Flexible and fiber-shaped batteries—A review

-

摘要: 纤维电池具有维度低、灵活性好、形状普适性强、与纺织品高度融合等特点,可满足柔性电子产品电路元件的供能需求。近年来纤维电池的研究,不仅关注于电极材料的微纳复合,探索多功能、可扩展和高集成系统的纤维电池逐渐成为研发的焦点。此外,规模化生产纤维状电池也取得了一定的突破,包括电池组装、集成、连续生产等。基于此,本文从纤维基底材料和制备工艺两方面对近期纤维电池的研究成果展开论述,并对工业化生产纤维电池的最新突破进行评述,最后,总结纤维状电池发展存在的问题并分析展望未来需要攻克的重点难点。Abstract: With low dimensionality, flexibility, shape-adaptable, and high integration with textiles, fiber batteries can meet the energy supply needs of circuit elements of flexible electronics. In recent years, research on fiber batteries has not only focused on active materials composited in electrodes, but exploring multi-functional, scalable, and highly integrated systems of fiber batteries. In addition, certain breakthroughs have been made in the large-scale production of fiber-based batteries, including battery assembly, integration, and continuous production. Based on this, this paper discusses the recent research results of fiber batteries in terms of fiber substrate materials and preparation processes, and it also review the latest breakthroughs in the industrial production of fiber batteries. Finally, this paper summarize the problems in the development of fiber batteries and analyze the key difficulties that need to be overcome in the future.

-

Keywords:

- fiber-sharped batteries /

- electrode materials /

- liquid metal /

- industrialization /

- wearable

-

树脂基纤维增强复合材料(简称“复材”)具有轻质、高强、耐腐蚀等突出优点,被广泛应用于建筑、交通、能源、航空航天及体育等行业[1]。全球复合材料市场规模预计将从2019年的906亿美元增长至2024年的

1316 亿美元[2]。随着复合材料应用日益广泛,制造期间产生的废料、测试样品以及退役产品等复合材料固体废弃物(复材固废)总量也逐年攀升[3-4]。以风电领域为例,根据我国现有风电装机容量和未来总体规划预测,2010至2024期间年我国风力发电叶片废弃物累计总量为1~1.3万吨,其后5年将增至19.7万吨,预计到2040年累计总量将达到240万吨左右[5]。这些复材废弃物不可降解,其数量的快速增长将对环境造成巨大压力[6]。传统复材固废的处理方法包括直接填埋和焚烧。前者简单便捷、应用最广,但占用大量土地,并对填埋地的自然环境造成持久性污染[6]。各国日益收紧的固废填埋政策也导致固废填埋费用逐步攀升[7-8]。焚烧处理成本同样较高,且会产生有毒有害气体,而原固废体积一半左右的残余灰烬仍需填埋处理[9-11]。

常见复材固废回收再利用方法主要有化学回收法、热解回收法以及机械回收法[6, 11-13]。化学回收法采用不同溶剂使聚合物的化学键断裂,从而将树脂基体与纤维分离[14]。化学法成本高、耗时长,目前处于实验室研究阶段,尚未推广应用[6]。热解法一般指采用450℃以上的高温将复材固废进行裂解,从而将纤维从复材固废中分离出来[11]。该法适用于化学性能稳定且产品附加值较高的碳纤维复材固废(碳纤固废)的再生利用[15-16],已成功商业化,采用此法对碳纤固废进行再生利用的公司包括英国ELG Carbon Fiber Ltd.、意大利Karborek Spa、美国Material Innovation Technology和国内的复源新材料科技有限公司等[11, 17]。然而,热解法对回收利用占总体复材市场规模95%以上的玻璃纤维(玻纤)复材固废并不经济适用[6]。其原因为玻璃纤维附加值低,且力学性能在回收处理后显著降低[8, 11]。

机械回收法指通过破碎、粉碎、研磨等工序将复材固废处理成不同形状的回收产物,并作为填充材料[12, 18-20]或抗裂增强材料[21-23]用于制备水泥基产品或其他产品。有学者将复材固废处理成不同尺寸的块体、颗粒以及粉末,用于部分替代砂石骨料以制备混凝土[12, 18-20]。相比砂石骨料,玻纤固废粉碎料的弹性模量小、与包裹基体的粘结性能弱,从而导致混凝土强度相对较低[12, 18-20]。将复材固废处理成短条状或细纤维,作为抗裂增强材料制备纤维混凝土,所获混凝土的力学性能要优于基于粗、细骨料替代法制备的混凝土[21-24]。综上所述,机械回收法可能是解决玻纤固废回收利用难题的有效方法之一。

本研究团队此前已经提出了一种新的玻纤复材固废回收利用方法:通过机械切割及铣削将玻纤复材固废加工成长度30~100 mm,宽度3~5 mm,厚度0.5~1.5 mm的粗纤维,并用于制备玻纤复材固废粗纤维混凝土(Macro fibre reinforced concrete,MFRC)[25]。目前,关于MFRC的研究还处于起步探索阶段,仅有少数文献对MFRC材料开展了试配试验研究和基本力学性能测试[25-30]。结果表明,玻纤复材固废粗纤维具有作为混凝土中抗裂增强材料的潜力,然而关于粗纤维对混凝土力学性能的影响规律尚未有系统的研究成果。鉴于此,本文通过一系列轴压、劈拉试验,研究了粗纤维体积掺量、厚度、长度对两种配比混凝土的力学性能的影响,评估了现有FRC劈拉强度预测公式对MFRC劈拉强度的预测效果,并基于试验结果提出了MFRC劈拉强度预测公式。

1. 玻纤复材固废粗纤维

本研究所用粗纤维由某废弃风机叶片通过机械切割及铣削处理得到,主要步骤包括:(1)将完整叶片解体为若干便于运输的粗切节段,并将其切割为长度为0.5~3 m的板材(图1(a));(2)将板材切割为长度30~100 mm的块体(图1(b));(3)采用自动铣削机床(图1(c)),顺着原始叶片的纤维铺层主方向将块体进一步切割成长度30~100 mm,宽度3~5 mm,厚度0.5~1.5 mm的粗纤维(图1(d))。经测试,本文所用粗纤维的密度为1.97 g/cm3。

光学显微镜(OM)和扫描电镜(SEM)图像显示:粗纤维由树脂基体和纤维两相组成,大部分纤维丝嵌置于树脂基体中,但也有少量纤维丝裸露于粗纤维表面,粗纤维表面存在纤维丝损伤断裂和树脂基体剥落的现象(图2)。回收粗纤维的力学性能低于新出厂的风机叶片,主要原因为:(1)叶片在服役期间的性能退化;(2)运输退役叶片过程中造成的损伤;(3)切割及铣削处理造成的损伤[25]。单根粗纤维可能包含多层原始复合材料铺层,而层间在铣削加工剪切力作用下容易受到损伤,因而发生层间脱离现象,造成粗纤维力学性能的降低。对于本研究所采用的机械加工工艺,所制备的粗纤维厚度超过1.5 mm时层间脱离现象较为明显。

本研究采用5种不同尺寸的粗纤维,从中各随机挑选200根以对其实际几何尺寸进行了统计(表1)。对于名义尺寸为90 mm×4.5 mm×0.5 mm的粗纤维,其实际平均长度、宽度和厚度分别为91.20、4.49和0.54 mm。其余4种规格粗纤维的实际几何尺寸也接近对应的名义尺寸。

表 1 回收粗纤维统计参数Table 1. Statistical properties of recycled macro fibres (MF)Designation Nominal

dimensions/

mmLength/mm Width/mm Thickness/mm Tensile strength/MPa Elastic modulus/GPa Average Standard

deviationAverage Standard

deviationAverage Standard

deviationAverage Standard

deviationAverage Standard

deviationMF-1 90×4.5×0.5 91.20 1.94 4.49 0.43 0.54 0.16 554 135 37.7 7.3 MF-2 90×4.5×1.2 90.57 4.56 4.57 0.36 1.26 0.26 MF-3 90×4.5×2.2 87.60 2.97 4.57 0.75 2.26 0.53 MF-4 60×4.5×0.5 58.25 1.94 4.63 0.80 0.54 0.19 MF-5 30×4.5×0.5 33.30 1.20 4.81 0.48 0.50 0.12 根据ASTM 3039标准[31]对9个粗纤维测试试件的静力拉伸性能进行测试。拉伸试件名义尺寸为150 mm×4.5 mm×1 mm,名义标距为60 mm。为防止夹持部位发生破坏,采用环氧树脂将尺寸为45 mm×34 mm×1 mm的铝片粘贴于拉伸试件端部。拉伸试验破坏后的粗纤维试件如图3所示。粗纤维平均拉伸强度为554 MPa,标准差为135 MPa,其弹性模量平均值为37.7 GPa,标准差为7.3 GPa。可见粗纤维在力学性能上有显著的离散性,这与前期研究中的观察一致[25, 32]。其离散性来源于:(1)固废来源不同;即便来源于同一叶片,不同部位的纤维铺层方向、纤维含量也不同;(2)切割和铣削处理造成的损伤差异。

2. 试验方案

2.1 试件设计与制作

本文设置两批次共11组试件,如表2所示。批次1的试件用于研究粗纤维体积分数对MFRC轴压和劈拉性能的影响,批次2的试件用于研究粗纤维长度、厚度以及混凝土配合比的影响。每组制备尺寸均为150 mm×300 mm(直径×高度)的圆柱抗压试件和劈拉试件各3个。在试件组别的命名中,“S”代表批次,“W”代表水灰比,“L”代表纤维长度,“V”代表纤维体积分数,“T”代表纤维厚度。例如,S1W0.32L90V-0.5%T0.5-1代表第一批,混凝土水灰比为0.32,粗纤维长度为90 mm,粗纤维体积分数为0.5vol%,粗纤维厚度为0.5 mm的同组3个试件中的第一个。此外,为便于后续讨论,每个组别也被赋予一个简化编号。例如,组别1-3代表批次1中的第3组。

表3为本研究采用的两种依据普通混凝土配合比设计规程JGJ 55—2011[33] 确定的配合比(C60和C40);在本文中,对混凝土配比无特别说明时,所讨论对象均为配比一混凝土。在预试验中,掺入1.5vol%粗纤维的C40混凝土的坍落度由180 mm急剧下降至30 mm以下,且掺入2vol%粗纤维的混凝土搅拌困难,未能成型。原因在于粗纤维尺寸较大且表面粗糙,容易“结团”。因此,在正式试验中,除原C40配比(水灰比0.47,砂率0.4)外,新加入了一种C60配比(水灰比0.32,砂率0.45)。C60配比的水灰比较低,胶凝材料用量大,容易形成粘稠的浆体,因此提升砂率可以改善流动性,减少空隙率,提升密实度。因掺入粗纤维会显著影响混凝土的流动性,在试配试验中将不含粗纤维的两种配比混凝土的目标坍落度定为200 mm,以给后续因粗纤维而导致的坍落度下降提供空间。此外,通过试配确定了两种混凝土配比的减水剂用量。两种不同配比混凝土的实测坍落度分别为220 mm和195 mm,接近预期的200 mm。

表 2 试件设计Table 2. Specimen designNo. Mix Water/cement ratio Fibre length/mm Fibre thickness/mm Fibre volume

fraction/vol%No. of specimens Compression Splitting 1-1 S1W0.32L0V0%T0 0.32 – – 0 3 3 1-2 S1W0.32L90V0.5%T0.5 0.32 90 0.5 0.5 3 3 1-3 S1W0.32L90V1%T0.5 0.32 90 0.5 1 3 3 1-4 S1W0.32L90V1.5%T0.5 0.32 90 0.5 1.5 3 3 1-5 S1W0.32L90V2%T0.5 0.32 90 0.5 2 3 3 2-1 S2W0.32L90V1.5%T1.2 0.32 90 1.2 1.5 3 3 2-2 S2W0.32L90V1.5%T2.2 0.32 90 2.2 1.5 3 3 2-3 S2W0.32L60V1.5%T0.5 0.32 60 0.5 1.5 3 3 2-4 S2W0.32L30V1.5%T0.5 0.32 30 0.5 1.5 3 3 2-5 S2W0.47L90V1.5%T0.5 0.47 90 0.5 1.5 3 3 2-6 S2W0.47L0V0%T0 0.47 – – 0 3 3 表 3 混凝土基体配合比Table 3. Mix proportions of concrete matrixMix Strength grade Fresh water/

cement ratioFresh water/

(kg·m−3)Cement/

(kg·m−3)Fine aggregate/

(kg·m−3)Coarse aggregate/

(kg·m−3)Water reducer/% 1 C60 0.32 160 500 795 970 0.45 2 C40 0.47 185 395 715 1075 0.19 粗骨料为5~20 mm碎石集料,细骨料为天然河砂,水泥采用强度等级为42.5R的石井牌普通硅酸盐水泥。在混凝土浇筑前对碎石集料进行清洗以去除其表面淤泥及其他杂质,河砂和碎石集料经过阳光晒干以去除其内部水分。在混凝土搅拌过程中,先将其他组份拌合均匀,然后继续搅拌1 min,在此期间匀速加入粗纤维。对坍落度进行测试后,将混凝土拌合物浇筑至模具内,24 h后对试件进行脱模,然后将其置于湿润室温环境下进行养护。需要说明的是,因疫情影响,至加载时试件的实际龄期约为6个月。所有试件的试验工作都在13 d内完成。

2.2 试验方法

采用意大利MATEST 4000 kN伺服控制压力试验机对MFRC圆柱体进行轴压强度测试(图4(a)),具体操作依照ASTM C39规范执行[34]。试件加载前,采用高强石膏对圆柱体试件上下两端表面进行找平,确保荷载能够均匀地施加于试件上下端。试验全程采用位移控制,加载速率设为0.18 mm/min,当轴压荷载降至峰值荷载的20%时,加载结束。

在圆柱试件半高处设置有两个标距为80 mm的环向应变片,以及两个标距为100 mm的纵向应变片,纵向应变片主要用于监测加载初始阶段试件的同心度。采用位移计测量试件的轴向变形,通过套箍将两个位移计对称设置于圆柱体试件的中心高度120 mm(即位移计的标距=120 mm)区域上,其平均读数除以标距为轴向应变。需要说明的是,当荷载达到峰值后,试件表面裂纹逐渐发展,套箍可能发生移位,致使位移传感器数值不能正确反映轴向应变。因此,上述位移计读数仅用于测量峰值荷载前的轴向应变。在加载平台上另外设置两个位移传感器以监测试件全高的轴向变形。峰值荷载后的实际轴向应变由以下方法求得:实际轴向应变=(全高位移计平均读数−峰值荷载处的全高位移计平均读数)/试件全高+峰值荷载处的套箍位移计平均读数/位移计标距。依据试验所得圆柱体轴压应力-应变全曲线(包含上升和下降段),依照ASTM C469 规程[35]获取弹性模量(E)、峰值应变(εco)及其他力学参数。

依照ASTM C496 实验规程,采用前述相同压力试验机对MFRC圆柱体进行劈拉强度测试(图4(b))[36]。为保证劈拉力沿试件长度方向均匀分布,将尺寸为300 mm×2.5 mm×3 mm的木垫片粘贴于圆柱试件上下承压表面,并与中心线对齐;其后,将圆柱试件置于劈拉夹具内,加载条沿试件中心线对齐。试验全程采用劈拉应力控制,以1.2 MPa/min的速率加载至试件破坏。劈拉强度fsp由下式计算:

fsp=2Pπld (1) 其中:P为劈拉峰值荷载;l和d分别为圆柱体试件的长度和直径。

3. 试验结果与讨论

3.1 MFRC流动性

粗纤维掺入降低了混凝土拌合物的流动性,对采用配合比一的混凝土,坍落度由不含纤维时的220 mm降低至2vol%纤维掺量时的140 mm(图5(a))。原因在于:(1)各组分总表面积增加,需水量上升;(2)粗纤维的“棚架”效应。粗纤维的厚度和长度,以及不同配比对坍落度的影响如图5(b)所示。2-1组和2-2组的坍落度分别为165 mm和175 mm。这表明,在其他参数不变的情况下,随着纤维厚度的增加,坍落度略有提升,这是由于粗纤维的根数降低。粗纤维掺量为1.5vol%时,掺入30 mm和60 mm粗纤维的混凝土(2-4组和2-3组)的塌落度均在160 mm左右。

采用配合比一的情况下,1-1组和1-4组的坍落度分别为220 mm和170 mm。而采用配合比二的情况下,2-6组和2-5组的坍落度分别为195 mm和30 mm。同样掺入1.5vol%的粗纤维,配合比二混凝土的坍落度下降幅度显著大于配合比一混凝土。这表明不同基体配比的粗纤维混凝土具有不同的流动性。值得注意的是,纤维的掺量较高(≥1.5vol%)且长度较长(如90 mm)时,可能出现明显的粗纤维“棚架”效应。此时,振捣不够均匀可能引起浇筑质量控制不佳,而振捣过久易引起混凝土泌水。

3.2 MFRC轴压性能

受压试件典型破坏模态如图6所示。轴压试验过程中,随着荷载上升,试件开始出现表面裂纹。达到峰值荷载后,未掺纤维的控制试件发生部分块体剥落(图6(a));MFRC试件无大块体剥落,可清晰看到起桥接作用的粗纤维,试件裂而不散,整体性保持较好(图6(b))。

轴压实验数据如表4所示。受压试件的轴压强度如图7所示。在批次1的试件中(均为配合比一混凝土),纤维掺量为0vol%、0.5vol%和1vol%的试件的平均轴压强度分别为51.7 MPa、46.0和49.1 MPa,表明粗纤维的掺入对轴压强度产生了轻微不利影响。然而,当纤维含量增加到1.5vol%和2vol%时,轴压强度和弹性模量均有明显下降,该两组试件在浇筑中有轻微泌水现象。如前文所述,粗纤维的“棚架”效应会引起混凝土的浇筑质量问题,在纤维的掺量和长度较高的情况下,可采取添加外加剂等措施以保证浇筑质量。

表 4 MFRC轴压实验结果Table 4. Key results of MFRC compression testsNo. Group fc,m/MPa CoV/% εco,m/% CoV/% Em/GPa CoV/% vm CoV/% 1-1 S1W0.32L0V0%T0 51.7 2.1 0.223 13.7 35.5 5.9 0.18 6.2 1-2 S1W0.32L90V0.5%T0.5 46.0 6.4 0.175 10.6 36.2 0.7 0.19 0.0 1-3 S1W0.32L90V1%T0.5 49.1 4.7 0.183 3.8 35.4 3.6 0.20 5.0 1-4 S1W0.32L90V1.5%T0.5 37.4 5.3 0.167 9.0 32.7 6.8 0.19 11.2 1-5 S1W0.32L90V2%T0.5 38.0 7.3 0.194 6.2 28.6 6.7 0.17 3.5 2-1 S2W0.32L90V1.5%T1.2 74.5 1.6 0.264 4.7 39.7 1.2 0.17 0.0 2-2 S2W0.32L90V1.5%T2.2 65.5 1.2 0.245 11.9 39.5 1.9 0.21 4.8 2-3 S2W0.32L60V1.5%T0.5 57.4 1.0 0.236 16.2 37.1 5.4 0.19 6.0 2-4 S2W0.32L30V1.5%T0.5 60.2 2.7 0.208 1.7 40.2 2.5 0.19 5.3 2-5 S2W0.47L90V1.5%T0.5 50.9 2.9 0.272 0.7 32.4 4.6 0.19 16.6 2-6 S2W0.47L0V0%T0 50.1 2.4 0.218 7.2 36.0 2.9 0.22 16.2 Notes: fc,m—Average compressive strength; εco,m—Average value of strain at compressive strength; Em—Average value of modulus of elasticity in compression; vm—Average Poisson's ratio; CoV—Coefficient of variation. 在第2批次的试件中,纤维长度从30 mm提升至60 mm时,混凝土轴压强度从60.2 MPa降至57.4 MPa。纤维厚度从1.2 mm提升至2.2 mm时,混凝土轴压强度从74.5 MPa降至65.5 MPa。此外,在采用配合比二的情况下,粗纤维掺入对轴压强度没有显著影响。相关研究表明[25, 32],粗纤维掺入的主要影响有:(1)吸收部分自由水,致使水灰比轻微下降;(2)限制裂纹的发展;(3)产生粗纤维和水泥基体之间的弱界面。当前两种效应占主导地位时,混凝土强度受到有利影响。

如表4所示,批次2中C60配比的抗压强度和模量接近预期,而批次1中C60配比的抗压性能略低于预期,导致其与C40配比的数据相近。造成批次1中C60配比的抗压性能低于预期的原因有:(1)对于同批次试件的浇筑,所用粗细骨料均为同批次采购且同时进行清洗晾晒处理,而不同批次间所采用的原料可能有细微不同,进而造成了试件抗压性能的差异。因此,本文仅在同一批次试件中进行单因素影响分析。例如,采用批次2中的2-1组(粗纤维厚度为1.2 mm)和2-2组(粗纤维厚度为2.2 mm)进行粗纤维厚度的影响分析,而批次1中的1-4组(粗纤维厚度为0.5 mm)不包括在内;(2)如前文所述,粗纤维对混凝土强度有不利影响,尤其是纤维掺量较高(如≥1.5vol%)且长度较长(如90 mm)时可能出现明显的粗纤维“结团”效应,进而影响该组混凝土的浇筑质量(如1-4和1-5组)。

圆柱体试件轴压应力-应变曲线如图8所示。粗纤维掺入对峰值前曲线的斜率(即弹性模量)影响较小,而对峰值后曲线形状产生较为明显的影响。如图8(a)所示,随着纤维掺量的上升(0vol%~1.5vol%),曲线峰值点有所下降,同时峰值后曲线形状逐渐变得平缓,应力下降速率降低。但纤维掺量提升至2vol%时,峰值后曲线的下降速率并未进一步降低。如前文所述,粗纤维掺入能有效桥接裂缝以限制其发展,因而试件能更持久地维持高轴压应力状态,表现为更平缓的峰值后曲线。

粗纤维厚度对曲线的影响如图8(b)所示。纤维厚度从1.2 mm (2-1组)提升至2.2 mm (2-2组)时,曲线峰值和抗压延性均有所降低。本研究所用的机械加工工艺所能产生的粗纤维最薄为0.5 mm左右,厚度超过1.5 mm时粗纤维自身的层间脱离现象较为明显。因此,本研究认为粗纤维厚度的合理范围为0.5~1.5 mm。

粗纤维长度对曲线的影响如图8(c)所示。粗纤维越长,曲线下降段越平缓,这与采用其他种类纤维的混凝土特性类似[37]。对于未掺入粗纤维的两种不同配比混凝土(图8(a)中S1W0.32L0V0T0组和图8(d)中S2W0.47L0V0T0组),峰值后应力下降至峰值的20%时其轴压应变均在0.5%左右。而掺入1.5vol%粗纤维后,该值均超过1%,增韧效果明显。

3.3 MFRC劈拉性能

图9为劈拉试件的两种典型破坏模态。未掺粗纤维的控制试件均于峰值荷载处沿中心线劈裂成两半。对于MFRC试件,达到峰值荷载后其加载面出现可视裂缝,荷载突然下降;由于有粗纤维横跨裂缝,MFRC试件此时并未被完全劈开,裂而不断。继续加载可使试件最终被劈裂成两半,在劈裂面可以看到许多横跨主裂缝分布的粗纤维。

圆柱体劈拉试验结果见图10。粗纤维掺量从0vol%提升至2vol%时,劈拉强度从4.2 MPa提升至5.2 MPa。如图10(b)所示,粗纤维厚度从1.2 mm提升至2.2 mm时,劈拉强度的变化不明显。粗纤维长度从30 mm提升至60 mm时,劈拉强度从4.8 MPa提升至5.4 MPa。这与采用其他纤维的混凝土特性类似,即长细比越大,强度越高。此外,在采用配合比二的情况下,2-6组和2-5组的劈拉强度分别为3.5 MPa和4.9 MPa。这表明,同样掺入1.5vol%的粗纤维,采用配合比二的混凝土劈拉强度提升幅度(40%)显著大于配合比一(10%)。

4. MFRC劈拉强度预测模型

4.1 现有FRC劈拉强度预测模型

纤维的掺入对混凝土拉伸性能影响显著。影响纤维混凝土(Fibre reinforced concrete,FRC)劈拉强度的因素包括基体强度,纤维体积掺量[38-39]、纤维直径和长度[40-47]。现有的众多纤维混凝土劈拉强度模型[38-47](表5)通常包括基体贡献项和纤维贡献项,两项结合方式或为乘积形式[40, 42, 44, 47]或为相加形式[38-39, 41, 43, 45-46]:

表 5 纤维混凝土(FRC)劈拉强度预测模型Table 5. Models for predicting the splitting tensile strength of fibre reinforced concrete (FRC)Parameter Equation Note Ref. f′c,Vf fspf=0.58(f′c)0.5+3.02Vf f′c⩽ [38] f_{\rm{c}}^{\prime},{V_{\rm{f}}},L,{d_{\rm{f}}} {f_{\rm{spf}}} = 0.83{(f_{\rm{c}}^{\prime})^{0.47}}\left(\dfrac{{ - 2}}{{1 + {{(0.125 R_{\mathrm{i}})}^{0.8}}}} + 3\right) \begin{gathered} R_{\mathrm{i}}{\text{ = }}{V_{\rm{f}}}L/{d_{\rm{f}}} \\ f_{\rm{c}}^{\prime} \leqslant 150\;{\text{MPa}} \\ \end{gathered} [40] f_{\rm{c}}^{},{V_{\rm{f}}} f_{\rm{spf}}=0.63(f_{\mathrm{c}})^{0.5}+3.01V_{\rm{f}}-0.02V_{\rm{f}}^2 {f_{\rm{c}}} \leqslant 100\;{\text{MPa}} [39] f_{\rm{c}}^{},{V_{\rm{f}}},L,{d_{\rm{f}}},{b_{\rm{f}} } {f_{\rm{spf}}} = 0.47{(f_{\rm{c}}^{})^{0.5}} + 4.2 F \begin{gathered} F{\text{ = }}{V_{\rm{f}}}{{\text{b}}_{\rm{f}}}L/{d_{\rm{f}}} \\ 41 \leqslant f_{\rm{c}}^{} \leqslant 115\;{\text{MPa}} \\ \end{gathered} [41] f_{\rm{cf} }^{},{V_{\rm{f}} },L,{d_{\rm{f}} } {f_{\rm{spf} }} = {({f_{\rm{cf} }})^{0.5}}\left(0.6 + 0.4{V_{\rm{f}}}\dfrac{L}{{{d_{\rm{f}} }}}\right) 4 \leqslant {f_{\rm{cf} }} \leqslant 120\;{\text{MPa}} [42] f_{\rm{cf} }^{},{V_{\rm{f}} },L,{d_{\rm{f}} },{b_{\rm{f}}} {f_{\rm{spf} }} = 0.095\left[{f_{\rm{cf} }} + 10\sqrt F \left(3 - \dfrac{{20}}{{{f_{\rm{cf} }}}}\right)\right] F{\text{ = }}{V_{\rm{f}} }{{\text{b}}_{\rm{f}}}L/{d_{\rm{f}}} [43] f_{\rm{cf} }^{},{V_{\rm{f}}},L,{d_{\rm{f}}},{b_{\rm{f}}} {f_{\rm{spf}}} = {({f_{\rm{cf} }})^{0.5}}\left(0.94{V_{\rm{f}} }\dfrac{L}{{{d_{\rm{f}}}}}{b_{\rm{f}} } + 0.67\right) 120 \leqslant {f_{\rm{cf} }} \leqslant 200\;{\text{MPa}} [44] Notes: fc'—Characteristic compressive strength of plain concrete; fc— Measured compressive strength of plain concrete; fcf—Measured compressive strength of FRC; Vf—Fibre volume fraction; L—Fibre length; df—Fibre diameter; bf—Bond factor; fspf—Splitting tensile strength of FRC; Ri—Reinforcing index; F—Fibre factor. {f}_{{\mathrm{sp}}}=U({f}'_{{\mathrm{c}}}) G(R_{\mathrm{i}}) (2) 或

f_{\mathrm{sp}}=U(f_{\mathrm{c}}')+G(R_{\mathrm{i}}) (3) 其中:fsp为混凝土劈拉强度;fc'为混凝土轴压强度标准值;U(fc')为基体贡献项,常采用以fc'为自变量的幂函数,JSCE和FIB规范采用的指数为0.67[48-49],而ACI规范采用的指数为0.5[50-51];G(Ri)为纤维贡献项,是以Ri为自变量的函数,多采用幂函数或多项式函数;参数Ri (Reinforcing index)为纤维影响系数,可表示为

{R_{\text{i}}} = \frac{{V_{{\mathrm{f}}} }L} {d_{{\mathrm{f}}} } (4) 其中:Vf为纤维体积掺量;L为纤维长度;df为纤维直径。在预测纤维混凝土强度、弹性模量、泊松比以及坍落度时,采用型如Vf(L/df)α或ndLα/dfβ (nd为单位体积纤维数量,a和β均为拟合系数)的纤维影响系数可以获得较好的拟合效果[52]。

4.2 现有模型预测效果

采用预测值/实验值之比的统计参数和积分绝对误差(Integral absolute error,IAE)评估了现有FRC劈拉强度预测公式对MFRC劈拉强度的预测效果,其统计参数见表6。IAE由下式计算:

表 6 FRC模型对MFRC劈拉强度的预测效果Table 6. Evaluation of FRC models for predicting the splitting tensile strength of MFRCRatio of predicted value and test value IAE/% Ref. Average SD CoV/% 0.83 0.14 16 19.8 [38] 1.32 0.14 10 30.5 [40] 0.98 0.16 16 12.6 [39] 0.92 0.13 15 13.5 [41] 1.19 0.12 10 18.5 [42] 1.28 0.16 13 27.5 [43] 1.34 0.13 10 33.5 [44] 1.00 0.08 8 6.0 Eq. (5) 1.02 0.15 15 7.4 Eq. (6) Notes: SD—Standard deviation; IAE—Integral absolute error. \mathrm{IAE}=\sum_{ }^{ }\frac{\left| {{O_{\rm{i}}} - {P_{\rm{i}}}} \right|}{\displaystyle\sum_{ }^{ }O_{\mathrm{i}}} (5) 其中:Oi为实验值;Pi为预测值。IAE小于10%,代表模型预测效果较好[40]。如表6所示,各模型预测效果不一,其预测值与实验值之比的平均值在0.83~1.34,IAE在12.6%~33.5%之间。

4.3 MFRC劈拉强度预测公式

参考现有FRC模型的特征和基本形式,经过试算及优选,建议以下MFRC劈拉强度预测模型:

{f_{{\mathrm{sp}}}} = 0.53{(f_{\mathrm{c}}^{})^{0.5}} + 8.58{V_{\mathrm{f}}}{L^{0.51}}{\left(\frac{\psi }{A}\right)^{0.056}} (6) 其中,ψ和A分别为粗纤维的截面周长及截面积,因此该模型适用于任意截面形状的粗纤维。考虑到式(5)较为复杂,经过试算也可以采用以下较为简单的表达式:

f_{\mathrm{sp}}=(f_{\mathrm{c}})^{0.67}\left(\text{0}\text{.28}+0.021V_{\mathrm{f}}L\frac{\psi}{A}\right) (7) 当粗纤维掺量为0vol%时,公式(6)退化为普通混凝土劈拉强度预测公式:

{f_{{\mathrm{sp}}}} = {\text{0}}{\text{.28}}{(f_{\mathrm{c}}^{})^{0.67}} (8) 其形式与JSCE[48]和FIB[49]规范中普通混凝土劈拉强度预测公式相同:

f_{\mathrm{sp}}=\text{0}\text{.23}(f_{\mathrm{c}}^{ }\mathrm{'})^{0.67},\begin{array}{*{20}{c}} & 20\; \text{MPa}\leqslant f_{\mathrm{c}}^{ }\mathrm{'}\leqslant\end{array}80\; \text{MPa} (9) f_{\mathrm{sp}}=\text{0}\text{.3}(f_{\mathrm{c}}^{ }\mathrm{'})^{0.67},\begin{array}{*{20}{c}} & f_{\mathrm{c}}^{ }\mathrm{'}\leqslant\end{array}50\; \text{MPa} (10) 式(6)中的拟合系数0.28 处于JSCE和FIB规范公式中的拟合系数0.23~0.3之间。

本文所提式(5)和式(6)的预测效果见图11。式(5)的R2为0.75,IAE为5.96%,式(6)的R2为0.70,IAE为7.4%,总体预测效果较好。值得注意的是,由于砂石等原材料的性能差异,部分试件的抗压性能低于预期。然而,这些实验数据仍被纳入数据库和预测公式推导中。一方面,尽管抗压强度数据存在误差,劈裂强度数据仍然具有价值。另一方面,在实际应用中,砂石骨料来源不同所带来的性能差异也应在数据库中得到体现。在进一步研究中,建议扩大实验规模以研究更广泛的实验参数范围对数据结果的影响。同时,预测公式中应考虑除抗压强度外的更多指标。

5. 结 论

(1)添加粗纤维降低了混凝土拌合物的流动性,坍落度随粗纤维掺量提升而降低。例如,在配比一混凝土中掺入2vol%体积掺量的粗纤维后,混凝土坍落度从220 mm降至140 mm。纤维掺量较高且长度较长时,其“棚架”效应可能会影响混凝土的浇筑质量。

(2)粗纤维的掺入对轴压强度有轻微不利影响,粗纤维过厚会造成混凝土强度明显降低。例如,在配比一混凝土中,纤维厚度从1.2 mm提升至2.2 mm时,混凝土轴压强度从74.5 MPa降至65.5 MPa。

(3)粗纤维的掺入提升了混凝土的劈拉强度。在配比二混凝土中,粗纤维掺量从0vol%提升至1.5vol%时,劈拉强度由3.5 MPa提升至4.9 MPa,提升了40%。

(4)对于本文的粗纤维混凝土试验数据,所提出的劈拉强度公式的积分绝对误差(IAE)为5.96%~7.40%,总体预测效果较好。

致谢:感谢广东工业大学提供的场地和试验设备。

-

图 2 锂离子纤维电池:(a) 空心卷绕纤维电池结构示意图及制备[7];(b) 不锈钢纤维(SSFs)基底纤维电池制备[8];(c) 同轴结构锂离子纤维电池[9];(d) 纤维状锂空气电池结构及制备[10];(e-i) 卷绕制备电极;(e-ii) 包缠制备纤维电池[11];(f) 棉纱基底的锂空气电池[12];(g) 高电解质容量的同轴锂离子电池[13]

RGO—Redox graphene; CNT—Carbon nanotubes; CVD—Chemical vapor deposition; LMO—Lithium manganate; LCO—Lithium cobalt oxide; PVDF—Polyvinylidene difluoride

Figure 2. Fiber-sharped lithium-ion batteries: (a) Schematic illustration of hollow wound fiber battery structure and preparation process[7]; (b) Stainless steel fibre (SSFs) substrate fiber-sharped battery preparation[8]; (c) Coaxial structure lithium-ion fiber-sharped battery[9]; (d) Fiber-sharped lithium-air battery structure and preparation[10]; (e-i) Winding preparation of electrodes; (e-ii) Double wrapping preparation of fiber-sharped battery[11]; (f) Lithium-air battery used cotton yarn substrate[12]; (g) Coaxial lithium-ion battery with high electrolyte capacity[13]

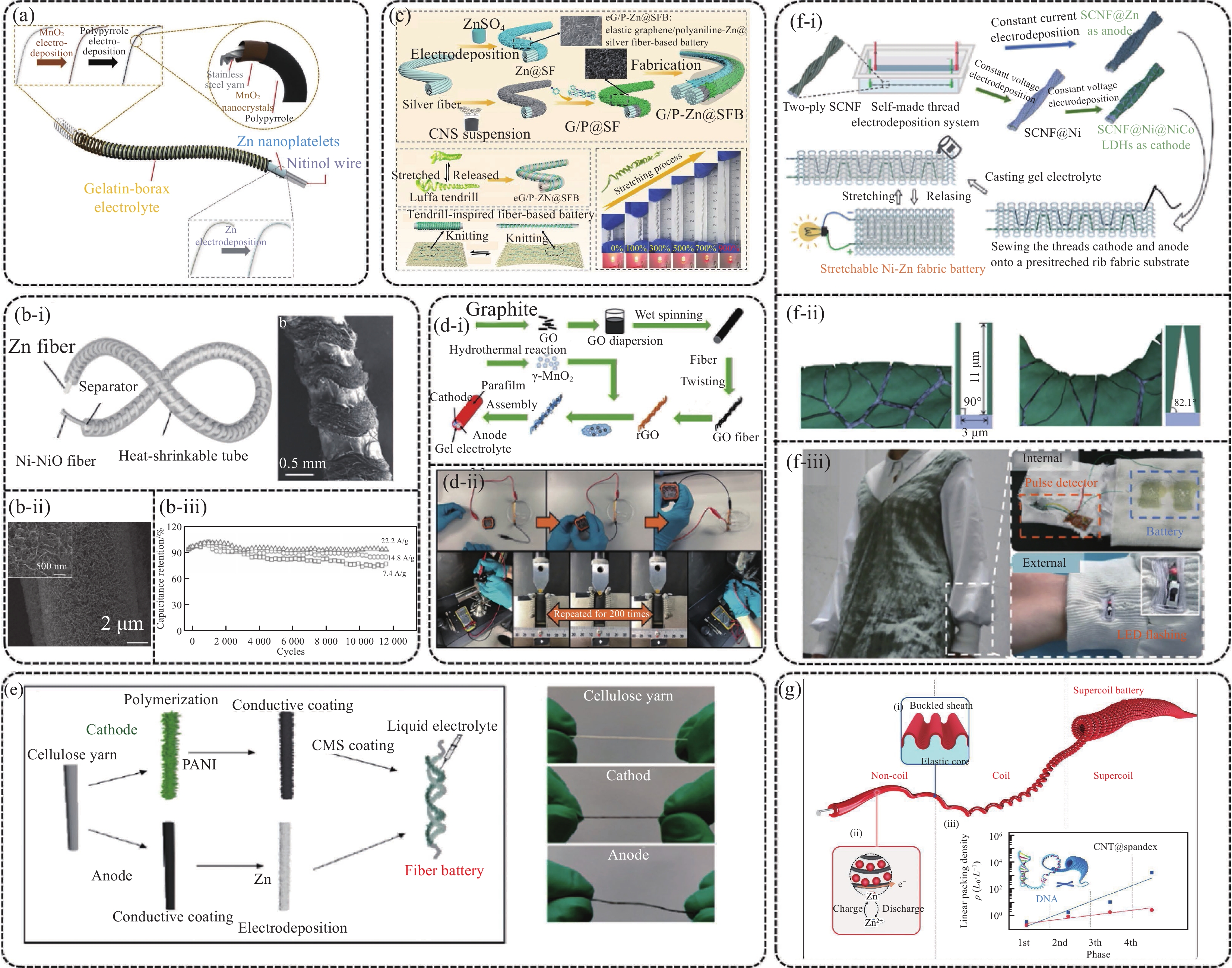

图 3 (a) 不锈钢丝(SS)基底锌离子电池[14];(b-i) 全固态镍锌纤维电池结构及SEM图像;(b-ii) 多孔Ni-NiO纳米片异质结构;(b-iii) 电池循环充放电寿命[15];(c) 超高形变纤维电池[16];(d-i) 湿法纺丝制备纤维电池;(d-ii) 锌离子纤维电池柔性展示[17];(e) 纤维素基底纤维电池[18];(f-i) 螺旋状多组分芯壳结构的纤维电池制备;(f-ii) 活性材料的裂纹结构;(f-iii) 纤维电池为脉冲系统供电示意图[19];(g) 超螺旋结构锌离子纤维电池[20]

eG/P-Zn@SFB—Elastic graphene/polyaniline-Zn@silver fiber-based battery; GNS—Graphene nanoplatelets; GO—Graphene oxide; rGO—Reduced graphene oxide; SCNF—Separately sewing core–shell silver-coated nylon fiber; LDHs—Layered double hydroxides; PANI—Polyaniline; CMS—Carboxymethyl cellulose; L0—Initial linear length; L—Linear length after stacking

Figure 3. (a) Stainless steel (SS) substrate zinc-ion battery[14]; (b-i) All-solid-state Ni-Zn fiber battery structure and SEM images; (b-ii) Porous Ni-NiO nanosheet heterostructure; (b-iii) Battery cyclic charge/discharge life[15]; (c) Ultra-high deformation fiber-sharped battery[16]; (d-i) Wet spinning preparation of fiber-sharped battery; (d-ii) Flexible demonstration of fiber-sharped ZIBs[17]; (e) Cellulose substrate fiber-sharped battery[18]; (f-i) Preparation of fiber battery with spiral multi-component core-shell structure; (f-ii) Cracked structure of active material; (f-iii) Schematic illustration of fiber-sharped battery to power a pulsed system[19]; (g) Super spiral structure zinc-ion fiber battery[20]

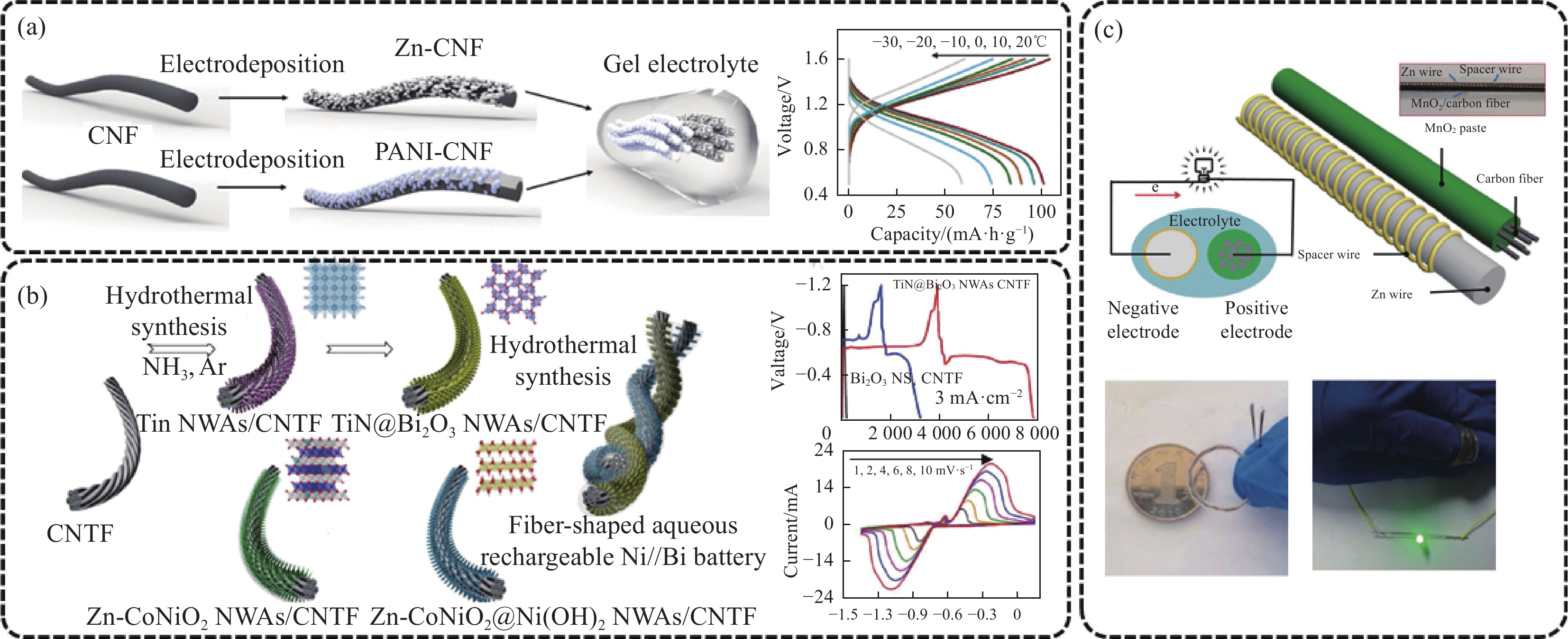

图 4 (a) 碳纳米纤维(CNFs)基底纤维电池示意图及电化学性能[21];(b) 碳纳米管纤维(CNTFs)基底纤维电池示意图及电化学性能[22];(c) 碳纤维(CFs)基底纤维电池示意图及柔性展示[23]

PANI—Polyaniline; NWAs—Nanowire arrays; NSs—Nanosheets

Figure 4. (a) Schematic illustration and electrochemical performance of carbon nanofibers (CNFs) substrate fiber-sharped battery[21]; (b) Schematic illustration and electrochemical performance of carbon nanotube fibers (CNTFs) substrate fiber-sharped battery[22]; (c) Schematic illustration and flexible demonstration of carbon fiber (CFs) substrate fiber-sharped battery[23]

图 5 新型材料基纤维电池:(a) 加捻型Zn/Ag2O电池示意图[24];(b-i) 自支撑金属有机骨架(MOF)纤维电池;(b-ii) 无黏结电极的优势[25];(c) 自组装钴材料纤维电池[26];(d-i) 液态金属基纤维电池结构示意图;(d-ii) 液态金属电池电流调控[27];(e) 超大变形的液态金属基纤维电池结构示意图[28];(f) 钒酸铵基纤维电池结构示意图[29]

NC—Nnanocarbon; PEDOT : PSS—Poly(3,4-ethylenedioxythiophene) : poly(styrenesulfonate); PVA—Polyvinyl alcohol

Figure 5. New material-based fiber-sharped battery: (a) Schematic illustration of twisted Zn/Ag2O battery[24]; (b-i) Self-standing metal-organic frameworks (MOF) fiber-sharped battery; (b-ii) Advantages of unbonded electrodes[25]; (c) Self-assembled cobalt material fiber-sharped battery[26]; (d-i) Schematic illustration of liquid metal-based fiber-sharped battery structure; (d-ii) Liquid metal battery current regulation[27]; (e) Structure schematic illustration of oversized deformed liquid metal-based fiber-sharped battery[28]; (f) Schematic illustration of ammonium vanadate-based fiber-sharped battery[29]

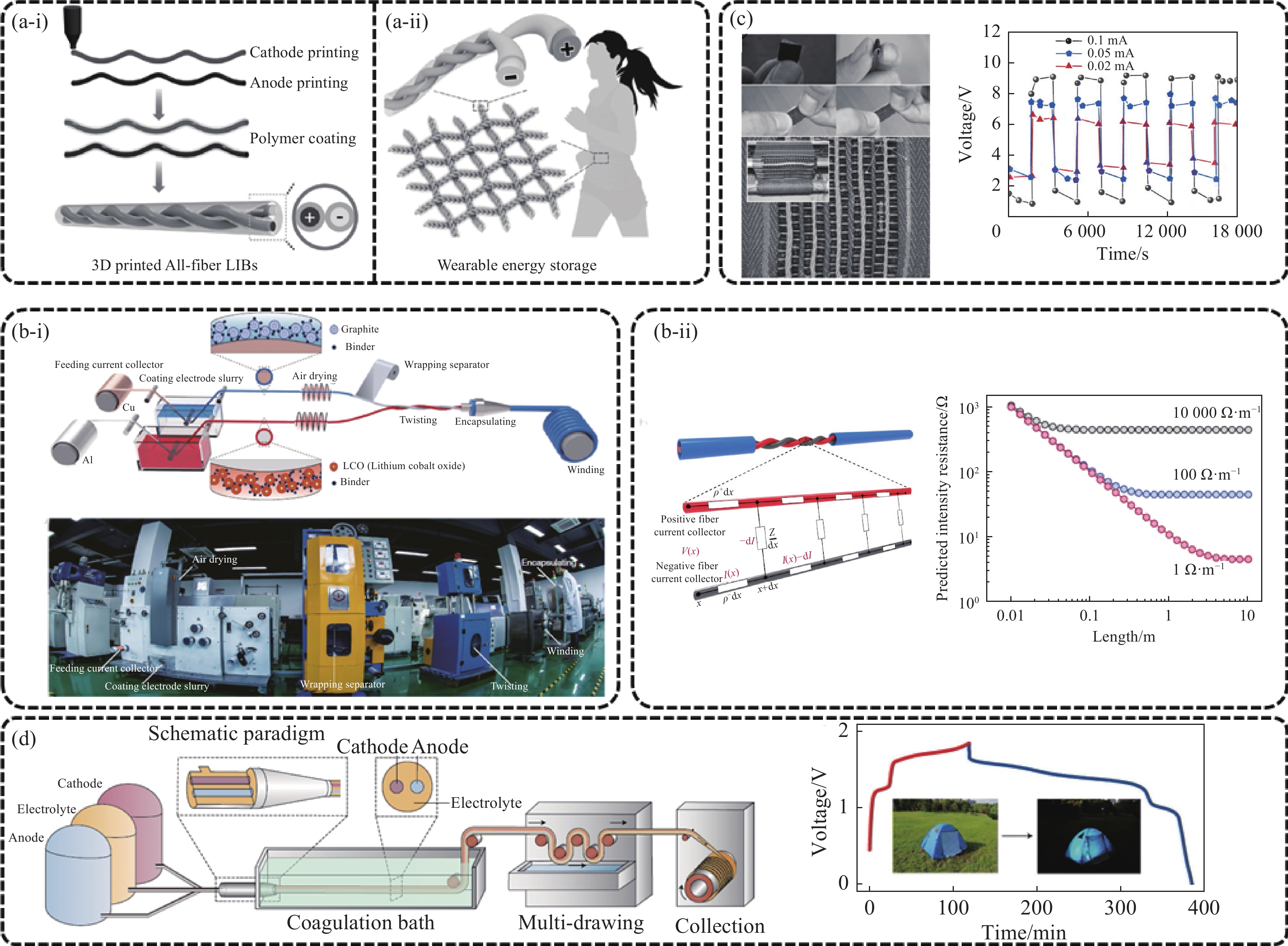

图 6 纤维电池生产工艺:(a-i) 3D打印纤维电池;(a-ii)纤维电池与纺织品融合示意图[33];(b-i)上浆涂覆工艺生产纤维电池;(b-ii)纤维电池内阻与长度理论模型[34];(c)拉伸挤出纤维状电池示意图及电化学性能[35];(d)溶液挤压工艺制备纤维电池示意图[36]

LIBs—Lithium-ion batteries; V(x)—Voltage between the fiber electrodes; ρ+dx—Resistances of positive for each unit length of dx; ρ–dx—Resistances of negative for each unit length of dx; I—Current; Z—Polarization resistance

Figure 6. Fiber-sharped battery production process: (a-i) 3D printed fiber-sharped battery; (a-ii) Schematic illustration of fiber-sharped battery fusion with textile[33]; (b-i) Fiber-sharped battery production by sizing and coating process; (b-ii) Theoretical model of fiber-sharped battery internal resistance and length[34]; (c) Schematic illustration and electrochemical properties of stretch extruded fiber-sharped battery[35]; (d) Schematic illustration of fiber-sharped battery solution extrusion process[36]

表 1 不同类型纤维电池性能评价

Table 1 Summary of fiber-shaped batteries discussed in this review

Fiber devices Cathode/Anode Specific capacity Energy density Capacity retention/Cycles/

Current densityRef. LIBs Al

/Ni-Sn@Cu– − − [7] RGO@S@SSF/

Li wire762.5 mA·h/g

(0.1 A/s)− 50.3%/100/0.1 A/s [8] N-CNTs@Ti

/CO29292.3 mA·h/g

(250 mA/g)− 100%/45/250 mA/g [10] Si@CNT/

CNT1250 mA·h/g

(0.1 mA)512 W·h/kg 80%/100/0.1 mA [9] CNT-LMO/

CNT-Si@CNT0.22 mA·h/cm

(0.4 A/s)0.75 mW·h/cm 94%/100/1 A/s [11] RuO2@N-CNTs/

O21981 mA·h/g

(320 mA/g)− − [12] Graphite-CNT/

Graphite-CNT353 mA·h/g

(0.5 A/s)144 mW·h/cm3 99.8%/500/1 A/s [13] ZIBs MnO2@PPy@SS

/Zn@SS174.2 mA·h/g

(0.5 A/s)− 60%/1000/2 A/s [14] Ni-NiO/

Zn237.8 µA·h/cm3

(3.7 A/g)6.6 µW·h/cm2 96.6%/10000/3.7 A/g [15] Zn@SF/

G@P@SF32.5 mA·h/cm3

(10 mA/cm3)36 mW·h/cm3 76.5%/1000/10 mA [16] MnO2@rGO

/Zn230 mA·h/g

(0.4 A/s)− 80%/200/0.4 A/s [17] PANI@Cellulse

/Zn@Cellulse189.1 mA·h/g

(2 A/g)61.1 W·h/kg 91.9%/1000/5 A/g [18] SCNF@Ni@NiCo/

SCNF@Zn19.15 μA·h/cm

(0.1 mA/cm)249.2 W·h/kg 50%/500/ 9.2 A/g [19] MnO2-CNT/

Zn-CNT@spandex0.029 mA·h/cm

(0.05 mA/cm)− − [20] Zn@CNF/

PANI@CNF145 mA·h/g

(0.2 A/g)58.8 W·h/kg 75.1%/1000/0.2 A/g [21] Zn-CoNiO2@Ni(OH)2/TiN@Bi2O3 314.96 mW·h/cm3

(3 mA/cm2)20.04 W/cm3 88.6%/5000/ 3 mA/cm2 [22] Zn

/MnO2@A/s166 mA·h/g

(70 mA/g)0.2 mW·h/cm Not rechargeable [23] MOFs CNTF-NCA-Ag2O

/Zn1.03 mA·h/cm2

(0.5 mA/cm2)14.4 mW·h/cm2 79.5%/200/0.5 mA [24] Ni-MOF-74@CNTF/

Zn108 mW·h/cm3

(0.5 A/cm3)186.28 mW·h/cm3 87.66%/1000/2 A/cm3 [25] Co3O4 NSs@CNTF/

Zn@CNTF158.70 mA·h/g

(1 A/g)− 97.27%/10000/1 A/g [26] Liquid

metalEGILM

/O2214.8 mA·h/g

(0.5 mA/cm2)303.2 mW·h/g − [27] PANI/

Ga68In22Sn10223.9 mA·h/g

(0.2 A/g)4300 mW/g 80.3%/500/ 0.2 A/g [28] NH4+ CF@NH4V4O10/

CF@PANI167 mA·h/g

(0.1 A/g)− 73.3%/1000/0.1 A/g [29] -

[1] MIN X, SUN B, CHEN S, et al. A textile-based SnO2 ultra-flexible electrode for lithium-ion batteries[J]. Energy Storage Materials,2019,16:597-606. DOI: 10.1016/j.ensm.2018.08.002

[2] LIANG S, YAN W, WU X, et al. Gel polymer electrolytes for lithium ion batteries: Fabrication, characterization and performance[J]. Solid State Ionics,2018,318:2-18. DOI: 10.1016/j.ssi.2017.12.023

[3] CHO Y G, HWANG C, CHEONG D S, et al. Gel/solid polymer electrolytes characterized by in situ gelation or polymerization for electrochemical energy systems[J]. Advanced Materials,2019,31(20):1804909. DOI: 10.1002/adma.201804909

[4] CHOI Y S, PHARR M, OH K H, et al. A simple technique for measuring the fracture energy of lithiated thin-film silicon electrodes at various lithium concentrations[J]. Journal of Power Sources,2015,294:159-166. DOI: 10.1016/j.jpowsour.2015.06.063

[5] NOSSOL E, SOUZA V H R, ZARBIN A J G. Carbon nano-tube/Prussian blue thin films as cathodes for flexible, transparent and ITO-free potassium secondary battery[J]. Journal of Colloid and Interface Science,2016,478:107-116. DOI: 10.1016/j.jcis.2016.05.056

[6] YU C, LI X, MA T, et al. Silicon thin films as anodes for high-performance lithium-ion batteries with effective stress relaxation[J]. Advanced Energy Materials,2012,2(1):68-73. DOI: 10.1002/aenm.201100634

[7] KWON Y H, WOO S W, JUNG H R, et al. Cable-type flexible lithium ion battery based on hollow multi-helix electrodes[J]. Advanced Materials,2012,24(38):5192-5197. DOI: 10.1002/adma.201202196

[8] LIU R, LIU Y, CHEN J, et al. Flexible wire-shaped lithium-sulfur batteries with fibrous cathodes assembled via capillary action[J]. Nano Energy,2017,33:325-333. DOI: 10.1016/j.nanoen.2016.12.049

[9] ZHANG Y, JIAO Y, LU L, et al. An ultraflexible silicon-oxygen battery fiber with high energy density[J]. Angewandte Chemie International Edition,2017,56(44):13741-13746. DOI: 10.1002/anie.201707840

[10] LI Y, ZHOU J, ZHANG T, et al. Highly surface-wrinkled and N-doped CNTs anchored on metal wire: A Novel fiber-shaped cathode toward high-performance flexible Li-CO2 batteries[J]. Advanced Functional Materials,2019,29(12):1808117. DOI: 10.1002/adfm.201808117

[11] WENG W, SUN Q, ZHANG Y, et al. Winding aligned carbon nanotube composite yarns into coaxial fiber full batteries with high performances[J]. Nano Letters,2014,14(6):3432-3438. DOI: 10.1021/nl5009647

[12] LIN X, KANG Q, ZHANG Z, et al. Industrially weavable metal/cotton yarn air electrodes for highly flexible and stable wire-shaped Li-O2 batteries[J]. Journal of Materials Chemistry A,2017,5(7):3638-3644. DOI: 10.1039/C6TA09806A

[13] SONG H, JEON S Y, JEONG Y. Fabrication of a coaxial high performance fiber lithium-ion battery supported by a cotton yarn electrolyte reservoir[J]. Carbon,2019,147:441-450. DOI: 10.1016/j.carbon.2019.02.081

[14] WANG Z, RUAN Z, LIU Z, et al. A flexible rechargeable zinc-ion wire-shaped battery with shape memory function[J]. Journal of Materials Chemistry A,2018,6(18):8549-8557. DOI: 10.1039/C8TA01172A

[15] ZENG Y, MENG Y, LAI Z, et al. An ultrastable and high-performance flexible fiber-shaped Ni-Zn battery based on a Ni-NiO heterostructured nanosheet cathode[J]. Advanced Materials,2017,29(44):1702698. DOI: 10.1002/adma.201702698

[16] LI M, LI Z, YE X, et al. Tendril-inspired 900% ultrastretching fiber-based Zn-ion batteries for wearable energy textiles[J]. ACS Applied Materials & Interfaces,2021,13(14):17110-17117.

[17] SUBJALEARNDEE N, HE N, CHENG H, et al. Gamma(γ)-MnO2/rGO fibered cathode fabrication from wet spinning and dip coating techniques for cable-shaped Zn-ion batteries[J]. Advanced Fiber Materials,2022, 4 (3):1-18.

[18] YI H, MA Y, ZHANG S, et al. Robust aqueous Zn-ion fiber battery based on high-strength cellulose yarns[J]. ACS Sustainable Chemistry & Engineering,2019,7(23):18894-18900.

[19] WU M, XIA Z, MAO Z, et al. Stretchable Ni-Zn fabric battery based on sewable core-shell SCNF@Ni@NiCo LDHs thread cathode for wearable smart garment[J]. Journal of Materials Science,2021,56(17):10537-10554. DOI: 10.1007/s10853-021-05936-9

[20] LEE J M, CHUN S, SON W, et al. DNA-inspired, highly packed supercoil battery for ultra-high stretchability and capacity[J]. Nano Energy,2021,85:106034. DOI: 10.1016/j.nanoen.2021.106034

[21] CONG Z, GUO W, ZHANG P, et al. Wearable antifreezing fiber-shaped Zn/PANI batteries with suppressed Zn dendrites and operation in sweat electrolytes[J]. ACS Applied Materials & Interfaces,2021,13(15):17608-17617.

[22] LI Q, JING S, YONG Z, et al. Towards ultrahigh-energy-density flexible aqueous rechargeable Ni//Bi batteries: Free-standing hierarchical nanowire arrays core-shell heterostructures system[J]. Energy Storage Materials,2021,42:815-825. DOI: 10.1016/j.ensm.2021.08.032

[23] YU X, FU Y, CAI X, et al. Flexible fiber-type zinc-carbon battery based on carbon fiber electrodes[J]. Nano Energy,2013,2(6):1242-1248. DOI: 10.1016/j.nanoen.2013.06.002

[24] LI C, ZHANG Q, SONG F, et al. An ultra-high endurance and high-performance quasi-solid-state fiber-shaped Zn-Ag2O battery to harvest wind energy[J]. Journal of Materials Chemistry A,2019,7(5):2034-2040. DOI: 10.1039/C8TA10807B

[25] MAN P, HE B, ZHANG Q, et al. A one-dimensional channel self-standing MOF cathode for ultrahigh-energy-density flexible Ni-Zn batteries[J]. Journal of Materials Chemistry A,2019,7(48):27217-27224. DOI: 10.1039/C9TA11759H

[26] LU Y, ZHANG H, LIU H, et al. Electrolyte dynamics engi-neering for flexible fiber-shaped aqueous zinc-ion battery with ultralong stability[J]. Nano Letters,2021,21(22):9651-9660. DOI: 10.1021/acs.nanolett.1c03455

[27] LIU G, KIM J Y, WANG M, et al. Soft, highly elastic, and discharge-current-controllable eutectic gallium-indium liquid metal-air battery operated at room temperature[J]. Advanced Energy Materials,2018,8(16):1703652. DOI: 10.1002/aenm.201703652

[28] FU H, LIU G, XIONG L, et al. A shape-variable, low-temperature liquid metal-conductive polymer aqueous secondary battery[J]. Advanced Functional Materials,2021,31(50):2107062. DOI: 10.1002/adfm.202107062

[29] LI H, YANG J, CHENG J, et al. Flexible aqueous ammonium-ion full cell with high rate capability and long cycle life[J]. Nano Energy,2020,68:104369. DOI: 10.1016/j.nanoen.2019.104369

[30] XU Y, ZHAO Y, REN J, et al. An all-solid-state fiber-shaped aluminum-air battery with flexibility, stretchability, and high electrochemical performance[J]. Angewandte Chemie International Edtion,2016,55(28):7979-7982. DOI: 10.1002/anie.201601804

[31] WANG H, ZHANG S, DENG C. In situ encapsulating metal oxides into core-shell hierarchical hybrid fibers for flexible zinc-ion batteries toward high durability and ultrafast capability for wearable applications[J]. ACS Applied Materials & Interfaces,2019,11(39):35796-35808.

[32] ZHAI S, WANG N, TAN X, et al. Interface-engineered dendrite-free anode and ultraconductive cathode for durable and high-rate fiber Zn dual-ion microbattery[J]. Advanced Functional Materials,2021,31(13):2008894. DOI: 10.1002/adfm.202008894

[33] WANG Y, CHEN C, XIE H, et al. 3D-printed all-fiber Li-ion battery toward wearable energy storage[J]. Advanced Functional Materials,2017,27(43):1703140. DOI: 10.1002/adfm.201703140

[34] HE J, LU C, JIANG H, et al. Scalable production of high-performing woven lithium-ion fibre batteries[J]. Nature,2021,597(7874):57-63. DOI: 10.1038/s41586-021-03772-0

[35] LIU Y, GORGUTSA S, SANTATO C, et al. Flexible, solid electrolyte-based lithium battery composed of LiFePO4 cathode and Li4Ti5O12 anode for applications in smart textiles[J]. Journal of the Electrochemical Society,2012,159(4):A349-A356. DOI: 10.1149/2.020204jes

[36] LIAO M, WANG C, HONG Y, et al. Industrial scale production of fibre batteries by a solution-extrusion method[J]. Nature Nanotechnology,2022, 17 (4):1-6.

-

期刊类型引用(3)

1. 范浩博,豆书亮,李垚. 二氧化钒智能热控涂层光学结构原理及研究进展. 材料导报. 2025(01): 34-43 .  百度学术

百度学术

2. 张新宇,徐慧妍,杨立凯,王尚,杨帅军,蒋绪川. 智能窗用二氧化钒基复合结构薄膜的制备及研究进展. 复合材料学报. 2025(02): 679-691 .  本站查看

本站查看

3. 张丽萍,孟晓荣,宋锦峰,杜金晶. VO_2@KH550/570@PS复合薄膜的制备及其热致相变性能. 化工学报. 2024(09): 3348-3359 .  百度学术

百度学术

其他类型引用(7)

-

下载:

下载: