Experimental study on flexural performance of ECC beams reinforced with CFRP bars

-

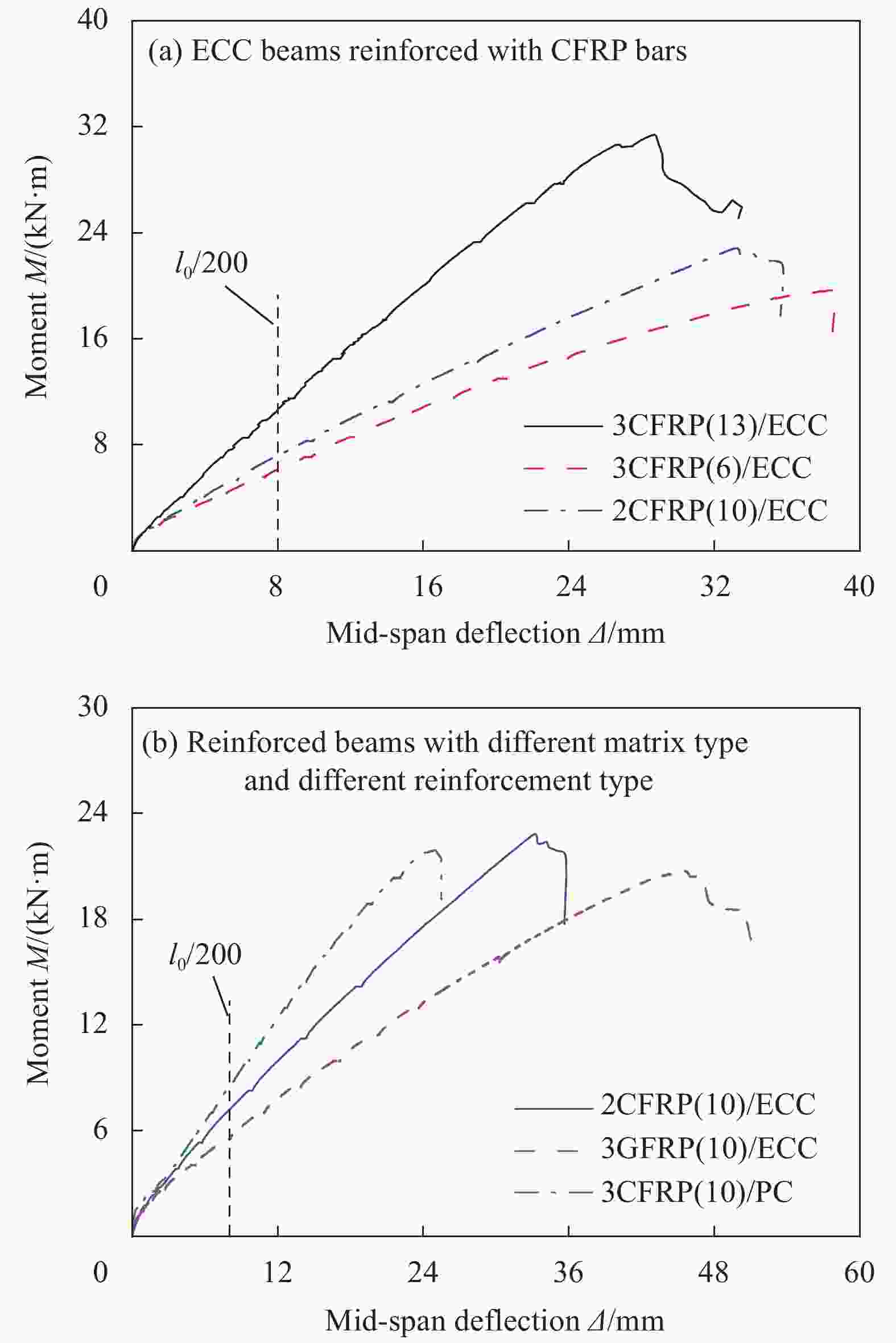

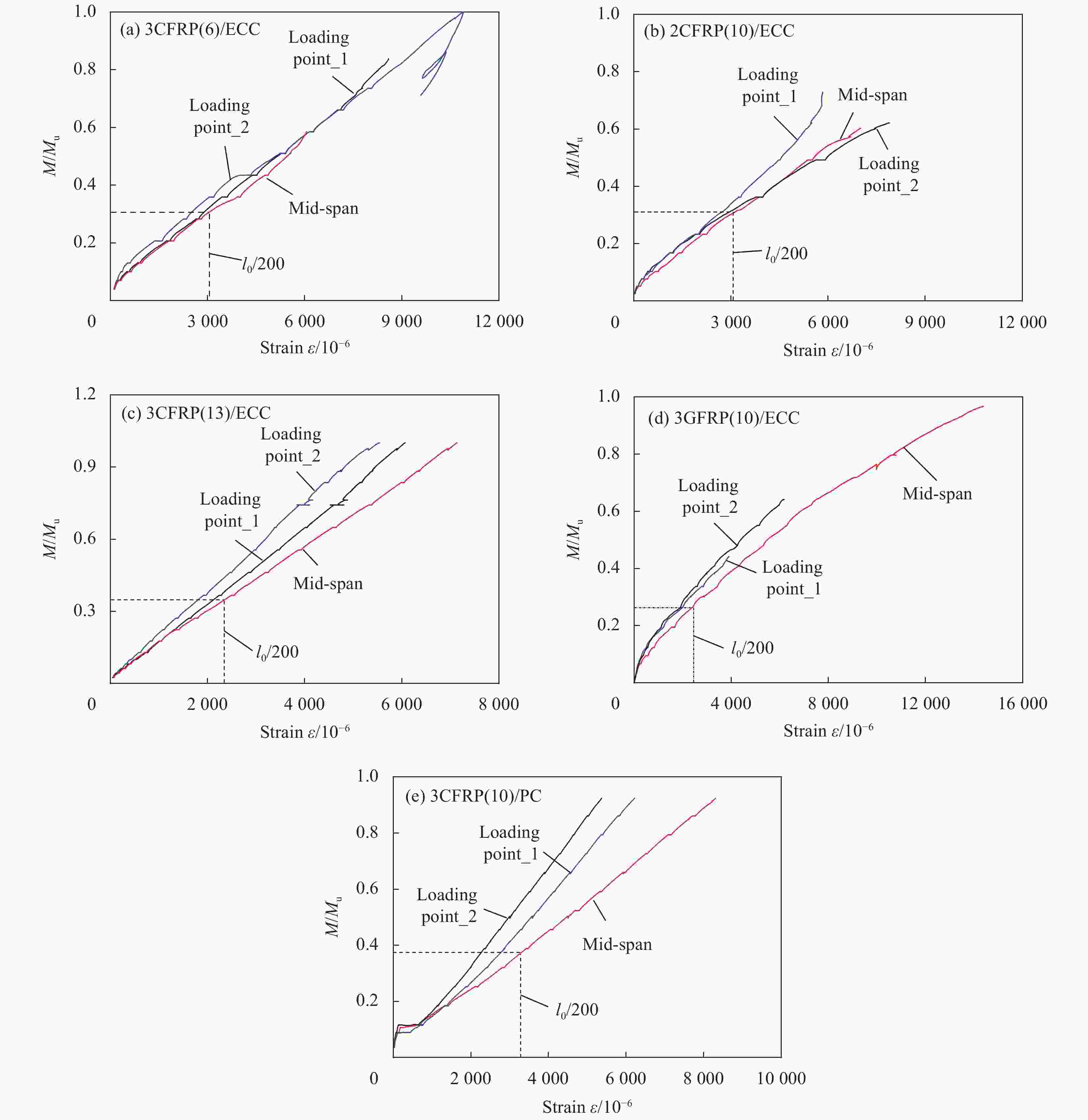

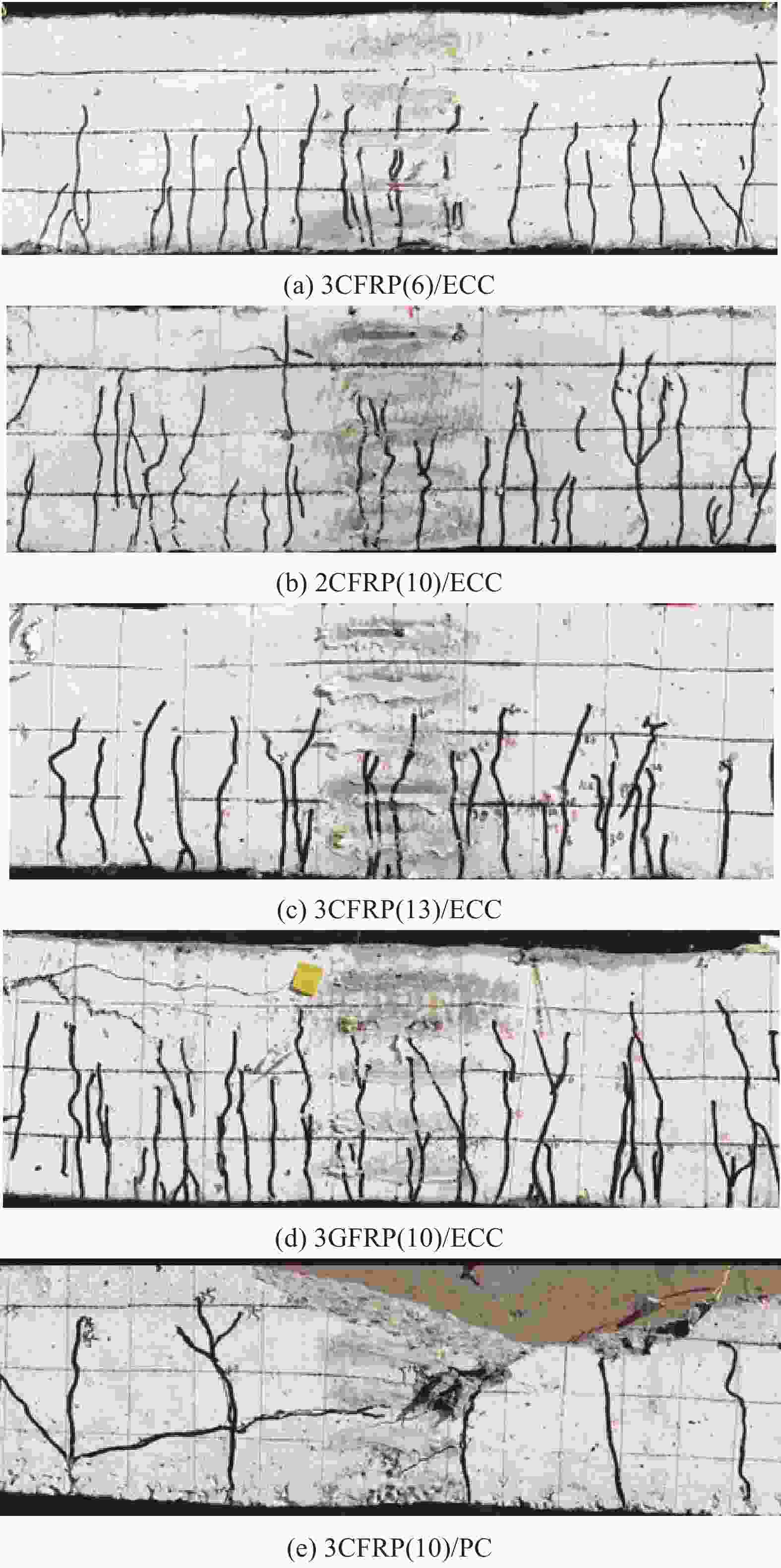

摘要: 为研究碳纤维增强树脂复合材料(Carbon fiber reinforced polymer,CFRP)筋/超高韧性纤维增强水泥基复合材料(Engineered cementitious composite,ECC)梁的抗弯性能,对3根CFRP筋/ECC梁、1根玻璃纤维增强树脂复合材料(Glass fiber reinforced polymer,GFRP)筋/梁和1根CFRP筋混凝土梁进行了四点弯曲试验,分析了配筋率、纤维增强树脂复合材料(Fiber reinforced polymer,FRP)筋类型和基体类型对梁抗弯性能的影响。试验结果表明:CFRP筋/ECC梁与GFRP筋/ECC梁和CFRP筋混凝土梁类似,均经历了弹性阶段、带裂缝工作阶段和破坏阶段;配筋率对CFRP筋/ECC梁的受弯性能影响较大。随着配筋率的增加,CFRP筋/ECC梁的承载能力不断提高,延性性能逐渐减弱;ECC材料优异的应变硬化能力和受压延性,使得CFRP筋/ECC梁的极限承载能力和变形能力均优于CFRP筋混凝土梁;由于ECC材料多裂缝开裂能力,CFRP筋/ECC梁开裂后,纵筋表面应变分布比CFRP筋混凝土梁更均匀; 由于聚乙烯醇(Polyvinyl alcohol,PVA)纤维的桥联作用,CFRP筋/ECC梁破坏时,其表面出现了大量的细密裂缝,且能保持较好的完整性和自复位能力;正常使用阶段,CFRP筋/ECC梁的最大弯曲裂缝宽度均小于CFRP筋混凝土梁。最后,根据试验结果,建立了基于等效应力图的CFRP筋/ECC梁弯曲承载力简化计算模型,确定模型中的相关系数。由简化模型计算的极限承载力与试验结果具有较好的相关性。Abstract: To study the flexural performance of engineered cementitious composite (ECC) beams reinforced with carbon fiber reinforced polymer (CFRP) bars, four-point flexural experimental investigates were carried out on three ECC beams reinforced with CFRP bars, one ECC beam reinforced with glass fiber reinforced polymer (GFRP) bars and one concrete beam reinforced with CFRP bars. The main parameters were the reinforcement ratios, the reinforcement type and the matrix type. The experimental results show that the load-deflection curves of ECC beam reinforced with CFRP bars are similar with the ECC beam reinforced with GFRP bars and concrete beam reinforced with CFRP bars, which have an elastic stage, a working stage with cracks and a failure stage. The reinforcement ratio has a great influence on the flexural performance of ECC beams reinforced with CFRP bars. With the increase of reinforcement ratio, the ultimate bearing capacity of ECC beams is improved, and the ductility performance is gradually weakened. The excellent strain-hardening ability and ductility of ECC materials make the ultimate bearing capacity and deformation of ECC beams with CFRP bars superior to the concrete beam reinforced with CFRP bars. Based on the multi-cracking ability of ECC, the strain distribution on the surface of longitudinal bars is more uniform than that of concrete beams with CFRP bars after cracking. Due to the bridging effect of polyvinyl alcohol (PVA) fiber, a large number of fine cracks appear on the surface of ECC beams reinforced with CFRP bars. When ECC beams reinforced with CFRP bars fail, it could maintain good integrity and self-recovering ability. In service stage, the maximum crack width of reinforced ECC beams presents smaller than that of concrete beams. Finally, a simplified calculation model for ultimate bearing capacity of ECC beams reinforced with fiber reinforced polymer (FRP) rebars is proposed, predicting good agreement with the experimental results.

-

Key words:

- CFRP bars /

- ECC beam /

- flexural performance /

- ultimate bearing capacity /

- crack width

-

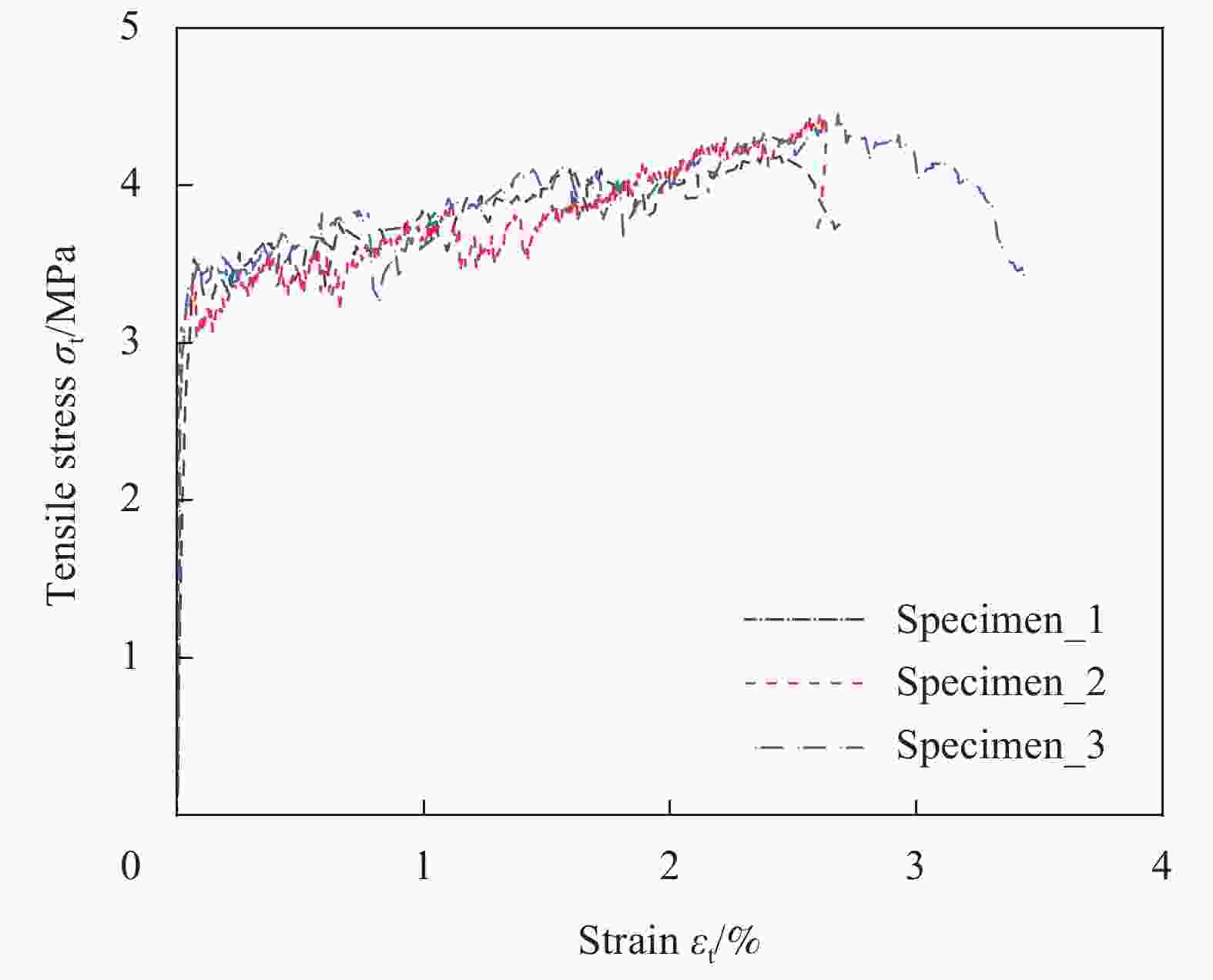

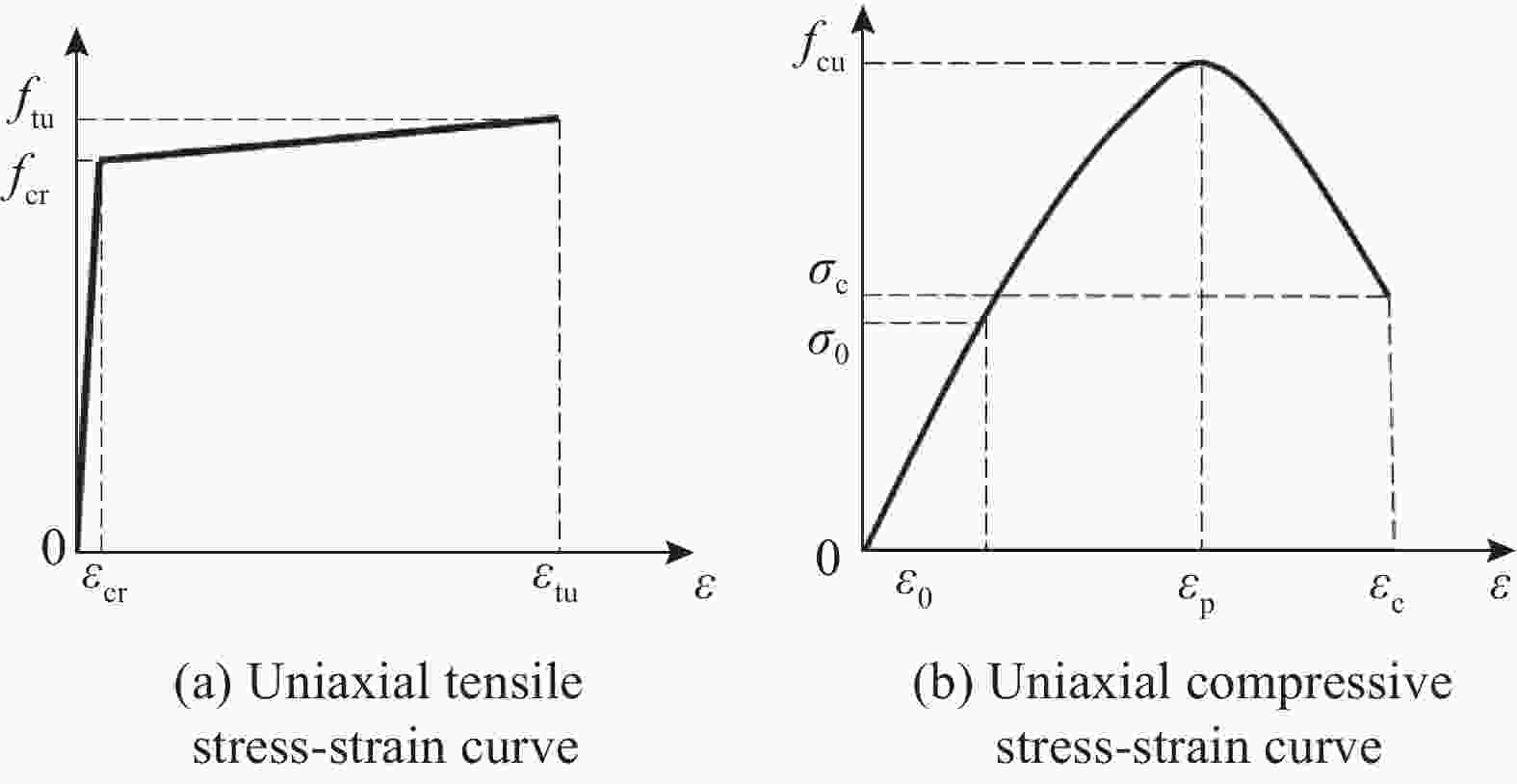

图 9 ECC材料单轴应力-应变曲线

fcr—Cracking strength; ftu—Tensile strength; εcr—Cracking strain; εtu—Ultimate tensile strain; σ0—Elastic compressive strength; ε0—Elastic compressive strain; εp—Strain corresponding to compressive strength; εc—Ultimate compressive strain; σc—Residual compressive strength; fcu—Uniaxial compressive strength

Figure 9. Uniaxial stress-strain curves of ECC

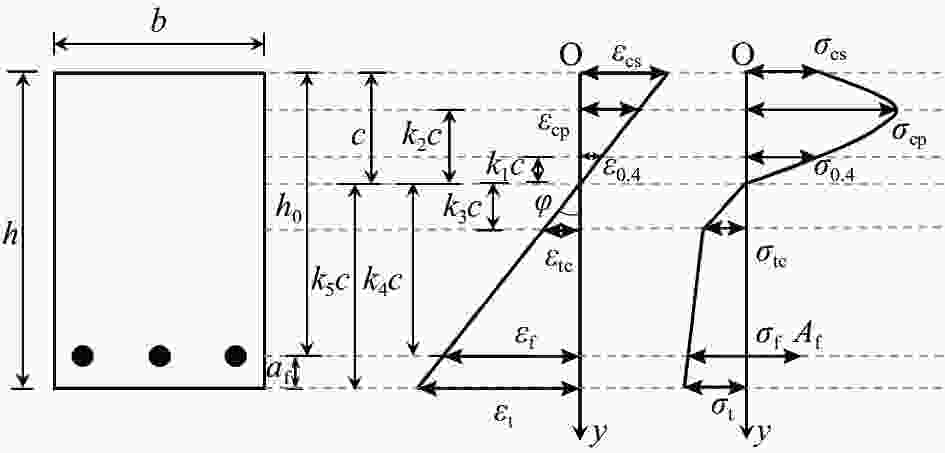

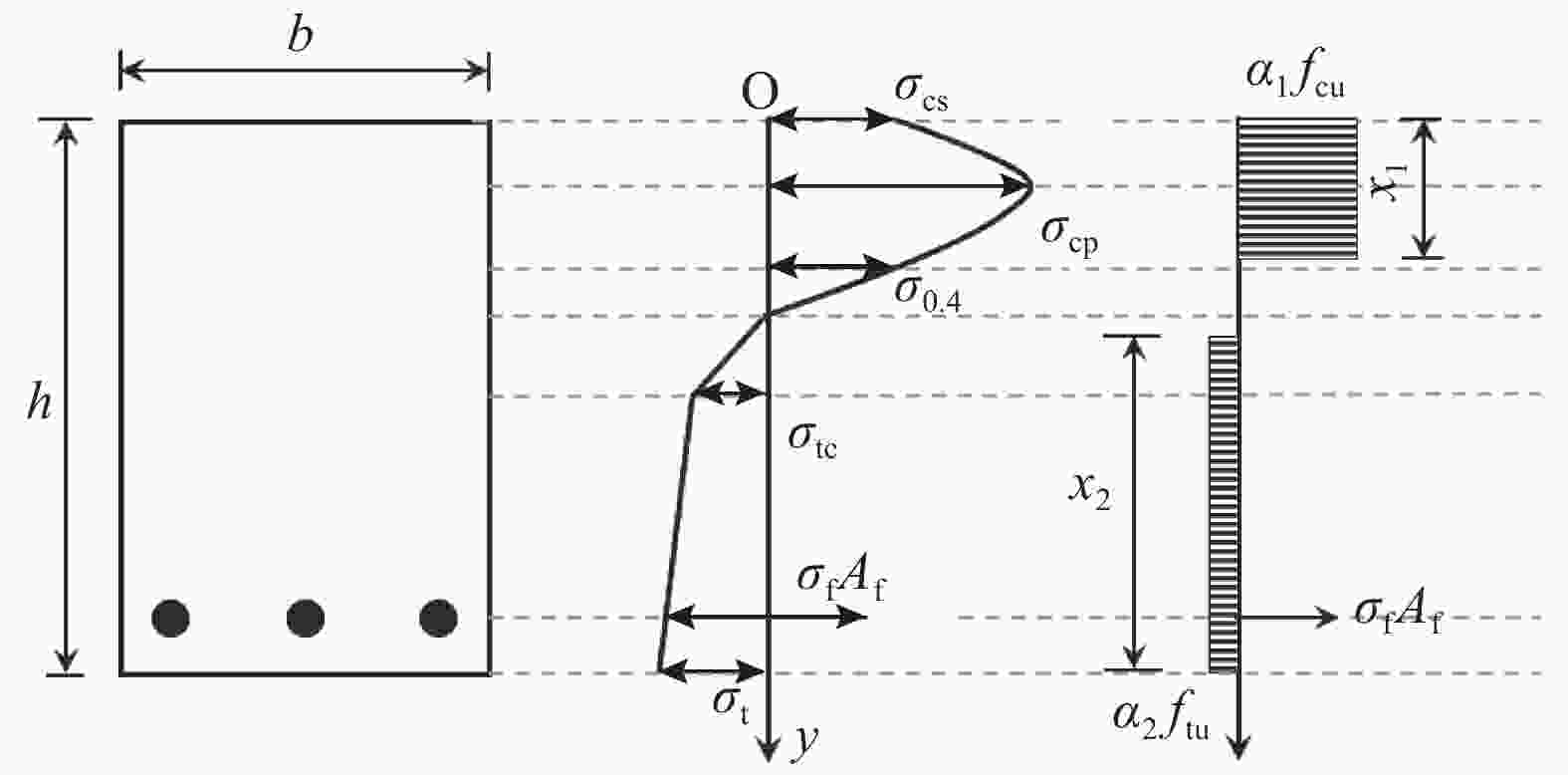

图 10 破坏阶段梁截面上应力和应变分布

Figure 10. Stress and strain distribution of the tested beams at failure stage

h, b—Height and width of the tesed ECC beams; εcs—Ultimate compressive strain of ECC; εcp— Compressive strain of ECC corresponding to the ultimate compressive strength; ε0.4—Elastic compressive strain of ECC; εf—Tensile strain of FRP rebar; εt—Tensile strain of ECC; εtc—Cracking strain of ECC; φ—Curvature of the beams; c—Height of the actual compression zone; σ0.4—Elastic ultimate strength of ECC under uniaxial compression; σcp—Uniaxial compressive strength of ECC; σcs—Residual compressive strength of ECC when reaches the ultimate compressive strain; σtc—Cracking strength ECC under uniaxial tension; σt—Tensile strength ECC; σf—Tensile stress of FRP rebars; Af—Cross-sectional area of FRP rebars; h0—Effective height of beam section; af—Distance from the resultant force point of FRP bars to the tensile edge of the beam; k1, k2, k3, k4, k5—Related material coefficients

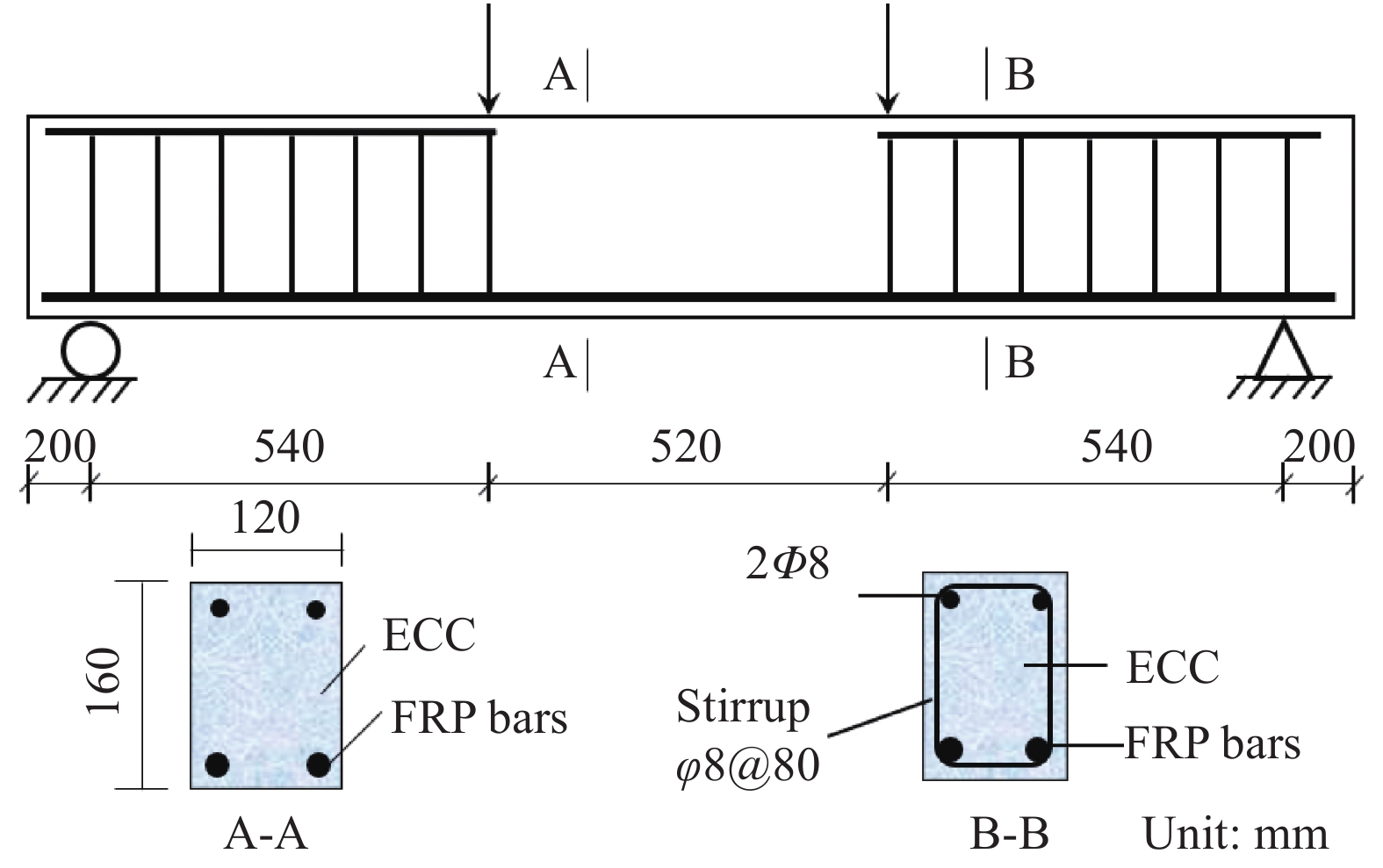

表 1 梁试件主要参数

Table 1. Detailed parameters of tested beams

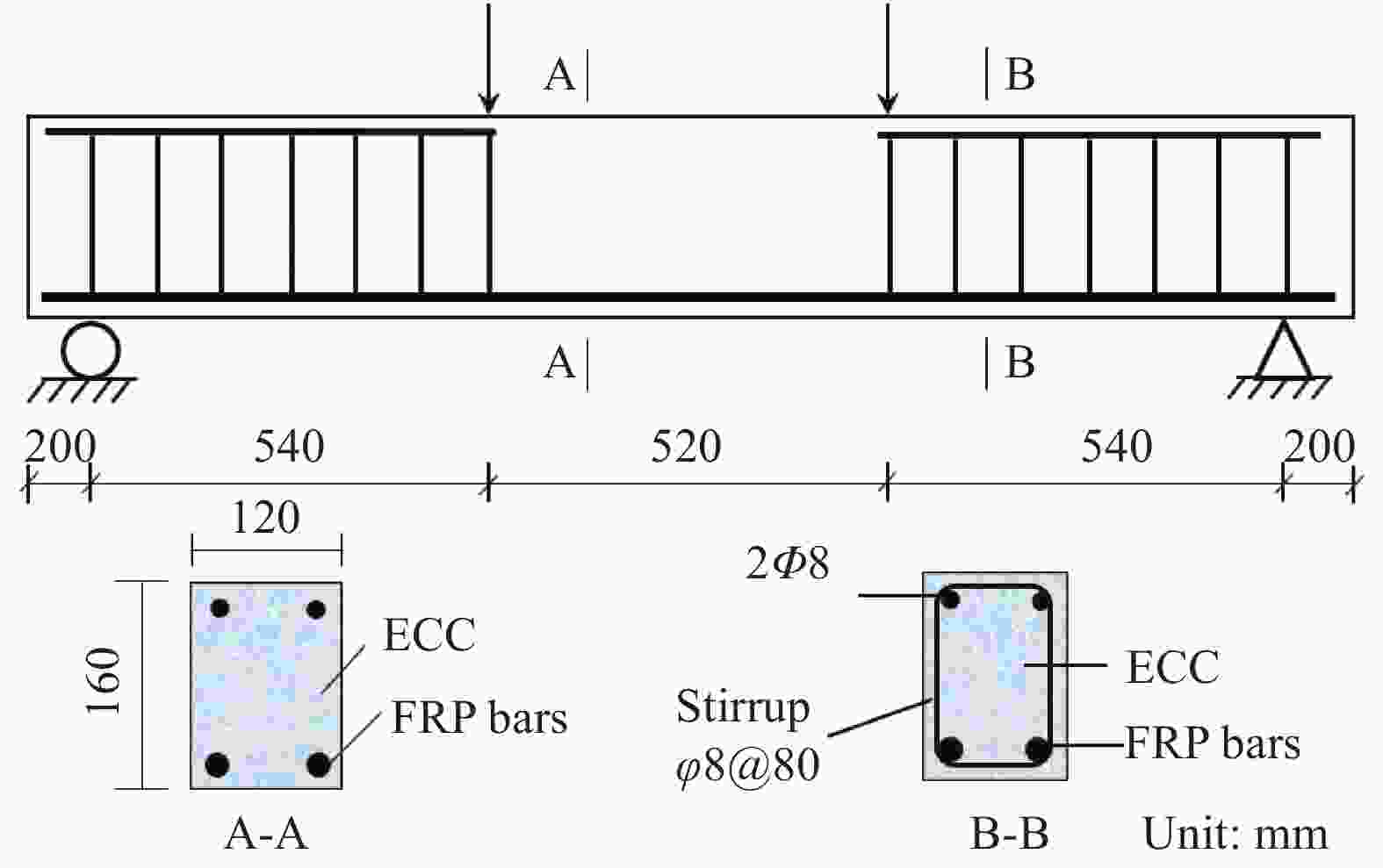

Sample Dimension of the

beam/mm3FRP rebar Matrix type Longitudinal

barReinforcement

ratio/%Stirrup Supplementary

reinforcement3CFRP(6)/ECC 120×160×2000 CFRP ECC 3Φ6 0.54 Φ8@80 2Φ8 2CFRP(10)/ECC 120×160×2000 CFRP ECC 2Φ10 1.01 Φ8@80 2Φ8 3CFRP(13)/ECC 120×160×2000 CFRP ECC 3Φ13 2.55 Φ8@80 2Φ8 3GFRP(10)/ECC 120×160×2000 GFRP ECC 3Φ10 1.51 Φ8@80 2Φ8 3CFRP(10)/PC 120×160×2000 CFRP Concrete 3Φ10 1.51 Φ8@80 2Φ8 Notes: yCFRP(x)—Number of FRP rebars designed in the beam is y, x means the diameter of used FRP rebars; PC—Plain concrete; CFRP—Carbon fiber reinforced polymer; GFRP—Glass fiber reinforced polymer. 表 2 筋材基本力学参数

Table 2. Mechanical parameters of FRP rebars

FRP D

/mmffu

/MPaEf

/GPaεfu

/%CFRP 6 2700.0 163.6 1.65 10 2436.0 143.3 1.70 13 2001.1 132.5 2.00 GFRP 10 1080.0 50.0 2.00 Notes: D—Diameter of FRP rebar; ffu—Tensile strength of FRP rebar; Ef—Elastic modulus of FRP rebar; εfu—Ultimate tensile strain of FRP rebar. 表 3 ECC配合比

Table 3. Mix proportion of ECC

Cement

+Fly ashSilica sand Water Fiber Super-

plasticizer1 0.2 0.28 0.009 0.006 表 4 聚乙烯醇(PVA)纤维的材料性能

Table 4. Material properties of polyvinyl alcohol (PVA) fiber

L

/mmdf

/µmffiber

/MPaδf

/%Efiber

/GPaρ

/(g·cm−3)12 39 1620 7 42.8 1.6 Notes: df—Diameter of PVA fiber; L—Length of PVA fiber; ρ—Density; ffiber—Tensile strength of fiber; Efiber—Elastic modulus of fiber; δf—Elongation of PVA fiber. 表 5 FRP筋增强ECC梁和FRP筋/混凝土梁试验结果

Table 5. Test results of ECC beam reinforced with FRP bars and concrete beam reinforced with FRP bars

Sample Mcr

/(kN·m)Mu

/(kN·m)Δcr

/mmΔu

/mmFailure mode 3CFRP(6)/ECC 1.09 19.67 0.29 38.40 ECC crushed 2CFRP(10)/ECC 1.13 22.83 0.36 33.28 ECC crushed 3CFRP(13)/ECC 1.14 31.41 0.37 28.73 ECC crushed 3GFRP(10)/ECC 1.11 20.76 0.44 45.31 ECC crushed 3CFRP(10)/PC 1.42 21.92 0.23 24.98 Concrete crushed Notes: Mcr—Crack moment; Mu—Ultimate moment; Δcr—Crack deflection at mid-span; Δu—Ultimate deflection at mid span. 表 6 挠度为l0/200时各梁跨中位置CFRP筋应变

Table 6. Strain of CFRP rebar at mid-span of the tested beam with deflection l0/200

Sample Strain of CFRP rebar at mid-span/10−6 3CFRP(6)/ECC 3065 2CFRP(10)/ECC 3066 3CFRP(13)/ECC 2349 3GFRP(10)/ECC 2660 3CFRP(10)/PC 3200 表 7 FRP筋/ECC梁受压区高度计算结果

Table 7. Calculation results of the actual compression zone height of ECC beams reinforced with FRP bars

Sample Reinforce-

ment ratio/%c

/

mmcb

/

mmFailure

mode3CFRP(6)/ECC 0.54 45.85 37.36 ECC crushed 2CFRP(10)/ECC 1.01 53.70 36.57 ECC crushed 3CFRP(13)/ECC 2.55 70.05 32.45 ECC crushed 3GFRP(10)/ECC 1.51 44.50 32.45 ECC crushed Note: cb—Actual compression zone height at boundary failure. 表 8 FRP筋/ECC梁等效矩形应力图系数

Table 8. Equivalent rectangular stress coefficients of FRP rebar reinforced ECC beams

Sample Reinforcement ratio/% α1 β1 α2 β2 3GFRP(10)/ECC 1.51 0.768 0.853 0.828 0.925 3CFRP(6)/ECC 0.54 0.768 0.853 0.820 0.927 2CFRP(10)/ECC 1.01 0.768 0.853 0.784 0.938 3CFRP(13)/ECC 2.55 0.768 0.853 0.735 0.954 Notes: β1—Ratio of compression zone height to neutral axis height of ECC; β2—Ratio of calculation height to actual height of tension zone of ECC. 表 9 FRP筋/ECC梁极限承载力试验值与计算值对比

Table 9. Comparison of experimental and calculated ultimate bearing capacity of FRP bars reinforced ECC beams

Sample Mu,exp/(kN·m) Mu,cal/(kN·m) Mu,cal/Mu,exp 3CFRP(6)/ECC 19.67 19.88 1.011 2CFRP(10)/ECC 22.83 21.47 0.940 3CFRP(13)/ECC 31.41 28.30 0.919 3GFRP(10)/ECC 20.76 20.06 0.966 Notes: Mu,exp—Test value of ultimate bending moment; Mu,cal—Calculated value of ultimate bending moment. -

[1] YUAN F, WU Y F. Analytical method for derivation of stress block parameters for flexural design of FRP reinforced concrete members[J]. Composite Structures,2019,229:111459. doi: 10.1016/j.compstruct.2019.111459 [2] 刘晋宏, 罗小勇, 肖烨. 钢筋非均匀锈蚀及剩余截面积分布模型[J]. 华中科技大学学报(自然科学版), 2021, 49(11):83-88.LIU Jinhong, LUO Xiaoyong, XIAO Ye. Non-uniform corrosion and distribution models of residual cross-sectional areas of rebars[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition),2021,49(11):83-88(in Chinese). [3] 王洋, 董恒磊, 王震宇. GFRP筋混凝土梁受弯性能试验[J]. 哈尔滨工业大学学报, 2018, 50(12):23-30. doi: 10.11918/j.issn.0367-6234.201804109WANG Yang, DONG Henglei, WANG Zhenyu. Flexural experiment of concrete beams reinforced with GFRP bars[J]. Journal of Harbin Institute of Technology,2018,50(12):23-30(in Chinese). doi: 10.11918/j.issn.0367-6234.201804109 [4] DONG Z Q, WU G, ZHAO X L, et al. Durability test on the flexural performance of seawater sea-sand concrete beams completely reinforced with FRP bars[J]. Construction and Building Materials,2018,192:671-682. [5] 朱海堂, 程晟钊, 高丹盈, 等. BFRP筋钢纤维高强混凝土梁受弯承载力试验与理论[J]. 复合材料学报, 2018, 35(12):3313-3323.ZHU Haitang, CHENG Shengzhao, GAO Danying, et al. Experimental and theoretical study on the flexural capacity of high-strength concrete beams reinforced with BFRP bars and steel fiber[J]. Acta Materiae Compositae Sinica,2018,35(12):3313-3323(in Chinese). [6] EL-NEMR A, AHMED E A, EL-SAFTY A, et al. Evaluation of the flexural strength and serviceability of concrete beams reinforced with different types of GFRP bars[J]. Engineering Structures,2018,173:606-619. doi: 10.1016/j.engstruct.2018.06.089 [7] JU M, PARK Y, PARK C. Cracking control comparison in the specifications of serviceability in cracking for FRP reinforced concrete beams[J]. Composite Structures,2017,182:674-684. doi: 10.1016/j.compstruct.2017.09.016 [8] XIAO S H, LIN J X, LI L J, et al. Experimental study on flexural behavior of concrete beam reinforced with GFRP and steel-fiber composite bars[J]. Journal of Building Engi-neering,2021,43:103087. doi: 10.1016/j.jobe.2021.103087 [9] LI V C, LEUNG C K Y. Steady-state and multiple cracking of short random fiber composites[J]. Journal of Engineering Mechanics,1992,118(11):2246-2264. doi: 10.1061/(ASCE)0733-9399(1992)118:11(2246) [10] XU L Y, HUANG B T, LI V C, et al. High-strength high-ductility engineered/strain-hardening cementitious composites (ECC/SHCC) incorporating geopolymer fine aggregates[J]. Cement and Concrete Composites,2022,125:104296. doi: 10.1016/j.cemconcomp.2021.104296 [11] XU S L, XU H L, HUANG B T, et al. Development of ultrahigh-strength ultrahigh-toughness cementitious composites (UHS-UHTCC) using polyethylene and steel fibers[J]. Composites Communications,2021(100992):1-6. [12] WU C, LEUNG C K Y, LI V C. Derivation of crack bridging stresses in engineered cementitious composites under combined opening and shear displacements[J]. Cement and Concrete Research,2018,107:253-263. doi: 10.1016/j.cemconres.2018.02.027 [13] LI V C, WANG S. Flexural behaviors of glass fiber-reinforced polymer (GFRP) reinforced engineered cementitious composite beams[J]. Materials Journal,2002,99(1):11-21. [14] YUAN F, PAN J L, LEUNG C K Y. Flexural behaviors of ECC and concrete/ECC composite beams reinforced with basalt fiber-reinforced polymer[J]. Journal of Composites for Construction,2013,17(5):591-602. doi: 10.1061/(ASCE)CC.1943-5614.0000381 [15] 周甲佳, 姚少科, 景川, 等. FRP筋-ECC梁受弯性能[J]. 建筑科学与工程学报, 2020, 37(6):46-54.ZHOU Jiajia, YAO Shaoke, JING Chuan, et al. Flexural behavior of FRP-reinforced ECC beam[J]. Journal of Architecture and Civil Engineering,2020,37(6):46-54(in Chinese). [16] 蒋祖发. FRP筋ECC梁受弯性能研究[D]. 郑州: 郑州大学, 2020.JIANG Zufa. Study on flexural behavior of FRP rebar reinforced ECC beams[D]. Zhengzhou: Zhengzhou University, 2020(in Chinese). [17] GE W J, ASHOUR A F, CAO D F, et al. Experimental study on flexural behavior of ECC-concrete composite beams reinforced with FRP bars[J]. Composite Structures,2019,208:454-465. doi: 10.1016/j.compstruct.2018.10.026 [18] GE W J, ASHOUR A F, YU J M, et al. Flexural behavior of ECC-concrete hybrid composite beams reinforced with FRP and steel bars[J]. Journal of Composites for Construction,2019,23(1):1-14. doi: 10.1061/(ASCE)CC.1943-5614.0000910 [19] YUAN F, HU R. Flexural behaviour of ECC and ECC-concrete composite beams reinforced with hybrid FRP and steel bars[J]. Advances in Structural Engineering,2021,24(15):3171-3183. [20] CAI J M, PAN J L, ZHOU X M. Flexural behavior of basalt FRP reinforced ECC and concrete beams[J]. Construction and Building Materials,2017,142:423-430. doi: 10.1016/j.conbuildmat.2017.03.087 [21] HOU W, LI Z Q, GAO W Y, et al. Flexural behavior of RC beams strengthened with BFRP bars-reinforced ECC matrix[J]. Composite Structures,2020,241:112092. doi: 10.1016/j.compstruct.2020.112092 [22] ZHANG L, ZHENG Y, YU Y, et al. Structural performance evaluation of ECC link slabs reinforced with FRP bars for jointless bridge decks[J]. Construction and Building Materials,2021,304:124462. doi: 10.1016/j.conbuildmat.2021.124462 [23] 何佶轩. FRP增强ECC梁及ECC/混凝土组合梁抗剪性能研究[D]. 南京: 东南大学, 2016.HE Jixuan. Study on shear behaviors of FRP reinforced ECC beams and ECC/concrete composite beam[D]. Nanjing: Southeast University, 2016(in Chinese). [24] 廖桥, 苏元瑞, 余江滔, 等. 海水海砂ECC梁的抗剪性能试验及有限元模拟[J]. 复合材料学报, 2022, 39(8): 3929-3939.LIAO Qiao, SU Yuanrui, YU Jiangtao, et al. Experimental study and finite element analysis of seawater sea-sand engineered cementitious composites beams[J]. Acta Materiae Compositae Sinica, 2022, 39(8): 3929-3939(in Chinese). [25] ZHOU J, SHEN W, WANG S. Experimental study on torsional behavior of FRC and ECC beams reinforced with GFRP bars[J]. Construction and Building Materials,2017,152:74-81. doi: 10.1016/j.conbuildmat.2017.06.131 [26] FISCHER G, LI V C. Deformation behavior of fiber-reinforced polymer reinforced engineered cementitious composite (ECC) flexural members under reversed cyclic loading conditions[J]. ACI Structural Journal,2003,100(1):25-35. [27] YUAN F, PAN J L, DONG L T, et al. Mechanical behaviors of steel reinforced ECC or ECC/concrete composite beams under reversed cyclic loading[J]. Journal of Materials in Civil Engineering,2014,26(8):04014047. doi: 10.1061/(ASCE)MT.1943-5533.0000935 [28] American Society for Testing Materials. Standard test method for tensile properties of fiber reinforced polymer matrix composite bars: ASTM D7205/D7205M-06[S]. West Conshohocken: American Society for Testing Materials, 2006. [29] 中华人民共和国住房和城乡建设部. 纤维增强复合材料工程应用技术标准: GB/T 50608—2020[S]. 北京: 中国计划出版社, 2020.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Technical standard for fiber reinforced polymer (FRP) in construction: GB/T 50608—2020[S]. Beijing: China Planning Press, 2020(in Chinese). [30] ZHOU J J, PAN J L, LEUNG C K Y. Mechanical behavior of fiber-reinforced engineered cementitious composites in uniaxial compression[J]. Journal of Materials in Civil Engineering,2015,27(1):04014111. doi: 10.1061/(ASCE)MT.1943-5533.0001034 [31] 中华人民共和国住房和城乡建设部. 混凝土结构设计规范: GB/T 50010—2010[S]. 北京: 中国建筑工业出版社, 2015.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Design code for concrete structures: GB/T 50010—2010[S]. Beijing: China Building Industry Press, 2015(in Chinese). -

下载:

下载: