Microstructure and thermoelectric properties of MWCNT/PEDOT composites

-

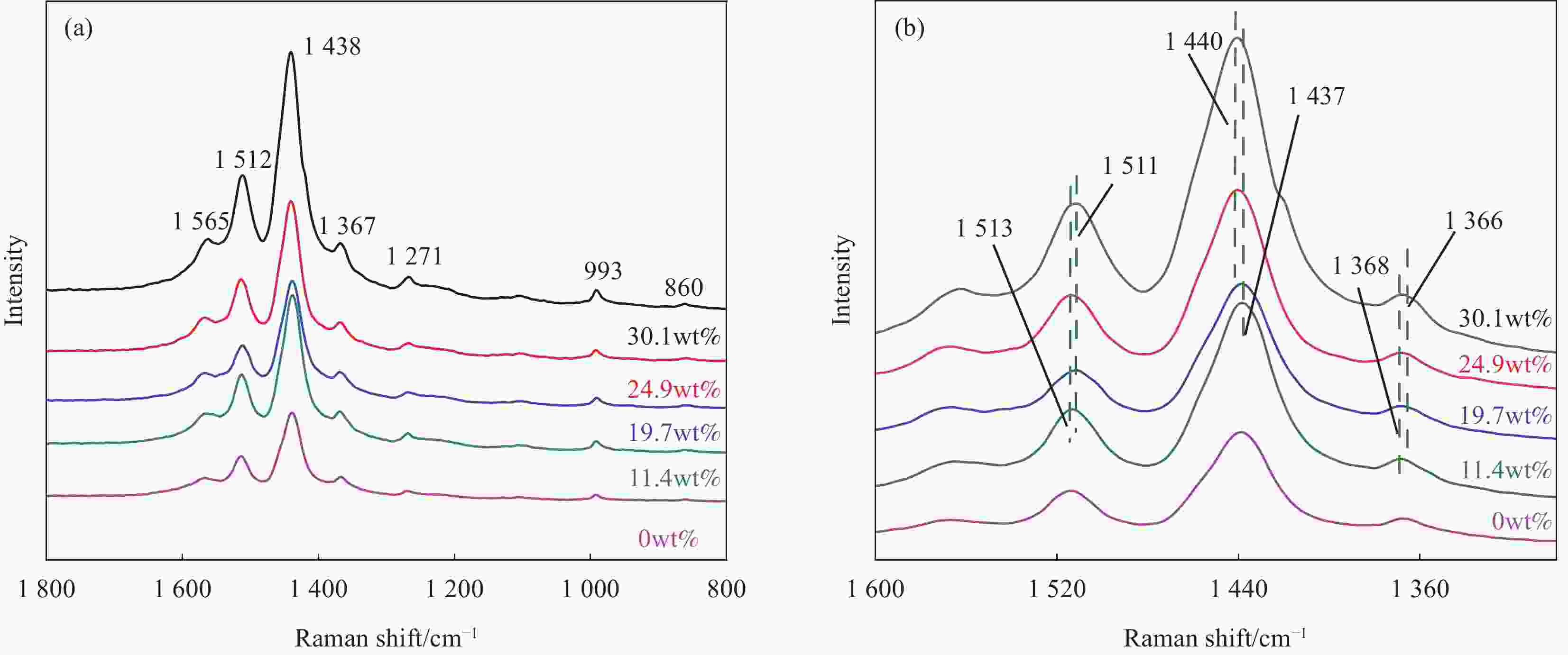

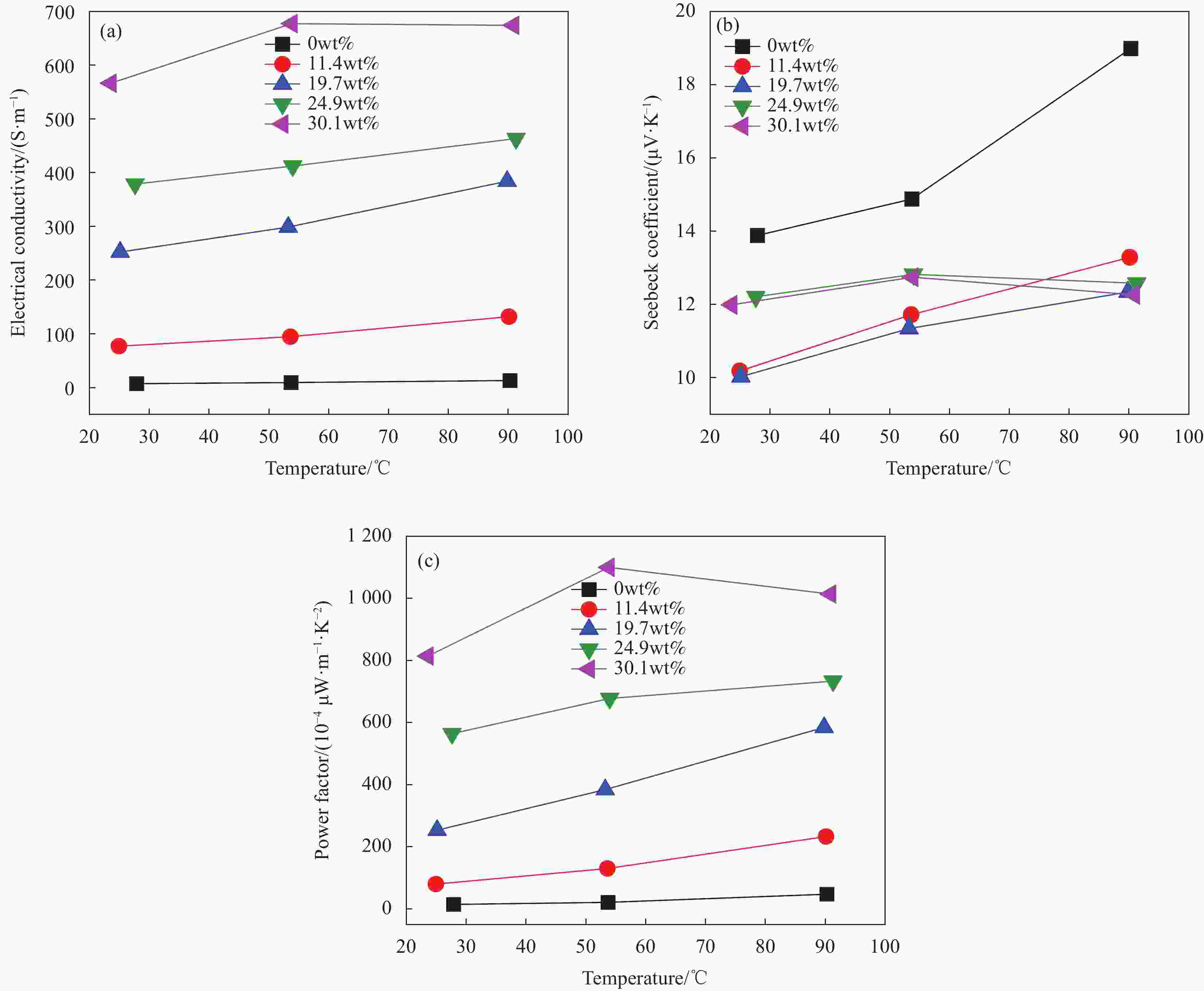

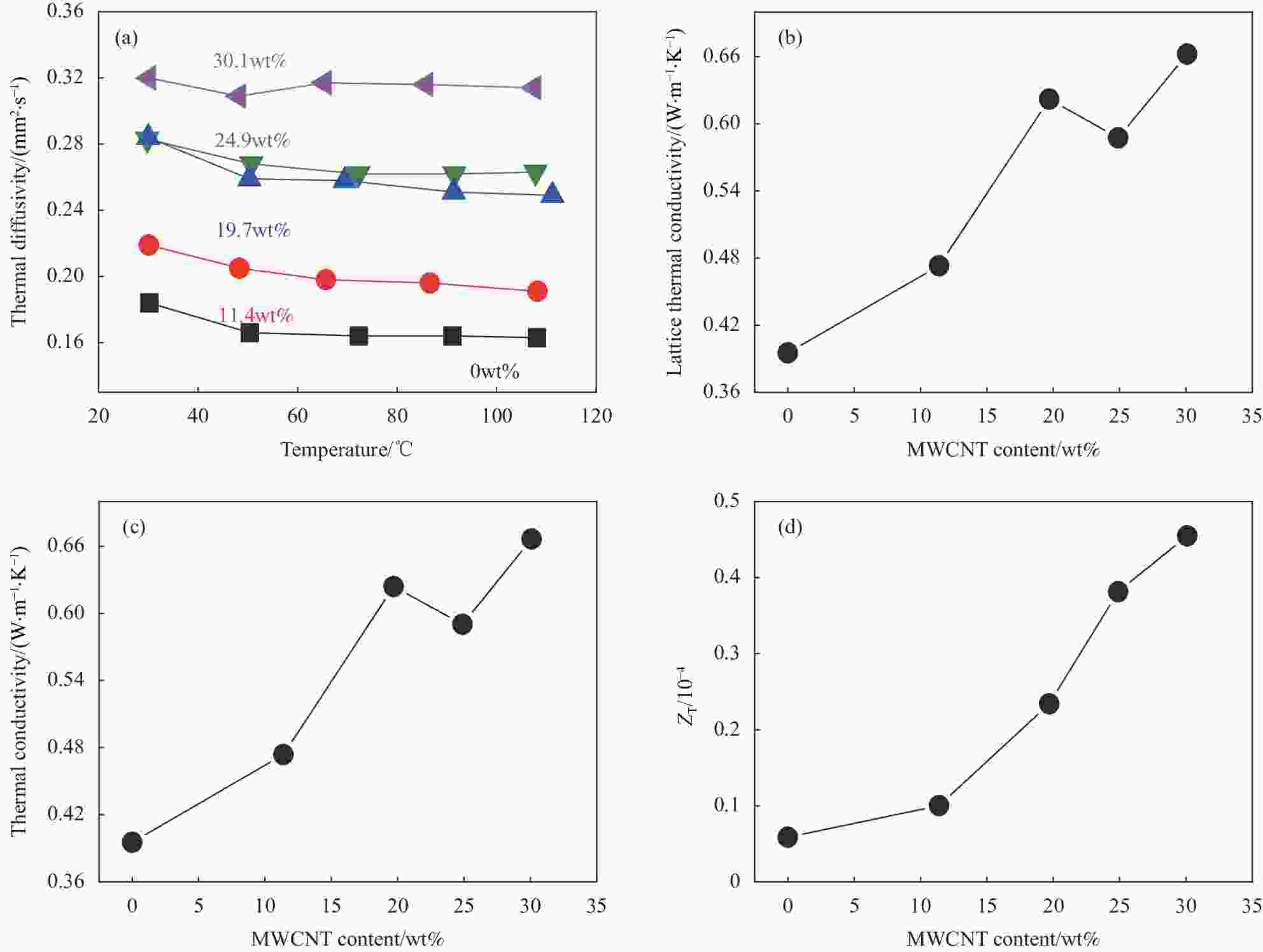

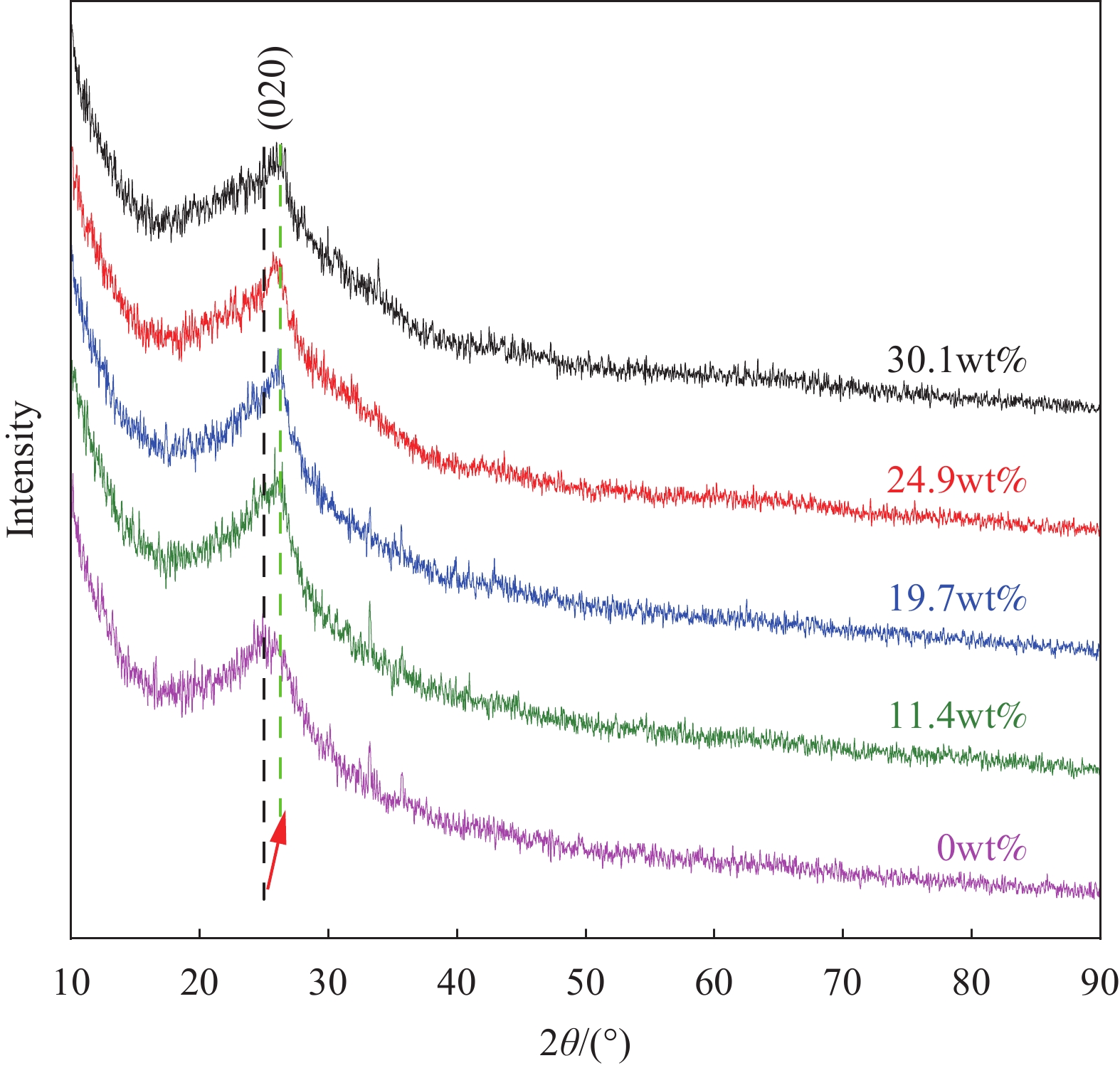

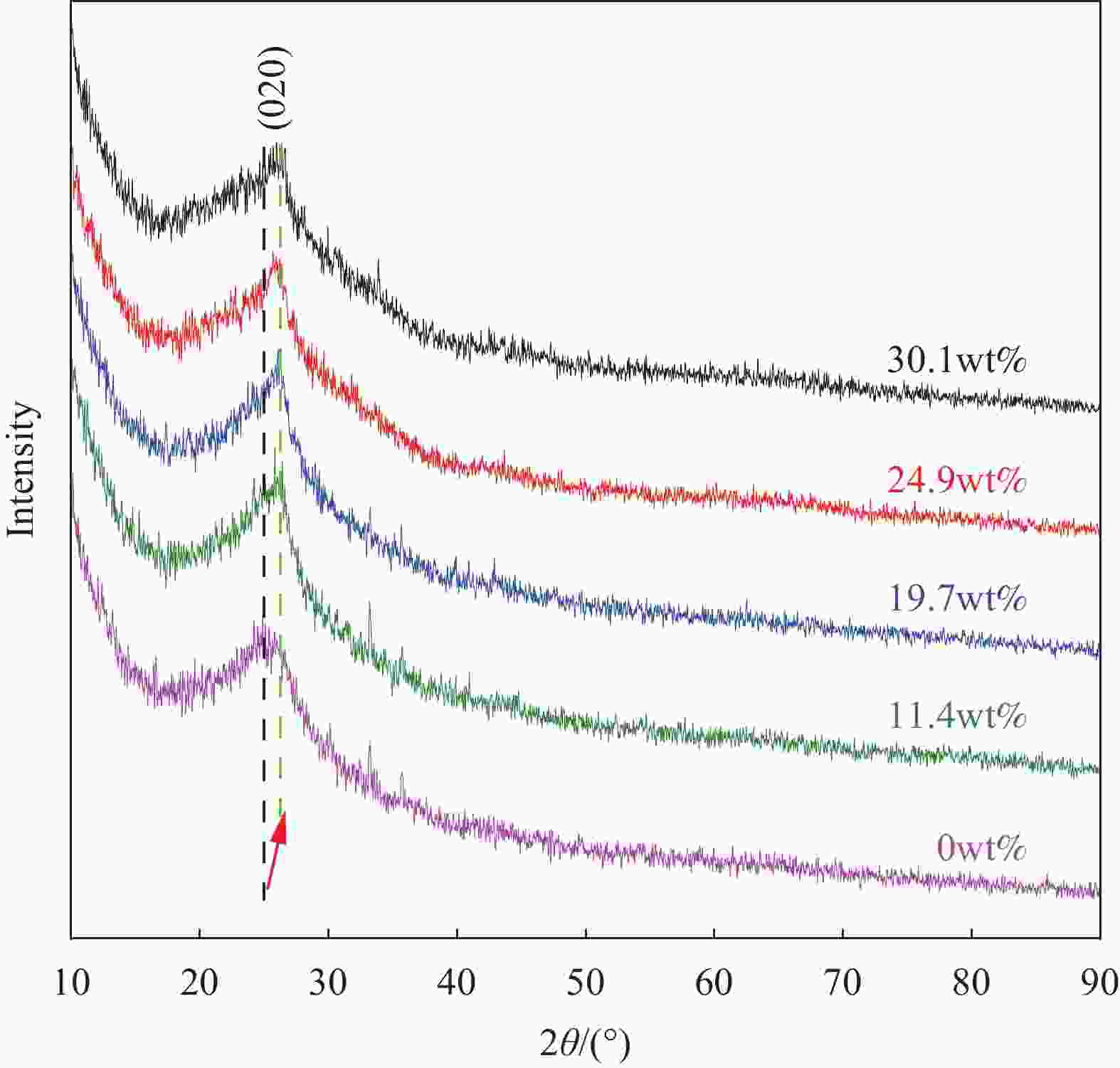

摘要: 热电转换技术能将大量的废弃热能转换为电能以重新利用,是一种绿色能源转换技术,可以有效提高能源利用效率,缓解煤炭、石油等主要化石类能源过度开采、使用带来的能源危机及环境污染问题,因此受到科研工作者的广泛关注,是近年来的研究热点。基于此,本文以电子型导电高聚物中机能较优的聚(3, 4-乙烯二氧噻吩)(PEDOT)作为研究主体,通过化学原位氧化聚合将多壁碳纳米管(MWCNT)复合到载体中得到MWCNT/PEDOT复合材料。利用XRD、拉曼、TEM及正电子湮没寿命(PAL)等方法对MWCNT/PEDOT复合材料的形貌和微观结构进行了系统研究,研究表明:当MWCNT含量高于24.9wt%时,复合材料中出现MWCNT团聚现象,其分散性变差。同时,MWCNT/PEDOT复合材料的热电性能测试结果显示,未掺杂PEDOT的电导率仅为7.5 S·m−1,而MWCNT含量为30.1wt%时,该复合材料的电导率高达566.59 S·m−1,提高近76倍。同时,30.1wt%MWCNT/PEDOT的功率因子(814.3×10−4 μW·(m·K2)−1)相对于未掺杂PEDOT(14.5×10−4 μW·(m·K2)−1)提高约56倍,这主要是由于PEDOT分子链与MWCNT掺杂物间π-π相互作用及MWCNT的高导电性。随着MWCNT含量的增加,PAL测试结果中第一寿命成分τ1(即正电子在材料中湮没的第一寿命成分)的下降证实了该复合材料中MWCNT与PEDOT间界面变小或者界面间相互作用减弱,导致其热导率相对于未掺杂PEDOT有一定的上升,但远远低于功率因子的升高。最终,该MWCNT/PEDOT复合材料的热电优值(即热电材料ZT值)由0.015×10−4升至0.45×10−4,增加了约30倍。结果表明:掺杂的高电导率MWCNT能够极大地提高PEDOT类电子型导电聚合物的热电性能。

-

关键词:

- 热电复合材料 /

- 多壁碳纳米管 /

- 聚(3, 4-乙烯二氧噻吩) /

- 热电优值 /

- 热电转换技术

Abstract: Thermoelectric conversion technology can convert a large amount of waste heat energy into electric energy for reuse. It is a green energy conversion technology, which can effectively improve energy utilization, and alleviate the energy crisis and environmental pollution caused by the over-exploitation and utilization of coal, oil and other major fossil energy. Therefore, it has been widely concerned by researchers and has become a research hotspot recently. Base on this, one of the more excellent electronic conductive polymers, poly(3, 4-ethylenedioxythiophene) (PEDOT), was used as the research subject, and multiwall carbon nanotubes (MWCNT)/PEDOT composites were synthesized by chemical in situ oxidation synthesis method. X-ray diffraction, raman spectroscopy, transmission electron microscope and positron annihilation lifetime spectroscopy were used to study the microstructure of the composites, the results of which indicate that when the MWCNT content is higher than 24.9wt%, the MWCNTs of MWCNT/PEDOT composites aggregate seriously and are badly dispersed. Thermal and electrical measurements of MWCNT/PEDOT composites show that their electrical conductivity increases sustainably with the MWCNT content increasing. For the pure PEDOT sample, the electrical conductivity is only 7.5 S·m−1, and the electrical conductivity of MWCNT/PEDOT sample is up to 566.59 S·m−1 at MWCNT content of 30.1wt%, the increase is nearly 76 times. Meanwhile, the power factor of the composites increases rapidly from 14.5×10−4 to 814.3×10−4 μW·(m·K2)−1 with the increase of 56, which is mainly due to the high conductivity of MWCNT and the π-π interaction between PEDOT molecular chain and MWCNT. With the increase of MWCNT content, the decrease of the first lifetime τ1 of positron annihilation in materials of PAL test confirms that the interface between MWCNT and PEDOT became smaller and the interfacial interaction between the MWCNT and PEDOT was weakened. As a result, the thermal conductivity of the composite exhibits a bit increase with the addition of MWCNT, but it was far lower than the increase of power factor. Eventually, the thermoelectric figure of merit (ZT, an index or measure of the thermoelectric properties of a thermoelectric material) value of the MWCNT/PEDOT composites increases from 0.015×10−4 to 0.45×10−4, that's a nearly 30-fold increase. In summary, the doped MWCNT of higher conductivity can greatly enhance the thermoelectric properties of electronic conductive polymers of PEDOT. -

图 7 (a) 30~111oC间不同MWCNT含量的MWCNT/PEDOT复合材料的热扩散系数;室温下不同MWCNT含量的MWCNT/PEDOT复合材料的晶格热导率 (b)、热导率 (c) 和热电优值ZT值 (d) 变化曲线

Figure 7. (a) Thermal diffusivity of the MWCNT/PEDOT composites with various MWCNT contents between 30-110oC; Lattice thermal conductivity (b), thermal conductivity (c) and thermoelectric figure of merit ZT value (d) for the MWCNT/PEDOT composites with various MWCNT contents at room temperature

-

[1] CHATTERJEE K, GHOSH T K. Thermoelectric materials for textile applications[J]. Molecules,2021,26(11):3154-3165. doi: 10.3390/molecules26113154 [2] PARK D, KIM M, KIM J. High-performance PANI-coated Ag2Se nanowire and PVDF thermoelectric composite film for flexible energy harvesting[J]. Journal of Alloys and Compounds,2021,884:161098. doi: 10.1016/j.jallcom.2021.161098 [3] ZHOU X Y, YAN Y C, LU X, et al. Routes for high-perfor-mance thermoelectric materials[J]. Materials Today,2018,21(9):974-988. doi: 10.1016/j.mattod.2018.03.039 [4] BELL L E. Cooling, heating, generating power, and recovering waste heat with thermoelectric systems[J]. Science,2008,321(5895):1457-1461. doi: 10.1126/science.1158899 [5] BAKKER F L, SLACHTER A, ADAM J P, et al. Interplay of Peltier and Seebeck effects in nanoscale nonlocal spin valves[J]. Physical Review Letters,2010,105(13):136601. doi: 10.1103/PhysRevLett.105.136601 [6] YANG J H, CAILLAT T. Thermoelectric materials for space and automotive power generation[J]. MRS Bulletin,2006,31(3):224-229. doi: 10.1557/mrs2006.49 [7] CHEN Z G, HAN G, YANG L, et al. Nanostructured thermoelectric materials: Current research and future challenge[J]. Progress in Natural Science-Materials International,2012,22(6):535-549. doi: 10.1016/j.pnsc.2012.11.011 [8] SHI X L, ZHENG K, HONG M, et al. Boosting the thermoelectric performance of p-type heavily Cu-doped polycrystalline SnSe via inducing intensive crystal imperfections and defect phonon scattering[J]. Chemical Science,2018,9(37):7376-7389. doi: 10.1039/C8SC02397B [9] SHI X L, ZHENG K, LIU W D, et al. Realizing high thermoelectric performance in n-type highly distorted Sb-doped SnSe microplates via tuning high electron concentration and inducing intensive crystal defects[J]. Advanced Energy Materials,2018,8(21):1800775. doi: 10.1002/aenm.201800775 [10] SNYDER G J, TOBBER E S. Complex thermoelectric materials[J]. Nature Materials,2008,7(2):105-114. doi: 10.1038/nmat2090 [11] ZHAO L D, LO S H, ZHANG Y S, et al. Ultralow thermal conductivity and high thermoelectric Fig. of merit in SnSe crystals[J]. Nature,2014,508(7496):373-377. doi: 10.1038/nature13184 [12] SOOTSMAN J R, CHUNG D Y, KANATZIDIS M G. New and old concepts in thermoelectric materials[J]. Angewandte Chemie International Edition,2009,48(46):8616-8639. doi: 10.1002/anie.200900598 [13] MCGRAIL B T, SEHIRLIOGLU A, PENTZER E. Polymer composites for thermoelectric applications[J]. Angewandte Chemie International Edition,2015,54(6):1710-1723. doi: 10.1002/anie.201408431 [14] VENKATASUBRAMANIAN R. Lattice thermal conductivity reduction and phonon localizationlike behavior in superlattice structures[J]. Physical Review B,2000,61(4):3091-3097. doi: 10.1103/PhysRevB.61.3091 [15] TIAN Z, GARG J, ESFARJANI K, et al. Phonon conduction in PbSe, PbTe, and PbTe1-xSex from first-principles calculations[J]. Physical Review B, 2012, 85(18): 184303. [16] 王艳, 陈南迪, 杨陈, 等. 二维材料XTe2(X = Pd, Pt)热电性能的第一性原理计算[J]. 物理学报, 2021, 70(11):116301. doi: 10.7498/aps.70.20201939WANG Yan, CHEN Nandi, YANG Chen, et al. Thermoelectric transport properties of XTe2 (X = Pd, Pt) two-dimensional materials calculations[J]. Acta Physics Sinica,2021,70(11):116301(in Chinese). doi: 10.7498/aps.70.20201939 [17] HE H F, LI X F, CHEN Z Q, et al. Interplay between point defects and thermal conductivity of chemically synthe-sized Bi2Te3 nanocrystals studied by positron annihilation[J]. The Journal of Physical Chemistry C,2014,118(38):22389-22394. doi: 10.1021/jp508085a [18] WU D, ZHAO L D, HAO S Q, et al. Origin of the high performance in GeTe-based thermoelectric materials upon Bi2Te3 doping[J]. Journal of the American Chemical Society,2014,136(32):11412-11419. doi: 10.1021/ja504896a [19] 范人杰, 江先燕, 陶奇睿, 等. In1+xTe化合物的结构及热电性能研究[J]. 物理学报, 2021, 70(13): 137102.FAN Renjie, JIANG Xianyan, TAO Qirui, et al. Structure and thermoelectric properties of In1+xTe compounds[I]. Acta Physical Sinica, 2021, 70(13): 137102(in Chinese). [20] WANG F Q, ZHANG S H, YU J B, et al. Thermoelectric pro-perties of single-layered SnSe sheet[J]. Nanoscale,2015,7(38):15962-15970. doi: 10.1039/C5NR03813H [21] 王作成, 李涵, 苏贤礼, 等. In0.3Co4Sb12-xSex方钴矿热电材料的制备和热电性能[J]. 物理学报, 2011, 60(2):027202. doi: 10.7498/aps.60.027202WANG Zuocheng, LI Han, SU Xianli, et al. Synthesis and thermoelectric properties of thermoelectric materials of the skutterudites In0.3Co4Sb12-xSex[J]. Acta Physical Sinica,2011,60(2):027202(in Chinese). doi: 10.7498/aps.60.027202 [22] APPEL O, GELBSTEIN Y. A comparison between the effects of Sb and Bi doping on the thermoelectric properties of the Ti0.3Zr0.35Hf0.35NiSn half-heusler alloy[J]. Jour-nal of Electronic Materials,2013,43(6):1976-1982. [23] ZHOU H, CHUA M H, ZHU Q, et al. High-performance PEDOT : PSS-based thermoelectric composites[J]. Compo-sites Communications, 2021, 27: 100877. [24] HAN J F, GANLEY C, HU Q, et al. Using preformed meisenheimer complexes as dopants for n-type organic thermoelectrics with high Seebeck coefficients and power factors[J]. Advanced Functional Materials,2021,31(18):2010567. doi: 10.1002/adfm.202010567 [25] DENG L, CHEN G M. Recent progress in tuning polymer oriented microstructures for enhanced thermoelectric performance[J]. Nano Energy, 2021, 80: 105448. [26] KAUL P B, DAY K A, ABRAMSON A R. Application of the three omega method for the thermal conductivity measurement of polyaniline[J]. Journal of Applied Physics,2007,101(8):083507. doi: 10.1063/1.2714650 [27] 刘祎, 张荔. 聚3, 4-乙烯二氧噻吩: 聚苯乙烯磺酸盐基柔性复合热电材料研究进展[J]. 复合材料学报, 2021, 38(2):287-297.LIU Wei, ZHANG Li. Recent progress on poly(3, 4-ethyl-enedioxythiophene): polystyrenesulfonate-based flexible composite thermoelectric materials[J]. Acta Materiae Compositae Sinica,2021,38(2):287-297(in Chinese). [28] KIM D, KIM Y, CHOI K, et al. Improved thermoelectric behavior of nanotube-filled polymer composites with poly(3, 4-ethylenedioxythiophene) poly(styrenesulfonate)[J]. ACS Nano,2010,4(1):513-523. doi: 10.1021/nn9013577 [29] SCHOLDT M, DO H, LANG J, et al. Organic semiconductors for thermoelectric applications[J]. Journal of Eelctro-nic Materials,2010,39(9):1589-1592. doi: 10.1007/s11664-010-1271-8 [30] LIU C C, XU J K, LU B Y, et al. Simultaneous increases in electrical conductivity and Seebeck coefficient of PEDOT: PSS films by adding ionic liquids into a polymer solution[J]. Journal of Electronic Materials,2012,41(4):639-645. doi: 10.1007/s11664-012-1942-8 [31] LU W, LAI X F, LIU Q L, et al. Enhanced thermoelectric performance of BiSe by Sn doping and ball milling[J]. Ceramics International,2021,47(18):26375-26382. doi: 10.1016/j.ceramint.2021.06.048 [32] LI H B, ZONG Y D, DING Q J, et al. Paper-based thermoelectric generator based on multi-walled carbon nano-tube/carboxylated nanocellulose[J]. Journal of Power Sources,2021,500(15):229992. [33] CHEN R S, TANG J H, YAN Y J, et al. Solvent-mediated n-type doping of SWCNTs to achieve superior thermoelectric power factor[J]. Advanced Materials Technologies,2020,5(9):2000288. [34] 陶颖, 祁宁, 王波, 等. 氧化铟/聚(3, 4-乙烯二氧噻吩)复合材料的微结构及其热电性能研究[J]. 物理学报, 2018, 67(19):197201. doi: 10.7498/aps.67.20180382TAO Ying, QI Ning, WANG Bo, et al. Microstructure and thermoelectric properties of In2O3/poly(3, 4-ethylenedioxythiophene) composites[J]. Acta Physical Sinica,2018,67(19):197201(in Chinese). doi: 10.7498/aps.67.20180382 [35] XU K L, CHEN G M, QIU D. Convenient construction of poly(3, 4-ethylenedioxythiophene)-graphene pie-like structure with enhanced thermoelectric performance[J]. Journal of Materials Chemistry A,2013,1(40):12395-12399. doi: 10.1039/c3ta12691a [36] FU P J, XU K L, SONG H Z, et al. Preparation, stability and rheology of polyacrylamide/pristine layered double hydroxide nanocomposites[J]. Journal of Materials Che-mistry,2010,20(19):3869-3876. doi: 10.1039/b927391c [37] HARUNA M A, PERVAIZ S, HU Z L, et al. Improved rheology and high-temperature stability of hydrolyzed polyacrylamide using graphene oxide nanosheet[J]. Journal of Applied Polymer Science,2019,136(22):47582. doi: 10.1002/app.47582 [38] XU K L, CHEN G M, QIU D. In situ chemical oxidative polymerization preparation of poly(3, 4-ethylenedioxythiophene)/graphene nanocomposites with enhanced thermoelectric performance[J]. Chemistry, An Asian Journal,2015,10(5):1225-1231. doi: 10.1002/asia.201500066 [39] KSHIRSAGAR A S, HIRAGOND C, DEY A, et al. Band engi-neered I/III/V-VI binary metal selenide/MWCNT/PANI nanocomposites for potential poom temperature thermoelectric applications[J]. ACS Applied Energy Materials,2019,2(4):2680-2691. doi: 10.1021/acsaem.9b00013 [40] ZHANG Z, CHEN G M, WANG H F, et al. Template-directed in situ polymerization preparation of nanocomposites of PEDOT: PSS-coated multi-walled carbon nanotubes with enhanced thermoelectric property[J]. Chemistry, An Asian journal,2015,10(1):149-153. doi: 10.1002/asia.201403100 [41] RDEST M, JANAS D. Effective doping of single-walled carbon nanotubes with polyethyleneimine[J]. Materials,2020,14(1):65. doi: 10.3390/ma14010065 [42] ZHANG Y C, ZHANG Q C, CHEN G M. Carbon and carbon composites for thermoelectric applications[J]. Carbon Energy,2020,2(3):408-436. doi: 10.1002/cey2.68 [43] GAO C Y, CHEN G M. Conducting polymer/carbon particle thermoelectric composites: Emerging green energy materials[J]. Composites Science and Technology, 2016, 124: 52-70. [44] TZOUNIS L, GARTNER T, LIEBSCHER M, et al. Influence of a cyclic butylene terephthalate oligomer on the processability and thermoelectric properties of polycarbonate/MWCNT nanocomposites[J]. Polymer,2014,55(21):5381-5388. doi: 10.1016/j.polymer.2014.08.048 [45] BADR H, YOUSSEF M A, ELSALAM H S A, et al. Thermoelectric behaviour of polyvinyl acetate/CNT composites[C]//146th Annual Meeting & Exhibition Supplemental Proceedings. San Diego: Springer International Publishing, 2017: 287-294. [46] IGNATIOUS V, RAVEENDRAN N, PRABHAKARAN A, et al. MWCNT/thienothiophene based all-organic thermoelectric composites: Enhanced performance by realigning of the Fermi level through doping[J]. Chemical Engineering Journal, 2021, 409: 128294. [47] CHOI J W, HAN M G, KIM S Y, et al. Poly(3, 4-ethylenedioxythiophene) nanoparticles prepared in aqueous DBSA solutions[J]. Synthetic Metals,2004,141(3):293-299. doi: 10.1016/S0379-6779(03)00419-3 [48] GARREAU S, LOUARN G, BUISSON J P, et al. In situ spectroelectrochemical raman studies of poly(3, 4-ethylenedioxythiophene) (PEDT)[J]. Macromolecules,1999,32(20):6807-6812. doi: 10.1021/ma9905674 [49] LIU Y L, CHEN W H. Modification of multiwall carbon nanotubes with initiators and macroinitiators of atom transfer radical polymerization[J]. Macromolecules,2007,40(25):8881-8886. doi: 10.1021/ma071700s [50] BASKARAN D, MAYS J W, BRATCHER M S. Noncovalent and nonspecific molecular interactions of polymers with multiwalled carbon nanotubes[J]. Chemistry of Materials,2005,17(13):3389-3397. doi: 10.1021/cm047866e [51] MENG C Z, LIU C H, FAN S S. A promising approach to enhanced thermoelectric properties using carbon nanotube networks[J]. Advanced Materials,2010,22(4):535-539. doi: 10.1002/adma.200902221 [52] ZHENG Y, ZENG H N, ZHU Q, et al. Recent advances in conducting poly(3, 4-ethylenedioxythiophene): polystyrene sulfonate hybrids for thermoelectric applications[J]. Journal of Materials Chemistry C,2018,6(33):8858-8873. doi: 10.1039/C8TC01900B [53] 王少阶, 陈志权, 王波, 等. 应用正电子谱学[M]. 武汉: 湖北科学技术出版社, 2008.WANG Shaojie, CHEN Zhiquan, WANG Bo, et al. Applied positron spectroscopy[M]. Wuhan: Hubei Science and Technology Press, 2008(in Chinese). [54] LI C Y, ZHAO B, ZHOU B, et al. Effects of electrical conductivity on the formation and annihilation of positronium in porous materials[J]. Physical Chemistry Chemical Physics,2017,19(11):7659-7667. doi: 10.1039/C6CP07483A [55] YAO Q, CHEN L D, ZHANG W Q, et al. Enhanced thermoelectric performance of single-walled carbon nanotubes/polyaniline hybrid nanocomposites[J]. ACS Nano,2010,4(4):2445-2451. doi: 10.1021/nn1002562 [56] YU C, KIM Y S, KIM D, et al. Thermoelectric behavior of segregated-network polymer nanocomposites[J]. Nano Letters,2008,8(12):4428-4432. doi: 10.1021/nl802345s [57] YAO Q, WANG Q, WANG L M, et al. Abnormally enhanced thermoelectric transport properties of SWNT/PANI hybrid films by the strengthened PANI molecular ordering[J]. Energy & Environmental Science,2014,7(11):3801-3807. -

下载:

下载: