Fabrication and application of mesh flexible strain sensor

-

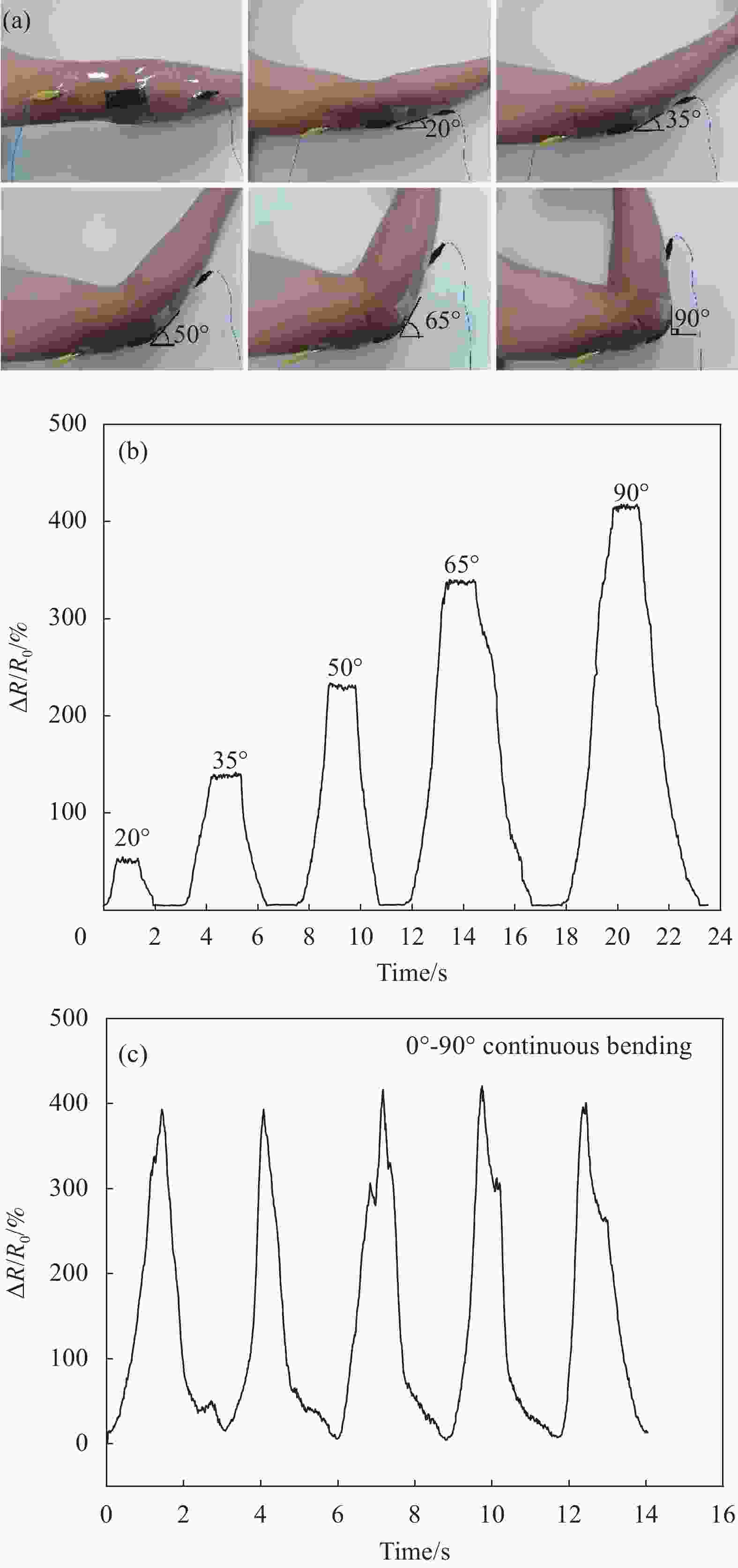

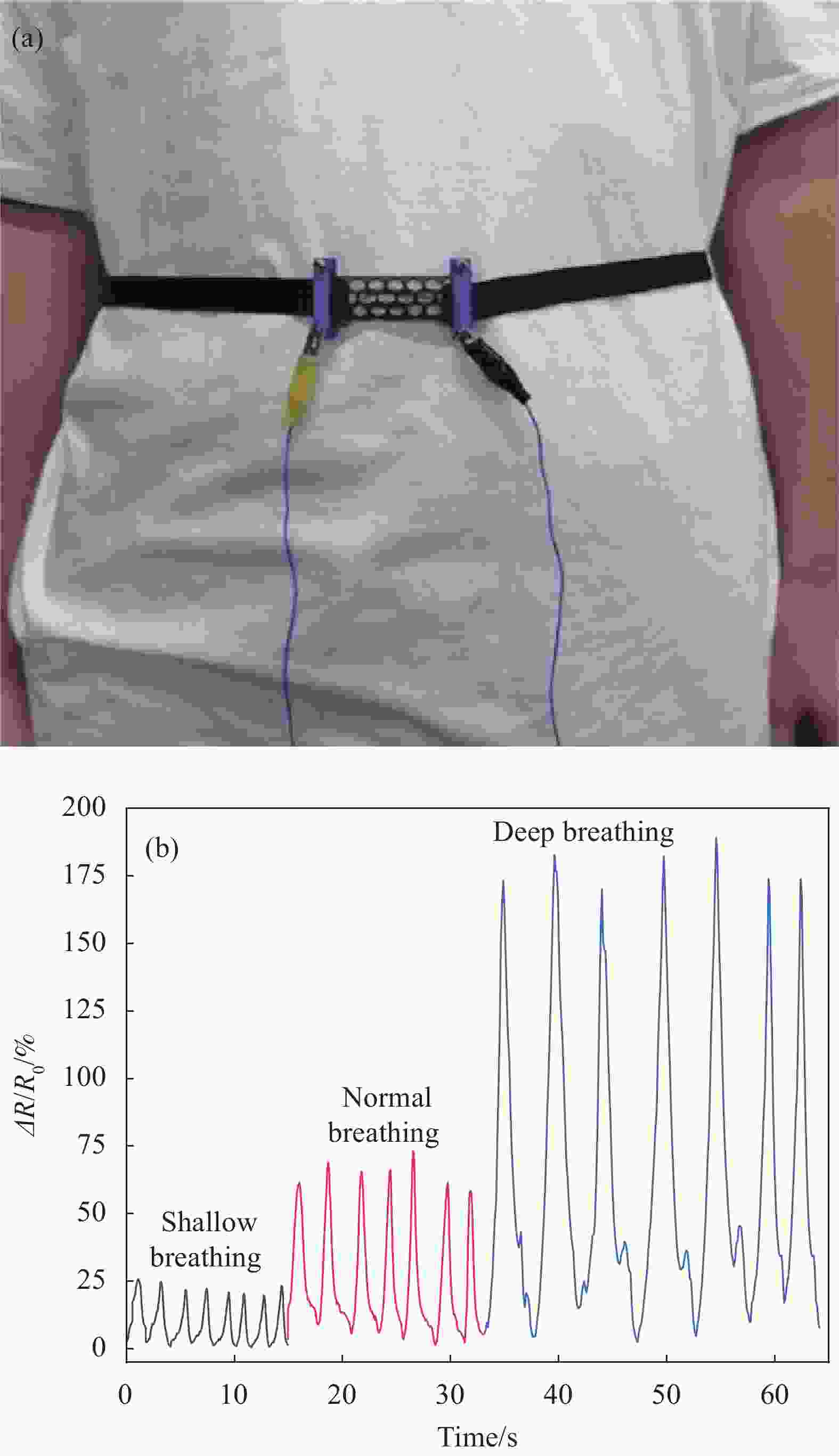

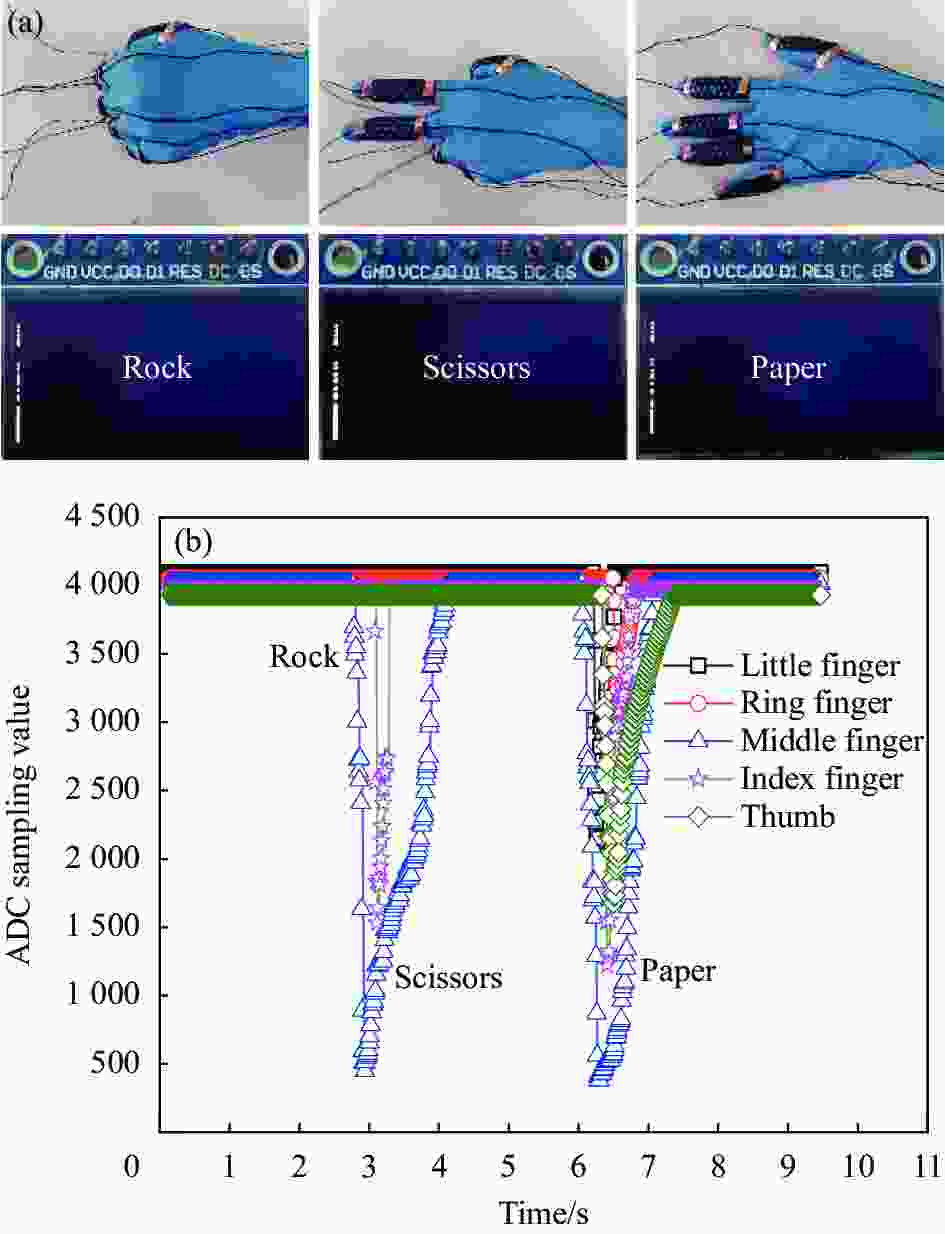

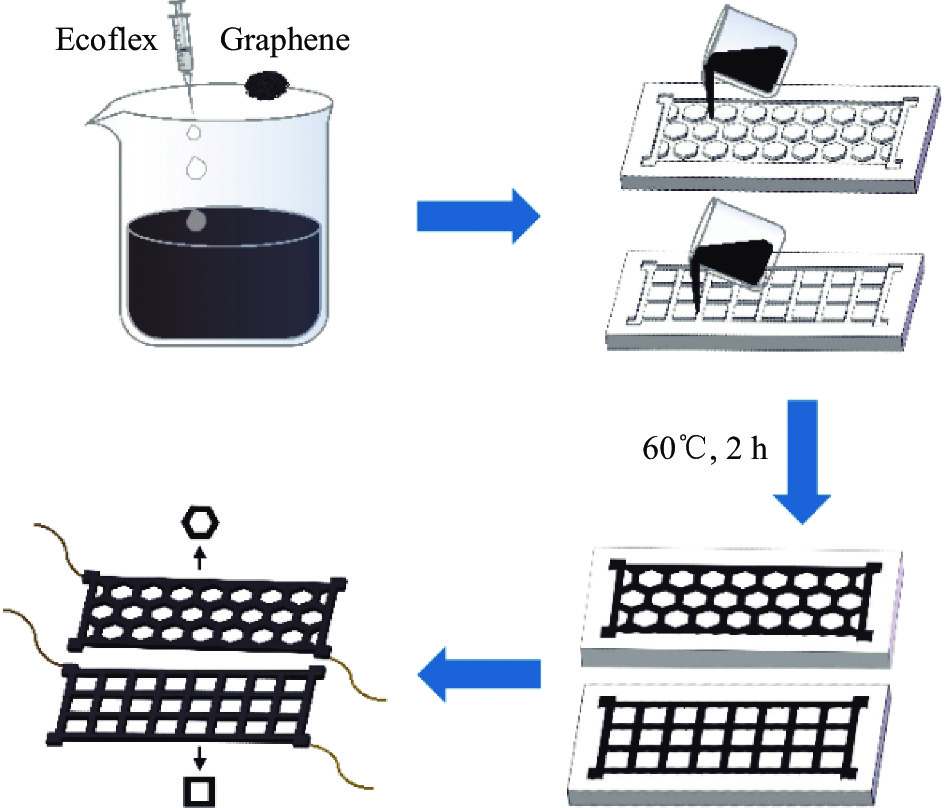

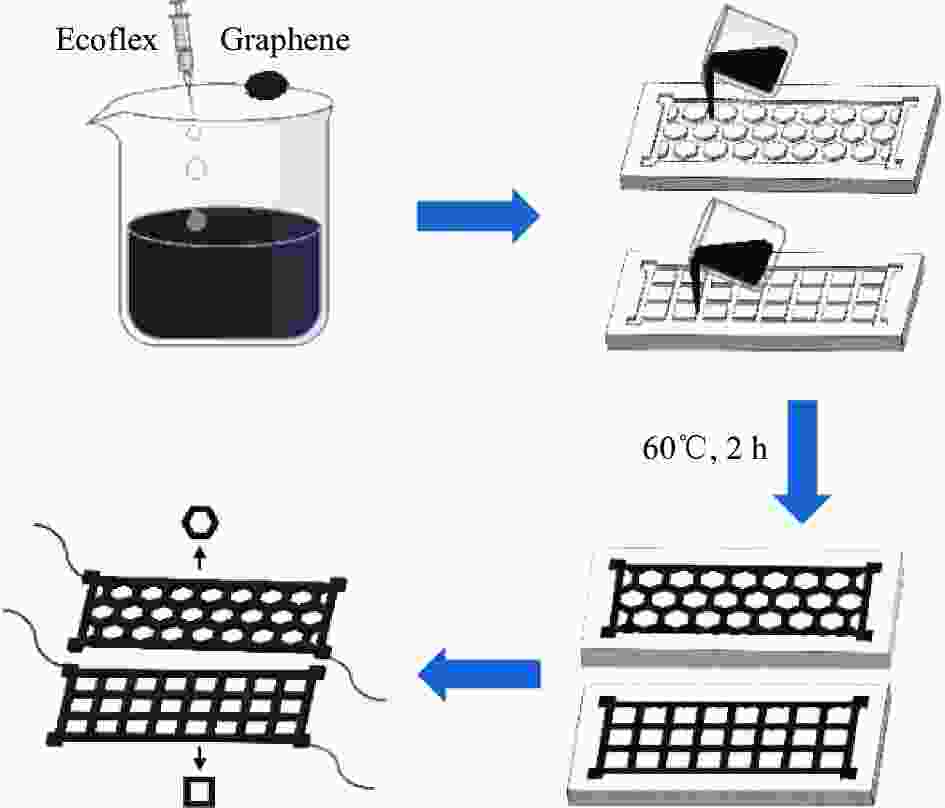

摘要: 鉴于柔性应变传感器在人体运动监测、健康监测等领域的广泛应用,设计出兼具高灵敏度和大应变范围的柔性应变传感器具有重要的意义。本文基于Ecoflex-石墨烯复合材料,通过模板法制备了四边形和六边形网格式柔性应变传感器。通过对比两种不同网格结构传感器的应变范围与拉伸断裂极限,发现六边形网格柔性应变传感器的综合性能更优异,并在80%应变条件下进行拉伸/释放疲劳寿命检测,此传感器表现出良好的可靠性,同时该传感器在手肘关节运动和人体不同呼吸状况监测方面表现良好。将六边形网格柔性应变传感器组合构建多通道检测系统,实现了多种手势识别,这在人工智能和运动识别领域具有广阔的市场应用前景。Abstract: In view of the wide application of strain sensors in human motion monitoring, health monitoring and other fields, it is important to design flexible strain sensors with high sensitivity and large strain range. In this paper, the quadrilateral and hexagonal mesh flexible strain sensors were prepared by template method based on Ecoflex-graphene composites. By comparing the strain range and tensile breaking limit of two different mesh sensors, it is found that the comprehensive performance of hexagonal mesh flexible strain sensor is more excellent, and under the condition of 80% strain, the tensile/releasing fatigue life detection is carried out. The sensor shows good reliability, and the sensor performs well in monitoring the elbow joint movement and different breathing conditions of the human body. A multi-channel detection system was constructed by combining hexagonal mesh flexible strain sensors to realize multiple gesture recognition, which has a broad market application prospect in the field of artificial intelligence and motion recognition.

-

Key words:

- flexible strain sensors /

- graphene /

- mesh structure /

- health monitoring /

- gesture recognition

-

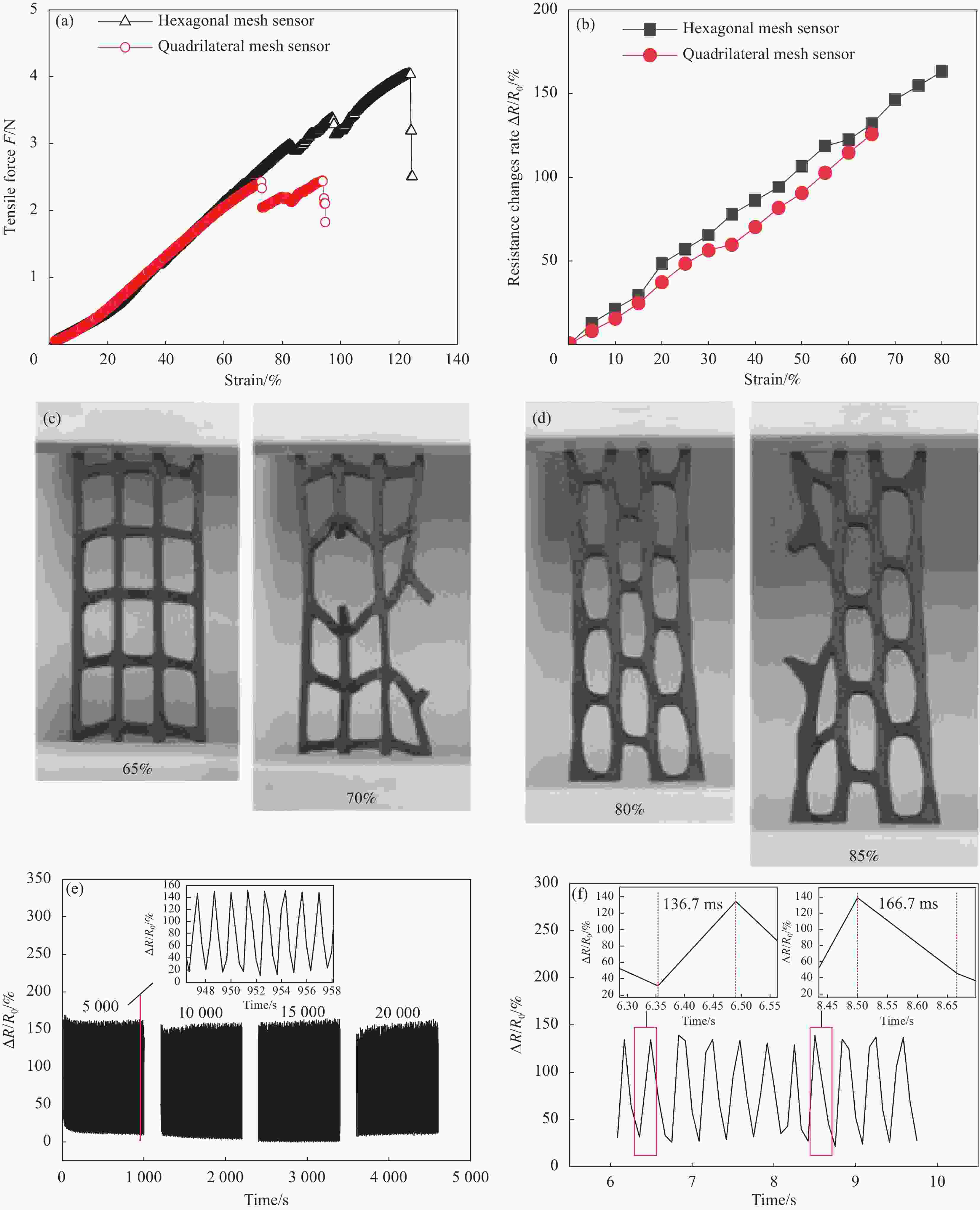

图 4 (a) 传感器断裂极限载荷与拉伸应变关系曲线;(b) 传感器电阻变化率与拉伸应变关系曲线;((c), (d)) 传感器断裂实物图;(e) 六边形网格柔性应变传感器20000次拉伸/释放曲线;(f) 六边形网格柔性应变传感器在80%应变下响应与恢复时间

Figure 4. (a) Relationship curve between the ultimate breaking load and the tensile strain of the sensor; (b) Relationship curve between sensor resistance changes rate and tensile strain; ((c), (d)) Sensor fracture diagram; (e) Hexagonal mesh flexible strain sensor 20000 stretch/release curve; (f) Response and recovery time of hexagonal mesh flexible strain sensor under 80% strain

表 1 Ecoflex-石墨烯不同含量电阻率与拉伸应变参数对比

Table 1. Comparison of resistivity and tensile strain parameters of different Ecoflex-graphene contents

Sample Mass ratio of

Ecoflex : grapheneElectrical resistivity/(Ω·m) Strain/% a 1∶0.10 10350.00 460 b 1∶0.11 2420.00 320 c 1∶0.12 58.91 245 d 1∶0.13 1.94 160 e 1∶0.14 1.05 114 f 1∶0.15 0.68 95 -

[1] ZHAO S, LI J, CAO D, et al. Recent advancements in flexible and stretchable electrodes for electromechanical sensors: Strategies, materials, and features[J]. ACS Applied Materials & Interfaces,2017,9(14):12147-12164. [2] WANG X, LIU Z, ZHANG T. Flexible sensing electronics for wearable/attachable health monitoring[J]. Small,2017,13(25):1602790. doi: 10.1002/smll.201602790 [3] TRICOLI A, NASIRI N, DE S. Wearable and miniaturized sensor technologies for personalized and preventive medicine[J]. Advanced Functional Materials,2017,27(15):1605271. doi: 10.1002/adfm.201605271 [4] JASON N N, HO M D, CHENG W. Resistive electronic skin[J]. Journal of Materials Chemistry C,2017,5(24):5845-5866. doi: 10.1039/C7TC01169E [5] TRUNG T Q, LEE N E. Flexible and stretchable physical sensor integrated platforms for wearable human-activity monitoringand personal healthcare[J]. Advanced Materials,2016,28(22):4338-4372. doi: 10.1002/adma.201504244 [6] AMJADI M, KYUNG K U, PARK I, et al. Stretchable, skin-mountable, and wearable strain sensors and their potential applications: A review[J]. Advanced Functional Materials,2016,26(11):1678-1698. doi: 10.1002/adfm.201504755 [7] XU F, LI X, SHI Y, et al. Recent developments for flexible pressure sensors: A review[J]. Micromachines,2018,9(11):1-17. [8] KHAN S, ALI S, BERMAK A. Recent developments in printing flexible and wearable sensing electronics for healthcare applications[J]. Sensors,2019,19(5):1-34. doi: 10.1109/JSEN.2018.2885905 [9] HEO J S, HOSSAIN M F, KIM I. Challenges in design and fabrication of flexible/stretchable carbon- and textile-based wearable sensors for health monitoring: A critical review[J]. Sensors,2020,20(14):1-29. doi: 10.1109/JSEN.2020.2999769 [10] XU H, ZHANG M K, LU Y F, et al. Dual-mode wearable strain sensor based on graphene/colloidal crystal films for simultaneously detection of subtle and large human motions[J]. Advanced Materials Technologies,2020,5(2):1901056. doi: 10.1002/admt.201901056 [11] YIN B, WEN Y, HONG T, et al. Highly stretchable, ultrasensitive, and wearable strain sensors based on facilely prepared reduced graphene oxide woven fabrics in an ethanol flame[J]. ACS Applied Materials & Interfaces,2017,9(37):32054-32064. [12] AN B, MA Y, LI W, et al. Three-dimensional multi-recognition flexible wearable sensor via graphene aerogel printing[J]. Chemical Communications,2016,52(73):10948-10951. doi: 10.1039/C6CC05910D [13] ZHOU K, ZHANG C, XIONG Z, et al. Template-directed growth of hierarchical MOF hybrid arrays for tactile sensor[J]. Advanced Functional Materials,2020,30(38):2070257. doi: 10.1002/adfm.202070257 [14] YANG T, WANG W, HUANG Y, et al. Accurate monitoring of small strain for timbre recognition via ductile fragmentation of functionalized graphene multilayers[J]. ACS Applied Materials & Interfaces,2020,12(51):57352-57361. [15] SUN X, SUN J, LI T, et al. Flexible tactile electronic skin sensor with 3D force detection based on porous CNTs/PDMS nanocomposites[J]. Nano-Micro Letters,2019,11(1):57. doi: 10.1007/s40820-019-0288-7 [16] LEE H, KIM M J, KIM J H, et al. Highly flexible graphene nanoplatelet-polydimethylsiloxane strain sensors with proximity-sensing capability[J]. Materials Research Express,2020,7(4):054603. [17] POPOV V I, KOTIN I A, NEBOGATIKOVA N A, et al. Graphene-PEDOT : PSS humidity sensors for high sensitive, low-cost, highly-reliable, flexible, and printed electronics[J]. Materials,2019,12(21):1-9. [18] JEONG S, HEO S, KIM H J. Mechanical property variation of AgNW/PDMS nanocomposites for fully elastomeric electrodes[J]. Journal of Materials Science: Materials in Electronics,2021,32(4):4727-4736. doi: 10.1007/s10854-020-05210-9 [19] ALI S, MADDIPATLA D, NARAKATHU B B, et al. Flexible capacitive pressure sensor based on PDMS substrate and Ga-In liquid metal[J]. IEEE Sensors Journal,2019,19(1):97-104. doi: 10.1109/JSEN.2018.2877929 [20] ZHANG Y, REN E, TANG H, et al. Carbon nanotubes/acetylene black/Ecoflex with corrugated microcracks for enhanced sensitivity for stretchable strain sensors[J]. Journal of Materials Science: Materials in Electronics,2020,31(17):14145-14156. doi: 10.1007/s10854-020-03969-5 [21] SLOBODIAN P, DANOVA R, OLEJNIK R, et al. Multifunctional flexible and stretchable polyurethane/carbon nanotube strain sensor for human breath monitoring[J]. Polymers for Advanced Technologies,2019,30(7):1891-1898. doi: 10.1002/pat.4621 [22] 金凡, 吕大伍, 张天成, 等. 基于微结构的柔性压力传感器设计、制备及性能[J]. 复合材料学报, 2021, 38(10):3133-3150. doi: 10.13801/j.cnki.fhclxb.20210520.004JIN Fan, LV Dawu, ZHANG Tiancheng, et al. Design, fabrication and performance of flexible pressure sensors based on microstructures[J]. Acta Materiae Compositae Sinica,2021,38(10):3133-3150(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210520.004 [23] ZHANG S, WEN L, WANG H, et al. Vertical CNT-Ecoflex nanofins for highly linear broad-range-detection wearable strain sensors[J]. Journal of Materials Chemistry C,2018,6(19):5132-5139. doi: 10.1039/C7TC05571D [24] ZHOU W, LI Y, LI P, et al. Metal mesh as a transparent omnidirectional strain sensor[J]. Advanced Materials Technologies,2019,4(4):1800698. doi: 10.1002/admt.201800698 [25] XU A, WANG Y, GAO J, et al. Facile fabrication of a homogeneous cellulose/polylactic acid composite film with improved biocompatibility, biodegradability and mechanical properties[J]. Green Chemistry,2019,21(16):4449-4456. doi: 10.1039/C9GC01918A [26] JIBRIL L, RAMIREZ J, ZARETSKI A V, et al. Single-nanowire strain sensors fabricated by nanoskiving[J]. Sensors and Actuators A: Physical,2017,263:702-706. doi: 10.1016/j.sna.2017.07.046 [27] MA J, WANG P, CHEN H, et al. Highly sensitive and large-range strain sensor with a self-compensated two-order structure for human motion detection[J]. ACS Applied Materials & Interfaces,2019,11(8):8527-8536. [28] WANG Y, GONG S, WANG S J, et al. Volume-invariant ionic liquid microbands as highly durable wearable biomedical sensors[J]. Materials Horizons,2016,3(3):208-213. doi: 10.1039/C5MH00284B -

下载:

下载: