Simulation and optimization of infusion process for perforated foam sandwich composite

-

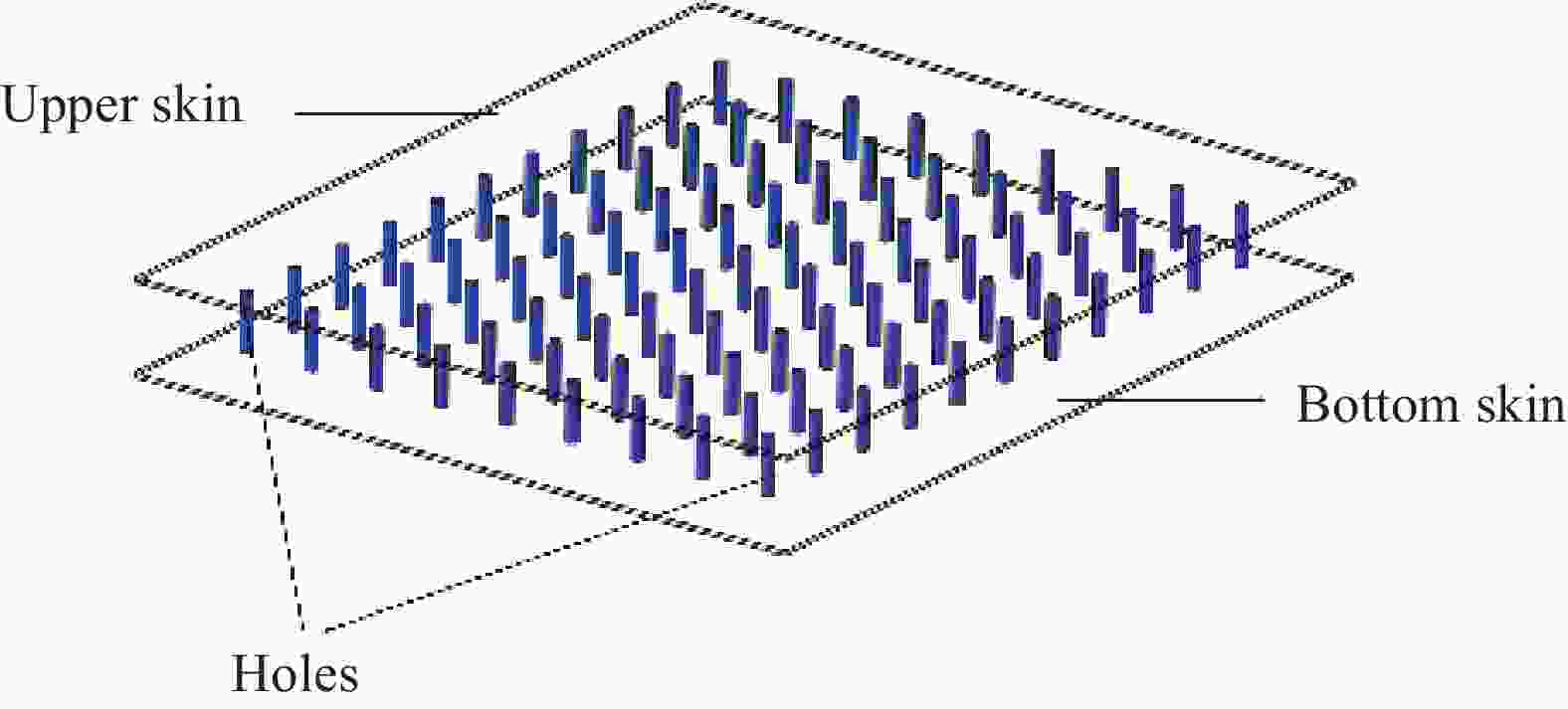

摘要: 以穿孔泡沫夹芯复合材料为研究对象,对其真空辅助树脂灌注(VARI)工艺进行了实验研究、仿真分析和方案优选。首先,通过实验测试与数值计算分别得到穿孔夹芯结构织物与芯材孔洞的渗透率;然后,对穿孔夹芯结构灌注过程进行三维仿真模拟,并通过实尺度灌注实验验证了仿真模拟的可靠性;最后,基于验证的仿真模型进行工艺参数优选,拟合得到了灌注时间的预测模型。结果表明:数值仿真与实验值基本吻合,能较准确地模拟穿孔夹芯结构成型时的流动过程和孔隙分布;灌注时间的预测模型可用于指导实际生产;通过优化成型工艺参数可控制树脂的流动行为,达到缩短成型时间和降低构件孔隙率的目的。

-

关键词:

- 穿孔夹芯结构复合材料 /

- 真空辅助树脂传递模塑 /

- 数值仿真 /

- 工艺优选 /

- 孔隙

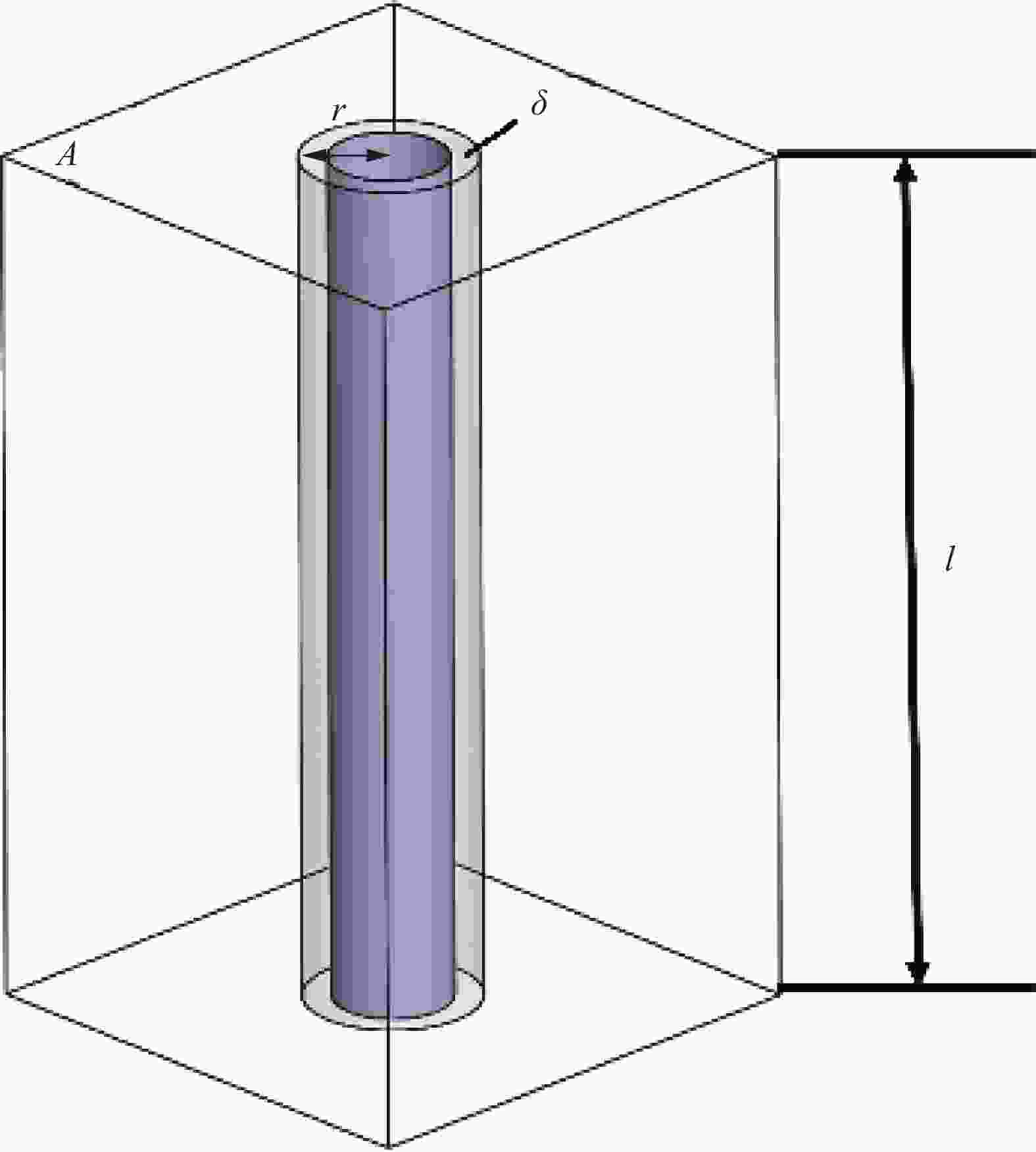

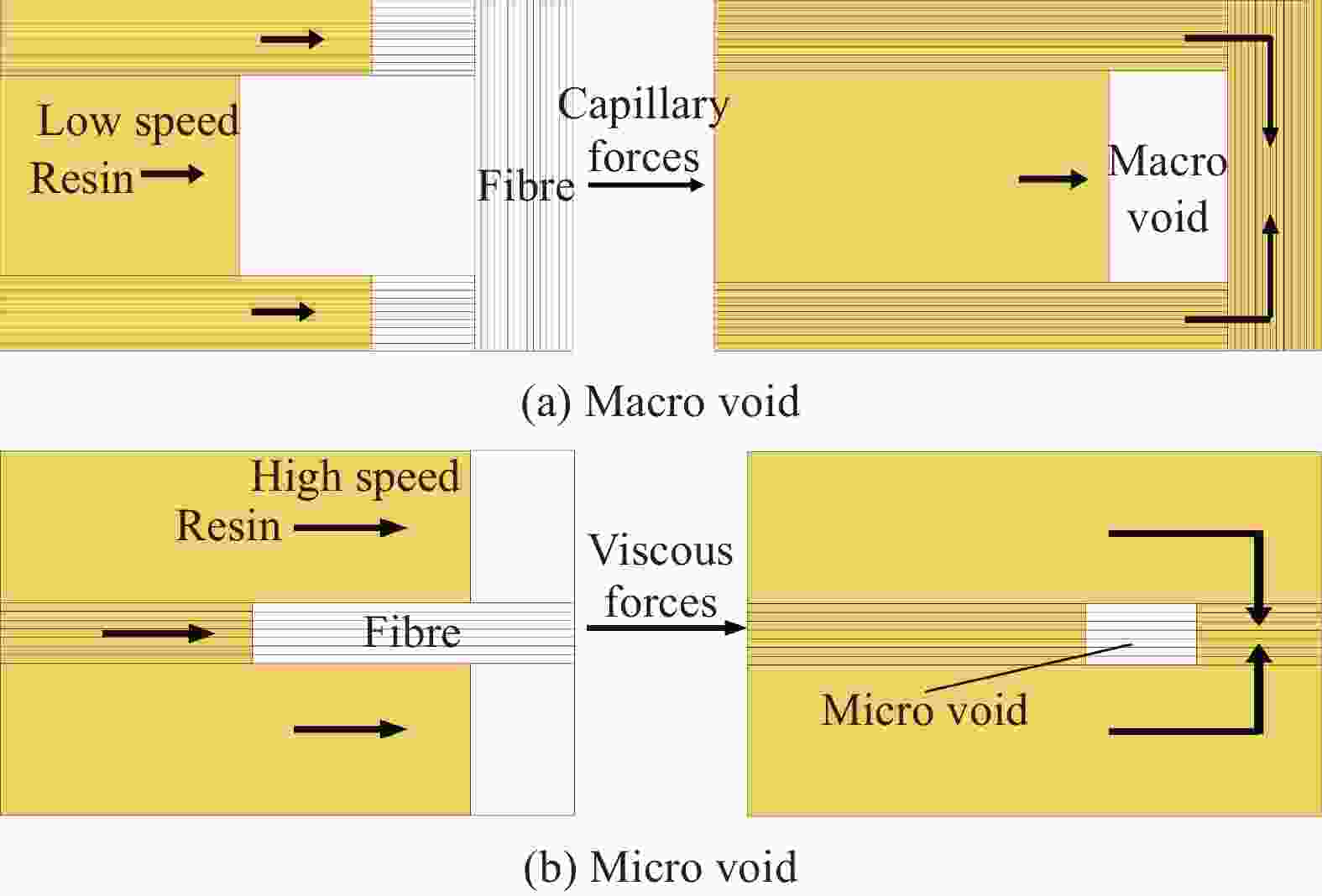

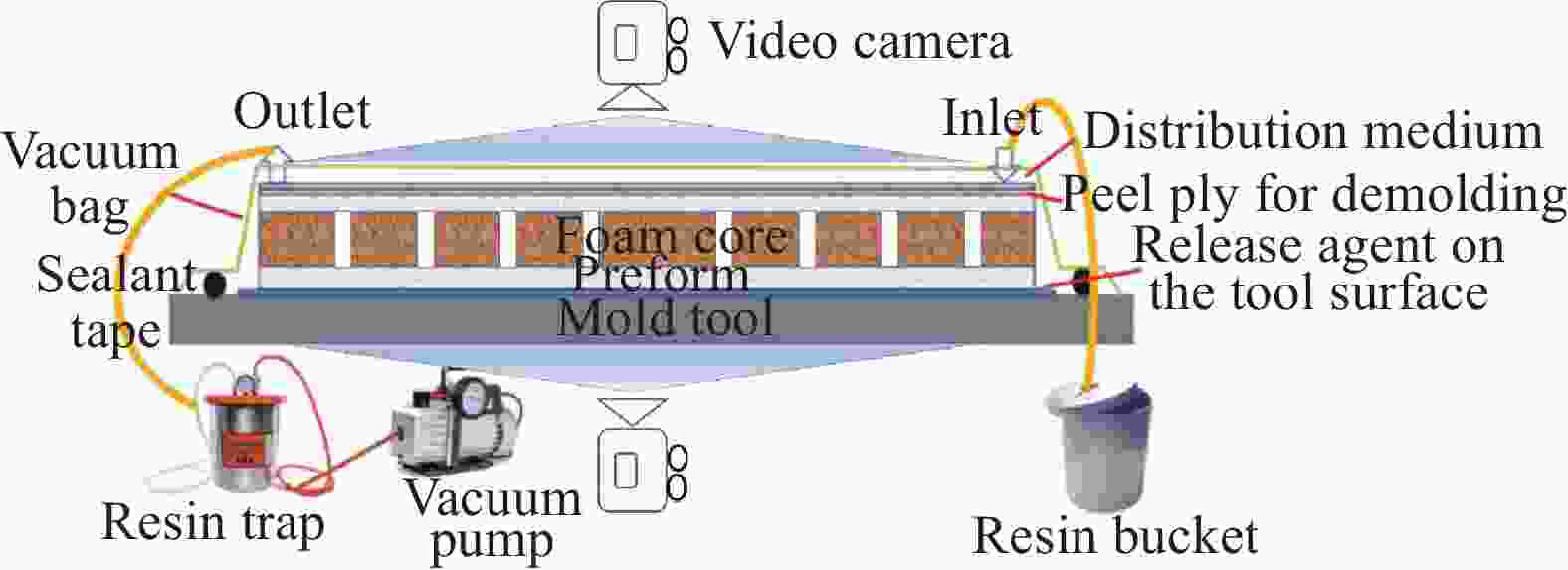

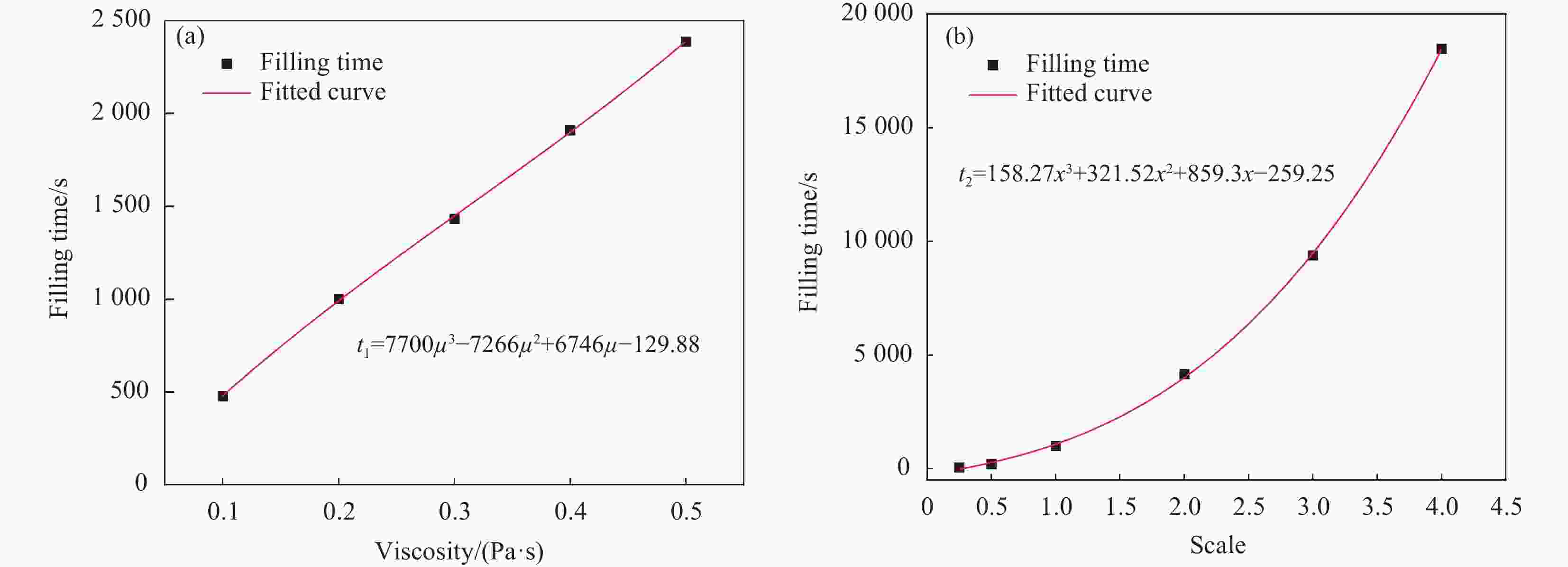

Abstract: The numerical simulation of the vacuum assisted resin infusion (VARI) process of perforated sandwich composite was verified experimentally, and process optimization was presented thereafter. Firstly, the permeabilities of the fabric and holes of perforated core were obtained experimentally and numerically, respectively. Then, 3D simulation was carried out for the infusion process of the perforated sandwich composite structure and verified by real-scale infusion experiments. Finally, based on the simulation, the process was optimized by investigating the effects of injection position and type on the filling time and product porosity, and later a methodology was proposed to predict the filling time needed. The results show that the numerical simulation is in good agreement with the experiment. The flow patterns during the filling and the porosities of the perforated sandwich structures are in good match with experimental results. The filling time prediction method can be used for practical production instruction. The selection of proper parameters, such as injection position and type, can minimize molding time and product porosity. -

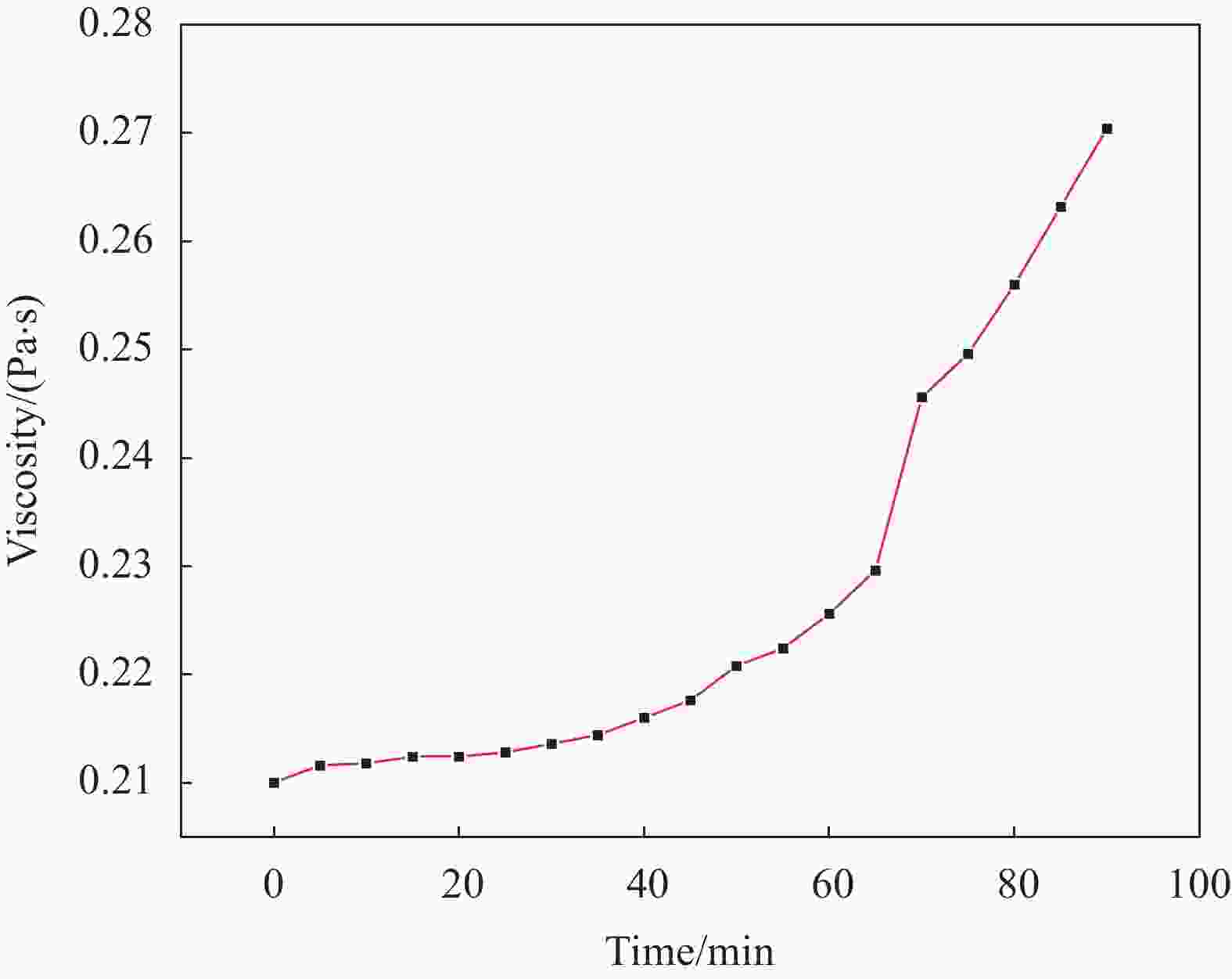

表 1 材料参数测试结果

Table 1. Test results of material parameters

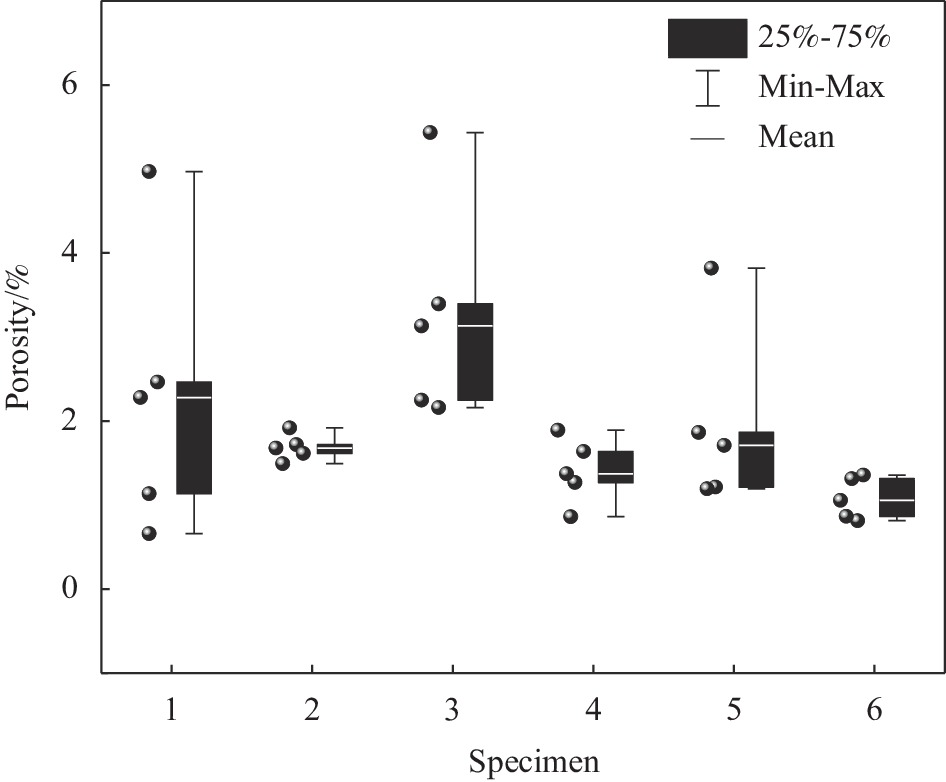

Resin viscosity/(Pa·s) Silicone oil viscosity/(Pa·s) Fiber volume fraction/vol% Permeability/(10–11 m2) Kx Ky Kz 0.21 0.1 49.2 3.26 3.26 0.1987 Notes: Kx, Ky—In-plane permeability; Kz—Permeability in thickness direction. 表 2 穿孔泡沫夹芯复合材料典型位置孔隙率结果对比

Table 2. Porosity measurement results in typical locations of perforated foam sandwich composite

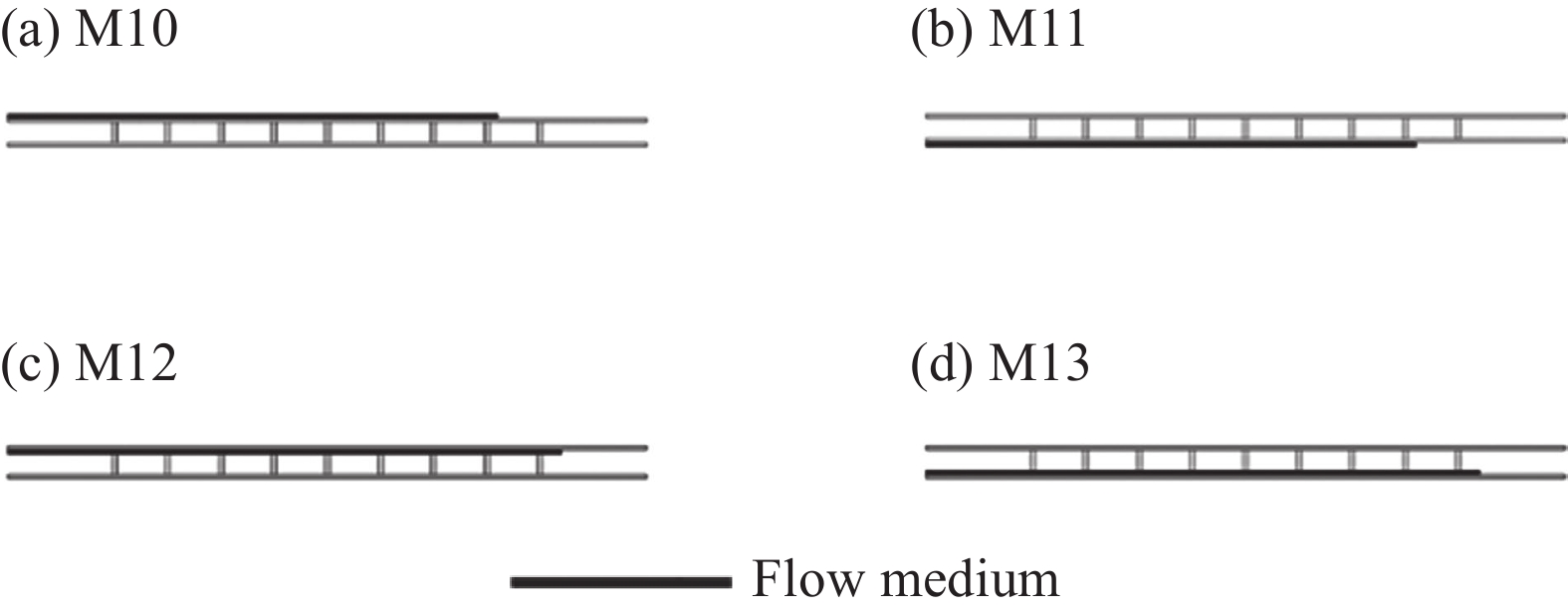

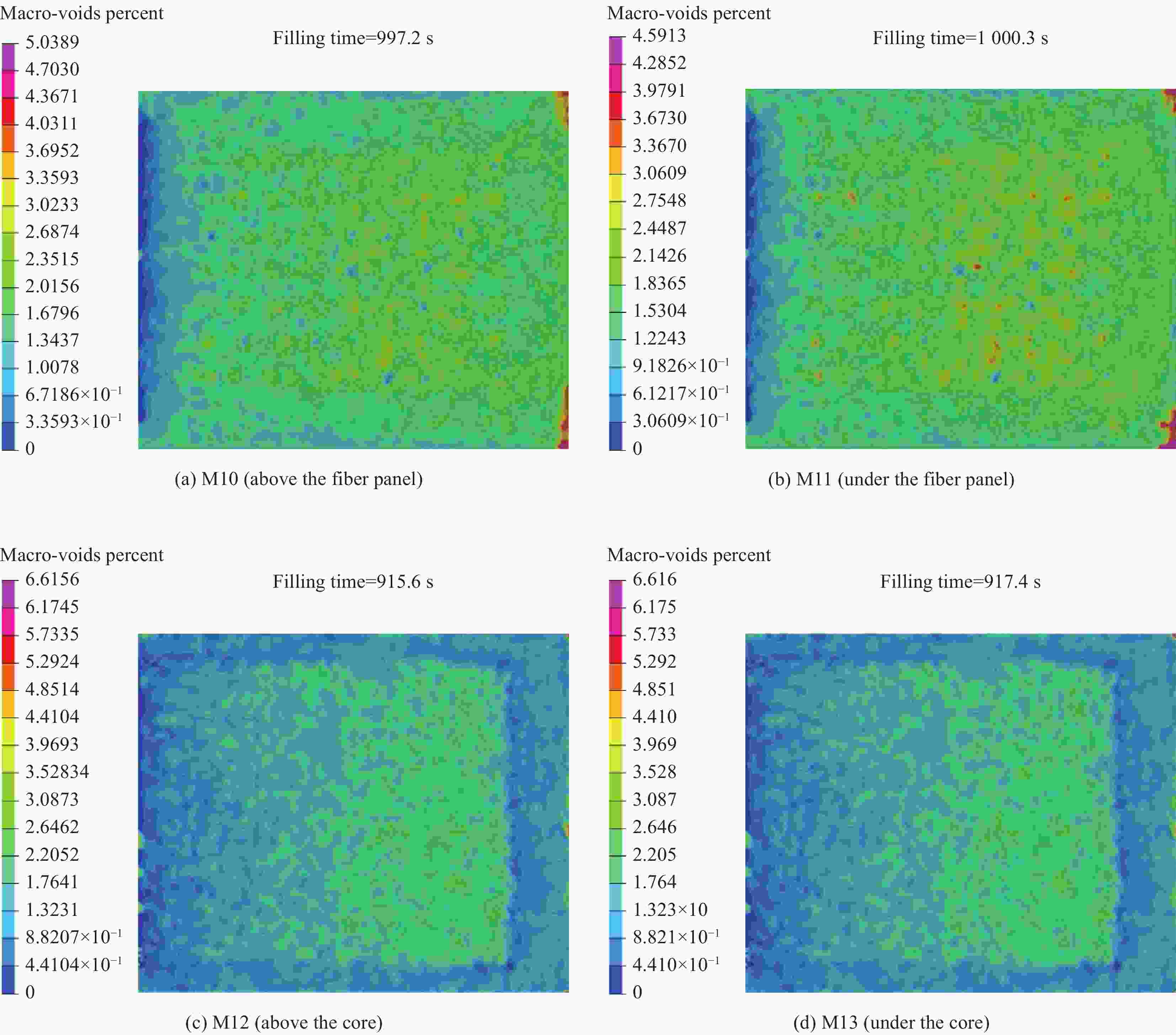

Position 1 2 3 4 5 6 Porosity/% Simulation 2.31 1.63 3.56 1.45 1.66 0.90 Experiment 2.30 1.68 3.27 1.41 1.96 1.08 表 3 穿孔泡沫夹芯复合材料真空辅助树脂灌注(VARI)工艺设计方案

Table 3. Different vacuum assisted resin infusion (VARI) process setups for perforated foam sandwich composite

Distribution medium (DM) location Injection form Short side

Long side

Central section

-

[1] 朱基炜. 穿孔泡沫夹层复合材料力学性能研究及应用[D]. 南京: 南京航空航天大学, 2017.ZHU Jiwei. Study and application of mechanical properties of perforated foam sandwich composites[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2017(in Chinese). [2] MOHAMED M, ANANDAN S, HUO Z, et al. Manufacturing and characterization of polyurethane based sandwich composite structures[J]. Composite Structures,2015,123(5):169-179. [3] YANG B X, OUYANG J, LI X J. Simulation of fiber reinforced composite materials mold filling process and mechanical properties analysis[J]. Fuel and Energy Abstracts,2011,166(7):1129-1136. [4] YALKIN H E, ICTEN B M, ALPYILDIZ T. Enhanced mechanical performance of foam core sandwich composites with through the thickness reinforced core[J]. Composites Part B: Engineering,2015,79(9):383-391. [5] YALKIN H E, ICTEN B M, ALPYILDIZ T. Tensile and compressive performances of foam core sandwich composites with various core modifications[J]. Journal of Sandwich Structures & Materials,2017,19(1):49-65. [6] TAO J, LI F, ZHAO Q L, et al. In-plane compression properties of a novel foam core sandwich structure reinforced by stiffeners[J]. Journal of Reinforced Plastics & Composites,2018,37(2):134-144. [7] STEEVES C A, FLECK N A. In-plane properties of compo-site laminates with through-thickness pin reinforcement[J]. International Journal of Solids and Structures,2006,43(10):3197-3212. doi: 10.1016/j.ijsolstr.2005.05.017 [8] GROSSING H, STADLMAJER N, FAUSTER E, et al. Flow front advancement during composite processing: Predictions from numerical filling simulation tools in compari-son with real-world experiments[J]. Polymer Composites,2016,37(9):2782-2793. doi: 10.1002/pc.23474 [9] SHAH M, CHAUDHARY V. Flow modeling and simulation study of vacuum assisted resin transfer molding (VARTM) process: A review[J]. IOP Conference Series: Materials Science and Engineering,2020,872(1):012087. [10] 马彦旭, 王继辉, 倪爱清, 等. 大厚度复合材料曲面典型构件的工艺优化[J]. 复合材料学报, 2021, 38(10): 3302-3313.MA Yanxu, WANG Jihui, NI Aiqing, et al. Process optimization of typical components with large thickness composite curved surface[J]. Acta Materiae Compositae Sinica, 2021, 38(10): 3302-3313(in Chinese). [11] 金世奇, 李文晓, 刘昊鑫. 缝合夹层结构复合材料树脂传递模塑成型工艺充模仿真[J]. 复合材料学报, 2018, 35(12):3342-3349.JIN Shiqi, LI Wenxiao, LIU Haoxin. Filling simulation of resin transfer molding process for stitched sandwich structure composites[J]. Acta Materiae Compositae Sinica,2018,35(12):3342-3349(in Chinese). [12] ZHAO C H, ZHANG G C, WU Y B. Resin flow behavior simulation of grooved foam sandwich composites with the vacuum assisted resin infusion (VARI) molding process[J]. Materials,2012,5(12):1285-1296. [13] HALIMI F, GOLZAR M, ASADI P, et al. Core modifications of sandwich panels fabricated by vacuum-assisted resin transfer molding[J]. Journal of Composite Materials,2013,47(15):1853-1863. doi: 10.1177/0021998312451763 [14] PETRESCUE L. An investigation of defect evolution in foam core sandwich structures produced using vacuum assisted resin transfer molding[D]. Ottawa: University of Ottawa, 2007. [15] 王科, 赖家美, 鄢冬冬, 等. 缝合泡沫夹芯结构复合材料VARTM工艺树脂充填模拟及验证[J]. 高分子材料科学与工程, 2015, 31(11):124-129.WANG Ke, LAI Jiamei, YAN Dongdong, et al. Simulation and verification of resin filling for stitched foam sandwich composite VARTM process[J]. Polymer Materials Science & Engineering,2015,31(11):124-129(in Chinese). [16] 魏俊伟, 张兴刚, 郭万涛. 典型夹芯结构复合材料VARI工艺成型仿真计算研究[J]. 材料开发与应用, 2013, 28(5):71-78.WEI Junwei, ZHANG Xinggang, GUO Wantao. Simulation calculation of VARI process for typical sandwich structure composites[J]. Development and Application of Materials,2013,28(5):71-78(in Chinese). [17] JHAN Y T, LEE Y J, CHUNG C H. Experimental and numerical investigation of the VARTM process with a sandwich structure[J]. Journal of Composite Materials,2012,46(12):1417-1430. doi: 10.1177/0021998311418703 [18] POODTS E, MINAK G, DOLCINI E, et al. FE analysis and production experience of a sandwich structure component manufactured by means of vacuum assisted resin infusion process[J]. Composites Part B: Engineering,2013,53(10):179-186. [19] FALASCHETTI M P, RONDINA F, ZAVATTA N, et al. Material characterization for reliable resin transfer molding process simulation[J]. Journal of Applied Sciences,2020,10(5):1814. doi: 10.3390/app10(05):1814 [20] YAN C, WU H L, REN X M, et al. Experimental and numeri-cal study on the permeation behavior of foam-core sandwich panels in LCM[J]. Fibers and Polymers,2021,22(9):2612-2625. doi: 10.1007/s12221-021-0310-9 [21] 刘金良, 吴晓青. RTM工艺中树脂流动管道的优化设计[J]. 玻璃钢/复合材料, 2008(6):41-43.LIU Jinliang, WU Xiaoqing. Optimal design of resin flow pipeline in RTM process[J]. Fiber Reinforced Plastics/Composites,2008(6):41-43(in Chinese). [22] 徐绍良, 岳湘安, 侯吉瑞, 等. 边界层流体对低渗透油藏渗流特性的影响[J]. 西安石油大学学报(自然科学版), 2007, 22(2):26-28.XU Shaoliang, YUE Xiang'an, HOU Jirui, et al. Effect of boundary layer fluid on seepage characteristics of low permeability reservoir[J]. Journal of Xi'an Shiyou University (Natural Science Edition),2007,22(2):26-28(in Chinese). [23] PORTO T N, BARBOSAD L A G, DE AMORIM JÚNIOR W F. Multiphase fluid flow in porous-fibrous media: Fundamentals, mathematical modeling and applications on polymeric composites manufacturing[J]. Diffusion Foundations,2018,20:55-77. doi: 10.4028/www.scientific.net/DF.20.55 [24] 张浩, 李书欣, 王继辉, 等. 基于新型测试装置的网孔板层开孔率对纤维厚度方向渗透率的影响[J]. 复合材料学报, 2020, 37(5):1175-1183.ZHANG Hao, LI Shuxin, WANG Jihui, et al. Influence of ratio of hole area for mesh plate layer on through-thickness permeability based on a new designed test bench[J]. Acta Materiae Compositae Sinica,2020,37(5):1175-1183(in Chinese). [25] 杨旭静, 王跃飞, 韦凯, 等. 基于孔隙控制的车身结构树脂传递模塑成型工艺设计[J]. 复合材料学报, 2017, 34(5):970-977.YANG Xujing, WANG Yuefei, WEI Kai, et al. Process design of resin transfer molding for body structure based on pore control[J]. Acta Materiae Compositae Sinica,2017,34(5):970-977(in Chinese). [26] LABAT L, BREARD J, PILUT L S. Void formation prevision in LCM parts[J]. European Physical Journal Applied Physics,2001,16(2):157-164. [27] PATEL N, LEE L J. Modeling of void formation in liquid composite molding. Part I: Wettability analysis[J]. Polymer Composites,1996,17(1):96-103. doi: 10.1002/pc.10594 [28] PATEL N, LEE L J. Modeling of void formation in liquid composite molding. Part II: Model development and impregnation[J]. Polymer Composites,1996,17(1):104-114. doi: 10.1002/pc.10595 [29] 中国国家标准化管理委员会. 碳纤维增强塑料孔隙含量和纤维体积含量试验方法: GB/T 3365—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People's Republic of China. Carbon fiber reinforced plastics-Determination of void content and fiber volume content: GB/T 3365—2008[S]. Beijing: Standards Press of China, 2008(in Chinese). [30] 戴福洪, 张博明, 杜善义, 等. RTM工艺注模过程模拟的有限元/控制体积方法和流动分析网络技术比较[J]. 复合材料学报, 2004, 21(2):92-98.DAI Fuhong, ZHANG Boming, DU Shanyi, et al. Comparison of finite element/control volume method and flow analysis network technology for injection molding process simulation of RTM process[J]. Acta Materiae Compositae Sinica,2004,21(2):92-98(in Chinese). [31] 詹明樊, 王继辉, 倪爱清, 等. 基于数字图像技术的纤维织物面内渗透率表征[J]. 复合材料学报, 2021, 38(12):4180-4209.ZHAN Mingfan, WANG Jihui, NI Aiqing, et al. In-plane permeability characterization of fiber fabric based on digital image technology[J]. Acta Materiae Compositae Sinica,2021,38(12):4180-4209(in Chinese). [32] 秦贞明, 陈以蔚, 李树虎, 等. 复合材料夹芯泡沫开孔对树脂充模的影响分析[J]. 材料工程, 2009(S2):141-146.QIN Zhenming, CHEN Yiwei, LI Shuhu, et al. Influence of composite foam core opening on resin filling process[J]. Journal of Materials Engineering,2009(S2):141-146(in Chinese). [33] 肖飞, 姜茂川, 刘强, 等. 复合材料副翼典型结构件的 VARI 工艺模拟及试验验证[J]. 航空材料学报, 2015, 35(3):69-76.XIAO Fei, JIANG Maochuan, LIU Qiang, et al. Vari process simulation and experimental verification of typical structural parts of composite aileron[J]. Journal of Aeronautical Materials,2015,35(3):69-76(in Chinese). [34] SHEN Y, GUO Z W, FENG Y Q, et al. Ultrasonic estimation of porosity in composite materials using acoustic attenuation[J]. Insight-Non-Destructive Testing and Condition Monitoring,2019,61(6):310-315. doi: 10.1784/insi.2019.61.6.310 -

下载:

下载: