Tensile bearing behavior of composite structures considering filament wound morphology

-

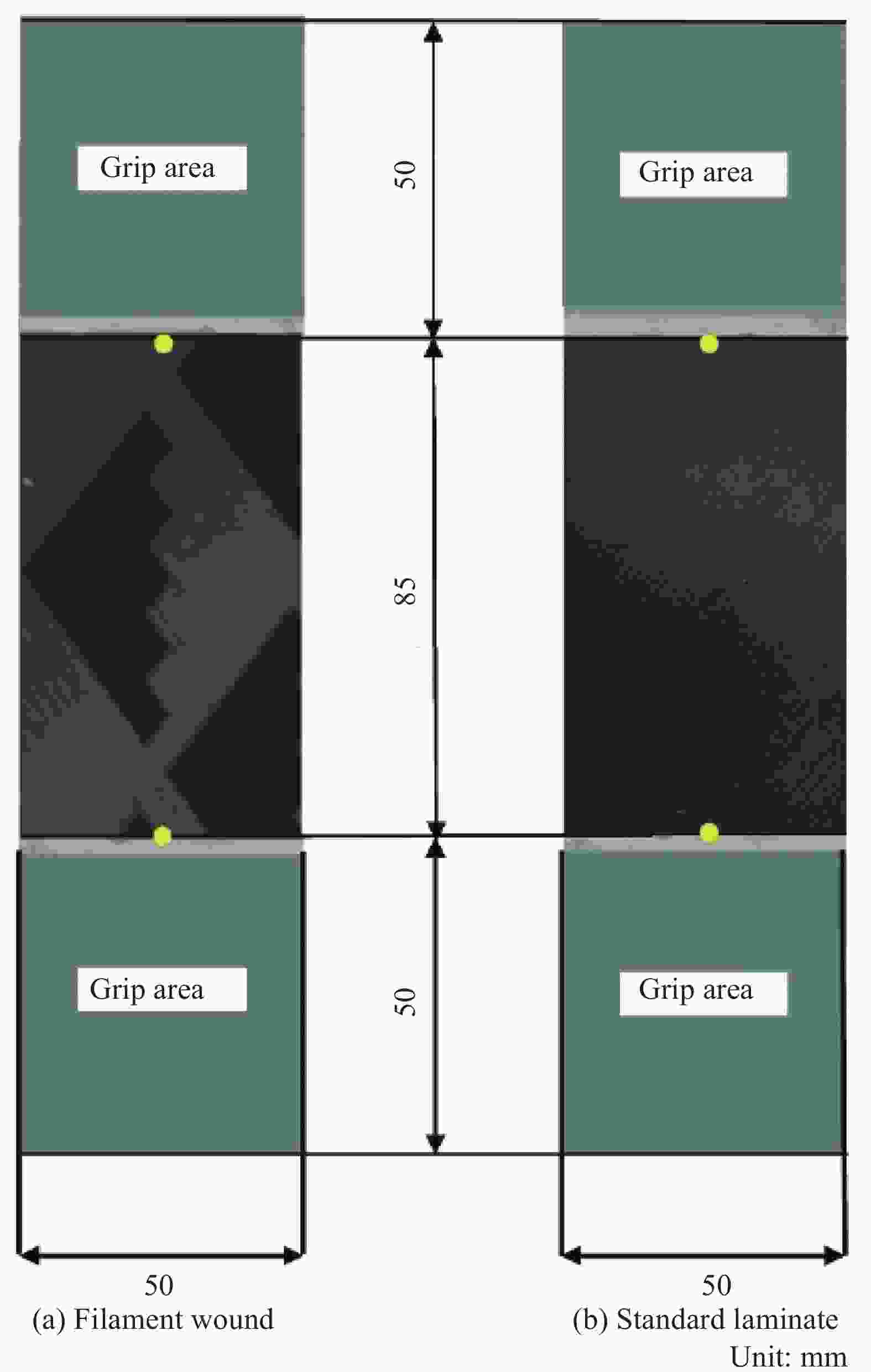

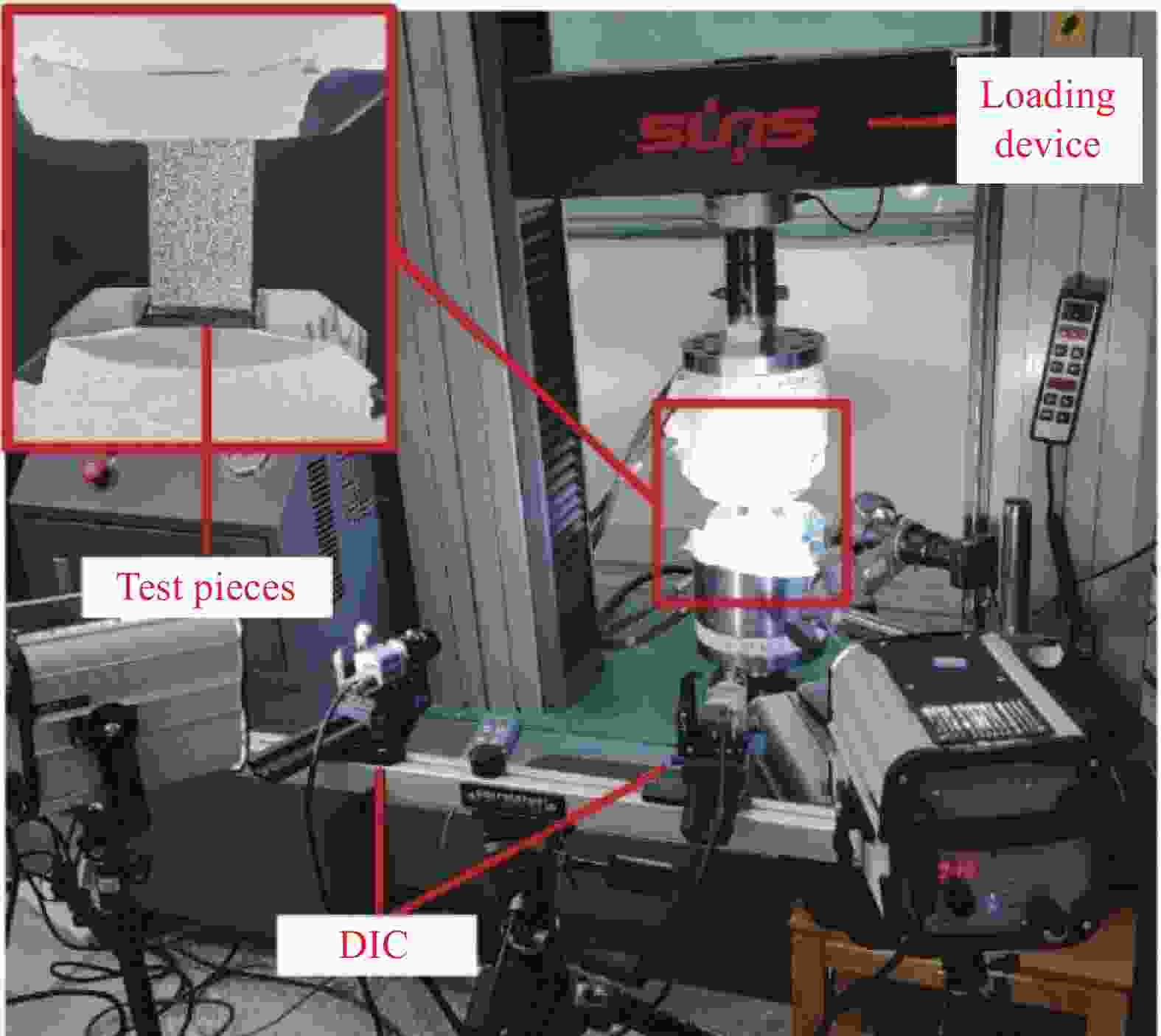

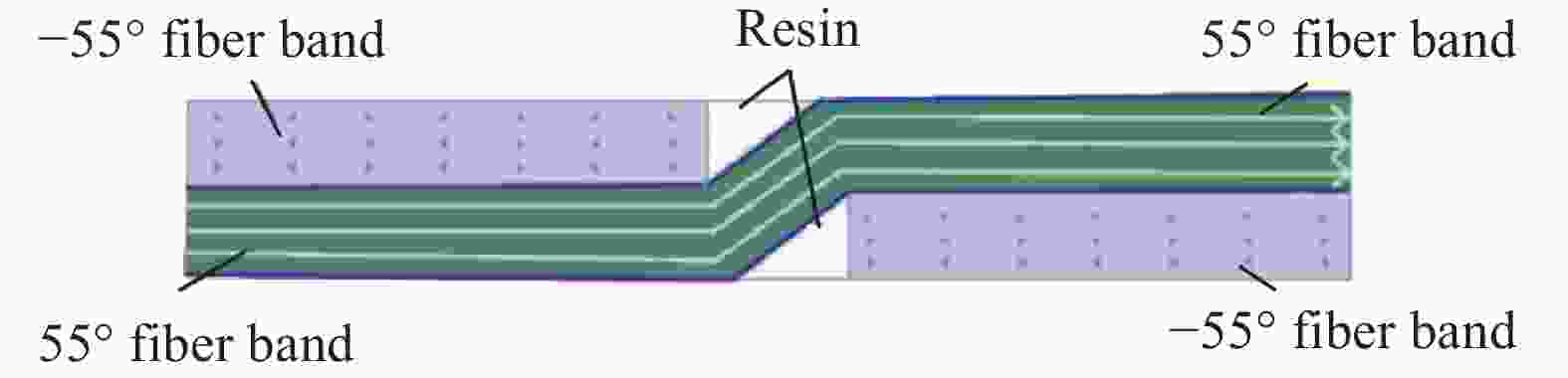

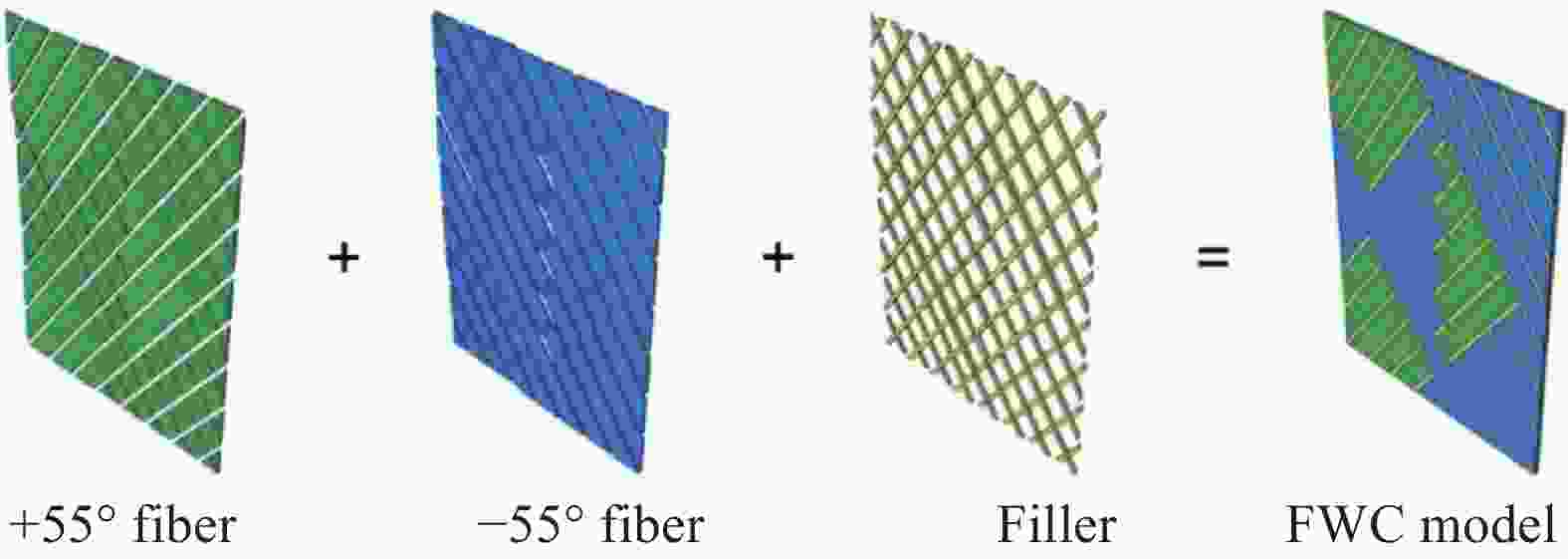

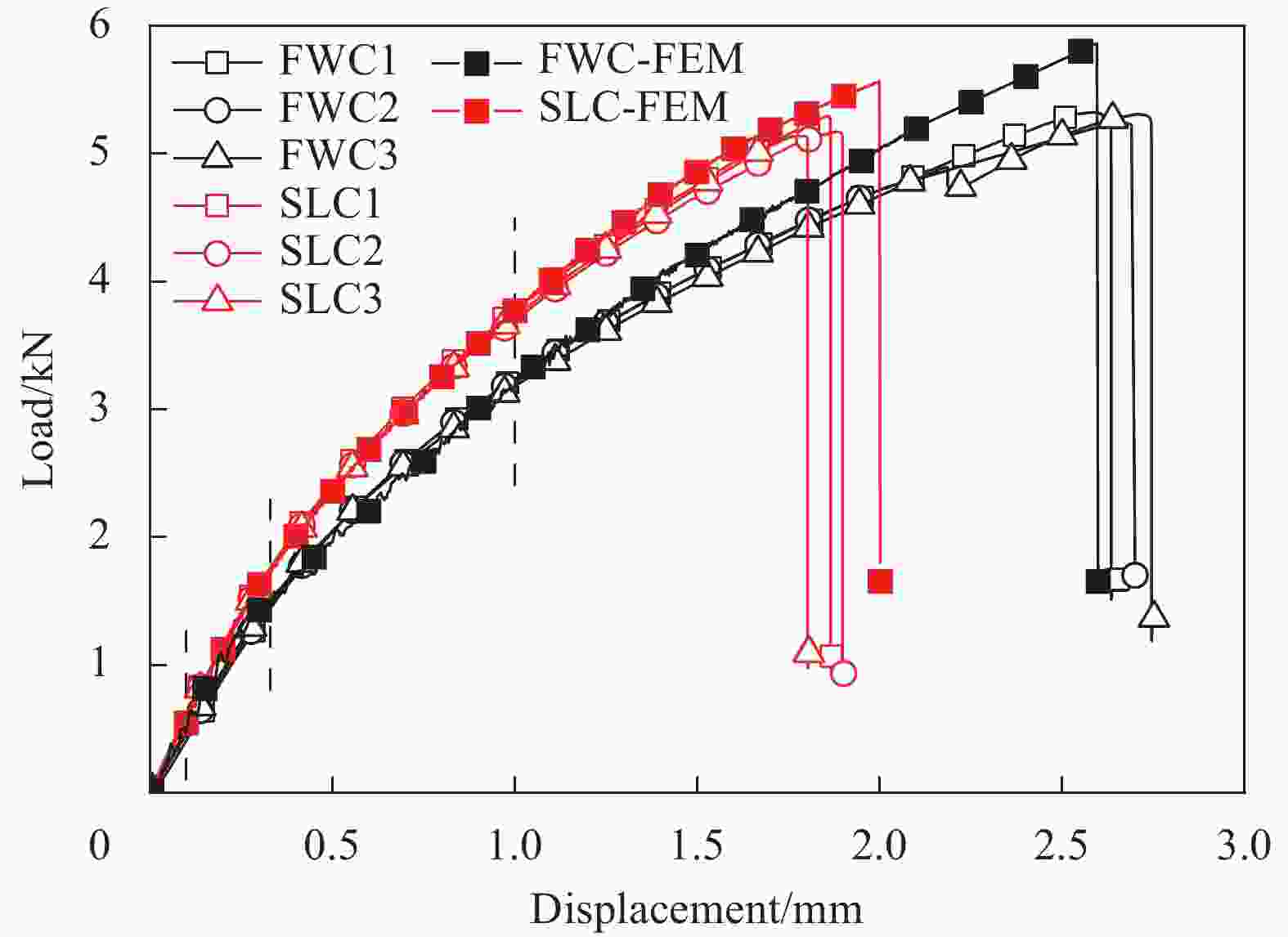

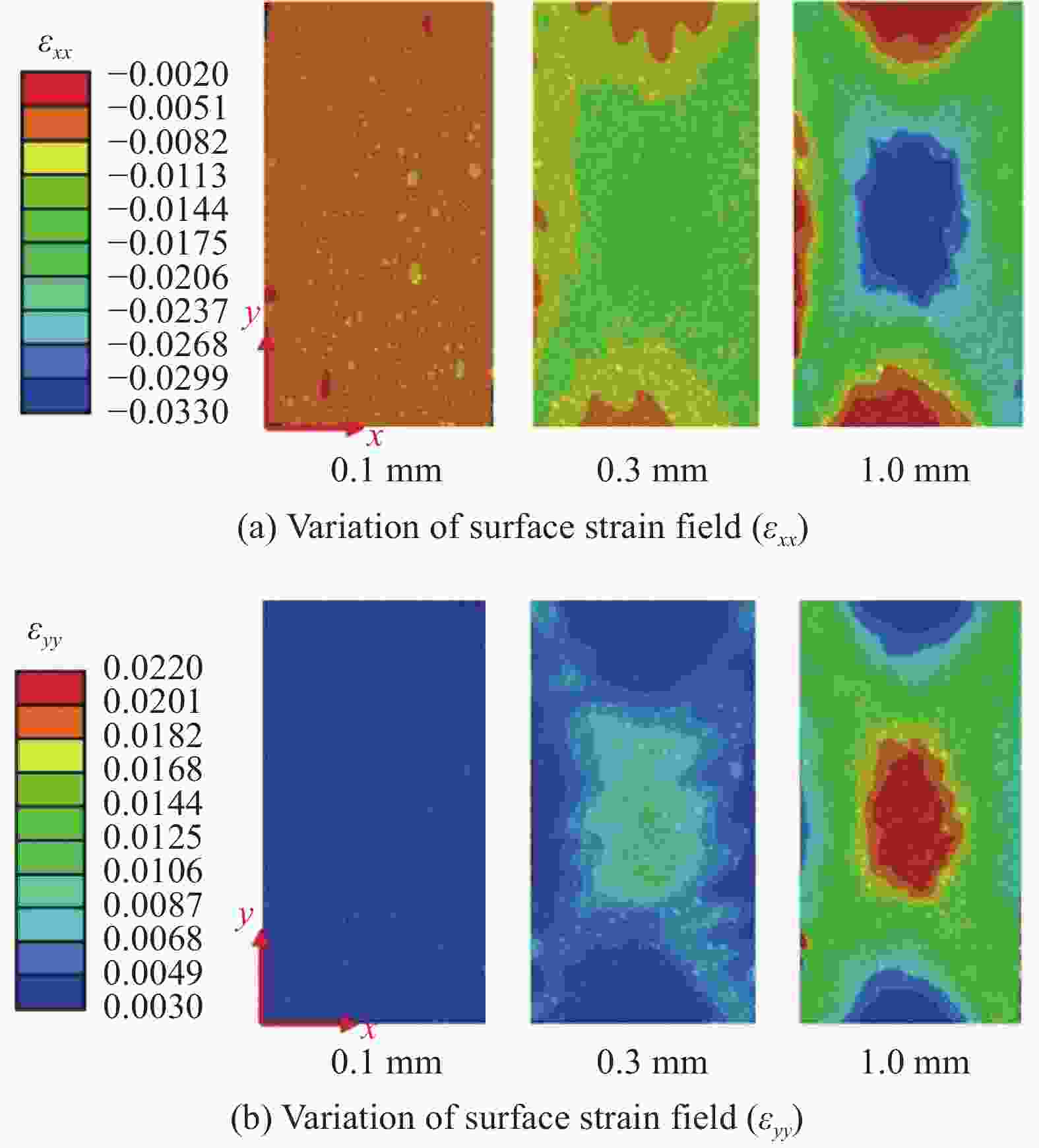

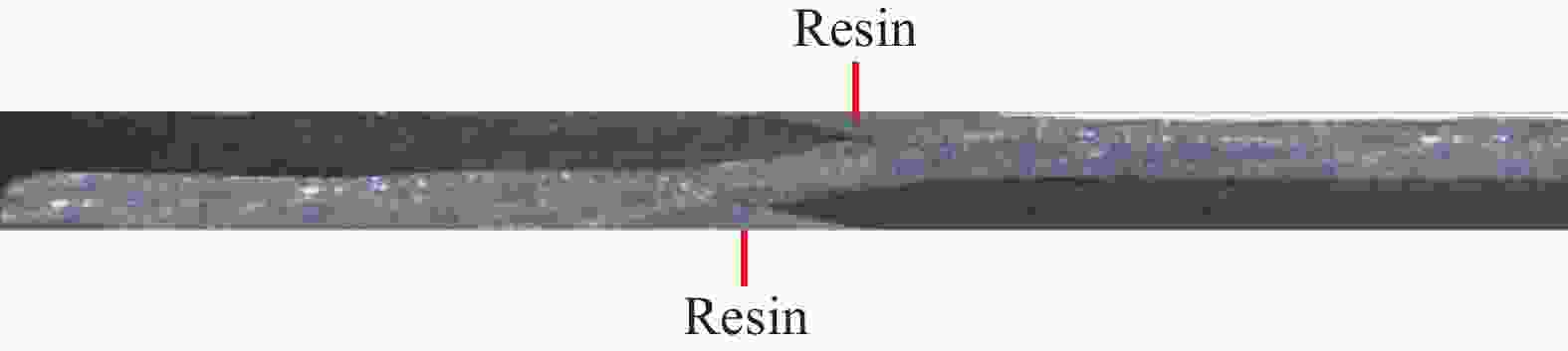

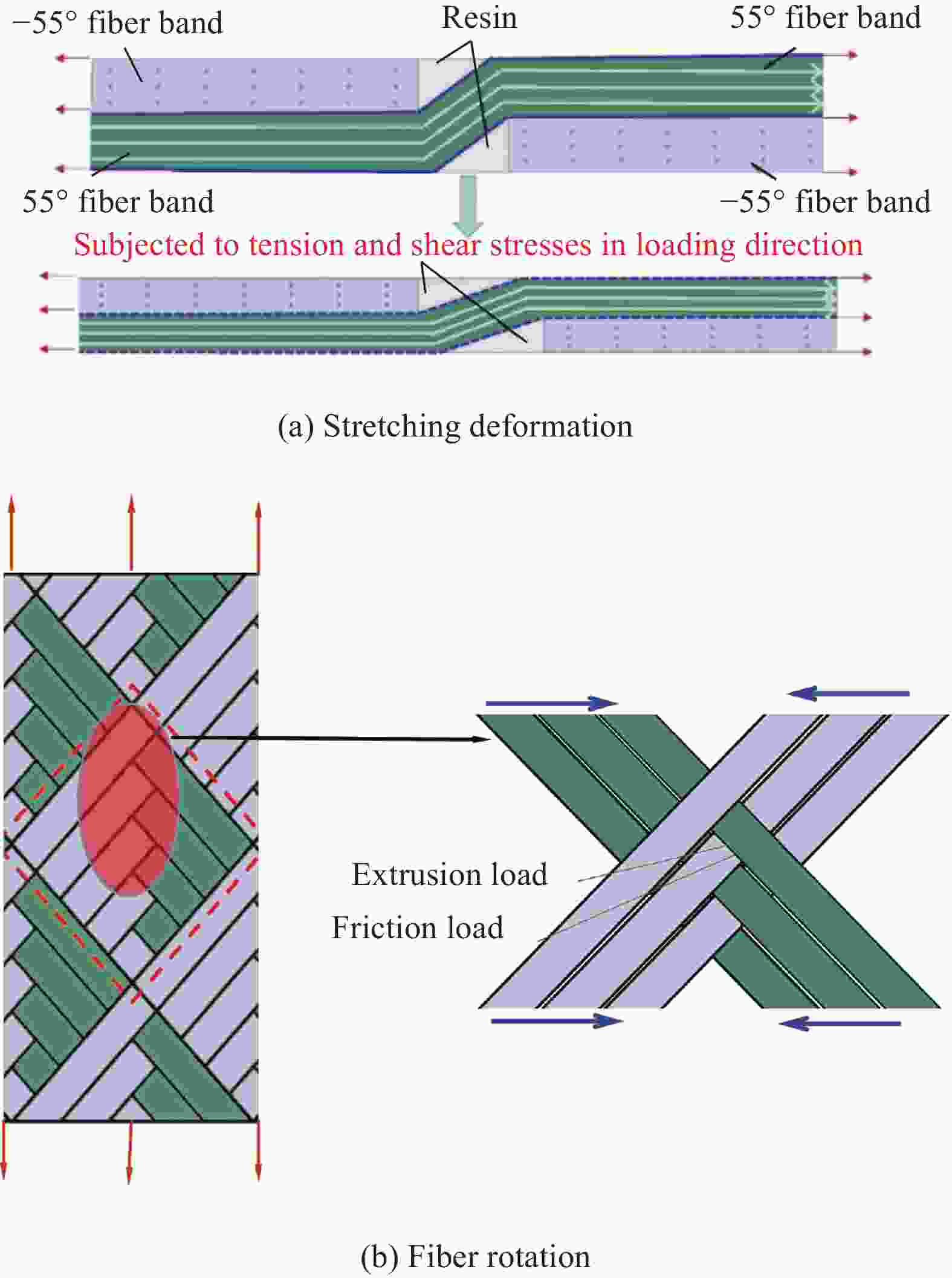

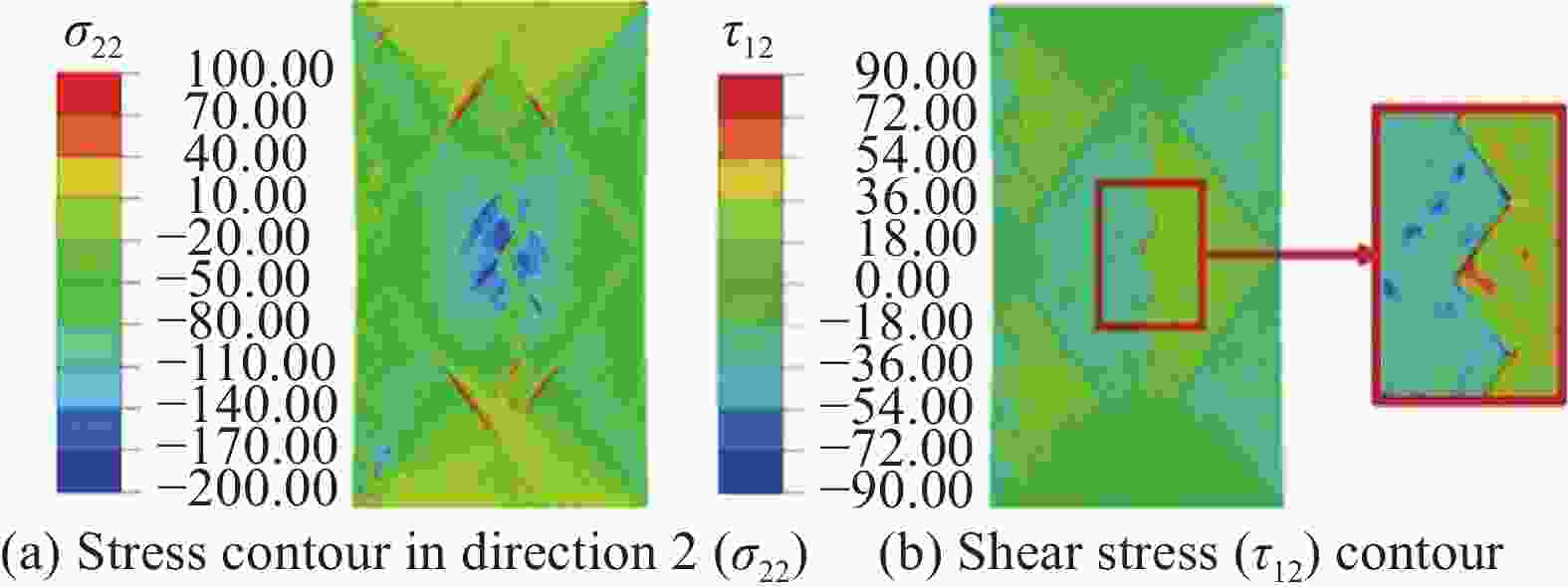

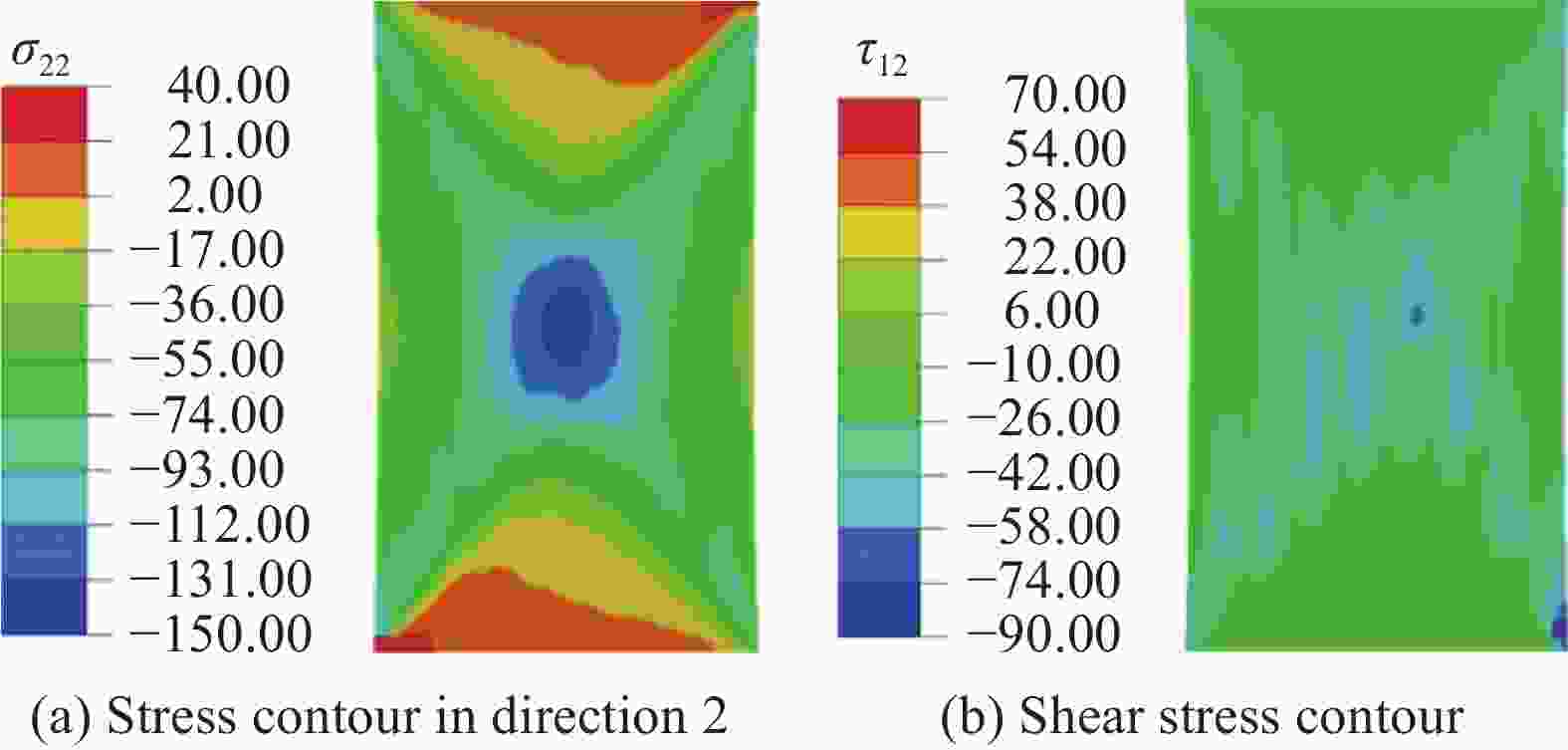

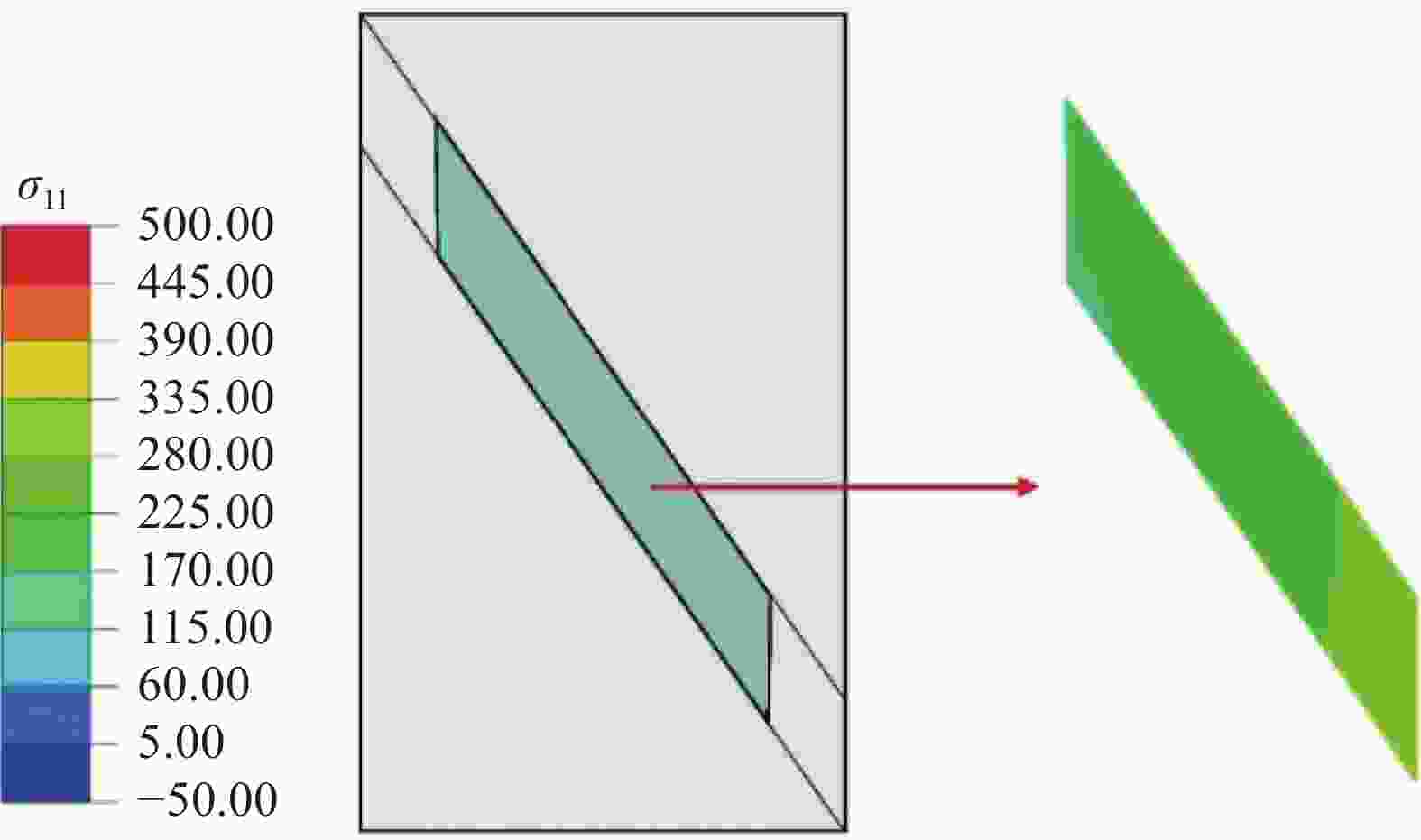

摘要: 纤维缠绕复合材料的纤维束具有交叉起伏形态特征,该形态对复合材料结构的力学行为有显著的影响。本文采用数值仿真和实验手段研究了纤维缠绕复合材料平板结构的拉伸力学行为。实验方面,开展纤维缠绕复合材料平板的准静态拉伸实验,通过数字图像相关技术(DIC)监测其表面应变场的演化过程,研究交叉起伏特征对载荷-位移曲线和应变分布特征的影响;数值分析方面,构建包含纤维缠绕形态的介观有限元模型,基于3D Hashin失效准则开展渐进损伤过程模拟,并引入了复合材料的剪切非线性行为。选取层合板结构为参照组,同时开展实验和数值分析。实验结果表明:对于层合结构,缠绕结构的整体刚度更低,失效位移更大,失效载荷基本相同,且缠绕结构菱形特征单元中部纤维交叉起伏区域存在明显的应变集中现象。所构建的有限元模型和实验结果吻合较好,呈现出纤维起伏区域的应变集中、失效起始和扩展行为。Abstract: Fiber bundles of filament wound structure have the morphology characteristic of crossover and undulation, which has significant impact on the mechanical behavior of composite structures. In this research, the tensile mechanical behavior of filament wound composite plate was investigated by numerical and experimental methods. In experimental study, quasi-static tensile experiment of fiber-wound composite plate was carried out, and the evolutions of surface strain field were recorded by digital imaging correlation (DIC). The influences of crossover and fluctuation characteristics on the load-displacement curve and strain distribution were investigated. For the numerical analysis, a meso-scale finite element model was created based on the filament wound morphology. The progressive failure process was simulated based on 3D Hashin failure criterion, and the nonlinear shearing behavior of composites was also involved. The experimental and numerical studies of laminated structures were also carried out as the reference group. The experimental results indicate that, compared with the laminated structures, the filament wound structure gives a lower stiffness, a larger failure displacement, and almost a same failure load. An obvious strain concentration is observed in the fiber crossover and undulating region which locates at the middle area of the filament wound rhombus unit. The finite element analysis results are in good agreement with the experimental ones. The strain concentration in the fiber fluctuation region, as well as the failure initiation and propagation behaviors, are represented properly by the numerical analysis.

-

表 1 试样编号和数量

Table 1. Lable and number of samples

Lable Number of sample FWC 3 SLC 3 Notes: FWC—Filament wound composites; SLC—Standard laminate composites. 表 2 T300碳纤维/环氧树脂复合材料预浸料材料参数

Table 2. Material properties of T300 carbon fiber/epoxy resin composite prepreg

Parameter Value E11/GPa 127.0 E22/GPa 7.9 E33/GPa 7.9 μ12 0.35 μ13 0.35 μ23 0.45 G12/GPa 2.1 G13/GPa 2.1 G23/GPa 4.8 XT/GPa 2.0 XC/GPa 1.2 YT/MPa 38.5 YC/MPa 180.7 S/MPa 135.0 Gft/(N·mm-1) 133 Gfc/(N·mm-1) 60 Gmt/(N·mm-1) 0.352 Gmc/(N·mm-1) 1.450 Notes: E—Elastic modulus; μ—Poisson's ratio; G—Shear modulus; 1—Direction of fiber; 2—Direction of matrix; 3—Thickness direction of layer; XT—Longitudinal tensile strength; XC—Longitudinal compressive strength; YT—Transverse tensile strength; YC—Transverse compressive strength; S—In-plane shear strength; Gft, Gfc, Gmt, Gmc—Critical value of strain energy release rate. 表 3 环氧树脂弹性参数

Table 3. Elastic parameters of epoxy resin

Parameter Value E/GPa 3.0 μ 0.37 表 4 内聚力单元界面性能参数

Table 4. Interface performance parameters of cohesive element

Parameter Value TI/MPa 48.0 TII/MPa 79.0 K/(N·mm–2) 106 GIC/(N·mm–1) 0.128 GIIC/(N·mm–1) 0.653 Notes: TI, TII—Mode I/II strength; K—Interface stiffness; GIC, GIIC—Critical strain energy release rates. 表 5 T300碳纤维/环氧树脂复合材料实验结果比较

Table 5. Comparison of experimental results of T300 carbon fiber/epoxy resin composites

Structure Ultra load/kN Failure displacement/mm FWC 5.2 2.7 SLC 5.2 1.8 -

[1] ELLYIN F, MARTENS M. Biaxial fatigue behaviour of a multidirectional filament-wound glass-fiber/epoxy pipe[J]. Composites Science and Technology,2001,61(4):491-502. doi: 10.1016/S0266-3538(00)00215-3 [2] ZHENG J Y, LIU P F. Elasto-plastic stress analysis and burst strength evaluation of Al-carbon fiber/epoxy composite cylindrical laminates[J]. Computational Materials Science,2008,42(3):453-461. doi: 10.1016/j.commatsci.2007.09.011 [3] DATTA M, HATUA P. Influence of winding angle on the physical properties of filament wound composite pipe[C]//Proceedings of the 3rd National Conference on Emerging Trends in Textile, Fibre and Apparel Engineering. Berhampore, 2016: 1-9. [4] GUO Z, LI Z, CUI J, et al. The effect of winding patterns on the mechanical behavior of filament-wound cylinder shells[J]. Multidiscipline Modeling in Materials and Structures,2019,16(3):508-518. doi: 10.1108/MMMS-03-2019-0059 [5] 穆建桥. 复合材料压力容器的非测地线缠绕成型及强度分析研究[D]. 武汉: 武汉理工大学, 2017.MU Jianqiao. Research on non-geodesic winding and strength analysis of composite pressure vessels[D]. Wuhan: Wuhan University of Technology, 2017(in Chinese). [6] 张靖. 纤维缠绕复合材料的等效刚度性能研究[D]. 大连: 大连理工大学, 2016.ZHANG Jing. Study on the equivalent stiffness of filament wound composite materials[D]. Dalian: Dalian University of Technology, 2016(in Chinese). [7] LIU P F, ZHENG J Y. Progressive failure analysis of carbon fiber/epoxy composite laminates using continuum damage mechanics[J]. Materials Science and Engineering: A,2008,485(1-2):711-717. doi: 10.1016/j.msea.2008.02.023 [8] LIN S, YANG L, XU H, et al. Progressive damage analysis for multiscale modelling of composite pressure vessels based on Puck failure criterion[J]. Composite Structures,2021,255:113046. doi: 10.1016/j.compstruct.2020.113046 [9] LIAO B B, DU Y, ZHENG J, et al. Prediction of residual burst strength for composite pressure vessels after low velocity impact[J]. International Journal of Hydrogen Energy,2020,45(18):10962-10976. doi: 10.1016/j.ijhydene.2020.02.021 [10] ALAM S, YANDEK G, LEE R C, et al. A study of residual burst strength of composite over wrapped pressure vessel due to low velocity impact[J]. International Journal of Pressure Vessels and Piping,2021,194:104511. doi: 10.1016/j.ijpvp.2021.104511 [11] ZU L, XU H, WANG H, et al. Design and analysis of filament-wound composite pressure vessels based on non-geodesic winding[J]. Composite Structures,2019,207:41-52. doi: 10.1016/j.compstruct.2018.09.007 [12] ROUSSEAU J, PERREUX D, VERDIERE N. The influence of winding patterns on the damage behavior of filament-wound pipes[J]. Composites Science & Technology,1999,59(9):1439-1449. [13] ARELLANO M T, CROUZEIX L, DOUCHIN B, et al. Strain field measurement of filament-wound composites at ±55° using digital image correlation: An approach for unit cells employing flat specimens[J]. Composite Structures,2010,92(10):2457-2464. doi: 10.1016/j.compstruct.2010.02.014 [14] 沈创石, 韩小平, 何欣辉. 计及纤维交叉起伏影响的缠绕复合材料刚度分析[J]. 复合材料学报, 2016, 33(1): 174-182.SHEN Chuangshi, HAN Xiaoping, HE Xinhui. Stiffness analysis of filament wound composites considering filament crossover and undulation[J]. Acta Materiae Composiae Sinica, 2016, 33(1): 174-182(in Chinese). [15] 姜云鹏, 岳珠峰, 卢文书, 等. 计入纤维交叉影响的缠绕复合材料等效模量计算方法[J]. 燃气涡轮试验与研究, 2005, 18(3):33-37. doi: 10.3969/j.issn.1672-2620.2005.03.008JIANG Yunpeng, YUE Zhufeng, LU Wenshu, et al. Effect of fiber undulating zoneon the macro elastic modulus of fiber winding composites[J]. Gas Turbine Experimentand Research,2005,18(3):33-37(in Chinese). doi: 10.3969/j.issn.1672-2620.2005.03.008 [16] HENRY T C, BAKIS C E. Compressive strength and stiffness of filament-wound cylinders[J]. Journal of Reinforced Plastics and Composites,2016,35(21):1543-1553. doi: 10.1177/0731684416659545 [17] RICHARD R M, BLACKLOCK J R. Finite element analysis of inelastic structures[J]. AIAA Journal,1969,7(3):432-438. doi: 10.2514/3.5125 [18] ASTM. Standard test method for in-plane shear response of polymer matrix composite materials by tensile test of ±45° laminate: D3518/D3518 M-18[S]. West Conshohocken: ASTM, 2018. [19] HASHIN Z. Failure criteria for unidirectional fiber compo-sites[J]. Journal of Applied Mechanics,1980,47(2):329-334. doi: 10.1115/1.3153664 [20] HASHIN Z, ROTEM A. A fatigue failure criterion for fiber reinforced materials[J]. Journal of Composite Materials,1973,7(4):448-464. doi: 10.1177/002199837300700404 [21] DS. SIMULIA. ABAQUS user manual[EB/OL]. Version 6.10, ABAQUS Inc., Providence, 2010. https://help.3ds.com/HelpProductsDS.aspx. [22] CAO D, HU H, DUAN Q, et al. Experimental and three-dimensional numerical investigation of matrix cracking and delamination interaction with edge effect of curved composite laminates[J]. Composite Structures,2019,225:111154. doi: 10.1016/j.compstruct.2019.111154 [23] FULLER J, MITCHELL S, POZEGIC T, et al. Experimental evaluation of hygrothermal effects on pseudo-ductile thin ply angle-ply carbon/epoxy laminates[J]. Composites Part B: Engineering,2021,227:109388. doi: 10.1016/j.compositesb.2021.109388 [24] CZEL G. Development of bi-directional pseudo-ductile glass/carbon-epoxy hybrid composites for improved safety in structural applications[J]. Composites Part B: Engineering,2022,231:109546. doi: 10.1016/j.compositesb.2021.109546 [25] WU X, FULLER J D, WISNOM M R. An investigation into fatigue behaviour and damage progression in pseudo-ductile thin-ply angle-ply laminates[J]. Composites Part A: Applied Science and Manufacturing,2021 , 149:106518. [26] DIZMAN E A, ÖZDDEMIR İ. Crystal plasticity based modelling of shear response of carbon fibre reinforced compo-sites[J]. Procedia Structural Integrity,2022,35:91-97. doi: 10.1016/j.prostr.2021.12.052 [27] KWON J, CHOI J, HUH H, et al. Evaluation of the effect of the strain rate on the tensile properties of carbon-epoxy composite laminates[J]. Journal of Composite Materials,2017,51(22):3197-3210. doi: 10.1177/0021998316683439 [28] WAN L, ISMAIL Y, SHENG Y, et al. Progressive failure analysis of CFRP composite laminates under uniaxial tension using a discrete element method[J]. Journal of Composite Materials,2021,55(8):1091-1108. doi: 10.1177/0021998320961460 -

下载:

下载: