Preparation and mechanical properties of multi-walled carbon nanotubes-bacterial cellulose composite films

-

摘要: 开发和利用绿色生物质材料能够降低石油基聚合物的消耗,但与单根细菌纤维素(BC)相比,BC薄膜表现出较低的力学性能,限制了其应用领域。为协同提高BC复合薄膜的强度和韧性,本文以BC为基体,通过对其碱处理、2, 2, 6, 6-四甲基哌啶-氮-氧化物(TEMPO)氧化处理得到TEMPO氧化的BC(TOBC),并引入羧基化多壁碳纳米管(CNT)作为增强体,采用真空抽滤技术制备出CNT-TOBC复合薄膜,着重探究了CNT的添加对TOBC薄膜力学性能和微观形貌的影响,并探讨其增强增韧机制。研究结果表明:当CNT的添加量为7.5wt%时,CNT-TOBC复合薄膜的力学性能最佳,其断裂应力、伸长率及韧性分别为174 MPa、10.83%和12.01 MJ·m−3,相比纯的TOBC薄膜分别提高了56.76%、144.47%和295.07%,这主要归因于CNT与TOBC间的氢键相互作用、CNT内在高强度及外在增韧机制。研究结果为提高复合材料的界面结合和力学性能提供了一种切实可行的方法,并进一步拓宽了TOBC在柔性电子衬底、智能包装等领域的应用。Abstract: Exploiting and utilizing green biomass materials can reduce the consumption of petroleum-based polymers. However, compared with the single bacterial cellulose (BC), BC film always exhibits the poor mechanical properties, which limits its application. In this study, in order to improve the strength and toughness of BC composite films synergistically, BC was treated by alkaline and 2, 2, 6, 6-tetramethyl-1-piperidinyloxy (TEMPO) oxidation to obtain TEMPO-oxidized BC (TOBC), which was utilized as matrix to prepare the TOBC-based composite films enhanced by carboxylic multi-walled carbon nanotubes (CNT) via vacuum filtrating technique. The effect of CNT amounts on the mechanical properties and microstructure of TOBC-based composite films were investigated emphatically and the strengthening and toughening mechanism was also discussed. The results show that: When CNT content is 7.5wt%, CNT-TOBC composite films exhibit the best mechanical properties. The tensile stress, elongation and toughness of CNT-TOBC-7.5wt% composite films are 174 MPa, 10.83% and 12.01 MJ·m−3, respectively, which are increased by 56.76%, 144.47% and 295.07% compared with the pure TOBC films, respectively. The improvement is attributed to the hydrogen bonding interaction between CNT and TOBC, the high strength of CNT, as well as the external toughening mechanism. This study provides a feasible method to improve the interface bonding and mechanical properties of composites, and further broadens the application of TOBC in flexible electronic substrates, intelligent packaging and other fields.

-

Keywords:

- nanofibers /

- carbon nanotubes /

- composite films /

- strength /

- toughness /

- green biomass materials

-

随着经济的发展,石油基聚合物等不可再生资源的消耗量迅速增加。然而,这些石油基聚合物在环境中难以生物降解和再生,不仅会导致自然资源的枯竭,还会严重污染生态系统,进一步危害人类健康。因此,利用和开发可降解和可再生资源对环境保护具有重要意义,而利用绿色生物质材料作为替代品是一种有效的策略。

纤维素由于具有丰富的羟基、可生物降解性和低成本的特点,已成为世界上应用最广泛的生物质材料[1-3]。纳米纤维素具有较大的比表面积、良好的分散性和丰富的活性基团,可作为复合膜、水凝胶及气凝胶的增强相。纳米纤维素可分为纤维素纳米纤丝(NFC)、纤维素纳米晶和细菌纤维素(BC),其中BC因其具有更高比强度、结晶度和纯度等特点,因而受到研究者的广泛关注[4-5]。然而,BC纳米复合薄膜的力学性能远低于单根纳米纤维。高强度和高韧性是大多数纳米复合材料难以同时获得的重要和关键问题,这决定了其应用场景、领域和性能。因此,深入研究BC复合薄膜的界面增强增韧机制,提高其力学性能对拓宽其应用领域尤为重要。

复合材料的界面强化策略包括氢键[6-8]、离子键[9-10]、共价键[11-12]及π-π交联[13-14]。E等[15]将硼砂和聚乙烯醇(PVA)引入到四甲基哌啶氮氧化物(TEMPO)氧化的纳米纤维素(TOCN)基体中,通过真空抽滤法制备出三元复合薄膜。PVA与TOCN间的氢键相互作用及硼砂、TOCN和PVA间的共价交联作用协同提高了TOCN基复合薄膜的强度和韧性。Wang等[16]受珍珠层的启发,通过蒸发诱导自组装技术构筑了具有高强度、高韧性和抗疲劳性能的蒙脱土(MMT)/PVA/NFC复合薄膜,成功地证明了MMT、PVA与NFC间形成的多重氢键具有协同增强增韧作用。

细而强的碳纳米管(CNT)由于其超高的强度和模量而成为复合材料增强材料的首选,其还具有优异的电学和热学性能,应用前景广阔[17-19]。Zhu等[20]采用真空辅助层层自组装法制备出高强高模的CNT/芳纶纳米纤维(ANF)复合薄膜。结果表明CNT与ANF间存在多种界面相互作用,包括氢键和π-π相互作用是导致复合薄膜力学性能改善的关键因素。

因此,本文首先对BC进行碱处理和TEMPO氧化处理得到的TEMPO氧化细菌纤维素(TOBC),然后将其与高强度的、羧基化的CNT复合通过真空辅助自组装法制备出CNT-BC复合薄膜,并分别采用FTIR、XED、XPS、多功能高低温控制试验机和场发射高分辨率扫描电镜对其化学、结晶结构、力学性能及微观形貌进行表征。重点研究CNT的添加量对TOBC薄膜力学性能的影响,并探究了其增强增韧机制。本文为提高复合材料的界面结合和力学性能提供了一种切实可行的方法,并进一步拓宽了TOBC在柔性电子衬底、智能包装等领域的应用。

1. 实验材料及方法

1.1 原材料

细菌纤维素凝胶块(BC):含量为2.01wt%,尺寸为2 cm×2 cm×2 cm,桂林奇宏科技有限公司;NaOH(AR)、次氯酸钠(NaClO,有效氯含量为8wt%)、四甲基哌啶氮氧化物(TEMPO,98wt%)、NaBr(AR),上海阿拉丁生化科技股份有限公司;去离子水,实验室纯水/超纯水一体机;羧基化的碳纳米管(CNT):多壁,含量为2wt%,长度为40~50 μm,直径为5~40 nm,羧基含量为2.56wt%,南京先丰纳米材料科技有限公司;纤维素酯滤膜:孔径为0.1 μm,上海市新亚净化器件厂。

1.2 实验方法

1.2.1 BC悬浮液的制备

40 g的NaOH溶解于1000 mL的去离子水中,得到1 mol·L−1的NaOH溶液;将1 g(绝干)的BC凝胶块剪成小块,置于NaOH溶液中煮沸处理1 h,除去杂质后,得到透明的BC凝胶[21];将其在豆浆机(AKL-AJL-PB0830,中山市奔迈电器有限公司)中高速剪切处理2次,获得均匀的BC悬浮液,然后用去离子水洗涤至pH为中性。

1.2.2 BC的TEMPO氧化处理

在经步骤1.2.1处理后的BC悬浮液中依次加0.016 g TEMPO、0.1 g NaBr和5 mmol NaClO[22],于pH为10.5的条件下反应3 h后,加入少量的无水乙醇终止反应,然后通过真空抽滤除去多余的反应剂,用去离子水调节其pH至中性,得到TEMPO氧化的BC分散液(TOBC)。

1.2.3 CNT-TOBC复合薄膜的制备

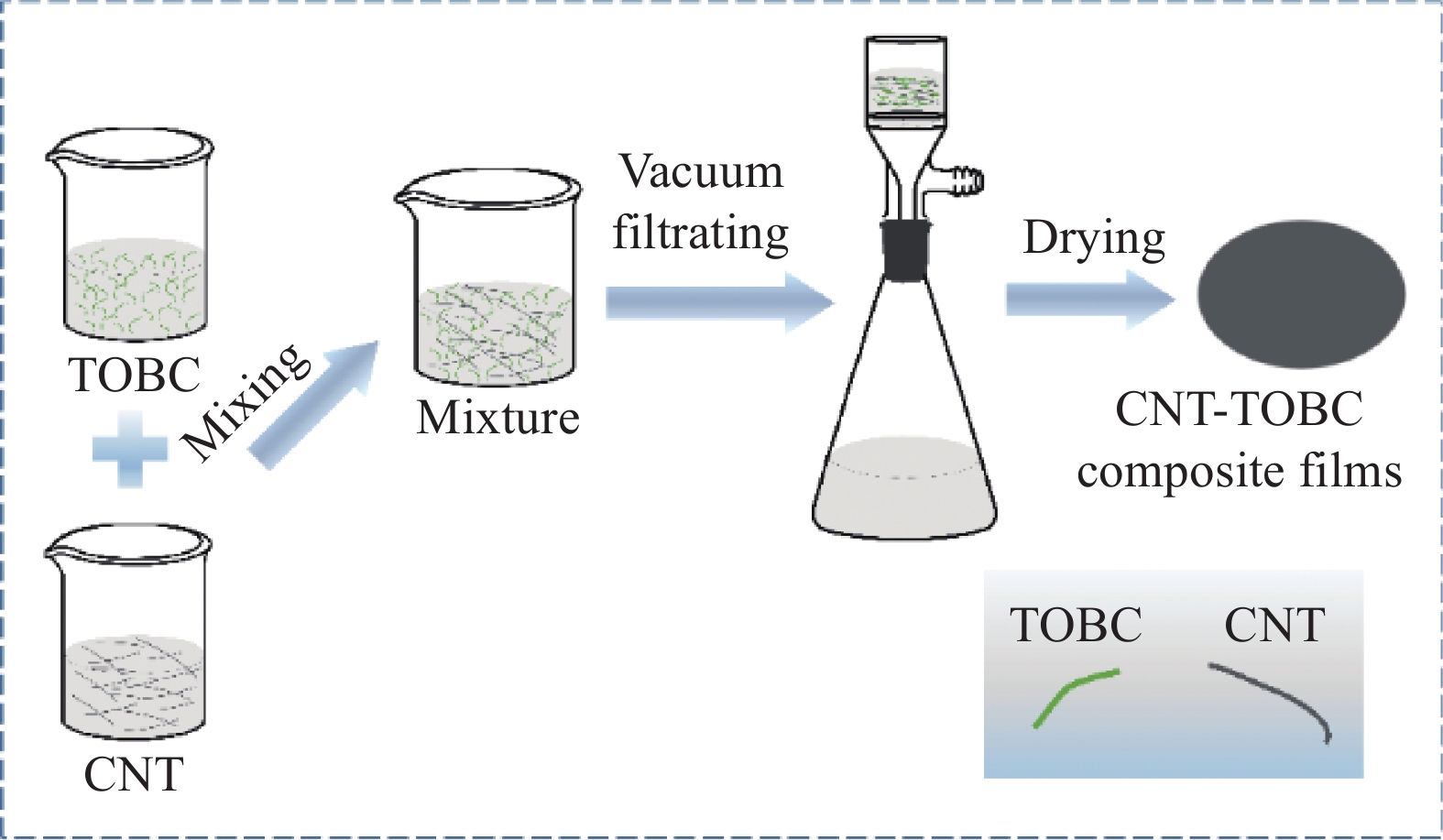

CNT的添加量分别为0wt%、2.5wt%、5wt%、7.5wt%和10wt%(参考Zhu等[20]的实验方法,并且保证CNT-TOBC复合薄膜总质量为50 mg),分别被命名为TOBC、CNT-TOBC-2.5wt%、CNT-TOBC-5wt%、CNT-TOBC-7.5wt%和CNT-TOBC-10wt%,如表1所示。以CNT-TOBC-2.5wt%样品为例,分别称取48.75 mg的BC和1.25 mg的CNT,加水稀释至溶液浓度为1 mg·mL−1,超声处理20 min后,置于磁力搅拌器(ZHCL-GS,上海越众仪器设备有限公司)中搅拌12 h,得到均匀的CNT-TOBC悬浮液;将其倒入真空抽滤装置中进行真空抽滤(混合纤维素滤膜,孔径0.1 μm),得到CNT-TOBC复合湿凝胶,然后置于油压机(TD11-H,咸阳通达轻工设备有限公司)上在30 MPa下压榨3 min,并于105℃下干燥15 min,最终获得CNT-TOBC-2.5wt%复合薄膜,其制备流程如图1所示。不同CNT添加量的CNT-TOBC复合薄膜的定量均为4 mg·cm−2,其厚度和紧度如表2所示。

表 1 不同CNT添加量的羧基化多壁碳纳米管-TEMPO氧化的细菌纤维素(CNT-TOBC)复合薄膜的配方Table 1. Formulations of carboxylic multi-walled carbon nanotubes-TEMPO-oxidized bacterial cellulose (CNT-TOBC) composite films with different CNT contentsSample TOBC/wt% CNT/wt% TOBC 100.0 0.0 CNT-TOBC-2.5wt% 97.5 2.5 CNT-TOBC-5wt% 95.0 5.0 CNT-TOBC-7.5wt% 92.5 7.5 CNT-TOBC-10wt% 90.0 10.0 Note: TEMPO—2, 2, 6, 6-tetramethyl-1-piperidinyloxy. 表 2 不同CNT添加量的CNT-TOBC复合薄膜的厚度和紧度Table 2. Thickness and tightness of CNT-TOBC composite films with different CNT contentsSample Thickness/μm Tightness/(g·cm−3) TOBC 28 1.43 CNT-TOBC-2.5wt% 30 1.33 CNT-TOBC-5wt% 31 1.29 CNT-TOBC-7.5wt% 32 1.25 CNT-TOBC-10wt% 34 1.18 1.3 分析与表征

(1) 对所有的薄膜样品采用傅里叶红外光谱仪(FTIR,VERTEX 70,德国Bruker公司)的ATR附件模式进行测试,用于表征样品的化学结构和官能团变化。扫描范围为4000~400 cm−1,分辨率为4 cm−1。

(2) 纯TOBC薄膜和CNT-TOCN-7.5wt%复合薄膜的化学结构采用X射线光电子能谱(XPS,AXIS SUPRA,英国Kratos Analytical公司)进行测试,测试条件为单色Al Kα源(1486.6 eV)。

(3) 所有样品的结晶结构是用X射线衍射仪分析仪(XRD,D8 Advance,德国Bruker公司)进行测试的。Cu Kα (0.01541 nm)辐射,扫描范围为5°~50°,扫描速率为0.02°·min−1。TOBC基体的结晶指数计算方法参考Segal法[23],CNT薄膜的结晶指数根据Jade软件计算而得。

(4) 所有试样的力学性能均在伺服高低温万能试验机(AI-700-NGD,中国高特威尔公司)上进行。样品尺寸为5 mm×30 mm,夹距为10 mm,加载速度为0.5 mm·min−1,载荷为500 N。通过对应力-应变曲线进行积分来表征所有复合薄膜的韧性。

(5) TOBC和CNT水分散液及所有复合薄膜断面的微观形貌是通过场发射扫描电子显微镜(FESEM,S-4800,日本Hitachi公司)来进行观察。采用Image J软件从TOBC和CNT水分散液的SEM图像上随机选取100根纤维进行直径的测量和分析,分别得出TOBC和CNT的直径分布。

2. 结果与讨论

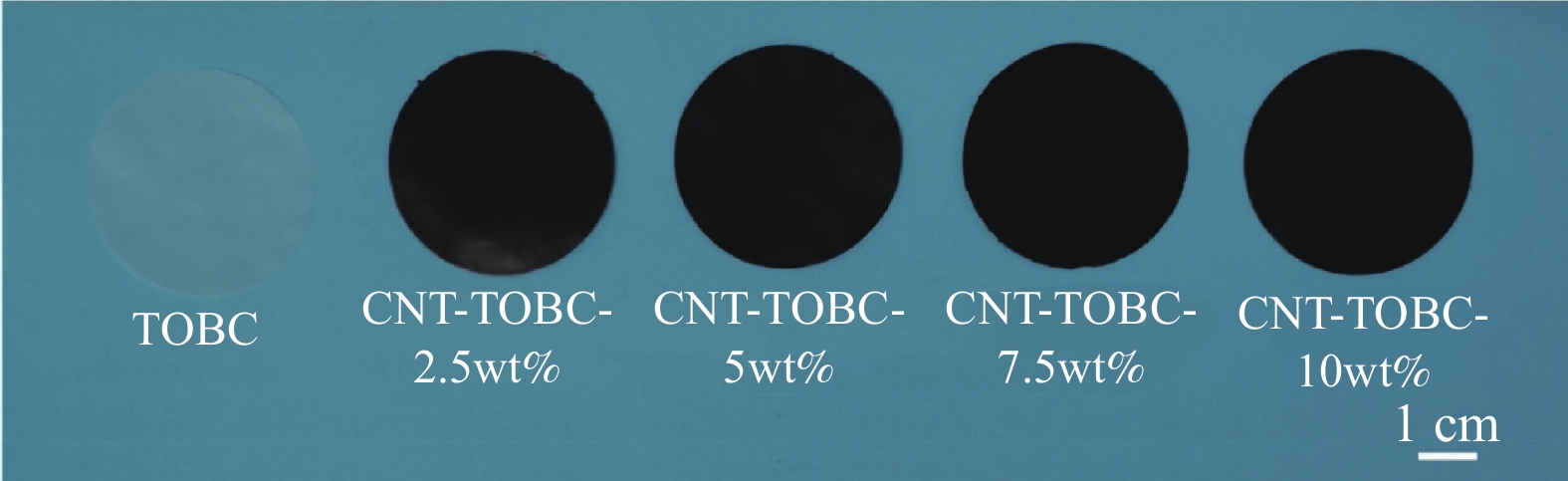

首先,对BC进行剪碎、碱处理和TEMPO氧化处理后得到TOBC。将BC凝胶块剪碎是为了增大其比表面积,增加与碱液的接触面积;碱处理是为了更好地除去BC形成过程中残留的杂质;之后对其进行TEMPO氧化处理是为了将纤维素分子C6位上的羟基(—OH)选择性地氧化为羧基负离子(—COO−),增加其静电排斥,从而将获得直径更小、水分散性更好的TOBC纳米纤维。图2分别为TOBC和CNT水分散液的光学照片、SEM图像和直径分布图。TOBC水分散液呈现出透明状,且具有明显的丁达尔效应,其平均直径约为22 nm,长度为10~20 μm,长径比约为500~1000;CNT水分散液呈现出黑色透明状,也表现出明显的丁达尔效应,其平均直径约为21 nm,长度为40~50 μm,具有比TOBC更大的长径比,约为2000~2500。之后,将CNT引入到TOBC时,CNT上的—COOH和TOBC上的—OH、—COO−形成了氢键相互作用,并通过真空辅助层层自组装法获得了CNT-TOBC复合薄膜,不同CNT添加量的CNT-TOBC复合薄膜的光学照片如图3所示。可以看出,纯的TOBC薄膜呈现均匀、透明的外观;而CNT-TOBC复合薄膜表现出平坦、光滑的外观,并且其颜色随着CNT添加量的增多逐渐加深。

2.1 不同CNT添加量的CNT-TOBC复合薄膜的化学结构

为了揭示CNT与TOBC间的相互作用,对不同CNT添加量的CNT-TOBC复合薄膜进行了FTIR和XPS分析。图4为不同CNT添加量的CNT-TOBC复合薄膜的FTIR图谱。纯的TOBC薄膜在3338 cm−1处宽而强的振动峰归属于—OH的伸缩振动,而其在2900 cm−1处的振动峰归属于C—H的对称伸缩振动,其在1649 cm−1处的振动峰归属于—OH的弯曲振动和C—O的伸缩振动[24]。不同CNT添加量的CNT-TOBC复合薄膜也同样表现出了纤维素的特征峰。并且随着CNT添加量的增多,CNT-TOBC复合薄膜的FTIR图谱中纤维素特征峰的强度呈现出下降的趋势,从侧面反映出CNT与TOBC间存在相互作用。据文献[7, 25]报道,—OH的峰位受氢键形成的影响很大,并倾向于向低波数移动。与纯的TOBC薄膜的FTIR图谱相比,CNT-TOBC-2.5wt%、CNT-TOBC-5wt%、CNT-TOBC-7.5wt%和CNT-TOBC-10wt%复合薄膜的—OH伸缩振动峰从3338 cm−1分别红移到3336 cm−1、3334 cm−1或3332 cm−1,表明在TOBC和CNT之间形成了分子间氢键相互作用。

图5(a)和图5(b)分别为纯的TOBC薄膜和CNT-TOBC-7.5wt%复合薄膜的高分辨率C1s XPS图谱,表3为其对应的结合能。可以看出,纯TOBC薄膜的C1s XPS图谱在284.6 eV、286.4 eV、287.8 eV和288.8 eV处的分峰分别代表TOBC中的C—C、C—OH、C—O—C和O—C=O。同时,CNT-TOBC-7.5wt%复合薄膜在284.6 eV、286.6 eV、288.0 eV和289.2 eV处的分峰归属于C—C、C—OH、C—O—C和O—C=O。与纯的TOBC薄膜相比,CNT-TOBC-7.5wt%复合薄膜上的C—OH、C—O—C和O—C=O分峰对应的结合能的值均有所增大,这可以归因于CNT与TOBC间的氢键相互作用[26]。除此之外,CNT-TOBC-7.5wt%复合薄膜在285.1 eV处的分峰是CNT上碳原子sp2杂化所形成的C=C,其进一步证明CNT与TOBC的成功复合。

表 3 TOBC薄膜和CNT-TOBC-7.5wt%复合薄膜XPS分峰对应的结合能Table 3. XPS peak binding energy assignments of TOBC film and CNT-TOBC-7.5wt% composite filmFunctional group Binding energy/eV TOBC C—C 284.6 C—OH 286.4 C—O—C 287.8 O—C═O 288.8 CNT-TOBC-7.5wt% C—C 284.6 C═C 285.1 C—OH 286.6 C—O—C 288.0 O—C═O 289.2 2.2 不同CNT添加量下的TOBC基体的结晶结构

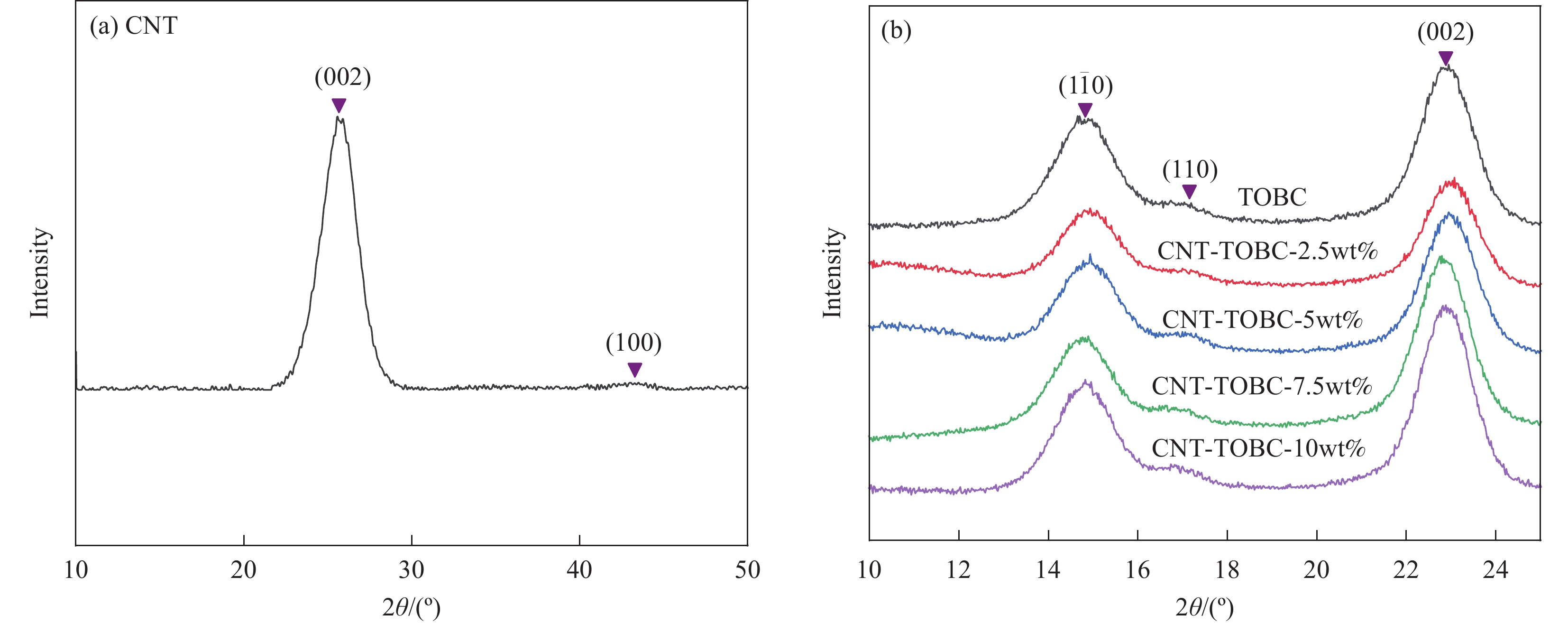

图6(a)、图6(b)分别为CNT薄膜和不同CNT添加量的CNT-TOBC复合薄膜的XRD图谱。从图6(a)中可以看出,CNT分别在25.7°和43.2°处分别出现了一个尖锐和一个微弱的衍射峰,对应(002)和(100)晶面,经计算其结晶度为96.16%。从图6(b)中可以看出,不同的CNT-TOBC复合薄膜在2θ为14.8°、17.2°和22.8°时均出现了3个特征衍射峰,对应于TOBC上的(

1ˉ10 )、(110)和(002)晶面,属于典型的纤维素I的晶型结构,表明CNT的添加不会改变TOBC的晶体结构。表4为不同CNT添加量下TOBC基体的结晶指数。纯的TOBC薄膜的结晶指数为90.42%,远高于从植物纤维中提取出的NFC。随着CNT添加量的增多,CNT-TOBC复合薄膜中TOBC基体的结晶指数呈现出整体上升的趋势,最高可达94.02%。这可能是由于CNT的添加会起到异相成核的作用,诱导TOBC在其表面的吸附,并促进TOBC的成核过程,最终在CNT与TOBC间的界面处生长出高结晶度的TOBC,因此提高了TOBC基体的结晶指数[27]。同时,CNT与TOBC间界面黏附的提高也有利于CNT-TOBC复合薄膜力学性能的增加。表 4 不同CNT添加量下的TOBC基体的结晶指数Table 4. Crystalline indexes of TOBC matrix with different CNT contentSample Crystalline index/% TOBC 90.42 CNT-TOBC-2.5wt% 89.74 CNT-TOBC-5wt% 91.71 CNT-TOBC-7.5wt% 93.35 CNT-TOBC-10wt% 94.02 2.3 CNT的添加量对CNT-TOBC复合薄膜力学性能的影响

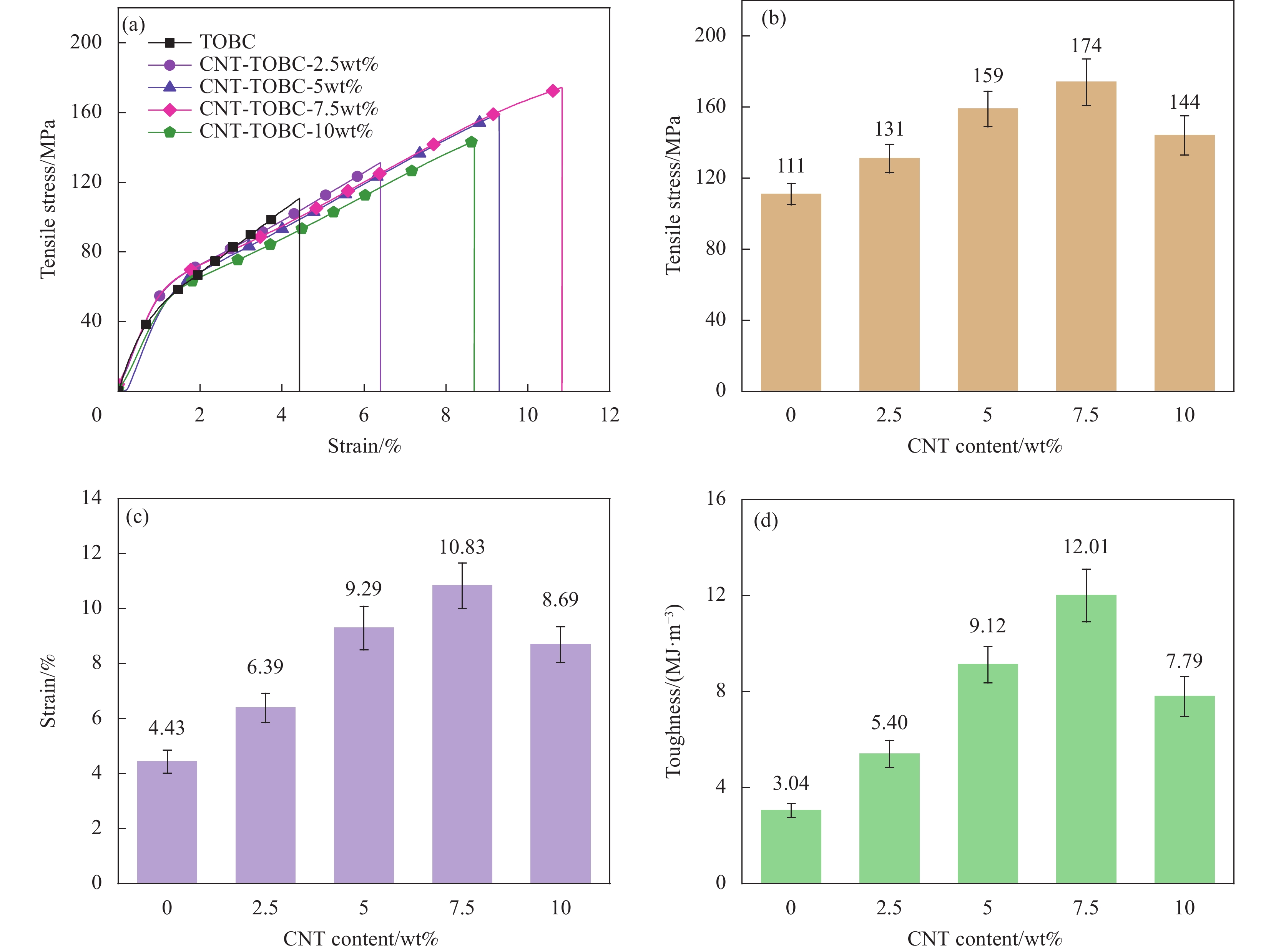

图7分别为不同CNT添加量的CNT-TOBC复合薄膜的应力-应变曲线、断裂应力、断裂伸长率和韧性对比结果。可以看出,纯的TOBC薄膜的断裂应力为111 MPa,断裂伸长率为4.43%,断裂韧性为3.04 MJ·m−3。随着CNT的添加量从2.5wt%增加到10wt%,CNT-TOBC复合薄膜的力学性能呈现出先增大后减小的趋势,其断裂应力从131 MPa增加到174 MPa再降低到144 MPa,断裂伸长率从6.39%增加到10.83%再降低到8.69%,断裂韧性从5.40 MJ·m−3增加到12.01 MJ·m−3再降低到7.79 MJ·m−3。其中,当CNT的添加量为7.5wt%时,CNT-TOBC-7.5wt%复合薄膜的力学性能最佳,其断裂应力、断裂伸长率及断裂韧性分别为174 MPa、10.83%和12.01 MJ·m−3,相比纯的TOBC薄膜分别提高了56.76%、144.47%和295.07%。CNT-TOBC复合薄膜力学强度的提高主要归因于CNT内在高强高模的特性、TOBC与CNT间的氢键相互作用及TOBC与CNT间强的界面黏附;而其断裂伸长率的提高主要归因于大长径比的CNT在复合薄膜的断裂过程中会产生更大的滑移。当CNT的添加量适当(低于7.5wt%)时,其的引入可以同时提高TOBC复合薄膜的拉伸强度和断裂伸长率,并且随着CNT添加量的增加,这种增强增韧的效果会得到提高;CNT-TOBC复合薄膜中存在着TOBC间较强的氢键作用、TOBC与CNT间强的氢键作用及CNT间较弱的氢键作用。当CNT的添加量过量(超过7.5wt%)时,CNT间较弱的氢键相互作用在体系中所占据的比例会逐渐增大,削弱了CNT-TOBC复合薄膜的界面相互作用,进而造成复合薄膜力学性能的下降,但仍高于纯的TOBC薄膜。

2.4 增强增韧机制

为进一步探究CNT-TOBC复合薄膜力学性能的增强增韧机制,对不同CNT添加量的CNT-TOBC复合薄膜断裂截面的微观形貌进行了分析,如图8所示。在纯的TOBC薄膜的断裂面(图8(a))上可以观察到较多的TOBC纤维的滑移、拉断和拔出。然而,在CNT-TOBC复合薄膜的断裂截面上不仅可以观察到TOBC和CNT纤维的滑移、断裂和拔出,这种现象使CNT-TOBC复合薄膜在断裂过程中产生更大的应变和消耗更多的能量;而且还可以看出长径比大的CNT使CNT-TOBC复合薄膜断裂过程中所产生的微裂纹产生更多的裂纹偏转和桥联作用(图8中虚线框),进一步提高了断裂过程所需要的载荷,这属于外在增韧机制。特别是CNT-TOBC-7.5wt%复合薄膜的断裂截面(图8(d)、8(e))上的裂纹桥联和偏转最密集,因此其表现出最佳的力学性能。而CNT-TOBC-10wt%复合薄膜的断裂截面(图8(f))较杂乱疏松,可能是由于CNT添加量较大使复合薄膜的分散性和匀度下降,因而其力学性能有所下降。综上所述,适量添加CNT可以协同提高CNT-TOBC复合薄膜的强度和韧性。

3. 结 论

(1) 采用FTIR和XPS测试表明,羧基化多壁碳纳米管(CNT)与2, 2, 6, 6-四甲基哌啶-氮-氧化物(TEMPO)氧化的细菌纤维素(TOBC)间存在着氢键相互作用。

(2) 当CNT的添加量为7.5wt%时,CNT-TOBC-7.5wt%复合薄膜的力学性能最佳,其断裂应力、断裂伸长率及断裂韧性分别为174 MPa、10.83%和12.01 MJ·m−3,相比纯的TOBC薄膜分别提高了56.76%、144.47%和295.07%。

(3) CNT-TOBC-7.5wt%复合薄膜的增强增韧机制主要为TOBC与CNT间形成的氢键相互作用、CNT内在高强高模的特性及协同的外在增韧机制。

-

表 1 不同CNT添加量的羧基化多壁碳纳米管-TEMPO氧化的细菌纤维素(CNT-TOBC)复合薄膜的配方

Table 1 Formulations of carboxylic multi-walled carbon nanotubes-TEMPO-oxidized bacterial cellulose (CNT-TOBC) composite films with different CNT contents

Sample TOBC/wt% CNT/wt% TOBC 100.0 0.0 CNT-TOBC-2.5wt% 97.5 2.5 CNT-TOBC-5wt% 95.0 5.0 CNT-TOBC-7.5wt% 92.5 7.5 CNT-TOBC-10wt% 90.0 10.0 Note: TEMPO—2, 2, 6, 6-tetramethyl-1-piperidinyloxy. 表 2 不同CNT添加量的CNT-TOBC复合薄膜的厚度和紧度

Table 2 Thickness and tightness of CNT-TOBC composite films with different CNT contents

Sample Thickness/μm Tightness/(g·cm−3) TOBC 28 1.43 CNT-TOBC-2.5wt% 30 1.33 CNT-TOBC-5wt% 31 1.29 CNT-TOBC-7.5wt% 32 1.25 CNT-TOBC-10wt% 34 1.18 表 3 TOBC薄膜和CNT-TOBC-7.5wt%复合薄膜XPS分峰对应的结合能

Table 3 XPS peak binding energy assignments of TOBC film and CNT-TOBC-7.5wt% composite film

Functional group Binding energy/eV TOBC C—C 284.6 C—OH 286.4 C—O—C 287.8 O—C═O 288.8 CNT-TOBC-7.5wt% C—C 284.6 C═C 285.1 C—OH 286.6 C—O—C 288.0 O—C═O 289.2 表 4 不同CNT添加量下的TOBC基体的结晶指数

Table 4 Crystalline indexes of TOBC matrix with different CNT content

Sample Crystalline index/% TOBC 90.42 CNT-TOBC-2.5wt% 89.74 CNT-TOBC-5wt% 91.71 CNT-TOBC-7.5wt% 93.35 CNT-TOBC-10wt% 94.02 -

[1] ZHANG C L, CHA R T, ZHANG P, et al. Cellulosic substrate materials with multi-scale building blocks: Fabrications, properties and applications in bioelectronic devices[J]. Chemical Engineering Journal,2022,430(2):132562.

[2] OPERAMOLLA A, MAZZUCA C, CAPODIECI L, et al. Toward a reversible consolidation of paper materials using cellulose nanocrystals[J]. ACS Applied Materials & Interfaces,2021,13(37):44972-44982.

[3] MA Q, WANG K, MOHAWK D, et al. Strong, ductile, transparent, water-resistant cellulose nanofibril composite films via UV-induced inter-cross-linked networks[J]. ACS Sustainable Chemistry & Engineering,2021,9(32):10749-10760.

[4] CHEN C T, QIAN J S, CHEN H W, et al. Molecular origin of the biologically accelerated mineralization of hydroxyapatite on bacterial cellulose for more robust nanocomposites[J]. Nano Letters,2021,21(24):10292-10300. DOI: 10.1021/acs.nanolett.1c03411

[5] 贺玮, 刘晓彤, 郑裕东, 等. 用于空气过滤的改性大豆蛋白-细菌纤维素复合材料的制备及性能[J]. 复合材料学报, 2021, 38(3):843-853. HE Wei, LIU Xiaotong, ZHENG Yudong, et al. Preparation and properties of modified soy protein-bacterial cellulose composites for air filtration[J]. Acta Materiae Compositae Sinica,2021,38(3):843-853(in Chinese).

[6] CHEN K, SHI B, YUE Y H, et al. Binary synergy strengthening and toughening of bio-inspired nacre-like graphene oxide-sodium alginate composite paper[J]. ACS Nano,2015,9(8):8165-8175. DOI: 10.1021/acsnano.5b02333

[7] HUANG H D, LIU C Y, ZHANG L Q, et al. Simultaneous reinforcement and toughening of carbon nanotube/cellulose conductive nanocomposite films by interfacial hydrogen bonding[J]. ACS Sustainable Chemistry & Engineering,2015,3(2):317-324.

[8] 陈科, 岳永海, 郭林. 二元协同增强、增韧仿珍珠母层状氧化石墨烯/海藻酸钠(GO/SA)复合薄膜材料的构建[J]. 中国科技论文, 2016, 11(10):1151-1155. DOI: 10.3969/j.issn.2095-2783.2016.10.016 CHEN Ke, YUE Yonghai, GUO Lin. Construction of binary synergy strengthening and toughening bio-inspired nacre-like graphene oxide/sodium alginate composite paper[J]. China Science Paper,2016,11(10):1151-1155(in Chinese). DOI: 10.3969/j.issn.2095-2783.2016.10.016

[9] LIANG B L, ZHAO H W, ZHANG Q, et al. Ca2+ enhanced nacre-inspired montmorillonite-alginate film with superior mechanical, transparent, fire retardancy, and shape memory properties[J]. ACS Applied Materials & Interfaces,2016,8(42):28816-28823. DOI: 10.1021/acsami.6b08203

[10] GONG S S, CHENG Q F. Bioinspired graphene-based nanocomposites via ionic interfacial interactions[J]. Composites Communications,2018,7:16-22. DOI: 10.1016/j.coco.2017.12.002

[11] AN Z, COMPTON O C, PUTZ K W, et al. Bio-inspired borate cross-linking in ultra-stiff graphene oxide thin films[J]. Advanced Materials,2011,23(33):3842-3846.

[12] DUAN J L, GONG S S, GAO Y, et al. Bioinspired ternary artificial nacre nanocomposites based on reduced graphene oxide and nanofibrillar cellulose[J]. ACS Applied Materials & Interfaces, 2016, 8(16): 10545-10550.

[13] WANG Y, MENG F B, HUANG F, et al. Ultrastrong carbon nanotubes/graphene papers via multiple pi-pi cross-linking[J]. ACS Applied Materials & Interfaces,2020,12(42):47811-47819. DOI: 10.1021/acsami.0c12501

[14] HACOPIAN E F, YANG Y C, NI B, et al. Toughening graphene by integrating carbon nanotubes[J]. ACS Nano,2018,12(8):7901-7910. DOI: 10.1021/acsnano.8b02311

[15] E S F, NING D D, WANG Y F, et al. Ternary synergistic strengthening and toughening of bio-inspired TEMPO-oxidized cellulose nanofibers/borax/polyvinyl alcohol composite film with high transparency[J]. ACS Sustainable Chemistry & Engineering,2020,8(41):15661-15669.

[16] WANG J F, CHENG Q F, LIN L, et al. Synergistic toughening of bioinspired poly(vinyl alcohol)-clay-nanofibrillar cellulose artificial nacre[J]. ACS Nano,2014,8(3):2739-2745. DOI: 10.1021/nn406428n

[17] ZHANG L, ZHANG G, LIU C H, et al. High-density carbon nanotube buckypapers with superior transport and mechanical properties[J]. Nano Letters,2012,12(9):4848-4852. DOI: 10.1021/nl3023274

[18] HAN Y, ZHANG X H, YU X P, et al. Bio-inspired aggregation control of carbon nanotubes for ultra-strong composites[J]. Scientific Reports,2015,5:11533. DOI: 10.1038/srep11533

[19] LIU K, SUN Y H, LIN X Y, et al. Scratch-resistant, highly conductive, and high-strength carbon nanotubebased composite yarns[J]. ACS Nano,2010,4(10):5827-5834. DOI: 10.1021/nn1017318

[20] ZHU J Q, CAO W X, YUE M L, et al. Strong and stiff aramid nanofiber/carbon nanotube nanocomposites[J]. ACS Nano,2015,9(3):2489-2501. DOI: 10.1021/nn504927e

[21] YAO J J, CHEN S Y, CHEN Y, et al. Macrofibers with high mechanical performance based on aligned bacterial cellulose nanofibers[J]. ACS Applied Materials & Interfaces,2017,9(24):20330-20339.

[22] YANG B, ZHANG M Y, LU Z Q, et al. Comparative study of aramid nanofiber (ANF) and cellulose nanofiber (CNF)[J]. Carbohydrate Polymers,2019,208:372-381. DOI: 10.1016/j.carbpol.2018.12.086

[23] SEGAL L, CREELY J J, MARTIN A E, et al. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer[J]. Textile Research Journal,1959,29(10):786-794. DOI: 10.1177/004051755902901003

[24] 周可可, 唐亚丽, 卢立新, 等. 氧化纳米纤维素增强再生纤维素全纤维素复合薄膜的制备及性能[J]. 复合材料学报, 2020, 37(7):1657-1666. ZHOU Keke, TANG Yali, LU Lixin, et al. Preparation and properties of all-cellulose composite films with oxidized cellulose nanofibrils reinforcing regenerated cellulose[J]. Acta Materiae Compositae Sinica,2020,37(7):1657-1666(in Chinese).

[25] ZHANG Q, WAN S J, JIANG L, et al. Bioinspired robust nanocomposites of cooper ions and hydroxypropyl cellulose synergistic toughening graphene oxide[J]. Science China Technological Sciences,2017,60(5):758-764. DOI: 10.1007/s11431-016-0529-3

[26] LIN F C, WANG Z, CHEN J S, et al. A bioinspired hydrogen bond crosslink strategy toward toughening ultrastrong and multifunctional nanocomposite hydrogels[J]. Journal of Materials Chemistry B,2020,8(18):4002-4015. DOI: 10.1039/D0TB00424C

[27] LI C H, GUO J W, JIANG T, et al. Extensional flow-induced hybrid crystalline fibrils (shish) in CNT/PLA nanocomposite[J]. Carbon,2018,129:720-729. DOI: 10.1016/j.carbon.2017.12.063

-

期刊类型引用(2)

1. 刘云鹏,李浩义,李乐,尹晓萱,吴欣玥,周松松. 用于光伏板静电除尘的单壁碳纳米管透明导电薄膜老化性能研究. 电工技术学报. 2025(03): 864-877 .  百度学术

百度学术

2. 陈钦钦,徐兆梅,马廷方,付飞亚,刘向东. 细菌纤维素纳米纤维膜及纤维的制备与性能. 现代纺织技术. 2023(05): 66-75 .  百度学术

百度学术

其他类型引用(3)

-

下载:

下载: