Modified diatomite with enhanced moisture-regulating by surface hydrophobicity and its effect on water vapor permeability of polyurethane film

-

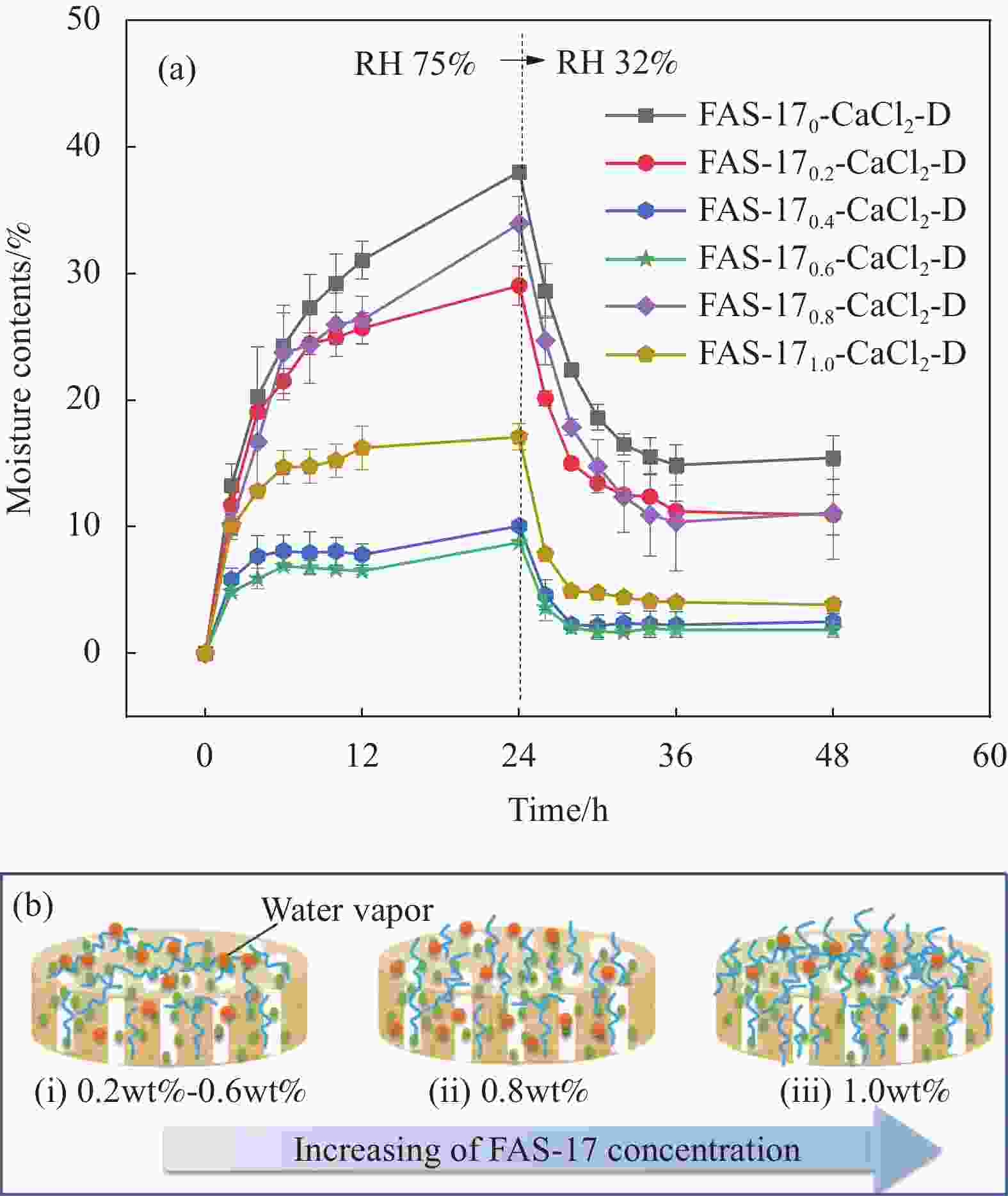

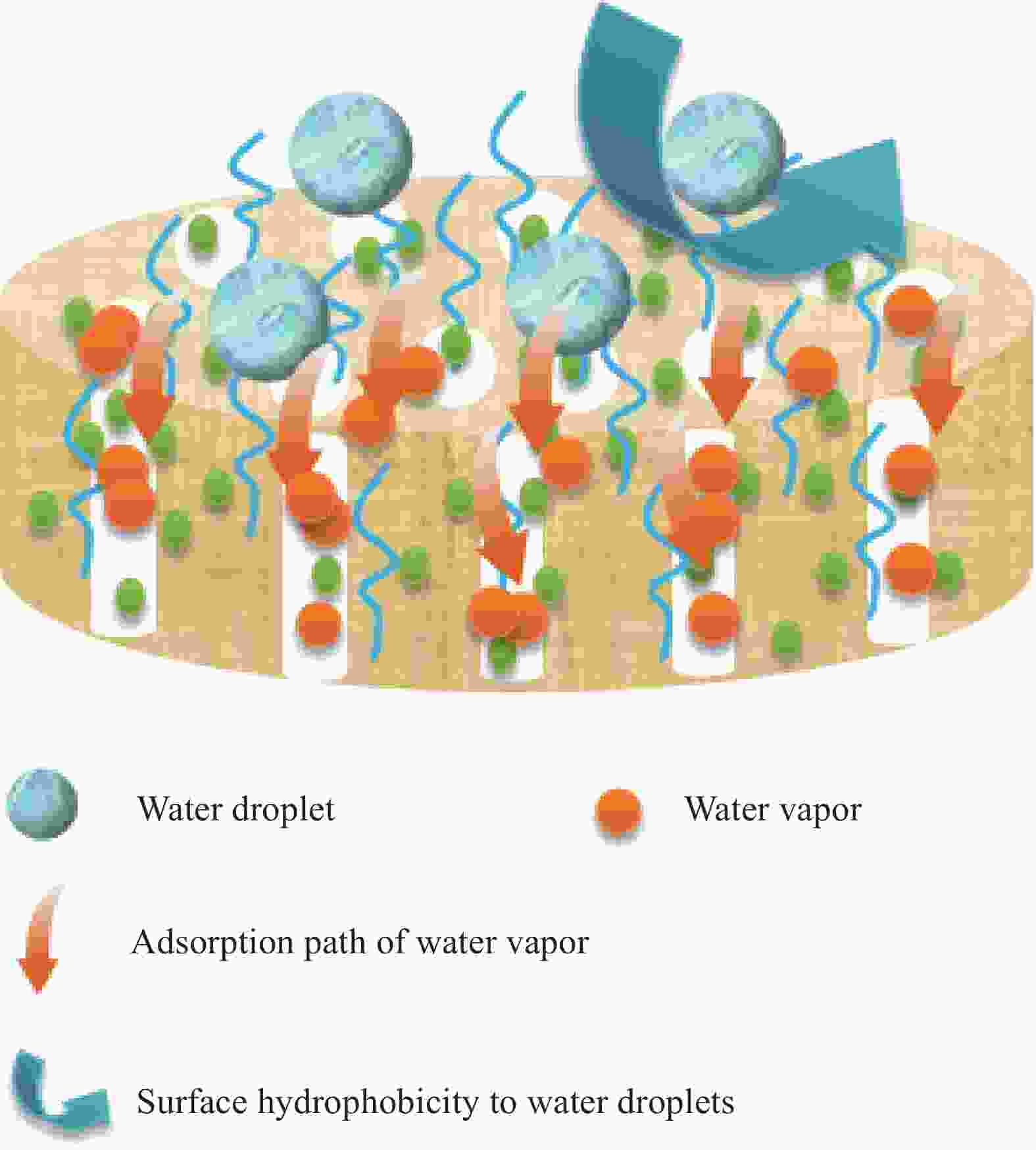

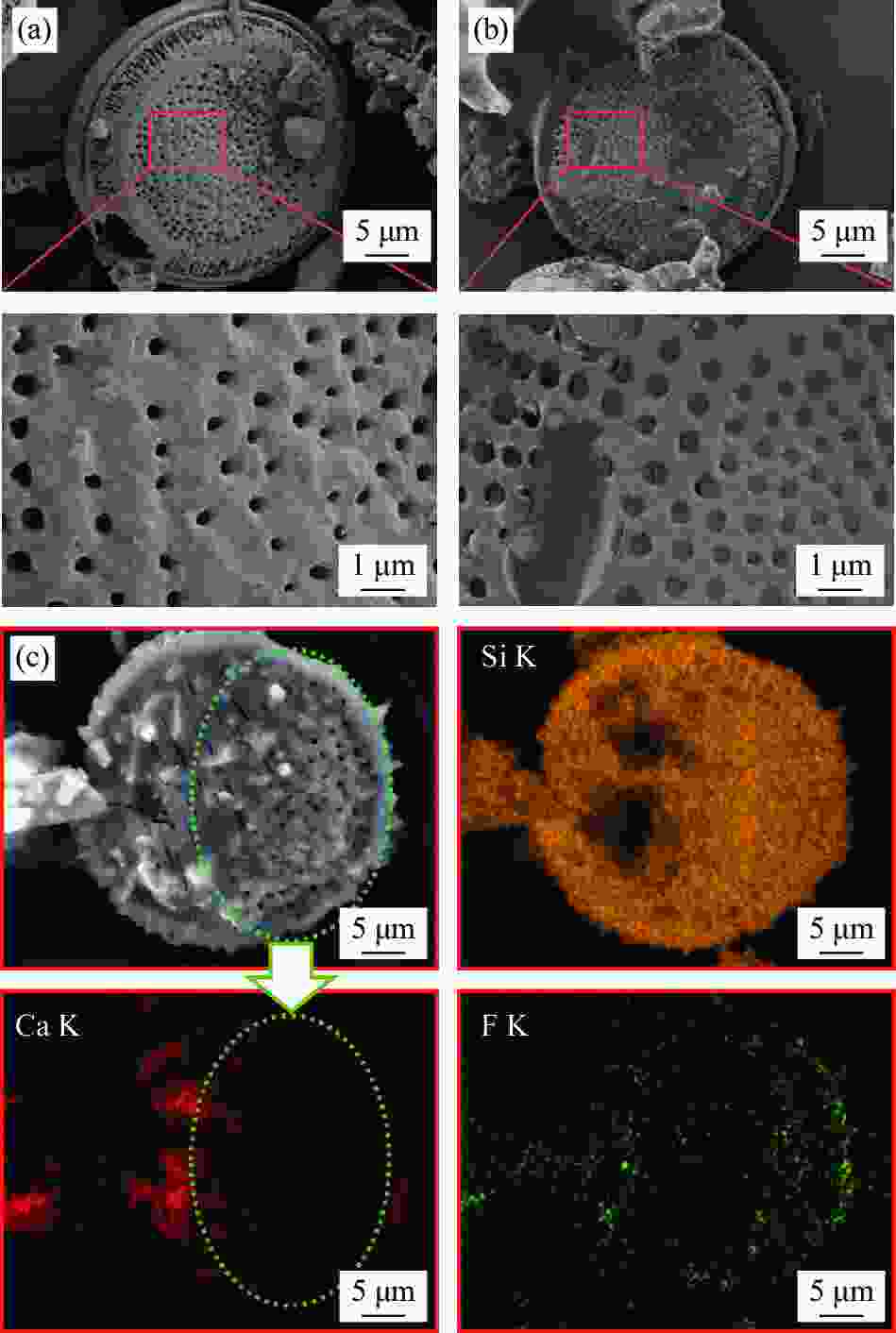

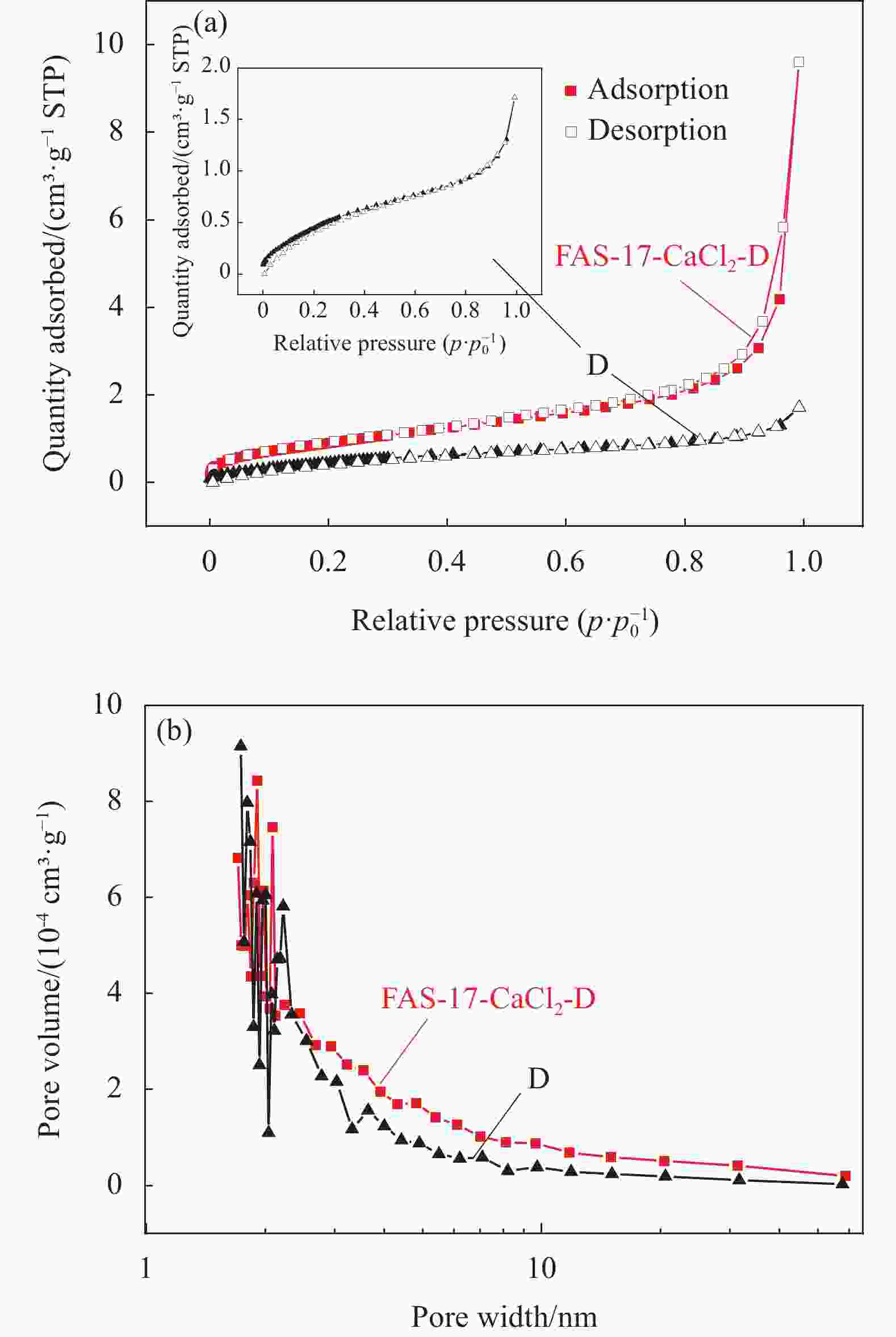

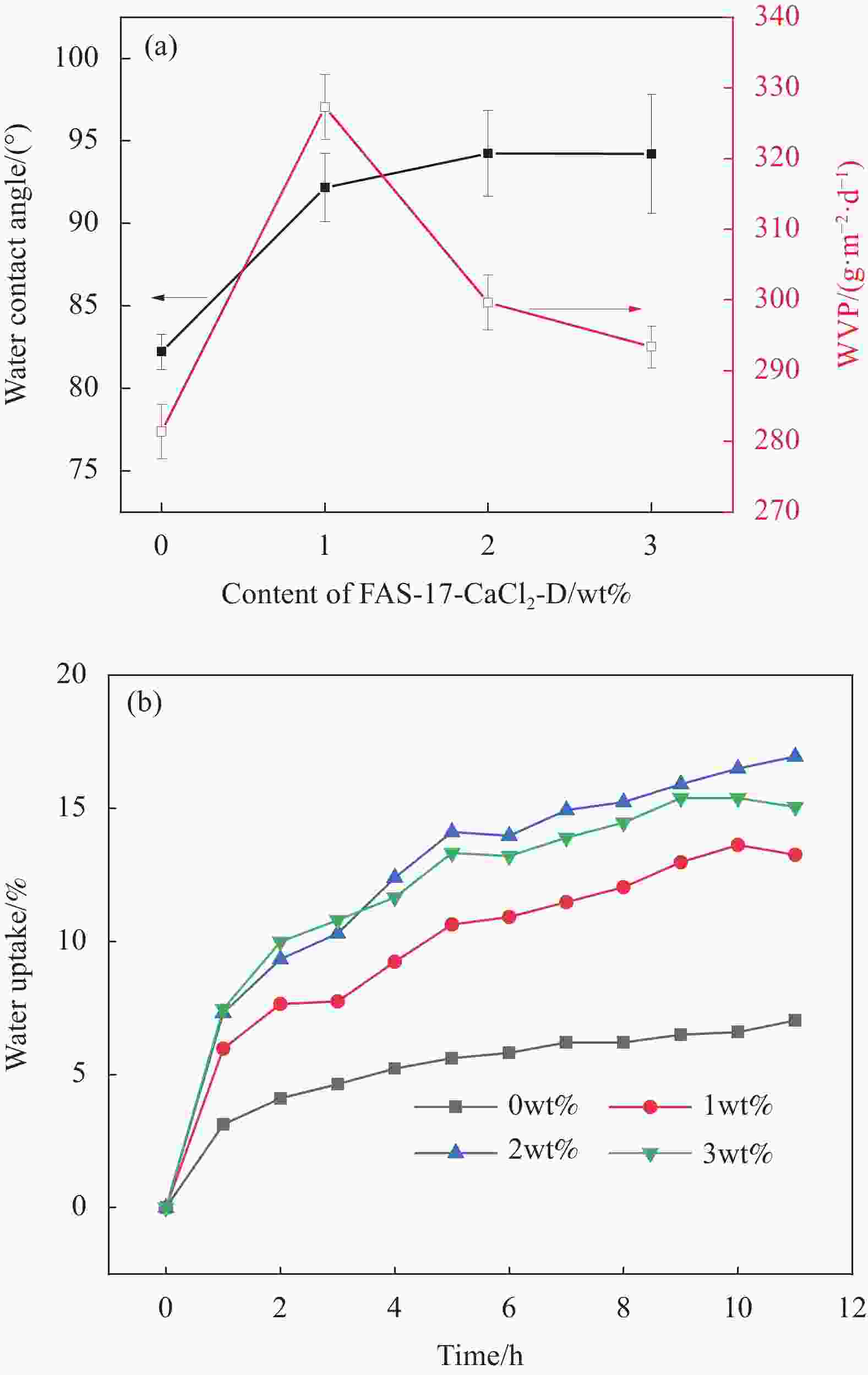

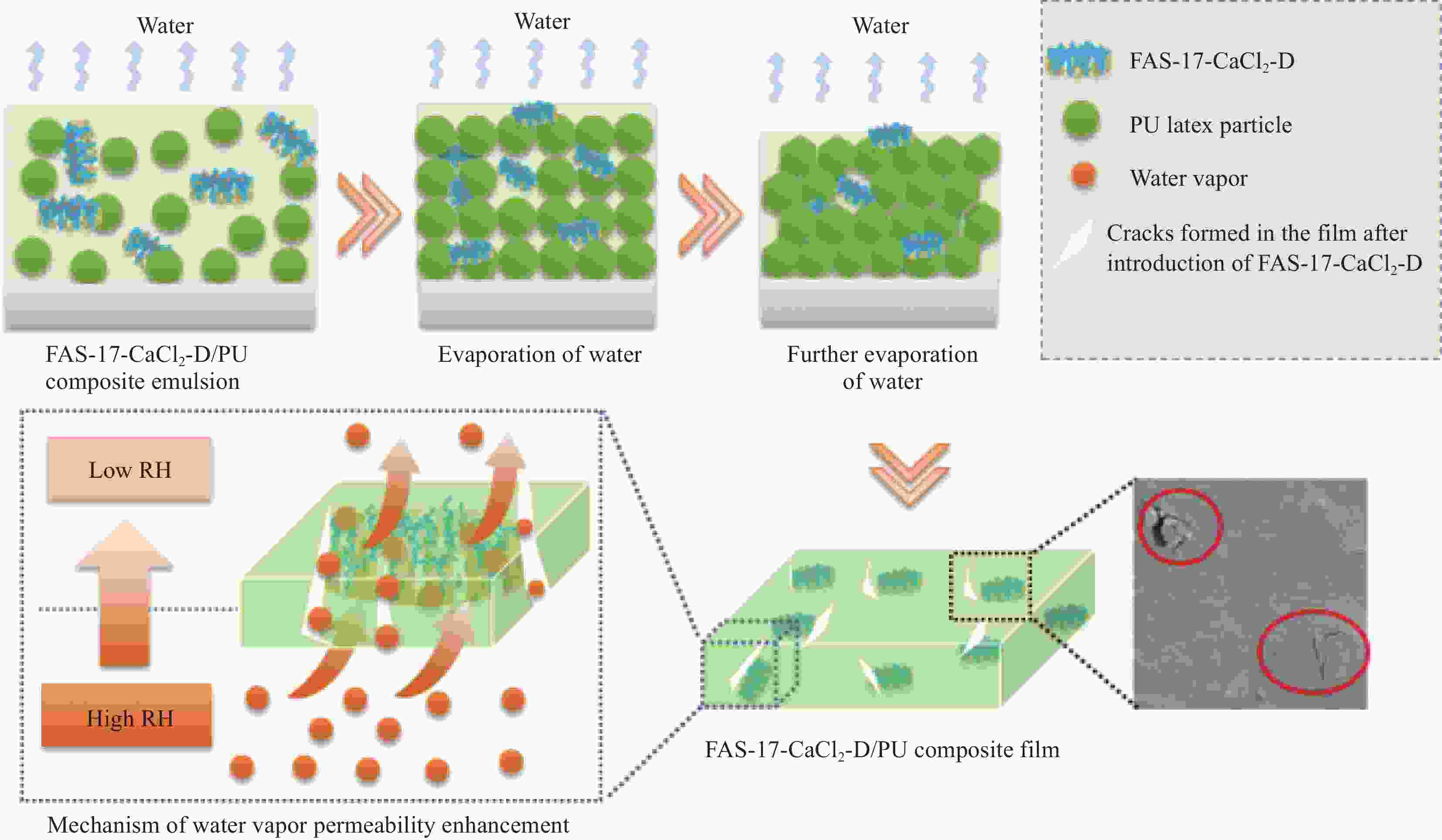

摘要: 水性聚氨酯(PU)是一种环保绿色的涂层材料,广泛应用于皮革、纺织、建筑涂层等领域。作为皮革、纺织涂层时,聚氨酯的透湿性决定服装的穿着舒适性,而常规水性聚氨酯的透湿性较差,需要对其进行改性获得透湿性优异的涂层。本文采用CaCl2和十七氟癸基三甲氧基硅烷(FAS-17)对硅藻土进行改性,研究了改性条件对硅藻土结构和性能的影响,将调湿性能较好的改性硅藻土(FAS-17-CaCl2-D)与PU复合,研究复合膜的透湿性。结果表明:采用质量浓度为30wt%CaCl2和0.8wt%FAS-17改性的硅藻土综合性能最好,改性后硅藻土的比表面积、孔隙结构增大,调湿性能提高,FAS-17表面疏水修饰进一步强化了其调湿作用。将性能最好的FAS-17-CaCl2-D与PU复合后,FAS-17-CaCl2-D/PU透湿性随着FAS-17-CaCl2-D用量的增加先增大后减小,复合膜的疏水性提高。1%FAS-17-CaCl2-D与PU复合制备的复合膜透湿率最大,较纯PU膜提高了16.3%,SEM-EDS显示该复合膜表面和截面有Si、Ca和F等FAS-17-CaCl2-D的特征元素,PU与FAS-17-CaCl2-D相界面出现了孔隙,为水蒸气的透过提供通道,从而使透湿性增强。本文制备的透湿聚氨酯材料,有望用于纺织品和皮革涂层,改善湿热舒适性。Abstract: Waterborne polyurethane (PU) is a kind of environment-friendly coating material, widely used in leather, textile, construction coating and other fields. As a coating for leather and textile, the water vapor permeability (WVP) of polyurethane determines the wearing comfort of clothing. However, the water vapor permeability of conventional waterborne polyurethane is poor and needs to be modified to obtain coatings with excellent WVP. CaCl2 and Heptafluorodecyl trimethoxysilane (FAS-17) were used to modify diatomite to prepare hydrophobic diatomite base materials. The effects of modification conditions on the structure and properties of diatomite were investigated. The modified diatomite with excellent performance was combined with PU emulsion and the WVP of composite film was studied. The results indicate that the diatomite modified with 30wt%CaCl2 and 0.8wt%FAS-17 present the best comprehensive performance with increased specific surface area and pore structure. The moisture-regulating performance is improved and further enhanced by surface hydrophobic modification of FAS-17. After modified diatomite FAS-17-CaCl2-D with best performance is combined with PU, the WVP of FAS-17-CaCl2-D/PU composite film increase first then decrease with the increasing of FAS-17-CaCl2-D dosage, and the hydrophobicity is improved. The composite PU film with 1% of FAS-17-CaCl2-D shows the largest WVP, which increased by 16.3% compared with pure PU film. The SEM-EDS reveal that the the surface and cross section of FAS-17-CaCl2-D/PU composite film appear the characteristic elements of FAS-17-CaCl2-D such as Si, Ca and F. The pores appeared at the interface between PU and FAS-17-CaCl2-D provided channels for the transfer of water vapor, resulting in improved WVP. The WVP enhanced PU in this work are expected to be applied in textile and leather coatings to improve the thermal comfort.

-

Key words:

- modified diatomite /

- moisture-regulating /

- hydrophobic /

- polyurethane film /

- water vapor permeability

-

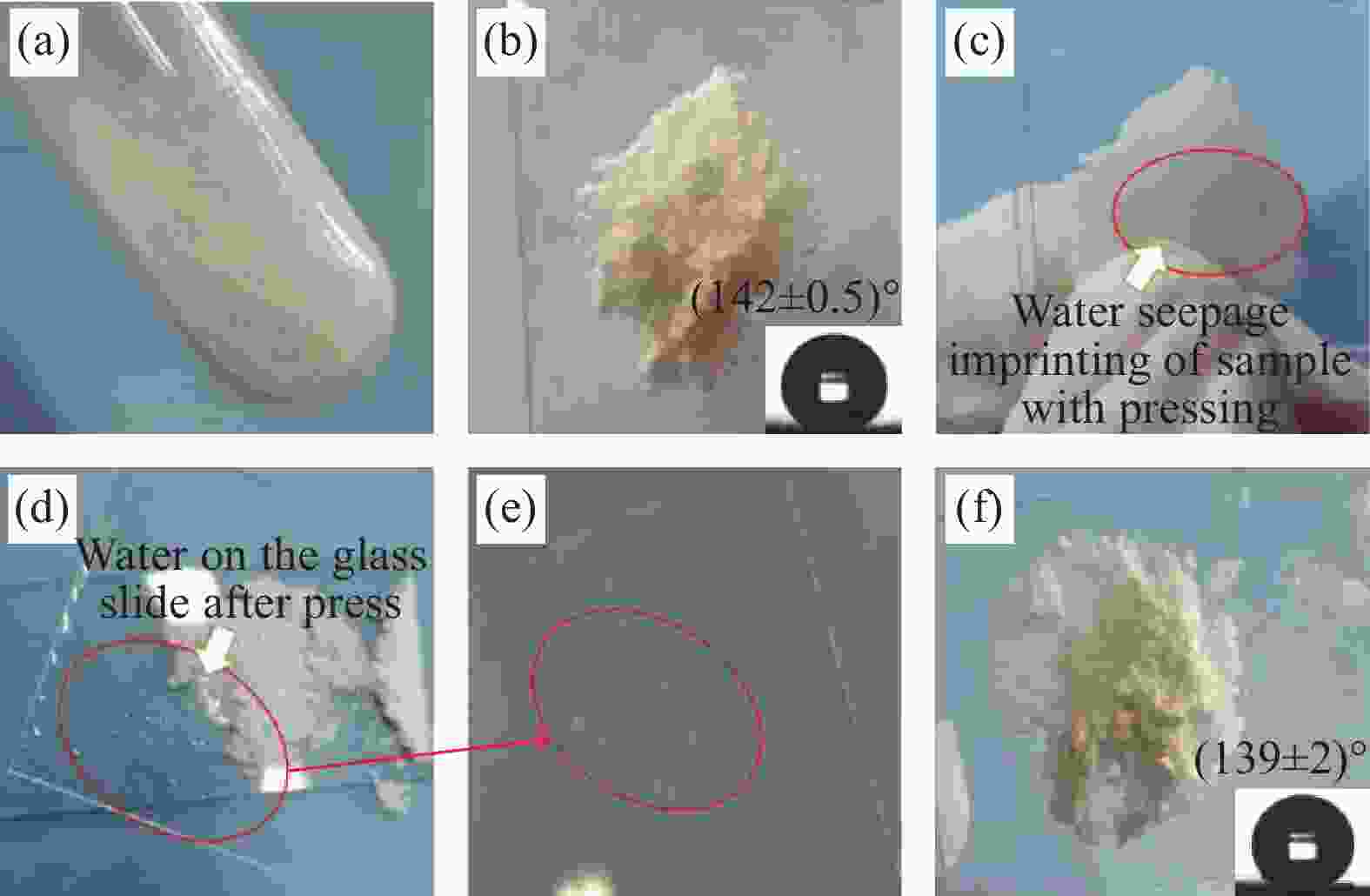

图 5 吸湿后的FAS-170.8-CaCl2-D 经挤压的照片:((a), (b))吸湿样品;(c)用载玻片挤压样品有渗水印迹;((d), (e))玻璃片上的水滴;(f)挤压后样品仍成粉末状态;(图(b)和图(f)的插图分别为挤压前后样品的表面水接触角)

Figure 5. Photo of moisture-adsorption FAS-170.8-CaCl2-D after pressed: ((a), (b)) Moisture-adsorption FAS-170.8-CaCl2-D; (c) Water seepage imprinting of sample with pressing; Water on the glass slide after pressed ((d), (e)) and the pressed sample (f) (Insets of (b) and (f) were the contact angle of original and pressed samples)

表 1 样品名称缩写

Table 1. Sample name abbreviation

Sample CaCl2/wt% FAS-17/wt% PU/wt% D – – – 10%CaCl2-D 10 – – 20%CaCl2-D 20 – – 30%CaCl2-D 30 – – 40%CaCl2-D 40 – – FAS-170-CaCl2-D 30 – – FAS-170.2-CaCl2-D 30 0.2 – FAS-170.4-CaCl2-D 30 0.4 – FAS-170.6-CaCl2-D 30 0.6 – FAS-170.8-CaCl2-D 30 0.8 – FAS-171.0-CaCl2-D 30 1.0 – (FAS-17-CaCl2-D)1%/PU 30 0.8 99 (FAS-17-CaCl2-D)2%/PU 30 0.8 98 (FAS-17-CaCl2-D)3%/PU 30 0.8 97 Notes: D—Diatomite; FAS-17−Heptafluorodecyl trimethoxysilane; PU—Polyurethane. 表 2 FAS-17-CaCl2-D和D的孔结构参数

Table 2. Pore structure parameters of FAS-17-CaCl2-D and D

BET surface

area/(m2·g−1)BJH adsorption cumulative

volume of pores/(cm³·g−1)BJH adsorption average pore

width (4 V/A)/nmFAS-17-CaCl2-D 2.6235 0.006103 10.7674 D 1.9396 0.002341 6.3299 Notes: BET—Brunauer-Emmett-Teller; BJH—Barret-Joyner-Halenda. -

[1] LOSIC D, MITCHELL J G, VOELCKER N H. Diatomaceous lessons in nanotechnology and advanced materials[J]. Advanced Materials,2009,21(29):2947-2958. doi: 10.1002/adma.200803778 [2] FAN H, REN Q, WANG S, et al. Synthesis of the Ag/Ag3PO4/diatomite composites and their enhanced photocatalytic activity driven by visible light[J]. Journal of Alloys and Compounds,2019,775:845-852. doi: 10.1016/j.jallcom.2018.10.152 [3] LIU G, ABUKHADRAM R, ELSHERBEENY A M, et al. Insight into the photocatalytic properties of diatomite@Ni/NiO composite for effective photo-degradation of malachite green dye and photo-reduction of Cr(VI) under visible light[J]. Journal of Environmental Management,2020,254:109799-109808. doi: 10.1016/j.jenvman.2019.109799 [4] MAO Z, ZHANG H, LI Y, et al. Preparation and characterization of composite scallop shell powder-based and diatomite-based hygroscopic coating materials with metal-organic framework for indoor humidity regulation[J]. Jour-nal of Building Engineering,2021,43:103122-103133. doi: 10.1016/j.jobe.2021.103122 [5] MUJTABA M, FERNÁNDEZ-MARÍN R, ROBLES E, et al. Understanding the effects of copolymerized cellulose nanofibers and diatomite nanocomposite on blend chitosan films[J]. Carbohydrate Polymers,2021,271:118424-118436. doi: 10.1016/j.carbpol.2021.118424 [6] DOBOR J, PER N, VARGA I, et al. A new carbon-diatomite earth composite adsorbent for removal of heavy metals from aqueous solutions and a novel application idea[J]. Microporous and Mesoporous Materials,2015,217:63-70. doi: 10.1016/j.micromeso.2015.06.004 [7] XIA P, WANG X, WANG X, et al. Struvite crystallization combined adsorption of phosphate and ammonium from aqueous solutions by mesoporous MgO-loaded diatomite[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2016,506:220-227. doi: 10.1016/j.colsurfa.2016.05.101 [8] 孔伟, 杜玉成, 卜仓友, 等. 硅藻土基调湿材料的制备与性能研究[J]. 非金属矿, 2011, 34(1):57-59, 62. doi: 10.3969/j.issn.1000-8098.2011.01.017KONG Wei, DU Yucheng, BU Cangyou, et al. Study on preparation and performance of diatomite-based humidity controlling materials[J]. Non-Metallic Mines,2011,34(1):57-59, 62(in Chinese). doi: 10.3969/j.issn.1000-8098.2011.01.017 [9] LIU X, CHEN Z, YANG G, et al. Bioinspired ant-nest-like hierarchical porous material using CaCl2 as additive for smart indoor humidity control[J]. Industrial & Engineering Chemistry Research, 2019, 58: 7139-7145 [10] 邓妮, 武双磊, 陈胡星. 氯化钙改性硅藻土的调湿性能[J]. 材料科学与工程学报, 2014, 32(4):493-498.DENG Ni, WU Shuanglei, CHEN Huxing. Humidity-control performance of diatomite modified by calcium chloride[J]. Journal of Materials Science and Engineering,2014,32(4):493-498(in Chinese). [11] LIU X, CHEN Z, YANG G, et al. Colorful wall-bricks with superhydrophobic surfaces for enhanced smart indoor humidity control[J]. ACS Omega,2019,4(9):13896-13901. doi: 10.1021/acsomega.9b01588 [12] 冯蕾, 楼岱, 冉泽, 等. 改性硅藻土对水泥基调湿材料性能的影响[J]. 硅酸盐学报, 2021, 40(1):180-186.FENG Lei, LOU Dai, RAN Ze, et al. Influence of modified diatomite on cement-based humidity control materials performance[J]. Bulletin of the Chinese Ceramic Society,2021,40(1):180-186(in Chinese). [13] 张磊, 张亚楠, 荣辉, 等. 基于溶胶凝胶法改性的硅藻土对水泥基材料性能的影响[J]. 材料导报, 2016, 30(8):120-126.ZHANG Lei, ZHANG Yanan, RONG Hui, et al. The impact of diatomite modified by sol-gel method on the performce of cement-based materials[J]. Materials Review,2016,30(8):120-126(in Chinese). [14] CUI M, LI J, CHEN X, et al. A halogen-free, flame retardant, waterborne polyurethane coating based on the synergistic effect of phosphorus and silicon[J]. Progress in Organic Coatings,2021,158:106359-106370. doi: 10.1016/j.porgcoat.2021.106359 [15] SUN Z, WEN J, WANG W, et al. Polyurethane covalently modified polydimethylsiloxane (PDMS) coating with increased surface energy and re-coatability[J]. Progress in Organic Coatings,2020,146:105744-105755. doi: 10.1016/j.porgcoat.2020.105744 [16] XU W, ZHAO W, HAO L, et al. Synthesis and characterization of novel fluoroalkyl-terminated hyperbranched polyurethane latex[J]. Applied Surface Science,2018,436:1104-1112. doi: 10.1016/j.apsusc.2017.12.148 [17] WEN J, SUN Z, XIAN J, et al. Preparation and characteristics of waterborne polyurethane with various lengths of fluorinated side chains[J]. Applied Surface Science,2019,494:610-618. doi: 10.1016/j.apsusc.2019.07.170 [18] TIAN S, ZHANG P, FAN H, et al. Fabrication of retro-reflec-tive polyurethane via covalently embedding with amino-functionalized glass microspheres[J]. Progress in Organic Coatings,2018,115:115-121. doi: 10.1016/j.porgcoat.2017.10.026 [19] ZHANG P, XU P, FAN H, et al. Covalently functionalized graphene towards molecular-level dispersed waterborne polyurethane nanocomposite with balanced comprehen-sive performance[J]. Applied Surface Science,2019,471:595-606. doi: 10.1016/j.apsusc.2018.11.235 [20] CHEN Y, WANG R, ZHOU J, et al. Membrane formation temperature-dependent gas transport through thermo-sensitive polyurethane containing in situ-generated TiO2 nanoparticles[J]. Polymer,2011,52:1856-1867. doi: 10.1016/j.polymer.2011.02.021 [21] YAN K, LIU C, MA J. Dendritic fibrous nanosilica loaded chitosan for improving water vapor permeability and antibacterial properties of waterborne polyurethane acrylate membranes[J]. Journal of Cleaner Production,2021,291:125922-125929. doi: 10.1016/j.jclepro.2021.125922 [22] BAO Y, GAO L, FENG C, et al. Hollow flower-like ZnO: Synthesis, growth mechanism and application in polyacrylate[J]. Advanced Powder Technology, 2020, 31: 1975-1984 [23] BHUIYAN M A R, WANG L, SHAID A, et al. Polyurethane-aerogel incorporated coating on cotton fabric for chemical protection[J]. Progress in Organic Coatings, 2019, 131: 100-110. [24] SI Y, WANG X, YAN C, et al. Ultralight biomass-derived carbonaceous nanofibrous aerogels with superelasticity and high pressure-sensitivity[J]. Advanced Materials,2016,28:9512-9518. doi: 10.1002/adma.201603143 [25] WILLIAMS J T. Waterproof and water repellent textiles and clothing[M]. Cambridge: Woodhead Publishing, 2018. [26] 全国纺织品标准化技术委员会基础标准分会. 纺织品 织物透湿性试验方法 第1部分: 吸湿法: GB/T 12704.1—2009[S]. 北京: 中国标准出版社, 2009.Basic Standard Branch of National Technical Committee of Textile Standardization. Textile-Test method for water-vapor transmission of fabrics—Part 1: Desiccant method: GB/T 12704.1—2009[S]. Beijing: Standards Press of China, 2009(in Chinese). [27] 胡志波, 郑水林, 李渝, 等. 煅烧处理硅藻土的孔道结构及分形特征[J]. 硅酸盐学报, 2021, 49(7):1395-1402.HU Zhibo, ZHENG Shuilin, LI Yu, et al. Effect of calcination on pore structure and fractal characteristics of diatomite[J]. Journal of the Chinese Ceramic Society,2021,49(7):1395-1402(in Chinese). -

下载:

下载: