Hardening mechanism and pore size analysis of new magnetic epoxy cement grout

-

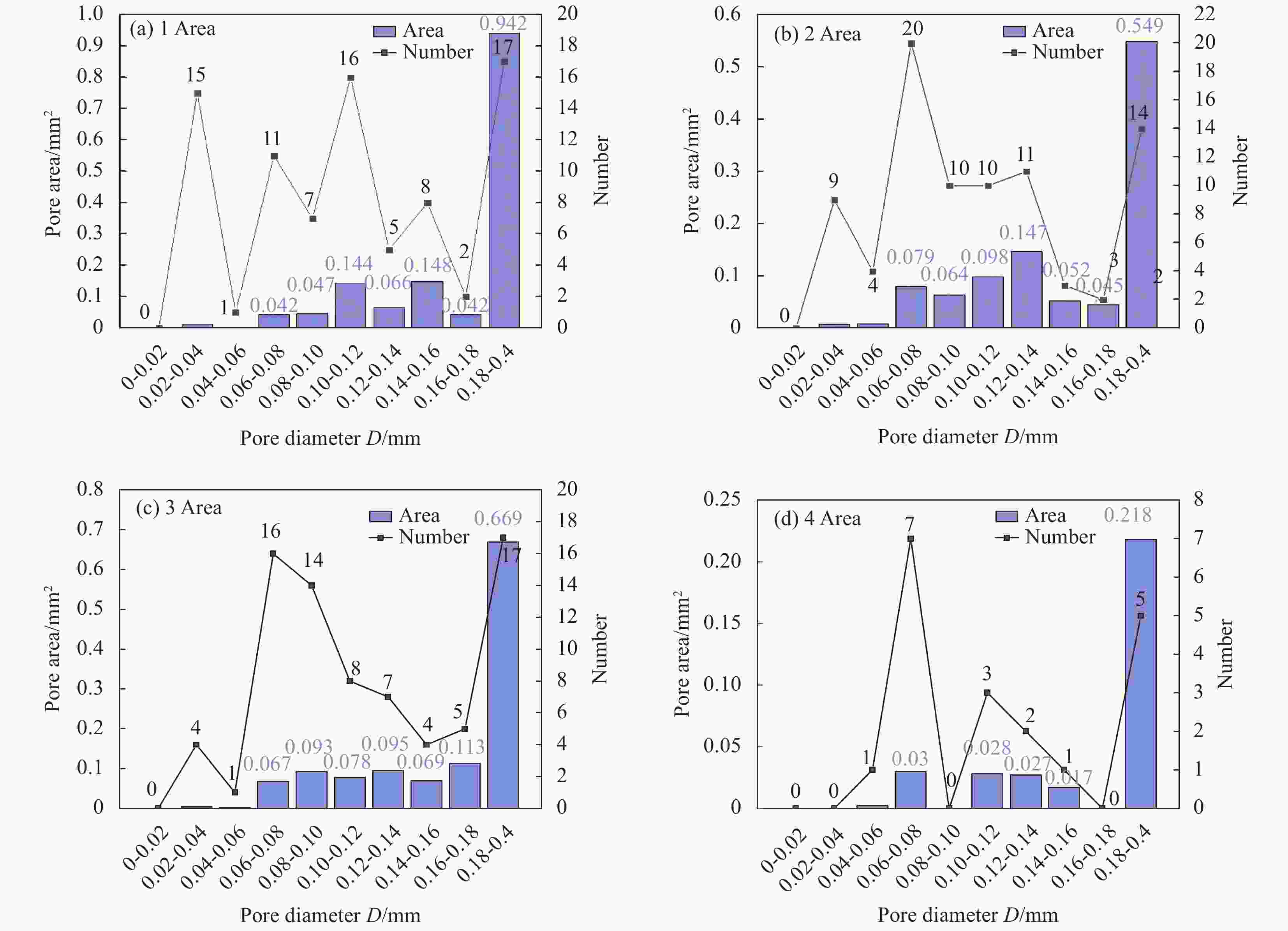

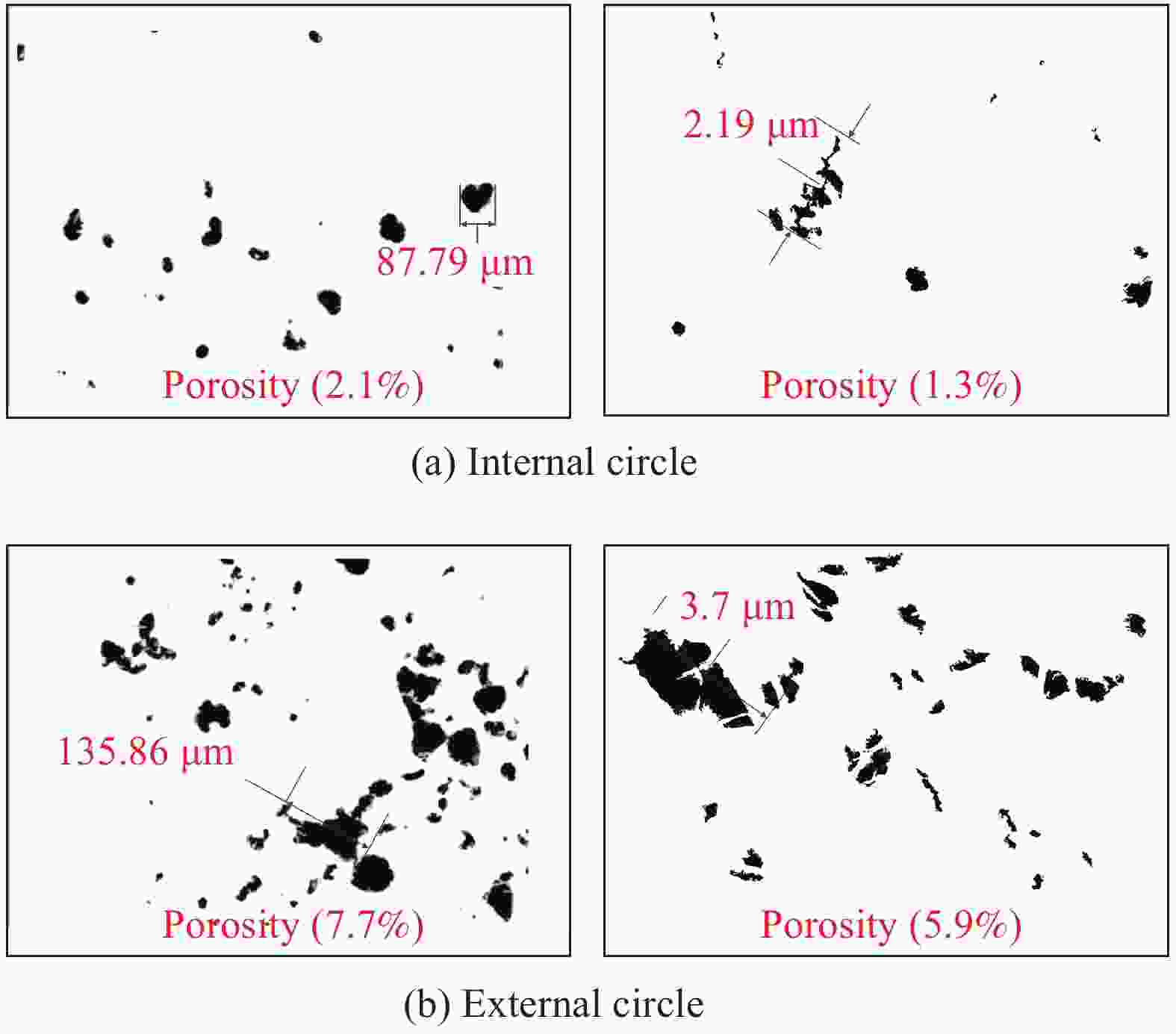

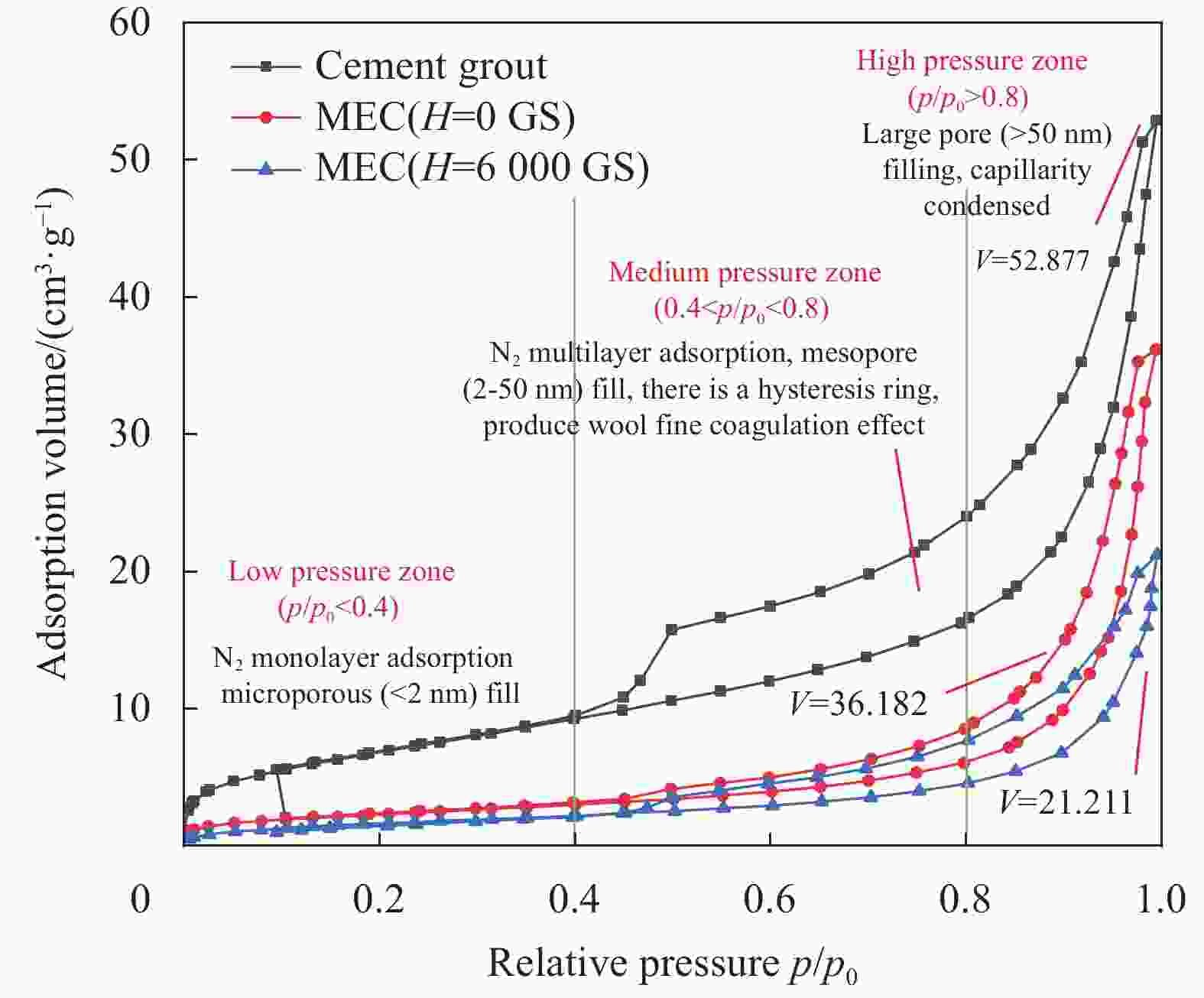

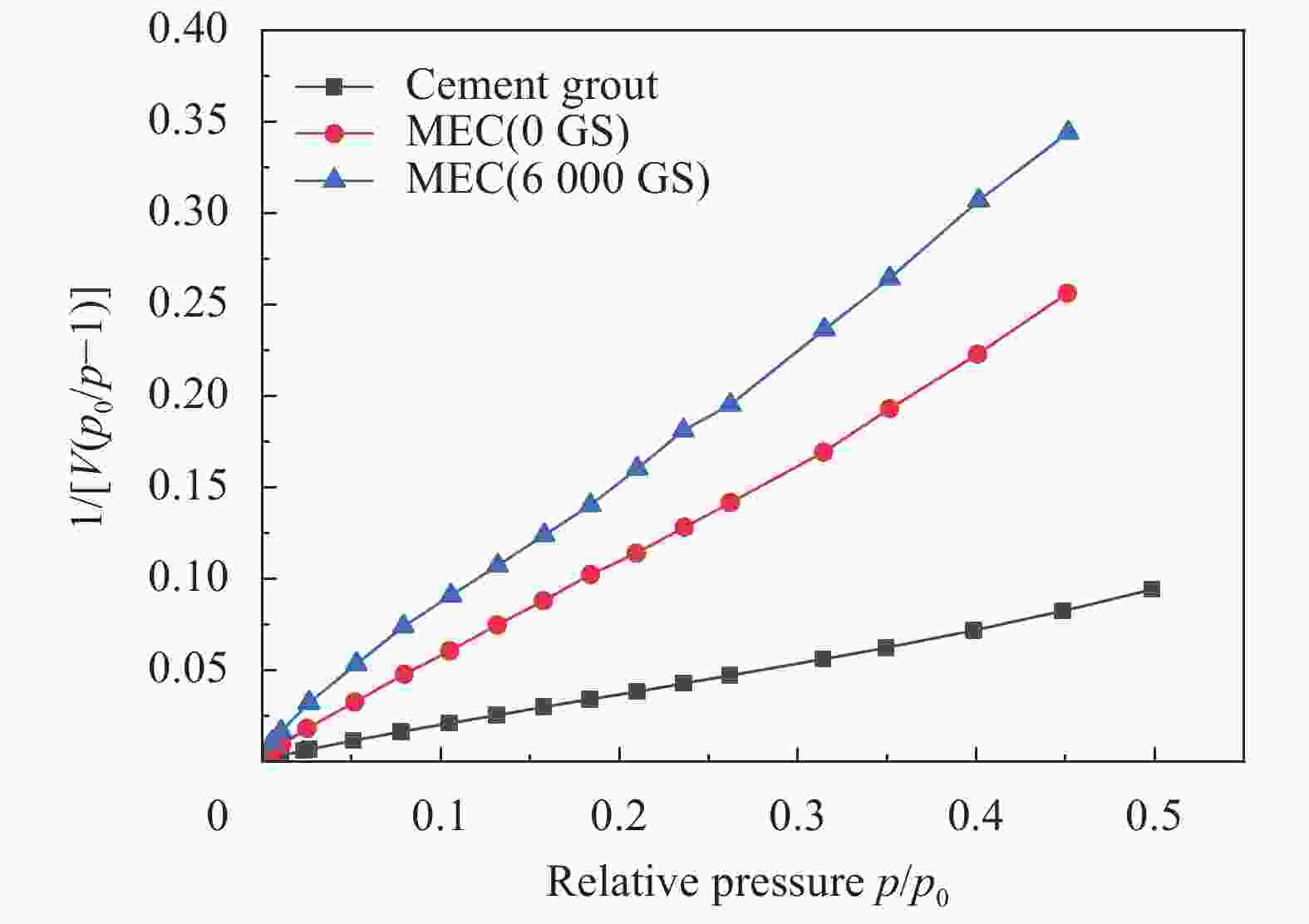

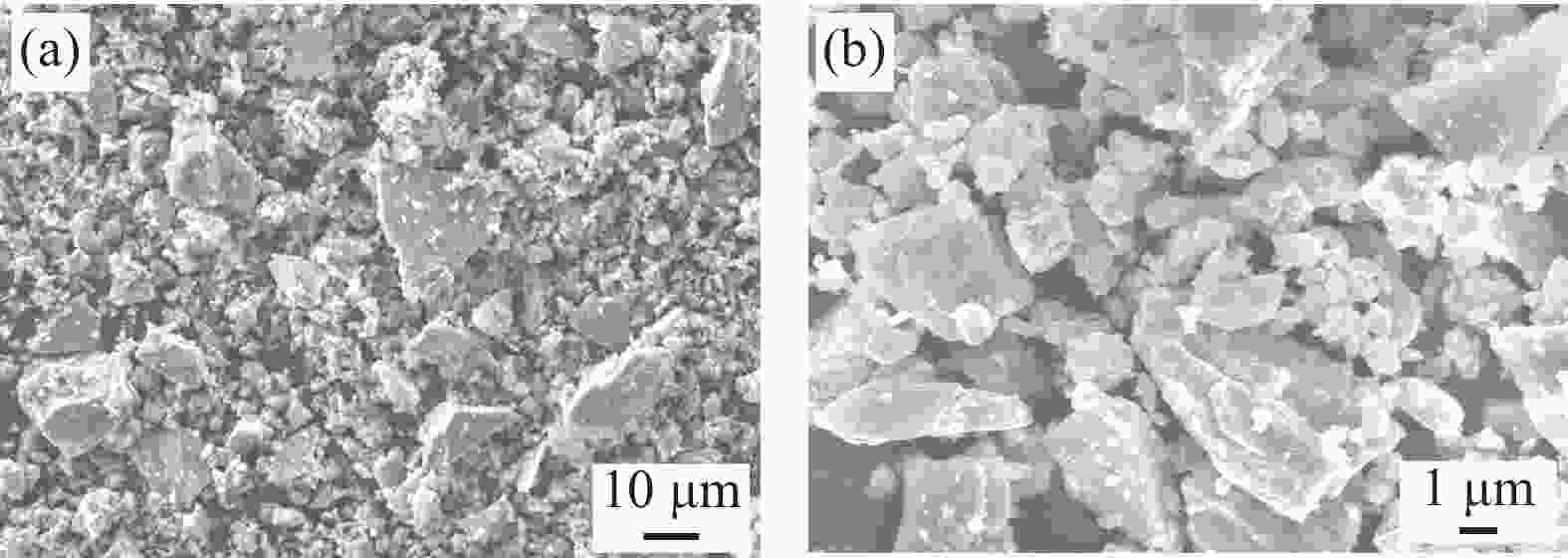

摘要: 常规砂浆无法满足反倾斜裂隙和缺陷的工程填充要求,在注浆压力驱使下会引入大量气泡,浆液密实度得不到保障。针对此,研发了一种新型磁性环氧树脂水泥(MEC)浆液,可实现反重力式注浆锚固、导向式流动、增大浆体密实度、浆液黏度实时调控。采用SEM、XRD、N2吸附测试方法,对MEC浆液在不同磁场作用下的微观形貌、水化产物和孔径进行了分析。结果表明:MEC浆液主要分为环氧树脂固化、水泥水化两个硬化过程。固化产物对水化产物进行包裹,与钙矾石(Ettringite,AFt)和Ca(OH)2中的Ca2+发生离子作用,形成络合物包裹磁粉,对浆液中存在的微小孔隙进行填充;磁场强度由400 GS增大到6000 GS时,孔隙面积减小率达77.6%,孔隙数量减小率达76.8%。N2吸附试验表明:附加磁场会降低介孔和大孔的数量,显著减小比表面积,磁性浆液符合H4型滞回线,主要表现为墨水瓶孔;基于磁偶极子理论,数值模拟了磁颗粒受力,分析结果表明在磁场强度为2000~6000 GS可高效减小孔隙面积。

-

关键词:

- 磁性环氧树脂水泥(MEC)浆液 /

- 微观结构 /

- XRD衍射分析 /

- 氮气吸附法 /

- 孔径分布

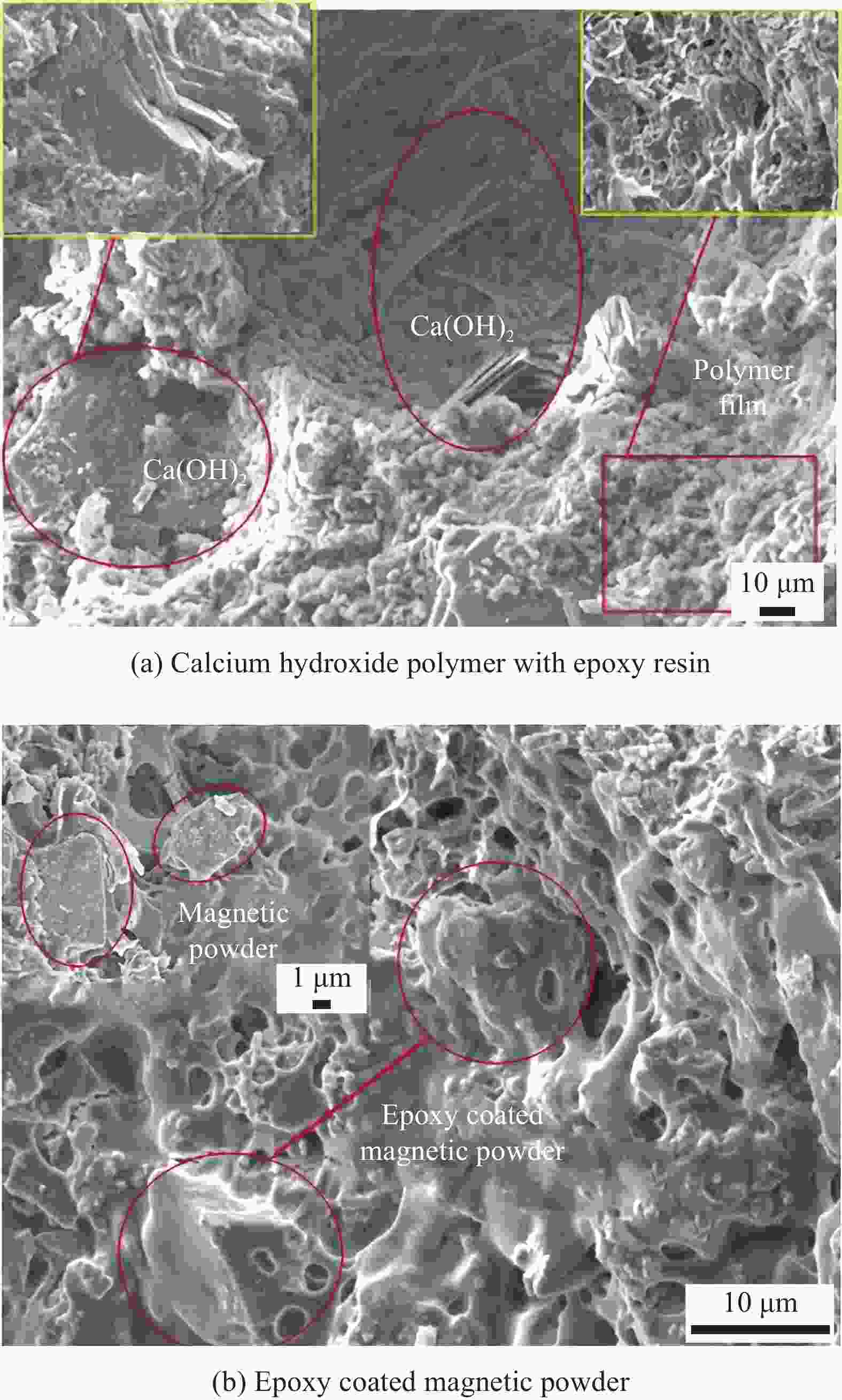

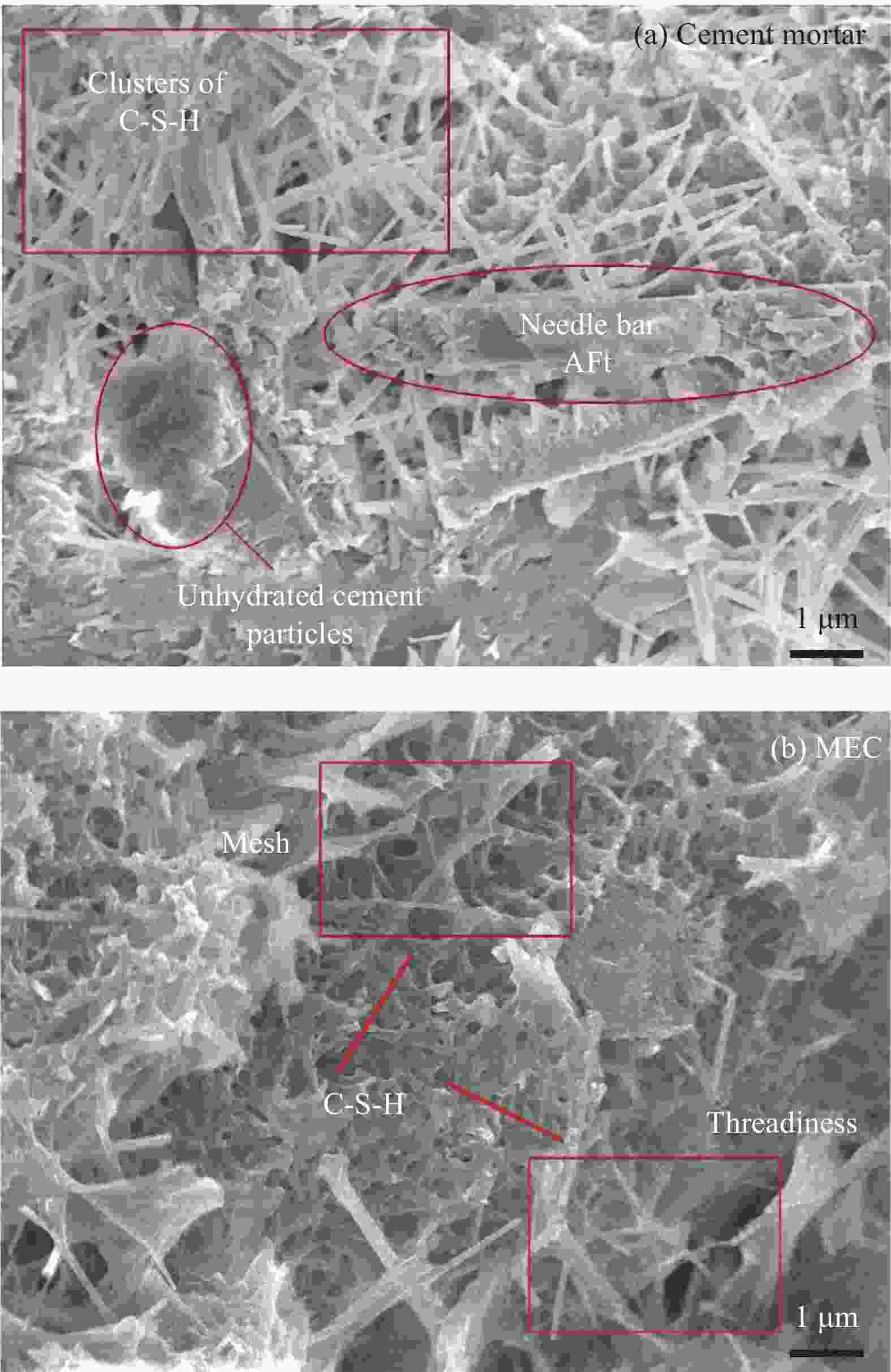

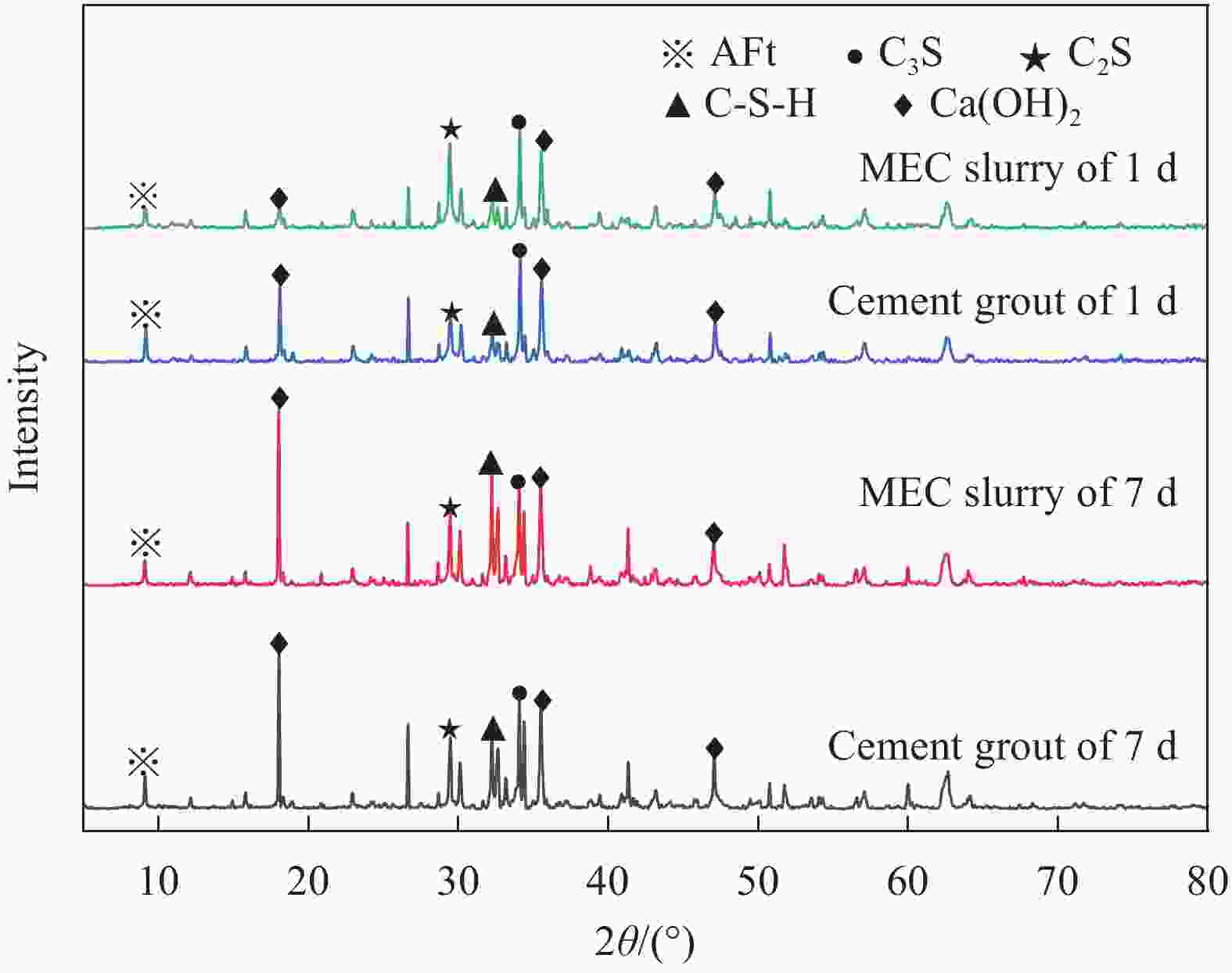

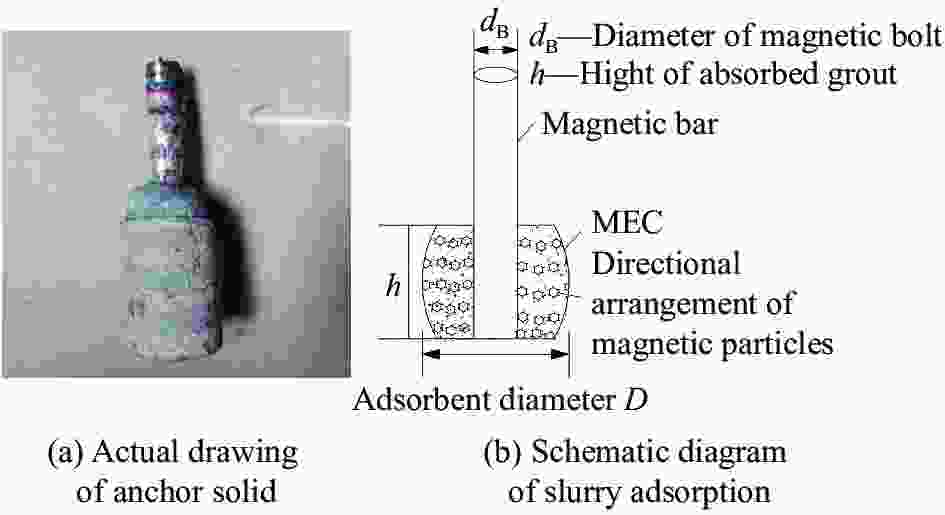

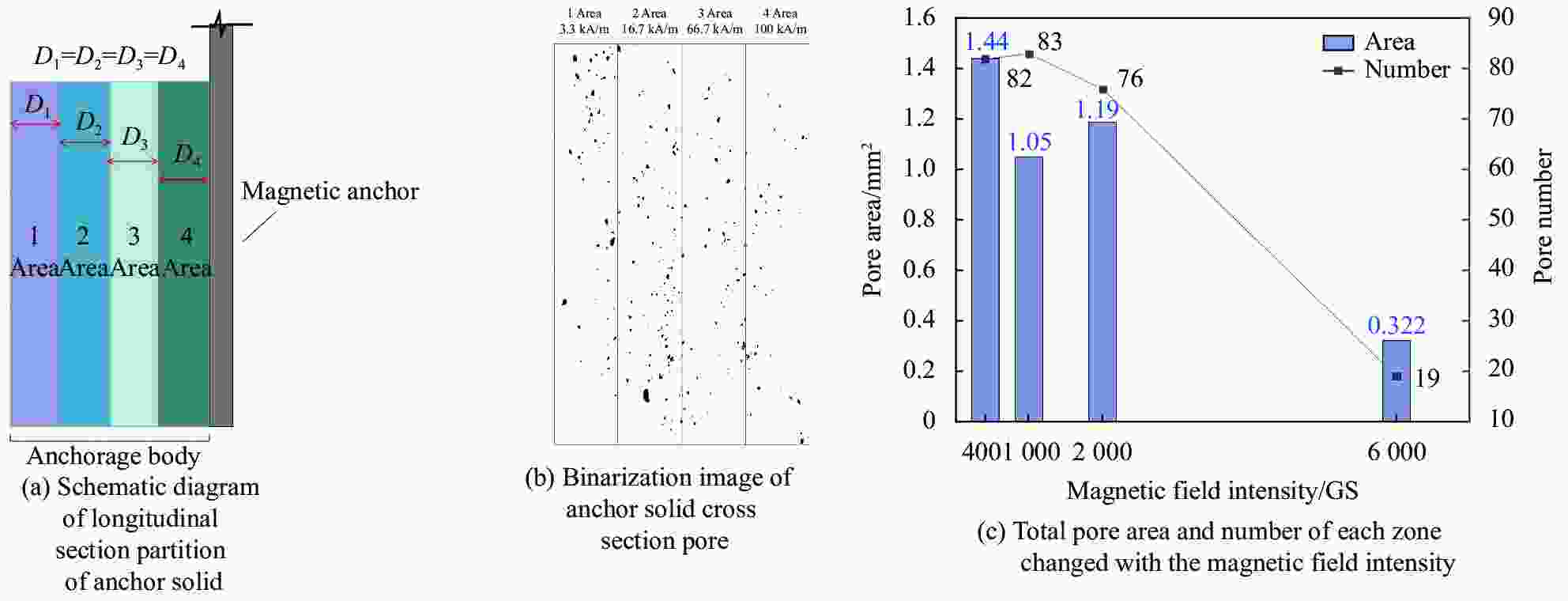

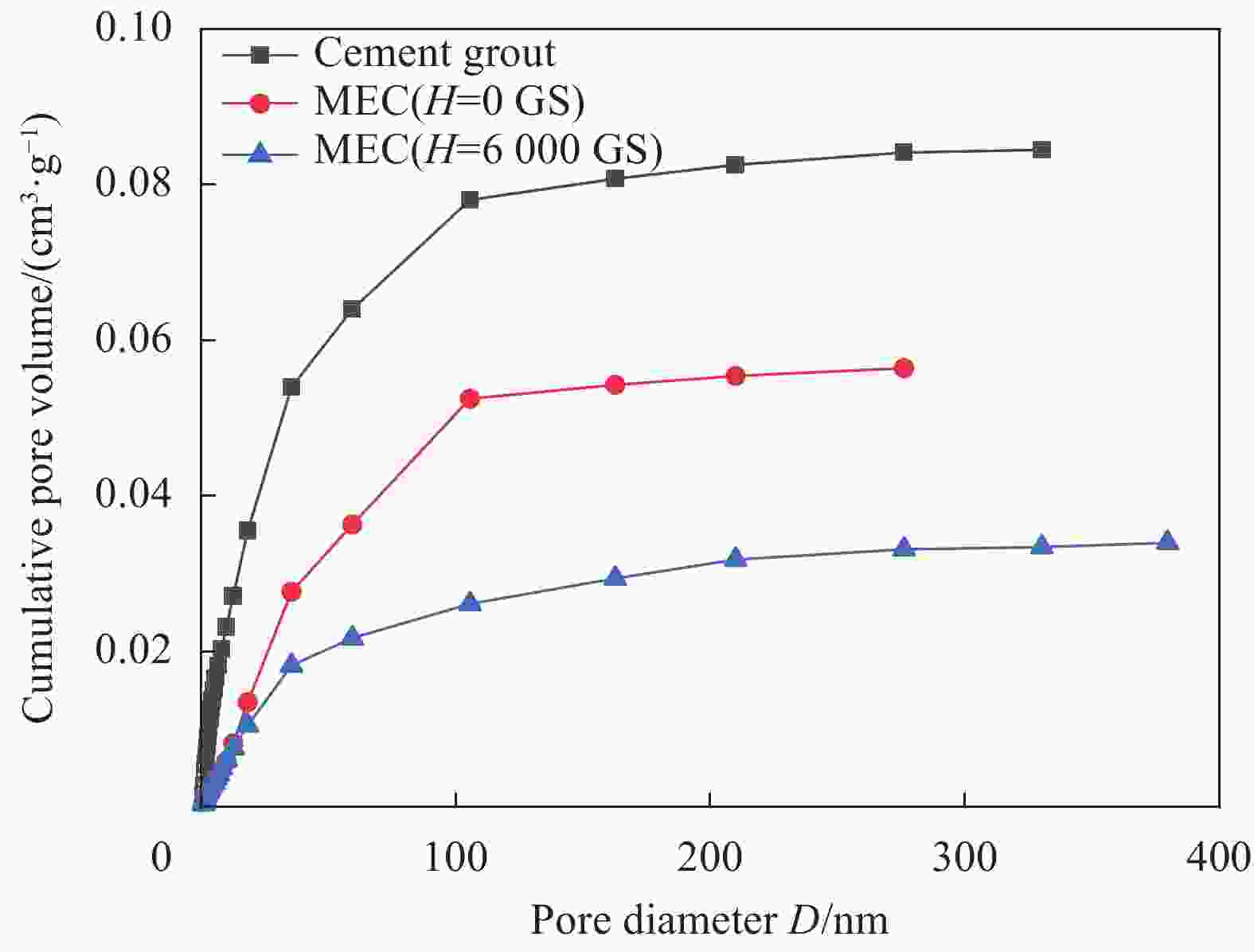

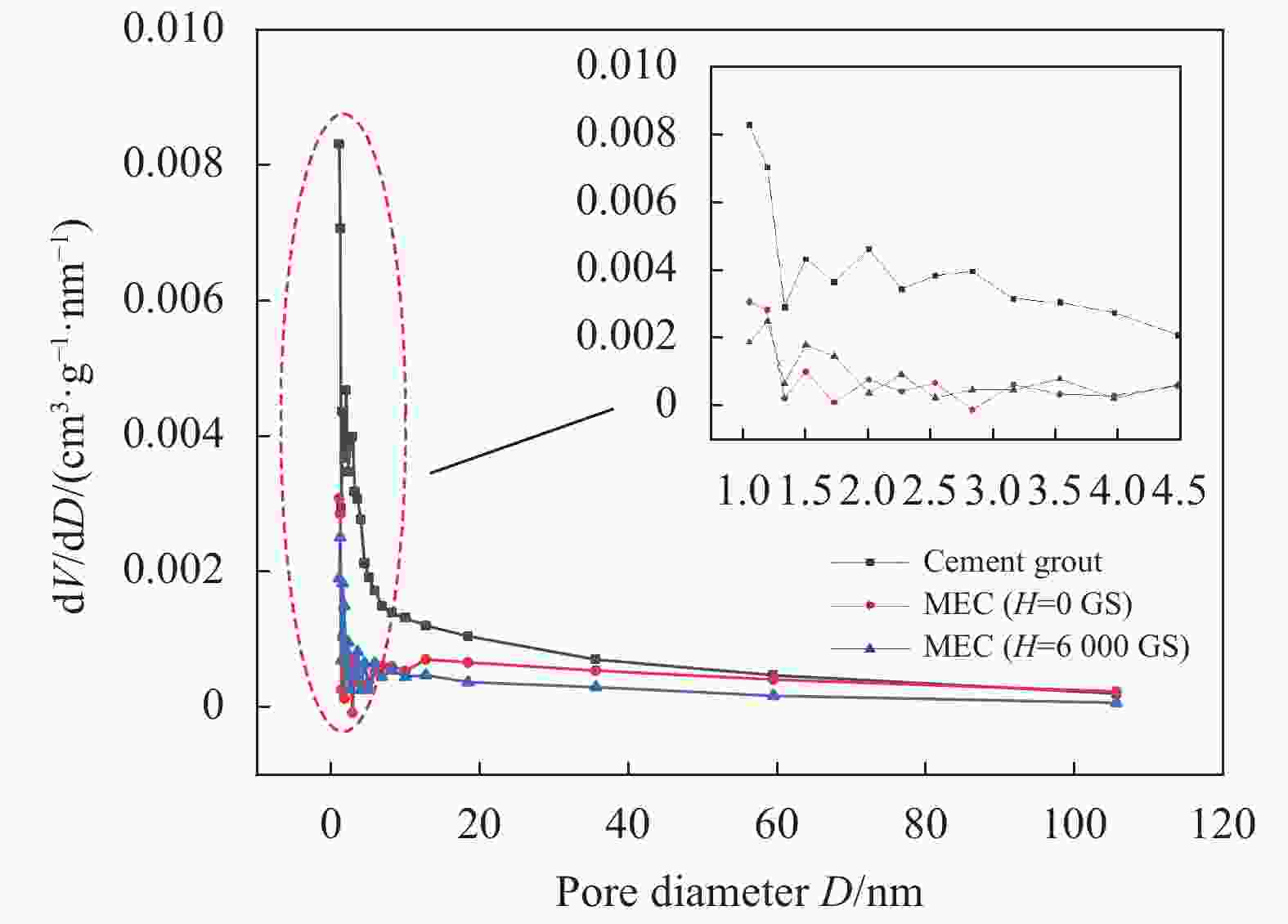

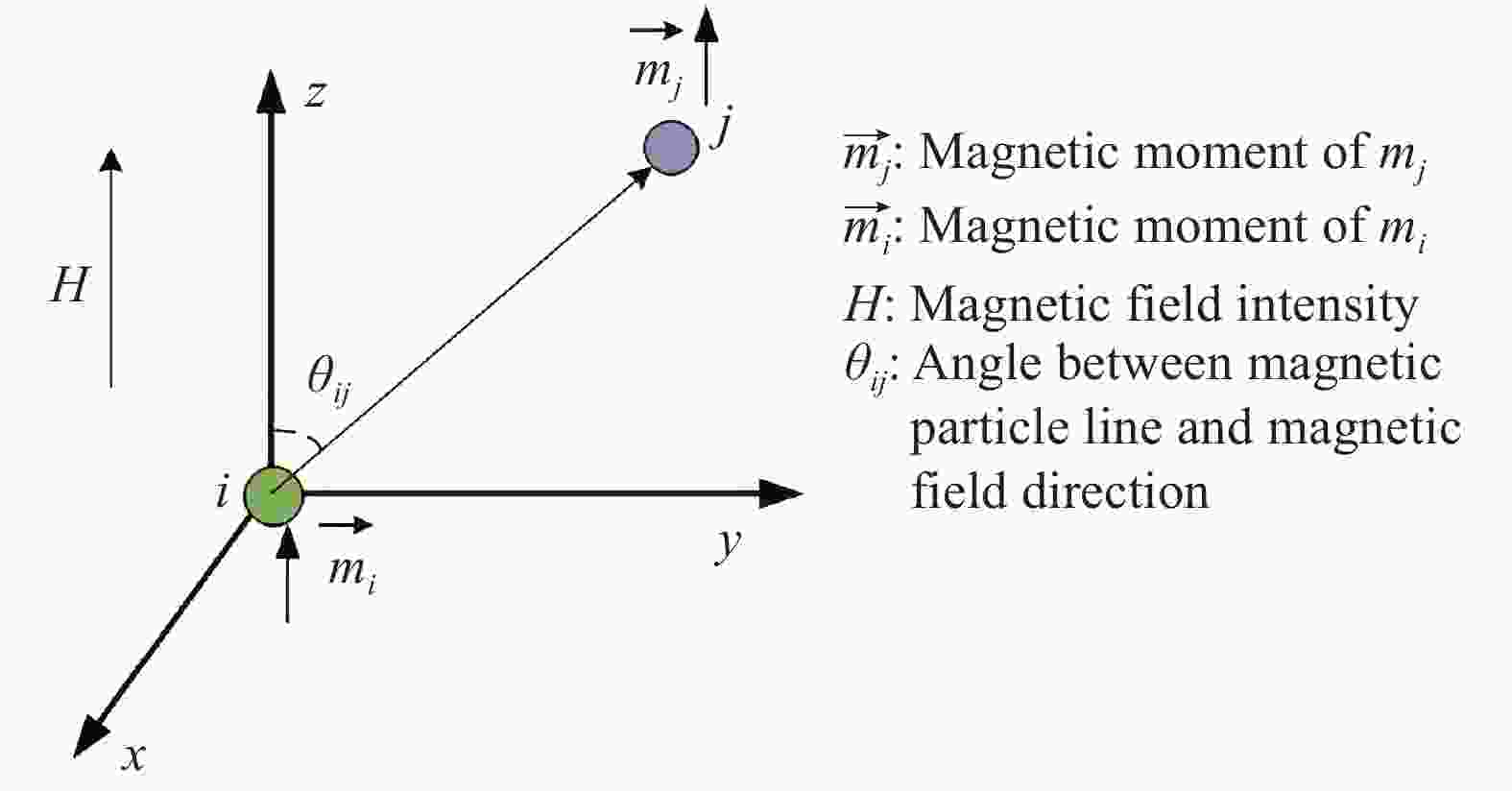

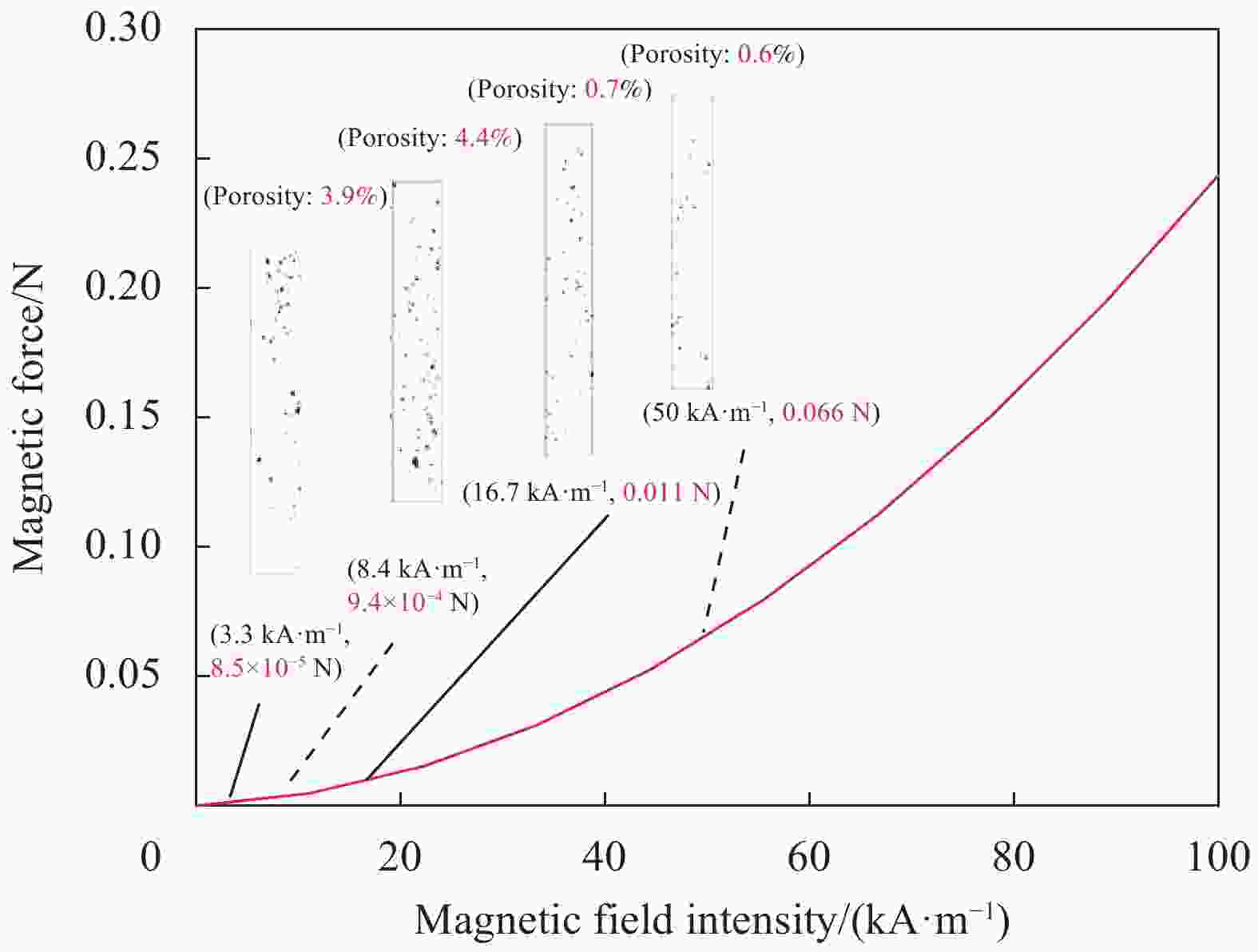

Abstract: Conventional mortar can not meet the engineering filling requirements of anti-inclined fractures and defects, and a large number of bubbles will be introduced under the pressure of grouting, and the density of slurry can not be guaranteed. In view of this, a new magnetic epoxy cement (MEC) slurry was developed, which can realize anti-gravity grouting anchoring, guided flow, increase of slurry density and real-time control of slurry viscosity. The SEM,XRD and N2 adsorption tests were used to analyze the microstructure, hydration products and pore size of MEC slurry under different magnetic fields. The results show that the MEC slurry can be divided into the following two hardening processes: Epoxy curing and cement hydration. The solidified product encapsulate the hydration product and ionize with Ca2+ in ettringite (AFt) and Ca(OH)2 to form a complex to fill the tiny pores in the slurry. When the magnetic field intensity increases from 400 GS to 6000 GS, the pore area and pore number decrease rate reach 77.6% and 76.8% respectively. The test of N2 adsorption shows that the number of mesopores and macropores and the specific surface area decrease significantly with the addition of magnetic field. The magnetic grout is in line with H4 hysteresis loop and mainly represents as ink bottle pores. Based on magnetic dipole theory, the force of magnetic particles is simulated numerically. The analysis results show that the pore area can be effectively reduced when the magnetic field intensity is from 2000 GS to 6000 GS. -

表 1 磁性环氧树脂水泥(MEC)浆液配合比

Table 1. Design of magnetic epoxy cement (MEC) slurry

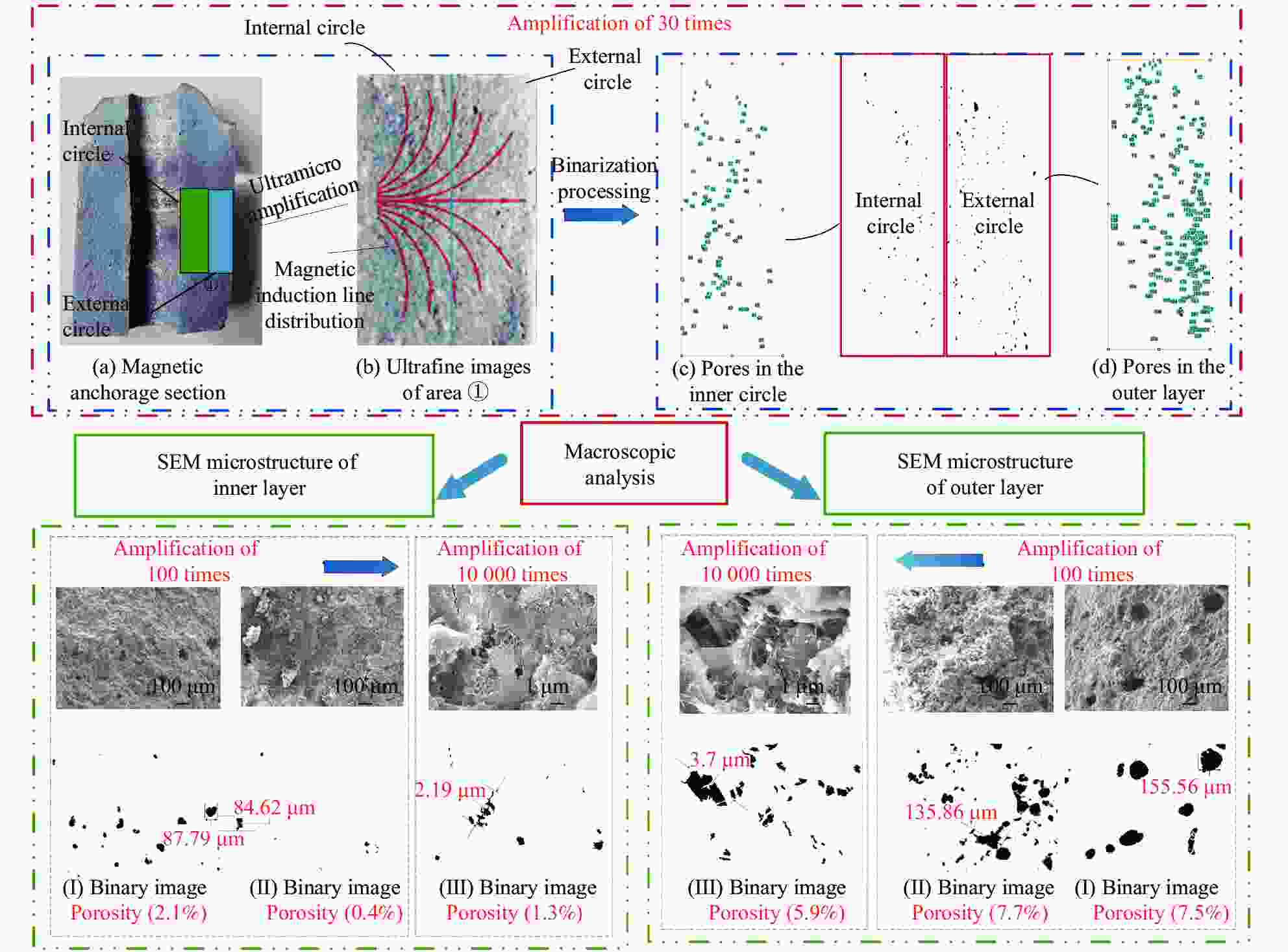

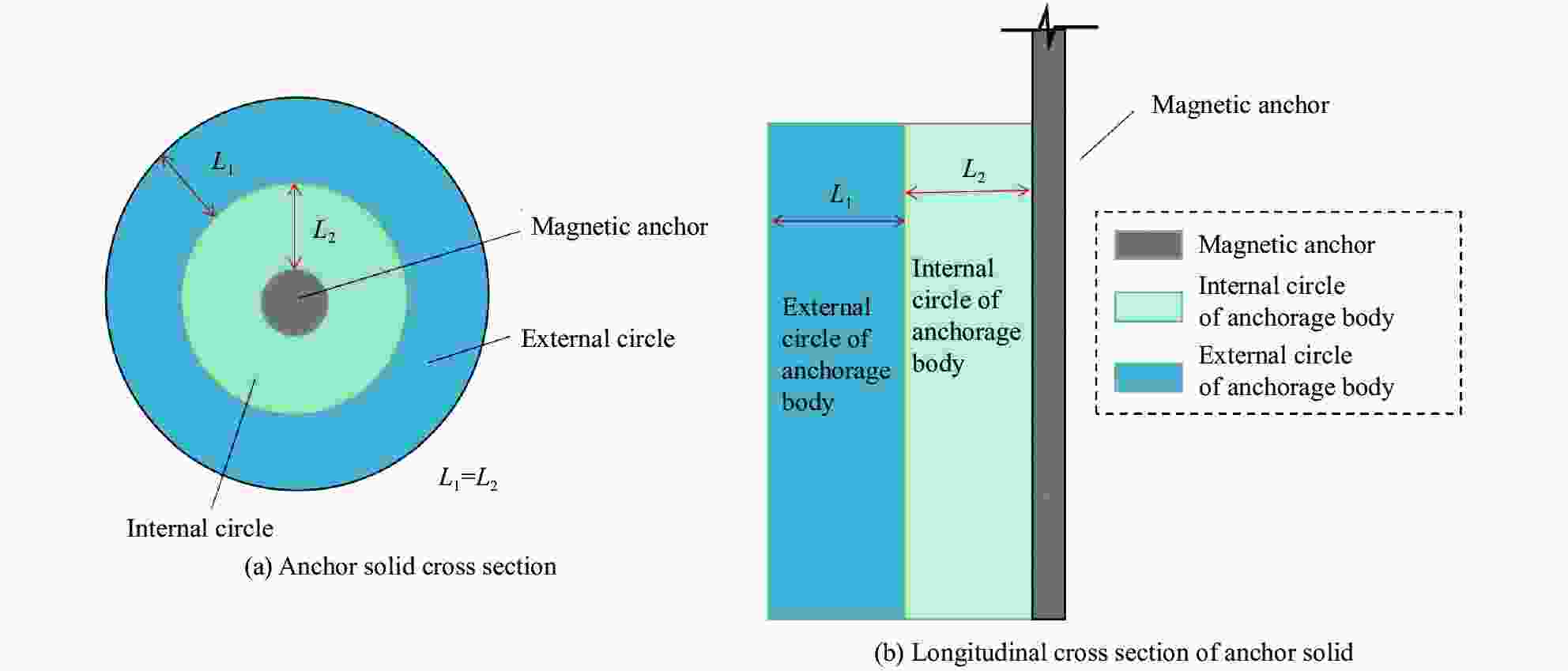

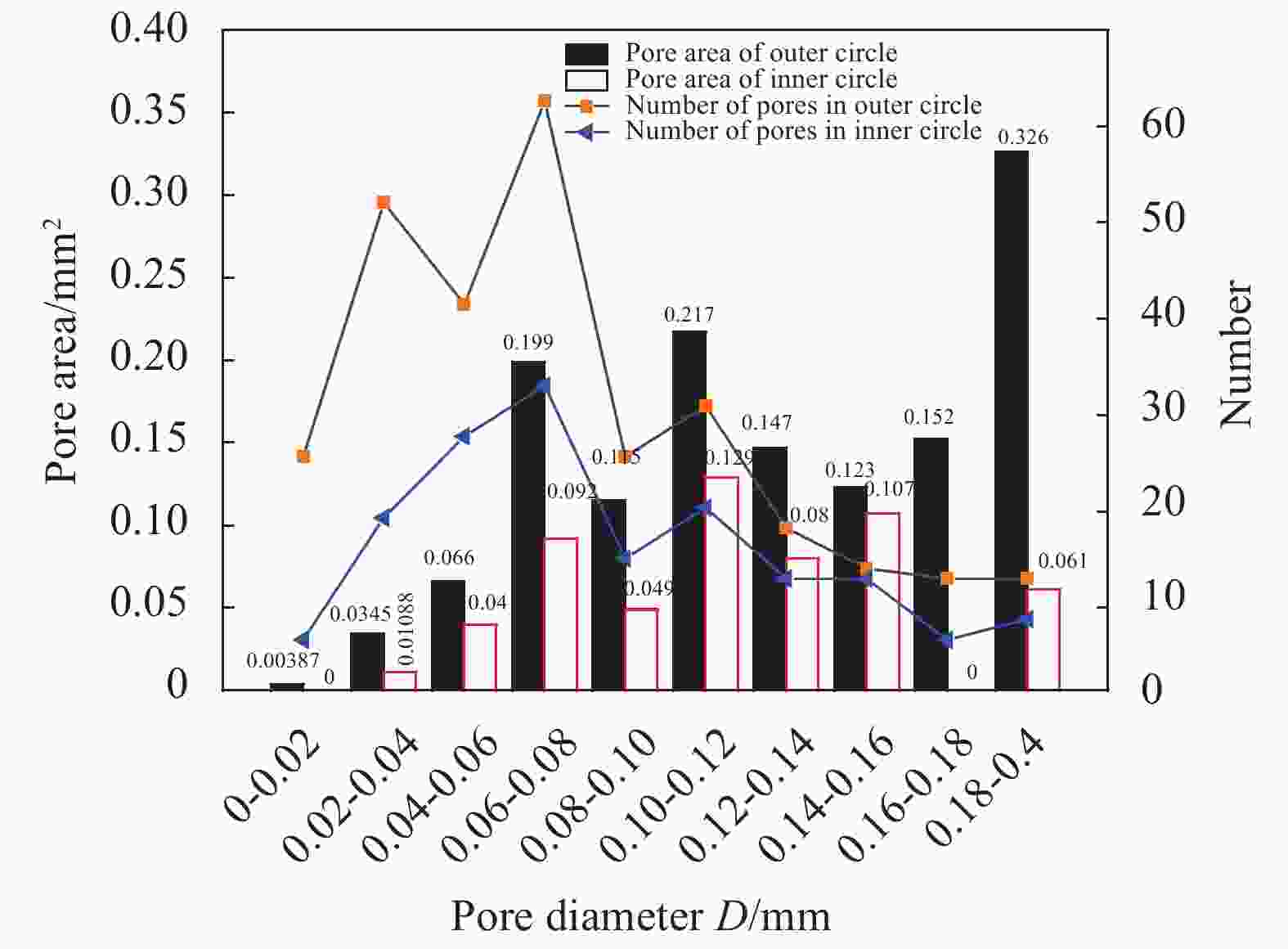

g Materials Cement Absolute water consumption Water-borne epoxy resin Curing agent Magnetic powder content Disperser Cement grout 400 160 0 0 0 0.0 MEC 400 110 100 85 100 1.5 表 2 MEC锚固体内外圈层孔隙统计

Table 2. Porosity statistics in the inner and outer circles of MEC anchorage

Layered

categoryTotal pore number Macrovoid (0.18-0.4 mm) Fine pore (Pore diameter d<0.1 mm) Area/mm2 Number Area/mm2 Number External circle 218 0.326 6 0.4180 165 Internal circle 92 0.061 2 0.1918 65 表 3 水泥浆液和MEC的孔结构参数

Table 3. Hole structure parameters of cement grout and MEC

Sample Specific surface area/(m2·g−1) Adsorption constant cBET Total volume/(m3(STP)·g−1) Cement grout 25.734 47.021 5.9124 MEC (H=0 GS) 8.205 95.022 1.8853 MEC (H=6000 GS) 6.368 34.645 1.4632 Note: STP—Standard temperature and pressure. -

[1] 陈文, 刘永球, 仇学明. 锦屏水电站左岸帷幕灌浆试验与分析[J]. 水利水电技术, 2008, 39(9):22-25. doi: 10.3969/j.issn.1000-0860.2008.09.007CHEN Wen, LIU Yongqiu, QIU Xueming. Experiment and analysis of curtain grouting on left bank of Jinping hydropower station[J]. Water Resources and Hydro-power Engineering,2008,39(9):22-25(in Chinese). doi: 10.3969/j.issn.1000-0860.2008.09.007 [2] 李小波, 吴莉, 祝华平. 锦屏一级水电站左岸深部裂缝岩体灌浆试验研究[J]. 水电站设计, 2009, 25(91):54-56.LI Xiaobo, WU Li, ZHU Huaping. Experimental study on grouting of deep fractured rock mass on the left bank of Jinping I hydropower station[J]. Design of Hydroelectric Power Station,2009,25(91):54-56(in Chinese). [3] 林宝玉, 吴绍章. 混凝土工程材料设计与施工[M]. 北京: 中国水利水电出版社, 1998.LIN Baoyu, WU Shaozhang. Concrete engineering material design and construction[M]. Beijing: China Water Power Press, 1998(in Chinese). [4] SCHULZE J. Influence of water-cement ratio and cement content on the properties of polymer-modified mortars[J]. Cement and Concrete Research,1999,29(6):909-915. doi: 10.1016/S0008-8846(99)00060-5 [5] MA H, LI Z. Microstructures and mechanical properties of polymer modified mortars under distinct mechanisms[J]. Construction and Building Materials,2013,47:579-587. [6] LIU S J, HU Q Q, ZHAO F Q, et al. Utilization of steel slag, iron tailings and fly ash as aggregates to prepare a polymer-modified waterproof mortar with a core-shell styrene-acrylic copolymer as the modifier[J]. Construction and Building Materials,2014,72:15-22. doi: 10.1016/j.conbuildmat.2014.09.016 [7] 沈凡, 黄绍龙, 孙政, 等. 水性环氧树脂-水泥-乳化沥青复合胶结体系的硬化机理[J]. 中南大学学报(自然科学版), 2012, 43(1):105-110.SHEN Fan, HUANG Shaolong, SUN Zheng, et al. Hardening mechanism of waterborne epoxy-cement-emulsified asphalt bonding system[J]. Journal of Central South University,2012,43(1):105-110(in Chinese). [8] 李明, 徐文, 王康臣, 等. 高吸水树脂在水泥浆体硬化过程中的释水行为[J]. 建筑材料学报, 2022, 25(2): 111-116.LI Ming, XU Wen, WANG Kangchen, et al. Desorption behavior of superabsorbent polymers in cement paste during harden process[J]. Journal of Building Materials, 2022, 25(2): 111-116(in Chinese). [9] SHAKER F A, EI-DIEB A S, REDA M M. Durability of styrene-butadiene latex modified concrete[J]. Cement and Concrete Research,1997,27(5):711-720. [10] 文生, 叶家元, 王妍萍, 等. 掺杂有机大分子水化硅酸钙的孔结构及表面分形特征[J]. 硅酸盐学报, 2006(12):1497-1502. doi: 10.3321/j.issn:0454-5648.2006.12.015WEN Sheng, YE Jiayuan, WANG Yanping, et al. Pore structure and surface fractal characteristics of calcium silicatehydrates contained organic macromolecule[J]. Journal of the Chinese Ceramic Society,2006(12):1497-1502(in Chinese). doi: 10.3321/j.issn:0454-5648.2006.12.015 [11] 佘安明, 马坤, 王中平, 等. 低场核磁共振低温 测孔技术表征硬化水泥浆体孔结构[J]. 建筑材料学报, 2021, 24(5): 916-920.SHE Anming, MA Kun, WANG Zhongping, et al. Characterization of pore structure in hardened cement paste by low field NMR crvoporometry[J]. Journal of Building Materials, 2021, 24(5): 916-920(in Chinese). [12] 陈宗丽, 李俊锋, 宋杨. 基于图像观测的硬化水泥浆体孔径分析[J]. 硅酸盐通报, 2020, 39(2):440-446.CHEN Zongli, LI Junfeng, SONG Yang. Pore size analysis of hardened cement paste based on image observation[J]. Bulletin of the Chinese Ceramic Society,2020,39(2):440-446(in Chinese). [13] FAURE P F, CARE S, MAGAT J, et al. Drying effect on cement paste porosity at early age observed by NMR methods[J]. Construction and Building Materials,2012,29:496-503. doi: 10.1016/j.conbuildmat.2011.07.012 [14] HERSCHEL W H, BULKLEY R. Konsistenzmessungen von Gummi-Benzoll 8 sungen[J]. Kolloid-Z,1926,39(5):291-300. [15] 金伟良, 张军, 陈才生, 等. 基于压磁效应的钢筋混凝土疲劳研究新方法[J]. 建筑结构学报, 2016, 37(4):133-142.JIN Weiliang, ZHANG Jun, CHEN Caisheng, et al. A new method for fatigue study of reinforced concrete structures based on piezomagnetism[J]. Journal of Building Structures,2016,37(4):133-142(in Chinese). [16] 金伟良, 项凯潇, 毛江鸿, 等. 基于压磁效应的锈蚀钢筋应力状态检测试验研究[J]. 海洋工程, 2017, 35(6):62-70.JIN Weiliang, XIANG Kaixiao, MAO Jianghong, et al. Experimental study on stress detection of corroded steel bars based on piezomagnetic effect[J]. The Ocean Engineering,2017,35(6):62-70(in Chinese). [17] 李月光, 伊书国, 张霖波, 等. 磁化水水泥混凝土研究现状与发展前景[J]. 材料科学与工程学报, 2019, 37(2):331-338.LI Yueguang, YIN Shuguo, ZHANG Linbo, et al. Recent and prospective research on magnetized water-based concrete[J]. Journal of Materials Science and Engineering,2019,37(2):331-338(in Chinese). [18] 赵华玮, 代学灵, 曾宪桃, 等. 磁化水降低喷射混凝土粉尘含量的试验研究[J]. 采矿与安全工程学报, 2008(3):371-374. doi: 10.3969/j.issn.1673-3363.2008.03.026ZHAO Huawei, DAI Xueling, ZENG Xiantao, et al. Experiment study on using magnetized water for decreasing shotcrete dust density[J]. Journal of Mining & Safety Engineering,2008(3):371-374(in Chinese). doi: 10.3969/j.issn.1673-3363.2008.03.026 [19] 殷青英, 翁光远. 智能材料在结构振动控制中的应用研究[J]. 科技导报, 2009, 27(12):93-97. doi: 10.3321/j.issn:1000-7857.2009.12.019YIN Qingying, WENG Guangyuan. Applications of intelligent materials in structural vibration[J]. Science & Technology Review,2009,27(12):93-97(in Chinese). doi: 10.3321/j.issn:1000-7857.2009.12.019 [20] 慕儒, 李辉, 王晓伟, 等. 单向分布钢纤维增强水泥基复合材料(II)制备及钢纤维增强作用[J]. 建筑材料学报, 2015, 18(3):388-392.MU Ru, LI Hui, WANG Xiaowei, et al. Aligned steel fibre reinforced cement based composites(II): Preparation and reinforcement of aligned steel fibres[J]. Journal of Building Materials,2015,18(3):388-392(in Chinese). [21] 田稳苓, 马林翔, 张楷婕, 等. 定向钢纤维水泥基复合材料的纤维分布研究[J]. 建筑科学, 2016, 32(3):14-18.TIAN Wenlin, MA Linxiang, ZHANG Kaijie, et al. Investigation of fibre distribution on aligned steel fibre cement-based composite materials[J]. Building Science,2016,32(3):14-18(in Chinese). [22] 慕儒, 赵全明, 田稳苓. 单向分布钢纤维增强水泥浆的制备与性能研究[J]. 河北工业大学学报, 2012, 41(2):101-104. doi: 10.3969/j.issn.1007-2373.2012.02.023MU Ru, ZHAO Quanming, TIAN Wenlin. Investigation on the preparation and properties of aligned steel fibre reinforce cement paste[J]. Journal of Hebei University of Technology,2012,41(2):101-104(in Chinese). doi: 10.3969/j.issn.1007-2373.2012.02.023 [23] 宋贺月, 丁一宁. 钢纤维在混凝土基体中空间分布的研究方法评述[J]. 材料科学与工程学报, 2015, 33(5):768-775.SONG Heyue, DING Yining. Research methods of spatial distribution of steel fiber in concrete matrix[J]. Journal of Materials Science and Engineering,2015,33(5):768-775(in Chinese). [24] TANG H S, KALYON D M. Estimation of the parameters of Herschel-Bulkley fluid under wall sip using a combination of capillary and squeeze flow viscometers[J]. Rheologica Acta,2004,43(15):80-88. [25] PAPANASTASIOU T C. Flows of materials with yield[J]. Jourmal of Rheology,1987,31(5):385-404. doi: 10.1122/1.549926 [26] LI H T, PENG X H, CHEN W G. A micro- to- macroscopic analysis for the yield stress of magnetorheological fluids[C]//International Conference on Heterogeneous Materials Mechanics. Chongqing: Chongqing University Press, 2004: 276-280. [27] 李海涛, 彭向和, 易成建. 附着颗粒对磁流变液偶极子链力学特性的影响[J]. 重庆大学学报, 2010, 33(7):81-85. doi: 10.11835/j.issn.1000-582X.2010.07.015LI Haitao, PENG Xianghe, YI Chengjian. Effect of attached particles on the mechanical properties of dipolar chains in magnetorheological fluids[J]. Journal of Chongqing University,2010,33(7):81-85(in Chinese). doi: 10.11835/j.issn.1000-582X.2010.07.015 -

下载:

下载: