Preparation of ZIF-67@PDA/fluorine-containing polyimide mixed matrix membrane and gas separation performance

-

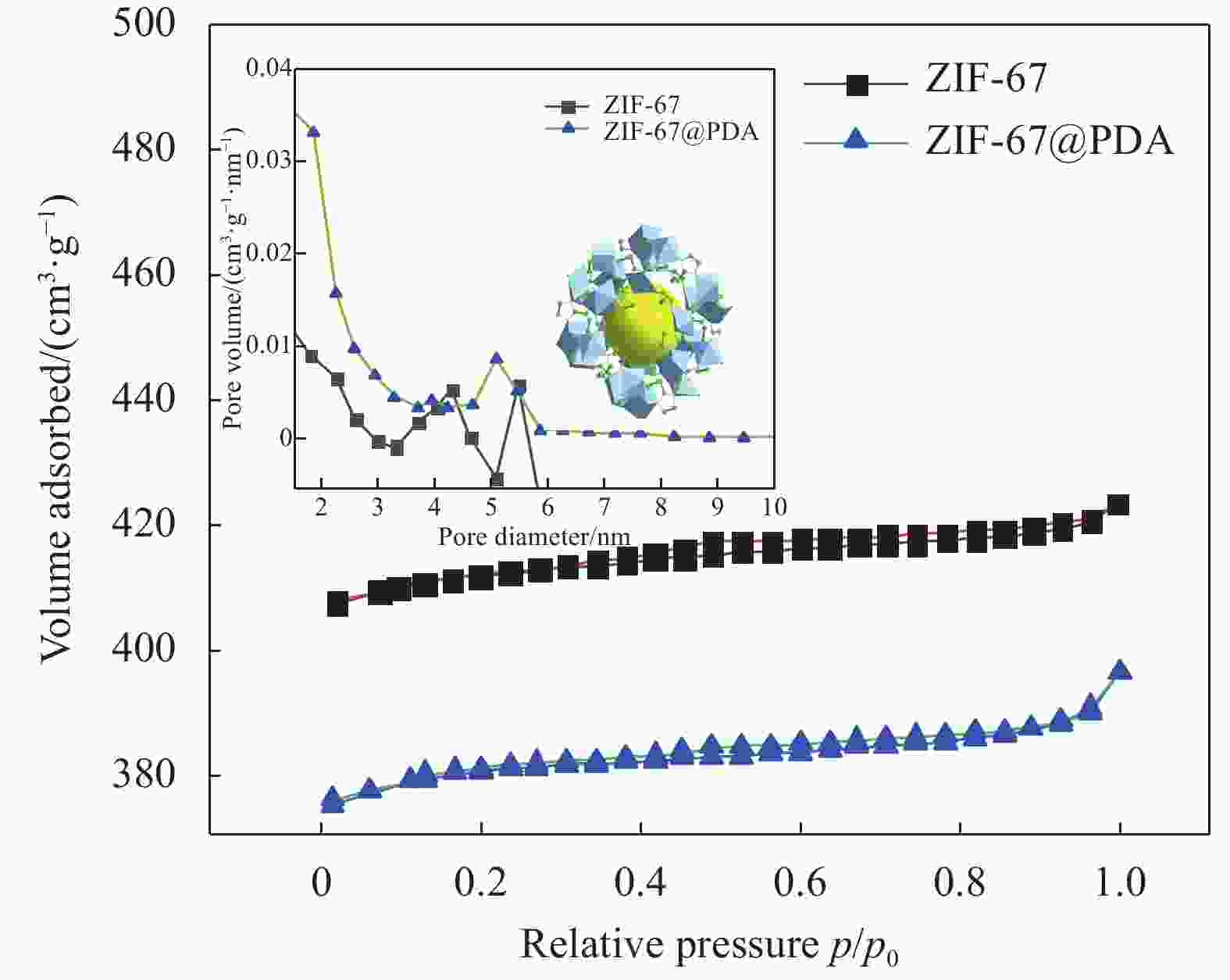

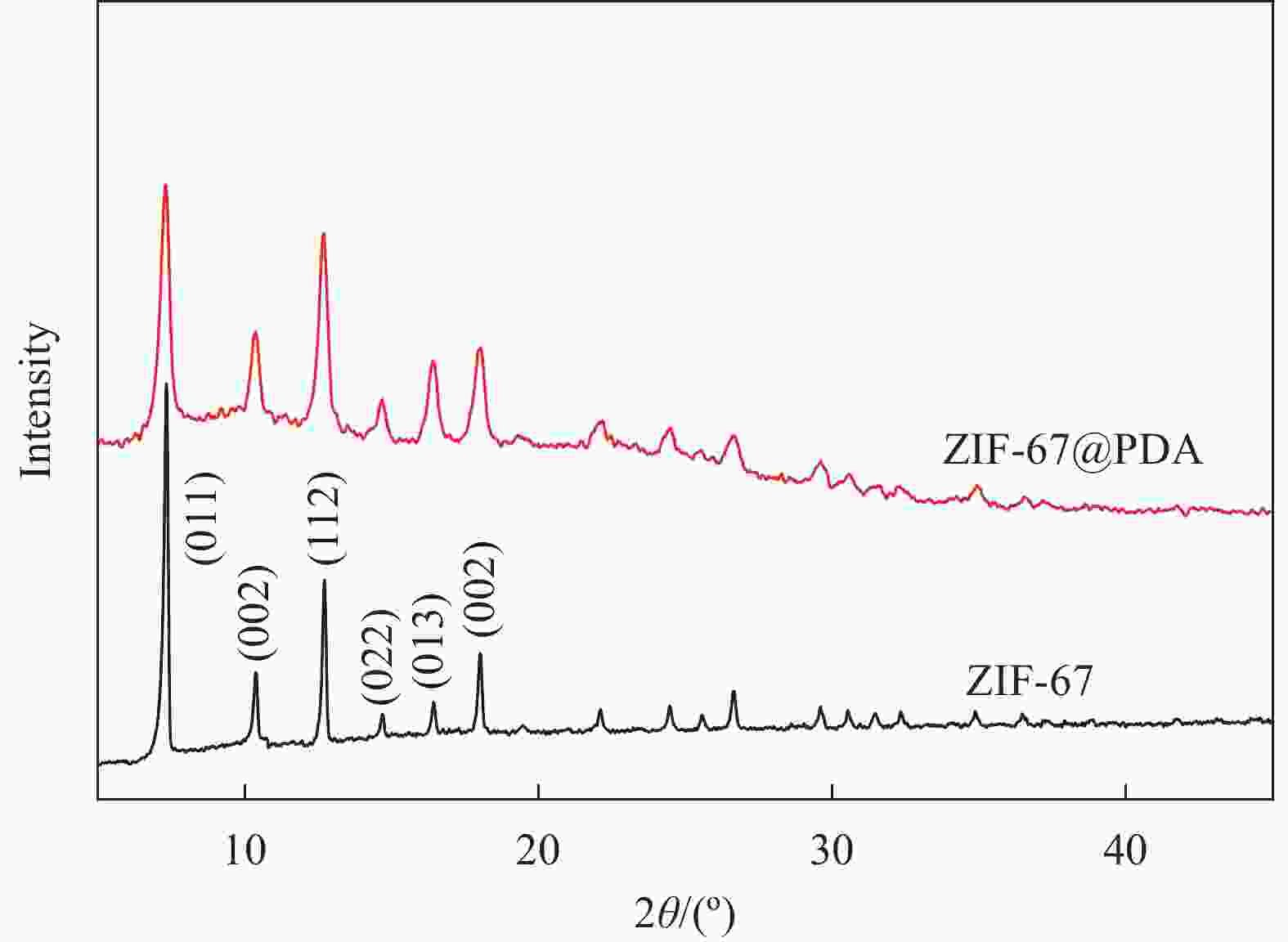

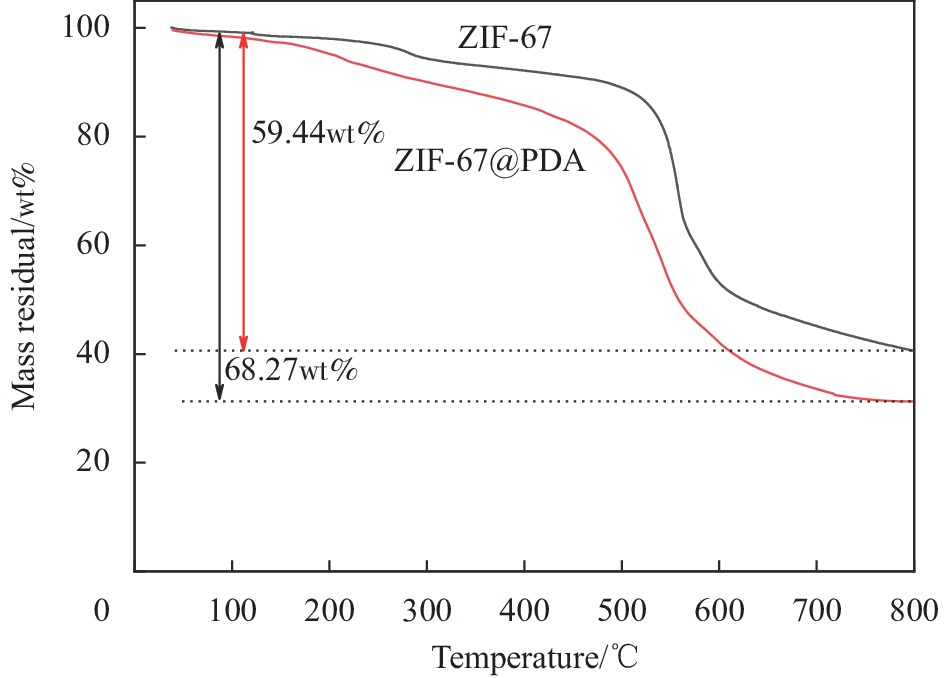

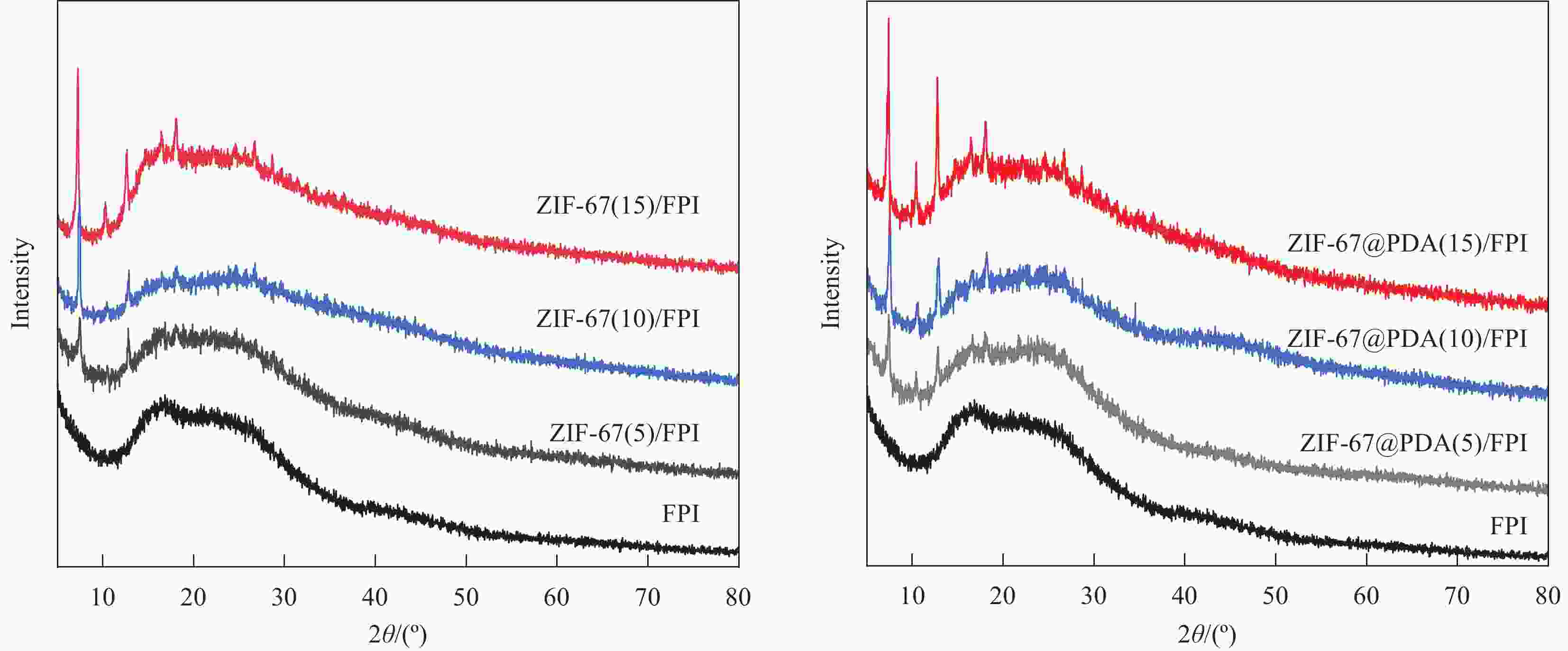

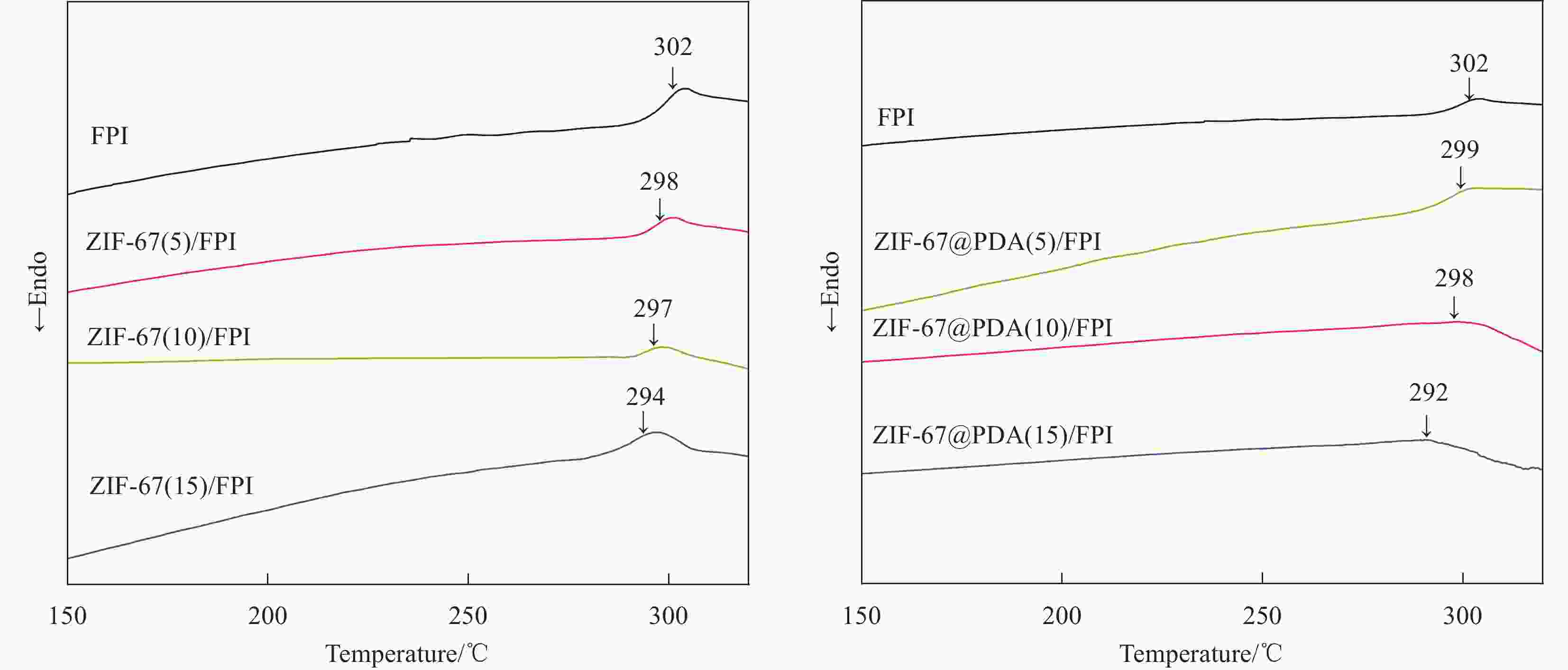

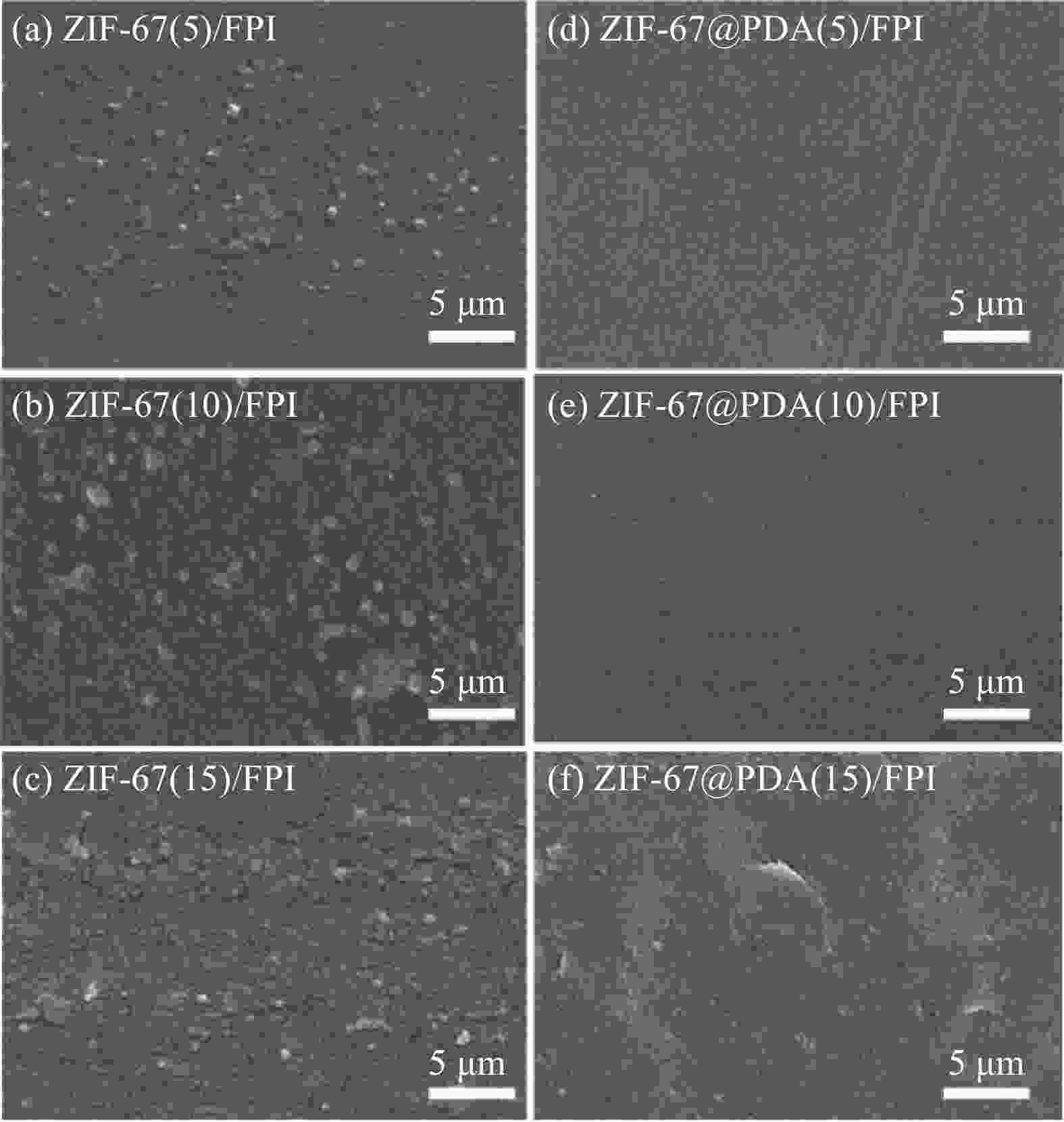

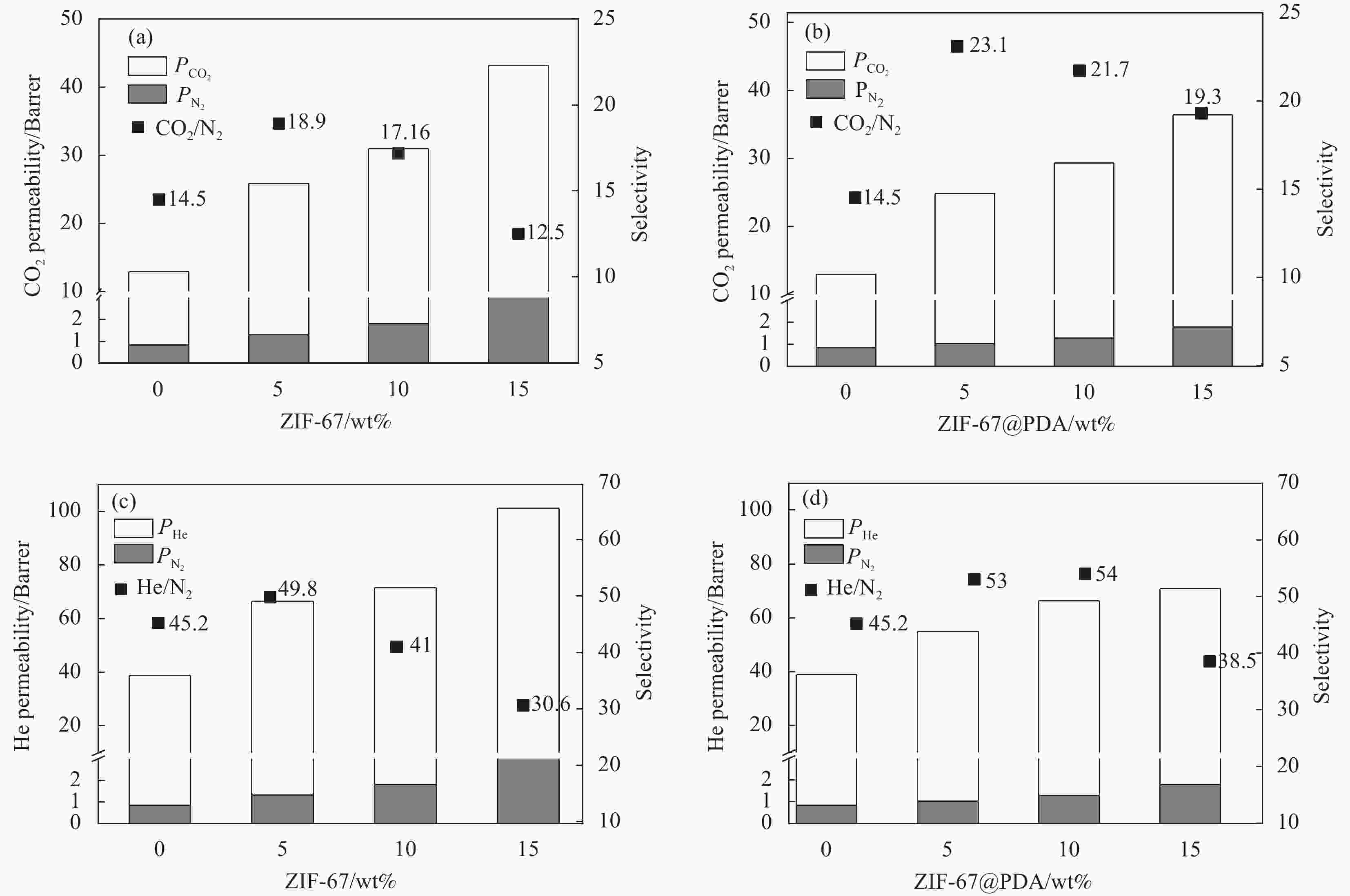

摘要: 金属有机框架材料(MOF)/聚合物混合基质膜(MMMs)通过结合MOF的分子筛效应和聚合物基质成本较低、加工性能好、机械强度高的特征,使其在气体分离领域展现出巨大的应用前景。然而由于MOF在聚合物基体中存在分散性差问题,极大地限制了其应用。采用溶剂热法合成金属框架材料ZIF-67,并通过溶液氧化法在ZIF-67表面修饰聚多巴胺(PDA)层制备ZIF-67@PDA纳米多孔材料。以4, 4'-二氨基二苯醚-2, 2'-双(3, 4-二羧酸)六氟丙烷二酐(ODA-6 FDA)型含氟聚酰亚胺(FPI)为基体、ZIF-67和ZIF-67@PDA为填料,制备不同质量分数的ZIF-67/FPI和ZIF-67@PDA/FPI。通过FTIR、WAXD、TGA、SEM、比表面和孔径分布分析仪、气体渗透仪等测试对MMMs的结构和性能进行表征并测试了N2、O2、CO2、He 4种气体的渗透性。结果表明:经聚多巴胺修饰后的纳米微孔材料ZIF-67在聚合物基体中能均匀分散并为气体分子的通过提供快速通道,且表现出良好的热稳定性。ZIF-67@PDA对CO2具有良好的亲和性,这有利于提高CO2/N2选择性。当ZIF-67@PDA负载量为10wt%时,MMMs的CO2渗透性和CO2/N2选择性协同增加,和纯FPI膜相比分别增加了131%、50%,MMMs表现出良好的气体分离性能。Abstract: Metal-organic framework (MOF)/polymer mixed matrix membranes (MMMs) have shown great promising application in gas separation fields by combining the features of MOF with molecular sieving effect and polymer matrix with lower cost, better processing properties, and high mechanical strength. However, their applications are greatly limited due to MOF poor dispersity in polymer matrix. The metal frame material ZIF-67 was synthesized by solvothermal method, and the polydopamine (PDA) layer was modified on the surface of ZIF-67 by solution oxidation to prepare ZIF-67@PDA nano-porous materials. The ZIF-67/FPI composite membrane and ZIF-67@PDA/FPI composite membrane with different mass fraction were prepared by using 4, 4'-oxydianiline-2, 2'-(hexafluoroisopropylidene)diphthalic anhydride (ODA-6FDA) fluorinated polyimide (FPI) as matrix and ZIF-67 and ZIF-67@PDA as fillers. The structure and properties of MMMs were characterized by FTIR, WAXD, TGA, SEM, specific surface and pore size distribution analyzer, gas permeant, and the permeability of four gases including N2, O2, CO2, and He was tested. The results show that the nanomicro porous material ZIF-67 modified with polydopamine can disperse uniformly in the polymer matrix and provides fast channels for the passage of gas molecules, and exhibits good thermal stability. ZIF-67@PDA has a good affinity for CO2, which is beneficial to improve the CO2/N2 selectivity. When the ZIF-67@PDA loading is 10wt%, the CO2 permeability and CO2/N2 selectivity of MMMs increases by 131% and 50% respectively compared with pure FPI membrane, and MMMs show good gas separation performance.

-

Key words:

- ZIF-67 /

- polydopamine /

- fluorinated polyimide /

- gas separation /

- mixed matrix membrane

-

表 1 样品名称缩写

Table 1. Sample name abbreviation

Sample ZIF-67/

wt%ZIF-67@

PDA/wt%FPI/

wt%FPI – – 100 ZIF-67(5)/FPI 5 – 95 ZIF-67(10)/FPI 10 – 90 ZIF-67(15)/FPI 15 – 85 ZIF-67@PDA(5)/FPI – 5 95 ZIF-67@PDA(10)/FPI – 10 90 ZIF-67@PDA(15)/FPI – 15 85 Notes: FPI—Fluorinated polyimide; PDA—Polydopamine. 表 2 FPI、ZIF-67/FPI和ZIF-67@PDA/FPI的热性能

Table 2. Thermal performance of FPI, ZIF-67/FPI and ZIF-67@PDA/FPI

Sample T10%/℃ Vmax/(%·℃−1) Residual mass/wt% FPI 514.2 0.34 46.53 ZIF-67(10)/FPI 440.4 0.34 41.04 ZIF-67@PDA(10)/FPI 378.3 0.31 37.35 Notes: T10%—Onset decomposition temperature at 10wt% mass loss recorded by TGA at a heating rate of 10℃/min in N2; Vmax—Maximum decomposition rate. 表 3 FPI、ZIF-67/FPI和ZIF-67@PDA/FPI复合膜的气体分离数据

Table 3. Gas separation data of FPI, ZIF-67/FPI和ZIF-67@PDA/FPI composite membranes

Sample Permeability/Barrers Ideal selectivity N2 O2 CO2 He CO2/N2 He/N2 FPI 0.84 3.60 12.10 38.0 14.50 45.2 ZIF-67(5)/FPI 1.31 5.50 24.60 65.2 18.90 49.7 ZIF-67(10)/FPI 1.80 6.50 29.18 69.7 17.16 41.0 ZIF-67(15)/FPI 3.20 8.86 40.00 88.0 12.50 27.5 ZIF-67@PDA(5)/FPI 1.03 4.00 23.80 54.6 23.10 53.0 ZIF-67@PDA(10)/FPI 1.29 5.80 28.00 65.0 21.70 54.0 ZIF-67@PDA(15)/FPI 1.79 6.60 34.60 69.0 20.60 38.5 Note: 1 Barrer=1×10−10 cm3·cm·cm−2·s−1·cm Hg−1. 表 4 本工作所得到的气体分离性能与文献报道的混合基质膜(MMMs)的比较

Table 4. Comparisons of gas separation performance achieved in this work with those of reported mixed matrix membranes (MMMs)

Membrane types PCO2 α(CO2/N2) Testing conditions Ref. SO3H-MCM-41/SPEEK 21.0 22.9 25℃, 1.0 MPa [31] ZIF-8/PI 27.9 13.6 25℃, 0.4 MPa [32] LDH/MPI 24.2 12.1 25℃, 0.1 MPa [33] Cu3(BTC)2/MPI 27.2 19.0 25℃, 0.1 MPa [33] ZIF-67(10)/FPI 29.2 17.2 35℃, 0.4 MPa This work ZIF-67@PDA(10)/FPI 28.0 21.7 35℃, 0.4 MPa This work Notes: PCO2—Gas permeability coefficient of carbon dioxide; α(CO2/N2)—Gas selectivity of CO2/N2; MCM-41—Molecular sieve; SPEEK—Sulfonated polyether ether ketone; LDH—Layered double hydroxide; MPI—Odified polyimide. -

[1] 崔晓萍, 朱光明, 刘文元. 纳米Al2O3/聚酰亚胺复合薄膜的介电与力学性能[J]. 复合材料学报, 2016, 33(11):2419-2425.CUI Xiaoping, ZHU Guangming, LIU Wenyuan. Dielectric and mechanical properties of nano Al2O3/polyimide composite film[J]. Acta Materiae Compositae Sinica,2016,33(11):2419-2425(in Chinese). [2] ROBESON L M. The upper bound revisited[J]. Journal of Membrane Science,2008,320(1-2):390-400. doi: 10.1016/j.memsci.2008.04.030 [3] 牛红超. 新型含氟聚酰亚胺的合成及其气体分离性能研究[D]. 桂林: 桂林理工大学, 2020.NIU Hongchao. Synthesis of novel fluoropolyimide and its gas separation performance[D]. Guilin: Guilin University of Technology, 2020(in Chinese). [4] 薛佳佳. 原位制备MOFs/PI混合基质膜及其气体分离性能研究[D]. 大连: 大连理工大学, 2020.XUE Jiajia. Study on in situ preparation of MOFs/PI hybrid matrix membranes and their gas separation performance[D]. Dalian: Dalian University of Technology, 2020(in Chinese). [5] 王天琦, 肖国勇, 鲁云华, 等. 镧系金属有机骨架/聚酰亚胺复合材料的制备及其性能[J]. 复合材料学报, 2018, 35(11):2927-2934.WANG Tianqi, XIAO Guoyong, LU Yunhua, et al. Preparation and properties of lanthanide metal organic skeleton/polyimide composites[J]. Acta Materiae Compositae Sinica,2018,35(11):2927-2934(in Chinese). [6] YANG Q P, LI L J, TAN W Q, et al. Exceptional high selectivity of hydrogen/methane separation on a phosphonate-based MOF membrane with exclusion of methane molecules[J]. Chemical Communications,2017,53(70):9797-9800. doi: 10.1039/C7CC05486F [7] KRAUSE S, BON V, SENKOVSKA I, et al. A pressure-amplifying framework material with negative gas adsorption transitions[J]. Nature,2016,532(7599):348-352. doi: 10.1038/nature17430 [8] 文桂林, 李莹, 张红星, 等. 离子液体/金属-有机骨架复合材料制备方法、理论计算及应用研究进展[J]. 复合材料学报, 2021, 38(2):298-314.WEN Guilin, LI Ying, ZHANG Hongxing, et al. Research progress on preparation method, theoretical calculation and application of ionic liquid/metal-organic skeleton composites[J]. Acta Materiae Compositae Sinica,2021,38(2):298-314(in Chinese). [9] PENG Y, LI Y, BAN Y, et al. Two-dimensional metal-organic framework nano sheets for membrane-based gas separation[J]. Angewandte Chemie-International Edition,2017,56(33):9757-9761. doi: 10.1002/anie.201703959 [10] IU Z, CUI X, PHAM T, et al. A MOF-based ultra-strong acetylene nano-trap for highly efficient C2H2/CO2 separation[J]. Angewandte Chemie-International Edition,2021,133(10):5343-5348. doi: 10.1002/ange.202016225 [11] WANG Z B, KNEBEL A, GROSJEAN S, et al. Tunable molecular separation by nanoporous membranes[J]. Nature Communications,2016,7:13872. doi: 10.1038/ncomms13872 [12] LI L, LIN R B, KRISHNA R, et al. Flexible-robust metal-organic framework for efficient removal of propyne from propylene[J]. Journal of the American Chemical Society,2017,139(23):7733-7736. doi: 10.1021/jacs.7b04268 [13] TAN L L, ZHU Y, LONG H, et al. Pillar [n] arene-based supramolecular organic frameworks with high hydrocarbon storage and selectivity[J]. Chemical Communications,2017,53(48):6409-6412. doi: 10.1039/C7CC03638H [14] LIN R J, GE L, HOU L, et al. Mixed matrix membranes with strengthened MOFs/polymer interfacial interaction and improved membrane performance[J]. ACS Applied Materials & Interfaces,2014,6(8):5609-5618. [15] RODENAS T, LUZ I, PRIETO G, et al. Metal-organic framework nano sheets in polymer composite materials for gas separation[J]. Nature Materials,2015,14(1):48-55. doi: 10.1038/nmat4113 [16] 王钰淇. 多孔材料改性聚二甲基硅氧烷/聚醚酰亚胺复合膜用于气体分离的研究[D]. 北京: 北京化工大学, 2015.WANG Yuqi. Study on the use of polydimethylsiloxane/polyetherimide composite membrane for gas separation with porous materials[D]. Beijing: Beijing University of Chemical Technology, 2015(in Chinese). [17] BARANKOVA E, TAN X, VILLALOBOS L F, et al. A metal chelating porous polymeric support: The missing link for a defect-free metal-organic framework composite membrane[J]. Angewandte Chemie-International Edition,2017,56(11):2965-2968. doi: 10.1002/anie.201611927 [18] 廉玉姣, 王永洪, 张新儒, 等. N2优先渗透ZIF-8复合膜的制备及其CO2捕集[J]. 化工学报, 2019, 70(9):3573-3581.LIAN Yujiao, WANG Yonghong, ZHANG Xinru, et al. Preparation of N2-priority permeation ZIF-8 composite membrane and its CO2 capture[J]. CIESC Journal,2019,70(9):3573-3581(in Chinese). [19] BACHMAN J E, SMITH Z P, LI T, et al. Enhanced ethylene separation and plasticization resistance in polymer membranes incorporating metal-organic framework nanocrystals[J]. Nature Materials,2016,15(8):845-849. doi: 10.1038/nmat4621 [20] FENG X, CARREON M A. Kinetics of transformation on ZIF-67 crystals[J]. Journal of Crystal Growth,2015,418:158-162. doi: 10.1016/j.jcrysgro.2015.02.064 [21] MRIDUSMITA B, BISHNUPADA M. Synthesis, characterization and CO2 separation performance of novel PVA/PG/ZIF-8 mixed matrix membrane[J]. Journal of Membrane Science,2019,572:198-209. doi: 10.1016/j.memsci.2018.11.001 [22] MESHKAT S, KALIAGUINE S, RODRIGUE D. Comparison between ZIF-67 and ZIF-8 in Pebax® MH-1657 mixed matrix membranes for CO2 separation[J]. Separation and Purification Technology,2020,235:116150. doi: 10.1016/j.seppur.2019.116150 [23] YANG Y W, DENG F, ZAN J, et al. Core-shell-structured ZIF-8@PDA-HA with controllable zinc ion release and superior bioactivity for improving a poly-L-lactic acid scaffold[J]. ACS Sustainable Chemistry & Engineering, 2021, 9(4): 1814-1825. [24] YING C T, HUA C Z. Self-templating synthesis of hollow spheres of MOFs and their derived nanostructures[J]. Chemical Communications,2016,52(77):11591-11594. doi: 10.1039/C6CC05699G [25] SALIBA D, AMMAR M, RAMMAL M, et al. Crystal growth of ZIF-8, ZIF-67, and their mixed-metal derivatives[J]. Jour-nal of the American Chemical Society,2018,140(5):1812-1823. doi: 10.1021/jacs.7b11589 [26] CHEN M, DONG L, WU X, et al. Multi-functional polydopamine coating: Simultaneous enhancement of interfacial adhesion and CO2 separation performance of mixed matrix membranes[J]. New Journal of Chemistry,2016,40(11):9148-9159. doi: 10.1039/C6NJ02013E [27] ANJUM M W, VERTRLE F, KHAN A L, et al. Modulated UiO-66-based mixed-matrix membranes for CO2 separation[J]. ACS Applied Materials & Interfaces,2015,7(45):25193-25201. [28] SHIN J E, LEE S K, CHO Y H, et al. Effect of PEG-MEA and graphene oxide additives on the performance of Pebax®1657 mixed matrix membranes for CO2 separation[J]. Journal of Membrane Science,2019,572:300-308. doi: 10.1016/j.memsci.2018.11.025 [29] XING Y W, WEI L, HONG W, et al. Nanoporous ZIF-67 embedded polymers of intrinsic microporosity membranes with enhanced gas separation performance[J]. Journal of Membrane Science,2018,548:309-318. doi: 10.1016/j.memsci.2017.11.038 [30] WANG Z, WANG D, ZHANG S, et al. Interfacial design of mixed matrix membranes for improved gas separation performance[J]. Advanced Materials,2016,28(17):3399-3405. doi: 10.1002/adma.201504982 [31] KHAN A L, KLAYSAM C, GAHLAUT A, et al. SPEEK and functionalized mesoporous MCM-41 mixed matrix membranes for CO2 separations[J]. Journal of Materials Che-mistry,2012,22:20057-20064. doi: 10.1039/c2jm34885c [32] 朱娜娜, 李越, 高会元. PI/ZIF-8杂化膜的制备及CO2/N2分离性能研究[J]. 功能材料, 2016, 47(4):4099-4104. doi: 10.3969/j.issn.1001-9731.2016.04.020ZHU Nana, LI Yue, GAO Huiyuan. Preparation of PI/ZIF-8 hybrid membrane and separation performance of CO2/N2[J]. Functional Materials,2016,47(4):4099-4104(in Chinese). doi: 10.3969/j.issn.1001-9731.2016.04.020 [33] 龚金华, 王臣辉, 卞子君, 等. 多孔材料表面修饰聚酰亚胺非对称混合基质膜对CO2/N2和CO2/CH4的气体分离[J]. 物理化学学报, 2015, 31(10):1963-1970. doi: 10.3866/PKU.WHXB201508282GONG Jinhua, WANG Chenhui, BIAN Zijun, et al. Gas separation of CO2/N2 and CO2/CH4 by polyimide asymmetric mixed matrix membrane modified on porous material surface[J]. Journal of Physical Chemistry,2015,31(10):1963-1970(in Chinese). doi: 10.3866/PKU.WHXB201508282 -

下载:

下载: