Study on calculation method of RC beam's shear bearing capacity of CFRP grid-polymer cement mortar

-

摘要: 为揭示碳纤维增强树脂复合材料(Carbon fiber reinforced polymer,CFRP)网格-聚合物水泥砂浆(Polymer cement mortar,PCM)抗剪加固钢筋混凝土(RC)梁的受剪机制并建立其承载力计算方法,对RC梁进行了四点弯曲试验和有限元模拟,重点分析了CFRP网格对RC加固梁的抗剪贡献,建立了基于改进的桁架拱模型的抗剪承载力计算方法。结果表明:RC梁侧粘贴CFRP网格-PCM加固层不仅可以抑制斜裂缝的发展,而且还提高了抗剪承载力;CFRP网格与钢筋之间具有良好的协同工作性能,其中,横向CFRP网格筋分担了约16%的箍筋应变;回归分析指出纵向CFRP网格筋的应变约为横向CFRP网格筋应变的0.29倍;综合考虑纵向CFRP网格的销栓作用和横向CFRP网格分担的箍筋应变,提出了基于改进桁架-拱模型的承载力计算方法,具有更好的适用性和准确性,能够满足设计要求。

-

关键词:

- CFRP网格-PCM抗剪加固RC梁 /

- 四点弯曲试验 /

- 有限元分析 /

- 改进的桁架-拱模型 /

- 承载力计算方法

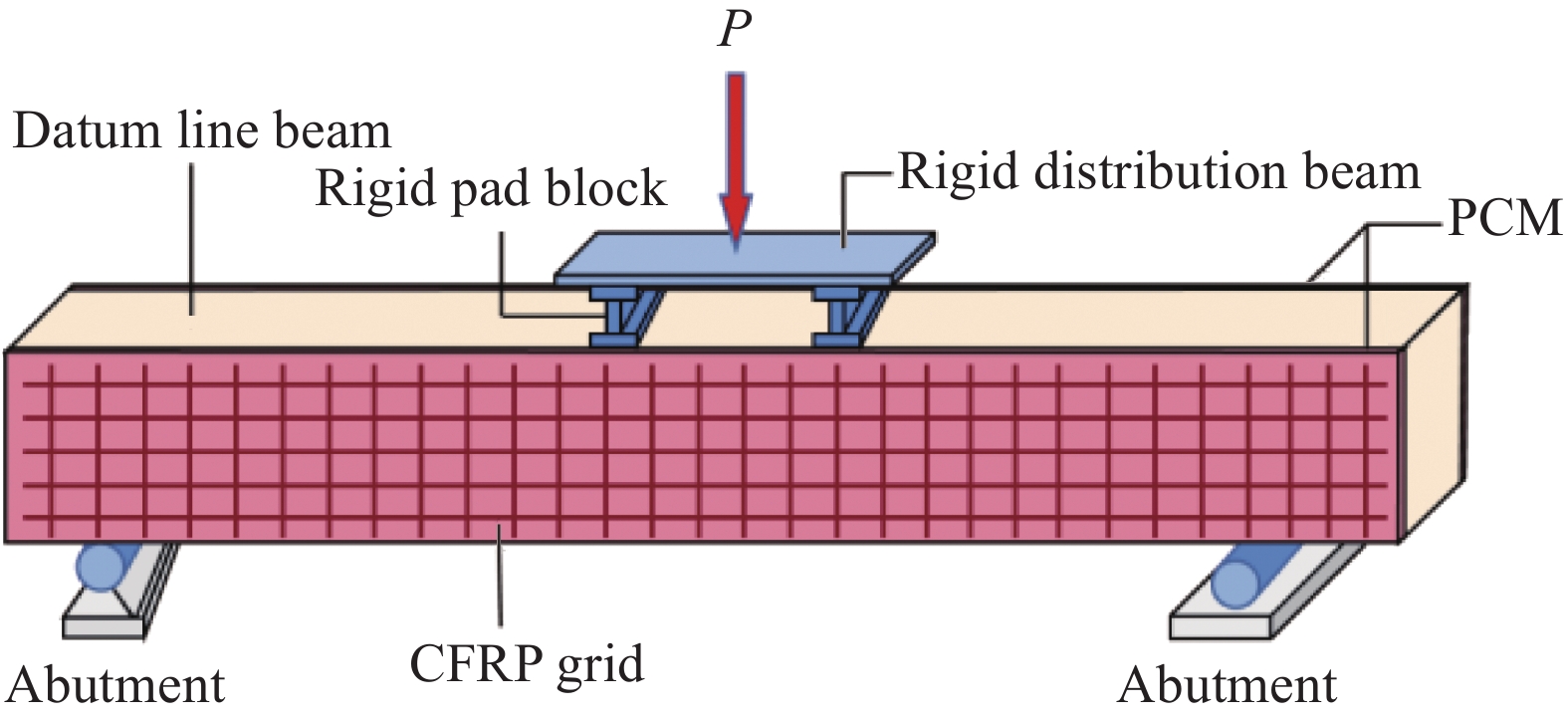

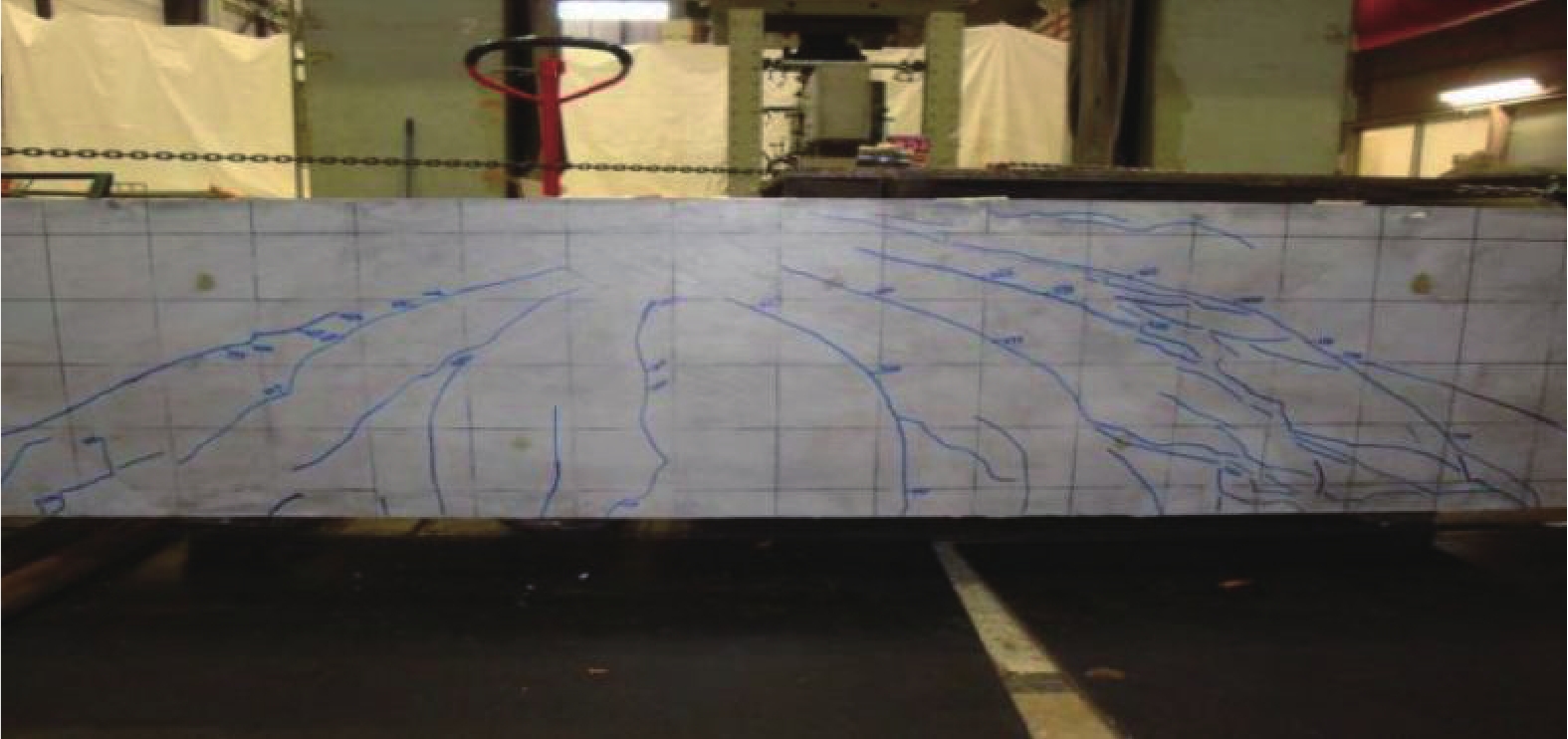

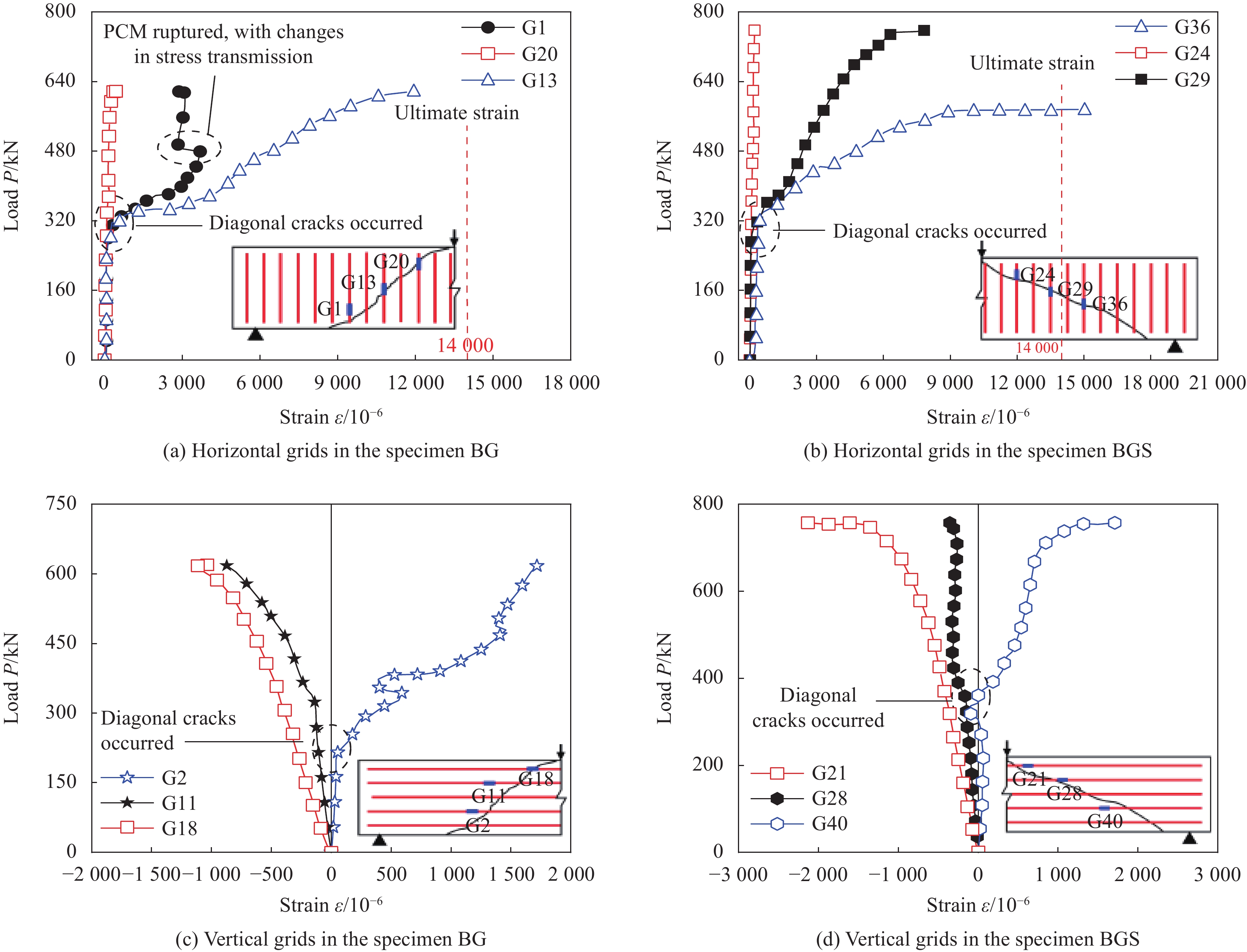

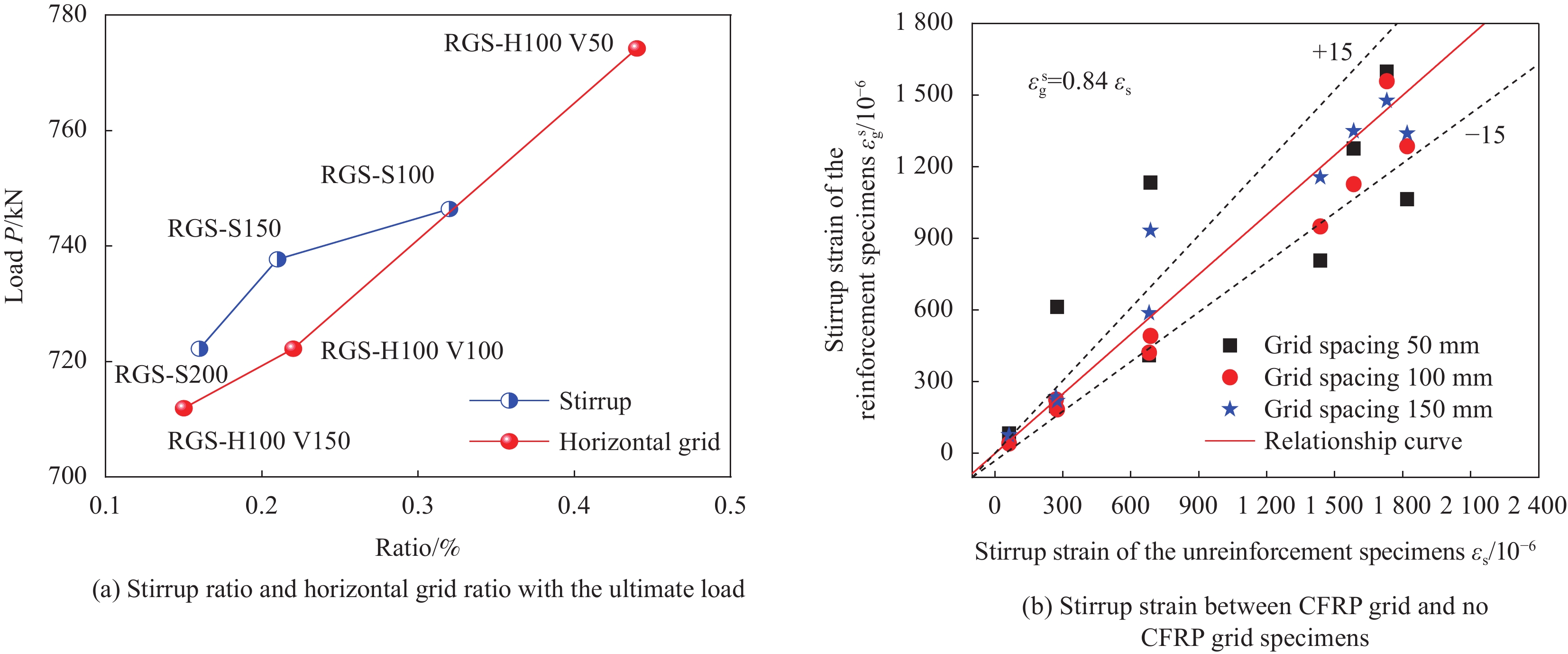

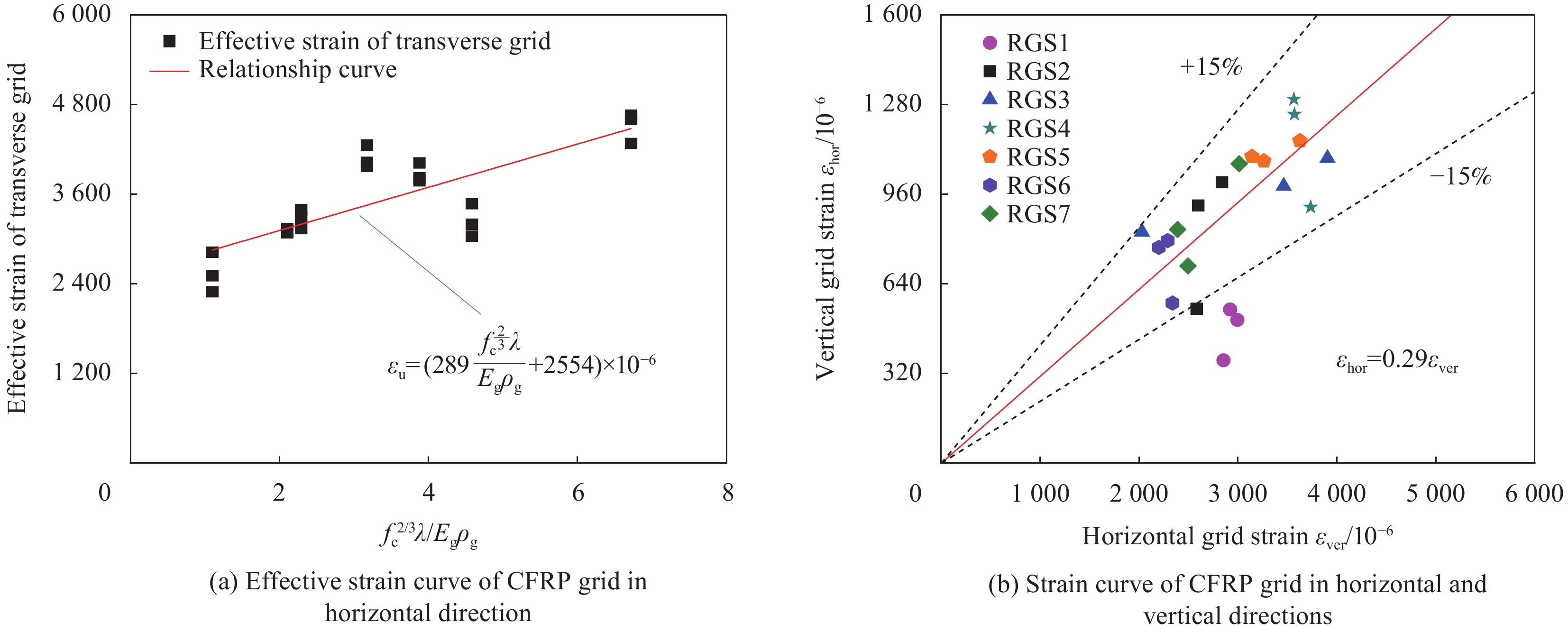

Abstract: In order to reveal the shear mechanism of the carbon fiber reinforced polymer (CFRP) grid-polymer cement mortar (PCM) shear reinforced reinforced concrete (RC) beam and establish its bearing capacity calculation method, four-point bending tests and finite element simulation were conducted on the RC beams. The shear contribution of the CFRP grid to the RC reinforced RC beam was analyzed, and the shear bearing capacity calculation method was established based on the improved truss arch model. The results show that the CFRP grid-PCM reinforcement layer can not only inhibit the development of inclined cracks, but also improve the shear bearing capacity. CFRP grid and reinforcement have good cooperative working performance, where the horizontal CFRP grid shares about 16% of the stirrup strain. Regression analysis indicates that the strain of the vertical CFRP grid is about 0.29 times than that of the horizontal CFRP grid. Comprehensively considering the dowel action of the longitudinal CFRP grid and the stirrup strain shared by the horizontal CFRP grid, the bearing capacity calculation method is presented based on the improved truss-arch model, which has better applicability and accuracy to meet the design requirements. -

钢筋/混凝土是国内外顶管工程中使用较多的管材[1]。混凝土作为生产该类管的主要材料,由于其抗拉强度低、韧性差,使管节在受到顶推作用、土体挤压后易产生裂缝,加快了钢筋锈蚀和管结构恶化,降低工程的使用寿命。虽然利用钢筋抗剪加固可一定程度地控制钢筋/混凝土管节开裂,但并非是解决混凝土表面微裂缝的理想方案[2]。已有研究[3-5]证明在混凝土管中加入钢纤维和合成纤维是加强管节裂缝控制的有效措施。但是钢纤维易受到氯化物环境腐蚀,相比而言,合成纤维成为一种更理想的混凝土管增强纤维,其中聚丙烯纤维价格低廉、耐腐蚀性好、稳定性高被较早推广,而且聚丙烯纤维在提高混凝土的韧性和开裂后残余强度方面甚至比钢纤维性能更优[6]。

按照纤维直径大小,可将聚丙烯纤维分为聚丙烯细纤维(直径不大于0.1 mm)和聚丙烯粗纤维(直径大于0.1 mm)即塑钢纤维。Wilson等[7]采用三点试验法初步研究了375~900 mm七种内径混凝土管在不同聚丙烯粗纤维纤维含量下的荷载-位移曲线和破坏裂缝模式,表明随着纤维含量的增加管节峰值强度提高,而且不同管径下存在相应的最佳掺量范围。Rikabi等[8]分析单掺9 kg/m3聚丙烯粗纤维对钢筋/混凝土管节极限强度、刚度和变形能力的影响,指出加入纤维可以减少管壁厚度和钢筋用量,提高管节韧性的同时降低生产运输成本。为充分发挥不同纤维的增强加固作用,已有学者提出将钢纤维与合成纤维混杂掺入混凝土管中。Perk等[9]研究表明混掺钢-聚丙烯纤维在提高混凝土管强度、延性和抗裂方面比单掺纤维增强材料(钢纤维或聚丙烯纤维)更显著。但是仍然面临着钢纤维易被腐蚀的缺点,有必要采用其他纤维代替钢纤维与聚丙烯纤维进行混掺,在获得良好抗拉[10]和抗裂[11]效果的同时又提高混凝土管的耐久性。其中,罗洪林等[12]指出聚丙烯粗纤维和细纤维增强混凝土抗拉性能的机制不尽相同、各有优势;而且混掺多种尺度的聚丙烯纤维能够有效阻止混凝土的塑性开裂,限制早期和后期裂缝发展[13]。然而目前关于多尺度聚丙烯纤维对钢筋/混凝土管的作用方面鲜有研究。

鉴于此,本文开展单掺聚丙烯粗纤维和混掺三种尺度聚丙烯纤维的钢筋/混凝土管节三点试验,建立管节三点试验的有限元模型,分析管节破坏形态、载荷-挠度曲线和能量吸收能力,研究单掺和混掺下聚丙烯粗纤维含量对混凝土管承载力和延性的影响规律。

1. 试验材料与方法

1.1 原材料及配合比

试验所采用的聚丙烯纤维外观如图1所示,其中聚丙烯细纤维分为FPF1与FPF2两种,呈直型束丝状;聚丙烯粗纤维为CPF,呈波纹型单根状。其物理和力学性能指标见表1,推荐单掺量[14]中聚丙烯细纤维为0.9 kg/m3,聚丙烯粗纤维为6.0 kg/m3。为确保聚丙烯纤维在混凝土中的均匀分散不成团,混凝土采用先掺法搅拌[14]。试验混凝土的强度等级设计为C50,其中普通硅酸盐水泥强度为52.5R,粗骨料采用粒径大小分别为10~20 mm和5~10 mm的碎石块,细骨料采用0.15~5 mm粒径的天然砂,并添加1%水泥含量的聚羧酸高效减水剂以提高混凝土成型性能。混凝土设计配合比如表2所示。

表 1 不同尺度聚丙烯纤维的物理力学性能Table 1. Physical and mechanical properties of polypropylene fibers of different scalesFiber code Diameter/mm Length/mm Aspect ratio Tensile

strength/MPaElasticity

modulus/GPaDensity/

(kg·m−3)Recommended single

dosage/(kg·m−3)FPF1 0.026 19 730.8 641 8.5 0.91 0.9 FPF2 0.1 19 190 322 3.9 0.91 0.9 CPF 0.8 50 62.5 706 7.4 0.95 6.0 Notes: FPF1—Type of fine polypropylene fiber; FPF2—Another type of fine polypropylene fiber; CPF—Crude polypropylene fiber. 表 2 C50混凝土设计配合比Table 2. Design mix ratio of C50 concreteMaterial Cement Coarse aggregate Sand Water Water reducer 10-20 mm 5-10 mm Dosage/(kg·m−3) 375 545 545 850 135 3.75 1.2 管节试件设计

根据多尺度聚丙烯纤维混凝土基本拉压性能的研究成果[13, 15],采用对混凝土抗拉和抗裂提升较高的聚丙烯纤维组合,针对同一尺寸和配筋率的钢筋/混凝土管节,最终确定试验试件的纤维组数为三类(见表3),其他聚丙烯纤维掺量组合通过数值模拟实现。

其中,S/C试件由普通混凝土浇筑,作为基准参照的标准管节;CPF-S/C为单掺聚丙烯粗纤维CPF的管节,纤维掺量为6.0 kg/m3;FPF1-FPF2-CPF-S/C为混掺粗细三种聚丙烯纤维的管节,FPF1、 FPF2、CPF三种纤维的掺量分别为0.6、0.6、4.8 kg/m3。管节截面尺寸和配筋形式如图2所示,其内、外直径分别为1 000 mm和1 200 mm,长度1 m,外层混凝土保护层厚度为27 mm,内层厚度为20 mm,环向配筋率为1%,非螺旋配筋。

表 3 试验各组不同尺度聚丙烯纤维的配比Table 3. Proportions of polypropylene fibers of different scales in each specimenkg·m−3 Pipe code Fine polypropylene fibers Crude polypropylene fiber Total content FPF1 FPF2 CPF S/C 0 0 0 0 CPF-S/C 0 0 6 6 FPF1-FPF2-CPF-S/C 0.6 0.6 4.8 6 Notes: S/C—Reinforced concrete pipe without fiber; CPF-S/C—Reinforced concrete pipe with crude polypropylene fiber; FPF1-FPF2-CPF-S/C—Reinforced concrete pipe with multi-scale polypropylene fibers. 1.3 三点试验过程

三点试验法是测试钢筋/混凝土排水管外压荷载的标准方法[16],通过在管顶径向施压,测定钢筋/混凝土管产生0.3 mm裂缝宽度对应的荷载及峰值荷载,确定管节所属强度等级。本试验加载装置如图3所示,主要由试验机架、加荷与显示量值的系统及位移传感器等组成。

在三点试验中,管底部支撑于两硬木支承梁上,支承梁净距取100 mm,各截面尺寸为80 mm×100 mm,并且支承梁与管节接触处制成半径12.5 mm的圆弧;管的顶部设置橡胶垫板与加载钢梁,橡胶垫板截面尺寸为25 mm×120 mm,以使荷载均匀地作用在试验管上。在ASTM C76[17]中规定了关于钢筋/混凝土管节的评价标准,管的支承强度采用D-load (DL)值表征,即单位长度与内径下管所承受的荷载,计算公式如下:

DL=DL×Di (1) 其中:D为管顶承受的集中荷载(N);L为管节长度(m);Di为管节内径(mm)。各强度值对应的管节等级如表4所示,表中D-load0.3(D0.3)指的是当裂缝宽度为0.3 mm时的荷载值,即管节的使用强度;D-loadu(Du)指的是最大荷载值,即管节的极限强度。文中试验设计的混凝土管等级为V级,其使用和极限强度应分别达到140 N/m/mm与175 N/m/mm。

表 4 基于ASTM C76[17]的钢筋/混凝土管节等级强度要求Table 4. Grade strength requirements for reinforced concrete pipe based on ASTM C76[17]Concrete pipe class D-load(DL)/(N·m−1·mm−1) D-load0.3(D0.3) D-loadu(Du) I 40 60 II 50 75 III 65 100 IV 100 150 V 140 175 Notes: D-load(DL)—Supporting load value of pipe; D-load0.3(D0.3)—Load value when crack width is 0.3 mm, namely service strength; D-loadu(Du)—Maximum load value, namely ultimate strength. 管节三点试验过程参考GB/T 16752—2017[16]和ASTM C497[18]中的相关条文执行,采用单向逐级加载,分成三个阶段控制。第一阶段保持加荷速度为1.8 kN/m/s,直至荷载达到使用强度的75% (即105 N/m/mm);此后在第二阶段将加荷速度降为0.7 kN/m/s,直至荷载达到管的极限强度;当荷载超过极限强度后,第三阶段采用位移控制方法对试件施加竖向位移,加载速率为2 mm/min。在整个试验过程中,加载设备采用微机控制电液伺服压剪试验机,通过计算机的数据采集系统记录和控制三点试验的加载量;并采用东华DH3816N数据采集仪量测顶部挠度、记录钢筋、混凝土的应变数据;使用综合裂纹测试仪监测管节顶部、底部及两侧的裂纹宽度,并实时对裂缝标记编号,检查管节是否出现局部破坏或发生不适合继续承载的变形,部分试验过程如图4所示。

2. 试验结果与分析

2.1 钢筋/混凝土管开裂破坏形态

试验管在加载的过程中,由于管顶部和底部混凝土为内壁受拉,而管两侧混凝土为外壁受拉,而且分析表明顶部承担弯矩作用较两侧大[19],因此三类管均表现为在管节顶部内壁首先出现弯曲裂缝,且第一条观测裂缝出现的DL值约为75~85 N/m/mm。随着荷载的持续增加,顶部内壁裂缝沿管径向和轴向延伸,管节底部内壁和两侧外壁的混凝土亦产生裂缝并逐渐发展增多,最终在该四个区域形成较大的贯通主裂缝,混凝土管压溃进而破坏,表现出较明显的弯曲破坏特征,三类试验管的开裂破坏形态如图5所示。对比分析S/C、CPF-S/C与FPF1-FPF2-CPF-S/C的破坏形态,在顶部和底部区域,S/C组试件较CPF-S/C和FPF1-FPF2-CPF-S/C组产生的裂缝更早、宽度更大,裂缝分布更集中,而且管破坏时混凝土剥落掉块现象更严重。CPF-S/C与FPF1-FPF2-CPF-S/C组试件顶部内壁存在多缝开裂现象(如图5(b)、图5(c)所示),在裂缝发展时,掺入的纤维既可以继续承载,同时又可使混凝土基体在其他截面再次交替开裂。在两侧区域,可以明显观察到CPF-S/C与FPF1-FPF2-CPF-S/C试件的裂缝中存在聚丙烯粗纤维的桥接现象,不少纤维被拔出或拉断,说明掺入聚丙烯纤维不仅能抑制管节宏观裂缝的发展,而且有效限制混凝土剥落。

2.2 钢筋/混凝土管DL与管顶挠度曲线

各组管的DL值与管顶挠度的关系曲线如图6所示,可见极限强度均高于Ⅴ类管要求。由于钢筋是决定整体强度响应的主要因素,故而S/C、CPF-S/C和FPF1-FPF2-CPF-S/C试件的曲线变化趋势表现得基本一致。加载初期,钢筋与混凝土的应变随荷载呈线性变化,整个管节构件处于弹性阶段,各试验管DL值随挠度呈线性增长;当管顶部混凝土超过其开裂应变后,混凝土产生裂缝,此时粗纤维与钢筋在受拉张力区已发挥作用,使管能够继续受荷直至极限荷载,该阶段荷载挠度曲线仍保持上升趋势;之后挠度继续增加,达到16~19 mm范围后,环向钢筋屈服,试验管达到最大承载力;随后DL值开始下降,试验管进入破坏阶段。但FPF1-FPF2-CPF-S/C和CPF-S/C组管的下降段明显高于S/C组管,FPF1-FPF2-CPF-S/C组亦高于CPF-S/C组,说明混掺聚丙烯粗细纤维能在混凝土管开裂后提供更高的承载能力。

将各试验管的使用强度和极限强度列于表5。单掺聚丙烯粗纤维CPF-S/C组和混掺多尺度聚丙烯纤维FPF1-FPF2-CPF-S/C组及标准S/C组的极限强度分别为270.7、278.5、216.4 N/m/mm,前两组相较于S/C组分别提高了25.1%和28.7%,混凝土管强度得到明显提高。这是由于一方面聚丙烯纤维的抗拉强度高于混凝土基体的抗拉强度,掺入纤维可改善复合基体的抗拉性能;另一方面混凝土产生裂缝后,聚丙烯粗纤维发挥桥接作用,改善了混凝土基体的薄弱受力面。此外,S/C、CPF-S/C、FPF1-FPF2-CPF-S/C组的D0.3分别为126.7、164.8、171.4 N/m/mm,其中S/C组的使用强度未满足Ⅴ类管要求;但与S/C相比,CPF-S/C和FPF1-FPF2-CPF-S/C组的使用强度分别提高了31.1%和36.4%,且均高于140 N/m/mm,满足V级管要求,表明掺入聚丙烯纤维能够改善混凝土管抗裂性能。而且,FPF1-FPF2-CPF-S/C组的D0.3与Du值高出CPF-S/C组约4.0%与2.9%,进一步说明多尺度聚丙烯纤维形成的三维乱向支撑体系,在早期收缩和后期承载过程中发挥了协同作用[20],调整管节裂缝处混凝土的局部应力,控制了裂缝宽度,提高了管强度。

表 5 各钢筋/混凝土试验管节的使用强度与极限强度Table 5. Service load and ultimate load of each reinforced concrete pipesPipe code DL/(N·m−1·mm−1) D0.3 Du S/C 126.7 216.4 CPF-S/C 164.8 270.7 FPF1-FPF2-CPF-S/C 171.4 278.5 2.3 钢筋/混凝土管裂后延性指标

进一步分析纤维对混凝土管延性的影响,结合国内外纤维混凝土管的相关研究[3, 5],采用开裂后强度(Post-cracking strength,SPC)来表征试验管的延性和吸能性能,计算过程如下式所示:

SPC=(Epost)C(δ−δpeak)Lh2 (2) 其中:SPC指某一挠度下的开裂后强度;Epost指在荷载-挠度曲线(图7)中某一挠度至峰值挠度和曲线围成的面积;δ为挠度;δpeak为峰值荷载对应的峰值挠度;C为管节内部周长的一半;L为管节长度;h为管节壁厚。

计算SPC所用的荷载-挠度曲线如图7所示。SPC是包含了管节形状尺寸、结构性能如挠度与承载能力等多个指标的综合标准,SPC较高代表管节能量吸收能力较高,延性较好。

图8为三组管在20~120 mm挠度下的SPC值计算结果曲线。可见,在该计算范围内,各管节试件的SPC值随挠度的增大而减小,其变化趋势与荷载-挠度曲线基本一致。在相同挠度δ下,含有纤维的混凝土管表现出更高的开裂后强度。例如在挠度为40 mm时,S/C、CPF-S/C、FPF1-FPF2-CPF-S/C组的开裂后强度分别为31.2、37.3和40.4 N/mm2。而且在同一纤维掺量(6 kg/m3)下,混掺的FPF1-FPF2-CPF-S/C组均体现出更优的SPC值,较CPF-S/C组的提升范围为4.6%~10.0%,表明多种粗细聚丙烯纤维可更好地提高混凝土管的延性和截面内力重分布的能力,而且其改善程度还高于上述对强度的作用,发挥出较好的阻裂增韧效果。

3. 钢筋/混凝土管数值模拟

3.1 有限元模型建立

为进一步探究纤维掺量对混凝土管力学性能的影响情况,采用有限元方法来模拟管三点试验的宏观力学行为[21]。基于通用的数值模拟软件ABAQUS 6.16,建立了上述管节三点试验的有限元模型,如图9所示。模型主要由混凝土管、钢筋笼及上、下部支承梁四部分组成,管的尺寸及配筋率均与前述试验保持一致。其中,上、下部支承梁的截面尺寸分别为25 mm×120 mm和80 mm×100 mm,下部支承梁净距为100 mm。经试算分析不同单元类型与网格尺寸,确定混凝土管与支承梁采用八结点六面体实体非协调单元模拟,钢筋笼采用两结点三维桁架单元模拟,各组件的单元类型与数量如表6所示。此外,在上、下部支承梁与管接触的位置采用绑定作用,钢筋与混凝土管之间采用内置区域相互作用。同时,于下部支承梁底面施加平动约束,上部支承梁顶面施加120 mm位移模拟管径向受压。

表 6 钢筋/混凝土管节有限元模型单元类型与数量Table 6. Number and types of the model elements of reinforced concrete pipeModel part Element number Element type Concrete pipe 37 500 C3D8I Lower bearing strips 1 900 Upper bearing strip 600 Steel cage 5 390 T3D2 3.2 模拟材料本构

3.2.1 纤维混凝土本构

聚丙烯纤维/混凝土的单轴拉压应力-应变关系可采用B 50010—2010[22]提供的本构模型进行拟合[23],如图10所示,主要通过单轴抗拉(抗压)强度ft与fc、峰值拉(压)应变εt与εc、弹性模量Ec、抗拉(抗压)曲线下降段形状参数αt和αc,四类力学指标确定材料的单轴应力-应变曲线和损伤破坏情况。

![]() 图 10 聚丙烯纤维/混凝土单轴拉压应力-应变曲线Figure 10. Uniaxial compressive and tensile stress-strain curves of polypropylene fiber/concretefc, ft—Compressive and tensile strength vaules of concrete; Ec—Elasticity modulus of concrete; αc, αt—Shape parameters of the falling section of the concrete compressive and tensile stress-strain curves; σc and σt—Compressive and tensile stress vaules of concrete; ε—Strain vaule of concrete; ρc, ρt, n and x—Intermediate parameters during the stress calculation process; εc and εt—Compressive and tensile peak strain vaules of concrete

图 10 聚丙烯纤维/混凝土单轴拉压应力-应变曲线Figure 10. Uniaxial compressive and tensile stress-strain curves of polypropylene fiber/concretefc, ft—Compressive and tensile strength vaules of concrete; Ec—Elasticity modulus of concrete; αc, αt—Shape parameters of the falling section of the concrete compressive and tensile stress-strain curves; σc and σt—Compressive and tensile stress vaules of concrete; ε—Strain vaule of concrete; ρc, ρt, n and x—Intermediate parameters during the stress calculation process; εc and εt—Compressive and tensile peak strain vaules of concrete基于试验测得的前述配比下素混凝土的拉压性能参数,参考缪庆旭对多尺度聚丙烯纤维混凝土提出的各个控制指标混杂效应函数W=f (λi,λj,λk)[23],量化聚丙烯纤维对混凝土力学性能的作用,得到纤维混凝土的各项指标值,其中λi、λj、λk分别为3种纤维FPF1、FPF2和CPF的特征值,计算如下:

λ=mfρf⋅lfdf (3) 其中:mf为纤维的质量掺量;ρf为纤维的密度;lf为纤维的长度;df为纤维的当量直径。计算得到三类管试件的混凝土拉压性能指标如表7所示。

表 7 钢筋/混凝土管拉压力学性能指标Table 7. Tensile and compressive mechanical properties indexes of reinforced concrete pipesPipe code λi+λj+λk Ec/MPa fc/MPa εc/10−6 αc ft/MPa εt/10−6 αt S/C 0+0+0 42 500 47.1 2 096 1.94 2.65 142 3 CPF-S/C 0+0+0.39 43 601 52.3 2 607.8 0.31 3.20 165.8 1.38 FPF1-FPF2-CPF-S/C 0.48+0.13+0.32 40 792 56.4 3 018.4 0.12 3.32 224.5 1.40 Note: λi , λj and λk—Eigenvalues of FPF1, FPF2 and CPF. 在ABAQUS软件中,混凝土损伤塑性(Concrete damaged plastic,CDP)模型能够较好地模拟钢筋/混凝土构件在各类加载条件下的非线性力学响应[24],可适用于本次模拟。采用CDP模型时,除输入上述混凝土单轴应力与应变关系外,为确定混凝土的屈服面和塑性流动法则,需定义一组参数,如膨胀角Ψ、流动势偏心率、双轴抗压与单轴抗压的极限强度之比fb0/fc0、应力不变量比K、黏性参数μ,基于相关文献[25]和试算取值如表8所示。

表 8 混凝土损伤塑性模型(CDP)模型的塑性参数取值Table 8. Values of the concrete damaged plastic model (CDP) model plasticity parametersCDP model plasticity parameter Value Dilatation angel Ψ/(°) 36 Flow potential eccentricity 0.1 fb0/fc0 1.16 Stress invariant ratio K 0.67 Viscosity parameter μ 0.0009-0.001 Note: fb0/fc0—Ratio of ultimate strength of biaxial compression to uniaxial compression. 3.2.2 钢筋本构

钢筋采用理想弹塑性本构,钢筋的屈服强度为400 MPa,弹性模量为200 GPa,泊松比为0.3。上下部支承梁采用刚性材料模拟。

3.3 模型结果验证

3.3.1 破坏形态对比

以FPF1-FPF2-CPF-S/C组试验管数值模拟结果为例,在管顶竖向位移加载至0.4 mm和0.9 mm左右时,管混凝土水平和竖向应力云图如图11所示,顶部和侧部混凝土分别达到最大拉应力即3.32 MPa,而后在顶部和侧部逐渐产生明显塑性区。对比钢筋/混凝土管节在试验与模拟中的破坏过程(图5),由图12的塑性区云图发展过程可知,随着竖向位移的增大,管顶部内壁混凝土的塑性应变高于其他区域混凝土的塑性应变(图12(a)),故首先出现受拉塑性开裂区[26];随后管底部内壁和侧部外壁混凝土进入塑性然后开裂(图12(b)和图12(c)),并向深部发展;最后混凝土压溃、环向钢筋达到极限拉应变,试验管达到最大承载力,此渐进弯曲破坏过程与试验现象基本一致。

3.3.2 DL与管顶挠度曲线对比

各组数值模拟和室内试验的DL与挠度曲线如图13所示,两者曲线形式较吻合。对于极限(峰值)强度值,模拟得到Du分别为220.8、252.9、262.8 N/m/mm,由于未考虑纤维的空间非均匀分布特点,相比室内试验极限强度值的误差最大为−6.6%。对于含有纤维试件的峰后阶段,由于模拟中未能考虑裂缝持续张开后,实际纤维被拔出和拉断从而失去桥接作用的影响,造成纤维在峰后同样发挥作用,使模拟结果高于试验结果,如图13(b)和图13(c)所示。此外,以峰后挠度40 mm对应的SPC-40值为例,对比结果如表9所示,FPF1-FPF2-CPF-S/C组比CPF-S/C、S/C组仍处于较高的水平,试验与模拟的最大误差为7.6%。总体而言,基于混凝土宏观拉压本构的有限元方法能够较好地体现出纤维对混凝土构件极限承载力和延性的贡献。

表 9 钢筋/混凝土管SPC-40试验值与模拟值对比Table 9. Comparison of SPC-40 between numerical simulation and laboratory test for reinforced concrete pipesPipe code Test value/

(N·m−2)Simulation

value/(N·m−2)Error/% S/C 31.2 33.6 7.7 CPF-S/C 37.3 38.7 3.8 FPF1-FPF2-CPF-S/C 40.4 40.9 1.4 进一步,得到截面1-1上混凝土弯矩与管顶挠度的关系曲线,如图14所示,可以看出,S/C、CPF-S/C和FPF1-FPF2-CPF-S/C三组的最大截面弯矩各为33.6、38.2、39.4 kN·m,FPF1-FPF2-CPF-S/C高于S/C组与CPF-S/C组约17.2%和3.2%。表明在加载后期FPF1-FPF2-CPF-S/C组仍能提供较高的截面弯矩,也反映出多尺度聚丙烯纤维混凝土管具有较高的裂后延性和残余强度。

4. 纤维掺量对钢筋/混凝土管极限强度的影响

上述结果表明该有限元模型可以合理地预测纤维混凝土管的极限承载能力与荷载-挠度响应,可用于研究聚丙烯纤维掺量对钢筋/混凝土管节极限强度的影响规律,提高试验的可控性。因此,在前述三组模拟结果的基础上,针对单掺聚丙烯粗纤维-钢筋/混凝土管,设计10组不同掺量的模拟比较组进行计算;针对混掺多尺度聚丙烯纤维-钢筋/混凝土管,在总掺量一定下(6 kg/m3),设计8组粗细纤维占比不同的模拟比较组进行计算。

4.1 单掺聚丙烯粗纤维

单掺纤维组的Du值模拟结果如表10所示,随粗纤维掺量的变化趋势如图15所示,其中粗纤维含量设计的范围为0~9 kg/m3。结果表明,在该范围内钢筋/混凝土管节的极限强度并非随掺量单调变化,而是存在一个最优的单掺量值。由于混凝土的拉压性能直接影响了管极限强度的模拟结果,当聚丙烯粗纤维掺量过多时,会使混凝土各组分交界面缺陷增多,而且纤维的搭接缠绕削弱了基体的黏结强度,引起高掺量纤维混凝土对应拉压力学性能指标的降低,因此在推荐掺量下钢筋/混凝土管(CPF-S/C)的承载力模拟值较高。同时根据图15中的拟合公式,可得出在纤维含量约为6.22 kg/m3时,混凝土管的拟合极限强度最高为250.62 N/m/mm。

表 10 单掺聚丙烯粗纤维各组钢筋/混凝土管的Du模拟值Table 10. Du simulation value of each group of reinforced concrete with single-scale crude polypropylene fiberPipe code CPF content/

(kg·m−3)λk Ec/MPa fc/MPa εc/10−6 αc ft/MPa εt/10−6 αt Du/(N·m−1·mm−1) S/C 0 — 42 500 47.10 2 096.0 1.94 2.65 142.0 3.00 223.22 CPF-S/C-1 1.0 0.07 42 856 48.77 2 261.3 1.41 2.83 149.7 2.48 232.44 CPF-S/C-2 2.0 0.13 43 105 49.95 2 377.4 1.05 2.96 155.1 2.11 237.36 CPF-S/C-3 3.0 0.20 43 333 51.02 2 483.1 0.71 3.07 160.0 1.77 241.83 CPF-S/C-4 4.0 0.26 43 472 51.68 2 548.0 0.50 3.14 163.0 1.57 245.87 CPF-S/C-5 5.0 0.33 43 571 52.14 2 593.9 0.36 3.19 165.2 1.42 249.71 CPF-S/C 6.0 0.39 43 601 52.28 2 607.8 0.31 3.20 165.8 1.38 252.94 CPF-S/C-7 7.0 0.46 43 579 52.18 2 597.9 0.34 3.19 165.3 1.41 250.03 CPF-S/C-7.5 7.5 0.49 43 537 51.98 2 578.2 0.41 3.17 164.4 1.47 248.24 CPF-S/C-8 8.0 0.53 43 472 51.68 2 548.0 0.50 3.14 163.1 1.57 247.20 CPF-S/C-8.5 8.5 0.56 43 409 51.38 2 518.5 0.60 3.11 161.6 1.66 246.12 CPF-S/C-9.0 9.0 0.59 43 333 51.02 2 483.1 0.71 3.07 160.0 1.77 244.99 4.2 混掺多尺度聚丙烯纤维

混掺聚丙烯纤维组的Du值模拟结果如表11所示,随粗纤维掺量的变化趋势如图16所示。考虑总掺量(6 kg/m3)和细纤维推荐单掺量(0.9 kg/m3)的条件,取粗纤维含量的范围为4.2~6.0 kg/m3。与单掺相似,在该范围内钢筋/混凝土管节的极限强度也并非随粗纤维掺量增加而单调提升,模拟结果表明,FPF1=FPF2=0.4 kg/m3、CPF=5.2 kg/m3的FPF1-FPF2-CPF-S/C-5.2组表现出的极限强度略高于其他组。说明虽然通过不同粗细纤维配比,能够获得前述各拉压性能指标各自的最大值[23],但是混凝土管的极限强度受各个指标的影响程度不尽相同。相比之下,当混凝土抗拉峰值强度越高时,其模拟的管节Du值较大,即提升混凝土抗拉强度对混凝土管的承载能力更有利。同样,根据图16中的拟合公式,可得出在粗纤维含量约为5.18 kg/m3、两种细纤维含量分别为0.41 kg/m3时,混凝土管的拟合极限强度最高为263.78 N/m/mm。

表 11 混掺多尺度聚丙烯纤维各组钢筋/混凝土管的Du值Table 11. Du value of each group of reinforced concrete with multi-scale polypropylene fibersPipe code FPF1+FPF2+CPF content/(kg·m−3) λi+λj+λk Ec/MPa fc/MPa εc/10−6 αc ft/MPa εt/10−6 αt Du/(N·m−1·mm−1) CPF-S/C 0.0+0.0+6.0 0.00+0.00+0.39 43 600 52.28 2 607.8 0.31 3.20 165.8 1.38 252.94 FPF1-FPF2-CPF-S/C-5.8 0.1+0.1+5.8 0.08+0.02+0.38 44 519 49.60 2 692.2 0.22 3.30 176.3 1.50 255.54 FPF1-FPF2-CPF-S/C-5.6 0.2+0.2+5.6 0.16+0.04+0.37 44 816 48.23 2 770.7 0.16 3.37 186.6 1.58 258.44 FPF1-FPF2-CPF-S/C-5.4 0.3+0.3+5.4 0.24+0.06+0.36 44 543 48.16 2 843.4 0.12 3.40 196.6 1.61 262.78 FPF1-FPF2-CPF-S/C-5.2 0.4+0.4+5.2 0.32+0.08+0.34 43 821 49.96 2 912.0 0.12 3.40 206.0 1.59 265.45 FPF1-FPF2-CPF-S/C-5 0.5+0.5+5.0 0.40+0.10+0.33 42 631 52.65 2 973.6 0.14 3.37 215.4 1.54 263.47 FPF1-FPF2-CPF-S/C 0.6+0.6+4.8 0.48+0.13+0.32 40 792 56.43 3 018.4 0.12 3.32 224.5 1.40 262.75 FPF1-FPF2-CPF-S/C-4.6 0.7+0.7+4.6 0.56+0.15+0.30 39 076 63.10 3 072.8 0.21 3.23 232.8 1.27 259.01 FPF1-FPF2-CPF-S/C-4.4 0.8+0.8+4.4 0.64+0.17+0.29 36 880 70.14 3 118.3 0.29 3.11 241.4 1.11 253.01 FPF1-FPF2-CPF-S/C-4.2 0.9+0.9+4.2 0.72+0.19+0.28 34 478 78.50 3 157.8 0.40 2.97 249.8 0.94 251.45 5. 结 论

(1) 聚丙烯粗纤维能够改善三点试验下钢筋/混凝土管节的破坏形态,纤维通过桥接作用调节局部应力,使管节顶部裂缝分散增多,控制了内壁的宏观裂缝扩展,有效防止管节混凝土产生碎裂、剥落等严重破坏。

(2) 针对环向配筋率为1%的1 m内径管节,纤维掺量为6 kg/m3时,单掺聚丙烯粗纤维混凝土管和混掺三种尺度聚丙烯纤维混凝土管的使用强度和极限强度分别比传统混凝土管提高了31.1%、36.4%和25.1%、28.7%,加入纤维使钢筋/混凝土管满足了Ⅴ级管的使用要求,在顶管施工中能够提供更高的抗裂能力。

(3) 与内径1 m的标准管节相比,含有聚丙烯纤维的混凝土管节拥有更高的开裂后延性,而且多尺度纤维混凝土管节的开裂后强度SPC值较单掺纤维混凝土管提升范围为4.6%~10.0%,粗细纤维的协同作用有利于发挥出更好的吸能增韧效果。

(4) 有限元方法能够计算纤维混凝土管节三点外压试验的极限承载能力与荷载挠度响应,反映管节的宏观破坏过程。针对1 m内径管节的极限强度值,单掺一种和混掺三种尺度的聚丙烯纤维均存在粗纤维的最优掺量,分别为6.22 kg/m3和5.18 kg/m3。

-

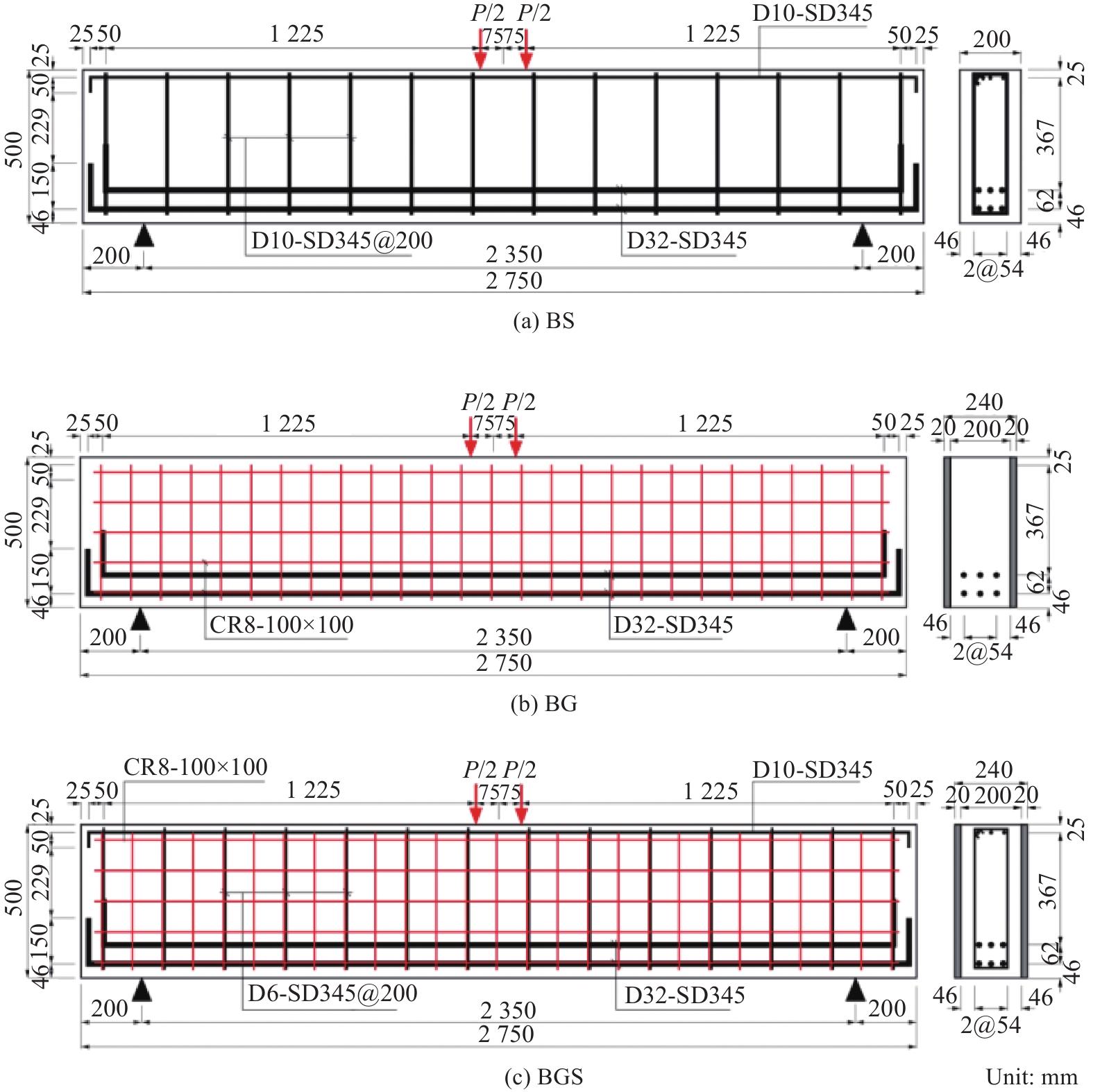

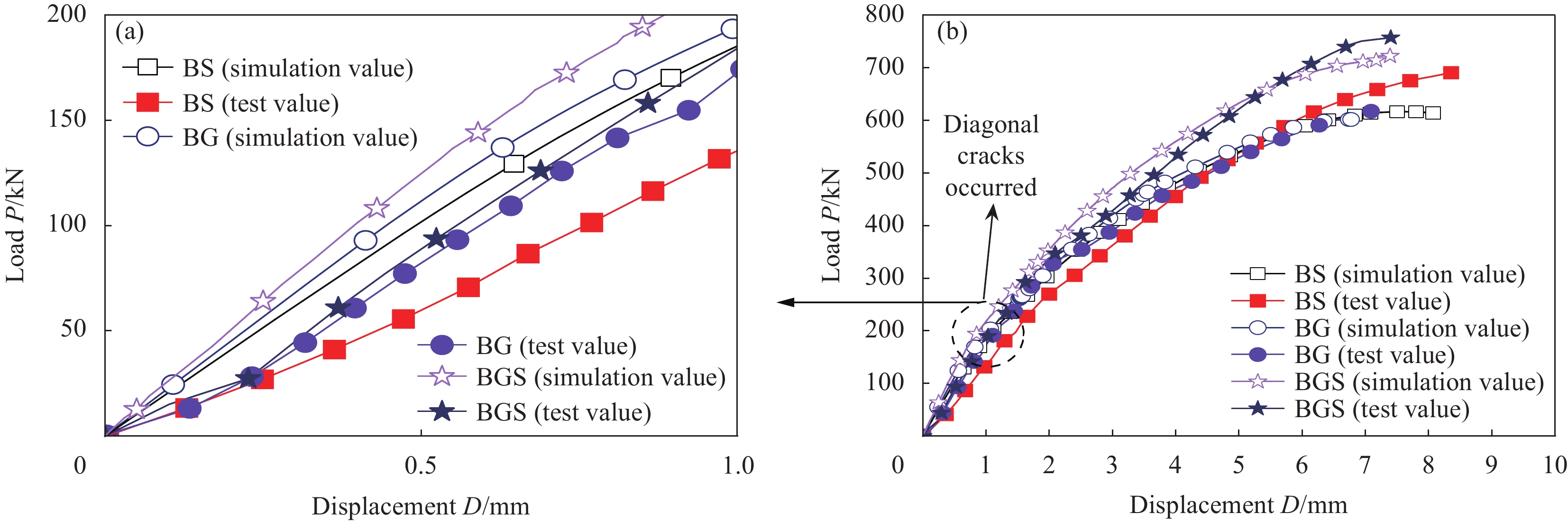

表 1 试件设计

Table 1 Specimen design

Specimen Existing steel bars FRP grid Shear

span λPCM thickness/

mmExisting vertical reinforcement ratio/% Anti-shear reinforcement ratio/% Tensile reinforcement Handling reinforcement Stirrup BS D32-SD345 D10-SD345 D10-SD345@200 — 2.63 — 5.8 0.36 BG D32-SD345 — — CR8-100×100 20 5.6 0.22 BGS D32-SD345 D10-SD345 D6-SD345@200 CR8-100×100 20 5.8 0.35 Notes: B—Reinforced concrete beam; S—Beam is equipped with stirrup; G—Stick carbon fiber reinforced polymer (CFRP) grid-polymer cement mortar (PCM) reinforcement layer on both sides; BS—Reinforced concrete beams provided with stirrups; BG—Reinforced concrete beam with only CFRP-PCM reinforced layer without stirrup; BGS—Reinforced concrete beams with stirrups and CFRP-PCM reinforcement layer; D—Diameter; SD—Reinforcement strength grade; CR8—CFRP grid of 8 mm in diameter; FRP—Fiber reinforced polymer. 表 2 混凝土配合比

Table 2 Concrete mix proportion

Maximum

grain size/mmColony/

mmWater cement

ratio/%Air ratio/% Measurement unit/(kg·m–3) Water Cement Fine aggregate Coarse aggregate Admixture 20 120 55.6 4.5 158 284 792 1126 1.3 表 3 混凝土和聚合物水泥砂浆(PCM)材料性能

Table 3 Properties of concrete and polymer cement mortar (PCM) materials

Material Compression strength/MPa Tensile strength/MPa Modulus of elasticity/GPa Concrete 34.1 2.92 31.9 PCM 36.7 2.87 30.1 表 4 钢筋与碳纤维增强树脂复合材料(CFRP)网格的力学性能

Table 4 Mechanical properties of steel and carbon fiber reinforced polymer (CFRP) grids

Material Type Cross-sectional area/mm2 Yield strength

/MPaModulus of elasticity/GPa Tensile strength

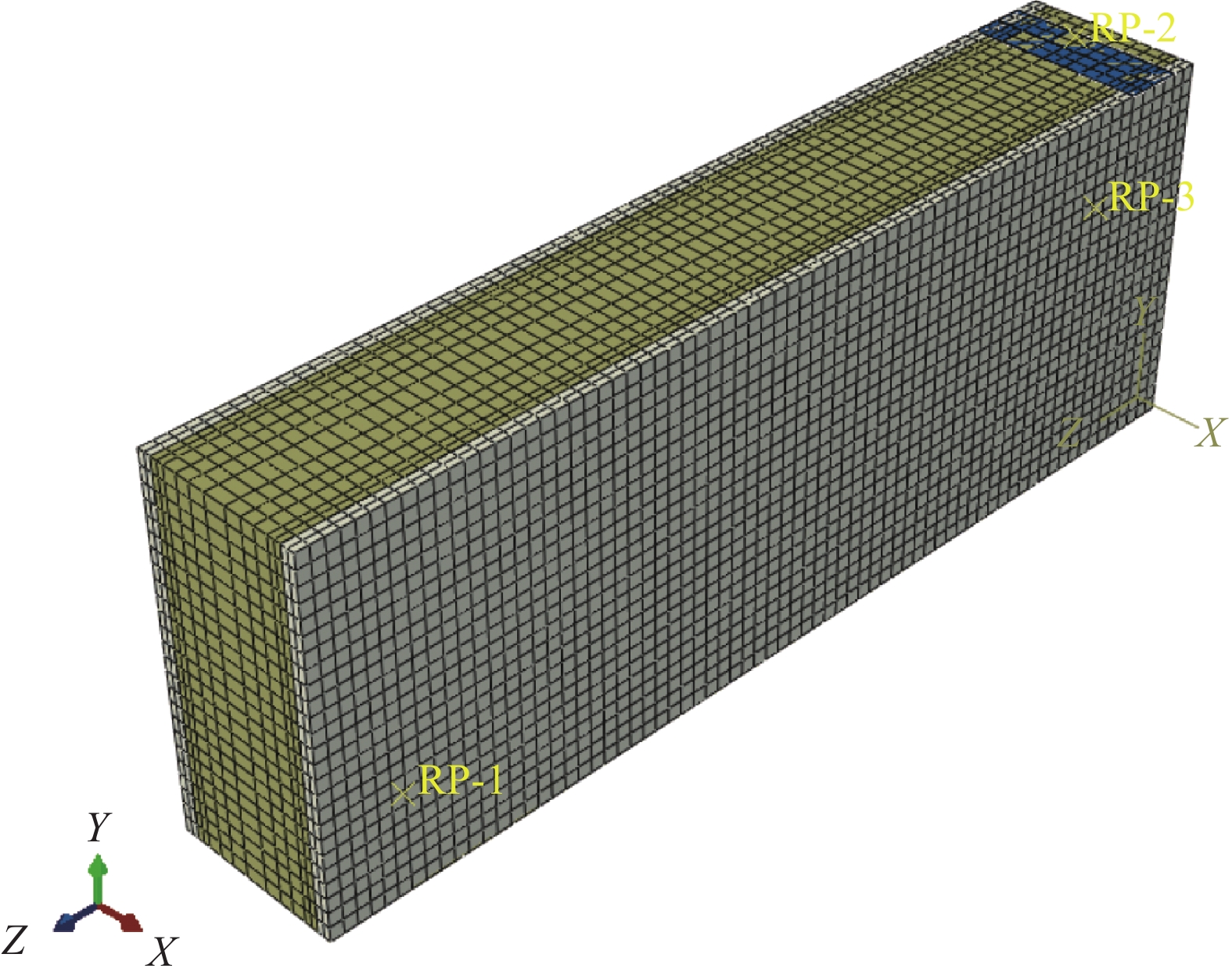

/MPaConcrete iron D32 794.2 389 200 587 D10 71.3 413 200 561 D6 31.7 417 200 570 CFRP grid CR8 26.4 — 100 1400 表 5 混凝土塑性损伤模型参数取值

Table 5 Parameters of plastic damage model for concrete

Type Expansion angle ψ Offset ε σb0/σc0 Kc Coefficient of viscosity μ Value 38 0.1 1.16 0.6667 0.0005 Notes: σb0/σc0—Ratio of biaxial and uniaxial compression limit strength; Kc—Ratio of stretching and the second stress invariant on the compression meridian. 表 6 CFRP网格-PCM加固RC梁试验结果汇总

Table 6 Summary of test results for CFRP grid-PCM shear-reinforced RC beams

Specimen Peak load P/kN

Pt/PcCross-mid deflection D/mm

Dt/DcShear cracking load Ps/kN

Pst/PscTest value

Pt/kNSimulation value

Pc/kNTest value

Dt/mmSimulation value

Dc/mmTest value

Pst/kNSimulation value

Psc/kNBS 690 614 1.12 8.35 8.07 1.03 210 172 1.22 BG 617 601 1.03 7.09 6.77 1.05 225 188 1.19 BGS 757 722 1.05 7.40 7.39 1.00 320 256 1.25 表 7 RGS试件参数信息

Table 7 Parameter information of RGS specimens

Specimen Stirrup Stirrup ratio

/%Grid type-spacing: Vertical and horizontal

/(mm×mm)Reinforcement ratio

/%Ultimate load

/kNRGS-S200 D6-SD345@200 0.16 CR8-100×100 0.22 722.2 RGS-S150 D6-SD345@150 0.21 737.7 RGS-S100 D6-SD345@100 0.32 746.4 RGS-H100 V150 D6-SD345@200 0.16 CR8-100×150 0.15 711.9 RGS-H100 V100 CR8-100×100 0.22 722.2 RGS-H100 V50 CR8-100×50 0.44 774.2 Notes: RGS—Reinforced concrete (RC) beam with stirrup and CFRP-PCM reinforcement layer; S200—Stirrup spacing is 200 mm; H—Horizontal grid spacing; V—Vertical grid spacing. 表 8 CFRP网格-PCM加固RC梁试件与未加固试件参数信息

Table 8 Parameter information of CFRP grid-PCM shear-reinforced RC beam specimens and unreinforced specimens

Type of specimen Specimen number Vertical reinforcement Stirrup CFRP grid PCM thickness

/mmHorizontal grid ratio/% Tensile reinforcement Compressive reinforcement First group NRS-50 6-D32-SD345 2-D10-SD345 D6-SD345@200 — — — RGS-50 CR8@50 20 0.44 Second group NRS-100 — — — RGS-100 CR8@100 20 0.22 Third group NRS-150 — — — RGS-150 CR8@150 20 0.15 Notes: NRS-50—Reinforced concrete (RC) beam with no CFRP-PCM reinforcement layer but with stirrup in 50 mm spacing (NRS-100 and NRS-150 are in the same manner); RGS-50—Reinforced concrete (RC) beam with CFRP-PCM reinforcement layer and stirrup in 50 mm spacing (RGS-100 and RGS-150 are in the same manner). 表 9 纵向和横向CFRP网格应变信息汇总

Table 9 Summary of grid strain information for horizontal and vertical CFRP

Specimen Shear

span λConcrete strength/MPa CFRP grid

typeRatio ρg/% PCM thickness/ mm Vertical grid strain

εver/10−6Horizontal grid strain

εhor/10−6Tensile

strength ftCompression strength

fcRGS1 2.6 2.92 34.1 CR8@50 0.44 20 2853.17 367.52 2993.50 511.91 2919.94 548.94 RGS2 2.6 2.92 34.1 CR8@100 0.22 2581.23 551.82 2837.57 1003.05 2599.29 920.19 RGS3 2.6 2.92 34.1 CR8@150 0.15 2029.87 825.87 3905.37 1088.63 3461.74 988.99 RGS4 1.8 2.92 34.1 CR8@100 0.22 3735.11 913.96 3564.48 1299.26 3570.80 1245.58 RGS5 2.2 2.92 34.1 CR8@100 0.22 3625.54 1150.78 3141.04 1094.90 3260.70 1078.79 RGS6 2.6 2.20 26.6 CR8@100 0.22 2337.90 571.62 2200.77 770.38 2289.55 794.90 RGS7 2.6 2.64 38.0 CR8@100 0.22 2494.30 704.24 3012.34 1069.08 2389.03 834.12 表 10 不同FRP网格抗剪加固RC梁抗剪承载力计算值与试验值比较

Table 10 Comparison of calculated and experimental values of shear capacity of RCbeams strengthened with different FRP grids

Data

sourcesSpecimen Pexp/kN Pcal[5]/kN Pcal/kN Pexp/Pcal[5] Pexp/Pcal Pexp/Pcal analysis Pexp/Pcal[5] analysis Mean

valueVariable

coefficientMean

valueVariable

coefficientText BG 617 330 466 1.87 1.32 1.22 0.16 1.85 0.32 BGS 757 414 562 1.83 1.35

[5]RCF4 881 768 625 1.15 1.41 RCF6 949 887 704 1.07 1.35 RCF8 943 939 769 1.00 1.23 RCF4’ 950 810 721 1.17 1.32 RCF64 860 823 704 1.04 1.22

[6]PGB 352 105 290 3.35 1.21

[11]S150-CGM 677 449 458 1.51 1.48 S250-CGM 571 248 428 2.30 1.33

[12]L3 373 186 385 2.00 0.97 L4 511 253 385 2.01 1.33

[21]NO.2 588 320 408 1.84 1.44 NO.4 631 332 498 1.90 1.27

[22]SB1 376 245 304 1.53 1.24 SB2 449 230 446 1.95 1.01 SB3 471 190 601 2.48 0.78

[23]SB2-3 449 229 441 1.96 1.02

[24]D 195 122 255 1.60 0.76

[25]C35 S3-M2-G2 674 261 472 2.58 1.43 C40 S0-M2-G2 bc 484 181 395 2.67 1.22 Notes: Pcal—Shear bearing capacity of the FRP grid reinforced RC beam which is calculated based on the proposed method; Pexp—Shear bearing capacity of the FRP grid reinforced RC beam which is calculated based on the corresponding test; RCF4, RCF6 and RCF8—Reinforced by CR4 CFRP, CR6 CFRP and CR8 CFRP grid whose vertical reinforcement interval was 50 mm compared with 150 mm of other specimens (CR4, CR6 and CR8 are the type of the CFRP grid in ABAQUS); RCF4'—Reinforced by CR4 CFRP grid whose vertical reinforcement interval was 50 mm compared with 50 mm of other specimens; RCF64—Reinforced by CR6&4 CFRP grid whose horizontal grid was CR4 and vertical grid was CR6; PGB—Beam was strengthened with high strength PCM and high strength carbon fiber-reinforced plastics (CFRP) gride bars; S150-CGM and S250-CGM—Beam with CFRP grid embedded in mortar (CGM), and the beam with 6 mm stirrups @150 mm c/c and @250 mm c/c; L3—Fiber grid and polymer mortar reinforced concrete beams (FRP GRID&NC-RC); L4—Fiber grid and engineered cementitous composite (ECC) reinforced concrete beams (FRP GRID&ECC-RC); NO.2 and NO.4—Beam with 2 row and 4 row of CFRP grid; SB1, SB2, SB3—FRP grid used in the ultra high toughness cementitious composite (UHTCC) layer (Measured thickness: 1 mm, 3 mm and 5 mm respectively); SB2-3—A 3 mm BFRP grid reinforced ECC composite SB2 reinforced concrete beam; D—RC beam strengthened with FRP grid; C35 S3-M2-G2—Beam C35 S3 with stirrup was strengthed by the use of mortar 2 and grid M; C40 S0-M2-G2 bc—Beam C40 S0 without stirrup but was strengthed by the use of mortar 2 and grid M; c/c—Center/Center; BFRP—Boron fiber reinforced plastic. -

[1] 袁廷朋, 陆洲导, 张鑫. 钢筋混凝土结构受氯离子严重腐蚀后的加固处理[J]. 四川建筑科学研究, 2007, 33(1):98-99. DOI: 10.3969/j.issn.1008-1933.2007.01.028 YUAN Tingpeng, LU Zhoudao, ZHANG Xin. Reinforcement of reinforced concrete structure after severe corrosion by chloride ion[J]. Architectural Science Research in Sichuan,2007,33(1):98-99(in Chinese). DOI: 10.3969/j.issn.1008-1933.2007.01.028

[2] WANG B U, JI K, WU T, et al. Experimental investigation of stress transfer and failure mechanism between existing concrete and CFRP grid-sprayed PCM[J]. Construction and Building Materials,2019,215:43-58. DOI: 10.1016/j.conbuildmat.2019.04.168

[3] WANG B, WANG Z, UJI K. Experimental verification of a novel anchorage method of CFRP grid in mortar[J]. Structures,2020,28:1646-1660. DOI: 10.1016/j.istruc.2020.09.044

[4] 江佳斐, 隋凯. 纤维网格增强超高韧性水泥复合材料加固混凝土圆柱受压性能试验[J]. 复合材料学报, 2019, 36(8):1957-1967. JIANG Jiafei, SUI Kai. Experimental study of compression performance of concrete cylinder strengthened by textile reinforced engineering cement composites[J]. Acta Materiae Compositae Sinica,2019,36(8):1957-1967(in Chinese).

[5] GUO R, PAN Y, CAI L H, et al. Study on design formula of shear capacity of RC beams reinforced by CFRP grid with PCM shotcrete method[J]. Engineering Structures,2018,166:427-440. DOI: 10.1016/j.engstruct.2018.03.095

[6] AMIRUDDIN A A. Shear behavior of concrete beams strengthened with CFRP grid and PCM shotcrete[J]. EPI International Journal of Engineering,2019,2(1):5-8. DOI: 10.25042/epi-ije.022019.02

[7] KHALIFA A. Rehabilitation of rectangular simply supported RC beams with shear deficiencies using CFRP composites[J]. Construction and Building Materials,2002,16(2):135-146.

[8] 曹亮, 张海燕, 吴波. 纤维编织网增强低聚物砂浆加固钢筋混凝土梁受剪性能研究[J]. 工程力学, 2019, 36(1):207-215. DOI: 10.6052/j.issn.1000-4750.2017.11.0881 CAO Liang, ZHANG Haiyan, WU Bo. Shear performance research on reinforced concrete beams strengthened with the fiber woven mesh and oligomic mortar[J]. Engineering Mechanics,2019,36(1):207-215(in Chinese). DOI: 10.6052/j.issn.1000-4750.2017.11.0881

[9] 中国工程建设标准化协会. 碳纤维片材加固混凝土结构技术规程: CECS 146—2003[S]. 北京: 中国计划出版社, 2007. China Engineering Construction Standardization Association. Standardization of engineering construction: CECS 146—2003[S]. Beijing: China Planning Press, 2007(in Chinese).

[10] 郑宇宙. FRP格栅增强ECC复合加固混凝土梁试验与计算方法研究[D]. 南京: 东南大学, 2018. ZHENG Yuzhou. Experiment and calculation method research on reinforced concrete (RC) beams strengthened with the composite of FRP grid and ECC[D]. Nanjing: Southeast China University, 2018(in Chinese).

[11] AZAM R, SOUDKI K, WEST J S, et al. Strengthening of shear-critical RC beams: Alternatives to externally bonded CFRP sheets[J]. Construction and Building Materials,2017,151:494-503. DOI: 10.1016/j.conbuildmat.2017.06.106

[12] 陈文永, 陈小兵, 丁一, 等. 纤维网格及ECC材料抗剪加固性能研究[J]. 工业建筑, 2009, 39(12):118-122. CHEN Wenyong, CHEN Xiaobing, DING Yi, et al. The shear behavior of concrete beam reinforced with ECC and FRP grid[J]. Industrial Architecture,2009,39(12):118-122(in Chinese).

[13] GUO R, CAI L H, HINO S, et al. Experimental study on shear strengthening of RC beams with FRP grid-PCM reinforcement layer[J]. Applied Sciences,2019,9(15):1-21. DOI: 10.3390/app9152984

[14] Concrete Committee of Civil Engineering Society. Civil engineering society concrete standard square document[S]. Japan: Japan Civil Engineering Society, 2007(in Chinese).

[15] NAKAMURA S, YAMAGUCHI K, ARWINM A. Bending reinforcing effect of RC beams using a two-layer contact placed CFRP grid by PCM spraying method[J]. Proceeding of the Japan Concrete Institute,2009,131(2):1429-1434.

[16] MIYANO N, YAMAGUCHI K, TANIGUCHI K. Shear capacity for RC beam retrofitted by CFRP covering PCM shotcrete[J]. Proceedings of the Japan Concrete Institute,2013,35(2):1423-1428.

[17] 刘巍, 徐明, 陈忠范. ABAQUS混凝土损伤塑性模型参数标定及验证[J]. 工业建筑, 2014, 44(S1):167-171, 213. LIU Wei, XU Ming, CHEN Zhongfan. Parameters calibration and verification of concrete damage plasticity model of ABAQUS[J]. Industrial Architecture,2014,44(S1):167-171, 213(in Chinese).

[18] Japan Road Association. Specifications for highway bridges, Part V seismic design[S]. Tokyo: Japan Road Association, 2002.

[19] 国家标准抗震规范管理组. 建筑抗震设计规范: GB/T 50011—2010[S]. 北京: 中国建筑工业出版社, 2016. National Standard Seismic Code Management Group. Code for the seismic design of buildings: GB/T 50011—2010[S]. Beijing: China State Construction Industry Press, 2016(in Chinese).

[20] American Concrete Institute. Guide for the design and construction of externally bonded FRP systems for strengthening concrete structures: ACI 440.2 R-08[S]. Farmington Hills: American Concrete Institute, 2008.

[21] LIANG J, UJI K, MATSUMURA S, et al. Shear strengthening of RC beam with CFRP grid and sprayed mortar[J]. Proceeding of the Japan Concrete Institute,2008,30(2):607-612.

[22] 郑宇宙, 王文炜, 戴建国, 等. FRP-UHTCC复合层抗剪增强钢筋混凝土梁受力性能试验研究[J]. 建筑结构学报, 2019(8): 118-126. ZHENG Yuzhou, WANG Wenwei, DAI Jianguo, et al. Experimental study on mechanical performance of reinforced concrete beams shear-strengthened with FRP-UHTCC composite[J]. Journal of Architectural Structures, 2019(8): 118-126(in Chinese).

[23] 王文炜, 郑宇宙. BFRP格栅增强ECC加固钢筋混凝土梁抗剪承载力试验研究[C]//第九届全国建设工程FRP应用学术交流会. 重庆: 中国土木工程学会FRP及工程应用专业委员会, 2015: 326-331. WANG Wenwei, ZHENG Yuzhou. Experimental research on shear capacity of concrete beams strengthened with BFRP grid reinforced ECC[C]//The 9th National Construction Engineering FRP Application Academic Exchange Conference. Chongqing: FRP and Engineering Application Professional Committee of the Chinese Society of Civil Engineering, 2015: 326-331(in Chinese).

[24] LU Z D, YANG X, DAI J G . Shear behavior of RC beams strengthened with FRP grid reinforced engineered cementitious composites[C]//The Sixth Asia-Pacific Conference on FRP in Structures (APFIS2017). Singapore: International Institute for FRP in Construction (IIFC), 2017: 1-5.

[25] BLANKSVARD T, TALJSTEN B, CAROLIN A. Shear strengthening of concrete structures with the use of mineral-based composites[J]. Journal of Composites for Construction,2009,13(1):25-34. DOI: 10.1061/(ASCE)1090-0268(2009)13:1(25)

-

期刊类型引用(6)

1. 唐百晓. 聚丙烯纤维混凝土纤维增强作用机理研究. 粘接. 2023(02): 78-82 .  百度学术

百度学术

2. 李锐,王飞,张凯宏. 聚丙烯纤维轻质高强混凝土动态力学特性研究. 实验技术与管理. 2023(02): 115-120+139 .  百度学术

百度学术

3. 贾静恩,张彬. 扰动荷载下聚丙烯纤维喷射混凝土力学性能研究. 复合材料科学与工程. 2023(06): 73-79+94 .  百度学术

百度学术

4. 郑祥盘,何伟,魏作友,陈龙. 树脂混凝土微型顶管技术研究与分析. 化学工程与装备. 2023(06): 10-15+22 .  百度学术

百度学术

5. 肖敏,欧阳春生,杨芬,夏艳波,王威. 聚丙烯纤维混凝土受弯构件正截面承载力的理论分析. 新型工业化. 2022(06): 170-173+255 .  百度学术

百度学术

6. 梁宁慧,游秀菲,兰菲,刘新荣,邓志云. 玄武岩粗聚丙烯纤维钢筋混凝土管力学性能. 地下空间与工程学报. 2022(04): 1177-1187+1198 .  百度学术

百度学术

其他类型引用(0)

-

下载:

下载: