Recent progress in carbon fiber electrodes for structural supercapacitors composites

-

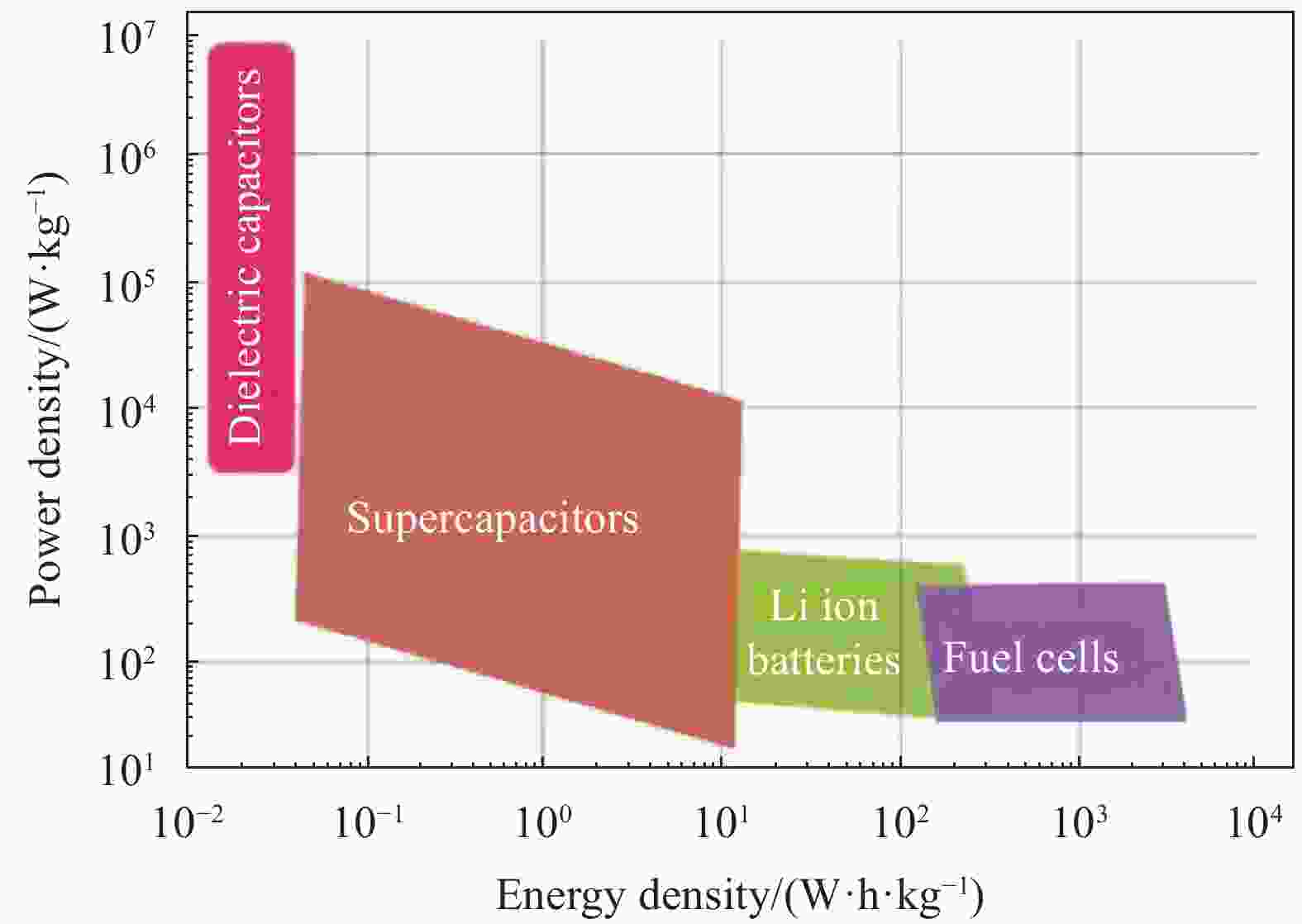

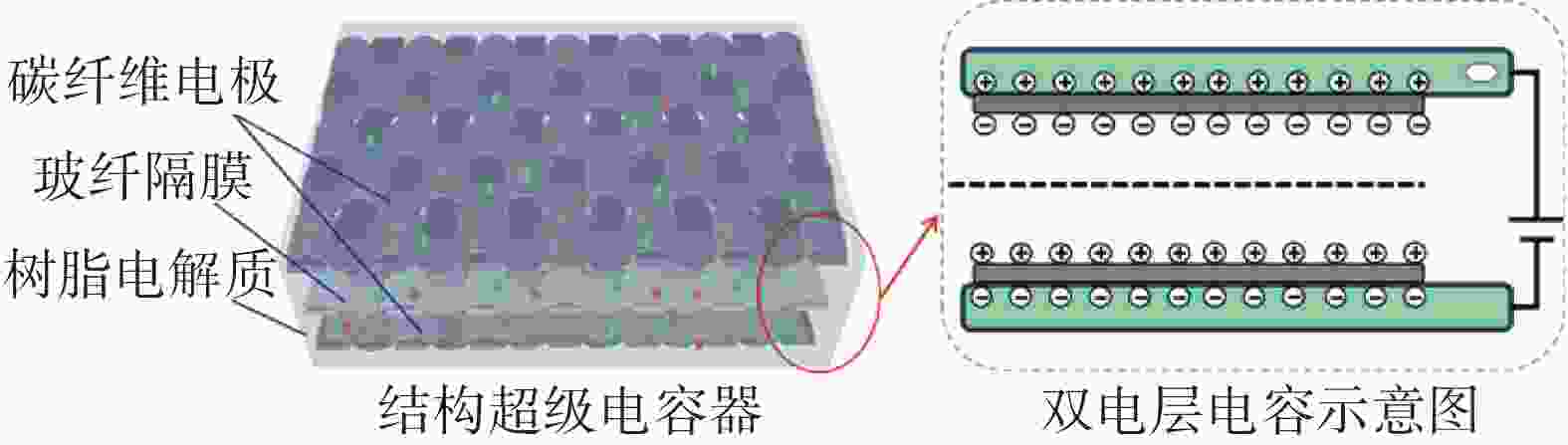

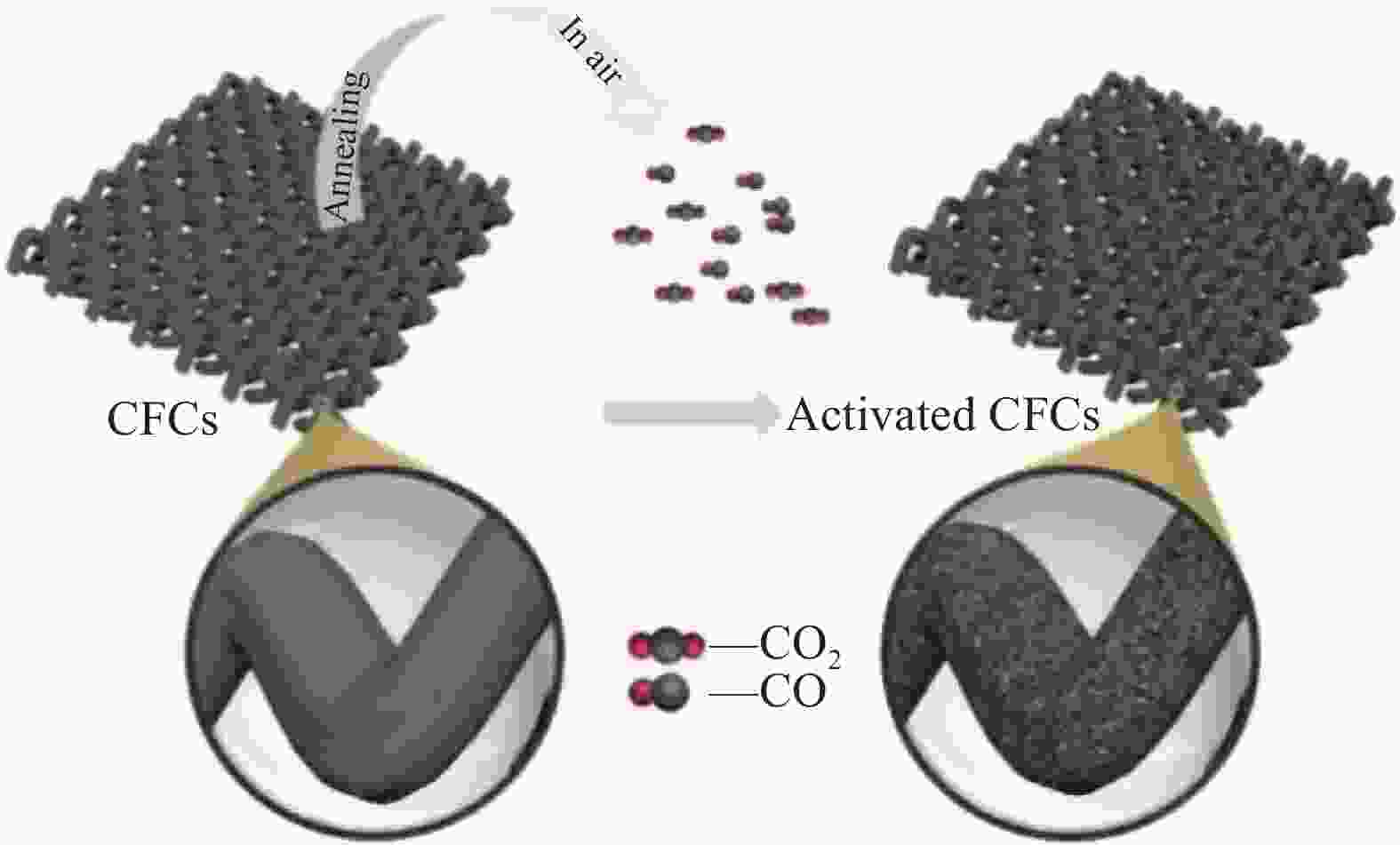

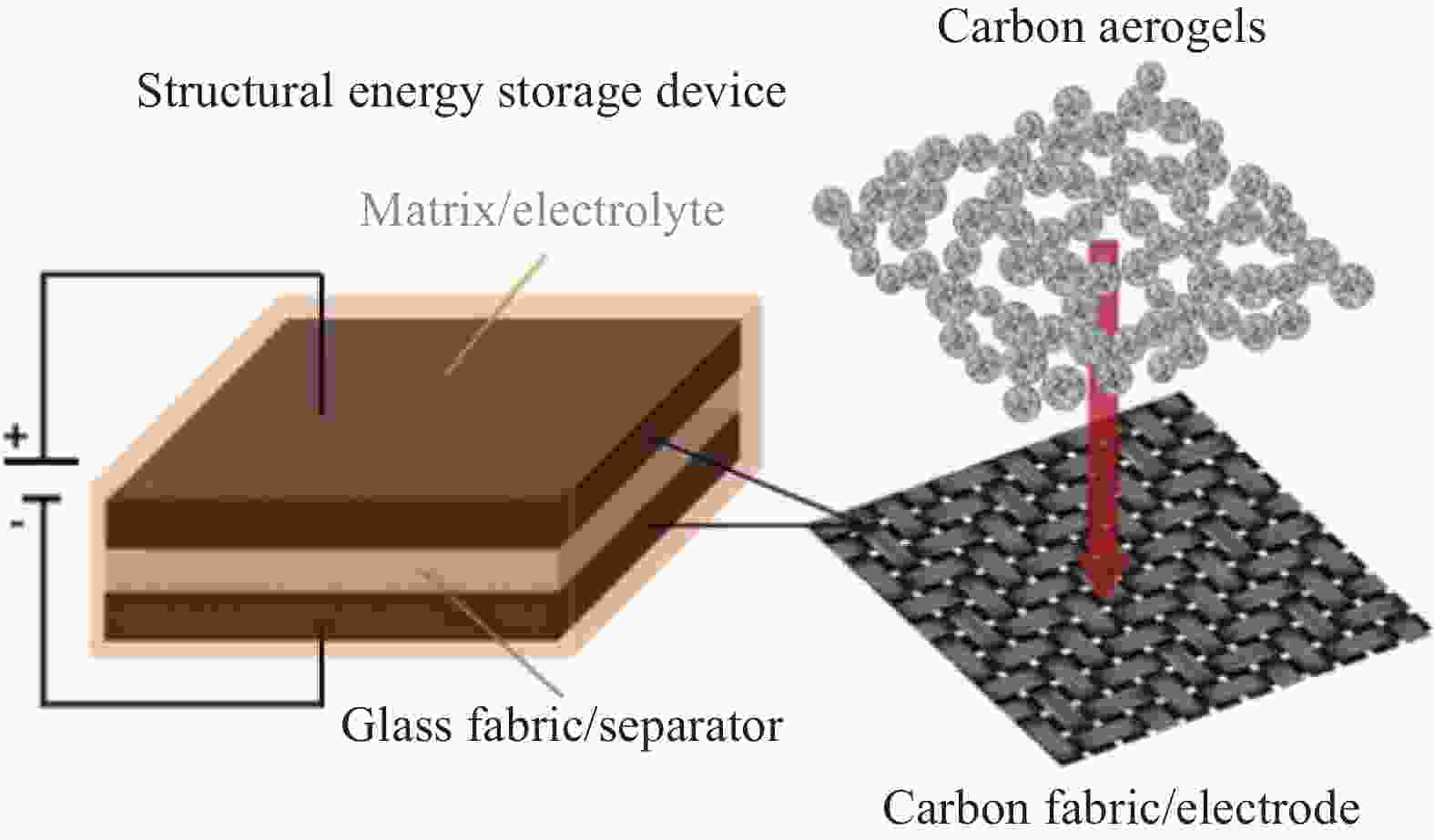

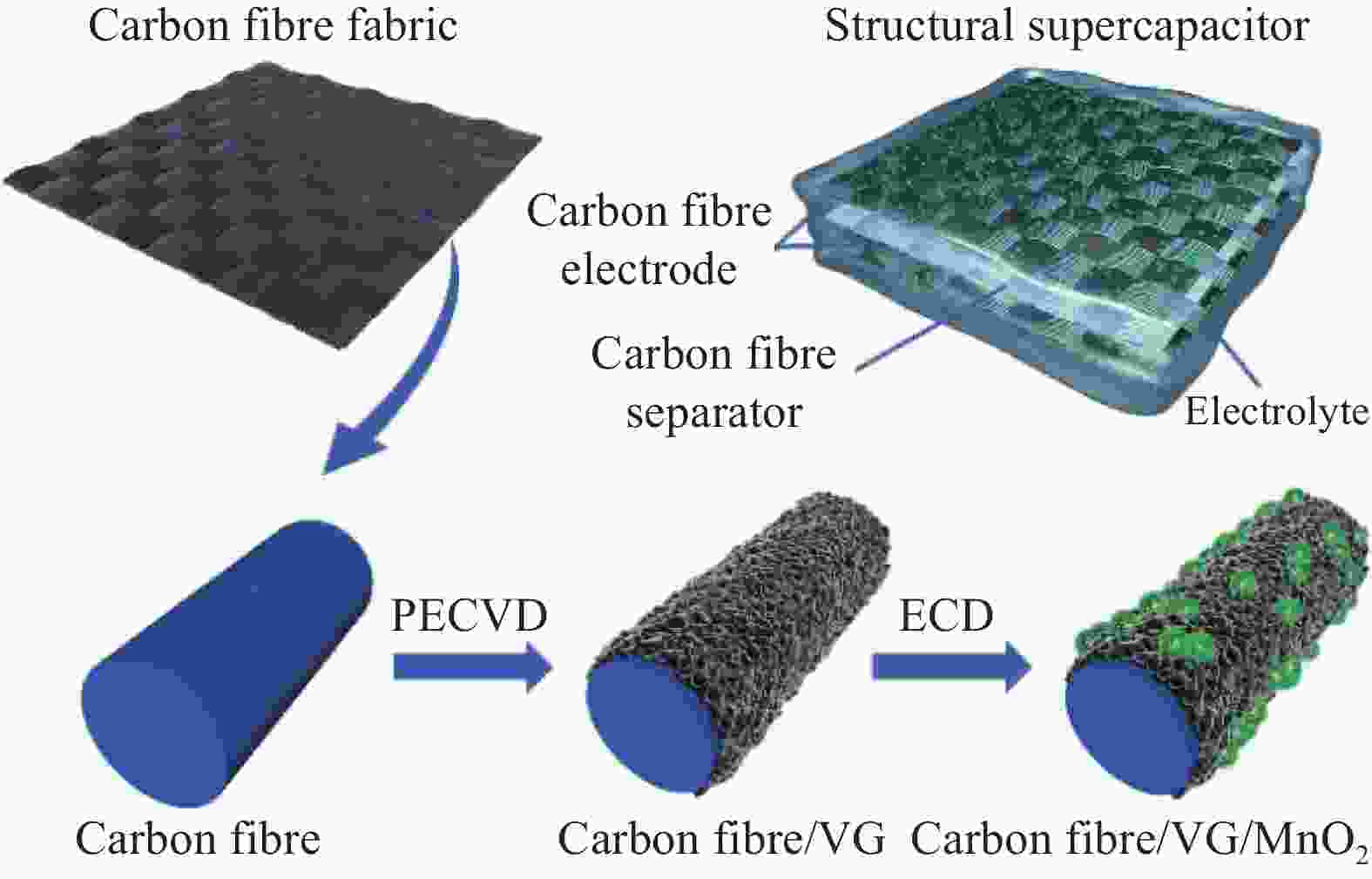

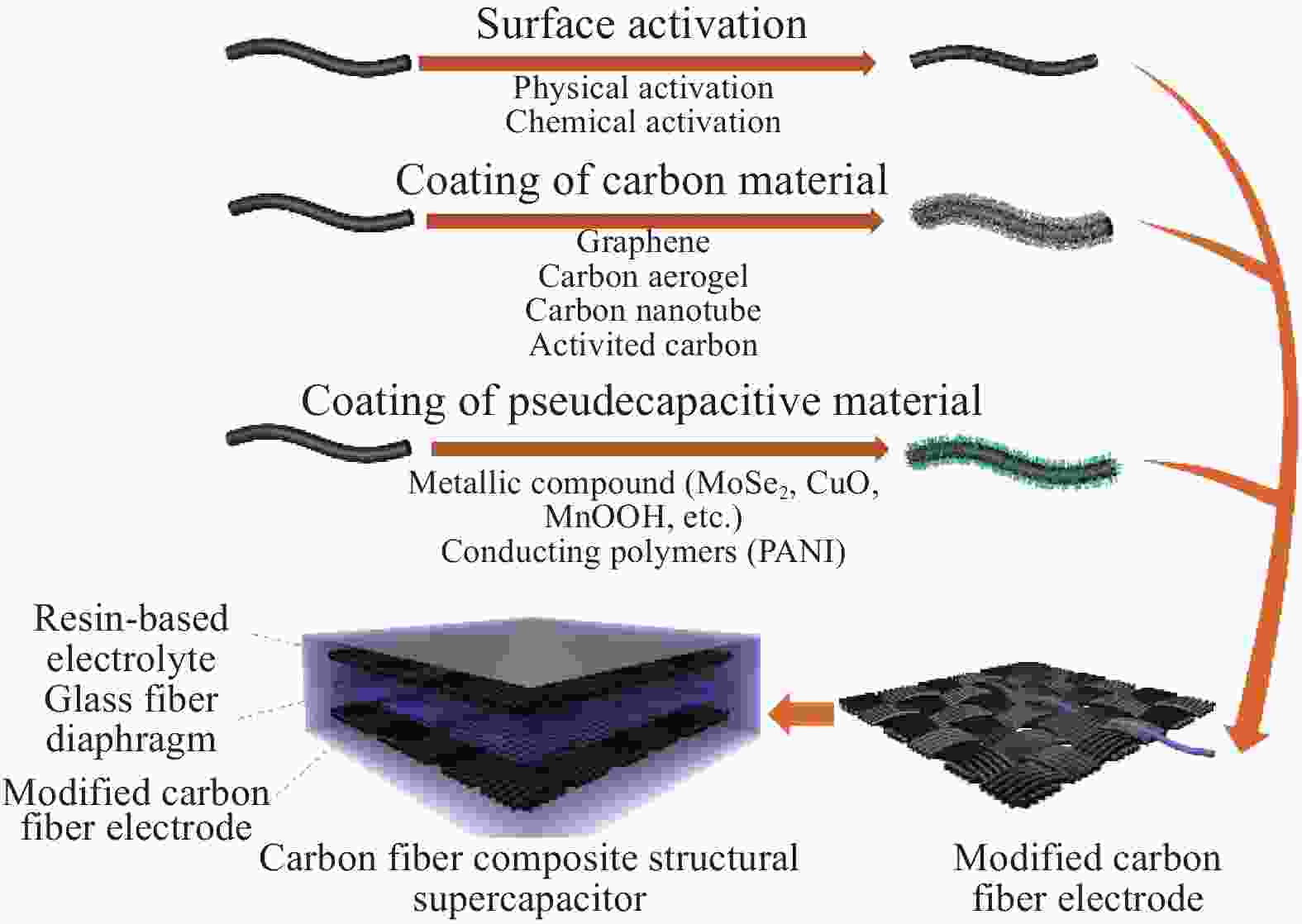

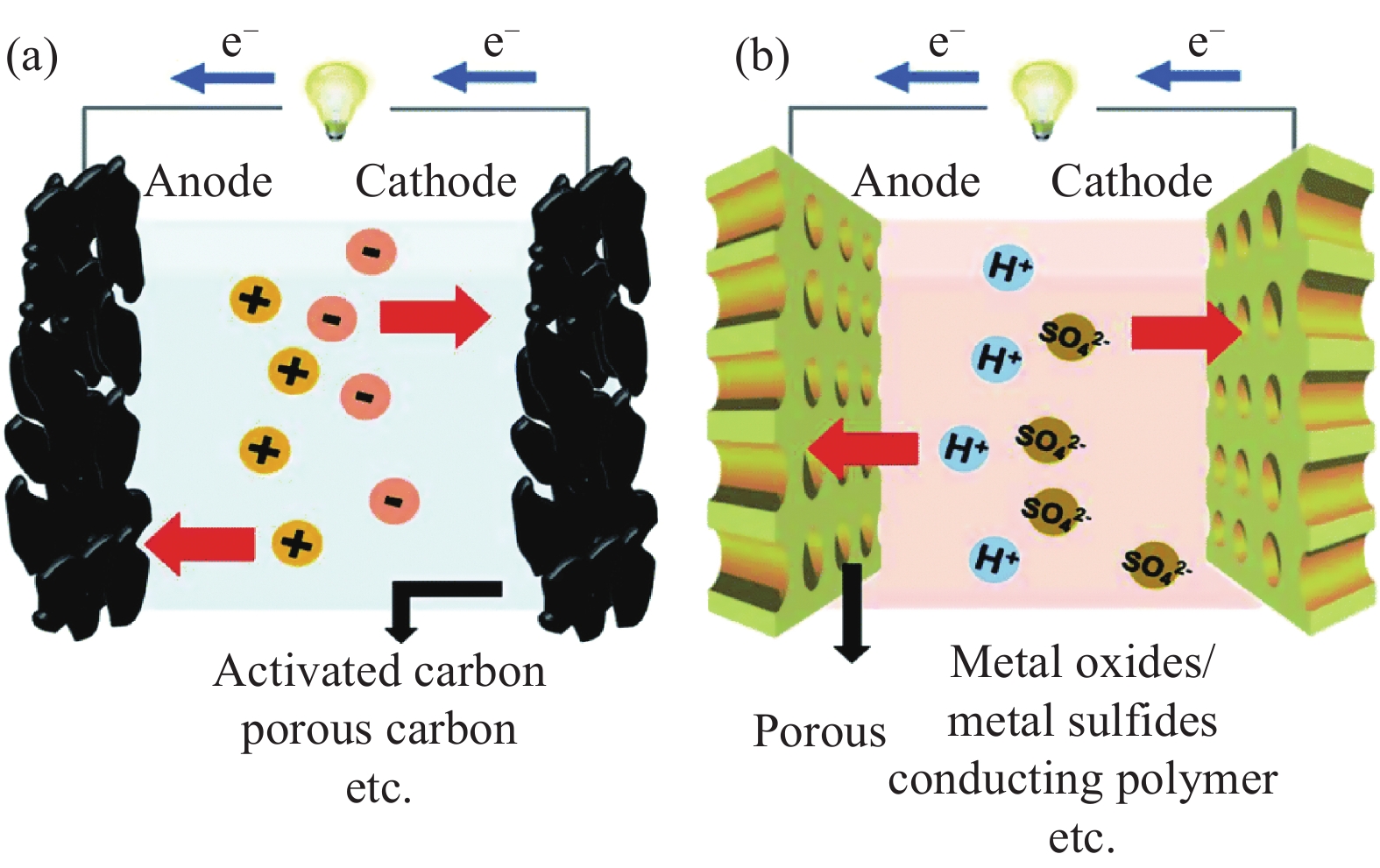

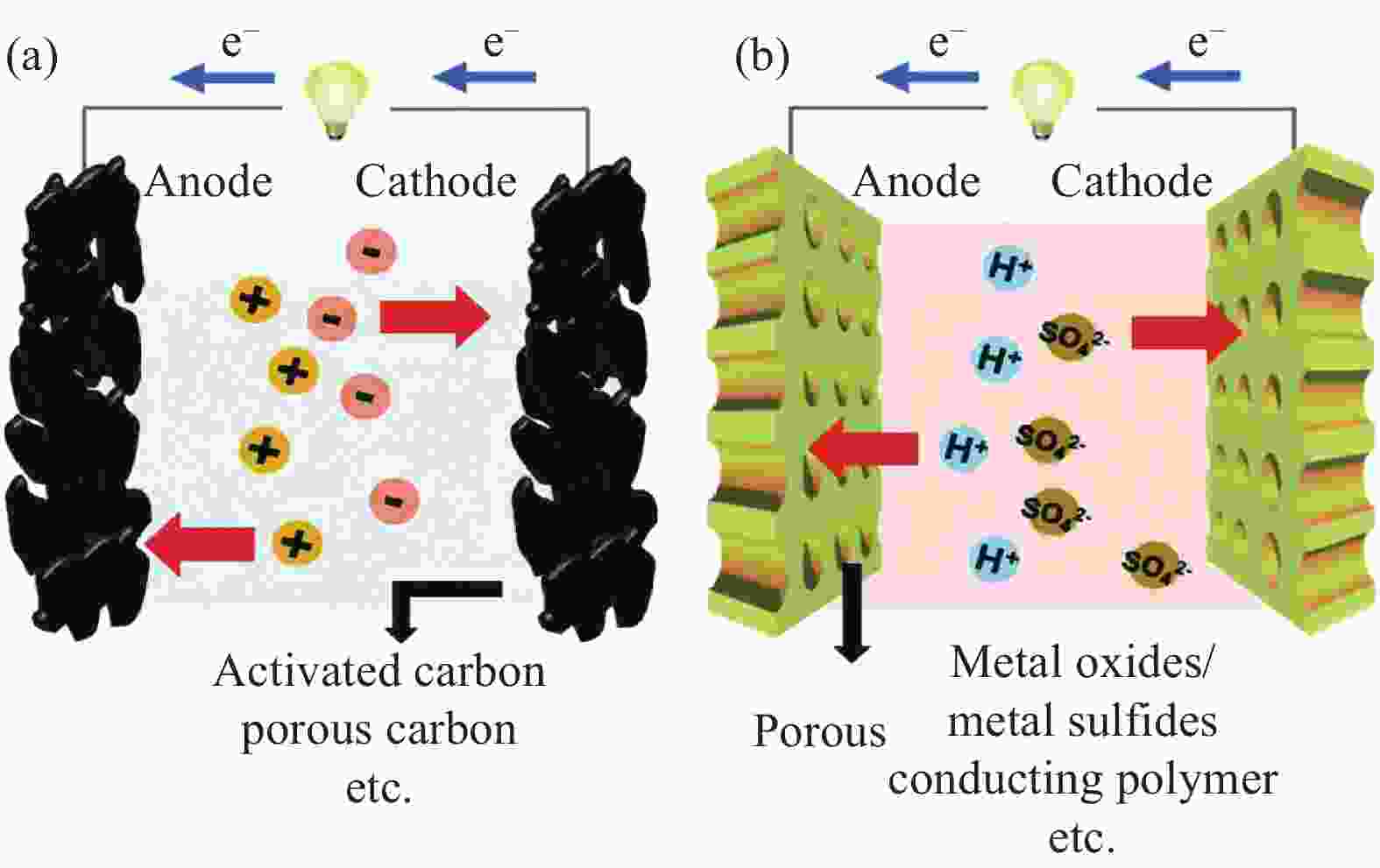

摘要: 在能源危机与生态环境持续恶化的大背景下,开发先进储能技术成为各国竞相研究的重点。将碳纤维作为多功能结构电极与聚合物电解质复合,制备兼具储能与结构承载的复合材料结构超级电容器(Structural supercapacitor composites,SSC),有望满足现代装备对高效储能与轻量化结构的双重需求,在新能源汽车、航空航天等领域具有广泛应用前景。碳纤维电极是SSC的重要组件,承担着富集电荷与力学承载的双重任务,应具有高比表面积、优良的力学性能及树脂电解质浸润能力。然而常规碳纤维表面光滑,比表面积小,化学惰性大,不利于电荷的存储及树脂电解质的浸润,限制了高性能SSC的制备与应用,必须对其进行表面改性处理。本文介绍了SSC用碳纤维电极材料的研究现状,重点阐述了刻蚀活化改性、碳基活性材料修饰、纳米金属化合物活性材料修饰、聚苯胺修饰等改性方法,总结了不同碳纤维电极制备方法对SSC储能及力学性能的影响行为与机制,归纳了各自优缺点,并展望了SSC用碳纤维电极研制面临的挑战及发展趋势。Abstract: In the context of energy crisis and continuous deterioration of ecological environment, the development of advanced energy storage technology has become the focus of competing research in global. Structural supercapacitor composites (SSC) with both energy storage and structural bearing capacity are developed by using multifunctional carbon fiber electrode and polymer electrolyte, which is expected to meet the dual demands of modern equipment for efficient energy storage and lightweight structures. Therefore, SSC has a wide application prospect in electric vehicles, aerospace and other fields. Carbon fiber electrode is a key component of SSC, which plays an important role in charge accumulation and mechanical loading. It should have high specific surface area, excellent mechanical properties and good wettability with polymer electrolyte. However, the pristine surface of carbon fiber is smooth and chemically inert, which is not conducive to ion storage and resin electrolyte infiltration in carbon fiber electrodes, and thus limits the preparation and application of high-performance SSC, so surface modification of carbon fiber electrode is necessary. This paper introduces the current research status of carbon fiber electrode materials for SSC, mainly focuses on several important surface modification methods of carbon fiber (such as chemical etching activation, modification with carbon-based active materials, modification with nano metal compounds and polyaniline modification), summarizes the influence of different carbon fiber electrode preparation methods on the energy storage and mechanical properties of SSC and the corresponding mechanisms, and their respective advantages and disadvantages. The challenges and development trend of carbon fiber electrode for SSC are also prospected.

-

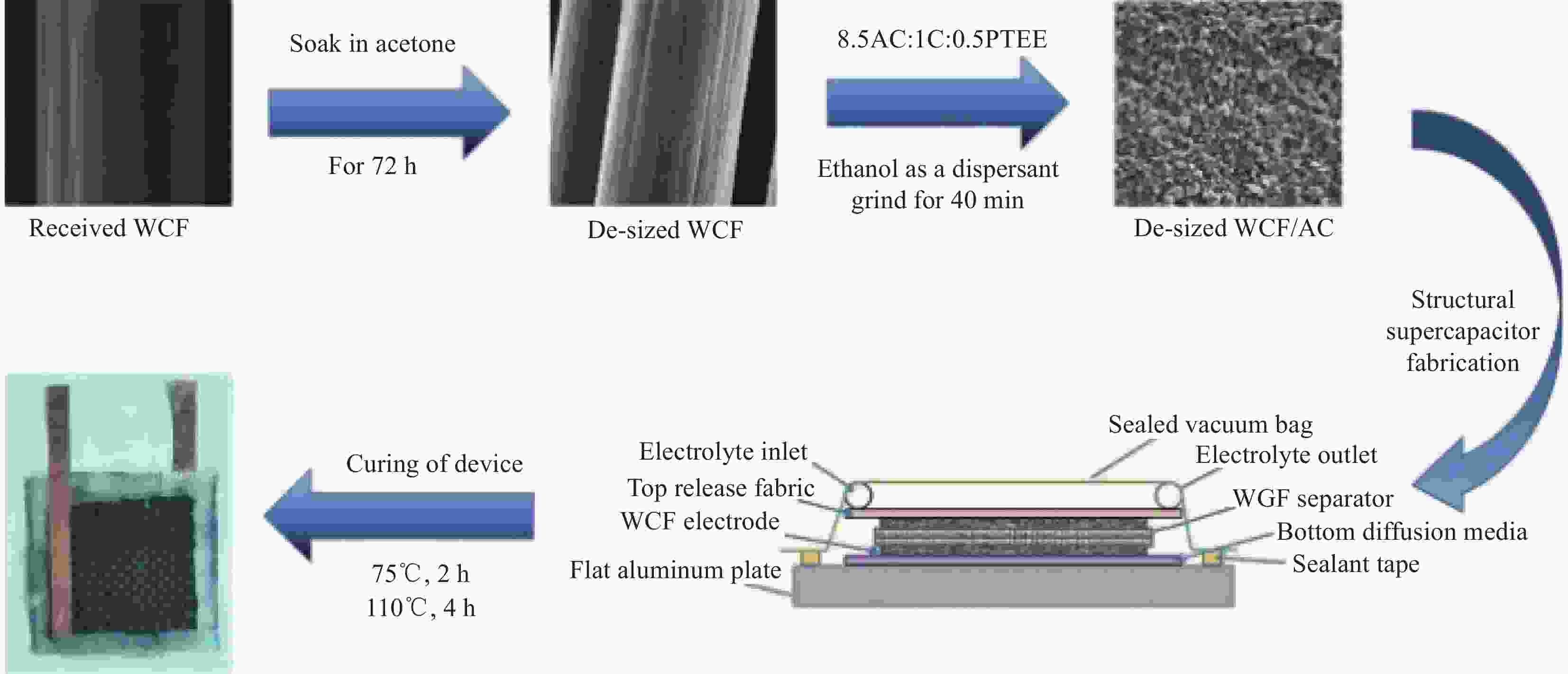

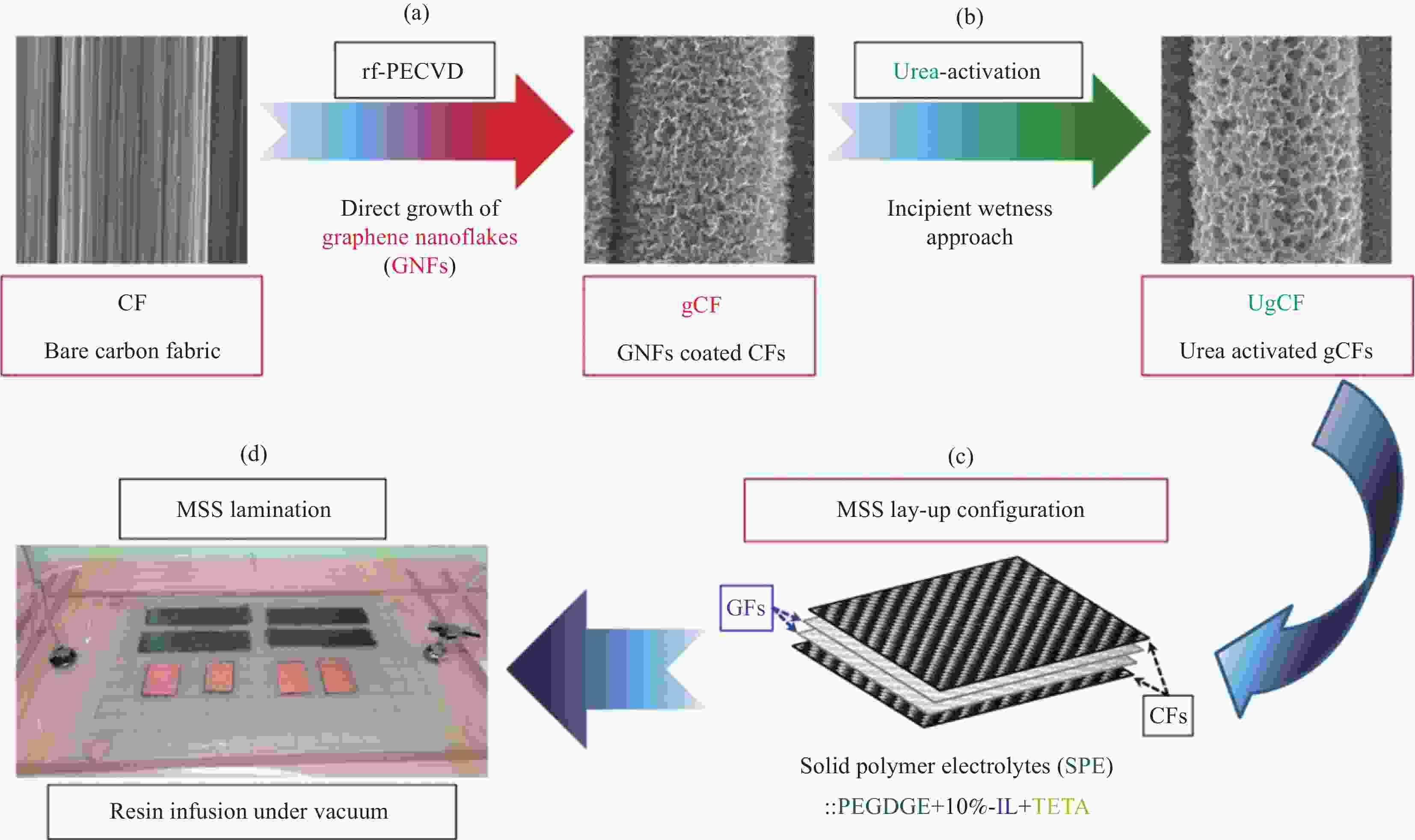

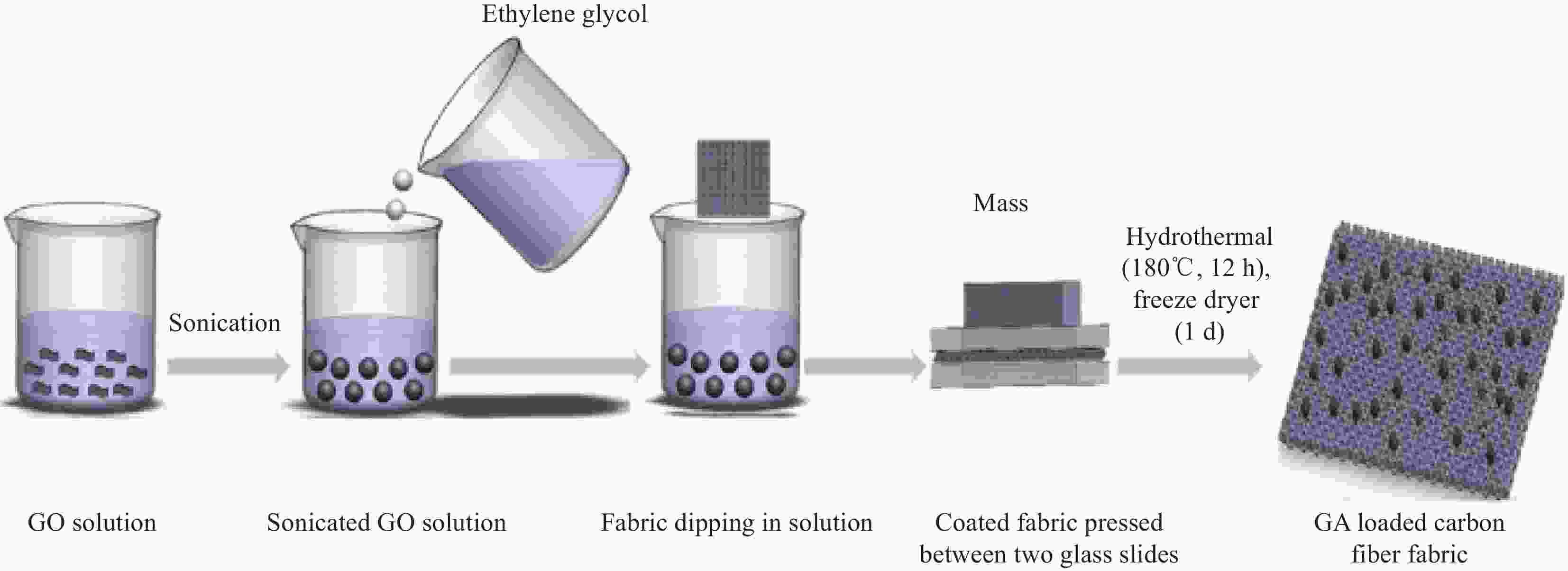

图 11 SSC制备过程示意图:(a) CF → gCF : 等离子体强化气相沉积技术(rf-PECVD)在裸碳纤维布上生长石墨烯纳米片(GNFs);(b) gCF → UgCF:通过尿素活化石墨烯纳米片沉积过的碳纤维布;(c) CF–(2GFs:SPE)–CF叠放的多功能结构超级电容器(MSS)结构示意图;(d)树脂灌注法制备碳纤维增强聚合物(CFRP)复合材料 MSS 层压板[29]

PEGDGE—Polyethylene glycol diglycidyl ether; IL—Ionic liquid; TETA—Triethylene-tetramine; GFs—Glass fabrics

Figure 11. Schematic illustration of steps used for the fabrication of structural supercapacitor: (a) CF → gCF : direct growth of graphene nanoflakes (GNFs) on bare carbon fiber (CF) fabrics by plasma enhanced vapor deposition technique (rf-PECVD); (b) gCF → UgCF : urea activation of GNFs-coated carbon fiber ( gCF ) fabrics ( UgCF ); (c) CF–(2GFs:SPE)–CF lay-up configuration of multifunctional structural supercapacitor (MSS); (d) Fabrication of carbon fiber reinforced polymer (CFRP) composite-based MSS laminates via the resin infusion method[29]

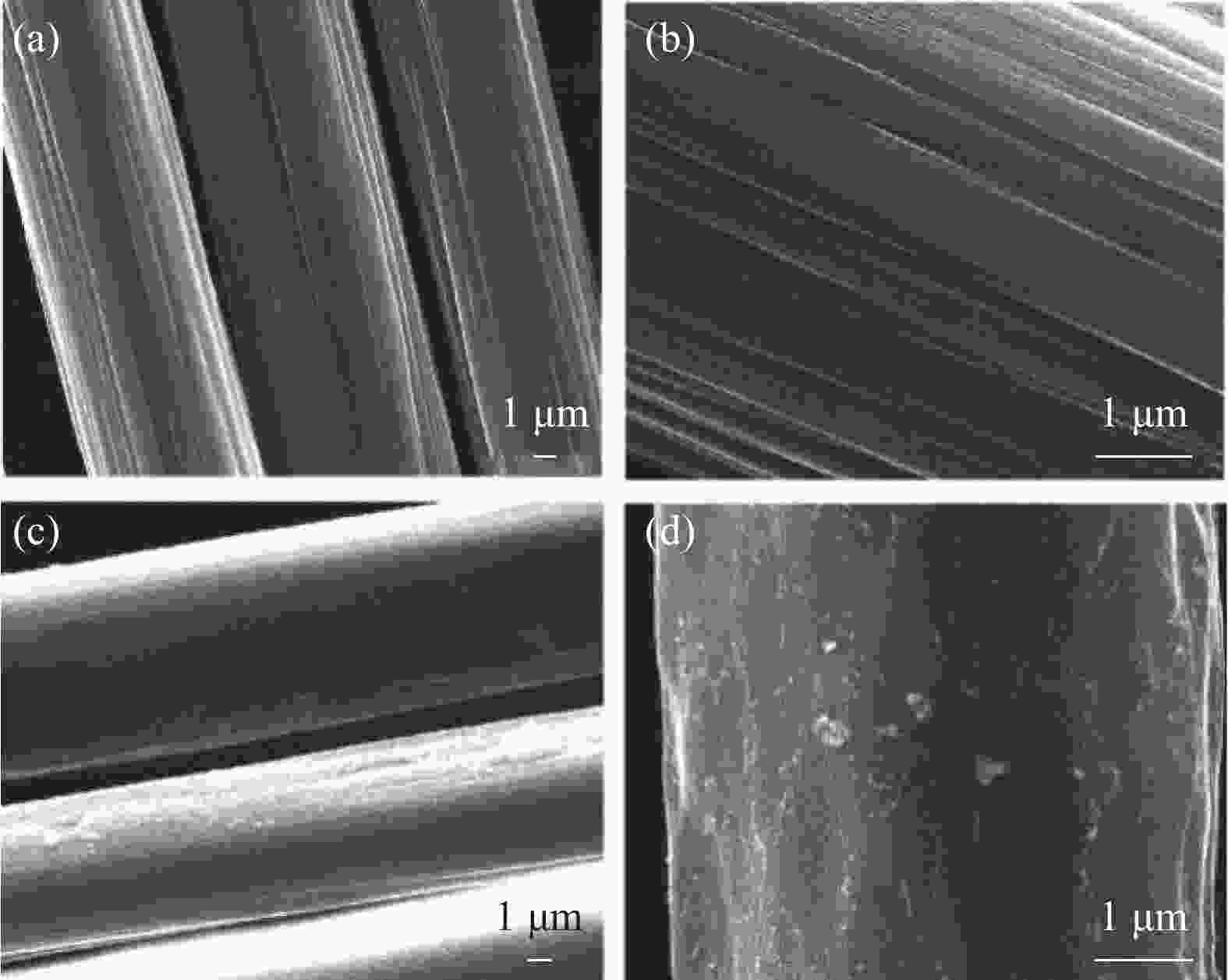

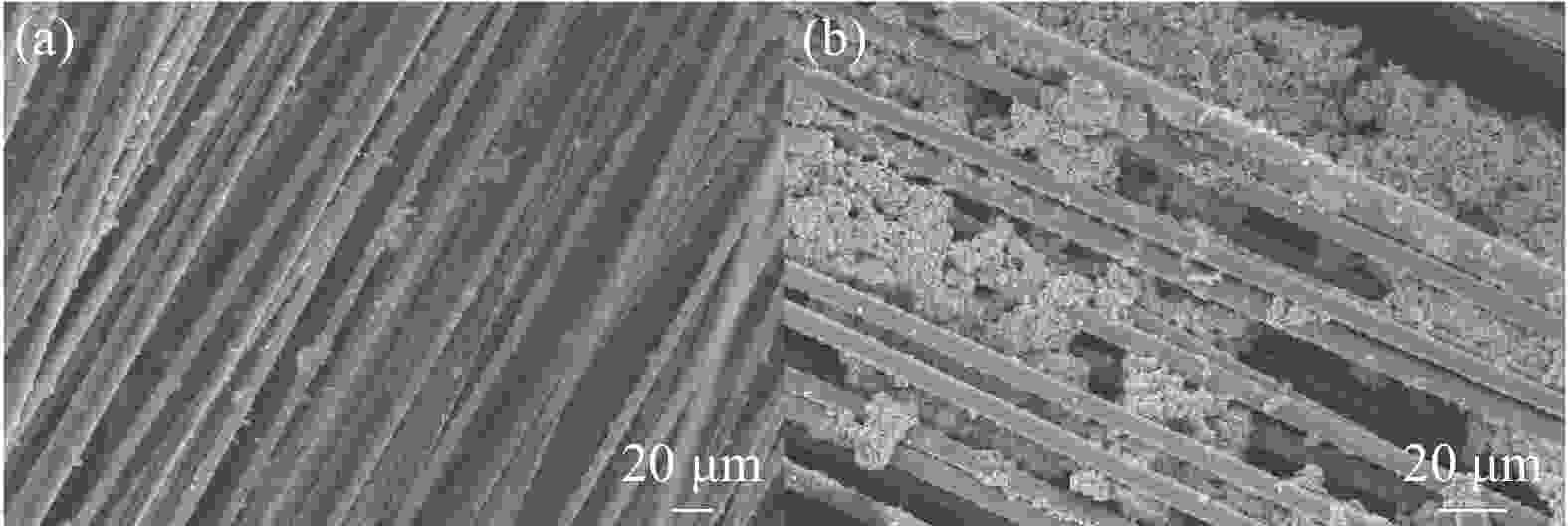

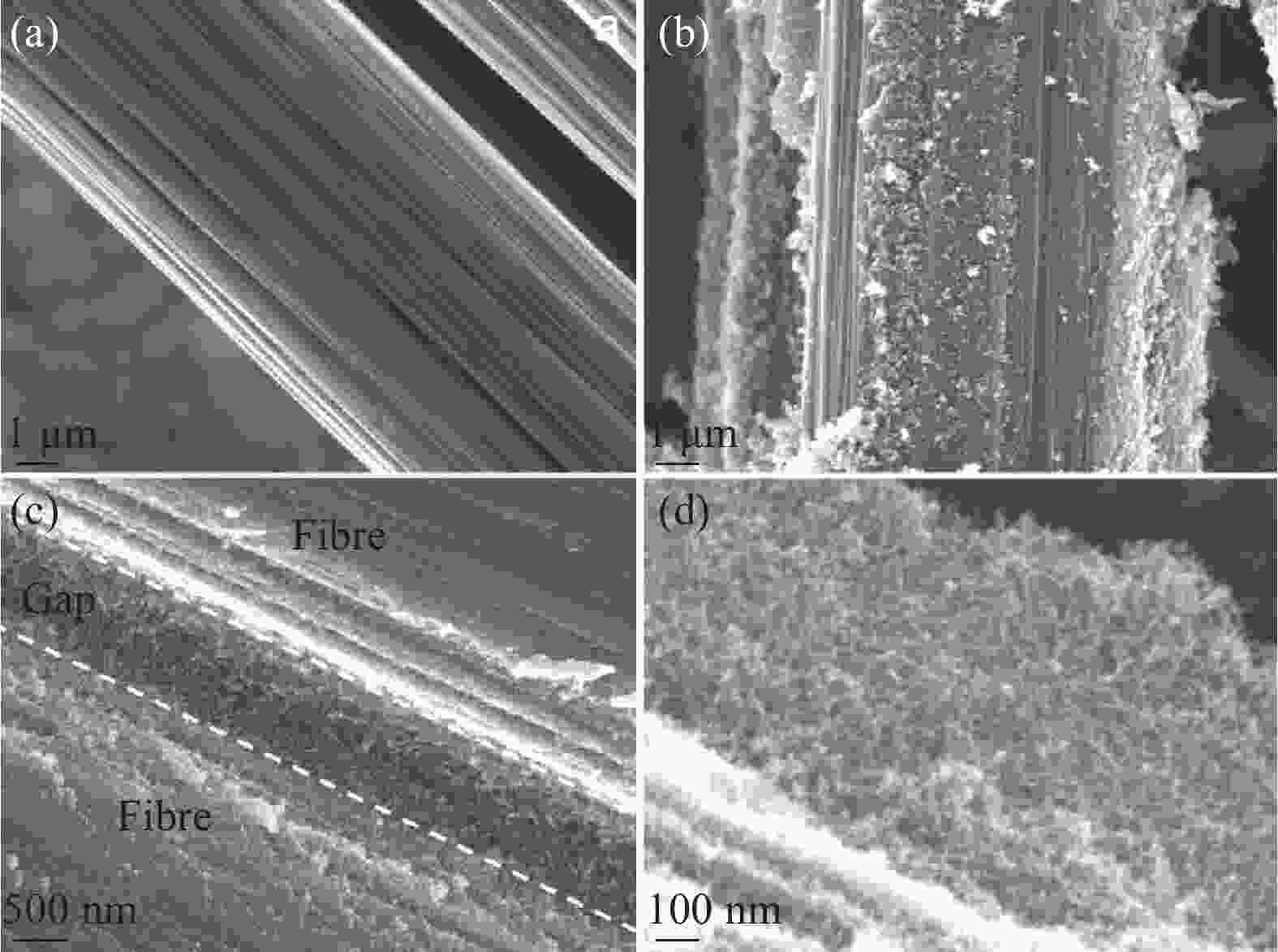

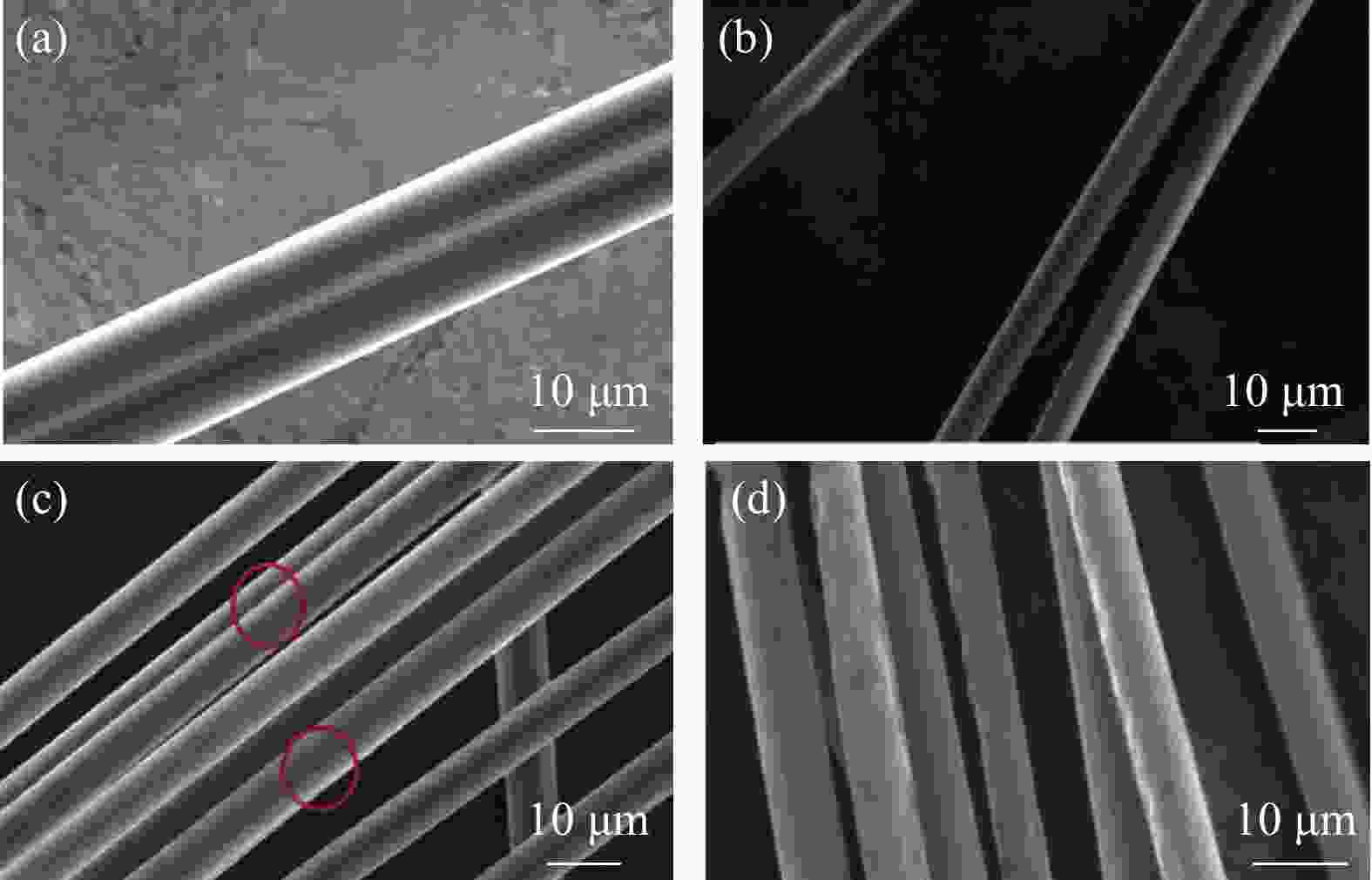

图 19 (a) ZnO纳米棒修饰WCF的表面微观形貌;((b)~(f)) 在0.18 mol/L KOH水溶液刻蚀2 h、4 h、5 h、5.5 h、6 h得到的ZnO纳米管修饰WCF的微观形貌[34]

Figure 19. (a) Surface micromorphology of ZnO nanorods/WCF; ((b)-(f)) Surface micromorphology of ZnO nanotubes/WCF obtained by etching in 0.18 mol/L KOH aqueous solution for different time (2 h, 4 h, 5 h, 5.5 h and 6 h)[34]

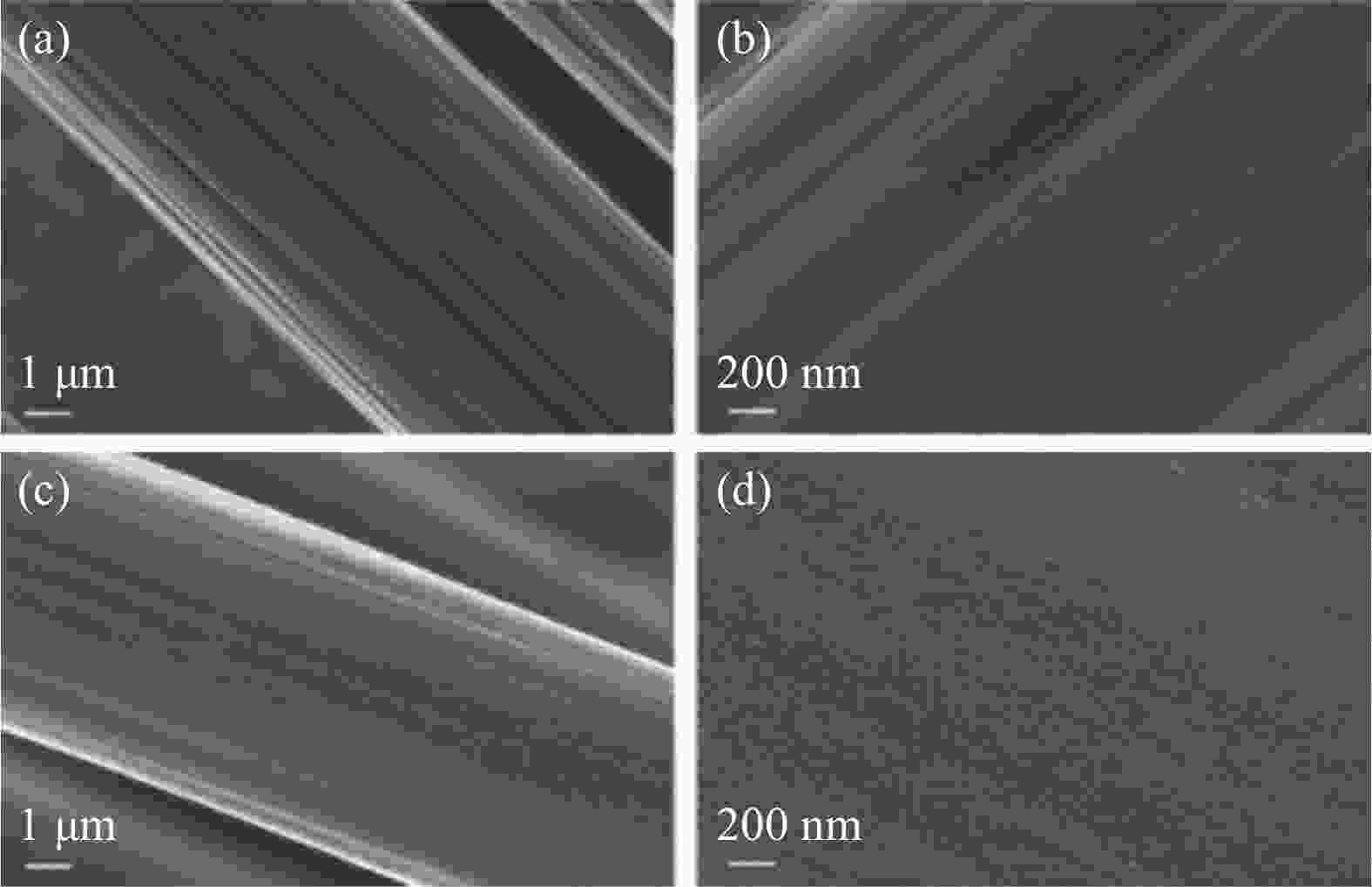

表 1 未改性碳纤维与活化改性碳纤维的比表面积与拉伸强度[22]

Table 1. Specific surface area and tensile strength of as-received and activated carbon fibre[22]

Sample Specific surface

area/

(m2·g-1)Tensile strength/

MPaAs-received 0.21 3300±200 HNO3 activated 0.50 3100±260 Air activated 0.60 1900±220 CO2 activated 1.10 2400±250 KOH activated 23.30 3600±320 表 2 不同改性碳纤维电极的比表面积与比电容[17]

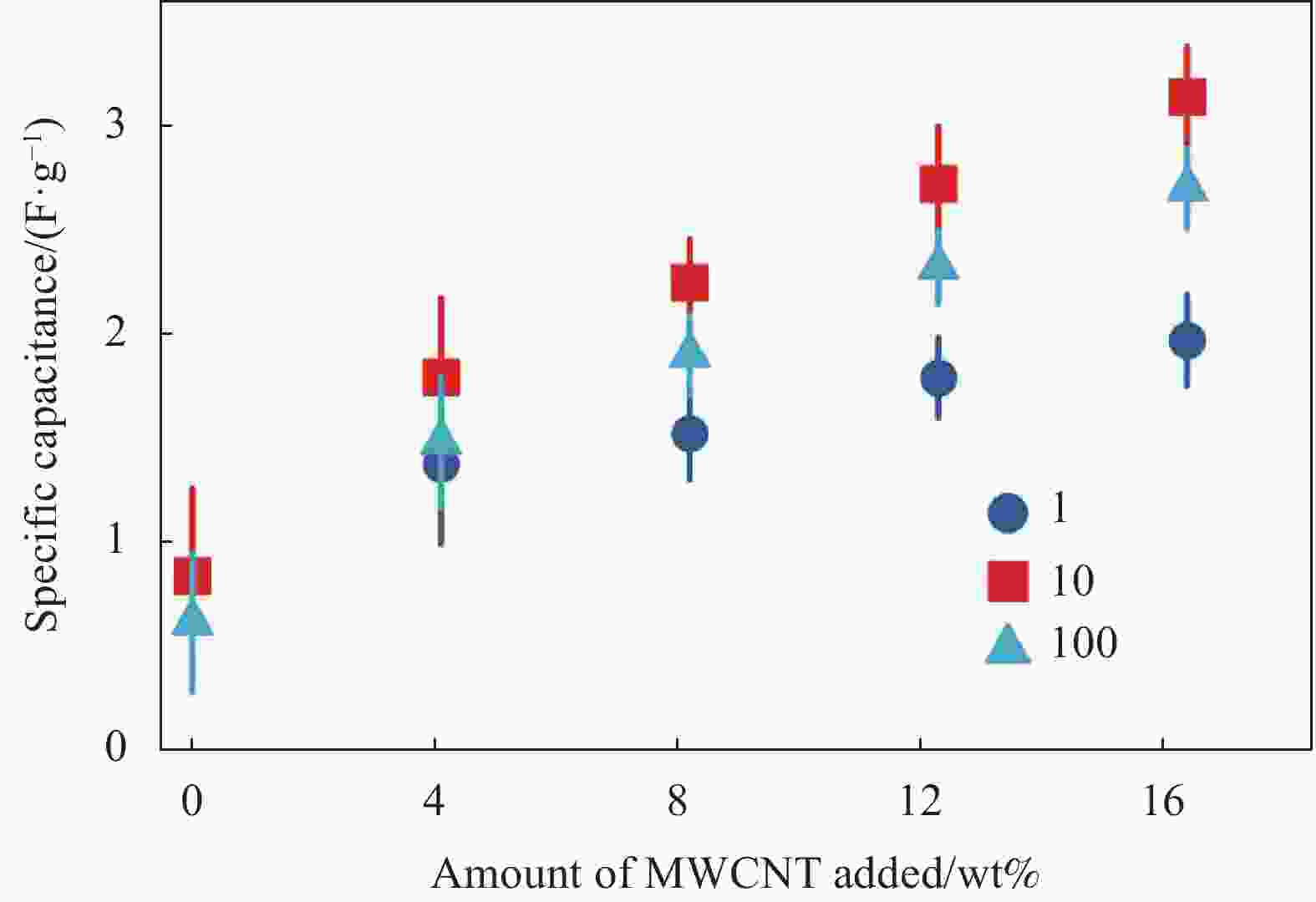

Table 2. Surface area and specific capacitance of carbon fiber electrodes by different modification[17]

Sample CAG loading/wt% BET surface area/(m2·g−1) Specific capacitance/

(F·g−1)As-received – 0.21 0.06 CAG-modified

(press)22.0 163.10 14.30 CAG-modified

(infusion)15.9 118.00 8.70 CAG-modified

(infusion)9.5 80.70 5.90 Notes: CAG—Carbon aerogels; BET—Brunauer-Emmett-Teller. 表 3 不同改性碳纤维电极的性能对比

Table 3. Performance comparison of different modified carbon fiber electrodes

电极材料 电解质 比电容 力学性能 文献 ACF PC/PEGDGE/TBAPF6 3.1 F/g (SSC) 器件压缩强度:28.81 MPa;

器件压缩模量:35.08 MPa[24] WCF/AC15 DGEBA/AG-85/EMIMTFSI 13.12 F/g (SSC) 器件拉伸强度:257.78 MPa;

器件拉伸模量:23.20 MPa[18] GNP-WCF TEABF4/PC 1.44 F/g (小尺寸SSC) 器件拉伸强度:350 MPa;

器件拉伸模量:26 GPa[27] 623 mF/g (大尺寸SSC) CNT-CF 1 mol/L KCl 3.1 F/g (电极) – [30] CD553/SR494/EMITSFI 125 mF/g (SSC) – ZnO-WCF LSP-8020 B/EMITSFI/LiTf/PANI 18.8 F/g (SSC) 器件拉伸强度:325.82 MPa; [34] Cu-CoSe NWs@WCF LPS-8020 B/EMIMBF4/LiTf 28.63 F/g (SSC) 器件拉伸强度:488.89 MPa;

器件拉伸模量:32.65 GPa[10] CF/VG/MnO2 1 mol/L Na2SO4 240 F/g (电极 ) – [12] PEGDGE/EMITSFI/LiTFSI) 30.7 mF/cm2 (SSC) 器件拉伸强度:85.6 MPa CF/PANI LiClO4/DGEBA/PC 20.05 mF/g (SSC) – [42] Notes: PEGDGE—Poly(ethylene glycol) diglycidyl ether; TBAPF6—Tetra-n-butylammonium hexafluorophosphate; DGEBA—Digycidylether of bis-phenol-A; EMIMTFSI—1-ethyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide; TEABF4—Tetraethylammonium tetrafluoroborate; LiTf—Lithium trifluoromethanesulfonate; EMIMBF4—1-ethyl-3-methylimidazolium tetrafluoroborate; LiTFSI—Lithium bis((trifluoromethyl)sulfonyl)azanide. -

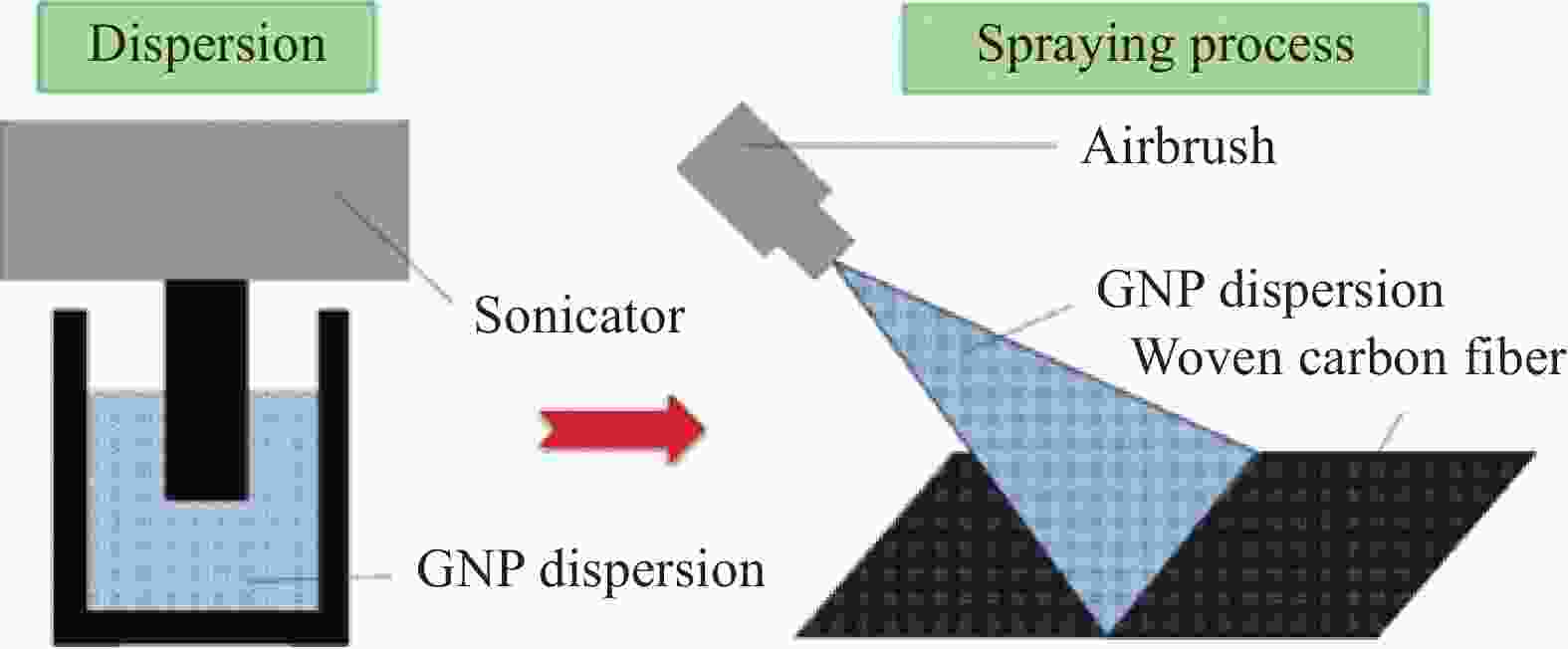

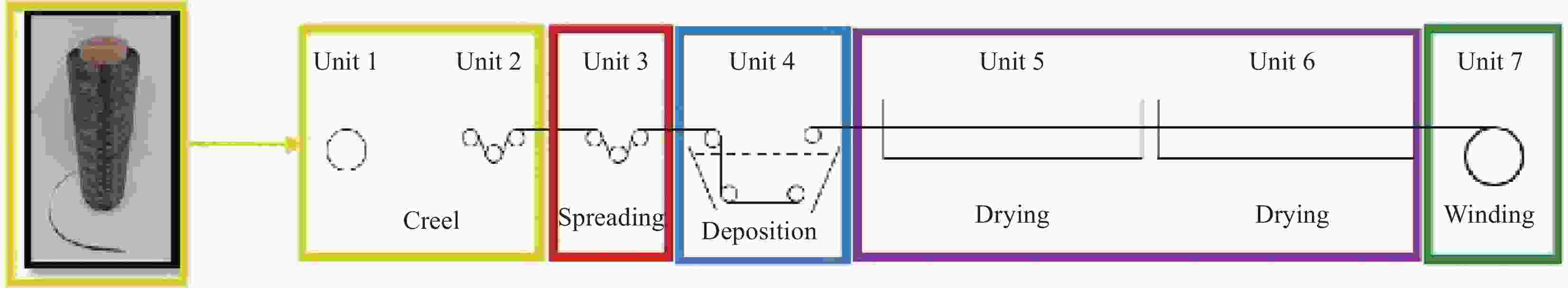

[1] ZHOU Y, QI H L, YANG J Y, et al. Two-birds-one-stone: Multifunctional supercapacitors beyond traditional energy storage[J]. Energy & Environmental Science,2021,14(4):1854-1896. [2] XU Y F, LU W B, XU G B, et al. Structural supercapacitor composites: A review[J]. Composites Science and Technology,2021,204:108636. doi: 10.1016/j.compscitech.2020.108636 [3] 丁颖慧, 祁国成, 张博明. 结构储电碳纤维复合材料研究进展[J]. 复合材料学报, 2021, 38(1):16-24. doi: 10.13801/j.cnki.fhclxb.20200921.006DING Yinghui, QI Guocheng, ZHANG Boming. Recent progress in carbon fiber reinforced composites for electricity storage[J]. Acta Materiae Compositae Sinica,2021,38(1):16-24(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200921.006 [4] DEKA B K, HAZARIKA A, KIM J, et al. Recent development and challenges of multifunctional structural supercapacitors for automotive industries[J]. International Journal of Energy Research,2017,41(10):1397-1411. doi: 10.1002/er.3707 [5] CARLSTEDT D, ASP L E. Performance analysis framework for structural battery composites in electric vehicles[J]. Composites Part B: Engineering,2020,186(4):107822. [6] GREENHALGH E S, NGUYEN S, VALKOVA M, et al. A critical review of structural supercapacitors and outlook on future research challenges[J]. Composites Science and Technology,2023,235:109968. doi: 10.1016/j.compscitech.2023.109968 [7] TYNAN B, ZHOU Y, BROWN S A, et al. Structural supercapacitor electrodes for energy storage by electroless deposition of MnO2 on carbon nanotube mats[J]. Compo-sites Science and Technology,2023,238:110016. doi: 10.1016/j.compscitech.2023.110016 [8] DEKA B K, HAZARIKA A K, JISOO K, et al. Bimetallic copper cobalt selenide nanowire-anchored woven carbon fiber-based structural supercapacitors[J]. Chemical Engineering Journal, 2019, 355: 551-559. [9] ZHANG S L, PAN N. Supercapacitors performance evaluation[J]. Advanced Energy Materials,2015(6):1-19. [10] DEKA B K, HAZARIKA A, KIM J, et al. Bimetallic copper cobalt selenide nanowire-anchored woven carbon fiber-based structural supercapacitors[J]. Chemical Engineering Journal,2019,355:551-559. doi: 10.1016/j.cej.2018.08.172 [11] PANDEY D, SAMBATH KUMAR K, HENDERSON L N, et al. Energized composites for electric vehicles: A dual function energy-storing supercapacitor-based carbon fiber compo-site for the body panels[J]. Small,2022,18(9):2107053. doi: 10.1002/smll.202107053 [12] SHA Z, HUANG F, ZHOU Y, et al. Synergies of vertical graphene and manganese dioxide in enhancing the energy density of carbon fibre-based structural supercapacitors[J]. Composites Science and Technology,2021,201:108568. doi: 10.1016/j.compscitech.2020.108568 [13] HUBERT O, TODOROVIC N, BISMARCK A. Towards separator-free structural composite supercapacitors[J]. Composites Science and Technology,2022,217:109126. doi: 10.1016/j.compscitech.2021.109126 [14] HUDAK N S, SCHLICHTING A D, EISENBEISER K. Structural supercapacitors with enhanced performance using carbon nanotubes and polyaniline[J]. Journal of the Electrochemical Society,2017,164(4):A691-A700. doi: 10.1149/2.0721704jes [15] JAVAID A, HO K K C, BISMARCK A, et al. Improving the multifunctional behaviour of structural supercapacitors by incorporating chemically activated carbon fibres and mesoporous silica particles as reinforcement[J]. Journal of Composite Materials,2018,52(22):3085-3097. doi: 10.1177/0021998318761216 [16] SENOKOS E, ANTHONY D B, RUBIO N, et al. Robust single-walled carbon nanotube-infiltrated carbon fiber electrodes for structural supercapacitors: From reductive dissolution to high performance devices[J]. Advanced Functional Materials, 2023, 33(16): 2212697. [17] QIAN H, KUCERNAK A R, GREENHALGH E S, et al. Multifunctional structural supercapacitor composites based on carbon aerogel modified high performance carbon fiber fabric[J]. ACS Applied Materials & Interfaces,2013,5(13):6113-6122. [18] DING Y H, QI G C, CUI Q, et al. High-performance multifunctional structural supercapacitors based on in situ and ex situ activated-carbon-coated carbon fiber electrodes[J]. Energy & Fuels,2022,36(4):2171-2178. [19] SUBHANI K, JIN X, MAHON P J, et al. Graphene aerogel modified carbon fiber reinforced composite structural supercapacitors[J]. Composites Communications,2021,24(11):100663. [20] GREENHALGH E S, ANKERSEN J, ASP L E, et al. Mechanical, electrical and microstructural characterisation of multifunctional structural power composites[J]. Journal of Composite Materials,2015,49(15):1823-1834. doi: 10.1177/0021998314554125 [21] ZHENG Y, DENG T, ZHANG W, et al. Optimizing the micropore-to-mesopore ratio of carbon-fiber-cloth creates record-high specific capacitance[J]. Journal of Energy Chemistry,2020,47:210-216. doi: 10.1016/j.jechem.2019.12.014 [22] QIAN H, DIAO H L, SHIRSHOVA N, et al. Activation of structural carbon fibres for potential applications in multifunctional structural supercapacitors[J]. Journal of Colloid and Interface Science,2013,395:241-248. doi: 10.1016/j.jcis.2012.12.015 [23] SHIRSHOVA N, QIAN H, SHAFFER M S P, et al. Structural composite supercapacitors[J]. Composites Part A: Applied Science and Manufacturing,2013,46:96-107. doi: 10.1016/j.compositesa.2012.10.007 [24] LI S M, ZHAO Y T, ZHANG Z, et al. Electrochemical and mechanical effects of acid and thermal treatments of carbon fiber[J]. Advanced Engineering Materials,2015,17(1):52-57. doi: 10.1002/adem.201400033 [25] CHEN X L, PAUL R, DAI L M. Carbon-based supercapacitors for efficient energy storage[J]. National Science Review,2017,4(3):453-489. doi: 10.1093/nsr/nwx009 [26] FENG X, BAI Y, LIU M Q, et al. Untangling the respective effects of heteroatom-doped carbon materials in batteries, supercapacitors and the ORR to design high performance materials[J]. Energy & Environmental Science,2021,14(4):2036-2089. [27] SÁNCHEZ-ROMATE X F, DEL BOSQUE A, ARTIGAS-ARNAUDAS J, et al. A proof of concept of a structural supercapacitor made of graphene coated woven carbon fibers: EIS study and mechanical performance[J]. Electrochimica Acta,2021,370:137746. doi: 10.1016/j.electacta.2021.137746 [28] WANG X W, YANG C, LI J, et al. Insights of heteroatoms doping-enhanced bifunctionalities on carbon based energy storage and conversion[J]. Advanced Functional Materials,2021,31(11):2009109. doi: 10.1002/adfm.202009109 [29] GANGULY A, KARAKASSIDES A, BENSON J, et al. Multifunctional structural supercapacitor based on urea-activated graphene nanoflakes directly grown on carbon fiber electrodes[J]. ACS Applied Energy Materials,2020,3(5):4245-4254. doi: 10.1021/acsaem.9b02469 [30] ARTIGAS-ARNAUDAS J, MUÑOZ B K, SÁNCHEZ M, et al. Surface modifications of carbon fiber electrodes for structural supercapacitors[J]. Applied Composite Materials, 2022, 29(2): 889-900. [31] JAVAID A, IRFAN M. Multifunctional structural supercapacitors based on graphene nanoplatelets/carbon aerogel composite coated carbon fiber electrodes[J]. Materials Research Express,2018,6(1):016310. doi: 10.1088/2053-1591/aae862 [32] ASFAW H D, KUCERNAK A, GREENHALGH E S, et al. Electrochemical performance of supercapacitor electrodes based on carbon aerogel-reinforced spread tow carbon fiber fabrics[J]. Composites Science and Technology,2023,238:110042. doi: 10.1016/j.compscitech.2023.110042 [33] ZHAO Y, XU H B, CAI G B, et al. Multi-functional structural supercapacitor based on manganese oxide-hydroxide nanowires modified carbon fiber fabric electrodes[J]. Polymer Composites,2022,43(11):8458-8470. doi: 10.1002/pc.27016 [34] DEKA B K, HAZARIKA A, KWON O B, et al. Multifunctional enhancement of woven carbon fiber/ZnO nanotube-based structural supercapacitor and polyester resin-domain solid-polymer electrolytes[J]. Chemical Engineering Journal,2017,325:672-680. doi: 10.1016/j.cej.2017.05.093 [35] DEKA B K, HAZARIKA A, KIM J, et al. Multifunctional CuO nanowire embodied structural supercapacitor based on woven carbon fiber/ionic liquid-polyester resin[J]. Composites Part A: Applied Science and Manufacturing,2016,87:256-262. doi: 10.1016/j.compositesa.2016.05.007 [36] KWON O B, DEKA B K, KIM J, et al. Electrochemical performance evaluation of tin oxide nanorod-embedded woven carbon fiber composite supercapacitor[J]. International Journal of Energy Research,2018,42(2):490-498. doi: 10.1002/er.3827 [37] ROH H D, DEKA B K, PARK H W, et al. Multifunctional composite as a structural supercapacitor and self-sensing sensor using NiCo2O4 nanowires and ionic liquid[J]. Composites Science and Technology,2021,213:108833. doi: 10.1016/j.compscitech.2021.108833 [38] DEKA B K, HAZARIKA A, KWAK M J, et al. Triboelectric nanogenerator-integrated structural supercapacitor with in situ MXene-dispersed N-doped Zn-Cu selenide nanostructured woven carbon fiber for energy harvesting and storage[J]. Energy Storage Materials,2021,43:402-410. doi: 10.1016/j.ensm.2021.09.027 [39] WANG X, CHEN S, LI D H, et al. Direct interfacial growth of MnO2 nanostructure on hierarchically porous carbon for high-performance asymmetric supercapacitors[J]. ACS Sustainable Chemistry & Engineering,2018,6(1):633-641. [40] BAE S H, JEON C, OH S, et al. Load-bearing supercapacitor based on bicontinuous PEO-b-P(S-co-DVB) structural electrolyte integrated with conductive nanowire-carbon fiber electrodes[J]. Carbon,2018,139:10-20. doi: 10.1016/j.carbon.2018.06.039 [41] EFTEKHARI A, LI L, YANG Y. Polyaniline supercapacitors[J]. Journal of Power Sources,2017,347:86-107. doi: 10.1016/j.jpowsour.2017.02.054 [42] JAVAID A, KHALID O, SHAKEEL A, et al. Multifunctional structural supercapacitors based on polyaniline deposited carbon fiber reinforced epoxy composites[J]. Journal of Energy Storage,2021,33:102168. doi: 10.1016/j.est.2020.102168 [43] 刘超, 李世林, 高宏全, 等. 水蒸气二氧化碳共活化制备聚苯胺基活性碳在离子液体超级电容器中的应用[J]. 中国材料进展, 2021, 40(4):308-313. doi: 10.7502/j.issn.1674-3962..201909007LIU Chao, LI Shilin, GAO Hongquan, et al. Preparation and application of H2O(gas)-CO2 co-activated polyaniline-based carbon materials for ionic liquid supercapacitor[J]. Materials China,2021,40(4):308-313(in Chinese). doi: 10.7502/j.issn.1674-3962..201909007 [44] LIU J, MA L Y, ZHAO Y, et al. Porous structural effect of carbon electrode formed through one-pot strategy on performance of ionic liquid-based supercapacitors[J]. Chemical Engineering Journal,2021,411:128573. doi: 10.1016/j.cej.2021.128573 [45] PENG H R, YAO B, WEI X J, et al. Pore and heteroatom engineered carbon foams for supercapacitors[J]. Advanced Energy Materials,2019,9(19):1803665. doi: 10.1002/aenm.201803665 [46] ZHOU H M, DUONGTHIPTHEWA A, ZHANG J, et al. A composite structural supercapacitor based on Ni-Co-layered double hydroxide-coated carbon cloth electrodes[J]. Composites Science and Technology,2023,240:110068. doi: 10.1016/j.compscitech.2023.110068 -

下载:

下载: