Long-term mechanical properties of carbon fiber reinforced vinyl resin composites in hygrothermal environment

-

摘要: 碳纤维增强聚合物基复合材料(CFRP)因其耐腐蚀、轻质高强等特点被广泛应用于海洋环境,进而长期遭受湿热环境的考验。为了解湿热环境和极端温度对碳纤维增强乙烯基树脂复合材料的影响,测试了湿热老化前后和不同温度下CFRP的压缩性能、面内剪切性能和层间剪切强度变化。FTIR和SEM结果表明:纯树脂试样在湿热环境中发生了水解,使试样表面的微裂纹和孔隙不断扩展并向试样内部渗透;碳纤维的埋入抑制了水的扩散和水解,因而CFRP的吸湿曲线与Fickian模型高度吻合;纯树脂由于水解反应影响了吸湿通道使吸湿曲线偏离Fickian模型。力学性能表明:湿热老化90天后压缩强度和层间剪切强度分别降低7.6%、12.3%;试样在高温(70℃)下的压缩强度、面内剪切强度、层间剪切强度分别急剧降低36.2%、26.9%、37.4%,且高温对试样力学性能的影响具有部分可逆性。Abstract: Carbon fiber reinforced polymers (CFRP) were widely used in marine environments due to their corrosion resistance, light weight and high strength, and thus were subjected to hygrothermal environment for a long time. To understand the effects of hygrothermal environment and extreme temperatures on carbon fiber reinforced vinyl resin composites, the changes of compression properties, in-plane shear properties and interlaminar shear strength of CFRP before and after hygrothermal aging and at different testing temperatures were determined. The results of Fourier transform infrared spectroscopy (FTIR) and scanning electron microscope (SEM) show that the pure resin specimens undergo hydrolysis in the hygrothermal environment, which cause the microcracks and pores on the surfaces of the specimens to expand and penetrate into the interior of the specimens. The moisture absorption curve of CFRP is in high agreement with Fickian model, while the moisture absorption curve of pure resin deviated from Fickian model because the hydrolysis reaction affected the moisture absorption channels. Meanwhile, the measurement on mechanical properties reveals that the compressive strength and interlaminar shear strength decrease by 7.6% and 12.3%, respectively, after hygrothermal aging for 90 days, and the compressive strength, in-plane shear strength, and interlaminar shear strength of the specimens at elevated temperature (70℃) decrease sharply by 36.2%, 26.9% and 37.4%, respectively. Meanwhile, it can be concluded that the effect of elevated tempera-ture on the mechanical properties of the specimens is partially reversible.

-

相对于传统金属材料而言,纤维增强聚合物复合材料(FRP)具有较高的比强度和比刚度以及在复杂环境下良好的耐久性,在国防先进装备的应用不断增加,应用部位已从次承力转向主承力构件,其在装备中的应用占比是衡量一个国家科技发展水平的重要指标[1]。随着FRP的应用领域越来越广泛,其所面临的服役环境也越来越复杂,低估环境对FRP的影响可能造成严重的安全事故[2]。同时,由于FRP相对较高的制造成本和难以回收处理的弊端,高估环境对FRP的影响会造成大量的浪费。为了保障结构安全性,同时兼顾环境保护和经济效益,研究FRP在特定环境下的耐久性具有重要意义。

在湿热环境中水分子向材料内部的扩散行为是影响FRP耐久性的重要因素[3-4]。Shen等[5]使用Fick定理描述湿热环境下复合材料对水的吸附与解吸附行为,推导适用于描述复合材料吸湿行为的Fickian扩散模型。此后大量文献报道了各类FRP的Fickian吸湿行为[6-8]。吻合Fickian模型的材料在吸湿的早期阶段吸水率与暴露时间的平方根呈线性关系,后期吸水率稳定在最大饱和吸水率。一些研究发现在极端的老化环境(如较高的温度和较长的老化时间)下材料的吸水率会偏离Fickian扩散模型,其吸湿行为会符合Langmuir或耦合反应扩散模型等[9]。树脂中吸附的水分可分为占据自由体积的自由水和与聚合物分子链以氢键形式缔合的结合水。Zhou等[10]的研究表明树脂内的结合水可分为I型结合水和II型结合水。I型结合水与树脂分子链以单个氢键结合,减弱了聚合物分子链间的范德华力,起到塑化作用。II型结合水分子不充当增塑剂,而是形成链段之间的桥梁,且II型结合水的含量取决于湿热温度和老化时间,较高的环境温度和更长的暴露时间会导致II型结合水的大量形成[11]。水分扩散会对复合材料结构造成可逆和不可逆的变化,其中可逆的变化称之为物理变化,可在除去材料吸收的水分后恢复;但随着材料在湿热环境中的持续暴露,水分对复合材料的树脂基体和界面造成不可逆的变化,如微裂纹和水解等[12]。FRP的树脂基体、纤维/树脂界面和层间界面容易受到水分扩散的影响而使FRP的力学性能降低[13]。随着界面粘结性能的降低,为毛细现象的发生提供了有利的场所,加速了水分向材料内部的渗透,对材料的性能造成进一步的损伤。已有大量实验结果表明湿热老化后FRP的拉伸强度、压缩强度和弯曲强度显著降低[12, 14-19]。

纤维种类对水分在纤维/树脂界面间的传输有很大影响,表面具有较多极性亲水基团的纤维(如玻璃纤维)对水分子具有吸附作用促进了水分的传输,而表面极性基团较少,具有疏水性的增强纤维(如碳纤维)对水分的扩散有一定的抑制作用[20]。树脂基体种类也是影响吸湿行为的重要因素,目前工程结构中常用的树脂基体主要有环氧和乙烯基树脂,它们具有类似的分子骨架,不同的是乙烯基树脂通常采用自由基作为固化剂,固化后的树脂中含有30wt%~40wt%的小分子物质(如聚苯乙烯),且分子链中的极性基团少于环氧树脂[21]。此外乙烯基树脂由于其聚合物分子链上酯键旁的甲基具有疏水性,使得乙烯基树脂相对于环氧树脂具有较好的耐腐蚀性,因而被广泛应用于海洋工程领域。

目前国内外关于玻璃纤维增强聚合物基复合材料(GFRP)和碳纤维增强聚合物基复合材料(CFRP)湿热老化机制的研究已有众多报道[11, 22-25],但缺乏全面和一致性的认识。Micelli等[26]的研究指出,每一种FRP都有独特的成分和制造工艺。因此,对一种材料得出的结论不一定适用于其他材料。这也是大量关于FRP的老化研究中测试方法和测试结果不同的主要原因。由于各研究中试验数据的分散性较大,结果难以统一,目前仍缺乏关于复合材料耐久性的试验数据库。对力学性能的表征主要集中在拉伸性能、弯曲性能和层间剪切性能的测试,而忽视了同样重要的压缩性能和面内剪切性能。已经有研究表明,湿热环境对纤维控制的性能影响较小而对树脂控制的性能影响较大[16]。与其他研究中大量对拉伸和弯曲性能进行测试不同,本研究着重研究了受基体和界面控制的压缩性能和面内剪切性能受湿热的影响。本研究针对目前研究较少的碳纤维增强乙烯基树脂复合材料,设计了实验室人工老化实验,表征材料在严酷环境下的力学性能,以获得更全面、有效的力学试验数据。CFRP试样在湿热环境中暴露的最长时间为120天,并在不同温度下表征了压缩强度/模量、面内剪切强度/模量、层间剪切强度。不同温度下的测试结果能更好地反映材料在真实服役环境下的力学性能变化。同时结合吸湿率测试、FTIR和SEM,分析了湿热老化机制和性能变化情况。

1. 实验材料及方法

1.1 试样制备

实验采用的碳纤维增强聚合物基复合材料层合板由碳纤维编织物和乙烯基树脂组成,树脂采用南京金陵帝斯曼树脂有限公司的430 LV型乙烯基树脂,结构简式见图1。固化剂型号为阿克苏Butanox M50,主要成分为过氧化甲乙酮。碳纤维采用日本东丽公司生产的T300斜纹编织布。将430 LV型树脂与Butanox M50固化剂和E4促进剂按质量比100∶2∶0.2混合,真空干燥箱中脱泡20 min。采用真空灌注成型工艺制备厚度为4 mm的碳纤维复合材料层合板。树脂灌注后在室温下固化24 h,随后放入烘箱中在100℃下后固化4 h。制备的碳纤维层合板的纤维体积分数为54.5vol%。

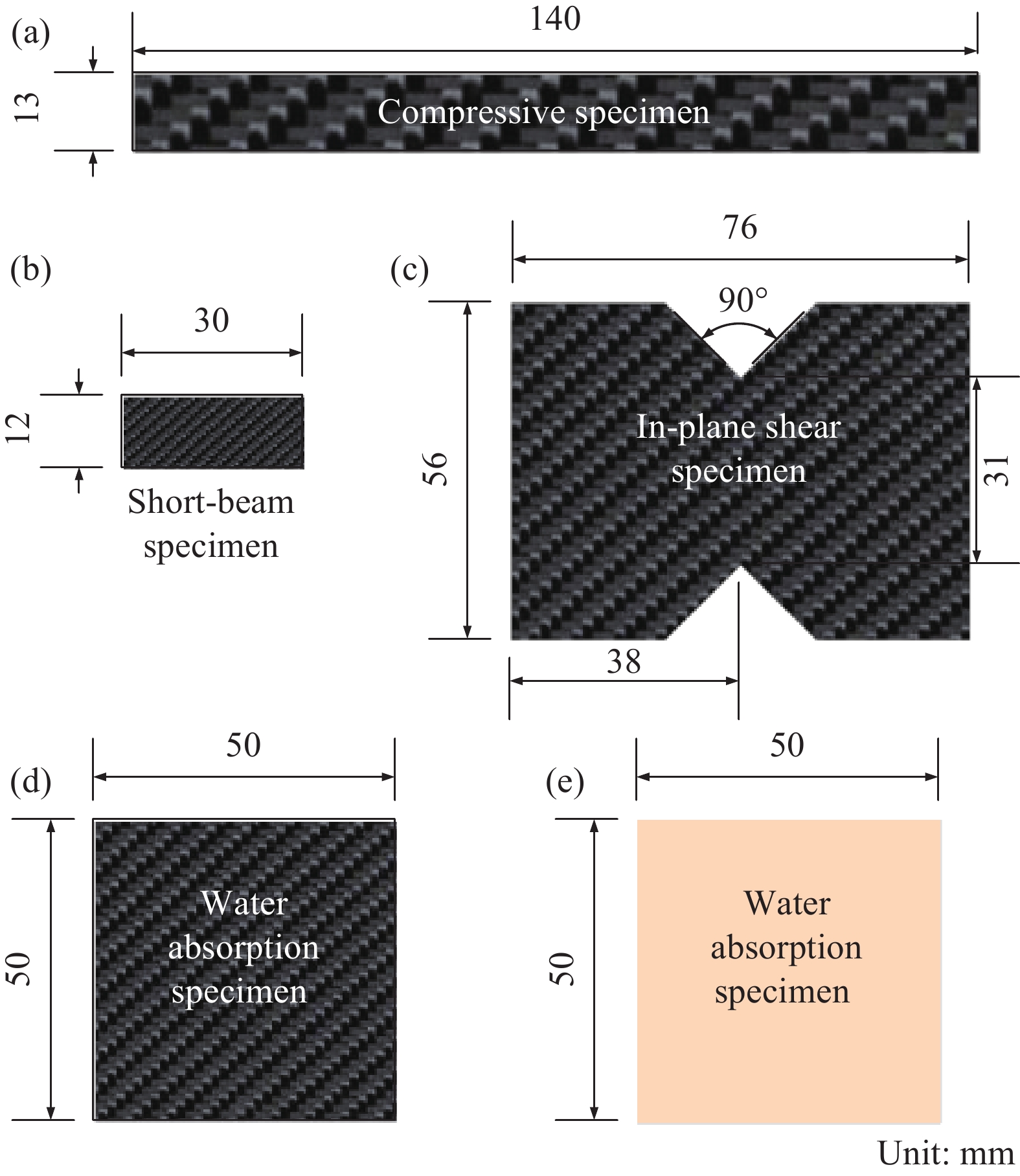

根据相应的测试标准(见1.3节和1.6节的内容)确定试样的形状和尺寸,如图2所示。使用CP-6590型数控雕刻机(洛克机电系统工程(上海)有限公司)对层合板进行加工。将加工后的标准试样用细砂纸打磨,用无水乙醇擦拭表面灰尘及污渍,在50℃下干燥48 h。试样经干燥处理后进行封边处理,将常温固化聚四氟乙烯溶液涂抹于试样的边缘。待聚四氟乙烯固化后将标准试样存放于干燥器中备用。采用浇注工艺制备纯乙烯基树脂吸水率测试试样,树脂配比及固化工艺与层合板一致。

1.2 老化环境及测试环境

依据材料在实际服役过程中可能面临的环境设置了表1所示的老化环境参数。

表 1 CFRP和纯树脂的老化环境Table 1. Ageing environment for CFRP and pure resinEnvironment Hygrothermal environment Medium Deionized water Material CFRP, pure resin Temperature/℃ 70 Ageing time/d 7, 14, 90 将CFRP标准试样和纯树脂标准试样分组编号,使用电子分析天平(梅特勒-托利多ME200-0.1 mg)称取标准试样的初始质量后,按序浸没于恒温水箱中,保持试样完全浸没且不触箱底。恒温水箱环境参数如表1所示。

测试环境和试样状态是影响复合材料力学性能表征的重要因素。为研究长期服役的复合材料结构老化前后的力学性能,设定如表2所示4种测试环境。环境温度通过WGDN-7350型高低温试验箱(力试(上海)科学仪器有限公司)控制。

表 2 CFRP的测试环境Table 2. Testing environment for CFRPTesting environments Testing temperature/℃ Ageing time/d Specimen conditions RTD 20±5 0 Dry ETD 70 0 Dry RTW 20±5 7, 14, 90 Wet ETW 70 90 Wet Notes: RTD—Room temperature dry condition; ETD—Elevated temperature dry condition; RTW—Room temperature wet condition; ETW—Elevated temperature wet condition. 1.3 吸湿率测试

材料老化后的力学性能与其吸湿行为有密切的关联。吸水率测试标准试样如图2(d)和图2(e)所示。试样的吸水率测试过程参照ASTM D5229(聚合物基复合材料水分吸收性能和平衡条件的标准试验方法)[27]和ASTM D570(塑料吸水性试验方法)[28]进行。在规定时间从恒温水箱中取出吸水率测试试样,用吸水纸擦干试样表面水分,置于精度为0.1 mg的电子分析天平上,记录试样放入湿热环境t时后的质量。试样在老化环境中浸泡t时的吸水率通过下式计算。

Mt=(wt−w0w0)×100% (1) 式中:Mt为试样t时的吸水率;wt和w0分别为试样吸水后和干燥时的重量。

吸水率测试标准试样经120天浸没吸湿后拿出,在40℃下干燥至吸湿前初重,再次放入恒温水箱中测试老化后的吸湿行为。

1.4 FTIR图谱分析

树脂基复合材料的耐久性受树脂基体在湿热环境中所发生的化学变化影响,为探究长期的湿热环境对聚合物分子链的影响及其发生的化学变化,使用Nicolet 6700傅里叶变换红外光谱仪(赛默飞世尔科技(中国)有限公司)表征纯树脂试样老化前后分子链官能团变化。扫描的分辨率为2 cm−1,波数范围为4 000~400 cm−1。

1.5 微观形貌分析

利用JSM-IT300型扫描电子显微镜(SEM,日本电子株式会社)观察老化前后试样表面微观形貌特征的变化,同时用于观察破坏试样断口的微观形貌特征。

1.6 力学性能测试

使用LE055(100 kN)万能试验机(力试(上海)科学仪器有限公司)在不同环境温度下测试老化前后CFRP试样的压缩强度/模量、面内剪切强度/模量和层间剪切强度。每组试验包含7个试样,根据试样的破坏形式选取4~6个有效的试验数据。

压缩性能试验:CFRP的压缩性能试验参考ASTM D6641(采用复合加载测试装置的聚合物基复合材料压缩性能试验标准方法)[29]。试验采用的标准试样如图2(a)所示。试验加载速度为1.3 mm/min。试样工作段的正反两面均贴有120-5 AA型应变片用于测量压缩应变及监测试样的弯曲度。

层间剪切强度测试:CFRP的层间剪切强度测试依照ASTM D2344(聚合物基复合材料及其层合板短梁剪切强度试验标准方法)[30]进行。试验采用的标准试样如图2(b)所示,加载速度为1 mm/min。

面内剪切性能试验:CFRP的面内剪切性能试验参考ASTM D7078(由V形轨道剪切方法测定复合材料剪切性能标准试验方法)[31]。试验采用的标准试样如图2(c)所示。两个120-5 AA型应变片相互垂直粘贴在试样表面,应变片与纤维方向呈45°夹角,加载速度为2 mm/min。

2. 结果与讨论

2.1 CFRP试样的化学结构

纯树脂试样在湿热环境中老化120天后,试样表面有泛白现象。为探究树脂表面发生的变化,刮取老化前后树脂表面进行FTIR图谱分析,见图3。老化前后试样表面的红外光谱具有较高的一致性,表明老化后表面出现的白色物质系树脂在老化环境中与水作用的产物,而非介质中可能引入的其他杂质附着。老化前乙烯基树脂在3454 cm−1处具有一个较强且宽的吸收峰,为羟基O—H伸缩振动特征峰。3060 cm−1和3026 cm−1两个尖锐的峰是苯环C—H伸缩振动特征峰,2964~2873 cm−1的吸收峰是树脂分子链骨架上C—H伸缩振动峰。1726 cm−1尖锐且强的吸收峰是C=O伸缩振动特征峰。1606~1454 cm−1尖锐的吸收峰为苯环骨架的伸缩振动吸收峰。758 cm−1和700 cm−1为苯环上C—H面外弯曲振动特征峰。老化后3454 cm−1羟基的特征峰略有增强,且向低波数区域移动。这是由于水分子与聚合物分子链以氢键形式缔合,羟基数量增加,峰强度增加,而O—H伸缩振动频率降低。老化后3060 cm−1、3026 cm−1苯环C—H伸缩振动峰减弱,758 cm−1、700 cm−1苯环C—H面外弯曲峰消失,表明聚合物分子链中苯环的偶极矩发生较大变化,易水解的酯键发生断裂,生成含有羧酸和羟基的小分子链段溶解于水中流失。水解造成试样质量的下降同时也影响了吸水率的测定。

2.2 CFRP试样微观形貌变化

图4为纯树脂试样在未老化前、70℃去离子水浸泡7天和120天后的表面SEM图像。从图4(a)中可以观察到未老化干燥的纯树脂表面遍布大量褶皱,结合目前关于固化残余应力的研究,聚合物在固化过程中收缩,产生额外的体积变化与热效应导致聚合物局部发生变形[32]。老化7天后(图4(b)),树脂表面的褶皱消失变得平整,大面积区域出现孔隙、坑洞和裂纹,这是由于在老化环境中,树脂内部残余应力释放,树脂吸水膨胀导致褶皱消失,树脂表面变得平整。与此同时,水分不断通过树脂表面的微裂纹和孔隙向树脂内部渗透,使表面的裂纹扩张,并形成更多的孔隙和坑洞。老化120天后(图4(c)),树脂表面已布满孔隙、坑洞和裂纹。随着水分向树脂内部不断扩散,孔洞也向树脂内部扩张形成通道(图4(d))。树脂表面大量的孔隙和坑洞的形成及孔隙向树脂内部的扩张均表明树脂的吸水过程并不是简单的物理吸附和扩散过程,部分聚合物链段与水作用后脱落,流失在介质中。

图5为CFRP试样在未老化前、70℃去离子水浸泡120天后的表面SEM图像。与纯树脂试样不同,老化120天后的CFRP试样表面变得更加光滑,试样表面多余的树脂颗粒大幅减少。层合板成型时由于树脂固化收缩造成大量纤维凸起,老化120天后,树脂吸湿膨胀,可见的纤维数量减少。疏水性的碳纤维抑制了水分在材料内部的吸收和扩散,使CFRP表面未出现水分侵蚀的孔洞。

2.3 CFRP试样吸水率

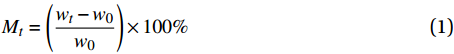

图6(a)为纯树脂和CFRP试样在实验规定的湿热环境中测试得到吸湿率曲型和基于Fickian扩散模型拟合得到的非线性曲线。由于试样在放入老化环境前进行了封边处理,可认为水分子在试样中的扩散行为是无边界效应的单向扩散。暴露在湿热环境中的干燥试样其吸湿行为遵循菲克第二定律(Fick’s second law):

∂C∂t=Dd2Cdx2 (2) 式中:C为试样中扩散方向上某处水的浓度,是时间t和位置x的函数;D为扩散系数。该偏微分方程的解可近似表示为

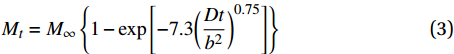

Mt=M∞{1−exp[−7.3(Dtb2)0.75]} (3) 式中:Mt和M∞分别为t时试样的吸水率和饱和吸水率;b为试样厚度。扩散系数可由下式计算:

D=π(Mtb4M∞)21t (4) 基于式(4)采用非线性最小二乘法对吸湿率进行拟合,纯树脂和CFRP在给定的湿热环境中的扩散系数分别为0.03354 mm2/h、0.01617 mm2/h,饱和吸水率分别为1.41358%、0.32059%。纯树脂试样的扩散系数和饱和吸水率远大于CFRP试样,即使剔除具有疏水性的碳纤维的质量,仅比较纯树脂与CFRP树脂基体的饱和吸湿量仍然是纯树脂大于CFRP基体的饱和吸水率。CFRP试样对于Fickian模型具有很高的拟合优度,纯树脂试样在5天后开始偏离Fickian拟合曲线,并在12天后吸湿率出现下降。这是由于水解反应的发生影响了纯树脂试样的吸湿行为,部分聚合物的水解产物流失于介质中造成试样质量下降。水解反应改变了水分子的扩散通道,使吸水率偏离Fickian曲线。将吸湿120天后的试样在40℃下干燥至吸湿前重量后再次放入给定的湿热环境中进行吸水率测试,二次吸湿曲线如图6(b)所示。纯树脂试样和CFRP试样的第二次吸水速率相较于第一次的吸水均在24 h后开始减缓。第一次的湿热老化过程对试样,尤其是纯树脂试样,造成了不可逆的影响。水解过程给纯树脂试样表面造成的大量孔洞和裂纹(图4(c))增加了二次吸水时水分子与试样的接触面积,使水解反应在短时间内就剧烈进行,导致试样的质量损失。由于吸水率是通过对浸泡前后试样进行称重获得的,因此水解造成的质量损失表现在吸水率的表观值低于真实值,所得的吸湿速率也因此降低。由于碳纤维具有良好的疏水性,能有效阻碍水分子的扩散,同时减缓了水解反应进行,因此CFRP试样具有更低的饱和吸水率,且二次吸湿30天后达到第一次的吸水率水平,两次的吸湿行为具有更高的吻合度。

2.4 CFRP的力学性能

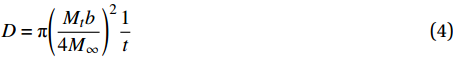

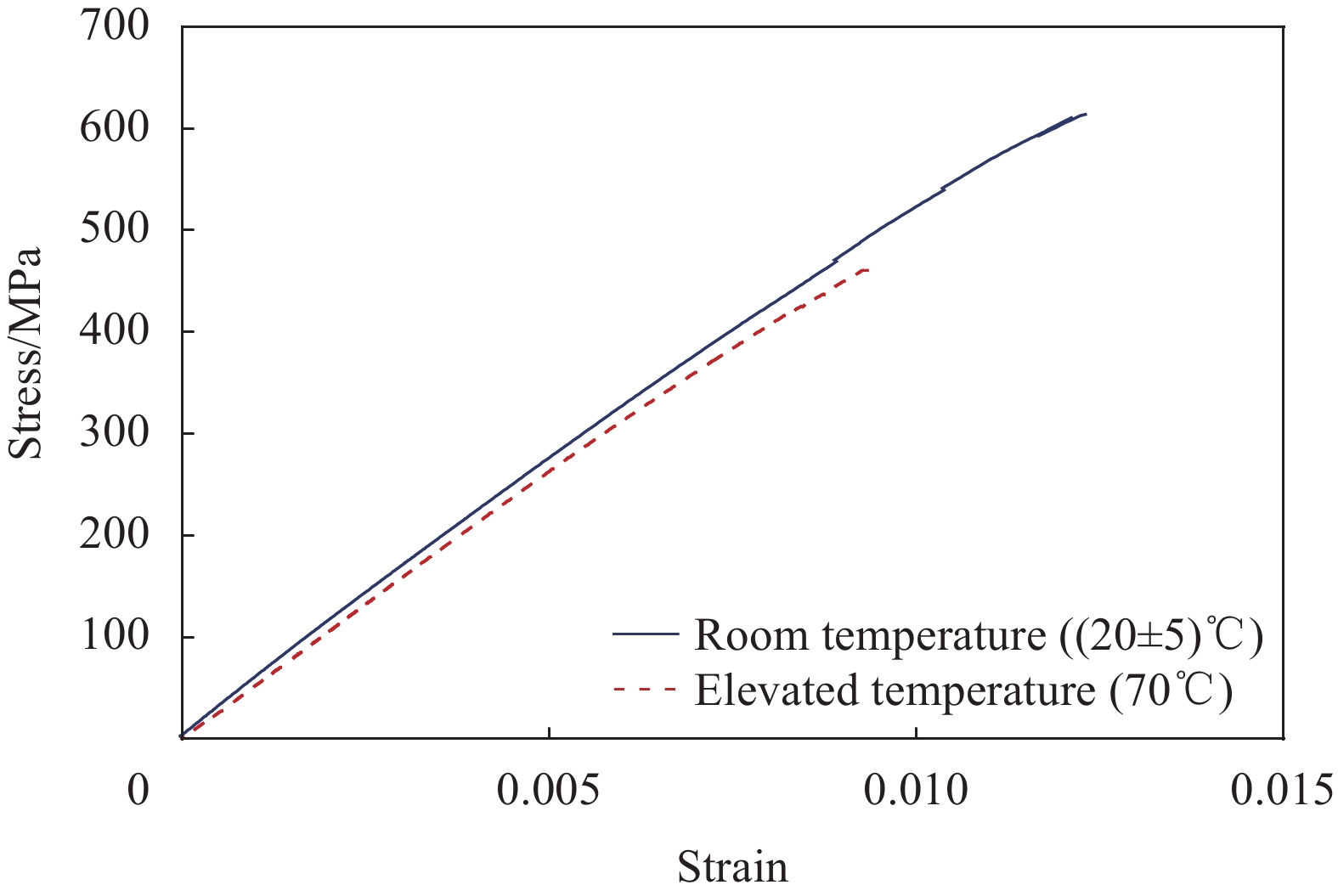

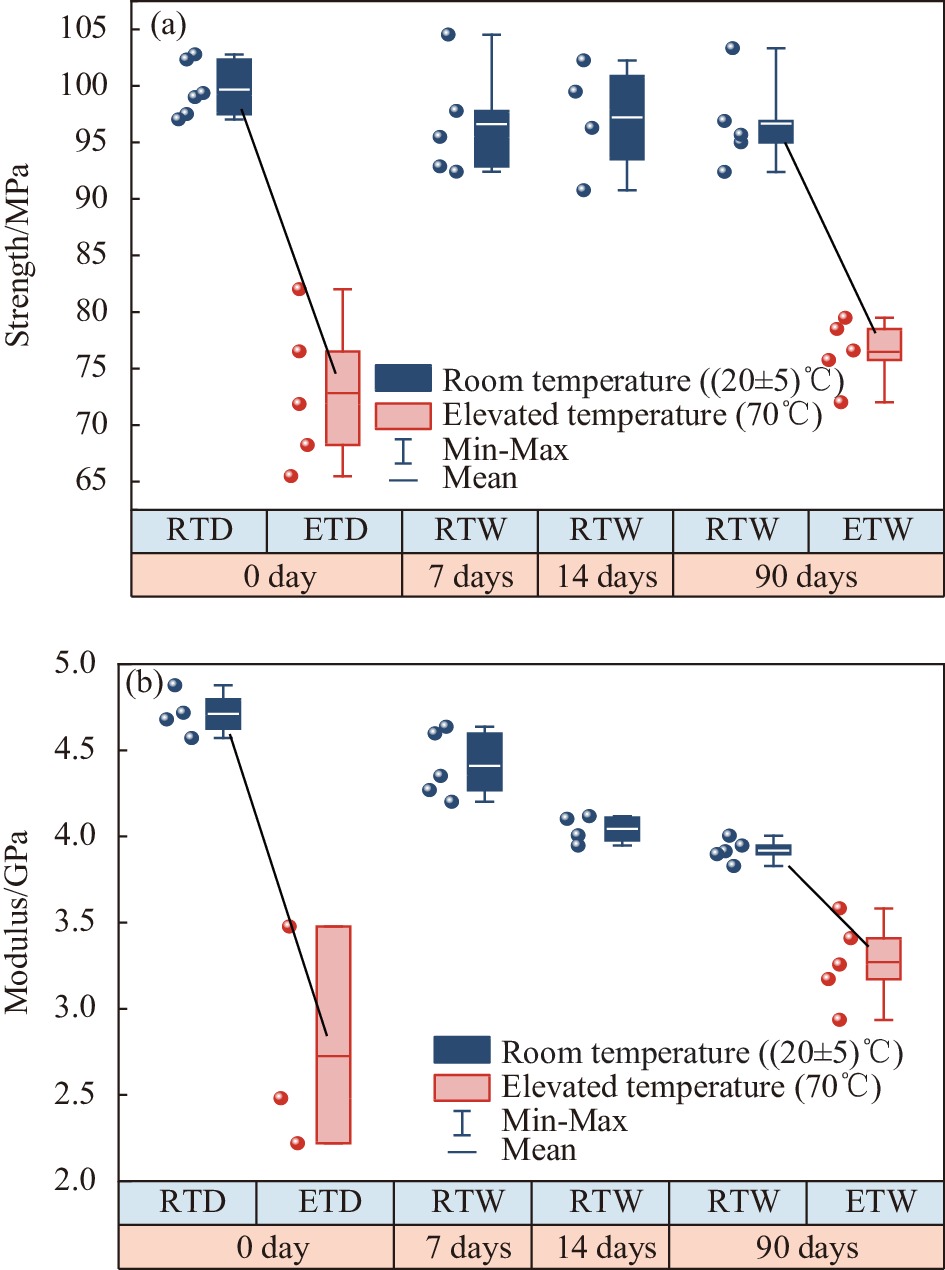

图7为不同环境下CFRP的压缩强度和模量。在室温测试环境(室温干态(RTD),室温湿态(RTW))下,层合板的压缩强度和模量在湿热老化后均有所下降,老化90天后压缩强度降低了7.6%,压缩模量降低了3.7%。CFRP的压缩性能对湿热环境具有较高的敏感度。高温环境对层合板的压缩性能有显著的降低作用,高温干态(ETD)环境下,压缩强度降低了36.2%,压缩模量降低了8.9%。高温测试环境对CFRP压缩强度、模量的降低效应随着老化时间的增加而减弱,ETD与高温湿态(ETW)环境下的压缩强度、模量与老化90天试样在RTW下压缩强度、模量处于相当的水平。上述现象表明CFRP层合板的压缩性能对温度具有很高的敏感性,高温对CFRP的影响是部分可逆的。试样在70℃的去离子水中老化后冷却至室温,其压缩强度、模量与70℃时相比有一定程度的恢复。压缩强度和模量在老化7天后显著降低,随后只发生小幅波动。这与CFRP的吸水率变化规律类似。因此水分在试样中的扩散是影响CFRP压缩强度的重要因素。图8为不同测试温度下的压缩试验典型应力-应变曲线,压缩模量取自应变为0.001、0.003两点间的斜率。试样在不同温度下均表现为脆性断裂,加载过程表现为线弹性。温度对试样粘弹性的影响造成了不同测试温度下压缩模量的差异。压缩试验部分典型的破坏试样照片如图9所示。不同测试温度下破坏模式无明显差异,均以厚度方向的断裂和层间开裂为主,破坏发生的区域主要集中在试样的工作段和夹块处,均为可接受的破坏模式和区域。压缩试验中大量的层间开裂现象表明CFRP的压缩性能很大程度上受到层间性能的影响。

![]() 图 9 CFRP试样压缩试验典型破坏模式Figure 9. Typical failure modes of compression test for CFRP specimensFailure identification codes (such as HAT) consisting of 3 characters marked describe the failure mode, failure area and failure location respectively; Failure mode: B—Brooming; D—Delamination; H—Thyrough-thickness; M(xyz)—Multi-mode; Failure area: A—At grip/tab; G—Gage; Failure location: T—Top; M—Middle; V—Various

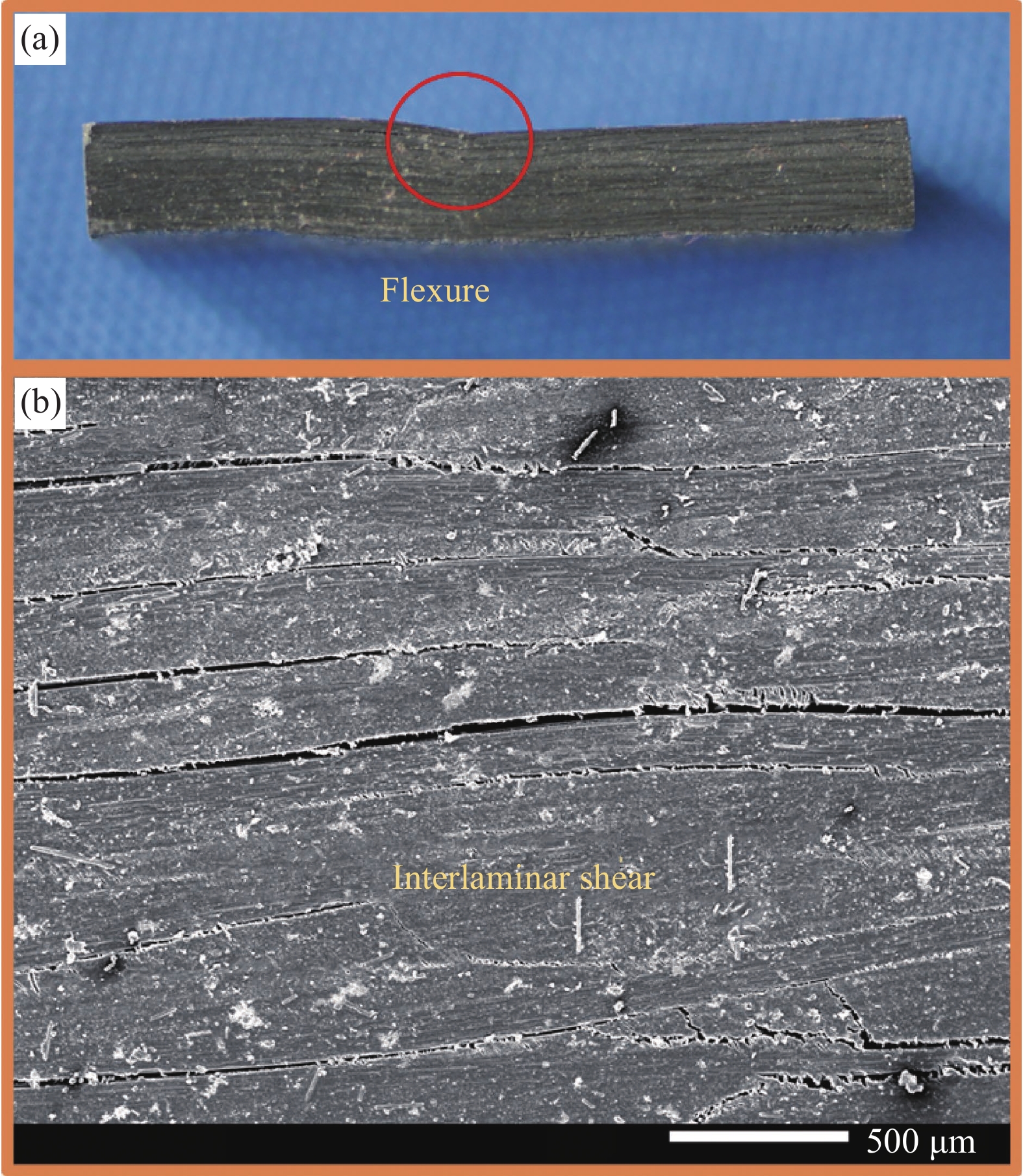

图 9 CFRP试样压缩试验典型破坏模式Figure 9. Typical failure modes of compression test for CFRP specimensFailure identification codes (such as HAT) consisting of 3 characters marked describe the failure mode, failure area and failure location respectively; Failure mode: B—Brooming; D—Delamination; H—Thyrough-thickness; M(xyz)—Multi-mode; Failure area: A—At grip/tab; G—Gage; Failure location: T—Top; M—Middle; V—Various图10为不同环境下CFRP的层间剪切强度。老化7天、14天、90天后(RTW),CFRP层合板的层间剪切强度与老化前(RTD)相比有小幅下降,90天后强度降低12.3%。在高温下未老化(ETD)的CFRP层间剪切强度相比室温环境(RTD)衰减约37.4%。结果表明CFRP的层间剪切强度受湿热环境的影响较小,受测试温度(高温)的影响显著且可逆。由于试样在浸泡前进行了封边处理,抑制了水分通过厚度方向直接在层间传输,在短期内水分还未渗透到试样内部,层间受到的影响较小,因此老化7天后层间剪切强度降低不明显。但当试样达到吸湿饱和后,层间剪切强度显著降低。

图11为不同测试温度下短梁剪切试验典型载荷-位移曲线。室温测试环境下,载荷增加到最大值后有一个瞬时大幅下降的过程,而在高温测试环境下载荷缓慢平稳下降。载荷-位移曲线的线性段斜率随测试温度的升高而减小。这是由于温度升高导致CFRP树脂基体的刚性降低,黏弹性增加。图12为CFRP试样短梁剪切试验典型破坏模式。不同测试温度下的破坏模式类似,表现为弯曲破坏和层间破坏(图12(a)),均为可接受的破坏模式。部分试样加载后未发现明显破坏,在SEM下可观察到试样侧面大量层间裂纹(图12(b))。

图13为不同环境下CFRP的面内剪切强度与模量。面内剪切性能能够反映CFRP的纤维/树脂界面的性能。RTD与RTW环境下试样的面内剪切强度没有差异,模量出现一定的降低。老化后强度和模量变化的差异表明试样的吸湿行为对CFRP纤维/基体界面的影响较小而对树脂基体的整体性能影响较大。高温对CFRP的面内剪切性能具有显著的影响。ETD环境下,试样的面内剪切强度相比RTD环境降低了26.9%,模量降低了42.1%,且均与试样是否经历湿热老化无明显依赖关系,表明高温对剪切性能的影响远大于湿热环境。高温下面内剪切模量数据的离散性明显增大,表明高温对面内剪切性能的影响具有多种可能的机制。RTW与ETW环境下的试验结果表明高温对CFRP面内剪切性能的影响是可逆的。

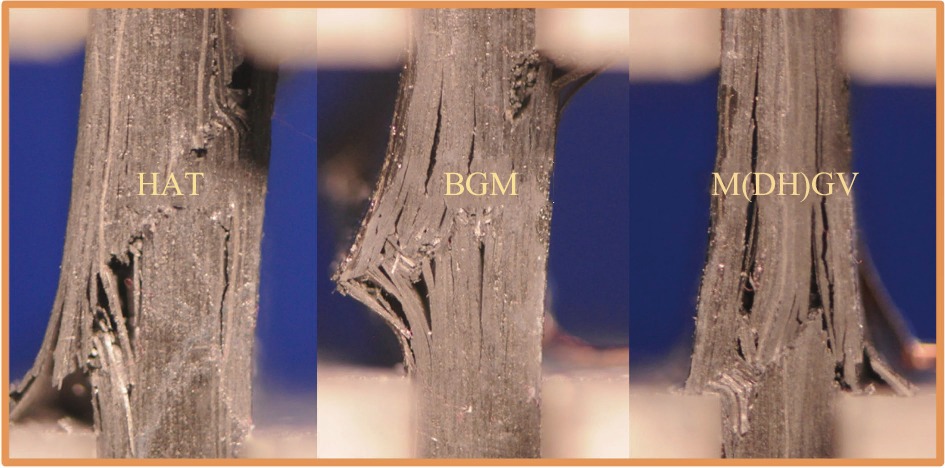

图14为不同测试温度下面内剪切试验的典型应力-应变曲线,模量取自应变为0.002、0.006两点间的斜率。剪切过程具有明显的弹性形变和塑性形变过程。ETD环境下强度和模量较低,最大应变较大,具有很长的塑性形变过程。图15为ASTM D7078中给出的4种面内剪切典型破坏模式[31],其中在“V”形槽口区域产生纵向裂纹、横向裂纹及纵向横向裂纹的混合为CFRP面内剪切试验发生的典型破坏模式。在不同测试温度下,试样的破坏模式不同(图16)。在室温测试环境下,试样以纵向和横向裂纹的混合破坏模式为主,在高温测试环境下,试样破坏以横向裂纹为主。不同测试温度下面内剪切试验破坏试样失效部位的SEM图像如图16(c)和图16(d)所示。室温测试环境下破坏试样的断口有大量被拔出的纤维发生断裂(图16(c)),室温下CFRP纤维/树脂界面受到的破坏较少,以纤维断裂和拔出为主。在高温测试环境下,纤维断裂较少,树脂沿纤维方向扩展裂纹(图16(d)),高温对CFRP试样的树脂和纤维/树脂界面均具有较大的影响。

![]() 图 15 CFRP面内剪切试验可接受的典型破坏模式Figure 15. Typical acceptable failure modes of in-plane shear test for CFRPFailure identification codes (such as VGN) consisting of three characters marked describe the failure mode, failure area and failure location respectively; Failure mode: H—Horizontal cracking; V—Vertical cracking; Failure area: G—Gage; Failure location: N—Between notches

图 15 CFRP面内剪切试验可接受的典型破坏模式Figure 15. Typical acceptable failure modes of in-plane shear test for CFRPFailure identification codes (such as VGN) consisting of three characters marked describe the failure mode, failure area and failure location respectively; Failure mode: H—Horizontal cracking; V—Vertical cracking; Failure area: G—Gage; Failure location: N—Between notches3. 结 论

碳纤维增强乙烯基树脂复合材料层合板试样在实验给定的湿热环境中老化特定的时间,采用称重法、FTIR、SEM研究其吸湿行为,并测试碳纤维增强聚合物基复合材料(CFRP)试样的力学性能。由实验结果可得出如下结论:

(1) 纯乙烯基树脂试样长时间暴露于湿热环境其聚合物分子链发生严重的水解反应,导致小分子链段流失,孔隙和微裂纹大面积扩散。碳纤维的埋入能有效阻碍水分的扩散,抑制水解反应的发生。

(2) CFRP的吸湿曲线符合Fickian扩散模型,纯树脂由于水解反应的发生影响了水分扩散的通道使其吸湿曲线偏离Fickian扩散模型。纯树脂第一次吸湿过程造成的大量孔隙和微裂纹增加了二次吸湿过程水与试样的接触面积,使水解过程在初始阶段表现剧烈。水解造成的质量损失影响了吸水率测试,因此所得的吸湿速率降低。

(3) 湿热环境使CFRP的压缩性能显著降低,且降低幅度对老化时间具有依赖性,老化90天后压缩强度和模量分别降低7.6%和3.7%。高温测试环境下CFRP的压缩性能急剧降低,压缩强度和模量分别降低了36.2%和8.9%。CFRP的层间剪切强度在湿热老化90天后降低了12.3%,高温下(ETD)大幅下降约37.4%。高温下面内剪切强度降低26.9%,模量降低42.1%。由于高温测试采用的温度与老化环境的温度一致,室温湿态(RTW))和高温湿态(ETW)条件下的力学性能结果表明高温对CFRP的力学性能的影响具有可逆性。

-

图 9 CFRP试样压缩试验典型破坏模式

Figure 9. Typical failure modes of compression test for CFRP specimens

Failure identification codes (such as HAT) consisting of 3 characters marked describe the failure mode, failure area and failure location respectively; Failure mode: B—Brooming; D—Delamination; H—Thyrough-thickness; M(xyz)—Multi-mode; Failure area: A—At grip/tab; G—Gage; Failure location: T—Top; M—Middle; V—Various

图 15 CFRP面内剪切试验可接受的典型破坏模式

Figure 15. Typical acceptable failure modes of in-plane shear test for CFRP

Failure identification codes (such as VGN) consisting of three characters marked describe the failure mode, failure area and failure location respectively; Failure mode: H—Horizontal cracking; V—Vertical cracking; Failure area: G—Gage; Failure location: N—Between notches

表 1 CFRP和纯树脂的老化环境

Table 1 Ageing environment for CFRP and pure resin

Environment Hygrothermal environment Medium Deionized water Material CFRP, pure resin Temperature/℃ 70 Ageing time/d 7, 14, 90 表 2 CFRP的测试环境

Table 2 Testing environment for CFRP

Testing environments Testing temperature/℃ Ageing time/d Specimen conditions RTD 20±5 0 Dry ETD 70 0 Dry RTW 20±5 7, 14, 90 Wet ETW 70 90 Wet Notes: RTD—Room temperature dry condition; ETD—Elevated temperature dry condition; RTW—Room temperature wet condition; ETW—Elevated temperature wet condition. -

[1] 马立敏, 张嘉振, 岳广全, 等. 复合材料在新一代大型民用飞机中的应用[J]. 复合材料学报, 2015, 32(2):317-322. MA Limin, ZHANG Jiazhen, YUE Guangquan, et al. Application of composites in new generation of large civil aircraft[J]. Acta Materiae Compositae Sinica,2015,32(2):317-322(in Chinese).

[2] 于洋, 樊威, 薛利利, 等. 热氧老化对三维编织碳纤维-玻璃纤维/双马来酰亚胺树脂复合材料力学性能的影响[J]. 复合材料学报, 2021, 38(12):4060-4072. YU Yang, FAN Wei, XUE Lili, et al. Influence of thermo-oxidative aging on the mechanical performance of three-dimensional braided carbon fiber-glass fiber/bismaleimide composites[J]. Acta Materiae Compositae Sinica,2021,38(12):4060-4072(in Chinese).

[3] GRAMMATIKOS S A, EVERNDEN M, MITCHELS J, et al. On the response to hygrothermal aging of pultruded FRPs used in the civil engineering sector[J]. Materials & Design,2016,96:283-295.

[4] 张祥林, 孟庆春, 许名瑞, 等. 吸湿后碳纤维复合材料正交层板拉伸疲劳性能[J]. 材料工程, 2021, 49(8):169-177. ZHANG Xianglin, MENG Qingchun, XU Mingrui, et al. Tensile fatigue properties of carbon fiber reinforce composite orthogonal laminates after moisture absorption[J]. Journal of Materials Engineering,2021,49(8):169-177(in Chinese).

[5] SHEN C H, SPRINGER G S. Moisture absorption and desorption of composite materials[J]. Journal of Composite Materials,1975,10(1):2-20.

[6] LIU L, ZHAO Z, CHEN W, et al. An experimental investigation on high velocity impact behavior of hygrothermal aged CFRP composites[J]. Composite Structures,2018,204:645-657. DOI: 10.1016/j.compstruct.2018.08.009

[7] TUAL N, CARRERE N, DAVIES P, et al. Characterization of sea water ageing effects on mechanical properties of carbon/epoxy composites for tidal turbine blades[J]. Composites Part A: Applied Science and Manufacturing,2015,78:380-389. DOI: 10.1016/j.compositesa.2015.08.035

[8] SUN P, ZHAO Y, LUO Y, et al. Effect of temperature and cyclic hygrothermal aging on the interlaminar shear strength of carbon fiber/bismaleimide (BMI) composite[J]. Materials & Design,2011,32(8-9):4341-4347.

[9] DAVIES P, RAJAPAKSE Y. Durability of composites in a marine environment[M]//Durability of Composites in a Marine Environment. Berlin: Springer, 2013.

[10] ZHOU J, LUCAS J P. Hygrothermal effects of epoxy resin. Part I: The nature of water in epoxy[J]. Polymer,1999,40(20):5505-5512. DOI: 10.1016/S0032-3861(98)00790-3

[11] WANG Y, ZHU W, WAN B, et al. Hygrothermal ageing behavior and mechanism of carbon nanofibers modified flax fiber-reinforced epoxy laminates[J]. Composites Part A: Applied Science and Manufacturing,2021,140:106142. DOI: 10.1016/j.compositesa.2020.106142

[12] EFTEKHARI M, FATEMI A. Tensile behavior of thermoplastic composites including temperature, moisture, and hygrothermal effects[J]. Polymer Testing,2016,51:151-164. DOI: 10.1016/j.polymertesting.2016.03.011

[13] DOS SANTOS J C, DE OLIVEIRA L A, PANZERA T H, et al. Ageing of autoclaved epoxy/flax composites: Effects on water absorption, porosity and flexural behaviour[J]. Composites Part B: Engineering,2020,202:108380. DOI: 10.1016/j.compositesb.2020.108380

[14] SILVA L V D, SILVA F W D, TARPANI J R, et al. Ageing effect on the tensile behavior of pultruded CFRP rods[J]. Materials & Design,2016,110:245-254.

[15] DING A, WANG J, NI A, et al. Assessment on the ageing of sandwich composites with vinylester-based composite faces and PVC foam core in various harsh environments[J]. Composite Structures,2019,213:71-81.

[16] LIU T, LIU X, FENG P. A comprehensive review on mechanical properties of pultruded FRP composites subjected to long-term environmental effects[J]. Composites Part B: Engineering,2020,191:107958. DOI: 10.1016/j.compositesb.2020.107958

[17] NIU Y F, YAN Y, YAO J W. Hygrothermal aging mechanism of carbon fiber/epoxy resin composites based on quantitative characterization of interface structure[J]. Polymer Testing,2021,94:107019. DOI: 10.1016/j.polymertesting.2020.107019

[18] 高坤, 史汉桥, 孙宝岗, 等. 湿热老化对玻璃纤维/环氧树脂复合材料性能的影响[J]. 复合材料学报, 2016, 33(6):1147-1152. GAO Kun, SHI Hanqiao, SUN Baogang, et al. Effects of hydro-thermal aging on properties of glass fiber/epoxy composites[J]. Acta Materiae Compositae Sinica,2016,33(6):1147-1152(in Chinese).

[19] 李宏福, 王淑范, 孙海霞, 等. 连续碳纤维/尼龙6热塑性复合材料的吸湿及力学性能[J]. 复合材料学报, 2019, 36(1):114-121. LI Hongfu, WANG Shufan, SUN Haixia, et al. Water absorption and mechanical property of continuous carbon fiber/polyamide 6 composites[J]. Acta Materiae Compositae Sinica,2019,36(1):114-121(in Chinese).

[20] JESTHI D K, NAYAK R K. Evaluation of mechanical properties and morphology of seawater aged carbon and glass fiber reinforced polymer hybrid composites[J]. Compo-sites Part B: Engineering,2019,174:106980. DOI: 10.1016/j.compositesb.2019.106980

[21] YIN X, LIU Y, MIAO Y, et al. Water absorption, hydrothermal expansion, and thermomechanical properties of a vinylester resin for fiber-reinforced polymer composites subjected to water or alkaline solution immersion[J]. Polymers,2019,11(3):505-515. DOI: 10.3390/polym11030505

[22] KARBHARI V M. Durability of composites for civil structural applications[M]. Cambridge: Woodhead Publishing in Materials, 2007: 72-79.

[23] CHU W, WU L, KARBHARI V M. Durability evaluation of moderate temperature cured E-glass/vinylester systems[J]. Composite Structures,2004,66(1/4):367-376.

[24] SVETLIK S L. An investigation in the hygrothermal degradation of an E-glass/vinyl-ester composite in humid and immersion environments[D]. San Diego: University of California, 2008.

[25] HOTA G, BARKER W, MANALO A. Degradation mechanism of glass fiber/vinylester-based composite materials under accelerated and natural aging[J]. Construction and Building Materials,2020,256:119462. DOI: 10.1016/j.conbuildmat.2020.119462

[26] MICELLI F, NANNI A. Durability of FRP rods for concrete structures[J]. Construction and Building Materials,2004,18(7):491-503. DOI: 10.1016/j.conbuildmat.2004.04.012

[27] ASTM Standards. Standard test moisture absorption properties and equilibrium conditioning of polymer matrix composite materials: D5229-14[S]. West Conshohocken: ASTM International, 2014.

[28] ASTM Standards. Standard test method for water absorption of plastics: D570-98(2018)[S]. West Conshohocken: ASTM International, 2018.

[29] ASTM Standards. Standard test method for compressive properties of polymer matrix composite materials using a combined loading compression (CLC) test fixture: D6641-14[S]. West Conshohocken: ASTM International, 2014.

[30] ASTM Standards. Standard test method for short-beam strength of polymer matrix composite materials and their laminates: D2344-16[S]. West Conshohocken: ASTM International, 2016.

[31] ASTM Standards. Standard test method for shear properties of composite materials by V-notched rail shear method: ASTM D7078-12[S]. West Conshohocken: ASTM International, 2012.

[32] WISNOM M R, GIGLIOTTI M, ERSOY N, et al. Mechanisms generating residual stresses and distortion during manufacture of polymer–matrix composite structures[J]. Composites Part A: Applied Science and Manufacturing,2006,37(4):522-529. DOI: 10.1016/j.compositesa.2005.05.019

-

期刊类型引用(8)

1. 程超,张晨宇,裴志磊,陈正国,周飞,周金利,张辉,孙泽玉,余木火. 双环戊二烯单体预聚增粘及其碳纤维增强复合材料性能评价. 复合材料学报. 2024(01): 155-169 .  本站查看

本站查看

2. 余咏兴. 碳纤维复合材料粘贴加固混凝土力学性能及应用研究. 粘接. 2024(07): 97-101 .  百度学术

百度学术

3. 成朝辉,刘斌,向栋,徐绯,冯威. 水分-载荷耦合作用下2D编织复合材料的力学行为. 复合材料学报. 2024(10): 5283-5293 .  本站查看

本站查看

4. 张标富. 掺石墨烯硫铝酸盐水泥力学性能分析. 江西建材. 2024(08): 78-80 .  百度学术

百度学术

5. 魏建辉,刘明,高进城,张裕恒,丁安心. 吸湿老化后碳纤维增强乙烯基脂树脂复合材料高低温力学性能. 复合材料学报. 2023(06): 3279-3290 .  本站查看

本站查看

6. 淳道勇,付善龙,刘鑫. 国产T800级碳纤维/聚酰亚胺复合材料耐环境性能研究. 失效分析与预防. 2023(06): 380-386 .  百度学术

百度学术

7. 马彩霞,张诚,游弋义,高晓平. 多轴向经编玻璃纤维织物增强复合材料的蠕变特性研究. 产业用纺织品. 2023(12): 20-26 .  百度学术

百度学术

8. 于德润,张松,陈浩然,荆佳奇,曲广岩. 运载火箭用纤维复合材料整流罩研究进展. 纤维复合材料. 2022(03): 140-144 .  百度学术

百度学术

其他类型引用(4)

-

下载:

下载: