Isocyanate modified fumed silica and its effects on the mechanical properties of casting polyurethane elastomer

-

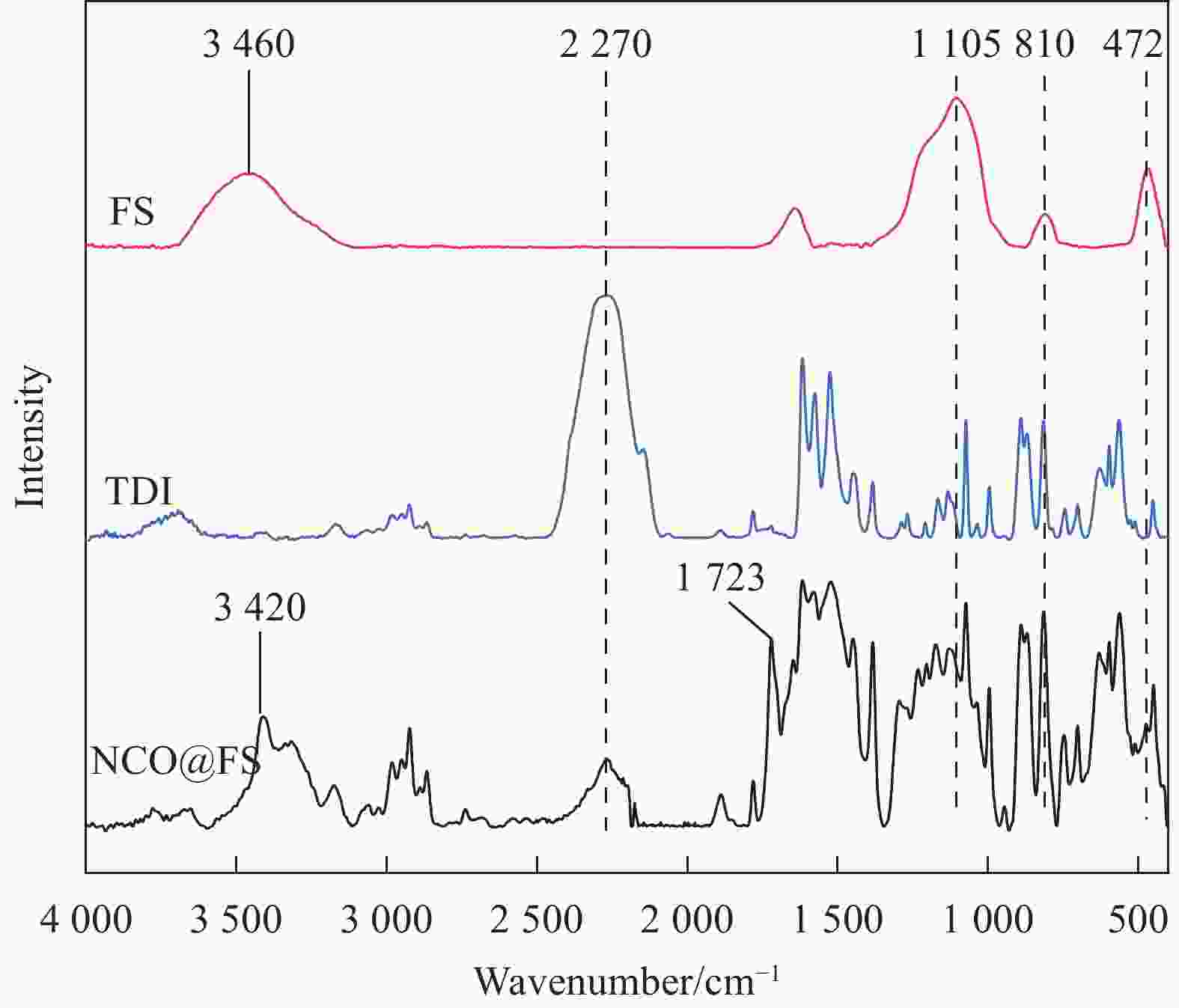

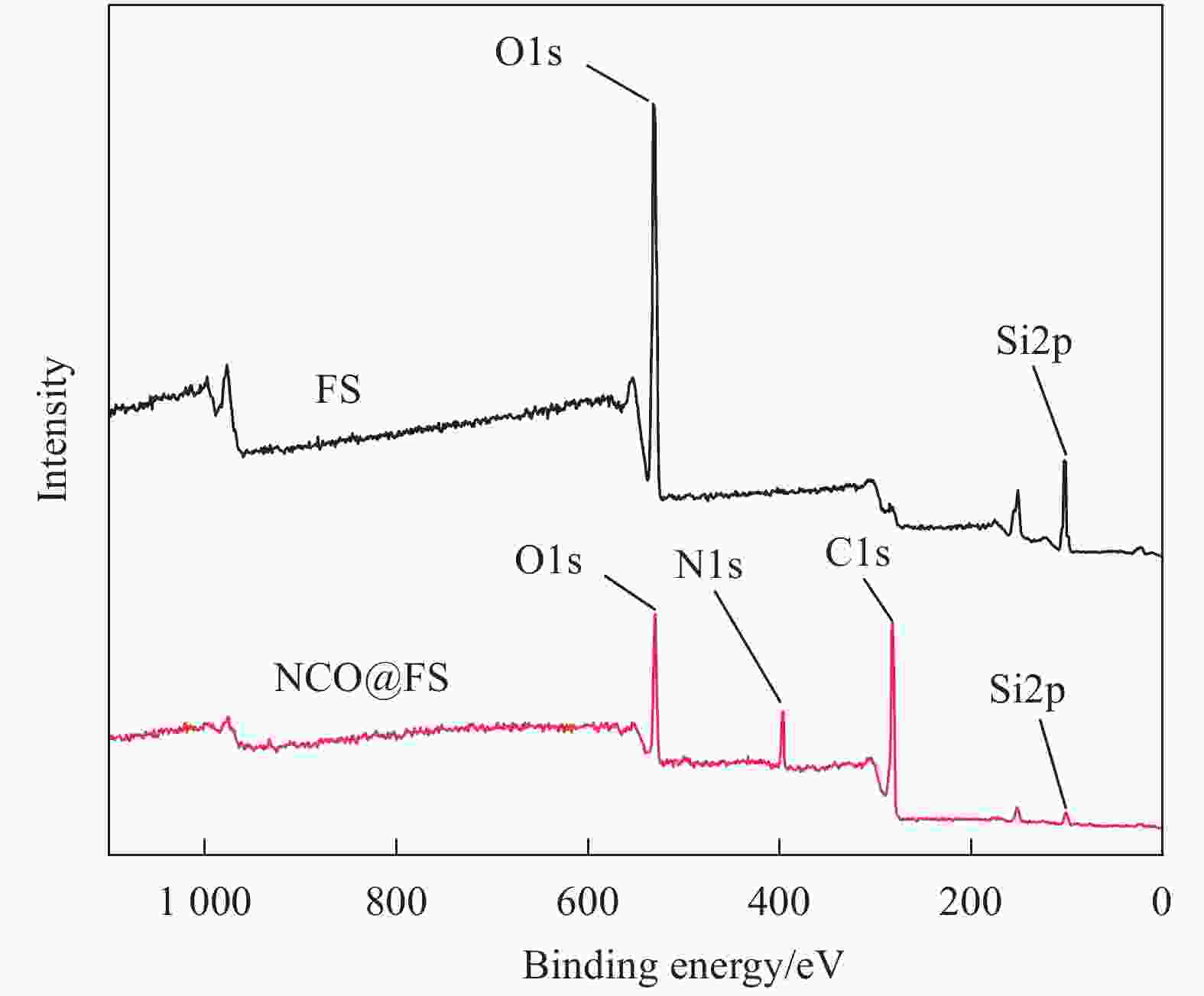

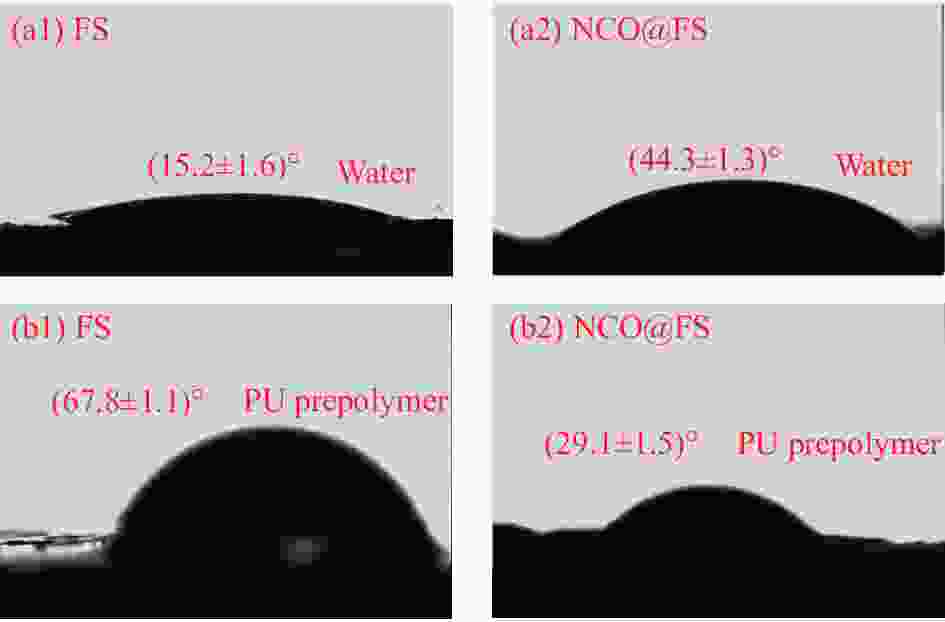

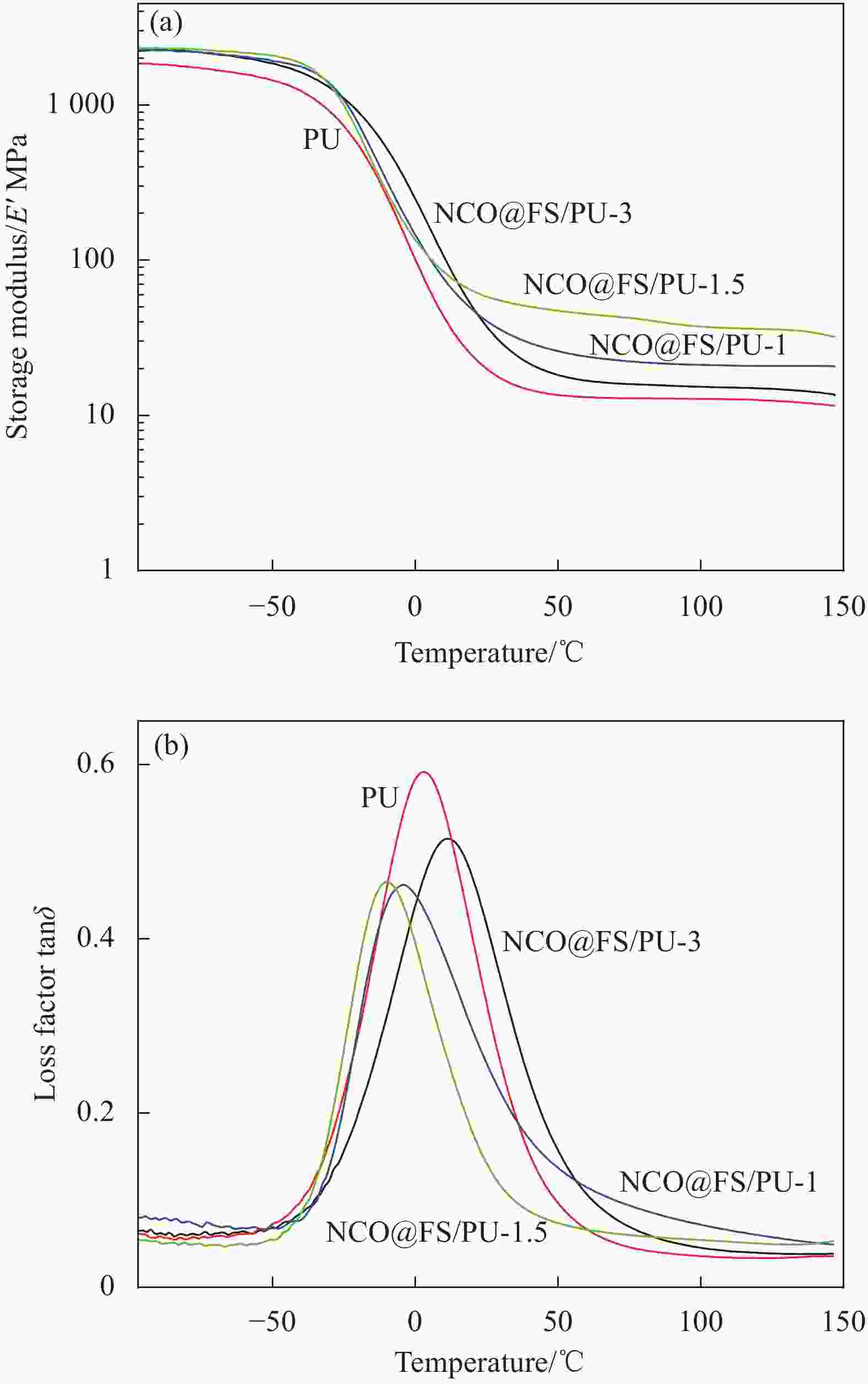

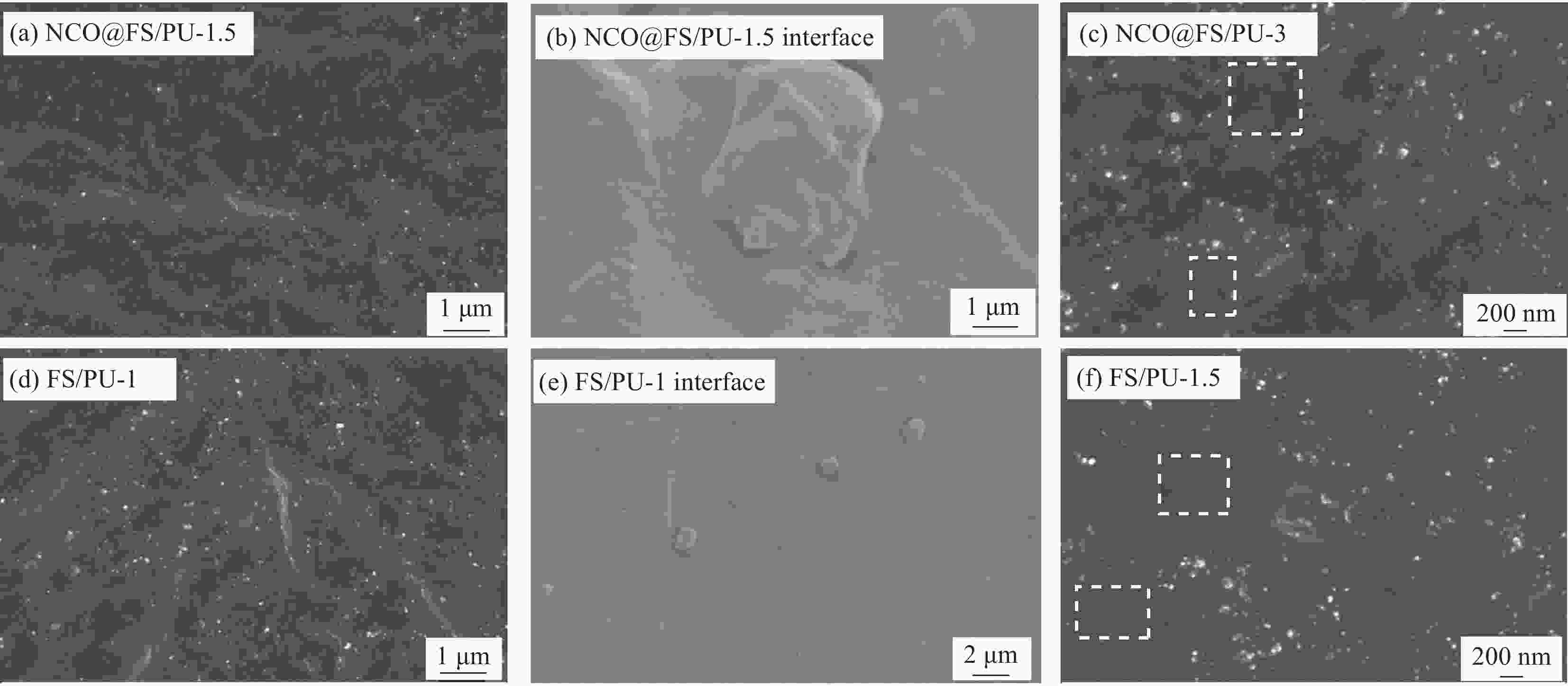

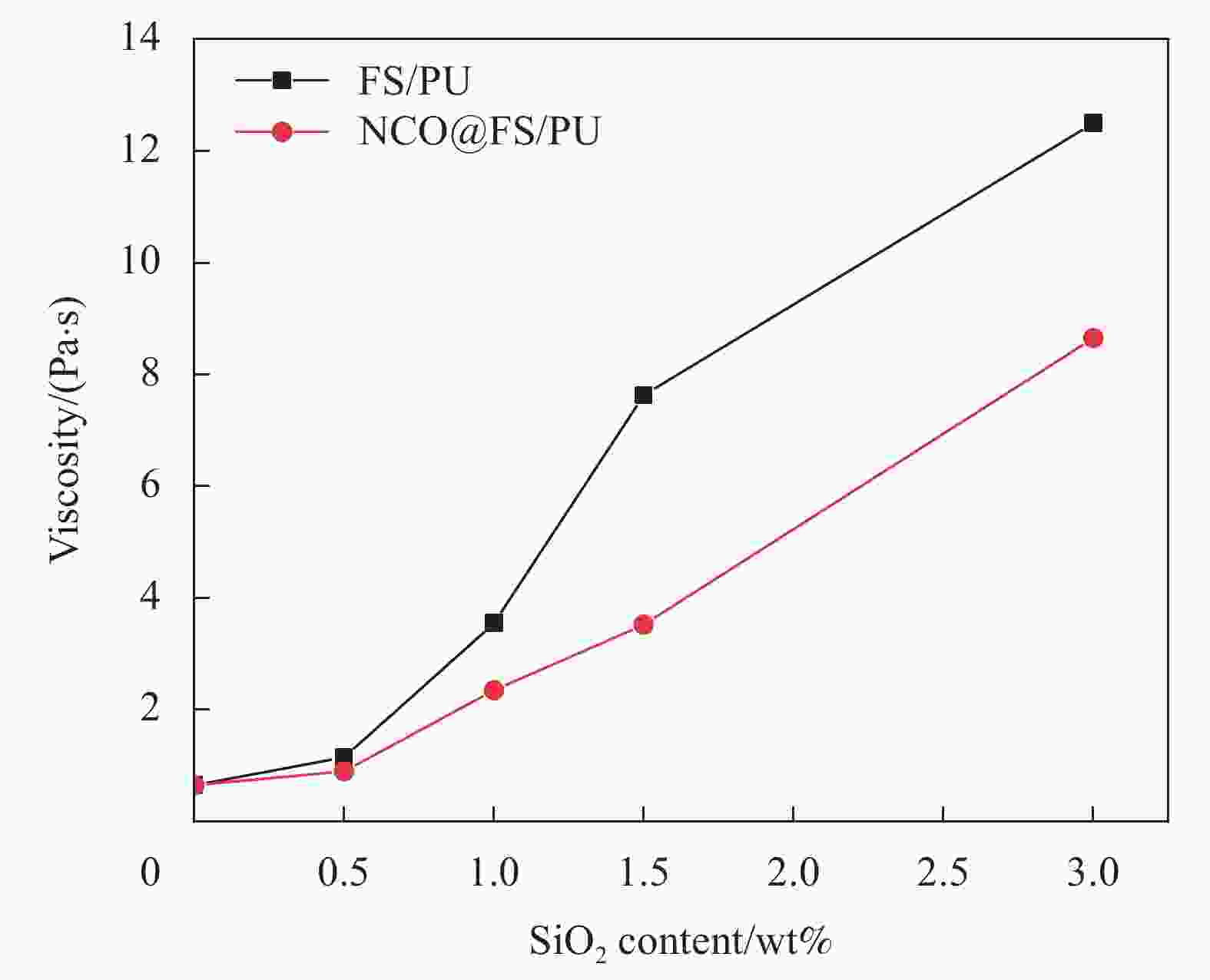

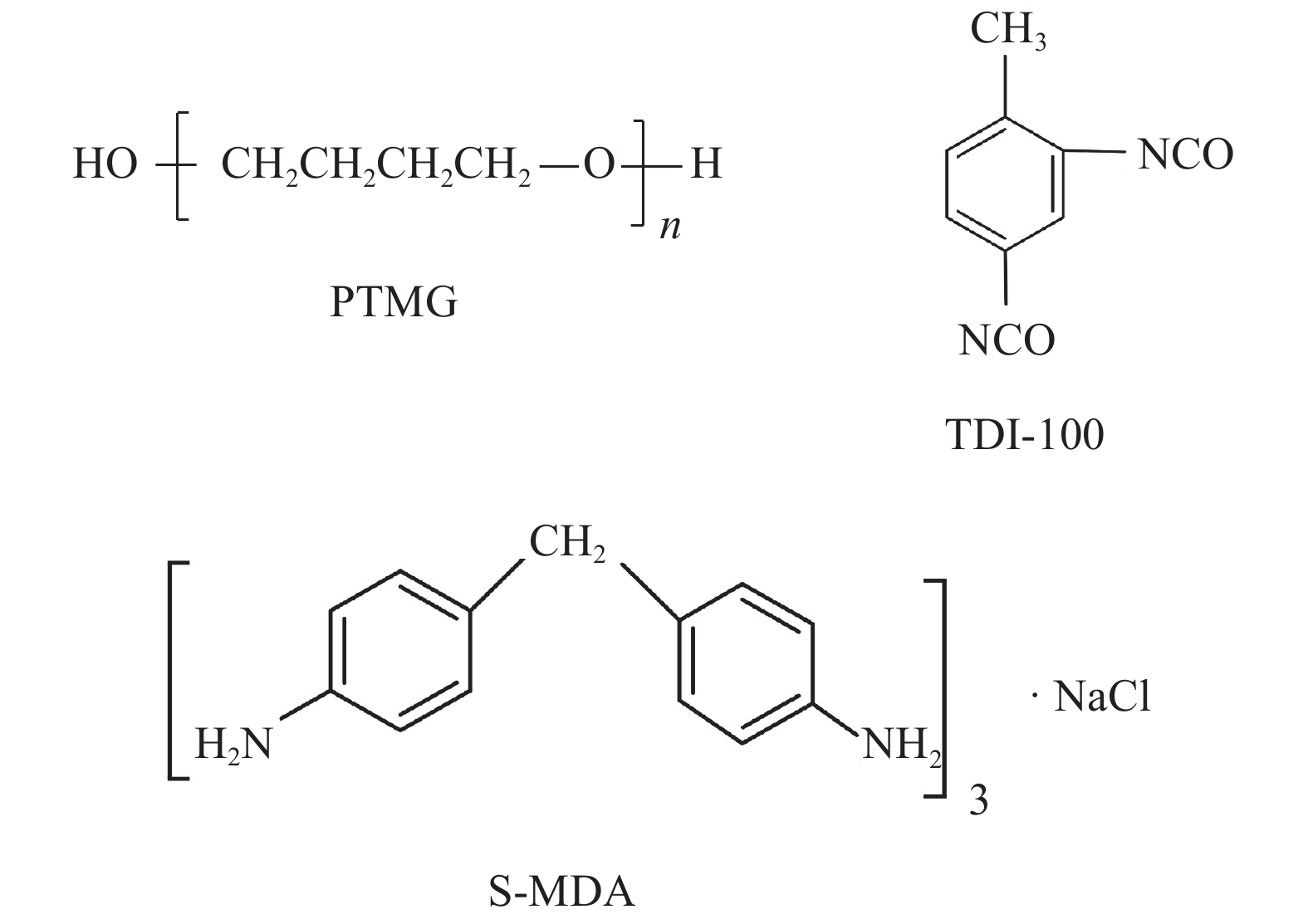

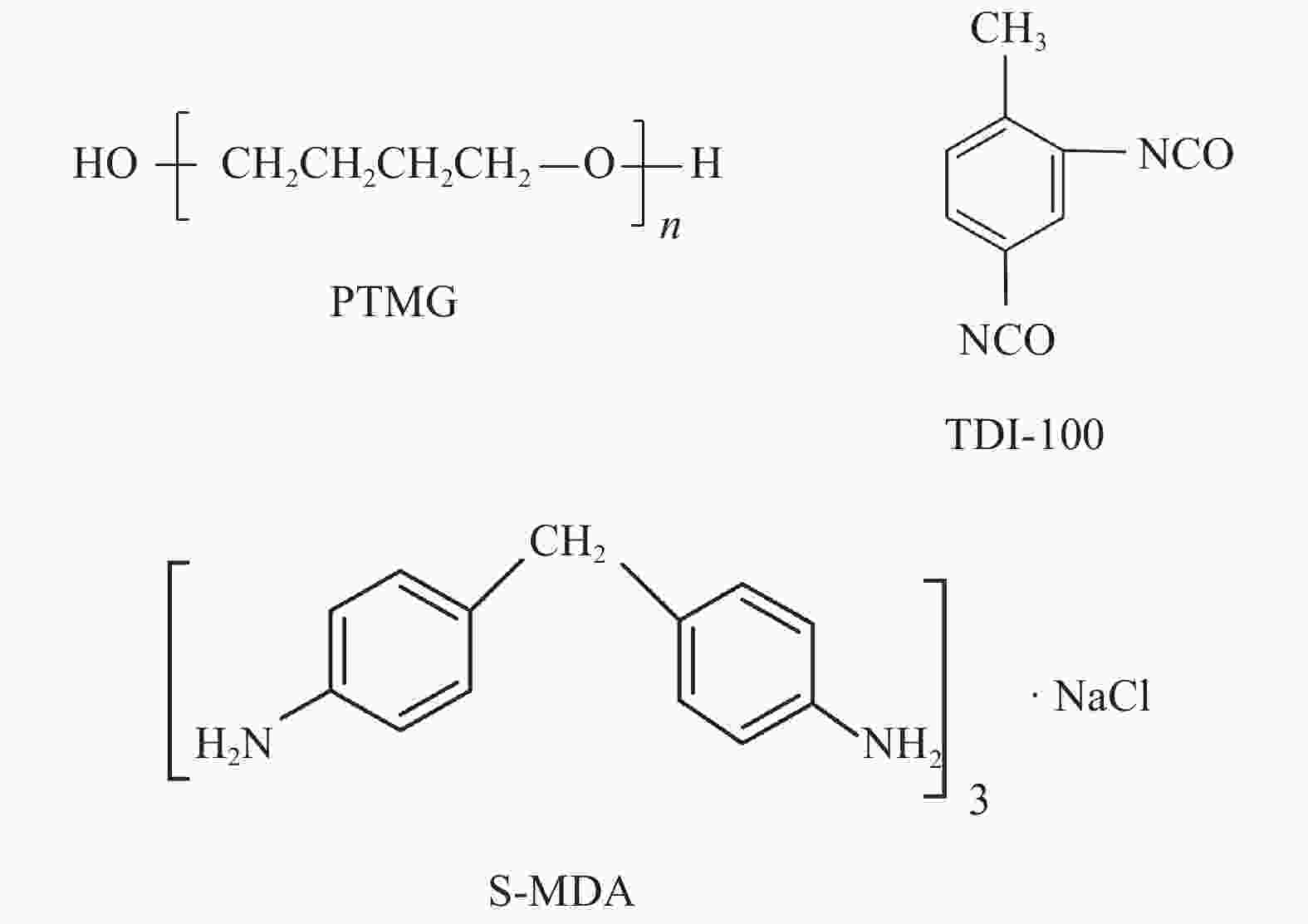

摘要: 为了改善气相二氧化硅(FS)/浇注型聚氨酯(PU)体系成型流动性,在制备预聚体的过程中,采用2, 4-甲苯二异氰酸酯(TDI)进行改性获得异氰酸酯改性的二氧化硅(NCO@FS),通过原位聚合法制备了NCO@FS/PU弹性体复合材料。采用FTIR、XPS及动态接触角对NCO@FS及FS进行了表征。结果表明:FS的表面羟基与TDI的—NCO基团发生反应生成了氨酯基(—NHCOO),改善了FS与PU间的界面相容性及界面结合。复合材料中NCO@FS质量分数为1.5wt%时,NCO@FS/PU复合材料的拉伸和撕裂强度分别为57 MPa和110.5 kN/m,比纯浇注型PU分别提高了31.6%和23.6%;玻璃化转变温度由3.4℃下降到−11.2℃,损耗因子tanδ由0.59下降到0.46。异氰酸酯改性FS适合制备FS增强浇注型聚氨酯复合材料。Abstract: In order to improve the molding fluidity of fumed silica (FS)/cast polyurethane (PU) system, in the process of preparing prepolymer, the fumed silica (FS) was modified by 2, 4-toluene diisocyanate (TDI) to obtain TDI modified silica (NCO@FS), and TDI modified silica/reinforced pouring polyurethane (NCO@FS/PU) elastomer composite material was prepared by in-situ polymerization. NCO@FS and FS were characterized by fourier transform infrared spectroscopy (FTIR), X-ray photoelectron spectroscopy (XPS) and contact angle testing. The results show that the active hydroxyl groups on the surface of FS react with the —NCO groups of TDI to form urethane groups aminoester group (—NHCOO), which improves the interfacial compatibility and interfacial bonding between silica and casting polyurethane. When the mass fraction of NCO@FS in the composite material is 1.5wt%, the tensile and tearing strengths of the NCO@FS/PU composite material are 57 MPa and 110.5 kN/m, respectively, which are 31.6% and 23.6% higher than that of pure casting PU. The glass transition temperature dropped from 3.4°C to –11.2°C, and the loss factor tanδ dropped from 0.59 to 0.46. TDI modified fumed silica is suitable for preparing silica-reinforced cast polyurethane composites.

-

Key words:

- isocyanate modification /

- fumed silica /

- polyurethane /

- composites /

- mechanical properties

-

表 1 不同2, 4-甲苯二异氰酸酯改性的二氧化硅(NCO@FS)和气相二氧化硅(FS)含量的聚氨酯 (PU)试样

Table 1. Polyurethane (PU) samples with different content of 2, 4-toluene diisocyanate modified silica (NCO@FS) and fumed silica (FS)

Sample NCO@FS/wt% FS/wt% NCO@FS/PU-0.5 0.5 – NCO@FS/PU-1.0 1.0 – NCO@FS/PU-1.5 1.5 – NCO@FS/PU-3.0 3.0 – FS/PU-1.0 – 1.0 FS/PU-1.5 – 1.5 FS/PU-3.0 – 3.0 表 2 FS和NCO@FS的XPS图谱中元素含量比较

Table 2. XPS atomic content for elements in FS and NCO@FS

System C/at% O/at% Si/at% N/at% C/Si O/Si FS 45.74 38.03 16.23 0.00 2.82 2.34 NCO@FS 71.96 14.06 4.89 9.09 14.72 2.88 表 3 FS/PU和NCO@FS/PU复合材料力学性能随FS质量分数的变化

Table 3. Variations in mechanical properties of FS/PU and NCO@FS/PU with the mass fraction of FS

Sample Tensile strength

/MPaTear strength

/(kN·m−1)Elongation at break/% Hardness

(Shore D)PU 43.3(0.9) 89.4(1.6) 447(10) 40(1) NCO@FS/PU-0.5 45.4(1.3) 88.7(1.9) 424(18) 41(1) NCO@FS/PU-1 51.6(1.0) 95.1(2.3) 576(14) 43(1) NCO@FS/PU-1.5 57.0(0.8) 110.5(1.3) 516(10) 43(1) NCO@FS/PU-3 17.7(1.5) 87.2(2.9) 303(23) 43(1) FS/PU-1 47.7(0.8) 82.8(2.0) 459(15) 40(1) FS/PU-1.5 28.0(0.6) 51.9(1.3) 478(20) 41(1) FS/PU-3 7.9(1.2) 36.3(2.6) 243(21) 42(2) -

[1] GHOLAMIPOUR N, SADEGHI M, SHAFIEI M. Effect of silica nanoparticles on the performance of polysulfone membranes for olefin-paraffin separation[J]. Chemical Engineering & Technology,2019,42(11):2292-2301. [2] GORKY F, GUTHRIE S R, SMOLJAN C S, et al. Plasma ammonia synthesis over mesoporous silica SBA-15[J]. Journal of Physics D: Applied Physics,2021,54(26):1-10. [3] JALIL R R, HUSSEIN H. Influence of nano fluid on interfacial tension oil/water and wettability alteration of limestone[J]. IOP Conference Series: Materials Science and Engineering,2019,518(6):1-7. [4] SALAHUDDIN N, ABO-EI-ENEIN S A, SELIM A, et al. Synthesis and characterization of polyurethane-urea clay nanocomposites using montmorillonite modified by oxyethylene-oxypropylene copolymer[J]. Polymers for Advanced Technologies,2010,21(8):533-542. doi: 10.1002/pat.1449 [5] AKRAM D, AHMAD S, SHARMIN E, et al. Silica reinforced organic-inorganic hybrid polyurethane nanocomposites from sustainable resource[J]. Macromolecular Chemistry & Physics,2010,211(4):412-419. [6] KURIYAGAWA M, KAWAMURA T, HAYASHI S, et al. Reinforcement of polyurethane-based shape memory polymer by hindered phenol compounds and silica particles[J]. Journal of Applied Polymer Science,2010,117(3):1695-1702. [7] ZHANG J, JIANG G, HUANG T, et al. Preparation and characterization of polyurethane-silica hybrid films[J]. Pigment and Resin Technology,2019,48(5):357-362. doi: 10.1108/PRT-03-2019-0029 [8] NAVIDFAR A, SANCAK A, YILDIRIM K B, et al. A study on polyurethane hybrid nanocomposite foams reinforced with multiwalled carbon nanotubes and silica nanoparticles[J]. Journal of Macromolecular Science: Part D-Reviews in Polymer Processing,2018,57(14):1463-1473. [9] CHUNG Y C, CHUNG K H, CHOI J W, et al. Preparation of hybrid polyurethane-silica composites by a lateral sol-gel process using tetraethyl orthosilicate[J]. Journal of Composite Materials,2017,52(2):159-168. [10] 李灵琦, 叶伟华, 童真, 等. 聚氨酯预聚物对沉淀法SiO2表面改性的研究[J]. 聚氨酯工业, 2012, 27(3):21-23. doi: 10.3969/j.issn.1005-1902.2012.03.006LI Lingqi, YE Weihua, TONG Zhen, et al. Study on surface modification of precipitation method SiO2 with polyurethane prepolymer[J]. Polyurethane Industry,2012,27(3):21-23(in Chinese). doi: 10.3969/j.issn.1005-1902.2012.03.006 [11] NGUYEN T V, NGUYEN T A, NGUYEN T H. The synergistic effects of SiO2 nanoparticles and organic photo stabilizers for enhanced weathering resistance of acrylic polyurethane coating[J]. Journal of Composites Science,2020,4(23):1-11. [12] 穆晓东, 崔雨果, 方庆红, 等. 白炭黑的功能化改性及其改性橡胶基复合材料的制备与表征[J]. 复合材料学报, 2017, 34(1):67-74.MU Xiaodong, CUI Yuguo, FANG Qinghong, et al. Preparation and characterization of functionalization of silica and its rubber matrix composites[J]. Acta Materiae Compositae Sinica,2017,34(1):67-74(in Chinese). [13] XIA T, CHEN X, XU J H, et al. Key role of network formation in rutting, fatigue and brittle performance of bitumen/PEG/MDI/SiO2 composites[J]. Construction and Building Materials,2021,296:1-8. [14] HU F, QI F, XIANG Z H, et al. Synergistic enhancement effect of nano-SiO2 and ionic liquids on mechanical properties and impact resistance of polyurethane elastomer[J]. Composites Communications,2021,27:1-7. [15] 李嘉晋, 范仁祥, 李雅迪, 等. 三种形貌纳米SiO2的调控合成及其原位增强亲水性聚氨酯注浆复合材料[J]. 复合材料学报, 2017, 34(5):957-962.LI Jiajin, FAN Renxiang, LI Yadi, et al. Synthesis and characterization of three kinds of nano SiO2 particles with different morphologies and their application in reinforced polyurethane grouting composities[J]. Acta Materiae Compositae Sinica,2017,34(5):957-962(in Chinese). [16] 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶拉伸应力应变性能的测定: GB/T 528—2009[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People’s Republic of China. Rubber, vulcanized or thermoplastic—Determination of tensile stress-strain properties: GB/T 528—2009[S]. Beijing: China Standards Press, 2009(in Chinese). [17] 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶撕裂强度的测定(裤形、直角形和新月形试样): GB/T 529—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People’s Republic of China. Rubber, vulcanized or thermoplastic—Determination of tear strength (Trouser, angle and crescent test pieces): GB/T 529—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [18] 中国国家标准化管理委员会. 橡胶袖珍硬度计压入硬度试验方法: GB/T 531—1999[S]. 北京: 中国标准出版社, 1999.Standardization Administration of the People’s Republic of China. Rubber—Determination of indentation hardness by means of pocket hardness meters: GB/T 531—1999[S]. Beijing: China Standards Press, 1999(in Chinese). [19] 陈和生, 孙振亚, 邵景昌. 八种不同来源二氧化硅的红外光谱特征研究[J]. 硅酸盐通报, 2011, 30(4):934-937.CHEN Hesheng, SUN Zhenya, SHAO Jingchang. Investigation on FTIR spectroscopy for eight different sources of SiO2[J]. Bulletin of the Chinese Ceramic Society,2011,30(4):934-937(in Chinese). [20] 李延洁, 周竹发, 王春蓉, 等. 纳米白碳黑的复合改性及性能表征[J]. 化工学报, 2010, 61(3):789-794.LI Yanjie, ZHOU Zhufa, WANG Chunrong, et al. Compo-site modification and characterization of nano silica[J]. Journal of Chemical Engineering,2010,61(3):789-794(in Chinese). [21] CHEN L J, WANG X P, JIA Z X, et al. Use of precipitated silica with silanol groups as an inorganic chain extender in polyurethane[J]. Materials & Design,2015,87:324-330. [22] 艾青松, 陈虹, 赵磊, 等. 反应温度对PTMG-MDI型聚氨酯弹性体结构及性能的影响[J]. 塑料科技, 2017, 45(1):46-50.AI Qingsong, CHEN Hong, ZHAO Lei, et al. Influence of reaction temperature on structure and properties of PTMG-MDI type polyurethane elastomer[J]. Plastics Science and Technology,2017,45(1):46-50(in Chinese). [23] 谭井华. 聚氨酯/白炭黑有机-无机杂化材料及其对橡胶的互穿网络改性研究[D]. 广州: 华南理工大学, 2012.TAN Jinghua. PU/silica organic-inorganic hybrid materials and their interpenetrating networks with rubber[D]. Guangzhou: South China University of Technology, 2012(in Chinese). -

下载:

下载: