Compression after impact properties of carbon-fiber/aluminum-honeycomb sandwich panels with short-Kevlar-fiber toughening

-

摘要: 碳纤维夹芯板受到冲击载荷后易发生分层损伤,在工程应用中严重影响结构安全。首先对碳纤维/铝蜂窝夹芯板界面进行Kevlar短纤维增韧设计;其次对比研究了Kevlar短纤维界面增韧及未增韧夹芯板的低速冲击行为和冲击后压缩行为,将其冲击后剩余压缩强度、能量吸收及破坏模式进行对比;最后运用数字图像相关技术(DIC)获取增韧及未增韧试件在冲击后压缩过程中的应变云图。结果表明:低速冲击过程中,Kevlar短纤维增韧可以有效提高碳纤维/铝蜂窝夹芯板的冲击损伤阻抗,增韧试件的临界损伤阈值载荷明显高于未增韧试件;相比于未增韧试件,4种冲击能量下增韧试件的冲击后剩余压缩强度(CAI)值分别提高了2.68%、9.24%、4.65%、11.13%,能量吸收分别提高了69.09%、52.88%、55.03%、101.70%;对碳纤维/铝蜂窝夹芯板冲击后压缩过程中的DIC观测,进一步验证了芳纶短纤维对界面的增韧效果,并揭示了增韧界面对结构的增强机制。Abstract: Delamination between face sheets and core is one of the most common damage mode of carbon-fiber sandwich panels under impact loading, which seriously affects structural safety. Firstly, short-Kevlar-fibers were used for toughening the interface of carbon-fiber/aluminum-honeycomb sandwich panel. Secondly, low velocity impact and compression after impact tests were conducted for plain and toughened specimens. The residual compression strength, energy absorption and failure mode were compared. Finally, the strains of plain and toughened specimens during compression after impact test were obtained by digital image correlation (DIC). The results show that short-Kevlar-fiber toughening is capable to effectively increase the impact damage resistance of carbon-fiber/aluminum-honeycomb sandwich panel, and the damage threshold load of toughened specimens is signifi-cantly higher than that of plain specimens. Compared with the plain specimens, the residual compression strength values after impact of toughened specimens are increased by 2.68%, 9.24%, 4.65% and 11.13%, respectively, under four different impact energies. Meanwhile the energy absorption values of toughened specimens are increased by 69.09%, 52.88%, 55.03% and 101.70%, respectively. Furthermore, DIC observations were used to investigate the toughening effects of short-Kevlar-fibers and the strengthening mechanism.

-

碳纤维/铝蜂窝复合材料夹芯结构因其优异的比强度与比刚度及抗疲劳、隔热、减振等性能已广泛应用于航空航天、轨道交通及海洋船舶等领域,在轻量化、节能减排等方面发挥出重要作用[1-3]。上下两层高强度碳纤维面板与中间的铝蜂窝芯体共同作用使整体结构的力学性能得到充分的发挥与利用[4-5]。而夹芯结构在服役过程中对冲击载荷非常敏感,一些外来物体的低速冲击会对其造成严重的内部损伤,从而影响结构后期的承载能力[6-7]。由于面板与芯体之间的性能差异,在研究其低速冲击和冲击后压缩性能过程中,常出现界面分层破坏,导致结构整体失效。

一些学者对蜂窝夹芯板的低速冲击性能进行了一系列研究,Zhang等[8]研究发现,碳纤维夹芯结构具有良好的能量吸收性能,铝蜂窝芯体在能量吸收方面起主导作用。Liu等[9]、齐佳旗等[10]、Wang等[11]、Wu等[12]通过实验和数值模拟的方法,研究了芯体参数、冲头直径、蒙皮厚度等参数对结构抗冲击性能的影响。Zhang等[13]基于连续损伤力学(CDM)建立精细化有限元预测模型,研究了碳纤维面板-Nomex蜂窝夹层结构低速冲击过程中的损伤机制。Yang等[14]将花瓣形状的介观结构结合到规则的圆形细胞蜂窝中,提出了一种新型的花瓣形蜂窝(PSH),运用有限元分析软件LS-DYNA对比分析了圆形蜂窝、单瓣嵌套圆形蜂窝和PSH在不同冲击速度下的面内破坏行为和能量吸收能力,发现PSH具有优异的力学性能和能量吸收特性。张亚文等[15]研究了不同冲击位置和冲击角度下格栅-蜂窝混式芯体夹芯结构的低速冲击破坏模态及力学响应。结果表明,混式芯体能够显著提高夹芯结构的抗冲击性能,对于面板的损伤扩展具有良好的抑制作用。Zhang等[16]在蜂窝孔中填充了金属管,通过低速冲击实验分析发现管状增强蜂窝夹芯结构可以提高夹芯板的承载能力和抗冲击能力。

碳纤维夹芯板受到冲击载荷后易发生分层损伤,抑制界面分层破坏可以有效提高材料的抗冲击性能。为此,众多学者提出了多种界面增韧方法。

仲越等[17]研究了超高分子量聚乙烯短纤维增韧的碳纤维/环氧树脂基复合材料层合板的冲击性能及失效机制,发现短纤维的加入可以有效提高层合板的冲击损伤阻抗和抗分层能力。Jiang等[18]提出在碳纤维增强树脂基复合材料(CFRP)层间界面嵌入芳纶浆可以明显提高CFRP的模量、强度和韧性。Sun等[19]提出了Kevlar短纤维和碳纤维带增韧碳纤维/铝蜂窝夹芯板,并研究不同速率下的三点弯曲性能,实验结果表明Kevlar短纤维和碳纤维带增韧均能提高夹芯试件的能量吸收和峰值载荷。郑昊等[20]选用碳纤维、亚麻纤维及Kevlar纤维作为增韧短纤维,分析讨论了短纤维种类、增韧面密度和纤维长度对碳纤维/环氧树脂复合材料层间增韧的影响,对比发现Kevlar短纤维具有良好的增韧效果。Yuan等[21-22]研究表明,Kevlar短纤维增韧的层合板在界面断裂韧性和抗冲击性能等方面表现优异。Sun等[23-24]和Shi等[25]对Kevlar短纤维界面增韧的夹芯结构进行三点弯曲、面内压缩等实验,并通过细观桥联模型分析了Kevlar短纤维的力学原理和能量耗散机制,充分说明增韧后夹芯结构的整体力学性能有大幅提升。刘浩洋等[26]通过非对称双悬臂梁实验对Kevlar短纤维增韧碳纤维/铝蜂窝夹芯梁进行界面断裂韧性测量,进一步说明了界面的具体破坏形式。

以上研究一方面通过改变夹芯板的结构参数进而探究其冲击性能,另一方面通过界面增韧的方式提高结构的整体力学性能,而对于短纤维增韧夹芯结构的冲击后剩余压缩强度研究较少。本文研究了Kevlar短纤维界面增韧对碳纤维/铝蜂窝夹芯板低速冲击性能及冲击后剩余压缩强度的影响。首先对碳纤维/铝蜂窝夹芯板的面-芯界面进行Kevlar短纤维增韧设计;之后在10 J、20 J、30 J、50 J冲击能量下对增韧与未增韧试件进行低速冲击及冲击后压缩实验,对比分析了两种试件的临界损伤阈值载荷、冲击后剩余压缩强度和能量吸收;最后通过数字图像相关技术(DIC),提取冲击后压缩过程中增韧与未增韧试件在不同时刻的变形云图与工程应变,揭示了Kevlar短纤维界面增韧对碳纤维/铝蜂窝夹芯结构的增强机制。

1. 增韧设计及实验方法

1.1 Kevlar短纤维薄膜的制备

Kevlar49短纤维由美国DuPont公司生产。首先用电动剪刀将Kevlar纤维丝束剪为12 mm长的纤维簇,之后将0.5 g的纤维簇投入容量为2 L带有钝头的搅拌机中,在2 000 r/min的转速下点动控制整个搅拌过程(持续匀速搅拌会导致纤维缠绕),最终形成松散稀疏的絮状纤维团。Kevlar短纤维薄膜通过湿法制备,将一定量的纤维团投入水箱中,通过方头搅拌叶在水中将其充分搅拌,静置片刻之后用打捞网捞起,常温干燥之后即可形成Kevlar短纤维薄膜,制备过程如图1所示。该方法相较于手工平铺法制备简单、耗时短,在工业上可以实现批量生产。

1.2 Kevlar短纤维界面增韧碳纤维/铝蜂窝夹芯试件的制备

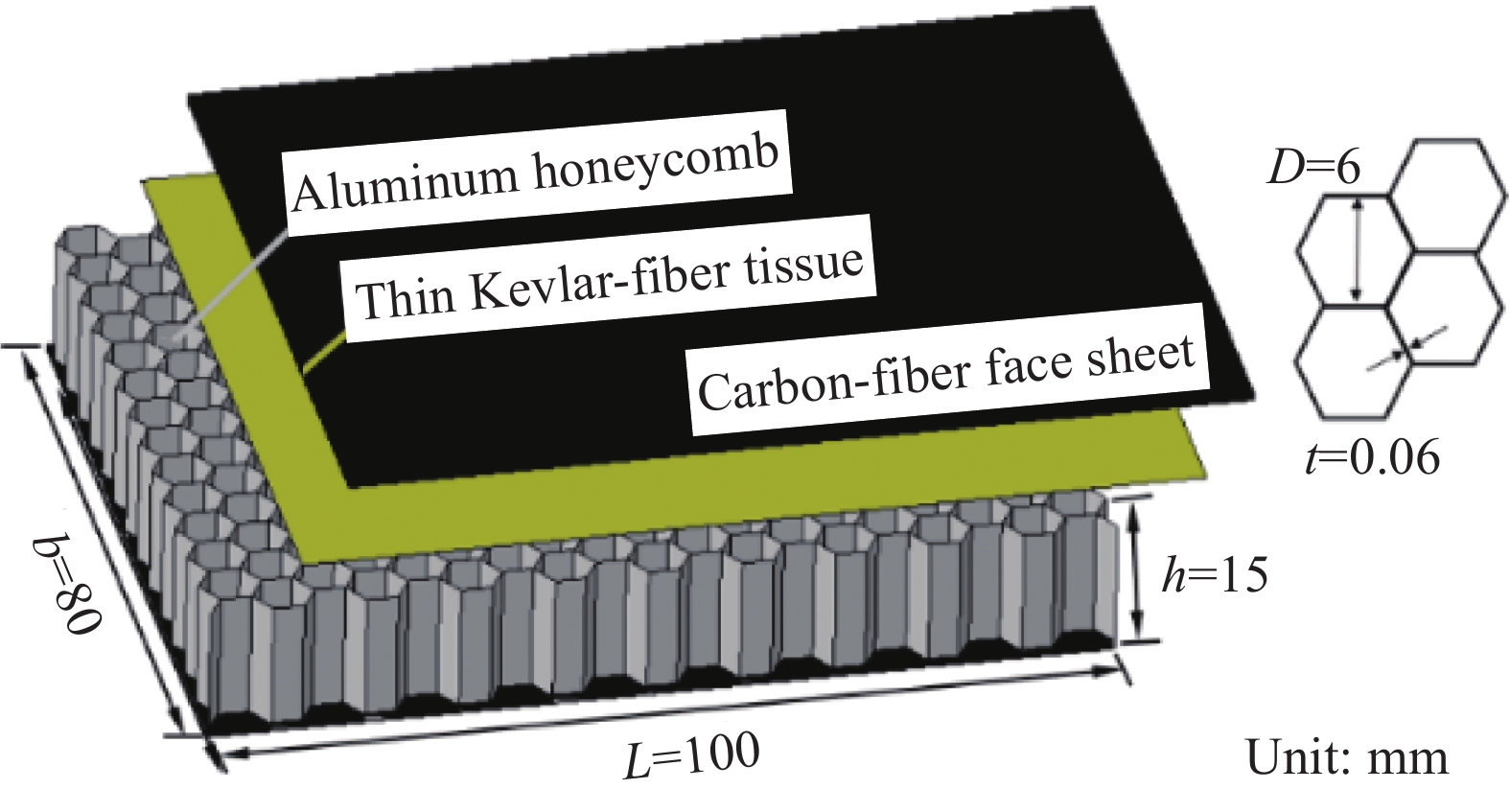

碳纤维面板材料采用由神鹰复合材料科技有限公司生产的CS03T-200斜纹编织布,面密度为200 g/m2。铝蜂窝芯体孔径D=6 mm,高度h=15 mm,壁厚t=0.06 mm。粘接面板及面板与芯体之间的基体由LY5288环氧树脂与LY5289固化剂按照质量比100∶23均匀混合而成。

在制备试件之前,将碳纤维布裁剪为250 mm×250 mm备用,上下蒙皮各6层。将面密度为12 g/m2的Kevlar薄膜均匀地铺在准备好的两块碳纤维布上。由于Kevlar短纤维薄膜的质量不足整体结构的0.4%,因此对整体试件质量的影响可以忽略。用混合均匀的树脂-固化剂基体充分浸润每层碳纤维布,基体密度为208~210 g/m2。具有Kevlar短纤维界面增韧的碳纤维/铝蜂窝夹芯试件按照碳纤维布、Kevlar短纤维薄膜、铝蜂窝芯体的顺序在模具中组装,如图2所示。整个过程在室温条件下进行,操作时间控制在0.5 h之内。最后进行热压固化,热压过程中的压强恒定为0.48 MPa,首先将热压机温度从室温升高到50℃,保温30 min,之后继续升高温度到80℃,保温30 min。待模具冷却至室温将试件取出并切割为80 mm×100 mm的试件进行后续实验。

1.3 低速冲击实验

Kevlar短纤维界面增韧碳纤维/铝蜂窝夹芯试件长L为100 mm,宽b为80 mm,厚度H为16.8 mm,质量m为(48±2) g,每组实验测试5个样本。低速冲击实验在长春市彼特福科技有限公司生产的BTF-068型落锤冲击实验机上进行,冲击过程参考ASTM D7136/D7136M-2015[27]实验标准。冲击装置主要包括钢质半球形冲头、传感器、试件夹具、防二次冲击装置等,如图3所示。冲头质量为14 kg,直径为16 mm,选取10 J、20 J、30 J、50 J这4组能量分别对增韧与未增韧试件进行冲击实验。冲击位置为试件的面板中心,每组能量进行5次重复实验。在冲头上安装加速度传感器,获取载荷-时间曲线。每次冲击过程结束之后,冲头离开面板的瞬间防二次冲击装置顶出,防止冲头对试件的二次破坏。

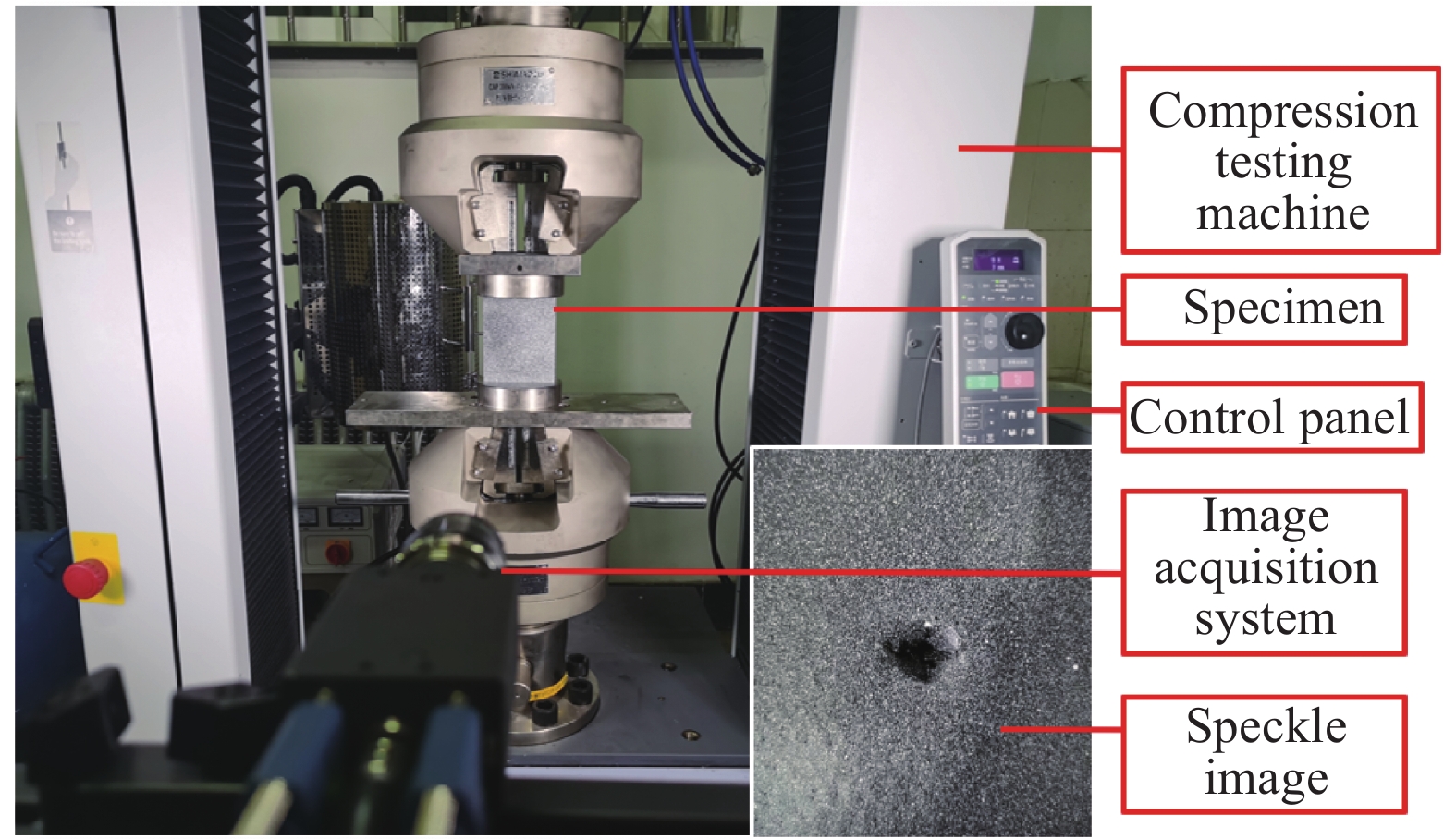

1.4 冲击后压缩实验

冲击后压缩实验在岛津公司生产的AGS-X电子力学万能实验机上进行,以1 mm/min的加载速率对试件施加沿100 mm长度方向的位移载荷,传感器每隔10 ms捕捉一次载荷响应。实验机提取的载荷-位移曲线与X轴围成的面积为试件在压缩过程中的能量吸收,剩余压缩强度为压缩过程中试件的极限载荷与上压头和试件接触面的比值。为了比较增韧与未增韧试件在压缩过程中的吸能情况,压缩位移统一设定为6 mm。每组实验测试5个样品,并在压缩过程中记录试件在不同时刻的破坏模式。

1.5 DIC在压缩实验中的应用

DIC是一种非接触式的光学测量方法,通过追踪被测试件表面散斑点的变形进而输出全场位移和应变。DIC测试系统主要由图像采集系统、控制与计算系统及数字图像相关分析软件构成。DIC测试方法及试件散斑如图4所示。本文将应用DIC技术获取不同冲击能量下夹芯板在压缩过程中的应变变化情况,进而研究其失效过程。每组冲击能量分别选取两个增韧与未增韧试件进行测试。

2. 实验结果与讨论

2.1 Kevlar短纤维界面增韧碳纤维/铝蜂窝夹芯板低速冲击实验结果

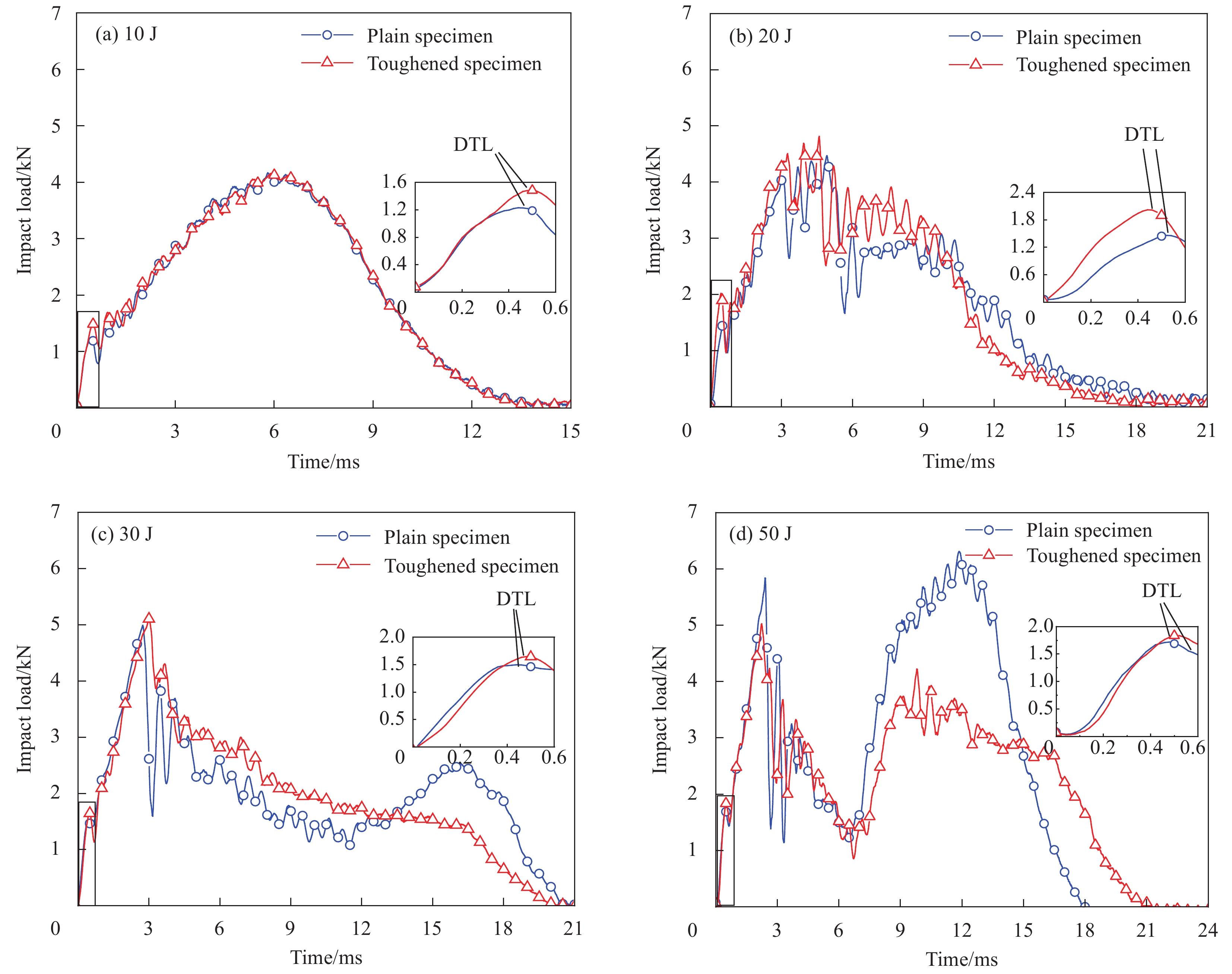

图5与表1为4种不同冲击能量下(10 J、20 J、30 J、50 J)碳纤维/铝蜂窝夹芯板的冲击力-时间曲线与其面板受到冲击后的破坏形貌。由于增韧与未增韧试件在不同能量冲击后上下面板的破坏形貌图相同,因此表1选取其中1组增韧试件并对其受到冲击后的破坏形貌进行展示。在低速冲击试验过程中,冲头刚接触试件时,夹芯板发生弹性变形,结构未发生损伤或破坏,冲击力随着时间的增大近似线性增加。随着冲击的进行,冲击力随冲击时间的增加幅值变小,随后冲击力发生第一次骤降,骤降前的最大冲击力即为临界损伤阈值载荷(Damage threshold load,DTL)[28],在图5中用放大图表示。冲击力骤降是由夹芯板破坏模式转变导致的,此时面板发生了基体开裂和分层损伤[29]。由于结构的整体性破坏,造成夹芯板的刚度下降。随着冲头的继续下降,损伤持续扩展,造成冲击力在波动中上升,直到冲击力达到最大值。

表 1 不同冲击能量下Kevlar短纤维界面增韧碳纤维/铝蜂窝夹芯板面板破坏形貌Table 1. Failure morphologies of carbon-fiber/aluminum-honeycomb sandwich panel with short-Kevlar-fiber toughening under different impact energiesImpact energy/J 10 20 30 50 Top surface

Bottom surface

当冲击能量为10 J时,如表1所示,冲头接触试件的上面板并对其造成目视不可见的损伤。由图5(a)可以发现,增韧与未增韧试件的曲线趋势相同,最大冲击力差别不大。这是由于在试件制备过程中Kevlar短纤维薄膜铺设在面板与芯体之间,较低能量的冲击并未破坏增韧层的结构完整性。在损伤持续扩展的过程中,Kevlar短纤维增韧发挥的作用很小。

当冲击能量为20 J时,如表1所示,冲头对试件的损伤进一步加大,冲击区域发生纤维断裂损伤,蜂窝芯体出现轻微坍塌。由图5(b)可以发现,增韧与未增韧试件的冲击力到达最大值之后发生骤降,冲击过程进入平台区,此时冲头穿透上面板并继续下降,对Kevlar短纤维薄膜及蜂窝芯体造成进一步破坏。在此阶段,增韧试件的冲击力明显高于未增韧试件,Kevlar短纤维薄膜在破坏过程中抑制了冲头的下侵,与未增韧试件相比,增韧试件具有较高的冲击损伤阻抗。在卸载阶段,由于Kevlar短纤维断裂消耗了一部分冲头的能量,因此增韧试件的冲击力下降较快。

当冲击能量为30 J时,如表1所示,冲头穿透上面板后继续下降,蜂窝芯体被压缩为致密化。与20 J冲击能量相似,如图5(c)所示,平台区增韧试件的冲击力明显高于未增韧试件,两种能量下增韧层对夹芯板整体结构的增强方式相同。在冲击后期,冲头的剩余动能对未增韧试件下面板造成一定程度的损伤,冲击力曲线出现小幅度上升趋势。而对于增韧试件,由于在平台区Kevlar短纤维断裂消耗了一部分冲击能量,导致冲头未到达下面板,平台区过后冲击力持续下降到最小值。

当冲击能量为50 J时,如表1所示,冲头穿透上下面板及蜂窝芯体,图5(d)冲击力曲线出现“双峰”现象。该过程可以分为两个阶段:第一阶段为冲头穿透上面板并使中间芯体致密化的过程;第二阶段为冲头穿透下面板的过程。在第一阶段,冲头接触试件,冲击力不断上升直到达到最大值,此时上面板发生纤维断裂损伤。在冲头继续下降的过程中,随着试件刚度的减小,上面板发生穿透损伤,蜂窝芯体被压缩为致密化,在此过程中冲击力不断下降。对比第一阶段冲击力曲线可以发现,增韧与未增韧试件的冲击力相差不大,在冲头穿透上面板继续下降的过程中,虽然增韧层的破坏消耗了一部分动能,但由于蜂窝芯体刚度较弱,冲击曲线在下降过程中的差别并不明显。在第二阶段,冲头继续下降并作用于下面板,可以看出此时增韧试件的冲击力曲线明显低于未增韧试件,接触时间变长。增韧试件在下面板破坏过程中,上下两层Kevlar短纤维薄膜破坏所吸收的能量发生叠加,导致冲头动能大幅削减。

图6进一步分析了5组试件在不同冲击能量下的临界损伤阈值载荷(DTL),结果表明未增韧试件的DTL随着冲击能量的增大而不断提高,增韧试件的DTL在20 J、30 J、50 J冲击能量下相差不大,且明显高于10 J的DTL。在4种冲击能量下(10 J、20 J、30 J、50 J),与未增韧试件相比,增韧试件的DTL分别提高了14.69%、22.03%、2.57%、4.12%,可以看出增韧试件具有较高的冲击损伤阻抗能力,短纤维增韧可以有效抑制结构初始损伤的发生,从而提高试件的刚度[30]。综合分析数据可以发现,未增韧试件的临界损伤阈值载荷对冲击速度具有一定的敏感性,而增韧试件对速度的敏感性较小。

2.2 Kevlar短纤维界面增韧碳纤维/铝蜂窝夹芯板冲击后压缩实验结果

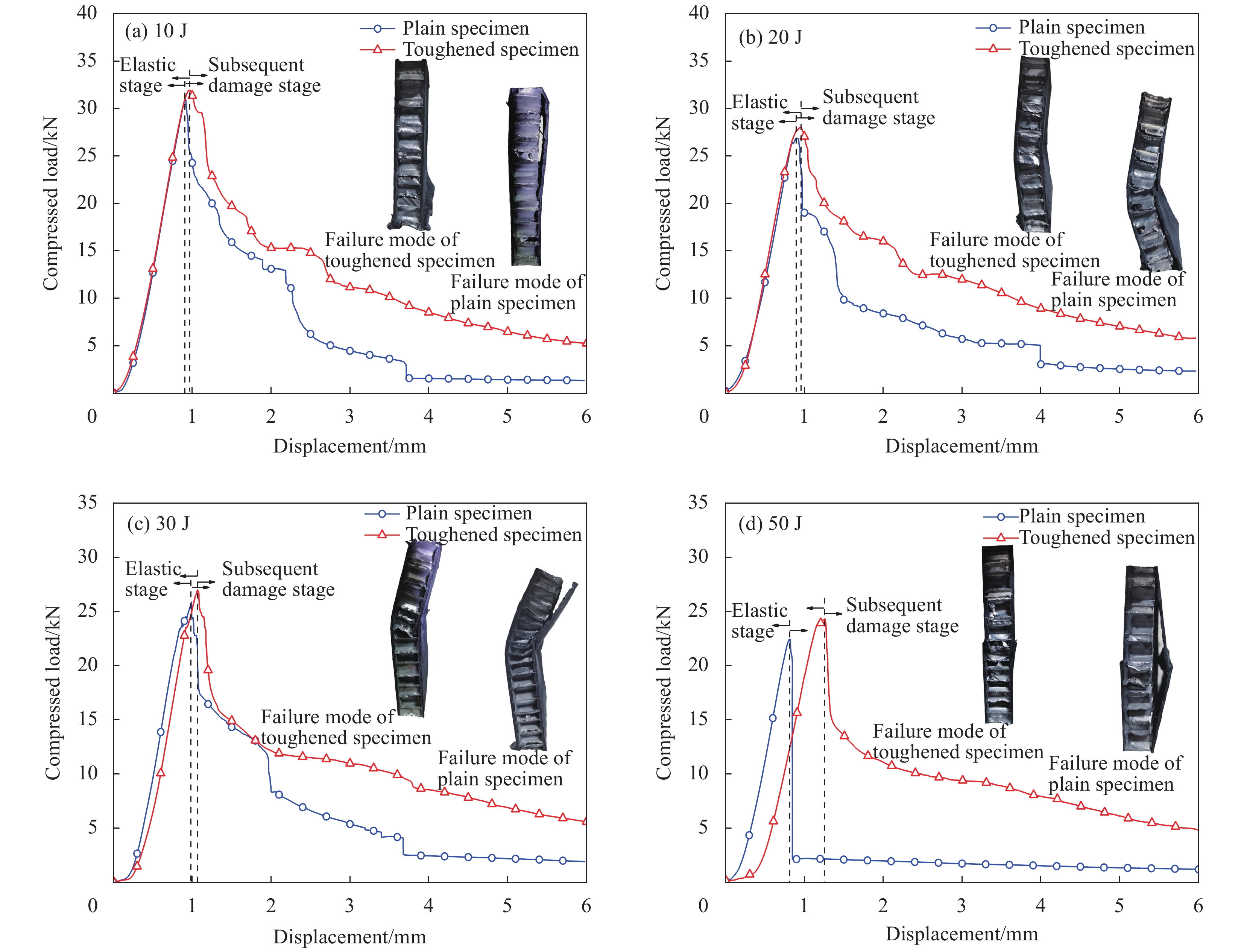

图7为4种不同能量冲击后压缩的典型位移-载荷曲线,曲线分为两个阶段,分别为弹性阶段与后继破坏阶段。如图7(a)所示,10 J能量冲击后压缩曲线在弹性阶段的力学响应趋势基本一致,增韧与未增韧试件的初始破坏模式均为端部剪切破坏,增韧试件的极限载荷高于未增韧试件。在后继破坏阶段,未增韧试件发生由剪切破坏处开始的界面脱粘,同时伴随着由冲击区域开始的损伤扩展。随着压缩位移的增加,增韧试件并未发生界面脱粘现象,而是沿高度方向被逐渐压溃,在压溃的过程中冲击区域发生裂纹扩展,但扩展速度较慢。

如图7(b)所示,20 J能量冲击后压缩过程中,增韧与未增韧试件在弹性阶段的力学响应趋势基本一致,但增韧试件的极限载荷值明显高于未增韧试件。观察压缩过程中试件的损伤变化,可以发现增韧与未增韧试件的初始破坏模式均为由冲击损伤区域开始的裂纹扩展。随着压缩位移的增加,未增韧试件在后继破坏阶段发生界面脱粘与端部剪切破坏,试件的承载能力大幅下降,直到面芯完全分离,夹芯板整体失稳。而增韧试件在后继破坏阶段出现整体屈曲现象,载荷-位移曲线下降较缓。当冲击能量为30 J时,如图7(c)所示,两组试件的破坏模式与20 J冲击能量相似,三种能量下(10 J、20 J、30 J)随着压缩位移的增加,未增韧试件的位移-载荷曲线均呈阶梯状下降,而增韧试件曲线较平滑,下降幅度较缓。

如图7(d)所示,50 J能量冲击后夹芯板被穿透,在压缩过程中,未增韧试件在极限载荷处面芯完全脱粘,整个试件的承载能力瞬间下降到最低。增韧试件在极限载荷处两侧面板沿冲击区域同时出现裂纹扩展,随着压缩位移的增加,夹芯板在后继破坏阶段出现整体屈曲现象,碳纤维面板侵入面-芯界面的Kevlar短纤维增韧层。

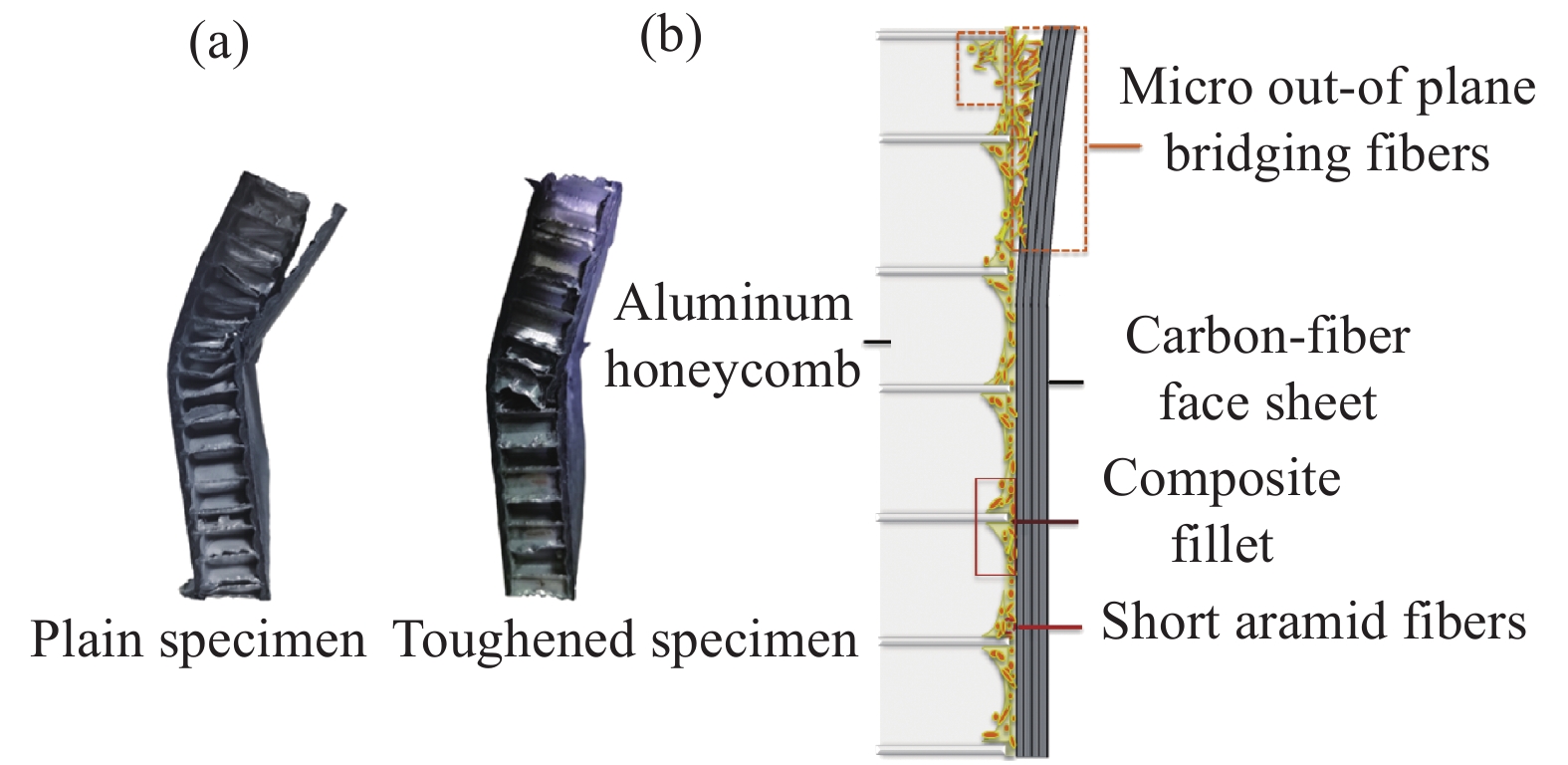

图8对比了不同冲击能量下5组数据的冲击后剩余压缩强度(CAI)值与能量吸收。可以看出,随着冲击能量的增大,增韧与未增韧试件的CAI值不断降低。同一冲击能量下,增韧试件的CAI值与能量吸收均高于未增韧试件。4种冲击能量下增韧试件比未增韧试件的CAI值分别提高了2.68%、9.24%、4.65%、11. 13%,能量吸收分别提高了69.09%、52. 88%、55.03%、101.70%。观察不同冲击能量下增韧与未增韧试件的CAI破坏模态,如图9所示,可以发现未增韧试件在极限载荷之后界面分层持续扩展。而增韧试件由于Kevlar短纤维的“桥联”作用及复合材料圆角增强结构的存在,有效抑制了碳纤维/铝蜂窝夹芯板界面脱粘现象及脱粘面积的扩展,减小界面分层破坏对结构强度造成的影响[25],从而提高试件的CAI极限载荷与后继破坏阶段的承载能力[31-32]。

![]() 图 9 碳纤维/铝蜂窝夹芯板CAI破坏模式及短纤维增韧示意图:(a) 30 J冲击能量下未增韧和增韧试件CAI破坏模态;(b) Kevlar短纤维界面增韧示意图[25]Figure 9. Schematic diagram of CAI failure mode of carbon fiber/aluminum honeycomb sandwich panel and sketch of the toughening effects: (a) CAI failure mode of carbon fiber/aluminum honeycomb sandwich panel with and without toughening under the impact energy of 30 J; (b) Sketch of the toughening effects with short Kevlar fibers[25]

图 9 碳纤维/铝蜂窝夹芯板CAI破坏模式及短纤维增韧示意图:(a) 30 J冲击能量下未增韧和增韧试件CAI破坏模态;(b) Kevlar短纤维界面增韧示意图[25]Figure 9. Schematic diagram of CAI failure mode of carbon fiber/aluminum honeycomb sandwich panel and sketch of the toughening effects: (a) CAI failure mode of carbon fiber/aluminum honeycomb sandwich panel with and without toughening under the impact energy of 30 J; (b) Sketch of the toughening effects with short Kevlar fibers[25]3. Kevlar短纤维界面增韧碳纤维/铝蜂窝夹芯板DIC结果与分析

在冲击后压缩过程中,对不同冲击能量的试件进行DIC观测,分别提取平均压缩应变

ε 为0.002、0.005、0.008时的工程应变εXX (X方向应变)、εYY (Y方向应变)、εXY (剪切应变)云图。表2为20 J能量冲击后压缩增韧与未增韧试件不同时刻的应变云图,其中εXX 与εYY 正数表示拉伸应变,负数表示压缩应变。观察表2中Y方向的压缩应变,第一阶段(ε =0.002)试件加载端局部应力集中,造成应变较大,其他区域均匀受压;第二阶段(ε =0.005)冲击区域出现损伤,局部压缩应变大于整体平均压缩应变;第三阶段(ε =0.008)损伤由冲击区域开始横向扩展,未增韧试件在冲击区域的应变约等于加载端应变,而增韧试件在冲击区域的应变明显小于加载端应变。观察表2中X方向应变,第一阶段(ε =0.002)和第二阶段(ε =0.005)增韧试件与未增韧试件应变云图差别不大;第三阶段(ε =0.008)未增韧试件在冲击区域的拉伸应变范围明显大于增韧试件,损伤中心左右对称处出现应变值为负的圆形区域,对应凹坑两侧的横向压缩。观察表2中剪切应变,第二阶段(ε =0.005)和第三阶段(ε =0.008)未增韧试件在冲击区域及其±45°方向剪切应变范围均明显大于增韧试件。表 2 Kevlar短纤维界面增韧与未增韧碳纤维/铝蜂窝夹芯板在20 J能量冲击后压缩过程中不同压缩应变对应的工程应变云图Table 2. Engineering strain nephograms of carbon-fiber/aluminum-honeycomb sandwich panels with and without short-Kevlar-fiber toughening at different compression strain under the impact energy of 20 JEngineering strain Plain specimen Toughened specimen ε =0.002 ε =0.005 ε =0.008 ε =0.002 ε =0.005 ε =0.008 εYY

εXX

εXY

Notes: ε—Average compression strain; εYY—Engineering strain in Y direction; εXX—Engineering strain in X direction; εXY—Shear strain. 图10提取了20 J冲击能量下沿X与Y方向的工程应变曲线,分析不同平均压缩应变(

ε =0.002、ε =0.005、ε =0.008)下增韧与未增韧试件在X与Y方向的工程应变。穿过面板损伤区域的中线分别为AB、CD。坐标轴建立在试件上,沿着面板中线由A到B提取X方向的工程应变,由C到D提取Y方向的工程应变。如图10(a)所示,AB段应变最大值出现在40 mm左右,对应云图中在凹坑处的X方向拉伸应变。30 mm和50 mm时应变为负值,对应云图中在凹坑两侧的X方向压缩应变。AB段其他点的应变相差不大,几乎为0。如图10(b)所示,在0~10 mm之间,Y方向应变值为负,对应压缩过程中试件的端部剪切破坏。在50 mm左右出现应变最小值,此时试件发生由损伤中心开始的裂纹扩展。由图10可以看出,随着平均压缩应变的增加,增韧试件在X与Y方向损伤区域的应变显著小于未增韧试件。当ε =0.008时,增韧试件在X与Y方向损伤区域的应变分别减小了38.87%、40.24%。由此得出碳纤维/铝蜂窝夹芯板面-芯界面处Kevlar短纤维薄膜的存在,有效抑制了试件在冲击后压缩过程中损伤的扩展,避免了结构的整体性能遭到严重破坏。4. 结 论

(1) 在夹芯板低速冲击过程中,Kevlar短纤维增韧可以提高试件的临界损伤阈值载荷。当冲头穿透上面板后,增韧层可以有效抑制冲头的下侵,从而提高夹芯板的冲击损伤阻抗。

(2) Kevlar短纤维界面增韧可以抑制碳纤维/铝蜂窝夹芯板的冲击损伤,但抑制效果较小;抑制冲击损伤的扩展效果显著。相比于未增韧试件,4种冲击能量下(10 J、20 J、30 J、50 J)增韧试件的冲击后剩余压缩强度(CAI)值分别提高了2.68%、9.24%、4.65%、11.13%,能量吸收分别提高了69.09%、52.88%、55.03%、101.70%。

(3) 对碳纤维/铝蜂窝夹芯板冲击后压缩过程的数字图像相关技术(DIC)观测,进一步验证了芳纶短纤维对界面的增韧效果,并揭示了增韧界面对结构的增强机制。DIC测量结果显示,Kevlar短纤维的加入可有效抑制试件在冲击后压缩过程中损伤的扩展,避免了结构整体性能遭到严重破坏。

-

图 9 碳纤维/铝蜂窝夹芯板CAI破坏模式及短纤维增韧示意图:(a) 30 J冲击能量下未增韧和增韧试件CAI破坏模态;(b) Kevlar短纤维界面增韧示意图[25]

Figure 9. Schematic diagram of CAI failure mode of carbon fiber/aluminum honeycomb sandwich panel and sketch of the toughening effects: (a) CAI failure mode of carbon fiber/aluminum honeycomb sandwich panel with and without toughening under the impact energy of 30 J; (b) Sketch of the toughening effects with short Kevlar fibers[25]

表 1 不同冲击能量下Kevlar短纤维界面增韧碳纤维/铝蜂窝夹芯板面板破坏形貌

Table 1 Failure morphologies of carbon-fiber/aluminum-honeycomb sandwich panel with short-Kevlar-fiber toughening under different impact energies

Impact energy/J 10 20 30 50 Top surface

Bottom surface

表 2 Kevlar短纤维界面增韧与未增韧碳纤维/铝蜂窝夹芯板在20 J能量冲击后压缩过程中不同压缩应变对应的工程应变云图

Table 2 Engineering strain nephograms of carbon-fiber/aluminum-honeycomb sandwich panels with and without short-Kevlar-fiber toughening at different compression strain under the impact energy of 20 J

Engineering strain Plain specimen Toughened specimen ε =0.002 ε =0.005 ε =0.008 ε =0.002 ε =0.005 ε =0.008 εYY

εXX

εXY

Notes: ε—Average compression strain; εYY—Engineering strain in Y direction; εXX—Engineering strain in X direction; εXY—Shear strain. -

[1] DAS T K, GHOSH P, DAS N C. Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: A review[J]. Advanced Composites and Hybrid Materials,2019,2(2):214-233. DOI: 10.1007/s42114-018-0072-z

[2] BIRMAN V, KARDOMATEAS G A. Review of current trends in research and applications of sandwich structures[J]. Composites Part B: Engineering,2018,142:221-240. DOI: 10.1016/j.compositesb.2018.01.027

[3] SHIN K B, LEE J Y, CHO S H. An experimental study of low-velocity impact responses of sandwich panels for Korean low floor bus[J]. Composite Structures,2008,84(3):228-240. DOI: 10.1016/j.compstruct.2007.08.002

[4] HE W T, LU S J, YI K, et al. Residual flexural properties of CFRP sandwich structures with aluminum honeycomb cores after low-velocity impact[J]. International Journal of Mechanical Sciences,2019,161:105026.

[5] YANG B, WANG Z Q, ZHOU L M, et al. Study on the low-velocity impact response and CAI behavior of foam-filled sandwich panels with hybrid facesheet[J]. Composite Structures,2015,132:1129-1140. DOI: 10.1016/j.compstruct.2015.07.058

[6] SUN X C, HALLETT S R. Failure mechanisms and damage evolution of laminated composites under compression after impact (CAI): Experimental and numerical study[J]. Composites Part A: Applied Science and Manufacturing,2018,104:41-59. DOI: 10.1016/j.compositesa.2017.10.026

[7] BHATTACHARYYA R, BASU P. Multiscale progressive damage analysis of CFRP composites using a mechanics based constitutive relation[J]. Composite Structures,2020,235:111759. DOI: 10.1016/j.compstruct.2019.111759

[8] ZHANG D H, JIANG D, FEI Q G, et al. Experimental and numerical investigation on indentation and energy absorption of a honeycomb sandwich panel under low-velocity impact[J]. Finite Elements in Analysis and Design,2016,117-118:21-30. DOI: 10.1016/j.finel.2016.04.003

[9] LIU J X, HE W T, XIE D, et al. The effect of impactor shape on the low-velocity impact behavior of hybrid corrugated core sandwich structures[J]. Composites Part B: Engineering,2017,111:315-331. DOI: 10.1016/j.compositesb.2016.11.060

[10] 齐佳旗, 段玥晨, 铁瑛, 等. 结构参数对CFRP蒙皮-铝蜂窝夹层板低速冲击性能的影响[J]. 复合材料学报, 2020, 37(6):1352-1363. QI Jiaqi, DUAN Yuechen, TIE Ying, et al. Effect of structural parameters on the low-velocity impact performance of aluminum honeycomb sandwich plate with CFRP face sheets[J]. Acta Materiae Compositae Sinica,2020,37(6):1352-1363(in Chinese).

[11] WANG J, WAAS A M, WANG H. Experimental and numeri-cal study on the low-velocity impact behavior of foam-core sandwich panels[J]. Composite Structures,2013,96:298-311. DOI: 10.1016/j.compstruct.2012.09.002

[12] WU Y H, LIU Q, FU J, et al. Dynamic crash responses of bio-inspired aluminum honeycomb sandwich structures with CFRP panels[J]. Composites Part B: Engineering,2017,121:122-133. DOI: 10.1016/j.compositesb.2017.03.030

[13] ZHANG X Y, XU F, ZHANG Y Y, et al. Experimental and numerical investigation on damage behavior of honeycomb sandwich panel subjected to low-velocity impact[J]. Composite Structures,2020,236:111882. DOI: 10.1016/j.compstruct.2020.111882

[14] YANG X F, XI X L, PAN Q F, et al. In-plane dynamic crushing of a novel circular-celled honeycomb nested with petal-shaped mesostructure[J]. Composite Structures,2019,226:111219. DOI: 10.1016/j.compstruct.2019.111219

[15] 张亚文, 陈秉智, 石姗姗, 等. 格栅-蜂窝混式芯体夹芯结构的低速冲击性能[J]. 复合材料学报, 2022, 39(1):386-394. ZHANG Yawen, CHEN Bingzhi, SHI Shanshan, et al. Low-velocity impact performance of grid-honeycomb hybrid core sandwich structure[J]. Acta Materiae Compositae Sinica,2022,39(1):386-394(in Chinese).

[16] ZHANG Y W, YAN L L, ZHANG C, et al. Low-velocity impact response of tube-reinforced honeycomb sandwich structure[J]. Thin-Walled Structures,2021,158:107188. DOI: 10.1016/j.tws.2020.107188

[17] 仲越, 徐铭涛, 王萍, 等. 碳纤维-超高分子量聚乙烯纤维混杂增强环氧树脂复合材料低速冲击性能及失效机制[J]. 复合材料学报, 2022, 39(7):3202-3211. ZHONG Yue, XU Mingtao, WANG Ping, et al. Low-velocity impact properties and failure mechanism of carbon fiber-UHMWPE fiber hybrid reinforced epoxy resin composites[J]. Acta Materiae Compositae Sinica,2022,39(7):3202-3211(in Chinese).

[18] JIANG H Y, CHENG F, HU Y S, et al. Micro-mechanics modeling of compressive strength and elastic modulus enhancements in unidirectional CFRP with aramid pulp micro/nano-fiber interlays[J]. Composites Science and Technology,2021,206(2):108664.

[19] SUN Z, CHEN H J, SONG Z W, et al. Three-point bending properties of carbon fiber/honeycomb sandwich panels with short-fiber tissue and carbon-fiber belt interfacial toughening at different loading rate[J]. Composites Part A: Applied Science and Manufacturing,2021,143(5):106289.

[20] 郑昊, 李岩, 涂昊昀. 短纤维插层碳纤维/环氧树脂复合材料层间性能研究[J]. 复合材料学报, 2022, 39(8):3674-3683. ZHENG Hao, LI Yan, TU Haoyun. Research on interlayer properties of short fiber intercalated carbon fiber/epoxy composites[J]. Acta Materiae Compositae Sinica,2022,39(8):3674-3683(in Chinese).

[21] YUAN B Y, YE M X, HU Y S, et al. Flexure and flexure-after-impact properties of carbon fibre composites interleaved with ultra-thin non-woven aramid fibre veils[J]. Compo-sites Part A: Applied Science and Manufacturing,2020,131:1-10.

[22] YUAN B Y, TAN B, HU Y S, et al. Improving impact resistance and residual compressive strength of carbon fibre composites using un-bonded non-woven short aramid fibre veil[J]. Composites Part A: Applied Science and Manufacturing,2019,121:105813.

[23] SUN Z, HU X Z, CHEN H R. Effects of aramid-fibre toughening on interfacial fracture toughness of epoxy adhesive joint between carbon-fibre face sheet and aluminium substrate[J]. International Journal of Adhesion and Adhesives,2014,48:288-294. DOI: 10.1016/j.ijadhadh.2013.09.023

[24] SUN Z, SHI S S, HU X Z, et al. Adhesive joints between carbon fiber and aluminum foam reinforced by surface-treated aramid fibers[J]. Polymer Composites,2015,36(1):192-197. DOI: 10.1002/pc.22929

[25] SHI S S, SUN Z, HU X Z, et al. Carbon-fiber and aluminum-honeycomb sandwich composites with and without Kevlar-fiber interfacial toughening[J]. Composites Part A: Applied Science and Manufacturing,2014,67:102-110. DOI: 10.1016/j.compositesa.2014.08.017

[26] 刘浩洋, 吕超雨, 石姗姗, 等. 芳纶纤维增韧碳纤维增强环氧树脂复合材料-铝蜂窝夹芯结构界面性能和增韧机制[J]. 复合材料学报, 2022, 39(2):567-575. LIU Haoyang, LV Chaoyu, SHI Shanshan, et al. Interfacial toughening and toughening mechanism of aramid staple fiber to carbon fiber/aluminum honeycomb sandwich structure[J]. Acta Materiae Compositae Sinica,2022,39(2):567-575(in Chinese).

[27] American Society for Testing and Materials. Standard test method for measuring the resistance of a fiber reinforced polymer matrix composite to a drop-weight impact event: ASTM D7136/D7136M-2015[S]. West Conshohockens: American Society for Testing and Materials International, 2015.

[28] SCHOEPPNER G A, ABRTE S. Delamination threshold loads for low velocity impact on composite laminates[J]. Composites Part A: Applied Science and Manufacturing, 2000, 31(9): 903-915.

[29] 屈天骄, 郑锡涛, 范献银, 等. 复合材料层合板低速冲击损伤影响因素分析[J]. 航空材料学报, 2011, 31(12):81-86. QU Tianjiao, ZHENG Xitao, FAN Xianyin, et al. Exploration of several influence factors of low-velocity impact damage on composite laminates[J]. Journal of Aeronauti-cal Materials,2011,31(12):81-86(in Chinese).

[30] 管清宇, 冯剑飞, 夏品奇, 等. 复合材料层压板低速冲击行为及剩余拉伸强度[J]. 北京航空航天大学学报, 2021, 47(6):1220-1232. GUAN Qingyu, FENG Jianfei, XIA Pinqi, et al. Low velocity impact behavior and residual tensile strength of compo-site laminates[J]. Journal of Beijing University of Aeronautics and Astronautics,2021,47(6):1220-1232(in Chinese).

[31] SUN Z, JEYARAMAN J, SUN S Y, et al. Carbon-fiber aluminum-foam sandwich with short aramid-fiber interfacial toughening[J]. Composites Part A: Applied Science and Manufacturing,2012,43(11):2059-2064. DOI: 10.1016/j.compositesa.2012.06.002

[32] 石姗姗, 陈秉智, 陈浩然, 等. Kevlar短纤维增韧碳纤维/铝蜂窝夹芯板三点弯曲与面内压缩性能[J]. 复合材料学报, 2017, 34(9):1953-1959. SHI Shanshan, CHEN Bingzhi, CHEN Haoran, et al. Three-point bending and in-plane compression properties of carbon-fiber/aluminum honeycomb sandwich panels with short-Kevlar-fiber toughening[J]. Acta Materiae Compositae Sinica,2017,34(9):1953-1959(in Chinese).

-

期刊类型引用(2)

1. 田楠,卢政斌,李闻达,吕秀雷,韦宁. 聚酯无纺布增强复合材料夹层结构的抗低速冲击性能. 纤维复合材料. 2025(01): 57-61 .  百度学术

百度学术

2. 吕航宇,陈秉智,周鑫,石姗姗. 碳纤维/格栅增强蜂窝夹芯结构抗冲击性能试验与车体顶棚仿真. 工程力学. 2023(12): 234-244 .  百度学术

百度学术

其他类型引用(7)

-

下载:

下载: