Effect of low-temperature plasma surface modification on the adhesive performance of CFRP

-

摘要: 采用低温等离子体处理技术对碳纤维增强树脂复合材料(CFRP)表面进行处理,以氩气(Ar)、N2和O2作为等离子体激发气体,通过接触角测量仪、AFM、SEM和XPS等测试分析手段,对CFRP表面的润湿性、粗糙度、微观形貌和化学组分进行表征,并结合拉伸剪切试验测试和失效形貌分析,研究了等离子体气体类型、放电功率P和处理时间t对CFRP表面理化特性和胶接性能的影响。结果表明:Ar、N2和O2等离子体处理可以显著改善CFRP胶接性能,当P=800 W,t=20 s时,与未处理相比,CFRP胶接强度分别提高了138%、172%和253%。表面测试分析可知,Ar等离子体处理后,CFRP胶接强度的增加主要是通过提高表面清洁度和增大界面粘接表面积,试样失效模式由界面失效转变为内聚失效为主的混合失效模式。与Ar相比,N2等离子体处理后,CFRP表面生成了较多—NH2极性基团,表面活性增加,进一步提高了CFRP和胶粘剂之间界面的结合力。与以上两种气体相比,O2等离子体刻蚀CFRP表面更为剧烈,并对表层基团进行重组,形成了极性较强—COOH官能团,试样胶接强度提高效果最佳,试样失效模式由界面失效转变为基板失效。此外,当活性粒子的密度和能量过高时,较大的等离子体刻蚀孔隙,在一定程度上会降低胶接性能。Abstract: Ar, N2 and O2 were used as low-temperature plasma excitation gases to treat the surface of carbon fiber reinforced plastics (CFRP). The effects of plasma gas, discharge power and treatment time on the physicochemical properties, including wettability, roughness, microscopic morphology and chemical components of CFRP surface, were characterized by contact angle measurement, AFM, SEM and XPS. The adhesive joint property was investigated through tensile shear experiment and failure morphology analysis. Compared with untreated, the tensile shear strength of CFRP adhesive joints after Ar, N2 and O2 plasma treatment can significantly improve the bonding performance of CFRP, and when the plasma discharge power is 800 W and treatment time is 20 s, the adhesive joint strength increases by 138%, 172% and 253%, respectively. The surface test analysis shows that the improvement of CFRP adhesive strength after argon plasma treatment is mainly induced by improving the surface cleanliness and increasing the surface area for interfacial adhesive, and the failure modes of samples changes from interfacial failure to mixed failure mode with cohesive failure as the main mode. Compared with Ar, a greater number of polar chemical groups (—NH2) are generated on the CFRP surface after N2 plasma treatment, which increase the surface activity and further improve the interfacial adhesive strength between CFRP and adhesive. Compared with the above two gases, O2 plasma etch the CFRP surface more vigorously, as well as reorganize the surface chemical groups, forming a more polar —COOH functional group, so that the specimen adhesive strength is improved most effectively, and the specimen failure mode changes from interface failure to substrate failure. In addition, under the excessively high density and energy of the active particles, the adhesive performance will be reduced to some extent with the expansion of the pores by plasma etching.

-

Keywords:

- CFRP /

- low temperature plasma /

- adhesive property /

- surface modification /

- wettability

-

碳纤维增强树脂复合材料(CFRP)具有比强度高、比模量高、耐热性好、可设计性强及易于大面积整体成型等优良特点,广泛应用于航空航天等领域[1-3]。理想情况下,复合材料结构件可以作为部件被整体成型,但受限于工艺技术,通常需要对结构件进行连接。与传统铆接、焊接和螺接等连接方法相比,胶接连接具有结构质量轻、制造成本低和有效缓解应力集中等优势,在复合材料结构连接中得到广泛应用[4-5]。然而,未经处理的CFRP表面通常呈现疏水性,与胶粘剂粘合时亲和力较差,导致胶接界面稳定性和粘接强度较低,不利于工程应用。因此,在胶接前有必要对CFRP表面进行预处理,以改善粘接性能。常见的表面处理方法有砂纸打磨[6]、喷砂处理[7-8]、可剥布[9]、化学处理[10-11]、激光处理[12]和等离子体处理[13-14]等,其中砂纸打磨和喷砂处理操作误差大、易于损伤材料表面;可剥布会在材料经度和纬度交叉处形成凸起和凹陷,固化后容易产生孔隙;化学方法使用的溶剂会对环境造成污染;激光处理中产生过高的热量容易造成纤维损伤。目前研究发现,与其他处理方式相比,等离子体表面处理可以显著改善CFRP粘接性能,例如,Prolongo等[15]对比了可剥布、喷砂和等离子体处理方式对CFRP粘接性能的影响,研究发现,与前两种处理方法相比,等离子体处理后的CFRP表面能极性组分明显增加,胶接强度提高更显著。Liu等[16]对比了砂纸打磨和等离子体处理方式对CFRP单搭接接头力学性能的影响,试验结果表明,经等离子体处理后的CFRP粘接强度为11.31 MPa,明显优于砂纸打磨处理试件的8.14 MPa。此外,等离子体表面处理可以在保持材料固有属性的前提下对表面进行修饰并赋予其新的表面功能状态,是一种高效、经济、环保和可重复性的处理方法,在复合材料表面处理中具有广泛应用前景[17-18]。

目前等离子表面处理方式主要分为两类,即低压等离子体处理和常压等离子体处理。近年来国内外学者围绕这两种处理方式分别进行了研究。Yoozbashizadeh等[19]采用大气压空气等离子体射流对CFRP表面进行处理,研究发现,经等离子体处理后的CFRP表面润湿性能得到明显改善。翟全胜等[20]研究了低温常压空气等离子体处理对T800碳纤维/高韧性环氧树脂复合材料胶接性能的影响,研究发现,经等离子体处理后的材料表面活性显著增加,胶接试样拉伸剪切强度和浮辊剥离性能均得到显著提高。Sun等[21]研究了常压空气等离子体处理参数对CFRP胶接接头静态单搭接剪切强度的影响,与未处理相比,当装置喷嘴速度v=5 mm/s,喷嘴距离h=18 mm时,CFRP胶接接头的剪切强度增加约267%。Lin等[22]研究常压空气等离子处理条件下,等离子体气体类型(Ar、N2、空气)对CFRP与胶粘剂界面结合强度的影响,研究发现,等离子体处理后,CFRP表面污染物得到有效清除,同时表面产生了较多含氧、氮极性基团,界面粘接强度得到明显改善。Pizzorni等[23]采用空气和纯氧作为等离子体工艺气体,研究了等离子体处理对CFRP胶接接头耐久性的影响变化,发现经纯氧等离子体处理后的CFRP接头抗老化性能更优。目前相关研究多关注在被胶接件表面理化性能或材料胶接性能的评价上,被胶接件表面状态与胶接性能的联系及影响的研究较少。此外,相比于大气压等离子体处理,低压等离子体处理条件下的离子发射方向性较弱,可以深入清洗形状复杂材料表面微细凹陷和孔眼等部位,并且处理过程在真空下进行,有效避免了温度、水分和空气等外界环境的影响,缩减了试验误差,提高了试验可重复性,有利于相关理论的研究。

本文采用低温低压等离子体处理技术对CFRP表面进行预处理,研究了等离子体气体类型(Ar、N2和O2)、放电功率和处理时间对CFRP胶接性能的影响。通过接触角测量仪、SEM、AFM和XPS等测试表征手段,系统分析等离子体处理对CFRP胶接界面粘接性能的影响机制。

1. 实验材料及方法

1.1 原材料

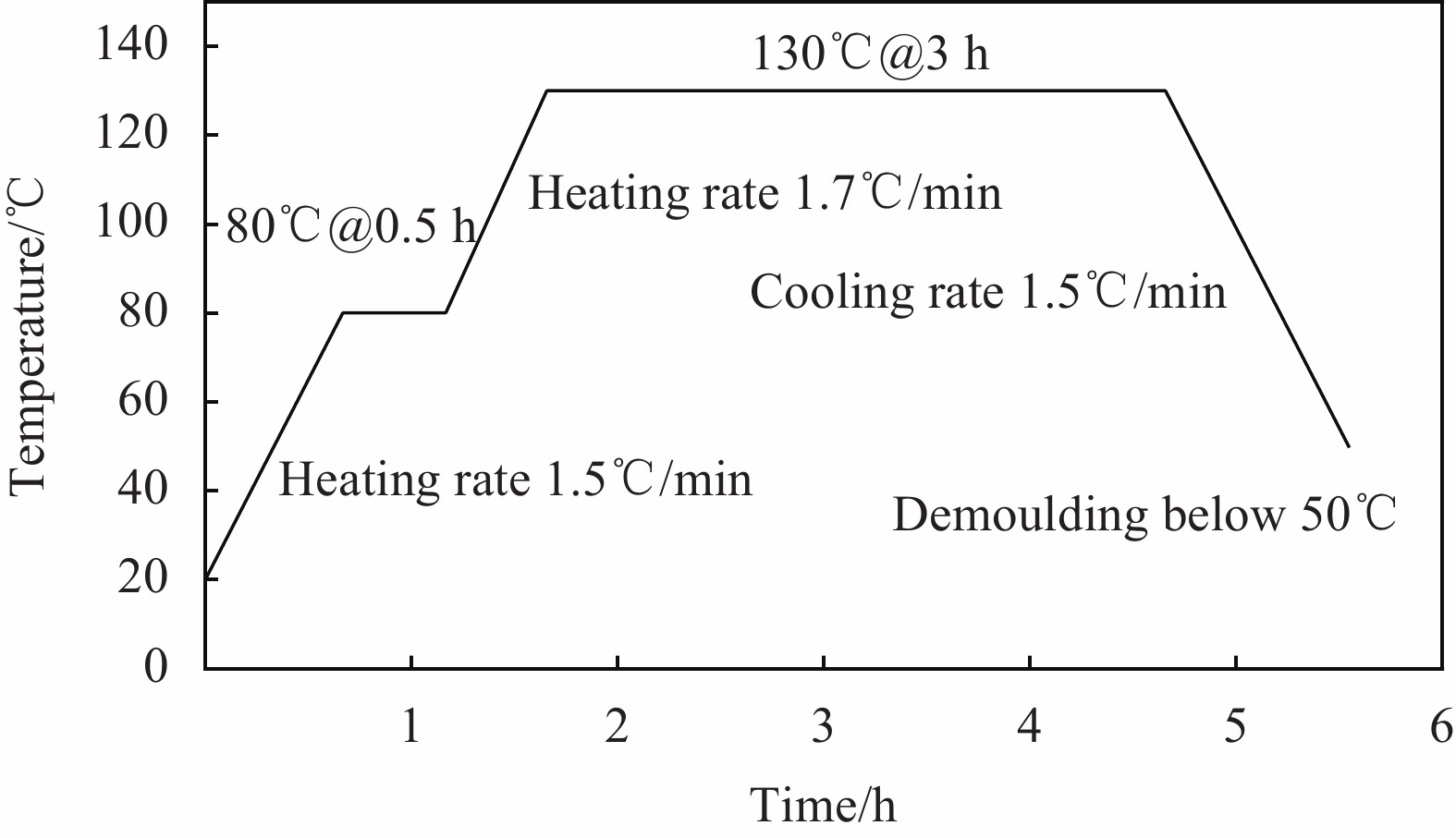

通过热压罐在0.26 MPa恒压下制备CFRP层合板(芜湖钻石飞机制造有限公司提供),制作工艺如图1所示,其中,单向碳纤维预浸料/环氧树脂牌号为USN15000/7901/RC33,铺层方式为[0/90]4S,复合材料主要性能参数如表1所示。胶粘剂选用双组分、室温固化的环氧类胶粘剂Araldite 2015(美国Huntsman公司),胶粘剂主要性能参数见表2。

表 1 CFRP复合材料主要性能参数Table 1. Main performance parameters of CFRP compositesMechanical property Value E11/GPa 121 E22/GPa 8.6 E33/GPa 8.6 G12/MPa 3450 G13/MPa 3450 G23/MPa 2800 Poisson’s ratio 0.3 Density/(kg·m−3) 1467 Notes: E—Young’s modulus; i (i=1, 2, 3)—Direction; G—Shear modulus. 表 2 Araldite 2015主要力学性能参数Table 2. Main mechanical property parameters of the Araldite 2015Araldite 2015 Value Tensile strength/MPa 21.63 Shear strength/MPa 17.90 Elongation/% 0.33 1.2 等离子体表面处理

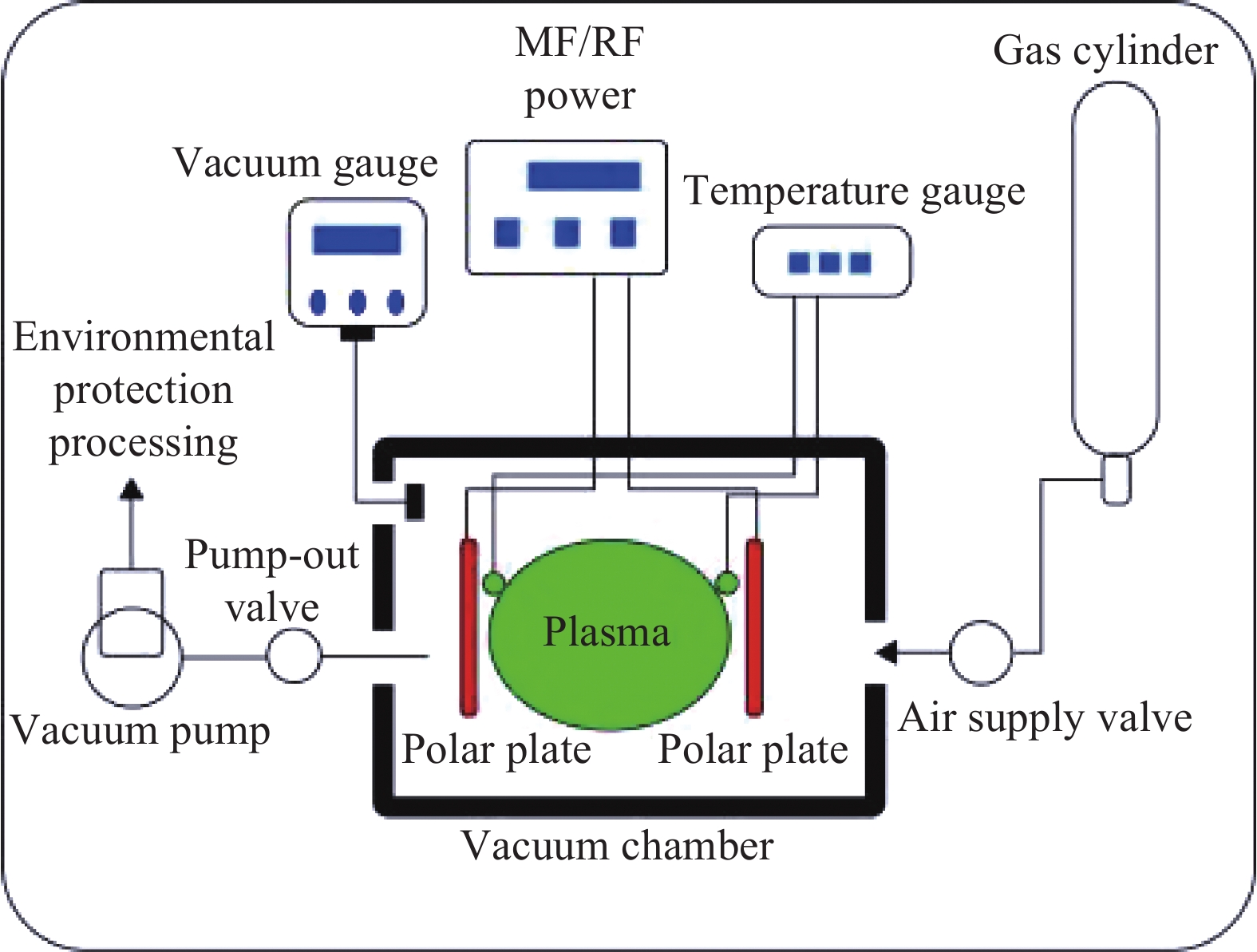

采用TS-PL150型低温低压等离子体处理设备(深圳东信高科有限公司)对CFRP表面进行处理。设备组成包括电源、反应腔室和真空泵组等,设备处理原理如图2所示。将CFRP层合板,放置于真空腔室中进行表面预处理,如图3所示。等离子体处理工艺参数如表3所示。选取气体种类为Ar、N2和O2,设置放电功率P分别为200 W、500 W和800 W,设置处理时间t分别为10 s、20 s和30 s。

表 3 低压等离子体处理工艺参数Table 3. Process parameters of low pressure plasma treatmentItem Nominal parameter value Plasma frequency/MHz 13.56 Power input/W 0-1000 Process pressure/Pa 100 Speed/(mL·min−1) 150 1.3 试样制备及单搭接拉伸试验

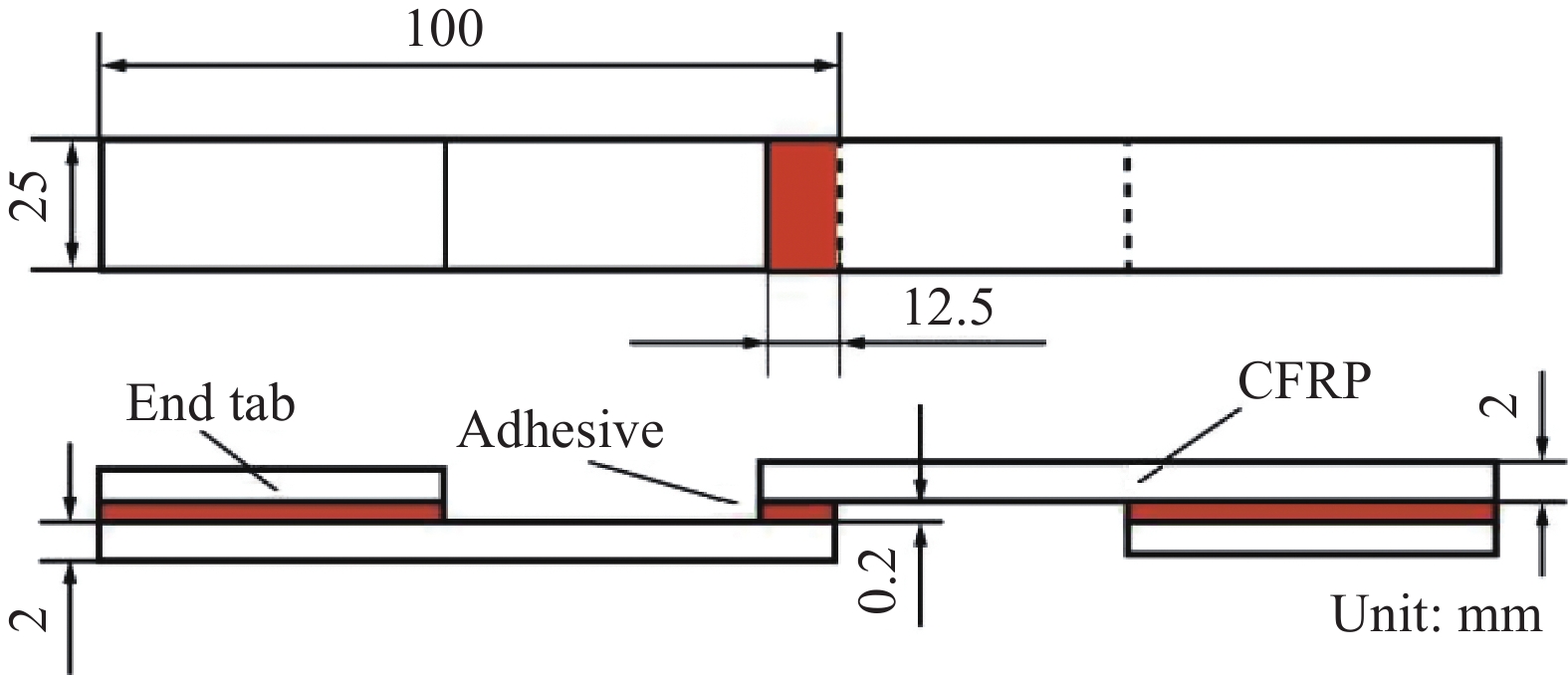

由于等离子体改性后材料表面微观形貌及化学基团含量会随着时间的推移发生衰减,需及时将处理完成后的试样进行胶接。单搭接胶接试样制备参考ASTM D1002标准[24],试样尺寸为100 mm×25 mm×2 mm,搭接区域面积为25 mm×12.5 mm,将直径为0.2 mm的玻璃微珠均匀撒在涂胶面,用来控制胶层厚度,粘接完成后,每个样品在整个表面承受1500 Pa均匀压力,以保持粘合剂固化过程中所需的平整度,并去除边缘多余胶瘤,之后于室温下静置24 h,以确保胶粘剂完全固化。为方便夹持,试样两端粘接加强垫片,单搭接试样尺寸如图4所示。

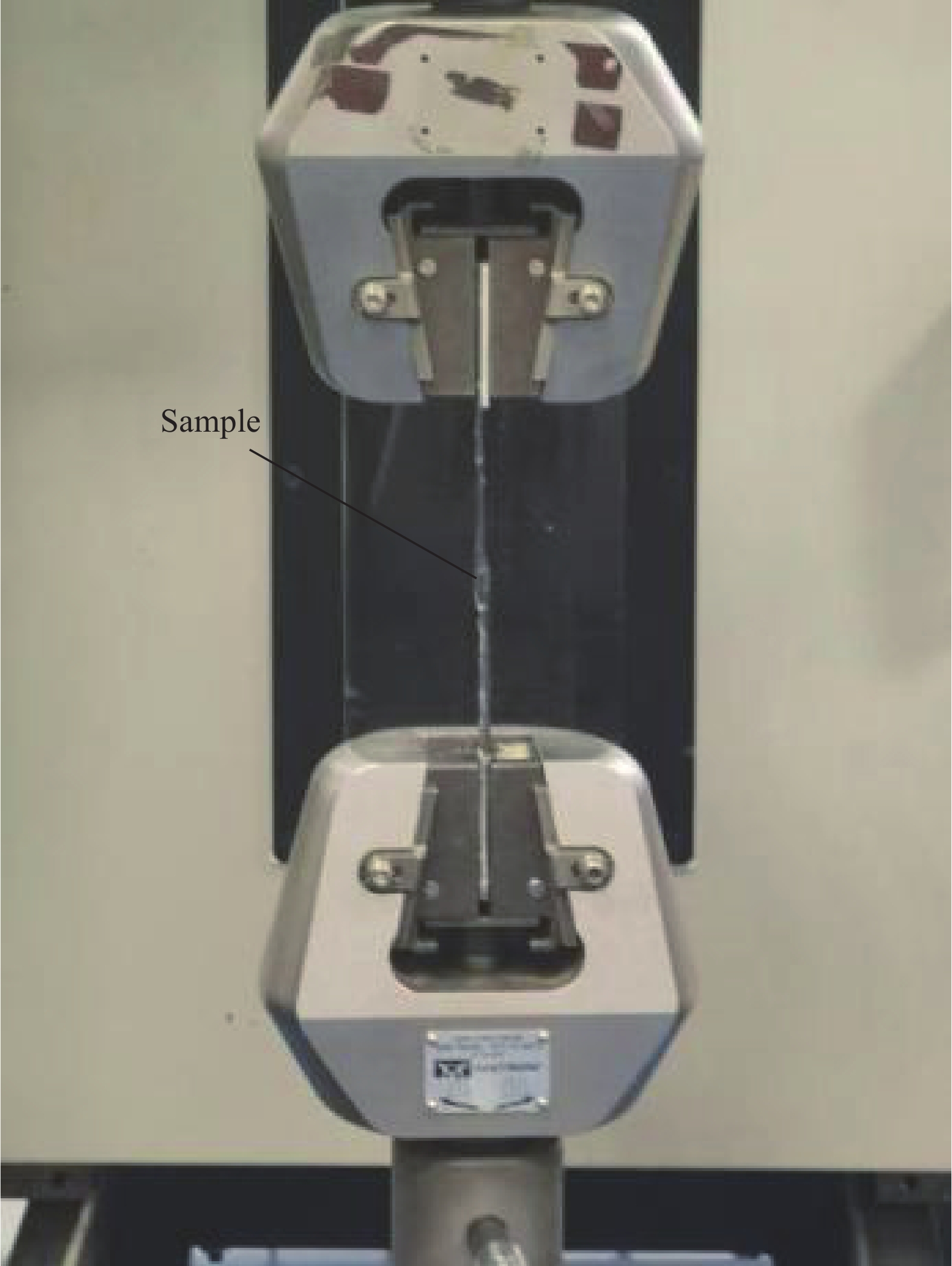

试样整体固化完成后,采用Instron5982电子万能材料试验机(美国英斯特朗公司),对试样进行拉伸加载试验,试验设置参考ASTM D5868-01标准[25],试验机加载速率为2 mm/min,试验装置如图5所示,为减小误差,每种处理参数下的单搭接试样测试5组。

1.4 测试与表征

1.4.1 CFRP表面接触角测试

采用SDC-200 S研究型接触角测量仪(东莞晟鼎精密仪器有限公司),通过图像轮廓分析方式对处理后的CFRP表面接触角进行测量,测量液体为去离子水,试滴体积为2 μL。试验结果选取5次测量后的平均值。

1.4.2 CFRP表面微观形貌表征

采用S-3400 N型扫描电镜(日本日立公司)和SPM-9700型原子力显微镜(日本岛津公司)对处理后的CFRP表面微观形貌和粗糙度进行表征。试验中扫描电镜放大倍数为1000倍,原子力显微镜扫描面积为5 μm×5 μm。

1.4.3 CFRP表面化学成分表征

采用K-Alpha X 射线光电子能谱仪(美国赛默飞世尔科技公司)测定处理后CFRP表面化学元素成分及官能团的变化。并使用XPS-PEAK分峰软件计算出试样表面C1s、O1s、N1s和Si2p中各官能团的相对含量。

2. 结果与讨论

2.1 等离子体处理对CFRP胶接性能的影响

2.1.1 等离子体处理对CFRP胶接接头拉伸剪切性能的影响

图6为未处理和等离子体处理后试样的拉伸剪切强度。可以看出,未处理试样的胶接强度仅为8.12 MPa,经等离子体处理后胶接强度均有明显提高。在相同P和t下,O2等离子体处理对试样胶接强度的改善效果最显著,其次为N2,而Ar对试样胶接强度的提升效果相对较弱。当P≤500 W时,随着t的增加,等离子体处理后的试样胶接强度不断提高。当P=800 W时,随着t的增加,胶接强度呈现先增加后减小的趋势,当t=20 s时,Ar、N2和O2处理条件下的试样胶接强度达到最大值,分别为19.34 MPa、22.16 MPa和28.71 MPa,与未处理相比,相应的提高了138%、172%和253%。而当P=800 W,t=30 s时,与t=20 s相比,试样胶接强度出现了不同程度的下降,其中O2处理后的试样胶接强度下降最明显,降低幅度约33.09%。

2.1.2 等离子体处理对CFRP接头失效模式的影响

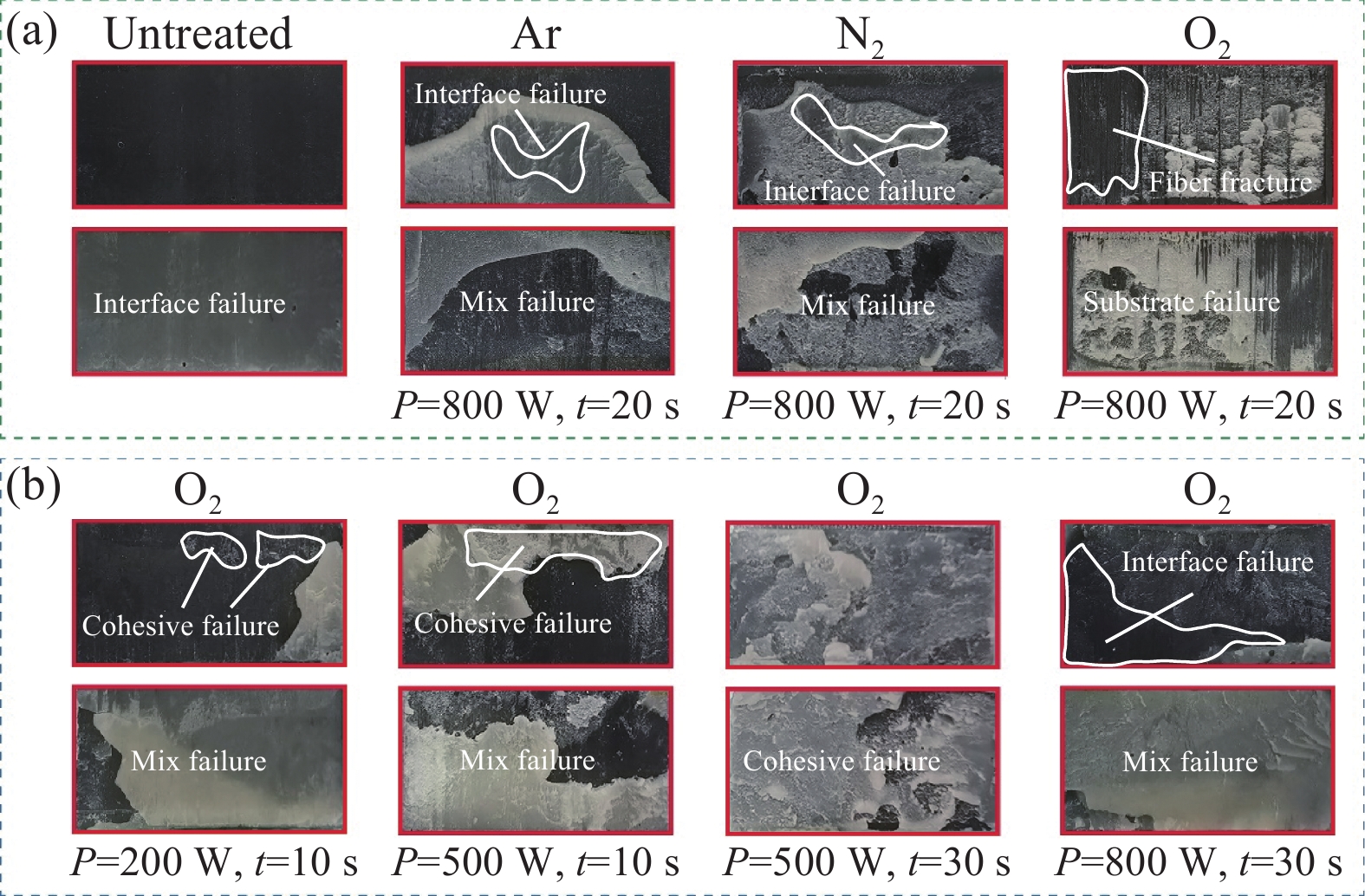

除了剪切强度外,单搭接胶接接头失效模式也是评价CFRP界面粘接性能好坏的一个重要指标。图7(a)为未处理和P=800 W,t=20 s时,Ar、N2和 O2等离子体处理后试样胶接接头断裂形貌图。由图可知,未处理试样的胶接接头主要破坏模式为胶粘剂与CFRP界面破坏,表明界面粘接强度相对较低。Ar、N2处理后的试样破坏形貌呈现以内聚破坏为主的混合失效,破坏主要发生在胶层内部,说明此时胶接面大部分区域界面粘接强度高于胶粘剂,胶粘剂性能得以充分利用,试样粘接强度得到提高。与Ar、N2相比,O2等离子体处理后的试样失效模式为CFRP基板失效,这是由于胶粘剂粘接界面强度处于较高水平,从而导致基板表层发生破坏,这也是最理想的破坏模式,在此模式下基板充分发挥了承载作用。

![]() 图 7 (a) 不同气体等离子体处理后CFRP试样的拉伸断裂形貌(放电功率P=800 W,处理时间t=20 s);(b) 不同P和t下O2等离子体处理后CFRP的拉伸断裂形貌Figure 7. (a) Effect of plasma treatment with different gases on the tensile fracture morphologies of the CFRP samples (Discharge power P=800 W, treatment time t=20 s); (b) Tensile fracture morphologies of the CFRP samples under O2 plasma treatment with different P and t

图 7 (a) 不同气体等离子体处理后CFRP试样的拉伸断裂形貌(放电功率P=800 W,处理时间t=20 s);(b) 不同P和t下O2等离子体处理后CFRP的拉伸断裂形貌Figure 7. (a) Effect of plasma treatment with different gases on the tensile fracture morphologies of the CFRP samples (Discharge power P=800 W, treatment time t=20 s); (b) Tensile fracture morphologies of the CFRP samples under O2 plasma treatment with different P and t图7(b)为不同放电功率和处理时间下,O2等离子体处理后试样胶接接头断裂形貌。可以看出,当P≤500 W时,随着放电功率和处理时间的增大,接头破坏模式的内聚失效面积占比不断增多,胶接强度不断提高,当P=500 W,t=30 s时,接头破坏模式呈现完全内聚失效,此时胶层充分发挥了承载能力,胶接强度达到了较高水平。以上结果表明,随着等离子体P和t的增大,促进胶接接头失效模式由界面失效向内聚失效转变,从而提高了胶接强度。而当P=800 W,t=30 s时,与t=20 s时的失效形貌相比(图7(a)),部分区域出现界面失效,胶接性能下降。

2.2 等离子体处理对CFRP表面理化特性的影响

由胶接界面理论可知,材料待胶接面的亲水性、表面轮廓和极性基团种类及含量对胶接性能均有影响[18]。为探究等离子体气体类型、放电功率和处理时间对CFRP胶接性能的影响机制,对等离子体处理后试样表面的润湿性、表面形貌和表面活性基团含量化学元素组分进行测试分析。

2.2.1 等离子体处理对CFRP表面润湿性能的影响

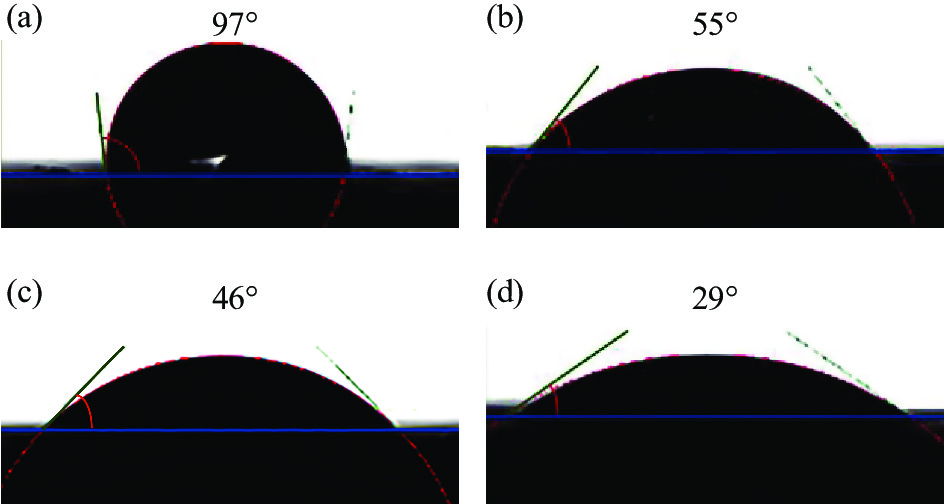

等离子体处理后试样表面接触角如图8所示,可知,未处理试样表面水接触角约为97°(图9(a)),表面呈疏水性,不利于试样与胶粘剂粘合。经等离子体处理后,随着放电功率和处理时间的增加,试样表面接触角呈现先下降后趋于平缓的趋势,表面由疏水性逐渐转变为亲水性。这是由于经等离子体处理后,高能粒子清除了表面污染物并在表面引入了极性自由基团,使试样表面润湿性能提高。此外,随着放电功率和处理时间的进一步增大,表面接触角测量值逐渐达到稳定。这是由于当试样表面润湿性达到一定时,表面新形成的官能团被高能粒子破坏并重组,基体表面润湿性能逐渐达到饱和。

表面接触角测试结果表明,Ar等离子体处理后的试样表面润湿性相对较差,接触角最低下降至55°(图9(b))。这是由于携能氩离子呈现化学惰性,仅在试样表面产生物理刻蚀和清洗作用,无法与材料表面发生活化反应。而经N2和O2处理后的试样表面接触角分别下降至46°和29°(图9(c)~9(d)),表明试样表面引入O、N元素,能够产生活化作用,增加了表面亲水性。同时,与N2相比,O2等离子体电离后的氧离子更易引入试样表面,形成较多的含氧活性基团,使表面含氧活性基团增多,提高了表面极性,有利于表面润湿性的增加。

结合图6和图8可知,表面润湿性的改善对试样胶接强度提升有明显影响,但不构成线性关系,当润湿性能达到稳定时,随着放电功率和处理时间的增加,Ar、N2和O2等离子体处理后试样剪切强度仍产生较大变化。

2.2.2 等离子体处理对CFRP表面形貌的影响

图10为P=800 W,t=20 s时等离子体处理前后的2D、3D AFM图像。从图10(a)可以看出,未处理的试样表面相对光滑,不利于粘接。经Ar、N2、O2等离子体处理后(图10(b)~10(d)),试样表面纵向高度差由247.31 nm分别降至164.53 nm、152.63 nm和140.17 nm,表面粗糙度Ra从77.46 nm分别降至47.51 nm、38.69 nm和22.84 nm,其中,O2等离子体处理后的试样表面最大高度差和Ra降低最明显,此时试样表面形成更小起伏的沟壑,并出现了较陡峭的峰状凸起结构,提高了试样与胶粘剂之间的表面接触面积,有利于胶粘剂与CFRP基体更好的浸润。而N2和Ar处理后的CFRP表面凸起相对平滑,表面沟壑密度较低,接触面积相对较小。这是由于在相同处理参数下,Ar等离子体主要是物理刻蚀,依靠离子轰击增加其表面缺陷位点并提高比表面积,刻蚀能力较弱。N2和O2等离子体对试样表面产生刻蚀的同时与表面分子结构发生键合反应,引入N、O基团,刻蚀程度高于Ar,同时相对于N2,O2激发的氧离子能快速促进含碳材料表面亲水性增加,过量的氧离子会进一步刻蚀表面碳元素,达到快速刻蚀的效果。因此,当放电功率和处理时间相同时,与N2和Ar相比,O2等离子体刻蚀试样更剧烈,对胶接强度提升效果较好。

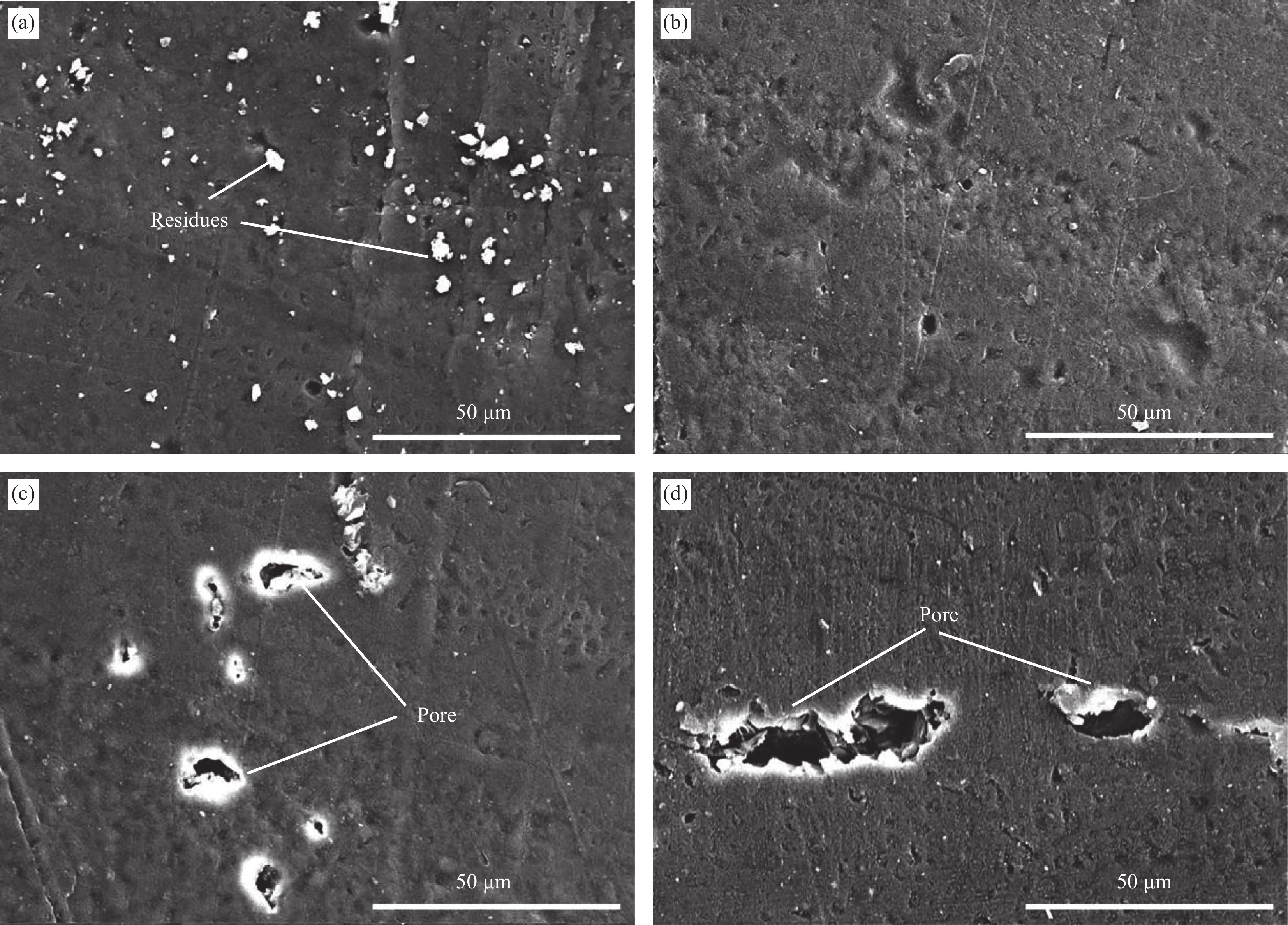

为探究等离子体处理后试样胶接强度随着放电功率和处理时间增加而下降的原因,以刻蚀效果较显著的O2为例,采用SEM对表面形貌进行检测。图11为O2等离子体处理前后CFRP表面的SEM图像。从图11(a)可以看到,未经处理的试样表面存在较多颗粒杂质,这些杂质存在会导致表面粘接时形成易发生破坏的弱界面层,并缩小胶粘剂与基体的接触面积,不利于胶粘剂与基体粘接。由图11(b)~11(d)可知,经O2等离子体处理后试样表面颗粒污染物的数量和体积明显缩小。其原因是,激发的高能粒子撞击材料表面污染物时,与之发生反应并生成新的气相物质游离出表面。与P=200 W相比,P=800 W的条件下,材料表面出现了较多孔隙,且随着处理时间的延长,孔隙不断扩大。这是由于随着放电功率的增加,提高了活性粒子的密度和能量,高能粒子破坏了表层环氧树脂中的羟基并使之形成C=C,导致在环氧树脂表面产生孔隙,并随着处理时间的延长,表面新生成的孔隙深度和范围逐渐增加[26]。

![]() 图 11 不同放电功率和处理时间下O2等离子体处理后CFRP样品表面的SEM图像:(a)未处理;(b) P=200 W, t=30 s;(c) P=800 W, t=20 s;(d) P=800 W, t=30 sFigure 11. SEM images of CFRP samples surface treated under O2 plasma treatment with different discharge powers and processing time: (a) Untreated; (b) P=200 W, t=30 s; (c) P=800 W, t=20 s; (d) P=800 W, t=30 s

图 11 不同放电功率和处理时间下O2等离子体处理后CFRP样品表面的SEM图像:(a)未处理;(b) P=200 W, t=30 s;(c) P=800 W, t=20 s;(d) P=800 W, t=30 sFigure 11. SEM images of CFRP samples surface treated under O2 plasma treatment with different discharge powers and processing time: (a) Untreated; (b) P=200 W, t=30 s; (c) P=800 W, t=20 s; (d) P=800 W, t=30 s结合图6、图8和图11可知,当润湿性达到稳定时,表面孔隙对CFRP胶接性能有明显影响。这是由于表面一定大小孔隙的存在,有利于胶粘剂的渗入,形成机械互锁作用,从而提高胶接强度。当孔隙过大时,胶粘剂不能与孔隙充分接触,致使孔隙内残余空气,胶接部分区域发生界面破坏,导致胶接性能下降。

2.2.3 等离子体处理对CFRP表面化学成分的影响

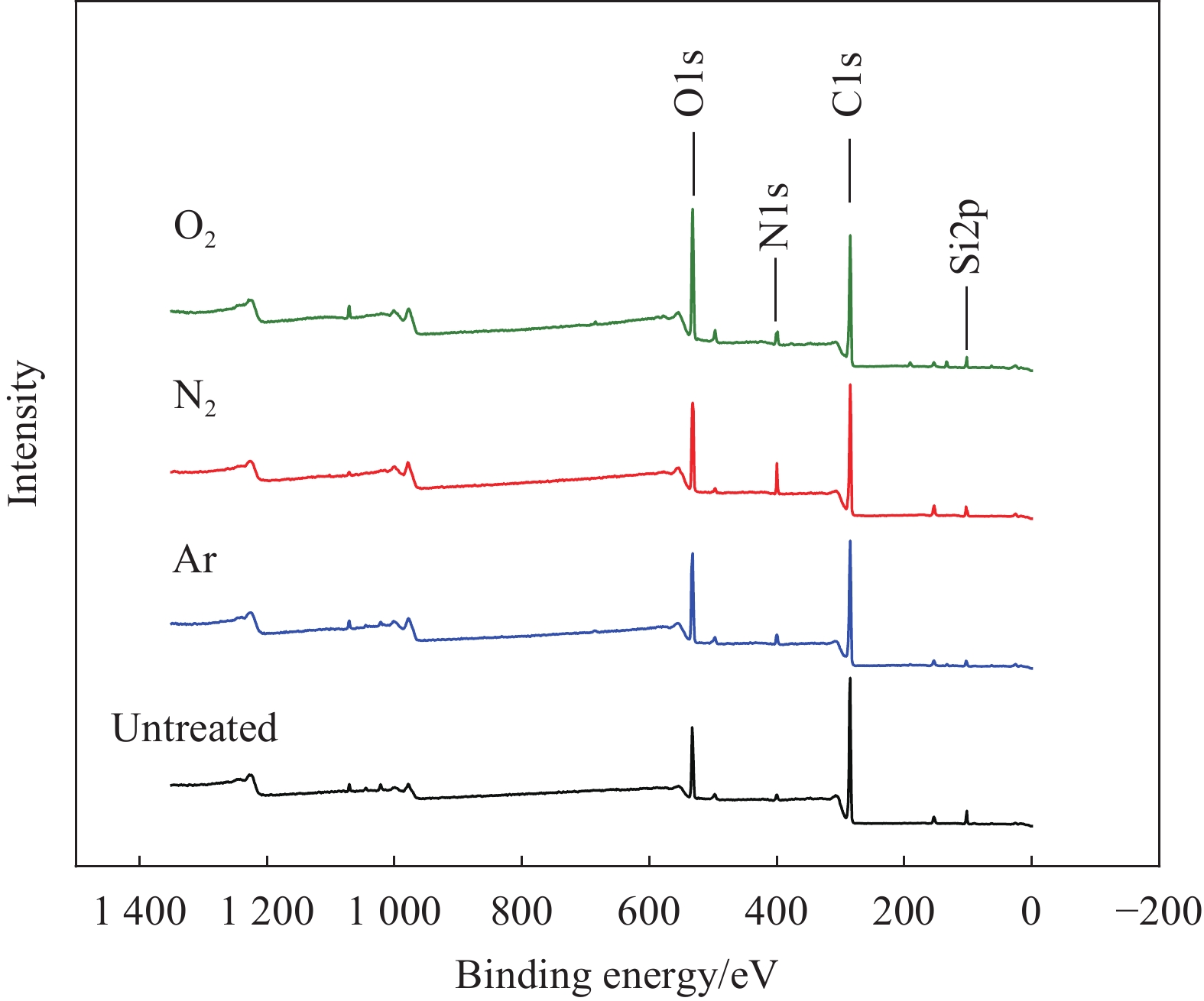

为探究等离子体处理对CFRP表面化学成分的影响,对未处理和P=800 W,t=20 s条件下不同气体处理后的CFRP表面进行元素分析。图12为等离子体处理前后CFRP表面的XPS图谱。可以看出,CFRP表面元素主要由C、N、O、Si组成,其中C、O和N元素来源于表层树脂、碳纤维织物和含碳污染物,Si元素来自脱模剂的残留成分,在CFRP表层以—(CH3)2Si—O—基团的形式存在,阻碍了胶粘剂与CFRP基体粘合[21]。

表4列出了等离子体处理后试样表面的元素含量,可见,试样表面C元素含量均有不同程度的下降,O2处理后的O元素含量和N2处理后的N元素含量提升最为明显,与未处理相比,O/C或N/C元素含量比值分别达到了49.45%和17.25%,O/C与N/C比值越高,说明表面生成了更多的O、N基团,表面极性和亲水性增强,有利于粘接强度的提高,因此O2处理后CFRP表面接触角更低,胶接强度提高最显著。对比Si元素含量可以发现,经过Ar和N2处理后的试样表面Si元素含量分别降低40.69%、36.97%,而O2处理后的CFRP表面Si元素含量无明显下降,这表明Ar和N2有效清除了试样表面的含硅污染物,而经O2处理后的含硅污染物可能转化成更稳定的硅化物。

表 4 不同气体等离子体处理后CFRP试样表面化学元素组成及其所占比例(P=800 W,t=20 s)Table 4. Surface chemical composition and proportion of CFRP samples under plasma treatment with different gases (P=800 W, t=20 s)Surface treatment C/at% O/at% N/at% Si/at% O/C/% N/C/% Untreated 74.52 17.85 3.87 3.76 23.95 5.19 Ar 72.89 21.42 3.46 2.23 29.39 4.75 N2 66.54 19.61 11.48 2.37 29.47 17.25 O2 62.47 30.89 3.17 3.47 49.45 5.07 为探究等离子体处理对CFRP表面化学基团的影响,图13为未处理和P=800 W,t=20 s条件下,Ar、N2和O2等离子体处理后的试样表面的C1s、O1s、N1s和Si2p拟合图。表5是与之对应的CFRP表面XPS的C1s、O1s、N1s和Si2p分峰拟合数据。从图13(a)和表5可以看出,与未处理相比,Ar、N2和O2处理后,表面C—C/C—H(284.6 eV)[27]基团含量下降,这是由于经电离的高能离子对试样表层分子进行高速撞击,表层分子中的C—C和含硅污染物(—(CH3)2Si—O—)中甲基(—CH3)发生断裂导致的。O2处理后C—O/C—N(286.5 eV)和C=O(288.5 eV)[27]含量分别提高了40.74%和43.48%,说明激发的氧活性离子与试样表面不饱和的碳键进行了重组,生成更多的含氧极性官能团。Ar、N2处理后C—O/C—N含量分别提高了7.51%和17.92%,而C=O/O—C=O含量略有下降,其中,N2处理后C—O/C—N含量的提高主要是由于C—N基团的生成,而Ar处理后C=O/C—N含量的提升可能是来自C=O的断裂或电离表面残留空气和水分生成含氧自由基重组形成。

表 5 不同气体等离子体处理后CFRP试样XPS的C1s、O1s、N1s和Si2p分峰表面基团相对含量拟合数据(P=800 W,t=20 s)Table 5. C1s, O1s, N1s and Si2p peak-differentiating and imitating data of relative content of surface groups for XPS of CFRP samples surface under plasma treatment with different gases (P=800 W, t=20 s)at% Element Surface group Surface treatment Untreated Ar N2 O2 C1s C—C/C—H 71.92 70.95 68.01 60.36 C—O/C—N 23.71 25.49 27.96 33.37 C=O 4.37 3.56 4.03 6.27 O1s C—O 79.57 86.13 81.28 61.76 C=O 20.43 13.87 18.72 25.96 O=C—O 0.00 0.00 0.00 12.28 N1s C—NH2 100.00 100.00 100.00 100.00 Si2p Si—C 69.21 66.32 67.17 45.47 Si—O 30.79 33.68 32.83 54.53 图13(b)~13(c)是等离子体处理后试样表面的O1s和N1s拟合图,由图13(b)可见,试样表面存在两种形式的含氧基团,分别是C—O(532.2 eV)和C=O(531.1 eV)[28]基团,其中C—O基团可能以C—O—C或C—OH两种官能团形式存在,而O2处理后表面生成了较多极性较强的—COOH (533.5 eV)[29]基团。从图13(c)可以看出,N元素主要以—NH2(399.6 eV)[30]基团存在试样表面,经N2处理后表面—NH2基团含量大幅度提高。O2和N2等离子体处理后,试样表面O、N极性基团含量的增多,改善了试样表面润湿性,有利胶接性能的进一步提高。

图13(d)是等离子体处理后试样表面的Si2p拟合图,从图13(d)和表5可知,与未处理相比,Ar和N2处理后Si—O(103.2 eV)/Si—C(102.1 eV)[31]基团比值无显著变化,而O2处理后试样的Si—O/Si—C基团比值提高了269.57%,这表明O2处理后,CFRP表面的Si—C大量断裂,断裂的Si键与激发的氧离子结合生成了易于粘接的SiO2颗粒附着在试样表面。

3. 结 论

(1) 低温等离子体处理可以显著提高碳纤维增强树脂复合材料(CFRP)表面粘接性能,随着放电功率P和处理时间t的增大,胶接接头失效模式由界面失效向内聚失效转变。当P=800 W,t=20 s时,O2处理后的CFRP胶接强度效果最佳,试样失效模式出现了较理想的基板失效。

(2) 经等离子体处理后,CFRP表面润湿性能提高,并产生了较多粗糙沟壑,提高了表面粘接表面积,其中O2刻蚀效果最为显著,同时,随着P和t的增加,表面刻蚀加剧,部分区域出现有利于胶粘剂渗入的孔隙,机械互锁性能提高。此外,当活性粒子的密度和能量过高时,表面孔隙进一步扩大,进而对胶接性能产生不利影响。

(3) 等离子体处理可以改善CFRP表面化学组分,氩气等离子体清除了影响CFRP粘接性能的含硅污染物,表面清洁度增加;与氩气相比,N2和O2等离子体处理后,CFRP表面N/C和O/C元素原子比大幅提高,表面生成了较多—NH2、C=O和C—O基团,提高了试样表面活性;同时,O2等离子体处理后CFRP表面生成了易于粘接的SiO2颗粒和极性力较强的—COOH官能团,进一步改善了胶接性能。

-

图 7 (a) 不同气体等离子体处理后CFRP试样的拉伸断裂形貌(放电功率P=800 W,处理时间t=20 s);(b) 不同P和t下O2等离子体处理后CFRP的拉伸断裂形貌

Figure 7. (a) Effect of plasma treatment with different gases on the tensile fracture morphologies of the CFRP samples (Discharge power P=800 W, treatment time t=20 s); (b) Tensile fracture morphologies of the CFRP samples under O2 plasma treatment with different P and t

图 11 不同放电功率和处理时间下O2等离子体处理后CFRP样品表面的SEM图像:(a)未处理;(b) P=200 W, t=30 s;(c) P=800 W, t=20 s;(d) P=800 W, t=30 s

Figure 11. SEM images of CFRP samples surface treated under O2 plasma treatment with different discharge powers and processing time: (a) Untreated; (b) P=200 W, t=30 s; (c) P=800 W, t=20 s; (d) P=800 W, t=30 s

表 1 CFRP复合材料主要性能参数

Table 1 Main performance parameters of CFRP composites

Mechanical property Value E11/GPa 121 E22/GPa 8.6 E33/GPa 8.6 G12/MPa 3450 G13/MPa 3450 G23/MPa 2800 Poisson’s ratio 0.3 Density/(kg·m−3) 1467 Notes: E—Young’s modulus; i (i=1, 2, 3)—Direction; G—Shear modulus. 表 2 Araldite 2015主要力学性能参数

Table 2 Main mechanical property parameters of the Araldite 2015

Araldite 2015 Value Tensile strength/MPa 21.63 Shear strength/MPa 17.90 Elongation/% 0.33 表 3 低压等离子体处理工艺参数

Table 3 Process parameters of low pressure plasma treatment

Item Nominal parameter value Plasma frequency/MHz 13.56 Power input/W 0-1000 Process pressure/Pa 100 Speed/(mL·min−1) 150 表 4 不同气体等离子体处理后CFRP试样表面化学元素组成及其所占比例(P=800 W,t=20 s)

Table 4 Surface chemical composition and proportion of CFRP samples under plasma treatment with different gases (P=800 W, t=20 s)

Surface treatment C/at% O/at% N/at% Si/at% O/C/% N/C/% Untreated 74.52 17.85 3.87 3.76 23.95 5.19 Ar 72.89 21.42 3.46 2.23 29.39 4.75 N2 66.54 19.61 11.48 2.37 29.47 17.25 O2 62.47 30.89 3.17 3.47 49.45 5.07 表 5 不同气体等离子体处理后CFRP试样XPS的C1s、O1s、N1s和Si2p分峰表面基团相对含量拟合数据(P=800 W,t=20 s)

Table 5 C1s, O1s, N1s and Si2p peak-differentiating and imitating data of relative content of surface groups for XPS of CFRP samples surface under plasma treatment with different gases (P=800 W, t=20 s)

at% Element Surface group Surface treatment Untreated Ar N2 O2 C1s C—C/C—H 71.92 70.95 68.01 60.36 C—O/C—N 23.71 25.49 27.96 33.37 C=O 4.37 3.56 4.03 6.27 O1s C—O 79.57 86.13 81.28 61.76 C=O 20.43 13.87 18.72 25.96 O=C—O 0.00 0.00 0.00 12.28 N1s C—NH2 100.00 100.00 100.00 100.00 Si2p Si—C 69.21 66.32 67.17 45.47 Si—O 30.79 33.68 32.83 54.53 -

[1] 马立敏, 张嘉振, 岳广全, 等. 复合材料在新一代大型民用飞机中的应用[J]. 复合材料学报, 2015, 32(2):317-322. DOI: 10.13801/j.cnki.fhclxb.20150122.001 MA Limin, ZHANG Jiazhen, YUE Guangquan, et al. Application of composite in new generation of large civil aircraft[J]. Acta Materiae Compositae Sinica,2015,32(2):317-322(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20150122.001

[2] KATNAM K B, DA SILVA L F M, YOUNG T M. Bonded repair of composite aircraft structures: A review of scientific challenges and opportunities[J]. Progress in Aerospace Sciences,2013,61:26-42. DOI: 10.1016/j.paerosci.2013.03.003

[3] BARILE C, CASAVOLA C, DE C F. Mechanical comparison of new composite materials for aerospace applications[J]. Composites Part B: Engineering,2019,162:122-128. DOI: 10.1016/j.compositesb.2018.10.101

[4] 孙振起, 吴安如. 先进复合材料在飞机结构中的应用[J]. 材料导报, 2015, 29(11):61-64, 69. SUN Zhenqi, WU Anru. Application of advanced composite in aircraft structures[J]. Materials Reports,2015,29(11):61-64, 69(in Chinese).

[5] DENG S, DJUKIC L, PATON R, et al. Thermoplastic-epoxy interactions and their potential applications in joining composite structures—A review[J]. Composites Part A: Applied Science and Manufacturing,2015,68:121-132. DOI: 10.1016/j.compositesa.2014.09.027

[6] QIN G, NA J, MU W, et al. Effect of continuous high temperature exposure on the adhesive strength of epoxy adhesive CFRP and adhesively bonded CFRP-aluminum alloy joints[J]. Composites Part B: Engineering,2018,154:43-55. DOI: 10.1016/j.compositesb.2018.07.059

[7] PARK S M, ROY R, KWEON J H, et al. Strength and failure modes of surface treated CFRP secondary bonded single-lap joints in static and fatigue tensile loading regimes[J]. Composites Part A: Applied Science and Manufacturing,2020,134:105897. DOI: 10.1016/j.compositesa.2020.105897

[8] DI B Y, JOSHI S C, ONG L S. Interfacial bonding between CFRP and mechanically-treated aluminum liner surfaces for risers[J]. Composite Structures,2018,188:374-386. DOI: 10.1016/j.compstruct.2018.01.047

[9] BUCHMANN C, LANGER S, FILSINGER J, et al. Analysis of the removal of peel ply from CFRP surfaces[J]. Composites Part B: Engineering,2016,89:352-361. DOI: 10.1016/j.compositesb.2015.11.019

[10] HU Y, YUAN B, CHENG F, et al. NaOH etching and resin pre-coating treatments for stronger adhesive bonding between CFRP and aluminium alloy[J]. Composites Part B: Engineering,2019,178:107478. DOI: 10.1016/j.compositesb.2019.107478

[11] 尚文翰, 李姜. 旧橡胶颗粒的表面改性及粘接性能[J]. 高分子材料科学与工程, 2018, 34(10):99-104. SHANG Wenhan, LI jiang. Surface modification of ground tire rubber and its adhesion property[J]. Polymer Materials Science & Engineering,2018,34(10):99-104(in Chinese).

[12] AKMAN E, ERDOĞAN Y, BORA M Ö, et al. Investigation of accumulated laser fluence and bondline thickness effects on adhesive joint performance of CFRP composites[J]. International Journal of Adhesion and Adhesives,2019,89:109-116. DOI: 10.1016/j.ijadhadh.2018.12.003

[13] ZALDIVAR R J, NOKES J, STECKEL G L, et al. The effect of atmospheric plasma treatment on the chemistry, morphology and resultant bonding behavior of a PAN-based carbon fiber-reinforced epoxy composite[J]. Journal of Composite Materials,2010,44(2):137-156. DOI: 10.1177/0021998309345343

[14] HOLTMANNSPÖTTER J. How surfaces of carbon fiber reinforced plastics with thermoset matrices need to be treated for structural adhesive bonding[J]. The Journal of Adhesion,2018,96(9):839-854.

[15] PROLONGO S G, GUDE M R, DEL R G, et al. Surface pretreatments for composite joints: Study of surface profile by SEM image analysis[J]. Journal of Adhesion Science and Technology,2010,24(11-12):1855-1867. DOI: 10.1163/016942410X507623

[16] LIU G, XU Y, YANG W, et al. Bonding repair of CFRP based on cold plasma treatment surface modification[J]. Journal of Adhesion Science and Technology,2020,34(16):1796-1808. DOI: 10.1080/01694243.2020.1730663

[17] SUNDRIYAL P, PANDEY M, BHATTACHARYA S. Plasma-assisted surface alteration of industrial polymers for improved adhesive bonding[J]. International Journal of Adhesion and Adhesives,2020,101:102626. DOI: 10.1016/j.ijadhadh.2020.102626

[18] CHO B G, HWANG S H, PARK M, et al. The effects of plasma surface treatment on the mechanical properties of polycarbonate/carbon nanotube/carbon fiber composites[J]. Composites Part B: Engineering,2019,160:436-445. DOI: 10.1016/j.compositesb.2018.12.062

[19] YOOZBASHIZADEH M, CHARTOSIAS M, VICTORINO C, et al. Investigation on the effect of process parameters in atmospheric pressure plasma treatment on carbon fiber reinforced polymer surfaces for bonding[J]. Materials and Manufacturing Processes,2019,34(6):660-669. DOI: 10.1080/10426914.2019.1566613

[20] 翟全胜, 苗春卉, 崔海超, 等. 基于表面改性的国产T800碳纤维/高韧性环氧树脂复合材料胶接性能[J]. 复合材料学报, 2021, 38(7):2162-2171. ZHAI Quansheng, MIAO Chunhui, CUI Haichao, et al. Bonding performance of domestic T800/high toughness epoxy resin composites based on surface modification[J]. Acta Materiae Compositae Sinica,2021,38(7):2162-2171(in Chinese).

[21] SUN C, MIN J, LIN J, et al. Effect of atmospheric pressure plasma treatment on adhesive bonding of carbon fiber reinforced polymer[J]. Polymers,2019,11(1):139. DOI: 10.3390/polym11010139

[22] LIN J, SUN C, MIN J, et al. Effect of atmospheric pressure plasma treatment on surface physicochemical properties of carbon fiber reinforced polymer and its interfacial bonding strength with adhesive[J]. Composites Part B: Engi-neering,2020,199:108237. DOI: 10.1016/j.compositesb.2020.108237

[23] PIZZORNI M, LERTORA E, MANDOLFINO C. Low pressure plasma treatment of CFRP substrates for adhesive bonding: An investigation of joint durability under severe temperature-moisture conditioning[J]. International Journal of Adhesion and Adhesives,2020,99:102592. DOI: 10.1016/j.ijadhadh.2020.102592

[24] ASTM International. Standard test method for apparent shear strength of single-lap-joint adhesively bonded metal specimens by tension loading: ASTM D1002-10[S]. West Conshohocken: ASTM International, 2010.

[25] ASTM International. Standard test method for lab shear adhesion for fiber reinforced plastic (FRP) bonding: ASTM D5868-01[S]. West Conshohocken: ASTM International, 2014.

[26] HARTWIG A, VITR G, DIECKHOFF S, et al. Surface treatment of an epoxy resin by CO2 laser irradition[J]. Die Angewandte Makromolekulare Chemie: Applied Macromolecular Chemistry and Physics,1996,238(1):177-189. DOI: 10.1002/apmc.1996.052380115

[27] YANG D, ZHOU L, CHEN L, et al. Chemically modified graphene oxides as a hole transport layer in organic solar cells[J]. Chemical Communications,2012,48(65):8078-8080. DOI: 10.1039/c2cc33829g

[28] JIANG L, DING H, LU S, et al. Photoactivated fluorescence enhancement in F, N-doped carbon dots with piezochromic behavior[J]. Angewandte Chemie,2020,132(25):10072-10077. DOI: 10.1002/ange.201913800

[29] ZHANG L, LI Y, ZHANG L, et al. Electrocatalytic oxidation of NADH on graphene oxide and reduced graphene oxide modified screen-printed electrode[J]. International Journal of Electrochemical Science,2011,6(3):819-829.

[30] LI X, ZHANG P, HUANG H, et al. Etched carbon fiber/polyaniline composite with p-n heterojunction for high-energy electrochemical supercapacitor[J]. ECS Journal of Solid State Science and Technology,2021,10(1):013005. DOI: 10.1149/2162-8777/abdd84

[31] ZHAO X, MAGTOTO N P, KELBER J A. Chemical vapor deposition of tantalum nitride with tertbutylimino tris(diethylamino) tantalum and atomic hydrogen[J]. Thin Solid Films,2005,478(1-2):188-195. DOI: 10.1016/j.tsf.2004.10.042

-

期刊类型引用(3)

1. 张凯强,周文明,冯永国,祁蓉,庞惠文. 碳纤维改性增强复合材料界面研究进展. 材料导报. 2024(S2): 535-542 .  百度学术

百度学术

2. 许笑堃,胡俊涛,万海浪,赵冲,林建平,闵峻英. 常压等离子改性对碳纤维复合材料表面温度与Ⅰ型断裂韧性的影响. 复合材料学报. 2024(12): 6438-6449 .  本站查看

本站查看

3. 徐新媛,申晓星,李会弟,张康,唐冰冰,顾挺业. 等离子体对改善氨纶染色性能的研究. 纺织报告. 2023(04): 4-6 .  百度学术

百度学术

其他类型引用(2)

-

下载:

下载: