Molecular simulation of the interaction mechanism between wollastonite and silane and the properties of modified powder filled nylon 6

-

摘要:

通过采用硅烷对硅灰石进行干法改性优化硅灰石物化性能,探究了改性温度、时间、硅烷用量对改性效果的影响。采用红外光谱对改性前后硅灰石粉体表面官能团进行表征;分别将未改性硅灰石原样与改性粉体填充尼龙6制备复合材料,对复合材料的冲击强度、拉伸强度、弯曲强度、弯曲模量、热变形温度等指标进行测试;使用分子模拟分析了3-氨丙基三乙氧基硅烷(硅烷SCA1113 )改性硅灰石的微观机制。结果表明:改性温度80℃,改性时间20 min,硅烷用量0.8wt%为优化工艺条件;未改性硅灰石填充尼龙6样品较尼龙6纯样刚性提高但降低韧性,而改性后的硅灰石填充尼龙6可以同时提高尼龙6材料的刚性与韧性;硅烷SCA1113改性硅灰石时其反应性不来自于硅灰石晶体内部,晶面(100)最具反应性,硅烷SCA1113与硅灰石表面吸附为化学吸附,形成了Si—O—Ca键。

Abstract:The physical and chemical properties of wollastonite were optimized through dry modification with silane, and the effects of modification temperature, time, and silane dosage on the modification effect of wollastonite were explored. Infrared spectroscopy was used to characterize the surface functional groups of wollastonite and modified wollastonite. Polyamide 6 (PA 6) composite materials were prepared by filling wollastonite and modified wollastonite powder in PA 6, and the impact strength, tensile strength, flexural strength, and flexural modulus of the composite materials were tested. The microscopic mechanism of wollastonite modified by 3-aminopropyltriethoxysilane (SCA1113) was analyzed using molecular simulation. The results show that the optimize modification process conditions of wollastonite are the modification temperature of 80℃, the modification time of 20 min, and the silane dosage of 0.8wt%. Unmodified wollastonite filled nylon 6 can improve the rigidity of the composite material but reduce its toughness compared to pure nylon 6 samples, while modified wollastonite filled nylon 6 can simultaneously improve the rigidity and toughness of the material. When silane SCA1113 modifies wollastonite, its reactivity does not come from inside the wollastonite crystal, and the crystal surface (100) is the most reactive, and silane SCA1113 and wollastonite surface are adsorbed to form Si—O—Ca bond.

-

Keywords:

- wollastonite /

- silane SCA1113 /

- nylon 6 /

- mechanical properties /

- molecular simulation

-

再生粗骨料(RCA)的成分、性能、掺量对再生混凝土的力学性能有较大影响[1-2],GB/T 25177—2010[3]中定义RCA:由建(构)筑废物中的混凝土、砂浆、石、砖瓦等加工而成。目前,以废弃混凝土为主要成分的RCA在混凝土中运用的研究较为成熟,而实际很多在建设、拆迁、修缮过程中产生的建筑垃圾主要成分不单是混凝土,还有砂浆、石、砖瓦等。为了更好的促进建筑废弃物的再利用,研究由多种成分组成的再生骨料对混凝土力学性能的影响及破坏机制具有实际意义。肖建庄等[1,4-5]的研究表明,不同来源的废弃混凝土较单一来源混凝土抗压强度减小,标准差和变异系数明显增大,并进一步研究了再生混凝土的细微观结构和破坏机制。李文贵等[6]采用高速摄像仪对再生混凝土裂纹演变进行了研究。郭远新等[2]对不同品质的RCA混凝土强度进行了研究。陈宗平等[7]研究了再生混凝土在多轴受力情况下的破坏准则和本构关系。高丹盈等[8]在微细观层次分析了再生砖骨料混凝土破坏机制。Casuccio等[9]研究发现,由于RCA刚度较低,再生混凝土破坏时表现出明显的断裂区域减少,分支裂纹数量和弯曲程度降低。Otunyo等[10]以再生骨料取代率为变量,建立了不同水胶比下的再生混凝土抗压强度预测模型。Rao等[11]通过SEM观察了RCA混凝土界面过渡区的微观结构,测试并计算了其维氏显微硬度与抗压强度的关系。

分形几何学主要用于研究外观不规则、无序的图形,对其形貌进行定量描述。近些年,国内外结合CT扫描、声发射技术等广泛研究了混凝土在骨料空间分布、孔隙率、破坏裂纹和断裂面等方面表现出的分形特征。在国内谢和平等[12-13]最早对混凝土细观裂纹的分形效应进行研究。党发宁等[14-15]借助CT较全面地研究了混凝土在静、动力破坏下裂纹的分形特征。郑山锁等[16-17]采用Weierstrass-Mandelbrot(W-M)分形曲面法构造了具有不同分形特征参数的混凝土分形断裂面,得到了混凝土分形断裂面的多重分形谱曲线,并推导出分形损伤本构模型。吴泽弘等[18]利用CT扫描观察了水泥净浆从1 d到40 d龄期的水化过程,得到了试件内部未水化水泥颗粒、水化产物和孔隙的清晰图像。Carpinteri等[19]基于分形几何学,提出了多重分形尺寸的裂纹扩展规律。Ren等[20-21]在CT扫描图像的基础上,相继研究了二维和三维情况下混凝土损伤演化和破坏裂纹扩展过程。Yang等[22-23]通过二值化矩阵优化了分形维数的计算,建立随机分形混凝土的数值骨料模型,研究了粗骨料含量及分形维数对混凝土宏观力学性能的影响。

本文以C30等级不同RCA取代率的再生混凝土为研究对象,借助工业CT扫描技术研究了再生混凝土加载到90%预估破坏荷载时内部细观裂纹的发展情况及破坏机制,基于分形理论计算裂纹的分形维数及多重分形谱,探究裂纹扩展与分形维数和多重分形谱特征参数间的规律,并建立分形特征参数与RCA取代率和混凝土抗压强度间的关系,以期实现对再生混凝土细观破坏裂纹与天然混凝土异同的准确描述和定量分析。

1. 试验材料及方法

1.1 原材料

1.1.1 粗骨料

天然粗骨料(NCA)采用安山岩碎石,表面棱角分明,无孔洞。再生粗骨料(RCA)为吉林市某绿色建材公司利用建筑废弃物生产而成,主要成分有(按质量分数测定):混凝土(66.5wt%)、粘土砖(28.6wt%)、瓷砖(3.5wt%)和杂物(1.4wt%)。NCA和RCA的形貌如图1所示。

依据GB/T 14685—2011[24]和GB/T 25177—2010[3]对NCA和RCA的压碎指标、吸水率等性能进行测定(如表1所示),为保证试验的统一性,NCA和RCA均采用5~16 mm连续级配,级配曲线如图2所示。

试验设计了5种RCA取代率(R) 的再生混凝土,即0(普通混凝土),25%、50%、75%、100%,再生混凝土强度设计等级为C30,配合比如表2所示。拌制后的混凝土浇筑进尺寸为100 mm×100 mm×100 mm的立方体模具中,各模具放置在振动台上15 s进行压实。24 h后拆模,并将试件放入标准养护室养护至7 d和28 d。最后将试件取出按GB/T 50081—2002[25]进行抗压强度试验。

表 1 粗骨料基本性能Table 1. Properties of coarse aggregateAggregate

typeCrushing

index/%Natural stacking

density/(kg·m−3)Voidage/% Apparent density/

(kg·m−3)Water absorption

of 24 h/%RCA 20.2 1 073 56 2 425 6.73 NCA 6.3 1 479 46 2 750 0.57 表 2 再生混凝土配合比Table 2. Mix proportions of recycled aggregate concreteCode R/% mw/mc Mix proportion/(kg·m−3) Cement Sand NCA RCA Water Fly ash Silica fume Superplasticizer R0 0 0.50 288 726 1 184 0 180 54 18 7.2 R25 25 0.50 288 726 888 296 180 54 18 7.2 R50 50 0.50 288 726 592 592 180 54 18 7.2 R75 75 0.50 288 726 296 888 180 54 18 7.2 R100 100 0.50 288 726 0 1 184 180 54 18 7.2 Notes: R—Replacement rate of RCA; mw/mc—Water-to-cementitious material ratio. 1.1.2 其他原材料及性能

水泥采用冀东水泥产的盾石牌P·O42.5水泥;细骨料采用吉林松花江河砂,细度模数为2.6,表观密度为2 580 kg/m3;粉煤灰采用吉林市某热电厂产Ⅰ级粉煤灰,密度为2 868 kg/m3;硅灰采用上海天恺920硅灰,SiO2含量为92%,比表面积为23×104 cm2/g;减水剂采用江苏苏博特PCA-Ⅴ聚羧酸高性能减水剂;水采用吉林市自来水。

1.2 试验方法

1.2.1 抗压强度

1.2.2 扫描试样加载过程

采用压力机为华龙WAW-1000万能试验机进行测试。采用荷载、位移混合控制,设定的加载路径为:荷载控制,加载速率为0.5 kN/s,加载至预估破坏荷载的70%;停止加载,控制通道保持;随后位移控制,加载速率为0.005 mm/s,加载至预估破坏荷载的90%,停止加载,取出试件。试件为28 d抗压强度试验同一批试件,尺寸为100 mm×100 mm×100 mm的立方体试件。

1.2.3 CT扫描

CT扫描试验采用德国GE公司的Phoenix v | tome | x s240微焦点工业CT机,系统参数如表3所示,工业CT机采用锥束CT系统,360°旋转扫描,一次扫描时间为50 min,每秒转动0.12°,细节分辨能力为1 μm。最大管电压/功率可达240 kV/320 W,电压决定射线穿透能力,电流决定扫描试件中不同材料的对比度,在扫描过程中根据试块的尺寸和内部密度选择合适的电压和电流,以准确识别细微裂纹。

表 3 工业CT系统技术参数Table 3. Technical parameters of industrial CT systemParameter Result Maximum tube voltage/kV 240 Maximum tube power/W 320 Detail resolution/μm 1 在本次试验中,扫描参数为:电压为190 kV,电流为110 μA,滤波片为1片锡滤波片。图3为工业CT系统照片。按混凝土的加载方向与承重圆台面垂直的方向放置混凝土,然后进行扫描。选择垂直于加载方向的图片为输出图片,以0.1 mm为间隔,共输出1 000张分辨率为1 000×1 000的CT断面图,图片格式为BMP。

1.3 分形几何理论模型

1.3.1 分形维数计算

为了将图像信息转化为更精确的数学语言来定量描述,采用分形维数来表征混凝土内部细观破坏裂纹,应用盒维数法[26]裂纹分形维数计算,如图4所示。具体计算步骤为:用边长为r的正方形盒子覆盖裂纹图形,统计出有裂纹的正方形盒子数目N(r),减小盒子边长r继续统计含裂纹的正方形盒子数目,直至最小的盒子边长达到图片像素为止(图像调整为512×512像素),绘制lnN(r)-ln(r)曲线,则N(r)和r有如下关系:

N(r)∼(1/r)D (1) 即直线斜率的绝对值为破坏裂纹分形维数D:

D=−lim (2) 将RGB模式的裂纹图像进行二值化处理,白色(数值1)表示裂纹,黑色(数值0)表示背景,然后将二值化数据导入Matlab中计算分形维数。

为了减小样本误差,以距离承重圆台面50 mm处扫描断面为基准,0.2 mm为间隔,上、下各取10张,共取21张CT图像,求取21张CT图像分形维数平均值。

1.3.2 多重分形谱计算

分形维数适用于表示混凝土破坏裂纹整体的扩展情况和自相似规律,描述事物在某一标度尺寸下的特征,但无法反映局部特征。多重分形是从局部出发,用一个谱函数来描述分形体不同层次的特征,进而研究分形体最终的整体特征。

采用盒维数法计算裂纹多重分形谱[27]。用边长为

\varepsilon 的正方形盒子去覆盖裂纹图形,统计每个盒子(i , j)中含有裂纹的像素数目{n_{ij}} ,\sum {{n_{ij}}} 为图像中全部裂纹的像素数目,可求得每个盒子中裂纹占总体裂纹的概率,即裂纹分布概率{P_{ij}}(\varepsilon ) :{P_{ij}}(\varepsilon ) = \frac{{{n_{ij}}}}{{\sum {{n_{ij}}} }} (3) 则裂纹分布概率

{P_{ij}}(\varepsilon ) 、具有同分布概率的盒子总数{N_\alpha }(\varepsilon ) 均与\varepsilon 有幂函数关系:{P_{ij}}(\varepsilon ) \sim {\varepsilon ^\alpha } (4) {N_\alpha }(\varepsilon ) \sim {\varepsilon ^{ - f(\alpha )}} (5) 式中:

\alpha 为奇异指数,反映各盒子内部的奇异程度;f(\alpha ) 为具有相同奇异性的子集的分形维数。f(\alpha )\text{-} \alpha 的关系为裂纹的多重分形谱。基于统计物理方法来实现不规则图像的多重分形谱计算,定义配分函数

{\chi _q}(\varepsilon ) 为裂纹分布概率{P_{ij}}(\varepsilon ) 的q次方的总和,q为权重因子,则:{\chi _q}(\varepsilon ) \equiv \sum {{P_{ij}}{{(\varepsilon )}^q}} = {\varepsilon ^{\tau (q)}} (6) 若式(6)成立,则可由

\ln {\chi _q}(\varepsilon )\text{-}\ln \varepsilon 曲线的斜率求得质量指数\tau (q) :\tau (q) = \mathop {\lim }\limits_{\varepsilon \to 0} \left[ {\frac{{\ln {\chi _q}(\varepsilon )}}{{\ln \varepsilon }}} \right] (7) 奇异指数α和分形维数f (α)可表示为

\alpha = \frac{{{\rm{d}}\left[ {\tau (q)} \right]}}{{{\rm{d}}q}} (8) f(\alpha ) = \alpha q - \tau (q) (9) 由Legendre转换后可得

\alpha ,然后将\alpha 代入式(8)求出f(\alpha ) 。即能得到f(\alpha )\text{-}\alpha 的关系图。实际计算中,分形谱为离散的点序列,

\alpha 可由下式求得[28]:\alpha = \frac{{\tau (q) - \tau (q - \Delta q)}}{{\Delta q}} (10) 式中:q的范围取[−50, 50];计算步距

\Delta q 取1。2. 结果与分析

2.1 不同RCA取代率下混凝土的抗压强度

图5为不同RCA取代率下混凝土7 d和28 d的抗压强度(尺寸换算系数为0.95)。可以看出,用RCA代替NCA后,混凝土抗压强度下降,以R0为基准,7 d时R25~R100混凝土试件抗压强度分别降低了8.39%、10.1%、13.04%、16.26%,28 d时R25~R100混凝土试件抗压强度分别降低了2.62%、6.54%、8.41%、13.69%,与文献[1]和[2]结果一致。采用最小二乘法拟合,二者关系如下:

{f_{\rm{c}}} = - 0.0603R + 45.594 (11) 式中:

{f_{\rm{c}}} 为混凝土抗压强度;R为RCA取代率。决定系数{R^2} = 0.9793 。混凝土抗压强度值的离散程度也因加入了RCA而变大。此现象可能是由于RCA性能导致,低中强度等级的再生混凝土的RCA性能与骨料-水泥砂浆界面黏结强度对其力学性能的影响占主导地位,当RCA取代率增加时,RCA对混凝土的影响也增大,最终导致混凝土抗压强度值离散程度较大。文献[5]也得出了相似结果。

2.2 RCA取代率对混凝土破坏的影响

图6为RCA取代率为50%的再生混凝土的CT扫描图像,密度越大的物体吸收射线的能力越强,其所在地方越接近白色。可以观察到,存在密度较大接近白色的NCA和RCA、接近水泥砂浆密度的RCA和密度较小接近黑色的RCA以及制作时存在的孔洞和加载时出现的主裂纹、纵向裂纹和斜裂纹。

图7为90%预估破坏荷载下距离承重圆台面50 mm处再生混凝土的破坏形态(28 d)。可知,普通混凝土中,破坏裂纹主要沿NCA与水泥砂浆的界面发展,NCA基本未被破坏,裂纹为了寻找薄弱区域释放能量而发展较丰富。加入RCA后,混凝土中破坏裂纹发展至RCA时,遇到强度较高的RCA会选择沿RCA与水泥砂浆界面绕行,遇到强度较低的RCA会选择贯穿。随着RCA取代率的增加,裂纹分岔减小,发展路径趋近直线。试验现象与文献[9]相似。

试验结果说明,RCA的加入改变了混凝土的细观破坏模式。普通混凝土的破坏形态主要受NCA与水泥砂浆界面黏结强度的影响。再生混凝土的破坏不仅取决于RCA与水泥砂浆界面的黏结强度,还取决于RCA自身的强度,此细观破坏形态的发展与2.1节中混凝土抗压强度离散性的推测吻合。

2.3 基于分形维数的再生混凝土细观破坏裂纹定量表征

图8为不同RCA取代率的混凝土细观破坏裂纹lnN(r)-ln(r)曲线。可以看出,不同RCA取代率的混凝土细观破坏裂纹lnN(r)-ln(r)曲线均呈一条直线,决定系数R2非常接近1,说明破坏裂纹的发展具有良好的自相似性,因此可用分形维数来定量表述破坏裂纹。结合图7可知,普通混凝土的细观破坏裂纹分形维数为1.3249,裂纹较多,随RCA取代率的增加,分形维数逐渐下降,分别为1.3097、1.2987、1.192、1.217。裂纹由多变少,逐渐以主裂纹为主,时而分出几条纵向裂纹和斜裂纹,相对普通混凝土,分形维数分别减小了1.15%、1.99%、10.09%、8.14%。

图9为不同RCA取代率下的混凝土细观破坏裂纹分形维数平均值。可知,R0~R100混凝土试件的细观破坏裂纹分形维数平均值分别为1.3281、1.3117、1.2945、1.1926、1.2141。CT扫描图像的分形维数能很好地反映裂纹扩展的规律,即分形维数越大,裂纹越多,裂纹扩展越丰富。

2.4 再生混凝土细观破坏裂纹的多重分形特征

图10为RCA取代率为100%的再生混凝土的

\ln {\chi _q}(\varepsilon ) \text{-} \ln \varepsilon 曲线(图中步距\Delta q 为5)。可以看出,权重因子|q|≤50时,在一定范围内,\ln {\chi _q}(\varepsilon ) 随\ln \varepsilon 的变化有较好的线性关系,说明RCA取代率为100%的再生混凝土的破坏裂纹能满足标度不变性,属于多重分形,其他扫描图也有类似效果,因此可以用多重分形来定量描述裂纹。图11为不同RCA取代率下的混凝土细观破坏裂纹的多重分形谱,用特征参数

{\alpha _{\min }} 、{\alpha _{\max }} 、\alpha _{\rm{mean}} = ({\alpha _{\rm{max}}} + \alpha _{\rm{min}})/2 、f({\alpha _{\min }}) 、f({\alpha _{\max }}) 、\Delta f(\alpha ) = f({\alpha _{\max }}) - f({\alpha _{\min }}) 、f{(\alpha )_{\max }} 来描述裂纹的多重分形谱。{\alpha _{\min }} 和{\alpha _{\max }} 分别为CT图像中最大概率子集和最小概率子集,即裂纹最多和最少的局部区域。\alpha 越小,说明该区域中的裂纹分布越多,裂纹分支越复杂;\alpha 越大,说明该区域中的裂纹分布越少,裂纹分支越稀疏。{\alpha _{{\rm{mean}}}} 为局部概率子集的平均值,{\alpha _{{\rm{mean}}}} 越大,说明CT图像中局部区域裂纹分布数量和分支裂纹的平均值增加;{\alpha _{{\rm{mean}}}} 越小,说明CT图像中局部区域裂纹分布数量和分支裂纹的平均值减小。f({\alpha _{\min }}) 和f({\alpha _{\max }}) 分别为最大概率分形子集和最小概率分形子集的盒子数目。\Delta f(\alpha ) 为最小概率分形子集和最大概率分形子集的盒子数目之差,\Delta f(\alpha ) 越大,说明裂纹复杂程度增大;\Delta f(\alpha ) 越小,说明裂纹复杂程度减小。f{(\alpha )_{\max }} 为整个图像中裂纹的扩展程度,f{(\alpha )_{\max }} 越大,裂纹扩展越广越丰富;f{(\alpha )_{\max }} 越小,裂纹扩展越窄越稀疏,直至只剩主裂纹。表4为不同RCA取代率的混凝土细观破坏裂纹多重分形谱特征参数。由图11和表4可以发现,随RCA取代率的增加,

{\alpha _{{\rm{mean}}}} 总体为减小趋势,R0~R100混凝土试件的CT图像内裂纹像素点总数分别为9 999、3 984、5 993、2 753、3 128,相同尺寸盒子里裂纹像素数的改变没有各CT图像像素总数的改变大,起决定作用的是CT图像像素总数,因此实际CT图像中局部区域裂纹分布数量和分支裂纹减小;\Delta f(\alpha ) 总体为减小趋势,CT图像中裂纹的复杂程度减小;f{(\alpha )_{\max }} 总体为减小趋势,CT图像中向外扩展的斜裂纹和纵向裂纹逐渐减少。与郑山锁等[16]研究结果一致。表 4 不同RCA取代率的混凝土细观破坏裂纹的多重分形谱参数Table 4. Parameters of multi-fractal spectrum of meso-failure crack of concrete with different replacement rates of RCAαmin αmax αmean f (αmin) f (αmax) Δf (α) f (α)max R0 1.3655 1.5835 1.4745 0.8479 1.2056 0.3577 1.4648 R25 1.2571 1.5088 1.3830 0.6516 1.0229 0.3713 1.3376 R50 1.3110 1.5262 1.4186 0.8034 1.1018 0.2984 1.3694 R75 1.1791 1.3922 1.2857 0.6479 0.8794 0.2315 1.2486 R100 1.1640 1.4330 1.2985 0.6943 0.8958 0.2015 1.2506 Notes: In multi-fractal spectrum f ( α )- α: αmin, αmax, αmean—Minimum, maximum and mean of α ; f (αmin), f (αmax)—Corresponding to αmin and αmax ; Δf (α)=f (αmax)–f (αmin); f (α)max—Maximum of f (α). 结果表明,通过多重分形谱描述裂纹,既可获得局部裂纹分布和支路裂纹的变化规律,也可获得由局部影响带来的整体裂纹变化规律。

2.5 混凝土的分形特征参数与RCA取代率及抗压强度的关系

图12为RCA取代率和混凝土抗压强度与混凝土细观破坏裂纹分形维数的关系。可以看出,随着破坏裂纹分形维数D的增大,RCA取代率R略有波动,但整体呈下降趋势,RCA取代率R与细观破坏裂纹分形维数D呈线性关系:

R = - 585.7587D + 792.8592 (12) 式中,决定系数

{R^2} = 0.8133 。将式(12)代入式(11)中,则可用细观破坏裂纹分形维数D来表征混凝土抗压强度

{f_{\rm{c}}} :{f_{\rm{c}}} = 35.3095D - 2.1996 (13) 二维平面的分形维数D最大值为2,式(13)计算C30混凝土

{f_{{\rm{c}}\max }} \leqslant 68.42\;{\rm{MPa}} ,这出现在裂纹全覆盖的情况下,而实际上混凝土破坏不可能达到此种情况,需要进一步大量实验来确定D的变化区间及系数,从而更精确的确定R \text{-}D 、{f_{\rm{c}}} \text{-}D 关系。多重分形是在单重分形即分形维数基础上更深入的研究,因此RCA取代率R与裂纹的多重分形谱特征参数

f{(\alpha )_{\max }} 和\Delta f(\alpha ) 也有类似的线性关系,图13为RCA取代率和混凝土抗压强度与细观破坏裂纹多重分形谱特征参数的关系。其关系如下:R = - 396.496f{(\alpha )_{\max }} + 579.005 (14) R = - 502.5247\Delta f(\alpha ) + 196.7774 (15) 式(14)和式(15)中决定系数分别为

{R^2} = 0.8206 和{R^2} = 0.909 。将式(14)和(15)分别代入式(11)中,采用多重分形谱特征参数表征的混凝土抗压强度

{f_{\rm{c}}} 为{f_{\rm{c}}} = 23.9008f{(\alpha )_{\max }} + 10.6916 (16) {f_{\rm{c}}} = 30.2922\Delta f(\alpha ) + 33.7323 (17) f{(\alpha )_{\max }} 在二维空间内最大值也为2,\Delta f(\alpha ) 依据f({\alpha _{\max }}) 和f({\alpha _{\min }}) 的值而定。分析结果表明,可以通过混凝土细观破坏裂纹的分形维数和多重分形谱特征参数来推测RCA取代率及在相应RCA取代率下混凝土的抗压强度。由于试验数据有限,具体的关系与参数变化范围有待进一步深入研究。

3. 结 论

(1)普通混凝土中再生粗骨料(RCA)的存在,会降低混凝土抗压强度,且随着RCA取代率增加,再生混凝土强度逐渐降低。再生混凝土比普通混凝土抗压强度值的离散性偏大。

(2)再生混凝土的细观破坏模式与普通混凝土不同,混凝土中用RCA取代天然粗骨料(NCA)后,会改变混凝土的细观破坏模式。再生混凝土的破坏不仅取决于粗骨料与水泥砂浆界面的黏结强度,还取决于RCA的强度,破坏裂纹发展至强度较高的RCA时会选择绕RCA表面发展,而发展至强度较低的RCA时会选择贯穿RCA。

(3)分形维数可实现对混凝土内部细观裂纹整体扩展规律的定量描述,取代率分别为0%、25%、50%、75%、100%的混凝土CT图像细观破坏裂纹分形维数平均值分别为1.3281、1.3117、1.2945、1.1926、1.2141,即分形维数越大,裂纹越多,裂纹发展得越丰富,与CT扫描结果一致。

(4)多重分形谱能够反映从局部到整体不同层次的细观破坏裂纹特征,既可获得局部裂纹分布与支路裂纹的变化规律,也可获得局部影响带来的整体裂纹变化规律。不同取代率0%~100%的变化区间内,最小概率分形子集和最大概率分形子集的盒子数目之差

\Delta f(\alpha ) 总体为减小趋势,再生混凝土中裂纹的复杂程度减小;整个图像中裂纹的扩展程度f{(\alpha )_{\max }} 总体为减小趋势,再生混凝土中向外扩展的斜裂纹和纵向裂纹逐渐减少,直至只剩主裂纹。(5)细观破坏裂纹分形维数D、多重分形谱特征参数

f{(\alpha )_{\max }} 和\Delta f(\alpha ) 均与RCA取代率R呈线性下降关系,与抗压强度fc呈线性增长关系。基于分形理论,可有效开展再生混凝土宏观抗压强度和RCA取代率与细观破坏裂纹分形特征参数的多尺度研究。 -

表 1 几何优化前后晶体下部原子坐标及变化

Table 1 Coordinates and changes of lower atoms in crystals before and after geometric optimization

Atom Original coordinate

(x, y, z)Optimized coordinate

(x, y, z)Coordinate variation

(x, y, z)O1 (0.301, 0.939, 0.464) (0.302, 0.936, 0.468) (–0.001, 0.002, –0.004) O2 (0.571, 0.769, 0.199) (0.574, 0.771, 0.202) (–0.003, –0.002, –0.003) O3 (–0.018, 0.868, 0.265) (–0.021, 0.867, 0.266) (0.003, 0, –0.001) O4 (0.271, 0.87, 0.094) (0.27, 0.872, 0.093) (0.002, –0.002, 0.001) O5 (0.402, 0.727, –0.17) (0.403, 0.728, –0.171) (–0.001, –0.001, 0.001) O6 (0.274, 0.513, 0.093) (0.273, 0.513, 0.092) (0, 0, 0.001) O7 (–0.017, 0.374, 0.266) (–0.019, 0.375, 0.268) (0.002, –0.001, –0.002) O8 (0.303, 0.462, 0.463) (0.305, 0.466, 0.468) (–0.001, –0.004, –0.005) O9 (0.218, 0.179, 0.225) (0.22, 0.181, 0.228) (–0.002, –0.002, –0.003) Si1 (0.185, 0.954, 0.269) (0.185, 0.954, 0.271) (0, 0, –0.002) Si2 (0.397, 0.724, 0.056) (0.399, 0.725, 0.057) (–0.002, –0.002, –0.001) Si3 (0.185, 0.388, 0.268) (0.186, 0.39, 0.272) (–0.001, –0.003, –0.003) Ca1 (0.802, 0.577, 0.239) (0.803, 0.577, 0.238) (–0.001, 0, 0.001) Ca2 (0.503, 0.75, 0.527) (0.507, 0.752, 0.531) (–0.003, –0.001, –0.004) Ca3 (0.202, 0.929, 0.764) (0.201, 0.927, 0.764) (0.001, 0.002, 0) 表 2 硅灰石晶体的表面能

Table 2 Surface energy of wollastonite crystals

Surface Energy/(eV·nm−2) (100) − 2330 (010) − 2160 (001) − 2134 表 3 复合粉体填充尼龙6(PA 6)的力学性能

Table 3 Mechanical properties of composite powder filling in nylon 6 (PA 6)

Sample Impact strength/(kJ·m−2) Tensile strength/MPa Bending strength/MPa Bending modulus/MPa PA 6 6.80 60.56 72.54 1955.41 Wollastonite/PA 6 4.40 60.82 109.96 3280.27 Modified powder/PA 6 7.38 75.60 108.05 3439.40 -

[1] 李渴, 彭春艳, 魏博, 等. 国外硅灰石资源开发利用情况[J]. 建材世界, 2019, 40(5): 12-16. LI Ke, PENG Chunyan, WEI Bo, et al. Development and utilization of wollastonite in foreign countries[J]. The World of Building Materials, 2019, 40(5): 12-16(in Chinese).

[2] 蒋浩东, 李树蔚, 丁建, 等. 国内外硅灰石资源现状及应用研究进展[J]. 矿产保护与利用, 2023, 43(1): 162-168. JIANG Haodong, LI Shuwei, DING Jian, et al. Domestic and foreign status and application research progress of wollastonite resources[J]. Conservation and Utilization of Mineral Resources, 2023, 43(1): 162-168(in Chinese).

[3] 许怀凤. 陶瓷坯用硅灰石粉的质量控制及其方法[J]. 中国粉体技术, 2013, 19(6): 73-76. XU Huaifeng. Quality controlling factors and methods of wollastonite powders for ceramics[J]. China Powder Science and Technology, 2013, 19(6): 73-76(in Chinese).

[4] 韩秀丽, 张韩, 刘磊, 等. 硅灰石对连铸保护渣结晶性能的影响规律[J]. 钢铁钒钛, 2015, 36(1): 103-108. HAN Xiuli, ZHANG Han, LIU Lei, et al. Effect of wollastonite on crystallization properties of mould powder[J]. Iron Steel Vanadium Titanium, 2015, 36(1): 103-108(in Chinese).

[5] 邢君, 郭永伟, 张利军. 硅灰石和膨润土增强膨胀型钢结构防火涂料[J]. 消防科学与技术, 2020, 39(7): 1003-1007. DOI: 10.3969/j.issn.1009-0029.2020.07.032 XING Jun, GUO Yongwei, ZHANG Lijun. Experimental study on wollastonite and bentonite reinforced fire retardant coatings for expanded steel structures[J]. Fire Science and Technology, 2020, 39(7): 1003-1007(in Chinese). DOI: 10.3969/j.issn.1009-0029.2020.07.032

[6] LOTFOLLAHI S, JAIDARI A, BAKHTIARI P, et al. Effect of wollastonite microfibers and waste tire rubber on mechanical properties of concrete[J]. International Journal of Concrete Structures and Materials, 2023, 17(1): 33. DOI: 10.1186/s40069-023-00595-3

[7] 王泽红, 周鸭羊, 宁国栋. 高长径比硅灰石制备及机理研究[J]. 矿产保护与利用, 2015(1): 49-53. WANG Zehong, ZHOU Yayang, NING Guodong. Study on the preparation of high aspect ratio wollatonite and its mechanism[J]. Conservation and Utilization of Mineral Resources, 2015(1): 49-53(in Chinese).

[8] 刘坤. 汽车轻量化材料及制造工艺研究[J]. 汽车测试报告, 2023(2): 78-80. LIU Kun. Research on lightweight materials and manufacturing processes for automobiles[J]. Car Test Report, 2023(2): 78-80(in Chinese).

[9] 石照耀, 辛栋. 塑料齿轮研究的进展和方向[J/OL]. 北京航空航天大学学报, 1-18[2025-01-09]. SHI Zhaoyao, XIN Dong. A review on plastic gear's research progress and direction[J/OL]. Journal of Beijing University of Aeronautics and Astronautics, 1-18[2025-01-09]. (in Chinese).

[10] 何露露, 何敏, 何肖, 等. 尼龙6抗氧剂的应用进展[J]. 塑料, 2021, 50(5): 67-71. HE Lulu, HE Min, HE Xiao, et al. Application progress of nylon 6 antioxidants[J]. Plastics, 2021, 50(5): 67-71(in Chinese).

[11] SON S M, KIM M, YOO J J, et al. Fabrication of carbon fiber/polyamide 6 composites with water resistance and anti-icing performance using a superhydrophobic fluorinated-polydopamine coating[J]. Composites Science and Technology, 2023, 238: 110048. DOI: 10.1016/j.compscitech.2023.110048

[12] YE W, YUAN Y, LIU S, et al. A strategy towards simultaneously improving strength and processability of polyamide 6 using bespoke dynamic covalent chain extender[J]. Polymers Advanced Technologies, 2023, 35(1): e6266.

[13] KOZLOV G V, DOLBIN I V. Effect of the nanofiller structure on the heat resistance of polyamide-6/organoclay nanocomposites[J]. High Temperature, 2022, 60(1): 126-128. DOI: 10.1134/S0018151X2201014X

[14] 张鑫婷, 尹洪峰, 魏英, 等. 基体改性对连续玻纤增强尼龙复合材料性能的影响[J]. 复合材料学报, 2024, 41(7): 3577-3586. ZHANG Xinting, YIN Hongfeng, WEI Ying, et al. Effect of matrix modification on the properties of continuous glass fiber reinforced nylon composites[J]. Acta Materiae Compositae Sinica, 2024, 41(7): 3577-3586(in Chinese).

[15] DING H, LU S, DU G. Surface modification of wollastonite by the mechano-activated method and its properties[J]. International Journal of Minerals Metallurgy and Materials, 2011, 18(1): 83-88. DOI: 10.1007/s12613-011-0404-2

[16] CHEN F, BAO Y Z, ZHANG J M, et al. Comparative study on the mechanical and thermal properties of polycarbonate composites reinforced by KH570/SA/SDBS modified wollastonite fibers[J]. Polymer Composites, 2022, 43(11): 8125-8135. DOI: 10.1002/pc.26975

[17] 丁茜, 花超然, 伏豪, 等. β-成核废旧聚丙烯/硅灰石复合材料的制备与力学性能[J]. 塑料工业, 2020, 48(8): 39-42. DOI: 10.3969/j.issn.1005-5770.2020.08.009 DING Qian, HUA Chaoran, FU Hao, et al. Preparation and mechanical properties of β-nucleated recycled polypropylene/wollastonite composites[J]. China Plastics Industry, 2020, 48(8): 39-42(in Chinese). DOI: 10.3969/j.issn.1005-5770.2020.08.009

[18] YAO L Z, XIAO Y, TANG S S, et al. Application of environmentally friendly potassium oleate modified wollastonite in carbon black/natural rubber composites[J]. Journal of Applied Polymer Science, 2023, 140(15): 53723. DOI: 10.1002/app.53723

[19] YU Q, LUO M, CHEN H, et al. Adsorption configuration of stearic acid onto calcium sulfate whisker[J]. Colloid Polymer Science, 2022, 300(7): 825-834. DOI: 10.1007/s00396-022-04984-0

[20] MENG J, WANG J, WANG L, et al. Preparation and performance of superhydrophobic surfaces with low surface energy modified attapulgite[J]. Journal of Molecular Structure, 2024, 1295(1): 136586.

[21] 全国塑料标准化技术委员会. 塑料拉伸强度的测定: GB/T 1040—92[S]. 北京: 中国标准出版社, 2008. Plastics of Standardization Administration of China. Determination of tensile strength of plastics: GB/T 1040—92 [S]. Beijing: Standards Press of China, 2008(in Chinese).

[22] 全国塑料标准化技术委员会. 塑料拉伸强度的测定: GB/T 9341—2000[S]. 北京: 中国标准出版社, 2008. Plastics of Standardization Administration of China. Determination of tensile strength of plastics: GB/T 9341—2000[S]. Beijing: Standards Press of China, 2008(in Chinese).

[23] 国家技术监督局. 硬质塑料简支梁冲击实验方法: GB/T 1043—93[S]. 北京: 中国标准出版社, 1993. The State Bureau of Quality and Technical Supervision. Hard plastic simply supported beam impact test method: GB/T 1043—93[S]. Beijing: Standards Press of China, 1993(in Chinese).

[24] 李知俊, 胡智淇, 关岩, 等. 煅烧硅灰石粉对硫氧镁水泥力学性能的影响[J]. 复合材料学报, 2024, 41(1): 395-403. LI Zhijun, HU Zhiqi, GUAN Yan, et al. Effect of calcined wollastonite powder on mechanical properties of magnesium sulfade cement[J]. Acta Materiae Compositae Sinica, 2024, 41(1): 395-403(in Chinese).

[25] 方乐武, 李明, 李渊, 等. 表面改性硅灰石纤维增强油井水泥力学性能[J]. 精细石油化工进展, 2023, 24(5): 20-25. DOI: 10.3969/j.issn.1009-8348.2023.05.006 FANG Lewu, LI Ming, LI Yuan, et al. Mechanical properties of surface modified wollastonite fiber reinforced oil well cement[J]. Advances in Fine Petrochemicals, 2023, 24(5): 20-25(in Chinese). DOI: 10.3969/j.issn.1009-8348.2023.05.006

[26] 张陶忠, 陈晓龙, 郝晓宇, 等. 硅灰石表面改性及其在聚丙烯中的应用[J]. 合成树脂及塑料, 2023, 40(3): 17-20, 24. ZHANG Taozhong, CHEN Xiaolong, HAO Xiaoyu, et al. Surface modification of wollastonite and their application in polypropylene[J]. China Synthetic Resin and Plastics, 2023, 40(3): 17-20, 24(in Chinese).

[27] GONIAKOWSKI J, FINOCCHI F, NOGUERA C. Polarity of oxide surfaces and nanostructures[J]. Reports on Progress Physics, 2008, 71(1): 016501. DOI: 10.1088/0034-4885/71/1/016501

[28] LIU X, CHENG B, HU J. CaSiO3 (001) surface reconstruction and CO2 molecular adsorption[J]. Journal of Solid State Chemistry, 2023, 323: 124027. DOI: 10.1016/j.jssc.2023.124027

[29] LAN S, LI L, XU D, et al. Surface modification of magnesium hydroxide using vinyltriethoxysilane by dry process[J]. Applied Surface Science, 2016, 382: 56-62. DOI: 10.1016/j.apsusc.2016.04.119

[30] ZRILIĆ S S, ŽIVKOVIĆ J M, ZARIĆ S D. Computational and crystallographic study of hydrogen bonds in the second coordination sphere of chelated amino acids with a free water molecule: Influence of complex charge and metal ion[J]. Journal of Inorganic Biochemistry, 2024, 251: 112442. DOI: 10.1016/j.jinorgbio.2023.112442

[31] YU S, OH K H, HWANG J Y, et al. The effect of amino-silane coupling agents having different molecular structures on the mechanical properties of basalt fiber-reinforced polyamide 6, 6 composites[J]. Composites Part B: Engineering, 2019, 163: 511-521. DOI: 10.1016/j.compositesb.2018.12.148

-

期刊类型引用(18)

1. 吴剑锋,黄雨悦,李赫赫,马德源,王彩华. 混凝土单轴压缩表面裂纹分布的一致分形特征. 材料导报. 2025(04): 98-104 .  百度学术

百度学术

2. 郑传磊,李淑翔,孙呈凯,金宝宏. 纤维再生粗骨料混凝土冻融损伤及寿命预测. 中国测试. 2024(03): 29-36 .  百度学术

百度学术

3. 王小娟,李润琳,周宏元,母崇元,乔崎云. 再生粗骨料混凝土静动态抗压强度离散性试验研究. 复合材料学报. 2024(06): 3092-3102 .  本站查看

本站查看

4. 崔正龙,孙万吉,费海超,李正元. 碳化高温后再生混凝土受压声发射特性与损伤演化. 土木与环境工程学报(中英文). 2024(04): 175-185 .  百度学术

百度学术

5. 张坤,邵鑫辉,卫杨杨,兰官奇,芦白茹,杨文豪. 掺油泥改性生土材料动态荷载下的损伤及裂缝分形特征. 西安石油大学学报(自然科学版). 2024(04): 132-142 .  百度学术

百度学术

6. 詹界东,梁晨光,赵继冲,滕振超,李成武,马锦辉. 不同再生混凝土取代率与CFRP布层数高强方钢管再生混凝土柱轴压性能. 河南科学. 2024(09): 1298-1306 .  百度学术

百度学术

7. 孙杰,申紫豪,廖海峰. 基于分形理论的冻融荷载耦合作用下纤维混凝土的抗压强度. 复合材料学报. 2024(11): 6101-6110 .  本站查看

本站查看

8. 张向冈,周高强,范玉辉,高翔,冷发光,汪昉. 圆钢管玄武岩纤维再生混凝土短柱轴压力学性能. 复合材料学报. 2023(01): 369-382 .  本站查看

本站查看

9. 杨浩杰,张龙飞,李家正,冯吉利. 混凝土细观断裂模拟及损伤演化表征. 中国科技论文. 2023(06): 643-649+655 .  百度学术

百度学术

10. 吴剑锋,李赫赫,邵玉龙. 基于数值试验的混凝土单轴压缩裂纹分布多重分形特征. 河南科学. 2023(08): 1188-1195 .  百度学术

百度学术

11. 吴剑锋,李赫赫,马德源,王彩华. 混凝土单轴压缩下表面裂纹分布多重分形特征. 力学季刊. 2023(04): 904-913 .  百度学术

百度学术

12. 甘磊,冯先伟,沈振中,陈官运. 盐冻交替作用下混凝土强度与细观孔结构关系. 中南大学学报(自然科学版). 2023(12): 4860-4869 .  百度学术

百度学术

13. 张逸超,陈星伊,陈旭升,周静海,王飞,王庆贺. 单轴受压地质聚合物再生混凝土损伤特性及本构模型研究. 硅酸盐通报. 2022(10): 3608-3614 .  百度学术

百度学术

14. 范小春,张雯静,梁天福,陈凯风. 回收轮胎钢纤维再生骨料混凝土基本力学性能试验研究. 硅酸盐通报. 2021(07): 2331-2340 .  百度学术

百度学术

15. 陈宇良,刘杰,吴辉琴,晏方. 直剪作用下再生混凝土力学性能及强度指标换算. 复合材料学报. 2021(11): 3962-3970 .  本站查看

本站查看

16. 岳建伟,黄轩嘉,赵丽敏,孔庆梅,陈颖,王自法. 基于有限元遗址土应力-应变关系的方法研究. 力学与实践. 2021(06): 921-932 .  百度学术

百度学术

17. 郑传磊,王晋浩,金宝宏,周素蓉,李淑翔,赵亚娣. 多因素对自密实混凝土力学性能发展趋势的影响. 功能材料. 2021(12): 12022-12029+12035 .  百度学术

百度学术

18. 吴剑锋,李慧剑,王彩华,孟德亮,李佶芩. 混凝土单轴压缩破碎分形研究. 硅酸盐通报. 2020(07): 2172-2177 .  百度学术

百度学术

其他类型引用(19)

-

其他相关附件

-

目的

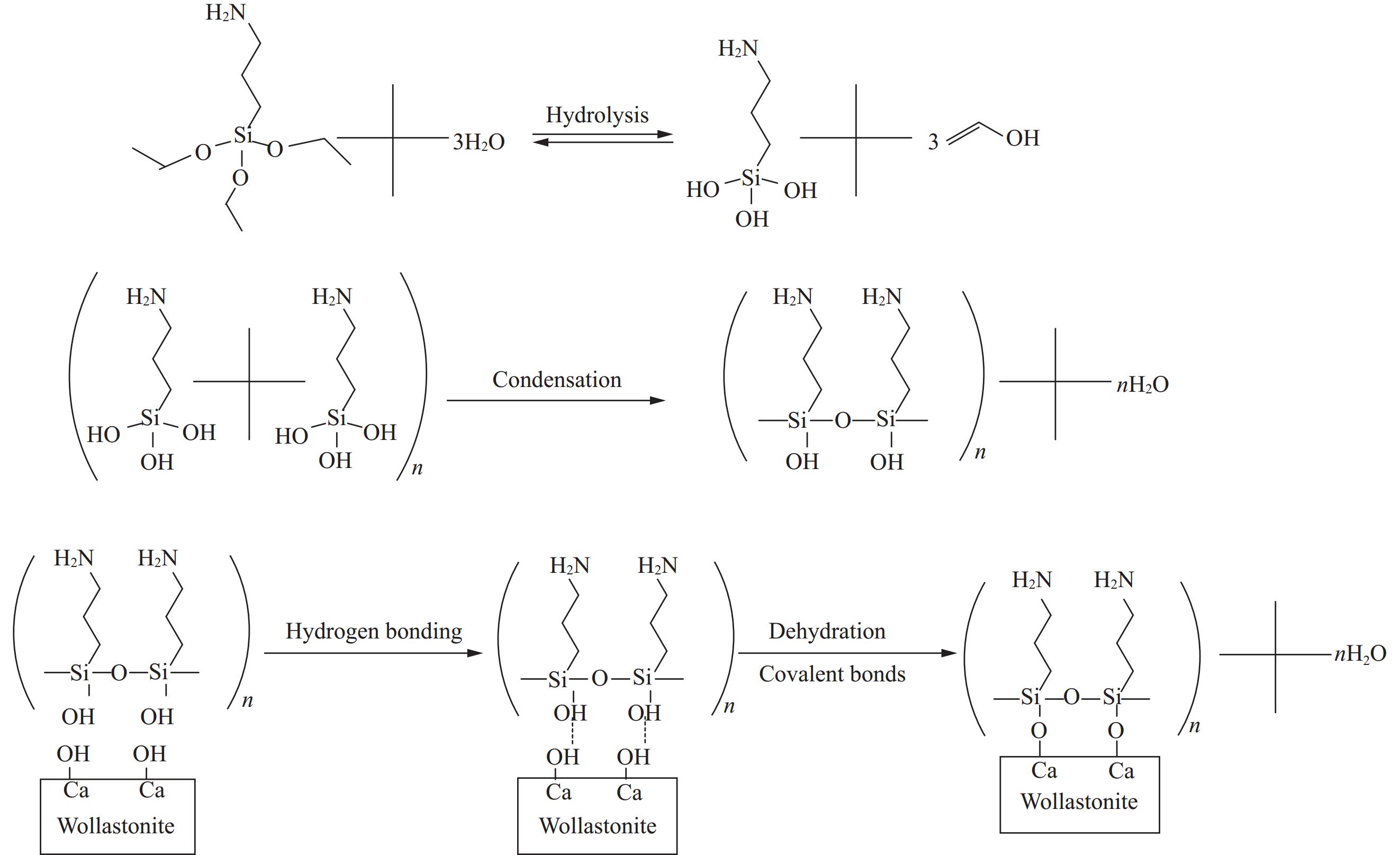

中国是世界上硅灰石出口量和进口量均为世界第一的国家,研究硅灰石的表面改性工艺与配方及其在塑料中的应用,对减少企业对进口产品的依赖度,为国家节省外汇,并提升相关企业产品科技含量都具有十分重要的意义。近些年来利用改性硅灰石填充聚合物的高附加值应用已有许多研究,但采用分子模拟硅烷与硅灰石表面结合微观机制尚未见报道。基于此,本研究以硅灰石为原料,采用3-氨丙基三乙氧基硅烷(SCA1113)对硅灰石进行了表面改性,研究了改性时间、改性温度和硅烷用量对硅灰石吸油值的影响;并将改性后的粉体填充入尼龙6制备了尼龙6复合材料,对复合材料的力学性能进行了探究,使用FTIR和分子模拟等手段分析了硅烷与硅灰石表面作用的微观机制。

方法使用吸油值为指标探究了改性温度、改性时间、硅烷用量对SCA1113改性硅灰石改性效果的影响,由于在尼龙中要加入30%质量的硅灰石,而在高聚物基料中应用的无机填料,填料吸油值的大小会直接材料的加工性能以及填充量。当填料与增塑剂同时并用时,如果填料吸油值高就会吸附增塑剂,降低增塑剂对树脂的增塑效果,或者需增大增塑剂的用量。吸油值可以作为研究改性剂配方比较的评价方法;根据国标分别测试尼龙6、硅灰石原样/尼龙6、改性硅灰石/尼龙6复合材料力学性能;使用Material Studio软件的CASTEP模块对改性过程进行模拟,结合傅里叶红外变化光谱仪对比改性前后样品的官能团变化以揭示硅烷对硅灰石表面改性的微观机制。

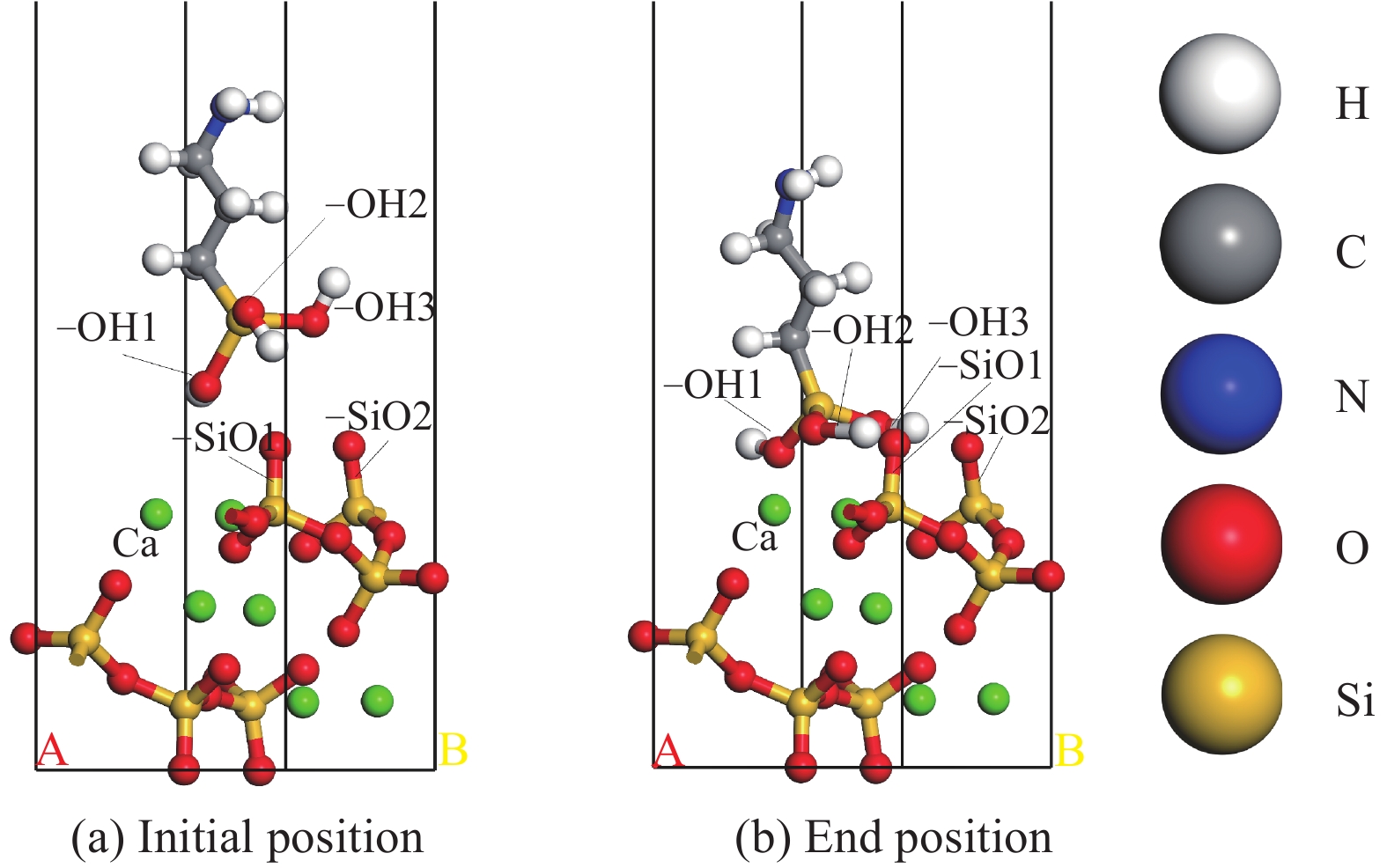

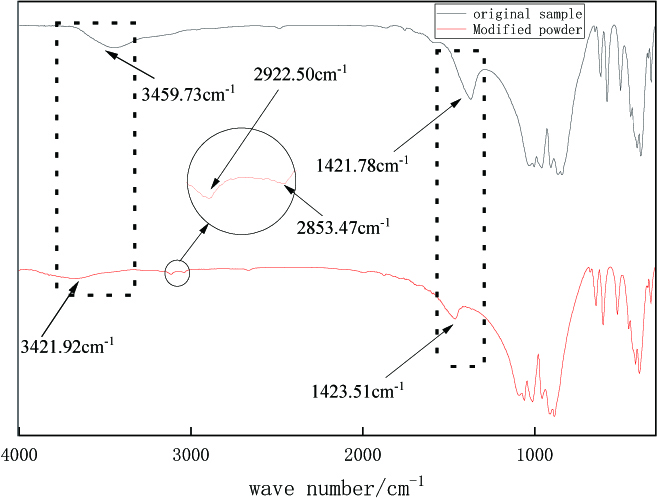

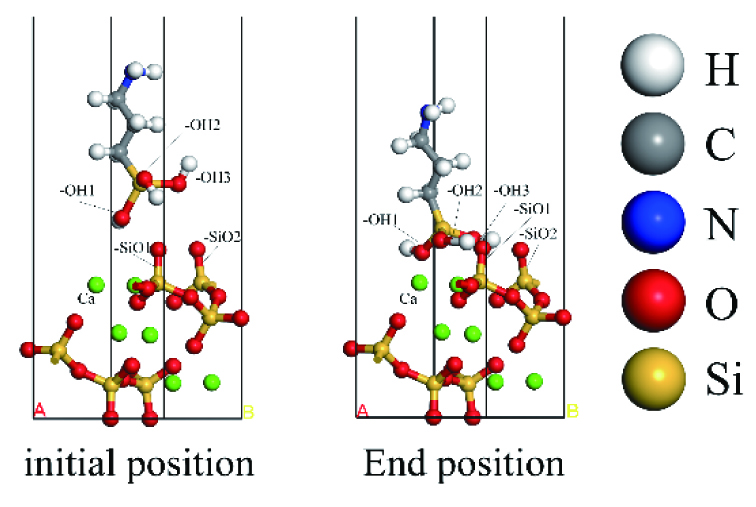

结果①当SCA1113用量为硅灰石质量的0.8%,改性时间为20min,改性温度80℃时改性粉体的吸油值达到最低为0.275ml/g,此时改性效果最好。②尼龙6原样冲击强度为6.8 KJ/m,抗拉强度为60.56Mpa,弯曲强度为72.54MPa,弯曲模量为1955.41MPa;硅灰石原样/尼龙6冲击强度为4.4 KJ/m,抗拉强度为60.82Mpa,弯曲强度为109.96MPa,弯曲模量为3280.27MPa;改性硅灰石粉体/尼龙6冲击强度为7.38KJ/m,抗拉强度为75.6Mpa,弯曲强度为108.05MPa,弯曲模量为3439.4MPa。③硅灰石原样相对改性后的粉体傅里叶红外光谱变化为:1421.78 cm的-OH特征峰偏移至1423.51 cm处;3459.73 cm的-OH特征峰偏移至3421.92 cm处;在2922.50 cm与2853.47 cm处多出了-CH-与-CH-特征峰。④对硅灰石原样晶体模拟发现模型各原子坐标变化最大不超过0.005 ;对硅灰石表面结构进行模拟,发现晶面(100)(010)(001)表面能分别为-23.30 eV/ 、-21.60 eV/ 、-21.34 eV/ ,晶面(100)上层原子发生了纵向收缩与横向拉伸现象,说明其具有吸附外部分子的潜力;对晶面(100)与水解后的SCA1113分子结合进行模拟,发现SCA1113的Si-[OH]端在吸附过程键长逐渐接近硅灰石晶体中硅氧链的键长,二者之间的结合能为-9.43eV,远大于单个氢键所能贡献的能量。

结论(1)硅烷SCA1113对硅灰石改性工艺条件宜为:改性温度80℃,改性时间20min,硅烷用量为硅灰石质量的0.8%。(2)相较于原样硅灰石填充尼龙6,改性后的硅灰石填充尼龙6能够形成柔性结合界面进而减少对抗冲击性能的破坏,能够显著提高尼龙6的力学性能。(3)硅烷SCA1113与硅灰石的结合属于化学吸附。硅烷SCA1113改性硅灰石时其反应性不来自于硅灰石晶体内部,晶面(100)最具反应性,硅灰石表面结构中暴露的钙原子与SCA1113脱去氢原子的羟基结合生成Si-O-Ca键。

-

中国是世界上硅灰石出口量和进口量均为世界第一的国家,研究硅灰石的表面改性工艺与配方及其在塑料中的应用,对减少企业对进口产品的依赖度,为国家节省外汇,并提升相关企业产品科技含量都具有十分重要的意义。近些年来利用改性硅灰石填充聚合物的高附加值应用已有许多研究,但采用分子模拟硅烷与硅灰石表面结合微观机制尚未见报道。

基于此,本研究以硅灰石为原料,采用3-氨丙基三乙氧基硅烷(SCA1113)对硅灰石进行了表面改性,研究了改性时间、改性温度和硅烷用量对硅灰石吸油值的影响;并将改性后的粉体填充入尼龙6制备了尼龙6复合材料,对复合材料的力学性能进行了探究,使用FTIR和分子模拟等手段分析了硅烷与硅灰石表面作用的微观机制。

硅灰石原样与改性后粉体的FTIR对比图谱

分子模拟硅烷SCA1113分子与硅灰石晶体表面结合

下载:

下载: