Research progress on adsorption properties of biomass materials for micro/nano plastics

-

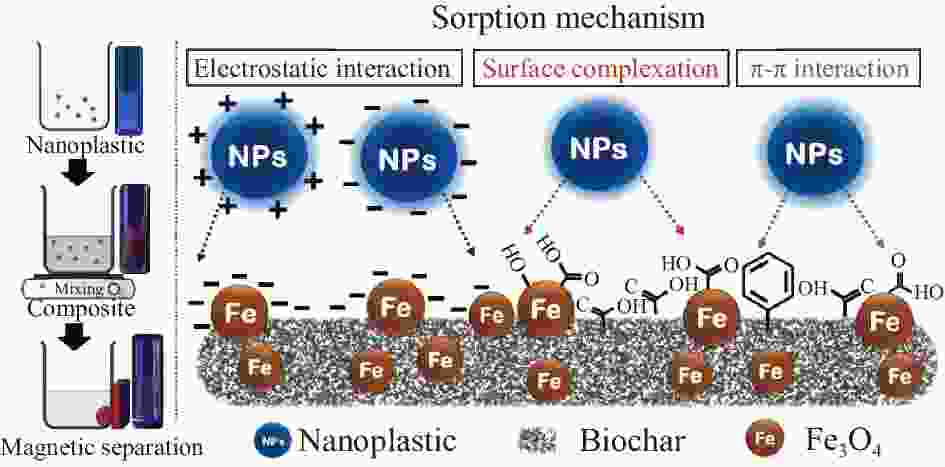

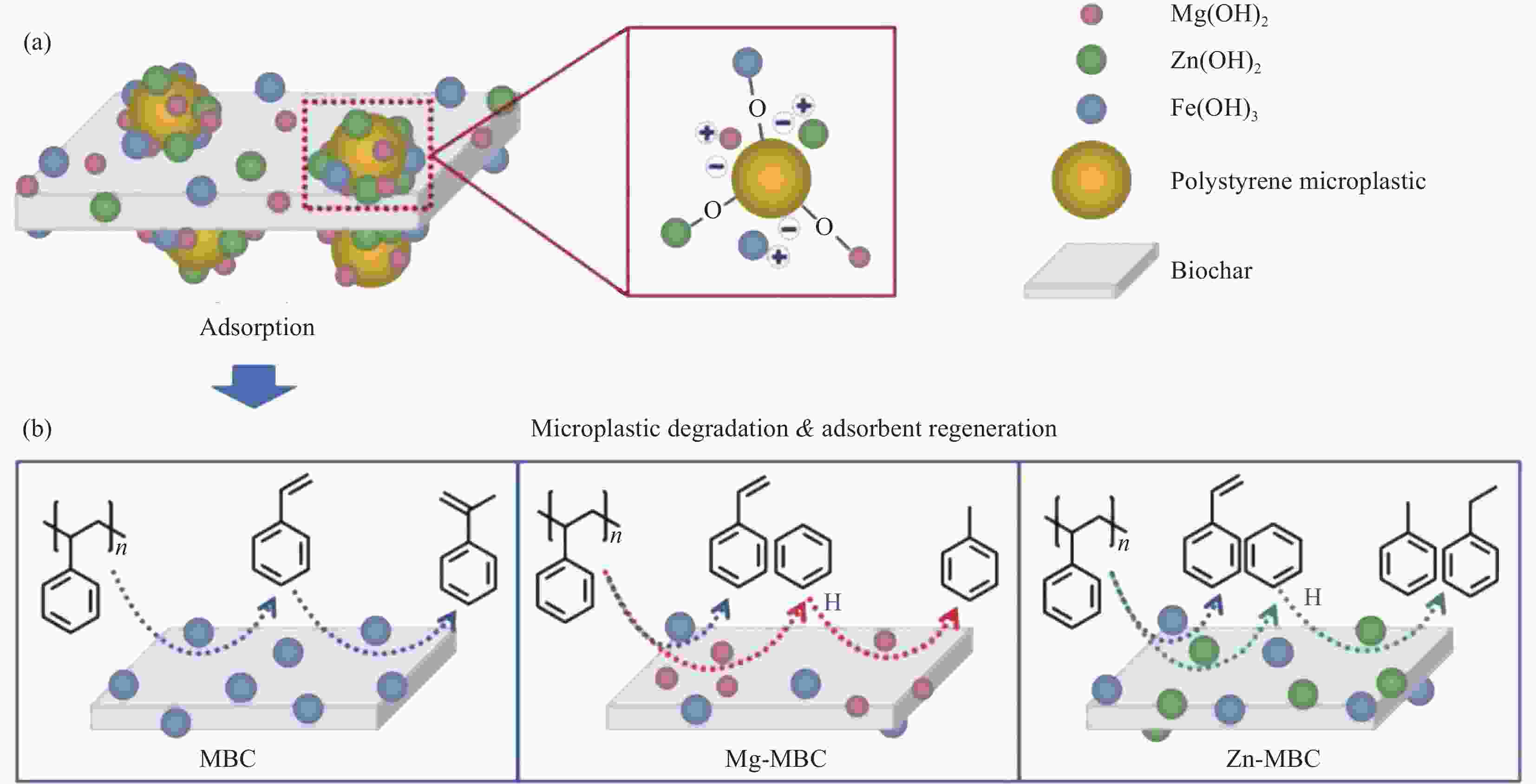

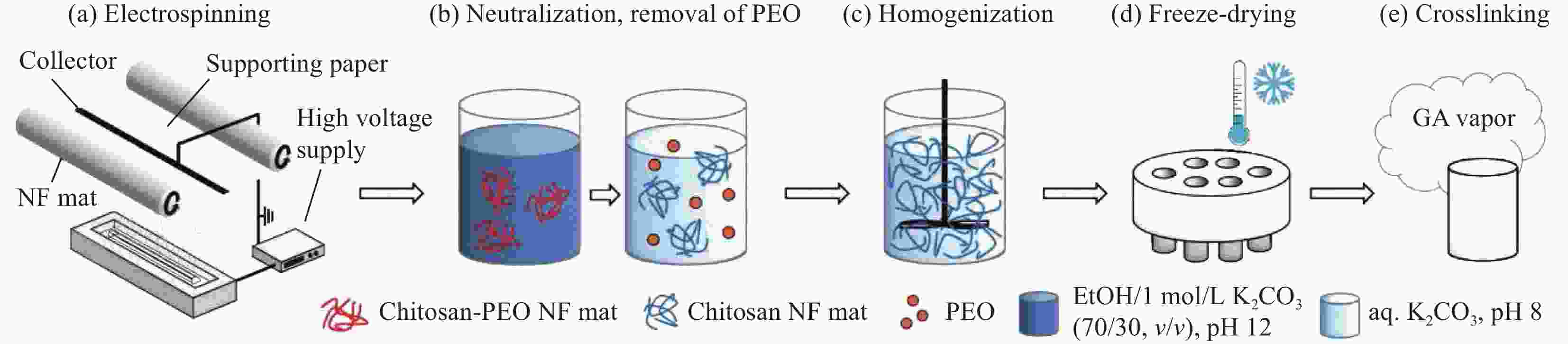

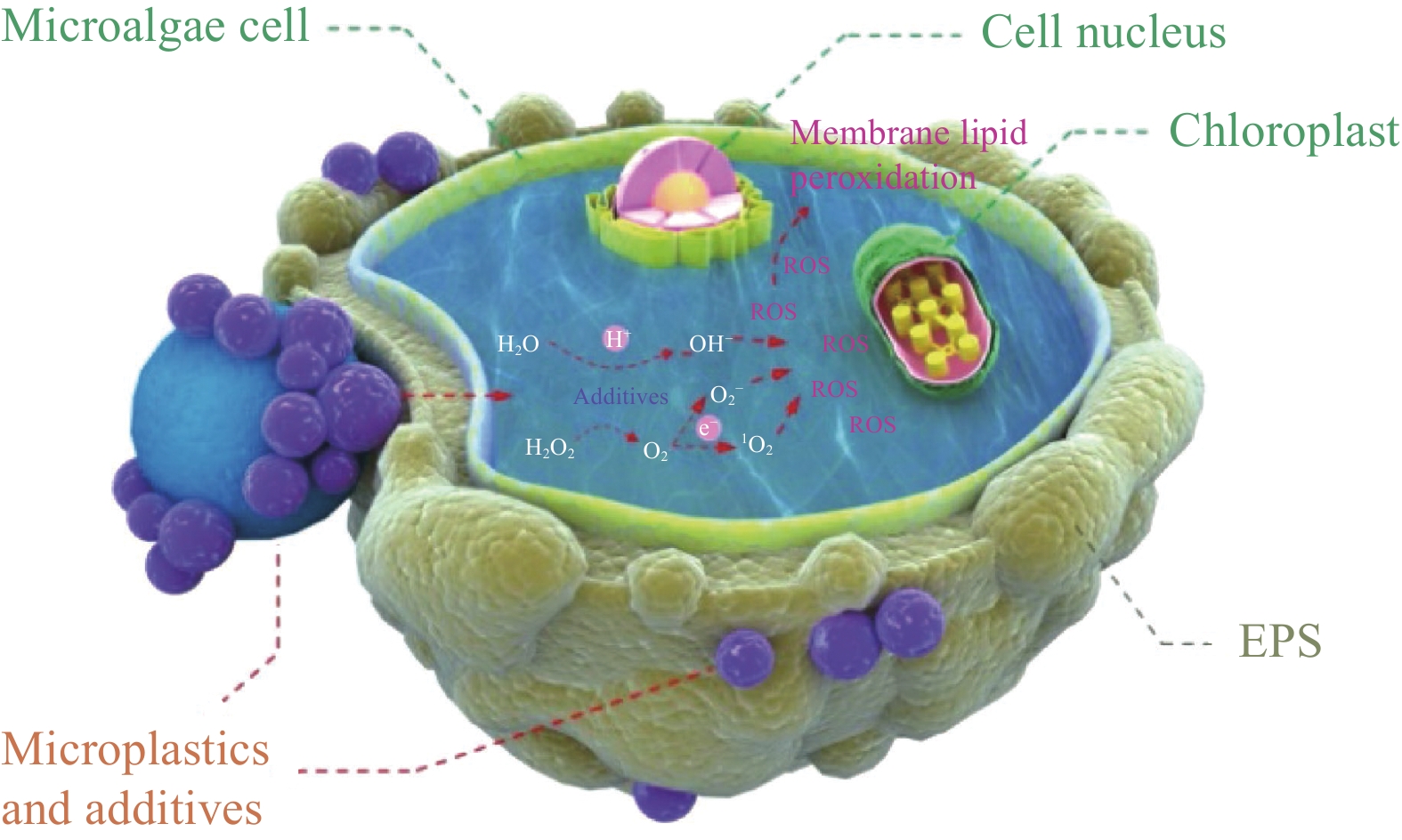

摘要: 废弃塑料在江河湖海中呈累积趋势,老化分解产生的微纳塑料严重污染水质,威胁生态环境和居民饮用水安全。传统处理方法,如物理絮凝、生物降解等,存在处理周期长、吸附效率低等问题。天然生物质含有大量的羟基、羧基等活性基团,对生物质进行物理处理或化学修饰改性能够改善孔隙结构和提高比表面积,可作为吸附微纳塑料的绿色材料。本文从微纳塑料的常规处理方法和基本特征出发,简要概况了不同类型微纳塑料对植物、动物和人体的潜在影响和危害,系统介绍了生物质材料(生物质炭、纤维素、甲壳素等)在微纳塑料吸附领域的研究现状,分析总结了生物质材料对微纳塑料的吸附行为、规律和作用机制,最后展望了生物质材料吸附微纳塑料的未来发展前景。Abstract: Waste plastics have been accumulated in rivers, lakes and seas. The micro/nano plastics generated by aging and decomposition pollute the water quality seriously and threaten the ecological environment and the safety of drinking water for residents. Traditional treatment methods including physical flocculation and biodegradation, still have problems such as long treatment period and low adsorption efficiency. Natural biomass contains large numbers of active hydroxyl and carboxyl groups. Physical treatment or chemical modification of biomass can be conducted to improve the pore structure and increase the specific surface area, and can be used as a green material for adsorbing micro/nano plastics. This work starts with the conventional treatment methods and the basic characteristics of micro/nano plastics, and briefly summarizes the potential effects and harm of different types of micro/nano plastics on plants, animals and human beings. Then research status of biomass materials (biochar, cellulose, chitin, etc.) in the field of the adsorption of micro/nano plastics is systematically introduced and the adsorption behavior, law and action mechanism of biomass materials on micro/nano plastics are analyzed and summarized. Finally, the future development prospects of the adsorption of micro/nano plastics by biomass materials are prospected.

-

Key words:

- biomass /

- absorbent material /

- micro/nano plastics /

- adsorption property /

- adsorption mechanism

-

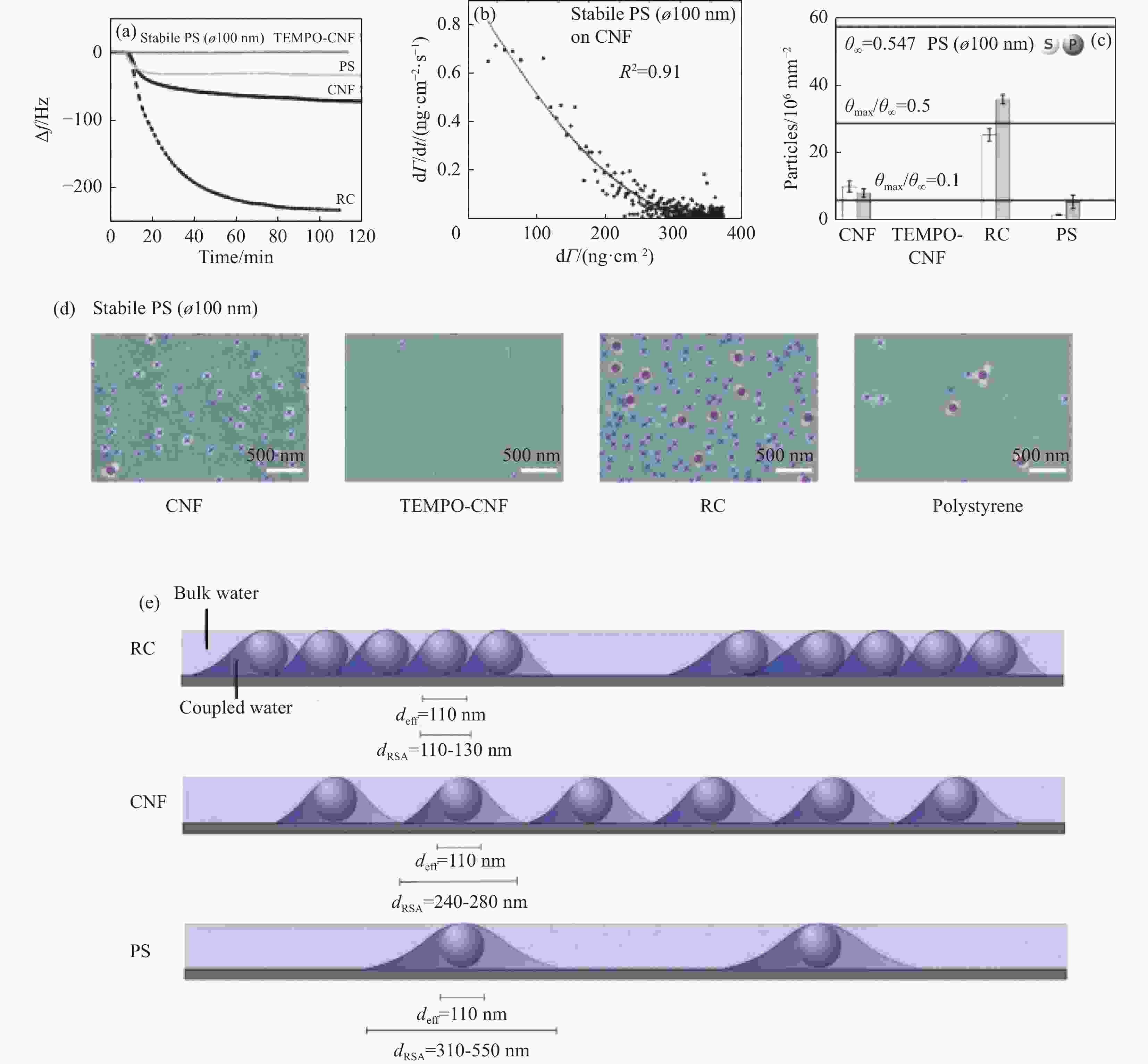

图 5 采用表面敏感方法、石英晶体微天平与损耗监测(QCM-D)、结合图像分析和随机顺序吸附(RSA)模型定量评估聚苯乙烯(PS)纳米塑料的表面结合[49]

Δf—Frequency; TEMPO-CNF—TEMPO oxidized cellulose nanofibrils; TEMPO—2, 2, 6, 6-tetramethylpiperidinyl-1-oxyl; CNF—Cellulose nanofibrils; RC—Regenrated cellulose; θmax—Actual surface coverage maximum; θ∞—Theoretical surface coverage maximum 0.547, which equals to ~5.8×10−7 circles mm−2; S—Stabile; P—Purified; Γ—Adsorbed mass per unit area (ng·cm−2); deff—Effective particle diameter; dRSA—Diameter of the occupied area; Φ—Diameter; t—Time

Figure 5. Quantitative assessment of surface binding of polystyrene (PS) nanoplastic particles using a surface-sensitive approach, quartz crystal microbalance with dissipation monitoring (QCM-D), coupled with image analysis and fittings with random sequential adsorption (RSA) model[49]

表 1 微纳塑料在淡水系统中的分布现状

Table 1. Distribution of micro/nano plastics in water

Region Type of micro/nano plastics Abundance Ref. Antarctica, Ross Sea PE, PP 3.2×10−3-1.18 n·m−3 [15] China, Three Gorges PE, PP, PS 5.5×104-3.42×107 n·km−2 [16] China, Lake Taihu PE, PET, PP 1×104-6.8×106 n·km−2 [17] Germany, Rhine River PS, PP, PVC 1.45×105-3.07×106 n·km−2 [18] USA, Chesapeake Bay PE, PS 5.5×102-2.6×105 n·km−2 [19] Switzerland, Swiss Lake PE, PP, PS 1.1×104-2.2×105 n·km−2 [20] Notes: PE—Polyethylene; PP—Polypropylene; PS—Polystyrene; PET—Poly(ethylene terephthalate); PVC—Polyvinyl chloride. 表 2 25℃下生物质材料对微纳塑料的吸附性能

Table 2. Adsorption properties of biomass materials on micro/nano plastics at 25℃

Material Preparation method Type of

MPs/NPsConcentration of MPs/NPs/(mg·L−1) Adsorption capacity/(mg·g−1) Adsorption mechanism Ref. Scotch pine/

Spruce barkPyrolysis/Steam activation PE 4000 200 Physical interception/

Intra-particle diffusion[39] Aged corn cob H2SO4/HNO3 oxidation/Pyrolysis PS 1000 18 Surface diffusion [41] Modified magnetic biochar Mg/Zn modification PS 100 99.21 Electrostatic interaction [43] Modified cellulose powder PEI crosslinking PMMA,

PVAc, PVC2000 881.8-900 Electrostatic interaction [47] Coffee grounds Purchase/Wash PS-NH2 100-125 4 Hydrogen bonding/

Electrostatic interaction[48] Chitin/GO/

ChitosanFreeze drying PS/PS-NH2,

PS-COOH1 8.79 Hydrogen bonding/

Electrostatic interaction/

π-π interaction[56] Chitosan NF Directional freeze

dryingPET 1000 309.8 Physical interception/

Intra-particle diffusion[57] Oat protein Freeze drying PS 1 6.58 Hydrophobic action/

Intra-particle diffusion[59] Notes: MPs/NPs—Microplastics/Nanoplastics; PMMA—Polymethyl methacrylate; PVAc—Polyvinyl acetate; PEI—Polyethyleneimine; GO—Graphene oxide; NF—Nanofiber. -

[1] CHEN X, YAN N. A brief overview of renewable plastics[J]. Materials Today Sustainability,2020,7:100031. [2] WANG G, WANG J, XUE Q. Efficient utilization of waste plastics as raw material for metallic iron and syngas production by combining heat treatment pulverization and direct reduction[J]. Process Safety and Environmental Protection,2020,137:49-57. doi: 10.1016/j.psep.2020.02.017 [3] MACLEOD M, ARP H P H, TEKMAN M B, et al. The global threat from plastic pollution[J]. Science,2021,373(6550):61-65. doi: 10.1126/science.abg5433 [4] 韦曦萍. 不同混凝-超滤工艺下微塑料/有机物体系的膜污染行为研究[D]. 西安: 西安建筑科技大学, 2021.WEI Xiping. Study on membrane fouling behavior of microplastics/organics under different coagulation ultrafiltration processes[D]. Xi'an: Xi'an University of Architecture and Technology, 2021(in Chinese). [5] 刘江峡, 刘欢, 刘清泉, 等. 多层级孔材料及水体微塑料处理的研究进展[J]. 合成材料老化与应用, 2020, 49(2):103-108.LIU Jiangxia, LIU Huan, LIU Qingquan, et al. Research progress of hierarchical porous materials and treatment of water microplastics pollution[J]. Synthetic Materials Aging and Application,2020,49(2):103-108(in Chinese). [6] RAJALA K, GRÖNFORS O, HESAMPOUR M, et al. Removal of microplastics from secondary wastewater treatment plant effluent by coagulation/flocculation with iron, aluminum and polyamine-based chemicals[J]. Water Research,2020,183:116045. doi: 10.1016/j.watres.2020.116045 [7] ARIZA-TARAZONA M C, VILLARREAL-CHIU J F, BARBIERI V, et al. New strategy for microplastic degradation: Green photocatalysis using a protein-based porous N-TiO2 semiconductor[J]. Ceramics International,2019,45(7):9618-9624. doi: 10.1016/j.ceramint.2018.10.208 [8] ZHENG B, LI B, WAN H, et al. Coral-inspired environmental durability aerogels for micron-size plastic particles removal in the aquatic environment[J]. Journal of Hazardous Materials,2022,431:128611. [9] KARIM M E, SANJEE S A, MAHMUD S, et al. Microplastics pollution in Bangladesh: Current scenario and future research perspective[J]. Chemistry and Ecology,2020,36(1):83-99. doi: 10.1080/02757540.2019.1688309 [10] LAPOINTE M, FARNER J M, HERNANDEZ L M, et al. Understanding and improving microplastic removal during water treatment: Impact of coagulation and flocculation[J]. Environmental Science & Technology,2020,54(14):8719-8727. [11] XU Q, HUANG Q S, LUO T Y, et al. Coagulation removal and photocatalytic degradation of microplastics in urban waters[J]. Chemical Engineering Journal,2021,416:129123. doi: 10.1016/j.cej.2021.129123 [12] ZHANG X L, CHEN J X, LI J. The removal of microplastics in the wastewater treatment process and their potential impact on anaerobic digestion due to pollutants association[J]. Chemosphere,2020,251:126360. doi: 10.1016/j.chemosphere.2020.126360 [13] SIGHICELLI M, PIETRELLI L, LECCE F, et al. Microplastic pollution in the surface waters of Italian Subalpine Lakes[J]. Environmental Pollution,2018,236:645-651. doi: 10.1016/j.envpol.2018.02.008 [14] LI P, LAI Y, LI Q, et al. Total organic carbon as a quantita-tive index of micro and nanoplastic pollution[J]. Analytical Chemistry,2022,94(2):740-747. doi: 10.1021/acs.analchem.1c03114 [15] CINCINELLI A, SCOPETANI C, CHELAZZI D, et al. Microplastic in the surface waters of the Ross Sea (Antarctica): Occurrence, distribution and characterization by FTIR[J]. Chemosphere,2017,175:391-400. doi: 10.1016/j.chemosphere.2017.02.024 [16] ZHANG K, XIONG X, HU H, et al. Occurrence and characteristics of microplastic pollution in Xiangxi Bay of Three Gorges Reservoir, China[J]. Environmental Science & Technology,2017,51(7):3794-3801. [17] SU L, XUE Y, LI L, et al. Microplastics in Taihu Lake, China[J]. Environmental Pollution,2016,216:711-719. doi: 10.1016/j.envpol.2016.06.036 [18] MANI T, HAUK A, WALTER U, et al. Microplastics profile along the Rhine River[J]. Scientific Reports,2015,5:17988. [19] YONKOS L T, FRIEDEL E A, PEREZ-REYES A C, et al. Microplastics in four estuarine rivers in the Chesapeake Bay, USA[J]. Environmental Science & Technology,2014,48(24):14195. [20] FAURE F, DEMARS C, WIESER O, et al. Plastic pollution in Swiss surface waters: Nature and concentrations, interaction with pollutants[J]. Environmental Chemistry,2015,12(5):582-591. doi: 10.1071/EN14218 [21] MARTIN C, CORONA E, MAHADIK G A, et al. Adhesion to coral surface as a potential sink for marine microplastics[J]. Environmental Pollution,2019,255:113281. doi: 10.1016/j.envpol.2019.113281 [22] SONG C, QIU Y, LI S, et al. A novel concept of bicarbonate-carbon utilization via an absorption-microalgae hybrid process assisted with nutrient recycling from soybean wastewater[J]. Journal of Cleaner Production,2019,237:117864. doi: 10.1016/j.jclepro.2019.117864 [23] SONG C, LIU Z, WANG C, et al. Different interaction performance between microplastics and microalgae: The bio-elimination potential of Chlorella sp. L38 and Phaeodactylum tricornutum MASCC-0025[J]. Science of the Total Environment,2020,723:138146. doi: 10.1016/j.scitotenv.2020.138146 [24] PELLER J, NEVERS M B, BYAPPANAHALLI M, et al. Sequestration of microfibers and other microplastics by green algae, Cladophora, in the US Great Lakes[J]. Envi-ronmental Pollution,2021,276:116695. doi: 10.1016/j.envpol.2021.116695 [25] SANTANA M F M, DAWSON A L, MOTTI C A, et al. Ingestion and depuration of microplastics by a planktivorous coral reef fish, Pomacentrus amboinensis[J]. Frontiers in Environmental Science,2021,9:641135. [26] CAPONE A, PETRILLO M, MISIC C. Ingestion and elimination of anthropogenic fibres and microplastic fragments by the European anchovy (Engraulis encrasicolus) of the NW Mediterranean Sea[J]. Marine Biology,2020,167(11):1-15. [27] LENGAR Ž, KLUN K, DOGSA I, et al. Sequestration of polystyrene microplastics by jellyfish mucus[J]. Frontiers in Marine Science,2021,9:690749. [28] BRÅTE I L N, BLÁZQUEZ M, BROOKS S J, et al. Weathering impacts the uptake of polyethylene microparticles from toothpaste in Mediterranean mussels (M. galloprovincialis)[J]. Science of the Total Environment,2018,626:1310-1318. doi: 10.1016/j.scitotenv.2018.01.141 [29] BULANNGA R B, SCHMIDT S. Uptake and accumulation of microplastic particles by two freshwater ciliates isolated from a local river in South Africa[J]. Environmental Research,2022,204:112123. doi: 10.1016/j.envres.2021.112123 [30] HUANG Z, WENG Y, SHEN Q, et al. Microplastic: A potential threat to human and animal health by interfering with the intestinal barrier function and changing the intestinal microenvironment[J]. Science of the Total Environment,2021,785:147365. doi: 10.1016/j.scitotenv.2021.147365 [31] BRAUN T, EHRLICH L, HENRICH W, et al. Detection of microplastic in human placenta and meconium in a clinical setting[J]. Pharmaceutics,2021,13(7):921-932. doi: 10.3390/pharmaceutics13070921 [32] NOR N H M, KOOI M, DIEPENS N J, et al. Lifetime accumulation of microplastic in children and adults[J]. Environmental Science & Technology,2021,55(8):5084-5096. [33] 刘慧. 功能化生物质复合材料的制备及其吸附水中砷的性能研究[D]. 南京: 南京林业大学, 2021.LIU Hui. Study on the preparation of functional biomass composite material and the adsorption for arsenic removal from water[D]. Nanjing: Nanjing Forestry University, 2021(in Chinese). [34] CHI N T L, ANTO S, AHAMED T S, et al. A review on biochar production techniques and biochar based catalyst for biofuel production from algae[J]. Fuel,2021,287:119411. doi: 10.1016/j.fuel.2020.119411 [35] MADADI R, BESTER K. Fungi and biochar applications in bioremediation of organic micropollutants from aquatic media[J]. Marine Pollution Bulletin,2021,166:112247. doi: 10.1016/j.marpolbul.2021.112247 [36] KUMAR M, DUTTA S, YOU S, et al. A critical review on biochar for enhancing biogas production from anaerobic digestion of food waste and sludge[J]. Journal of Cleaner Production,2021,305:127143. doi: 10.1016/j.jclepro.2021.127143 [37] ABUWATFA W H, AL-MUQBEL D, AL-OTHMAN A, et al. Insights into the removal of microplastics from water using biochar in the era of COVID-19: A mini review[J]. Case Studies in Chemical and Environmental Engineering,2021,4:100151. doi: 10.1016/j.cscee.2021.100151 [38] WANG Z, SEDIGHI M, LEA-LANGTON A. Filtration of microplastic spheres by biochar: Removal efficiency and immobilisation mechanisms[J]. Water Research,2020,184:116165. doi: 10.1016/j.watres.2020.116165 [39] SIIPOLA V, PFLUGMACHER S, ROMAR H, et al. Low-cost biochar adsorbents for water purification including microplastics removal[J]. Applied Sciences,2020,10(3):788-805. doi: 10.3390/app10030788 [40] GANIE Z A, KHANDELWAL N, TIWARI E, et al. Biochar-facilitated remediation of nanoplastic contaminated water: Effect of pyrolysis temperature induced surface modifications[J]. Journal of Hazardous Materials,2021,417:126096. doi: 10.1016/j.jhazmat.2021.126096 [41] MAGID A S I A, ISLAM M S, CHEN Y, et al. Enhanced adsorption of polystyrene nanoplastics (PSNPs) onto oxidized corncob biochar with high pyrolysis temperature[J]. Science of the Total Environment,2021,784:147115. doi: 10.1016/j.scitotenv.2021.147115 [42] SINGH N, KHANDELWAL N, GANIE Z A, et al. Eco-friendly magnetic biochar: An effective trap for nanoplastics of varying surface functionality and size in the aqueous envi-ronment[J]. Chemical Engineering Journal,2021,418:129405. doi: 10.1016/j.cej.2021.129405 [43] WANG J, SUN C, HUANG Q X, et al. Adsorption and thermal degradation of microplastics from aqueous solutions by Mg/Zn modified magnetic biochars[J]. Journal of Hazardous Materials,2021,419:126486. doi: 10.1016/j.jhazmat.2021.126486 [44] BOONMAHITTHISUD A, SOYKEABKAEW N, ONGTHIP L, et al. Review of the recent developments in all-cellulose nanocomposites: Properties and applications[J]. Carbohydrate Polymers,2022,286:119192. [45] PRASAD S, SINGH A, KORRES N E, et al. Sustainable utilization of crop residues for energy generation: A life cycle assessment (LCA) perspective[J]. Bioresource Technology,2020,303:122964. doi: 10.1016/j.biortech.2020.122964 [46] 蔡杰, 吕昂, 周金平, 等. 纤维素科学与材料[M]. 北京: 化学工业出版社, 2015: 345.CAI Jie, LYU Ang, ZHOU Jinping, et al. Cellulose science and materials[M]. Beijing: Chemical Industry Press, 2015: 345(in Chinese). [47] BATOOL A, VALIYAVEETTIL S. Surface functionalized cellulose fibers—A renewable adsorbent for removal of plastic nanoparticles from water[J]. Journal of Hazardous Materials,2021,413:125301. doi: 10.1016/j.jhazmat.2021.125301 [48] YEN P L, HSU C H, HUANG M L, et al. Removal of nano-sized polystyrene plastic from aqueous solutions using untreated coffee grounds[J]. Chemosphere,2022,286:131863. doi: 10.1016/j.chemosphere.2021.131863 [49] LEPPÄNEN I, LAPPALAINEN T, LOHTANDER T, et al. Capturing colloidal nano- and microplastics with plant-based nanocellulose networks[J]. Nature Communications,2022,13(1):1-12. doi: 10.1038/s41467-021-27699-2 [50] ZHUANG J, RONG N, WANG X, et al. Adsorption of small size microplastics based on cellulose nanofiber aerogel modified by quaternary ammonium salt in water[J]. Separation and Purification Technology,2022,291:121133. [51] CHEN C C, WU Q J, WAN Z M, et al. Mildly processed chitin used in one-component drinking straws and single use materials: Strength, biodegradability and recyclability[J]. Chemical Engineering Journal,2022,442:136173. doi: 10.1016/j.cej.2022.136173 [52] EL KNIDRI H, BELAABED R, ADDAOU A, et al. Extraction, chemical modification and characterization of chitin and chitosan[J]. International Journal of Biological Macromolecules,2018,120:1181-1189. doi: 10.1016/j.ijbiomac.2018.08.139 [53] YANG J, CHEN X, ZHANG J, et al. Role of chitosan-based hydrogels in pollutants adsorption and freshwater harvesting: A critical review[J]. International Journal of Biological Macromolecules,2021,189:53-64. doi: 10.1016/j.ijbiomac.2021.08.047 [54] ANITHA A, SOWMYA S, KUMAR P T S, et al. Chitin and chitosan in selected biomedical applications[J]. Progress in Polymer Science,2014,39(9):1644-1667. doi: 10.1016/j.progpolymsci.2014.02.008 [55] SUN C, WANG Z, CHEN L, et al. Fabrication of robust and compressive chitin and graphene oxide sponges for removal of microplastics with different functional groups[J]. Chemical Engineering Journal,2020,393:124796. doi: 10.1016/j.cej.2020.124796 [56] SUN C, WANG Z, ZHENG H, et al. Biodegradable and reusable sponge materials made from chitin for efficient removal of microplastics[J]. Journal of Hazardous Materials,2021,420:126599. doi: 10.1016/j.jhazmat.2021.126599 [57] RISCH P, ADLHART C. A chitosan nanofiber sponge for oyster-inspired filtration of microplastics[J]. ACS Applied Polymer Materials,2021,3(9):4685-4694. doi: 10.1021/acsapm.1c00799 [58] 林自明. 甲壳素/聚乙烯亚胺复合材料的制备及其对Cr(Ⅵ)、U(Ⅵ)的吸附行为和机理研究[D]. 南宁: 广西大学, 2021.LIN Ziming. Preparation of Chitin/polyvinyl imine composite and its adsorption behavior and mechanism for Cr(VI) and U(VI)[D]. Nanning: Guangxi University, 2021(in Chinese). [59] WANG Z, SUN C, LI F, et al. Fatigue resistance, reusable and biodegradable sponge materials from plant protein with rapid water adsorption capacity for microplastics removal[J]. Chemical Engineering Journal,2021,415:129006. doi: 10.1016/j.cej.2021.129006 [60] SUN M, CHEN W, FAN X, et al. Cooperative recyclable magnetic microsubmarines for oil and microplastics removal from water[J]. Applied Materials Today,2020,20:100682. doi: 10.1016/j.apmt.2020.100682 -

下载:

下载: