Effects of several modifiers on oil-bearing and tribological properties of porous polyimides

-

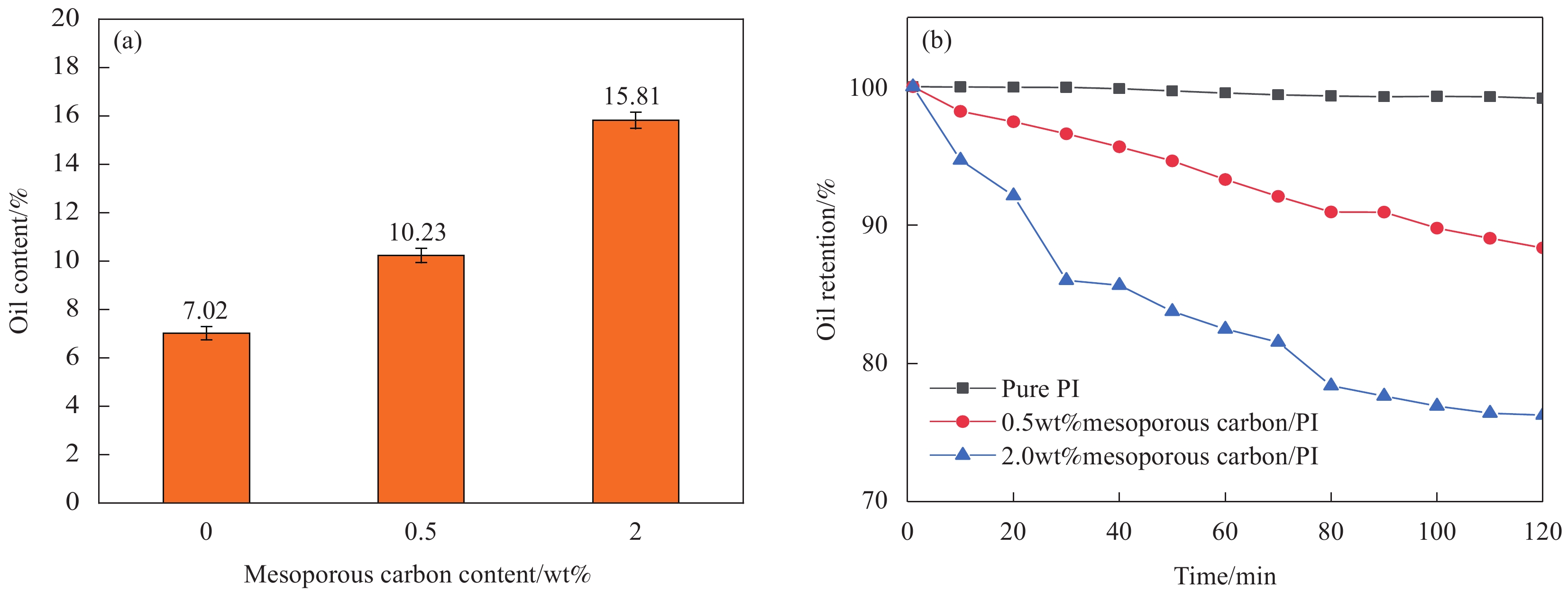

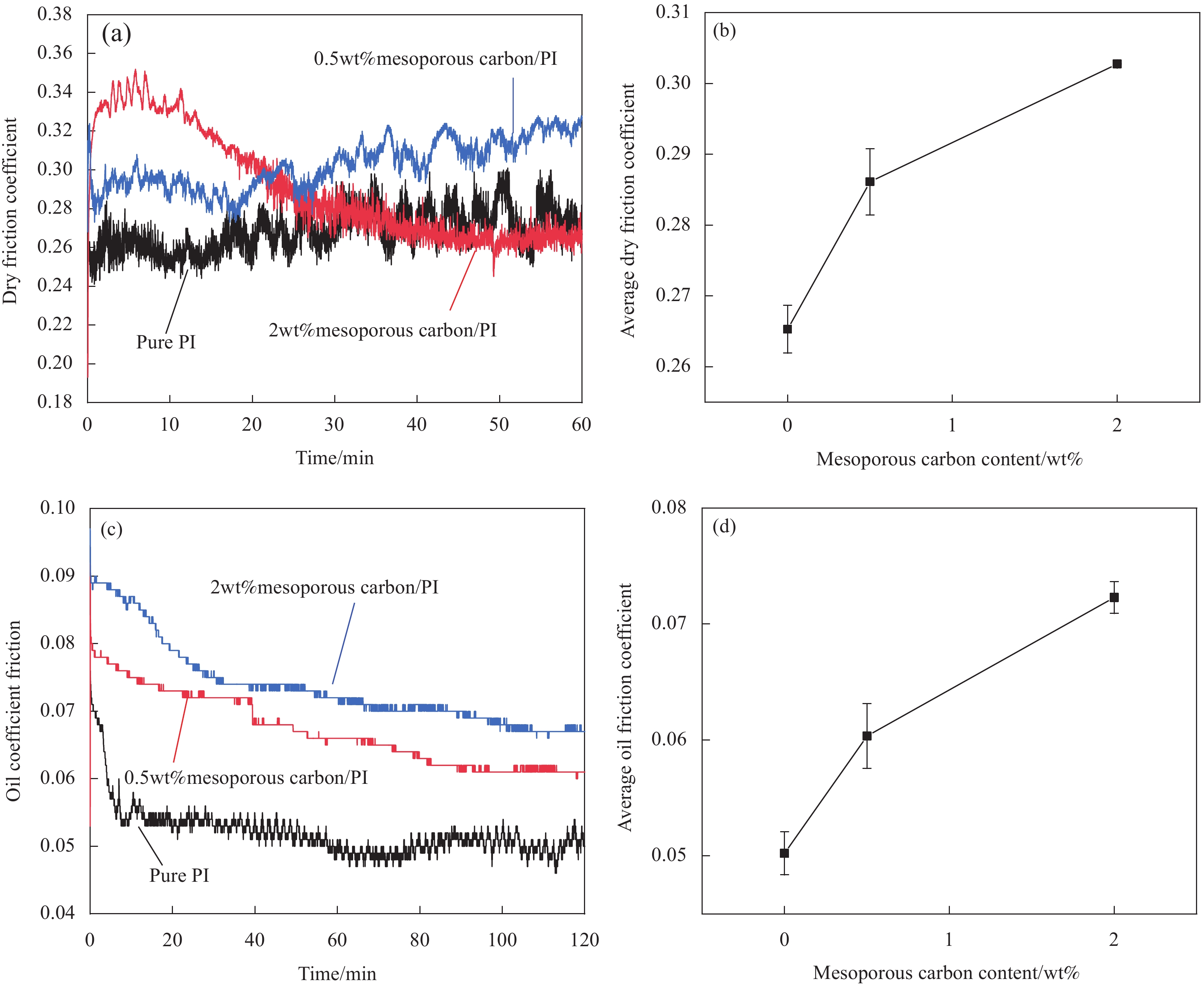

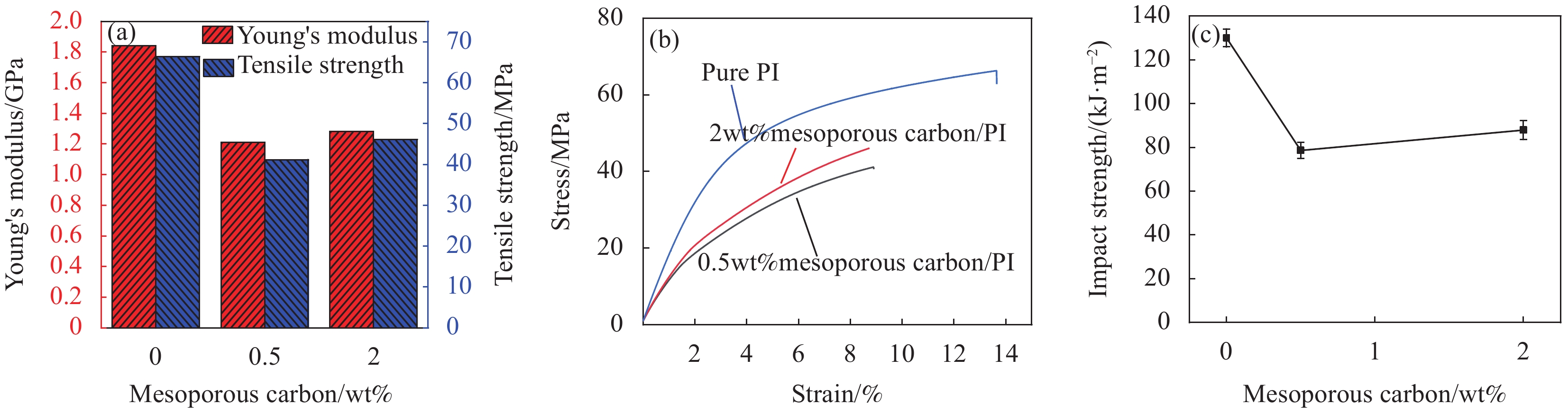

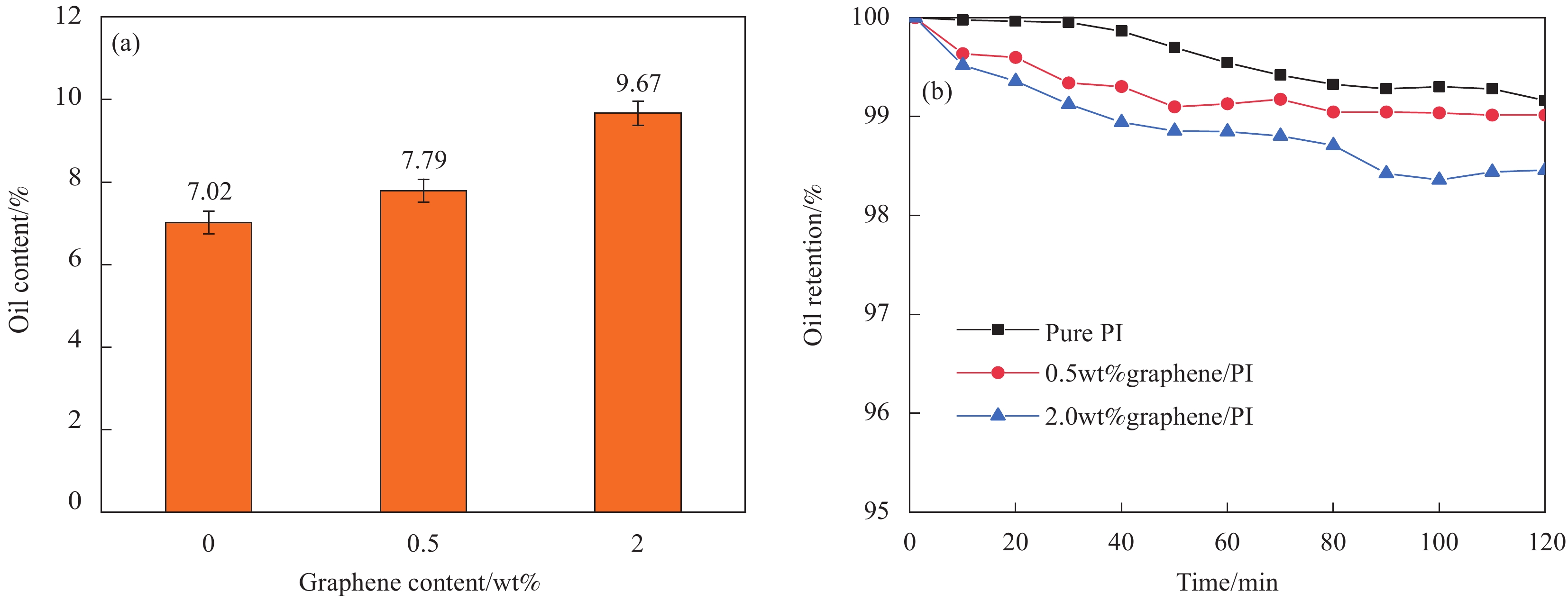

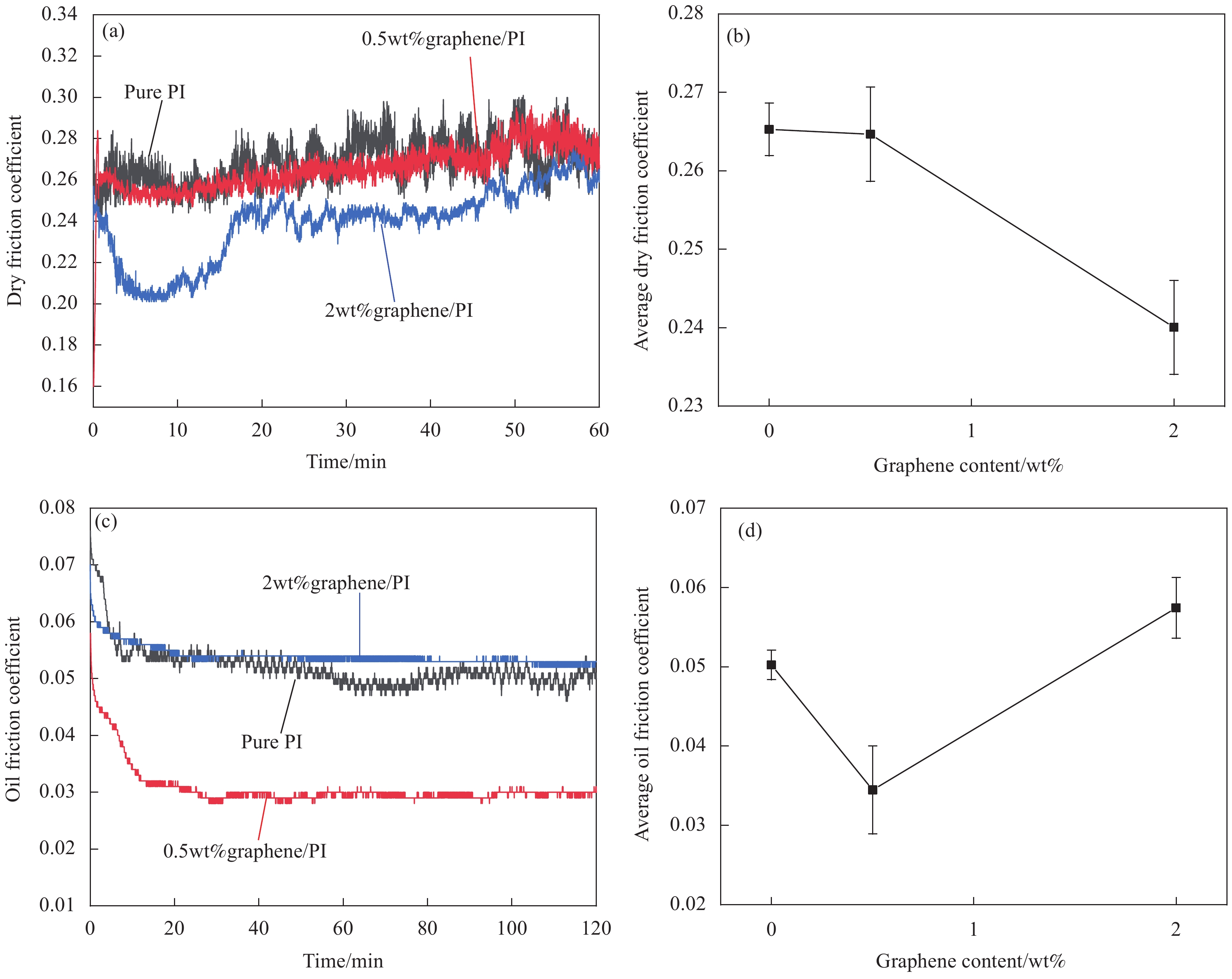

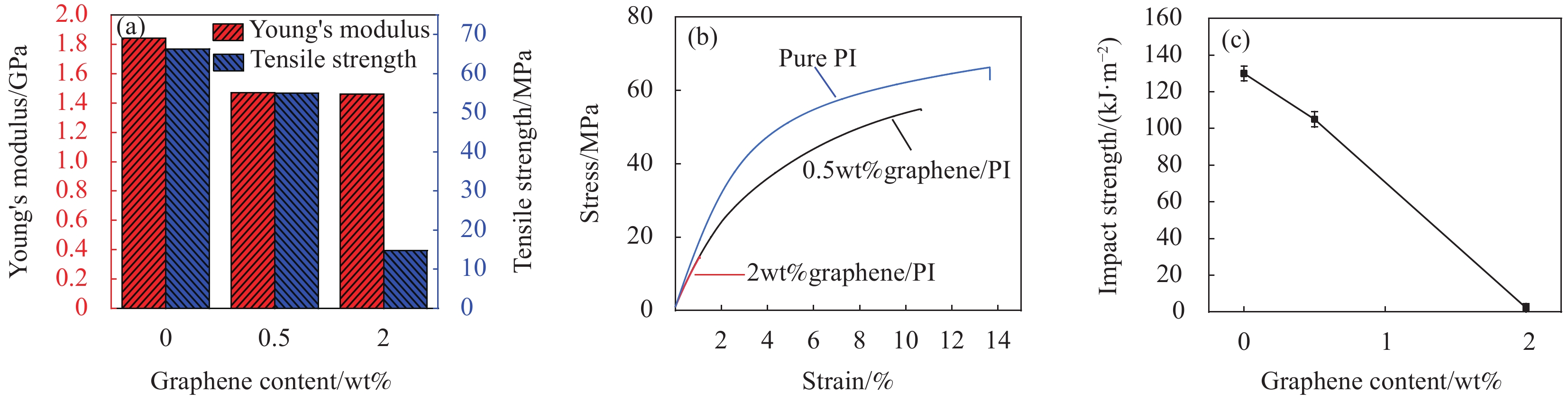

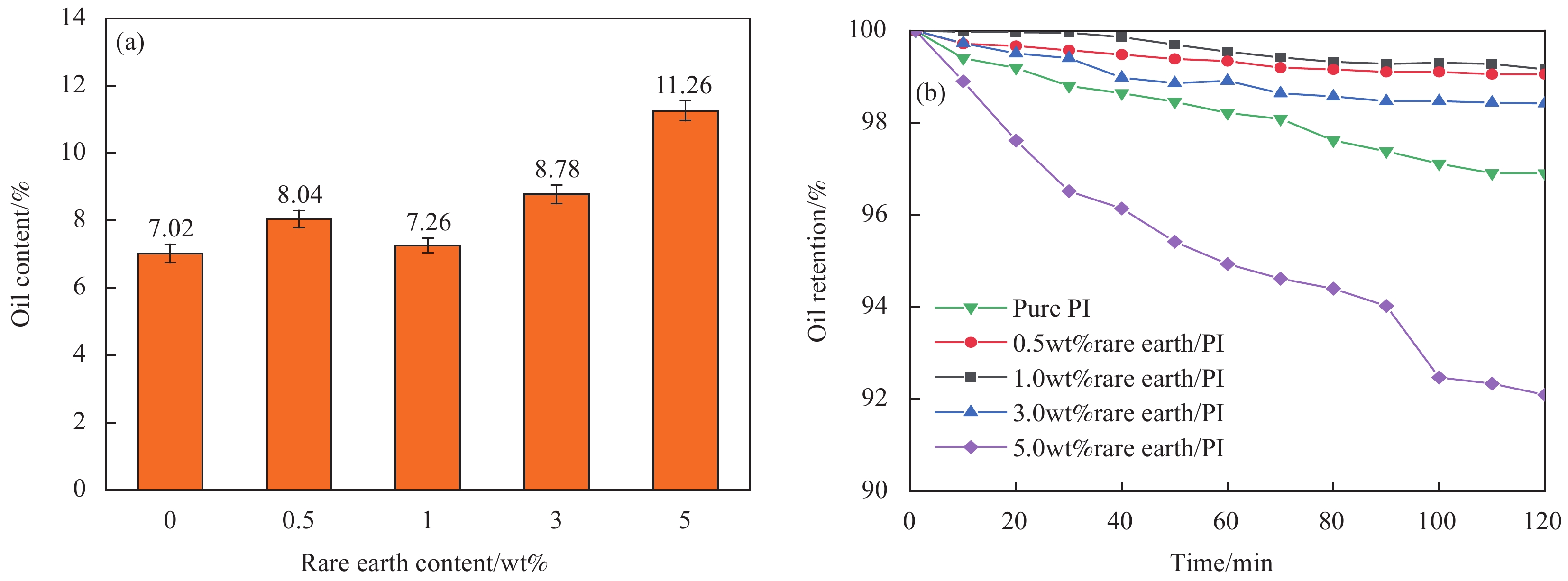

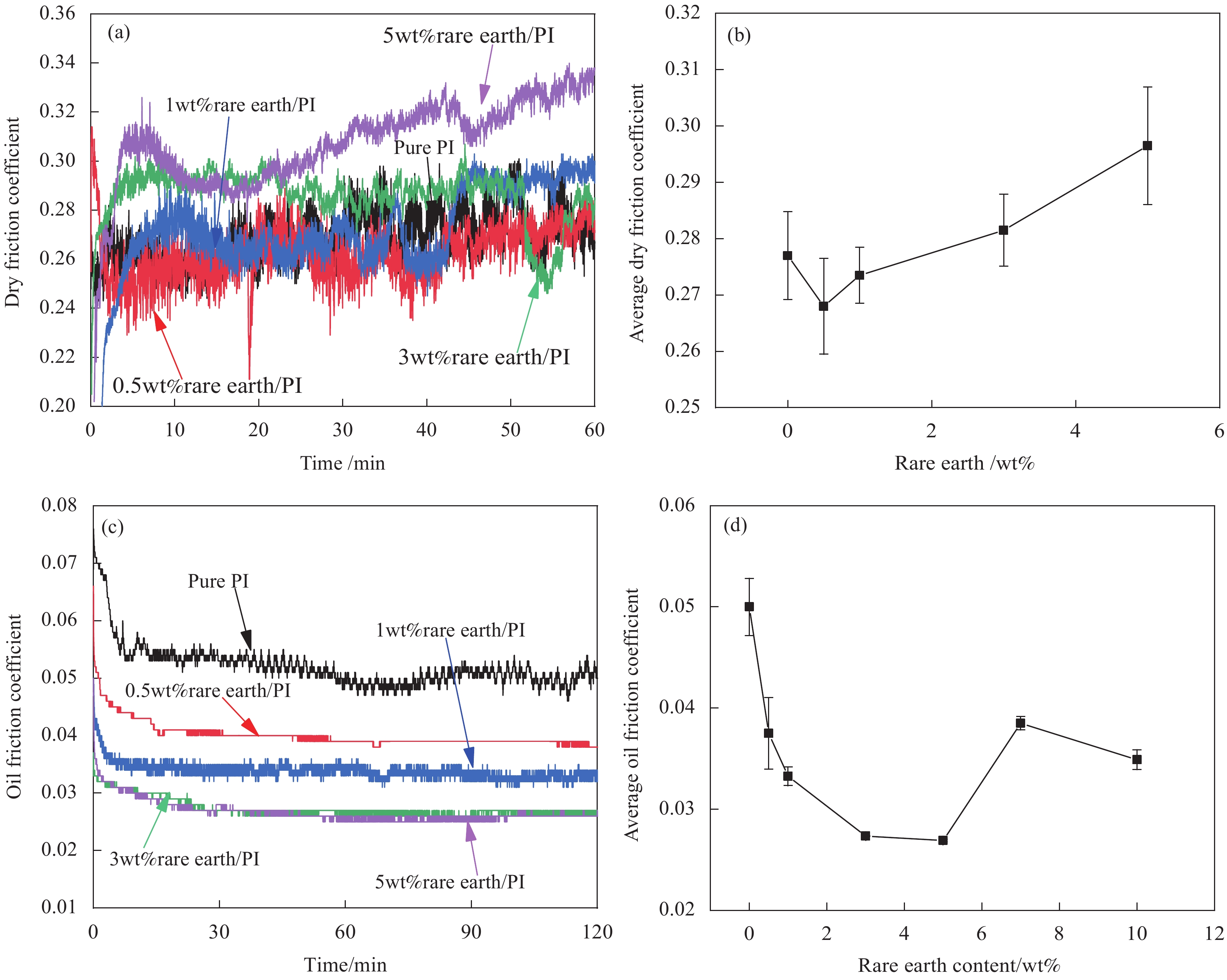

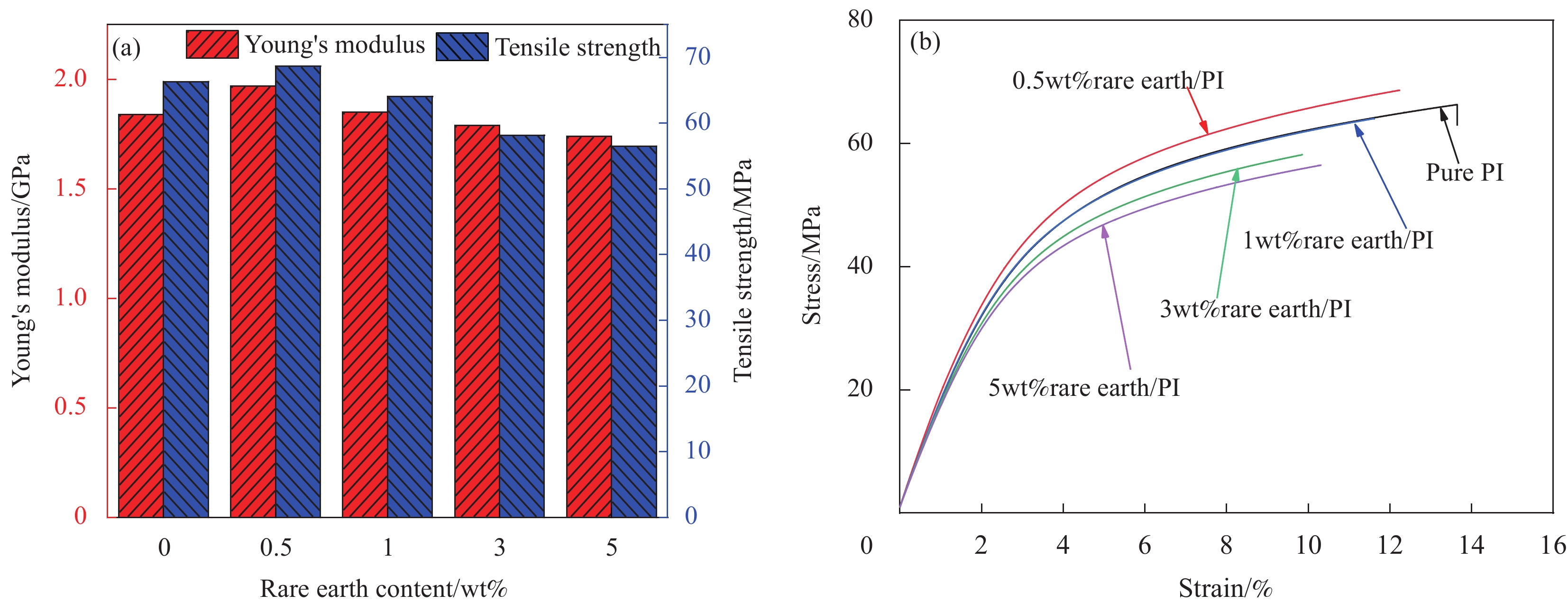

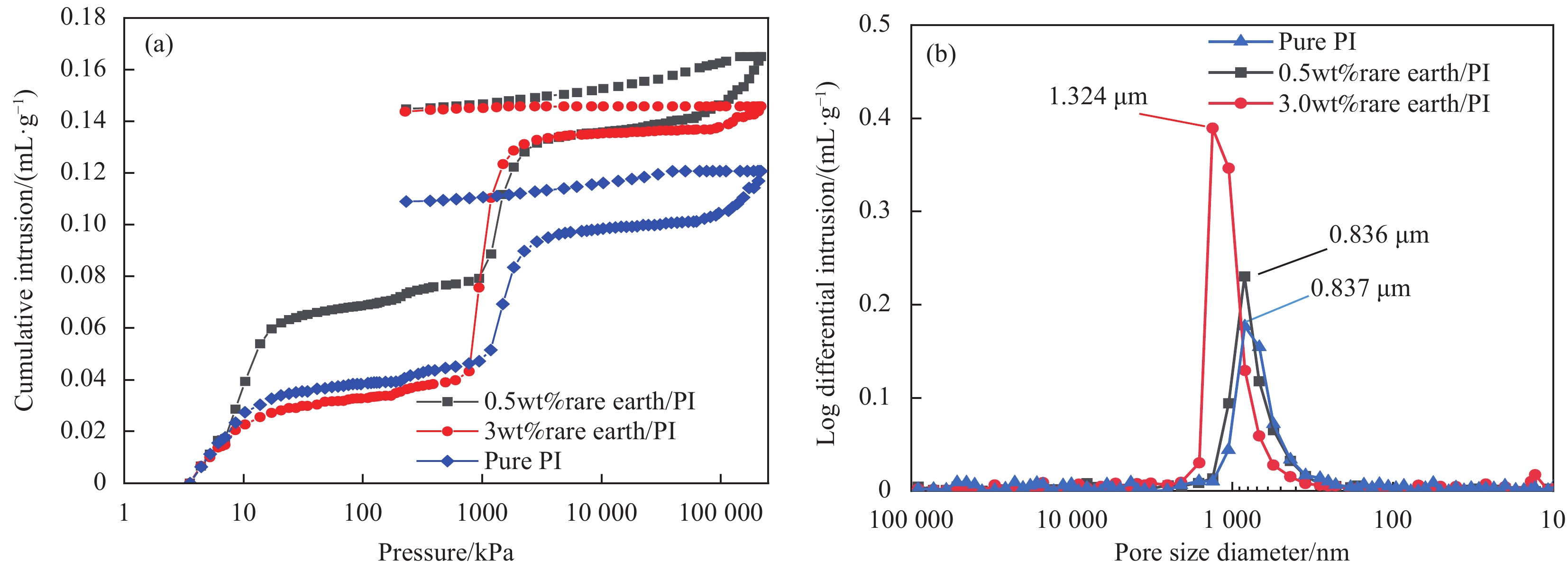

摘要: 为探索多孔聚酰亚胺(PI)材料含油性能及摩擦性能的增强改进方法,采用介孔碳、石墨烯和稀土为改性剂制备多孔PI材料。研究了不同改性剂对材料的含油性能、摩擦性能和力学性能的影响。实验结果表明,介孔碳可大幅提升多孔PI的含油率,相比纯PI,介孔碳含量2wt%时的含油率提高了55.6%,但材料的摩擦系数有增大的趋势,力学性能也明显下降;少量的石墨烯可以提高多孔PI的含油性能和摩擦性能,但随着石墨烯含量的增加,多孔PI的含油摩擦系数快速增加,且冲击强度大幅降低;稀土极大改善了多孔PI的含油摩擦性能,随着稀土含量从0wt%增至5wt%,摩擦系数从0.05下降到0.026,超过5wt%后出现拐点,但所有试样含油摩擦系数均低于纯PI,且含油率呈上升趋势。相比介孔碳和石墨烯,稀土改性多孔PI的力学性能没有出现大幅降低的情况,对多孔PI综合性能的增强效果最优。Abstract: In order to explore the enhancement and improvement of porous polyimide (PI) material’s oil content and tribological properties, PI materials were prepared by using mesoporous carbon, graphene and rare earth as modifiers, respectively. The effects of different modifiers on the oil content property, tribological property and mechanical property of the materials were studied. The experimental results show that mesoporous carbon can greatly increase the oil content of porous PI. Compared with pure PI, the oil content of 2wt% mesoporous carbon increases by 55.6%, but the friction coefficient tends to increase, the mechanical property decreases obviously; a small amount of graphene can improve the oil content and frictional properties of porous PI, but with the increase of graphene content, the oil content friction coefficient of porous PI increases rapidly, and the impact strength decreases significantly; rare earth has greatly improved the oil content friction properties of porous PI. As the rare earth content increases from 0wt% to 5wt%, the friction coefficient decreases from 0.05 to 0.026. There is an inflection point after 5wt%. However, the oil friction coefficients of all samples are lower than the pure PI, and the oil content rate goes up. The mechanical property of rare earth modified porous PI doesn’t decrease significantly compared with mesoporous carbon and graphene, which shows the best enhancement effect on the comperhensive performance of porous PI.

-

Keywords:

- porous polyimide /

- oil content property /

- tribological property /

- mesoporous carbon /

- graphene /

- rare earth

-

近年来,可穿戴技术由于具有轻便、即时的特点而被广泛应用于人体生理活动监测[1]、健康管理[2]、人造皮肤[3]、人机交互[4]等领域。目前,商业可穿戴设备全部或部分由平面和刚性材料组成,如以眼镜、手表、腕带或腰带的形式,需要使用突出的硬支撑或额外的可弯曲条带安装在人体上,这在一定程度上引起了个人的不适,并限制了人体生理数据的采集[5]。与此同时,随着柔性电子设备小型化和集成化的发展趋势,这些不可避免的电磁干扰会对设备正常运行及个人健康产生不利影响[6-9]。因此,寻求一种柔性屏蔽材料来替代传统可穿戴设备,使其具有灵活、重量轻、皮肤友好且高度耐用的特点是十分必要的。

水凝胶是一类具有三维交联网络结构、亲水性的聚合物功能材料,它特殊的结构可以使体系容纳大量水而不会发生破坏[7]。优异的高拉伸性、良好的形状适应性、黏附性、良好的生物相容性使其在柔性可穿戴电子设备中得到了广泛的应用。同时水凝胶的三维多孔结构能够实现电磁波的多重反射和散射,这对于提升电磁屏蔽性能有着拓扑结构优势。然而,单组分聚合物水凝胶通常是不导电的,这导致电磁屏蔽(EMI)能力不足。其中,添加导电填料作为提高水凝胶电磁屏蔽能力的有效手段之一,主要包括纳米管、石墨烯、银纳米线等[10]。但是,这类导电材料存在着在水溶液中难分散、稳定性差的问题,这极大地减弱了电磁屏蔽效果。近几年兴起的二维MXene纳米材料的结构与石墨烯相似,属于过渡金属碳化物、氮化物或碳氮化物家族的一员[11]。相比于碳纳米管、石墨烯、银纳米线,MXene不仅具有高导电性,同时还具有丰富的活性位点(如—OH、—F、—O)、电化学行为和独特的亲水性,使其在水凝胶电磁屏蔽材料中显示出了特有的优势。

此外,传统单一交联网络水凝胶,如聚丙烯酸(PAA)、聚丙烯酰胺(PAAm)等是由共价键或非共价键形成的网络,强度低,无法适应复杂的外部环境(共价键的永久断裂缩短了材料的使用寿命,非共价键的低强度限制了材料的应用范围)。为此,人们围绕提高水凝胶强度提出了一系列的策略,如添加纳米填料[12]、构建双网络结构[13]及引入超分子相互作用[14-15]。其中,双网络结构是由两个互穿的聚合物网络组成,第一网络的紧密交联和第二网络的松散交联的协同作用赋予水凝胶优异力学性能的同时又兼具高可拉伸性。鲁程程等[16]通过简单的两步法,制备了完全物理交联、高强度和敏感性的聚丙烯酸-Al3+/壳聚糖复合双网络水凝胶传感器。该水凝胶传感器显示出优异的力学性能(抗拉强度高达765.4 kPa,断裂伸长率至1025%)。在本文中,设计了一种具有动态可逆双网络(PAAm-聚甲基丙烯酸羟乙酯(PHEMA)/PAA-Fe3+-MXene)水凝胶,第一网络PAAm-PHEMA化学交联赋予了水凝胶高力学强度,第二网络PAA-Fe3+可逆动态配位提供了高可拉伸性和使用寿命。最后,采用水溶性MXene在双网络水凝胶中进行掺杂,制备了PAAm-PHEMA/PAA-Fe3+-MXene水凝胶。所制备的水凝胶表现出优异力学特性(高力学强度320.1 kPa,高拉伸应变1786%)、良好导电性(3.8 S/m)、强电磁屏蔽(在X波段内可以获得超过36 dB的出色 EMI 屏蔽效果,屏蔽效率高达99%)、强紫外屏蔽(在365和550 nm的特征波长下的透射率分别为0% 和79.2%)、对各种基材强黏附性、快速自愈合能力和高度形状适应性。该强配位双网络和双屏蔽机制的设计策略为柔性可穿戴水凝胶材料提供了新的设计思路和独特的见解,显示出了巨大的潜在应用价值。

1. 实验材料及方法

1.1 原材料

Ti3AlC2 购自一一科技有限公司(200 mesh);聚丙烯酸(PAA)购自上海安耐吉化学有限公司;LiF、HCl购自阿拉丁化学公司;丙烯酰胺(AAm)、甲基丙烯酸羟乙酯(HEMA)、N, N-亚甲基双丙烯酰胺(MBAA)、过硫酸铵(APS)和四甲基乙二胺(TEMED) 、硝酸铁九水合物、柠檬酸钠二水合物购自上海麦克林生化科技有限公司,均为分析纯。

1.2 试验表征

分别用扫描电子显微镜(SEM,S-4700,Hitachi)、透射电子显微镜(TEM,HT7700,Hitachi)和原子力显微镜(AFM,Dimension FastScan-SYS,Bruker)观察形态和微观结构。XRD图谱从Rigaku 2500VB2+PC获得。 XPS得自Thermo Fisher Escalab 250。EDS得自Hitachi S-4700。PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的电导率由 RTS-8 Probes Tech的四探针电阻率测试仪测量。流变学实验是在安东帕公司MCR002流变仪测得。万能拉伸试验机(ESM303,MARK-10)用于测量PAAm-PHEMA/PAA-Fe3+-MXene水凝胶在拉伸试验中的性能。超景深光学显微镜(LEICA DM4 M)购自兰瑞国际有限公司。

1.3 MXene(Ti3C2Tx)纳米片的制备

MXene(Ti3C2Tx)是使用 LiF/HCl 通过以下蚀刻方法合成的。将2 g Ti3AlC2缓慢溶解到由 1 g LiF和20 mL 9 mol/L HCl制备的蚀刻溶液中,然后将溶液在搅拌下在35℃加热24 h。之后,洗涤、收集和干燥酸性悬浮液。然后,将冷冻干燥的产品溶解在水中并超声处理40 min。最后,将混合溶液以3500 r/min 的转速离心1 h 以收集上清液。

1.4 PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的制备

首先,将PAA添加到去离子水中搅拌,形成2wt%PAA溶液。其次在PAA溶液中加入1 g AAm、0.1 g HEMA持续搅拌20 min,然后将48 µL MBAA溶液(1wt%)、110 µL APS溶液(10wt%)和1.0 g MXene水溶液(2wt‰)混合到去离子水中,最后将20 µL TEMED加入到上述溶液中搅拌,最后移入到聚四氟乙烯模具中在氮气环境中60℃ 聚合4 h获得凝胶。然后,将所制备的PAAm-PHEMA/PAA-Fe3+-MXene水凝胶浸入一定量的FeCA溶液中,该溶液是预先将Fe(NO3)3·9H2O和 Na3C6H5O7·2H2O以柠檬酸(CA)与Fe3+的摩尔比为1∶1混合制备,并保留在密封的聚乙烯袋中放置数天,以完全吸收并形成均匀的配位交联,见图1。

![]() 图 1 坚韧和黏性聚丙烯酰胺(PAAm)-聚甲基丙烯酸羟乙酯 (PHEMA)/聚丙烯酸 (PAA)-Fe3+-MXene水凝胶的的设计策略Figure 1. Design strategies for tough and sticky PAAm-PHEMA/PAA-Fe3+-MXene hydrogelsAAm—Acrylamide; HEMA—Hydroxyethyl methacrylate; PAA—Polyacrylic acid; MBAA—N, N'-methylenebis(2-propenamide); APS—Ammonium persulphate; CA—Citric Acid

图 1 坚韧和黏性聚丙烯酰胺(PAAm)-聚甲基丙烯酸羟乙酯 (PHEMA)/聚丙烯酸 (PAA)-Fe3+-MXene水凝胶的的设计策略Figure 1. Design strategies for tough and sticky PAAm-PHEMA/PAA-Fe3+-MXene hydrogelsAAm—Acrylamide; HEMA—Hydroxyethyl methacrylate; PAA—Polyacrylic acid; MBAA—N, N'-methylenebis(2-propenamide); APS—Ammonium persulphate; CA—Citric Acid2. 结果与讨论

2.1 MXene的表征

在本工作中,通过将导电MXene纳米片掺入到由PAAm和PAA组成的双网络中成功制备PAAm-PHEMA/PAA-Fe3+-MXene水凝胶。首先,通过选择性刻蚀的方法成功制备了单层Ti3C2Tx MXene纳米片,从Ti3AlC2粉末(图2(a))中去除铝层,然后在超声辅助下剥离成超薄Ti3C2Tx MXene纳米片(图2(b))[17],与未经剥离的Ti3C2Tx手风琴结构相比图2(c)显示了超声之后的MXene纳米片呈现稳定均一的分布,并且具有良好的透明性。图2(d)和图2(e)分别是TEM、AFM表征的Ti3C2Tx的形貌图。可以看出,Ti3C2Tx具有明显的二维结构并且具有超薄的尺寸,如图2(f)所示;XPS能谱(图2(g))证实了MXene 纳米片中存在特征性的钛、氧和氟元素,表明大量的极化官能团(—F、—OH、=O等)存在于 MXene 纳米片的表面。XRD图谱(图2(h))表明成功去除铝层,(002)衍射峰向低角度偏移,表明从Ti3AlC2相转变为单层Ti3C2。以上这些结果证明了超薄MXene 纳米片的成功蚀刻和剥离,并且其表面具有大量亲水基团,为MXene纳米片在水凝胶系统中的均匀分散提供了可能性,以增强材料的力学性能并提高导电性和灵敏度。

![]() 图 2 (a) Ti3AlC2(MAX)粉末的SEM图像;(b) HCl/LiF蚀刻的最小强度分层(MILD)-Ti3C2Tx粉末;((c), (d)) MXene的SEM图像和TEM图像;((e), (f)) 分层的Ti3C2Tx 纳米片的AFM图像和高度分布;((g), (h)) 分层的 Ti3C2Tx 纳米片的XPS、XRD图谱Figure 2. (a) SEM image of Ti3AlC2 (MAX) powder; (b) HCl/LiF etched minimally intensive layer delamination (MILD)-Ti3C2Tx powder; ((c), (d)) SEM image and TEM image of MXene; ((e), (f)) AFM image and height distribution of layered Ti3C2Tx nanosheets; ((g), (h)) XPS spectra and XRD patterns of highly distributed layered Ti3C2Tx MXene nanosheets

图 2 (a) Ti3AlC2(MAX)粉末的SEM图像;(b) HCl/LiF蚀刻的最小强度分层(MILD)-Ti3C2Tx粉末;((c), (d)) MXene的SEM图像和TEM图像;((e), (f)) 分层的Ti3C2Tx 纳米片的AFM图像和高度分布;((g), (h)) 分层的 Ti3C2Tx 纳米片的XPS、XRD图谱Figure 2. (a) SEM image of Ti3AlC2 (MAX) powder; (b) HCl/LiF etched minimally intensive layer delamination (MILD)-Ti3C2Tx powder; ((c), (d)) SEM image and TEM image of MXene; ((e), (f)) AFM image and height distribution of layered Ti3C2Tx nanosheets; ((g), (h)) XPS spectra and XRD patterns of highly distributed layered Ti3C2Tx MXene nanosheets2.2 PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的合成及力学性能

FTIR图谱表明了PAAm-PHEMA/PAA-Fe3+-MXene水凝胶中的分子间相互作用。从图3(a)可见,3种水凝胶在1400~1500 cm−1处都有明显的吸收,归属于PAA链中羧酸基团的对称伸缩振动,随着MXene和Fe3+的加入,此波数处的吸收逐渐减弱,说明—COOH基团发生络合反应。另外,PAAm-PHEMA/PAA水凝胶的—OH峰出现在3469 cm−1,是一个宽峰,这主要归因于—OH和PAAm链中的—NH及C=O之间的相互作用;随着MXene纳米片的加入,此峰移动到3440 cm−1;进一步加入Fe3+后,此峰移动至3429 cm−1处,这些都说明了MXene纳米片及Fe3+与水凝胶体系存在非共价的氢键和配位键相互作用,如图1所示[18-19]。图3(b)显示了冷冻干燥后的PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的SEM图像,可以看到三维(3D)互连的多孔微结构,同时图3(c)中的EDS验证了配位交联的均匀分布。以Fe3+为配位中心,通过二维MXene纳米片上的极化基团与PAA链中的羧基之间的配位交联形成PAAm-PHEMA/PAA-Fe3+-MXene水凝胶。二维MXene作为一种多功能交联剂均匀地分散在水凝胶中,通过氢键作用将施加的应力传递到聚合物链,极大地避免了因应力集中带来的裂纹断裂[20]。图3(d)显示了PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的拉伸应力-应变曲线(拉伸速率为1 mm/s),可以看出:随着PAA含量从0wt%升高到2.5wt%,拉伸强度从120.1 kPa增加到423.6 kPa,断裂伸长率从1785%降低到1526%,这表明相比于单一的PAAm-PHEMA水凝胶网络,PAA作为第二网络加入到水凝胶体系后,对于PAAm组成化学网络起到了增强的作用,双网络的形成大大增强了凝胶体系的力学性能。并且随着PAA第二网络含量的逐渐增加(含量从0wt%升高到2.5wt%),MXene纳米片和 PAA 链之间形成了更多的Fe3+介导的配位相互作用,聚合物链之间的相互作用变强,从而形成了更加致密的交联网络,可以承受并将更多的应力分散到更多的周围聚合物链上,表现出更高的拉伸强度[21]。综合力学性能,最终选择了1.7wt%的PAA作为第二网络的添加量。与此同时黏附性对于水凝胶的应用有很大的影响,即使在反复运动后也能保证结构的完整性,聚(甲基丙烯酸羟乙酯)(PHEMA)由于无毒、优异的力学性能和良好的生物相容性,是最重要和广泛应用的生物材料之一。因此,通过与HEMA共聚,羟基的存在提高了水凝胶与被黏材料表面的相互作用(氢键或配位相互作用),进一步提高PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的表面黏附性。从图3(e)中可以看出随着HEMA含量的升高,拉伸强度从320.1 kPa降低到165.6 kPa,断裂伸长率从1786%降低到762.8%,这主要是由于PHEMA的加入削弱了—OH与Fe3+的相互作用,与此同时PHEMA也可以通过自交联形成交联网络,从而对PAA第二网络的协同效应有所减弱。综合上述结果,最终选择10wt%的PHEMA作为水凝胶的添加量。如图3(f)显示了PAAm-PHEMA/PAA-Fe3+-MXene水凝胶在不同最大应变(100%、200%、400%和 600%)下加载-卸载循环期间的拉伸应力-应变曲线和耗散能量,可以看出:随着应变逐渐增大,磁滞回线逐渐增大,这也表明:由PAAm-PHEMA/PAA-Fe3+-MXene介导的Fe3+水凝胶中在拉伸过程中表现出更多动态交联的解离,即氢键和配位相互作用。结果,更多的相互作用破裂产生了更多的能量耗散,这通过不断增大的磁滞回线随着最大应变的增加而得以证明。同时在最大应变为600%的条件下进行了8个连续的加载-卸载循环测试,如图3(g)所示,随着循环次数的增加磁滞回线的面积逐渐增加,这主要是由于在不断加载卸载过程中Fe3+介导的配位键和氢键的大量断裂及在拉伸过程中水分的蒸发,大量解离的动态氢键和配位键不能在直接循环中立即重新结合所致。另外通过拉伸试验研究了PAAm-PHEMA/PAA-Fe3+-MXene水凝胶切断后的愈合力学性能。如图3(h)所示,将PAAm-PHEMA/PAA-Fe3+-MXene水凝胶切断后在室温下进行愈合测试,随着时间的增长愈合水凝胶的断裂伸长率逐渐增加,当愈合48 h断裂伸长率可以达到1190%,愈合效率可以达到60%。高力学自修复表明水凝胶中可逆金属配位和氢键相互作用可以使水凝胶快速重建。动态流变测试表明PAAm-PHEMA/PAA-Fe3+-MXene水凝胶具有明显的软物质特性,在角频率变化的整个区间,储能模量(G':~6241 Pa)总是远大于损耗模量(G'':~3328 Pa),并且在外部大变形下网络能够保持稳定如图3(i)所示。图3(j)显示了PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的高拉伸性。

![]() 图 3 (a) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的FTIR图谱;(b) 冷冻干燥后的SEM图像;(c) 冷冻干燥后的PAAm-PHEMA/ PAA-Fe3+-MXene水凝胶的元素分布扫描;((d), (e)) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶不同添加量下的拉伸应力-应变曲线;(f) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的不同应变(100%、200%、400%和 600%)下加载-卸载循环期间的耗散能量;(g) 8次连续加载-卸载循环的应力-应变曲线;(h) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的自愈合拉伸应力-应变曲线;(i) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的流变行为;(j) 拉伸试验中1000%伸长率的高拉伸性Figure 3. (a) FTIR spectra of PAAm-PHEMA/PAA-Fe3+-MXene hydrogel; (b) SEM image after freeze-drying; (c) Elemental distribution scan of the freeze-dried PAAm-PHEMA/PAA-Fe3+-MXene hydrogel; ((d), (e)) Tensile stress-strain curves of PAAm-PHEMA/PAA-Fe3+-MXene hydrogels with different loadings; (f) PAAm-PHEMA/PAA-Fe3+-MXene hydrogels loaded under different strains (100%, 200%, 400% and 600%)-energy dissipated during unloading cycles; (g) Stress-strain curves for eight consecutive loading-unloading cycles; (h) Self-healing tensile stress-strain curves of PAAm-PHEMA/PAA-Fe3+-MXene hydrogels; (i) Rheological behavior of PAAm-PHEMA/PAA-Fe3+-MXene hydrogels; (j) 1000% elongation in tensile test high stretchabilityG'—Energy storage modulus; G''—Loss modulus; w—Angular velocity

图 3 (a) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的FTIR图谱;(b) 冷冻干燥后的SEM图像;(c) 冷冻干燥后的PAAm-PHEMA/ PAA-Fe3+-MXene水凝胶的元素分布扫描;((d), (e)) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶不同添加量下的拉伸应力-应变曲线;(f) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的不同应变(100%、200%、400%和 600%)下加载-卸载循环期间的耗散能量;(g) 8次连续加载-卸载循环的应力-应变曲线;(h) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的自愈合拉伸应力-应变曲线;(i) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的流变行为;(j) 拉伸试验中1000%伸长率的高拉伸性Figure 3. (a) FTIR spectra of PAAm-PHEMA/PAA-Fe3+-MXene hydrogel; (b) SEM image after freeze-drying; (c) Elemental distribution scan of the freeze-dried PAAm-PHEMA/PAA-Fe3+-MXene hydrogel; ((d), (e)) Tensile stress-strain curves of PAAm-PHEMA/PAA-Fe3+-MXene hydrogels with different loadings; (f) PAAm-PHEMA/PAA-Fe3+-MXene hydrogels loaded under different strains (100%, 200%, 400% and 600%)-energy dissipated during unloading cycles; (g) Stress-strain curves for eight consecutive loading-unloading cycles; (h) Self-healing tensile stress-strain curves of PAAm-PHEMA/PAA-Fe3+-MXene hydrogels; (i) Rheological behavior of PAAm-PHEMA/PAA-Fe3+-MXene hydrogels; (j) 1000% elongation in tensile test high stretchabilityG'—Energy storage modulus; G''—Loss modulus; w—Angular velocity2.3 PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的黏附性能

PAAm-PHEMA/PAA-Fe3+-MXene水凝胶对各种材料表现出优异的黏合性能。如图4(a)所示,附着在手指上的PAAm-PHEMA/PAA-Fe3+-MXene水凝胶能够在塑料、玻璃、木材、橡胶、金属和聚四氟乙烯等多种基材上表现出良好的黏附性,此外从图4(b)中也可以看出水凝胶能在运动过程中保持良好的稳定性,这也从侧面证明了水凝胶良好的黏附性。与此同时黏合层水凝胶可以轻易的提起100 g的砝码而不会出现掉落,如图4(c)所示。以上这些主要是由于在PAAm-PHEMA/PAA-Fe3+-MXene水凝胶中,二维MXene纳米片和PAA链之间包含Fe3+介导的配位交联增强了凝胶的内聚力,化学交联和物理相互作用保证了与底物键合时凝胶本身不会发生破坏[22]。同时良好的黏附特性可归因于聚合物网络和基底之间的氢键和配位相互作用,多个结合位点产生牢固的界面连接,使凝胶和黏附基质难以脱落,如图4(d)所示。此外,对PAAm-PHEMA/PAA-Fe3+-MXene水凝胶与常用的基材表面的黏合性能通过拉伸-剪切测试进行量化。其中,图4(e)是拉伸-剪切测试的示意图,测试结果见图4(f),PAAm-PHEMA/PAA-Fe3+-MXene水凝胶对铝、聚氨酯(PU)涂层、玻璃、碳纤维、不锈钢等基材都显示出了良好的黏附性,这归因于水凝胶与材料被黏表面存在大量的氢键相互作用所致。其中,PAAm-PHEMA/PAA-Fe3+-MXene水凝胶对钢(30 kPa)的附着力最高,这是由于除了氢键之外还有金属配位存在,是两者的协同作用导致。

![]() 图 4 (a) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶可黏附各种固体材料,包括聚四氟乙烯(PTFE)、聚乙烯(PE)、玻璃、天然橡胶(NR)、铁;(b) 在手指活动过程中的黏附性;(c) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶对100 g砝码良好的黏附性;(d) 黏附机制;(e) 水凝胶黏附测量的示意图;(f) 水凝胶对各种基材的黏合强度Figure 4. (a) PAAm-PHEMA/PAA-Fe3+-MXene hydrogel adheres to various solid materials including polytetrafluoroethylene (PTFE), polyethylene (PE), glass, natural rubber (NR), iron; (b) On adhesion during finger movement; (c) Good adhesion of PAAm-PHEMA/PAA-Fe3+-MXene hydrogel to 100 g weight; (d) Adhesion mechanism; (e) Schematic illustration of hydrogel adhesion measurement; (f) Adhesion strength of hydrogel to various substratesPU—Polyurethane; M—Metal ion

图 4 (a) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶可黏附各种固体材料,包括聚四氟乙烯(PTFE)、聚乙烯(PE)、玻璃、天然橡胶(NR)、铁;(b) 在手指活动过程中的黏附性;(c) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶对100 g砝码良好的黏附性;(d) 黏附机制;(e) 水凝胶黏附测量的示意图;(f) 水凝胶对各种基材的黏合强度Figure 4. (a) PAAm-PHEMA/PAA-Fe3+-MXene hydrogel adheres to various solid materials including polytetrafluoroethylene (PTFE), polyethylene (PE), glass, natural rubber (NR), iron; (b) On adhesion during finger movement; (c) Good adhesion of PAAm-PHEMA/PAA-Fe3+-MXene hydrogel to 100 g weight; (d) Adhesion mechanism; (e) Schematic illustration of hydrogel adhesion measurement; (f) Adhesion strength of hydrogel to various substratesPU—Polyurethane; M—Metal ion2.4 PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的导电性能

二维MXene纳米片和Fe3+的存在都可以赋予PAAm-PHEMA/PAA-Fe3+-MXene水凝胶优异的的导电性。这主要是由于水凝胶中MXene导电网络和离子溶液的协同作用促进了离子迁移和电子传输。如图5(a)所示,在由PAAm-PHEMA/PAA-Fe3+-MXene水凝胶和蓝色LED小灯泡组成的闭合电路中,LED小灯泡在施加3 V电压的情况下成功点亮,这显示出了水凝胶的良好导电性。如图5(b)所示,为了进一步验证其自愈能力,在室温下将水凝胶切成两半,可以发现断开的水凝胶一旦接触,LED灯泡立即再次发光,显示出了良好的自愈性。当PAAm-PHEMA/PAA-Fe3+-MXene水凝胶在构建一个导电通路后对其拉伸,发现LED小灯泡的亮度逐渐变暗,这主要是由于在拉伸变形下Fe3+离子传输路径的拉长和变窄导致电阻增加所致,当去除应变后小灯泡又重新变亮。图5(c)显示了PAAm-PHEMA/PAA-Fe3+-MXene水凝胶在固含量为20wt%时的电导率。可以看出在没有Fe3+存在的情况下PAAm-PHEMA/PAA-MXene水凝胶的电导率仅为0.2 S/m,而随着MXene纳米片的加入,电导率增加到0.66 S/m,是未添加MXene的3倍。而在Fe3+溶液浸泡后电导率显著增加到3.8 S/m,这主要是由于水凝胶水环境中的大量离子迁移及二维MXene构建的导电通路两者协同所致,这种复杂的均质微网络结构在水凝胶中提供了电荷载流子的导电通道。在电场下,它允许带电离子的定向运动,并赋予水凝胶高导电性。如图5(d)所示,将PAAm-PHEMA/PAA-Fe3+-MXene水凝胶切成两半然后放置在室温下进行愈合,不需要外部刺激。随着时间的推移,48 h后能够在超景深光学显微镜下发现明显愈合,这表明PAAm-PHEMA/PAA-Fe3+-MXene水凝胶良好的自愈性[23]。

![]() 图 5 (a) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶在切割前后电导率的即时恢复;(b) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶在拉伸过程中LED小灯泡的变化;(c) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶在不同MXene含量和不同Fe3+浓度浸泡下的电导率;(d) 愈合过程的超景深光学显微镜图像,其中水凝胶上 100 μm宽的划痕随时间而变化Figure 5. (a) Immediate recovery of conductivity of PAAm-PHEMA/PAA-Fe3+-MXene hydrogel before and after cleavage; (b) LED light bulb change of PAAm-PHEMA/PAA-Fe3+-MXene hydrogel during stretching; (c) PAAm-PHEMA/PAA-Fe3+-MXene conductivity of MXene hydrogels soaked with different MXene contents and different Fe3+ concentrations; (d) Optical microscope images of the healing process with 100 μm wide scratches on the hydrogel as a function of time

图 5 (a) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶在切割前后电导率的即时恢复;(b) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶在拉伸过程中LED小灯泡的变化;(c) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶在不同MXene含量和不同Fe3+浓度浸泡下的电导率;(d) 愈合过程的超景深光学显微镜图像,其中水凝胶上 100 μm宽的划痕随时间而变化Figure 5. (a) Immediate recovery of conductivity of PAAm-PHEMA/PAA-Fe3+-MXene hydrogel before and after cleavage; (b) LED light bulb change of PAAm-PHEMA/PAA-Fe3+-MXene hydrogel during stretching; (c) PAAm-PHEMA/PAA-Fe3+-MXene conductivity of MXene hydrogels soaked with different MXene contents and different Fe3+ concentrations; (d) Optical microscope images of the healing process with 100 μm wide scratches on the hydrogel as a function of time2.5 PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的紫外屏蔽性能

对于目前的导电水凝胶来说,往往缺乏屏蔽紫外线的能力,特别是在臭氧层薄的高海拔地区和深空探索等恶劣条件下,这会对导电水凝胶的应用范围产生不利的影响。其次水凝胶的透明性对于材料应用有着很大的帮助,但往往透明水凝胶却缺乏过滤紫外线的能力。因此,一种兼具紫外线屏蔽能力和透明度的导电水凝胶受到了研究人员极大的关注。紫外光最强穿透和辐射能力的波段在320~400 nm,它会严重伤害人体皮肤甚至导致皮肤癌。在所有可见光分类中,人类视觉最敏感的波长位于550 nm处。因此选择了365和550 nm的波长来计量导电水凝胶的紫外屏蔽效率和透明度。如图6(a)、图6(b)所示,相比于单一组分的PAAm-PAA水凝胶来说,在320~400 nm波长区间内PAAm-PHEMA/PAA-Fe3+-MXene水凝胶有着优异的屏蔽能力。在 365 和 550 nm 的波长处,PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的透射率分别为0%和79.2%。PAAm-PHEMA/PAA-Fe3+-MXene水凝胶可以有效地吸收和反射紫外线,同时使更长波长的可见光通过,表现出了优异的强紫外线屏蔽能力。这主要是由于铁属于过渡元素,存在空的d轨道,在配位场中会发生能级分离。紫外光和可见光都可能引起电子跃迁从而产生紫外和可见光谱,另外铁配离子 (如水合离子)会发生电荷转移吸收 (内部电子的偏移而产生的吸收光谱)。图6(c)为PAAm-PHEMA/PAA-Fe3+-MXene水凝胶在切断后不同时间的紫外-可见光谱透射率图。可以明显看出,愈合12 h后320~400 nm的紫外光有一定透过,而愈合48 h后可以发现对于320~400 nm的不利紫外光有了明显的屏蔽效果,这主要归因于PAA与Fe3+的动态配位以及体系中大量的氢键相互作用,显示出了良好的自愈性能。实际上通过紫外灯照射荧光标记的字母也能够清楚地观察到,随着荧光区域被水凝胶覆盖后标记完全消失,如图6(d)所示。此外,10元人民币上的防伪标记在紫外线下没有出现,进一步证明了导电水凝胶具有优异的紫外线屏蔽能力,如图6(e)所示。更重要的是,在图6(f)中将水凝胶放在一张被覆盖的明信片上面,显示出了它的透明度。以上这些结果表明,PAAm-PHEMA/PAA-Fe3+-MXene水凝胶同时表现出优异的紫外线阻挡性能和高的透明度,可以安全地保护皮肤和被黏表面免受太阳照射和光老化。

![]() 图 6 ((a), (b)) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的紫外-可见光谱透射率图及在550和365 nm处的相应透射率;(c) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶在切断后不同愈合时间的紫外-可见光谱透射率图;(d) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的紫外线阻挡能力的图像;((e), (f)) 展示出强紫外吸收和对可见光的高透明度Figure 6. ((a), (b)) UV-Vis spectral transmittance plot of PAAm-PHEMA/PAA-Fe3+-MXene hydrogel and corresponding transmittance at 550 and 365 nm; (c) UV-Vis spectral transmittance of PAAm-PHEMA/PAA-Fe3+-MXene hydrogels at different healing time after cutting; (d) Images of the UV blocking ability of PAAm-PHEMA/PAA-Fe3+-MXene hydrogels; ((e), (f)) Showing strong UV absorption and high transparency to visible light

图 6 ((a), (b)) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的紫外-可见光谱透射率图及在550和365 nm处的相应透射率;(c) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶在切断后不同愈合时间的紫外-可见光谱透射率图;(d) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的紫外线阻挡能力的图像;((e), (f)) 展示出强紫外吸收和对可见光的高透明度Figure 6. ((a), (b)) UV-Vis spectral transmittance plot of PAAm-PHEMA/PAA-Fe3+-MXene hydrogel and corresponding transmittance at 550 and 365 nm; (c) UV-Vis spectral transmittance of PAAm-PHEMA/PAA-Fe3+-MXene hydrogels at different healing time after cutting; (d) Images of the UV blocking ability of PAAm-PHEMA/PAA-Fe3+-MXene hydrogels; ((e), (f)) Showing strong UV absorption and high transparency to visible light2.6 PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的电磁屏蔽性能

随着柔性电子设备和电路小型化的发展趋势,这些不可避免的电磁干扰会对设备正常运行及个人健康产生不利的影响。水凝胶是一类具有三维交联亲水聚合物网络的工程材料,三维网络的存在实现了多孔结构内的多重反射和散射,这极大地增加了屏蔽材料的安全性和可靠性。因此具有良好力学性能和EMI性能的导电水凝胶具有巨大的潜在应用空间。EMI屏蔽材料的屏蔽效能应高于20 dB,这意味着可以屏蔽90% 的电磁波。本文通过在8.2~12.4 GHz频率范围内测量散射参数来评估厚度为2.0 mm的MXene水凝胶的EMI屏蔽性能。如图7(a)所示,与单一组分的PAAm-PAA水凝胶相比,随着MXene含量从0wt%提高到2wt%,PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的电磁屏蔽效能从12 dB提高到36 dB,这主要归因于更高的辐射吸收和介电损耗。其机制是随着MXene的添加量升高,水凝胶相中形成了更加连续均匀的导电通路,具有较高的导电性以提高干扰电磁波的反射效率。图7(b)显示了该水凝胶在切断后愈合不同时间的EMI值。可以看出随着愈合时间增加,电磁屏蔽值也随着增加,愈合48 h后可达到29 dB,显示出了良好的愈合性能,这主要归因于第二物理网络在切断后的重新配位及丰富的氢键相互作用。因此这种具有良好的力学耐久性、可拉伸性、对各种表面的黏附性及自愈能力和高效屏蔽紫外线的导电水凝胶展示出了巨大的应用前景。

![]() 图 7 (a) 不同 MXene含量的PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的电磁屏蔽(EMI)曲线;(b) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶不同愈合时间的EMI曲线Figure 7. (a) EMI curves of PAAm-PHEMA/PAA-Fe3+-MXene hydrogels containing different MXene contents; (b) EMI curves of PAAm-PHEMA/PAA-Fe3+-MXene hydrogels with different healing timeEMI SE—Electromagnetic-interference shielding effect

图 7 (a) 不同 MXene含量的PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的电磁屏蔽(EMI)曲线;(b) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶不同愈合时间的EMI曲线Figure 7. (a) EMI curves of PAAm-PHEMA/PAA-Fe3+-MXene hydrogels containing different MXene contents; (b) EMI curves of PAAm-PHEMA/PAA-Fe3+-MXene hydrogels with different healing timeEMI SE—Electromagnetic-interference shielding effect3. 结 论

(1) 以丙烯酰胺(AAm)共聚甲基丙烯酸羟乙酯(HEMA)化学交联为第一网络,聚丙烯酸(PAA)-Fe3+为第二网络,二维MXene作为导电纳米填料制备了双屏蔽机制PAAm-PHEMA/PAA-Fe3+-MXene水凝胶,双网络的设计有效地提高复合水凝胶的力学性能(320.1 kPa)和高拉伸性(1786%)。

(2) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶对各种材料表现出优异的黏合性能,并且该复合水凝胶也具有良好的导电性和循环稳定性,其电导率可以达到 3.8 S/m。

(3) PAAm-PHEMA/PAA-Fe3+-MXene水凝胶还表现出了优异的紫外线屏蔽能力,在365和550 nm的波长处,PAAm-PHEMA/PAA-Fe3+-MXene水凝胶的透过率分别为0%和79.2%。同时该复合水凝胶在8.2~12.4 GHz 频率范围内可以获得超过36 dB的出色电磁屏蔽(EMI)效果,该复合水凝胶展示出了巨大的应用前景。

-

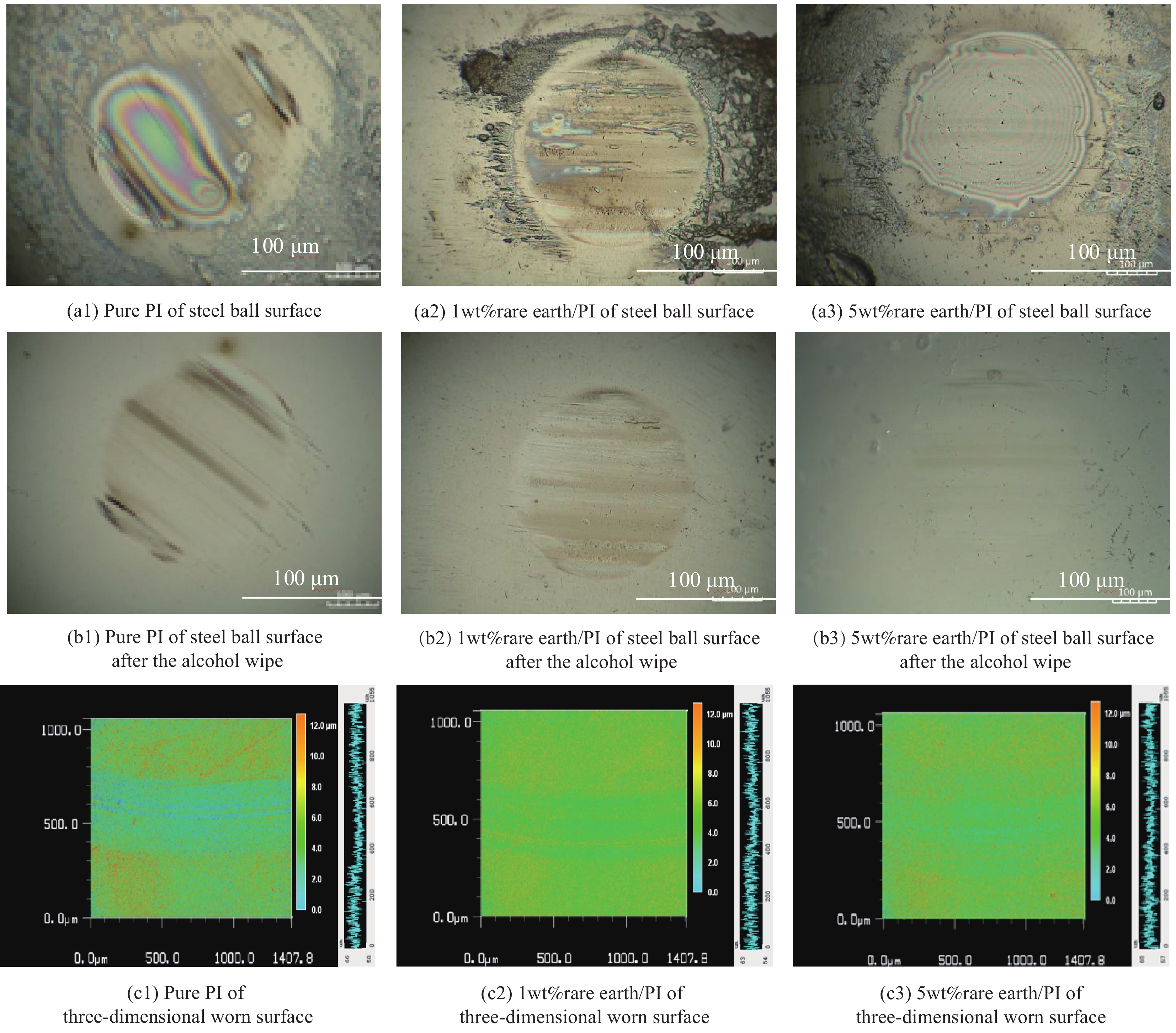

表 1 稀土改性的PI聚合物试样在光学显微镜下的磨痕宽度

Table 1 Wear mark width of rare earth modified PI polymer specimens under light microscope

Sample Grinding crack width/μm Pure PI 577.3 1wt%rare earth/porous PI 509.7 5wt%rare earth/porous PI 457.1 -

[1] LV Mei, WANG Chao, WANG Qihua, et al. Highly stable tribological performance and hydrophobicity of porous polyimide material filled with lubricants in a simulated space environment[J]. RSC Advances, 2015, 5: 53543-53549.

[2] 段春俭, 邵明超, 李宋, 等. 极端条件下的聚酰亚胺自润滑复合材料的研究进展[J]. 中国科学: 化学, 2018, 48(12):1561-1567. DOI: 10.1360/N032018-00188 DUAN Chunjian, SHAO Mingchao, LI Song, et al. The research progress in polyimide self-lubricating composites under extreme conditions[J]. Scientia Sinica: Chimica,2018,48(12):1561-1567(in Chinese). DOI: 10.1360/N032018-00188

[3] 李冰, 律微波, 赵宁, 等. 聚酰亚胺基固体润滑材料研究进展[J]. 化工新型材料, 2017, 45(6):8-10. LI Bing, LV Weibo, ZHAO Ning, et al. Research development of polyimide based solid lubricant[J]. New Chemical Materials,2017,45(6):8-10(in Chinese).

[4] ZHANG Di, WANG Chao, WANG Qihua, et al. High thermal stability and wear resistance of porous thermosetting heterocyclic polyimide impregnated with silicone oil[J]. Tribology International,2019,140:105728.

[5] PIETER S, PATRICK D B, GUSTAAF S. Role of internal additives in the friction and wear of carbon-fiber-reinforced polyimide[J]. Journal of Applied Polymer Science,2010,116(2):1146-1156.

[6] SATHYAN K, HSU H Y, LEE S H, et al. Long-term lubrication of momentum wheels used in spacecrafts—An overview[J]. Tribology International,2010,43(1-2):259-267.

[7] ROY A, MU L W, SHI Y J. Tribological properties of polyimide coating filled with carbon nanotube at elevated temperatures[J]. Polymer Composites,2020,41(7):2652-2661.

[8] 王云飞, 张朋, 刘刚, 等. 航空发动机用聚酰亚胺树脂基复合材料衬套研究进展[J]. 材料工程, 2016, 44(9):121-128. DOI: 10.11868/j.issn.1001-4381.2016.09.019 WANG Yunfei, ZHANG Peng, LIU Gang, et al. Progress in research on polymide composite bushings for aeroengine[J]. Journal of Materials Engineering,2016,44(9):121-128(in Chinese). DOI: 10.11868/j.issn.1001-4381.2016.09.019

[9] 卓航, 李是卓, 韩恩林, 等. 高强高模聚酰亚胺纤维/环氧树脂复合材料力学性能与破坏机制[J]. 复合材料学报, 2019, 36(9):2101-2109. ZHUO Hang, LI Shizhuo, HAN Enlin, et al. Mechanical properties and failure mechanism of high strength and high modulus polyimide fiber/epoxy composites[J]. Acta Materiae Compositae Sinica,2019,36(9):2101-2109(in Chinese).

[10] 阮洪伟, 张韶华, 王廷梅, 等. 多孔聚酰亚胺含油轴承保持架的磨损机理研究[J]. 空间控制技术与应用, 2019, 45(3):64-70. DOI: 10.3969/j.issn.1674-1579.2019.03.010 RUAN Hongwei, ZHANG Shaohua, WANG Tingmei, et al. On wear mechanism of porous polyimide oil-containing bearing[J]. Aerospace Control and Application,2019,45(3):64-70(in Chinese). DOI: 10.3969/j.issn.1674-1579.2019.03.010

[11] 邱优香, 王齐华, 王超, 等. 多孔聚酰亚胺含油材料的储油性能及摩擦学行为研究[J]. 摩擦学学报, 2012, 32(6):538-543. QIU Youxiang, WANG Qihua, WANG Chao, et al. Oil-containing and tribological properties of porous polyimide containing lubricant oil[J]. Tribology,2012,32(6):538-543(in Chinese).

[12] 赵华俊, 王晓雷, 黄巍. 多孔聚酰亚胺保持架对轴承贫油润滑性能研究[J]. 机械制造与自动化, 2018, 47(3):31-34. ZHAO Huajun, WANG Xiaolei, HUANG Wei. Study of effect of porous polyimide retainer on bearing at starved lubrication[J]. Machine Building & Automation,2018,47(3):31-34(in Chinese).

[13] 闫普选, 朱鹏, 黄丽坚, 等. 聚酰亚胺多孔 含油材料的摩擦磨损性能研究[J]. 摩擦学学报, 2008(3):272-276. DOI: 10.3321/j.issn:1004-0595.2008.03.016 YAN P X, ZHU P, HUANG L J, et al. Study on tribological properties of porous polyimide containing lubricants[J]. Tribology,2008(3):272-276(in Chinese). DOI: 10.3321/j.issn:1004-0595.2008.03.016

[14] 周宁宁, 卿涛, 张韶华, 等. 碳纳米管填充多孔聚合物材料含油性能研究[J]. 润滑与密封, 2017, 42(2):120-123. DOI: 10.3969/j.issn.0254-0150.2017.02.024 ZHOU Ningning, QING Tao, ZHANG Shaohua, et al. Research on oil-containing performance of porous polymer materials filled with carbon nanotubes[J]. Lubrication Engineering,2017,42(2):120-123(in Chinese). DOI: 10.3969/j.issn.0254-0150.2017.02.024

[15] JIA Weihong, YANG Shengrong, REN Sili, et al. Preparation and tribological behaviors of porous oil-containing polyimide/hollow mesoporous silica nanospheres compo-site films[J]. Tribology International,2020,145:106184.

[16] 叶锦宗, 李锦棒, 周宁宁, 等. 成型工艺对多孔PI材料摩擦学及力学性能的影响[J]. 材料工程, 2020, 48(9):144-151. YE Jinzong, LI Jinbang, ZHOU Ningning, et al. Effect of molding process on tribology and mechanical properties of porous PI materials[J]. Journal of Materials Engineering,2020,48(9):144-151(in Chinese).

[17] 卿涛, 周宁宁, 周刚, 等. 空间摩擦学在卫星活动部件轴系的应用研究现状及发展[J]. 润滑与密封, 2015, 40(2):100-108+115. QING Tao, ZHOU Ningning, ZHOU Gang, et al. Application research status and development of space tribology in shafting of statellite moving parts[J]. Lubrication Engineering,2015,40(2):100-108+115(in Chinese).

[18] 张执南, 谢友柏. 摩擦学系统的系统工程及其航天应用[J]. 飞控与探测, 2019, 2(6):1-11. ZHANG Zhinan, XIE Youbo. System engineering of tribology system for space application[J]. Flight Control & Detection,2019,2(6):1-11(in Chinese).

[19] 张迪, 王超, 卿涛, 等. 空间用多孔聚合物轴承保持架材料研究进展[J]. 机械工程学报, 2018, 54(9):17-26. ZHANG Di, WANG Chao, QING Tao, et al. Research progress of porous polymer bearing retainer materials used in aerospace[J]. Journal of Mechanical Engineering,2018,54(9):17-26(in Chinese).

[20] 张雪杨, 王挺, 吴礼光, 等. 介孔碳/聚酰亚胺杂化膜原位聚合法制备及其气体分离性能[J]. 复合材料学报, 2018, 35(11):2958-2965. ZHANG Xueyang, WANG Ting, WU Liguang, et al. Fabrication of mesoporous carbon/polymide hybrid membrane by in-situ polymerization and their gas separation perfor-mance[J]. Acta Materiae Compositae Sinica,2018,35(11):2958-2965(in Chinese).

[21] TIWARI S K, SAHOO S, WANG N N, et al. Graphene research and their outputs: Status and prospect[J]. Journal of Science: Advanced Materials and Devices,2020,5(1):10-29. DOI: 10.1016/j.jsamd.2020.01.006

[22] 叶恩淦, 朱月华, 蒋利华, 等. 稀土改性剂对玻璃纤维-SiO2/聚四氟乙烯复合材料性能的影响[J]. 复合材料学报, 2018, 35(6):1428-1435. YE Engan, ZHU Yuehua, JIANG Lihua, et al. Effect of rare earth modifier on properties of glass fiber-SiO2/polytetrafluoroethylene composites[J]. Acta Materiae Compositae Sinica,2018,35(6):1428-1435(in Chinese).

[23] 国家技术监督局. 塑性拉伸性能试验方法: GB/T 1040—1992[S]. 北京: 中国标准出版社, 1992. State Bureau of Technical Supervision. Test method for plastic tensile properties: GB/T 1040—1992[S]. Beijing: China Standard Press, 1992(in Chinese).

[24] JIA Zhining, YAN Yanhong, WANG Weizheng. Preparation and tribological properties of PI oil-bearing material with controllable pore size[J]. Industrial Lubrication and Tribology,2017,69(2):88-94.

[25] ZHANG Di, WANG Tingmei, WANG Qihua, et al. Selectively enhanced oil retention of porous polyimide bearing materials by direct chemical modification[J]. Journal of Applied Polymer Science,2017,134(29):45106. DOI: 10.1002/app.45106

[26] 贾卫红, 马立民, 任嗣利, 等. 多孔PI/MSNT复合含油润滑薄膜的设计制备及其摩擦学性能研究[J]. 摩擦学学报, 2020, 40(4):424-433. JIA Weihong, MA Limin, REN Sili, et al. Tribological behaviors of porous oil-containing PI/MSNT composite lubricating films[J]. Tribology,2020,40(4):424-433(in Chinese).

-

下载:

下载: