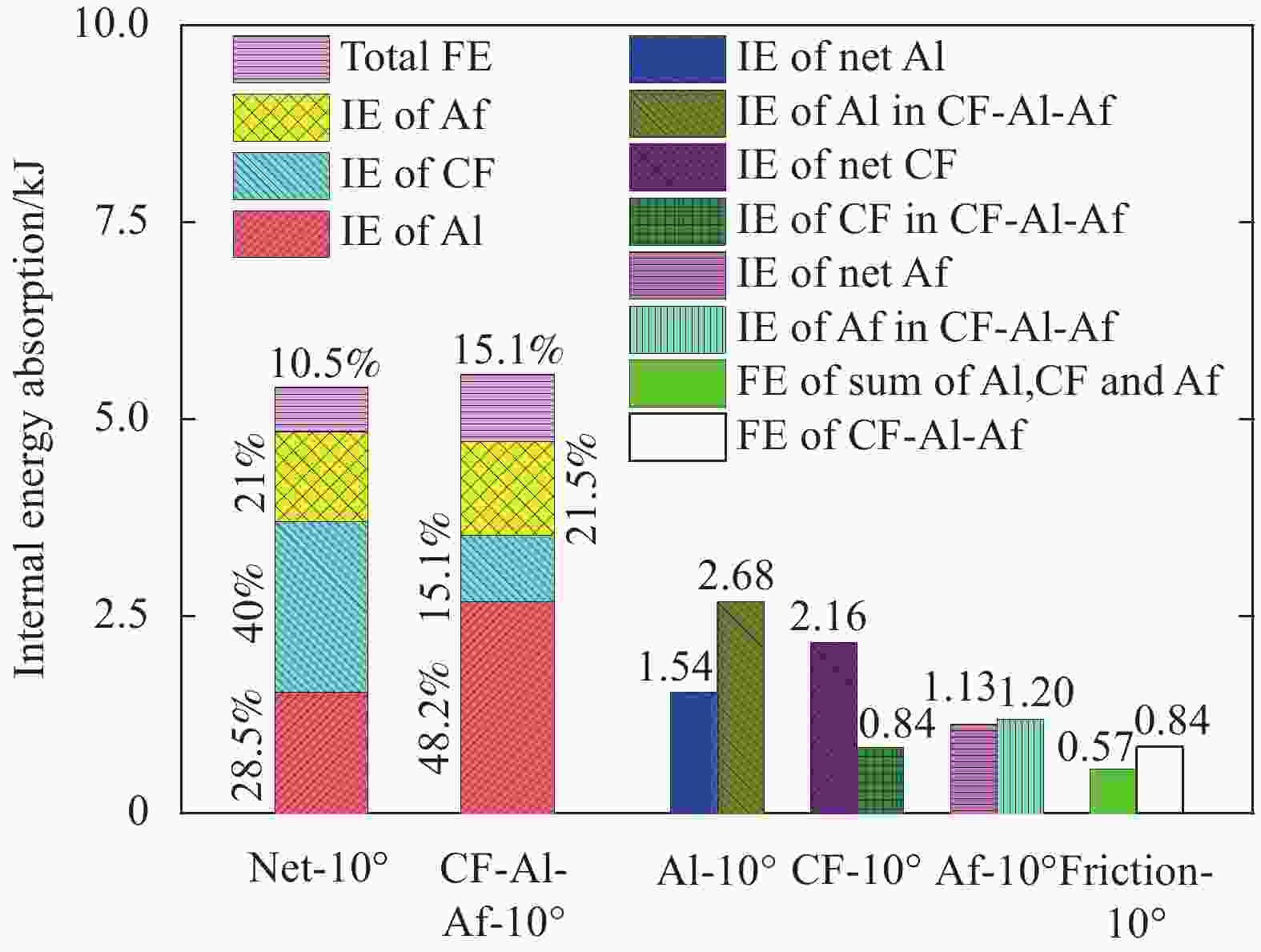

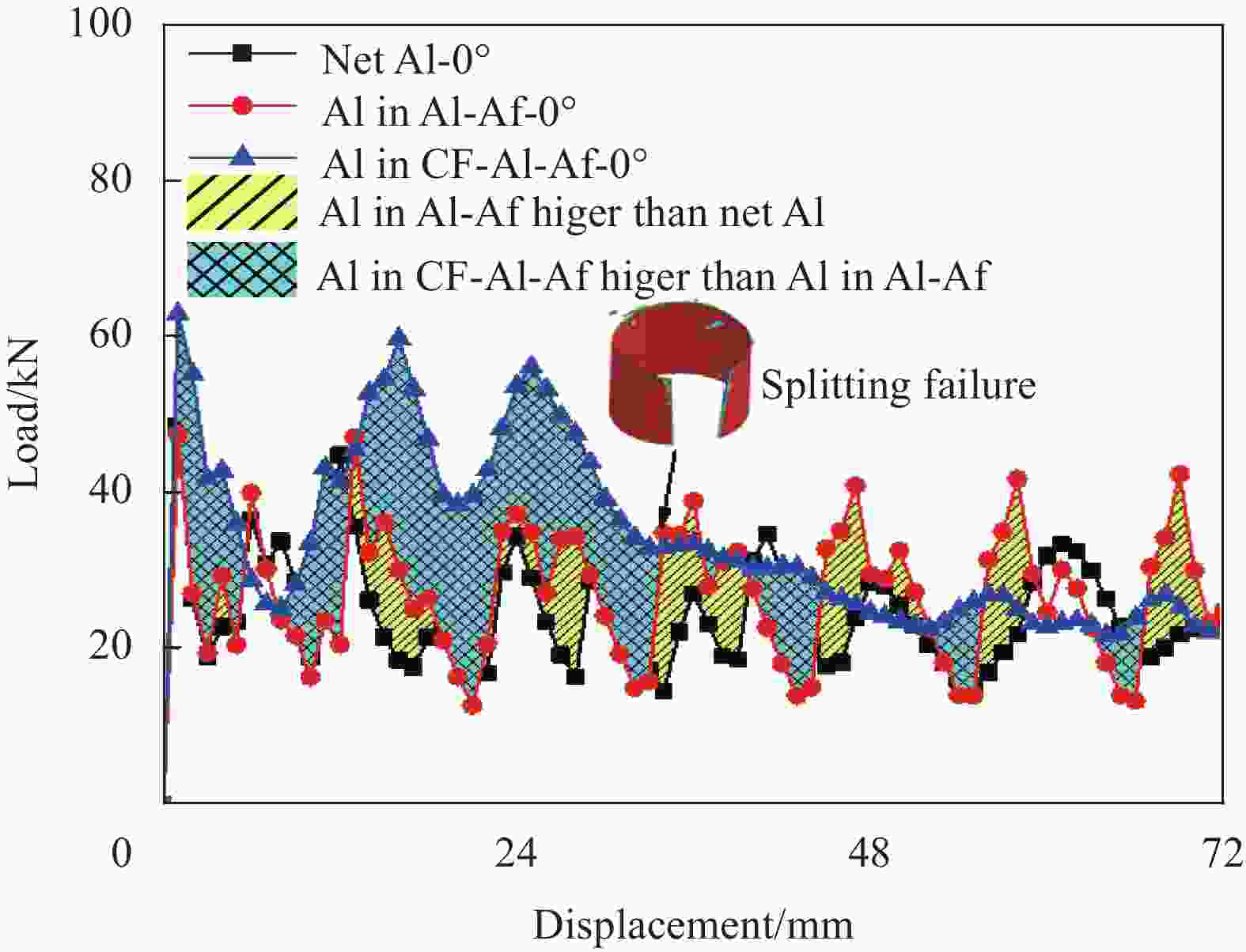

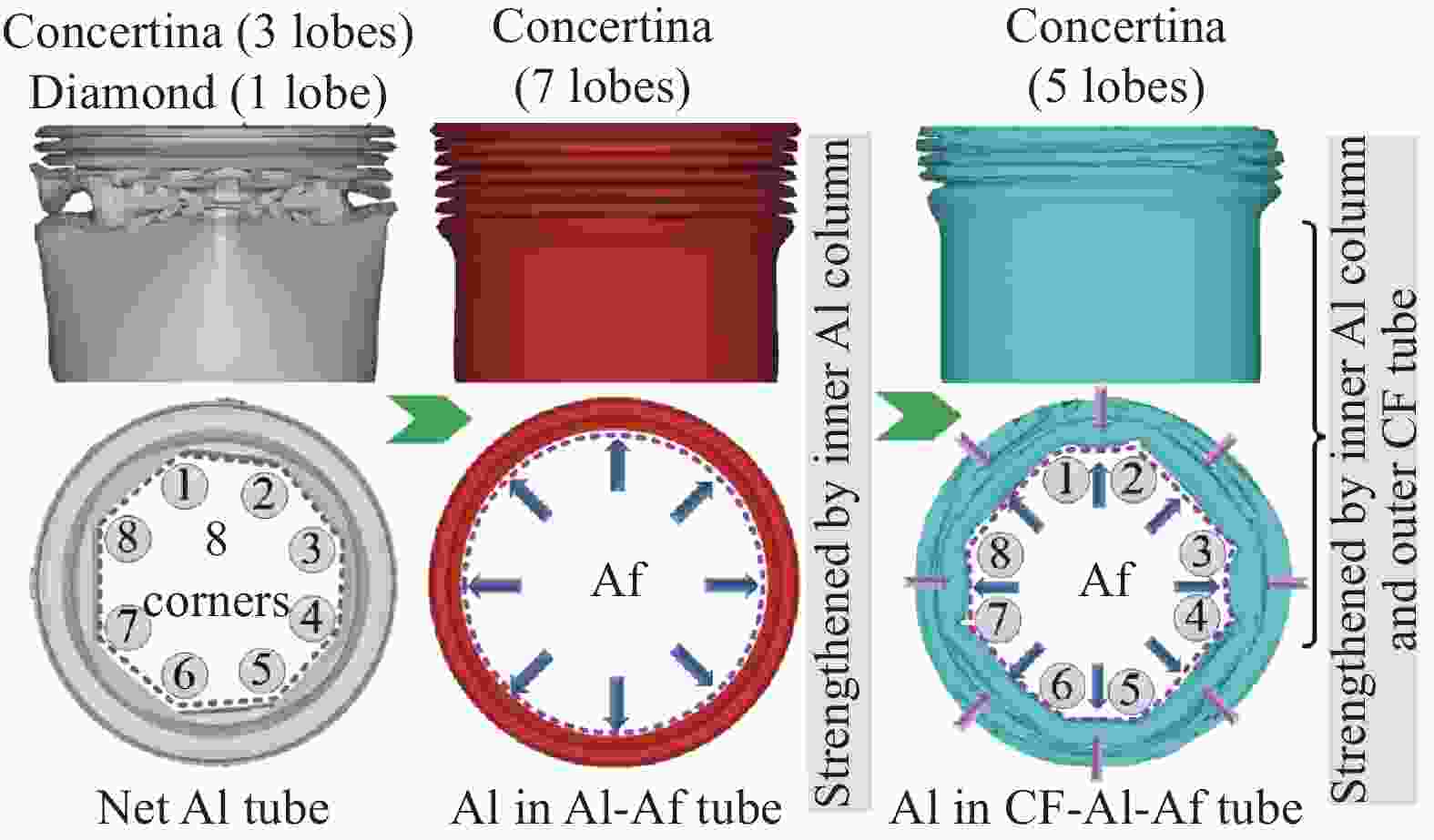

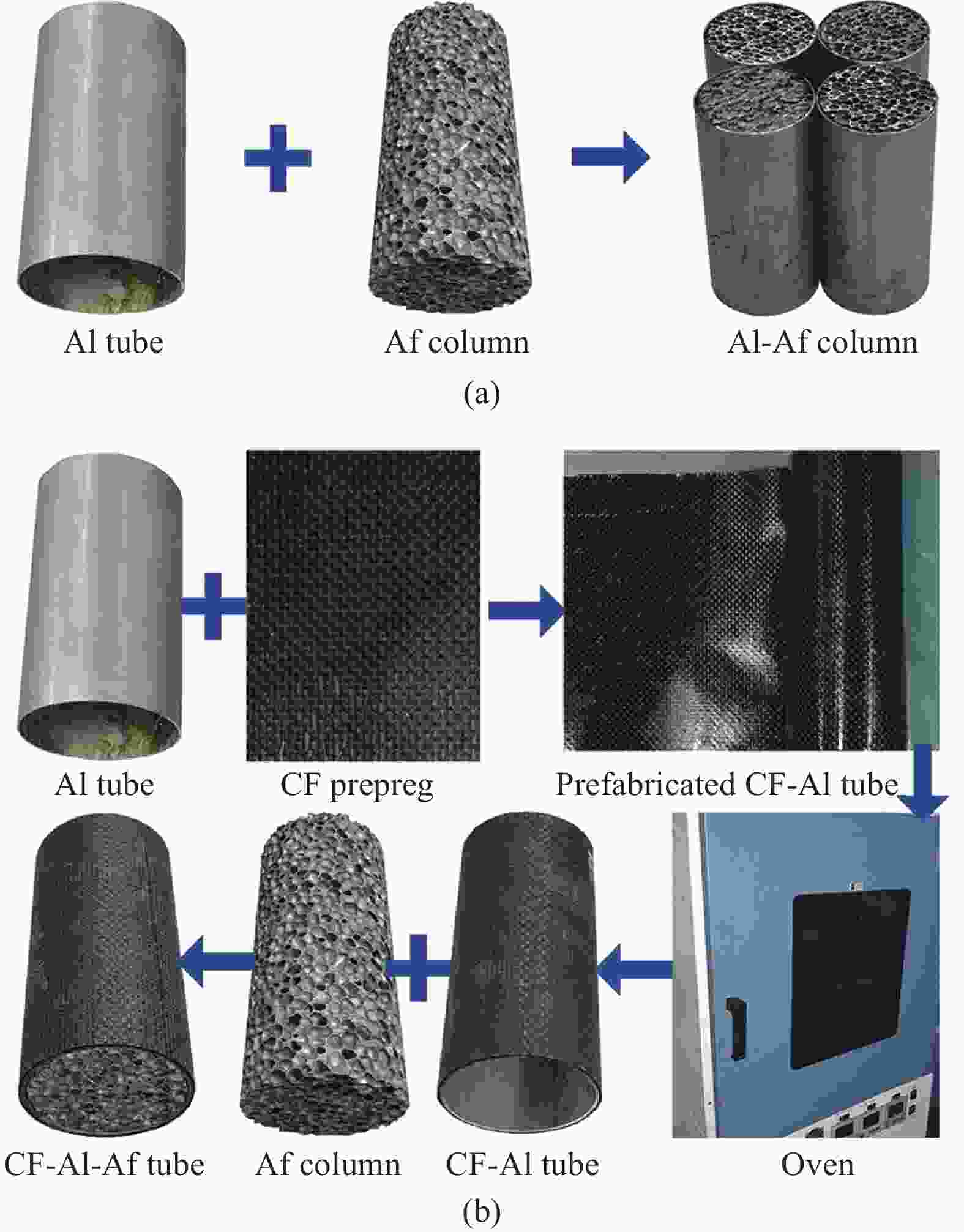

摘要: 本文旨在探讨碳纤维增强树脂(Carbon-fibre-reinforced polymer,CFRP)-铝合金-泡沫铝混杂管件在轴向(0°)和斜向(10°)荷载下的压溃变形特性和能量耗散机制。首先对纯碳纤维管(CF)、纯铝管(Al)、纯泡沫铝(Af)、Al-Af混杂管和CF-Al-Af混杂管进行了准静态压缩试验;在0°和10°的加载角下,Al-Af混杂管的能量吸收总是高于单一部件的能量吸收总量;与单一组分能量吸收之和相比,CF-Al-Af混杂管的能量吸收在0°加载角下减少,而在10°加载角时则显著提高。接着,在LS-DYNA中开发了混杂管件和相应的单一部件的数值模型,仿真结果表明,铝管能量吸收的提升促进了Al-Af和CF-Al-Af混杂管承载能力的提升,原因在于相比于单一铝管的“对称-钻石”混合变形,混杂管中的铝管发生了更稳定的对称变形,然而外部CF管能量吸收的降低主要削弱了CF-Al-Af混杂管的能量吸收,原因在于混杂管的CF管受到内部铝管的挤压出现了轴向撕裂失效。最后,建立了CF-Al-Af混合管和相应的单一管件在轴向荷载下的平均压溃载荷解析模型,结果表明,所开发的解析模型可以较好地预测混合管和单一部件的平均压溃载荷。Abstract: This study aims to explore the crushing deformation characteristics and underlying energy dissipating mechanisms of carbon-fibre-reinforced plastic (CFRP)-aluminum-aluminum foam hybrid tubes under both axial (0°) and oblique (10°) loads. Quasi-static compressive tests for net CFRP (CF) tubes, net aluminum (Al) tubes, net aluminum foams (Af), Al-Af hybrid tubes and CFRP-Al-Af hybrid tubes were performed first. The energy absorptions of the Al-Af hybrid columns are always higher than that of the sum net parts under loading angles of 0° and 10°; the energy absorption of the CF-Al-Af hybrid columns reduces under a 0° loading angle while improves remarkably under a 10° loading angle compared with the sum of net parts. Next, numerical models for these hybrid tubes and the corresponding net parts were developed in LS-DYNA, and numerical results indicate that the energy absorption improvement of Al tubes promotes the load-carrying enhancement of Al-Af and CF-Al-Af hybrid tubes, because the Al tubes in hybrid happen more stable symmetric deformation compared with the “symmetric-diamond” hybrid deformation of the net Al tubes; whereas the energy absorption reductions of external CF tubes primarily decrease energy absorption of CF-Al-Af hybrid tubes, because the CFRP tubes in the hybrid occur axial splitting failure due to compressions of inner Al tubes. Finally, the analytical models on mean crushing forces for CF-Al-Af hybrid columns and corresponding net components under axial load were developed, and the results indicate that the developed analytical models can better predict the mean crushing forces of both hybrid columns and net parts.

-

Key words:

- hybrid structure /

- energy absorption /

- quasi-static compression /

- numerical model /

- analytical model

-

表 1 所有实验试样的信息汇总

Table 1. Information summary of all testing samples

Sample Outer diameter/mm Thickness

/mmMass

/gLoad

angleAl-0° 60 1.00 58 0° Al-10° 60 1.00 58 10° Af-0° 58 1.00 94 0° Af-10° 58 1.00 94 10° CF-0° 63 1.51 44 0° CF-10° 63 1.51 44 10° Al-Af-0° 60 2.51 102 0° Al-Af-10° 60 2.51 102 10° CF-Al-Af-0° 63 – 195 0° CF-Al-Af-10° 63 – 196 10° 表 2 碳纤维复合材料(CFRP)力学性能参数

Table 2. Mechanical property parameters of carbon-fibre-reinforced polymer (CFRP)

Material property Value Density $ \rho $/(g·cm−3) 1.53 In-plane Young's modulus $ {E_1} = {E_2} $/GPa 55.4 In-plane shear modulus $ {G_1}{\text{ = }}{G_2} $/GPa 3.4 Poisson's ratio $ \nu $ 0.056 Tensile strength along weft direction $ {X_{\text{T}}} $/MPa 455 Tensile strength along warp direction $ {Y_{\text{T}}} $/MPa 405 Failure parameter of tension $ {D_{{\text{FAILT}}}} $ 0.05 Failure parameter of compression $ {D_{{\text{FAILC}}}} $ −0.05 Softening factor $ {S_{ {\text{OFT}}}} $ 0.5 Inter-laminar stiffness $ {G_{\text{N}}} $/MPa 40000 Inter-laminar critical distance $ {C_{{\text{CRIT}}}} $/mm 0.005 Inter-laminar normal strength $ {X_{{\text{NFLS}}}} $/MPa 38.2 Inter-laminar shear strength $ {X_{{\text{SFLS}}}} $/MPa 72.2 表 3 实验与仿真的耐撞性指标对比

Table 3. Comparisons in crashworthiness indicators between experiments and simulations

Sample Test $ {E_{\text{A}}} $/J $ {P_{{\text{CF}}}} $/kN $ {C_{{\text{FE}}}} $/% Al-0° Experiment 1735.20 61.52 39 Simulation 1785.60 58.43 42 Al-10° Experiment 1634.40 29.86 76 Simulation 1605.60 31.99 70 Af-0° Experiment 1191.60 17.12 84 Simulation 1282.32 21.35 83 Af-10° Experiment 1200.24 18.77 83 Simulation 1131.12 17.33 91 CF-0° Experiment 3191.04 55.74 80 Simulation 3175.92 55.31 80 CF-10° Experiment 2665.44 47.91 77 Simulation 2676.07 37.92 98 Al-Af-0° Experiment 3502.77 46.87 84 Simulation 3287.23 64.00 71 Al-Af-10° Experiment 3573.77 57.04 87 Simulation 3304.81 56.27 82 CF-Al-Af-10° Experiment 5723.28 143.50 55 Simulation 5405.04 134.66 56 CF-Al-Af-10° Experiment 5803.92 116.47 69 Simulation 5573.52 99.76 78 Notes: EA—Energy absorption; PCF—Peak crushing force; CFE—Crushing force efficiency. 表 4 CF-Al-Af-0°管件的轴向压溃性能实验与预测结果对比

Table 4. Comparisons in axial crushing performances of CF-Al-Af-0° tube between experimental and predicted results

Tube Method $ M_{_{{\rm{net \;Al}}}}^{{\rm{CF}}} $

/kN$ M_{{\rm{net \;Af}}}^{{\rm{CF}}} $

/kN$ M_{{\rm{net \;CF}}}^{{\rm{CF}}} $

/kN$ M_{{\rm{IE}}}^{{\rm{CF}}} $

/kN$ M_{{\rm{CF {\text{-}} Al {\text{-}} Af}}}^{{\rm{CF}}} $

/kNCF-Al-Af-0° Test 24.10 16.55 44.32 −5.48 79.49 FEA 24.80 17.81 44.11 −11.65 75.07 |Error|/% 2.90 7.61 0.47 112.50 5.56 Theory 24.15 17.96 47.55 −2.27 87.39 |Error|/% 0.21 8.52 7.29 58.60 9.90 Notes: $M_{{\rm{net Al}}}^{{\rm{CF}}} $—Crushing force of the net Al tube; $M_{{\rm{net Af}}}^{{\rm{CF}}} $—Crushing force of the net aluminum foam; $M_{{\rm{net CF}}}^{{\rm{CF}}} $—Crushing force of the net CFRP tube; $M_{{\rm{IE}}}^{{\rm{CF}}} $—Crushing force of the interactive effect; $M_{_{{\rm{CF - Al - Af}}}}^{{\rm{CF}}} $—Crushing force of the CF-Al-Af hybrid tube. -

[1] KIM H C, SHIN D K, LEE J J, et al. Crashworthiness of aluminum/CFRP square hollow section beam under axial impact loading for crash box application[J]. Composite Structures,2014,112:1-10. doi: 10.1016/j.compstruct.2014.01.042 [2] HUANG Z X, ZHANG X, YANG C Y. Experimental and numerical studies on the bending collapse of multi-cell aluminum/CFRP hybrid tubes[J]. Composites Part B: Engineering,2020,181:107527. doi: 10.1016/j.compositesb.2019.107527 [3] 王振, 朱国华, 吴永强, 等. 铝合金/碳纤维混合前纵梁的轴向冲击吸能特性[J]. 复合材料学报, 2022, 39(10):5020-5031.WANG Zhen, ZHU Guohua, WU Yongqiang, et al. Axial impact energy absorption characteristics of the aluminum/ carbon fiber reinforced plastic hybrid front rail[J]. Acta Materiae Compositae Sinica,2022,39(10):5020-5031(in Chinese). [4] 王振, 朱国华. Al-碳纤维增强聚丙烯混合帽型梁的热模压成形特性及三点弯曲特性[J]. 复合材料学报, 2022, 39(12):6096-6108.WANG Zhen, ZHU Guohua. Hot press molding characteristics and three-point bending characteristics of Al-carbon fiber reinforced polypropylene hybrid hat-shaped rail[J]. Acta Materiae Compositae Sinica,2022,39(12):6096-6108(in Chinese). [5] 王健, 郑学丰, 付昌云, 等. 碳纤维/环氧树脂复合材料-铝合金层合板深拉成型特性[J]. 复合材料学报, 2019, 36(12):2786-2794. doi: 10.13801/j.cnki.fhclxb.20190313.001WANG Jian, ZHENG Xuefeng, FU Changyun, et al. Deep drawing characteristics of carbon fiber/epoxy resin composite-aluminum alloy laminates[J]. Acta Materiae Compositae Sinica,2019,36(12):2786-2794(in Chinese). doi: 10.13801/j.cnki.fhclxb.20190313.001 [6] BAMBACH M R. Axial capacity and crushing behavior of metal-fiber square tubes-Steel, stainless steel and aluminum with CFRP[J]. Composites Part B: Engineering,2010,41(7):550-559. doi: 10.1016/j.compositesb.2010.06.002 [7] KALHOR R, AKBARSHAHI H, CASE S W. Numerical modeling of the effects of FRP thickness and stacking sequence on energy absorption of metal-FRP square tubes[J]. Composite Structures,2016,147:231-246. doi: 10.1016/j.compstruct.2016.03.038 [8] KALHOR R, CASE S W. The effect of FRP thickness on energy absorption of metal-FRP square tubes subjected to axial compressive loading[J]. Composite Structures,2015,130:44-50. doi: 10.1016/j.compstruct.2015.04.009 [9] HUANG Z X, ZHANG X. Crashworthiness and optimization design of quadruple-cell aluminum/CFRP hybrid tubes under transverse bending[J]. Composite Structures,2020,235:111753. doi: 10.1016/j.compstruct.2019.111753 [10] FENG P, HU L L, QIAN P, et al. Compressive bearing capacity of CFRP-aluminum alloy hybrid tubes[J]. Composite Structures,2016,140:749-757. doi: 10.1016/j.compstruct.2016.01.041 [11] ZHU G H, LIAO J P, SUN G Y, et al. Comparative study on metal/CFRP hybrid structures under static and dynamic loading[J]. International Journal of Impact Engineering,2020,141:103509. [12] YANG H Y, LEI H S, LU G X, et al. Energy absorption and failure pattern of hybrid composite tubes under quasi-static axial compression[J]. Composites Part B: Engineering,2020,198:108271. doi: 10.1016/j.compositesb.2020.108217 [13] MING S Z, SONG Z B, ZHOU C H, et al. The crashworthiness design of metal/CFRP hybrid tubes based on origami-ending approach: Experimental research[J]. Composite Structures,2022,279:114843. doi: 10.1016/j.compstruct.2021.114843 [14] BAMBACH M R, ZHAO X L, JAMA H. Energy absorbing characteristics of aluminium beams strengthened with CFRP subjected to transverse blast load[J]. International Journal of Impact Engineering,2010,37(1):37-49. doi: 10.1016/j.ijimpeng.2009.06.007 [15] 沈勇, 柯俊, 吴震宇. 不同编织角碳纤维增强聚合物复合材料-Al方管的吸能特性[J]. 复合材料学报, 2020, 37(3):591-600. doi: 10.13801/j.cnki.fhclxb.20190528.003SHEN Yong, KE Jun, WU Zhenyu. Energy-absorbing characteristics of carbon fiber reinforced polymer compo-site-Al square tubes with different braiding angles[J]. Acta Materiae Compositae Sinica,2020,37(3):591-600(in Chinese). doi: 10.13801/j.cnki.fhclxb.20190528.003 [16] 朱烨飞, 孙雨果. 单轴压缩载荷下闭孔泡沫铝的变形机制[J]. 复合材料学报, 2017, 34(8):1810-1816. doi: 10.13801/j.cnki.fhclxb.20161116.002ZHU Yefei, SUN Yuguo. Deformation mechanism of closed-cell aluminum foam under uniaxial compression[J]. Acta Materiae Compositae Sinica,2017,34(8):1810-1816(in Chinese). doi: 10.13801/j.cnki.fhclxb.20161116.002 [17] 卢子兴, 陈伟. 泡沫变形模式对泡沫填充圆管压溃行为的影响[J]. 复合材料学报, 2011, 28(5):168-173. doi: 10.13801/j.cnki.fhclxb.2011.05.031LU Zixing, CHEN Wei. Effect of the foam deformation modes on the crushing behavior of foam-filled circular tube[J]. Acta Materiae Compositae Sinica,2011,28(5):168-173(in Chinese). doi: 10.13801/j.cnki.fhclxb.2011.05.031 [18] 杨旭东, 安涛, 冯晓琳, 等. 泡沫铝填充碳纤维增强树脂复合材料薄壁管的压缩变形行为与吸能特性[J]. 复合材料学报, 2020, 37(8):1850-1860. doi: 10.13801/j.cnki.fhclxb.20191206.002YANG Xudong, AN Tao, FENG Xiaolin, et al. Compressive deformation behavior and energy absorption of Al foam-filled carbon fiber reinforced plastic thin-walled tube[J]. Acta Materiae Compositae Sinica,2020,37(8):1850-1860(in Chinese). doi: 10.13801/j.cnki.fhclxb.20191206.002 [19] COSTAS M, MORIN D, LANGSETH M, et al. Axial crushing of aluminum extrusions filled with PET foam and GFRP: An experimental investigation[J]. Thin-Walled Structures,2016,99:45-57. doi: 10.1016/j.tws.2015.11.003 [20] YANG H Y, GUO X G, WANG H P, et al. Low-velocity impact performance of composite-aluminum tubes prepared by mesoscopic hybridization[J]. Composite Structures,2021,274:114348. doi: 10.1016/j.compstruct.2021.114348 [21] YANG S, QI C. Multiobjective optimization for empty and foam-filled square columns under oblique impact loading[J]. International Journal of Impact Engineering,2013,54:177-191. doi: 10.1016/j.ijimpeng.2012.11.009 [22] YANG W L, XIE S C, LI H H, et al. Design and injury analysis of the seated occupant protection posture in train collision[J]. Safety Science,2019,117:263-275. doi: 10.1016/j.ssci.2019.04.028 [23] CHEN D D, XIAO S, YANG B, et al. Axial crushing response of carbon/glass hybrid composite tubes: An experimental and multi-scale computational study[J]. Composite Structures, 2022, 294: 115640. [24] HANSSEN A G, LANGSETH M, HOPPERSTAD O S. Static and dynamic crushing of circular aluminium extrusions with aluminium foam filler[J]. International Journal of Impact Engineering,2000,24(5):475-507. doi: 10.1016/S0734-743X(99)00170-0 [25] LU G X, YU T X. Energy absorption of structures and materials[M]. Cambridge: Woodhead Publishing Limited, 2003: 144-173. [26] ALEXANDER J M. An approximate analysis of the collapse of thin cylindrical shells under axial loading[J]. The Quarterly Journal of Mechanics and Applied Mathematics,1960,13(1):10-15. doi: 10.1093/qjmam/13.1.10 [27] ABRAMOWICZ W, JONES N. Dynamic axial crushing of circular tubes[J]. International Journal of Impact Engi-neering,1984,2(3):263-281. doi: 10.1016/0734-743X(84)90010-1 [28] ABRAMOWICZ W, JONES N. Dynamic axial crushing of square tubes[J]. International Journal of Impact Engineering,1984,2(2):179-208. doi: 10.1016/0734-743X(84)90005-8 [29] BORIA S, PETTINARI S, GIANNONI F. Theoretical analysis on the collapse mechanisms of thin-walled composite tubes[J]. Composite Structures,2013,103:43-49. doi: 10.1016/j.compstruct.2013.03.020 -

下载:

下载: