Experimental study on bond behavior of GFRP bar and seawater coral aggregate concrete after exposure to high temperatures

-

摘要: 为了研究高温后玻璃纤维增强树脂复合材料(GFRP)筋与海水珊瑚混凝土的残余粘结性能,对54个GFRP筋珊瑚混凝土试件及钢筋珊瑚混凝土对比试件进行了高温作用后的中心拔出试验,最高温度为350℃,混凝土强度等级考虑C20~C30。观察了高温后试件的表观变化及粘结破坏形态,获取了各试件的粘结-滑移曲线、粘结强度、粘结刚度和峰值滑移量,分析了不同温度、GFRP筋直径、海水珊瑚混凝土强度等因素对高温后GFRP筋与海水珊瑚混凝土粘结性能的影响。基于烧失率和XRD分析,剖析了GFRP筋海水珊瑚混凝土的高温劣化机制。最后,提出高温后GFRP筋与珊瑚混凝土的剩余粘结强度计算式和粘结-滑移本构模型。研究结果表明:高温作用后,尽管GFRP筋与珊瑚混凝土的粘结破坏形态与常温相似,GFRP筋的碳化和珊瑚混凝土的分解使得二者界面发生显著劣化;随着温度的提高,GFRP筋与珊瑚混凝土的粘结强度逐渐降低,峰值滑移量增大;GFRP筋直径越小,高温后的剩余粘结强度和剩余粘结刚度越小;珊瑚混凝土强度等级越高,剩余粘结刚度越大,峰值滑移量越小。所提出的高温后GFRP筋与珊瑚混凝土剩余粘结强度和粘结-滑移本构关系计算结果与试验结果均能较好吻合。Abstract: To study the residual bond performance of glass fiber reinforced polymer (GFRP) bars and seawater coral aggregate concrete after exposure to high temperature, the pull-out tests were performed through 54 GFRP bars coral aggregate concrete specimens and steel bars coral aggregate concrete specimens. The highest temperature of 350℃ and concrete classes of C20 to C30 were considered in this experiment. The surface changes and bond failure modes of specimens after high temperatures were observed. The bond stress-slippage curves, bond strength, stiffness and peak slippage were obtained. The influences of temperatures, bar diameters and concrete strengths on the bond properties of GFRP bars and coral aggregate concrete after high temperatures were analyzed. Furthermore, the deterioration mechanism of GRFP bars seawater coral aggregate concrete after high temperatures was revealed based on the analysis of mass loss rate and XRD tests. Finally, the bond stress-slippage constitutive relation and residual bond strength of GFRP bars and coral aggregate concrete after high temperatures were proposed. The results show that even though the failure modes of specimens after high temperature are similar to those at room temperature, the interface of GFRP bar and coral aggregate concrete is degraded significantly due to the carbonization of GFRP bar and pyrolysis of coral aggregate concrete. The bond strength of specimens decreases and the peak slippage increases as the temperature increasing. The smaller the diameter of GFRP bars, the lower the residual bond strength and stiffness of specimens after high temperatures. The higher the strength classes of coral aggregate concrete, the greater the residual bond stiffness and the smaller the peak slippage. The calculated results of the proposed bond stress-slippage constitutive model and residual bond strength of GFRP bars-coral aggregate concrete after high temperatures show a good agreement with the experimental results.

-

海水珊瑚混凝土是以珊瑚颗粒代替碎石、卵石等作为粗骨料,以珊瑚砂或海砂为细骨料,将海水作为拌合水配制的混凝土。在远海岛礁建设中,海水珊瑚混凝土可就地取材,有效解决骨料运输成本高、工期难以保证等问题。然而,海水和珊瑚骨料中含有大量的氯离子,会使钢材快速锈蚀,不能直接应用于传统钢筋混凝土结构中。玻璃纤维增强树脂复合材料(Glass fiber reinforced polymer,GFRP)筋耐氯离子腐蚀性好,代替钢筋应用于海水珊瑚混凝土中可以从根本上解决锈蚀问题。因此,GFRP筋珊瑚混凝土在岛礁工程中极具应用前景[1-4]。

GFRP筋与珊瑚混凝土的粘结性能作为二者共同工作的基础,直接影响到构件及结构的力学性能,是GFRP筋珊瑚混凝土结构工程应用和设计计算的关键。Yang等[5]通过GFRP筋海水珊瑚混凝土的拔出试验,研究了GFRP筋与珊瑚混凝土的粘结性能,结果表明:随着筋材直径和粘结长度的增大,GFRP筋与珊瑚混凝土的粘结强度逐渐降低,海水养护下的粘结性能略低于标准养护下的粘结性能。Wang等[6]进行了湿热环境下GFRP筋与珊瑚混凝土粘结性能的研究,结果表明:湿热环境下GFRP筋与珊瑚混凝土的粘结强度显著降低,二者由拔出破坏逐渐转变为筋材断裂破坏。王磊等[7]、杨超等[8]、高傲等[9]对不同GFRP类型、筋材直径、粘结长度和养护条件下GFRP筋与珊瑚混凝土的粘结性能进行了研究。Dai等[10]、Yang等[5]和陈爽等[11]根据珊瑚混凝土的特性,提出了GFRP筋与珊瑚混凝土的粘结-滑移本构模型。上述研究结果表明,GFRP筋与珊瑚混凝土的界面特性相比普通混凝土有较大差异,粘结性能与本构关系均有所不同。

火灾作为一种频发灾害,对结构安全的危害巨大。GFRP筋的耐火性能极差,当温度达到400℃时,GRRP筋的强度基本丧失殆尽,火灾后的残余强度也仅为常温下的19.3%[12]。GFRP筋与混凝土的粘结性能在火灾高温作用下也产生严重劣化,其劣化机制及规律对结构的抗火性能和灾后鉴定加固具有重要意义。目前,对于火灾高温下及高温后GFRP筋与普通混凝土的粘结性能已有一定研究。Katz等[13]、Galati等[14]、吕西林等[15]和王晓璐等[16]对高温下及高温后GFRP筋与混凝土的粘结性能进行了试验研究,结果表明:在高温作用影响下,GFRP筋与混凝土的粘结性能显著降低,200℃时强度损失在50%以上,350℃时强度损失达到80%。然而,对于火灾高温后GFRP筋与海水珊瑚混凝土粘结性能方面的研究国内外尚未见报道。由于界面特性的差异,高温后GFRP筋珊瑚混凝土的粘结性能与GFRP筋普通混凝土有所不同,相关研究对GFRP筋珊瑚混凝土的推广应用具有重要意义。

因此,本文通过GFRP筋海水珊瑚混凝土试件高温后的拔出试验,研究经历不同高温后GFRP筋与海水珊瑚混凝土粘结性能的退化规律,结合XRD测试结果,对其界面损伤机制进行了分析,提出高温后剩余粘结强度的计算方法和粘结-滑移本构模型。

1. 试验概况

1.1 原材料

筋材采用山西诚鑫达生产的螺旋肋GFRP筋,基体材料为高分子环氧树脂,玻璃化温度为110℃,增强材料为玻璃纤维丝,软化温度为700℃。筋材直径分别为8、12和16 mm,对照组钢筋为上海宝钢生产的12 mm直径HRB400级月牙肋钢筋,如图1所示。不同直径GFRP筋和钢筋的几何参数及实测力学性能见表1。

混凝土所用粗骨料为珊瑚颗粒,如图2所示,粒径为5~30 mm,堆积密度为928.2 kg/m³,表观密度1702.9 kg/m³,空隙率为53.6%,吸水率为13.8%,筒压强度1.4 MPa。细骨料为海砂,堆积密度1550.4 kg/m³,表观密度2000.5 kg/m³,空隙率22.5%。水泥采用安徽海螺水泥有限公司生产的海螺牌42.5普通硅酸盐水泥,拌和水为人工海水,根据美国规程ASTM D1141[17]配制。

1.2 混凝土配合比

混凝土设计强度等级为C20和C30,基础水灰比分别为0.5和0.4,附加海水量根据珊瑚骨料吸水率确定,具体配合比、拌合物性能及轴心抗压强度见表2。

表 1 筋材几何参数及力学性能Table 1. Geometrical parameter and mechanical properties of barsType of reinforcement Diameter/mm Rib spacing /mm Rib depth/mm Tensile strength f/MPa Elasticity modulus E/GPa GFRP bar 8 8.61 0.49 855.46 43.69 12 10.59 1.05 853.59 41.32 16 9.84 1.40 730.85 33.73 Steel rebar 12 8.00 1.20 629.08 219.84 表 2 海水珊瑚混凝土配合比及抗压强度Table 2. Mixture ratio and compressive strength of seawater coral aggregate concreteStrength class Composition/(kg·m−3) Slump/

mmfc/

MPaBasic sea water Additional sea water Total sea water Cement Silica fume Sea sand Coral Plasticizer C20 190 89 279 350 30 820 710 0.007 142 21.83 C30 190 91 281 400 70 810 720 0.012 190 25.44 Notes: fc—Axial compressive strength of concrete. 1.3 试件设计

考虑到混凝土保护层的存在,火灾时GFRP筋与珊瑚混凝土的界面温度远低于环境温度,并且400℃以上的高温作用后,GFRP筋自身强度已基本丧失殆尽。本文的试验以温度(20、150、200、250、300、350℃)、GFRP筋直径(8、12、16 mm)、混凝土强度等级(C20、C30)为变化参数,设计制作了15组GFRP筋海水珊瑚混凝土拔出试件及3组钢筋珊瑚混凝土对比试件,每组3个试件,共计54个,详细设计参数见表3。拔出试件尺寸根据《纤维增强复合材料筋基本力学性能试验方法》(GB/T 30022—2013)[18]确定,粘结长度为5倍筋材直径。由于规范要求粘结长度最小为50 mm,故直径8 mm的GFRP筋试件的粘结长度取50 mm。非粘结段通过聚氯乙烯(PVC)套管将GFRP筋与珊瑚混凝土隔离。自由端GFRP筋外露长度为20 mm,以便测量自由端滑移量。加载端长度为380 mm,筋材端部设置100 mm钢套管加载锚固段。

表 3 试件设计参数Table 3. Design parameters of specimensSpecimen number Strength class Reinforcement Bar diameter/mm Temperature/℃ GFRP8/CC30-20 C30 GFRP bar 8 20 GFRP8/CC30-200 C30 GFRP bar 8 200 GFRP8/CC30-350 C30 GFRP bar 8 350 GFRP12/CC30-20 C30 GFRP bar 12 20 GFRP12/CC30-150 C30 GFRP bar 12 150 GFRP12/CC30-200 C30 GFRP bar 12 200 GFRP12/CC30-250 C30 GFRP bar 12 250 GFRP12/CC30-300 C30 GFRP bar 12 300 GFRP12/CC30-350 C30 GFRP bar 12 350 GFRP16/CC30-20 C30 GFRP bar 16 20 GFRP16/CC30-200 C30 GFRP bar 16 200 GFRP16/CC30-350 C30 GFRP bar 16 350 GFRP12/CC20-20 C20 GFRP bar 12 20 GFRP12/CC20-200 C20 GFRP bar 12 200 GFRP12/CC20-350 C20 GFRP bar 12 350 SR12/CC30-20 C30 Rebar 12 20 SR12/CC30-200 C30 Rebar 12 200 SR12/CC30-350 C30 Rebar 12 350 Note: In GFRP8/CC30-20, GFRP8 means the GFRP bars with diameter of 8 mm, CC30 means coral concrete strength grade, 20 means test temperature. 1.4 试验装置及方法

1.4.1 高温试验装置及方法

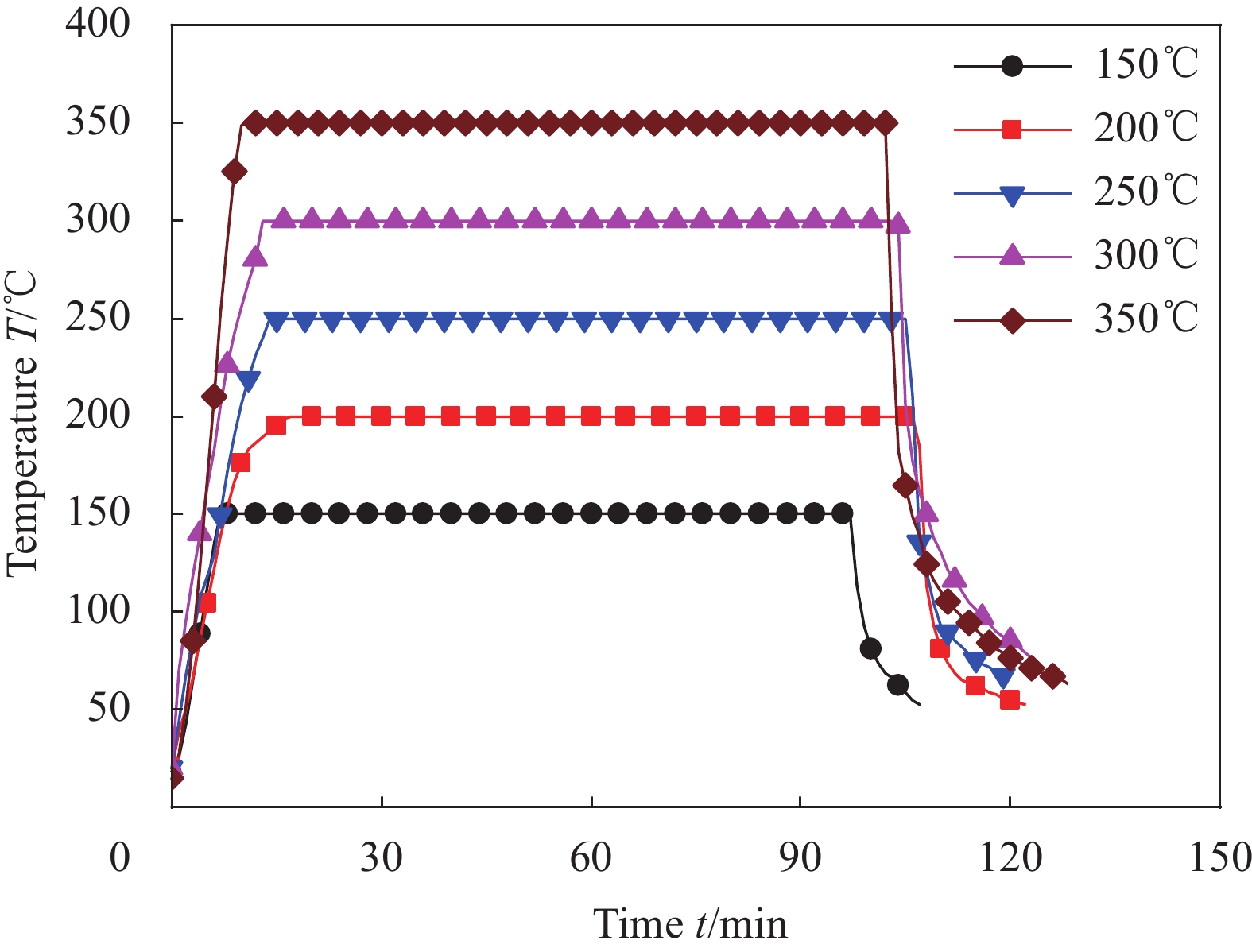

升温装置采用长春方锐科技有限公司生产的GWM-1100型电加热高温炉,最高升温温度为1100℃,炉壁自上而下均匀分布着6个热电偶,可实时采集炉内温度数据,如图3所示。文献[19, 20]的研究表明,在环境温度小于550℃的情况下,150 mm边长试件恒温1.5 h内筋材与混凝土的界面温度可与炉内温度一致。因此,试件在炉内为四面加热,当炉内温度达到目标温度后恒温1.5 h,最后停止加热并打开炉门,使试件在自然条件下降至室温,实测炉内升降温曲线见图4。

1.4.2 拔出试验装置及加载方法

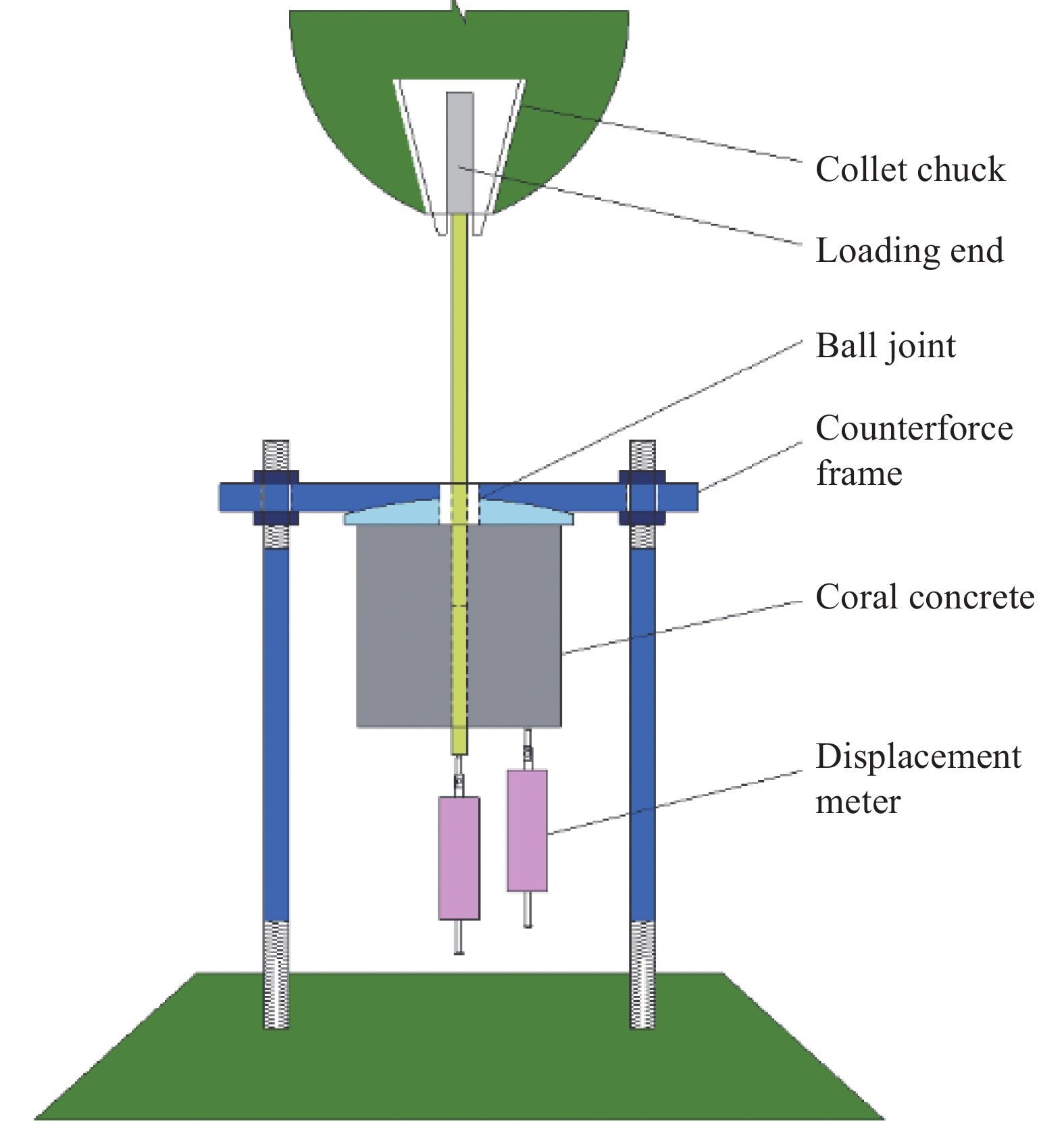

高温后试件的拔出试验采用深圳市新三思材料检测有限公司生产的WAW-6000液压伺服万能试验机进行加载。加载装置由带孔钢板和4根螺杆组成反力架,螺杆上端与钢板固定,下端与试验机相连,试件的筋材由穿心球铰的中心孔洞穿出,通过试验机夹头固定,位移计布置在试件下方,分别测量筋材位移和混凝土位移,装置如图5所示。试验过程中采用位移控制的加载制度,速率为0.5 mm/min,通过试验机自身采集系统获取荷载值,位移计获取滑移值。

1.4.3 XRD测试方法

为了揭示高温后海水珊瑚混凝土的损伤机制以及对界面性能的影响,采用XRD技术对常温和高温后海水珊瑚混凝土界面处的基体进行测试。首先将常温及高温后的海水珊瑚混凝土基体研磨成粉末,浸泡在无水乙醇中终止水化,然后将样品粉末进行低温烘干,采用D8 Advance Davinci X射线衍射仪获取样品的衍射图谱,最后根据不同晶体的衍射角度进行物相标定。

2. 试验结果及分析

2.1 高温后GFRP筋与海水珊瑚混凝土表观变化

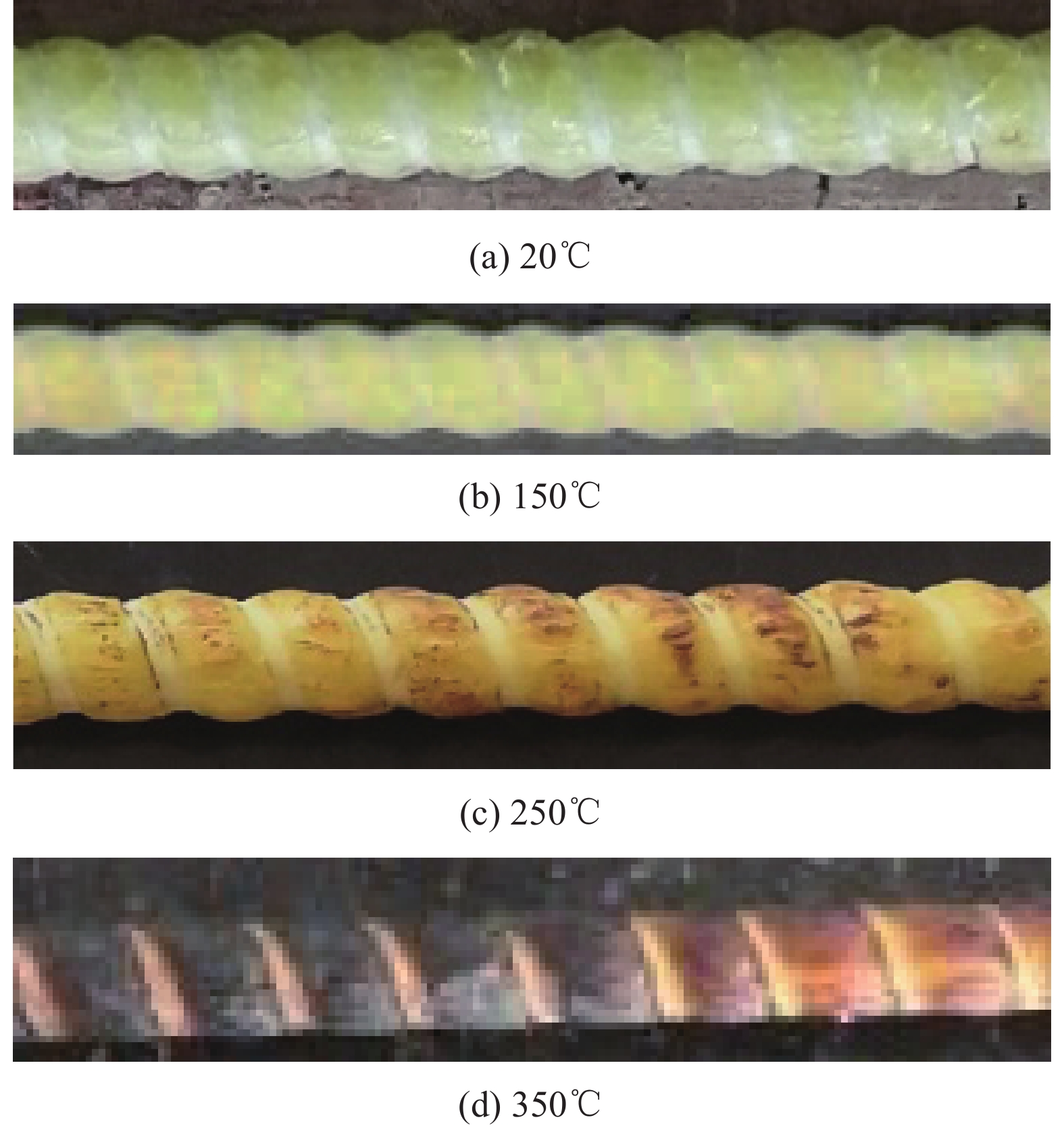

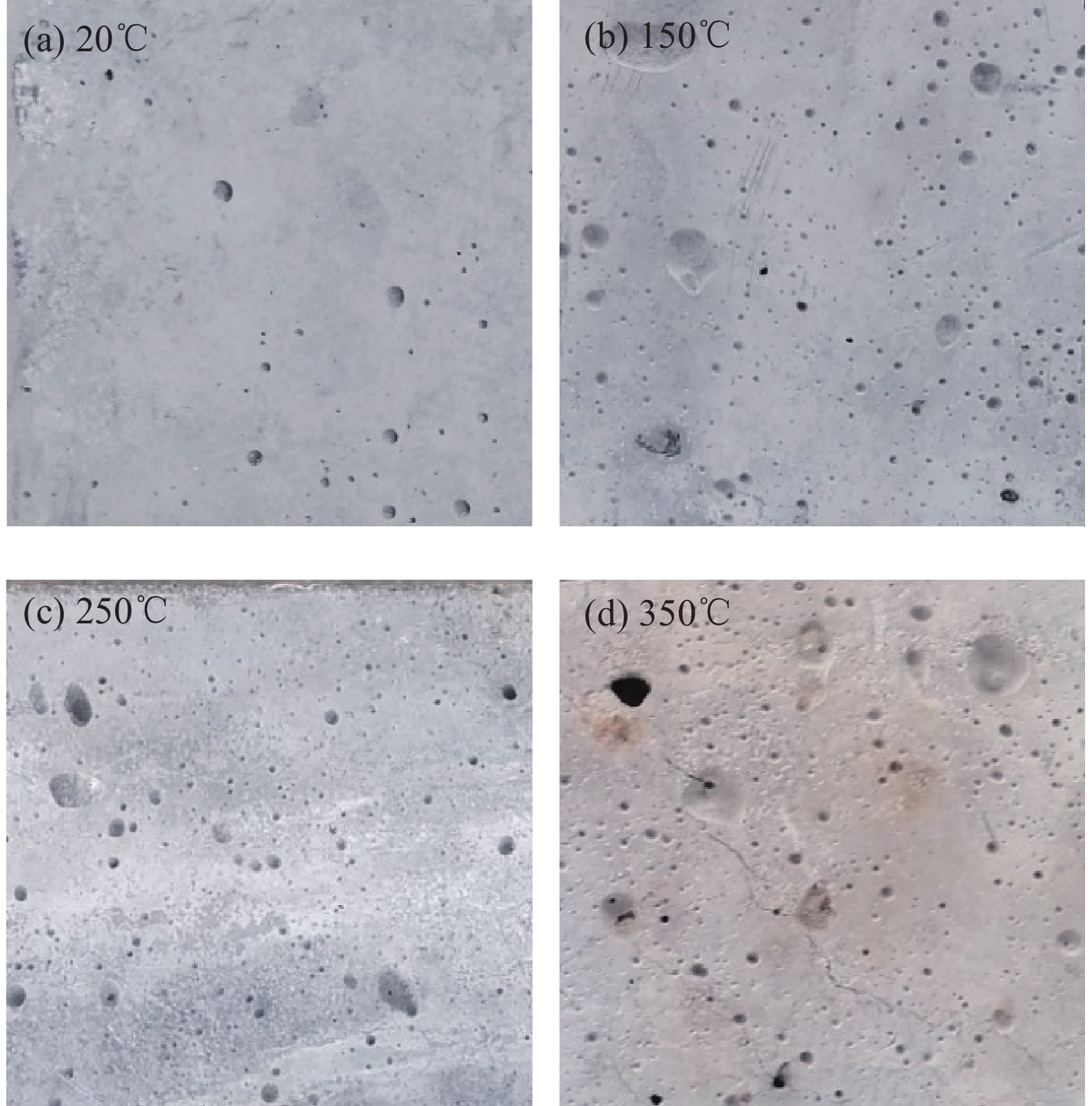

高温作用后GFRP筋与海水珊瑚混凝土发生一系列物理和化学变化,随着所经历温度的提高,它们的表观颜色和形态均有改变。GFRP筋150℃高温后与常温下相比无明显变化;250℃高温后表面颜色加深,树脂开始发生碳化;350℃高温后颜色变黑,树脂大量碳化和分解,筋材内部的部分纤维露出,如图6所示。海水珊瑚混凝土的颜色在150℃后与常温相同,250℃时颜色变浅,350℃时表面出现细小温度裂纹且边角处轻微剥落,如图7所示。

2.2 GFRP筋与海水珊瑚混凝土粘结破坏形态

高温后GFRP筋与海水珊瑚混凝土的破坏形态主要为筋材拔出破坏和混凝土劈裂破坏,影响破坏形态的因素主要为筋材直径,温度对破坏形态无明显影响。

2.2.1 筋材拔出破坏

筋材直径8 mm的试件无论常温还是高温后的破坏形态均为拔出破坏。加载过程中筋材缓慢从珊瑚混凝土中拔出,混凝土无肉眼可见裂缝。这是由于小直径GFRP筋的肋较浅,加载过程中GFRP筋与珊瑚混凝土的化学胶着力、机械咬合力相继减小,随着荷载的继续增大,GFRP筋表面树脂磨损,肋间混凝土被剪碎,逐渐从混凝土中拔出,最终破坏形态见图8(a)。

2.2.2 混凝土劈裂破坏

筋材直径12 mm、16 mm的试件,主要为珊瑚混凝土的劈裂破坏,与钢筋珊瑚混凝土试件的粘结破坏形式相同。在加载过程中,首先在珊瑚混凝土侧表面靠近加载端处出现细小的裂缝,随着滑移量的增大,裂缝逐渐向自由端扩展延伸,最终混凝土突然被劈裂,破坏后分成2~3块,粘结应力丧失。混凝土劈裂破坏是由于大直径的GFRP筋肋较深,其与混凝土的机械咬合力较大,珊瑚混凝土在筋肋的挤压下产生剪切裂缝并发生破坏,最终破坏形态见图8(b)。

2.3 GFRP筋海水珊瑚混凝土粘结-滑移曲线

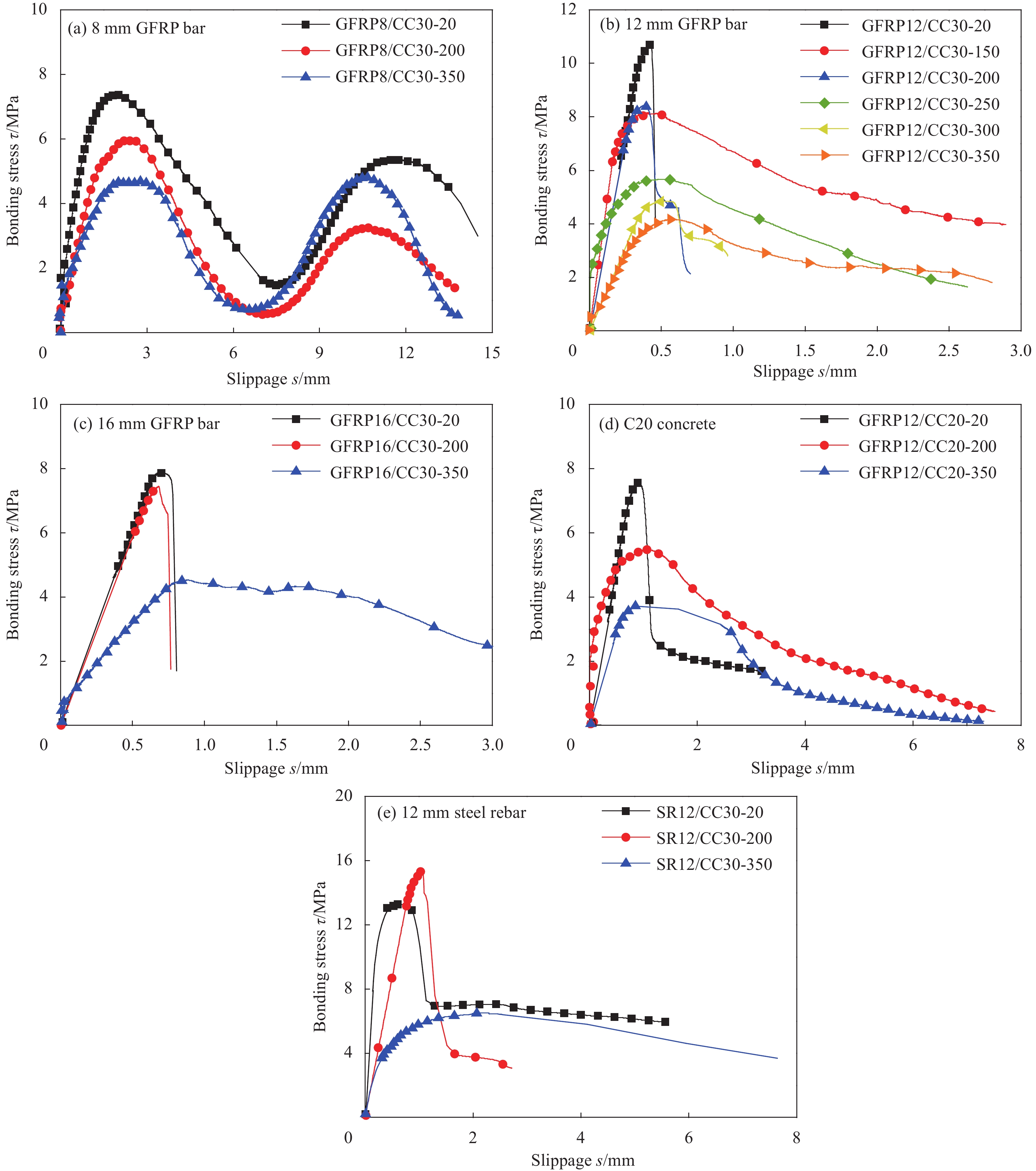

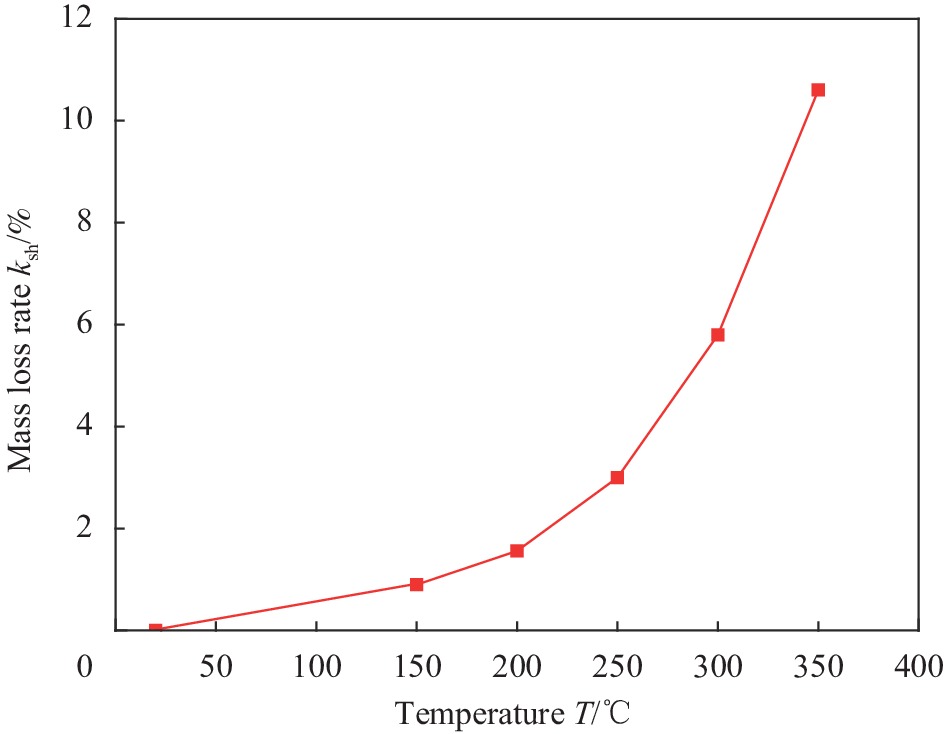

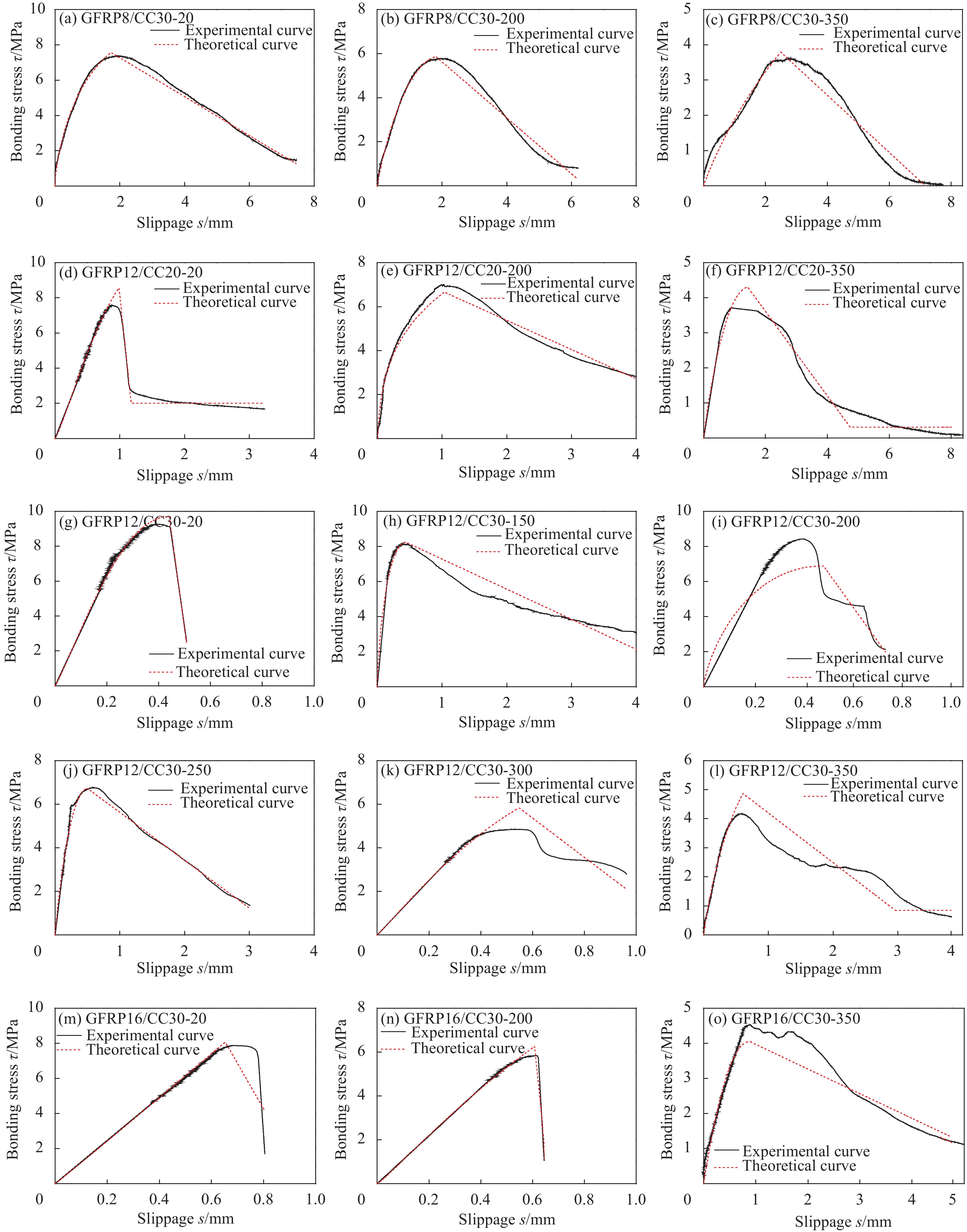

高温后GFRP筋与珊瑚混凝土的粘结-滑移(τ-s)曲线如图9所示。可见,粘结滑移过程可分为5个阶段:(1) 微滑移阶段(τ<0.2τu,τu为粘结强度),由于荷载较小,GFRP筋的自由端尚未开始滑移,该阶段的粘结应力主要由化学胶着力提供;(2) 滑移阶段(0.2τu<τ<0.8τu),随着荷载的增加,GFRP筋自由端开始出现滑移,此时粘结应力随着滑移量的增大而增大,近似呈线性关系,化学胶着力丧失,粘结应力主要由摩阻力与机械咬合力提供;随着温度的升高,试件粘结-滑移曲线在这一上升段的斜率逐渐降低;(3) 剥离阶段(0.8τu<τ<1.0τu),滑移量的增长速度逐渐大于粘结应力的增长速度,试件的粘结-滑移曲线表现出显著的非线性,随后应力达到峰点;随着温度的升高,峰点逐渐下降;(4) 下降阶段,对于劈裂破坏的试件,由于珊瑚混凝土开裂导致摩阻力与机械咬合力迅速降低,曲线下降段较为陡峭;对于拔出破坏的试件,摩阻力与机械咬合力逐渐衰减,曲线下降段较为平缓;无论何种破坏形式,随着温度的升高,试件粘结-滑移曲线的下降段逐渐趋于平缓;(5) 残余阶段,对于温度高于300℃的劈裂破坏试件,当滑移达到一定数值后,粘结应力不再下降,维持在一个相对稳定水平(5%τu~50%τu),试件经历的温度越高,残余阶段的粘结应力越小;但是,对于温度低于300℃的劈裂破坏试件没有残余阶段;对于拔出破坏的试件,曲线呈现往复上升、下降的衰减过程,出现第二峰点,但是峰点应力逐次降低,直至筋材被彻底拔出。

2.4 GFRP筋海水珊瑚混凝土粘结性能指标

通过高温后GFRP筋与珊瑚混凝土的粘结-滑移曲线,可获得其粘结强度τu、峰值滑移量s1和粘结刚度κ等粘结性能指标。其中粘结强度根据下式进行计算[18]:

τu=1000fmax (1) 式中:fmax为试件的粘结破坏荷载;d为GFRP筋直径;L为GFRP筋粘结长度。

粘结刚度通常取0.5~1倍峰值应力对应的割线刚度[21-23],故粘结刚度通过下式进行计算:

\kappa = \frac{{0.8{\tau _{\text{u}}}}}{{{s_{0.8}}}} (2) 式中,s0.8为0.8倍峰值荷载所对应的滑移量。

高温后GFRP筋与珊瑚混凝土各组试件的粘结性能指标见表4。

2.5 GFRP筋海水珊瑚混凝土高温劣化机制

高温作用后,GFRP筋与海水珊瑚混凝土均发生了一系列复杂的物理化学变化,它们的界面也产生了不同程度的劣化,可以分别从GFRP筋和海水珊瑚混凝土两方面解释其界面劣化机制。对于GFRP筋,已有研究从表面微观形态、树脂玻璃化转变和高温分解等角度解释了其高温劣化的原因[24-26]。对于海水珊瑚混凝土,通过物理变化和化学物质改变进行分析是一种有效的途径。

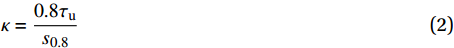

表 4 高温后GFRP筋珊瑚混凝土粘结性能Table 4. Bond properties of GFRP bar and coral aggregate concrete after high temperaturesSpecimen number τu/MPa s1/mm κ/(MPa·mm−1) Failure mode GFRP8/CC30-20 7.57 1.73 7.79 P GFRP8/CC30-200 5.93 1.99 4.10 P GFRP8/CC30-350 3.61 2.33 2.45 P GFRP12/CC20-20 7.22 0.99 9.05 S GFRP12/CC20-200 5.84 1.06 10.92 S GFRP12/CC20-350 3.73 1.27 5.63 S GFRP12/CC30-20 10.92 0.37 30.29 S GFRP12/CC30-150 8.95 0.40 35.10 S GFRP12/CC30-200 8.72 0.40 31.02 S GFRP12/CC30-250 6.21 0.54 25.35 S GFRP12/CC30-300 5.85 0.61 14.78 S GFRP12/CC30-350 5.01 0.61 11.37 S GFRP16/CC30-20 8.07 0.65 11.92 S GFRP16/CC30-200 7.11 0.66 12.25 S GFRP16/CC30-350 4.33 0.89 6.07 S SR12/CC30-20 13.18 0.60 55.20 S SR12/CC30-200 13.99 0.91 71.20 S SR12/CC30-350 9.15 1.80 19.32 S Notes: τu—Bonding strength; s1—Peak slippage; κ—Bond stiffness; P—Pull-out of bar; S—Splitting of concrete. 通过称量高温前后海水珊瑚混凝土试件的质量变化,根据下式可获取高温后海水珊瑚混凝土的烧失率:

{k_{{\text{sh}}}} = \frac{{{m_{\text{h}}} - {m_{\text{s}}}}}{{{m_{\text{h}}}}} \times 100\% (3) 式中:ksh为试件高温后的烧失率;mh为试件常温时的质量;ms为试件高温后的质量。

烧失率与温度关系如图10所示。可见,试件烧失率随温度的提高而增大,并且呈现出非线性的增长。在低于200℃时,烧失率增长较小,仅为1.56%,这一阶段质量的损失主要是由于珊瑚混凝土中的自由水受热溢出导致。而当温度高于200℃后,试件的烧失率增长较大,350℃时试件烧失率达到10.81%,这一阶段质量的损失是由于结晶水丧失和水泥水化物的分解。

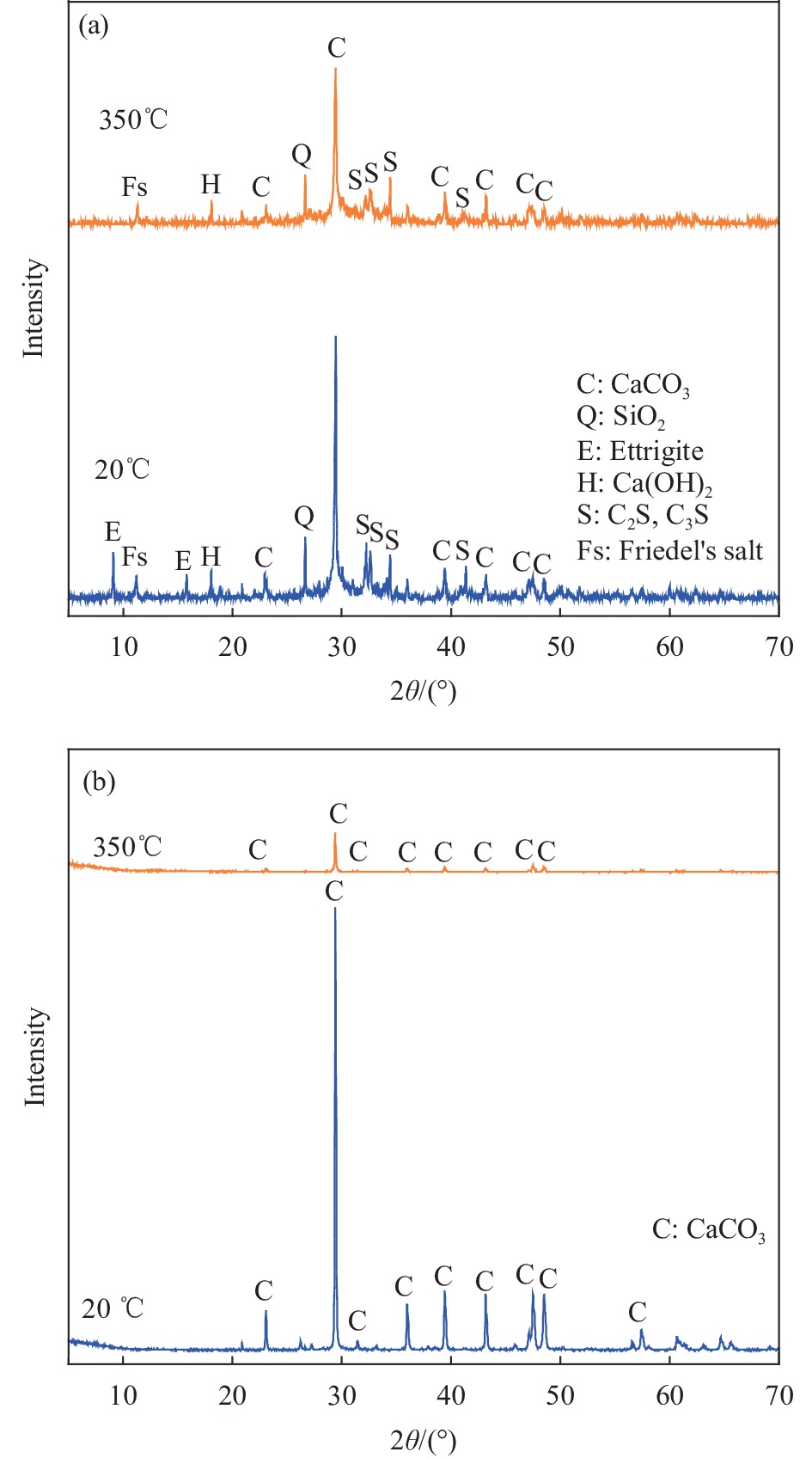

图11为常温、350℃高温后珊瑚混凝土界面水泥基体和珊瑚骨料的XRD图谱。图11(a)为珊瑚混凝土界面水泥基体的XRD图谱。可见,海水珊瑚混凝土基体的主要晶体成分为SiO2、CaCO3和钙矾石。高温后,SiO2、CaCO3的衍射峰小于常温下的衍射峰,钙矾石的衍射峰消失,说明它们在高温下发生了部分或完全分解,导致基体的结构疏松劣化,这与普通混凝土水泥基体高温后的表现一致[27-28]。基体的劣化使海水珊瑚混凝土的力学性能及与GFRP筋的粘结性能降低。

图11(b)为珊瑚骨料常温和350℃高温后的XRD图谱。可见,珊瑚骨料的主要晶体成分为CaCO3。CaCO3在高温后的衍射峰小于常温下的衍射峰,说明其在高温下发生了部分分解,导致骨料性能劣化,进而使珊瑚混凝土强度降低。

通过上述分析可见,高温后随着基体中的SiO2、CaCO3、钙矾石及珊瑚骨料中的CaCO3发生分解,海水珊瑚混凝土的质量降低,内部结构发生破坏,使混凝土内部发生损伤,进而导致与GFRP筋界面性能的劣化。

3. 影响因素分析

3.1 温度对GFRP筋与珊瑚混凝土粘结性能的影响

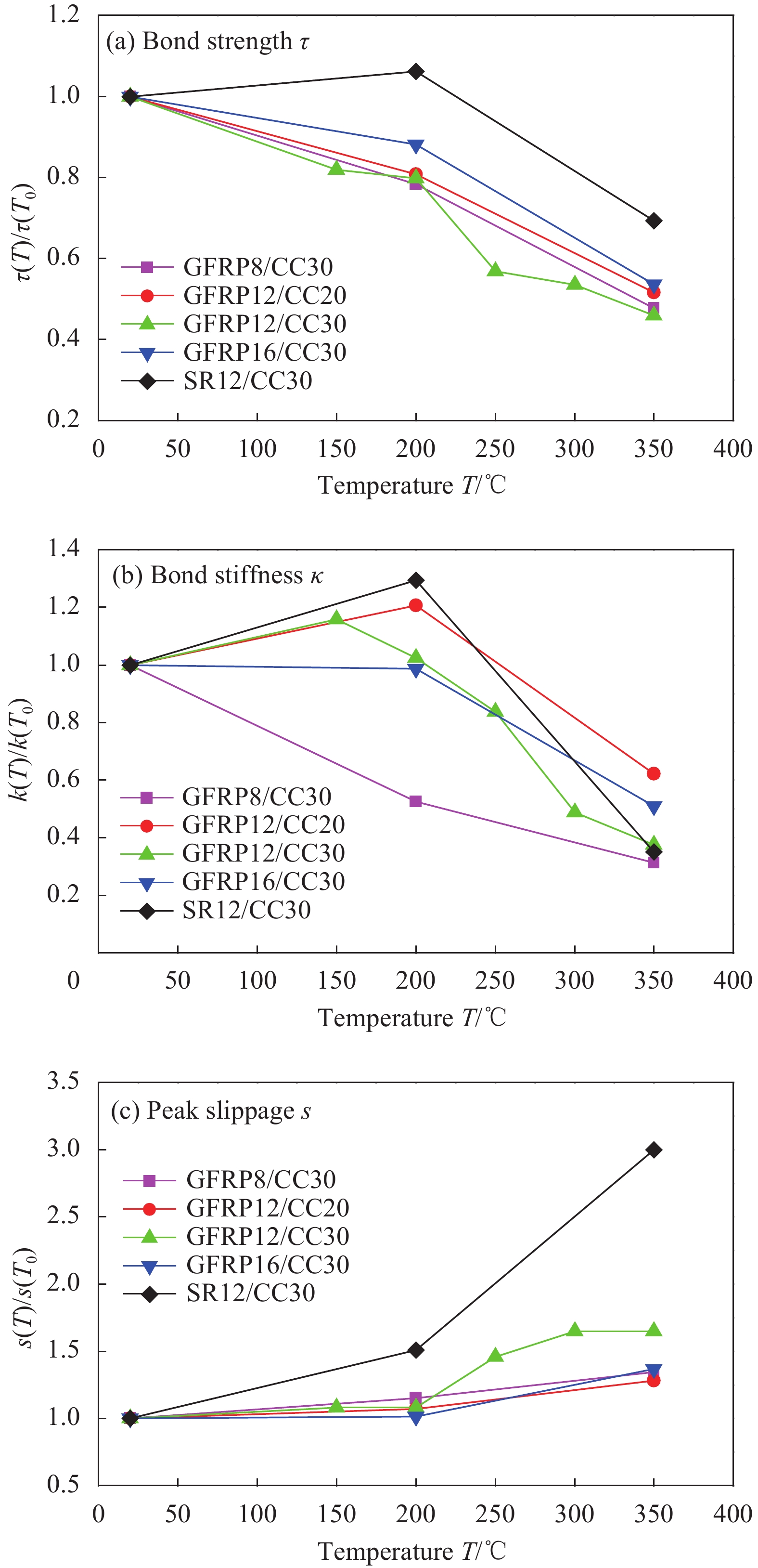

图12为高温后试件粘结强度、刚度和峰值滑移量随温度的变化规律。高温后试件粘结强度随温度的变化如图12(a)所示。可见,钢筋与珊瑚混凝土间的粘结强度随温度的升高先增大后减小,200℃后的粘结强度高于常温,350℃后的粘结强度为常温的69.38%。这是由于经历200℃高温后,钢筋的强度较常温没有降低,而水泥基体由于自由水的溢出,结构更密实,混凝土的强度反而略有提高,进而粘结强度有所提高;而在经历350℃高温后,珊瑚混凝土的基体和骨料发生分解和劣化,强度降低,导致钢筋与珊瑚混凝土的机械咬合力大幅减小。然而,GFRP筋与珊瑚混凝土的粘结强度随温度的升高逐渐减小,200℃为常温的78.34%~88.10%,350℃仅为常温的45.91%~55.63%,其降低程度大于钢筋与珊瑚混凝土的粘结强度。这是由于不仅珊瑚混凝土的强度受到温度的影响,GFRP筋中树脂在高温下发生玻璃化转变及分解,也产生了劣化。200℃高温后GFRP筋劣化对粘结强度的减弱作用大于混凝土强度提高的增强作用,因此粘结强度减小;350℃高温后,GFRP筋与混凝土的双重劣化,使其粘结强度的降低更显著。已有研究表明[29]:350℃高温后,GFRP筋与普通混凝土的剩余粘结强度为常温下的54.6%~68.4%。说明高温后GFRP筋与珊瑚混凝土粘结强度的劣化相比普通混凝土更为显著。

图12(b)为高温后试件粘结刚度随温度的变化。可见,破坏形态为劈裂破坏试件(筋材直径为12 mm和16 mm试件)的粘结刚度随温度升高先增大后减小,当所经历的温度≤200℃时,粘结刚度略高于常温试件,这是由于劈裂破坏试件的刚度主要由混凝土强度控制,经历200℃高温后,珊瑚混凝土由于自由水的脱出,结构更为密实,强度有所提高;当所经历的温度>200℃时,粘结刚度随温度上升而下降;350℃后为常温的35.06%~62.21%,这是由于当温度较高时珊瑚混凝土的结晶水脱出,基体和骨料分解,内部结构变得疏松。然而,破坏形态为拔出破坏试件(筋材直径为8 mm试件)的粘结刚度随温度的升高逐渐减小,200℃为常温的52.62%,350℃仅为常温的31.44%。这是由于拔出破坏试件的刚度主要由界面性能控制,随着温度的提高筋材表面逐渐劣化,使得界面损伤程度逐渐提高。

图12(c)给出了高温后试件峰值滑移量随温度的变化规律。可见,由于经历高温后,GFRP筋与珊瑚混凝土的弹性模量逐渐降低,滑移变形增大,钢筋及GFRP筋与珊瑚混凝土的峰值滑移量随温度的升高逐渐增大,200℃的峰值滑移量为常温的101.54%~150.85%,350℃的峰值滑移量为常温的128.28%~300.00%。钢筋/珊瑚混凝土试件峰值滑移量随温度提高的增大程度大于GFRP筋珊瑚混凝土试件。

3.2 混凝土强度对GFRP筋与珊瑚混凝土粘结性能的影响

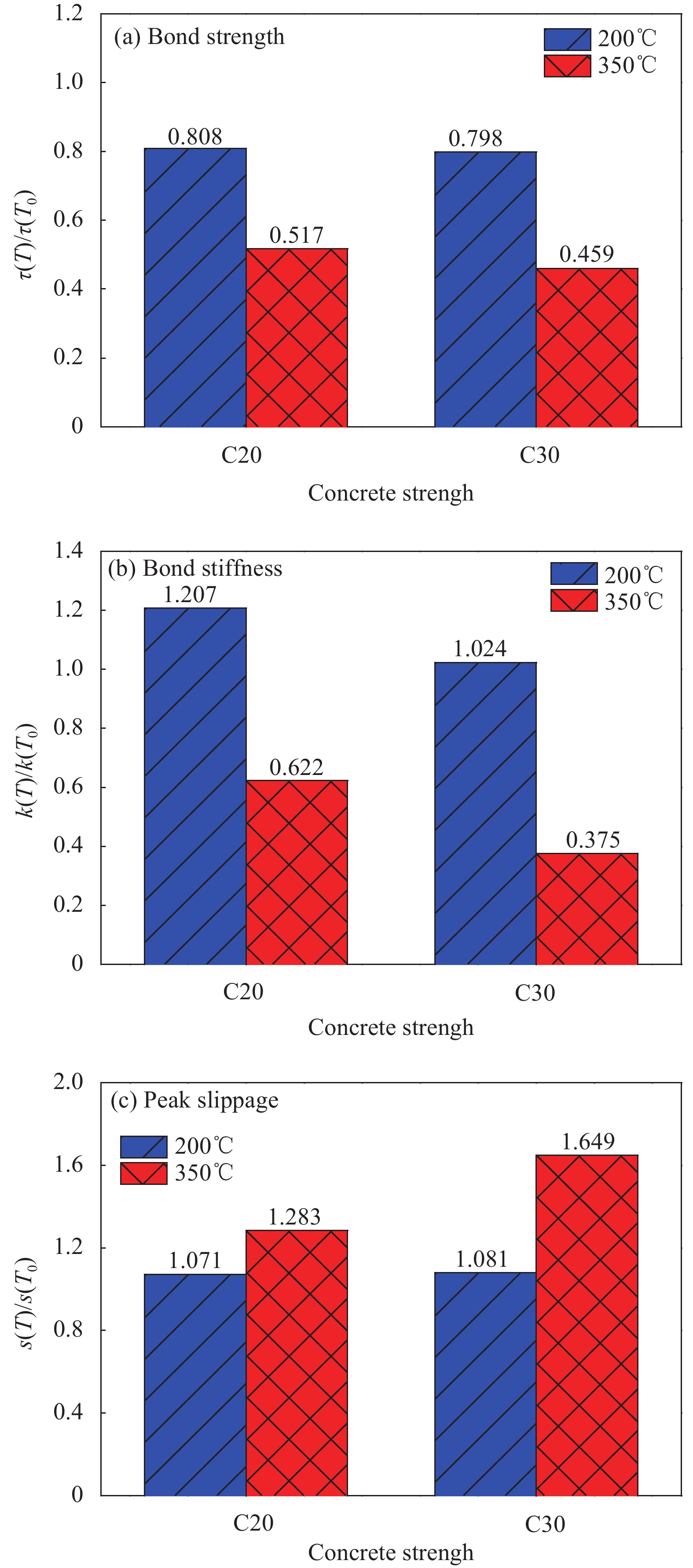

图13为混凝土强度等级对 GFRP 筋珊瑚混凝土试件粘结性能的影响。图13(a)为混凝土强度等级对高温后粘结强度的影响。可见,C30和C20珊瑚混凝土试件粘结强度在200℃后下降程度基本相同。而350℃时,C30试件的粘结强度衰减程度相比C20试件略大,前者较常温下降了54.09%,后者下降了48.34%。总体而言,混凝土强度改变对不同温度后GFRP筋与珊瑚混凝土的剩余粘结强度影响较小,与高温后GFRP筋和不同强度等级普通混凝土剩余粘结强度的研究结果一致[30]。

图13(b)为珊瑚混凝土强度等级对高温后粘结刚度的影响。可见,当经历200℃和350℃高温后,C20珊瑚混凝土试件粘结刚度分别为常温下的1.207和0.622倍,C30混凝土试件仅为常温下的1.024和0.375倍。可见,随着混凝土强度的提高,高温后试件的相对粘结刚度减小。

图13(c)给出了珊瑚混凝土强度等级对高温后GFRP筋与珊瑚混凝土峰值滑移量的影响。可见,混凝土强度等级越高,高温后试件峰值滑移量的提高程度越大。当所经历温度为200℃和350℃后,C20试件的峰值滑移量较常温分别升高了7.07%和28.28%,C30试件较常温分别升高了8.11%和64.86%。

3.3 GFRP筋直径对GFRP筋与珊瑚混凝土粘结性能的影响

图14为GFRP筋直径对GFRP筋珊瑚混凝土试件粘结性能的影响。图14(a)为GFRP筋直径对高温后粘结强度的影响。可见,随着GFRP筋直径的增大,高温后GFRP筋与珊瑚混凝土的剩余粘结强度逐渐提高。16 mm直径试件在200℃和350℃高温后的粘结强度分别为常温的88.1%和53.6%,而8 mm直径试件仅为78.3%和47.6%。说明GFRP筋直径越小,其与珊瑚混凝土的粘结强度受高温的影响越显著。这是由于直径越小的GFRP筋相对表面积越大,在高温作用下的劣化程度越高。

图14(b)为GFRP筋直径对高温后粘结刚度的影响。可见,随着GFRP筋直径的增大,高温后GFRP筋与珊瑚混凝土的剩余粘结刚度呈增大的趋势。同时,GFRP筋直径变化对粘结刚度的影响相比对粘结强度的影响更为显著。

图14(c)为GFRP筋直径对高温后峰值滑移量的影响。可见,在不同高温后,试件的相对峰值滑移量随着GFRP筋直径的增大呈现出不同的变化趋势。当所经历温度为200℃,相对峰值滑移量随着直径的增大而减小;而当所经历温度为350℃,相对峰值滑移量随着直径的增大先增大后减小。这是由于12 mm GFRP筋的肋距最大,当温度较高时峰值滑移量受到高温的影响最为显著。

4. GFRP筋与珊瑚混凝土剩余粘结强度计算

高温后GFRP筋与珊瑚混凝土的粘结强度随着所经历温度的不同,较常温有不同程度的降低。本文考虑温度、筋材直径、粘结长度和混凝土强度的影响,引入折减系数,提出高温后GFRP筋与珊瑚混凝土剩余粘结强度的计算式,如下所示:

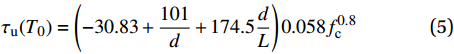

{\tau _{\text{u}}}(T) = k(T) {\tau _{\text{u}}}({T_0}) (4) {\tau _{\text{u}}}({T_0}) = \left( - 30.83 + \frac{{101}}{d} + 174.5\frac{d}{L}\right) 0.058f_{\text{c}}^{0.8} (5) k(T) =- 1.76 \times {10^{ - 6}} {(T - {T_0})^2}- 9.31 {10^{ - 4}} (T - {T_0}) + 1 (6) 式中:τu(T)为不同高温后GFRP筋与珊瑚混凝土的粘结强度;τu(T0)为室温下GFRP筋与珊瑚混凝土的粘结强度;k(T)为不同高温后GFRP筋与珊瑚混凝土粘结强度的折减系数;fc为珊瑚混凝土的轴心抗压强度;d为GFRP筋名义直径;L为GFRP筋埋入长度;T0为环境温度,取20℃。

表5给出了粘结强度计算值与试验实测值的对比结果。可见,计算值

\tau _{\text{u}}^{\text{c}}(T) 与试验值\tau _{\text{u}}^{\text{e}}(T) 之比的平均值μ=0.99,标准差D=0.10,计算值与试验值吻合较好。表 5 GFRP筋珊瑚混凝土试件剩余粘结强度计算值与试验值Table 5. Calculated values and test values of residual bond strength of GFRP bars-coral concrete specimensSpecimen number T/℃ d/mm L/mm fc/MPa \tau _{\text{u}}^{\text{c}}(T)/{\text{MPa}} \tau _{\text{u}}^{\text{e}}(T)/{\text{MPa}} \tau _{\text{u}}^{\text{c}}(T)/\tau _{\text{u}}^{\text{e}}(T) GFRP8/CC30-20 20 8 50 25.44 7.57 7.57 1.00 GFRP8/CC30-200 200 8 50 25.44 5.87 5.93 0.99 GFRP8/CC30-350 350 8 50 25.44 3.79 3.61 1.05 GFRP12/CC20-20 20 12 60 21.83 8.59 7.22 1.19 GFRP12/CC20-200 200 12 60 21.83 6.66 5.84 1.14 GFRP12/CC20-350 350 12 60 21.83 4.30 3.73 1.15 GFRP12/CC30-20 20 12 60 25.44 9.71 10.92 0.89 GFRP12/CC30-150 150 12 60 25.44 8.25 8.95 0.92 GFRP12/CC30-200 200 12 60 25.44 7.53 8.72 0.86 GFRP12/CC30-250 250 12 60 25.44 6.73 6.21 1.08 GFRP12/CC30-300 300 12 60 25.44 5.84 5.85 1.00 GFRP12/CC30-350 350 12 60 25.44 4.87 5.01 0.97 GFRP16/CC30-20 20 16 80 25.44 8.07 8.07 1.00 GFRP16/CC30-200 200 16 80 25.44 6.26 7.11 0.88 GFRP16/CC30-350 350 16 80 25.44 4.04 4.33 0.93 Notes: T—Temperature; d—Nominal diameter of GFRP bars; L—Embedded length of GFRP bars; fc—Axial compressive strength of concrete; \tau _{\text{u}}^{\text{c}} (T)—Calculated value of bond strength between GFRP bars and coral concrete at different high temperatures; \tau _{\text{u}}^{\text{e}} (T)—Test value of bond strength between GFRP bars and coral concrete at different high temperatures. 5. GFRP筋与珊瑚混凝土粘结-滑移本构模型

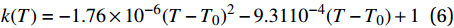

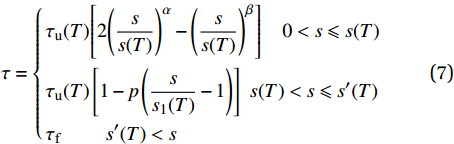

对于GFRP筋与混凝土的粘结-滑移本构模型,目前应用较为广泛的有CMR模型[31]、BPE模型[32]、mBPE模型[31]及Huang等[33]、Malvar[34]、张海霞[35]和高丹盈等[36]基于试验提出的本构模型。然而,上述模型均为常温下GFRP筋与普通混凝土的粘结-滑移本构模型,不适用于高温后的GFRP筋与珊瑚混凝土。因此,本文提出高温后GFRP筋与珊瑚混凝土粘结-滑移本构模型:

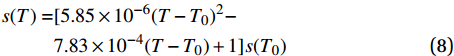

\tau = \left\{ \begin{gathered} {\tau _{\text{u}}}(T){\left[ {2 {{\left( {\frac{s}{{s(T)}}} \right)}^\alpha } - {{\left( {\frac{s}{{s(T)}}} \right)}^\beta }} \right]_{\mathop {}\limits^{} }}\quad 0 < s \leqslant s(T) \\ {\tau _{\text{u}}}(T)\left[ {1 - p\left( {\frac{s}{{{s_1}(T)}} - 1} \right)} \right]\mathop {}\limits^{} \mathop {}\limits^{} \mathop {}\limits^{} {\mathop {}\limits^{} _{\mathop {}\limits^{} }}s(T) < s \leqslant s'(T) \\ {\tau _{\text{f}}}\mathop {}\limits^{} \mathop {}\limits^{} \mathop {}\limits^{} \mathop {}\limits^{} \mathop {}\limits^{} \mathop {}\limits^{} \mathop {}\limits^{} \mathop {}\limits^{} \mathop {}\limits^{} \mathop {}\limits^{} \mathop {}\limits^{} \mathop {}\limits^{} \mathop {}\limits^{} \mathop {}\limits^{} \mathop {}\limits^{} \mathop {}\limits^{} \mathop {}\limits^{} \mathop {}\limits^{} \mathop {\mathop {}\limits^{} }\limits^{} s'(T) < s \\ \end{gathered} \right. (7) \begin{split} s(T) = &[5.85 \times {10^{ - 6}} {(T - {T_0})^2}- \\& 7.83 \times {10^{ - 4}} (T - {T_0}) + 1] s({T_0}) \end{split} (8) 式中:τ为GFRP筋与珊瑚混凝土平均粘结应力;τf为残余应力;s为GFRP筋与珊瑚混凝土的滑移量;s(T)为不同高温后GFRP筋与珊瑚混凝土峰值滑移量;s′(T)为残余段开始时的滑移量;s(T0)为常温下GFRP筋与珊瑚混凝土的峰值滑移量;α和β为模型参数,需满足β≤2α;p为下降段软化系数。

根据式(7)~(8)对不同高温后试件的粘结-滑移曲线进行回归分析,结果如图15所示。参数α、β、p、峰值滑移量计算值s(T)计算结果,以及回归分析相关系数R2见表6。其中,峰值滑移量计算值sc(T)与试验值se(T)之比的平均值μ=1.01,标准差D=0.07,相关系数R2为0.90~0.99。结果表明,计算曲线与试验曲线吻合较好。

表 6 GFRP筋珊瑚混凝土试件粘结-滑移曲线计算结果Table 6. Calculation results of bond stress-slippage curves of GFRP bars-coral concrete specimensSpecimen number sc(T)/mm se(T)/mm sc(T)/se(T) α β p R2 GFRP8/CC30-20 1.73 1.73 1.00 0.72 1.10 0.25 0.99 GFRP8/CC30-200 1.81 1.99 0.91 0.92 1.72 0.39 0.98 GFRP8/CC30-350 2.38 2.33 1.02 1.00 1.30 0.53 0.96 GFRP12/CC20-20 0.99 0.99 1.00 1.26 1.87 4.01 0.99 GFRP12/CC20-200 1.04 1.06 0.98 0.20 0.05 0.21 0.97 GFRP12/CC20-350 1.36 1.27 1.07 0.94 1.83 0.40 0.97 GFRP12/CC30-20 0.44 0.37 1.19 1.14 2.28 4.99 0.99 GFRP12/CC30-150 0.44 0.41 1.07 0.74 1.47 0.09 0.95 GFRP12/CC30-200 0.46 0.40 1.15 0.75 1.50 1.38 0.86 GFRP12/CC30-250 0.50 0.54 0.93 0.92 1.81 0.16 0.98 GFRP12/CC30-300 0.55 0.61 0.90 1.16 1.65 0.86 0.95 GFRP12/CC30-350 0.61 0.61 1.00 0.97 1.44 0.21 0.90 GFRP16/CC30-20 0.65 0.65 1.00 1.02 1.02 2.10 0.91 GFRP16/CC30-200 0.69 0.66 1.05 1.20 1.58 11.71 0.96 GFRP16/CC30-350 0.90 0.89 1.01 0.99 1.98 0.15 0.93 Notes: sc(T)—Calculated value of peak slippage; se(T)—Test value of peak slippage; α, β—Design conditions; p—Softening coefficient of descending stage; R2—Correlation coefficient. 6. 结 论

(1) 高温后,玻璃纤维增强树脂复合材料(GFRP)筋随着温度的提高,树脂逐渐碳化分解,颜色逐渐加深变黑;珊瑚混凝土随着温度的提高颜色逐渐变浅,并出现温度裂纹及轻微剥落。

(2) 高温后GFRP筋与珊瑚混凝土的粘结破坏形态主要受筋材直径和肋深的影响,当直径较小、肋深较浅时为拔出破坏,当直径较大、肋深较深时为劈裂破坏,温度对其破坏模式无显著影响。

(3) 界面处珊瑚混凝土基体中的SiO2、CaCO3、钙矾石及珊瑚骨料中的CaCO3在高温作用下发生分解,造成珊瑚混凝土的质量损失和结构破坏,是高温后GFRP筋与珊瑚混凝土界面发生劣化的原因之一。

(4) 随着温度的提高,高温对界面处珊瑚混凝土和GFRP筋的劣化作用增大,高温后GFRP筋与珊瑚混凝土的粘结强度逐渐减小,峰值滑移量逐渐增大;劈裂破坏试件的粘结刚度随着温度的提高先增大后减小,拔出破坏试件的粘结刚度则逐渐减小。

(5) 强度等级不大于C30时,珊瑚混凝土强度的变化对高温后GFRP筋与珊瑚混凝土剩余粘结强度的影响较小。

(6) 随着GFRP筋直径的增大,高温后其与珊瑚混凝土的剩余粘结强度和剩余粘结刚度逐渐提高,与常温下的趋势一致;而峰值滑移量同时受到肋距的影响,先增大后减小。

(7) 提出高温后GFRP筋与珊瑚混凝土的剩余粘结强度计算式及考虑剩余粘结强度的粘结-滑移本构方程,试验结果与计算结果能较好的吻合。

-

表 1 筋材几何参数及力学性能

Table 1 Geometrical parameter and mechanical properties of bars

Type of reinforcement Diameter/mm Rib spacing /mm Rib depth/mm Tensile strength f/MPa Elasticity modulus E/GPa GFRP bar 8 8.61 0.49 855.46 43.69 12 10.59 1.05 853.59 41.32 16 9.84 1.40 730.85 33.73 Steel rebar 12 8.00 1.20 629.08 219.84 表 2 海水珊瑚混凝土配合比及抗压强度

Table 2 Mixture ratio and compressive strength of seawater coral aggregate concrete

Strength class Composition/(kg·m−3) Slump/

mmfc/

MPaBasic sea water Additional sea water Total sea water Cement Silica fume Sea sand Coral Plasticizer C20 190 89 279 350 30 820 710 0.007 142 21.83 C30 190 91 281 400 70 810 720 0.012 190 25.44 Notes: fc—Axial compressive strength of concrete. 表 3 试件设计参数

Table 3 Design parameters of specimens

Specimen number Strength class Reinforcement Bar diameter/mm Temperature/℃ GFRP8/CC30-20 C30 GFRP bar 8 20 GFRP8/CC30-200 C30 GFRP bar 8 200 GFRP8/CC30-350 C30 GFRP bar 8 350 GFRP12/CC30-20 C30 GFRP bar 12 20 GFRP12/CC30-150 C30 GFRP bar 12 150 GFRP12/CC30-200 C30 GFRP bar 12 200 GFRP12/CC30-250 C30 GFRP bar 12 250 GFRP12/CC30-300 C30 GFRP bar 12 300 GFRP12/CC30-350 C30 GFRP bar 12 350 GFRP16/CC30-20 C30 GFRP bar 16 20 GFRP16/CC30-200 C30 GFRP bar 16 200 GFRP16/CC30-350 C30 GFRP bar 16 350 GFRP12/CC20-20 C20 GFRP bar 12 20 GFRP12/CC20-200 C20 GFRP bar 12 200 GFRP12/CC20-350 C20 GFRP bar 12 350 SR12/CC30-20 C30 Rebar 12 20 SR12/CC30-200 C30 Rebar 12 200 SR12/CC30-350 C30 Rebar 12 350 Note: In GFRP8/CC30-20, GFRP8 means the GFRP bars with diameter of 8 mm, CC30 means coral concrete strength grade, 20 means test temperature. 表 4 高温后GFRP筋珊瑚混凝土粘结性能

Table 4 Bond properties of GFRP bar and coral aggregate concrete after high temperatures

Specimen number τu/MPa s1/mm κ/(MPa·mm−1) Failure mode GFRP8/CC30-20 7.57 1.73 7.79 P GFRP8/CC30-200 5.93 1.99 4.10 P GFRP8/CC30-350 3.61 2.33 2.45 P GFRP12/CC20-20 7.22 0.99 9.05 S GFRP12/CC20-200 5.84 1.06 10.92 S GFRP12/CC20-350 3.73 1.27 5.63 S GFRP12/CC30-20 10.92 0.37 30.29 S GFRP12/CC30-150 8.95 0.40 35.10 S GFRP12/CC30-200 8.72 0.40 31.02 S GFRP12/CC30-250 6.21 0.54 25.35 S GFRP12/CC30-300 5.85 0.61 14.78 S GFRP12/CC30-350 5.01 0.61 11.37 S GFRP16/CC30-20 8.07 0.65 11.92 S GFRP16/CC30-200 7.11 0.66 12.25 S GFRP16/CC30-350 4.33 0.89 6.07 S SR12/CC30-20 13.18 0.60 55.20 S SR12/CC30-200 13.99 0.91 71.20 S SR12/CC30-350 9.15 1.80 19.32 S Notes: τu—Bonding strength; s1—Peak slippage; κ—Bond stiffness; P—Pull-out of bar; S—Splitting of concrete. 表 5 GFRP筋珊瑚混凝土试件剩余粘结强度计算值与试验值

Table 5 Calculated values and test values of residual bond strength of GFRP bars-coral concrete specimens

Specimen number T/℃ d/mm L/mm fc/MPa \tau _{\text{u}}^{\text{c}}(T)/{\text{MPa}} \tau _{\text{u}}^{\text{e}}(T)/{\text{MPa}} \tau _{\text{u}}^{\text{c}}(T)/\tau _{\text{u}}^{\text{e}}(T) GFRP8/CC30-20 20 8 50 25.44 7.57 7.57 1.00 GFRP8/CC30-200 200 8 50 25.44 5.87 5.93 0.99 GFRP8/CC30-350 350 8 50 25.44 3.79 3.61 1.05 GFRP12/CC20-20 20 12 60 21.83 8.59 7.22 1.19 GFRP12/CC20-200 200 12 60 21.83 6.66 5.84 1.14 GFRP12/CC20-350 350 12 60 21.83 4.30 3.73 1.15 GFRP12/CC30-20 20 12 60 25.44 9.71 10.92 0.89 GFRP12/CC30-150 150 12 60 25.44 8.25 8.95 0.92 GFRP12/CC30-200 200 12 60 25.44 7.53 8.72 0.86 GFRP12/CC30-250 250 12 60 25.44 6.73 6.21 1.08 GFRP12/CC30-300 300 12 60 25.44 5.84 5.85 1.00 GFRP12/CC30-350 350 12 60 25.44 4.87 5.01 0.97 GFRP16/CC30-20 20 16 80 25.44 8.07 8.07 1.00 GFRP16/CC30-200 200 16 80 25.44 6.26 7.11 0.88 GFRP16/CC30-350 350 16 80 25.44 4.04 4.33 0.93 Notes: T—Temperature; d—Nominal diameter of GFRP bars; L—Embedded length of GFRP bars; fc—Axial compressive strength of concrete; \tau _{\text{u}}^{\text{c}} (T)—Calculated value of bond strength between GFRP bars and coral concrete at different high temperatures; \tau _{\text{u}}^{\text{e}} (T)—Test value of bond strength between GFRP bars and coral concrete at different high temperatures. 表 6 GFRP筋珊瑚混凝土试件粘结-滑移曲线计算结果

Table 6 Calculation results of bond stress-slippage curves of GFRP bars-coral concrete specimens

Specimen number sc(T)/mm se(T)/mm sc(T)/se(T) α β p R2 GFRP8/CC30-20 1.73 1.73 1.00 0.72 1.10 0.25 0.99 GFRP8/CC30-200 1.81 1.99 0.91 0.92 1.72 0.39 0.98 GFRP8/CC30-350 2.38 2.33 1.02 1.00 1.30 0.53 0.96 GFRP12/CC20-20 0.99 0.99 1.00 1.26 1.87 4.01 0.99 GFRP12/CC20-200 1.04 1.06 0.98 0.20 0.05 0.21 0.97 GFRP12/CC20-350 1.36 1.27 1.07 0.94 1.83 0.40 0.97 GFRP12/CC30-20 0.44 0.37 1.19 1.14 2.28 4.99 0.99 GFRP12/CC30-150 0.44 0.41 1.07 0.74 1.47 0.09 0.95 GFRP12/CC30-200 0.46 0.40 1.15 0.75 1.50 1.38 0.86 GFRP12/CC30-250 0.50 0.54 0.93 0.92 1.81 0.16 0.98 GFRP12/CC30-300 0.55 0.61 0.90 1.16 1.65 0.86 0.95 GFRP12/CC30-350 0.61 0.61 1.00 0.97 1.44 0.21 0.90 GFRP16/CC30-20 0.65 0.65 1.00 1.02 1.02 2.10 0.91 GFRP16/CC30-200 0.69 0.66 1.05 1.20 1.58 11.71 0.96 GFRP16/CC30-350 0.90 0.89 1.01 0.99 1.98 0.15 0.93 Notes: sc(T)—Calculated value of peak slippage; se(T)—Test value of peak slippage; α, β—Design conditions; p—Softening coefficient of descending stage; R2—Correlation coefficient. -

[1] 周济, 陈宗平, 陈宇良, 等. 潮汐区GFRP筋珊瑚海洋混凝土柱轴压性能试验及承载力计算[J]. 复合材料学报, 2022, 39(1): 344-360. ZHOU Ji, CHEN Zongping, CHEN Yuliang, et al. Test on axial compression performance and bearing capacity calculation of GFRP bars reinforced coral aggregate marine concrete columns exposed to tidal area[J]. Acta Materiae Compositae Sinica, 2022, 39(1): 344-360(in Chinese).

[2] 刘霞, 李峰, 佘殷鹏. 玄武岩纤维增强聚合物筋增强珊瑚礁砂混凝土柱轴压试验[J]. 复合材料学报, 2020, 37(10):2428-2438. DOI: 10.13801/j.cnki.fhclxb.20200219.003 LIU Xia, LI Feng, SHE Yinpeng. Axial compression test of basalt fiber reinforced polymer reinforced coral reef and sand aggregate concrete column[J]. Acta Materiae Compositae Sinica,2020,37(10):2428-2438(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20200219.003

[3] DONG Z, WU G, ZHU H, et al. Flexural behavior of seawater sea-sand coral concrete–UHPC composite beams reinforced with BFRP bars[J]. Construction and Building Materials,2020,265:120279. DOI: 10.1016/j.conbuildmat.2020.120279

[4] WANG X, ZHANG X, DING L, et al. Punching shear behavior of two-way coral-reef-sand concrete slab reinforced with BFRP composites[J]. Construction and Building Materials,2020,231:117113.

[5] YANG S, YANG C, HUANG M, et al. Study on bond performance between FRP bars and seawater coral aggregate concrete[J]. Construction and Building Materials,2018,173:272-288. DOI: 10.1016/j.conbuildmat.2018.04.015

[6] WANG L, MAO Y, LV H, et al. Bond properties between FRP bars and coral concrete under seawater conditions at 30, 60, and 80°C[J]. Construction and Building Materials,2018,162:442-449.

[7] 王磊, 毛亚东, 陈爽, 等. GFRP筋与珊瑚混凝土黏结性能的试验研究[J]. 建筑材料学报, 2018, 21(2):286-292. DOI: 10.3969/j.issn.1007-9629.2018.02.018 WANG Lei, MAO Yadong, CHEN Shuang, et al. Experimental research on bond performance between GFRP bars and the coral concrete[J]. Journal of Building Materials,2018,21(2):286-292(in Chinese). DOI: 10.3969/j.issn.1007-9629.2018.02.018

[8] 杨超, 杨树桐, 戚德海. BFRP筋与珊瑚混凝土粘结性能试验研究[J]. 工程力学, 2018, 35(S1):172-180. DOI: 10.6052/j.issn.1000-4750.2017.06.S034 YANG Chao, YANG Shutong, QI Dehai. Experimental study on the bond performance between BFRP bars and coral concrete[J]. Engineering Mechanics,2018,35(S1):172-180(in Chinese). DOI: 10.6052/j.issn.1000-4750.2017.06.S034

[9] 高傲, 杨树桐, 高广希, 等. 海洋环境下BFRP筋与珊瑚混凝土粘结性能的试验研究[J]. 复合材料科学与工程, 2020(12):43-53. DOI: 10.3969/j.issn.1003-0999.2020.12.008 GAO Ao, YANG Shutong, GAO Guangxi, et al. Experimental study on the bond performance between BFRP bars and caral concrete in marine environment[J]. Composites Science and Engineering,2020(12):43-53(in Chinese). DOI: 10.3969/j.issn.1003-0999.2020.12.008

[10] DAI J, YIN S, HU C. Analysis of key influencing factors of the bond performance between BFRP bars and coral reef and sand concrete[J]. Construction and Building Materials,2021,269:121248. DOI: 10.1016/j.conbuildmat.2020.121248

[11] 陈爽, 吕海波, 王磊. 纤维增强塑料筋与珊瑚混凝土粘结滑移本构模型[J]. 桂林理工大学学报, 2019, 39(1):107-113. CHEN Shuang, LV Haibo, WANG Lei. Constitutive model of bond-slip relation between FRP bar and coral concrete[J]. Journal of Guilin University of Technology,2019,39(1):107-113(in Chinese).

[12] ZHOU C, PAN J, ZHANG Z, et al. Comparative study on the tensile mechanical behavior of GFRP bars under and after high temperature exposure[J]. Case Studies in Construction Materials,2022,16:e00905. DOI: 10.1016/j.cscm.2022.e00905

[13] KATZ A, BERMAN N. Modeling the effect of high temperature on the bond of FRP reinforcing bars to concrete[J]. Cement and Concrete Composites,2000,22(6):433-443. DOI: 10.1016/S0958-9465(00)00043-3

[14] GALATI N, NANNI A, DHARANI L R, et al. Thermal effects on bond between FRP rebars and concrete[J]. Composites Part A: Applied Science and Manufacturing,2005,37(8):1223-1230.

[15] 吕西林, 周长东, 金叶. 火灾高温下GFRP筋和混凝土粘结性能试验研究[J]. 建筑结构学报, 2007, 28(5):32-39, 88. DOI: 10.3321/j.issn:1000-6869.2007.05.004 LV Xilin, ZHOU Changdong, JIN Ye. Test study on bond behavior between GFRP bar and concrete in high temperature[J]. Journal of Building Structures,2007,28(5):32-39, 88(in Chinese). DOI: 10.3321/j.issn:1000-6869.2007.05.004

[16] 王晓璐, 査晓雄, 张旭琛. 高温下FRP筋与混凝土的粘结性能[J]. 哈尔滨工业大学学报, 2013, 45(6):8-15. DOI: 10.11918/j.issn.0367-6234.2013.06.002 WANG Xiaolu, ZHA Xiaoxiong, ZHANG Xuchen. Bond behavior of FRP rebar and concrete at elevated temperature[J]. Journal of Harbin Institute of Technology,2013,45(6):8-15(in Chinese). DOI: 10.11918/j.issn.0367-6234.2013.06.002

[17] ASTM International. Standard practice for the preparation of substitute ocean water: ASTM D1141—1998[S]. West Conshohocken: ASTM International, 1998.

[18] 中华人民共和国国家质量监督检验检疫总局. 纤维增强复合材料筋基本力学性能试验方法: GB/T 30022—2013[S]. 北京: 中国标准出版社, 2013. General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Test method for basic mechanical properties of fiber reinforced polymer bar: GB/T 30022—2013[S]. Beijing: Standards Press of China, 2013(in Chinese).

[19] LU L, YUAN G, SHU Q, et al. Bond behaviour between early age concrete and steel bar subjected to cyclic loading after fire[J]. Fire Safety Journal,2019,105:129-143. DOI: 10.1016/j.firesaf.2019.02.012

[20] LI Q, HUANG X, HUANG Z, et al. Bond characteristics between early aged fly ash concrete and reinforcing steel bar after fire[J]. Construction and Building Materials,2017,147:701-712. DOI: 10.1016/j.conbuildmat.2017.04.184

[21] XIONG Z, ZENG Y, LI L G, et al. Experimental study on the effects of glass fibres and expansive agent on the bond behaviour of glass/basalt FRP bars in seawater sea-sand concrete[J]. Construction and Building Materials,2021,274:122100. DOI: 10.1016/j.conbuildmat.2020.122100

[22] 牛建刚, 边钰, 谢承斌. 再生混凝土与锈蚀钢筋界面粘结性能[J]. 科学技术与工程, 2020, 20(19):7845-7851. NIU Jiangang, BIAN Yu, XIE Chengbin. Interfacial bond properties between recycled concrete and corroded steel bar[J]. Science Technology and Engineering,2020,20(19):7845-7851(in Chinese).

[23] IRSHIDAT M R. Bond strength evaluation between steel rebars and carbon nanotubes modified concrete[J]. Case Studies in Construction Materials,2021,14:e00477. DOI: 10.1016/j.cscm.2020.e00477

[24] ASHRAFI H, BAZLI M, NAJAFABADI E P, et al. The effect of mechanical and thermal properties of FRP bars on their tensile performance under elevated temperatures[J]. Construction and Building Materials,2017,157:1001-1010. DOI: 10.1016/j.conbuildmat.2017.09.160

[25] SPAGNUOLO S, MEDA A, RINALDI Z, et al. Residual behaviour of glass FRP bars subjected to high temperatures[J]. Composite Structures,2018,203:886-893. DOI: 10.1016/j.compstruct.2018.07.077

[26] 李趁趁, 王英来, 赵军, 等. 高温后FRP筋纵向拉伸性能[J]. 建筑材料学报, 2014, 17(6):1076-1081. DOI: 10.3969/j.issn.1007-9629.2014.06.024 LI Chenchen, WANG Yinglai, ZHAO Jun, et al. Longitudinal tensile properties of FRP bars after high temperature[J]. Journal of Building Materials,2014,17(6):1076-1081(in Chinese). DOI: 10.3969/j.issn.1007-9629.2014.06.024

[27] YAO Y, HAO L. Mechanical properties and failure mechanism of carbon nanotube concrete at high temperatures[J]. Construction and Building Materials,2021,297:123782. DOI: 10.1016/j.conbuildmat.2021.123782

[28] 朋改非, 王金羽, CHAN Y N S, 等. 火灾高温下硬化水泥浆的化学分解特征[J]. 南京信息工程大学学报(自然科学版), 2009, 1(1):76-81. DOI: 10.13878/j.cnki.jnuist.2009.01.012 PENG Gaifei, WANG Jinyu, CHAN Y N S, et al. Chemical decomposition characteristics of hardened cement paste subjected to high temperature of fire[J]. Journal of Nanjing University of Information Science and Technology: Natural Science Edition,2009,1(1):76-81(in Chinese). DOI: 10.13878/j.cnki.jnuist.2009.01.012

[29] 王英来. 高温后FRP筋拉伸性能及其与混凝土粘结性能试验研究[D]. 郑州: 郑州大学, 2013. WANG Yinglai. Experimental study on tensile property of FRP bars and bond behavior between FRP bars and concrete after high temperature[D]. Zhengzhou: Zhengzhou University, 2013(in Chinese).

[30] 刘华新, 朱伯衡. 高温对玄武岩纤维筋混杂纤维再生混凝土粘结性能的影响[J]. 科学技术与工程, 2022, 22(5):2049-2054. DOI: 10.3969/j.issn.1671-1815.2022.05.041 LIU Huaxin, ZHU Boheng. Effect of high temperature on bond behavior between basalt fiber reinforced polymer bars and hybrid fiber recycled aggregate concrete[J]. Science Technology and Engineering,2022,22(5):2049-2054(in Chinese). DOI: 10.3969/j.issn.1671-1815.2022.05.041

[31] COSENZA E, MANFREDI G, REALFONZO R. Behavior and modeling of bond of FRP rebars to concrete[J]. Journal of Composites for Construction,1997,1(2):40-51. DOI: 10.1061/(ASCE)1090-0268(1997)1:2(40)

[32] ELIGEHAUSEN R, POPOV E P, BERTERO V V. Local bond stress-slip relationships of deformed bars under generalized excitations[C]. Proceedings of the 7th European Conference on Earthquake Engineering. Berkeley, 1982: 69-80.

[33] HUANG L, CHEN J, QU J, et al. Modeling for bond-constitutive relationships of FRP rebars to concrete matrix[J]. Construction and Building Materials,2020,263:120654. DOI: 10.1016/j.conbuildmat.2020.120654

[34] MALVAR L J. Tensile and bond properties of GFRP reinforcing bars[J]. Materials Journal,1995,92(3):276-285.

[35] 张海霞. FRP筋与混凝土粘结滑移性能研究[D]. 沈阳: 东北大学, 2006. ZHANG Haixia. Study on bond-slip behavior between FRP bars and concrete[D]. Shenyang: Northeastern University, 2006(in Chinese).

[36] 高丹盈, 朱海堂, 谢晶晶. 纤维增强塑料筋混凝土粘结滑移本构模型[J]. 工业建筑, 2003, 33(7):41-43, 82. DOI: 10.3321/j.issn:1000-8993.2003.07.011 GAO Danying, ZHU Haitang, XIE Jingjing. The constitutive models for bond slip relation between FRP rebars and concrete[J]. Industrial Construction,2003,33(7):41-43, 82(in Chinese). DOI: 10.3321/j.issn:1000-8993.2003.07.011

-

期刊类型引用(4)

1. 胡强,李佳成,陈宇良,陈宗平. 高温后珊瑚海水海砂混凝土力学性能试验研究. 防灾减灾工程学报. 2024(03): 544-550+567 .  百度学术

百度学术

2. 谢剑,王雪寒,刘洋. 极地低温下CFRP筋与混凝土黏结性能数值分析. 哈尔滨工业大学学报. 2024(10): 1-13 .  百度学术

百度学术

3. 叶小宝. 玄武岩机制砂混凝土高温加热后性能变化及强度换算关系分析. 江西建材. 2024(12): 54-56+59 .  百度学术

百度学术

4. 陈宇良,刘志华,叶培欢,陈宗平. 高温后珊瑚海水海砂混凝土直剪力学性能及损伤演化. 复合材料学报. 2023(07): 4128-4138 .  本站查看

本站查看

其他类型引用(2)

-

下载:

下载: