Formation mechanism of multi-plastic regions in concrete flexural members with graded GFRP bars

-

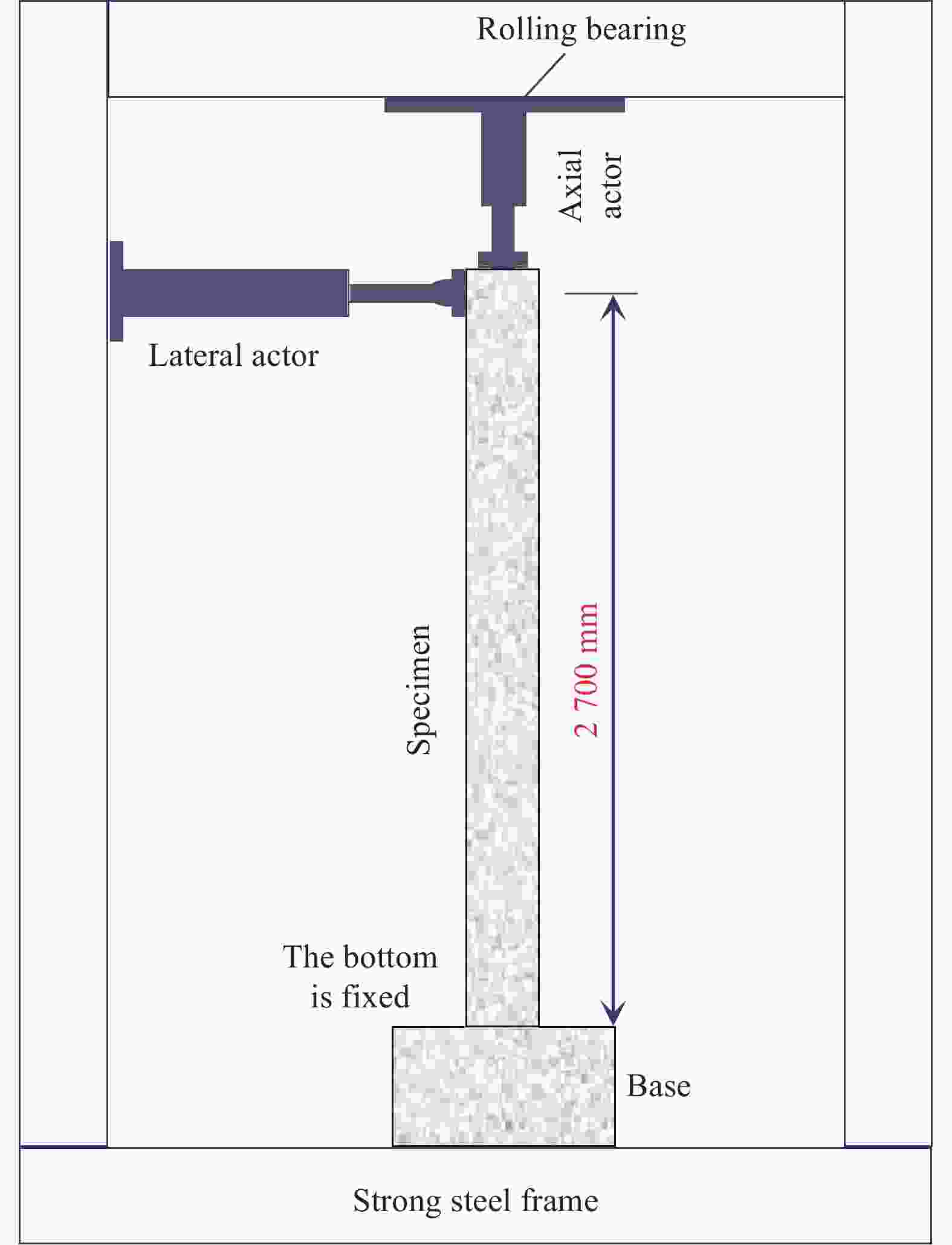

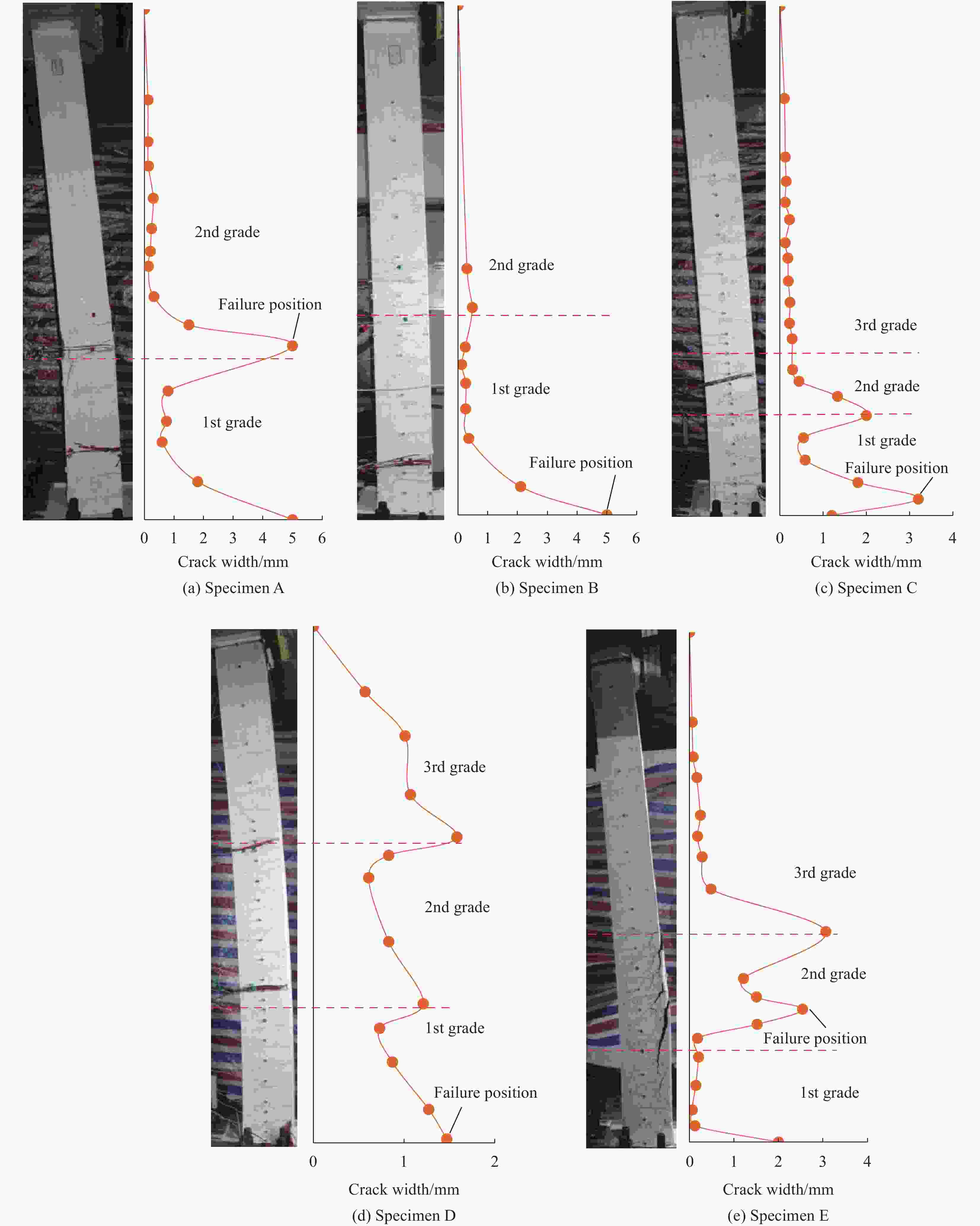

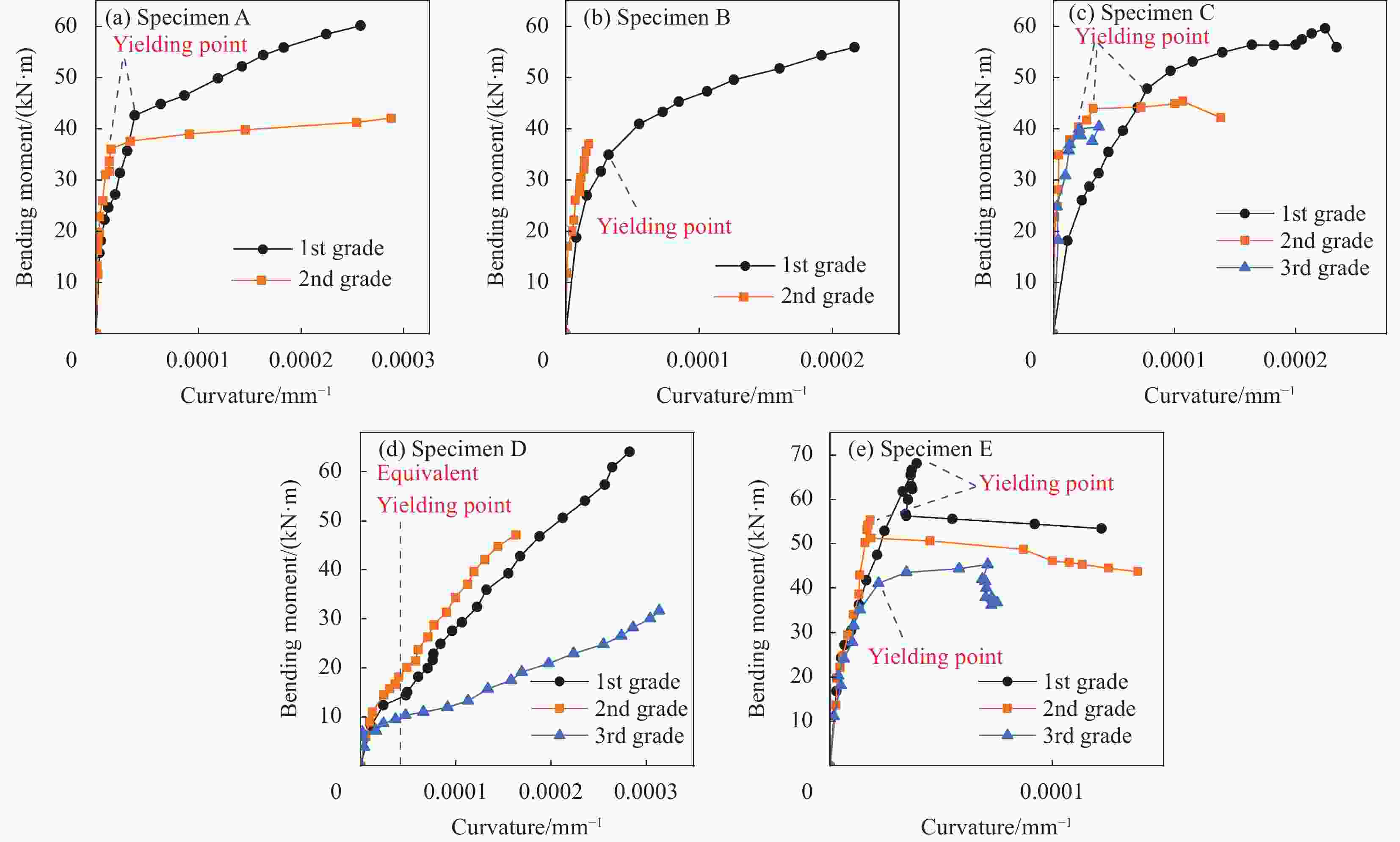

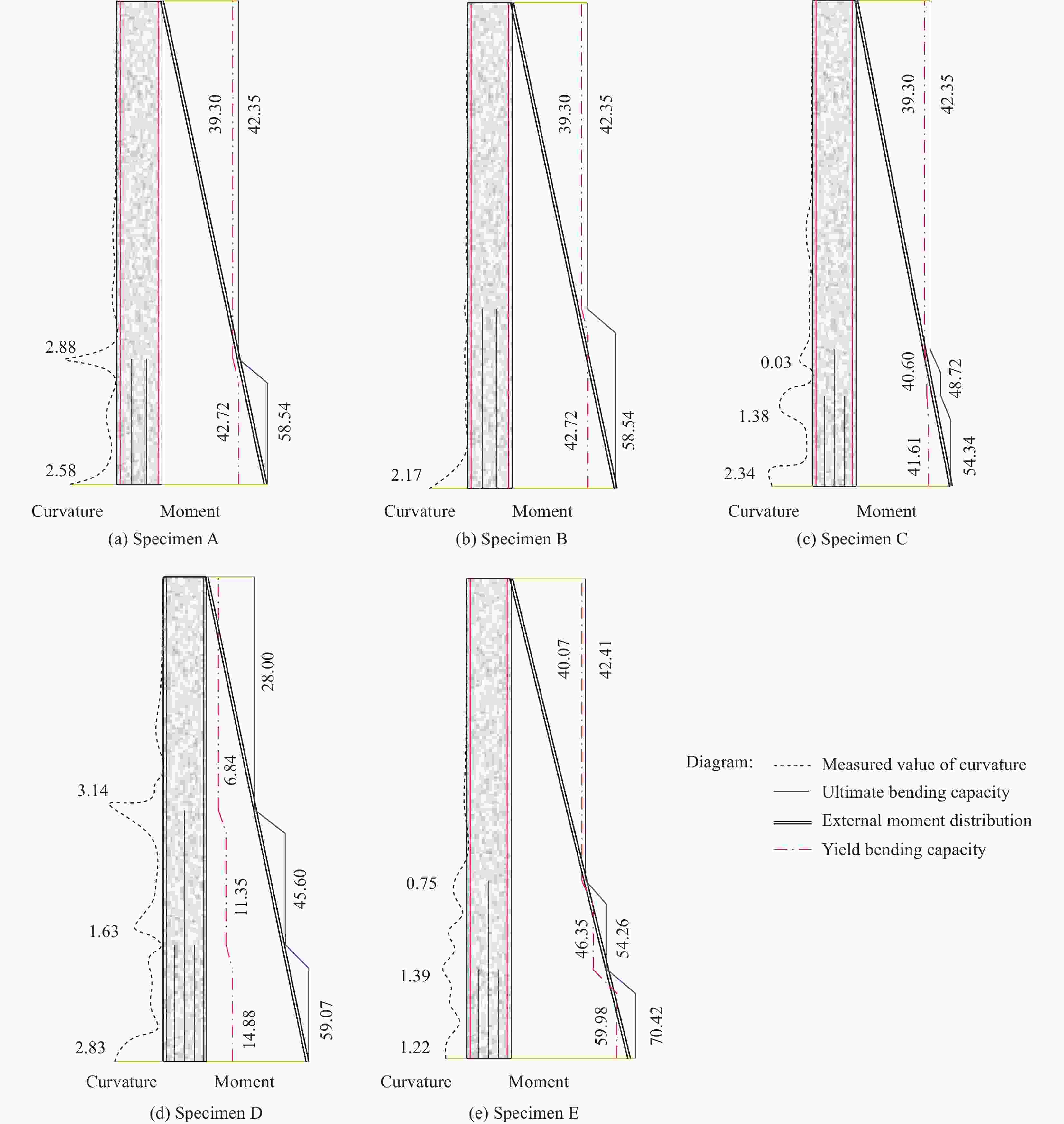

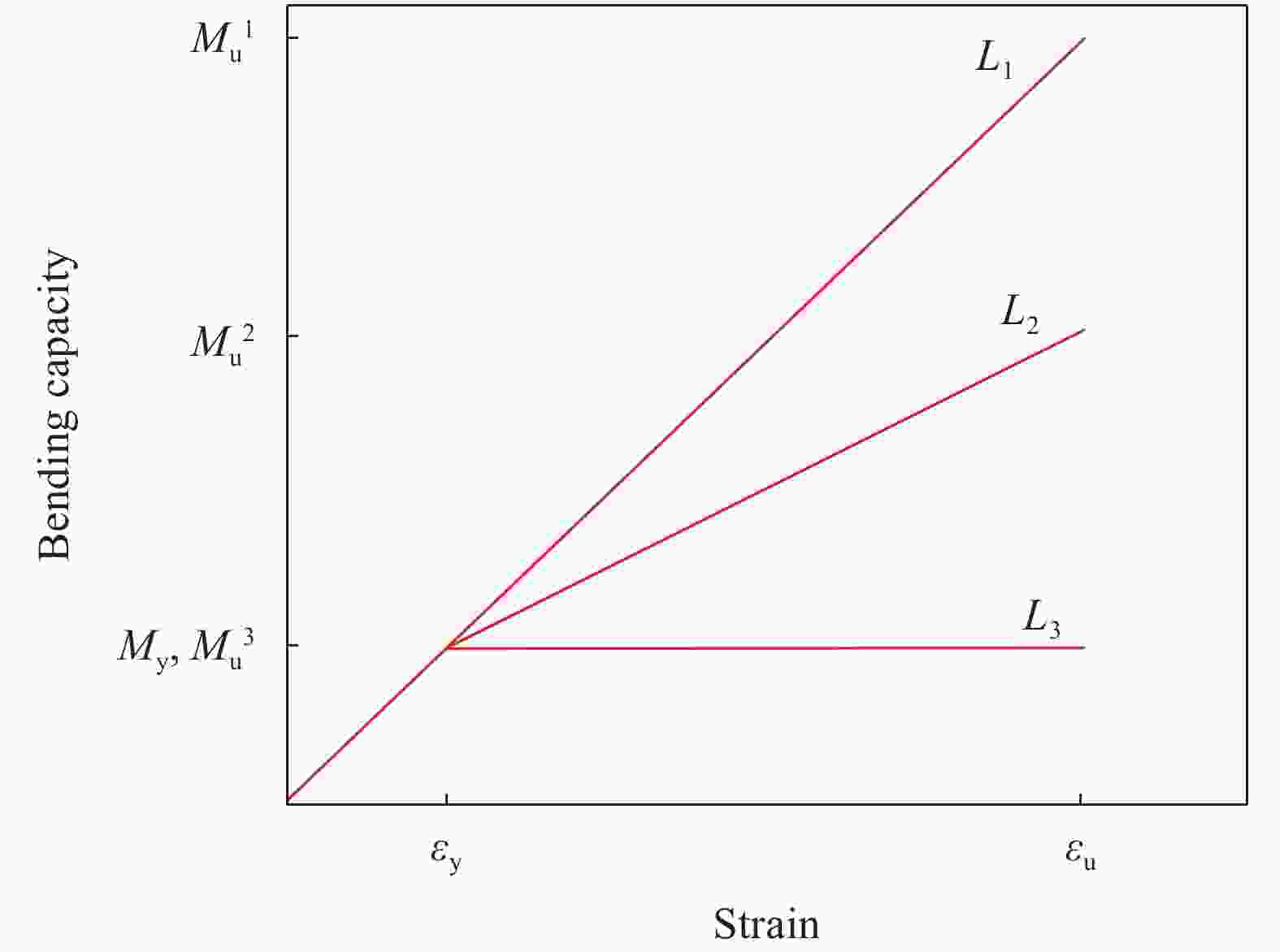

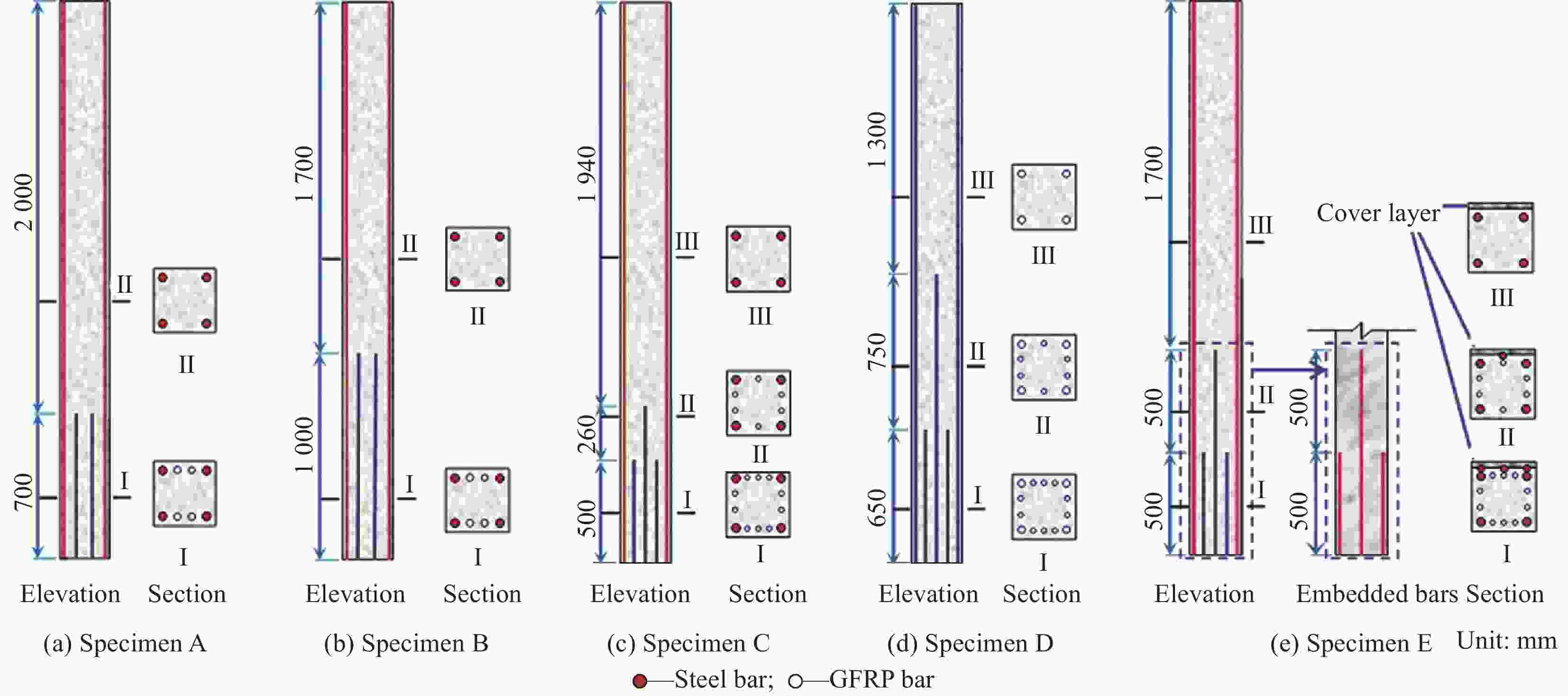

摘要: 为提高混凝土受弯构件的抗震性能,采用玻璃纤维增强树脂复合材料(Glass fiber reinforced plastic,GFRP)筋和钢筋梯级配置的方案,构建同外力分布相适配的承载能力梯级分布,以形成多塑性区。本文设计了5个具有不同梯级配筋参数的混凝土受弯试件,对比参数包括梯级高度、配筋种类、配筋量和配筋方式等,通过推覆(Pushover)试验对比分析各试件中多塑性区的产生情况和力学效果,研究多塑性区的形成机制。结果表明:合理的梯级配筋方案可以在混凝土受弯构件中形成多个塑性区,塑性区的个数和发展程度会显著影响构件的抗震行为。多塑性区形成的决定条件是构件中多个梯级段所受外弯矩介于其屈服弯矩与极限弯矩之间。通过调整梯级段长度与配筋参数,可有效地调控各塑性区的发展程度及构件的破坏位置和破坏模式。线弹性的GFRP筋为截面提供了较大的抗弯承载力屈服后增量,是多塑性区形成和调控的关键。Abstract: In order to enhance the seismic capacity of concrete flexural members, a graded reinforcement scheme with the glass fiber reinforced plastic (GFRP) bars and the steel bars was developed to make a graded distribution of bearing capacity that matches the external force distribution, and then multiple-plastic regions were formed. Five concrete flexural members with different graded reinforcement parameters were designed, and the comparison parameters included the height of the grades, the type of bars, the reinforcement ratios and the construction methods. Through the pushover experiment, the formation and mechanical effects of multi-plastic regions were studied, and the formation mechanism of multi-plastic regions was analyzed in details. The results show that the reasonable graded reinforcement scheme can form multi-plastic regions in the concrete flexural member. The number and development degree of plastic regions significantly affect the seismic behaviours of members. The formation condition of the multi-plastic regions is that the external moment is between the sectional yield moment and ultimate moment in several grades. The development level of each plastic region can be effectively controlled by adjusting the length and reinforcement of the grades, and the failure position and failure mode of the member can be designed. A great increment provided by GFRP bars with line elasticity properties on the bending bearing capacity after yielding is a key factor for the formation and regulation of multi-plastic regions.

-

图 8 梯级GFRP筋混凝土受弯试件截面的弯矩-应变关系

Figure 8. Bending moment-strain relationship of sections of concrete flexural specimens with graded GFRP bars

Li—Bending moment-strain relationship of sections in different reinforcement conditions; L1—FRP bars; L2—FRP bars and steel bars; L3—Steel bars; My, $M_{\rm{u}}^i $—Yield and ultimate moment, respectively; εy, εu—Yield and ultimate strain, respectively

表 1 各试件梯级配筋详细参数

Table 1. Parameters of each specimen's graded reinforcement

Specimen Grade Length of each

grade/mmDetails of reinforcement Reinforcement ratio/% Steel bars GFRP bars A 1 0-700 4$\phi $16 steel bars + 4$ \phi $14 GFRP bars 1.29 0.99 2 700-2700 4$ \phi $16 steel bars 1.29 — B 1 0-1000 4$ \phi $16 steel bars + 4$ \phi $14 GFRP bars 1.29 0.99 2 1000-2700 4$ \phi $16 steel bars 1.29 — C 1 0-500 4$ \phi $16 steel bars + 10$ \phi $10 GFRP bars 1.29 1.26 2 500-760 4$ \phi $16 steel bars + 6$ \phi $10 GFRP bars 1.29 0.75 3 760-2700 4$ \phi $16 steel bars 1.29 — D 1 0-650 4$ \phi $14 GFRP bars + 10$ \phi $10 GFRP bars — 2.24 2 650-1400 4$ \phi $14 GFRP bars +6$ \phi $10 GFRP bars — 1.74 3 1400-2700 4$ \phi $14 GFRP bars — 0.99 E 1 0-500 4$ \phi $16 steel bars + 10$ \phi $10 GFRP bars + 3$ \phi $10 steel bars (embed) 1.54 1.16 2 500-1000 4$ \phi $16 steel bars + 6$ \phi $10 GFRP bars + 1$ \phi $10 steel bars (embed) 1.31 0.70 3 1000-2700 4$ \phi $16 steel bars 1.19 — Notes: GFRP—Glass fiber reinforced plastic; $\phi $—Diameter. 表 2 GFRP筋和钢筋的力学性能

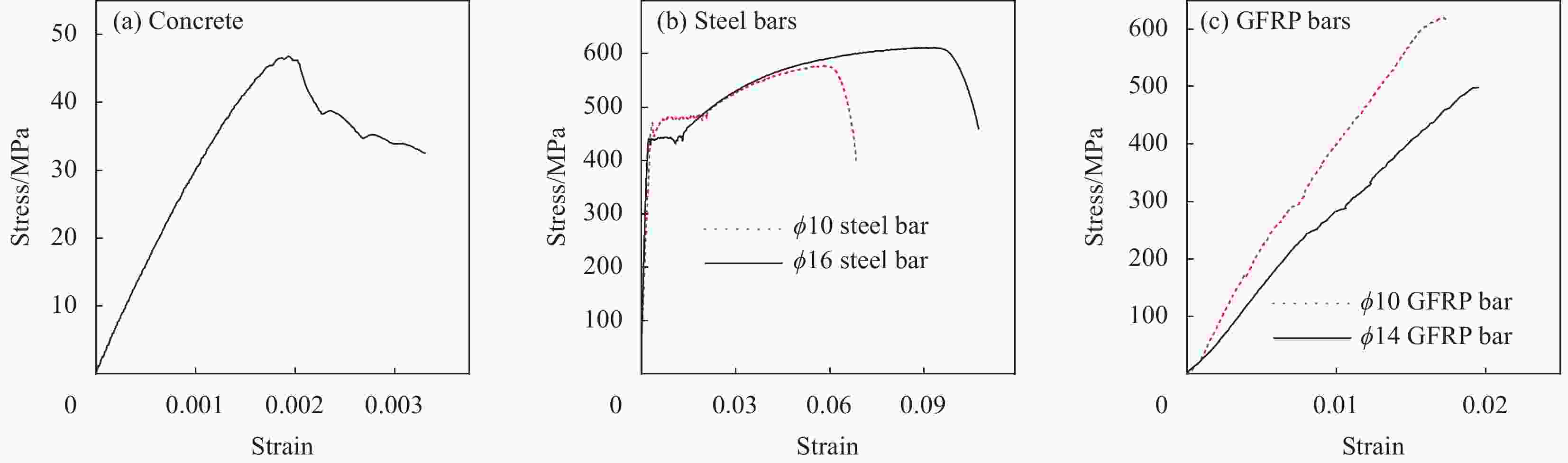

Table 2. Mechanical properties of GFRP and steel bars

Type Elastic

modulus/GPaStrength/MPa Yield Tensile $ \phi $14 GFRP bar 35.89 — 520.93 $ \phi $10 GFRP bar 30.92 — 620.83 $ \phi $16 steel bar 202.95 446.67 614.42 $ \phi $10 steel bar 191.08 471.19 575.34 表 3 梯级GFRP筋混凝土受弯试件各梯级段的变形及试件破坏模式

Table 3. Deformation of each grade and failure mode of concrete flexural specimens with graded GFRP bars

Specimen Grade Rotation/rad Top displacement of

the member produced by

each grade/mmPlastic development

degree of each gradeFailure mode A 1 0.0455 118.10 Full development Ductile failure 2 0.0472 83.90 Ultimate failure B 1 0.0396 100.50 Ultimate failure GFRP bars fracture 2 0.0097 9.50 Undeveloped C 1 0.0554 141.70 Ultimate failure GFRP bars fracture 2 0.0109 23.10 Partial development 3 0.0143 26.00 Slight development D 1 0.0598 149.25 Ultimate failure GFRP bars fracture 2 0.0400 67.77 Partial development 3 0.0613 33.00 Full development E 1 0.0477 120.50 Partial development Interface debonding 2 0.0464 83.90 Ultimate failure 3 0.0256 27.00 Partial development -

[1] PAREEK S, SUZUKI Y, ARAKI Y, et al. Plastic hinge relocation in reinforced concrete beams using Cu-Al-Mn SMA bars[J]. Engineering Structures,2018,175:765-775. doi: 10.1016/j.engstruct.2018.08.072 [2] ZHANG Y Y, DIAS-DA-COSTA D. Seismic vulnerability of multi-span continuous girder bridges with steel fibre reinforced concrete columns[J]. Engineering Structures,2017,150:451-464. doi: 10.1016/j.engstruct.2017.07.053 [3] 张于晔, 魏红一, 袁万城. 钢纤维混凝土局部增强桥墩抗震性能试验研究[J]. 振动与冲击, 2012, 31(21):102-107.ZHANG Yuye, WEI Hongyi, YUAN Wancheng. Tests for aseismic behavior of bridge piers with local steel fiber reinforced concrete[J]. Journal of Vibration and Shock,2012,31(21):102-107(in Chinese). [4] CHO C G, KIM Y Y, FEO L, et al. Cyclic responses of reinforced concrete composite columns strengthened in the plastic hinge region by HPFRC mortar[J]. Composite Structures,2012,94(7):2246-2253. doi: 10.1016/j.compstruct.2012.01.025 [5] GUAN D Z, CHEN Z X, LIU J B, et al. Seismic performance of precast concrete columns with prefabricated UHPC jackets in plastic hinge zone[J]. Engineering Structures,2021,245:112776. doi: 10.1016/j.engstruct.2021.112776 [6] 梁兴文, 康力, 车佳玲, 等. 局部采用纤维增强混凝土柱的抗震性能试验与分析[J]. 工程力学, 2013, 30(9):243-250. doi: 10.6052/j.issn.1000-4750.2012.06.0394LIANG Xingwen, KANG Li, CHE Jialing, et al. Experiments and analyses of seismic behavior of columns with fiber-reinforced concrete in bottom region[J]. Engineering Mechanics,2013,30(9):243-250(in Chinese). doi: 10.6052/j.issn.1000-4750.2012.06.0394 [7] 梁兴文, 康力, 邓明科, 等. 塑性铰区采用纤维增强混凝土柱抗震性能试验研究[J]. 建筑结构学报, 2014, 35(2):63-70.LIANG Xingwen, KANG Li, DENG Mingke, et al. Experimental investigation on seismic behavior of columns with fiber-reinforced concrete in potential plastic region[J]. Journal of Building Structures,2014,35(2):63-70(in Chinese). [8] 邓明科, 代龙, 何斌斌, 等. 塑性铰区采用高延性混凝土梁变形性能研究[J]. 工程力学, 2021, 38(1):52-63.DENG Mingke, DAI Long, HE Binbin, et al. An investigation of deformation behavior of beams with high ductile concrete in potential plastic region[J]. Engineering Mechanics,2021,38(1):52-63(in Chinese). [9] XU L, PAN J L, CAI J M. Seismic performance of precast RC and RC/ECC composite columns with grouted sleeve connections[J]. Engineering Structures,2019,188:104-110. doi: 10.1016/j.engstruct.2019.03.022 [10] XU Y, JIA Y F, TONG Z L, et al. Cyclic loading test for concrete bridge columns integrated with ECC segment at the plastic zone[J]. Engineering Structures,2021,246:112985. doi: 10.1016/j.engstruct.2021.112985 [11] YUAN F, CHEN M C, PAN J L. Experimental study on seismic behaviours of hybrid FRP-steel-reinforced ECC-concrete composite columns[J]. Composites Part B:Engineering,2019,176:107272. doi: 10.1016/j.compositesb.2019.107272 [12] 袁方, 赵修远. FRP筋-钢筋增强ECC-混凝土组合柱抗震性能研究[J]. 工程力学, 2021, 38(8):55-65.YUAN Fang, ZHAO Xiuyuan. Seismic behaviors of hybrid FRP-steel reinforced ECC-concrete composite columns[J]. Engineering Mechanics,2021,38(8):55-65(in Chinese). [13] ZHANG Y X, DENG M K, LI T, et al. Strengthening of flexure-dominate RC columns with ECC jackets: Experiment and analysis[J]. Engineering Structures,2021,231:111809. doi: 10.1016/j.engstruct.2020.111809 [14] 徐梁晋, 王义博, 张志刚, 等. 预制ECC管混凝土桥墩拟静力试验研究[J]. 工程力学, 2021, 38(5):229-238.XU Liangjin, WANG Yibo, ZHANG Zhigang, et al. Quasi-static test study on precast ECC concrete-filled tubular bridge piers[J]. Engineering Mechanics,2021,38(5):229-238(in Chinese). [15] 贾毅, 赵人达, 廖平, 等. PP-ECC用于墩底塑性铰区域的抗震性能试验[J]. 中国公路学报, 2019, 32(7):100-111.JIA Yi, ZHAO Renda, LIAO Ping, et al. Experimental investigation on seismic behavior of bridge piers with polypropylene-engineered cementitious composite in plastic hinge regions[J]. China Journal of Highway and Transport,2019,32(7):100-111(in Chinese). [16] 贾毅. 塑性铰区采用PP-ECC的桥墩模型抗震性能研究[D]. 成都: 西南交通大学, 2019.JIA Yi. Research on seismic behavior of bridge pier model with polypropylene-engineered cementitious composite in plastic hinge regions[D]. Chengdu: Southwest Jiaotong University, 2019(in Chinese). [17] ZHANG R, MENG Q L, SHUI Q J, et al. Cyclic response of RC composite bridge columns with precast PP-ECC jackets in the region of plastic hinges[J]. Composite Structures,2019,221:110844. doi: 10.1016/j.compstruct.2019.04.016 [18] 杨红, 陈进可, 陈银松. 填充墙对空间框架非线性地震反应特征的影响[J]. 四川大学学报(工程科学版), 2012, 44(5):38-46.YANG Hong, CHEN Jinke, CHEN Yinsong. Effects of infill walls on nonlinear seismic response characteristics of spatial frames[J]. Journal of Sichuan University (Engineering Science Edition),2012,44(5):38-46(in Chinese). [19] DENG J D, MA Z G, LIU A R, et al. Seismic performance of composite column with double plastic hinges[J]. Compo-site Structures,2017,182:435-446. doi: 10.1016/j.compstruct.2017.09.024 [20] CHOU C C, CHANG H J, JOSHUA T H. Two-plastic-hinge and two dimensional finite element models for post-tensioned precast concrete segmental bridge columns[J]. Engineering Structures,2013,46:205-217. doi: 10.1016/j.engstruct.2012.07.009 [21] PANAGIOTOU M, RESTREPO J I. Dual-plastic hinge design concept for reducing higher-mode effects on high-rise cantilever wall buildings[J]. Earthquake Engineering & Structural Dynamics,2009,38(12):1359-1380. [22] BEIRAGHI H, KHEYRODDIN A, KAFI M A. Energy dissipation of tall core-wall structures with multi-plastic hinges subjected to forward directivity near-fault and far-fault earthquakes[J]. The Structural Design of Tall and Special Buildings,2016,25(15):801-820. doi: 10.1002/tal.1284 [23] 梁兴文, 王照耀, 于婧, 等. 钢筋混凝土剪力墙结构多塑性铰区合理布置研究[J]. 西安建筑科技大学学报(自然科学版), 2018, 50(2):169-175.LIANG Xingwen, WANG Zhaoyao, YU Jing, et al. Research on a reasonable arrangement of multi-plastic hinge region in RC shear wall structure[J]. Journal of Xi'an University of Architecture & Technology (Natural Science Edition),2018,50(2):169-175(in Chinese). [24] KHANMOHAMMADI M, SAMADZ-ADEGAN N. Improving seismic behaviour of core walls of dual structural systems using multi-plastic hinges[J]. Bulletin of Earthquake Engineering,2019,17(3):1575-1602. doi: 10.1007/s10518-018-0514-6 [25] 郝庆多, 王言磊, 欧进萍, 等. 玻璃纤维增强复合材料筋肋参数优化试验研究[J]. 复合材料学报, 2008, 25(1):119-126. doi: 10.3321/j.issn:1000-3851.2008.01.021HAO Qingduo, WANG Yanlei, OU Jinping, et al. Experimental study on optimization of rib geometries for glass fiber reinforced composite rebars[J]. Acta Materiae Compositae Sinica,2008,25(1):119-126(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.01.021 [26] 徐可, 陆春华, 宣广宇, 等. 混合配筋钢纤维增强混凝土梁受弯承载力试验及理论计算[J]. 复合材料学报, 2020, 37(9):2348-2357.XU Ke, LU Chunhua, XUAN Guangyu, et al. Experimental and theoretical calculation on the flexural capacity of steel fiber reinforced concrete beams with hybrid reinforcing bars[J]. Acta Materiae Compositae Sinica,2020,37(9):2348-2357(in Chinese). [27] 许家婧, 朱鹏, 屈文俊. 钢筋-GFRP 筋增强混凝土梁的疲劳力学性能[J]. 复合材料学报, 2022, 39(5):2318-2328.XU Jiajing, ZHU Peng, QU Wenjun. Fatigue behaviors of steel bars-GFRP bars reinforced concrete beams[J]. Acta Materiae Compositae Sinica,2022,39(5):2318-2328(in Chinese). [28] 赵秋红, 刘凯, 王菲, 等. GFRP筋橡胶集料混凝土梁受弯性能[J]. 复合材料学报, 2021, 38(5):1611-1622. doi: 10.13801/j.cnki.fhclxb.20201106.002ZHAO Qiuhong, LIU Kai, WANG Fei, et al. Analyses on flexural behavior of GFRP-reinforced crumb rubber concrete beams[J]. Acta Materiae Compositae Sinica,2021,38(5):1611-1622(in Chinese). doi: 10.13801/j.cnki.fhclxb.20201106.002 [29] 中华人民共和国住房和城乡建设部. 建筑抗震设计规范: GB/T 50011—2010[S]. 北京: 中国建筑工业出版社, 2022.Ministry of Housing and Urban-Rural Construction of the People's Republic of China. Code for seismic design of building: GB/T 50011—2010[S]. Beijing: China Architecture & Building Press, 2022(in Chinese). [30] 中华人民共和国住房和城乡建设部. 纤维增强复合材料建设工程应用技术规范: GB/T 50608—2020[S]. 北京: 中国计划出版社, 2020.Ministry of Housing and Urban-Rural Construction of the People's Republic of China. Technical code for infrastructure application of FRP composites: GB/T 50608—2020[S]. Beijing: China Planning Press, 2020(in Chinese). [31] 中华人民共和国住房和城乡建设部. 混凝土物理力学性能试验方法标准: GB/T 50081—2019[S]. 北京: 中国建筑工业出版社, 2019.Ministry of Housing and Urban-Rural Construction of the People's Republic of China. Standard for test method of concrete physical and mechanical properties: GB/T 50081—2019[S]. Beijing: China Architecture & Building Press, 2019(in Chinese). [32] 中华人民共和国国家质量监督检验检疫总局. 金属材料 拉伸试验 第1部分: 室温试验方法: GB/T 228.1—2021[S]. 北京: 中国建筑工业出版社, 2021.State Administration for Market Regulation of the People's Republic of China. Metallic material—Tensile testing—Part 1: Method of test at room temperature: GB/T 228.1—2021[S]. Beijing: China Architecture & Building Press, 2021(in Chinese). [33] 中华人民共和国国家质量监督检验检疫总局. 定向纤维增强聚合物基复合材料 拉伸性能试验方法: GB/T 3354—2014[S]. 北京: 中国建筑工业出版社, 2014.State Administration for Market Regulation of the People's Republic of China. Test method for tensile properties of orientation fiber reinforced polymer matrix composite materials: GB/T 3354—2014[S]. Beijing: China Architecture & Building Press, 2014(in Chinese). [34] 冯鹏, 强翰霖, 叶列平. 材料、构件、结构的“屈服点”定义与讨论[J]. 工程力学, 2017, 34(3):36-46. doi: 10.6052/j.issn.1000-4750.2016.03.0192FENG Peng, QIANG Hanlin, YE Lieping. Discussion and definition on yield points of materials, members and structures[J]. Engineering Mechanics,2017,34(3):36-46(in Chinese). doi: 10.6052/j.issn.1000-4750.2016.03.0192 -

下载:

下载: