Low-velocity impact and interlaminar damage mechanism of carbon fiber-metal mesh reinforced composites

-

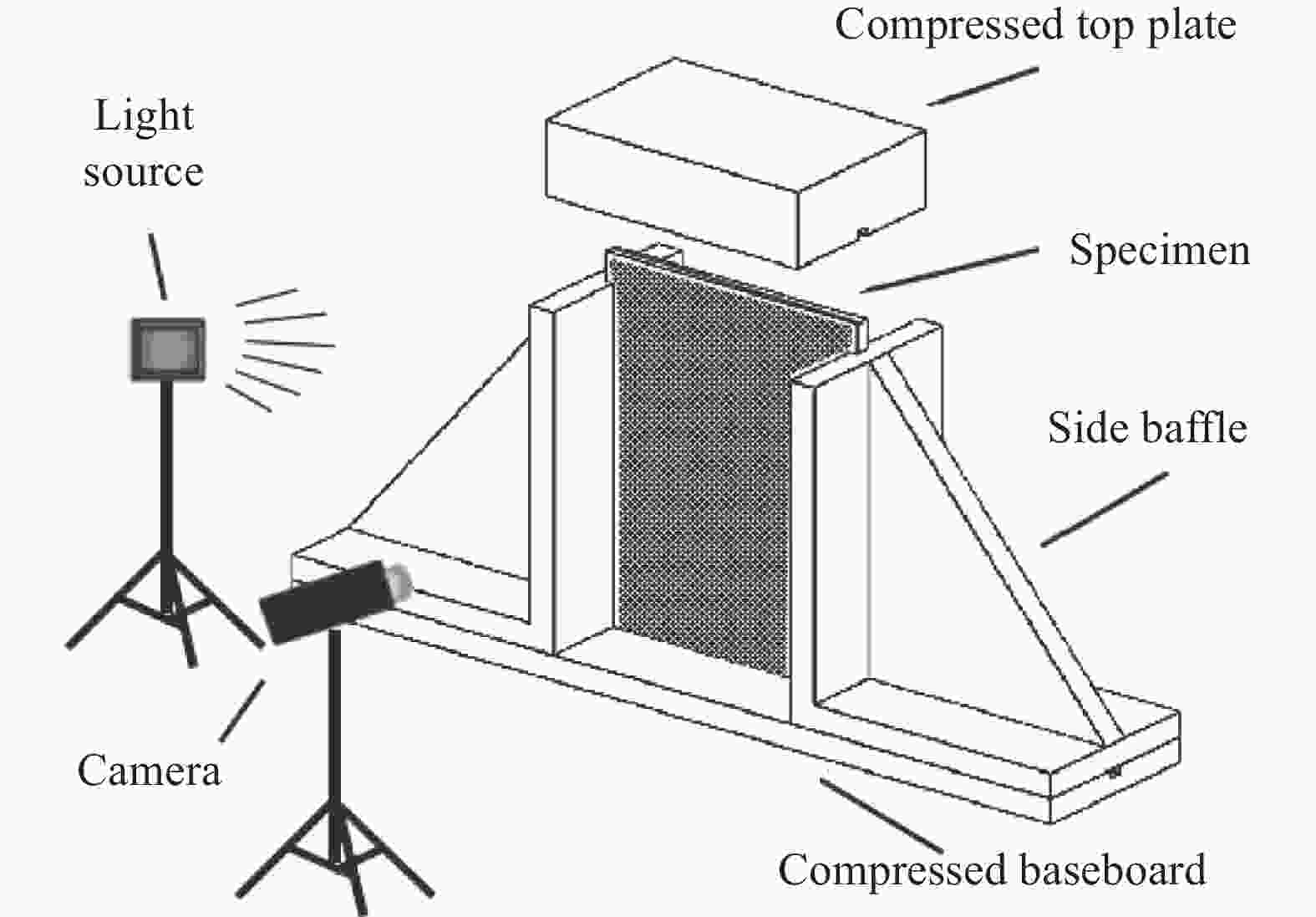

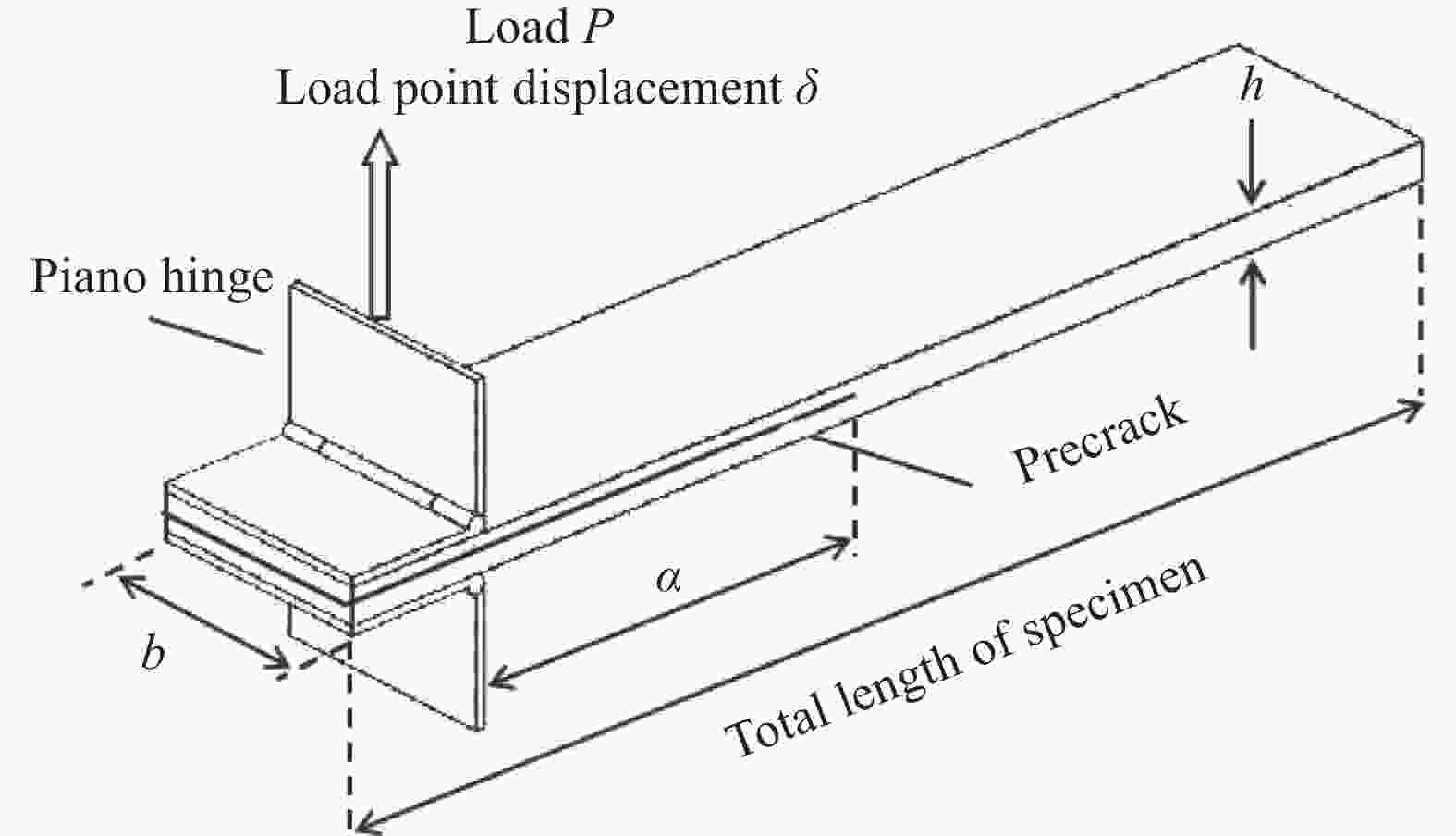

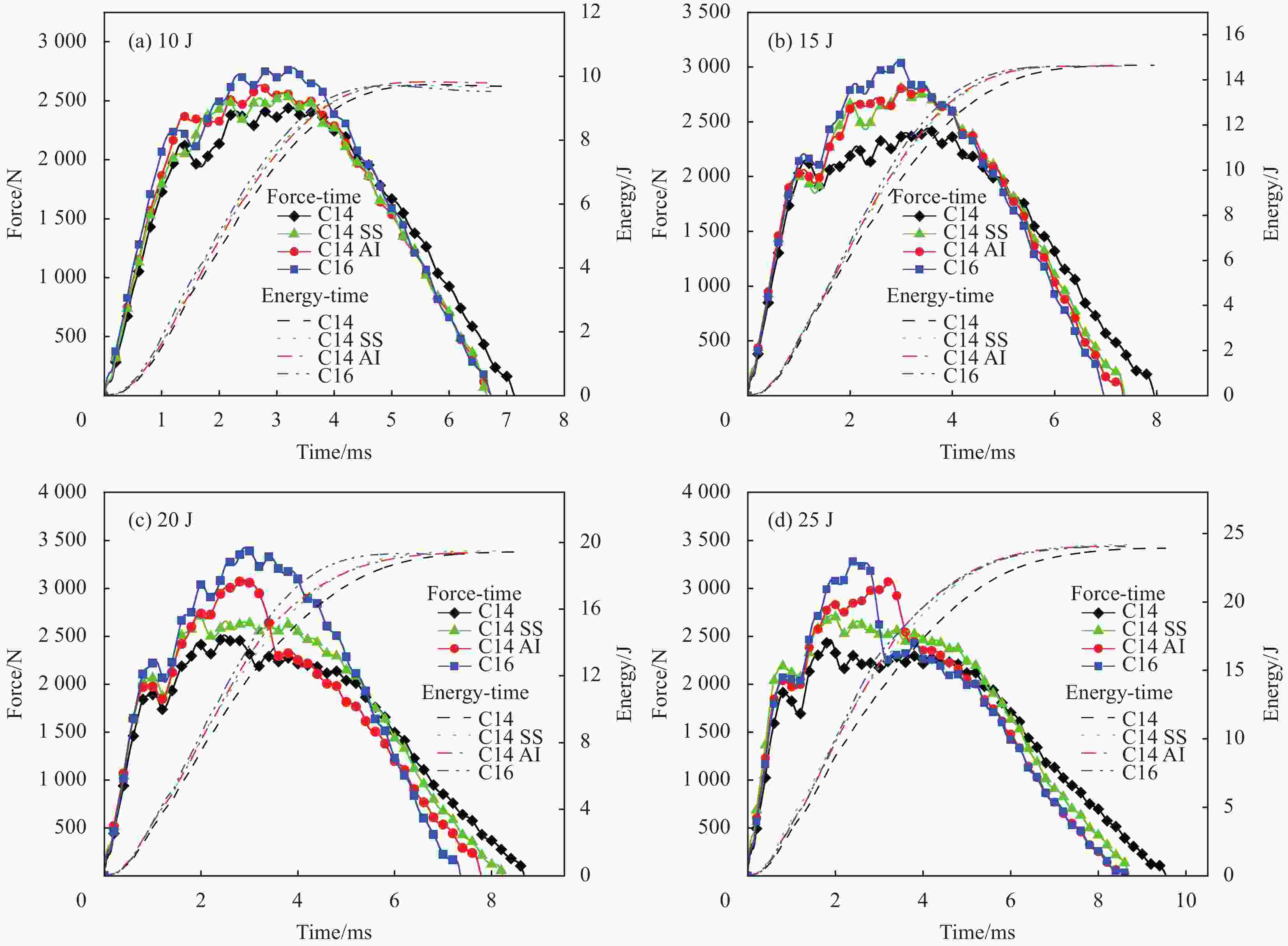

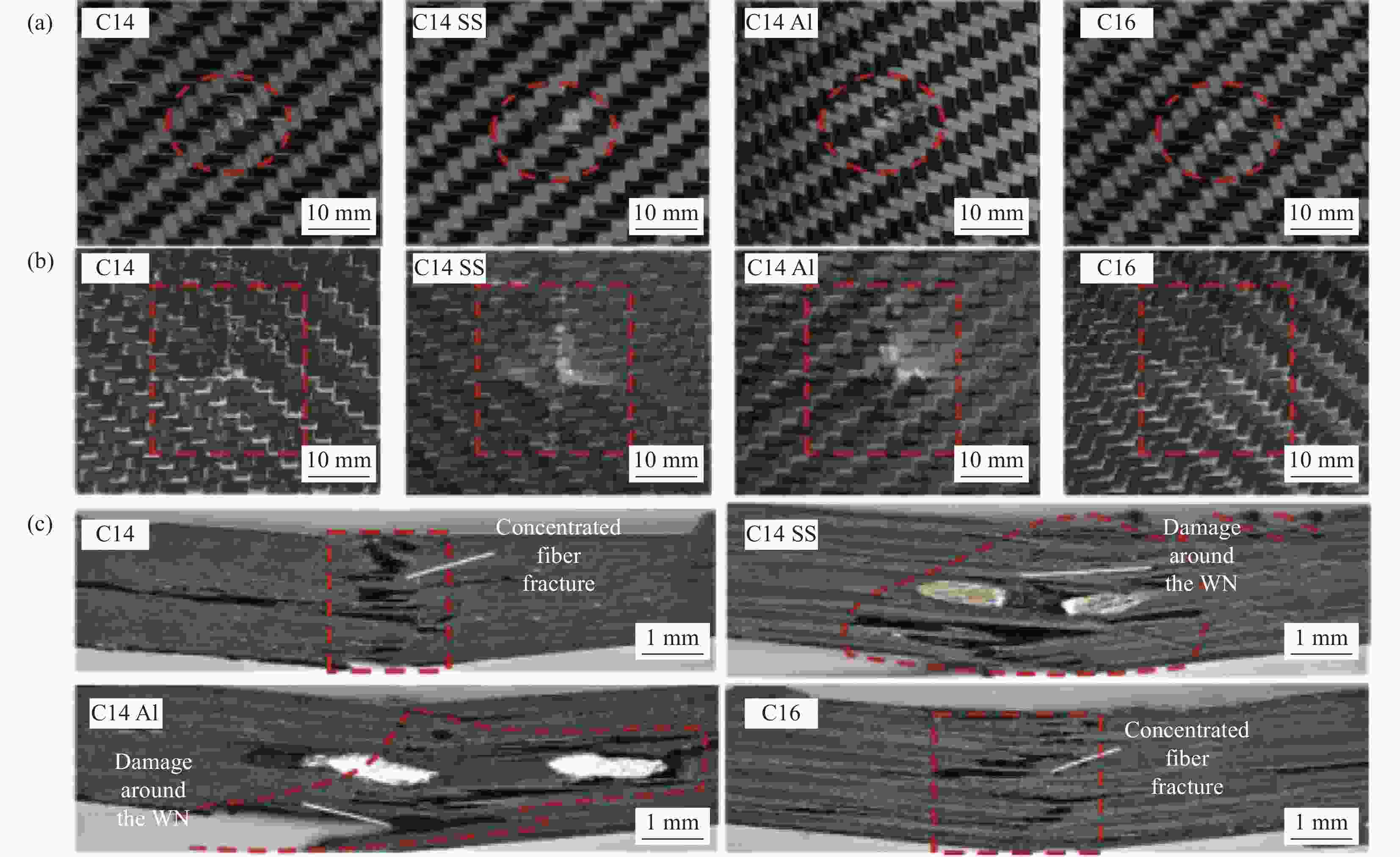

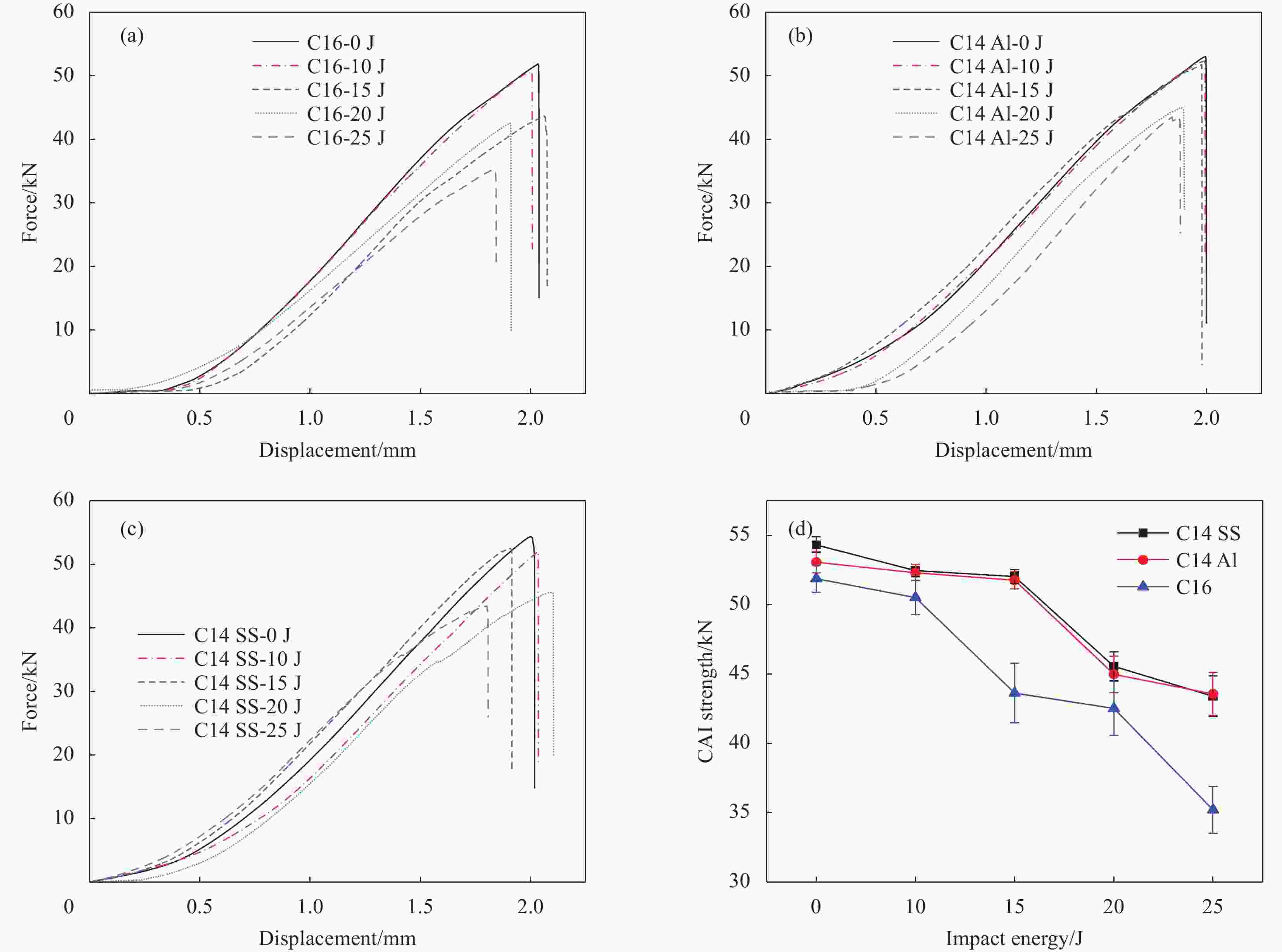

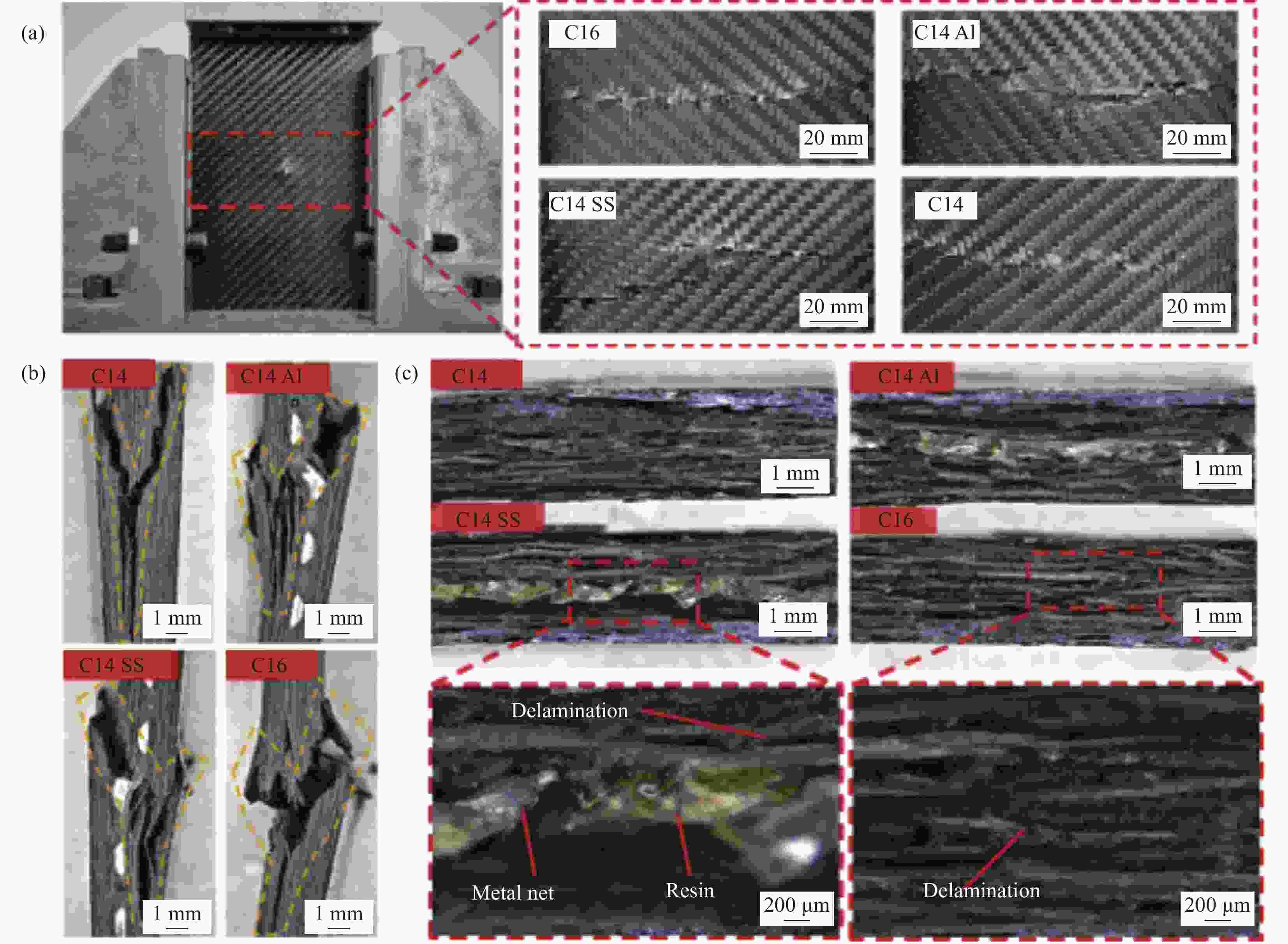

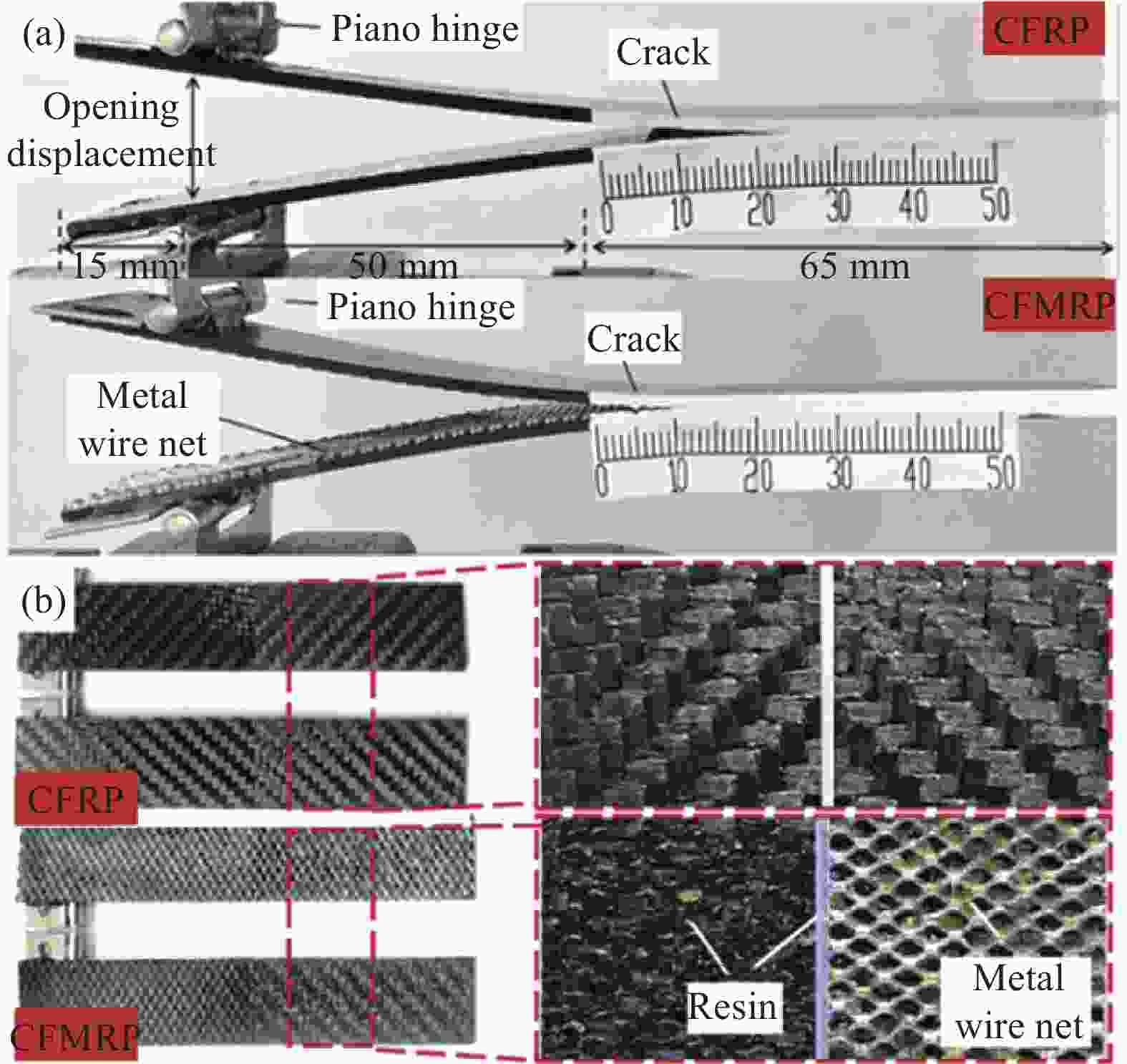

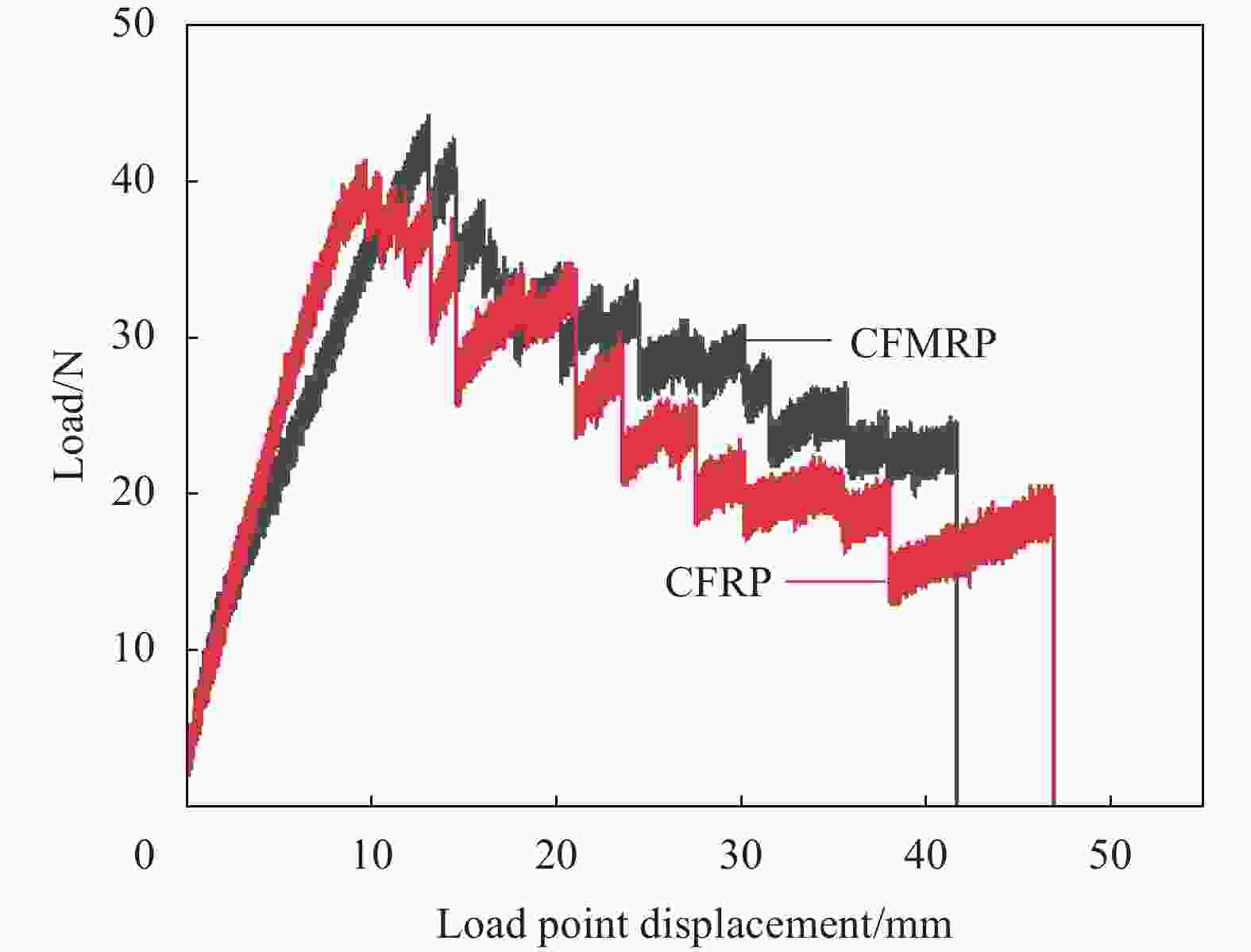

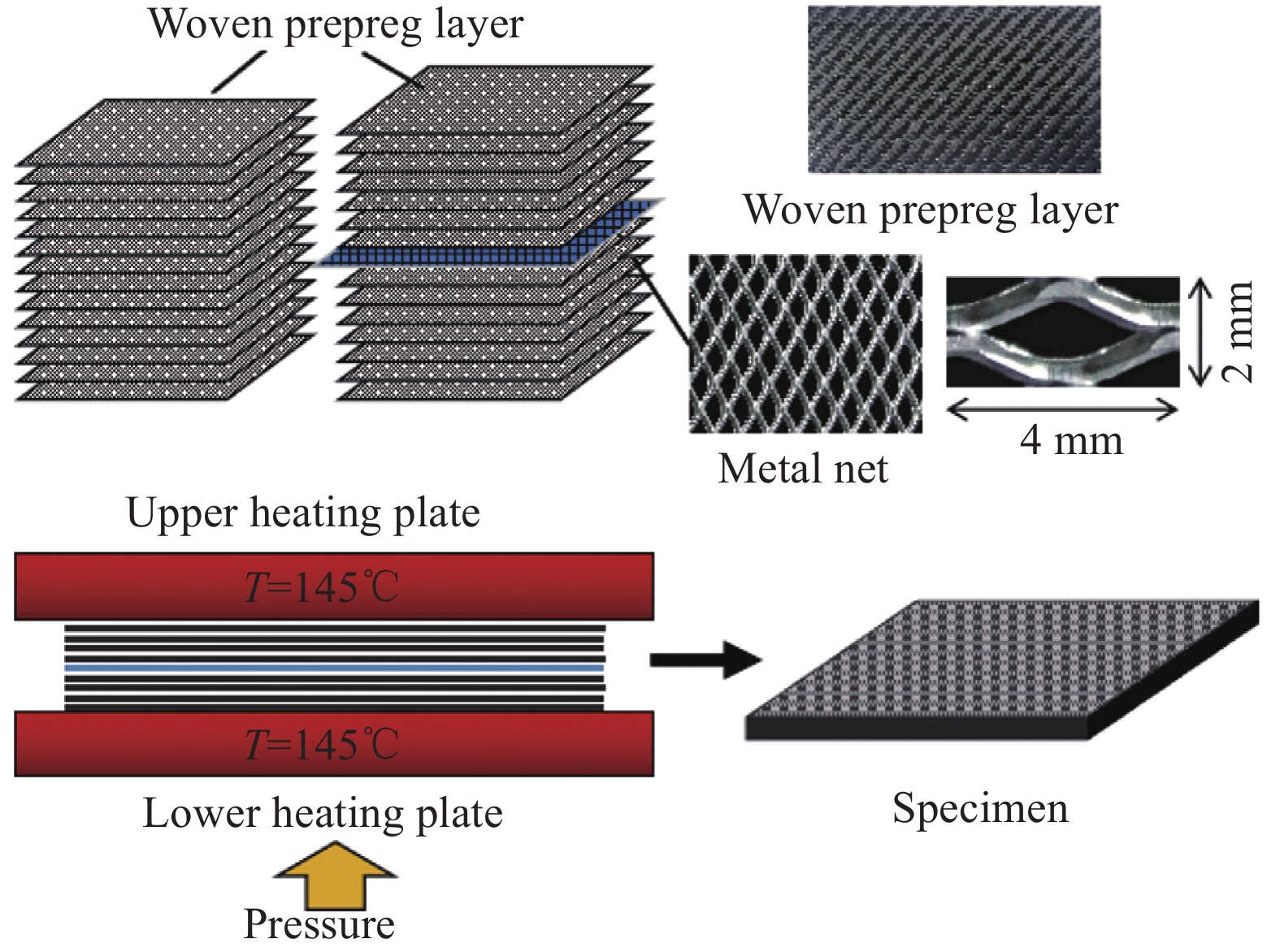

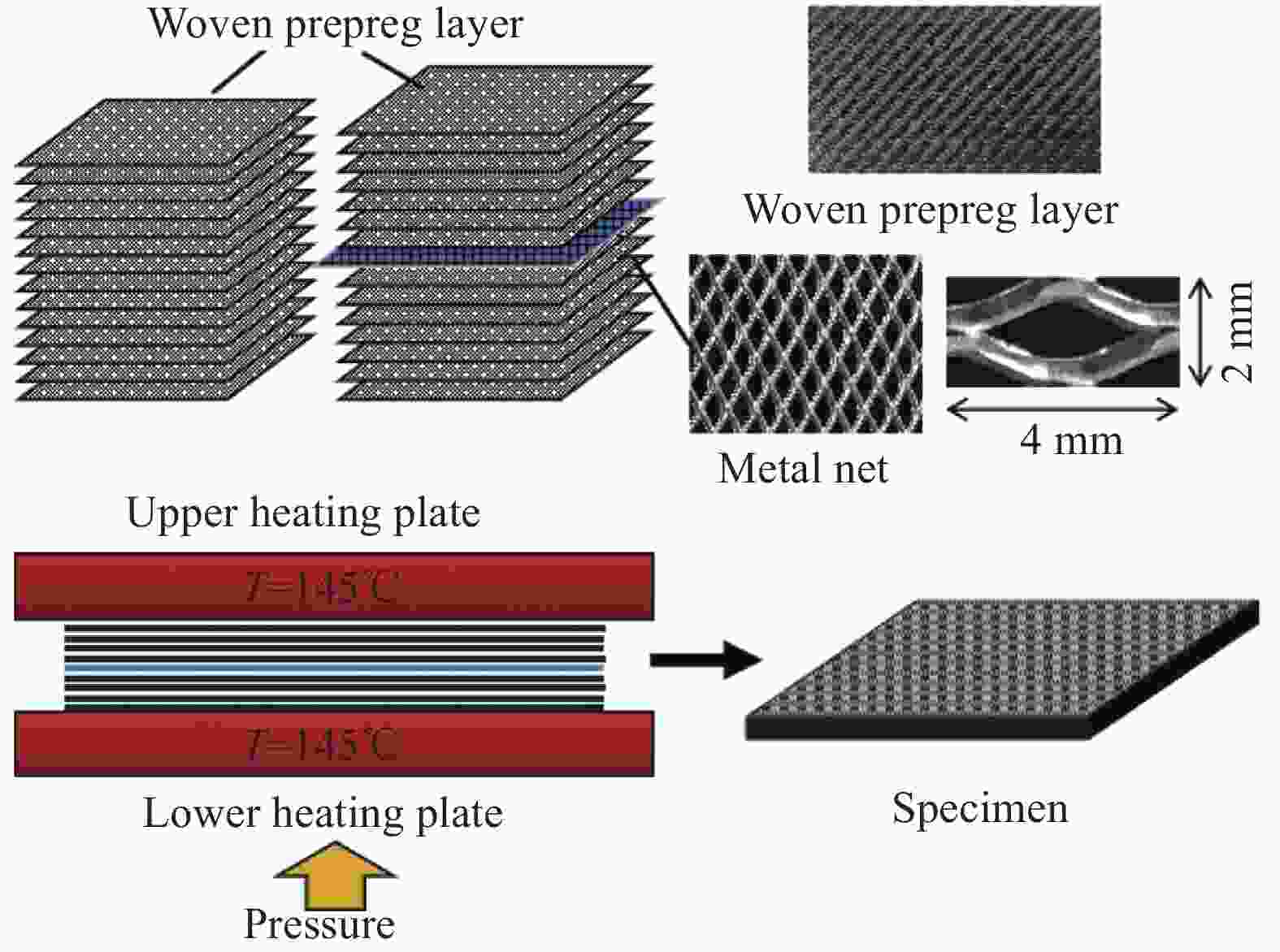

摘要: 采用热固性环氧斜纹编织预浸料、菱形的不锈钢丝网和铝合金丝网,制备了4种不同铺层结构的复合材料板。通过低速冲击和冲击后压缩(CAI)试验,研究混杂金属网结构在不同能级冲击下的损伤行为及冲击后的剩余压缩强度;同时采用双悬臂梁(DCB)拉伸和末端切口弯曲(ENF)试验,进而研究了金属网层对碳纤维复合材料层间断裂性能的影响。通过使用超声波扫描和二维虚拟图像关联(2D-VIC)测试系统对比了冲击后试件内部的损伤程度及冲击后压缩过程中变形云图,以揭示其增强机制。结果表明:金属网结构的引入可以改善面板的塑性和冲击能量影响范围,提高冲击能量吸收能力、CAI强度和层间剪切性能。此外,在混杂结构的ENF测试中,界面的破坏不仅有基体的破坏,还存在纤维的剪切断裂。Abstract: Four kinds of composite plates with different ply structures were fabricated, which are composed of thermosetting epoxy twill woven prepreg, diamond-shaped stainless steel wire mesh and aluminum alloy wire mesh. Further, low-velocity impact and compression after impact (CAI) experiments were conducted to study their damage behavior and post-impact residual compressive strength of the hybrid metal mesh structure under different energy levels. According to the double cantilever beam (DCB) tensile test and the end-notched flexure (ENF) test, the effects of metal mesh layers on the interlaminar fracture performance of carbon fiber composites were investigated. Ultrasonic scanning and two-dimensional virtual image correlation (2D-VIC) test system were employed to examine the damaged degree inside the specimen after impact and the deformation contour of the surface during the CAI test, then the strengthening mechanism were illuminated. The results show that the addition of metal mesh layers can improve the plasticity of the panel and effect area of incident energy, resulting in the improvement of absorbing impact energy, CAI strength and interlaminar shear performance. It is further found that in the ENF test of the hybrid panel, the interface damage includes not only the damage of matrix, but also the shear fracture of fiber.

-

图 11 碳纤维增强聚合物(CFRP)和碳纤维-金属网增强聚合物(CFMRP)的双悬臂梁(DCB)拉伸试验示意图:(a) 拉伸试验过程;(b) 拉伸后形貌

Figure 11. Schematic diagram of double cantilever beam (DCB) tensile test for carbon fiber reinforced polymer (CFRP) and carbon fiber-metal mesh reinforced polymer (CFMRP): (a) Tensile test process; (b) Morphology after tensile

表 1 材料力学性能和物理性能

Table 1. Mechanical and physical property of the raw materials

Specimen Tensile strength

/MPaTensile modulus

/GPaElongation

/%Density

/(g·cm−3)Gram mass

/(g·m−2)Curing temperature

/°CT300 3530 230 1.5 1.76 330.0 130 SSWN 550 208 5.0 7.93 1260.0 – AIWN 100 70 6.0 2.70 430.0 – Notes: T300—The grade of carbon fiber used to prepare the specimen is T300; SSWN—Stainless steel wire mesh; AIWN—Aluminum wire mesh. 表 2 不同试件的组成及尺寸

Table 2. Composition and size of different specimens

Specimen Configuration

of lay-upThickness/mm Areal density

/(g·m−2)C16 WCF16 3.2 4867.3 C14 Al WCF7Al1WCF7 3.2 4934.7 C14 SS WCF7SS1WCF7 3.2 5566.0 C14 WCF14 2.8 4259.3 Notes: WCF16—Specimen is composed of 16 layers of carbon fiber stacked; WCF7Al1WCF7—Specimen is composed of 14 layers of carbon fiber and one layer of aluminum alloy wire net stacked; WCF7SS1WCF7—Specimen is composed of 14 layers of carbon fiber and one layer of stainless steel wire net stacked; WCF14—Specimen is composed of 14 layers of carbon fiber stacked. 表 3 4种试件在不同冲击能量下的峰值力对应的位移及回弹情况

Table 3. Displacement and rebound of peak force corresponding to the four specimens under different impact energies

Impact energy Experimental results C14 C14 SS C14 Al C16 10 J Displacement/mm 3.907 4.695 4.730 3.124 Force-max/kN 2.404 2.509 2.575 2.739 Energy absorption rate/% 96.81 96.48 97.92 95.21 Rebound ○ ○ ○ ○ 15 J Displacement/mm 5.271 5.776 5.755 5.775 Force-max/kN 2.426 2.754 2.783 2.981 Energy absorption rate/% 97.42 97.69 97.43 97.29 Rebound × ○ ○ ○ 20 J Displacement/mm 6.819 6.760 7.202 6.643 Force-max/kN 2.443 2.622 3.042 3.327 Energy absorption rate/% 97.19 97.50 97.22 96.50 Rebound × × × ○ 25 J Displacement/mm 5.211 5.509 8.240 7.244 Force-max/kN 2.337 2.630 3.023 3.223 Energy absorption rate/% 95.72 96.76 96.37 96.20 Rebound × × × × Notes: ○—Specimens have rebound phenomenon during the impact process; ×—Specimens have not rebound phenomenon during the impact process. 表 4 CFRP和CFMRP的DCB试验参数

Table 4. Parameters of CFRP and CFMRP specimens in DCB test

Case Pmax

/Nδ

/mmb

/mma

/mmGI

/(kJ·m−2)CFMRP 42.51±1.05 13.47±0.57 24.05±0.25 4.75±0.23 0.65±0.034 CFRP 42.94±1.45 12.28±0.37 24.45±0.05 4.52±0.24 0.59±

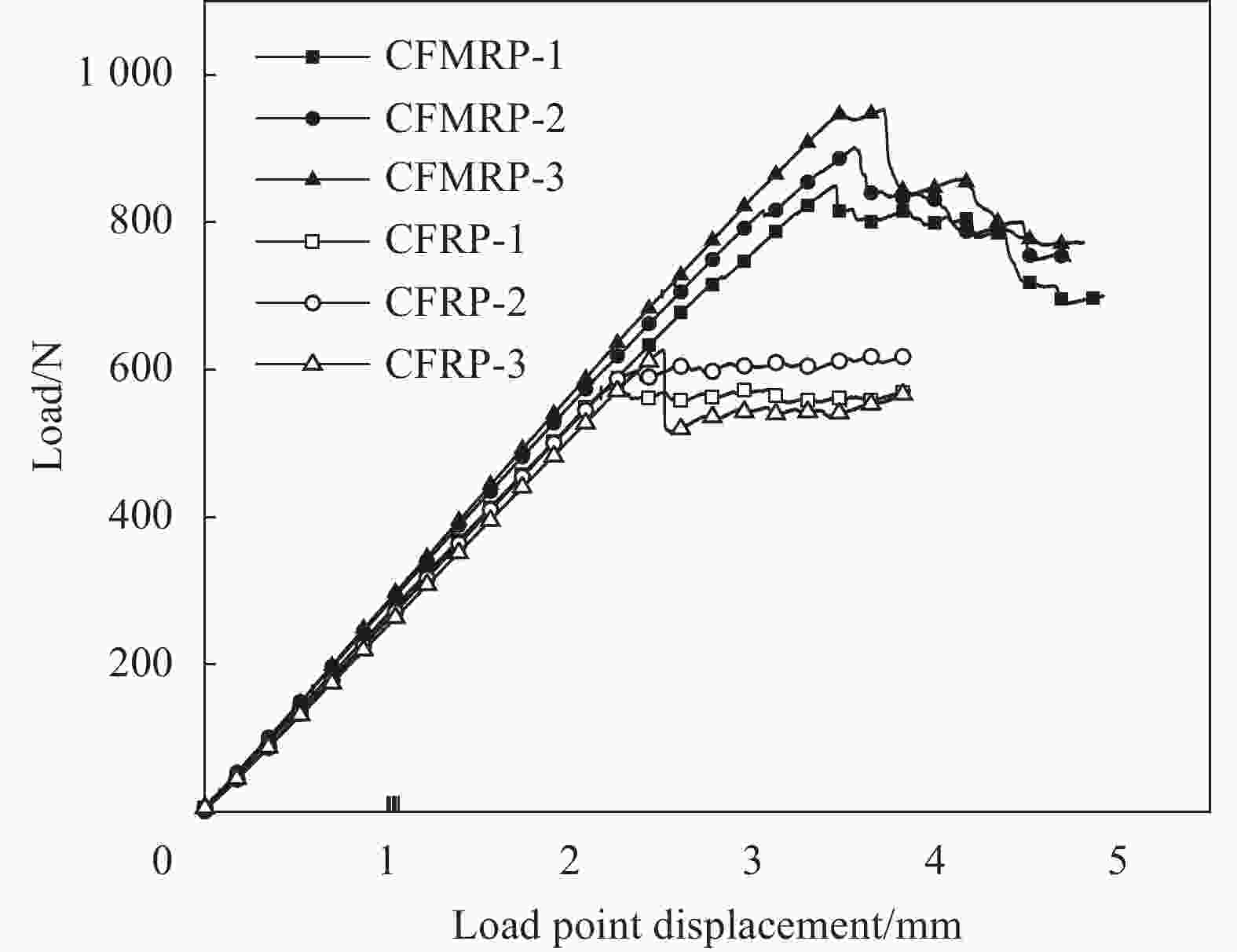

0.035Notes: Pmax—Maximum applied load during DCB test; GI—Mode I interlaminar fracture toughness. 表 5 ENF试验CFRP和CFMRP试件参数

Table 5. Parameters of CFRP and CFMRP specimens in ENF test

Case Pmax/N m h

/mmB

/mmGII

/(kJ·m−2)CFMRP 875.64±25.09 252.98±4.87 3.98±0.08 24.35±0.05 10.75±0.821 CFRP 623.48±4.19 251.15±1.32 3.97±0.03 24.15±0.15 5.46±0.068 Notes: m—Slope obtained by regression analysis; B—Width; GII—Mode II interlaminar fracture toughness. -

[1] XU L Y, LU J R, LI K M, et al. Experimental study of CFRP laser surface modification and bonding characteristics of CFRP/Al6061 heterogeneous joints[J]. Composite Structures,2022,283:115030. doi: 10.1016/j.compstruct.2021.115030 [2] 陈燕, 葛恩德, 傅玉灿, 等. 碳纤维增强树脂基复合材料制孔技术研究现状与展望[J]. 复合材料学报, 2015, 32(2):301-316. doi: 10.13801/j.cnki.fhclxb.20150211.002CHEN Yan, GE Ende, FU Yucan, et al. Review and prospect of drilling technologies for carbon fiber reinforced polymer[J]. Acta Materiae Compositae Sinica,2015,32(2):301-316(in Chinese). doi: 10.13801/j.cnki.fhclxb.20150211.002 [3] SUN G Y, YU H, WANG Z, et al. Energy absorption mechanics and design optimization of CFRP/aluminum hybrid structures for transverse loading[J]. International Journal of Mechanical Sciences,2019,150:767-783. doi: 10.1016/j.ijmecsci.2018.10.043 [4] DING Z, WEEGER O, QI H J, et al. 4D rods: 3D structures via programmable 1D composite rods[J]. Materials & Design,2018,137:256-265. [5] LIU G, XIONG Y, ZHOU L. Additive manufacturing of continuous fiber reinforced polymer composites: Design opportunities and novel applications[J]. Composites Communications,2021,27:100907. doi: 10.1016/j.coco.2021.100907 [6] 徐坚, 王亚会, 李林洁, 等. 2019 年先进纤维复合材料研发热点回眸[J]. 科技导报, 2020, 38(1):82-92.XU Jian, WANG Yahui, LI Linjie, et al. Hot topics of advanced fiber reinforced composites in 2019[J]. Science and Technology Review,2020,38(1):82-92(in Chinese). [7] 王士杰, 孙泽玉, 陶雷, 等. PMI泡沫对碳纤维复合材料抗低速 冲击性能的影响[J]. 玻璃钢/复合材料, 2019(8):53-58. doi: 10.3969/j.issn.1003-0999.2019.08.009WANG Shijie, SUN Zeyu, TAO Lei, et al. Effect of PMI foam on low-velocity impact resistance of carbon fiber compo-sites[J]. Fiber Reinforced Plastics/Composites,2019(8):53-58(in Chinese). doi: 10.3969/j.issn.1003-0999.2019.08.009 [8] 肖先林, 王长金, 赵桂平. 碳纤维复合材料-泡沫铝夹芯板的冲击响应[J]. 振动与冲击, 2018(15):110-117.XIAO Xianlin, WANG Changjin, ZHAO Guiping. Dynamic responses of carbon fiber composite sandwich panels with aluminum foam core subjected to impact loading[J]. Journal of Vibration and Shock,2018(15):110-117(in Chinese). [9] 李春晓. 碳纤维及其复合材料在汽车领域的应用[J]. 新材料产业, 2019, 302(1):5-7.LI Chunxiao. Application of carbon fiber and composite materials in automotive industry[J]. New Materials Industry,2019,302(1):5-7(in Chinese). [10] 杨斌, 章继峰, 周利民. 玻璃纤维-碳纤维混杂增强PCBT复合材料层压板的制备及低速冲击性能[J]. 复合材料学报, 2015, 32(2):435-443.YANG Bin, ZHANG Jifeng, ZHOU Limin. Preparation and low-velocity impact properties of glass fibercarbon fiber hybrid reinforced PCBT composite laminate[J]. Acta Materiae Compositae Sinica,2015,32(2):435-443(in Chinese). [11] SONG Z G, ZHANG L W, LIEW K M. Dynamic responses of CNT reinforced composite plates subjected to impact loading[J]. Composites Part B: Engineering,2016,99:154-161. doi: 10.1016/j.compositesb.2016.06.034 [12] GU G X, TAKAFFOLI M, HSIEH A J, et al. Biomimetic additive manufactured polymer composites for improved impact resistance[J]. Extreme Mechanics Letters,2016,9:317-323. doi: 10.1016/j.eml.2016.09.006 [13] 孙子恒, 王继辉, 倪爱清, 等. 不同铺层复合材料夹芯结构低速冲击与冲击后剩余强度研究[J]. 复合材料科学与工程, 2020, 322(11):102-110.SUN Ziheng, WANG Jihui, NI Aiqing, et al. Study on the low-speed impact performance and residual strength after impact of composite sandwich structure with different layup[J]. Composites Science and Engineering,2020,322(11):102-110(in Chinese). [14] REIS P N B, NETO M A, AMARO A M. Multi-impact behaviour of composite laminates under constant and different energy levels[J]. Composite Structures,2022,294:115788. doi: 10.1016/j.compstruct.2022.115788 [15] LIAO B, WANG P, ZHENG J, et al. Effect of double impact positions on the low velocity impact behaviors and damage interference mechanism for composite laminates[J]. Composites Part A: Applied Science and Manufacturing,2020,136:105964. doi: 10.1016/j.compositesa.2020.105964 [16] YAO L, SUN G, HE W, et al. Investigation on impact behavior of FMLs under multiple impacts with the same total energy: Experimental characterization and numerical simulation[J]. Composite Structures,2019,226:111218. doi: 10.1016/j.compstruct.2019.111218 [17] ZHU Q, ZHANG C, CURIEL-SOSA J L, et al. Finite element simulation of damage in fiber metal laminates under high velocity impact by projectiles with different shapes[J]. Composite Structures,2019,214:73-82. doi: 10.1016/j.compstruct.2019.02.009 [18] MISHRA P K, PRADHAN A K, PANDIT M K. Inter-laminar delamination analyses of spar wingskin joints made with flat FRP composite laminates[J]. International Journal of Adhesion and Adhesives,2016,68:19-29. doi: 10.1016/j.ijadhadh.2016.02.001 [19] BLALA H, LANG L, LI L, et al. Deep drawing of fiber metal laminates using an innovative material design and manufacturing process[J]. Composites Communications,2021,23:100590. doi: 10.1016/j.coco.2020.100590 [20] DANESHJOO Z, SHOKRIEH M M, FAKOOR M, et al. Physics of delamination onset in unidirectional composite laminates under mixed-mode I/II loading[J]. Engineering Fracture Mechanics,2019,211:82-98. doi: 10.1016/j.engfracmech.2019.02.013 [21] 王海雷, 段跃新, 王维维, 等. 玻璃纤维与碳纤维混杂复合材料的拉伸及低速冲击性能研究[J]. 复合材料科学与工程, 2021, 325(2):102-109.WANG Hailei, DUAN Yuexin, WANG Weiwei, et al. Study on tensile and low velocity impact performance of glass and carbon fibers hybrid composites[J]. Composites Science and Engineering,2021,325(2):102-109(in Chinese). [22] 张辰, 饶云飞, 李倩倩, 等. 碳纤维-玻璃纤维混杂增强环氧树脂复合材料低速冲击性能及其模拟[J]. 复合材料学报, 2021, 38(1):165-176.ZHANG Chen, RAO Yunfei, LI Qianqian, et al. Low-velocity impact behavior and numerical simulation of carbon fiber-glass fiber hybrid reinforced epoxy composites[J]. Acta Materiae Compositae Sinica,2021,38(1):165-176(in Chinese). [23] MOSTOFINEJAD D, HOSSEINI S A, RAZAVI S B. Influence of different bonding and wrapping techniques on performance of beams strengthened in shear using CFRP reinforcement[J]. Construction and Building Materials,2016,116:310-320. doi: 10.1016/j.conbuildmat.2016.04.113 [24] MACIEL M F, YUTAKA S M, JACOBUS C V H, et al. The synergy effect of carbon/glass/epoxy hybrid laminate in mode I delamination: A physical microfracture analysis[J]. Engineering Fracture Mechanics,2020,239:107295. doi: 10.1016/j.engfracmech.2020.107295 [25] MIKHALCHAN A, RIDHA M, TAY T E. Carbon nanotube fibres for CFRP-hybrids with enhanced in-plane fracture behaviour[J]. Materials & Design,2018,143:112-119. [26] BASCOM W D, BITNER J L, MOULTON R J, et al. The interlaminar fracture of organic-matrix, woven reinforcement composites[J]. Composites,1980,11(1):9-18. doi: 10.1016/0010-4361(80)90016-6 [27] WOOD M D K. A new ENF test specimen for the mode II delamination toughness testing of stitched woven CFRP laminates[J]. Journal of Composite Materials,2007,41(14):1743. doi: 10.1177/0021998306069890 [28] TRAUTH A, LOHR C, LALLINGER B, et al. Interface characterization of hybrid biocompatible fiber-metal laminates after laser-based surface treatment[J]. Composite Structures,2022,281:115054. doi: 10.1016/j.compstruct.2021.115054 [29] ZHANG Y, LIU X, JI F, et al. Effect of chemically grafted CNTs onto carbon fiber on the mechanical properties of fiber metal laminates[J]. Composites Communications,2022,29:101005. doi: 10.1016/j.coco.2021.101005 [30] ASTM. Standard test method for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event: ASTM D7136/D7136 M-15[S]. West Conshohocken: ASTM International, 2015. [31] ASTM. Standard test method for compressive residual strength properties of damaged polymer matrix composite plates: ASTM D7137/D7137 M-17[S]. West Conshohocken: ASTM International, 2017. [32] ASTM. Standard test method for mode I interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: D5528-13[S]. West Conshohocken: ASTM International, 2014. [33] ASTM. Standard test method for determination of the mode II interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: D7905/D7905 M-14[S]. West Conshohocken: ASTM International, 2014. [34] WAN Y, YAO J, LI H, et al. Experimental studies of low-velocity impact behavior on hybrid metal wire net/woven carbon-fiber reinforced composite laminates[J]. Compo-sites Communications,2022,32:101185. doi: 10.1016/j.coco.2022.101185 -

下载:

下载: