Research and prospect on interface strengthening methods for Ti/Mg bimetallic composites

-

摘要: 钛/镁双金属复合材料兼具了钛和镁的优点,在航空航天、交通运输等领域具有巨大的潜在应用价值,近年来受到了国内外研究者的广泛关注。针对熔点差异大,弱反应,低互溶的钛、镁两种金属,采用中间层金属实现钛/镁界面冶金结合是典型的界面强化方法,界面冶金结合的调控是提高界面结合强度的核心,界面反应的控制和优化是界面强化的难点。本文综述了不同复合方法制备钛/镁双金属复合材料的研究进展,分析了界面组织演变对界面结合强度的影响;总结了在不同的复合方法下所采用的界面强化方法时,钛/镁双金属复合材料界面的失效强度;归纳了钛/镁双金属的界面强化机制,并对钛/镁双金属的界面强化后续研究进行展望。Abstract: Ti/Mg bimetallic composite possesses the virtues of both elements and is endowed with significant potential for multiple applications in fields such as aerospace, transportation, and others. Recently, it has been widely concerned by global scholars and researchers. Employing an interlayer metal as a typical means of interfacial strengthening to realize the metallurgical bonding of Ti and Mg alloys for a substantial discrepancy in melting points, weak metallurgical reaction, and low mutual solid solubility between Mg and Ti. The control and optimization of interfacial reaction are crucial in enhancing interfacial bonding strength, but also the difficulty of interfacial strengthening. Overview of research progress of Ti/Mg bimetallic composites fabricated by different join methods and analyzing the effect of interfacial microstructure on interfacial bonding strength was analyzed. The interfacial bonding strength with different interfacial strengthening methods under various join technology was listed. The Ti/Mg bimetallic interface bonding mechanism was summarized and the future research of Ti/Mg bimetallic interfacial strengthening has been prospected.

-

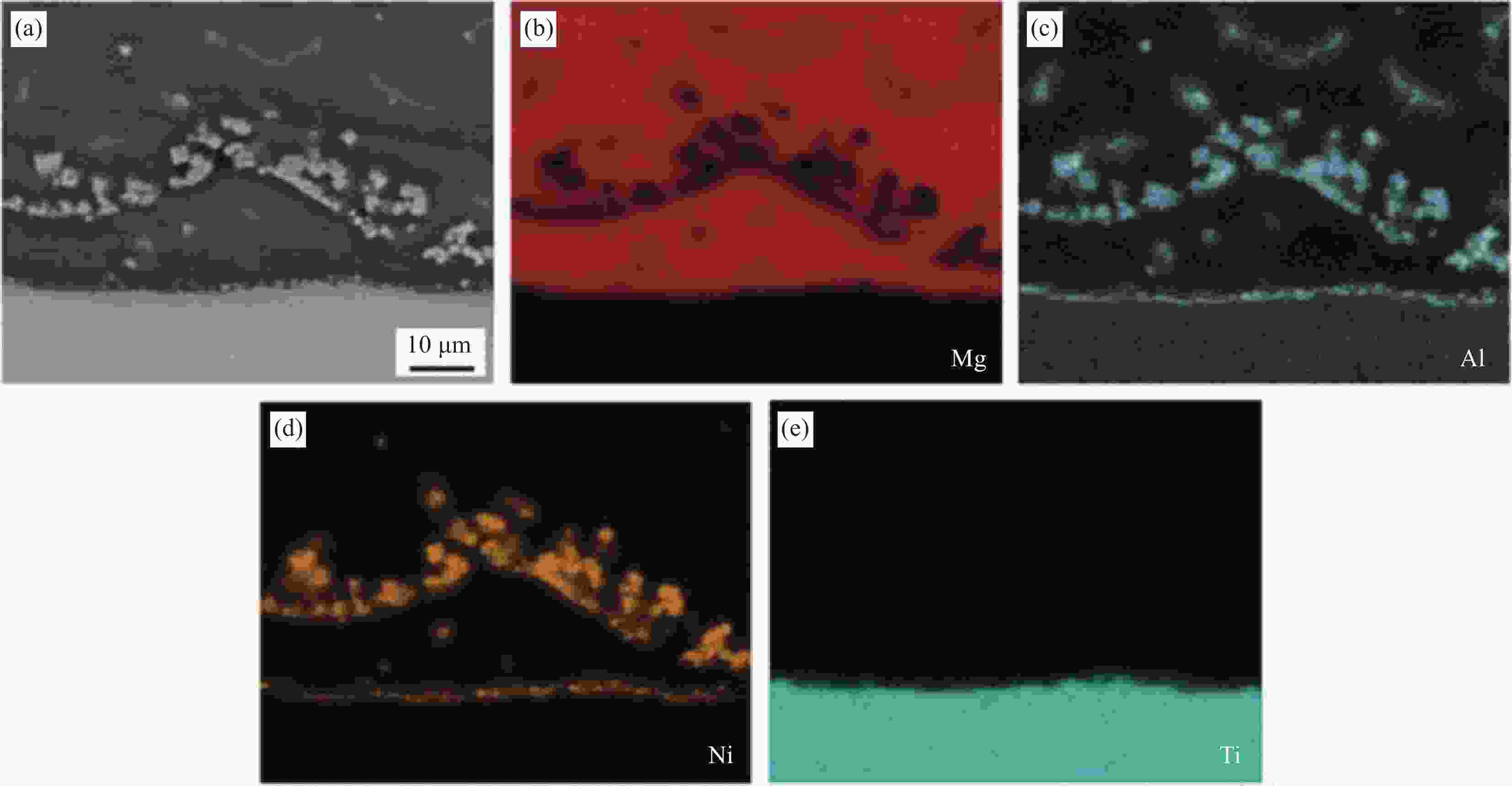

图 4 采用不同镀层时镁/钛界面的形貌;(a) 电镀Ni[48];(b) 纯Ni箔[47];(c) Ni纳米颗粒[50];(d) Cu纳米颗粒[50];(e) Cu-Ni纳米颗粒[50];(f) Cu-Ni箔[49]

AZ31—Grades of magnesium alloys; P1 and P2—Locations of EDS point scanning when investigating the microstructure; L1, L2, and L4—Reaction layer near the Mg side

Figure 4. SEM images of Mg/Ti interface with different coatings: (a) Electroplating Ni[48]; (b) Pure Ni foil[47]; (c) Ni nanoparticles[50]; (d) Cu nanoparticles[50]; (e) Cu-Ni nanoparticles[50]; (f) Cu-Ni foil[49]

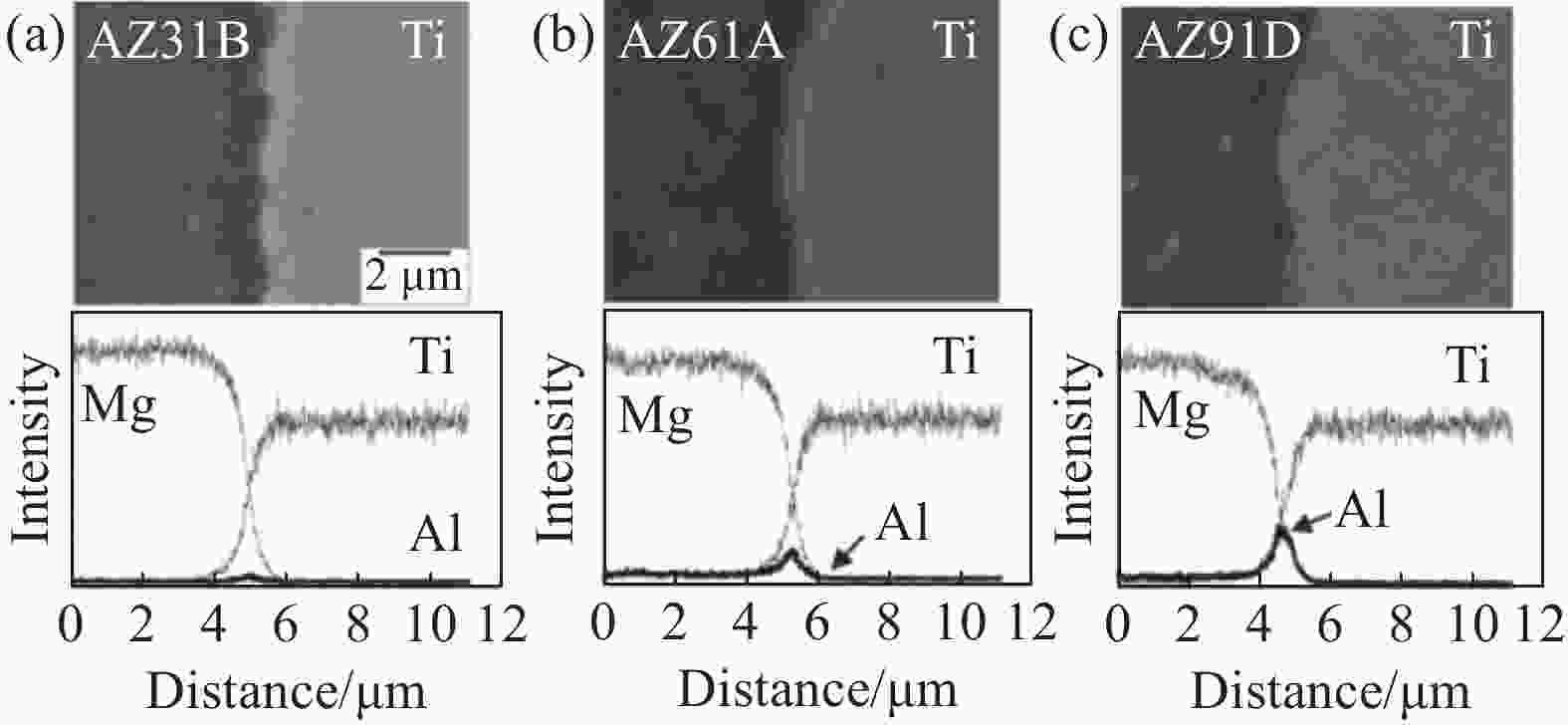

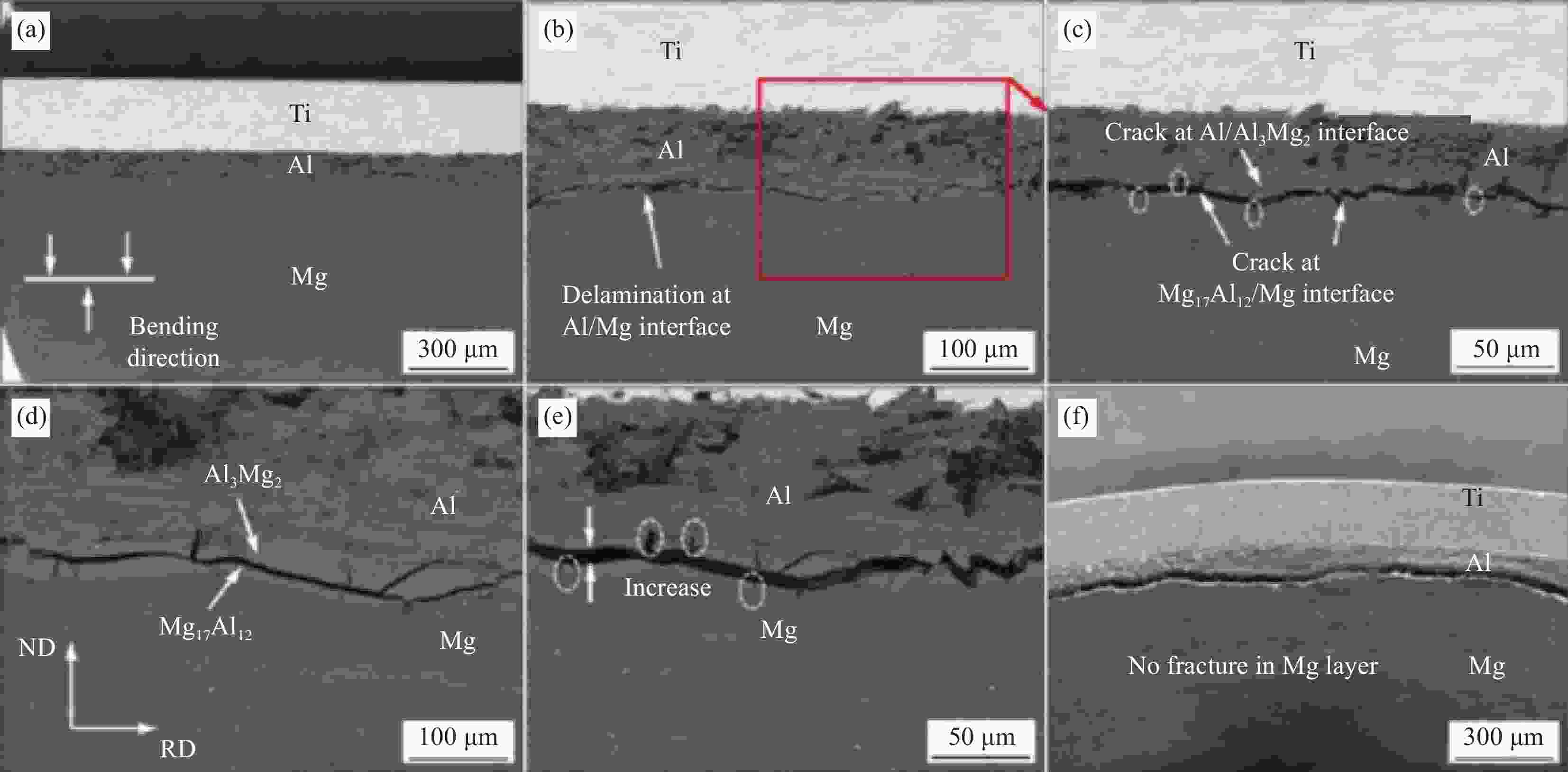

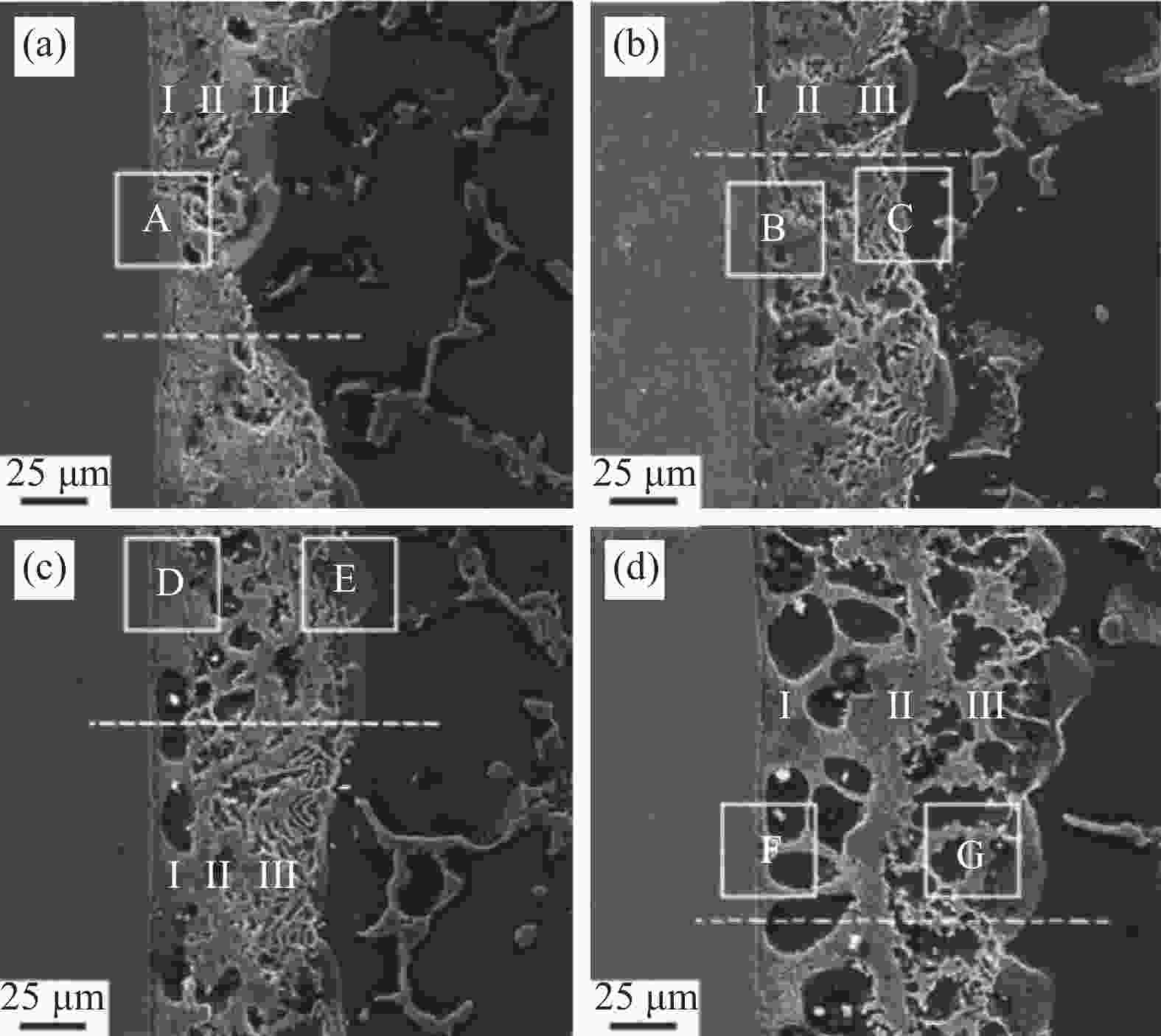

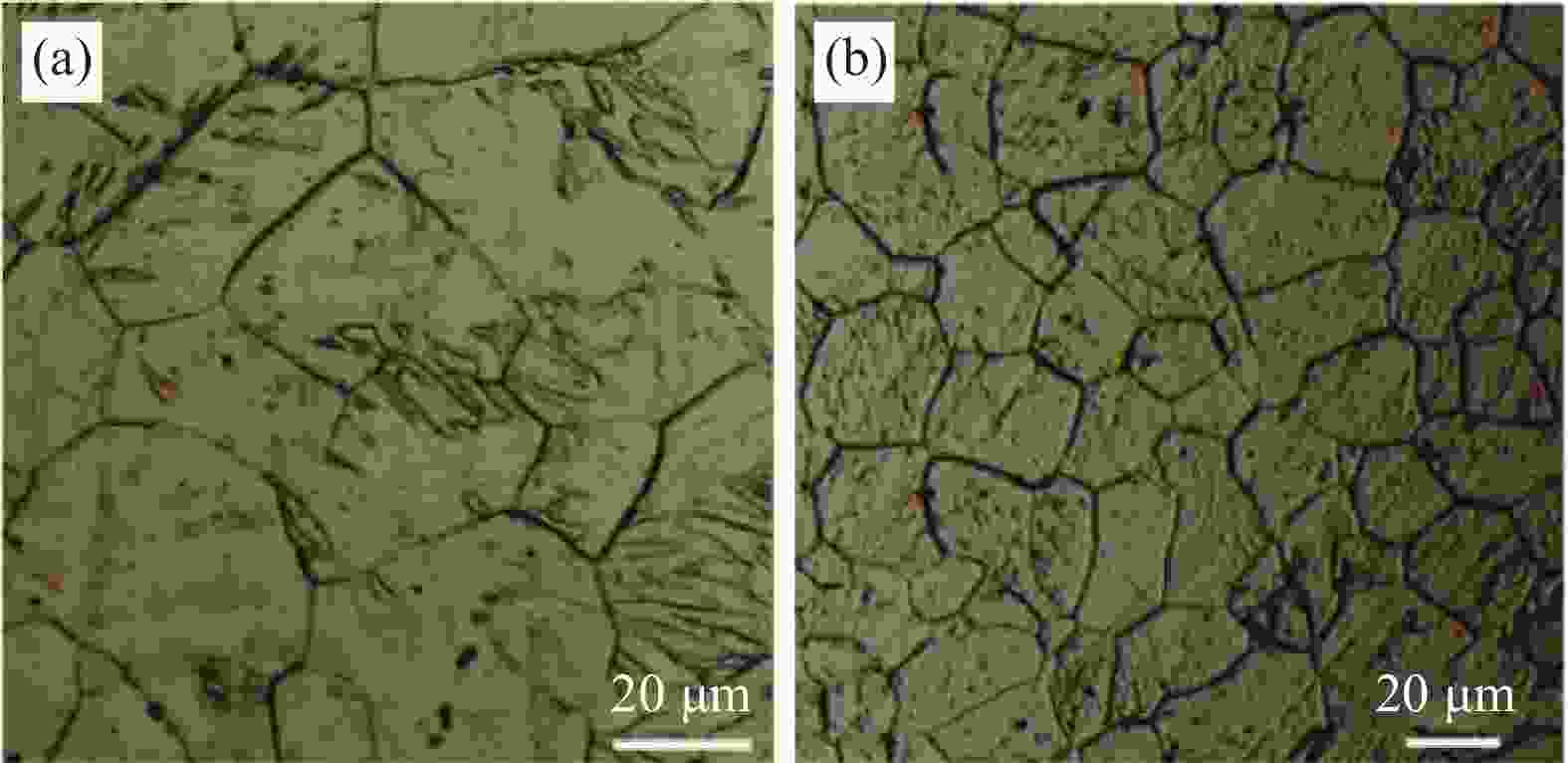

图 6 不同温度下采用Ni做中间层时TC4/AZ91D双金属材料界面显微组织扫描图像:(a) 660℃;(b) 690℃;(c) 720℃;(d) 750℃[68]

A-G—Region used for high-magnification SEM imaging when investigating the middle layer tissue; I, II, and III—Three reaction layers

Figure 6. SEM images of interface microstructures of the TC4/AZ91D bimetals with nickel coating and at different temperature: (a) 660℃; (b) 690℃; (c) 720℃; (d) 750℃[68]

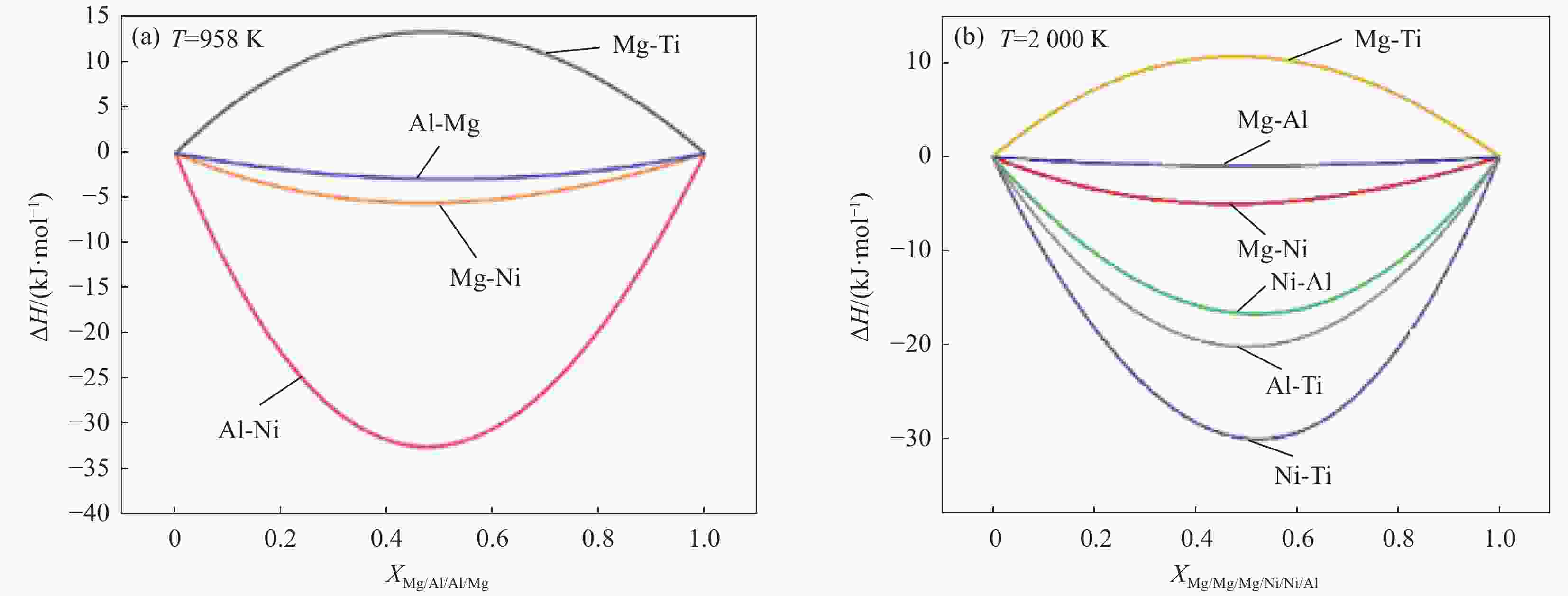

图 11 热力学模型计算结果:(a) 温度T=958 K时Al-Ni、Al-Mg、Mg-Ni和Mg-Ti二元熔体的生成焓ΔHAl-Ni、ΔHAl-Mg、ΔHMg-Ni和ΔHMg-Ti曲线图[71];(b) T=2000 K时Mg-Ni、Mg-Al、Mg-Ti和Ni-Al、Ni-Ti、Al-Ti二元熔体的生成焓ΔHMg-Ni、ΔHMg-Al、ΔHMg-Ti、ΔHNi-Al、ΔHNi-Ti和ΔHAl-Ti曲线图[27]

X—Percentage of element content

Figure 11. Calculation results of thermodynamic model: (a) Temperature T=958 K, formation enthalpy ΔHAl-Ni, ΔHAl-Mg, ΔHMg-Ni and ΔHMg-Ti curves of Al-Ni, Al-Mg, Mg-Ni and Mg-Ti binary melts[71]; (b) T=2000 K, formation enthalpy ΔHMg-Ni, ΔHMg-Al, ΔHMg-Ti, ΔHNi-Al, ΔHNi-Ti, ΔHAl-Ti curves of Mg-Ni, Mg-Al, Mg-Ti and Ni-Al, Ni-Ti, Al-Ti binary melts[27]

表 1 钛/镁双金属复合材料的界面强化方法和失效强度

Table 1. Interfacial strengthening methods and failure strength of Ti/Mg bimetallic composites

Materials and join method Interface strengthening methods and bonding strength TA2/AZ31B CMT AZ61 welding wire—262 N/mm[13] AZ91 welding wire—242 N/mm[14] Ti/AZ31B TIG AZ31B welding wire—228 N/mm[18] TC4(Ti-6Al-4V)/AZ31B LW Electroplating Cu—2314 N (85.7% of AZ31B strength) AZ31B welding wire—200 MPa (85.1% of AZ31B strength)[20] AZ91 welding wire—2057 N (50% of AZ31B strength)[21] Electroplating Ni—2387 N (88.5% of AZ31B strength)[27] TC4/AZ31B CMT Al foil—72 MPa[45],

Ni foil—61 MPa[46],

Cu foil—61 MPa[46],

Ni/Cu laminated foil—57 MPa [49],

electroplating Ni—61 MPa[48]TC4/AZ31B hot rolling Al sheet—521 MPa[60] TC4/AZ91D solid-liquid

compound castingElectroplating Ni—105 MPa[71] Electroplating Cu—65 MPa[72] Hot dip plating Al—49 MPa[74] Hot dip plating Zn—34 MPa[73] Zn/Al—67 MPa [76] Hot dip plating TiAlSi—80 MPa[75] Magnetron sputtering FeCoNiCr HEA layer—94 MPa[77] TC4 lattice structure—77 MPa[78] TC4(10%)/AZ91D stir casting Al element—250 MPa[81] powder metallurgy Al element—303 MPa[97] Notes: TA2—Ti content is 99wt%; AZ31B—Al and Zn contents are 3wt% and 1wt%; CMT—Cold metal transfer; TIG—Tungsten inert gas welding; LW—Laser welding; AZ91D—Al and Zn content is 9wt% and 1wt% (The suffix letters B and D are identification codes used to identify different alloys with different specific components or small differences in element content); AZ61—Al and Zn contents are 6wt% and 1wt%; AZ91—Al and Zn contents are 9wt% and 1wt%; HEA—High-entropy alloy. -

[1] MORDIKE B L, EBERT T. Magnesium: Properties-applications-potential[J]. Materials Science and Engineering: A,2001,302(1):37-45. doi: 10.1016/S0921-5093(00)01351-4 [2] 曾小勤, 王渠东, 吕宜振, 等. 镁合金应用新进展[J]. 铸造, 1998(11):41-45. doi: 10.3321/j.issn:1001-4977.1998.11.002ZENG Xiaoqin, WANG Qudong, LYU Yizhen, et al. New progress in the application of magnesium alloy[J]. Foundry,1998(11):41-45(in Chinese). doi: 10.3321/j.issn:1001-4977.1998.11.002 [3] 龙思远, 徐绍勇, 曹韩学, 等. 长安汽车轻量化与镁合金应用[J]. 现代零部件, 2010, 8(11):32-36.LONG Siyuan, XU Shaoyong, CAO Hanxue, et al. Changan automobile lightweighting and magnesium alloy application[J]. Modern Components,2010,8(11):32-36(in Chinese). [4] 宁兴龙. 镁合金在自行车上的应用[J]. 稀有金属快报, 2003,22(9):11-12.NING Xinglong. Magnesium alloy in bicycle applications[J]. Rare Metals Letters,2003,22(9):11-12(in Chinese). [5] 赵志远. 铸造稀土镁合金在我国航空工业中的应用[J]. 材料工程, 1993(7):8-10.ZHAO Zhiyuan. The application of RE-containing magnesium casting alloys in aviation industry in China[J]. Journal of Materials Engineering,1993(7):8-10(in Chinese). [6] 杨亚鹏. AZ91D镁合金激光冲击强化力学性能及新型LSP系统工艺研究[D]. 太原: 中北大学, 2019.YANG Yapeng. Study on mechanical properties of AZ91D magnesium alloy by laser shock peening and new LSP system process[D]. Taiyuan: North University of China, 2019(in Chinese). [7] PETERS M, KUMPFERT J, WARD C H, et al. Titanium alloys for aerospace applications[J]. Advanced Engineering Materials,2003,5(6):419-427. doi: 10.1002/adem.200310095 [8] 何阳, 屈孝和, 王越, 等. 钛合金的发展及应用综述[J]. 装备制造技术, 2014, 238(10):160-161. doi: 10.3969/j.issn.1672-545X.2014.10.058HE Yang, QU Xiaohe, WANG Yue, et al. The development and application of overview of titanium alloy[J]. Equipment Manufacturing Technology,2014,238(10):160-161(in Chinese). doi: 10.3969/j.issn.1672-545X.2014.10.058 [9] 唐仁政, 田荣璋. 二元合金相图及中间相晶体结构[M]. 长沙: 中南大学出版社, 2009.TANG Renzheng, TIAN Rongzhang. Binary alloy phase diagram and intermediate phase crystal structure[M]. Changsha: Central South University Press, 2009(in Chinese). [10] GAO M, MEI S W, LI X Y, et al. Characterization and formation mechanism of laser-welded Mg and Al alloys using Ti interlayer[J]. Scripta Materialia,2012,67(2):193-196. doi: 10.1016/j.scriptamat.2012.04.015 [11] 闫志飞, 田光元, 苏辉, 等. 高性能镁合金的研究进展[J]. 铸造技术, 2023, 44(2):101-113.YAN Zhifei, TIAN Guangyuan, SU Hui, et al. Research progress of high performance magnesium alloys[J]. Foundry Technology,2023,44(2):101-113(in Chinese). [12] 贾剑平, 毕凯强, 刘丹, 等. 冷金属过渡技术的研究现状与展望[J]. 热加工工艺, 2015, 44(1):6-8, 5. doi: 10.14158/j.cnki.1001-3814.2015.01.002JIA Jianping, BI Kaiqiang, LIU Dan, et al. Research status and prospect of cold metal transfer[J]. Hot Working Technology,2015,44(1):6-8, 5(in Chinese). doi: 10.14158/j.cnki.1001-3814.2015.01.002 [13] CAO R, WANG T, WANG C, et al. Cold metal transfer welding-brazing of pure titanium TA2 to magnesium alloy AZ31B[J]. Journal of Alloys and Compounds,2014,605(2):12-20. [14] 王涛. 镁/钛异种金属冷金属过渡技术(CMT)焊接性研究[D]. 兰州: 兰州理工大学, 2013.WANG Tao. The analysis of CMT weldability for dissimilar metals between magnesium and pure titanium[D]. Lanzhou: Lanzhou University of Technology, 2013(in Chinese). [15] 王岑, 曹睿, 林巧力, 等. 镁/钛异种金属冷金属过渡焊接的温度场模拟[J]. 焊接学报, 2015, 36(4):17-20, 114.WANG Cen, CAO Rui, LIN Qiaoli, et al. Numerical simulation on temperature distribution of cold metal transfer joining magnesium to titanium dissimilar metals[J]. Transactions of the China Welding Institution,2015,36(4):17-20, 114(in Chinese). [16] 车洪艳, 刘国辉, 王岑, 等. 镁/钛异种金属冷金属过渡焊接头应力场的有限元模拟[J]. 机械工程材料, 2017, 41(5):105-110. doi: 10.11973/jxgccl201705021CHE Hongyan, LIU Guohui, WANG Cen, et al. Finite element simulation on stress field of Mg/Ti dissimilar metal joint welded by cold metal transfer method[J]. Materials for Mechanical Engineering,2017,41(5):105-110(in Chinese). doi: 10.11973/jxgccl201705021 [17] XU C, SHENG G M, DENG Y Q, et al. Microstructure and mechanical properties of tungsten inert gas welded-brazed Mg/Ti lap joints[J]. Science and Technology of Welding and Joining,2014,19(5):443-450. doi: 10.1179/1362171814Y.0000000208 [18] XU C, SHENG G, WANG H, et al. Reinforcement of Mg/Ti joints using ultrasonic assisted tungsten inert gas welding-brazing technology[J]. Science and Technology of Welding and Joining,2014,19(8):703-707. doi: 10.1179/1362171814Y.0000000245 [19] GAO M, WANG Z M, LI X Y, et al. Laser keyhole welding of dissimilar Ti-6Al-4V titanium alloy to AZ31B magnesium alloy[J]. Metallurgical and Materials Transactions A-Physical Metallurgy and MaterialS Science,2012,43(1):163-172. doi: 10.1007/s11661-011-0825-6 [20] GAO M, WANG Z M, YAN J, et al. Dissimilar Ti/Mg alloy butt welding by fibre laser with Mg filler wire-preliminary study[J]. Science and Technology of Welding and Joining,2011,16(6):488-496. doi: 10.1179/1362171811Y.0000000033 [21] TAN C W, CHEN B, MENG S H, et al. Microstructure and mechanical properties of laser welded-brazed Mg/Ti joints with AZ91 Mg based filler[J]. Materials & Design,2016,99:127-134. [22] FRONCZEK D M, WOJEWODA-BUDKA J, CHULIST R, et al. Structural properties of Ti/Al clads manufactured by explosive welding and annealing[J]. Materials & Design,2016,91:80-89. [23] TAN C W, SONG X G, CHEN B, et al. Enhanced interfacial reaction and mechanical properties of laser welded-brazed Mg/Ti joints with Al element from filler[J]. Materials Letters,2016,167:38-42. doi: 10.1016/j.matlet.2015.12.119 [24] 檀财旺, 巩向涛, 李俐群, 等. 镁/钛异种金属预置Al夹层光纤激光熔钎焊接特性[J]. 中国激光, 2015, 42(1):114-121.TAN Caiwang, GONG Xiangtao, LI Liqun, et al. Laser welding-brazing characteristics of dissimilar metals Mg/Ti with Al interlayers[J]. Chinese Journal of Lasers,2015,42(1):114-121(in Chinese). [25] 檀财旺, 黄煜华, 陈波, 等. 镁/钛激光熔钎焊界面微观结构与元素热力学行为分析[J]. 中国激光, 2016, 43(3):87-95.TAN Caiwang, HUANG Yuhua, CHEN Bo, et al. Microstructure and thermodynamic behavior of laser welded-brazed Mg/Ti dissimilar joint[J]. Chinese Journal of Lasers,2016,43(3):87-95(in Chinese). [26] TAN C W, LU Q S, CHEN B, et al. Influence of laser power on microstructure and mechanical properties of laser welded-brazed Mg to Ni coated Ti alloys[J]. Optics & Laser Technology,2017,89:156-167. [27] TAN C W, YANG J, ZHAO X Y, et al. Influence of Ni coating on interfacial reactions and mechanical properties in laser welding-brazing of Mg/Ti butt joint[J]. Journal of Alloys and Compounds,2018,764:186-201. doi: 10.1016/j.jallcom.2018.06.039 [28] ZHANG Z, TAN C, WANG G, et al, Laser welding-brazing of immiscible AZ31B Mg and Ti-6Al-4V alloys using an electrodeposited Cu interlayer[J]. Journal of Materials Engineering & Performance, 2018, 27(3): 1414-1426. [29] YAO F J, YOU G Q, WANG L, et al. Design, fabrication, microstructure, and mechanical properties of interlayer-free vacuum diffusion bonding Mg/Ti composites[J]. Vacuum, 2022, 199: 110947. [30] GOGHERI M S, KASIRI-ASGARANI M, BAKHSHESHI-RAD H R, et al. Mechanical properties, corrosion behavior and biocompatibility of orthopedic pure titanium-magnesium alloy screw prepared by friction welding[J]. Transactions of Nonferrous Metals Society of China,2020,30(11):2952-2966. doi: 10.1016/S1003-6326(20)65434-6 [31] 高兴国. 用摩擦搅拌焊接法对纯钛与AZ31镁合金焊接性能的研究[J]. 稀有金属快报, 2007, 26(12):44-45.GAO Xingguo. Study on the welding performance of pure titanium and AZ31 magnesium alloy by friction stir welding method[J]. Rare Metals Letters,2007,26(12):44-45(in Chinese). [32] AONUMA M, NAKATA K. Effect of alloying elements on interface microstructure of Mg-Al-Zn magnesium alloys and titanium joint by friction stir welding[J]. Materials Science and Engineering: B,2009,161(1-3):46-49. doi: 10.1016/j.mseb.2009.02.020 [33] AONUMA M, NAKATA K. Effect of calcium on intermetallic compound layer at interface of calcium added magnesium-aluminum alloy and titanium joint by friction stir welding[J]. Materials Science and Engineering: B,2010,173(1-3):135-138. doi: 10.1016/j.mseb.2009.12.015 [34] AONUMA M, NAKATA K. Dissimilar metal joining of ZK60 magnesium alloy and titanium by friction stir welding[J]. Materials Science and Engineering: B,2012,177(7):543-548. doi: 10.1016/j.mseb.2011.12.031 [35] CHOI J W, LIU H H, USHIODA K, et al. Dissimilar friction stir welding of immiscible titanium and magnesium[J]. Materialia,2019,7:100389. doi: 10.1016/j.mtla.2019.100389 [36] DINAHARAN I, ZHANG S, CHEN G Q, et al. Titanium particulate reinforced AZ31 magnesium matrix compo-sites with improved ductility prepared using friction stir processing[J]. Materials Science and Engineering: A,2020,772:138793. doi: 10.1016/j.msea.2019.138793 [37] LI R D, LI J L, XIONG J T, et al. Friction heat production and atom diffusion behaviors during Mg-Ti rotating friction welding process[J]. Transactions of Nonferrous Metals Society of China,2012,22(11):2665-2671. doi: 10.1016/S1003-6326(11)61515-X [38] 梅张强. 基于Al合金化强化的Mg/Ti电阻点焊和激光熔钎焊研究[D]. 武汉: 湖北工业大学, 2012.MEI Zhangqiang. Based on the strengthening of the Al alloying Mg/Ti resistance spot welding and laser molten brazing research[D]. Wuhan: Hubei University of Technology, 2012(in Chinese). [39] 侯庆磊. 镁/钛合金异种金属电阻点焊接头组织和力学性能的研究[D]. 合肥: 合肥工业大学, 2021.HOU Qinglei. Study on microstructures and mechanical properties of resistance spot welded joints of magnesium and titanium alloy dissimilar metals[D]. Hefei: Hefei University of Technology, 2021(in Chinese). [40] HABIB M A, RUAN L Q, KIMURA R, et al. Cladding of titanium and magnesium alloy by explosive welding using underwater shockwave technique and effect on interface[J]. Materials Science Forum,2013,767:160-165. doi: 10.4028/www.scientific.net/MSF.767.160 [41] 张婷婷, 王文先, 魏屹, 等. 钛/铝/镁爆炸焊复合板波形界面及力学性能[J]. 焊接学报, 2017, 38(8):33-36, 130. doi: 10.12073/j.hjxb.20151021001ZHANG Tingting, WANG Wenxian, WEI Qi, et al. Wavy interface and mechanical properties of explosive welded Ti/Al/Mg cladded plate[J]. Transactions of the China Welding Institution,2017,38(8):33-36, 130(in Chinese). doi: 10.12073/j.hjxb.20151021001 [42] 武佳琪. 镁/钛异种金属爆炸焊接界面微观组织及性能的研究[D]. 太原: 太原理工大学, 2015.WU Jiaqi. Study on the interface microsiructure and the mechanical prorertie for the Mg/Ti composite materials with explosive welding[D]. Taiyuan: Taiyuan University of Technology, 2015(in Chinese). [43] PRIPANAPONG P, KARIYA S, LUANGVARANUNT T, et al. Corrosion behavior and strength of dissimilar bonding material between Ti and Mg alloys fabricated by spark plasma sintering[J]. Materials,2016,9(8):665. doi: 10.3390/ma9080665 [44] REN D X, ZHAO K M, PAN M, et al. Ultrasonic spot welding of magnesium alloy to titanium alloy[J]. Scripta Materialia,2017,126:58-62. doi: 10.1016/j.scriptamat.2016.08.003 [45] 熊江涛, 张赋升, 李京龙, 等. 镁合金与钛合金的瞬间液相扩散焊[J]. 稀有金属材料与工程, 2006, 35(10):1677-1680. doi: 10.3321/j.issn:1002-185X.2006.10.040XIONG Jiangtao, ZHANG Fusheng, LI Jinglong, et al. Transient liquid phase bonding of magnesium alloy (AZ31B) and titanium alloy (Ti6Al4V) using aluminium interlayer[J]. Rare Metal Materials and Engineering,2006,35(10):1677-1680(in Chinese). doi: 10.3321/j.issn:1002-185X.2006.10.040 [46] 秦倩. 镁-钛异种材料的瞬间液相扩散连接[D]. 西安: 西安科技大学, 2015.QIN Qian. Study on the Mg alloy and Ti alloy joint by transient liquid phase bonding process[D]. Xi'an: Xi'an University of Science and Technology, 2015(in Chinese). [47] ATIEH A M, KHAN T I. Effect of process parameters on semi-solid TLP bonding of Ti-6Al-4V to Mg-AZ31[J]. Journal of Materials Science,2013,48(19):6737-6745. doi: 10.1007/s10853-013-7475-6 [48] ATIEH A M, KHAN T I. TLP bonding of Ti-6Al-4V and Mg-AZ31 alloys using pure Ni electro-deposited coats[J]. Journal of Materials Processing Technology,2014,214(12):3158-3168. doi: 10.1016/j.jmatprotec.2014.07.028 [49] ATIEH A M, KHAN T I. Transient liquid phase (TLP) brazing of Mg-AZ31 and Ti-6Al-4V using Ni and Cu sandwich foils[J]. Science and Technology of Welding and Joining,2014,19(4):333-342. doi: 10.1179/1362171814Y.0000000196 [50] ATIEH A M, KHAN T I. Application of Ni and Cu nanoparticles in transient liquid phase (TLP) bonding of Ti-6Al-4V and Mg-AZ31 alloys[J]. Journal of Materials Science,2014,49(22):7648-7658. doi: 10.1007/s10853-014-8473-z [51] 王鹏举. 热轧钛/铝/镁层状复合板结构与性能研究[D]. 重庆: 重庆大学, 2020.WANG Pengju. Research on the structure and properties of hot rolled Ti/Al/Mg laminated plates[D]. Chongqing: Chongqing University, 2020(in Chinese). [52] WANG T L, NIE H H, MI Y J, et al. Microstructures and mechanical properties of Ti/Al/Mg/Al/Ti laminates with various rolling reductions[J]. Journal of Materials Research,2019,34(2):344-353. doi: 10.1557/jmr.2018.428 [53] 孟宣. Ti/Al/Mg/Al/Ti叠层板热轧复合与组织性能研究[D]. 秦皇岛: 燕山大学, 2016.MENG Xuan. Study on hot-rolled composite and microstructure properties of Ti/Al/Mg/Al/Ti laminates[D]. Qinhuangdao: Yanshan University, 2016(in Chinese). [54] NIE H H, HAO X W, CHEN H S, et al. Effect of twins and dynamic recrystallization on the microstructures and mechanical properties of Ti/Al/Mg laminates[J]. Materials & Design,2019,181:107948. [55] 马旻. 钛/铝/镁叠层板热轧复合及组织与性能研究[D]. 秦皇岛: 燕山大学, 2016.MA Yu. Study on microstructure and properties of hot rolled Ti/Al/Mg laminates[D]. Qinhuangdao: Yanshan University, 2016(in Chinese). [56] MI Y J, NIE H H, WANG T L, et al. Effect of anisotropy on microstructures and mechanical properties of rolled Ti/Al/Mg/Al/Ti laminates[J]. Journal of Materials Engineering and Performance,2019,28(7):4143-4151. doi: 10.1007/s11665-019-04172-2 [57] LUO W B, FENG Y Z, XUE Z Y, et al. Effect of Al layer thickness on the bonding and mechanical behavior of a Mg-(Al-)Ti laminated sheet prepared by hot-rolling after differential preheating treatment[J]. Materials, 2022, 15(8): 2805. [58] MOTEVALLI P D, EGHBALI B. Microstructure and mechanical properties of Tri-metal Al/Ti/Mg laminated composite processed by accumulative roll bonding[J]. Materials Science and Engineering: A,2015,628:135-142. doi: 10.1016/j.msea.2014.12.067 [59] 胡宏波. 铝/镁/钛层状复合板轧制工艺与结合界面研究[D]. 重庆: 重庆大学, 2015.HU Hongbo. Research on roll bonding process of Al/Mg/Ti multilayered composite sheet and its bonding interface[D]. Chongqing: Chongqing University, 2015(in Chinese). [60] 伍侠. 镁铝钛层状复合板制备工艺与性能研究[D]. 重庆: 重庆大学, 2015.WU Xia. Study on the fabrication and properties of magnesium aluminum titanium laminated sheet[D]. Chongqing: Chongqing University, 2015(in Chinese). [61] 张岩. 热轧制备Ti/Al/Mg复合板与组织性能研究[D]. 秦皇岛: 燕山大学, 2014.ZHANG Yan. The roll-bonding processes and properties of Ti/Al/Mg laminated composites[D]. Qinhuangdao: Yanshan University, 2014(in Chinese). [62] 祁梓宸. 异温轧制制备钛/铝/镁复合板工艺方法和组织性能研究[D]. 秦皇岛: 燕山大学, 2021.QI Zichen. Study on process method and microstructure properties of Ti/Al/Mg laminated composites prepared by differential temperature rolling[D]. Qinhuangdao: Yanshan University, 2021(in Chinese). [63] NIE H H, ZHENG L W, KANG X P, et al. In-situ investigation of deformation behavior and fracture forms of Ti/Al/Mg/Al/Ti laminates[J]. Transactions of Nonferrous Metals Society of China,2021,31(6):1656-1664. doi: 10.1016/S1003-6326(21)65605-4 [64] 王文焱, 史士钦, 尚郑平, 等. 铸轧法制备钛铝复合板的界面组织与性能[J]. 特种铸造及有色合金, 2016, 36(10):1084-1088.WANG Wenyan, SHI Shiqing, SHANG Zhengping, et al. Interfacial microstructure and properties of Ti-Al rolling-casted composite plate[J]. Special Casting & Nonferrous Alloys,2016,36(10):1084-1088(in Chinese). [65] KENEVISI M S, MOUSAVI KHOIE S M, ALAEI M. Microstructural evaluation and mechanical properties of the diffusion bonded Al/Ti alloys joint[J]. Mechanics of Materials,2013,64:69-75. doi: 10.1016/j.mechmat.2013.04.011 [66] QI Z C, XIAO H, YU C, et al. Preparation, microstructure and mechanical properties of CP-Ti/AA6061-Al laminated composites by differential temperature rolling with induction heating[J]. Journal of Manufacturing Processes,2019,44:133-144. doi: 10.1016/j.jmapro.2019.05.053 [67] 刘平, 刘腾, 王渠东. 固液双金属复合铸造研究进展[J]. 材料导报, 2014, 28(1):26-30.LIU Ping, LIU Teng, WANG Qudong. Research progress on liquid-solid bimetal compound casting[J]. Materials Review,2014,28(1):26-30(in Chinese). [68] WEN F L, ZHAO J H, YUAN M W, et al. Influence of Ni interlayer on interfacial microstructure and mechanical properties of Ti-6Al-4V/AZ91D bimetals fabricated by a solid-liquid compound casting process[J]. Journal of Magnesium and Alloys,2021,9(4):1382-1395. doi: 10.1016/j.jma.2020.05.021 [69] 张敏, 王莹, 王普, 等. Ni夹层AZ31B/Cu异种材料接触反应钎焊接头组织及性能分析[J]. 热加工工艺, 2017, 46(17):38-42.ZHANG Min, WANG Ying, WANG Pu, et al. Analysis of microstructures and properties of contact reactive brazing bonded joint of AZ31B and Cu dissimilar material with Ni interlayer[J]. Hot Working Technology,2017,46(17):38-42(in Chinese). [70] LI T T, SONG G, YU P N, et al. Interfacial microstructure evolution in fusion welding of immiscible Mg/Fe system[J]. Materials & Design,2019,181:107903. [71] ZHAO J H, WEN F L, FENG K Q, et al. Interface microstructure regulation of Mg/Ti bimetals by thermal diffusion treatment of Ni-coated TC4 alloy[J]. Intermetallics,2022,147:107594. doi: 10.1016/j.intermet.2022.107594 [72] WEN F L, ZHAO J H, FENG K Q, et al. Investigation of Cu interlayer on joint formation of Ti/Mg bimetal fabricated by liquid-solid compound casting process[J]. Metals and Materials International,2022,28(7):1711-1724. doi: 10.1007/s12540-021-01027-1 [73] SHANGGUAN J J, ZHAO J H, SHI Y, et al. Effects of Zn interlayer on microstructures and mechanical properties of TC4/AZ91D bimetal via solid-liquid compound casting process[J]. International Journal of Metalcasting,2022,16(1):419-434. doi: 10.1007/s40962-021-00612-9 [74] SHANGGUAN J J, ZHAO J H, ZHANG J X, et al. Improving shear strength of Ti/Mg bimetal composites prepared by hot-dip aluminizing and solid-liquid compound casting[J]. Advanced Engineering Materials,2022,24(11):2200298. [75] SHANGGUAN J J, ZHAO J H, XU B, et al. The role of TiAlSi intermetallic compounds in metallurgical bonding mechanism of Ti/Mg bimetal composite[J]. Materials Science and Engineering: A,2022,846:143295. [76] ZHAO J H, SHANGGUAN J J, GU C, et al. Microstructures and mechanical properties of TC4/AZ91D bimetal prepared by solid-liquid compound casting combined with Zn/Al composite interlayer[J]. Transactions of Nonferrous Metals Society of China,2022,32(4):1144-1158. doi: 10.1016/S1003-6326(22)65862-X [77] CHENG J, ZHAO J H, WANG C, et al. Effect of HEA/Al composite interlayer on microstructure and mechanical property of Ti/Mg bimetal composite by solid-liquid compound casting[J]. China Foundry,2023,20(1):1-11. doi: 10.1007/s41230-022-2105-z [78] WU Y B, ZHAO J H, PENG W L, et al. Optimization of additive manufactured Ti-based pyramidal lattice structure applied to interface strengthening of Mg/Ti bimetal composite[J/OL]. Transactions of Nonferrous Metals Society of China: 1-25[2023-11-15]. http://kns.cnki.net/kcms/detail/43.1239.tg.20230224.1420.004.html. [79] 谢耀, 康跃华, 李新涛, 等. 搅拌铸造金属Ti颗粒增强AZ91D复合材料的组织与力学性能[J]. 铸造, 2021, 70(7):793-799.XIE Yao, KANG Yuehua, LI Xintao. Microstructure and mechanical properties of metal Ti particles reinforced AZ91D composite processed by stir casting[J]. Foundry,2021,70(7):793-799(in Chinese). [80] 张晓辉. 搅拌铸造金属Ti颗粒增强AZ91D镁基复合材料高温塑性变形组织与力学性能研究[D]. 沈阳: 沈阳工业大学, 2022.ZHANG Xiaohui. Hot deformation microstructure and mechanical properties of metal Ti particulate reinforced AZ91D magnesium matrix composites processed by stir casting[D]. Shenyang: Shenyang University of Technology, 2022(in Chinese). [81] WANG X J, WANG X M, HU X S, et al. Effects of hot extrusion on microstructure and mechanical properties of Mg matrix composite reinforced with deformable TC4 particles[J]. Journal of Magnesium and Alloys,2020,8(2):421-430. doi: 10.1016/j.jma.2019.05.015 [82] WANG X M, WANG X J, HU X S, et al. Processing, microstructure and mechanical properties of Ti6Al4V particles-reinforced Mg matrix composites[J]. Acta Metallurgica Sinica-English Letters,2016,29(10):940-950. doi: 10.1007/s40195-016-0473-3 [83] AFSHARNADERI A, MALEKAN M, EMAMY M, et al. Microstructure evolution and mechanical properties of the AZ91 magnesium alloy with Sr and Ti additions in the As-cast and As-aged conditions[J]. Journal of Materials Engineering and Performance,2019,28(11):6853-6863. doi: 10.1007/s11665-019-04396-2 [84] CANDAN S, UNAL M, KOC E, et al. Effects of titanium addition on mechanical and corrosion behaviours of AZ91 magnesium alloy[J]. Journal of Alloys and Compounds,2011,509(5):1958-1963. doi: 10.1016/j.jallcom.2010.10.100 [85] CHENG J H, GUSSEV M, ALLEN J, et al. Deformation and failure of print cast A356/316L composites: Digital image correlation and finite element modeling[J]. Materials & Design,2020,195:109061. [86] RAIMONDI L, TOMESANI L, DONATI L, et al. Lattice material infiltration for hybrid metal-composite joints: Manufacturing and static strenght[J]. Composite Structures,2021,269:114069. doi: 10.1016/j.compstruct.2021.114069 [87] ZHANG M Y, ZHAO N, YU Q, et al. On the damage tolerance of 3D printed Mg-Ti interpenetrating-phase composites with bioinspired architectures[J]. Nature Communications, 2022, 13(1): 1-13. [88] ZHANG M Y, YU Q, LIU Z Q, et al. Compressive properties of 3D printed Mg-NiTi interpenetrating-phase composite: Effects of strain rate and temperature[J]. Composites Part B: Engineering, 2021, 215: 108783. [89] ZHANG M Y, YU Q, LIU Z Q, et al. 3D printed Mg-NiTi interpenetrating-phase composites with high strength, damping capacity, and energy absorption efficiency[J]. Science Advances, 2020, 6(19): 5581. [90] ZHANG M Y, ZHAO N, YU Q, et al. On the damage tolerance of 3D printed Mg-Ti interpenetrating-phase compo-sites with bioinspired architectures[J]. Nature Communications,2022,13(1):1-13. doi: 10.1038/s41467-021-27699-2 [91] YANG X X, HUANG W Y, ZHAN D S, et al. Biodegradability and cytocompatibility of 3D-printed Mg-Ti interpenetrating phase composites[J]. Frontiers in Bioengineering and Biotechnology, 2022,10: 891632. [92] 黄培云. 粉末冶金原理[M]. 北京: 冶金工业出版社, 1997: 5-6.HUANG Peiyun. Powder metallurgy principle[M]. Beijing: Metallurgical Industry Press, 1997: 5-6(in Chinese). [93] YU H, SUN Y, WAN Z P, et al. Nanocrystalline Ti/AZ61 magnesium matrix composite: Evolution of microstructure and mechanical property during annealing treatment[J]. Journal of Alloys and Compounds,2018,741:231-239. doi: 10.1016/j.jallcom.2018.01.136 [94] DINAHARAN I, ZHANG S, CHEN G Q, et al. Assessment of Ti-6Al-4V particles as a reinforcement for AZ31 magnesium alloy-based composites to boost ductility incorporated through friction stir processing[J]. Journal of Magnesium and Alloys,2022,10(4):979-992. doi: 10.1016/j.jma.2020.09.026 [95] ZHANG C L, WANG X J, WANG X M, et al. Fabrication, microstructure and mechanical properties of Mg matrix composites reinforced by high volume fraction of sphere TC4 particles[J]. Journal of Magnesium and Alloys,2016,4(4):286-294. doi: 10.1016/j.jma.2016.10.003 [96] RASHAD M, PAN F S, ASIF M, et al. Improved mechanical proprieties of "magnesium based composites" with titanium-aluminum hybrids[J]. Journal of Magnesium and Alloys,2015,3(1):1-9. doi: 10.1016/j.jma.2014.12.010 [97] LUO H, LI J B, YE J L, et al. Influence of Ti-6Al-4V particles on the interfacial microstructure and strength-ductility synergetic mechanism of AZ91 magnesium alloy[J]. Materials Characterization,2022,191:112154. doi: 10.1016/j.matchar.2022.112154 [98] UMEDA J, KAWAKAMI M, KONDOH K, et al. Microstructural and mechanical properties of titanium particulate reinforced magnesium composite materials[J]. Materials Chemistry and Physics,2010,123(2):649-657. [99] ESEN Z Y, BÜTEV E, KARAKAŞ M S. A comparative study on biodegradation and mechanical properties of pressureless infiltrated Ti/Ti-6Al-4V-Mg composites[J]. Journal of the Mechanical Behavior of Biomedical Materials,2016,63:273-286. doi: 10.1016/j.jmbbm.2016.06.026 [100] OUYANG S H, HUANG Q L, LIU Y, et al. Powder metallurgical Ti-Mg metal-metal composites facilitate osteoconduction and osseointegration for orthopedic application[J]. Bioactive Materials,2019,4:37-42. doi: 10.1016/j.bioactmat.2018.12.001 [101] LIU Y, LI K Y, LUO T, et al. Powder metallurgical low-modulus Ti-Mg alloys for biomedical applications[J]. Materials Science and Engineering: C,2015,56:241-250. [102] KALANTARI S M, ARABI H, MIRDAMADI S, et al. Biocompatibility and compressive properties of Ti-6Al-4V scaffolds having Mg element[J]. Journal of the Mechanical Behavior of Biomedical Materials,2015,48:183-191. doi: 10.1016/j.jmbbm.2015.04.015 [103] BALOG M, IBRAHIM A M H, KRIZIK P, et al. Bioactive Ti + Mg composites fabricated by powder metallurgy: The relation between the microstructure and mechanical properties[J]. Journal of the Mechanical Behavior of Biomedical Materials,2019,90:45-53. doi: 10.1016/j.jmbbm.2018.10.008 [104] KONDOH K, KAWAKAMI M, IMAI H, et al. Wettability of pure Ti by molten pure Mg droplets[J]. Acta Materialia,2010,58(2):606-614. doi: 10.1016/j.actamat.2009.09.039 [105] 郗雨林, 柴东朗, 张文兴, 等. 钛合金颗粒增强镁基复合材料的制备与性能[J]. 稀有金属材料与工程, 2006, 35(2):144-147. doi: 10.3321/j.issn:1002-185X.2006.02.032CHI Yulin, CHAI Donglang, ZHANG Wenxing, et al. Fabrication and properties of Ti-6Al-4V particles reinforced magnesium matrix composite by powder metallurgy[J]. Rare Metal Materials and Engineering,2006,35(2):144-147(in Chinese). doi: 10.3321/j.issn:1002-185X.2006.02.032 [106] YU H, ZHOU H P, SUN Y, et al. Microstructures and mechanical properties of ultrafine-grained Ti/AZ31 magnesium matrix composite prepared by powder metallurgy[J]. Advanced Powder Technology,2018,29(12):3241-3249. doi: 10.1016/j.apt.2018.09.001 [107] HASSAN S F, GUPTA M. Development of ductile magnesium composite materials using titanium as reinforcement[J]. Journal of Alloys and Compounds,2002,345(1):246-251. [108] PÉREZ P, GARCÉS G, ADEVA P. Mechanical properties of a Mg-10(vol.%)Ti composite[J]. Composites Science and Technology,2004,64(1):145-151. doi: 10.1016/S0266-3538(03)00215-X -

下载:

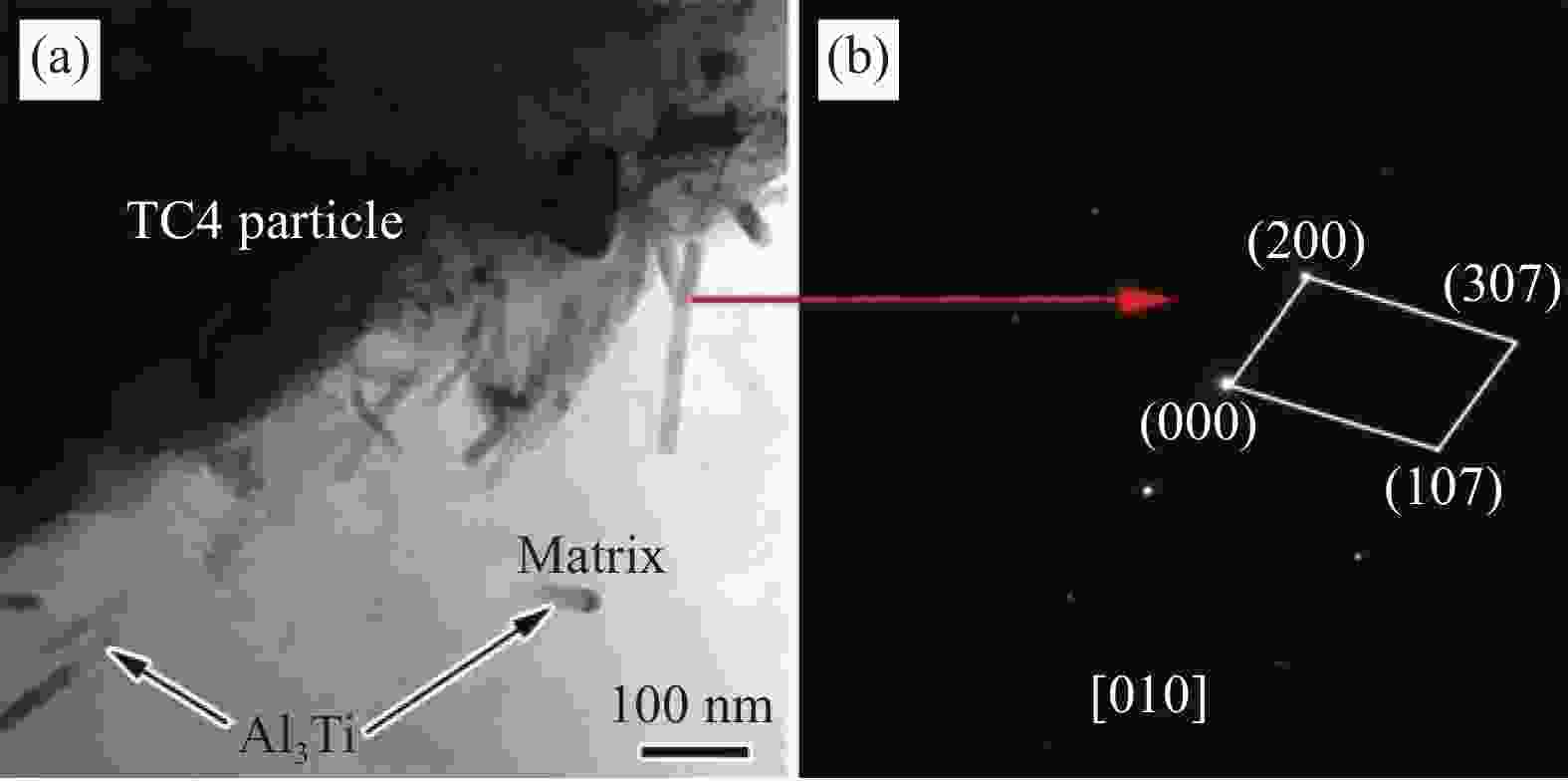

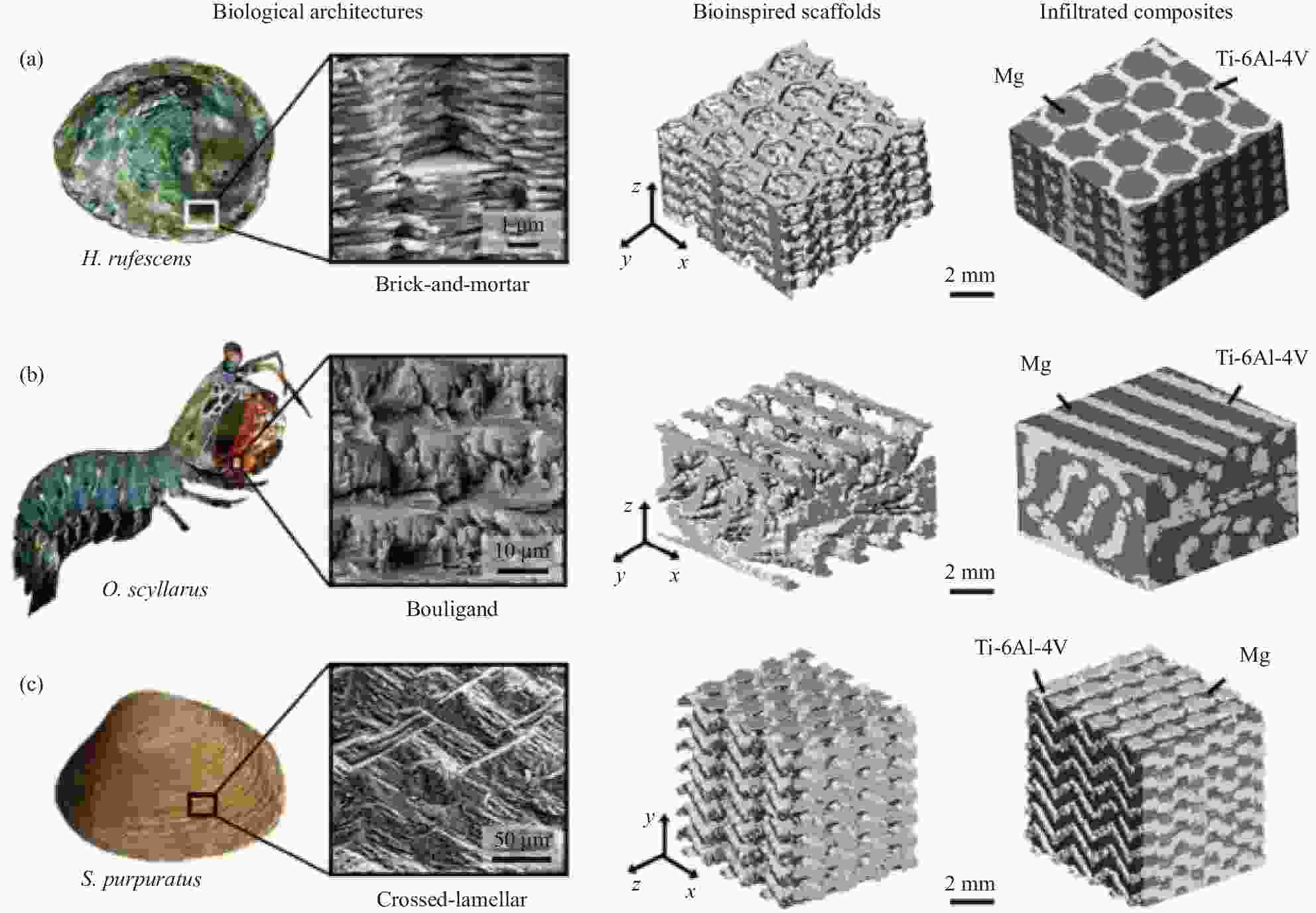

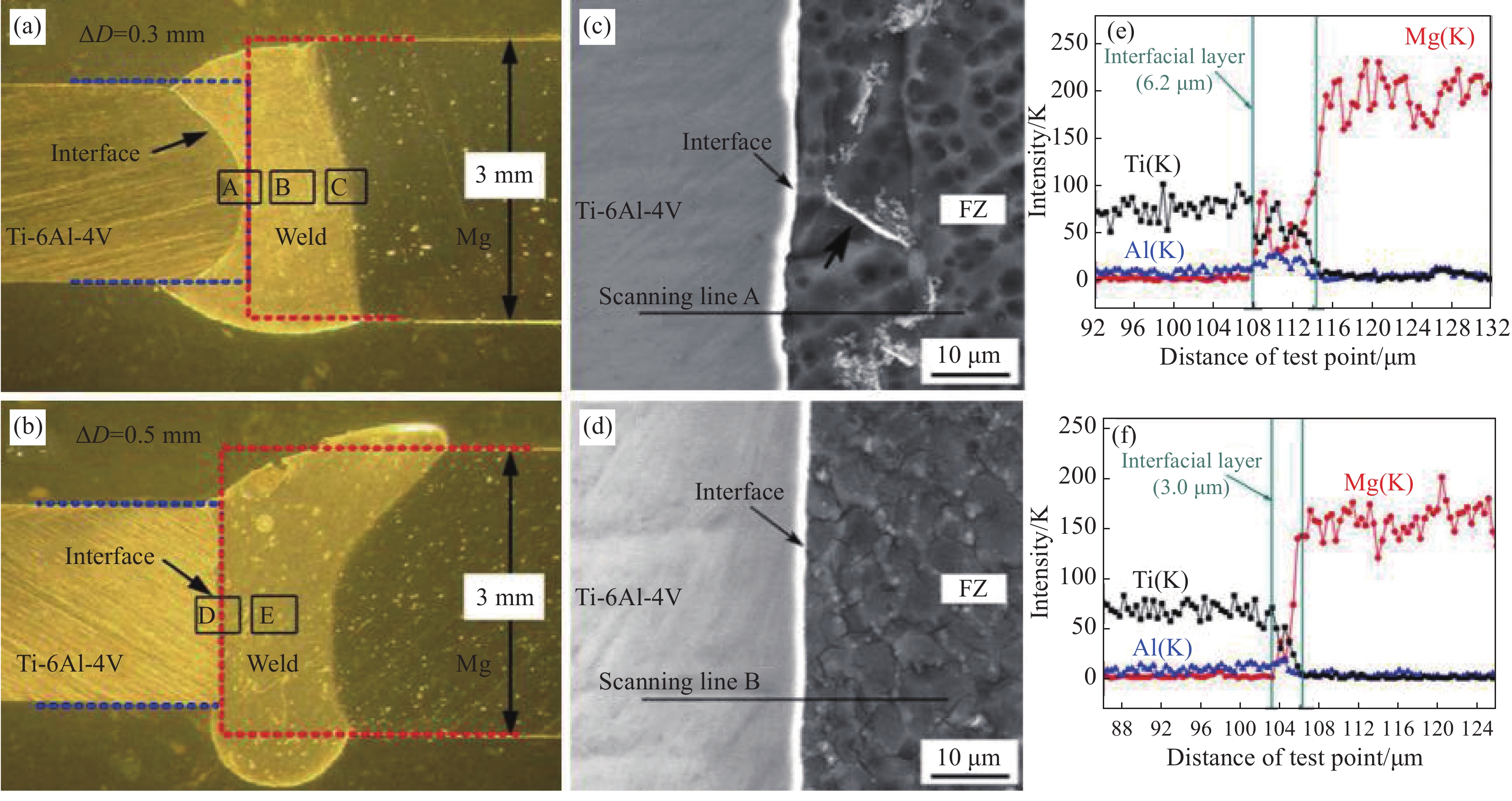

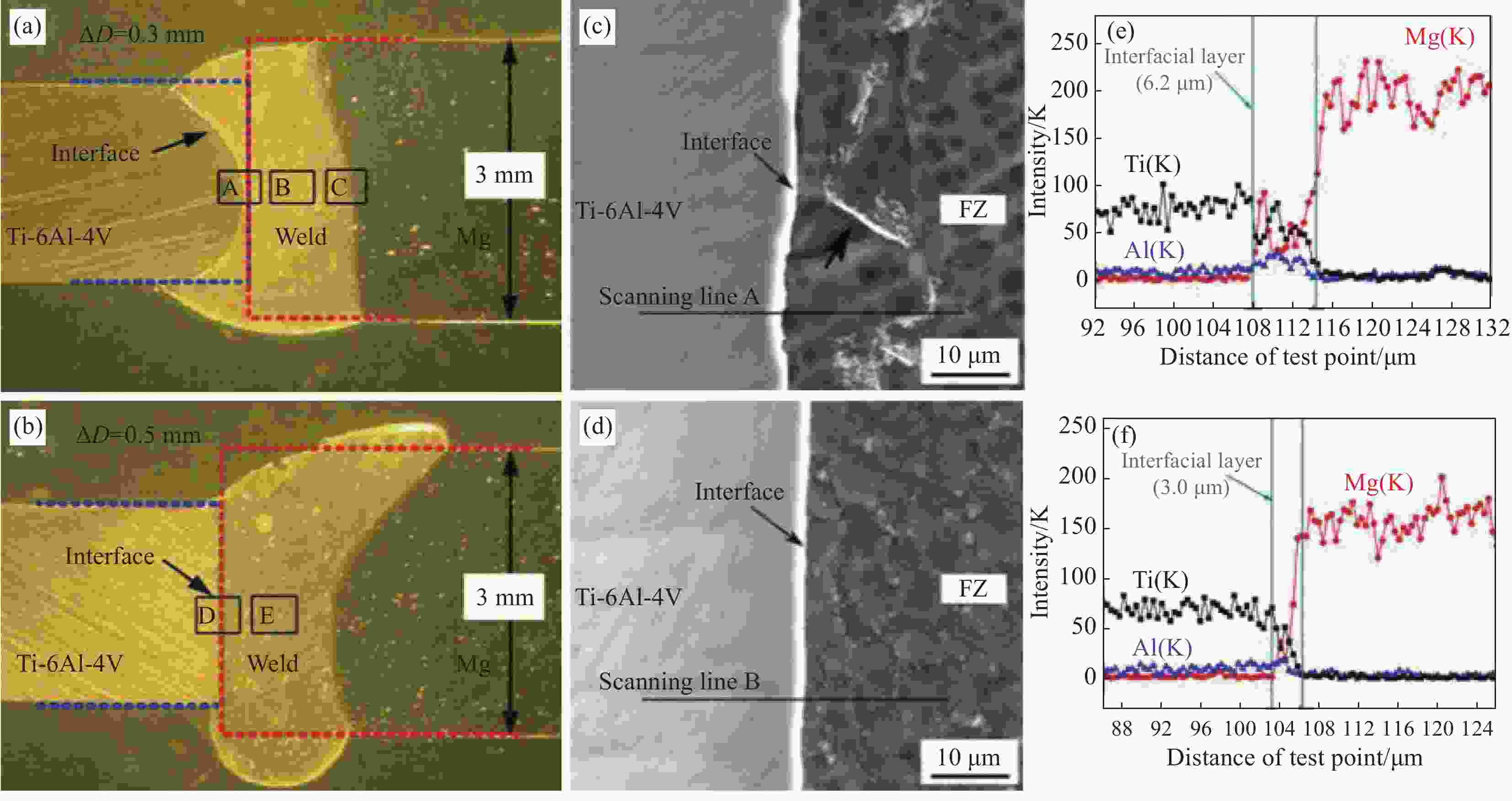

下载: