In-situ polysilazane modified carbon fiber for high temperature anti-oxidation

-

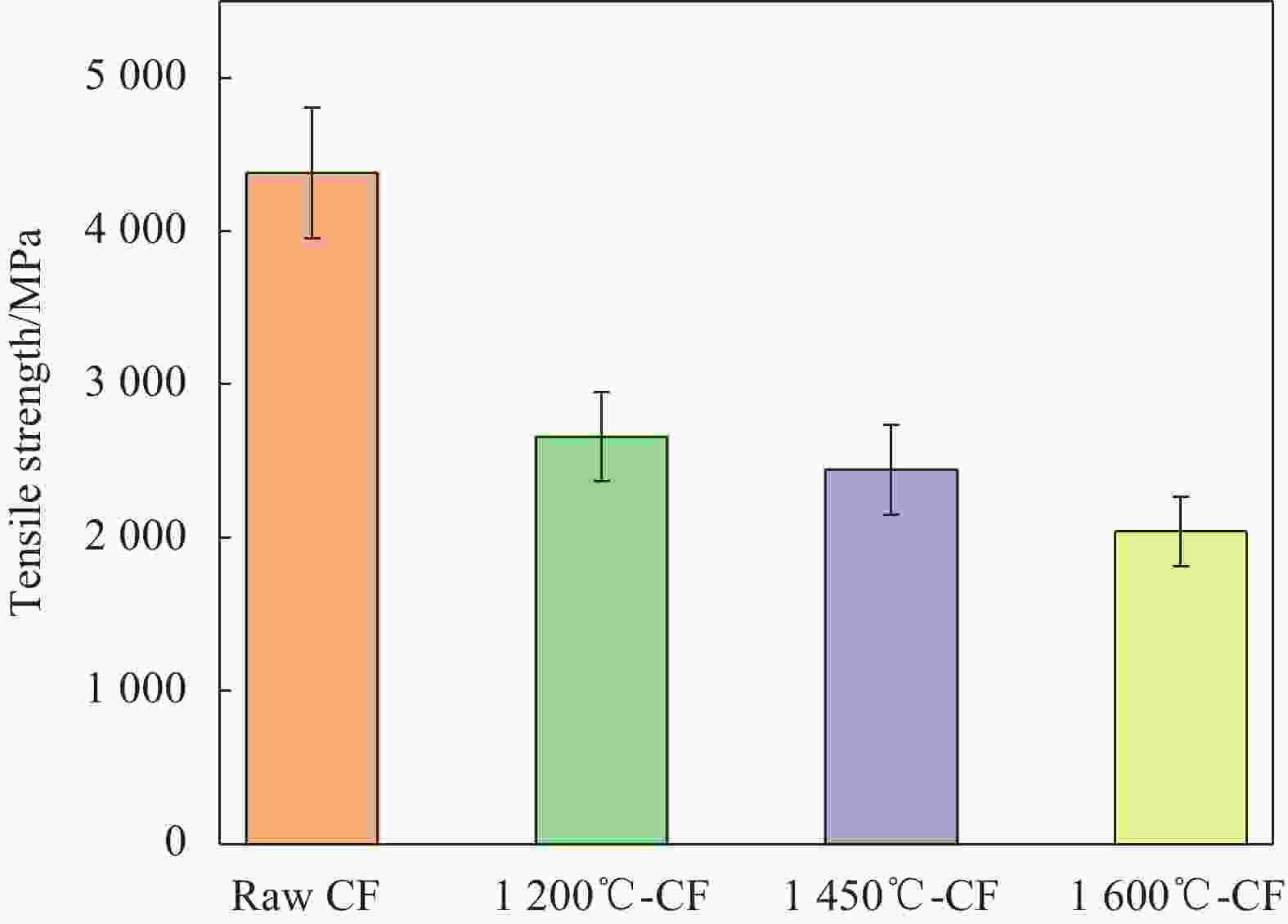

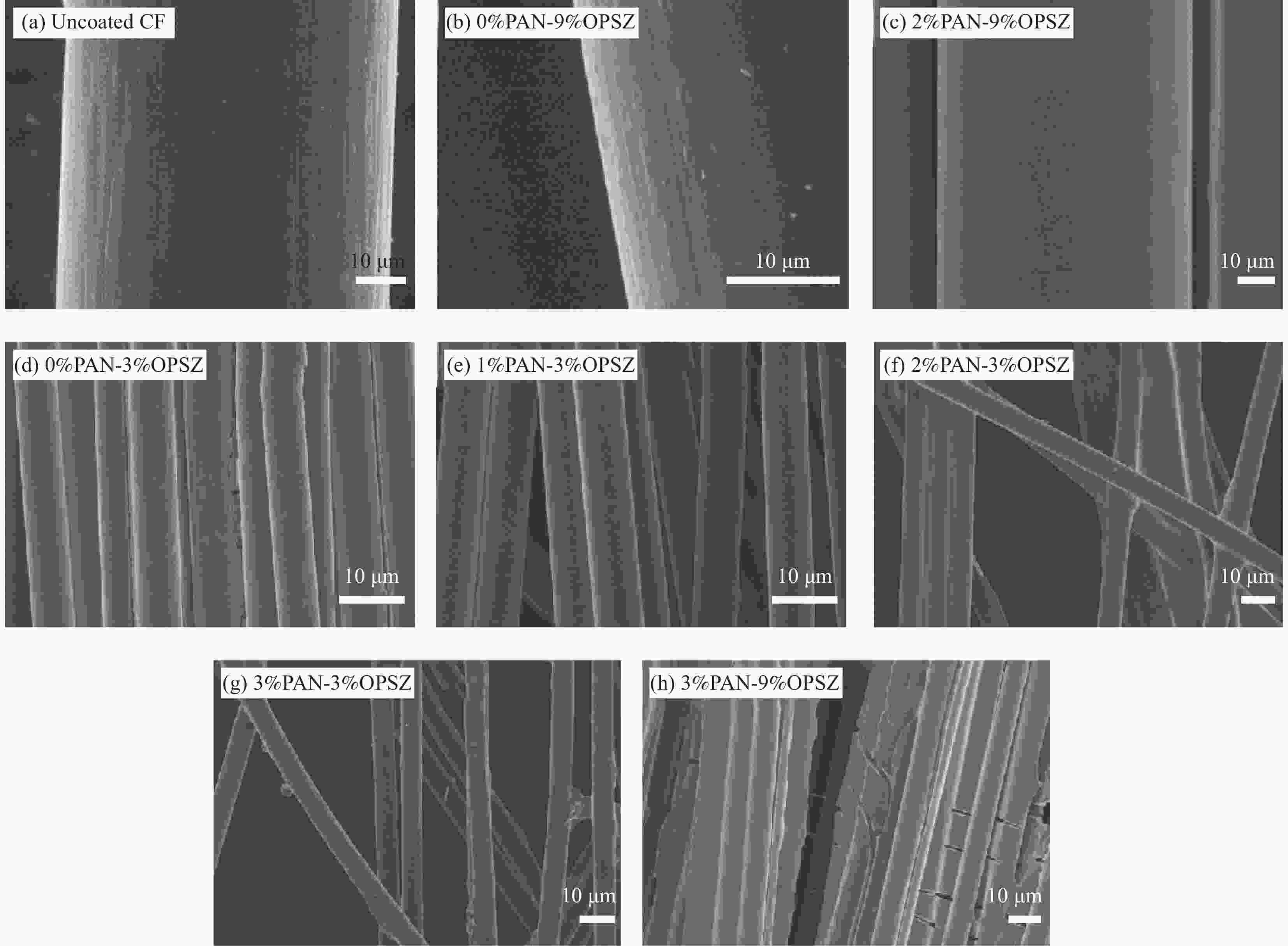

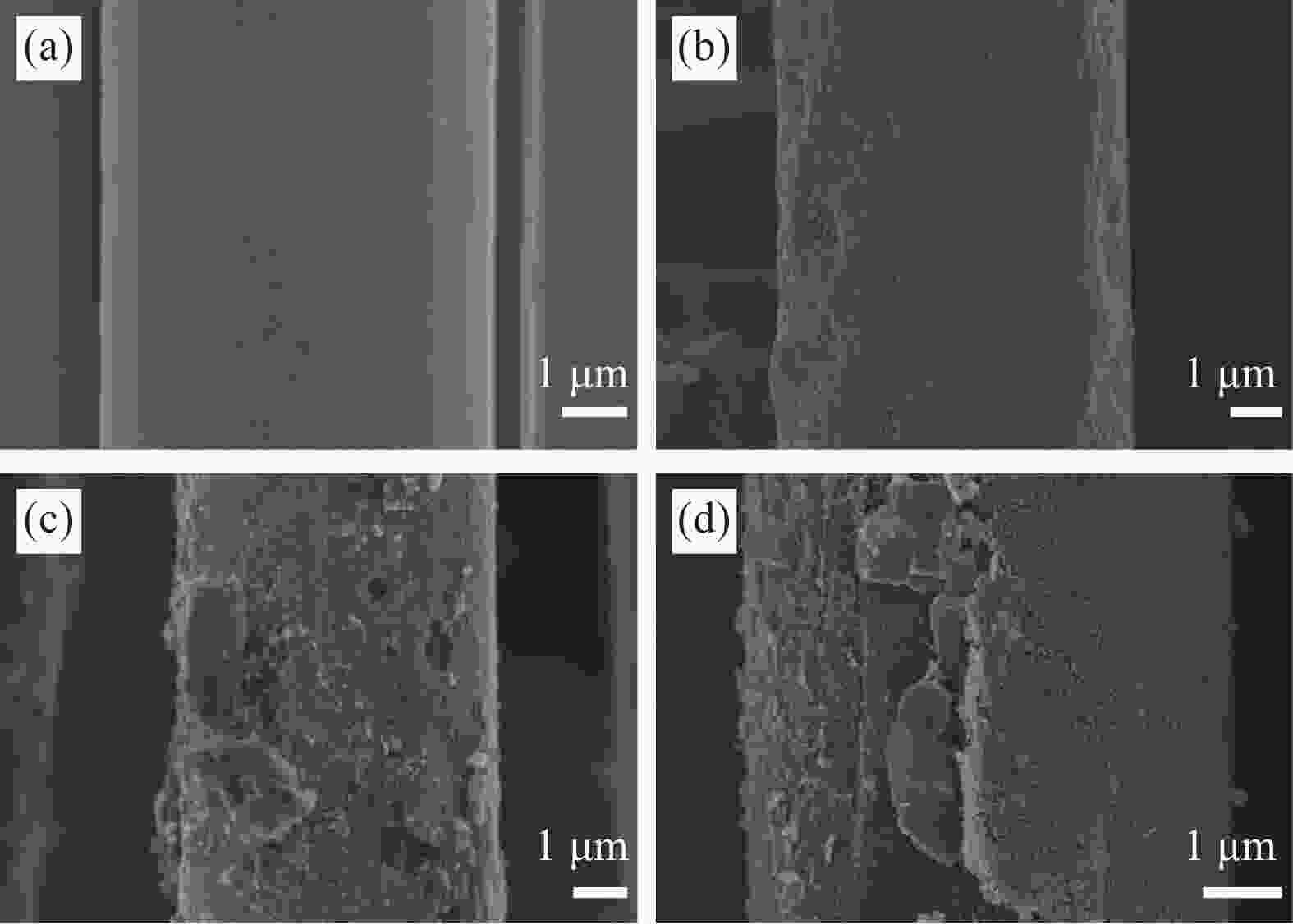

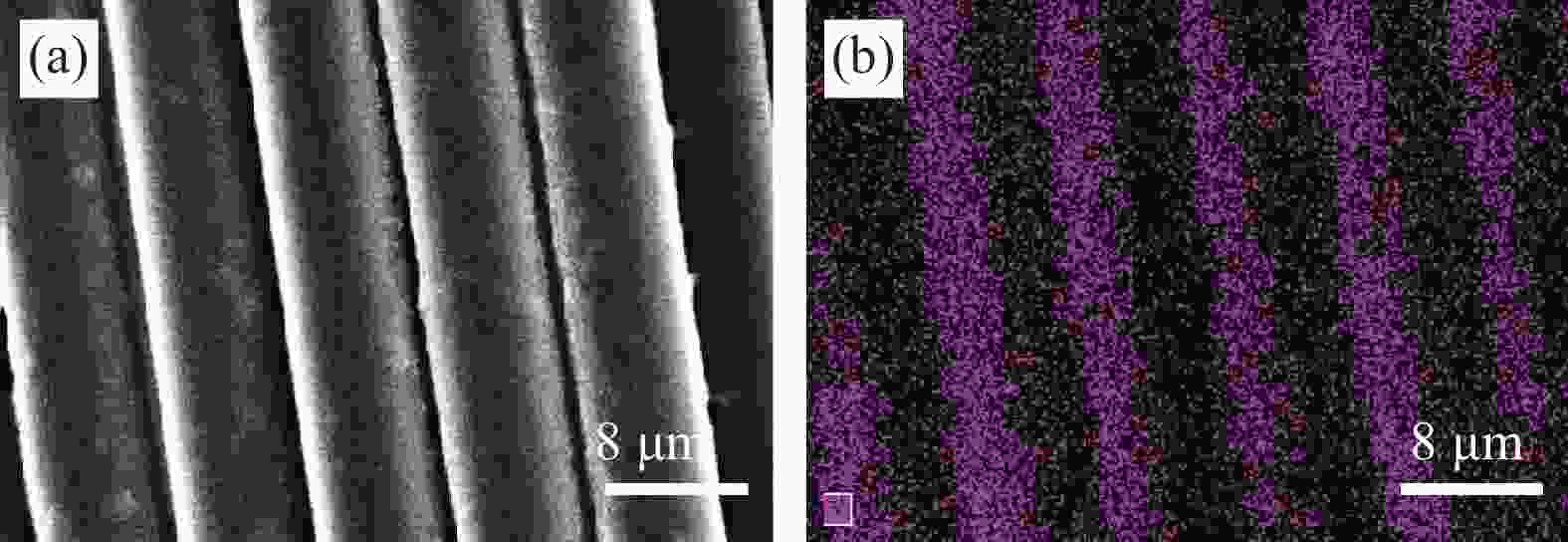

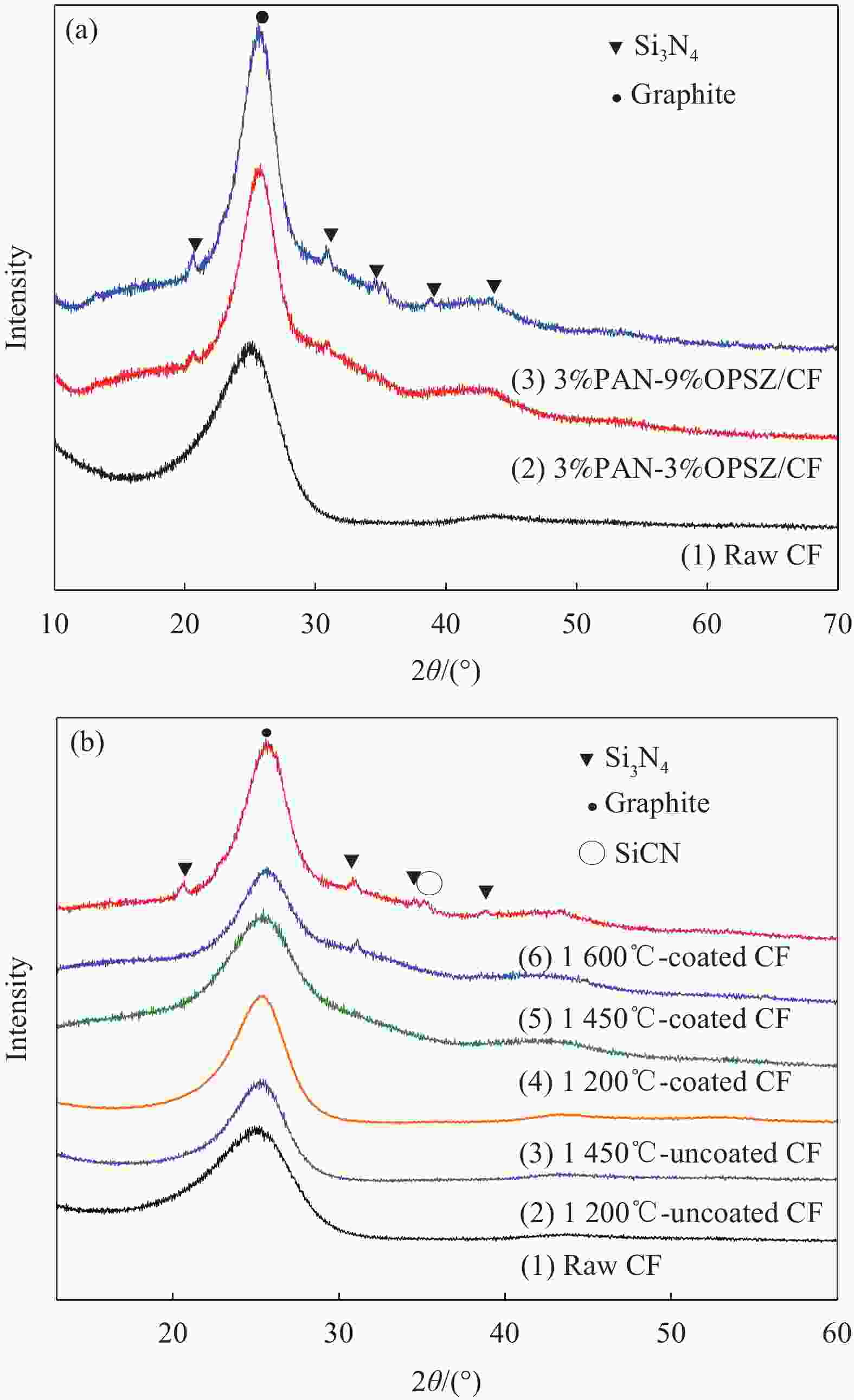

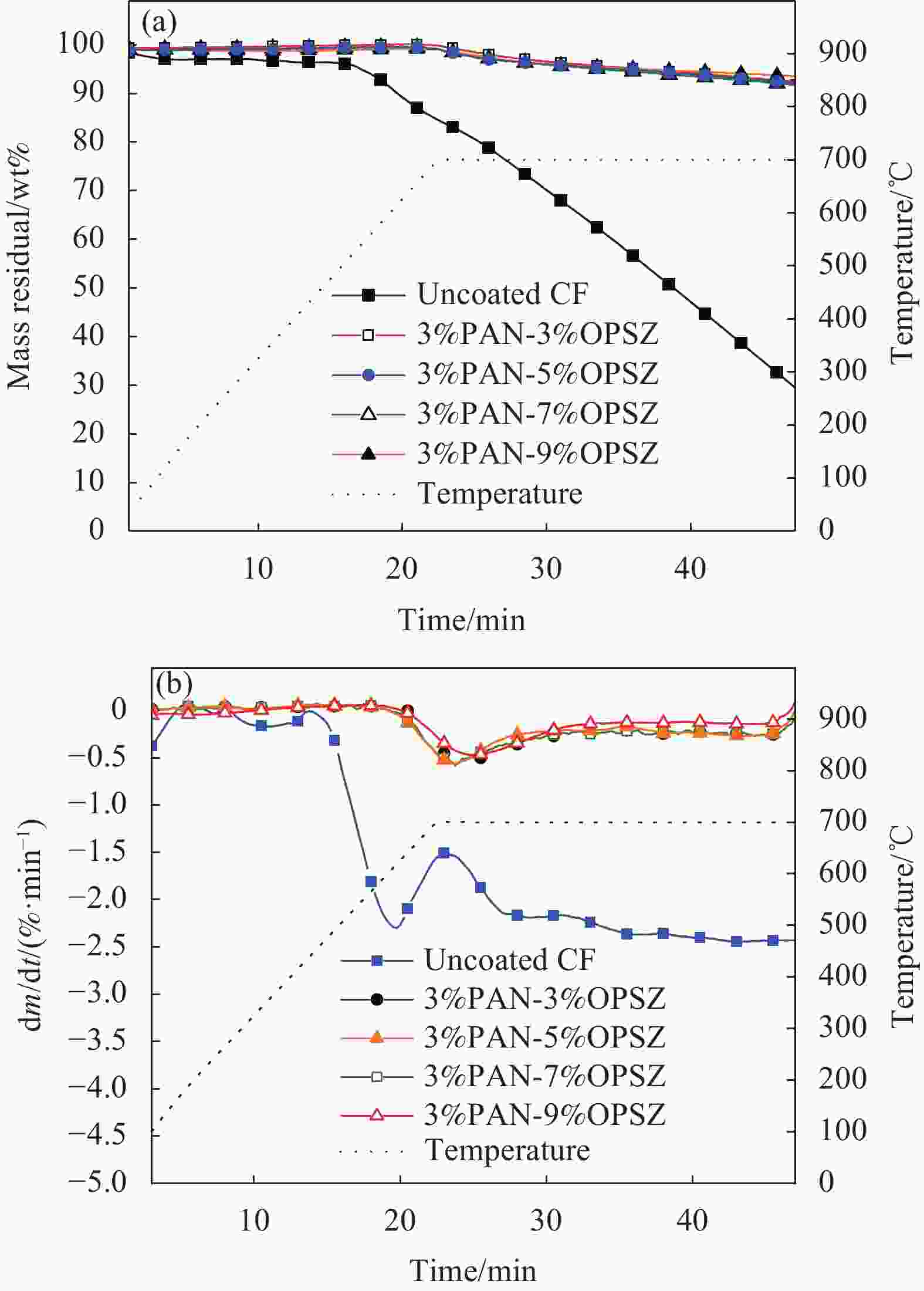

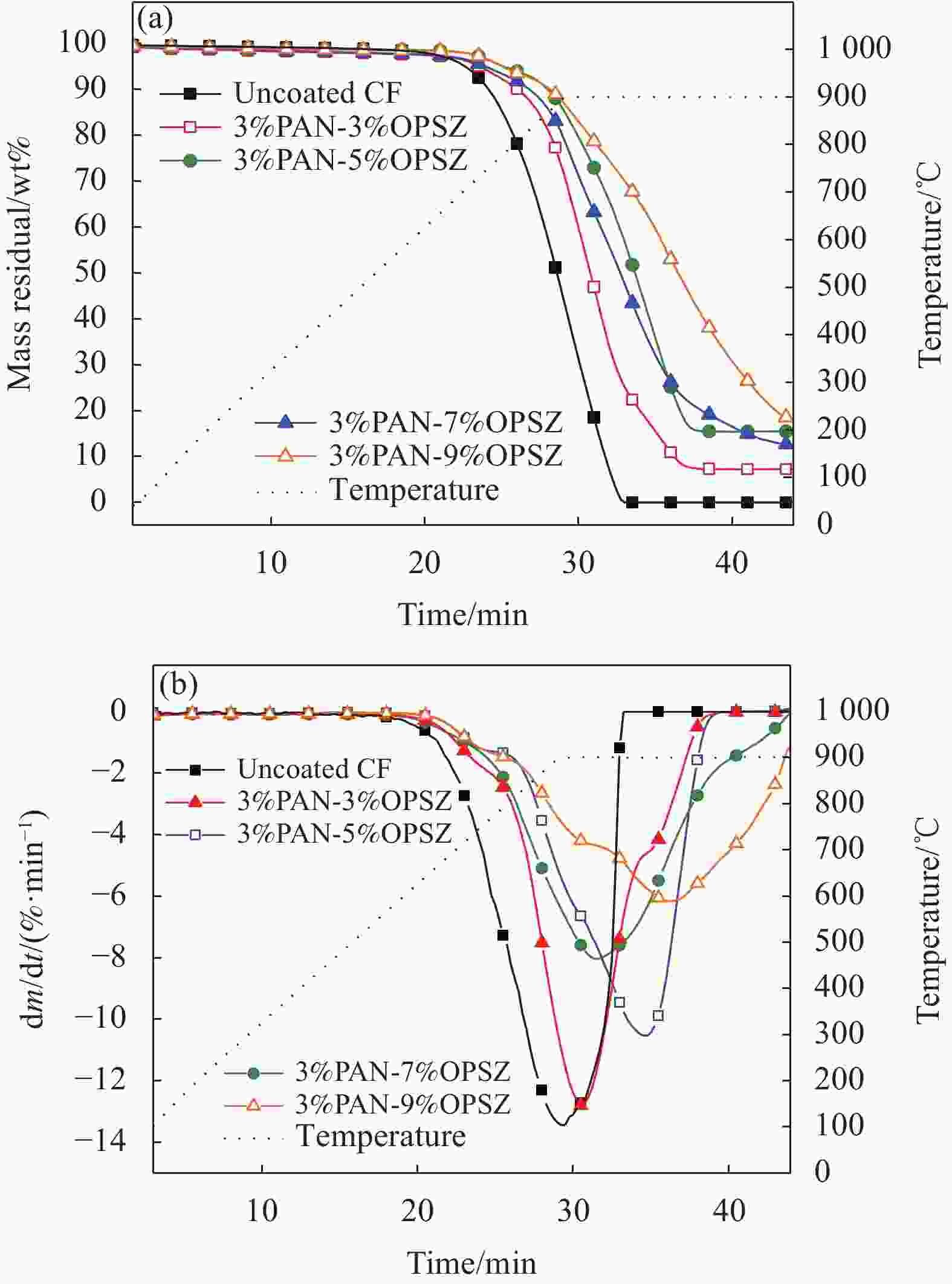

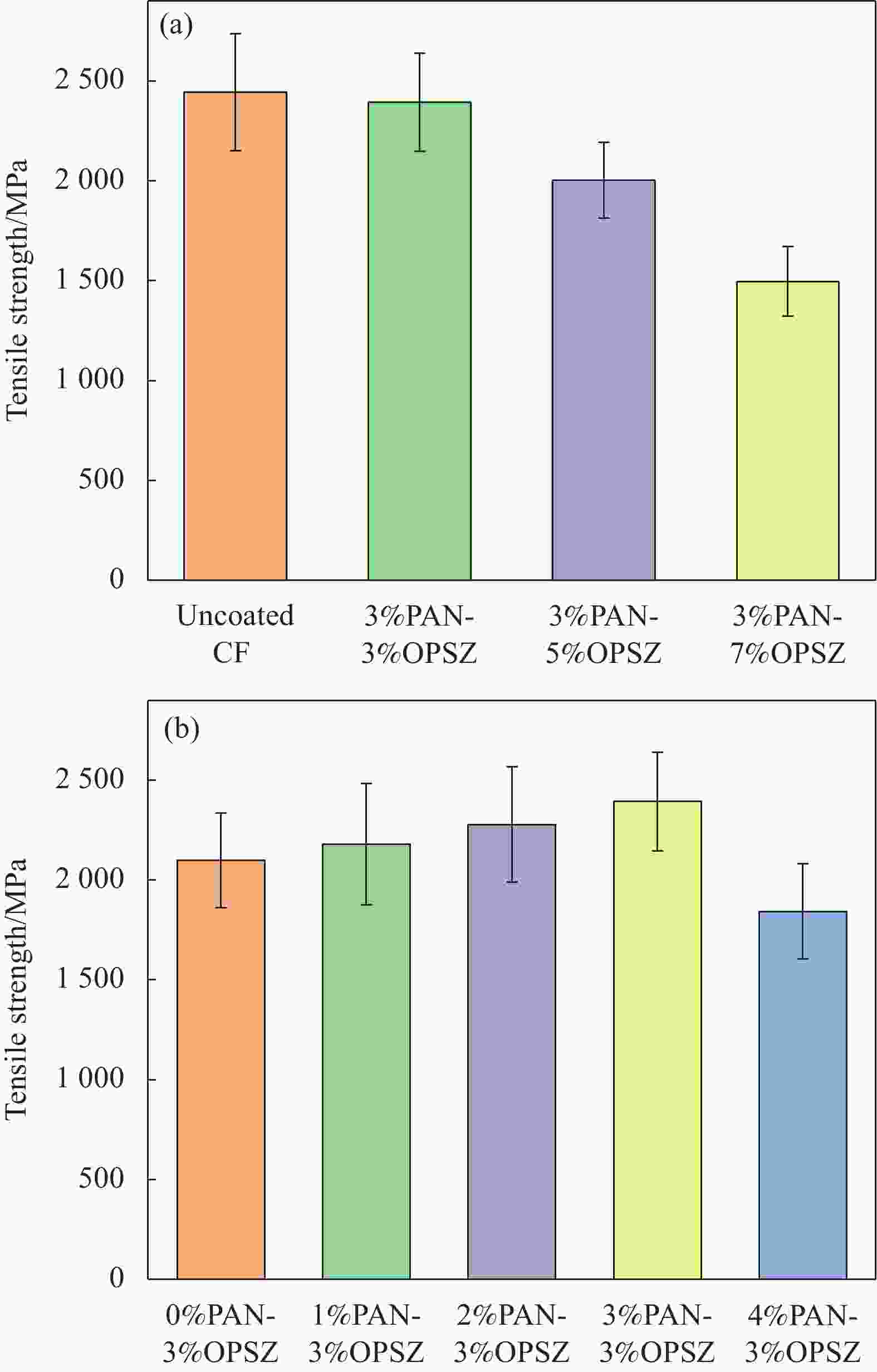

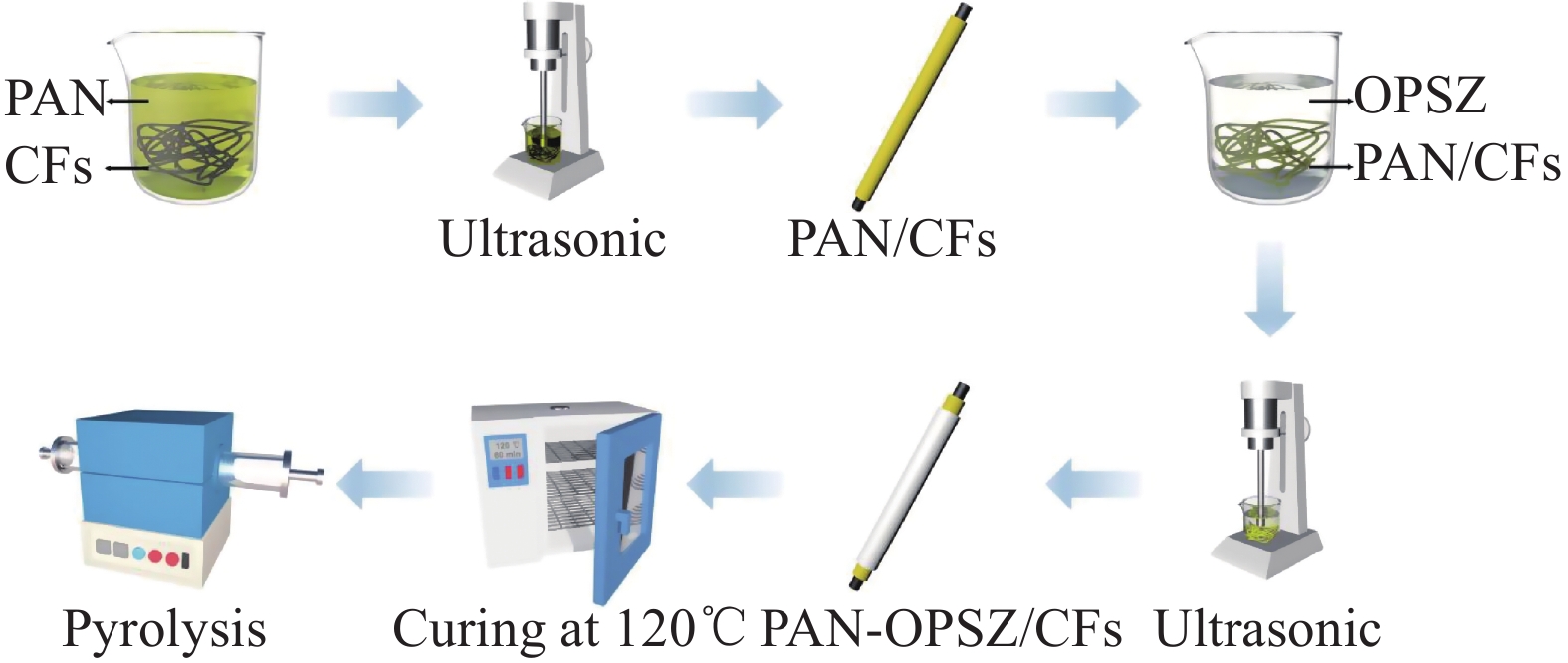

摘要: 由于碳纤维在高温含氧的环境下易被氧化,且与基体发生强界面反应而导致其性能劣化,影响了其在复合材料领域的应用。本文通过在碳纤维表面构筑聚丙烯腈(PAN)过渡层及有机聚硅氮烷(OPSZ)陶瓷前驱体层,经低温固化与高温裂解后形成C-Si3N4保护涂层,制备了具有高温抗氧化效能的PAN-OPSZ/碳纤维。扫描电镜与能谱仪的结果表明:PAN层的涂覆有助于Si元素在碳纤维表面附着,将PAN溶液的浓度从1%提高到3%,Si元素的相对含量随即从2.81%提高到了8.26%。采用PAN与OPSZ浓度为3wt%制备的PAN-OPSZ/碳纤维的拉伸强度仅比未涂层碳纤维降低了2.08%,表明其未对碳纤维力学性能造成明显降低。制备的PAN-OPSZ/碳纤维的抗氧化能力得到了显著提高,在700℃的空气气氛下失重率低于8wt%,而未涂层碳纤维的失重率高达70wt%。以上结果说明,PAN-OPSZ涂层能有效提高碳纤维的高温抗氧化性,在碳纤维增强复合材料领域具有十分广阔的应用前景。Abstract: Carbon fiber is easily oxidized in a high-temperature oxygen-containing environment. The strong interfacial reactions with the matrix result in deterioration of their performance, which limits their use in carbon fiber-reinforced composites. In this paper, a C-Si3N4 protective coating which has high-temperature anti-oxidation performance was formed by constructing a polyacrylonitrile (PAN) layer and an organopolysilazane (OPSZ) layer on the surface of carbon fibers with curing at low-temperature and cracking at high-temperature. The results of scanning electron microscope and energy dispersive spectrometer show that the coating of PAN layer is helpful for Si element to adhere to the surface of carbon fiber. Increasing the concentration of the PAN solution from 1% to 3%, the relative content of the Si element increased from 2.81% to 8.26%. The tensile strength of PAN-OPSZ/carbon fiber prepared with PAN and OPSZ concentration of 3wt% was only 2.08% lower than that of uncoated carbon fiber, indicating that it did not cause obvious damage to the mechanical properties of carbon fiber. The oxidation resistance of the as-prepared PAN-OPSZ/carbon fibers was significantly improved, with a mass loss of less than 8wt% in an air atmosphere at 700℃, while the mass loss of uncoated carbon fibers was as high as 70wt%. The above results show that the PAN-OPSZ coating can effectively improve the high temperature oxidation resistance of carbon fibers, and has a very broad application prospect in the field of reinforced composites.

-

表 1 样品名释义

Table 1. Interpretation of samples

Sample Coating Heat treatment Raw CF — — 1200℃-CF — 1200℃ for 2 h 1450℃-CF — 1450℃ for 2 h 1600℃-CF — 1600℃ for 2 h Uncoated CF — 400℃ for 0.5 h 0%PAN-9%OPSZ/CF 9%OPSZ — 2%PAN-9%OPSZ/CF 2%PAN and 9%OPSZ — 0%PAN-3%OPSZ/CF 3%OPSZ — 1%PAN-3%OPSZ/CF 1%PAN and 3%OPSZ — 2%PAN-3%OPSZ/CF 2%PAN and 3%OPSZ — 3%PAN-3%OPSZ/CF 3%PAN and 3%OPSZ — 3%PAN-5%OPSZ/CF 3%PAN and 5%OPSZ — 3%PAN-7%OPSZ/CF 3%PAN and 7%OPSZ — 3%PAN-9%OPSZ/CF 3%PAN and 9%OPSZ — 1200℃-uncoated CF — 1200℃ for 2 h 1450℃-uncoated CF — 1450℃ for 2 h 1200℃-coated CF 3%PAN and 9%OPSZ 1200℃ for 2 h 1450℃-coated CF 3%PAN and 9%OPSZ 1450℃ for 2 h 1600℃-coated CF 3%PAN and 9%OPSZ, 1600℃ for 2 h 表 2 涂层碳纤维的EDS面分析

Table 2. EDS analysis data of coated CF

Sample Coating T/℃ Element Element/wt% Atom/at% 1 1%PAN-3%OPSZ/CF 1200 C 85.36 88.97 Si 2.81 1.25 O 7.15 5.59 N 4.69 4.19 2 3%PAN-3%OPSZ/CF 1200 C 74.75 81.74 Si 8.26 3.86 O 13.16 10.80 N 3.83 3.59 3 1%PAN-9%OPSZ/CF 1200 C 82.49 86.92 Si 3.87 1.75 O 8.76 6.93 N 4.87 4.40 4 1%PAN-3%OPSZ/CF 1450 C 80.30 86.74 Si 7.04 3.26 O 6.93 4.53 N 5.73 5.47 5 3%PAN-3%OPSZ/CF 1450 C 70.11 78.29 Si 11.76 5.61 O 3.49 2.92 N 12.79 12.25 6 1%PAN-9%OPSZ/CF 1450 C 71.97 79.04 Si 7.80 3.66 O 2.83 2.33 N 14.25 13.42 Note: T—Temperature. 表 3 3%PAN涂覆组1450℃烧结后涂层纤维在700℃的热重分析数据

Table 3. Thermogravinmetric analysis data at 700℃ of 3%PAN/carbon fibers after sintering at 1450℃

Sample T1/℃ T2/℃ W1/wt% W2/wt% Uncoated CF 510 630 15.8 70.4 3%PAN-3%OPSZ/CF 700 700 0.1 7.5 3%PAN-5%OPSZ/CF 700 700 0.8 7.9 3%PAN-7%OPSZ/CF 700 700 0.9 8.2 3%PAN-9%OPSZ/CF 700 700 1.0 6.4 Notes: T1—Initial decomposition temperature; T2—Maximum decomposition temperature in the first stage; W1—Mass loss fraction at 700℃; W2—Total mass loss fraction. 表 4 1450℃烧结后的涂层碳纤维在900℃的热重分析数据

Table 4. Thermogravinmetric analysis data at 900℃ of 1450℃-coated carbon fiber

Sample T1/℃ W1/wt% W2/wt% Total weight-lessness time/min Uncoated CF 705 58.8 100.0 4.50 3%PAN-3%OPSZ/CF 735 30.8 92.6 8.00 3%PAN-5%OPSZ/CF 739 28.4 84.2 8.50 3%PAN-7%OPSZ/CF 750 22.5 87.3 14.25 3%PAN-9%OPSZ/CF 780 13.8 82.0 15.00 表 5 无涂层和有涂层CF的单丝拉伸性能

Table 5. Single silk tensile performance of uncoated and coated CF

Sample Tensile strength/

MPaStandard deviation of tensile strength/MPa Coefficient of variation (CV) for tensile strength

value/%Relative loss value of tensile strength/% 1450℃-CF 2444 293 11.98 — 1450℃-3%OPSZ/CF 2099 237 11.30 14.11 1450℃-1%PAN-3%OPSZ/CF 2179 305 13.99 10.84 1450℃-2%PAN-3%OPSZ/CF 2278 290 12.74 6.78 1450℃-3%PAN-3%OPSZ/CF 2393 246 11.23 2.08 1450℃-3%PAN-5%OPSZ/CF 2002 189 9.44 18.08 1450℃-3%PAN-7%OPSZ/CF 1496 175 11.69 38.78 1450℃-4%PAN-3%OPSZ/CF 1842 239 12.99 24.63 -

[1] 刘晨曦, 于惠舒, 张楠楠, 等. 碳纤维增强铝基复合材料的研究现状[J]. 钢铁研究学报, 2021, 33(12):1205-1218. doi: 10.13228/j.boyuan.issn1001-0963.20210027LIU Chenxi, YU Huishu, ZHANG Nannan, et al. Research status of carbon fiber reinforced aluminum matrix compo-sites[J]. Journal of Iron and Steel Research,2021,33(12):1205-1218(in Chinese). doi: 10.13228/j.boyuan.issn1001-0963.20210027 [2] 韦玉堂, 崔素华. 车用碳纤维增强Al-Cu基复合材料的微观组织及力学性能研究[J]. 粉末冶金工业, 2019, 29(4):42-46. doi: 10.13228/j.boyuan.issn1006-6543.20190029WEI Yutang, CUI Suhua. Microstructure and mechanical properties of carbon fiber reinforced Al-Cu matrix compo-sites for vehicles[J]. Powder Metallurgy Industry,2019,29(4):42-46(in Chinese). doi: 10.13228/j.boyuan.issn1006-6543.20190029 [3] 李晋. 金属基复合材料的现状与未来发展[J]. 现代盐化工, 2022, 49(2):22-23. doi: 10.3969/j.issn.1005-880X.2022.02.009LI Jin. Status and future development of metal-based composites[J]. Modern Salt and Chemical Industry,2022,49(2):22-23(in Chinese). doi: 10.3969/j.issn.1005-880X.2022.02.009 [4] 罗益锋. 新形势下全球碳纤维及其复合材料产业发展动向[J]. 高科技纤维与应用, 2022, 47(1):11-20. doi: 10.3969/j.issn.1007-9815.2022.01.001LUO Yifeng. Development trend of global carbon fibers and carbon fiber composites industries in new situations[J]. Hi-Tech Fiber and Application,2022,47(1):11-20(in Chinese). doi: 10.3969/j.issn.1007-9815.2022.01.001 [5] 靳高岭. 我国碳纤维产业现状及发展前景[J]. 高科技纤维与应用, 2021, 46(3):11-14. doi: 10.3969/j.issn.1007-9815.2021.03.001JIN Gaoling. The status quo and development prospect of carbon fiber industry in China[J]. Hi-Tech Fiber and Application,2021,46(3):11-14(in Chinese). doi: 10.3969/j.issn.1007-9815.2021.03.001 [6] 史清宇, 曹雄, 李积元, 等. FSP制备碳纤维增强铝基复合材料的强韧化机理[J]. 清华大学学报(自然科学版), 2017, 57(8):792-797.SHI Qingyu, CAO Xiong, LI Jiyuan, et al. Improved mechanical properties in friction stir processed carbon fiber reinforced aluminum composites[J]. Journal of Tsinghua University (Natural Science Edition),2017,57(8):792-797(in Chinese). [7] 徐翊桄, 靳玉伟, 张海龙, 等. 碳纤维热氧化行为及其机理[J]. 合成纤维工业, 2010, 33(6):5-7. doi: 10.3969/j.issn.1001-0041.2010.06.002XU Yuguang, JIN Yuwei, ZHANG Hailong, et al. Thermal oxidation behavior and mechanism of carbon fiber[J]. China Synthetic Fiber Industry,2010,33(6):5-7(in Chinese). doi: 10.3969/j.issn.1001-0041.2010.06.002 [8] ZHOU W, LONG L, XIAO P, et al. Comparison in dielectric and microwave absorption properties of SiC coated carbon fibers with PyC and BN interphases[J]. Surface and Coatings Technology,2019,359:272-277. doi: 10.1016/j.surfcoat.2018.10.104 [9] 王玲玲, 肖春, 王坤杰, 等. 不同制备方法下(C/C)/ZrB2-SiC复合材料的抗烧蚀性能[J]. 复合材料学报, 2019, 36(12):2878-2886.WANG Lingling, XIAO Chun, WANG Kunjie, et al. Ablation performance of (C/C)/ZrB-SiC composites by different fabrication methods[J]. Acta Materiae Compositae Sinica,2019,36(12):2878-2886(in Chinese). [10] WANG L Y, LUO R Y, CUI G Y. Effect of pyrolysis tempera-ture on the mechanical evolution of SiCf/SiC composites fabricated by PIP[J]. Ceramics International,2020,46(2):1297-1306. doi: 10.1016/j.ceramint.2019.09.087 [11] WEN Z L, XIAO P, LI Z, et al. Microstructure and oxidation behavior of sol-gel mullite coating on SiC-coated carbon/carbon composites[J]. Journal of the European Ceramic Society,2015,35(14):3789-3796. doi: 10.1016/j.jeurceramsoc.2015.06.033 [12] 晋磊. 溶胶-凝胶法制备碳/碳复合材料抗氧化涂层的研究[D]. 北京: 北京化工大学, 2018.JIN Lei. Research about preparation of anti-oxidation coating by sol-gel method for carbon-carbon composites[D]. Beijing: Beijing University of Chemical Technology, 2018(in Chinese). [13] 赵晓莉, 齐暑华, 刘建军, 等. 正交设计法优化碳纤维表面连续镀镍工艺及性能[J]. 工程塑料应用, 2019, 47(3):55-59, 64. doi: 10.3969/j.issn.1001-3539.2019.03.011ZHAO Xiaoli, QI Shuhua, LIU Jianjun, et al. Optimization of continuous nickel plating on carbon fiber surface by orthogonal design[J]. Engineering Plastics Application,2019,47(3):55-59, 64(in Chinese). doi: 10.3969/j.issn.1001-3539.2019.03.011 [14] 孙晨薇, 王丹, 邹铭, 等. 聚硅氮烷防护涂层材料的研究进展[J]. 涂料工业, 2021, 51(9):81-88. doi: 10.12020/j.issn.0253-4312.2021.9.81SUN Chenwei, WANG Dan, ZOU Ming, et al. Research progress in polysilazane-based protective coatings materials[J]. Paint & Coatings Industry,2021,51(9):81-88(in Chinese). doi: 10.12020/j.issn.0253-4312.2021.9.81 [15] 王丹, 张宗波, 王晓峰, 等. 聚硅氮烷旋涂介电材料研究进展[J]. 微纳电子技术, 2017, 54(8):514-521. doi: 10.13250/j.cnki.wndz.2017.08.002WANG Dan, ZHANG Zongbo, WANG Xiaofeng, et al. Research progress of polysilazane based spin-on-dielectric materials[J]. Micronanoelectronic Technology,2017,54(8):514-521(in Chinese). doi: 10.13250/j.cnki.wndz.2017.08.002 [16] LO T N H, HWANG H S, LEE J, et al. Synthesis of new semi-fluorinated polysilazanes and their amphiphobic coating applications[J]. Progress in Organic Coatings,2020,148:105853. doi: 10.1016/j.porgcoat.2020.105853 [17] SHAYED M A, CHERIF C, HUND R D, et al. Carbon and glass fibers modified by polysilazane based thermal resistant coating[J]. Textile Research Journal,2010,80(11):1118-1128. doi: 10.1177/0040517509357648 [18] 马百胜. 聚硅氮烷转化SiCN陶瓷结构性能及传感器应用[D]. 西安: 西北工业大学, 2018.MA Baisheng. Research on microstructures and properties of polysilizane derived SiCN ceramics and their application in sensors[D]. Xi'an: Northwestern Polytechnical University, 2018(in Chinese). [19] BAWANE K, LU K, LI Q, et al. High temperature oxidation behaviors of SiON coated AISI 441 in Ar+O2, Ar+H2O and Ar+CO2 atmospheres[J]. Corrosion Science,2020,166:108429-108436. doi: 10.1016/j.corsci.2020.108429 [20] 师建军, 张宗波, 冯志海, 等. 低密度碳粘接碳纤维复合材料(CBCF)抗氧化改性研究[J]. 无机材料学报, 2018, 33(7):728-734. doi: 10.15541/jim20170445SHI Jianjun, ZHANG Zongbo, FENG Zhihai, et al. Modification of oxidation resistance for low density carbon-bonded carbon fiber (CBCF) composite[J]. Journal of Inorganic Materials,2018,33(7):728-734(in Chinese). doi: 10.15541/jim20170445 [21] 国家市场监督管理总局、国家标准化管理委员会. 碳纤维单丝拉伸性能的测定: GB/T 31290—2014[S]. 北京: 中国标准出版社, 2022.State Administration for Market Regulation, Standardization Administration. Determination of tensile properties of carbon fiber monofilament: GB/T 31290—2014[S]. Beijing: Standards Press of China, 2022(in Chinese). [22] LONG M L, LI Y, QIN H X, et al. Formation mechanism of Si3N4 in reaction-bonded Si3N4-SiC composites[J]. Ceramics International,2016,42(15):16448-16452. doi: 10.1016/j.ceramint.2016.05.118 [23] 瞿玲. 碳氮化法制备晶态SiCN的研究[D]. 武汉: 武汉科技大学, 2018.QU Ling. Preparation of crystalline SiCN by carbonitriding[D]. Wuhan: Wuhan University of Technology, 2018(in Chinese). [24] PARK D J, JUNG Y I, KIM H G, et al. Oxidation behavior of silicon carbide at 1200℃ in both air and water-vapor-rich environments[J]. Corrosion Science,2014,88:416-422. doi: 10.1016/j.corsci.2014.07.052 [25] CAPPELEN H, JOHANSEN K H, MOTZFELDT K, et al. Oxidation of silicon carbide in oxygen and in water vapour at 1500℃[J]. Acta Chemica Scandinavica,1981,35(4):247-254. [26] 相宇博. 氮化物结合碳化硅耐火材料在不同气氛中的氧化行为研究[D]. 洛阳: 中钢集团洛阳耐火材料研究院, 2020.XIANG Yubo. Oxidation behavior of nitride-bonded silicon carbide refractories in different atmospheres[D]. Luoyang: Sinosteel Luoyang Refractory Research Institute, 2020(in Chinese). [27] 张梅英. 碳化硅涂层对碳纤维单丝拉伸性能的影响[D]. 兰州: 兰州理工大学, 2017.ZHANG Meiying. Effect of silicon carbide coating on tensile properties of carbon fiber monofilament[D]. Lanzhou: Lanzhou University of Technology, 2017(in Chinese). [28] 万小涵, 张广清, OSTROVSKI O. 碳热还原/氮化合成氮化硅工艺中碳化硅生成的分析[J]. 云南冶金, 2015, 44(3):47-49, 73. doi: 10.3969/j.issn.1006-0308.2015.03.011WAN Xiaohan, ZHANG Guangqing, OSTROVSKI O. Analysis on silicon carbide formation in the process of carbothermal reduction/nitration synthesis of silicon nitride[J]. Yunnan Metallurgy,2015,44(3):47-49, 73(in Chinese). doi: 10.3969/j.issn.1006-0308.2015.03.011 -

下载:

下载: