Comparison of pyrolysis and combustion characteristics of carbon fiber, glass fiber/epoxy resin

-

摘要: 民用飞机内饰壁板材料主要是纤维/树脂复合材料,该类复合材料具有一定的火灾危险性,因此研究其热稳定性和燃烧特性对于飞机防火具有重要意义。采用热重分析仪研究了不同升温速率对碳纤维/环氧树脂和玻璃纤维/环氧树脂两种典型飞机壁板材料热解的影响,并使用Kissinger法得到了分解阶段的表观活化能和指前因子;采用锥形量热仪研究了两种预浸料在不同火灾环境下的燃烧特性,并选取火势蔓延指数(

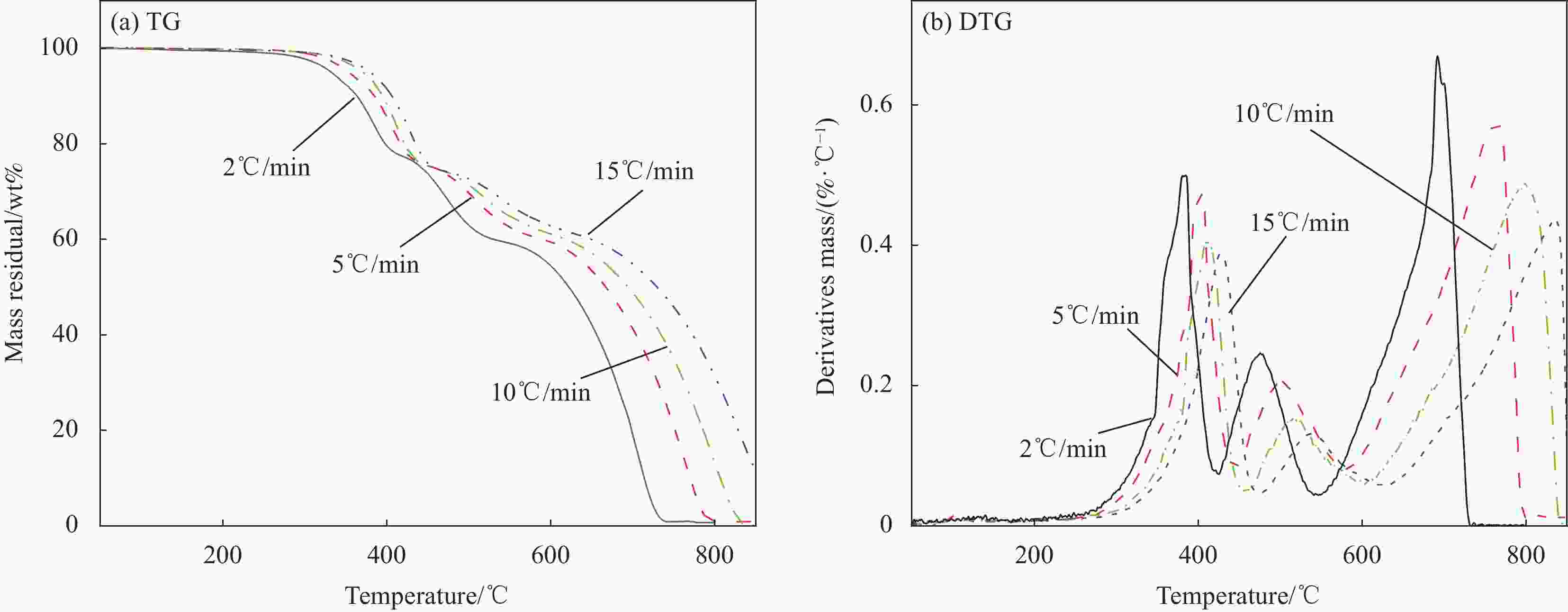

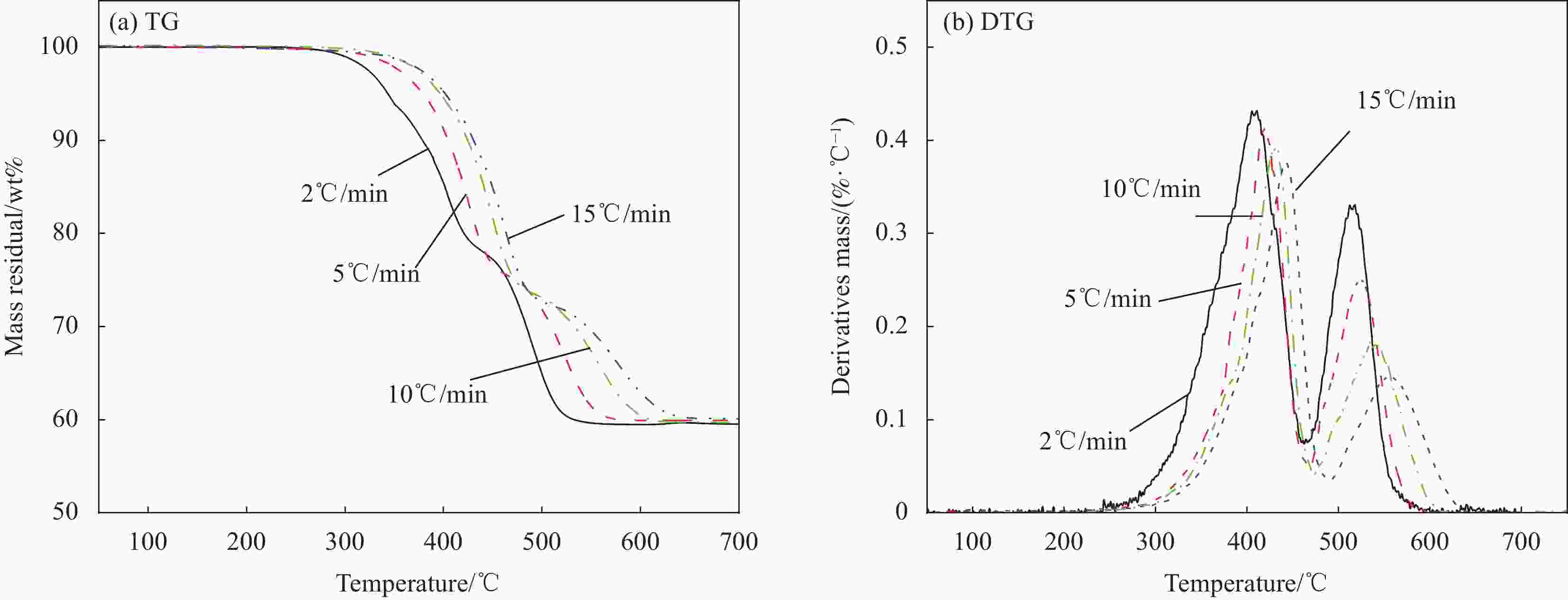

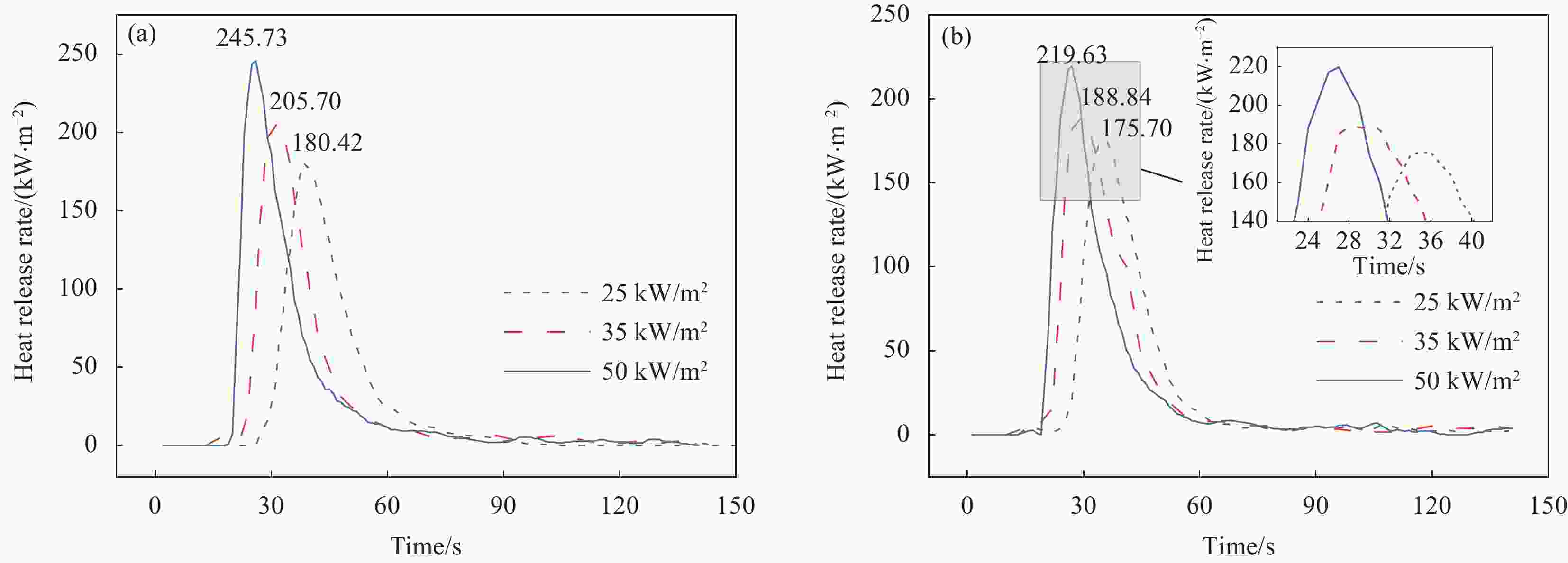

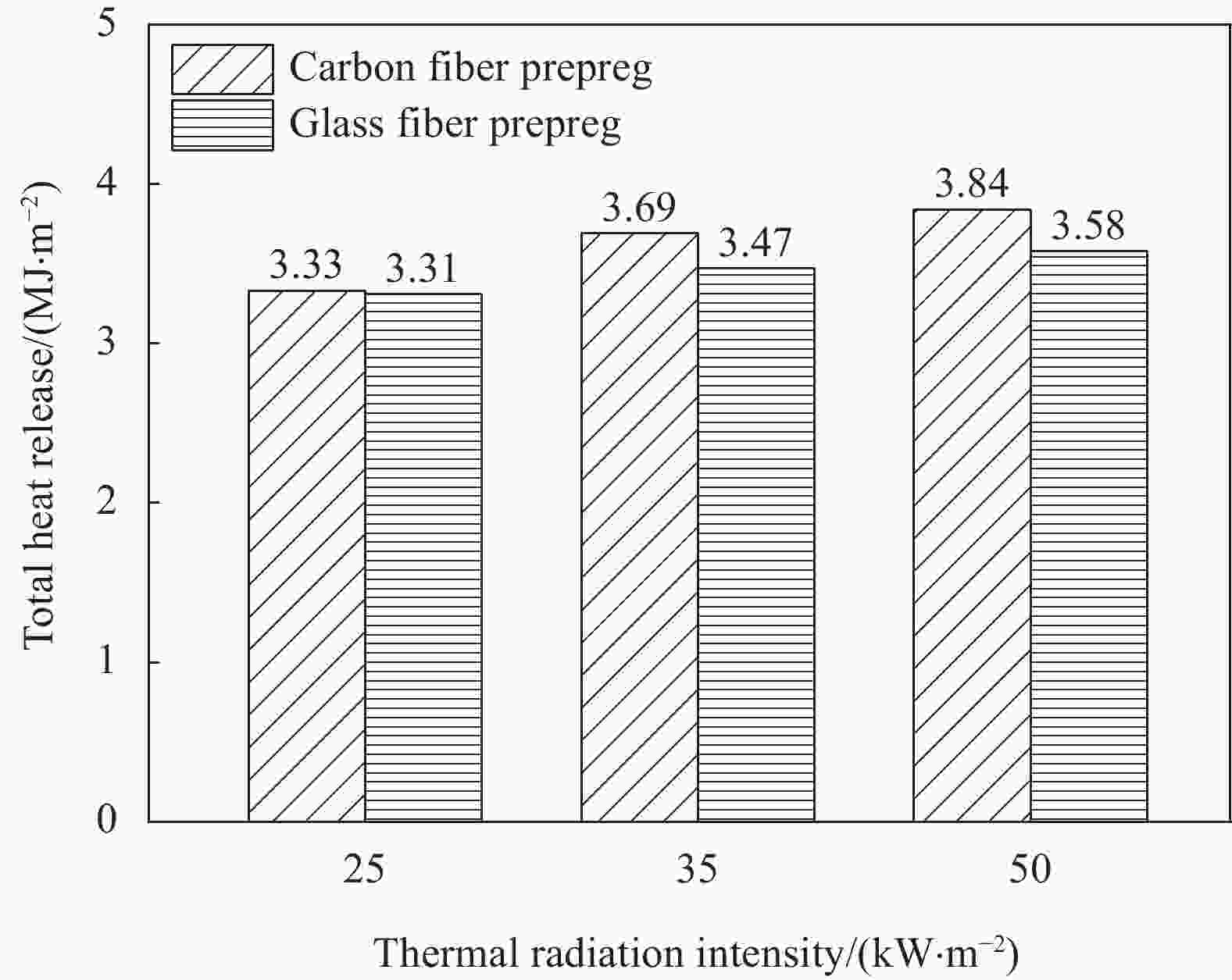

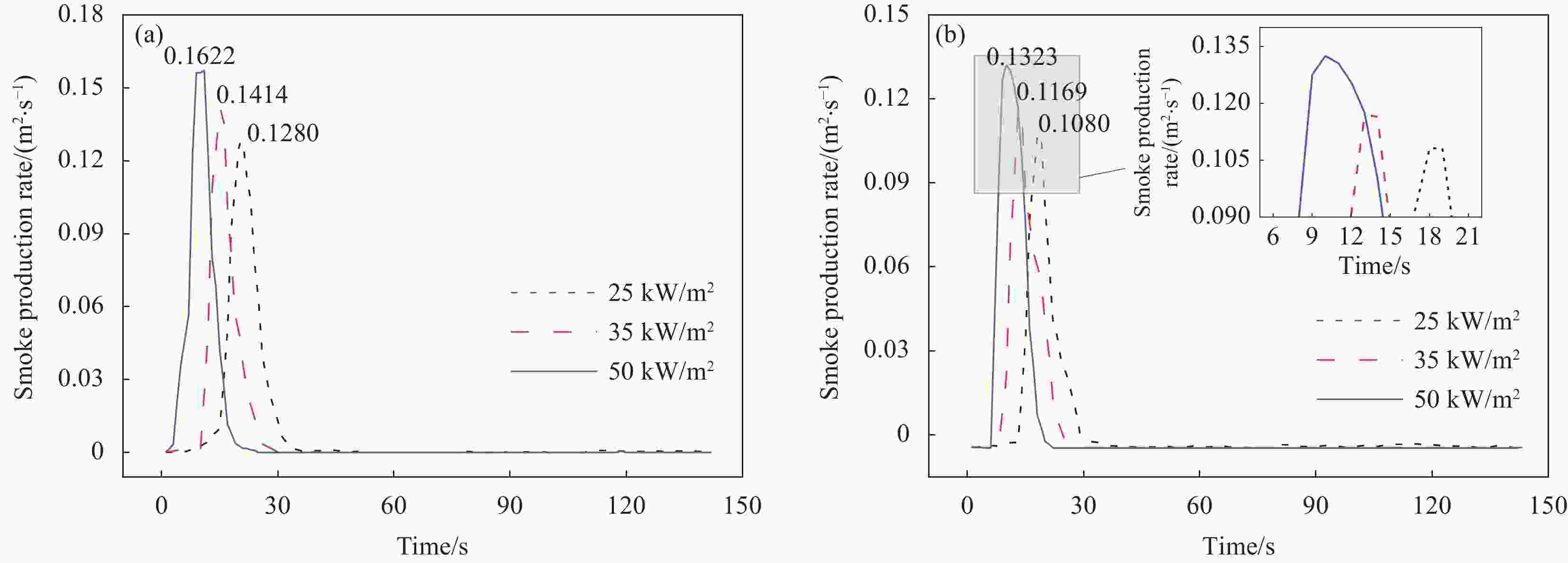

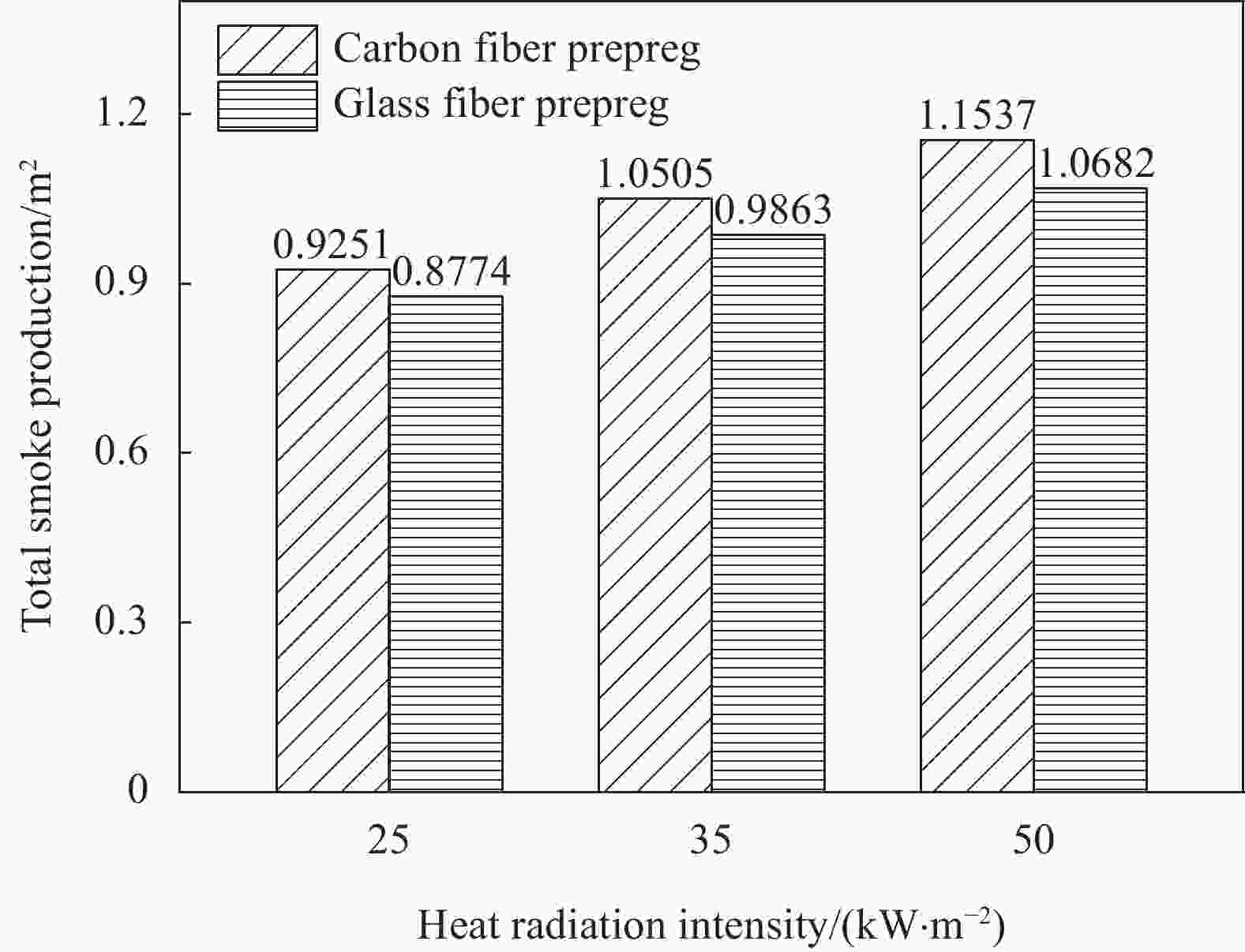

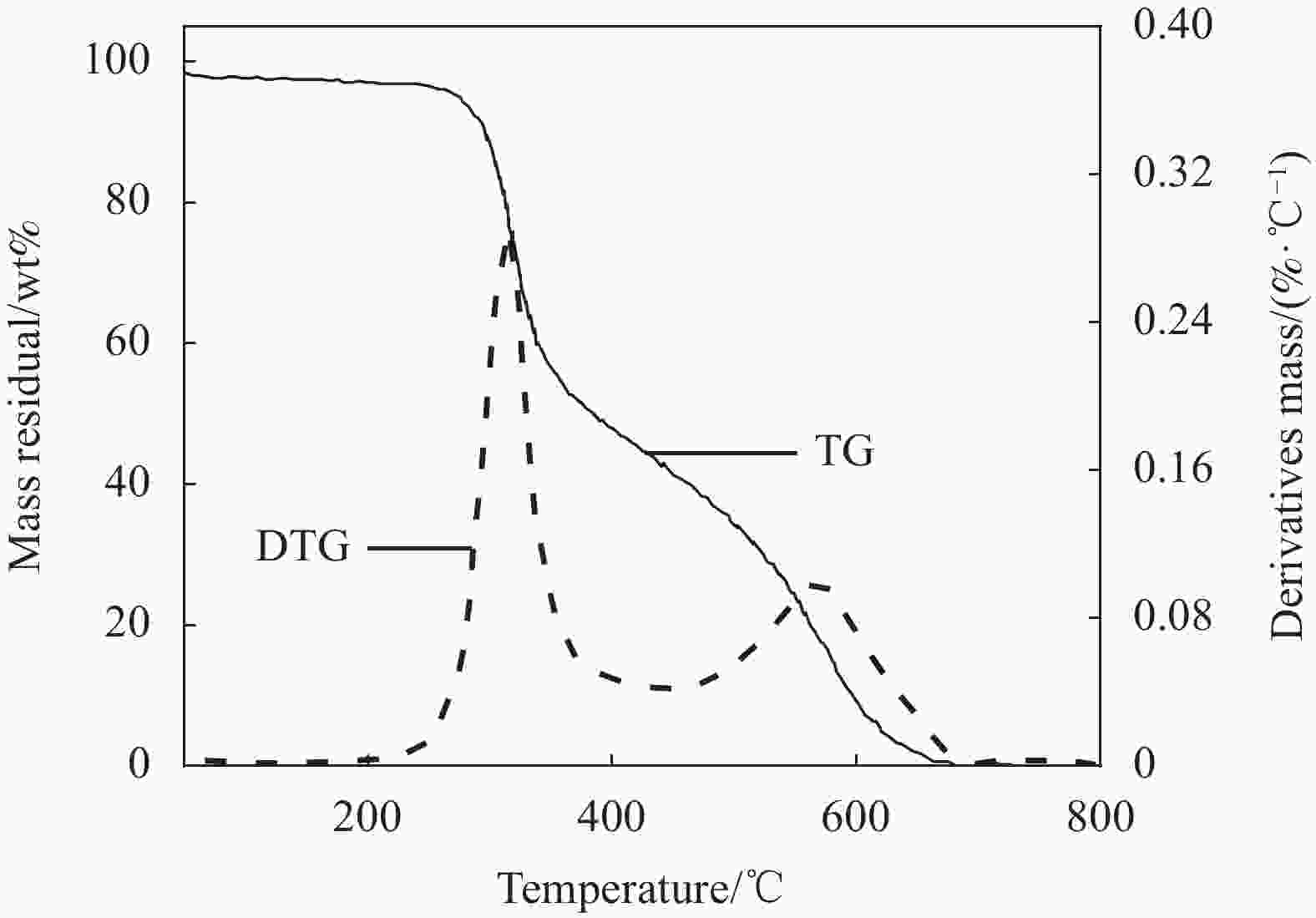

$ {\delta _{{\rm{FGI}}}} $ )、火险潜在指数($ {\delta _{{\rm{FPI}}}} $ )、放热指数($ {\delta _{{\rm{THRI}}}} $ )、发烟指数($ {\delta _{{\rm{TSPI}}}} $ ) 4种评价指标评估其火灾危险性;进而分析两种纤维在树脂复合材料热解、燃烧过程中的影响。结果表明:在空气气氛下,升温速率对两种预浸料的热解影响都较大,碳纤维在556℃以上发生分解,玻璃纤维未发生分解。在热解时玻璃纤维预浸料前两阶段的活化能明显高于碳纤维预浸料,表明玻璃纤维预浸料具有更高的热稳定性。碳纤维预浸料的热释放速率、产烟速率、总产热量、总产烟量均大于玻璃纤维预浸料,随着热辐射强度的增加,两种预浸料这些参数之间的差值都不断变大,碳纤维预浸料的$ {\delta _{{\rm{FGI}}}} $ 、$ {\delta _{{\rm{THRI}}}} $ 、$ {\delta _{{\rm{TSPI}}}} $ 均大于玻璃纤维预浸料,$ {\delta _{{\rm{FPI}}}} $ 值则相反。分析发现,两种纤维都对复合材料的热解有一定的抑制作用,但玻璃纤维抑制作用更明显,碳纤维/环氧复合材料火灾危险性更大。Abstract: Civilian aircraft interior wall panel materials are mainly fibre/resin composites, which have a certain fire hazard, so the study of their thermal stability and combustion characteristics is of great significance for aircraft fire protection. A thermogravimetric analyzer was used to study the influence of different heating rates on the pyrolysis of two typical aircraft siding materials: Carbon fiber/epoxy resin and glass fiber/epoxy resin, and the apparent activation energy and pre-digital factor of the decomposition stage were obtained using the Kissinger method. The cone calorimeter was used to study the combustion characteristics of two prepregs in different fire environments, and four evaluation indicators of fire growth index ($ {\delta _{{\rm{FGI}}}} $ ), fire potential index ($ {\delta _{{\rm{FPI}}}} $ ), thermal heat release index ($ {\delta _{{\rm{THRI}}}} $ ) and thermal smoke produce index ($ {\delta _{{\rm{TSPI}}}} $ ) were selected to evaluate the fire hazard; and then the two types of fibers were analyzed. Furthermore, the influence of the two kinds of fibers in the pyrolysis and combustion process of the resin composite was analyzed. The results show that in air atmosphere, the heating rate has a greater influence on the pyrolysis of the two prepregs. The carbon fiber decomposes above 556℃, and the glass fiber does not decompose. During pyrolysis, the activation energy of the first two stages of the glass fiber prepreg is significantly higher than that of the carbon fiber prepreg, indicating that the glass fibre prepreg has a higher thermal stability. The heat release rate, smoke production rate, total heat production, and total smoke production of carbon fiber prepregs are greater than those of glass fiber prepregs. As the heat radiation intensity increases, the differences between these parameters of the two prepregs are all keep getting bigger, the$ {\delta _{{\rm{FGI}}}} $ ,$ {\delta _{{\rm{THRI}}}} $ and$ {\delta _{{\rm{TSPI}}}} $ of carbon fiber prepreg are larger than glass fiber prepreg, while the$ {\delta _{{\rm{FPI}}}} $ value is the opposite. The analysis finds that both fibres inhibite the pyrolysis of the composite, but the glass fibre inhibites it more significantly and the carbon fibre/epoxy composite have a greater fire hazard.-

Key words:

- aircraft interior siding /

- epoxy prepreg /

- thermal stability /

- combustion characteristics /

- fire hazard

-

图 4

${\text{ln(}}{\beta _i}/T_{{\rm{p}}i}^2)$ 与$ 1/{T_{{\rm{p}}i}} $ 之间的关系:(a)碳纤维预浸料;(b)玻璃纤维预浸料Figure 4. Relationship between

${\text{ln(}}{\beta _i}/T_{{\rm{p}}i}^2)$ and$ 1/{T_{{\rm{p}}i}} $ : (a) Carbon fiber prepreg; (b) Glass fiber prepregβ—Heating rate; Tpi—Temperature corresponding to the maximum mass loss at each stage

表 1 两种预浸料热解温度参数

Table 1. Pyrolysis parameters of two prepregs

Material Heating rate/

(℃·min−1)Temperature scope of thermal decomposition/℃ Temperature of maximum mass loss rate/℃ First stage Second stage Third stage First stage Second stage Third stage Carbon fiber prepreg 2 296-424 424-556 556-728 378 475 692 5 305-435 435-568 568-796 396 502 768 10 317-452 452-595 595-836 412 518 797 15 328-467 467-628 628 427 538 838 Glass fiber prepreg 2 302-447 447-570 — 402 505 — 5 316-451 451-584 — 418 524 — 10 330-463 463-614 — 430 537 — 15 335-478 478-632 — 443 556 — 表 2 Kissinger方法计算了两种预浸料的热解动力学参数

Table 2. Pyrolysis kinetic parameters of the two prepregs calculated by Kissinger method

Material Heating rate/(℃·min−1) Slope k=−E/R Ek/(kJ·mol−1) lnAk R2

Carbon fiber prepreg2, 5, 10, 15 −16.613 138.12 16.089 0.9953 −17.831 148.25 14.197 0.9912 −12.869 106.99 2.845 0.9909 Glass fiber

prepreg−23.205 192.93 25.249 0.9936 −25.801 214.51 23.792 0.9926 — — — — Notes: k—Slope of the curve fitted to Fig.4; E—Activation energy; R—Molar gas constants; Ek—Apparent activation energy; Ak—Apparent pre-exponential factor; R2—Degree of fit. 表 3 两种预浸料的火灾危险性评价指数

Table 3. Fire hazard evaluation index of two prepregs

Risk evaluation index $ {\delta _{{\rm{FGI}}}} $/(kW·(m2·s)−1) $ {\delta _{{\rm{FPI}}}} $/((m2·s)·kW−1) $ {\delta _{{\rm{THRI}}}} $/(MJ·m−2) $ {\delta _{{\rm{TSPI}}}} $/(s·m−2) Carbon fiber prepreg 25 kW·m−2 4.74 0.127 −0.31 4.07 35 kW·m−2 6.23 0.097 −0.29 4.02 50 kW·m−2 9.10 0.073 −0.27 3.93 Glass fiber prepreg 25 kW·m−2 4.51 0.137 −0.34 4.03 35 kW·m−2 6.08 0.106 −0.31 3.98 50 kW·m−2 7.57 0.082 −0.30 3.82 Notes: $ {\delta _{{\rm{FGI}}}} $—Fire spread index; $ {\delta _{{\rm{FPI}}}} $—Fire potential index; $ {\delta _{{\rm{THRI}}}} $—Total heat release index; $ {\delta _{{\rm{TSPI}}}} $—Total smoke production index. -

[1] 吴良义. 先进复合材料的应用扩展: 航空、航天和民用航空先进复合材料应用技术和市场预测[J]. 化工新型材料, 2012, 40(1):4-9. doi: 10.3969/j.issn.1006-3536.2012.01.002WU Liangyi. The application extend of advanced compo-site materials: Technology markets of and application in aerona-utics, astronaut and civil aviation[J]. New Chemi-cal Materials,2012,40(1):4-9(in Chinese). doi: 10.3969/j.issn.1006-3536.2012.01.002 [2] LIU L, JIA C Y, HE J M, et al. Interfacial characterization, control and modification of carbon fiber reinforced polymer composites[J]. Composites Science and Technology,2015,121:56-72. doi: 10.1016/j.compscitech.2015.08.002 [3] 邢丽英, 冯志海, 包建文, 等. 碳纤维及树脂基复合材料产业发展面临的机遇与挑战[J]. 复合材料学报, 2020, 37(11):2700-2706.XING Liying, FENG Zhihai, BAO Jianwen, et al. Facing opportunity and challenge of carbon fiber and polymer mtrix composites industry development[J]. Acta Materiae Compositae Sinica,2020,37(11):2700-2706(in Chinese). [4] LIU W, ZHANG T, BAO J, et al. Effects of epoxy resin cross-linked structure characteristics on longitudinal compres-sive performance of carbon fiber reinforced composites[J]. Journal of Aeronautical Materials,2016,36(1):75-80. [5] 孙振起, 吴安如. 先进复合材料在飞机结构中的应用[J]. 材料导报, 2015, 29(11):61-64.SUN Zhenqi, WU Anru. Application of advanced compo-site in aircraft structures[J]. Materials Reports,2015,29(11):61-64(in Chinese). [6] Federal Aviation Administration. Department of transportation, federal aviation administration regulations for compartment interiors: FAR.25.853[S]. Washington: Federal Aviation Administration, 2000. [7] SEBASTIAN E. Influence of carbon fibre orientation on reaction-to-fire properties of polymer matrix composites[J]. Fire and Materials,2012,36(4):309-324. doi: 10.1002/fam.1112 [8] SZOLNOKI B, BOCZ K, SOTI P L, et al. Development of natural fibre reinforced flame retarded epoxy resin composites[J]. Polymer Degradation and Stability,2015,119:68-76. doi: 10.1016/j.polymdegradstab.2015.04.028 [9] 朱泽宇, 张旭, 王志, 等. 碳纤维/环氧复合材料燃烧及产烟特性研究[J]. 中国胶粘剂, 2020(7): 48-53.ZHU Zeyu, ZHANG Xu, WANG Zhi, et al. Study on combustion and smoke production characteristics of carbon fiber/epoxy composites[J]. China Adhesives, 2020(7): 48-53(in Chinese). [10] 徐艳英, 张雷, 王志, 等. 基于锥形量热法的典型碳纤维/环氧复合材料燃烧特性[J]. 复合材料学报, 2017, 34(8):1674-1682.XU Yanying, ZHANG Lei, WANG Zhi, et al. Combustion characteristics of typical carbon fiber/epoxy composites based on the method of CONE[J]. Acta Materiae Compositae Sinica,2017,34(8):1674-1682(in Chinese). [11] 徐艳英, 杨扬, 张颖, 等. 单向碳纤维/环氧树脂预浸料热解特性[J]. 复合材料学报, 2018, 35(9):2442-2448.XU Yanying, YANG Yang, ZHANG Ying, et al. Pyrolysis characteristics of unidirectional carbon fiber/epoxy prepreg[J]. Acta Materiae Compositae Sinica,2018,35(9):2442-2448(in Chinese). [12] 计智, 徐艳英, 李金都, 等. 碳纤维/环氧复合材料的热解特性及动力学研究[J]. 消防科学与技术, 2020, 39(7):994-997. doi: 10.3969/j.issn.1009-0029.2020.07.029JI Zhi, XU Yanying, LI Jindu, et al. Pyrolysis characteristics and kinetics of carbon fiber/epoxy composites[J]. Fire Science and Technology,2020,39(7):994-997(in Chinese). doi: 10.3969/j.issn.1009-0029.2020.07.029 [13] RÉGNIER N, FONTAINE S. Determination of the thermal degradation kinetic parameters of carbon fibre reinforced epoxy using TG[J]. Journal of Thermal Analysis and Calorimetry,2001,64(2):789-799. doi: 10.1023/A:1011512932219 [14] 宋金梅, 刘辉, 王雷, 等. 废弃碳纤维/环氧树脂复合材料的热解特性及动力学研究[J]. 玻璃钢/复合材料, 2019(1):47-53.SONG Jinmei, LIU Hui, WANG Lei, et al. Pyrolysis characteristics and kinetics of scrap carbon fiber reinforced epoxy resin matrix composites[J]. Fiber Reinforced Plastics/Composites,2019(1):47-53(in Chinese). [15] 王一明, 刘杰, 吴广峰, 等. 亚临界水介质回收酸酐固化环氧树脂/碳纤维复合材料[J]. 应用化学, 2013, 30(6):643-647.WANG Yiming, LIU Jie, WU Guangfeng, et al. Subcritical water medium recovery acid anhydride cured epoxy resin/carbon fiber composite material[J]. Chinese Journal of Applied Chemistry,2013,30(6):643-647(in Chinese). [16] WANG H Y, ZHANG L. Pyrolysis and combustion characteristics and reaction kinetics of carbon fiber/epoxy compo-sites[J]. AIP Advances,2019,9(12):125110. doi: 10.1063/1.5128460 [17] DAO D Q, LUCHE J, RICHARD F, et al. Determination of characteristic parameters for the thermal decomposition of epoxy resin/carbon fibre composites in cone calorimeter[J]. International Journal of Hydrogen Energy,2013,38(19):8167-8178. doi: 10.1016/j.ijhydene.2012.05.116 [18] 陈敏孙, 江厚满, 刘泽金. 玻璃纤维/环氧树脂复合材料热分解动力学参数的确定[J]. 强激光与粒子束, 2010, 22(9):1969-1972. doi: 10.3788/HPLPB20102209.1969CHEN Minsun, JIANG Houman, LIU Zejin. Determination of thermal decomposition kinetic parameters of glass fiber/epoxy composite[J]. High Power Laser and Particle Beams,2010,22(9):1969-1972(in Chinese). doi: 10.3788/HPLPB20102209.1969 [19] 郭云竹, 孙远君. 玻璃纤维/环氧树脂复合材料的热性能[J]. 纤维复合材料, 2011(2): 33-35.GUO Yunzhu, SUN Yuanjun. Thermal properties of glass fiber/epoxy composites[J]. Fiber Composites, 2011(2): 33-35(in Chinese). [20] 张颖, 王志, 徐艳英, 等. 高强玻璃纤维复合材料热解动力学研究[J]. 消防科学与技术, 2017, 36(2):149-152.ZHANG Ying, WANG Zhi, XU Yanying, et al. Study on pyrolysis kinetics of high-strength glass fiber/epoxy resin composites[J]. Fire Science and Technology,2017,36(2):149-152(in Chinese). [21] RAJAEI M, WANG D Y, BHATTACHARYYA D, et al. Combined effects of ammonium polyphosphate and talc on the fire and mechanical properties of epoxy/glass fabric compo-sites[J]. Composites Part B: Engineering,2017,113:381-390. doi: 10.1016/j.compositesb.2017.01.039 [22] 张成林, 董抒华, 李丽君, 等. E-玻璃纤/环氧树脂预浸料固化动力学及其动态热力学性能[J]. 材料工程, 2020, 48(9):152-157. doi: 10.11868/j.issn.1001-4381.2019.000865ZHANG Chenglin, DONG Shuhua, LI Lijun, et al. Curing kinetics and dynamic thermodynamic properties of E-glass fiber/epoxy resin prepreg[J]. Journal of Materials Engi-neering,2020,48(9):152-157(in Chinese). doi: 10.11868/j.issn.1001-4381.2019.000865 [23] LI Z Z, ZOU Z Y, QIN Y, et al. The effect of fibre content on properties of ceramifiable composites[J]. Plastics, Rubber and Composites,2020,49(5):230-236. doi: 10.1080/14658011.2020.1731258 [24] DAO D Q, ROGAUME T, LUCHE J, et al. Thermal degradation of epoxy resin/carbon fiber composites: Influence of carbon fiber fraction on the fire reaction properties and on the gaseous species release[J]. Fire and Materials,2016,40(1):27-47. [25] 张冰, 杨素洁, 杨亚东, 等. 三聚氰胺植酸/硬质聚氨酯泡沫复合材料的制备及其热解动力学特性[J]. 复合材料学报, 2021, 38(8):2505-2516.ZHANG Bing, YANG Sujie, YANG Yadong, et al. Preparation and pyrolysis kinetics of melamine phytates/rigid polyurethane foam composites[J]. Acta Materiae Compositae Sinica,2021,38(8):2505-2516(in Chinese). [26] HUANG G R, LIU H B, YANG L, et al. Pyrolysis behavior of graphene/phenolic resin composites[J]. New Carbon Materials,2015,30(5):412-418. [27] YANG T, YUAN G, XIA M, et al. Kinetic analysis of the pyrolysis of wood/inorganic composites under nonisothermal conditions[J]. European Journal of Wood and Wood Products,2021,79(8):1-12. [28] KAUR R, GERA P, JHA M K, et al. Pyrolysis kinetics and thermodynamic parameters of castor (Ricinus communis) residue using thermogravimetric analysis[J]. Bioresource Technology,2018,250:422-428. doi: 10.1016/j.biortech.2017.11.077 [29] LIU L S, ZHANG X Y, ZHAO R X, et al. Pyrolysis of phragmites hirsuta study on pyrolysis characteristics, kinetic and thermodynamic analyses[J]. International Journal of Energy Research,2021,45(10):15200-15216. doi: 10.1002/er.6795 [30] 徐翊桄, 靳玉伟, 张海龙, 等. 碳纤维热氧化行为及其机理[J]. 合成纤维工业, 2010, 33(6):5-7. doi: 10.3969/j.issn.1001-0041.2010.06.002XU Yiguang, JIN Yuwei, ZHANG Hailong, et al. Thermal oxidation behavior and mechanism of carbon fiber[J]. China Synthetic Fiber Industry,2010,33(6):5-7(in Chinese). doi: 10.3969/j.issn.1001-0041.2010.06.002 [31] REN N, ZHANG J J. Progress in datum treatment methods of thermal analysis kinetics[J]. Progress in Chemistry,2006,18(4):410-416. [32] MIRANDA M, PINTO F, GULYURTLU I, et al. Pyrolysis of rubber tyre wastes: A kinetic study[J]. Fuel,2013,103(1):542-552. [33] 许镇, 唐方勤, 任爱珠. 烟气毒性多气体的改进评价模型[J]. 清华大学学报(自然科学版), 2011, 51(2):194-197.XU Zhen, TANG Fangqin, REN Aizhu. Improved evaluation model of smoke toxicity and multi-gas[J]. Journal of Tsinghua University (Science and Technology),2011,51(2):194-197(in Chinese). [34] YANG Z, YI A H, LIU J Y, et al. Study of fire hazard of flooring materials on data of cone calorimeter[J]. Procedia Engineering,2016,135:584-587. doi: 10.1016/j.proeng.2016.01.113 [35] 李禄超, 王志, 徐艳英, 等. 碳纤维环氧复合材料火灾危险综合评价[J]. 安全与环境学报, 2016, 16(5):62-66.LI Luchao, WANG Zhi, XU Yanying, et al. Comprehensive evaluation of the fire risks faced by the typical epoxy resin/carbon fiber composites[J]. Journal of Safety and Environment,2016,16(5):62-66(in Chinese). [36] TIAN X A, RWA B, ZHI W A, et al. Comparative analysis of thermal oxidative decomposition and fire characteristics for different straw powders via thermogravimetry and cone calorimetry[J]. Process Safety and Environmental Protection,2020,134(C):121-130. -

下载:

下载: