Flexible and fiber-shaped batteries—A review

-

摘要: 纤维电池具有维度低、灵活性好、形状普适性强、与纺织品高度融合等特点,可满足柔性电子产品电路元件的供能需求。近年来纤维电池的研究,不仅关注于电极材料的微纳复合,探索多功能、可扩展和高集成系统的纤维电池逐渐成为研发的焦点。此外,规模化生产纤维状电池也取得了一定的突破,包括电池组装、集成、连续生产等。基于此,本文从纤维基底材料和制备工艺两方面对近期纤维电池的研究成果展开论述,并对工业化生产纤维电池的最新突破进行评述,最后,总结纤维状电池发展存在的问题并分析展望未来需要攻克的重点难点。Abstract: With low dimensionality, flexibility, shape-adaptable, and high integration with textiles, fiber batteries can meet the energy supply needs of circuit elements of flexible electronics. In recent years, research on fiber batteries has not only focused on active materials composited in electrodes, but exploring multi-functional, scalable, and highly integrated systems of fiber batteries. In addition, certain breakthroughs have been made in the large-scale production of fiber-based batteries, including battery assembly, integration, and continuous production. Based on this, this paper discusses the recent research results of fiber batteries in terms of fiber substrate materials and preparation processes, and it also review the latest breakthroughs in the industrial production of fiber batteries. Finally, this paper summarize the problems in the development of fiber batteries and analyze the key difficulties that need to be overcome in the future.

-

Key words:

- fiber-sharped batteries /

- electrode materials /

- liquid metal /

- industrialization /

- wearable

-

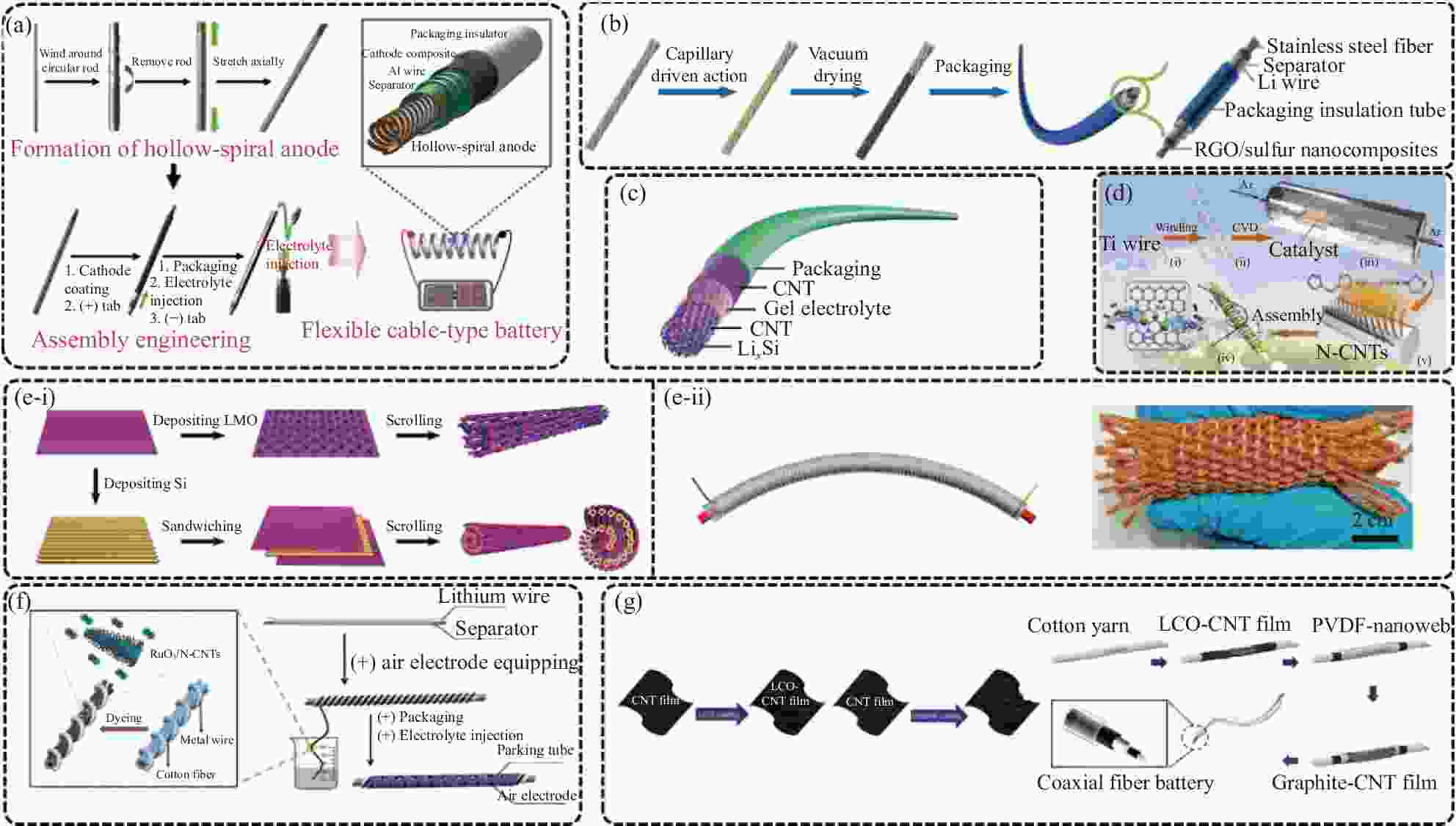

图 2 锂离子纤维电池:(a) 空心卷绕纤维电池结构示意图及制备[7];(b) 不锈钢纤维(SSFs)基底纤维电池制备[8];(c) 同轴结构锂离子纤维电池[9];(d) 纤维状锂空气电池结构及制备[10];(e-i) 卷绕制备电极;(e-ii) 包缠制备纤维电池[11];(f) 棉纱基底的锂空气电池[12];(g) 高电解质容量的同轴锂离子电池[13]

RGO—Redox graphene; CNT—Carbon nanotubes; CVD—Chemical vapor deposition; LMO—Lithium manganate; LCO—Lithium cobalt oxide; PVDF—Polyvinylidene difluoride

Figure 2. Fiber-sharped lithium-ion batteries: (a) Schematic illustration of hollow wound fiber battery structure and preparation process[7]; (b) Stainless steel fibre (SSFs) substrate fiber-sharped battery preparation[8]; (c) Coaxial structure lithium-ion fiber-sharped battery[9]; (d) Fiber-sharped lithium-air battery structure and preparation[10]; (e-i) Winding preparation of electrodes; (e-ii) Double wrapping preparation of fiber-sharped battery[11]; (f) Lithium-air battery used cotton yarn substrate[12]; (g) Coaxial lithium-ion battery with high electrolyte capacity[13]

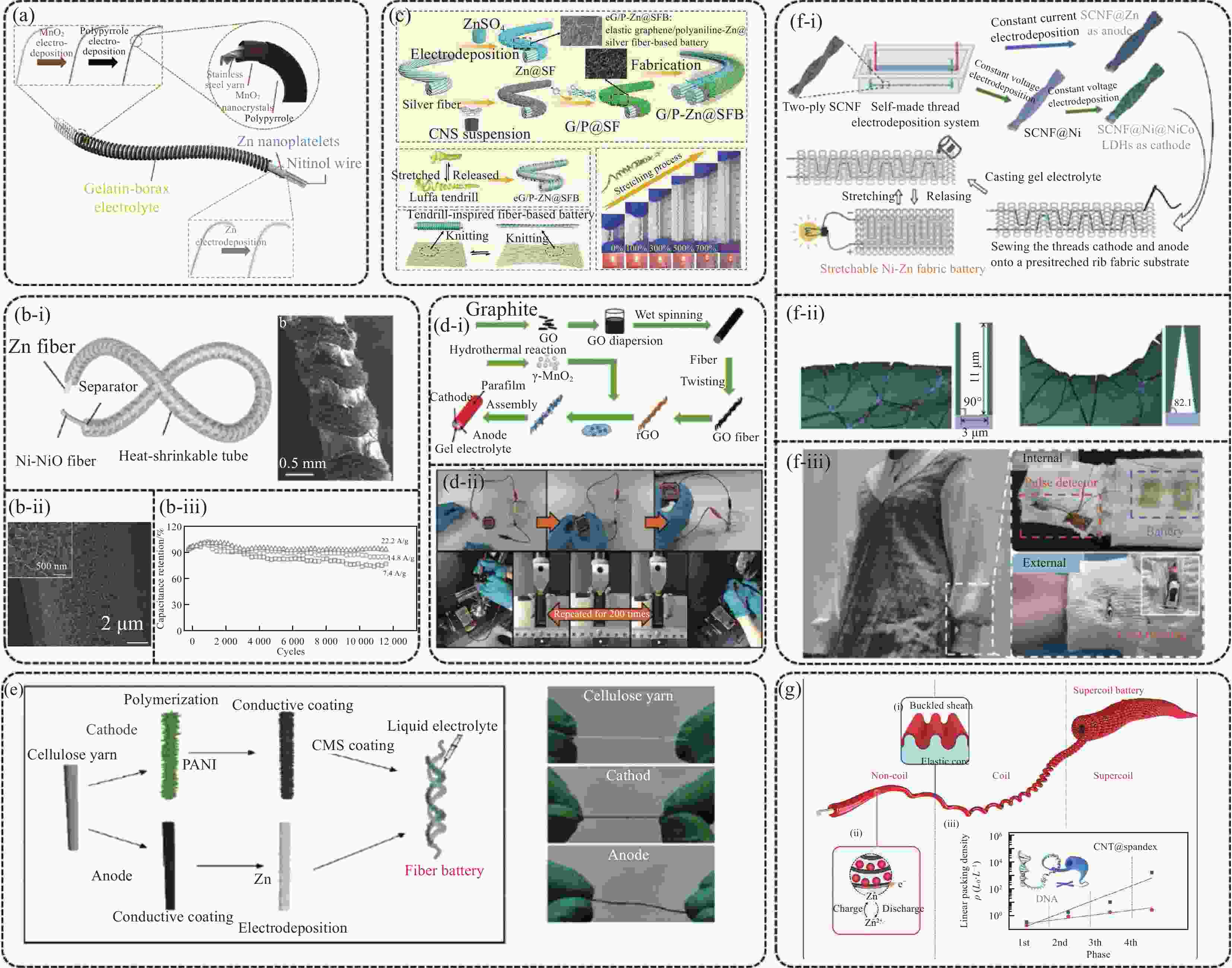

图 3 (a) 不锈钢丝(SS)基底锌离子电池[14];(b-i) 全固态镍锌纤维电池结构及SEM图像;(b-ii) 多孔Ni-NiO纳米片异质结构;(b-iii) 电池循环充放电寿命[15];(c) 超高形变纤维电池[16];(d-i) 湿法纺丝制备纤维电池;(d-ii) 锌离子纤维电池柔性展示[17];(e) 纤维素基底纤维电池[18];(f-i) 螺旋状多组分芯壳结构的纤维电池制备;(f-ii) 活性材料的裂纹结构;(f-iii) 纤维电池为脉冲系统供电示意图[19];(g) 超螺旋结构锌离子纤维电池[20]

eG/P-Zn@SFB—Elastic graphene/polyaniline-Zn@silver fiber-based battery; GNS—Graphene nanoplatelets; GO—Graphene oxide; rGO—Reduced graphene oxide; SCNF—Separately sewing core–shell silver-coated nylon fiber; LDHs—Layered double hydroxides; PANI—Polyaniline; CMS—Carboxymethyl cellulose; L0—Initial linear length; L—Linear length after stacking

Figure 3. (a) Stainless steel (SS) substrate zinc-ion battery[14]; (b-i) All-solid-state Ni-Zn fiber battery structure and SEM images; (b-ii) Porous Ni-NiO nanosheet heterostructure; (b-iii) Battery cyclic charge/discharge life[15]; (c) Ultra-high deformation fiber-sharped battery[16]; (d-i) Wet spinning preparation of fiber-sharped battery; (d-ii) Flexible demonstration of fiber-sharped ZIBs[17]; (e) Cellulose substrate fiber-sharped battery[18]; (f-i) Preparation of fiber battery with spiral multi-component core-shell structure; (f-ii) Cracked structure of active material; (f-iii) Schematic illustration of fiber-sharped battery to power a pulsed system[19]; (g) Super spiral structure zinc-ion fiber battery[20]

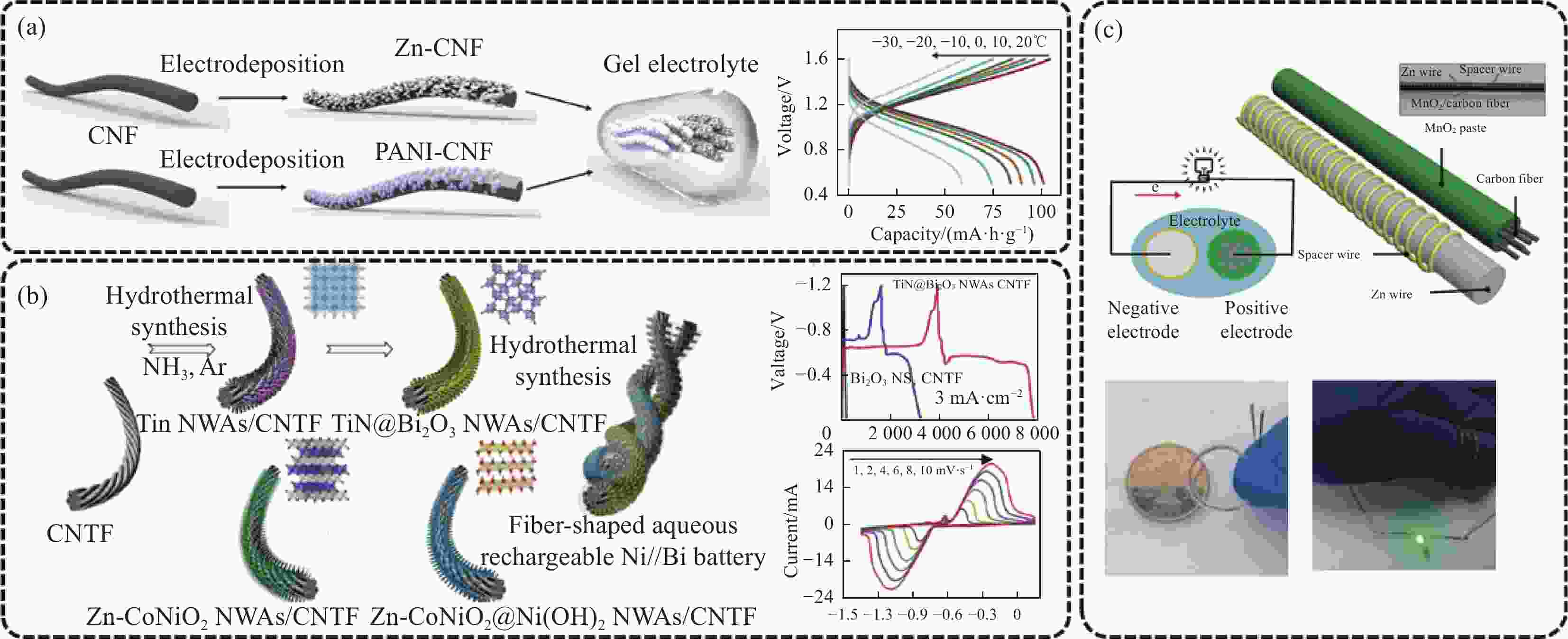

图 4 (a) 碳纳米纤维(CNFs)基底纤维电池示意图及电化学性能[21];(b) 碳纳米管纤维(CNTFs)基底纤维电池示意图及电化学性能[22];(c) 碳纤维(CFs)基底纤维电池示意图及柔性展示[23]

PANI—Polyaniline; NWAs—Nanowire arrays; NSs—Nanosheets

Figure 4. (a) Schematic illustration and electrochemical performance of carbon nanofibers (CNFs) substrate fiber-sharped battery[21]; (b) Schematic illustration and electrochemical performance of carbon nanotube fibers (CNTFs) substrate fiber-sharped battery[22]; (c) Schematic illustration and flexible demonstration of carbon fiber (CFs) substrate fiber-sharped battery[23]

图 5 新型材料基纤维电池:(a) 加捻型Zn/Ag2O电池示意图[24];(b-i) 自支撑金属有机骨架(MOF)纤维电池;(b-ii) 无黏结电极的优势[25];(c) 自组装钴材料纤维电池[26];(d-i) 液态金属基纤维电池结构示意图;(d-ii) 液态金属电池电流调控[27];(e) 超大变形的液态金属基纤维电池结构示意图[28];(f) 钒酸铵基纤维电池结构示意图[29]

NC—Nnanocarbon; PEDOT : PSS—Poly(3,4-ethylenedioxythiophene) : poly(styrenesulfonate); PVA—Polyvinyl alcohol

Figure 5. New material-based fiber-sharped battery: (a) Schematic illustration of twisted Zn/Ag2O battery[24]; (b-i) Self-standing metal-organic frameworks (MOF) fiber-sharped battery; (b-ii) Advantages of unbonded electrodes[25]; (c) Self-assembled cobalt material fiber-sharped battery[26]; (d-i) Schematic illustration of liquid metal-based fiber-sharped battery structure; (d-ii) Liquid metal battery current regulation[27]; (e) Structure schematic illustration of oversized deformed liquid metal-based fiber-sharped battery[28]; (f) Schematic illustration of ammonium vanadate-based fiber-sharped battery[29]

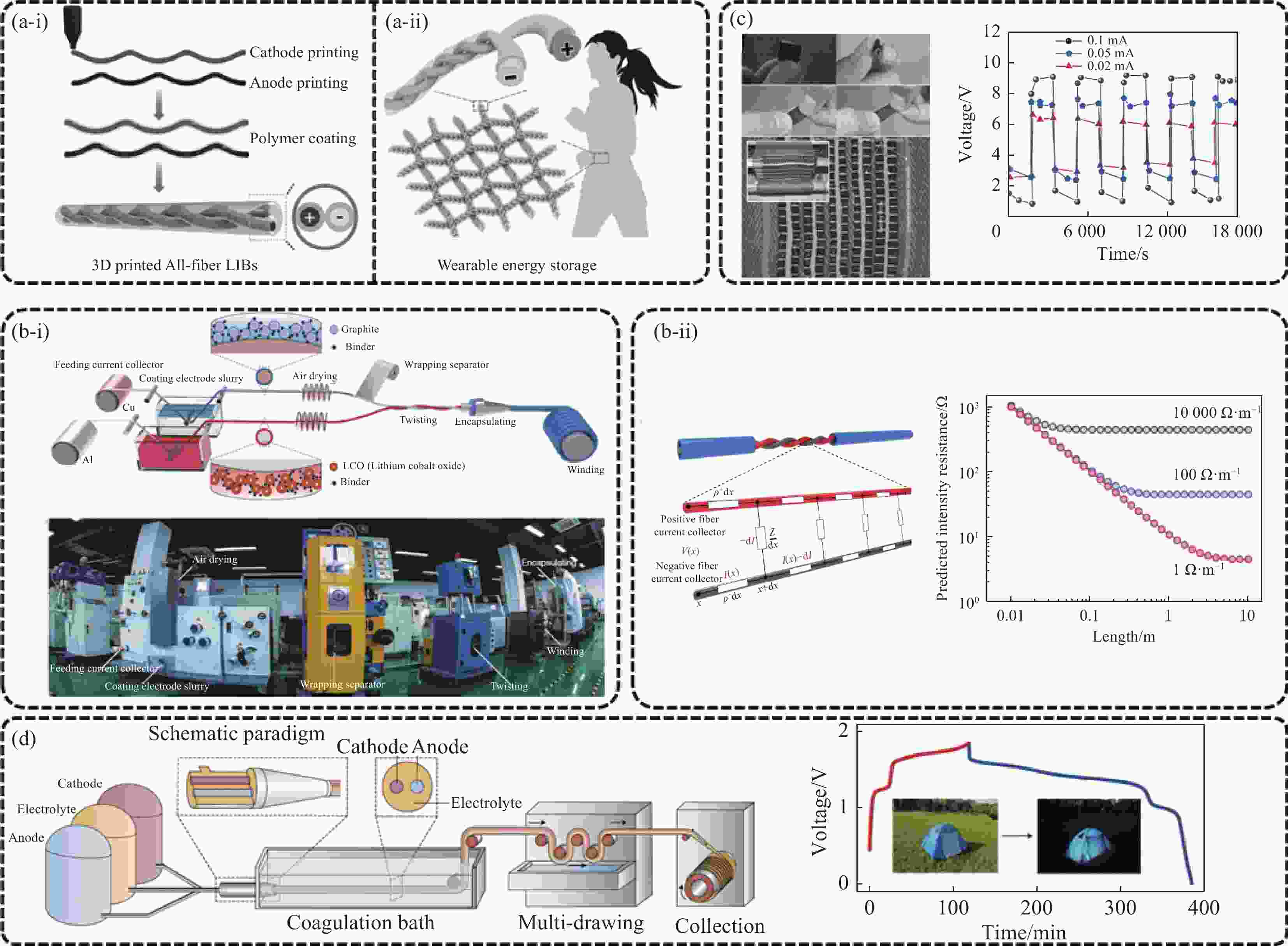

图 6 纤维电池生产工艺:(a-i) 3D打印纤维电池;(a-ii)纤维电池与纺织品融合示意图[33];(b-i)上浆涂覆工艺生产纤维电池;(b-ii)纤维电池内阻与长度理论模型[34];(c)拉伸挤出纤维状电池示意图及电化学性能[35];(d)溶液挤压工艺制备纤维电池示意图[36]

LIBs—Lithium-ion batteries; V(x)—Voltage between the fiber electrodes; ρ+dx—Resistances of positive for each unit length of dx; ρ–dx—Resistances of negative for each unit length of dx; I—Current; Z—Polarization resistance

Figure 6. Fiber-sharped battery production process: (a-i) 3D printed fiber-sharped battery; (a-ii) Schematic illustration of fiber-sharped battery fusion with textile[33]; (b-i) Fiber-sharped battery production by sizing and coating process; (b-ii) Theoretical model of fiber-sharped battery internal resistance and length[34]; (c) Schematic illustration and electrochemical properties of stretch extruded fiber-sharped battery[35]; (d) Schematic illustration of fiber-sharped battery solution extrusion process[36]

表 1 不同类型纤维电池性能评价

Table 1. Summary of fiber-shaped batteries discussed in this review

Fiber devices Cathode/Anode Specific capacity Energy density Capacity retention/Cycles/

Current densityRef. LIBs Al

/Ni-Sn@Cu– − − [7] RGO@S@SSF/

Li wire762.5 mA·h/g

(0.1 A/s)− 50.3%/100/0.1 A/s [8] N-CNTs@Ti

/CO29292.3 mA·h/g

(250 mA/g)− 100%/45/250 mA/g [10] Si@CNT/

CNT1250 mA·h/g

(0.1 mA)512 W·h/kg 80%/100/0.1 mA [9] CNT-LMO/

CNT-Si@CNT0.22 mA·h/cm

(0.4 A/s)0.75 mW·h/cm 94%/100/1 A/s [11] RuO2@N-CNTs/

O21981 mA·h/g

(320 mA/g)− − [12] Graphite-CNT/

Graphite-CNT353 mA·h/g

(0.5 A/s)144 mW·h/cm3 99.8%/500/1 A/s [13] ZIBs MnO2@PPy@SS

/Zn@SS174.2 mA·h/g

(0.5 A/s)− 60%/1000/2 A/s [14] Ni-NiO/

Zn237.8 µA·h/cm3

(3.7 A/g)6.6 µW·h/cm2 96.6%/10000/3.7 A/g [15] Zn@SF/

G@P@SF32.5 mA·h/cm3

(10 mA/cm3)36 mW·h/cm3 76.5%/1000/10 mA [16] MnO2@rGO

/Zn230 mA·h/g

(0.4 A/s)− 80%/200/0.4 A/s [17] PANI@Cellulse

/Zn@Cellulse189.1 mA·h/g

(2 A/g)61.1 W·h/kg 91.9%/1000/5 A/g [18] SCNF@Ni@NiCo/

SCNF@Zn19.15 μA·h/cm

(0.1 mA/cm)249.2 W·h/kg 50%/500/ 9.2 A/g [19] MnO2-CNT/

Zn-CNT@spandex0.029 mA·h/cm

(0.05 mA/cm)− − [20] Zn@CNF/

PANI@CNF145 mA·h/g

(0.2 A/g)58.8 W·h/kg 75.1%/1000/0.2 A/g [21] Zn-CoNiO2@Ni(OH)2/TiN@Bi2O3 314.96 mW·h/cm3

(3 mA/cm2)20.04 W/cm3 88.6%/5000/ 3 mA/cm2 [22] Zn

/MnO2@A/s166 mA·h/g

(70 mA/g)0.2 mW·h/cm Not rechargeable [23] MOFs CNTF-NCA-Ag2O

/Zn1.03 mA·h/cm2

(0.5 mA/cm2)14.4 mW·h/cm2 79.5%/200/0.5 mA [24] Ni-MOF-74@CNTF/

Zn108 mW·h/cm3

(0.5 A/cm3)186.28 mW·h/cm3 87.66%/1000/2 A/cm3 [25] Co3O4 NSs@CNTF/

Zn@CNTF158.70 mA·h/g

(1 A/g)− 97.27%/10000/1 A/g [26] Liquid

metalEGILM

/O2214.8 mA·h/g

(0.5 mA/cm2)303.2 mW·h/g − [27] PANI/

Ga68In22Sn10223.9 mA·h/g

(0.2 A/g)4300 mW/g 80.3%/500/ 0.2 A/g [28] NH4+ CF@NH4V4O10/

CF@PANI167 mA·h/g

(0.1 A/g)− 73.3%/1000/0.1 A/g [29] -

[1] MIN X, SUN B, CHEN S, et al. A textile-based SnO2 ultra-flexible electrode for lithium-ion batteries[J]. Energy Storage Materials,2019,16:597-606. doi: 10.1016/j.ensm.2018.08.002 [2] LIANG S, YAN W, WU X, et al. Gel polymer electrolytes for lithium ion batteries: Fabrication, characterization and performance[J]. Solid State Ionics,2018,318:2-18. doi: 10.1016/j.ssi.2017.12.023 [3] CHO Y G, HWANG C, CHEONG D S, et al. Gel/solid polymer electrolytes characterized by in situ gelation or polymerization for electrochemical energy systems[J]. Advanced Materials,2019,31(20):1804909. doi: 10.1002/adma.201804909 [4] CHOI Y S, PHARR M, OH K H, et al. A simple technique for measuring the fracture energy of lithiated thin-film silicon electrodes at various lithium concentrations[J]. Journal of Power Sources,2015,294:159-166. doi: 10.1016/j.jpowsour.2015.06.063 [5] NOSSOL E, SOUZA V H R, ZARBIN A J G. Carbon nano-tube/Prussian blue thin films as cathodes for flexible, transparent and ITO-free potassium secondary battery[J]. Journal of Colloid and Interface Science,2016,478:107-116. doi: 10.1016/j.jcis.2016.05.056 [6] YU C, LI X, MA T, et al. Silicon thin films as anodes for high-performance lithium-ion batteries with effective stress relaxation[J]. Advanced Energy Materials,2012,2(1):68-73. doi: 10.1002/aenm.201100634 [7] KWON Y H, WOO S W, JUNG H R, et al. Cable-type flexible lithium ion battery based on hollow multi-helix electrodes[J]. Advanced Materials,2012,24(38):5192-5197. doi: 10.1002/adma.201202196 [8] LIU R, LIU Y, CHEN J, et al. Flexible wire-shaped lithium-sulfur batteries with fibrous cathodes assembled via capillary action[J]. Nano Energy,2017,33:325-333. doi: 10.1016/j.nanoen.2016.12.049 [9] ZHANG Y, JIAO Y, LU L, et al. An ultraflexible silicon-oxygen battery fiber with high energy density[J]. Angewandte Chemie International Edition,2017,56(44):13741-13746. doi: 10.1002/anie.201707840 [10] LI Y, ZHOU J, ZHANG T, et al. Highly surface-wrinkled and N-doped CNTs anchored on metal wire: A Novel fiber-shaped cathode toward high-performance flexible Li-CO2 batteries[J]. Advanced Functional Materials,2019,29(12):1808117. doi: 10.1002/adfm.201808117 [11] WENG W, SUN Q, ZHANG Y, et al. Winding aligned carbon nanotube composite yarns into coaxial fiber full batteries with high performances[J]. Nano Letters,2014,14(6):3432-3438. doi: 10.1021/nl5009647 [12] LIN X, KANG Q, ZHANG Z, et al. Industrially weavable metal/cotton yarn air electrodes for highly flexible and stable wire-shaped Li-O2 batteries[J]. Journal of Materials Chemistry A,2017,5(7):3638-3644. doi: 10.1039/C6TA09806A [13] SONG H, JEON S Y, JEONG Y. Fabrication of a coaxial high performance fiber lithium-ion battery supported by a cotton yarn electrolyte reservoir[J]. Carbon,2019,147:441-450. doi: 10.1016/j.carbon.2019.02.081 [14] WANG Z, RUAN Z, LIU Z, et al. A flexible rechargeable zinc-ion wire-shaped battery with shape memory function[J]. Journal of Materials Chemistry A,2018,6(18):8549-8557. doi: 10.1039/C8TA01172A [15] ZENG Y, MENG Y, LAI Z, et al. An ultrastable and high-performance flexible fiber-shaped Ni-Zn battery based on a Ni-NiO heterostructured nanosheet cathode[J]. Advanced Materials,2017,29(44):1702698. doi: 10.1002/adma.201702698 [16] LI M, LI Z, YE X, et al. Tendril-inspired 900% ultrastretching fiber-based Zn-ion batteries for wearable energy textiles[J]. ACS Applied Materials & Interfaces,2021,13(14):17110-17117. [17] SUBJALEARNDEE N, HE N, CHENG H, et al. Gamma(γ)-MnO2/rGO fibered cathode fabrication from wet spinning and dip coating techniques for cable-shaped Zn-ion batteries[J]. Advanced Fiber Materials,2022, 4 (3):1-18. [18] YI H, MA Y, ZHANG S, et al. Robust aqueous Zn-ion fiber battery based on high-strength cellulose yarns[J]. ACS Sustainable Chemistry & Engineering,2019,7(23):18894-18900. [19] WU M, XIA Z, MAO Z, et al. Stretchable Ni-Zn fabric battery based on sewable core-shell SCNF@Ni@NiCo LDHs thread cathode for wearable smart garment[J]. Journal of Materials Science,2021,56(17):10537-10554. doi: 10.1007/s10853-021-05936-9 [20] LEE J M, CHUN S, SON W, et al. DNA-inspired, highly packed supercoil battery for ultra-high stretchability and capacity[J]. Nano Energy,2021,85:106034. doi: 10.1016/j.nanoen.2021.106034 [21] CONG Z, GUO W, ZHANG P, et al. Wearable antifreezing fiber-shaped Zn/PANI batteries with suppressed Zn dendrites and operation in sweat electrolytes[J]. ACS Applied Materials & Interfaces,2021,13(15):17608-17617. [22] LI Q, JING S, YONG Z, et al. Towards ultrahigh-energy-density flexible aqueous rechargeable Ni//Bi batteries: Free-standing hierarchical nanowire arrays core-shell heterostructures system[J]. Energy Storage Materials,2021,42:815-825. doi: 10.1016/j.ensm.2021.08.032 [23] YU X, FU Y, CAI X, et al. Flexible fiber-type zinc-carbon battery based on carbon fiber electrodes[J]. Nano Energy,2013,2(6):1242-1248. doi: 10.1016/j.nanoen.2013.06.002 [24] LI C, ZHANG Q, SONG F, et al. An ultra-high endurance and high-performance quasi-solid-state fiber-shaped Zn-Ag2O battery to harvest wind energy[J]. Journal of Materials Chemistry A,2019,7(5):2034-2040. doi: 10.1039/C8TA10807B [25] MAN P, HE B, ZHANG Q, et al. A one-dimensional channel self-standing MOF cathode for ultrahigh-energy-density flexible Ni-Zn batteries[J]. Journal of Materials Chemistry A,2019,7(48):27217-27224. doi: 10.1039/C9TA11759H [26] LU Y, ZHANG H, LIU H, et al. Electrolyte dynamics engi-neering for flexible fiber-shaped aqueous zinc-ion battery with ultralong stability[J]. Nano Letters,2021,21(22):9651-9660. doi: 10.1021/acs.nanolett.1c03455 [27] LIU G, KIM J Y, WANG M, et al. Soft, highly elastic, and discharge-current-controllable eutectic gallium-indium liquid metal-air battery operated at room temperature[J]. Advanced Energy Materials,2018,8(16):1703652. doi: 10.1002/aenm.201703652 [28] FU H, LIU G, XIONG L, et al. A shape-variable, low-temperature liquid metal-conductive polymer aqueous secondary battery[J]. Advanced Functional Materials,2021,31(50):2107062. doi: 10.1002/adfm.202107062 [29] LI H, YANG J, CHENG J, et al. Flexible aqueous ammonium-ion full cell with high rate capability and long cycle life[J]. Nano Energy,2020,68:104369. doi: 10.1016/j.nanoen.2019.104369 [30] XU Y, ZHAO Y, REN J, et al. An all-solid-state fiber-shaped aluminum-air battery with flexibility, stretchability, and high electrochemical performance[J]. Angewandte Chemie International Edtion,2016,55(28):7979-7982. doi: 10.1002/anie.201601804 [31] WANG H, ZHANG S, DENG C. In situ encapsulating metal oxides into core-shell hierarchical hybrid fibers for flexible zinc-ion batteries toward high durability and ultrafast capability for wearable applications[J]. ACS Applied Materials & Interfaces,2019,11(39):35796-35808. [32] ZHAI S, WANG N, TAN X, et al. Interface-engineered dendrite-free anode and ultraconductive cathode for durable and high-rate fiber Zn dual-ion microbattery[J]. Advanced Functional Materials,2021,31(13):2008894. doi: 10.1002/adfm.202008894 [33] WANG Y, CHEN C, XIE H, et al. 3D-printed all-fiber Li-ion battery toward wearable energy storage[J]. Advanced Functional Materials,2017,27(43):1703140. doi: 10.1002/adfm.201703140 [34] HE J, LU C, JIANG H, et al. Scalable production of high-performing woven lithium-ion fibre batteries[J]. Nature,2021,597(7874):57-63. doi: 10.1038/s41586-021-03772-0 [35] LIU Y, GORGUTSA S, SANTATO C, et al. Flexible, solid electrolyte-based lithium battery composed of LiFePO4 cathode and Li4Ti5O12 anode for applications in smart textiles[J]. Journal of the Electrochemical Society,2012,159(4):A349-A356. doi: 10.1149/2.020204jes [36] LIAO M, WANG C, HONG Y, et al. Industrial scale production of fibre batteries by a solution-extrusion method[J]. Nature Nanotechnology,2022, 17 (4):1-6. -

下载:

下载: