Research progress of flexible electronic devices based on conductive fibers

-

摘要: 柔性电子器件具有优异的灵活性,实现了与服装的无缝集成,在各种实际的可穿戴应用中具有巨大的潜力。一维纤维状电子器件由于其优异的柔韧性、可编织性及舒适性成为智能可穿戴领域的研究热点。首先,综述了用于纤维状柔性电子器件的一维可拉伸电极的研究进展,然后详细介绍了高性能一维纤维状柔性电子器件制备过程中具有代表性的导电材料、制造技术及一维柔性纤维进一步应用于各类电子器件的主要制备方法,另外总结了近年来基于柔性纤维状电子器件在智能可穿戴领域的应用。最后对一维纤维基智能可穿戴电子器件的机遇和挑战进行了批判性思考。Abstract: Flexible electronics have excellent flexibility, enabling seamless integration with clothing, and have great potential in various practical wearable applications. One-dimensional fibrous electronic devices have become a research hotspot in the field of smart wearables due to their excellent flexibility, weavability and comfort. First, the research progress of one-dimensional stretchable electrodes for fiber-like flexible electronic devices is reviewed, and then introduced the high-performance one-dimensional fibrous flexible electronics representative during the preparation of conductive material, manufacturing technology, as well as the further application of the one-dimensional flexible fiber become various main preparation methods for all kinds of electronic devices. Finally, we think critically about the opportunities and challenges of one-dimensional wikis smart wearable electronics.

-

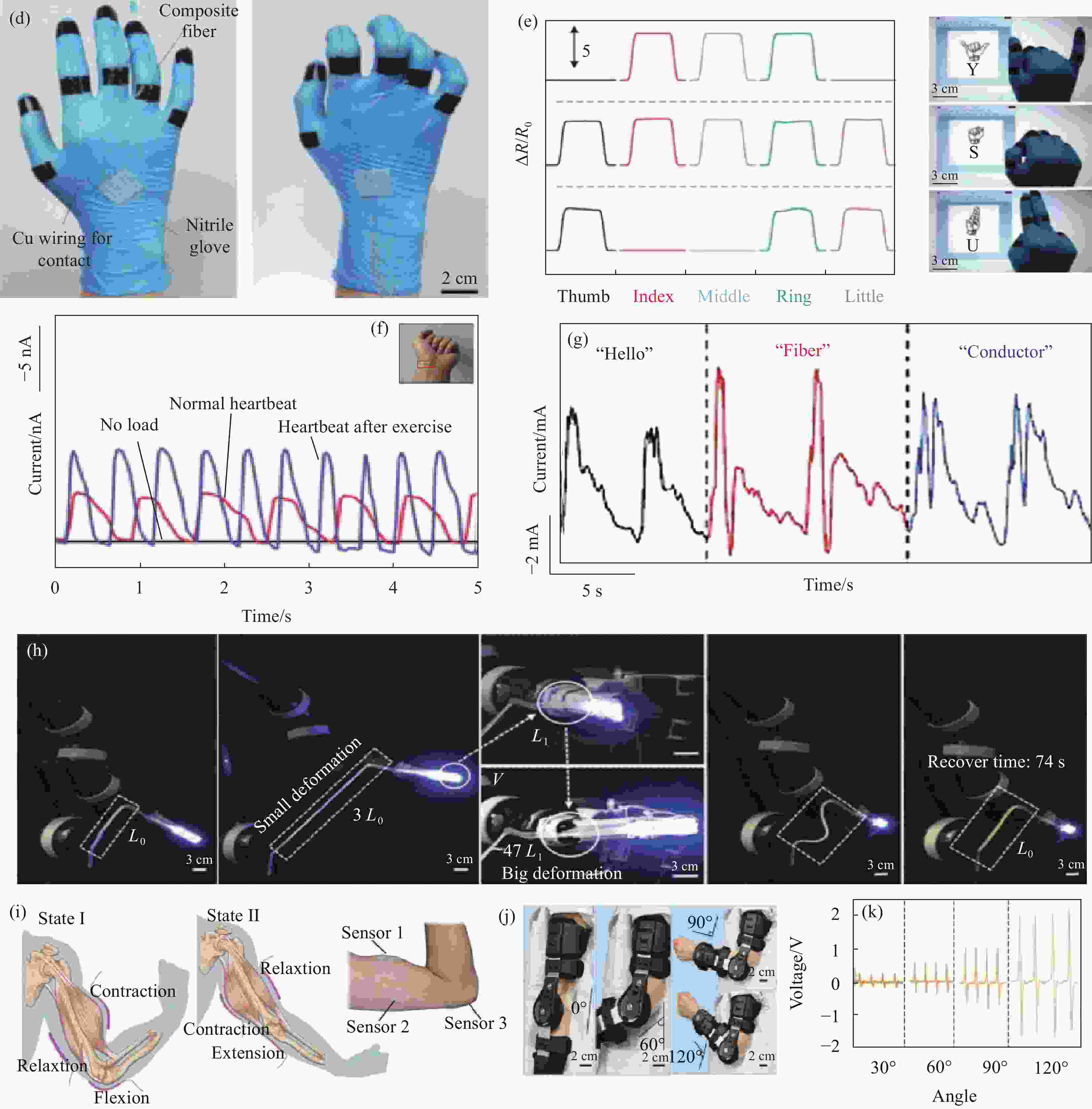

图 1 (a)石墨烯气凝胶纤维和石墨烯/相变材料(PCM)智能纤维的工艺示意图;(b)气凝胶导向智能纤维照片;(c)不同应变下的加卸载曲线(碳纳米管/聚氨酯(CNTs/PU)螺旋纱在900%拉伸下仍具有良好的回收性能);(d)发光二极管(LED)显示螺旋CNTs/PU纱在拉伸过程中具有良好的导电性;(e)应用CNTs/PU螺旋纱作为应变传感器(监测行走过程中的电阻变化及其对各种人体运动表现出快速的信号响应和稳定的电阻重复性)

Sc-CO2—Supercritical carbon dioxide

Figure 1. (a) Process schematics of graphene aerogel fibers and graphene/phase-change material (PCM) smart fibers; (b) Photo of aerogel-guided smart fibers; (c) Loading and unloading curves under different strains (Carbon nanotubes/polyurethane (CNTs/PU) helical yarn still has good recovery performance under 900% stretching); (d) Light emitting diode (LED) shows that the helical CNTs/PU yarn has good electrical conductivity during the stretching process; (e) Application of CNTs/PU helical yarns as strain sensors to monitor resistance changes during walking (They exhibit fast signal responses and stable resistance repeatability to various human motions)

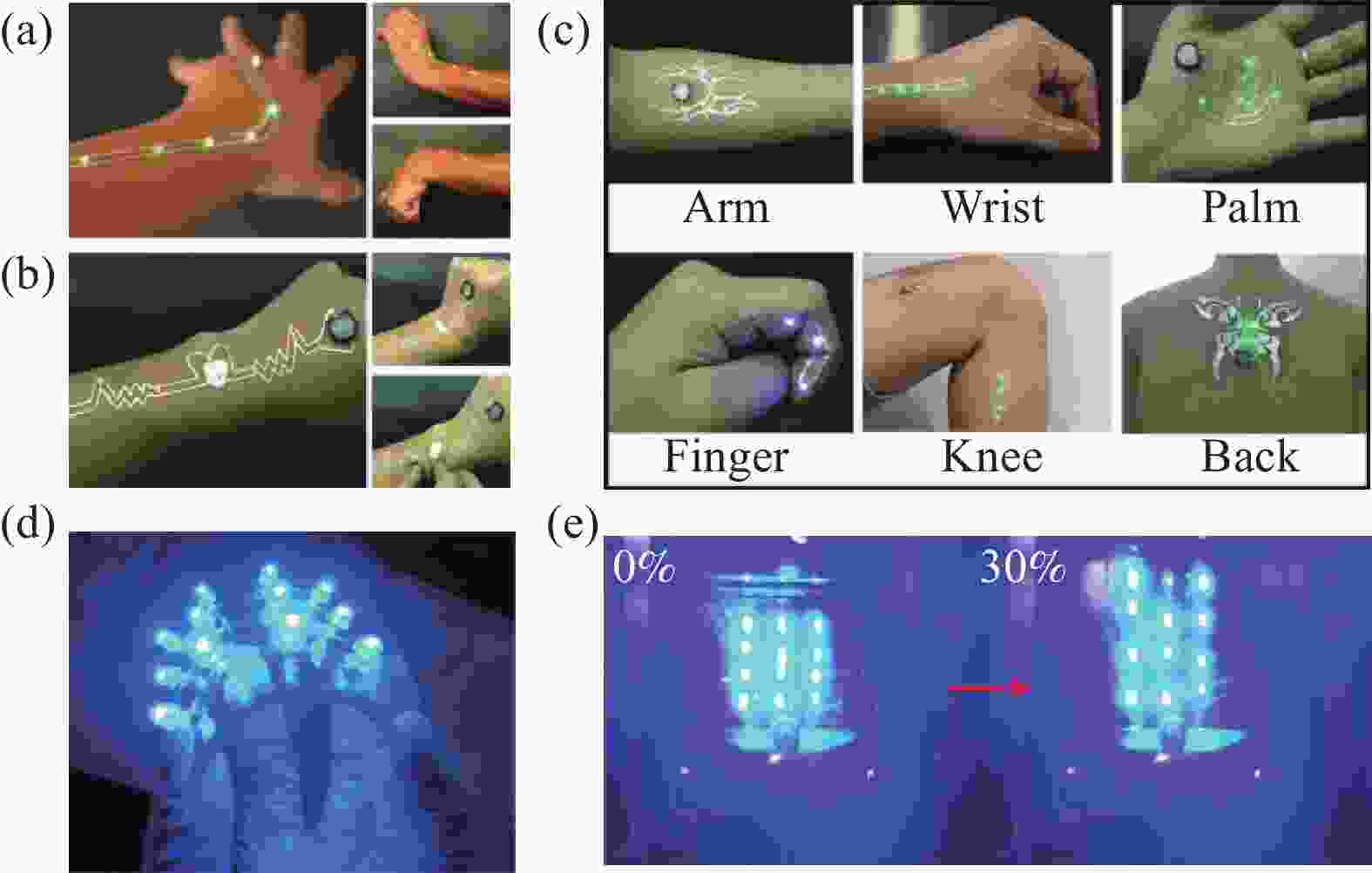

图 2 ((a), (b))超整合的镓-铟共晶合金(Ni-EGaIn)电子纹身多功能应用;(c)将半液态金属(Ni-EGaIn)电子纹身印在志愿者皮肤的几个身体部位;(d)在电路中使用包覆纱-银纳米线-聚二甲基硅氧烷(DCY-AgNW-PDMS)的透明、可弯曲和可拉伸的LED阵列;(e) LED阵列在拉伸到30%时仍能正常工作

Figure 2. ((a), (b)) Ultifunctional application of hyperintegrated gallium indium eutectic alloy (Ni-EGaIn) electronic tattoo; (c) Ni-EGaIn electronic tattoos printed on the volunteers' skin on several body parts; (d) Transparent, bendable and stretchable LED array using covering yarn-silver nanowire-polydimethylsiloxane (DCY-AgNW-PDMS) in circuit; (e) LED array still works fine when stretched to 30%

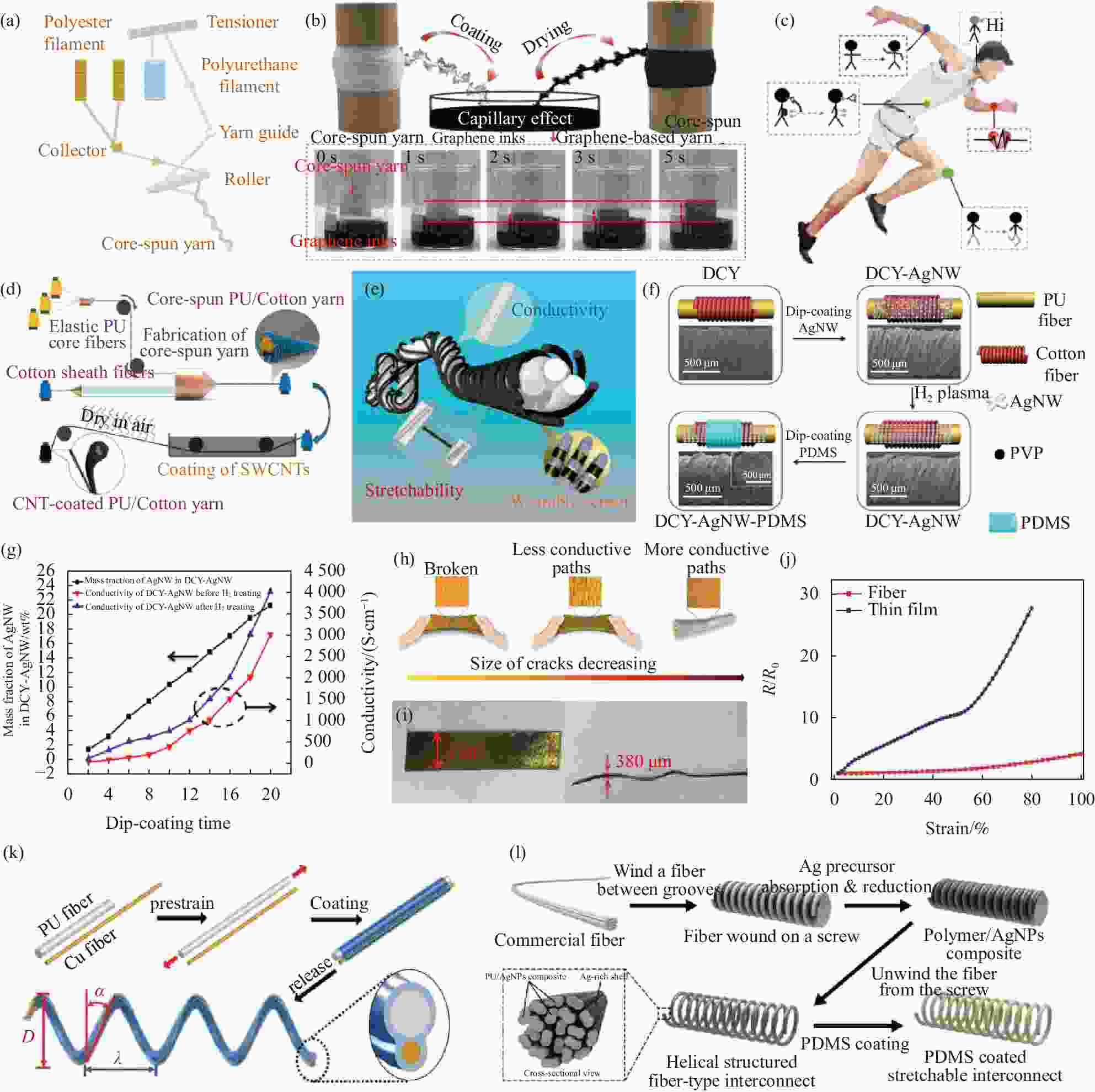

图 3 (a)包芯螺旋纱(CSYs)的制备;(b)浸涂及其毛细管效应现象;(c)石墨烯基包芯螺旋纱(GCSY)作为可穿戴传感器的潜在应用前景;(d)基于PU/棉/CNTs的可拉伸导电纤维的浸涂与制造示意图;(e) PU/棉/CNTs基导电纤维应用示意图;(f)复合材料纤维的制造工艺示意图、双层包芯纱(DCYs)的结构表征和SEM图像;(g) H2等离子体处理前后AgNWs的质量分数和DCY/AgNWs的电导率随AgNWs的浸涂覆时间的变化;(h)减少金基可拉伸导电纤维裂缝的长度和宽度的原理及在拉伸时提供了低电阻变化;(i)在聚二甲基硅氧烷(PDMS)薄膜上的金薄膜与制备导电纤维的照片;(j)纤维和薄膜的拉伸性和电阻变化;(k)三维螺旋纤维的制作工艺;(l)螺旋纤维型互连器的制造过程示意图

PVP—Polyvinylpyrrolidone; SWCNTs—Single-walled carbon nanotubes; AgNW—Ag nanowire; D—Outer helix diameter; α—Helical angle; λ—Pitch; AgNPs—Silver nanoparticles

Figure 3. (a) Preparation of core-spun helix yarn (CSYs); (b) Dip coating and its capillary effect; (c) Potential applications of graphene-based core-spun helix yarn (GCSY) as wearable sensors; (d) Schematic diagram of dip coating and fabrication of stretchable conductive fibers based on PU/cotton/CNTs; (e) Schematic diagram of application of PU/cotton/CNTs-based conductive fibers; (f) Schematic diagram of composite fiber manufacturing process, structure characterization and SEM image of double-covered yarn (DCYs); (g) Changes of AgNWs mass fraction and DCY/AgNWs conductivity with AgNWs dip coating time before and after H2 plasma treatment; (h) Principle of reducing the length and width of cracks in gold base stretchable conductive fibers provides low resistance changes during stretching; (i) Photographs of gold film on polydimethylsiloxane (PDMS) film and preparation of conductive fibers; (j) Changes in tensile properties and electrical resistance of fibers and films; (k) Fabrication process of three-dimensional spiral fiber; (l) Schematic diagram of the manufacturing process of spiral fiber type interconnect

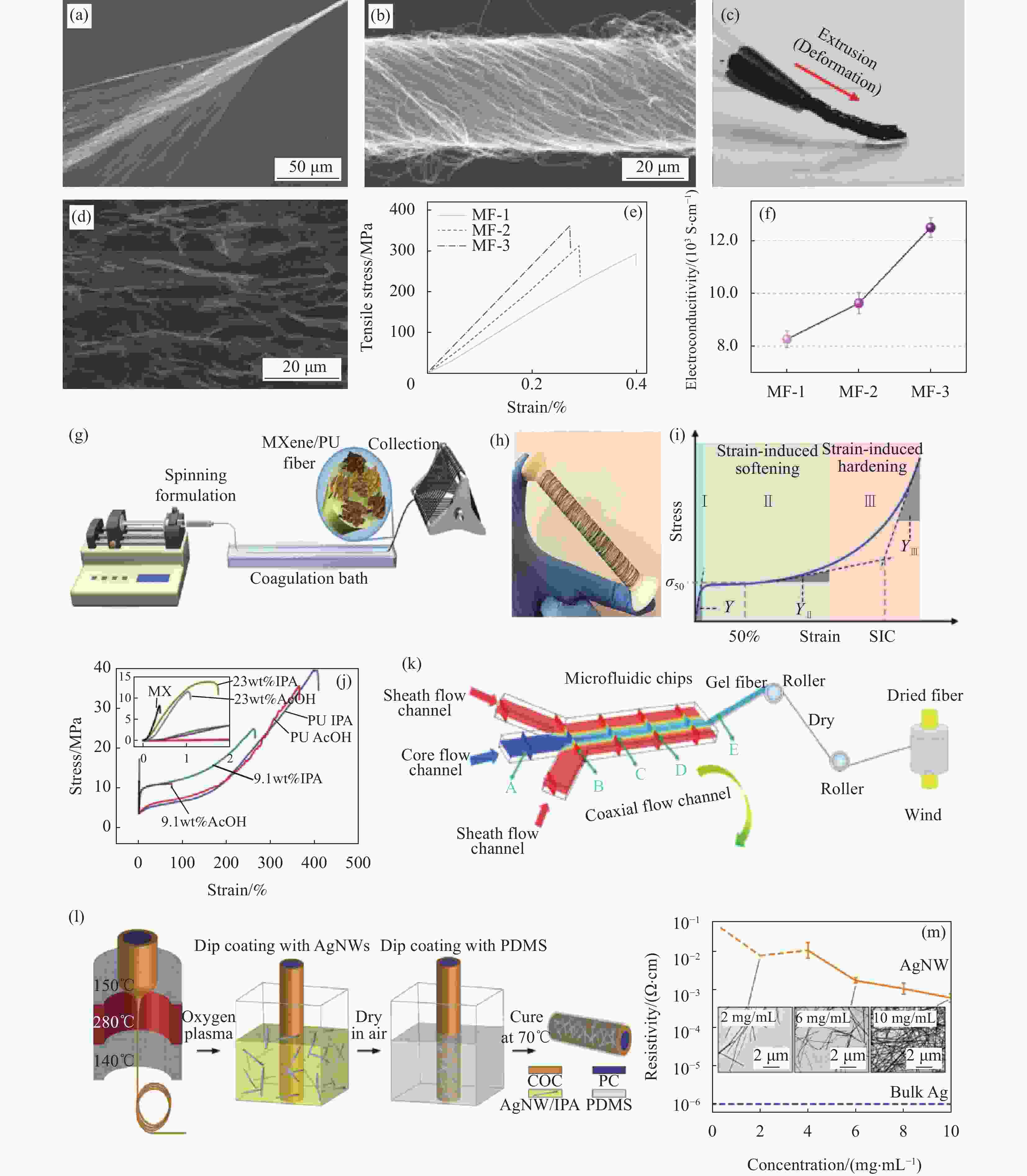

图 4 CNTs (a)和原始CNTs纱线(b)的SEM图像;(c)挤压凝固浴pH=9的MXene凝胶(MG9)的光学图像;(d)挤压MG9内部结构的SEM图像;不同MXene含量的纤维标记为MF-1、MF-2和MF-3的3种不同拉伸强度-应变曲线(e)和电导率(f);(g) MXene/PU纤维纺丝工艺示意图;(h)使用异丙醇(IPA)凝固浴纺丝的数码照片;(i) MXene/PU纤维不同阶段应力应变曲线示意图;(j)代表纤维的应力-应变曲线;(k)多尺度无序多孔弹性纤维制备示意图;(l)可拉伸导电纤维的热拉伸方法示意图;(m)可拉伸导电纤维的电学特性

COC/PC—Cycloolefin copolymer/Polycarbonate; AcOH—Acetic acid; MX—MXene; SIC—Strain-induced crystallization; Y—Young's modulus in the range 0-50; σ50—50% stress

Figure 4. SEM images of CNTs (a) and pristine CNTs yarns (b); (c) Optical image of MXene gel (MG9) in an extruded solidification bath with pH=9; (d) SEM image of the internal structure of extruded MG9; Tensile strength-strain curves (e) and electrical conductivity (f) of the fibers with different MXene contents labeled as MF-1, MF-2 and MF-3; (g) Schematic diagram of the spinning process of MXene/PU fibers; (h) Digital photos of spinning using an isopropanol (IPA) coagulation bath; (i) Schematic diagram of stress-strain curves of MXene/PU fibers at different stages; (j) Representing the stress-strain curves of the fibers; (k) Schematic diagram of the fabrication of multiscale disordered poroelastic fibers; (l) Schematic diagram of the thermal stretching method of the stretchable conductive fibers; (m) Electrical properties of the stretchable conductive fibers

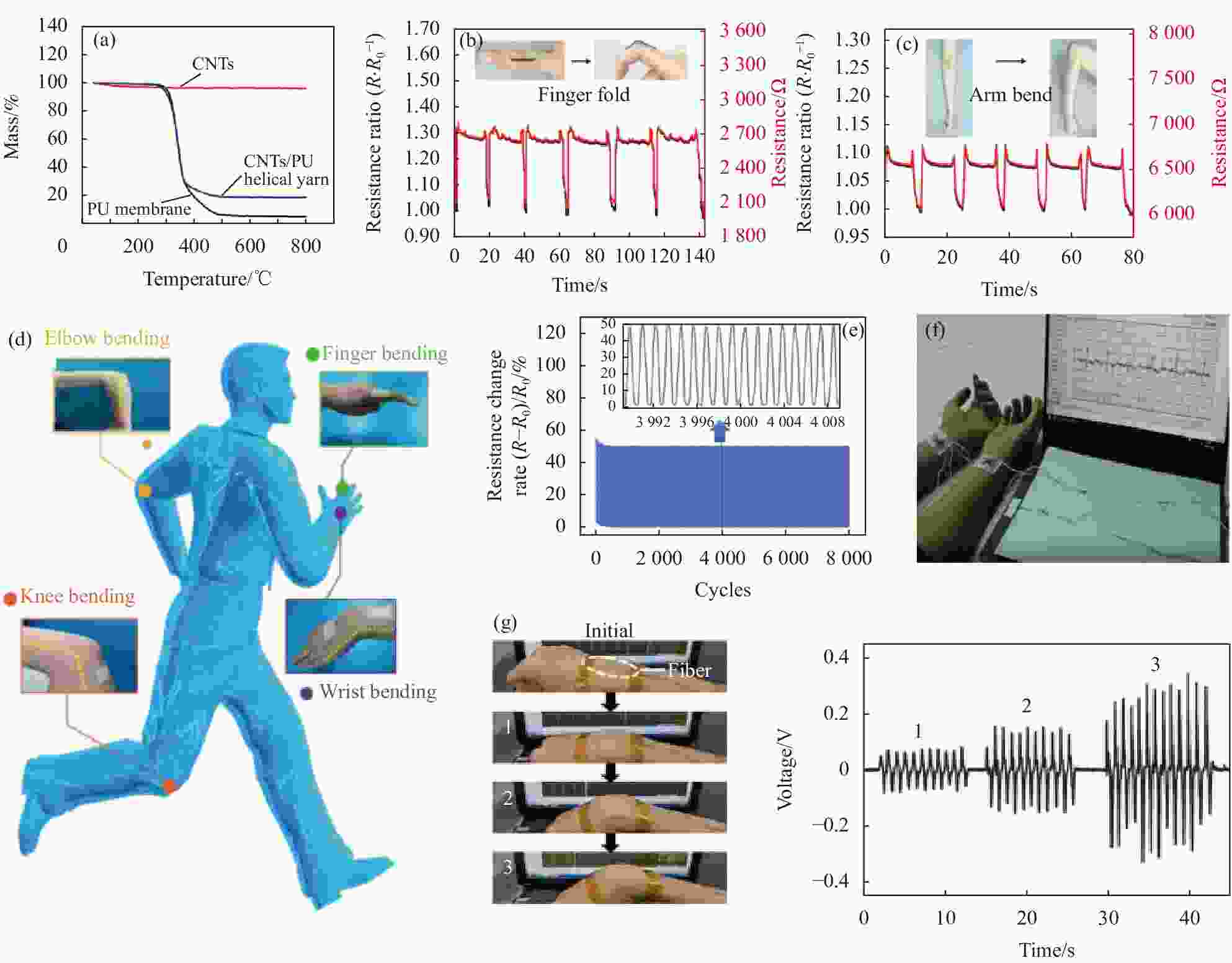

图 5 (a) PU薄膜、CNTs和CNTs/PU螺旋纱线的热重结果(CNT约占CNTs/PU螺旋纱质量比的11.7%);应用CNTs/PU螺旋纱作为应变传感器监测手指折叠(b)与臂弯曲(c);(d)采用聚氨酯@聚甲基丙烯酸酯@共晶-镓-铟(PPE)纤维作为监测人体运动的传感器;(e)传感器在40%应变循环拉伸装卸下8000次循环的性能;(f)连接在不同部件上的用于监测人体运动的PPE传感器的示意图;(g)附着在人体手腕上光纤传感器的照片和相应的电压信号

Figure 5. (a) Thermogravimetric results of PU films, CNTs and CNTs/PU helical yarns (CNTs accounted for about 11.7% of CNTs/PU helical yarns); CNTs/PU helical yarns applied as strain sensors to monitor finger folding (b) and arm bent (c); (d) Adoption of polyurethane@polymethacrylate@eutectic-gallium-indium (PPE) fiber as a sensor to detect human motion; (e) Performance of the sensor under 40% strain cyclic tensile loading and unloading for 8000 cycles; (f) Attached to different parts for use in schematic of a PPE sensor that detects human motion; (g) Photograph of the fiber optic sensor and corresponding voltage signal attached to the human wrist

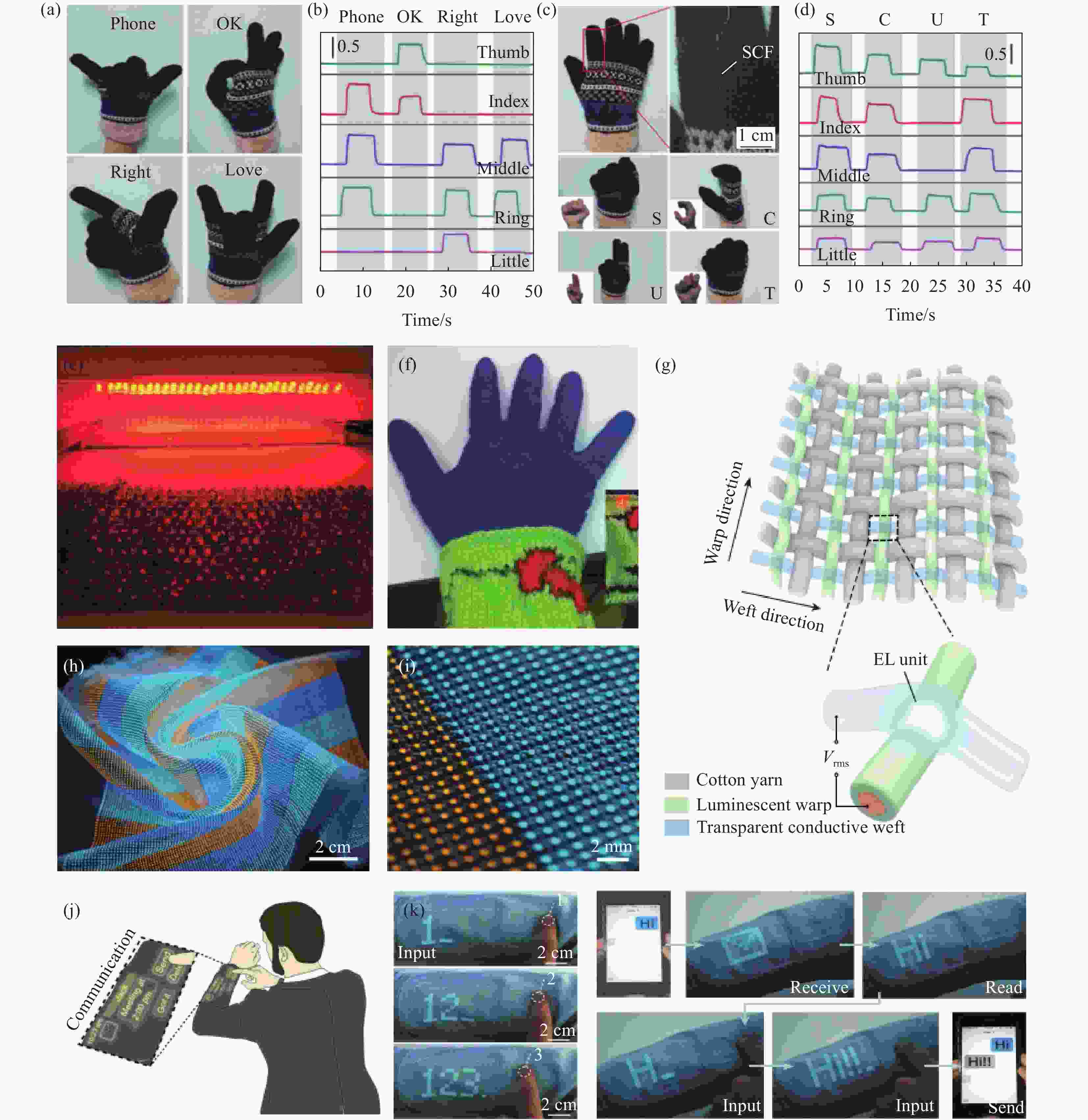

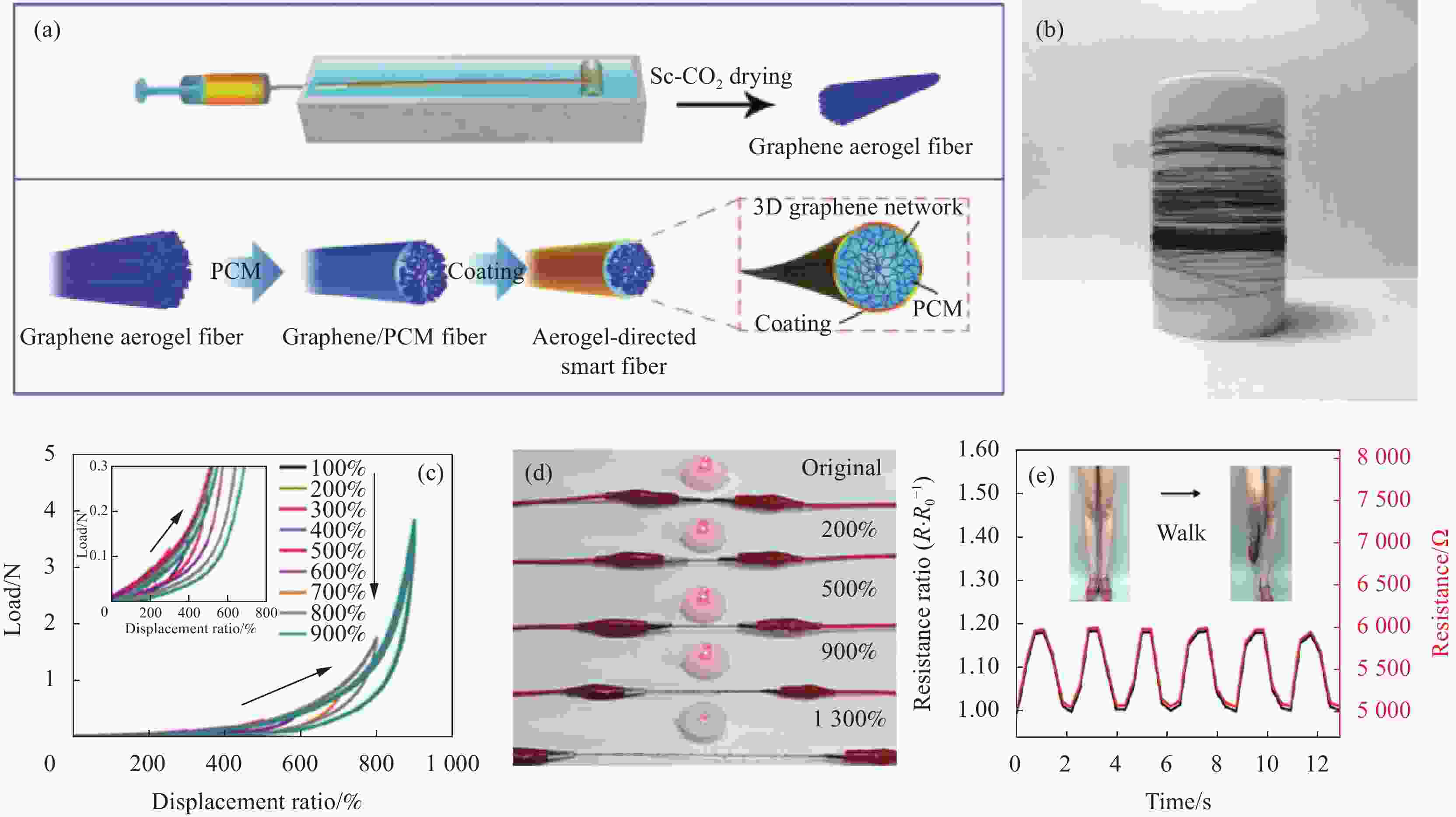

图 6 (a)预定义的手配置和相应的智能手套手势;(b)智能手套上的阻力变化;(c)编织成智能手套的手语和手势识别;(d)输出相对阻力曲线表达字母S、C、U和T;(e)由纱线制成的储能纺织品的照片(15 cm×10 cm的编织衣服可以照亮30个LED);(f)用图案编织的腕带(插图为LED的图案);(g) 纺织品的编织示意图(插图为每个接触的发光经纱和透明导电纬线形成一个发光单元);(h)功能多色显示纺织品在复杂变形下的照片;(i)多色显示纺织品放大照片(EL单元在距离为800 μm);(j)概念图像显示集成了显示器和键盘的纺织品可以用作一个通信平台;(k)按下编织成纺织品的键将信息输入到衣服上,在集成的纺织系统与智能手机之间接收和发送信息

EL—Electroluminescence; Vrms—Voltage

Figure 6. (a) Predefined hand configurations and corresponding smart glove gestures; (b) Resistance variation on the smart glove; (c) Sign language and gesture recognition woven into smart gloves; (d) Output relative resistance curve expressing letters S, C, U and T; (e) Photograph of energy storage textiles made of yarns (15 cm×10 cm woven clothes can illuminate 30 LEDs); (f) Wristbands woven with patterns (Inset is the pattern of LEDs); (g) Schematic of the weaving of the textile (Inset is each contacting luminescent warp and transparent conductive weft forms an EL unit); (h) Photo of a functional multicolor display textile under complex deformation, including bending and twisting; (i) Multicolor display textile magnified photo shows EL cells at ~800 μm distance; (j) Concept image shows that a textile with integrated display and keyboard can be used as a communication platform; (k) Pressing keys woven into a textile enters information onto clothing, receiving and sending information between an integrated textile system and a smartphone

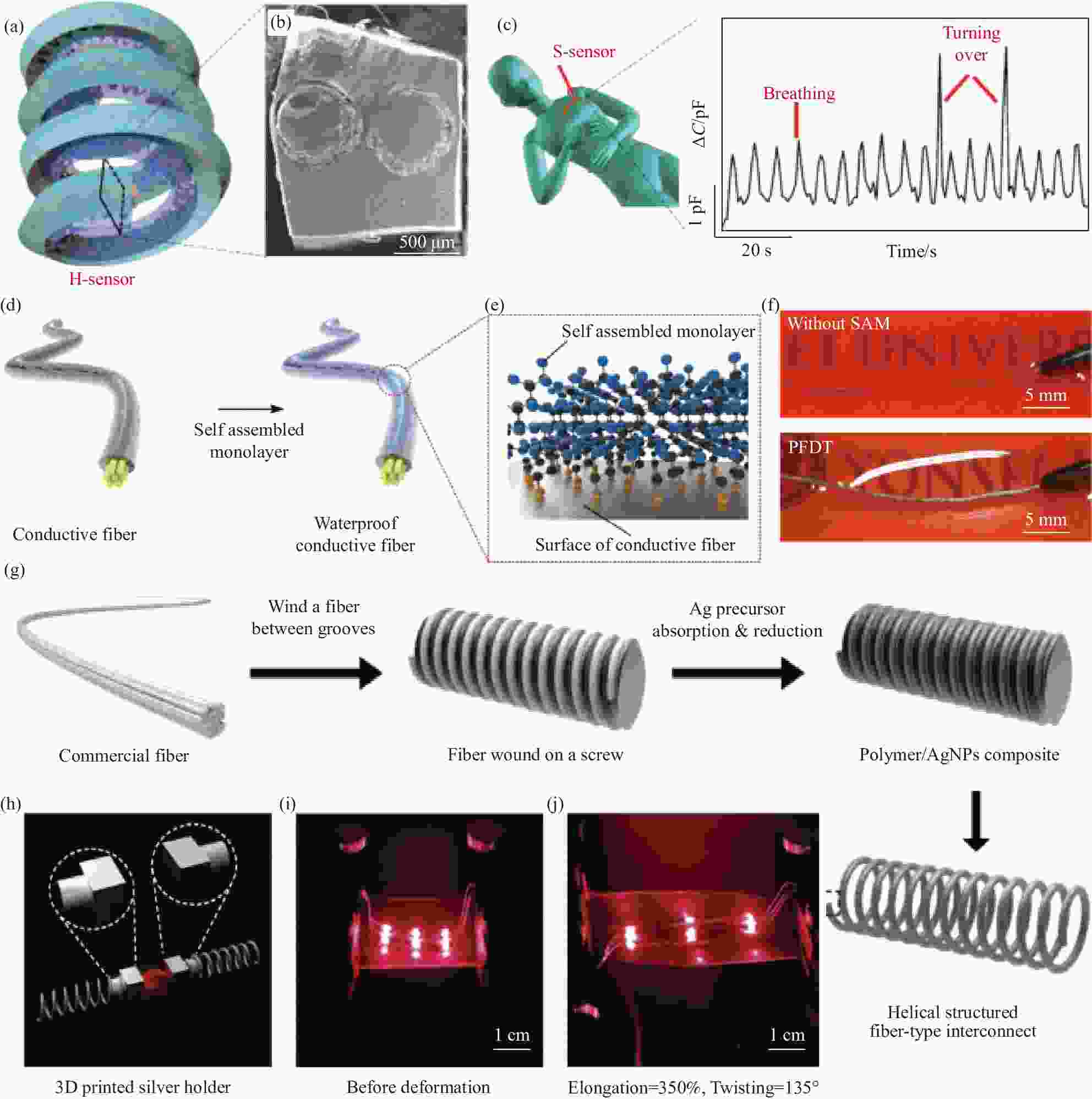

图 7 导电卷须作为电容应变传感器用于可穿戴传感应用:(a) H型传感器结构示意图;(b) H型传感器横截面的扫描电镜图像;(c) S型传感器通过记录呼吸和转换信号监测睡眠质量方面的应用;(d)防水导电纤维的制作工艺;(e)防水层微观原理示意图;(f)自组装层(SAM)涂层导电纤维排斥染色水的照片;(g)显示螺旋纤维型互连器的制造过程的示意图;(h) 3D打印银支架的示意图及其在螺旋光纤型互连和LED之间形成持久连接的应用;((i), (j))在同时应用单轴拉伸(350%)和扭曲(135°)之前可拉伸的3×3 LED阵列在软弹性基底上的操作

ΔC—Capacitance difference; PFDT—Perfluodecanethiol

Figure 7. Conductive tendrils as capacitive strain sensors for wearable sensing applications: (a) Schematic diagram of the structure of the H-type sensor; (b) SEM image of the cross-section of the H-type sensor; (c) S-sensor application in monitoring sleep quality by recording respiration and converting signals; (d) Fabrication process of the waterproof conductive fiber; (e) Schematic diagram of the microscopic principle of the waterproof layer; (f) Photographic image of the self-assembled monolayers (SAM)-coated conductive fiber repelling dyed water; (g) Schematic diagram showing the fabrication process of helical fiber-type interconnects; (h) Schematic diagram of 3D-printed silver scaffolds and their application to form durable connections between helical fiber-type interconnects and LEDs; ((i), (j)) Operation of a stretchable 3 × 3 LED array on a soft elastic substrate before simultaneous application of uniaxial stretching (350%) and twisting (135°)

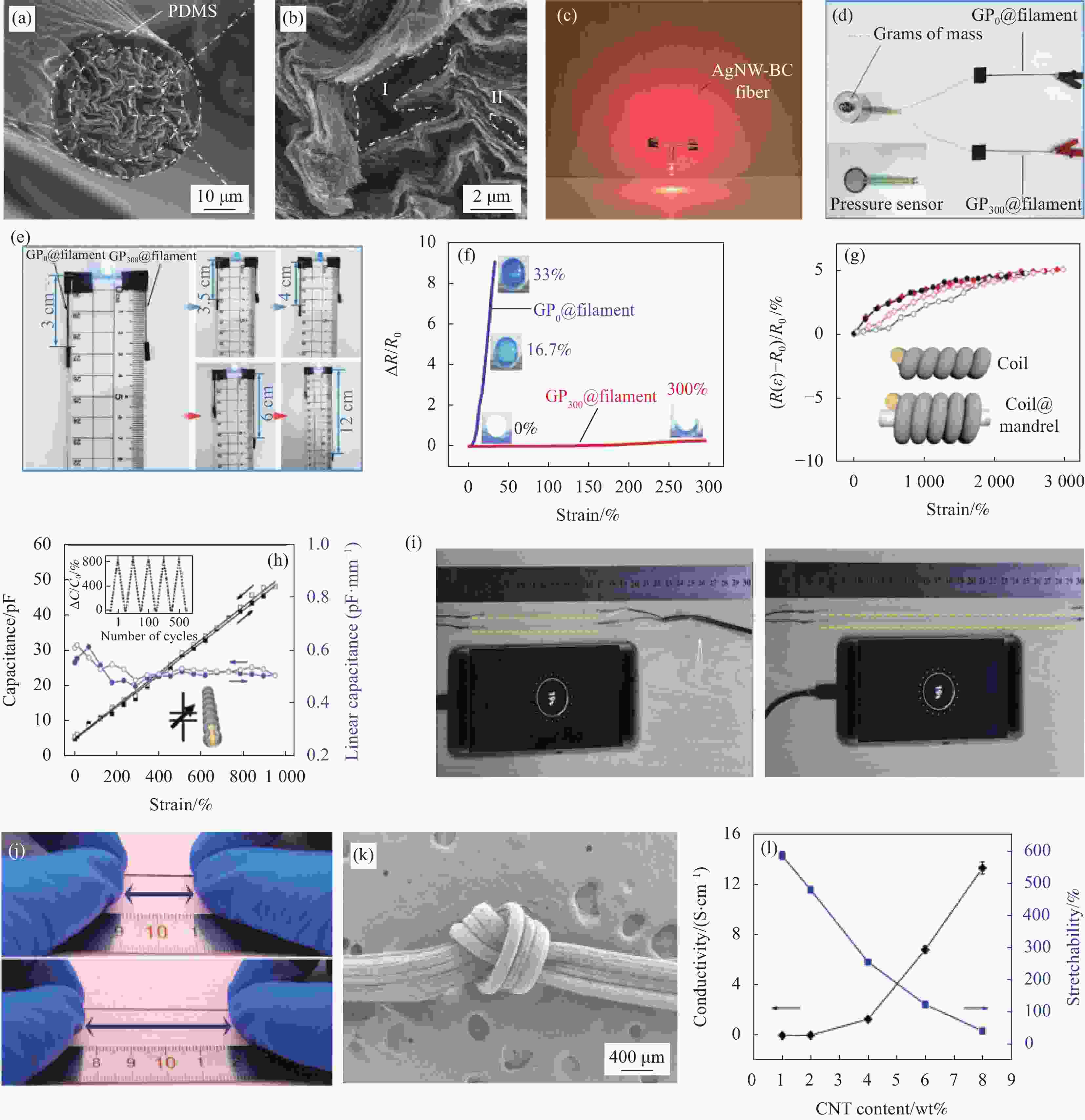

图 8 ((a), (b)) AgNWs-BC/PDMS的微观结构图像(虚线圈表示大孔I和微孔II);(c)照明LED由AgNWs-BC光纤悬挂2 V电压供电;(d)应变不敏感拉伸电子学的潜在应用(使用GP0@纤维和GP300@纤维作为可拉伸的电子电路);((e), (f))使用GP0@纤维和GP300@纤维作为电子电路的LED的照片;((g), (h))螺旋橡胶@19层CNTS(NTS19)@纤维的电阻与应变变化及NTS4@橡胶@NTS3@纤维的电容和线性电容(每瞬时长度)的应变依赖性(上插图显示电容变化在选定的周期到950%的应变,下插图显示光纤的结构);(i)使用PPE光纤作为柔性和可拉伸的手机充电电缆;(j)原始的和拉伸的MCP纤维的照片;(k) MCP纤维带结的扫描电镜图像;(l) CNTs含量对CP纤维拉伸性和电导率的影响

ΔC/C0—Change in capacitance; BC—Bacterial cellulose; GP0—Pre-stretched graphene-PU fiber of 0; GP300—Pre-stretched graphene-PU fiber of 300%; PU@PMA@EGaIn (PPE)—Polyurethane@propylene glycol methyl ether acetate@liquid metal; CP—CNT/PU

Figure 8. ((a), (b)) Microstructure images of AgNW-BC/PDMS (Dashed circles indicate macropore I and micropore II); (c) Illumination LEDs powered by a voltage of 2 V suspended from the AgNW-BC fiber; (d) Potential applications of strain-insensitive tensile electronics using GP0@filament and GP300@filament as stretchable electronic circuits; ((e), (f)) Photographs of LEDs using GP0@filament and GP300@filament as electronic circuits; ((g), (h)) Resistance and strain changes of helical rubber@NTS19@fibers and strain dependence of capacitance and linear capacitance (per instantaneous length) of NTS4@rubber@NTS3@fibers (Inset above shows the capacitance change over the selected cycle to 950% strain, inset below shows the structure of the fiber); (i) Using PPE fiber as a flexible and stretchable mobile phone charging cable; (j) Photographs of pristine and stretched MCP fibers; (k) SEM image of MCP fiber ribbon knots; (l) Effect of carbon nanotube content on the stretchability and electrical conductivity of CP fibers

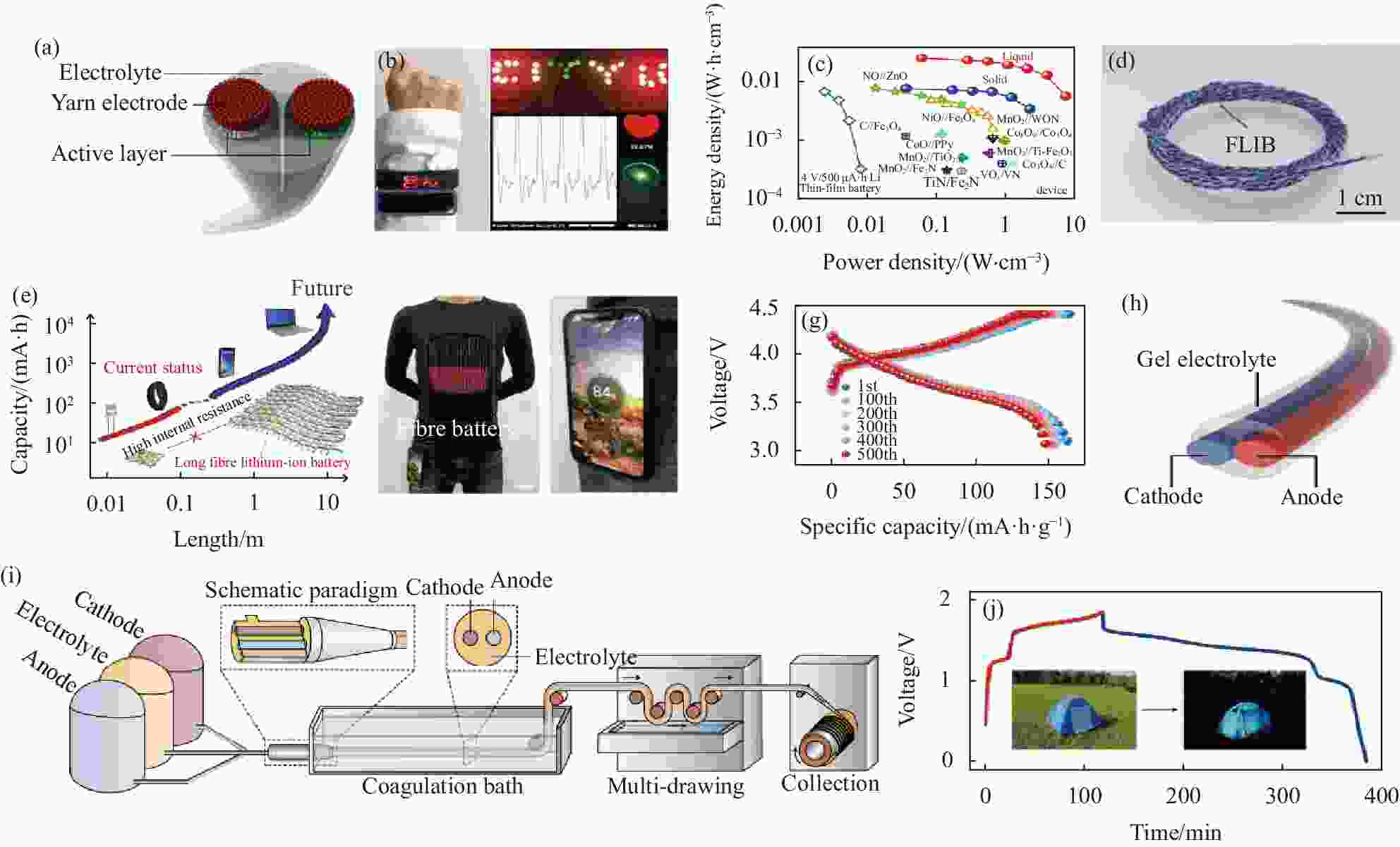

图 9 (a)固态纱线电池的原理图;(b)编织制成的能量腕带为手表(左)、一组LED(右上)和一个脉冲传感器(右下)提供动力;(c)水电池和非对称超级电容器的对比;(d) FLIB照片;(e)连续的纤维锂离子电池可以有效满足各种电子产品的用电需求;(f)纤维锂离子电池织物为智能手机进行无线充电;(g) 500次循环后容量保留率和库仑效率;(h)挤压纤维电池的原理图;(i)纤维电池的挤压过程和结构特性;(j)采用纺织太阳能电池的光电充电(上升曲线)和纺织电池的放电曲线(下降曲线)

PPy—Polypyrrole; WON—Tungsten oxynitride; VN—Vanadium nitride; FLIB—Fibre lithium-ion batteries

Figure 9. (a) Schematic of a solid-state yarn battery; (b) Woven energy wristband to power a watch (left), a set of LED (top right) and a pulse sensor (bottom right); (c) Comparison of water batteries and asymmetric supercapacitors; (d) Photo of FLIB; (e) Continuous fiber Li-ion batteries can effectively meet the power demand of various electronic products; (f) Fiber Li-ion battery fabric for wireless charging of smart phones; (g) Capacity retention and coulombic efficiency after 500 cycles; (h) Schematic of the extruded fiber battery; (i) Extrusion process and structural properties of the fiber battery; (j) Photoelectric charging (Ascending curve) and discharge curves (Descent curve) of textile solar cells using textile solar cells

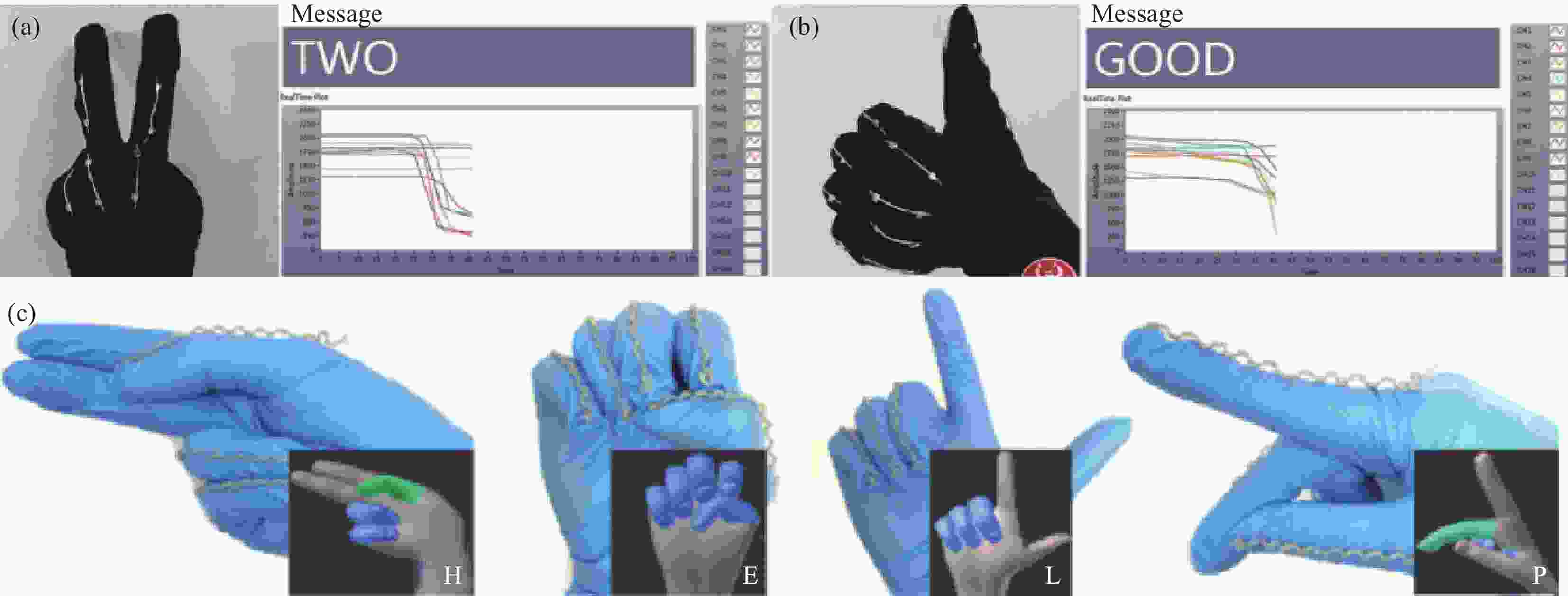

图 10 ((a), (b))不同的手势对应于不同的模拟显示和测试软件中阻力的相对变化;(c) H型传感器在符号字母表手势翻译中的应用;(d)连接在复合纤维上的智能手套的照片;(e)英语字母Y、S、U的运动检测及使用手语手套和检测每个字母的照片;(f)佩戴前(满载)和正常/运动条件下手腕上可穿戴传感器的响应曲线;(g)当佩戴者说“你好”、“纤维”和“导体”时可穿戴传感器的响应曲线;(h)自愈人工神经纤维的能量输送能力和快速恢复能力;(i)传感器在一组手臂运动中的工作过程示意图(右图是监测肌肉力量的图片);(j)主动探测传感器附着在肘部上的图片;(k)弯头分别在30°、60°、90°、120° 时传感器的电压曲线

L0—Length 0; L1—Length 1; V—Voltage

Figure 10. ((a), (b)) Different gestures correspond to relative changes in resistance in different simulated displays and test software; (c) Application of the H-type sensor in the translation of symbolic alphabet gestures; (d) Photograph of the smart glove attached to the composite fiber; (e) Motion detection of English letters Y, S, U to use sign language gloves and to detect photos of each letter; (f) Response curves of the wearable sensor on the wrist before wearing (full load) and under normal/exercise conditions; (g) Wearable sensor response curves when the wearer says "hello", "fiber" and "conductor"; (h) Self healing artificial nerve fiber has the ability of energy transmission and rapid recovery; (i) Schematic diagram of the working process of the sensor in a group of arm movements (Picture on the right is a picture of monitoring muscle strength); (j) An image of the active detection sensor attached to the elbow; (k) Voltage curve of the sensor when the elbow at 30°, 60°, 90° and 120°, respectively

-

[1] LOU Z, WANG L, JIANG K, et al. Reviews of wearable healthcare systems: Materials, devices and system integration[J]. Materials Science and Engineering: Reports,2020,140:100523. doi: 10.1016/j.mser.2019.100523 [2] SOURI H, BHATTACHARYYA D. Highly stretchable multifunctional wearable devices based on conductive cotton and wool fabrics[J]. ACS Applied Materials & Interfaces,2018,10(24):20845-20853. [3] ZHAO J, FU Y, XIAO Y, et al. A naturally integrated smart textile for wearable electronics applications[J]. Advanced Materials Technologies,2019,5(1):1900781. [4] SENEVIRATNE S, HU Y, NGUYEN T, et al. A survey of wearable devices and challenges[J]. IEEE Communications Surveys & Tutorials,2017,19(4):2573-2620. [5] TEYMOURIAN H, PARRILLA M, SEMPIONATTO J R, et al. Wearable electrochemical sensors for the monitoring and screening of drugs[J]. ACS Sensors,2020,5(9):2679-2700. doi: 10.1021/acssensors.0c01318 [6] RAHMAN M T, RANA S M S, SALAUDDIN M, et al. Biomechanical energy-driven hybridized generator as a universal portable power source for smart/wearable electro-nics[J]. Advanced Energy Materials,2020,10(12):1903663. doi: 10.1002/aenm.201903663 [7] LEE J, LLERENA Z B, WOO J, et al. Recent advances in 1D stretchable electrodes and devices for textile and wearable electronics: Materials, fabrications, and applications[J]. Advanced Materials,2020,32(5):e1902532. doi: 10.1002/adma.201902532 [8] LIU X, MIAO J, FAN Q, et al. Smart textile based on 3D stretchable silver nanowires/MXene conductive networks for personal healthcare and thermal management[J]. ACS Applied Materials & Interfaces, 2021, 13(47): 56607-56619. [9] DUAN Z, XU L J. Dual band wristband antenna with metal frame loaded for biomedical applications[J]. Microwave and Optical Technology Letters,2017,59(9):2155-2159. doi: 10.1002/mop.30690 [10] ABED H, BELLEMARE-ROUSSEAU S, BELANGER-HUOT B, et al. A wire-free and fiber-based smart T-shirt for real-time breathing rate monitoring[J]. IEEE Sensors Journal,2022,22(5):4463-4471. doi: 10.1109/JSEN.2021.3139032 [11] YAO S, SWETHA P, ZHU Y. Nanomaterial-enabled wearable sensors for healthcare[J]. Advanced Healthcare Materials,2018,7(1):1700889. doi: 10.1002/adhm.201700889 [12] LI X, HU H, HUA T, et al. Wearable strain sensing textile based on one-dimensional stretchable and weavable yarn sensors[J]. Nano Research,2018,11(11):5799-5811. doi: 10.1007/s12274-018-2043-7 [13] PACCHIEROTTI C, SINCLAIR S, SOLAZZI M, et al. Wearable haptic systems for the fingertip and the hand: Taxonomy, review, and perspectives[J]. IEEE Transactions on Haptics, 2017, 10(4): 580-600. [14] SHI Q, DONG B, HE T, et al. Progress in wearable electronics/photonics—Moving toward the era of artificial intelligence and internet of things[J]. InfoMat,2020,2(6):1131-1162. doi: 10.1002/inf2.12122 [15] 刘旭华, 苗锦雷, 曲丽君, 等. 用于可穿戴智能纺织品的复合导电纤维研究进展[J]. 复合材料学报, 2021, 38(1):67-83.LIU Xuhua, MIAO Jinlei, QU Lijun, et al. Research progress of composite conductive fibers for wearable smart textiles[J]. Journal of Composite Materials,2021,38(1):67-83(in Chinese). [16] JAYATHILAKA W, QI K, QIN Y, et al. Significance of nanomaterials in wearables: A review on wearable actuators and sensors[J]. Advanced Materials,2019,31(7):e1805921. doi: 10.1002/adma.201805921 [17] WU Y, LI X, ZHAO H, et al. Recent advances in transition metal carbides and nitrides (MXenes): Characteristics, environmental remediation and challenges[J]. Chemical Engineering Journal,2021,418:129296. doi: 10.1016/j.cej.2021.129296 [18] WANG C, XIA K, WANG H, et al. Advanced carbon for flexible and wearable electronics[J]. Advanced Materials,2019,31(9):e1801072. doi: 10.1002/adma.201801072 [19] LI G, HONG G, DONG D, et al. Multiresponsive graphene-aerogel-directed phase-change smart fibers[J]. Advanced Materials,2018,30(30):e1801754. doi: 10.1002/adma.201801754 [20] GAO Y, GUO F, CAO P, et al. Winding-locked carbon nanotubes/polymer nanofibers helical yarn for ultra-stretchable conductor and strain sensor[J]. ACS Nano,2020 , 14 (3):3442-3450. [21] ZHONG J W, ZHANG Y, ZHONG Q, et al. Fiber-based generator for wearable electronics and mobile medication[J]. ACS Nano,2014,8(6):6273-6280. [22] ABDULLAH H, AHMED K, ALAM M S, et al. High sensiti-vity refractive index sensor based on triple layer MgF2-gold-MgF2 coated nano metal films photonic crystal fiber[J]. Optik,2021,241:166950. doi: 10.1016/j.ijleo.2021.166950 [23] LIAO J, YANG M, ZHANG W, et al. Spider silk-inspired universal strategy: Directional patching of one-dimensional nanomaterial-based flexible transparent electrodes for smart flexible electronics[J]. Chemical Engineering Jour-nal,2020,389:123663. doi: 10.1016/j.cej.2019.123663 [24] ZHANG M, YAO S, RAO W, et al. Transformable soft liquid metal micro/nanomaterials[J]. Materials Science and Engineering R: Reports,2019,138:1-35. doi: 10.1016/j.mser.2019.03.001 [25] GUO R, SUN X, YAO S, et al. Semi-liquid-metal-(Ni-EGaIn)-based LTRA conformable electronic tattoo[J]. Advanced Materials Technologies,2019,4(8):1900183. doi: 10.1002/admt.201900183 [26] KIM J, KUMAR R, BANDODKAR A J, et al. Advanced materials for printed wearable electrochemical devices: A review[J]. Advanced Electronic Materials,2016,3(1):1600260. [27] CHENG Y, WANG R, SUN J, et al. Highly conductive and ultrastretchable electric circuits from covered yarns and silver nanowires[J]. ACS Nano,2015,9(4):3887-3895. doi: 10.1021/nn5070937 [28] LEE J, SHIN S, LEE S, et al. Correction to highly sensitive multifilament fiber strain sensors with ultrabroad sensing range for textile electronics[J]. ACS Nano,2018,12(9):9634. doi: 10.1021/acsnano.8b05295 [29] ZHOU J, TIAN G, JIN G, et al. Buckled conductive polymer ribbons in elastomer channels as stretchable fiber conductor[J]. Advanced Functional Materials,2019,30(5):1907316. [30] YI F, REN H, SHAN J, et al. Wearable energy sources based on 2D materials[J]. Chemical Society Reviews, 2018, 47(9): 3152-3188. [31] ETMAN A S, HALIM J, ROSEN J. Mixed MXenes: Mo1.33CTz and Ti3C2Tz freestanding composite films for energy storage[J]. Nano Energy,2021,88:106271. [32] SHIN H, EOM W, LEE K H, et al. Highly electroconductive and mechanically strong Ti3C2Tx MXene fibers using a deformable MXene gel[J]. ACS Nano,2021,15(2):3320-3329. doi: 10.1021/acsnano.0c10255 [33] ZHANG X, ZHANG Z, ZHOU Z. MXene-based materials for electrochemical energy storage[J]. Journal of Energy Chemistry,2018,27(1):73-85. doi: 10.1016/j.jechem.2017.08.004 [34] ZHANG J, SEYEDIN S, GU Z, et al. MXene: A potential candidate for yarn supercapacitors[J]. Nanoscale,2017,9(47):18604-18608. doi: 10.1039/C7NR06619H [35] WANG L, TIAN M, ZHANG Y, et al. Helical core-sheath elastic yarn-based dual strain/humidity sensors with MXene sensing layer[J]. Journal of Materials Science,2020,55(14):6187-6194. doi: 10.1007/s10853-020-04425-9 [36] WANG Z, HUANG Y, SUN J, et al. Polyurethane/cotton/carbon nanotubes core-spun yarn as high reliability stretchable strain sensor for human motion detection[J]. ACS Applied Materials & Interfaces,2016,8(37):24837-24843. [37] 谢晓旭, 王彦, 诸静, 等. 基于夹心结构的碳纳米管/石墨烯复合柔性导电纤维的制备及其应用[J]. 现代化工, 2020, 40(10):188-192.XIE Xiaoxu, WANG Yan, ZHU Jing, et al. Fabrication and application of carbon nanotubes/graphene composite flexible conductive fibers based on sandwich structure[J]. Modern Chemical Industry,2020,40(10):188-192(in Chinese). [38] ZHANG B, LEI J, QI D, et al. Stretchable conductive fibers based on a cracking control strategy for wearable electro-nics[J]. Advanced Functional Materials,2018,28(29):1801683. doi: 10.1002/adfm.201801683 [39] WOO J, LEE H, YI C, et al. Ultrastretchable helical conductive fibers using percolated Ag nanoparticle networks encapsulated by elastic polymers with high durability in omnidirectional deformations for wearable electronics[J]. Advanced Functional Materials,2020,30(29):1910026. doi: 10.1002/adfm.201910026 [40] YANG Z, ZHAI Z, SONG Z, et al. Conductive and elastic 3D helical fibers for use in washable and wearable electro-nics[J]. Advanced Materials,2020,32(10):e1907495. doi: 10.1002/adma.201907495 [41] FOROUGHI J, SPINKS G M, ANTIOHOS D, et al. Highly conductive carbon nanotube-graphene hybrid yarn[J]. Advanced Functional Materials,2014,24(37):5859-5865. doi: 10.1002/adfm.201401412 [42] SEYEDIN S, UZUN S, LEVITT A, et al. MXene composite and coaxial fibers with high stretchability and conductivity for wearable strain sensing textiles[J]. Advanced Functional Materials,2020,30(12):1910504. doi: 10.1002/adfm.201910504 [43] HU X, TIAN M, XU T, et al. Multiscale disordered porous fibers for self-sensing and self-cooling integrated smart sportswear[J]. ACS Nano,2020,14(1):559-567. doi: 10.1021/acsnano.9b06899 [44] LU C, PARK S, RICHNER T J, et al. Flexible and stretchable nanowire-coated fibers for optoelectronic probing of spinal cord circuits[J]. Science Advances,2017,3(3):1600955. doi: 10.1126/sciadv.1600955 [45] WANG L, TIAN M, QI X, et al. Customizable textile sensors based on helical core-spun yarns for seamless smart garments[J]. Langmuir,2021,37(10):3122-3129. doi: 10.1021/acs.langmuir.0c03595 [46] NING C, DONG K, CHENG R, et al. Flexible and stretchable fiber-shaped triboelectric nanogenerators for biomechanical monitoring and human-interactive sensing[J]. Advanced Functional Materials,2020,31(4):2006679. [47] CHEN G, WANG H, GUO R, et al. Superelastic EGaIn composite fibers sustaining 500% tensile strain with superior electrical conductivity for wearable electronics[J]. ACS Applied Materials & Interfaces,2020,12(5):6112-6118. [48] ZHENG L, ZHU M, WU B, et al. Conductance-stable liquid metal sheath-core microfibers for stretchy smart fabrics and self-powered sensing[J]. Science Advances, 2021, 7(22): 239-257. [49] DU X, TIAN M, SUN G, et al. Self-powered and self-sensing energy textile system for flexible wearable applications[J]. ACS Applied Materials & Interfaces,2020,12(50):55876-55883. [50] LI M, LI Z, YE X, et al. Tendril-inspired 900% ultrastretching fiber-based Zn-ion batteries for wearable energy textiles[J]. ACS Applied Materials & Interfaces,2021,13(14):17110-17117. [51] CHEN S, LIU H, LIU S, et al. Transparent and waterproof ionic liquid-based fibers for highly durable multifunctional sensors and strain-insensitive stretchable conductors[J]. ACS Applied Materials & Interfaces,2018,10(4):4305-4314. [52] HUANG Y, HU H, HUANG Y, et al. From industrially weavable and knittable highly conductive yarns to large wearable energy storage textiles[J]. ACS Nano, 2015, 9(5): 4766-4775. [53] SHENG M, WANG W, LI L, et al. All-in-one wearable electronics design: Smart electrochromic liquid-crystal-clad fibers without external electrodes[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2021,630:127535. doi: 10.1016/j.colsurfa.2021.127535 [54] SHI X, ZUO Y, ZHAI P, et al. Large-area display textiles integrated with functional systems[J]. Nature,2021,591(7849):240-245. doi: 10.1038/s41586-021-03295-8 [55] CHENG Y, WANG R, CHAN K H, et al. A biomimetic conductive tendril for ultrastretchable and integratable electronics, muscles, and sensors[J]. ACS Nano,2018,12(4):3898-3907. doi: 10.1021/acsnano.8b01372 [56] CHOI B, LEE J, HAN H, et al. Highly conductive fiber with waterproof and self-cleaning properties for textile electronics[J]. ACS Applied Materials & Interfaces,2018,10(42):36094-36101. [57] GUAN F, XIE Y, WU H, et al. Silver nanowire-bacterial cellulose composite fiber-based sensor for highly sensitive detection of pressure and proximity[J]. ACS Nano,2020,14(11):15428-15439. doi: 10.1021/acsnano.0c06063 [58] SUN F, TIAN M, SUN X, et al. Stretchable conductive fibers of ultrahigh tensile strain and stable conductance enabled by a worm-shaped graphene microlayer[J]. Nano Letters,2019,19(9):6592-6599. doi: 10.1021/acs.nanolett.9b02862 [59] LIU Z F, FANG S, MOURA F A, et al. Hierarchically buckled sheath-core fibers for superelastic electronics, sensors, and muscles[J]. Science,2015,349(6246):400-404. doi: 10.1126/science.aaa7952 [60] LAN L, JIANG C, YAO Y, et al. A stretchable and conductive fiber for multifunctional sensing and energy harvesting[J]. Nano Energy,2021,84:105954. [61] ZHAO Z, XIA K, HOU Y, et al. Designing flexible, smart and self-sustainable supercapacitors for portable/wearable electronics: From conductive polymers[J]. Chemical Society Reviews, 2021, 50(22): 12702-12743. [62] ZHANG X, WANG Q. Fibrous and flexible electrodes comprising hierarchical nanostructure graphene for supercapacitors[J]. Micro & Nano Letters,2020,15(14):992-996. [63] ZHANG J, SEYEDIN S, QIN S, et al. Highly conductive Ti3C2Tx MXene hybrid fibers for flexible and elastic fiber-shaped supercapacitors[J]. Small,2019,15(8):e1804732. doi: 10.1002/smll.201804732 [64] HUANG Y, IP W S, LAU Y Y, et al. Weavable, conductive yarn-based NiCo//Zn textile battery with high energy density and rate capability[J]. ACS Nano,2017,11(9):8953-8961. doi: 10.1021/acsnano.7b03322 [65] HE J, LU C, JIANG H, et al. Scalable production of high-performing woven lithium-ion fibre batteries[J]. Nature,2021,597(7874):57-63. doi: 10.1038/s41586-021-03772-0 [66] LIAO M, WANG C, HONG Y, et al. Industrial scale production of fibre batteries by a solution-extrusion method[J]. Nature Nanotechnology, 2022 , 17(4): 35058651. [67] MA Y, OUYANG J, RAZA T, et al. Flexible all-textile dual tactile-tension sensors for monitoring athletic motion during taekwondo[J]. Nano Energy,2021,85:105941. doi: 10.1016/j.nanoen.2021.105941 [68] JIN L, XIAO X, DENG W, et al. Manipulating relative permittivity for high-performance wearable triboelectric nanogenerators[J]. Nano Letters,2020,20(9):6404-6411. doi: 10.1021/acs.nanolett.0c01987 [69] COOPER C B, ARUTSELVAN K, LIU Y, et al. Stretchable capacitive sensors of torsion, strain, and touch using double helix liquid metal fibers[J]. Advanced Functional Materials,2017,27(20):1605630. doi: 10.1002/adfm.201605630 [70] ZHU Z, LIU C, JIANG F, et al. Flexible fiber-shaped hydrogen gas sensor via coupling palladium with conductive polymer gel fiber[J]. Journal of Hazardous Materials,2021,411:125008. doi: 10.1016/j.jhazmat.2020.125008 [71] ZHAI W, LI X, XIA Q, et al. Multi-functional and flexible helical fiber sensor for micro-deformation detection, temperature sensing and ammonia gas monitoring[J]. Composites Part B: Engineering,2021,211:108621. doi: 10.1016/j.compositesb.2021.108621 [72] CHEN S, LOU Z, CHEN D, et al. Polymer-enhanced highly stretchable conductive fiber strain sensor used for electronic data gloves[J]. Advanced Materials Technologies,2016,1(7):1600136. doi: 10.1002/admt.201600136 [73] LEE S, SHIN S, LEE S, et al. Ag nanowire reinforced highly stretchable conductive fibers for wearable electronics[J]. Advanced Functional Materials,2015,25(21):3114-3121. doi: 10.1002/adfm.201500628 [74] CHENG Y, WANG R, SUN J, et al. A stretchable and highly sensitive graphene-based fiber for sensing tensile strain, bending, and torsion[J]. Advanced Materials,2015,27(45):7365-7371. doi: 10.1002/adma.201503558 [75] CAO Z, WANG R, HE T, et al. Interface-controlled conduc-tive fibers for wearable strain sensors and stretchable conducting wires[J]. ACS Applied Materials & Interfaces,2018,10(16):14087-14096. doi: 10.1021/acsami.7b19699 [76] WANG C, LIU Y, QU X, et al. Ultra-stretchable and fast self-healing ionic hydrogel in cryogenic environments for artificial nerve fiber[J]. Advanced Materials,2022,34(16):e2105416. [77] WANG C, QU X, ZHENG Q, et al. Stretchable, self-healing, and skin-mounted active sensor for multipoint muscle function assessment[J]. ACS Nano,2021,15(6):10130-10140. doi: 10.1021/acsnano.1c02010 -

下载:

下载: