Water-based SPEKK sizing agent for improving the mechanical properties of CF/PEKK composites

-

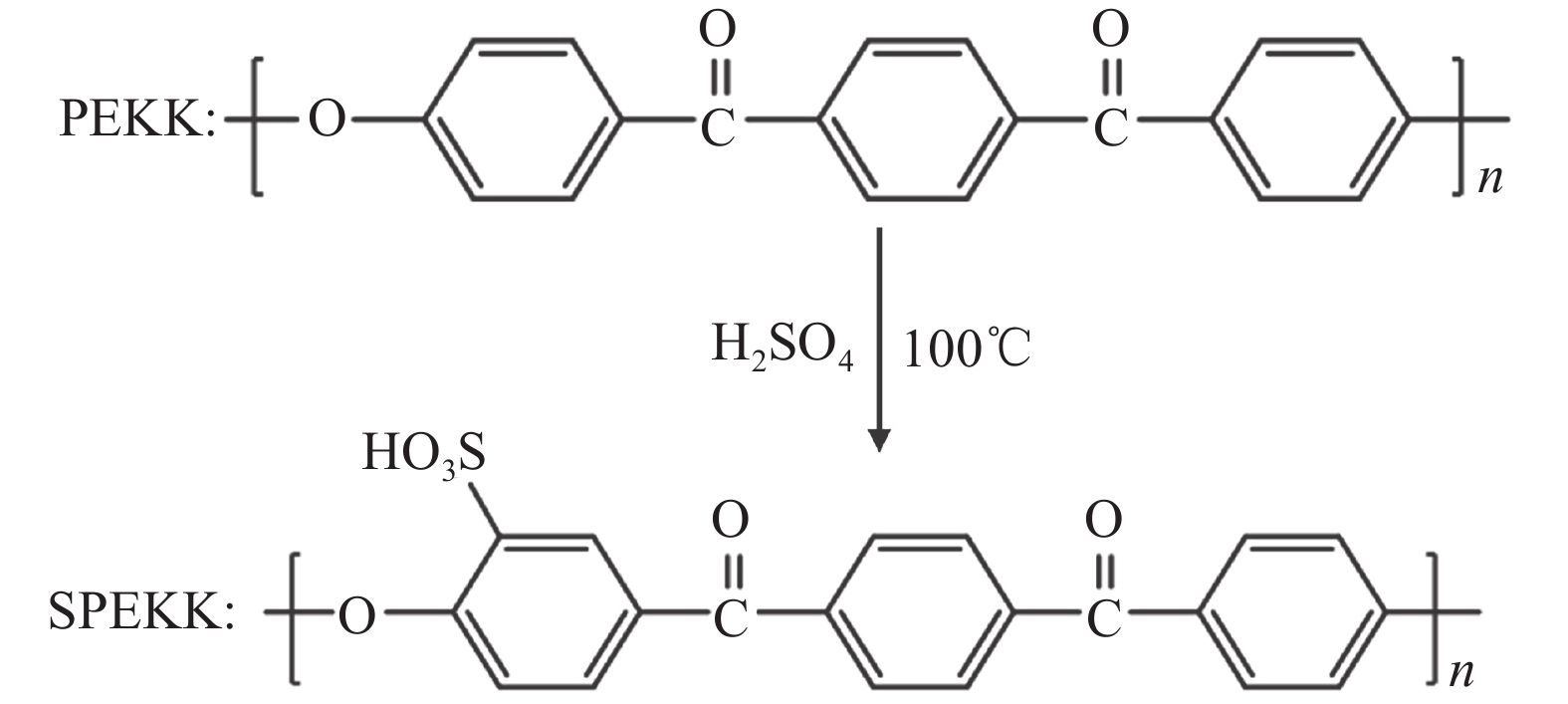

摘要: 由于碳纤维(CF)的化学惰性,导致了CF和聚醚酮酮(PEKK)的界面结合较差,限制了碳纤维增强聚醚酮酮(CF/PEKK)复合材料力学性能的发挥。本文通过将国产PEKK树脂进行磺化处理制备了磺化聚醚酮酮(SPEKK)水性上浆剂,以改善CF/PEKK复合材料的力学性能。通过调控SPEKK的磺化度使其能够形成稳定的水性乳液,对CF进行上浆改性,并通过真空热压制备了CF/PEKK复合材料。研究发现,当水性SPEKK乳液的浓度为0.5wt%时,改性后的CF/PEKK复合材料的弯曲强度、弯曲模量和层间剪切强度分别达到了1237 MPa、78 GPa和92 MPa,比未改性的CF/PEKK复合材料分别提升了35.5%、5.4%和26.0%。CF/PEKK复合材料力学性能的改善,可能归因于在CF表面引入的SPEKK通过与CF产生氢键、π-π相互作用及与PEKK树脂基体形成π-π相互作用、分子间扩散和缠结等显著增强了CF与PEKK的界面结合。采用水性SPEKK上浆剂对碳纤维表面处理,不会产生环境污染,工艺更加简单,且适合于碳纤维的工业化生产,对于发展国产高性能碳纤维增强热塑性复合材料具有重要意义。

-

关键词:

- 碳纤维/聚醚酮酮复合材料 /

- 磺化聚醚酮酮 /

- 水性上浆剂 /

- 界面改性 /

- 力学性能

Abstract: The interfacial interactions between carbon fiber (CF) and polyetherketoneketone (PEKK) are poor due to the chemical inertness of CF, limiting the mechanical properties of carbon fiber reinforced polyetherketoneketone (CF/PEKK) composites. In this study, a water-based sizing agent of sulfonated polyetherketoneketone (SPEKK) was prepared by sulfonating domestic PEKK resin, in order to improve the mechanical properties of CF/PEKK composites. By regulating the sulfonation degree, the stable SPEKK aqueous emulsion was obtained and used for CF sizing modification. Subsequently, CF/PEKK composites were fabricated via vacuum hot-press technique. When the concentration of SPEKK aqueous emulsion was 0.5wt%, the flexural strength, flexural modulus and interlaminar shear strength of the modified CF/PEKK composites reached 1237 MPa, 78 GPa, and 92 MPa, which were 35.5%, 5.4%, and 26.0% higher than that of the unmodified CF/PEKK composites, respectively. Such enhancement in mechanical properties could be attributed to the introduced SPEKK on the CF surfaces, which could form hydrogen bonds and π-π interactions with CF, as well as π-π interactions and diffusion and entanglement with PEKK, significantly promoting the interfacial bonding between CF and PEKK. As a simpler process, CF surface modification with water-based SPEKK sizing agent is environmentally friendly and suitable for the industrial production, which is of great significance for the development of domestic high-performance carbon fiber reinforced thermoplastic composites. -

图 3 SPEKK和PEKK的红外图谱(a)、酸碱滴定的磺化度(b)、热重曲线(c)、核磁氢谱(d)、XPS图谱(e);SPEKK-30 h水性乳液的粒径分布(f)

O/C—Oxygen/carbon ratio

Figure 3. FTIR spectra (a), sulfonation degree of SPEKK measured by acid-base titration (b), TGA curves (c), 1H NMR (d) and XPS spectra (e) of SPEKK and PEKK; Particle size distribution of SPEKK-30 h aqueous emulsion (f)

图 8 本文与其他CF表面改性方法制备的CF/PEKK和CF/聚醚醚酮(PEEK)复合材料力学性能对比[6-7, 15-16, 21, 27-28, 33, 45-48]

M-HPEEK—Hydroxylated PEEK grafted onto multi-walled carbon nanotubes; HPEEK-g-MWCNT—Hydroxylated PEEK grafted multi-walled carbon nanotubes; PAI & MXene—Polyamide-imide/Ti3C2Tx MXene; PEKC-COOH—Carboxyl pendant polyaryl-ether-ketone; s-PSF & GO—Sulfonated polyether sulfone and graphene oxide; BNO & PEI—Hydroxylated boron nitride nanosheets and polyetherimide; PEEK-NH2—Aminated polyether-ether-ketone; p-PEEK—Phosphorylated polyether-ether-ketone; MXene—Ti3C2Tx MXene; SA-PI—Semi-aliphatic polyimide; PANI—Polyaniline; GO—Graphene oxide

Figure 8. Comparison of mechanical properties of CF/PEKK and CF/polyether ether ketone (PEEK) composites with CF surface modification techniques in this study and previous works[6-7, 15-16, 21, 27-28, 33, 45-48]

图 9 CF/0 S/PEKK (a)、CF/0.10 S/PEKK (b)、CF/0.25 S/PEKK (c)、CF/0.50 S/PEKK (d)和CF/0.75 S/PEKK (e)复合材料在CF径向((a1)~(e1))和纬向 ((a2)~(e2))的SEM图像

Figure 9. SEM images of CF/0 S/PEKK (a), CF/0.10 S/PEKK (b), CF/0.25 S/PEKK (c), CF/0.50 S/PEKK (d) and CF/0.75 S/PEKK (e) composites in the wrap direction ((a1)-(e1)) and weft direction ((a2)-(e2)) of CF

表 1 材料简称及对应说明

Table 1. Material abbreviations and corresponding description

Sample Temperature/

℃Time/h Concentration

of SPEKK/wt%SPEKK-10 h 100 10 — SPEKK-20 h 100 20 — SPEKK-30 h 100 30 — SPEKK-40 h 100 40 — CF/0.10 S 100 2 0.10 CF/0.25 S 100 2 0.25 CF/0.50 S 100 2 0.50 CF/0.75 S 100 2 0.75 CF/0 S/PEKK 360 0.75 0.00 CF/0.10 S/PEKK 360 0.75 0.10 CF/0.25 S/PEKK 360 0.75 0.25 CF/0.50 S/PEKK 360 0.75 0.50 CF/0.75 S/PEKK 360 0.75 0.75 Notes: SPEKK—Sulfonated polyetherketoneketone; CF—Carbon fiber; PEKK—Polyetherketoneketone. 表 2 CF表面元素含量和O/C比

Table 2. Percentages of elemental content and O/C ratio on the surfaces of CF

Elemental content C/at% O/at% S/at% O/C/% Desized CF 83.34 16.66 0.00 19.99 CF/0.10 S 82.29 17.44 0.27 21.19 CF/0.25 S 79.62 19.87 0.51 24.50 CF/0.50 S 77.91 21.26 0.83 27.29 CF/0.75 S 73.89 22.90 1.31 30.99 表 3 C1s中几个含C基团的占比

Table 3. Percentages of several carbon-containing groups of C1s

Sample C—C/%

(284.7 eV)C—O/%

(285.6 eV)C=O/%

(286.6 eV)O—C=O/%

(288.9 eV)C—S/%

(286.8 eV)Desized CF 70.38 17.10 4.94 7.58 — CF/0.10 S 70.29 20.62 1.30 6.37 1.42 CF/0.25 S 60.47 31.57 2.72 2.12 3.12 CF/0.50 S 58.64 26.51 5.83 2.21 6.81 CF/0.75 S 64.07 18.60 3.35 4.60 9.37 -

[1] CHENG C, ZHANG C Y, ZHOU J L, et al. Improving the interlaminar toughness of the carbon fiber/epoxy composites via interleaved with polyethersulfone porous films[J]. Composites Science and Technology,2019,183:107827. doi: 10.1016/j.compscitech.2019.107827 [2] ZHAO H, CHEN L X, YUN J, et al. Improved thermal stabilities, ablation and mechanical properties for carbon fibers/phenolic resins laminated composites modified by silicon-containing polyborazine[J]. Engineered Science,2018,2(15):57-66. [3] 邢丽英, 冯志海, 包建文, 等. 碳纤维及树脂基复合材料产业发展面临的机遇与挑战[J]. 复合材料学报, 2020, 37(11):2700-2706.XING Liying, FENG Zhihai, BAO Jianwen, et al. Facing opportunity and challenge of carbon fiber and polymer matrix composites industry development[J]. Acta Materiae Compositae Sinica,2020,37(11):2700-2706(in Chinese). [4] 李国耀, 蔡忠龙, 段祝平, 等. 聚苯硫醚复合材料高速冲击破坏特征的微观分析[J]. 复合材料学报, 1996, 13(1): 1-8.LI Guoyao, CAI Zhonglong, DUAN Zhuping, et al. A microscope study of impact fracture characteristics of PPS composites[J]. Acta Materiae Compositae Sinica, 1996,13(1): 1-8(in Chinese). [5] 郑昊, 李岩, 涂昊昀. 短纤维插层碳纤维/环氧树脂复合材料层间性能[J]. 复合材料学报, 2022, 39(8):3674-3683.ZHENG Hao, LI Yan, TU Haoyun. Research on interlayer properties of short fiber intercalated carbon fiber/epoxy composites[J]. Acta Materiae Compositae Sinica,2022,39(8):3674-3683(in Chinese). [6] YANG X Q, LUO J M, REN H L, et al. Simultaneously improving the EMI shielding performances and mechanical properties of CF/PEKK composites via MXene interfacial modification[J]. Journal of Materials Science & Technology,2023,154:202-209. [7] LI Y Z, XU N, LYU H X, et al. Enhanced mechanical and tribological properties of carbon fiber/PEEK composites by hydroxylated boron nitride nanosheets and polyetherimide sizing agents[J]. Composites Science and Technology,2023,232:109851. doi: 10.1016/j.compscitech.2022.109851 [8] ZHANG Y H, TAO W, ZHANG Y, et al. Continuous carbon fiber/crosslinkable poly(ether ether ketone) laminated composites with outstanding mechanical properties, robust solvent resistance and excellent thermal stability[J]. Composites Science and Technology,2018,165:148-153. doi: 10.1016/j.compscitech.2018.06.020 [9] 章日超, 芦艾, 易勇, 等. 聚苯硫醚及其纤维增强复合材料的等温结晶形态[J]. 复合材料学报, 2007, 24(2):61-67.ZHANG Richao, LU Ai, YI Yong, et al. Morphologies of isothermal crystallized pure poly(phenylene sulfide) and fiber-reinforced poly(phenylene sulfide) composites[J]. Acta Materiae Compositae Sinica,2007,24(2):61-67(in Chinese). [10] 陈吉平, 李岩, 刘卫平, 等. 连续纤维增强热塑性树脂基复合材料自动铺放原位成型技术的航空发展现状[J]. 复合材料学报, 2019, 36(4):784-794.CHEN Jiping, LI Yan, LIU Weiping, et al. Development of AFP in-situ consolidation technology on continuous fiber reinforced thermoplastic matrix composites in aviation[J]. Acta Materiae Compositae Sinica,2019,36(4):784-794(in Chinese). [11] BENEDETTI L, BRULÉ B, DECREAMER N, et al. Shrinkage behaviour of semi-crystalline polymers in laser sintering: PEKK and PA12[J]. Materials& Design,2019,181:107906. [12] 杨雪勤, 吴健, 厉从雷, 等. 聚醚酮酮/羟基磷灰石复合植入物的力学性能与生物活性[J]. 功能高分子学报, 2019, 32(5):626-632.YANG Xueqin, WU Jian, LI Conglei, et al. Mechanical pro-perty and biological activity of polyetherketoneketone/hydroxyapatite composite implants[J]. Journal of Functional Polymers,2019,32(5):626-632(in Chinese). [13] YANG X, ZHAO J, WU K, et al. Making a strong adhesion between polyetherketoneketone and carbon nanotube fiber through an electro strategy[J]. Composites Science and Technology,2019,177:81-87. doi: 10.1016/j.compscitech.2019.04.015 [14] 陆承志, 赵乐, 杨雪勤, 等. 碳纤维增强聚醚酮酮模压复合材料结构与性能调控[J]. 复合材料学报, 2022, 39(8):3684-3694.LU Chengzhi, ZHAO Le, YANG Xueqin, et al. Study on structure and performance control of carbon fiber reinforced poly(ether ketone ketone) molding composites[J]. Acta Materiae Compositae Sinica,2022,39(8):3684-3694(in Chinese). [15] LYU H X, JIANG N Y, HU J Q, et al. Preparing water-based phosphorylated PEEK sizing agent for CF/PEEK interface enhancement[J]. Composites Science and Technology,2022,217:109096. doi: 10.1016/j.compscitech.2021.109096 [16] HU J L, YAN F, LIU H, et al. Water-based PEKC-COOH sizing agent for enhancing the interfacial adhesion of carbon fiber/polyether-ether-ketone composites[J]. Composites Part B: Engineering,2021,225:109279. doi: 10.1016/j.compositesb.2021.109279 [17] XU P, FENG T F, WANG Y F, et al. A novel approach based on stress-impedance effect to assess the interfacial properties in fiber-reinforced composites[J]. Composites Communications,2021,27:100854. doi: 10.1016/j.coco.2021.100854 [18] LI J Q, HUANG Y D, FU S Y, et al. Study on the surface performance of carbon fibres irradiated by γ-ray under different irradiation dose[J]. Applied Surface Science,2010,256(7):2000-2004. doi: 10.1016/j.apsusc.2009.09.035 [19] 曾汉民, 张志毅, 章明秋, 等. CF/PEEK复合材料界面层结构与性能关系研究[J]. 复合材料学报, 1994, 11(2):81-89. doi: 10.13801/j.cnki.fhclxb.1994.02.013ZENG Hanmin, ZHANG Zhiyi, ZHANG Mingqiu, et al. Studies on interfacial structure-proproperties of the carbon fiber reinforced PEEK[J]. Acta Materiae Compositae Sinica,1994,11(2):81-89(in Chinese). doi: 10.13801/j.cnki.fhclxb.1994.02.013 [20] LI C Q, DENG H A, WANG K, et al. Strengthening and toughening of thermoplastic polyolefin elastomer using polypropylene-grafted multiwalled carbon nanotubes[J]. Journal of Applied Polymer Science,2011,121(4):2104-2112. doi: 10.1002/app.33892 [21] LYU H X, JIANG N Y, LI Y Z, et al. Enhancing CF/PEEK interfacial adhesion by modified PEEK grafted with carbon nanotubes[J]. Composites Science and Technology,2021,210:108831. doi: 10.1016/j.compscitech.2021.108831 [22] 何芳, 李皓, 万怡灶, 等. 三维编织碳纤维增强聚醚醚酮复合材料等离子体处理及其表面仿生沉积[J]. 复合材料学报, 2011, 28(2):77-81. doi: 10.13801/j.cnki.fhclxb.2011.02.027HE Fang, LI Hao, WAN Yizao, et al. Plasma treatment and biomimetic deposition of the 3D braided carbon fiber reinforced PEEK composites[J]. Acta Materiae Compositae Sinica,2011,28(2):77-81(in Chinese). doi: 10.13801/j.cnki.fhclxb.2011.02.027 [23] 曹建凡, 白树林, 秦文贞, 等. 碳纤维增强热塑性复合材料的制备与性能研究进展[J]. 复合材料学报, 2023, 40(3):1229-1247.CAO Jianfan, BAI Shulin, QIN Wenzhen, et al. Research progress on preparation and properties of carbon fiber reinforced thermoplastic composites[J]. Acta Materiae Compositae Sinica,2023,40(3):1229-1247(in Chinese). [24] ZHANG J W, JU S, JIANG D Z, et al. Reducing dispersity of mechanical properties of carbon fiber/epoxy composites by introducing multi-walled carbon nanotubes[J]. Composites Part B: Engineering,2013,54:371-376. doi: 10.1016/j.compositesb.2013.05.046 [25] KONG W W, SHI J F, ZOU K, et al. Synergistically optimizing interlaminar and electromagnetic interference shielding behavior of carbon fiber composite based on interfacial reinforcement[J]. Carbon,2022,200:448-455. doi: 10.1016/j.carbon.2022.08.080 [26] LUO J M, YANG X Q, XUE Y, et al. Simultaneous optimization of the thermal conductivity and mechanical properties of epoxy resin composites through PES and AgNP functionalized BNs[J]. Composites Part B: Engineering,2023,248:110373. doi: 10.1016/j.compositesb.2022.110373 [27] LIU L, YAN F, LI M, et al. Improving interfacial properties of hierarchical reinforcement carbon fibers modified by graphene oxide with different bonding types[J]. Compo-sites Part A: Applied Science and Manufacturing,2018,107:616-625. doi: 10.1016/j.compositesa.2018.02.009 [28] YUAN C C, LI D Z, YUAN X Y, et al. Preparation of semi-aliphatic polyimide for organic-solvent-free sizing agent in CF/PEEK composites[J]. Composites Science and Technology,2021,201:108490. doi: 10.1016/j.compscitech.2020.108490 [29] 孙正, 刘力源, 刘德博, 等. 纳米改性连续纤维增强热塑性树脂复合材料及其力学性能研究进展[J]. 复合材料学报, 2019, 36(4):771-783. doi: 10.13801/j.cnki.fhclxb.20181018.002SUN Zheng, LIU Liyuan, LIU Debo, et al. Development and mechanical properties of nano-modified continuous fiber reinforced thermoplastic composites[J]. Acta Materiae Compositae Sinica,2019,36(4):771-783(in Chinese). doi: 10.13801/j.cnki.fhclxb.20181018.002 [30] CHEN J L, WANG K, ZHAO Y. Enhanced interfacial interactions of carbon fiber reinforced PEEK composites by regulating PEI and graphene oxide complex sizing at the interface[J]. Composites Science and Technology,2018,154:175-186. doi: 10.1016/j.compscitech.2017.11.005 [31] 李伟东, 张金栋, 刘刚, 等. 国产T800碳纤维/双马来酰亚胺复合材料的界面及力学性能[J]. 复合材料学报, 2016, 33(7):1484-1491. doi: 10.13801/j.cnki.fhclxb.20160511.005LI Weidong, ZHANG Jindong, LIU Gang, et al. Interfacial and mechanical properties of domestic T800 carbon fiber/bismaleimide composites[J]. Acta Materiae Compo-sitae Sinica,2016,33(7):1484-1491(in Chinese). doi: 10.13801/j.cnki.fhclxb.20160511.005 [32] WANG X K, HUANG Z G, LAI M L, et al. Highly enhancing the interfacial strength of CF/PEEK composites by introducing PAIK onto diazonium functionalized carbon fibers[J]. Applied Surface Science,2020,510:145400. doi: 10.1016/j.apsusc.2020.145400 [33] LYU H, JIANG N, LI Y, et al. Enhanced interfacial and mechanical properties of carbon fiber/PEEK composites by hydroxylated PEEK and carbon nanotubes[J]. Composites Part A: Applied Science and Manufacturing,2021,145:106364. doi: 10.1016/j.compositesa.2021.106364 [34] SU Y N, LIU P P, JING D Q, et al. Improved interfacial adhesion in carbon fiber/poly(ether ether ketone) composites with the sulfonated poly(ether ether ketone) sizing treatment[J]. Journal of Applied Polymer Science,2021,138(45):51326. doi: 10.1002/app.51326 [35] ZHOU N, JIA J, ZHAO S Y, et al. Interfacial enhancement of CF/PEEK composites by coating sulfonated PEEK sizing agent[J]. Surfaces and Interfaces,2023,37:102652. doi: 10.1016/j.surfin.2023.102652 [36] PALAMARA D, BRUZZANITI P, CALABRESE L, et al. Effect of degree of sulfonation on the performance of adsorbent SAPO-34/S-PEEK composite coatings for adsorption heat pumps[J]. Progress in Organic Coatings,2021,154:106193. doi: 10.1016/j.porgcoat.2021.106193 [37] 庄庄. 磺化聚醚醚酮类湿敏材料的设计及其湿度传感器的性能研究[D]. 长春: 吉林大学, 2020.ZHUANG Zhuang. The design and performance study of polymeric humidity sensors based on sulfonated poly(ether ether ketone)s[D]. Changchun: Jilin University, 2020(in Chinese). [38] ASTM. Standard test method for flexural properties of polymer matrix composite materials: ASTM D7264/D7264 M—07[S]. West Conshohocken: ASTM International, 2007. [39] ASTM. Standard test method for short-beam strength of polymer matrix composite materials and their laminates: ASTM D2344/D2344 M—16[S]. West Conshohocken: ASTM International, 2016. [40] 中华人民共和国国家质量监督检验检疫总局. 碳纤维增强塑料孔隙含量和纤维体积含量试验方法: GB/T 3365—2008[S]. 北京: 中国标准出版社, 2008.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Carbon fiber reinforced plastics—Determination of void content and fiber volume content: GB/T 3365—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [41] 魏浩然, 黄振圣, 程伟, 等. 磺化聚醚醚酮的合成工艺优化及表征[J]. 武汉纺织大学学报, 2013, 26(3):68-71. doi: 10.3969/j.issn.2095-414X.2013.03.017WEI Haoran, HUANG Zhensheng, CHEN Wei, et al. Characterization and synthesis process optimization of sulfonated poly(ether ether ketone)[J]. Journal of Wuhan Textile University,2013,26(3):68-71(in Chinese). doi: 10.3969/j.issn.2095-414X.2013.03.017 [42] 曾繁涤, 易回阳, 谈晓宏, 等. 磺化聚醚酮酮的合成和表征[J]. 高分子学报, 1997(2):129-135.ZENG Fandi, YI Huiyang, TAN Xiaohong, et al. Synthesis and characterization of sulfonated polyether ketone ketone[J]. Acta Polymerica Sinica,1997(2):129-135(in Chinese). [43] 霍瑞贞, 罗远芳, 梁理侃, 等. 聚芳醚醚酮和磺化聚芳醚醚酮的热分解动力学[J]. 高分子学报, 1990(4):426-433.HUO Ruizhen, LUO Yuanfang, LIANG Likan, et al. Kinetic studies on thermal degradation of poly(aryl ether ether ketone) and sulfonated poly(aryl ether ether ketone) by TG[J]. Acta Polymerica Sinica,1990(4):426-433(in Chinese). [44] SU Y N, ZHANG X H, JING D Q, et al. Effect of surface functionalization on the surface and interfacial properties of thermoplastic-coated carbon fibers[J]. New Carbon Materials,2021,36(6):1169-1176. doi: 10.1016/S1872-5805(21)60049-5 [45] YUAN X Y, JIANG J, WEI H W, et al. PAI/MXene sizing-based dual functional coating for carbon fiber/PEEK composite[J]. Composites Science and Technology,2021,201:108496. doi: 10.1016/j.compscitech.2020.108496 [46] REN T N, ZHU G M, HOU X A, et al. Improvement of interfacial interactions in CF/PEEK composites by an s-PSF/graphene oxide compound sizing agent[J]. Journal of Applied Polymer Science,2021,138(45):51327. doi: 10.1002/app.51327 [47] YAN T W, YAN F, LI S Y, et al. Interfacial enhancement of CF/PEEK composites by modifying water-based PEEK-NH2 sizing agent[J]. Composites Part B: Engineering,2020,199:108258. doi: 10.1016/j.compositesb.2020.108258 [48] KONG W W, YI S Q, SUN W J, et al. Polyaniline-decorated carbon fibers for enhanced mechanical and electromagnetic interference shielding performances of epoxy composites[J]. Materials & Design,2022,217:110658. -

下载:

下载: