Preparation and properties of hexagonal boron nitride/semi-aromatic polyamide 12T composites with high-temperature resistance and high thermal conductivity prepared by mixed solvent dispersion method

-

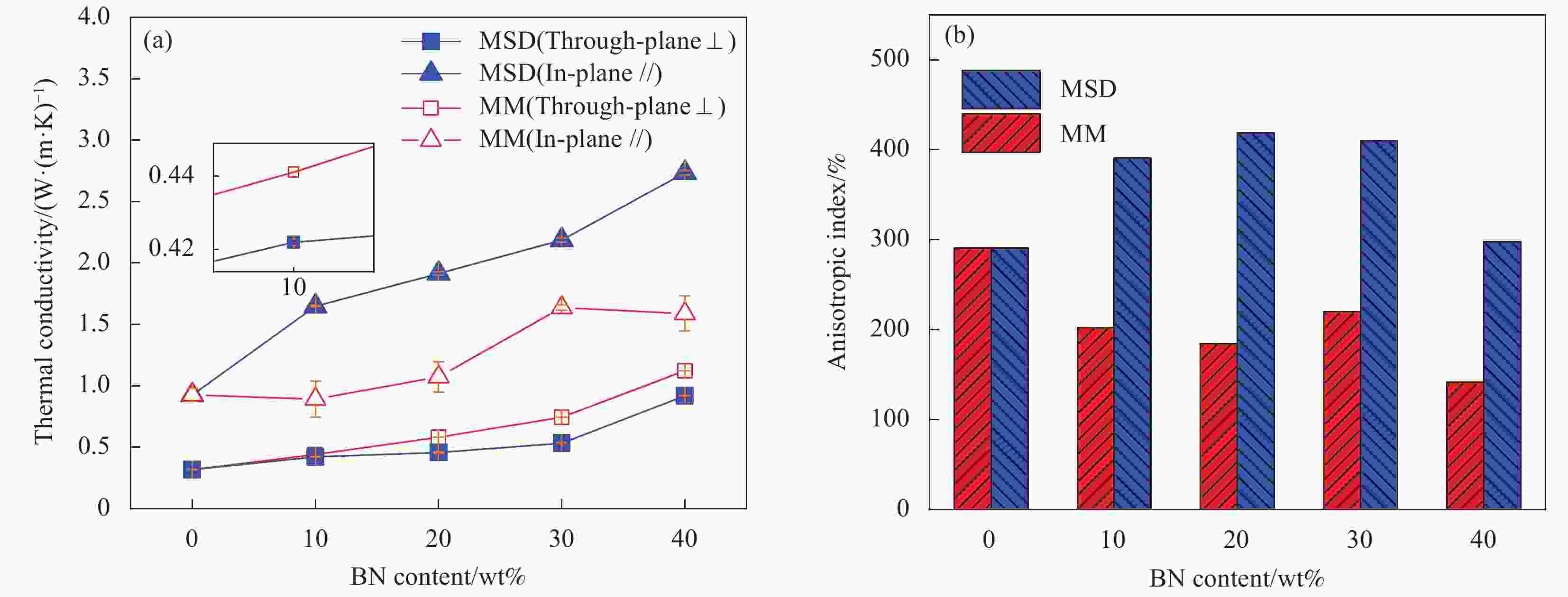

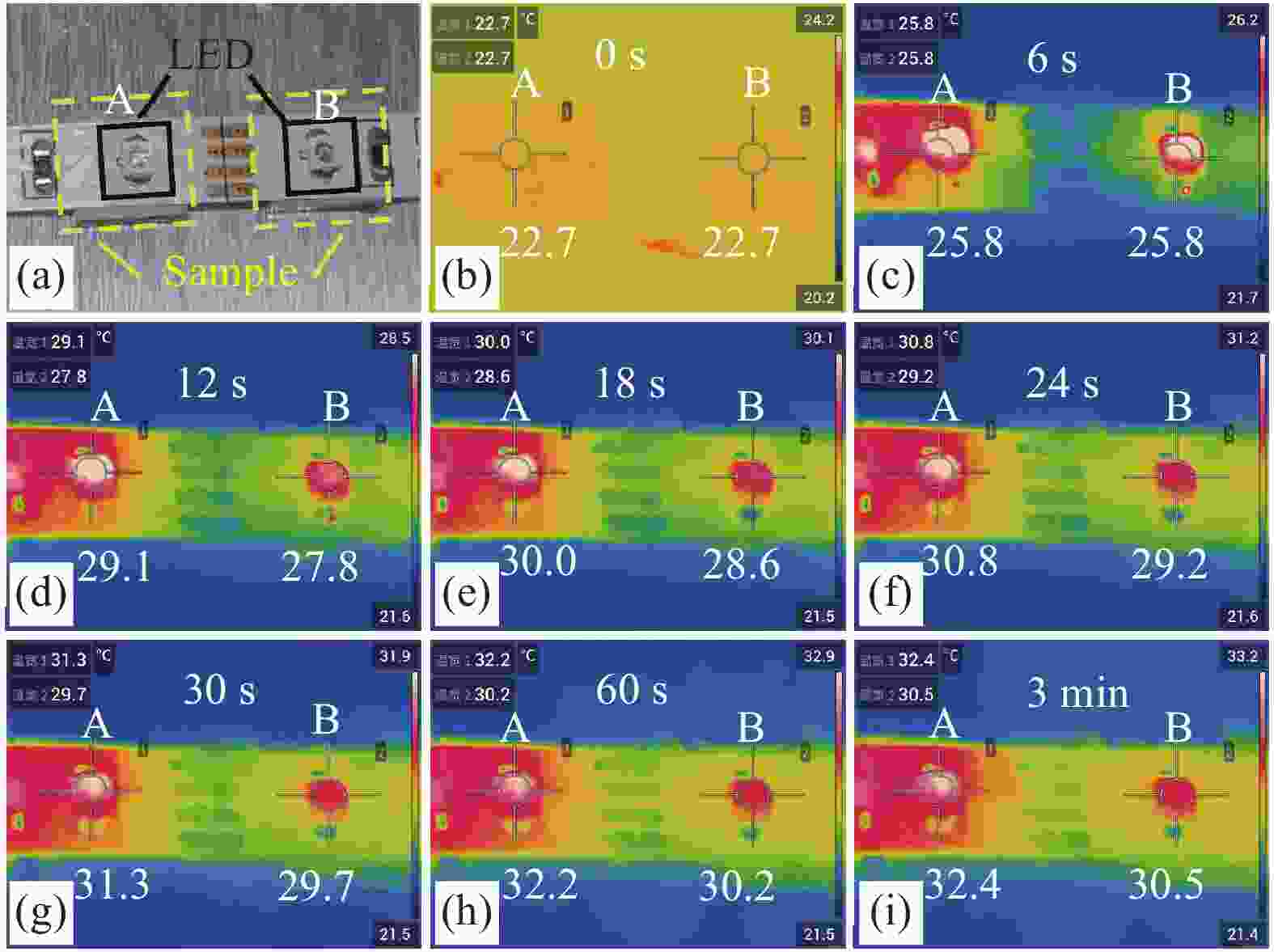

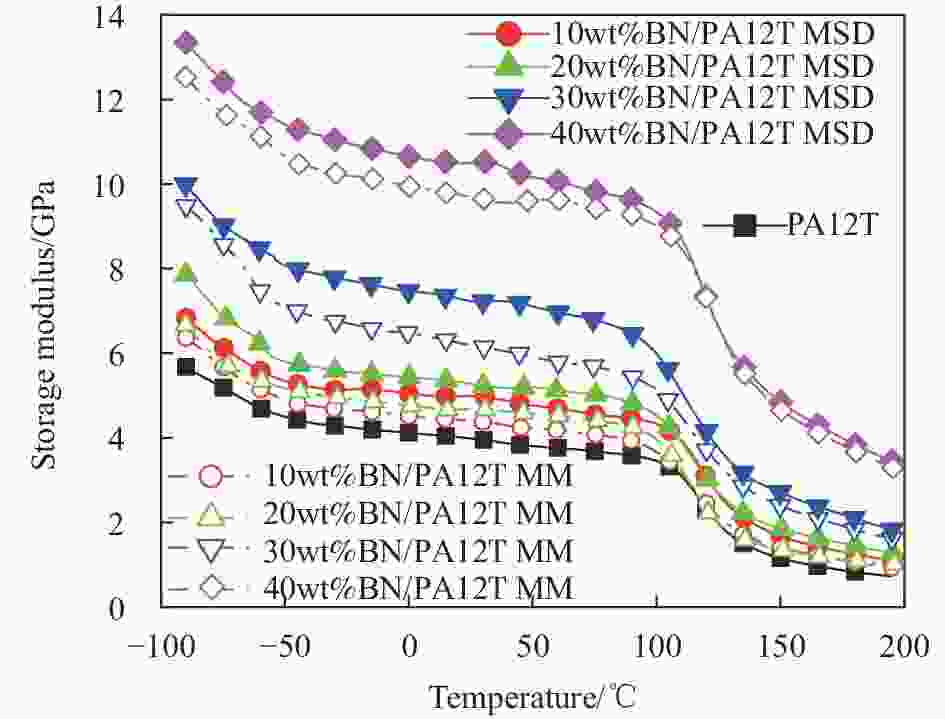

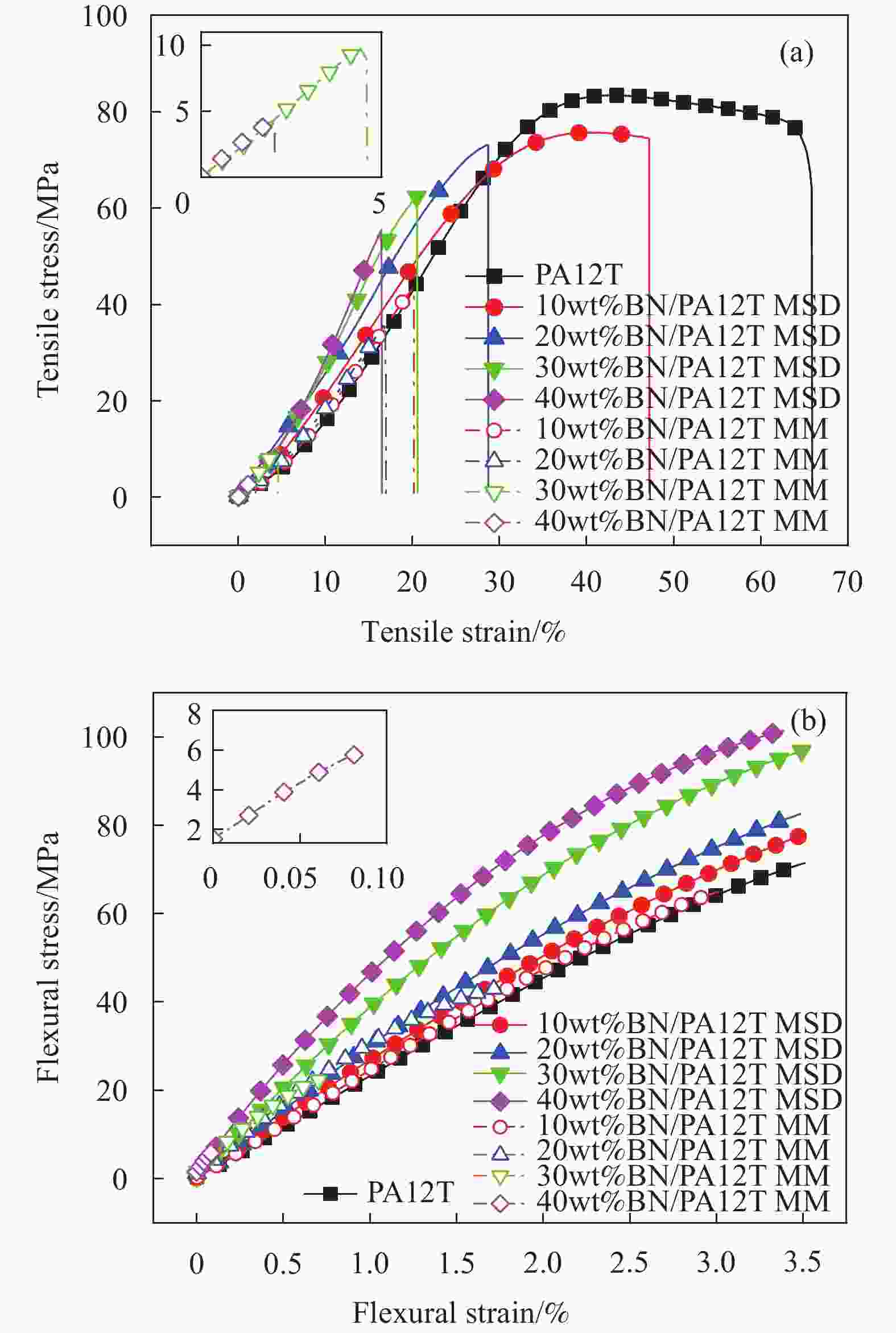

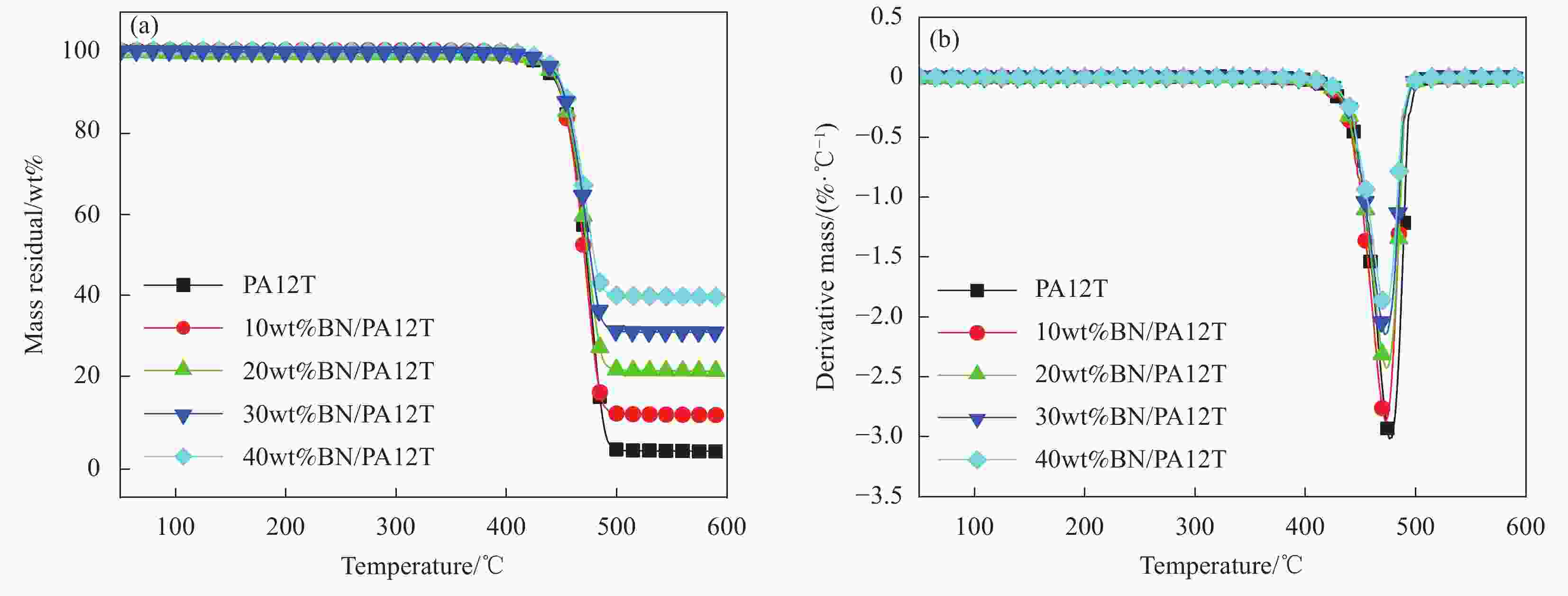

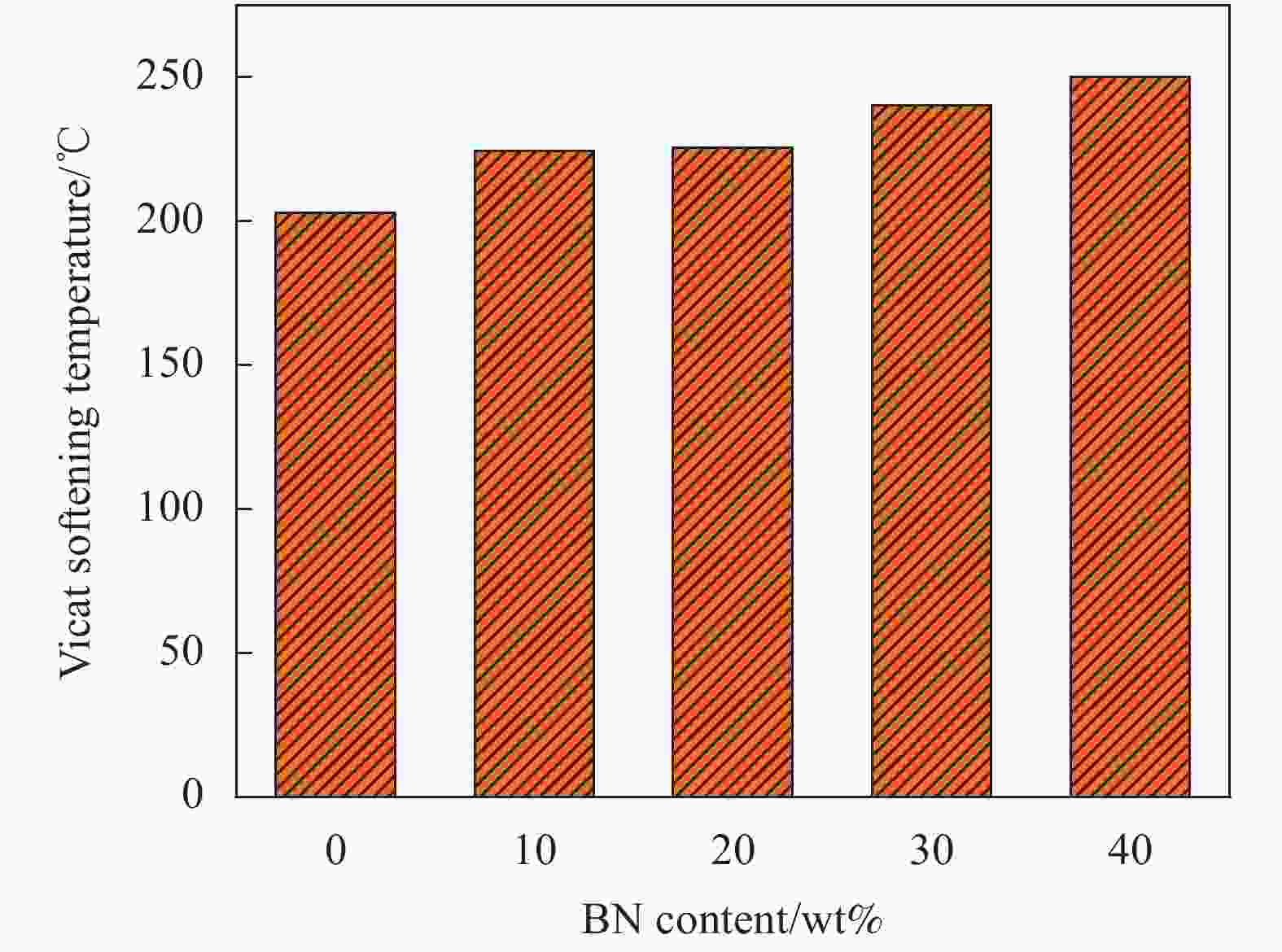

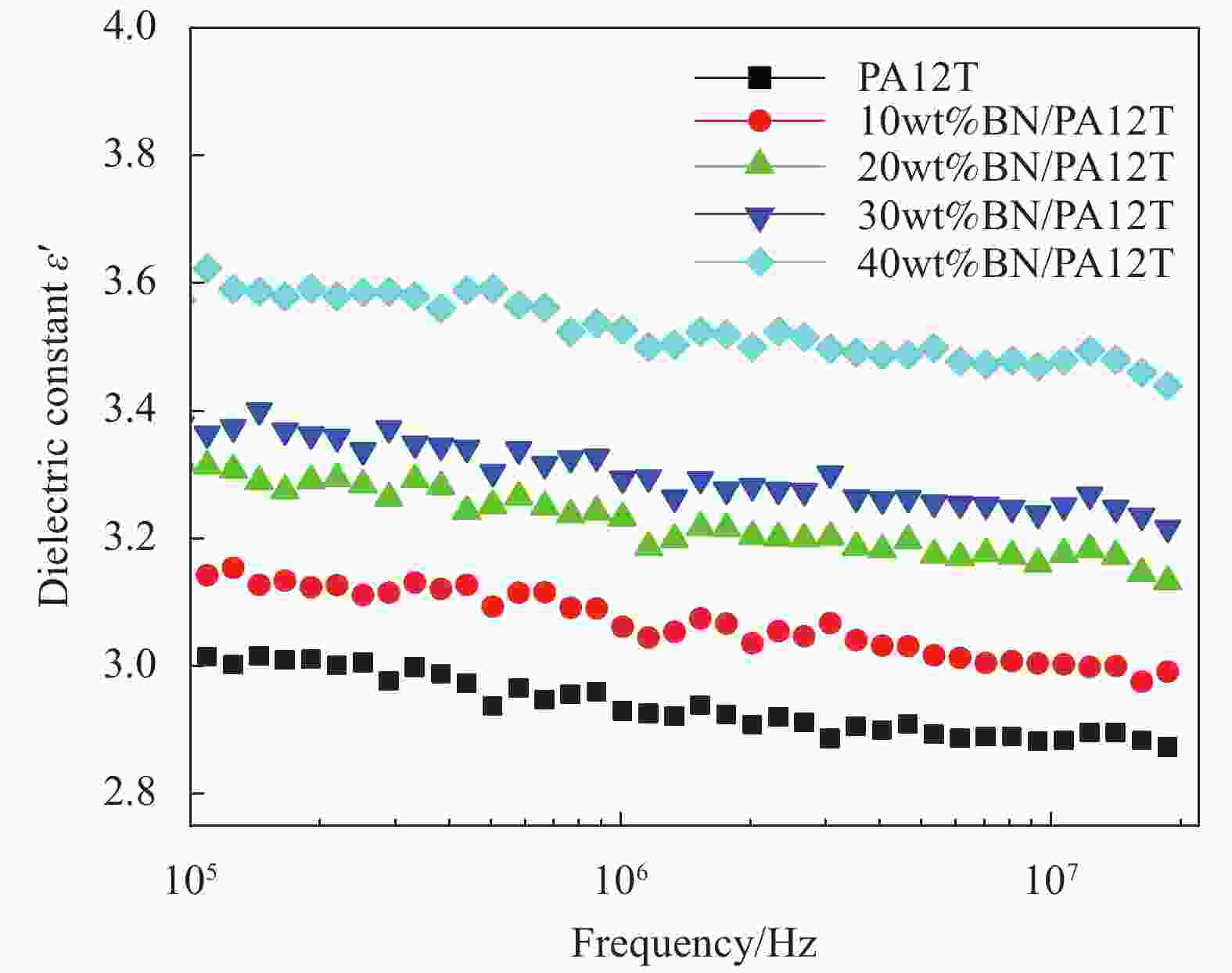

摘要: 制备兼具优异耐高温性能和导热性能的聚合物基复合材料对于电子元器件的封装保护、高效散热和稳定成型至关重要。本文通过混合溶剂分散法(MSD)制备了六方氮化硼(BN)/半芳香聚酰胺12T (PA12T)复合材料,并对复合材料的微观结构、导热、耐高温、介电和力学性能进行了表征。结果表明:混合溶剂分散法可以有效实现BN和PA12T粉末的均匀悬浮,并可协同真空辅助自组装法与真空热压法构筑具有均一分散和取向结构的复合材料。研究表明,当BN/PA12T复合材料中的BN含量为40wt%时,混合溶剂分散法制备的样品的平面导热率可以达到2.73 W/(m·K),是机械混合法(MM)制备的样品(1.59 W/(m·K))的1.72倍,同时其具有优异的力学性能、低介电常数(3.6)、介电损耗(0.016)和显著的耐高温性能(维卡软化点超过250℃且初始分解温度可达446℃)。综上所述,混合溶剂分散法制备的BN/PA12T复合材料在电子封装及热管理领域中具有广阔的应用前景。Abstract: Fabrication of the polymer-based composites with excellent high temperature resistance and thermal conductivity is very important for the packaging protection, efficient heat dissipation and processing of electronic components. In this work, high temperature resistant and thermally conductive hexagonal boron nitride (BN)/semi-aromatic polyamide 12T (PA12T) composites with uniform dispersion and orientation filler structure were prepared by mixed solvent dispersion (MSD) method, and the microstructure, thermal conductivity, high-temperature resistance, dielectric and mechanical properties of the composites were systematically characterized. The results show that the BN powder and PA12T powder can be suspended uniformly in the mixed solvent. Next, combining the vacuum-assisted self-assembly technique and vacuum hot compression method, the composites with uniformly dispersed and oriented BN structure are fabricated successfully. When the content of BN is 40wt% in BN/PA12T composite, the in-plane thermal conductivity of the composite prepared by the MSD method is 2.73 W/(m·K), which is 1.72 times that of the composite (1.59 W/(m·K)) prepared by the mechanical mixing (MM) method. Furthermore, the composite prepared by the MSD method also possesses excellent mechanical properties, low dielectric permittivity of 3.6 and dielectric loss of 0.016, outstanding high-temperature resistance with the initial decomposition temperature of 446℃ and Vicat softening temperature of more than 250℃. Therefore, the BN/PA12T composite prepared by the MSD method will have a wide range of applications in the fields of electronic packaging and thermal management.

-

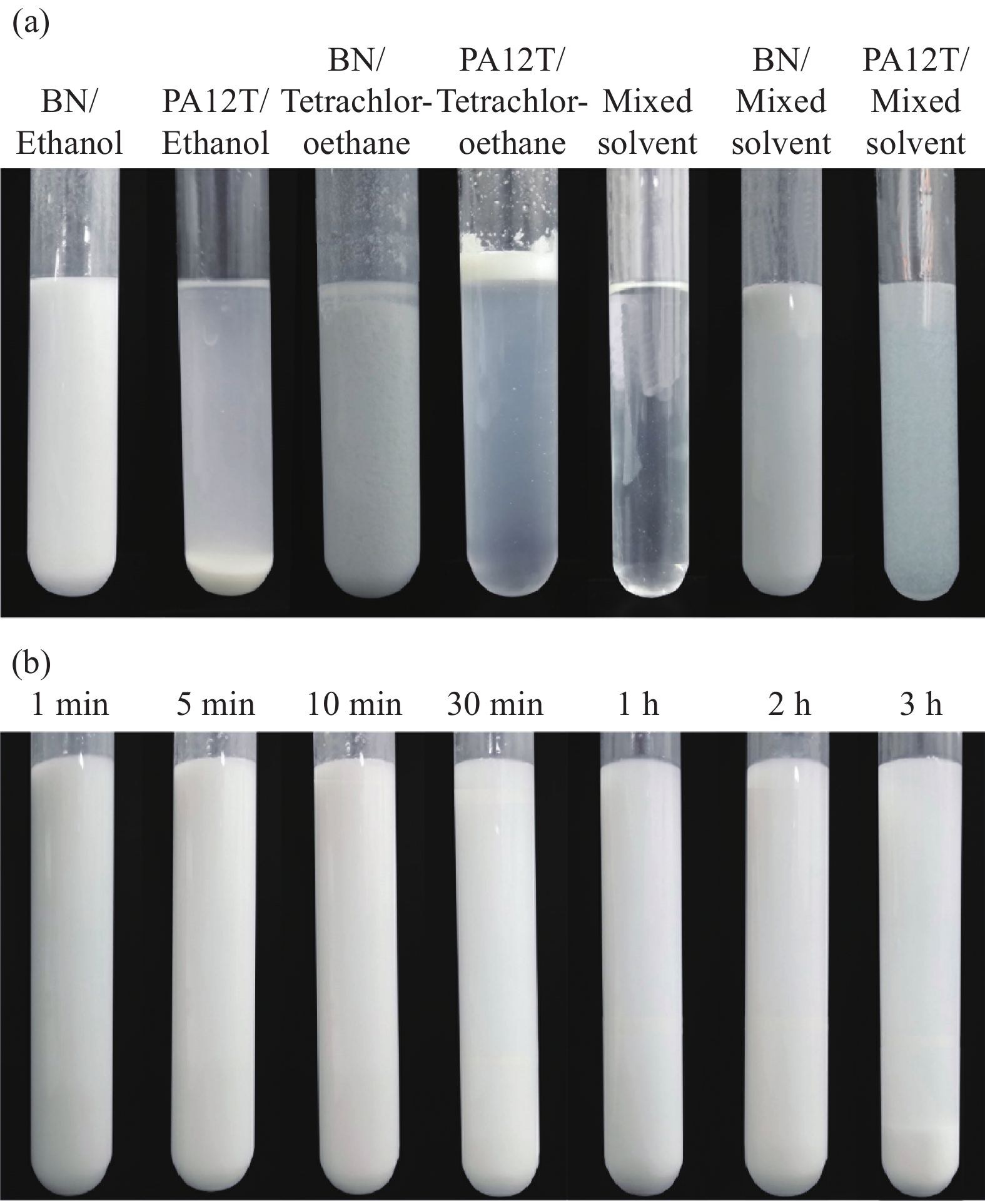

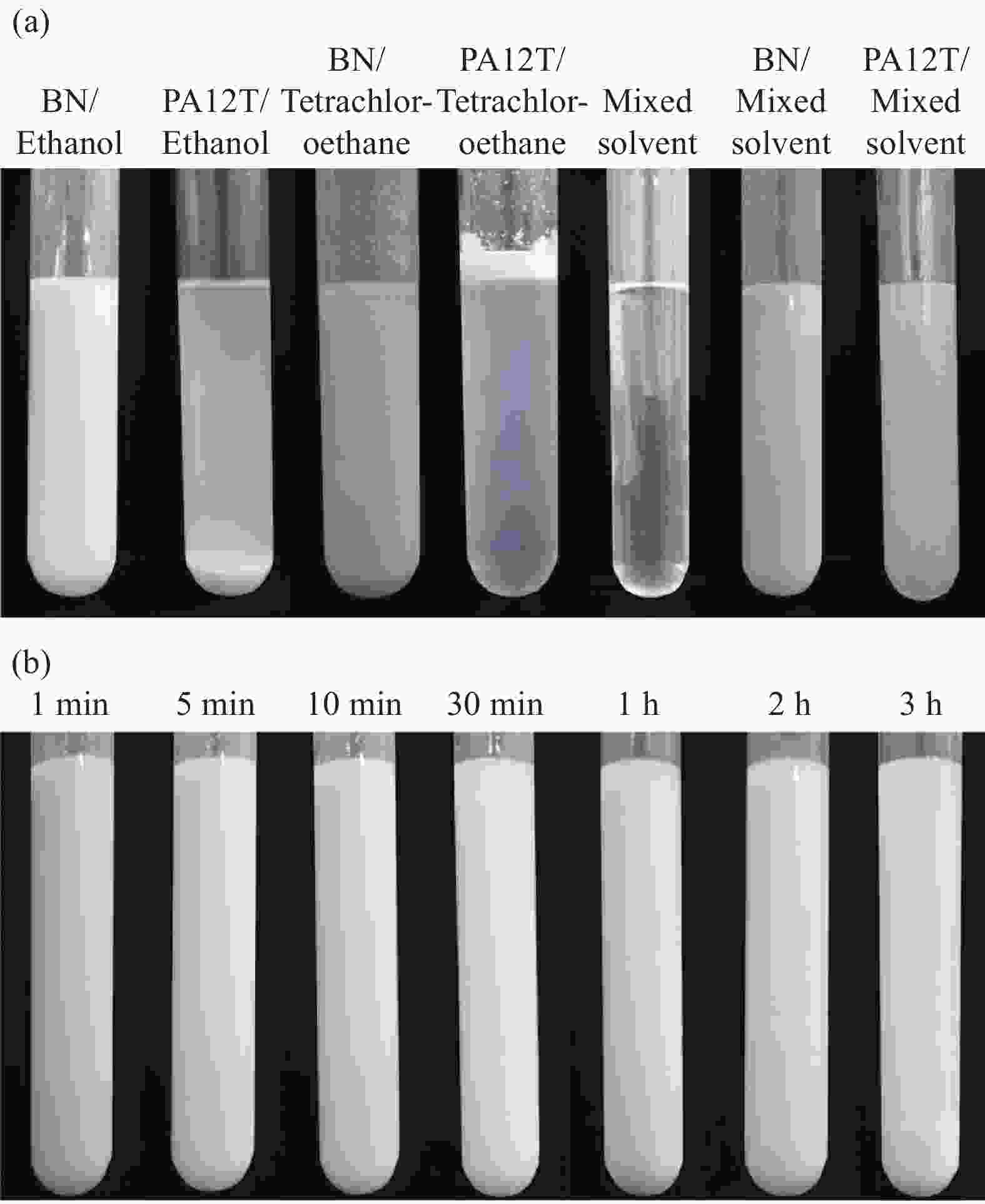

图 1 六方氮化硼(BN)和半芳香聚酰胺12T (PA12T)粉末悬浮于不同溶剂和混合溶剂(a)及不同静置时间的40wt%BN/PA12T混合粉末悬浮于混合溶剂(b)的光学图像

Figure 1. Images of hexagonal boron nitride (BN) and semi-aromatic polyamide 12T (PA12T) powder suspended in different solvents and mixed solvent (a) and 40wt%BN/PA12T mixed powder suspended in mixed solvent with different resting time (b)

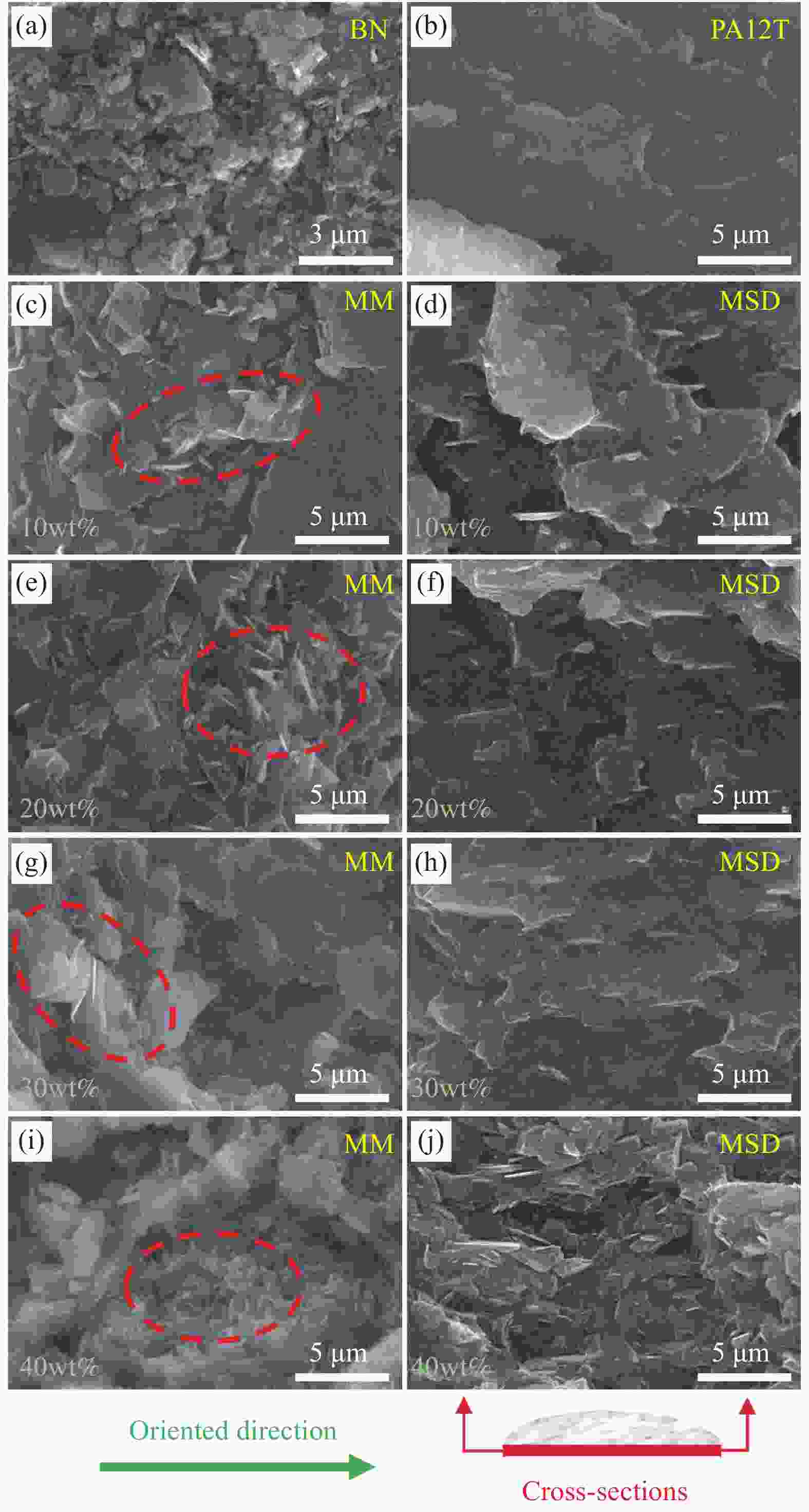

图 2 BN (a)、PA12T (b) 及机械混合法(MM) ((c), (e), (g), (i))和混合溶剂分散法(MSD) ((d), (f), (h), (j))制备BN/PA12T复合材料的SEM图像

Figure 2. SEM images of BN powder (a) and pure PA12T (b), the composites prepared by mechanical mixing (MM) method ((c), (e), (g), (i)) and mixed solvent dispersion (MSD) method ((d), (f), (h), (j))

表 1 BN的取向度分析

Table 1. Analysis on the orientation degree of BN

BN content/wt% Preparation

methodsI(002) I(100) I(002)/I(100) 10 MSD 63324 2369 27 10 MM 22879 4133 6 20 MSD 93765 3610 26 20 MM 50005 5838 9 30 MSD 89145 6069 15 30 MM 65127 7285 9 40 MSD 106008 7416 14 40 MM 97303 8151 12 Note: I—Intensity. 表 2 热塑性耐高温聚合物基导热复合材料的导热率

Table 2. Thermal conductivities of thermoplastic heat-resistance polymer-based composites

Matrix Filler Content TC/

(W·(m·K)−1)Preparation method/

Testing methodYear Liquid crystral polymer (LCP) BN (~60 μm) 33vol% 3.29 Clamped-air-cooling/Heat flow 2013[31] Poly(ether ether ketone)

(PEEK)BN nanopowders (~70 nm) 30wt% 1.04 Casting/LFA 2021[32] Poly(ether ether ketone)

(PEEK)BN (4-10 μm) 30wt% 1.01 Hot pressing/LFA 2020[33] Polyetherimide (PEI) Non-covalent modified BN 30wt% 0.82 Hot pressing/LFA 2021[34] Polyetherimide (PEI) Polyimide-coated BN 60wt% 2.55 Injection molding/LFA 2014[35] Polyphenylene sulfide (PPS) Micrometer BN/nanometer BN 60wt% 2.64 Hot pressing/Hot disk 2017[36] Polyphenylene sulfide (PPS) Siloxane modified BN 50wt% 1.60 Injection molding/LFA 2018[37] Polyphenylene sulfide (PPS) Siloxane modified nanometer BN 60wt% 1.12 Hot pressing/Hot disk 2017[38] Thermoplastic polyimide (TPI) Silver nanowires-decorated multi-walled carbon nanotubes 3wt% 0.44 Casting/Transient hot-wire 2022[39] Polyamide 46 (PA46) Carbon fiber (Diameter=7.2 μm, Aspect ratio=7) 40wt% 1.49 Injection molding/LFA 2017[40] PA12T BN (2-4 μm) 40wt% 2.73 Mixed solvent dispersion/LFA This work Notes: TC—Thermal conductivity; LFA—Laser flash apparatus. 表 3 混合溶剂分散法制备的BN/PA12T复合材料的热失重性能

Table 3. Thermogravimetic analysis of BN/PA12T composites prepared by mixed solvent dispersion method

BN content/wt% T5%/℃ Tmax/℃ −Vmax/(%·℃−1) ω/% (600℃) 0 439 476 3.018 1.353 10 442 473 2.654 10.375 20 441 474 2.426 21.261 30 444 473 2.146 30.852 40 446 472 1.896 39.622 Notes: T5%—Decomposition temperature in 5wt% mass loss fraction; Tmax—Temperature corresponding to the maximum decomposition rate; −Vmax—Maximum decomposition rate; ω—Mass residual rate at 600℃. 表 4 混合溶剂分散法制备的BN/PA12T复合材料的介电损耗

Table 4. Dielectric loss of BN/PA12T composites prepared by mixed solvent dispersion method

BN content/wt% Dielectric loss/(106 Hz) 0 0.050 10 0.041 20 0.033 30 0.025 40 0.016 -

[1] LIU H B, FU R L, SU X Q, et al. Electrical insulating MXene/PDMS/BN composite with enhanced thermal conductivity for electromagnetic shielding application[J]. Composites Communications,2021,23:100593. doi: 10.1016/j.coco.2020.100593 [2] HAN Y X, SHI X T, YANG X T, et al. Enhanced thermal conductivities of epoxy nanocomposites via incorporating in-situ fabricated hetero-structured SiC-BNNS fillers[J]. Composites Science and Technology,2020,187:107944. doi: 10.1016/j.compscitech.2019.107944 [3] WAN Y J, LI G, YAO Y M, et al. Recent advances in polymer-based electronic packaging materials[J]. Composites Communications,2020,19:154-167. doi: 10.1016/j.coco.2020.03.011 [4] 别正业. 无铅焊接技术的现状与应用[J]. 电机电器技术, 2002(6):12-14.BIE Zhengye. The present situations and applications of lead-free soldering technology[J]. Electric Machine and Apparatus Technology,2002(6):12-14(in Chinese). [5] 陈仕国, 戈早川, 杨海朋, 等. 聚合物基电子封装复合材料研究进展[J]. 宇航材料工艺, 2007(5):4-7. doi: 10.3969/j.issn.1007-2330.2007.05.002CHEN Shiguo, GE Zaochuan, YANG Haipeng, et al. Progress in polymer composite for electroinc packaging[J]. Aerospace Materials and Technology,2007(5):4-7(in Chinese). doi: 10.3969/j.issn.1007-2330.2007.05.002 [6] JIN F L, LI X, PARK S. Synthesis and application of epoxy resins: A review[J]. Journal of Industrial and Engineering Chemistry,2015,29:1-11. doi: 10.1016/j.jiec.2015.03.026 [7] OU X H, CHEN S S, LU X M, et al. Enhancement of thermal conductivity and dimensional stability of polyimide/boron nitride films through mechanochemistry[J]. Composites Communications,2021,23:100549. doi: 10.1016/j.coco.2020.100549 [8] GWON T M, KIM C, SHIN S, et al. Liquid crystal polymer (LCP)-based neural prosthetic devices[J]. Biomedical Engineering Letters,2016,6(3):148-163. doi: 10.1007/s13534-016-0229-z [9] ZHANG C H. Progress in semicrystalline heat-resistant polyamides[J]. E-Polymers,2018,18(5):373-408. doi: 10.1515/epoly-2018-0094 [10] LIU B W, LONG J W, CHEN L, et al. Semi-aromatic polyamides containing fluorenyl pendent toward excellent thermal stability, mechanical properties and dielectric performance[J]. Polymer,2021,224:123757. doi: 10.1016/j.polymer.2021.123757 [11] 张美林, 岳文斌, 郎绪志, 等. 半芳香族聚酰胺特种工程塑料的发展与应用现状[J]. 中国塑料, 2020, 34(5):115-122.ZHANG Meilin, YUE Wenbin, LANG Xuzhi, et al. Development and application of special engineering plastics: Semi-aromatic polyamide[J]. China Plastics,2020,34(5):115-122(in Chinese). [12] 张传辉, 麦堪成, 曹民, 等. 高温尼龙研究进展[J]. 工程塑料应用, 2012, 40(11):95-100. doi: 10.3969/j.issn.1001-3539.2012.11.023ZHANG Chuanhui, MAI Kancheng, CAO Min, et al. Research progress in heat-resistant nylon[J]. Engineering Plastics Application,2012,40(11):95-100(in Chinese). doi: 10.3969/j.issn.1001-3539.2012.11.023 [13] PAPASPYRIDES C D, PORFYRIS A D, RULKENS R, et al. The effect of diamine length on the direct solid state polycondensation of semi-aromatic nylon salts[J]. Journal of Polymer Science Part A-Polymer Chemistry,2016,54(16):2493-2506. doi: 10.1002/pola.28126 [14] LIU M Y, LI K F, YANG S H, et al. Synthesis and thermal decomposition of poly(dodecamethylene terephthalamide)[J]. Journal of Applied Polymer Science,2011,122(5):3369-3376. doi: 10.1002/app.34416 [15] CAO J P, ZHAO J, ZHAO X D, et al. High thermal conducti-vity and high electrical resistivity of poly(vinylidene fluoride)/polystyrene blends by controlling the localization of hybrid fillers[J]. Composites Science and Technology,2013,89:142-148. doi: 10.1016/j.compscitech.2013.09.024 [16] CAO B Y, LI Y W, KONG J, et al. High thermal conductivity of polyethylene nanowire arrays fabricated by an improved nanoporous template wetting technique[J]. Polymer,2011,52(8):1711-1715. doi: 10.1016/j.polymer.2011.02.019 [17] HU J T, HUANG Y, YAO Y M, et al. Polymer composite with improved thermal conductivity by constructing a hierarchically ordered three-dimensional interconnected network of BN[J]. ACS Applied Materials & Interfaces,2017,9(15):13544-13553. [18] PAN G R, YAO Y M, ZENG X L, et al. Learning from natural nacre: Constructing layered polymer composites with high thermal conductivity[J]. ACS Applied Materials & Interfaces,2017,9(38):33001-33010. [19] REN Y J, REN L C, LI J X, et al. Enhanced thermal conducti-vity in polyamide 6 composites based on the compatibilization effect of polyether-grafted graphene[J]. Composites Science and Technology,2020,199:108340. doi: 10.1016/j.compscitech.2020.108340 [20] GUO H C, ZHAO H Y, NIU H Y, et al. Highly thermally conductive 3D printed graphene filled polymer composites for scalable thermal management applications[J]. ACS Nano,2021,15(4):6917-6928. doi: 10.1021/acsnano.0c10768 [21] 刘民英, 赵清香, 付鹏, 等. 一种半芳香尼龙的制备方法: 中国专利, CN101768266A[P]. 2010-07-07.LIU Minying, ZHAO Qingxiang, FU Peng, et al. A preparation method of semi-aromatic nylon: Chinese patent, CN101768266A[P]. 2010-07-07(in Chinese). [22] ZHANG J, WANG X N, YU C P, et al. A facile method to prepare flexible boron nitride/poly(vinyl alcohol) composites with enhanced thermal conductivity[J]. Composites Science and Technology,2017,149:41-47. doi: 10.1016/j.compscitech.2017.06.008 [23] WANG X, WU P. Fluorinated carbon nanotube/nanofibrillated cellulose composite film with enhanced toughness, superior thermal conductivity, and electrical insulation[J]. ACS Applied Materials & Interfaces,2018,10(40):34311-34321. [24] 国家质量技术监督局. 热塑性塑料维卡软化温度(VST)的测定: GB/T 1633—2000[S]. 北京: 中国标准出版社, 2000.State Bureau of Quality and Technical Supervision. Plastics-Thermoplasitic materials-Determination of vicat softening temperature (VST): GB/T 1633—2000[S]. Beijing: Standards Press of China, 2000(in Chinese). [25] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 塑料 拉伸性能的测定 第2部分: 模塑和挤塑塑料的试验条件: GB/T 1040.2—2006[S]. 北京: 中国标准出版社, 2006.General Administration of Quality Supervision, Inspection and Quarantine, Standardization Administration of China. Plastic-Deformation of tensile properties-Determination for moulding or extrusion plastic: GB/T 1040.2—2006[S]. Beijing: Standards Press of China, 2006(in Chinese). [26] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 塑料 弯曲性能的测定: GB/T 9341—2008[S]. 北京: 中国标准出版社, 2008.General Administration of Quality Supervision, Inspection and Quarantine, Standardization Administration of China. Plasitc-Deformation of flexural properties: GB/T 9341—2008[S]. Beijing: Standards Press of China, 2008(in Chinese). [27] ZHANG X M, ZHANG J J, XIA L C, et al. Simple and consecutive melt extrusion method to fabricate thermally conductive composites with highly oriented boron nitrides[J]. ACS Applied Materials & Interfaces,2017,9(27):22977-22984. [28] YUAN C, DUAN B, LI L, et al. Thermal conductivity of polymer-based composites with magnetic aligned hexagonal boron nitride platelets[J]. ACS Applied Materials & Interfaces,2015,7(23):13000-13006. [29] LIN Z Y, LIU Y, RAGHAVAN S, et al. Magnetic alignment of hexagonal boron nitride platelets in polymer matrix: Toward high performance anisotropic polymer composites for electronic encapsulation[J]. ACS Applied Materials & Interfaces,2013,5(15):7633-7640. [30] SONG N, JIAO D J, DING P, et al. Anisotropic thermally conductive flexible films based on nanofibrillated cellulose and aligned graphene nanosheets[J]. Journal of Materials Chemistry C,2016,4(2):305-314. doi: 10.1039/C5TC02194D [31] LEUNG S N, KHAN O M, SHI H, et al. Study on liquid crystal polymer-hexagonal boron nitride composites for hybrid heat sinks[J]. Industrial & Engineering Chemistry Research,2013,52(24):8332-8339. [32] GHOSH B, XU F, HOU X H. Thermally conductive poly(ether ether ketone)/boron nitride composites with low coefficient of thermal expansion[J]. Journal of Materials Science,2021,56(17):10326-10337. doi: 10.1007/s10853-021-05923-0 [33] LIU X, GAO Y W, SHANG Y S, et al. Non-covalent modification of boron nitride nanoparticle-reinforced PEEK composite: Thermally conductive, interfacial, and mechanical properties[J]. Polymer,2020,203:122763. doi: 10.1016/j.polymer.2020.122763 [34] BOZKURT Y E, YILDIZ A, TÜRKARSLAN Ö, et al. Thermally conductive h-BN reinforced PEI composites: The role of processing conditions on dispersion states[J]. Materials Today Communications,2021,29:102854. doi: 10.1016/j.mtcomm.2021.102854 [35] LEE H L, KWON O H, HA S M, et al. Thermal conductivity improvement of surface-enhanced polyetherimide (PEI) composites using polyimide-coated h-BN particles[J]. Physical Chemistry Chemical Physics,2014,16(37):20041-20046. doi: 10.1039/C4CP02730B [36] GU J W, GUO Y Q, YANG X T, et al. Synergistic improvement of thermal conductivities of polyphenylene sulfide composites filled with boron nitride hybrid fillers[J]. Composites Part A: Applied Science and Manufacturing,2017,95:267-273. doi: 10.1016/j.compositesa.2017.01.019 [37] KIM K, LEE J, RYU S, et al. Laser direct structuring and electroless plating applicable super-engineering plastic PPS based thermal conductive composite with particle surface modification[J]. RSC Advances,2018,8(18):9933-9940. doi: 10.1039/C8RA00967H [38] YANG X T, TANG L, GUO Y Q, et al. Improvement of thermal conductivities for PPS dielectric nanocomposites via incorporating NH2-poss functionalized n-BN fillers[J]. Composites Part A: Applied Science and Manufacturing,2017,101:237-242. doi: 10.1016/j.compositesa.2017.06.005 [39] ZHANG X W, ZHANG B, SUN M M, et al. Preparation and thermal conductivity properties of high-temperature resistance polyimide composite films based on silver nanowires-decorated multi-walled carbon nanotubes[J]. Journal of Materials Science-Materials in Electronics, 2022, 33(3): 1577-1588. [40] YANG Y S, LI D X, SI G J, et al. Improved thermal and mechanical properties of carbon fiber filled polyamide 46 composites[J]. Journal of Polymer Engineering,2017,37(4):345-353. doi: 10.1515/polyeng-2016-0092 [41] 张娜娜. 短切玻纤增强尼龙12T复合材料的制备和性能研究[D]. 郑州: 郑州大学, 2018.ZHANG Nana. Preparation and properties of short glass fiber reinforced PA12T composites[D]. Zhengzhou: Zhengzhou University, 2018(in Chinese). [42] MENG H, SUI G X, XIE G Y, et al. Friction and wear behavior of carbon nanotubes reinforced polyamide 6 compo-sites under dry sliding and water lubricated condition[J]. Composites Science and Technology,2009,69(5):606-611. doi: 10.1016/j.compscitech.2008.12.004 [43] CHATTERJEE S, NUESCH F A, CHU B T. Comparing carbon nanotubes and graphene nanoplatelets as reinforcements in polyamide 12 composites[J]. Nanotechnology,2011,22(27):275714. doi: 10.1088/0957-4484/22/27/275714 [44] HOU J, LI G H, YANG N, et al. Preparation and characterization of surface modified boron nitride epoxy composites with enhanced thermal conductivity[J]. RSC Advances,2014,4(83):44282-44290. doi: 10.1039/C4RA07394K [45] DASTAKEER S, SAMINATHAN P, VENKATESAN S, et al. Studies on thermal degradation kinetics and dielectric properties of polyether imide foam/nanosilica-based nanocomposites[J]. Plastics Rubber and Composites,2019,48(8):356-363. doi: 10.1080/14658011.2019.1630200 [46] WU K, LEI C X, YANG W X, et al. Surface modification of boron nitride by reduced graphene oxide for preparation of dielectric material with enhanced dielectric constant and well-suppressed dielectric loss[J]. Composites Science and Technology,2016,134:191-200. doi: 10.1016/j.compscitech.2016.08.015 [47] LATURIA A, VAN DE PUT M L, VANDENBERGHE W G. Dielectric properties of hexagonal boron nitride and transition metal dichalcogenides: From monolayer to bulk[J]. NPJ 2D Materials and Applications,2018,2(1):6. doi: 10.1038/s41699-018-0050-x [48] 蔡德龙, 陈斐, 何凤梅, 等. 高温透波陶瓷材料研究进展[J]. 现代技术陶瓷, 2019, 40(Z1):4-120.CAI Delong, CHEN Fei, HE Fengmei, et al. Recent progress and prospestion on high-temperature wave-transparent ceramic materials[J]. Advanced Ceramics,2019,40(Z1):4-120(in Chinese). -

下载:

下载: