Effect of drilling delamination on compressive mechanical behaviour of open-hole laminates

-

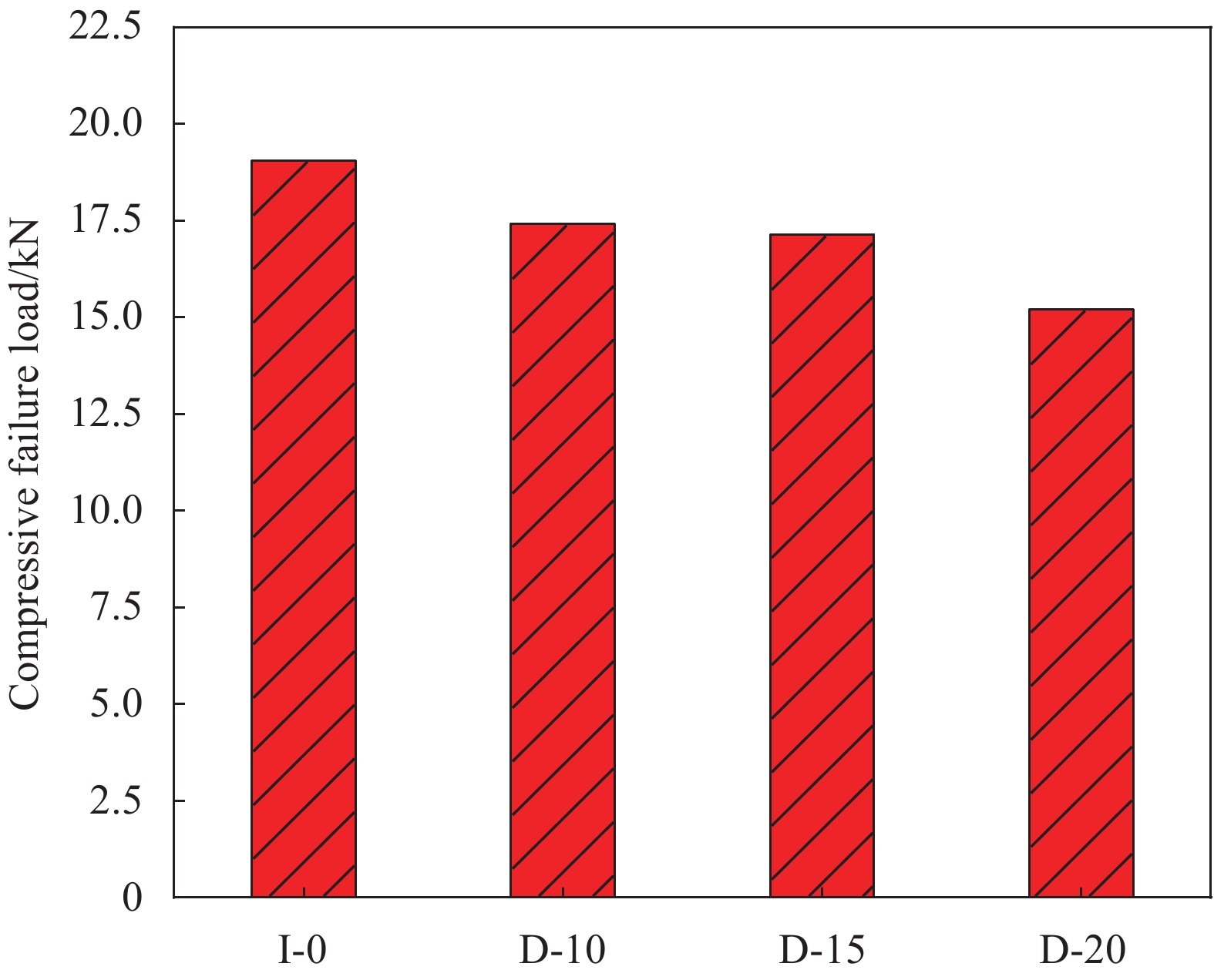

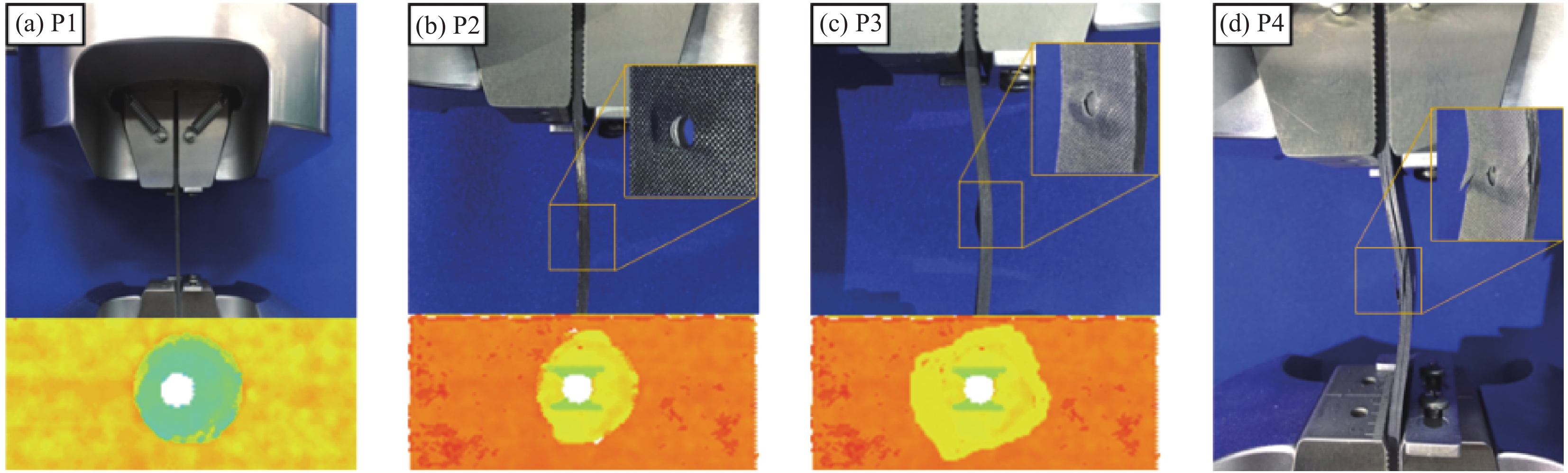

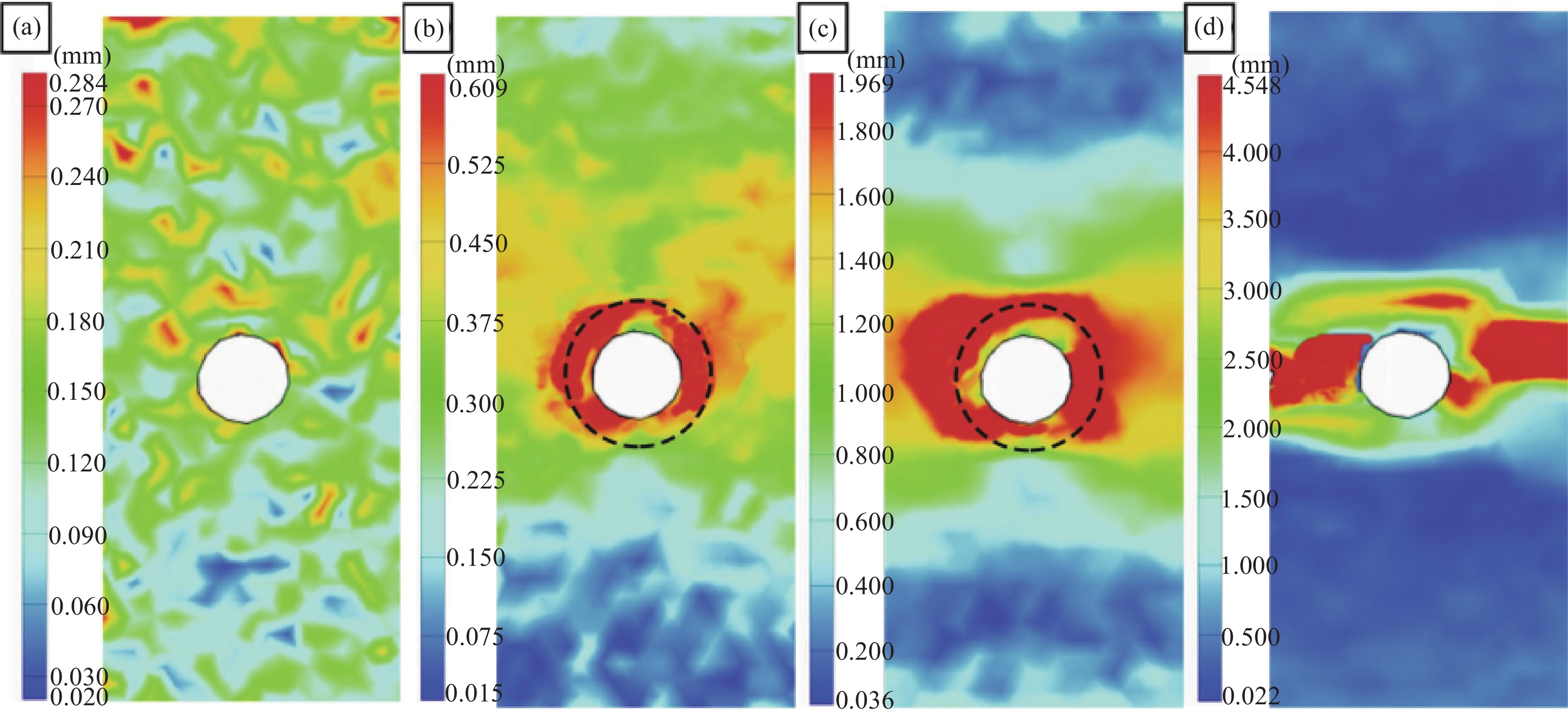

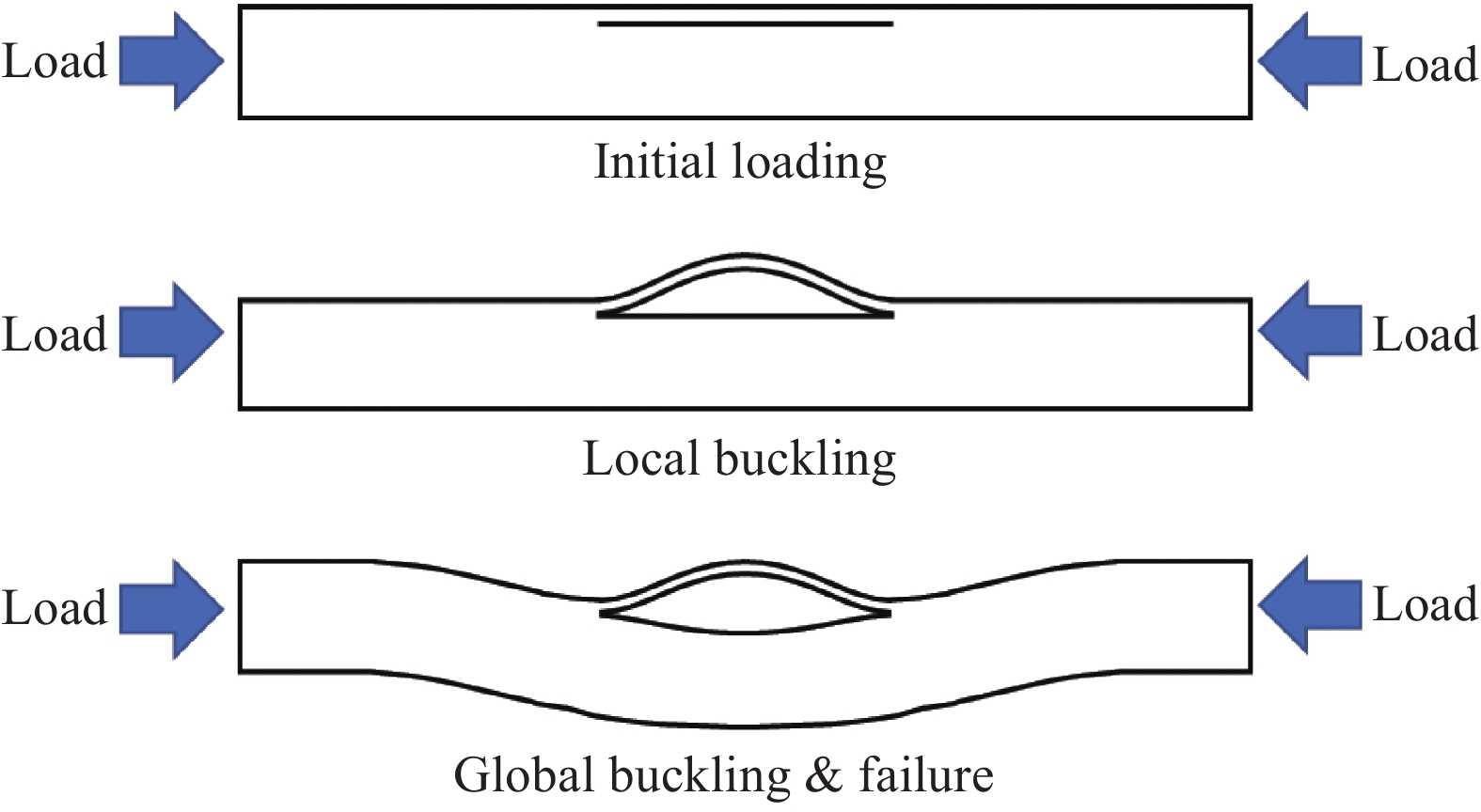

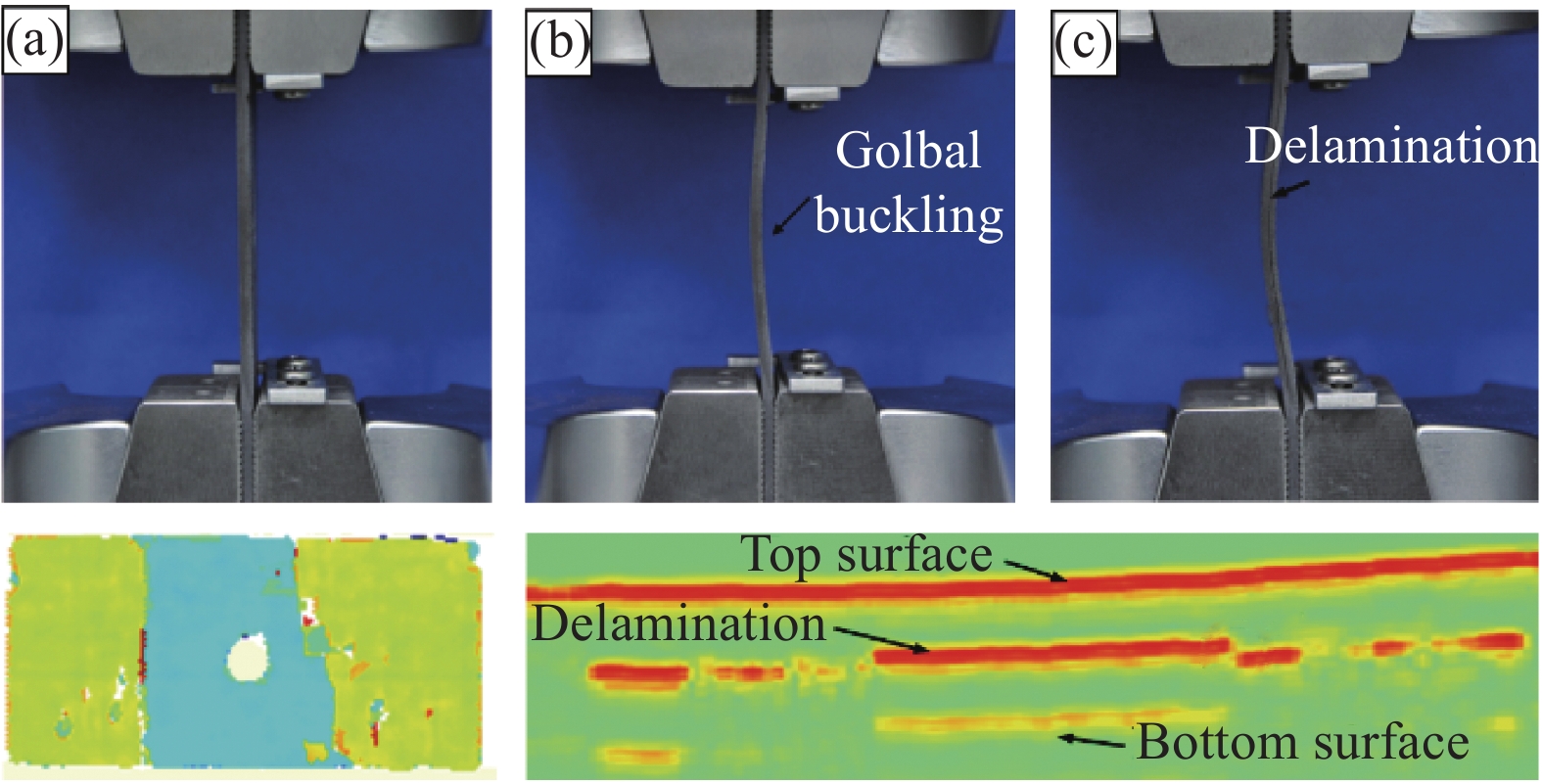

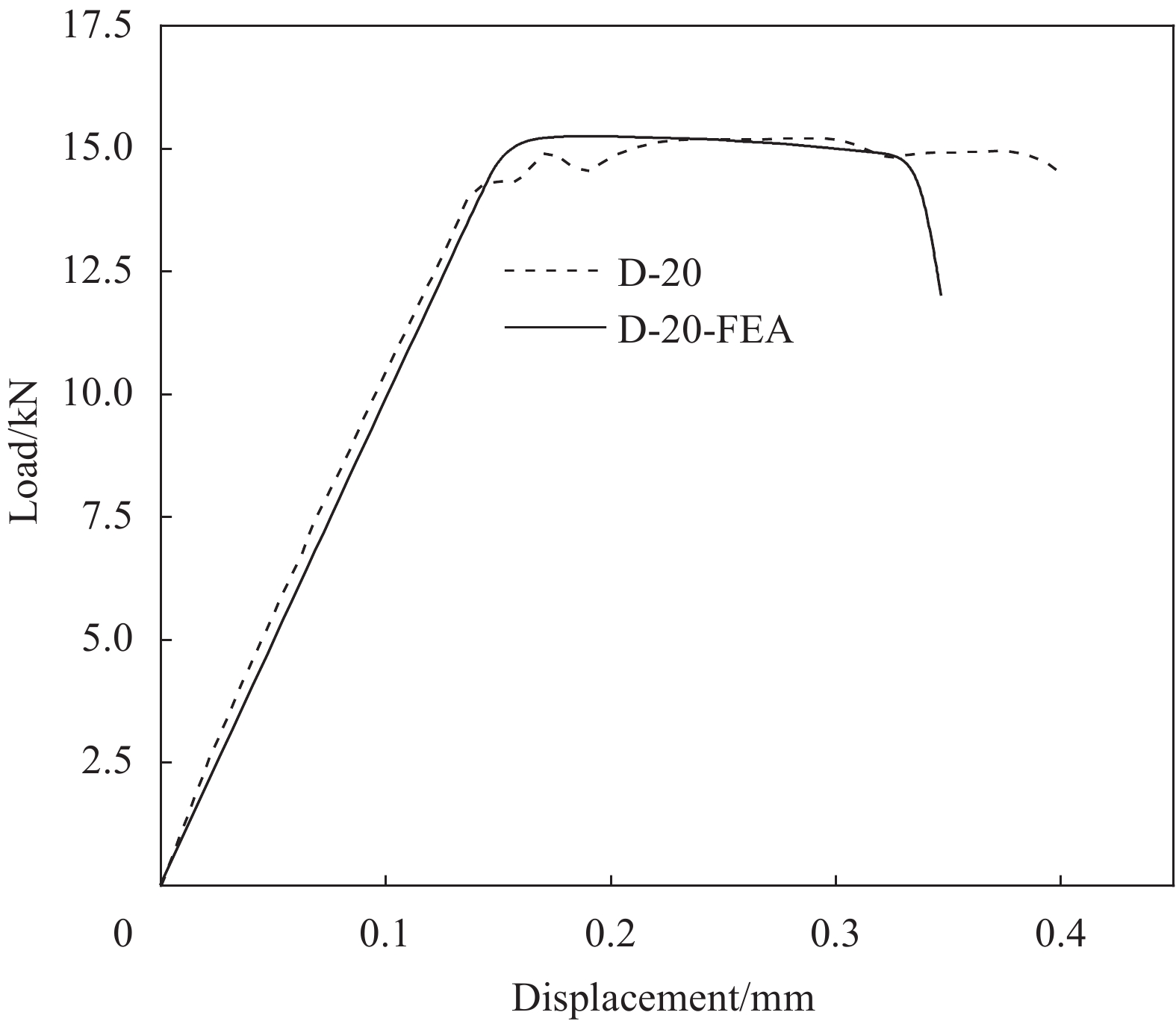

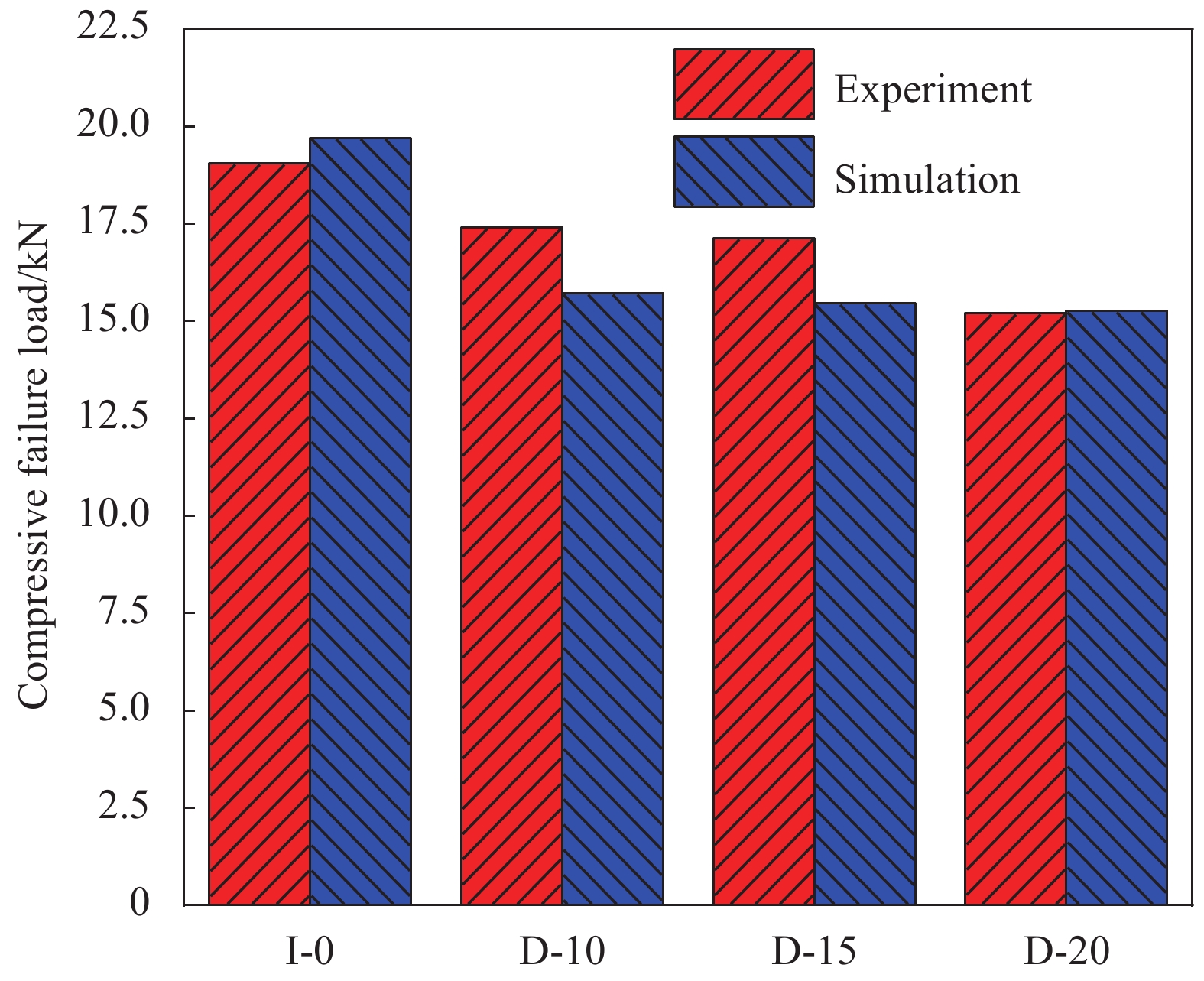

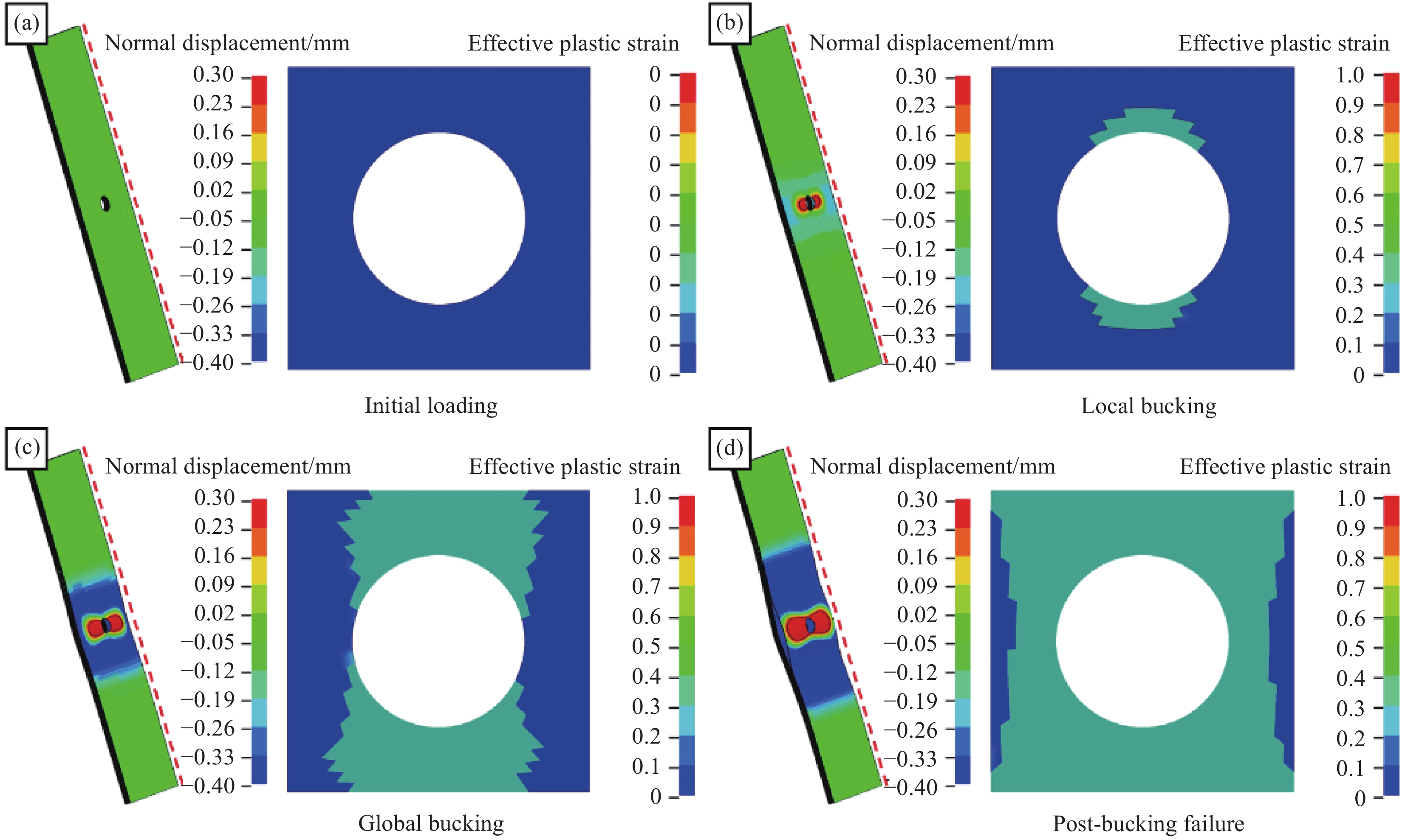

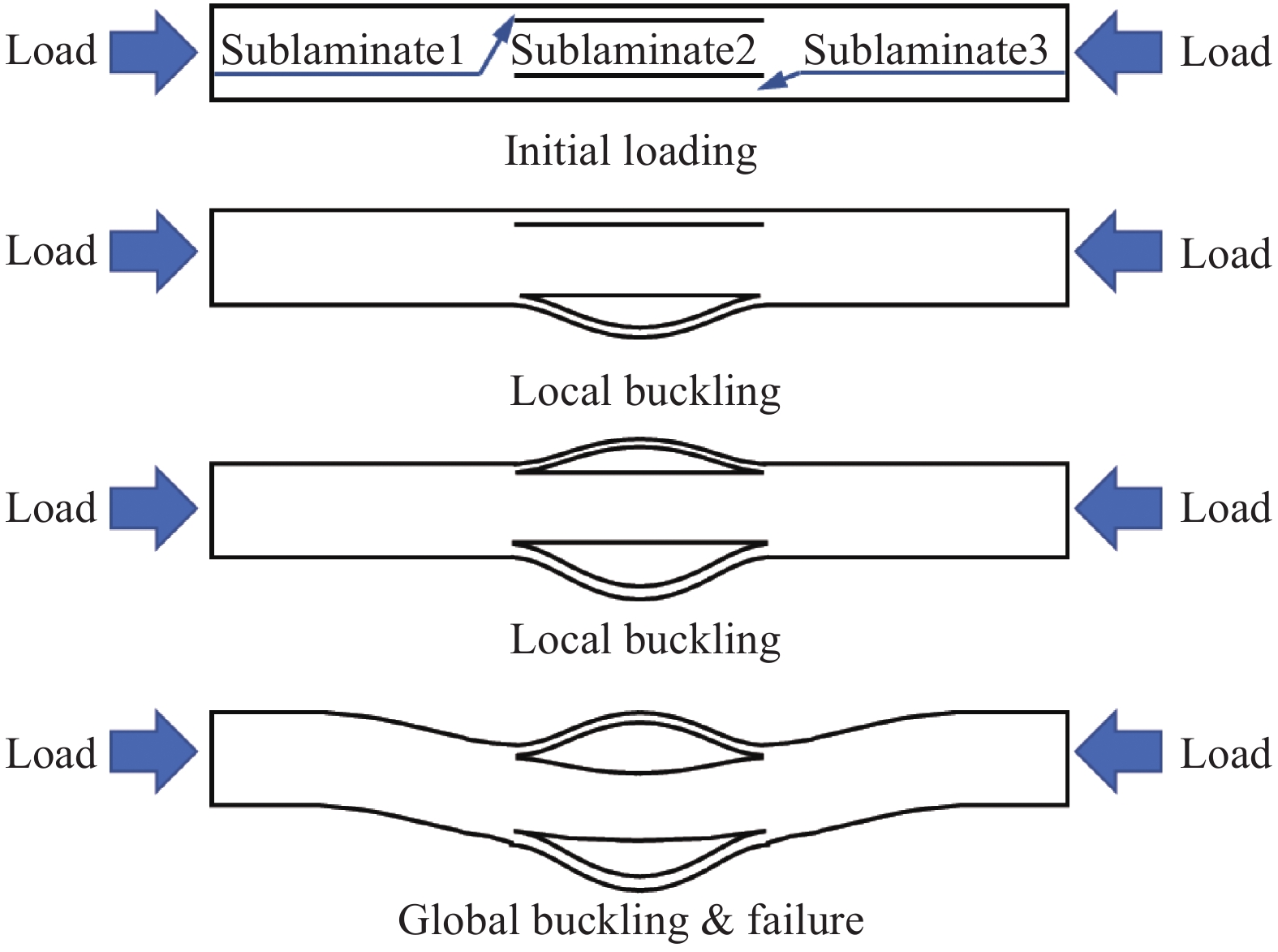

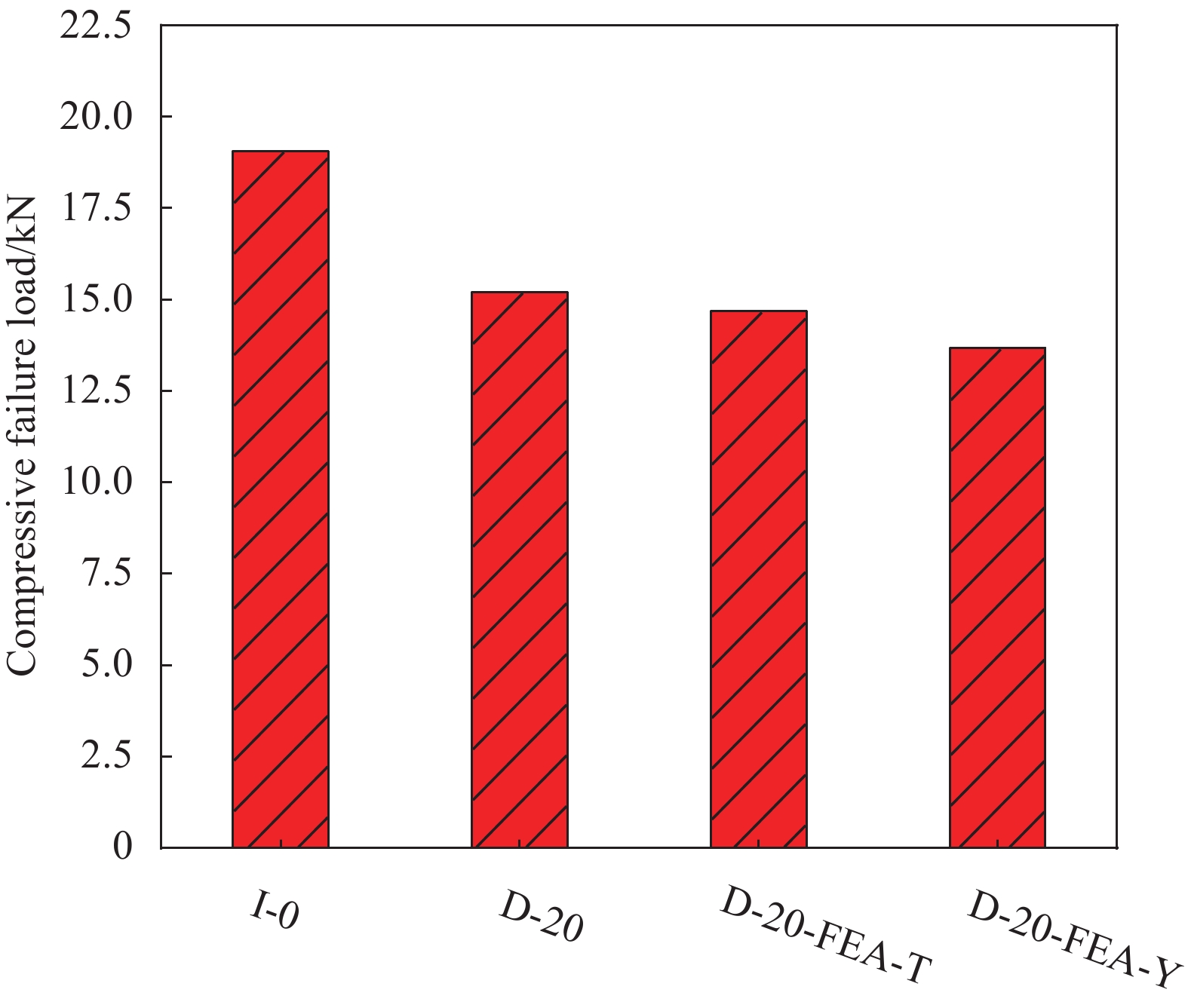

摘要: 钻孔分层损伤对复合材料层合孔板的承载能力和失效模式有着显著的影响。通过实验和仿真相结合的方式,开展单一预制分层缺陷下、双分层缺陷同侧耦合及双分层缺陷异侧耦合作用下复合材料层合孔板的压缩承载能力及失效模式的研究。通过预埋聚四氟乙烯薄膜,制备了含单一圆形预制分层缺陷的碳纤维增强树脂复合材料开孔板试件,采用浸没式超声C扫和数字图像DIC技术分别对复合材料层合板损伤和法向变形进行检测,研究含不同尺寸预制分层开孔层合板在压缩载荷下的分层扩展及失效变形特征,进而揭示分层缺陷大小对其承载能力的影响机制。构建基于内聚力单元方法的含孔复合材料层合板数值模型,对比实验修正模型,探索了单一预制分层缺陷下碳纤维增强树脂复合材料开孔板的损伤扩展机制,并在此模型基础上开展双分层缺陷耦合作用下复合材料开孔板在压缩载荷作用下的屈曲变形、分层扩展和承载能力的数值预测和分析。实验结果表明:含单一圆形预制分层缺陷的碳纤维增强环氧树脂复合材料开孔层合板试件呈现出初始受压、局部屈曲、整体屈曲后破坏的失效模式,预制分层缺陷对复合材料孔板压缩力学性能有显著影响,随着缺陷的增大压缩承载能力逐渐下降。双分层缺陷耦合作用数值分析表明:双分层缺陷进一步降低了复合材料孔板压缩承载能力,同侧非对称耦合分层缺陷结构的失效模式与单一缺陷结构基本一致,而异侧非对称耦合分层缺陷结构出现了双裂纹扩展,该裂纹扩展模式进一步削弱了孔板的压缩承载能力。Abstract: The delamination damage has significant influence on the bearing capacity and failure mode of open-hole laminates. By combining experiment and simulation, the compression bearing capacity and failure mode of composite open-hole laminates with single prefabricated laminated defects, two laminated coupling defects on the same side and double laminated coupling defects on the different side were studied. Through the embedded polytetrafluoroethylene (PTFE) membrane, the open-hole laminate containing single prefabricated delamination defects was prepared. By means of immersion ultrasonic C scan and digital image DIC technique, the damage evolution and normal deformation were characterized and monitored. The delamination propagation behavior and failure deformation characteristics of laminates with various defect sizes under compression loading were studied, and the influence mechanism of the size of the delamination defects on the bearing capacity of the laminates was revealed. A numerical model of open-hole laminate was established based on the cohesion element method. The damage propagation mechanism of open-hoe laminate with single prefabricated laminated defects was explored. Based on the optimized model, the numerical prediction and analysis of the buckling deformation, delamination expansion and bearing capacity of the open-hole laminate with two delaminated coupling defects were carried out. The experimental results show that the specimen with single delamination defect presents the initial compression, local buckling and overall buckling. The delamination size has significant impact on the compressive capability, which decreases with the increasing of delamination size. The numerical results of two delaminated defects show the second delaminated defect further reduces the compressive bearing capacity. The failure model of laminate with two coupling defects on the same sides is similar with that of laminates with single prefabricated defect; while, double-crack propagation occurs in the asymmetrical coupled laminated structure on the opposite side, which further weakens the compression bearing capacity of open-hole laminates.

-

分离过程在工业生产中占据重要地位,是化学工业的基础,传统的分离技术,如精馏、蒸发等需要消耗大量能源,占到工业总能耗的40%~70%[1]。新兴的膜分离技术由于具有低能耗、占地面积小、分离精度高、无二次污染等优势被认为是替代传统分离技术的新秀。膜材料是膜技术的核心,目前已经成功商业化的大多是有机聚合物膜,但其有渗透率-选择性权衡的限制及适用环境有限等问题。为了解决这一问题,开发和探索了碳分子筛、陶瓷及各种纳米材料及其与聚合物的复合膜[2]。完美的膜结构和高性能的膜材料一直是膜分离技术研究的核心,膜材料的结构组成和理化性质将直接影响膜分离技术的效率和经济性[3]。

近几年来,随着现代膜分离技术的不断发展,涌现出大批优异的膜材料,其中有众多纳米材料被开发出来应用于膜分离中,如氧化石墨烯(GO)[4-5]、二维氮化碳(g-C3N4)[6-7]、二维金属有机框架(MOFs)[8]、沸石分子筛(Zeolites)[9]、二维过渡金属硫化物(TMDs)[10]、二维氮化硼(BN)[11]和二维过渡金属碳/氮化物(MXene)[12]等。由于MXene具有类石墨烯结构,且具有出色的亲水性、柔韧性、热稳定性、抗菌性和丰富的表面末端基团(—OH、—O和—F等)等特性,推动了其在膜分离领域的开发和研究。

近年来,MXene纳滤膜取得了一系列重要进展,一些研究人员采用不同的纳米材料与MXene复合,调控层状结构的间距和排列方式,可以有效地提高复合膜的通量和分离效率[13-15]。此外,为了提升MXene复合纳滤膜的抗污染能力,研究人员通过表面改性、添加功能化纳米材料或设计新型支撑材料等方法,可以有效地减少污染物对复合膜的附着和堵塞,从而延长其使用寿命并提高稳定性[16-18]。虽然近年来已有许多综述聚焦于MXene基分离膜,但本文侧重描述MXene层状纳滤膜在纳滤领域的应用,特别强调了关于MXene层状复合纳滤膜的设计策略,同时还对其分离机制和在海水淡化、废水处理等领域应用的最新研究进展进行了总结(图1)。本文归纳总结了MXene层状复合纳滤膜面临的挑战,并概述了未来的发展方向,旨在有助于设计出高质量的MXene层状纳滤膜。

1. MXene材料

如图2所示,MXene材料的化学通式可以表示为Mn+1XnTx(n=1、2、3),M代表过渡金属,X代表碳或氮,T则代表其表面附着的活性基团(如—OH、—O和—F等)。另外,根据原子层数量和排列方式的不同,MXene可以分为M2XTx、M3X2Tx和M4X3Tx,分别对应3、5和7层原子层排列结构,例如Ti2CTx、Ti3C2Tx和Ti4N3Tx[19]。到目前为止已经报道了超过30个种类的MXene。其中研究最多的是Ti3C2Tx和Ti2CTx。通过选择不同的MAX (三元层状陶瓷材料)前驱体刻蚀及不同的刻蚀方法,能够制备出理化性质不同的MXene,从而构建出具有不同性能的膜[20]。

2. MXene层状纳滤膜的分类

作为二维材料中的一员,MXene材料被广泛应用于构筑高性能的分离膜。当前MXene纳滤膜的研究主要聚焦在MXene层状膜上,一般是通过真空或压力辅助过滤制备而成,其是MXene纳滤膜中研究最多的膜类型[20]。MXene层状膜是由相邻MXene纳米片堆叠而成,片层间的纳米级通道提供传质分离途径。因此,构建高度规则、致密且稳定的层间纳米通道是制备出高渗透选择性的MXene层状膜的前提[21]。MXene层状膜的类别主要可分为:(1)单一组分MXene层状纳滤膜;(2) MXene层状复合纳滤膜。复合方式一般是通过有机分子交联、不同维度纳米材料插层等方法制备出高渗透选择性的MXene层状膜。

2.1 单一组分MXene层状纳滤膜

单一组分MXene层状纳滤膜由MXene材料堆叠构建而成,常用于分离小分子有机物和离子。Han等[22]在聚醚砜(PES)超滤膜上通过简单的真空过滤方法制备出MXene层状膜,其具有115 L·m−2·h−1·bar−1的渗透通量和对刚果红(CR)染料达92.3%的截留率。Li等[23]报道了一种由高横向尺寸的MXene纳米片(2~4 μm)组装的MXene层状膜,表现出优异的抗生素截留性能,其渗透通量比大多数具有类似抗生素分离作用的聚合物纳滤膜至少高一个数量级。Xiang等[24]通过控制离心的转速和时间,得到不同横向尺寸的MXene纳米片。由此制备出的不同横向尺寸的MXene层状膜在亚甲基蓝(MeB)染料的截留实验中显示,纳米片的横向尺寸越大,制备出的MXene膜的截留效果也越好。这些研究都证实了制备得到的MXene纳米片的横向尺寸对MXene层状膜分离性能的巨大影响,为高性能的MXene层状膜的设计提供了新的思路。由于MXene纳米片表面存在丰富的羟基,相邻纳米片之间的静电相互作用会导致纳米片无序堆叠,从而形成无序的层间纳米通道,影响膜的分离性能[21]。针对这一问题,Sun等[25]成功开发了一种厚度~100 nm的超薄MXene衍生膜,通过煅烧使MXene膜层内发生自交联去官能团化(—OH)反应,以此来提高MXene膜的分离性能。其中采用400℃的煅烧温度制备出的MXene-T400膜,对Na2SO4的最大脱盐率为75.9%,相应的渗透通量达3.5 L·m−2·h−1·bar−1。这种简单的加热自交联去官能团化(—OH)的方法是提高MXene层状膜选择性的有效策略。

2.2 MXene层状复合纳滤膜

单一组分MXene层状纳滤膜存在纳米片堆叠严重及不规则的层间纳米通道等问题,为进一步提升膜的渗透选择性,研究人员利用MXene膜的可扩展性和可调性,在相邻的MXene纳米片之间嵌入不同尺寸的物质,如诸多有机分子[26-28]、零维颗粒[29-30]、一维纳米材料[31-34]和二维纳米材料[35-37]。这些层间复合材料的类型、尺寸、形貌对复合膜的形貌、孔隙率和机械强度等特性起着重要的作用[38]。因此,深入了解层间复合材料的物化性质对制备高渗透选择性的复合膜有重要意义。

2.2.1 层间有机分子交联

如图3(a)所示,Luo等[26]使用4种氨基酸(甘氨酸(Gly)、L-半胱氨酸(L-Cys)、L-谷氨酸(L-Glu)、L-赖氨酸(L-Lys))与MXene交联,其中由甘氨酸交联制备出Gly-3@MX-3膜表现出较高的盐截留性能和渗透通量,其对Na2SO4的截留率达到86.28%,相应的渗透通量为7.5 L·m−2·h−1·bar−1。Tao等[27]使用MXene纳米片与羧甲基-β-环糊精分子交联,通过真空过滤的方法,制备出的MXene膜具有超过366 L·m−2·h−1·bar−1的水渗透通量和对亚甲基蓝(MeB)、碱性红2 (BR2)、龙胆紫(CV)、罗丹明B (RhB)和甲基蓝(MB)染料超过97%的截留率。Zhang等[28]通过将MXene纳米片和带正电的聚乙烯亚胺(PEI)有机大分子交联,制备出MXene-PEI层状膜(图3(b)),其具有137.77 L·m−2·h−1·bar−1的渗透通量和对刚果红(CR)染料高达99%的截留率。由此可见,将MXene纳米片与一些有机分子进行交联反应,能制备出具有高通量和优异截留效果的MXene复合纳滤膜。

2.2.2 零维层间复合材料

零维层间复合材料通常以零维纳米颗粒形式存在,零维颗粒的插层能有效扩展和稳定MXene层状膜的层间纳米通道,增强传质,提高膜的渗透性和选择性。Pandey等[29]利用MXene纳米片的还原性,将AgNO3溶液与MXene纳米片混合,成功地将Ag+离子还原成Ag零维颗粒并附着在MXene纳米片的层间,通过真空过滤制备出Ag@MXene膜。该膜表现出对甲基绿(MG)染料达92.32%的截留率及相应的354.29 L·m−2·h−1·bar−1的优异渗透通量。此外该膜还兼具优异的抗菌性能。Long等[30]使用带正电荷的Al2O3零维颗粒,通过静电相互作用,插层在MXene膜的层间,如图4(a)所示。其中MXene与Al2O3零维颗粒质量比为1∶1的MXene/Al2O3复合膜表现出88.8 L·m−2·h−1·bar−1的优异渗透通量和对罗丹明B (RhB)染料高达99.8%的截留率。因此,零维颗粒的插层是一种制备高性能的MXene层状膜的有效途径。

2.2.3 一维层间复合材料

一维纳米材料以纤维结构为特征,其内壁的长度与直径比呈现独特的特点。将这些一维纳米材料引入MXene膜中能有效阻止MXene纳米片之间的团聚现象并扩大层间距。尤其是一维碳纳米管具有独特的机械强度、出色的柔韧性,最重要的是,其密闭的传质通道允许水分子快速流动,从而能制备出高性能的MXene复合膜。Ding等[31]报道了一种由一维碳纳米管(CNTs)嵌入MXene膜层间,形成具有新型梭形通道的CNTs-MXene层状膜,表现出高的染料分子截留和超高的水渗透性。其对龙胆紫(CV)和玫瑰红(RB)染料的截留率分别为100%和97.3%,同时表现出优异的渗透通量,约为

1270 L·m−2·h−1·bar−1。同时在水溶液中浸泡30 h后仍保持出色的分离性能,表现出良好的稳定性。如图4(b)所示,Sun等[32]报道了一种在MXene膜层间嵌入一维碳纳米管(CNTs),并通过真空过滤的方法在聚多巴胺(PDA)改性的Al2O3膜上制备出初始的MXene-CNT膜(PMCNM),随后通过热交联反应制备出MXene-CNT膜(MCNM)。该膜在错流过滤下对刚果红(CR)染料的截留率高达100%,相应的渗透通量为10.8 L·m−2·h−1·bar−1,且在50 h的错流过滤过程中表现出良好的稳定性。此外,Zhang等[33]也报道了一种由一维凹凸棒嵌入MXene膜层间的凹凸棒/MXene层状膜,在死端过滤下对亚甲基蓝(MeB)染料的截留率达90.67%,相应的水的渗透通量为46.51 L·m−2·h−1·bar−1。2.2.4 二维层间复合材料

二维纳米材料因其表面积大、出色的机械强度和柔韧性及通过表面功能化可改变的众多表面位点而备受关注。以氧化石墨烯(GO)为代表的二维材料已被广泛用于分离膜制备[34]。将二维纳米材料(如GO)与MXene纳米片进行复合,不仅能有效地调控MXene膜的层间距,而且可发挥出两种二维材料的不同优势,从而制备出具有优异选择性和渗透性的MXene层状膜。Liu等[35]将一定质量比的GO纳米片和MXene纳米片混合均匀,通过真空过滤的方式制备出GO/MXene层状膜,其中GO与MXene质量比为1∶4的GO/MXene膜表现出对亚甲基蓝(MeB)和龙胆紫(CV)染料接近100%的截留率,同时具有71.9 L·m−2·h−1·bar−1的优异水渗透通量,是纯GO膜的10倍。Gong等[37]通过静电自组装制备了不同比例的MXene/共价有机框架材料(COF)复合膜。其中COF与MXene质量比为1∶4的复合膜在甲基绿(MG)、乙基紫(EVT)、碱性品红(FB)、龙胆紫(CV)和亚甲基蓝(MeB)溶液中的渗透通量分别为217.6、185.3、203.9、169.3和190.7 L·m−2·h−1·bar−1,其对应截留率分别为99.7%、100%、100%、99.3%和99.8%。Wang等[37]通过将MoS2纳米片与使用木质素磺酸钠修饰的MXene纳米片进行复合,制备出的复合膜对刚果红(CR)和罗丹明B (RhB)染料的截留率分别为93%和99%。

目前将纳米材料与MXene材料复合,其层间中的位置都是随机的,通过功能化改性和膜制备方法调控,可控制纳米片分布的位置,实现层间有序排列。如图4(c)所示,本课题组通过使用乙酸铵(AA)修饰后的MXene (AA-Ti3C2Tx)与氧化石墨烯复合,通过慢速沉积法制备出了高渗透选择性的GO/AA-Ti3C2Tx复合纳滤膜[39]。在慢速沉积过程中,AA-Ti3C2Tx在GO层间能规则排列,形成有序的纳米孔道。该膜在错流过滤下对刚果红(CR)染料有着高达99.1%的截留率,与之相对应的水渗透通量为115.5 L·m−2·h−1·bar−1。此外对于其他的染料,如活性艳红(X-3 B)、甲基蓝(MB)和伊文思蓝(EB)等染料的截留率分别达到84.7%、99.2%和99.9%。

本节讨论了几种关于MXene层状膜的设计策略,通过自交联、有机分子交联及不同维度纳米材料插层等方法来设计和调控MXene层状膜的传输通道。尽管制备和精确控制层间复合材料的尺寸仍然具有挑战性,但是通过优化层间复合纳米材料的尺寸参数,可有效提升复合膜的传质效率。

3. MXene层状纳滤膜的分离机制

目前,关于MXene层状纳滤膜的分离机制大致分为3种:(1)孔径筛分;(2)静电排斥;(3)吸附作用,如图5所示。

3.1 孔径筛分

MXene层状纳滤膜的显著特征之一就是由高纵横比MXene纳米片构建的层间纳米通道,这些纳米通道是由纳米片之间的内部间距及纳米片边缘之间的空隙形成[20]。孔径筛分是指制备出的膜在过滤的过程中可以截留比膜内层间纳米通道尺寸大的物质(如染料、盐等),而尺寸较小的物质(如水)则能从膜内渗透出去[40-41]。Sun等[25]通过在不同的煅烧温度下,制备出有着不同层间间距的MXene膜。实验结果显示,随着膜的层间间距变小,膜对盐的截留率也随之提高。表明了孔径筛分在MXene纳滤膜的分离过程中起到至关重要的作用。

3.2 静电排斥

由于MXene纳米片自身具有强负电荷的特性,因此可以通过Donnan效应实现对带电离子和染料的有效分离,具体来说,就是与MXene膜具有相同电荷的离子通过静电相互作用被膜排斥,同时为了保持溶液的电中性,具有相反电荷的离子也会被阻拦在膜的表面[38]。Zhang等[42]将聚丙烯酸(PAA)有机大分子与MXene纳米片交联,通过真空过滤的方法制备出PAA/MXene膜,测得PAA/MXene膜带负电荷。其实验结果显示,该膜对带负电的刚果红(CR)染料的截留率达95%,而对中性分子的截留却不理想,表明静电排斥作用对其选择性的影响。因此静电排斥对提高MXene纳滤膜的选择性起到重要的作用。

3.3 吸附作用

由于MXene材料具有高比表面积、可调的表面化学性质、独特的层状结构和表面丰富的官能团等特性,因此MXene材料被认为是很有前途的吸附剂。因此在过滤过程中,溶液中的重金属、染料等溶质在经过MXene纳滤膜层间时也会被其表面官能团吸附从而达到良好的去除效果[43]。

4. MXene层状纳滤膜的抗溶胀策略

MXene纳米片已经被证实了能够构建出具有高截留和高通量的纳滤膜。然而,MXene层状膜在过滤的过程中会吸收大量水分子,导致膜的层间距增加,即类似于石墨烯膜的溶胀问题[38]。这种膜溶胀的问题会导致层间距离增加,膜分离性能下降。目前,针对这一问题,能通过自交联、有机分子交联及不同维度纳米材料插层等方法,来稳定MXene膜在过滤过程中的层间距,从而避免溶胀问题并保持稳定的分离性能[44]。Sun等[25]使用自交联的方法制备MXene膜,其中在400℃下制备出的MXene膜能有效地将层间距控制在0.268 nm,并在长达100 h的错流过滤下中仍保持优异的分离性能且不会产生缺陷,显示出优异的抗溶胀性能。如图6(a)所示,Zhang等[45]将葫芦[5]脲与MXene纳米片铆接,以此来稳定和控制MXene膜的层间距,制备出的MXene层状膜在干湿状态下层间距的变化在0.05 nm左右,同时该膜在30个循环过滤中仍保持稳定的分离性能,显示出优异的抗溶胀性和可重复使用性。如图6(b)所示,Zhang等[46]通过插入一维的羧化纤维素纳米纤维(CNFs)来有效的稳定MXene膜的层间结构,并使用真空过滤的方法在聚醚砜(PES)膜上沉积以制备出MXene纳滤(NF)膜,其在干态下的层间距为0.4 nm,而在湿态下层间距为0.47 nm,仅变化0.07 nm,远远低于单一MXene膜的层间距在干湿状态下0.29 nm的变化幅度,同时该膜在长达76 h的错流过滤中,水渗透通量和染料截留率都没有明显变化,显示出其优秀的稳定性和抗溶胀性能。Sun等[32]通过自交联反应制备出MXene-CNT膜,其在干湿状态下的层间距变化在0.13 nm左右,同时在50 h的长期错流过滤中仍保持优异的渗透选择性,表现出优异的抗溶胀性,这种一维纳米材料复合和热交联的共同使用策略,为开发具有良好抗溶胀性能的MXene层状膜提供了新途径。通过不同的方法合理设计出具有稳定层间距的MXene层状膜,提高其在运行过程中的抗溶胀性能和稳定性,对推进MXene层状纳滤膜的工业化应用具有非常重要的作用。

5. MXene层状纳滤膜的应用

MXene材料有着诸多优异的特性,被广泛应用于膜分离的研究中。当前,MXene层状纳滤膜主要集中在海水淡化和废水处理等领域的应用,如表1所示。

表 1 MXene基纳滤膜的应用Table 1. Application of MXene-based nanofiltration membraneApplication Membrane Design strategy Permeance/

(L·m−2·h−1·bar−1)Rejection Ref. Seawater

desalinationMXene-T400 Self-crosslinking 3.5 75.9% for Na2SO4 [25] Gly-3@MX-3 Glycine crosslinking 7.5 86.28% for Na2SO4 [26] PEI/MXene Polyethylenimine crosslinking 9 82% for MgCl2 [47] HPEI-AgNP@Ti3C2Tx Hyperbranched polyethylenimine crosslinking+Silver zero-dimensional

particle composite24.55 84.15% for MgCl2 [48] MXene – ~59 ~70% for Na2SO4 [49] GO-MXene Graphene oxide composite+Self-crosslinking ~0.2 ~95% for MgCl2 [50] Wastewater

treatmentMXene/CM-β-CD Carboxymethyl-β-cyclodextrin crosslinking 431.37 99.7% for methylene blue [27] MXene-PEI Polyethylenimine crosslinking 137.77 99% for Congo red [28] Ag@MXene Silver zero-dimensional

particle composite354.29 92.32% for methyl green [29] MXene/Al2O3 Al2O3 zero-dimensional

particle composite88.8 99.8% for rhodamine B [30] CNTs-MXene Carbon nanotubes composite 1270 100% for crystal violet [31] GO/MXene Graphene oxide composite 71.9 ~100% for methylene blue [35] MoS2@LS-MXene Sodium lignosulfonate modified+

MoS2 composite77 93% for Congo red [37] GO/AA-Ti3C2Tx Ammonium acetate modification+

graphene oxide composite115.5 99.1% for Congo red [39] PEI-MXene Polyethylenimine crosslinking 441.3 99.82% for Congo red [54] MXene Fe(OH)3 zero-dimensional particle composite+HCl treatment 1084 90% for Evans blue [55] Ti3C2Tx-EDA Ethylenediamine crosslinking 20 93.2%-99.8% for Mn2+, Zn2+, Cd2+, Cu2+, Ni2+, Pb2+ [56] Notes:MXene-T400—MXene-temperature-400℃; Gly-3@MX-3—Glycine-3@MXene-3; PEI/MXene—Polyethylenimine/MXene; HPEI-AgNP@Ti3C2Tx—Hyperbranched polyethylenimine-silver nanoparticle@Ti3C2Tx; GO-MXene—Graphene oxide-MXene; MXene/CM-β-CD—MXene/carboxymethyl-β-cyclodextrin; MXene-PEI—MXene-polyethylenimine; CNTs-MXene—Carbon nanotubes-MXene; GO/MXene—Graphene oxide/MXene; MoS2@LS-MXene—MoS2@sodium lignosulfonate-MXene; GO/AA-Ti3C2Tx—Graphene oxide/ammonium acetate-Ti3C2Tx; PEI-MXene—Polyethylenimine-MXene; Ti3C2Tx-EDA—Ti3C2Tx-thylenediamine. 5.1 海水淡化

目前水资源短缺严重,海水淡化是实现水资源增量的技术之一,一直受到广泛关注。其中设计高性能的膜以提高海水淡化效率是研究的热点。如图7(a)所示,Meng等[47]通过将聚乙烯亚胺(PEI)涂覆在MXene膜上,制备出了一种带正电的MXene复合膜,其具有9 L·m−2·h−1·bar−1的渗透通量和对MgCl2约为82%的截留率。Li等[48]采用银零维颗粒复合和超支化聚乙烯亚胺(HPEI)交联相结合的策略,制备出的HPEI-AgNP@Ti3C2Tx MXene膜具有24.55 L·m−2·h−1·bar−1的水渗透通量和对MgSO4达84.15%的截留率。同时该膜在长期的纳滤实验中仍保持优异的分离性能,具有良好的抗溶胀性能和稳定性。Liu等[49]报道了一种负载在聚合物中空纤维上的MXene层状膜,如图7(b)所示。制得的~90 nm厚的MXene层状膜具有纳滤脱盐性能,对Na2SO4的截留率为~70%,渗透通量为~59 L·m−2·h−1·bar−1。Tiwary等[50]报道了一种在120℃下热交联制得的GO-MXene复合膜,该膜对0.00525 mol/L的MgCl2溶液的截留率为~95%,表现出了较好的截留效果。以上几项研究证明了基于MXene的层状纳滤膜在海水淡化方面的潜力。

5.2 废水处理

Xing等[51]将带正电的壳聚糖(CTS)和MXene纳米片混合,制备出CTS-MXene膜,利用壳聚糖和MXene纳米片之间的强相互作用力,克服膜溶胀的问题,使CTS-MXene膜具有0.433 nm的固定层间距,该膜对刚果红(CR)染料的截留率为99%,渗透通量达178.82 L·m−2·h−1·bar−1。刘婷等[52]将二维材料MoS2插层到MXene膜的层间,制备出MXene/MoS2复合膜,同时使用FeCl3对MXene/MoS2复合膜进行轻微氧化,其中质量比为9.8∶0.2的膜对考马斯亮蓝(CBB)染料的截留率高达99.2%,同时还表现出良好的稳定性。如图8所示,Qiu等[53]通过使用单宁酸(TA)与MXene纳米片交联制得TA-MXene膜,随后将Fe3+离子插入TA-MXene膜中。该膜对阿尔新蓝8GX (AB8GX)、甲基蓝(MB)、刚果红(CR)、酸性品红(AF)、铬黑T (CBT)、甲基橙(MO)以及亚甲基蓝(MeB)染料具有较好的截留效果,其中对刚果红(CR)染料高达98.8%的截留率和90.5 L·m−2·h−1·bar−1的渗透通量。相较于纯MXene膜,该膜在水溶液中表现出长期的稳定性,为MXene膜的设计提供了新方案。Xing等[54]报道了一种PEI-MXene膜,通过使用聚乙烯亚胺(PEI)大分子与MXene纳米片交联,制备出的PEI-MXene膜的层间间距能够调控到0.415~0.452 nm。其中,PEI与MXene质量比为1∶1的PEI-MXene膜对阿尔新蓝8GX (AB8GX)、甲基橙(MO)、直接红80 (DR80)和刚果红(CR)等染料均表现出优异的截留效果,截留率分别为99.3%、99.9%和99.82%,渗透通量分别为282、266.8和441.3 L·m−2·h−1·bar−1,且在720 min的过滤过程中,染料的截留率仍保持在较高水平(>99%),显示出优异的长期稳定性和抗溶胀性能。Ding等[55]使用带正电的Fe(OH)3纳米颗粒与MXene纳米片复合,随后经真空过滤和盐酸溶液(HCl)处理以除去Fe(OH)3纳米颗粒,从而得到具有更多纳米通道的MXene膜。该膜在0.1 MPa的操作压力下对伊文思蓝染料(EB)的截留率达到90%,而水的渗透通量达到

1084 L·m−2·h−1·bar−1。此外,对于重金属废水,MXene膜也表现出优异的去除能力。Jang等[56]报道了一种由Ti3C2Tx纳米片和乙二胺(EDA)水热反应制备出的Ti3C2Tx-EDA膜,乙二胺的引入改变了Ti3C2Tx纳米片的表面电荷,制备出的Ti3C2Tx-EDA膜的表面带正电荷,其对Mn2+、Zn2+、Cd2+、Cu2+、Ni2+和Pb2+等重金属离子的截留率在93.2%~99.8%左右,渗透通量约为20 L·m−2·h−1·bar−1。该研究表明通过改变MXene膜的表面特性,使MXene膜在重金属离子去除中更具优势。王赛娣等[57]使用KOH溶液对MXene膜进行处理,制备出了表面羟基化的MXene膜,其中厚度为496 nm的羟基化的MXene膜对Cr6+、Pb2+、Cu2+和Cd2+等重金属离子的截留率分别为66.19%、76.57%、78.65%和79.21%,表现出较好的截留效果。6. MXene膜的规模化制备

目前,MXene膜在分子筛分方面显示出巨大的潜力,但所开发的膜的面积小,不足以用于实际应用。因此规模化制备是阻碍MXene膜产业化和实际应用的关键瓶颈。以下是一些报道的规模化制备技术,如图9(a)所示,Kim等[58]通过狭缝式涂布法制备出具有不同厚度的大面积MXene膜,该方法无需高浓度MXene分散液,同时在涂布过程中能防止污染物进入,制备出的膜均匀性好,对甲基红(MR)染料的截留率约为93.2%,水的渗透通量为200 L·m−2·h−1·bar−1。但狭缝式涂布法存在设备和维护成本高的问题,且制备连续性还有待证明,需要进一步的研究与发展。如图9(b)所示,Li等[59]使用Meyer棒状涂布方法在聚醚砜(PES)底膜上制备出超过5 m的MXene膜,且厚度在纳米和微米尺寸之间可调。制备出的MXene膜对亚甲基蓝(MeB)染料的截留率为99.95%,相应的渗透通量为43.2 L·m−2·h−1·bar−1。虽然该方法能连续制备出大面积的MXene膜,工艺简单,但其需要高浓度MXene分散液,且该方法缺乏对膜结构的有效调节。后续还需要进一步扩展和改进。Deng等[60]采用电泳沉积的方法,在电场力的推动下,快速的将带负电荷的MXene纳米片堆积在带正电的基板上,从而形成超过500 cm2的大面积MXene膜。同时通过控制沉积时间,可以将膜的厚度控制在100 nm~1 μm之间。使用该方法能在10 min内制备出大面积MXene膜,简单快速,为MXene膜的规模化制备提供了一个可行的途径,但这种方法会受到导电基板的限制。当前用于分子筛分的大面积MXene膜的研究较少,需研究新型的制备方案和制造工艺设计,开发出简单连续的膜制备方法,制备出具有优异分离性能的大面积MXene膜,以满足未来MXene膜的实际应用。

7. 结 语

二维MXene材料的出现,为膜分离技术的研究注入了新鲜的血液,推动了膜分离技术的发展。虽然MXene层状纳滤膜的研究逐年深入和增多,也展现出优异的渗透选择性,但仍面临着一些挑战。

(1) MXene纳米片的制备。MXene层状纳滤膜的性能与MXene纳米片的尺寸大小、表面缺陷、表面官能团有着直接的关系。目前最常用的原位HF生成刻蚀法,无法精准调控MXene纳米片的尺寸大小、表面官能团和避免表面缺陷。因此需要探索出一种合适的刻蚀方法来调控MXene纳米片的结构和理化性质。

(2) MXene纳米片易氧化。单层MXene胶体溶液在15天内会从黑色变为混浊白色,发生严重的氧化现象。这种氧化受氧气和水的促进,导致了金红石型二氧化钛的形成,严重影响了复合膜性能,阻碍了实际应用。

(3) MXene层状纳滤膜的规模化制备。当前研究的MXene层状纳滤膜大都是实验室通过真空过滤的小规模制备,规模化制备MXene膜的研究较少,为了应对将来的工业化发展,开发新的能够规模化制备MXene膜的工艺和技术是有必要的。

(4) MXene层状纳滤膜的抗溶胀和稳定性。目前,自交联、有机分子交联及与不同维度的纳米材料插层的方法能制备出具有抗溶胀的MXene层状纳滤膜,但这一般是在理想的实验环境下,仍需研究出结构更稳定的MXene纳滤膜,以应对未来工业应用中高温、氧化和酸碱等恶劣的操作环境。

尽管面临这些挑战,但MXene层状纳滤膜在不同应用中仍展现出令人振奋的前景。未来MXene膜的技术发展领域应聚焦在开发兼具高渗透选择性和高稳定性的MXene膜上,以实现更高效的纳滤应用。到目前为止,通常对于渗透选择性强的MXene膜,水滴能快速通过其表面,但其稳定性不佳。相反,当MXene膜具有高稳定性时,很难获得高的渗透选择性,甚至不具渗透性。要突破这一应用瓶颈,就必须考虑如何保持这两个方面的平衡,即从渗透选择性和稳定性两个方面来设计高质量的纳滤膜。针对现有的MXene膜在纳滤应用中存在渗透选择性和稳定性之间的平衡效应的问题,相关的研究策略如下:(1)对MXene组分进行功能化改性,通过化学反应引入不同的功能基团增强MXene亲水性和化学稳定性;(2)设计新型的MXene复合膜,与新型二维材料、高分子材料等复合,利用不同材料的协同效应提高膜的综合性能。当前,探索不同类型、尺寸和维度的层间复合材料是关键焦点和研究趋势。随着持续努力,MXene层状纳滤膜有望在不久的将来在不同领域实现工业应用。

-

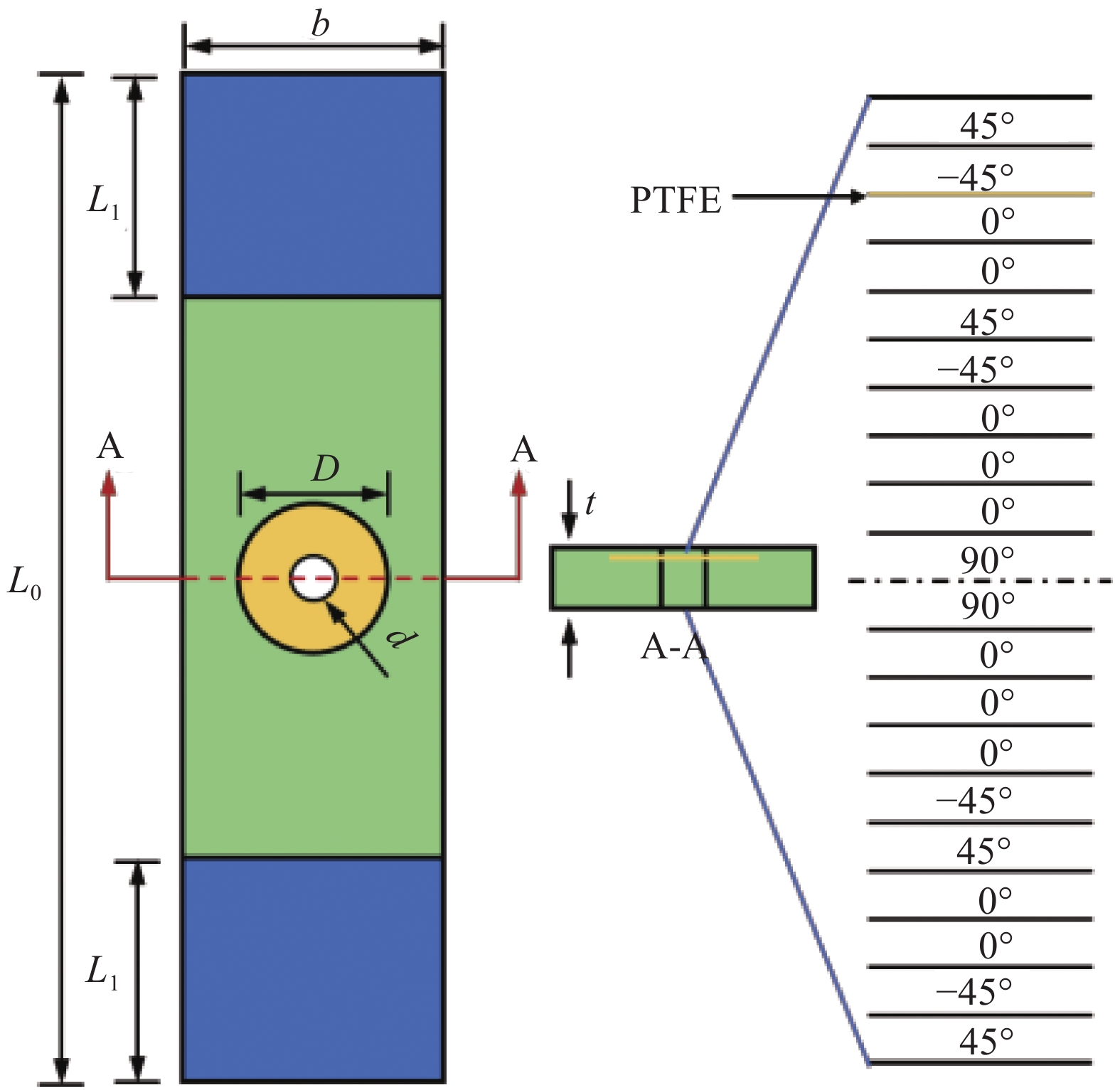

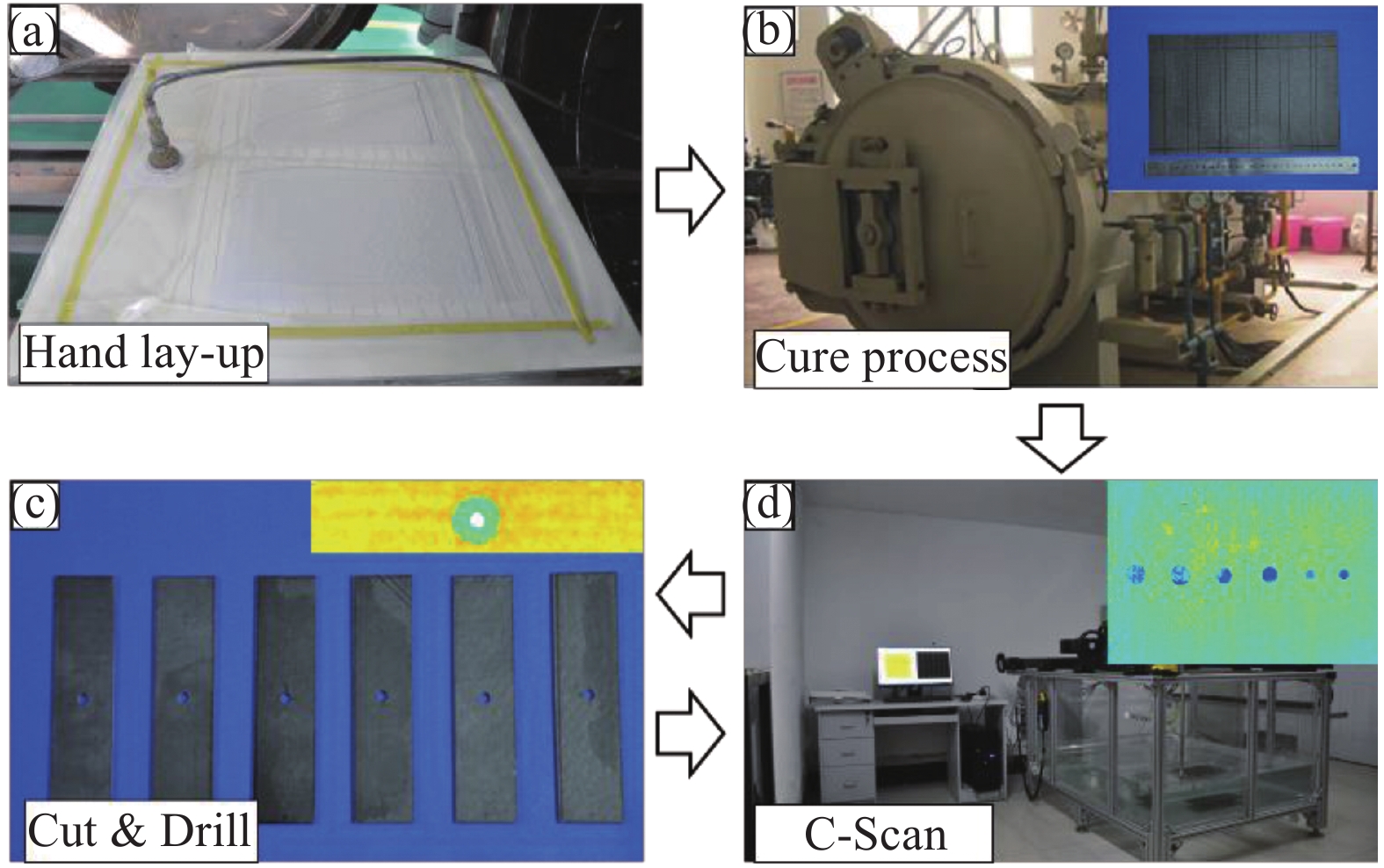

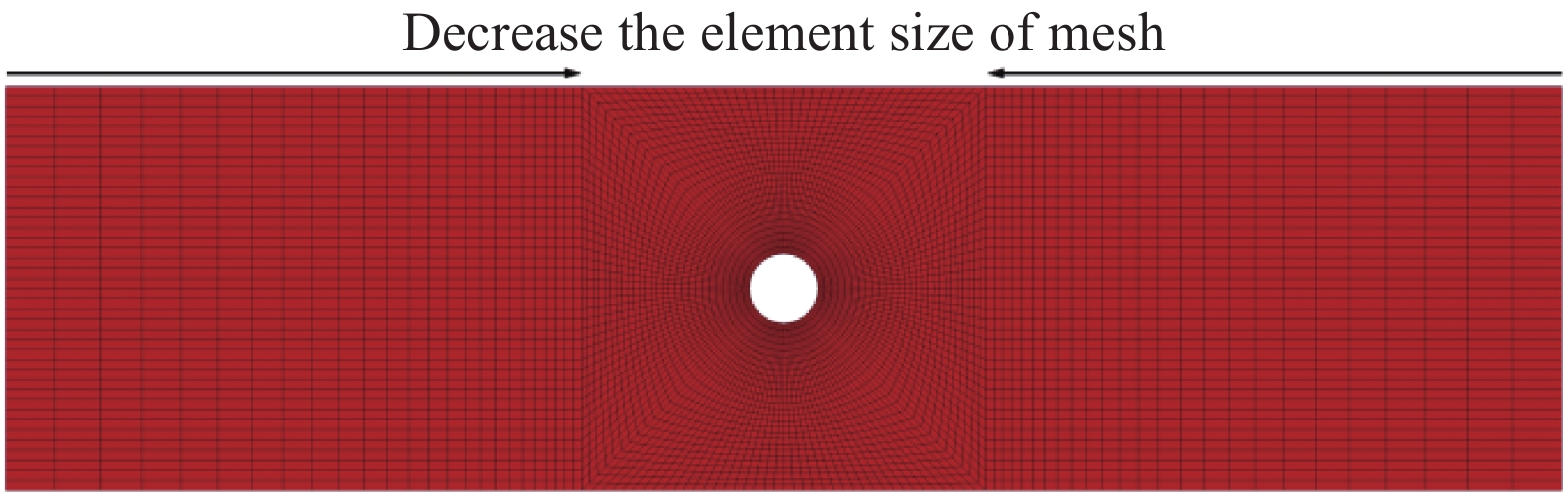

图 2 单一预制分层缺陷的CF/EP开孔层合板模型示意图

Figure 2. Schematic diagram of CF/EP open-hole laminates with a single prefabricated lamination defect

L0—Total length of laminate; L1—Length of clamping end; b—Width of laminate; D—Diameter of prefabricated defect; d—Diameter of open-hole; t—Thickness of laminates; PTFE—Polytetrafluoroethylene

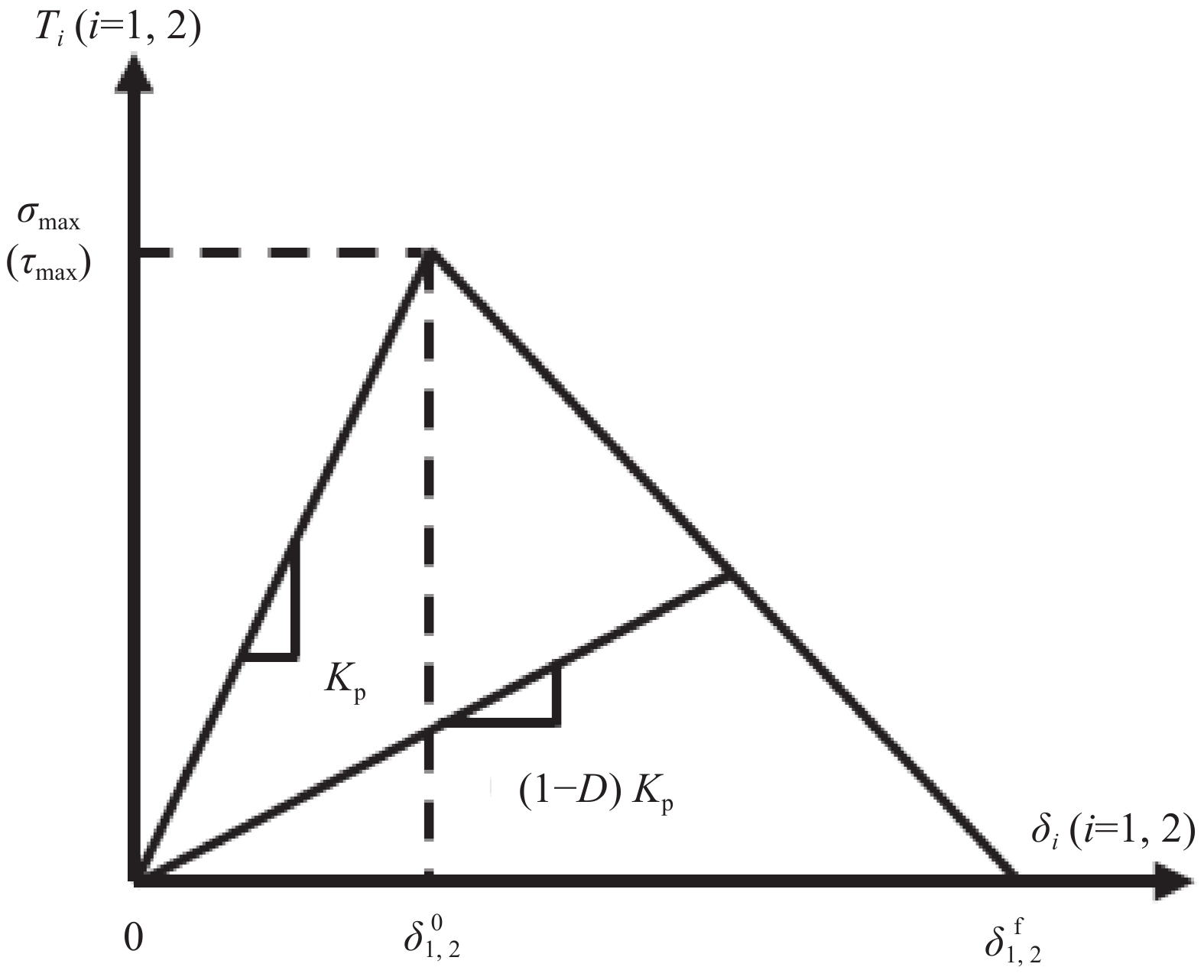

图 6 双线性内聚力单元损伤模型示意图

Figure 6. Diagram of bilinear cohesive damage model

Ti—Traction force of laminates during type i fracture; Kp—Penalty stiffness; δi—Displacement response under type i traction; δi0—Crack opening displacement corresponding to the maximum stress; σmax—Maximum normal stress value; τmax—Maximum tangential stress

表 1 CF/EP开孔层合板详细尺寸

Table 1 Detailed dimensions of CF/EP open-hole laminates

Type L0/mm L1/mm b/mm D/mm d/mm t/mm I-0 135 30 35 − 6 2.6 D-10 135 30 35 10 6 2.6 D-15 135 30 35 15 6 2.6 D-20 135 30 35 20 6 2.6 Notes: I—Defect-free porous composite plate; The number after the letter D is the diameter of the damaged area. 表 2 CF/EP预浸料材料属性及参数

Table 2 Material properties and parameters of CF/EP prepreg

Parameter Value E11/MPa 144700 E22/MPa 9650 E33/MPa 9650 G12/MPa 5800 G13/MPa 5800 G23/MPa 4800 ν12 0.3 ν13 0.3 ν23 0.45 Notes: E—Elastic modulus; ν—Poisson's ratio; G—Shear modulus; 1—Direction of fiber; 2—Direction of matrix; 3—Thickness direction of layer; Xt—Longitudinal tensile strength; Xc—Longitudinal compressive strength; Yt—Transverse tensile strength; Yc—Transverse compressive strength; S—In-plane shear strength. 表 3 双缺陷耦合作用下CF/EP开孔层合板压缩屈曲数值模拟结果(D-20-FEA-T)

Table 3 Numerical simulation results of compression buckling of CF/EP open-hole laminates under the coupling action of double defects (D-20-FEA-T)

State 1 2 3 4 Sublaminate 1

Sublaminate 2

表 4 双缺陷耦合作用下CF/EP开孔层合板压缩屈曲数值模拟结果(D-20-FEA-Y)

Table 4 Numerical simulation results of compression buckling of CF/EP open-hole laminates under the coupling action of double defects (D-20-FEA-Y)

State 1 2 3 4 5 Sublaminate 1

Sublaminate 3

-

[1] FREITAS M D, CARVALHO R D. Residual strength of a damaged laminated CFRP under compressive fatigue stresses[J]. Composites Science & Technology,2006,66(3-4):373-378.

[2] TAFRESHI A, OSWALD T. Global buckling behaviour and local damage propagation in composite plates with embedded delaminations[J]. International Journal of Pressure Vessels& Piping,2003,80(1):9-20.

[3] AUERSCH L, SCHMID G. A torque and thrust prediction model for drilling of composite materials[J]. Composites Part A: Applied Science & Manufacturing,2005,36(1):83-93.

[4] KHASHABA U A, EL-SONBATY I A, SELMY A I, et al. Machinability analysis in drilling woven GFR/epoxy composites: Part I-Effect of machining parameters[J]. Composites Part A: Applied Science & Manufacturing,2010,41(3):391-400.

[5] DUAN Q F, LI S X, SONG P H, et al. Effect of drilling-induced delamination on buckling behavior of open hole composite laminate specimens under compressive loading[J]. Strength of Materials,2019,51:624-632.

[6] HAN P K, WHITEHEAD R S, KAUTZ E F. Damage tolerance certification methodology for composite structures[C]. Eighth DOD(NASA)FAA Conference on Fibrous Compo-sites in Structural Design, Part 2. NASA. Langley Research Center, 1990.

[7] MCGOWAN D M, AMBUR D R. Structural response of composite sandwich panels impacted with and without compression loading[J]. Journal of Aircraft,1971,36(3):596-602.

[8] KARIMI N Z, HEIDARY H, FOTOUHI M, et al. Experimental analysis of GFRP laminates subjected to compression after drilling[J]. Composite Structures, 2017, 169: 144–152.

[9] OLSSON R. Analytical prediction of large mass impact damage in composite laminates[J]. Composites Part A: Applied Science & Manufacturing,2001,32(9):1207-1215.

[10] 王雪明, 谢富原, 李敏, 等. 热压罐成型复合材料复杂结构对制造缺陷的影响规律[J]. 航空学报, 2009, 30(4):757-762. DOI: 10.3321/j.issn:1000-6893.2009.04.029 WANG Xueming, XIE Fuyuan, LI Min, et al. Effect of complex structure on manufacturing defects of composite materials formed by auto-claves[J]. Acta Aeronautica et Astronautica Sinica,2009,30(4):757-762(in Chinese). DOI: 10.3321/j.issn:1000-6893.2009.04.029

[11] KATERELOS D G, PAIPETIS A, KOSTOPOULOS V. A simple model for the prediction of the fatigue delamination growth of impacted composite panels[J]. Fatigue & Fracture of Engineering Materials& Structures,2004,27(10):911-922.

[12] ISMAIL S O, OJO S O, DHAKAL H N. Thermo-mechanical modelling of FRP cross-ply composite laminates drilling: Delamination damage analysis[J]. Composites Part B: Engineering,2017,108:45-52. DOI: 10.1016/j.compositesb.2016.09.100

[13] 张明辉, 周储伟, 鲁浩. 碳纤维复合材料单向板钻孔分层损伤的数值模拟[J]. 机械工程材料, 2019, 43(9):73-77. ZHANG Minghui, ZHOU Chuwei, LU Hao. Numerical simulation of delamination dam-age of carbon fiber composite plate in borehole[J]. Materials for Mechanical Engineering,2019,43(9):73-77(in Chinese).

[14] 唐荆, 陈啸, 杨科. 碳纤维复合材料开孔层合板压缩损伤预测和模型比较[J]. 玻璃钢/复合材料, 2019(10):33-39. TANG Jing, CHEN Xiao, YANG Ke. Compression damage prediction and model comparison of carbon fiber compo-site open-hole laminates[J]. Fiber Reinforced Plastics/Composites,2019(10):33-39(in Chinese).

[15] 温泉, 郭东明, 高航, 等. 碳纤维/环氧树脂复合材料制孔损伤综合评价方法[J]. 复合材料学报, 2016, 33(2):265-272. WEN quan, GUO Dongming, GAO Hang, et al. Comprehensive evaluation method for hole damage of carbon fiber/epoxy resin composites[J]. Acta Materiae Compositae Sinica,2016,33(2):265-272(in Chinese).

[16] 卓越, 关志东, 周睿, 等. 复合材料开孔层板压缩渐进损伤试验[J]. 复合材料学报, 2015, 32(6):1762-1768. ZHUO Yue, GUAN Zhidong, ZHOU Rui, et al. Experimental study on progressive damage of composite laminates by compression[J]. Acta Materiae Compositae Sinica,2015,32(6):1762-1768(in Chinese).

[17] OJO S O, ISMAIL S O, PAGGI M, et al. A new analytical critical thrust force model for delamination analysis of laminated composites during drilling operation[J]. Composites Part B: Engineering, 2017, 124: 207–217.

[18] 姜晓伟, 朱书华, 李国弘, 等. 含分层缺陷复合材料层合板分层扩展研究[J]. 航空计算技术, 2014, 44(5):73-76. DOI: 10.3969/j.issn.1671-654X.2014.05.018 JIANG Xiaowei, ZHU Shuhua, LI Guohong,et al. Research on layered extension of composite laminates with layered defects[J]. Aeronautical Computing Technology,2014,44(5):73-76(in Chinese). DOI: 10.3969/j.issn.1671-654X.2014.05.018

[19] NILSSON K F, ASP L E, ALPMAN J E, et al. Delamination buckling and growth for delaminations at different depths in a slender composite panel[J]. International Journal of Solids & Structures, 2001, 38(17): 3039-3071.

[20] 刘雅玲, 王康康, 赵丽滨. 含预制分层复合材料层合板的压缩失效行为研究[C]//北京力学会第二十三届学术年会会议论文集. 北京: 北京力学会, 2017: 2. LIU Yaling, WANG Kangkang, ZHAO Libin. Study on compression failure behavior of laminated plates containing precast laminated composites[C]//Proceedings of the 23rd Annual Conference of Beijing Society of Mechanics. Beijing: Beijing Society of Mechanics, 2017: 2(in Chinese).

[21] RHEAD A T, BUTLER R, HUNT G W. Compressive strength of composite laminates with delamination-induced interaction of panel and sublaminate buckling modes[J]. Composite Structures, 2017, 171: 326-334.

[22] ASTM. Standard test method for tensile properties of polymer matrix composite materials: ASTM D3039/D3039M—17[S]. West Conshohocken: ASTM International, 2017.

[23] ASTM. Standard test method for compressive properties of polymer matrix composite materials using a combined loading compression (CLC) test fixture: ASTM D6641/D6641M—16[S]. West Conshohocken: ASTM International, 2016.

[24] ASTM. Standard test method for in-plane shear response of polymer matrix composite materials by tensile test of a ±45° laminate: ASTM D3518/D3518M—18[S]. West Conshohocken: ASTM International, 2018.

[25] ELICES M, GUINEA G V, GÓMEZ J, et al. The cohesive zone model: advantages, limitations and challenges[J]. Engineering Fracture Mechanics,2002,69(2):137-163. DOI: 10.1016/S0013-7944(01)00083-2

[26] WANG R G, ZHANG L, ZHANG J, et al. Numerical analysis of delamination buckling and growth in slender laminated composite using cohesive element method[J]. Computational Materials Science, 2010, 50(1): 20-31.

[27] LIU P F, GU Z P, PENG X Q, et al. Finite element analysis of the influence of cohesive law parameters on the multiple delamination behaviors of composites under compression[J]. Composite Structures, 2015, 131: 975-986.

[28] TURON A, CAMANHO P P, COSTA J, et al. Accurate simulation of delamination growth under mixed-mode loading using cohesive elements: Definition of interlaminar strengths and elastic stiffness[J]. Composite Structures,2010,92(8):1857-1864. DOI: 10.1016/j.compstruct.2010.01.012

[29] MOURA M F S F, GONÇALVES J P M, MARQUES A T, et al. Prediction of compressive strength of carbon-epoxy laminates containing delamination by using a mixed-mode damage model[J]. Composite Structures,2000,50(2):151-157. DOI: 10.1016/S0263-8223(00)00091-X

[30] LAKSHMINARAYANA H V, BOUKHILI R, GAUVIN R. Impact response of laminated composite plates: Prediction and verification[J]. Composite Structures, 1994, 28(1): 61-72.

[31] HÜHNE C, ZERBST A K, KUHLMANN G, et al. Progressive damage analysis of composite bolted joints with liquid shim layers using constant and continuous degradation models[J]. Composite Structures,2010,92(2):189-200. DOI: 10.1016/j.compstruct.2009.05.011

[32] 张延林, 李秋阳. 碳布增强木质层合板的有限元渐进损伤分析[J]. 沈阳工业大学学报, 2017, 39(1):22-27. ZHANG Yanlin, LI Qiuyang. Finite element progressive damage analysis of carbon fabric reinforced wood laminates[J]. Journal of Shenyang University of Technology,2017,39(1):22-27(in Chinese).

[33] LSTC. Keyword User’s Manual, Volume II[M]. Livermore: Version 11 R11.0. 0, 2018.

[34] HOU J P, PETRINIC N, RUIZ C, et al. Prediction of impact damage in composite plates[J]. Composites Science & Technology,2000,60(2):273-281.

-

下载:

下载: