Effect of ultra-low temperature on flexural behavior of ultra-high toughness cementitious composites

-

摘要: 超高韧性水泥基复合材料(UHTCC)作为一种具有良好力学性能和耐久性能的新型复合材料,弯曲韧性是评价其力学性能的重要指标。为探究UHTCC材料在超低温环境下的抗弯性能,设计了5组不同纤维体积掺量的UHTCC新材料,经过深冷处理后进行四点弯曲试验,对其进行等效强度分析,提出一种适用于超低温作用后的韧性评价方式,为UHTCC在超低温领域的广泛应用提供理论基础和技术支持。研究结果表明:超低温作用后UHTCC的弯拉强度显著提升,当温度降低至−160℃,UHTCC的弯拉强度最大可提升67.67%,但表现出明显的脆性;超低温环境下1.5vol%UHTCC的强度及韧性性能提升效果最佳,但超出最优掺量后,UHTCC的性能反而略微降低。

-

关键词:

- 超高韧性水泥基复合材料 /

- 超低温 /

- 弯拉强度 /

- 抗弯韧性 /

- 纤维掺量

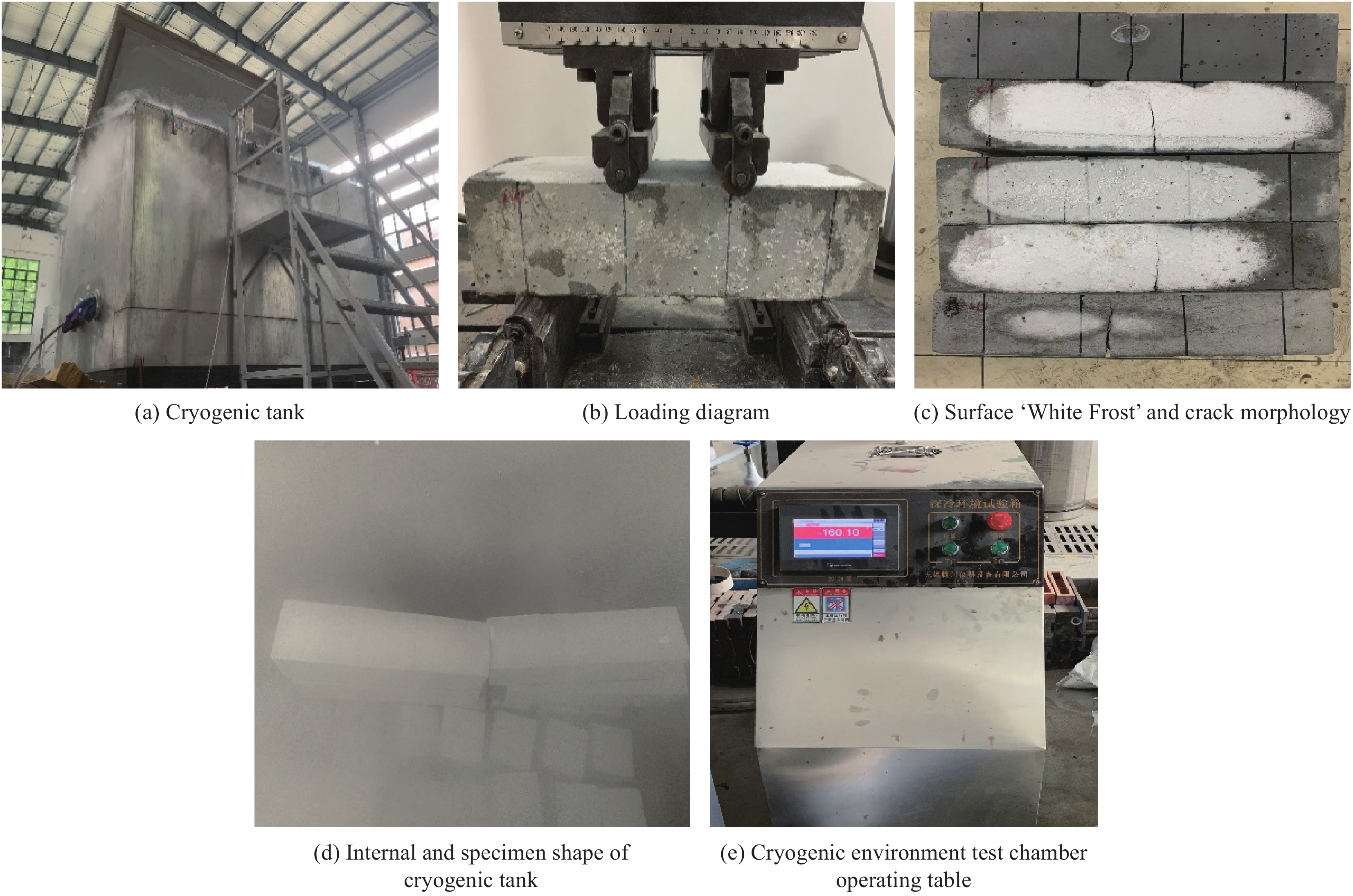

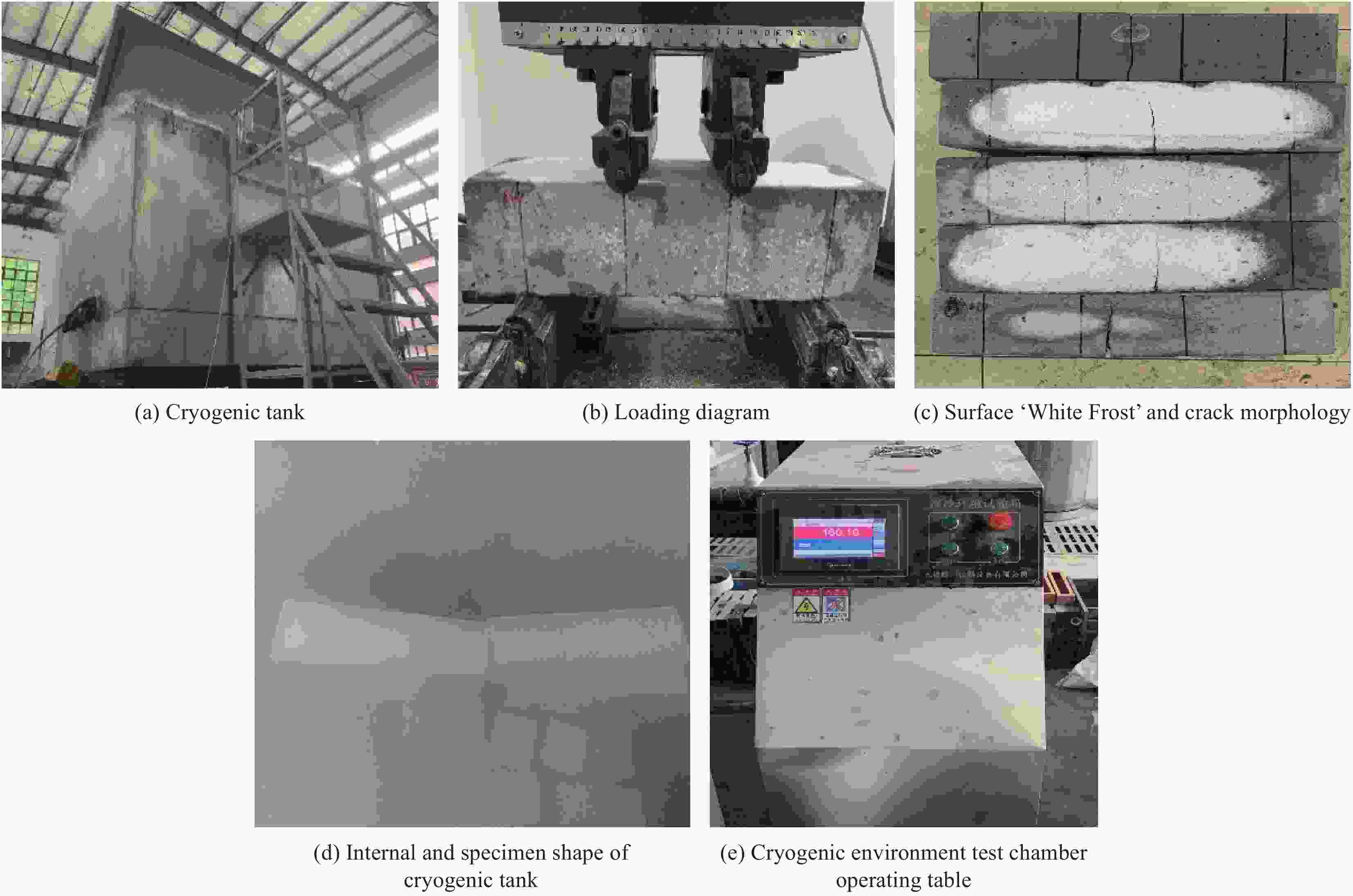

Abstract: As a new type of composite material with good mechanical properties and durability, the flexural toughness of ultra-high toughness cementitious composites (UHTCC) is an important indicator to evaluate its mechanical properties. To explore the bending performance of UHTCC materials under an ultra-low temperature environment, five groups of UHTCC materials with different fiber contents were designed. After cryogenic treatment, four-point bending tests were carried out, and the equivalent strength was analyzed. A toughness evaluation method suitable for ultra-low temperature was proposed, which provided the theoretical basis and technical support for the wide application of UHTCC in the field of ultra-low temperature. The results show that the flexural strength of UHTCC increases significantly after ultra-low temperatures. When the temperature decreases to −160℃, the flexural strength of UHTCC increases by 67.67%, but it shows obvious brittleness. In an ultra-low temperature environment, the strength and toughness of UHTCC with 1.5vol% volume fraction are the best, but the performance of UHTCC is slightly reduced after exceeding the optimal volume fraction. -

表 1 聚乙烯醇(PVA)纤维性能指标

Table 1. Polyvinyl alcohol (PVA) fiber performance index

Name Density/(g·cm−3) Diameter/mm Length/mm Elastic modulus/MPa Tensile strength/MPa Elongation/% REC15×12 1.3 0.04 12 120 526 6 表 2 试件分组

Table 2. Specimen grouping

Group PVA content/vol% Temperature/℃ Fly ash/(kg·m−3) Cement

/(kg·m−3)Sand/(kg·m−3) Silica fume/(kg·m−3) 0vol%PVA/C30 0 20/0/−40/−80/−120/−160 533.3 120 133.3 13.3 0.5vol%PVA/C30 0.5 20/0/−40/−80/−120/−160 533.3 120 133.3 13.3 1.0vol%PVA/C30 1.0 20/0/−40/−80/−120/−160 533.3 120 133.3 13.3 1.5vol%PVA/C30 1.5 20/0/−40/−80/−120/−160 533.3 120 133.3 13.3 2.0vol%PVA/C30 2.0 20/0/−40/−80/−120/−160 533.3 120 133.3 13.3 表 3 UHTCC试件平均弯拉强度试验值

Table 3. Test values of average flexural tensile strength of each group UHTCC specimens

MPa Group 20℃ 0℃ −40℃ −80℃ −120℃ −160℃ 0vol%PVA/C30 2.61 3.24 4.81 4.56 2.70 3.15 0.5vol%PVA/C30 3.46 2.81 3.75 3.81 2.95 4.85 1.0vol%PVA/C30 4.70 5.48 5.32 6.19 7.32 7.55 1.5vol%PVA/C30 5.30 6.09 6.32 7.13 7.88 8.88 2.0vol%PVA/C30 6.15 5.09 3.80 5.24 6.43 6.54 表 4 UHTCC强度及韧性指标

Table 4. Strength and toughness index of UHTCC

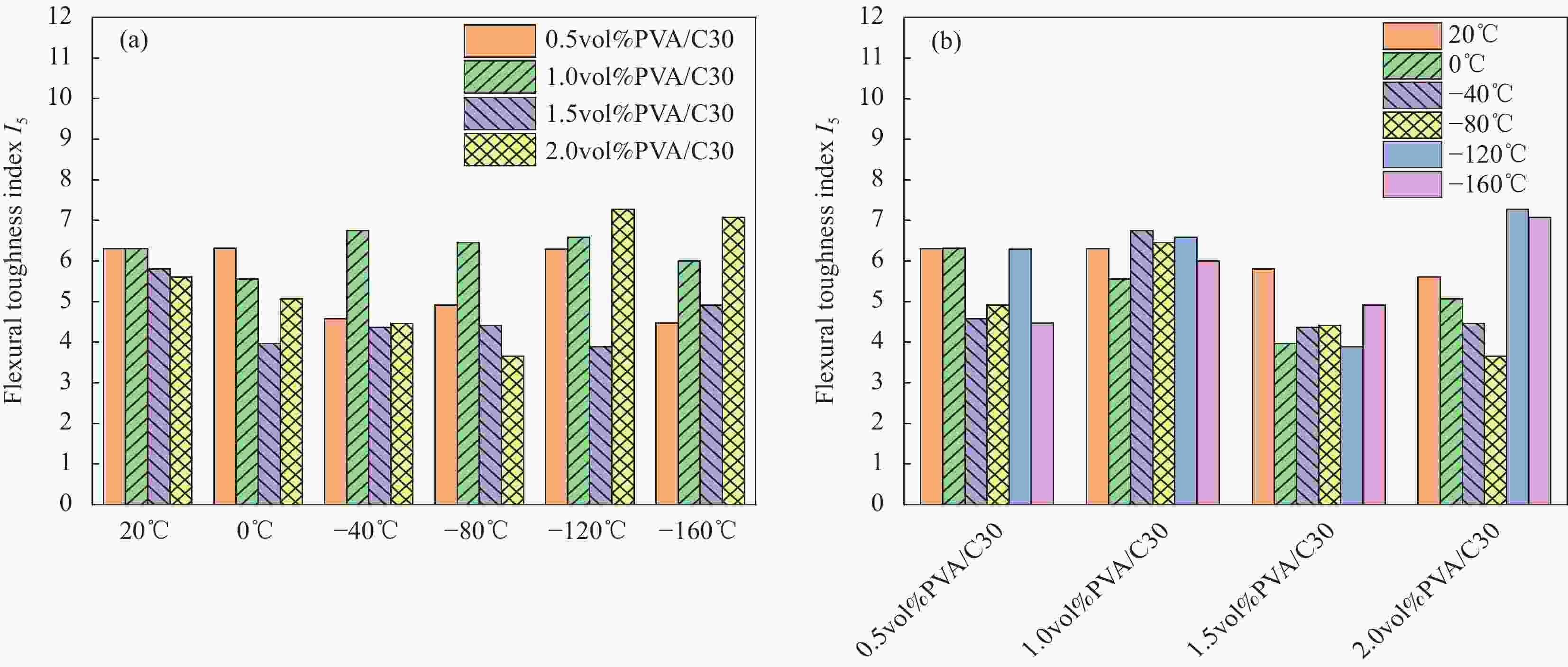

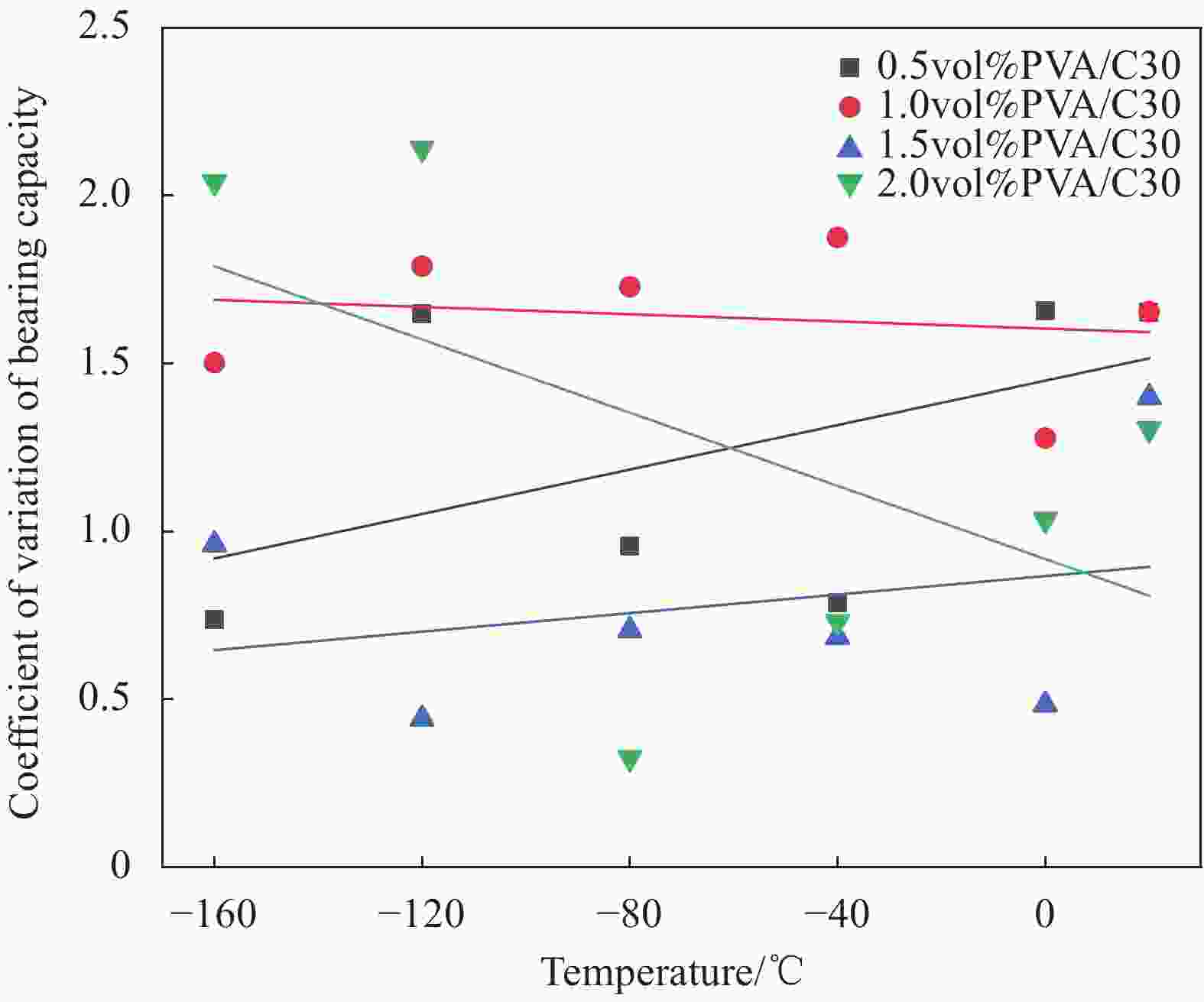

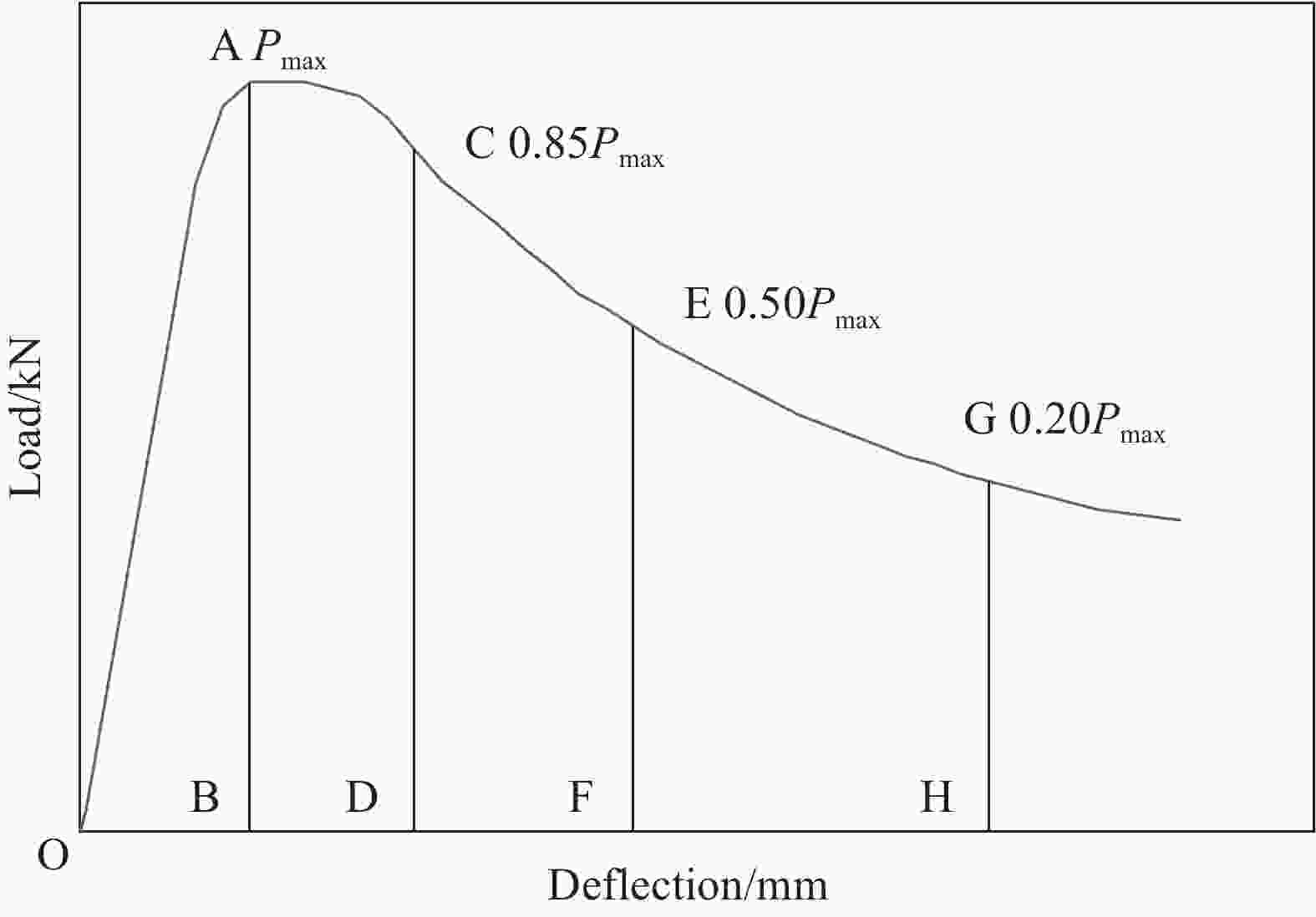

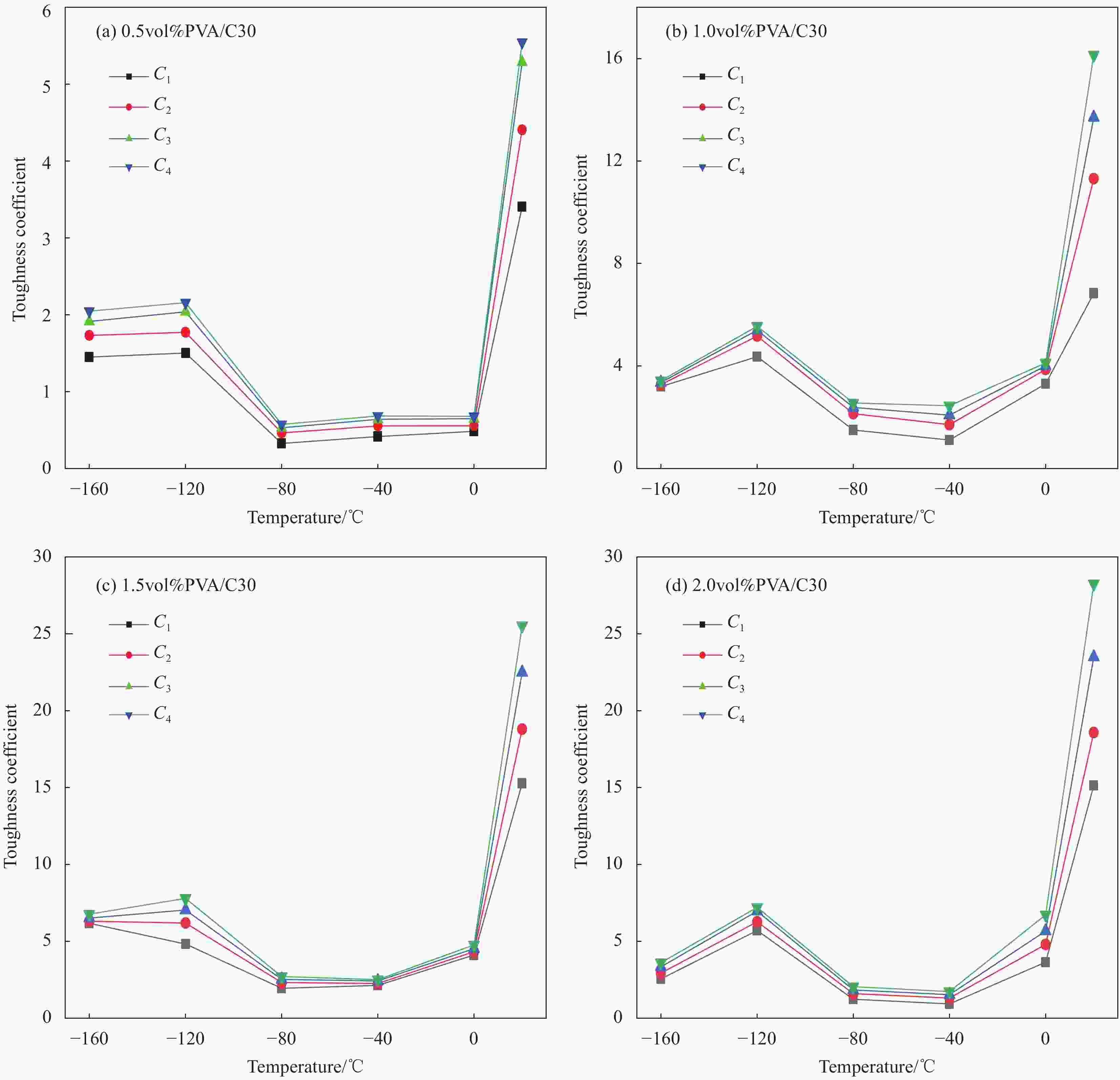

Group Temperature/℃ Initial crack load/kN Initial crack deflection/

mmPeak

load/

kNEquivalent bending strength/MPa Equivalent bending strength I5 Toughness coefficient Ci i=1 i=2 i=3 i=4 0vol%PVA/C30 20 8.70 0.27 8.70 − − − − − 0 10.80 0.54 10.80 − − − − − −40 16.02 0.76 16.02 − − − − − −80 15.21 0.86 15.21 − − − − − −120 9.01 0.64 9.01 − − − − − −160 10.49 0.65 10.49 − − − − − 0.5vol%PVA/C30 20 6.31 0.30 11.52 1.27 6.31 3.41 4.41 5.29 5.55 0 4.53 0.14 9.35 0.86 6.31 0.48 0.56 0.65 0.68 −40 7.95 0.24 12.49 1.28 4.57 0.42 0.55 0.64 0.68 −80 8.96 0.19 12.70 1.47 4.91 0.33 0.46 0.53 0.57 −120 5.09 0.37 9.82 0.97 6.30 1.50 1.77 2.04 2.16 −160 9.92 0.34 16.17 2.46 4.47 1.45 1.73 1.91 2.05 1.0vol%PVA/C30 20 10.06 0.39 15.65 2.11 6.31 6.84 11.31 13.70 16.15 0 9.57 0.44 18.28 1.58 5.55 3.30 3.86 4.00 4.12 −40 10.75 0.33 17.72 2.31 6.75 1.11 1.71 2.08 2.45 −80 11.86 0.44 20.64 2.38 6.46 1.50 2.14 2.38 2.55 −120 11.36 0.43 24.40 2.11 6.58 4.36 5.17 5.40 5.55 −160 11.29 0.33 25.17 1.82 6.01 3.20 3.28 3.36 3.43 1.5vol%PVA/C30 20 12.72 0.74 17.66 2.13 5.80 15.28 18.81 22.50 25.54 0 12.66 0.58 20.30 1.59 3.97 4.11 4.32 4.53 4.76 −40 12.74 0.61 21.05 1.68 4.37 2.13 2.26 2.42 2.51 −80 15.06 0.56 23.78 2.14 4.41 1.95 2.32 2.52 2.71 −120 18.24 0.64 26.28 2.62 3.88 4.82 6.19 7.04 7.79 −160 15.01 0.64 29.61 2.15 4.92 6.17 6.30 6.51 6.77 2.0vol%PVA/C30 20 13.96 0.81 20.50 2.49 5.61 15.13 18.58 23.50 28.26 0 10.87 0.74 16.97 1.97 5.07 3.64 4.80 5.67 6.72 −40 9.09 0.58 12.68 1.51 4.46 0.92 1.30 1.52 1.73 −80 13.11 0.64 17.48 1.79 3.65 1.23 1.60 1.83 2.04 −120 9.17 0.63 21.43 1.82 7.28 5.70 6.27 6.96 7.21 −160 10.78 0.37 21.80 2.09 7.08 2.55 2.93 3.34 3.61 Notes: Since the performance of UHTCC changes after the action of ultra-low temperature, its initial crack deflection increases, and its failure deflection decreases, resulting in that the toughness calculation method in the specification cannot well evaluate its toughness, and its toughness index I5 can only be calculated, while I10 and I20 cannot be evaluated and analyzed because they cannot meet the deflection requirements. 表 5 不同温度下各UHTCC试验组纤维增强效应系数

Table 5. Fiber reinforcement effect coefficients of each UHTCC test group at different temperatures

Group Temperature/℃ Fiber reinforcement effect coefficient 0.5vol%PVA/C30 20 5.20 0 0.67 −40 0.68 −80 0.56 −120 2.05 −160 1.94 1.0vol%PVA/C30 20 15.54 0 4.07 −40 2.57 −80 2.43 −120 5.35 −160 3.16 1.5vol%PVA/C30 20 24.55 0 5.21 −40 2.69 −80 2.56 −120 7.71 −160 6.47 2.0vol%PVA/C30 20 30.85 0 7.24 −40 1.85 −80 2.18 −120 7.23 −160 3.67 -

[1] LIU X M, ZHANG M H, CHIA K S, et al. Mechanical properties of ultra-lightweight cement composite at low tempera-tures of 0 to −60℃[J]. Cement and Concrete Composites,2016,73:289-298. doi: 10.1016/j.cemconcomp.2016.05.014 [2] DAHMANI L, KHENANE A, KACI S. The behavior of the reinforced concrete at cryogenic temperatures[J]. Cryogenics,2007,47(9):517-525. [3] GERWICK B. Eighth international congress of the FIP[J]. Engineering Structures, 1978, 1(1): 55. [4] 程旭东, 朱兴吉. LNG储罐外墙温度应力分析及预应力筋设计[J]. 石油学报, 2012, 33(3):499-505.CHENG X D, ZHU X J. Thermal stress analysis and prestressed reinforcement design of external wall of LNG storage tank[J]. Petroleum Journal,2012,33(3):499-505(in Chinese). [5] 吴中伟. 纤维增强──水泥基材料的未来[J]. 混凝土与水泥制品, 1999, 1:3-4.WU Z W. Fiber reinforcement-future of cement based materials[J]. Concrete and Cement Products,1999,1:3-4(in Chinese). [6] 李贺东, 徐世烺. 超高韧性水泥基复合材料弯曲性能及韧性评价方法[J]. 土木工程学报, 2010, 43(3):32-39.LI H D, XU S L. The evaluation method of flexural prop-erties and toughness of ultra-high toughness cementitious composites[J]. Journal of Civil Engineering,2010,43(3):32-39(in Chinese). [7] 徐世烺, 李贺东. 超高韧性水泥基复合材料研究进展及其工程应用[J]. 土木工程学报, 2008(6):45-60. doi: 10.3321/j.issn:1000-131X.2008.06.008XU S L, LI H D. Research progress and engineering application of ultra-high toughness cementitious composites[J]. Journal of Civil Engineering,2008(6):45-60(in Chinese). doi: 10.3321/j.issn:1000-131X.2008.06.008 [8] 张秀芳, 徐世烺, 侯利军. 采用超高韧性水泥基复合材料提高钢筋混凝土梁弯曲抗裂性能研究(II): 试验研究[J]. 土木工程学报, 2009, 42(10):53-66. doi: 10.3321/j.issn:1000-131X.2009.10.008ZHANG X F, XU S L, HOU L J. Using ultra-high toughness cementitious composites to improve the flexural crack re-sistance of reinforced concrete beams (II): Experimental study[J]. Journal of Civil Engineering,2009,42(10):53-66(in Chinese). doi: 10.3321/j.issn:1000-131X.2009.10.008 [9] MIURA T. The properties of concrete at very low tempera-tures[J]. Materials and Structures,1989,22(4):243-254. doi: 10.1007/BF02472556 [10] ELHACHA R, GREEN M F, WIGHT R G. Flexural behaviour of concrete beams strengthened with prestressed carbon fibre reinforced polymer sheets subjected to sustained loading and low temperature[J]. Canadian Journal of Civil Engineering,2004,31(2):239-252. doi: 10.1139/l03-091 [11] XIE J, LI X M, WU H H. Experimental study on the axial-compression performance of concrete at cryogenic tem-peratures[J]. Construction and Building Materials,2014,72:380-388. doi: 10.1016/j.conbuildmat.2014.09.033 [12] DANILLE D, HOULT N A, GREEN M F. Effects of varying temperature on the performance of reinforced concrete[J]. Springer Netherlands,2015,48(4):1109-1123. [13] YAN J B, XIE J. Behaviours of reinforced concrete beams under low temperatures[J]. Construction and Building Materials,2017,141:410-425. doi: 10.1016/j.conbuildmat.2017.03.029 [14] TOGNON G. Behavior of mortars and concretes in the temperature range from 20℃ to −196℃[R]. 5th International Congress on the Chemistry of Cement, 1969: 229-249. [15] 中国工程建设协会标准. 纤维混凝土试验方法标准: CECS 13—2010[S]. 北京: 计划出版社, 2010.China Association for Engineering Construction Standardization. Fiber reinforced concrete test method standard: CECS 13—2010[S]. Beijing: Planning Press, 2010(in Chinese). [16] 中华人民共和国住房和城乡建设部. 混凝土结构试验方法标准: GB/T 50152—2012[S]. 北京: 中国建筑工业出版社, 2012.Ministry of Housing Urban-Rural Development of the People's Republic of China. Concrete structure test method standard: GB/T 50152—2012[S]. Beijing: China Architecture & Building Press, 2012(in Chinese) [17] LEE G C, SHIH T S, CHANG K C. Mechanical properties of concrete at low temperature[J]. Journal of Cold Regions Engineering,1988,2(1):13-24. doi: 10.1061/(ASCE)0887-381X(1988)2:1(13) [18] YAMANA S, KASAMI H, OKUNO T. Properties of concrete at very low temperatures[J]. ACI Special Publication,1978,55:1-12. [19] CAI X P, YANG W C, YUAN J, et al. Mechanics properties of concrete at low temperature[J]. Advanced Materials Research,2011,1278:389-393. [20] 史占崇, 苏庆田, 邵长宇, 等. 粗骨料UHPC的基本力学性能及弯曲韧性评价方法[J]. 土木工程学报, 2020, 53(12):86-97.SHI Z C, SU Q T, SHAO C Y, et al. The basic mechanical properties and flexural toughness evaluation method of coarse aggregate UHPC[J]. Journal of Civil Engineering,2020,53(12):86-97(in Chinese). [21] American Concrete Institute Committee. Measurement of properties of fiber reinforced concrete: 544.2R—89[S]. Dtroit: American Concrete Institute, 2002. [22] SKAPSKI A, BILLUPS R, ROONEY A. Capillary cone method for determination of surface tension of solids[J]. Jour-nal of Chemical Physics, 1957, 26(5): 1350-1351. -

下载:

下载: