Research on carbon fiber composite properties based on (polyether sulfone)/ cyanate ester semi-interpenetrating resin system

-

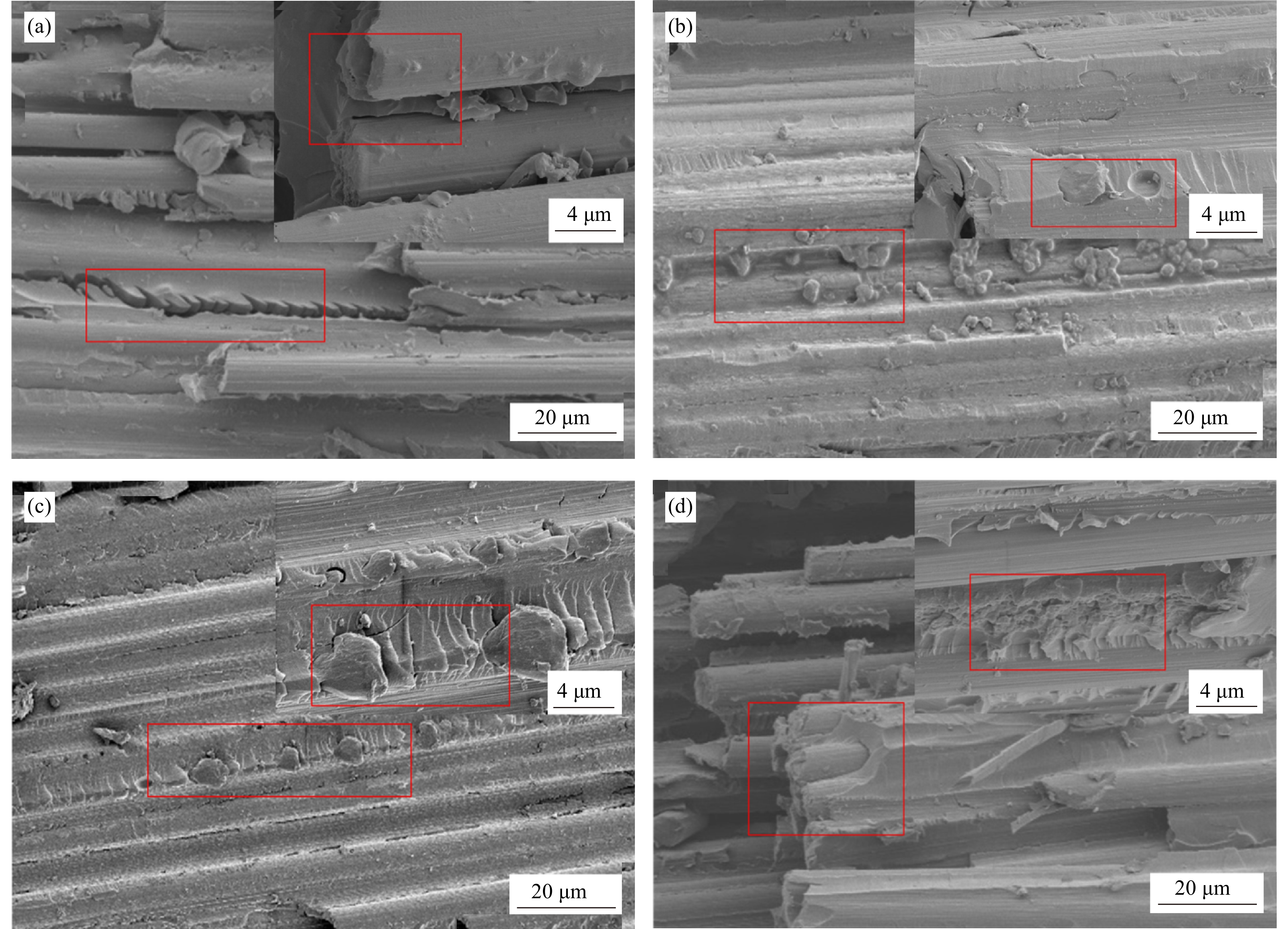

摘要: 氰酸酯(CE)树脂因具有高玻璃化转变温度、低固化收缩率和优异介电性能,常被作为耐高温或吸波纤维复合材料基体应用于航空航天领域。但由于CE树脂与碳纤维(CF)浸渍黏附性较差、固化温度高、固化物脆性较大,其复合材料制备工艺性较差且固化后易产生分层损伤,严重影响其产品质量及实际应用。本文利用聚醚砜(PES)对CE树脂进行改性,制备出浸润性良好的预浸料以适应各类干法成型复合材料制备工艺。结果表明,PES的引入能够显著提高CF/CE树脂基复合材料的力学性能和热稳定性。与CF/CE单向板相比,7.5wt%PES-CF/CE单向板的弯曲强度提高17%,层间剪切强度提高31%,冲击韧性提高39%,并且纵向热膨胀性系数从−2.07×10−8 K−1降低到−10.7×10−8 K−1,横向热膨胀系数降低20%,改性效果显著。Abstract: Cyanate ester (CE) resin, which has high glass transition temperature, low curing shrinkage and excellent dielectric properties, is commonly used as the material of high temperature resistant or microwave absorption in the aerospace field. However, after high temperature curing, the poor immigration adhesion between CE resin and carbon fiber (CF) would result in brittleness of its composite product. In addition, the preparation process of composites is complex, resulting in delamination damage. Therefore, the product quality and practical application are considerably affected. In this paper, polyether sulfone (PES) was used to modify CE resin and prepare prepreg. It prepares prepreg with good wettability and can apply to various dry forming composite preparation processes. The results show that the introduction of PES can significantly enhance the mechanical properties and thermal stability of CF/CE resin matrix composites. Compared with the CF/CE unidirectional plate, the flexural strength of 7.5wt%PES-CF/CE unidirectional plate is increased by 17%; the interlaminar shear strength is increased by 31%; the impact strength is increased by 39%; and the longitudinal thermal expansion coefficient is reduced from −2.07×10−8 K−1 to −10.7×10−8 K−1; the transverse thermal expansion coefficient is reduced by 20%. The modification effect is signifi-cant.

-

表 1 碳纤维(CF)/聚醚砜(PES)-氰酸酯(CE)树脂基复合材料的命名

Table 1. Naming of carbon fiber (CF)/polyether sulfone (PES)-cyanate ester (CE) resin matrix composite

Sample Proportion PES/wt% CF/CE/wt% CF/CE 0 100 2.5wt%CF/PES-CE 2.5 97.5 5.0wt%CF/PES-CE 5.0 95.0 7.5wt%CF/PES-CE 7.5 92.5 表 2 CF/PES-CE树脂基复合材料弯曲性能

Table 2. Flexural properties of CF/PES-CE resin matrix composite

Sample Flexural strength/MPa Flexural modulus/GPa CF/CE 1649.6 124.0 2.5wt%CF/PES-CE 1804.0(9%↑) 124.8(1%↑) 5.0wt%CF/PES-CE 1926.2(17%↑) 132.7(7%↑) 7.5wt%CF/PES-CE 1927.5(17%↑) 136.6(10%↑) Note: Values in parentheses represent the percentage increase compared to CF/CE composite. 表 3 CF/PES-CE树脂基复合材料层间剪切强度与冲击韧性

Table 3. Interlayer shear strength and impact toughness of CF/PES-CE resin matrix composites

Sample Interlaminar shear strength/MPa Impact strength/(kJ·m-2) CF/CE 61.3 248.0 2.5wt%CF/PES-CE 66.2(8%↑) 268.9(8%↑) 5.0wt%CF/PES-CE 72.3(18%↑) 288.5(16%↑) 7.5wt%CF/PES-CE 80.5(31%↑) 346.3(40%↑) -

[1] 张璇, 沈真. 航空航天领域先进复合材料制造技术进展[J]. 纺织导报, 2018(S1):72-79.ZHANG Xuan, SHEN Zhen. Advances in manufacturing technology of advanced composite materials in the field of aerospace[J]. Textile Herald,2018(S1):72-79(in Chinese). [2] 陈祥宝, 张宝艳, 邢丽英. 先进树脂基复合材料技术发展及应用现状[J]. 中国材料进展, 2009, 28(6):2-12.CHEN Xiangbao, ZHANG Baoyan, XING Liying. The development and application status of advanced resin matrix composite materials[J]. Progress in Chinese Materials,2009,28(6):2-12(in Chinese). [3] 郝建伟. 先进树脂基复合材料的技术现状及发展方向[J]. 航空制造技术, 2001(3):22-25. doi: 10.3969/j.issn.1671-833X.2001.03.002HAO Jianwei. The technical status and development direction of advanced resin-based composite materials[J]. Aeronautical Manufacturing Technology,2001(3):22-25(in Chinese). doi: 10.3969/j.issn.1671-833X.2001.03.002 [4] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU Shanyi. Advanced composite materials and aerospace[J]. Journal of Composite Materials,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [5] 何东晓. 先进复合材料在航空航天的应用综述[J]. 高科技纤维与应用, 2006(2):9-11. doi: 10.3969/j.issn.1007-9815.2006.02.003HE Dongxiao. Overview of the application of advanced composite materials in aerospace[J]. High-Tech Fiber & Application,2006(2):9-11(in Chinese). doi: 10.3969/j.issn.1007-9815.2006.02.003 [6] 马军现, 雷雪峰, 桑晓慧, 等. 氰酸酯/端氨基聚醚树脂的制备及性能[J]. 热固性树脂, 2018, 3(6):1-26.MA Junxian, LEI Xuefeng, SANG Xiaohui, et al. Preparation and properties of cyanate ester/amino-terminated polyether resin[J]. Thermosetting Resins,2018,3(6):1-26(in Chinese). [7] 刘锋, 周恒, 赵彤. 高性能树脂基体的最新研究进展[J]. 宇航材料工艺, 2012, 42(4):1-6. doi: 10.3969/j.issn.1007-2330.2012.04.001LIU Feng, ZHOU Heng, ZHAO Tong. The latest research progress of high-performance resin matrix[J]. Aerospace Materials Technology,2012,42(4):1-6(in Chinese). doi: 10.3969/j.issn.1007-2330.2012.04.001 [8] HU J T, GU A, LIANG G, et al. Preparation and properties of maleimide functionalized hyperbranched polysiloxane and its hybrids based on cyanate ester resin[J]. Journal of Applied Polymer Science,2012,126(1):205-215. doi: 10.1002/app.36688 [9] ZENG Pingzhang, PEI Jianzhong, FANG Changqing, et al. Modification of cyanate ester resin by epoxy-functionalized polyhedral oligomeric silsesquioxane[J]. Advanced Materials Research,2012,549:314-317. doi: 10.4028/www.scientific.net/AMR.549.314 [10] FENG, CHEN, LI, et al. Low-temperature cure high-performance cyanate ester resins/microencapsulated catalyst systems[J]. Polymer Engineering & Science,2013,53(9):1871-1877. [11] 崔志江, 吴晓青. 树脂基层合结构复合材料层间增韧研究[J]. 天津纺织科技, 2019(1):55-60.CUI Zhijiang, WU Xiaoqing. Research on interlayer toughening of resin-based laminated structure composite materials[J]. Tianjin Textile Science & Technology,2019(1):55-60(in Chinese). [12] 任鹏刚, 梁国正, 杨洁颖. CTBN改性双酚A型氰酸酯树脂的性能[J]. 材料研究学报, 2005(4):443-448.REN Penggang, LIANG Guozheng, YANG Jieying. Properties of CTBN modified bisphenol A cyanate ester resin[J]. Chinese Journal of Materials Research,2005(4):443-448(in Chinese). [13] 赵颖, 刘晓辉, 李欣, 等. 活性端基液体橡胶/环氧树脂改性氰酸酯胶粘剂的研究[A]. 北京粘接学会, 2006: 1.ZHAO Ying, LIU Xiaohui, LI Xin, et al. Research on reactive end-group liquid rubber/epoxy resin modified cyanate ester adhesive[A]. Beijing Institute of Adhesion, 2006: 1(in Chinese). [14] YU F, FANG Z, GU A. Toughening of cyanate ester resin by carboxyl terminated nitrile rubber[J]. Polymers for Advanced Technologies,2004,15(10):628-631. doi: 10.1002/pat.519 [15] 祝保林. 偶联剂表面处理对纳米SiO2/氰酸酯树脂复合材料力学性能的影响[J]. 机械工程材料, 2009, 33(2):78-81.ZHU Baolin. Effect of coupling agent surface treatment on mechanical properties of nano-SiO2/cyanate ester resin composites[J]. Materials for Mechanical Engineering,2009,33(2):78-81(in Chinese). [16] 王君龙, 梁国正, 祝保林. 纳米SiO2对氰酸酯树脂的增韧改性研究[J]. 宇航学报, 2006(4):745-750. doi: 10.3321/j.issn:1000-1328.2006.04.035WANG Junlong, LIANG Guozheng, ZHU Baolin. Toughening modification of cyanate ester resin by nano-SiO2[J]. Journal of Astronautics,2006(4):745-750(in Chinese). doi: 10.3321/j.issn:1000-1328.2006.04.035 [17] 姚雪丽. 二氧化硅/氰酸酯树脂基纳米复合材料的研究[D]. 西安: 西北工业大学, 2006.YAO Xueli. Research on silica/cyanate ester resin based nanocomposites[D]. Xi'an: Northwestern Polytechnical University, 2006(in Chinese). [18] 欧秋仁, 嵇培军, 肖军, 等. 环氧树脂改性双酚A型氰酸酯树脂的性能研究[J]. 功能材料, 2015, 46(S2):129-134.OU Qiuren, JI Peijun, XIAO Jun, et al. Study on the properties of epoxy resin modified bisphenol A cyanate ester resin[J]. Functional Materials,2015,46(S2):129-134(in Chinese). [19] 杨延风, 张学军. 氰酸酯树脂与环氧树脂催化共聚研究[J]. 化工新型材料, 2015, 43(6):208-210.YANG Yanfeng, ZHANG Xuejun. Study on the catalytic copolymerization of cyanate ester resin and epoxy resin[J]. New Chemical Materials,2015,43(6):208-210(in Chinese). [20] 张立颖, 于国良, 孙东洲, 等. 氰酸酯树脂改性的研究进展[J]. 化学与黏合, 2018, 40(4):298-302.ZHANG Liying, YU Guoliang, SUN Dongzhou, et al. Research progress of cyanate ester resin modification[J]. Chemistry and Adhesion,2018,40(4):298-302(in Chinese). [21] 祝保林. 热塑性树脂改性氰酸酯树脂的相结构表征[J]. 热固性树脂, 2008(3):19-24. doi: 10.3969/j.issn.1002-7432.2008.03.005ZHU Baolin. Phase structure characterization of cyanate ester resin modified by thermoplastic resin[J]. Thermosetting Resins,2008(3):19-24(in Chinese). doi: 10.3969/j.issn.1002-7432.2008.03.005 [22] 祝保林, 王君龙, 张文根. 热塑性树脂改性氰酸酯树脂的研究[J]. 工程塑料应用, 2008(1):12-16. doi: 10.3969/j.issn.1001-3539.2008.01.003ZHU Baolin, WANG Junlong, ZHANG Wengen. Research on cyanate ester resin modified by thermoplastic resin[J]. Engineering Plastics Application,2008(1):12-16(in Chinese). doi: 10.3969/j.issn.1001-3539.2008.01.003 [23] 牛磊, 朱光明, 王坤. 氰酸酯树脂增韧改性研究进展[J]. 中国胶粘剂, 2011, 20(11):49-53. doi: 10.3969/j.issn.1004-2849.2011.11.013NIU Lei, ZHU Guangming, WANG Kun. Research progress on toughening modification of cyanate ester resin[J]. China Adhesives,2011,20(11):49-53(in Chinese). doi: 10.3969/j.issn.1004-2849.2011.11.013 [24] MALLARINO S, CHAILAN J F, VERNET J L. Glass fiber sizing effect on dynamic mechanical properties of cyanate ester composites I—Single frequency investigations[J]. European Polymer Journal,2005,41(8):1804-1811. doi: 10.1016/j.eurpolymj.2005.02.022 [25] LIU Jingfeng, FAN Weifeng, GE Lu, et al. Semi-interpenetrating polymer networks based on cyanate ester and highly soluble thermoplastic polyimide[J]. Polymers,2019,11(5):862-872. [26] YE Y, YUAN L, LIANG G, et al. Simultaneously toughening and strengthening cyanate ester resin with better dielectric properties through building nanostructures in crosslinked network using polyimide-block-polysiloxane rod-coil block copolymers[J]. Rsc Advances,2016,6(55):49436-49447. doi: 10.1039/C6RA08229G [27] 王惠民, 梁伟荣. 聚醚砜/环氧树脂复合体系的研究[J]. 高分子材料科学与工程, 1999(6):155-157. doi: 10.3321/j.issn:1000-7555.1999.06.046WANG Huimin, LIANG Weirong. Research on polyethersulfone/epoxy resin composite system[J]. Polymer Mater-ials Science & Engineering,1999(6):155-157(in Chinese). doi: 10.3321/j.issn:1000-7555.1999.06.046 [28] 贾文品, 周金利, 余木火, 等. 聚醚砜增韧环氧树脂的力学性能及固化体系相分离[J]. 玻璃钢/复合材料, 2017(3):5-10.JIA Wenpin, ZHOU Jinli, YU Muhuo, et al. Mechanical properties of polyether sulfone toughened epoxy resin and phase separation of curing system[J]. Fiber Reinforced Plastics/Composites,2017(3):5-10(in Chinese). [29] 国家质量技术监督局. 单向纤维增强塑料弯曲性能试验方法: GB/T 3356—1999[S]. 北京: 中国标准出版社, 1999.State Bureau of Quality Technical Supervision. Test method for flexural properties of unidirectional fiber reinforced plastics: GB/T 3356—1999[S]. Beijing: China Standards Press, 1999(in Chinese). [30] 国家标准化管理委员会. 单向纤维增强塑料层间剪切强度试验方法: JC/T 773—82(96)[S]. 北京: 中国标准出版社, 1996.Standardization Administration of China. Test method for interply shear strength of unidirectional fiber reinforced plastics: JC/T 773—82(96)[S]. Beijing: China Standards Press, 1996(in Chinese). [31] 国家标准化管理委员会. 纤维增强塑料简支梁式冲击韧性试验方法: GB/T 1451−2005[S].北京: 中国标准出版社, 2005.Standardization Administration of China. Fibre reinforced plastics composites—Determination of charpy impact properties: GB/T 1451−2005[S]. Beijing: China Standards Press, 2005(in Chinese). [32] 曾汉民, 容敏智, 章明秋. 聚合物多相复合体系的结构和内耗行为特征[J]. 高分子通报, 1998(2):3-12.ZENG Hanmin, RONG Minzhi, ZHANG Mingqiu. Structure and internal friction behavior characteristics of polymer multiphase composite system[J]. Polymer Bulletin,1998(2):3-12(in Chinese). -

下载:

下载: