Thermal and electrochemical properties of polybenzimidazole-modified biphenyl polyimide electrospun lithium-ion battery separator

-

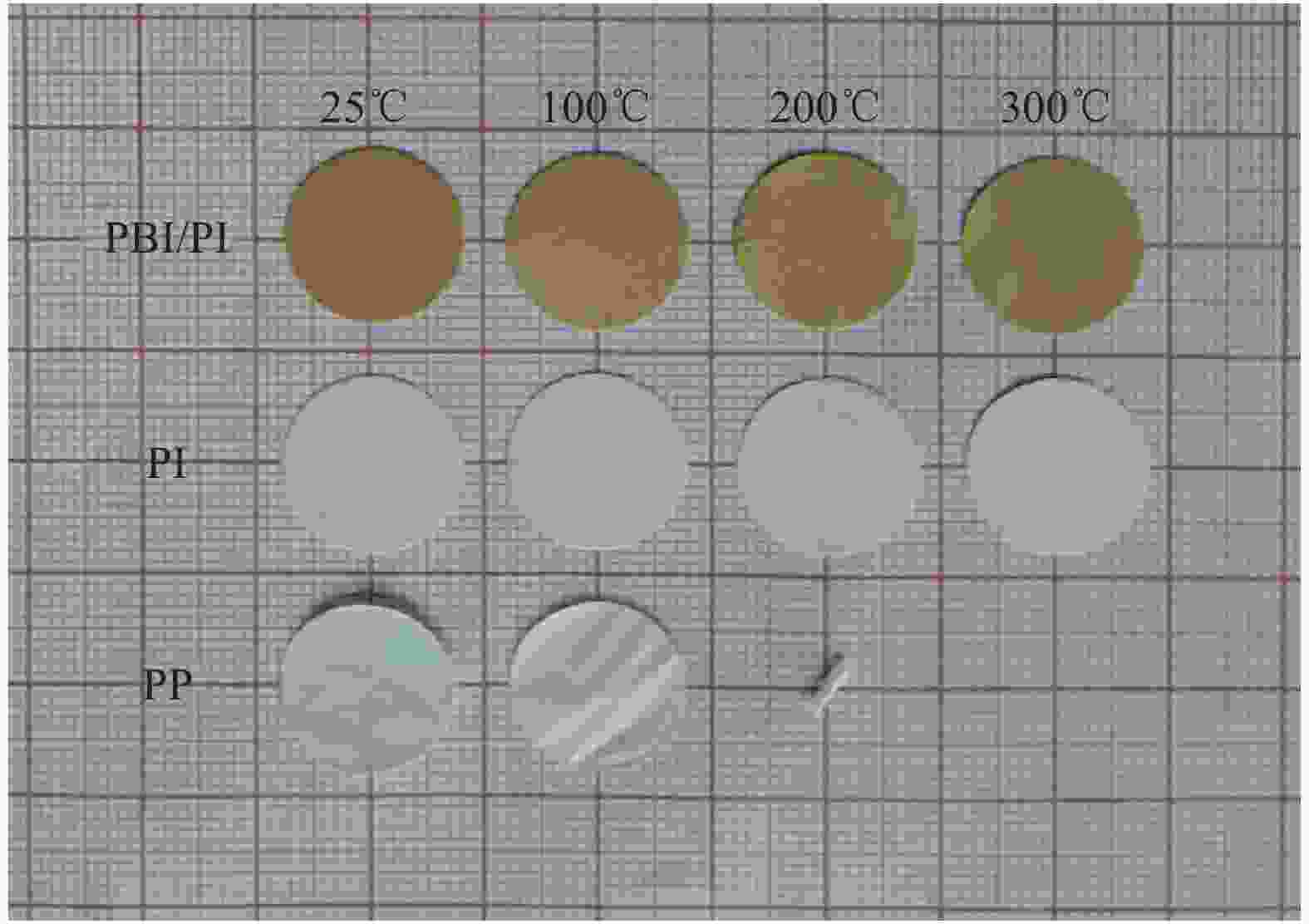

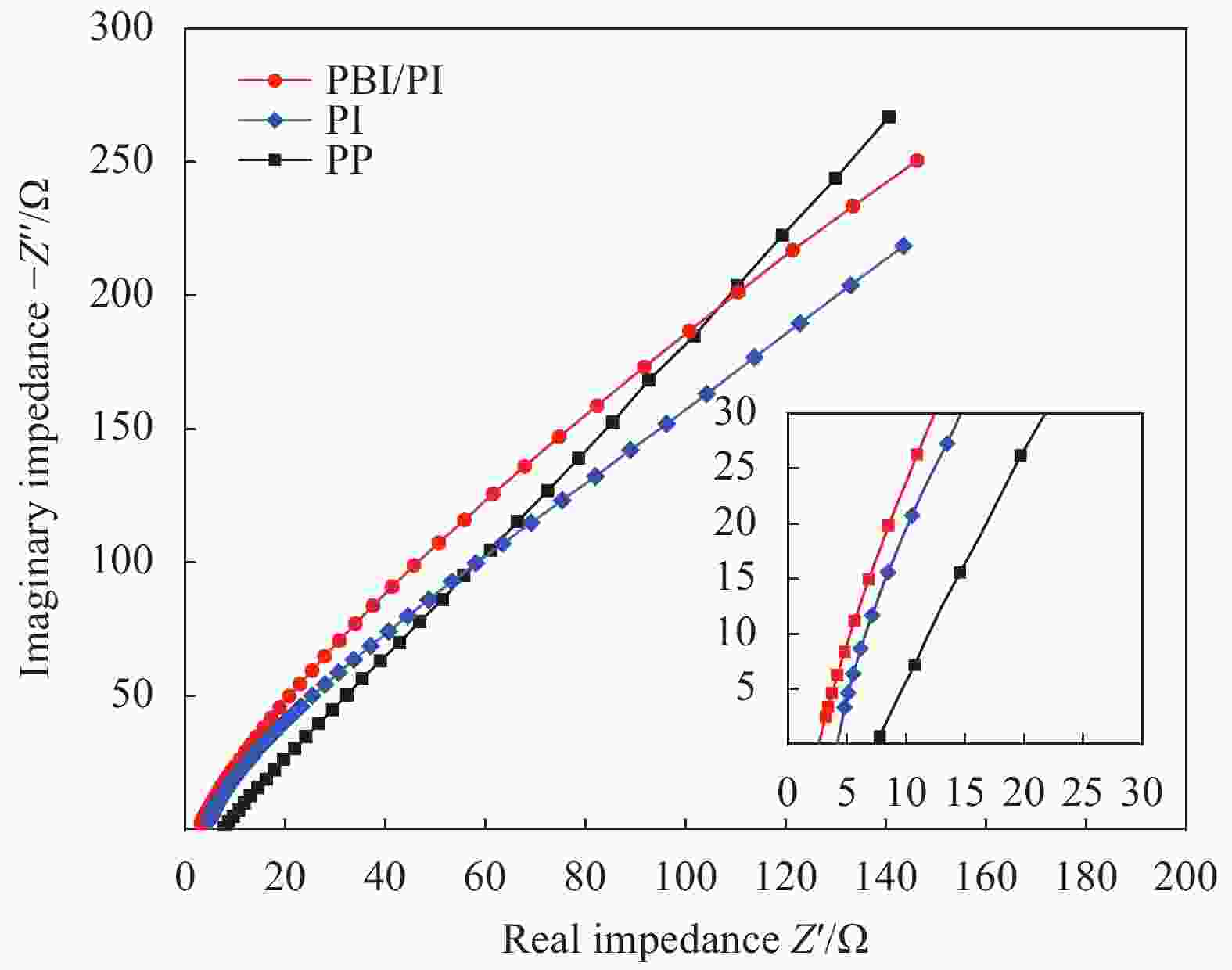

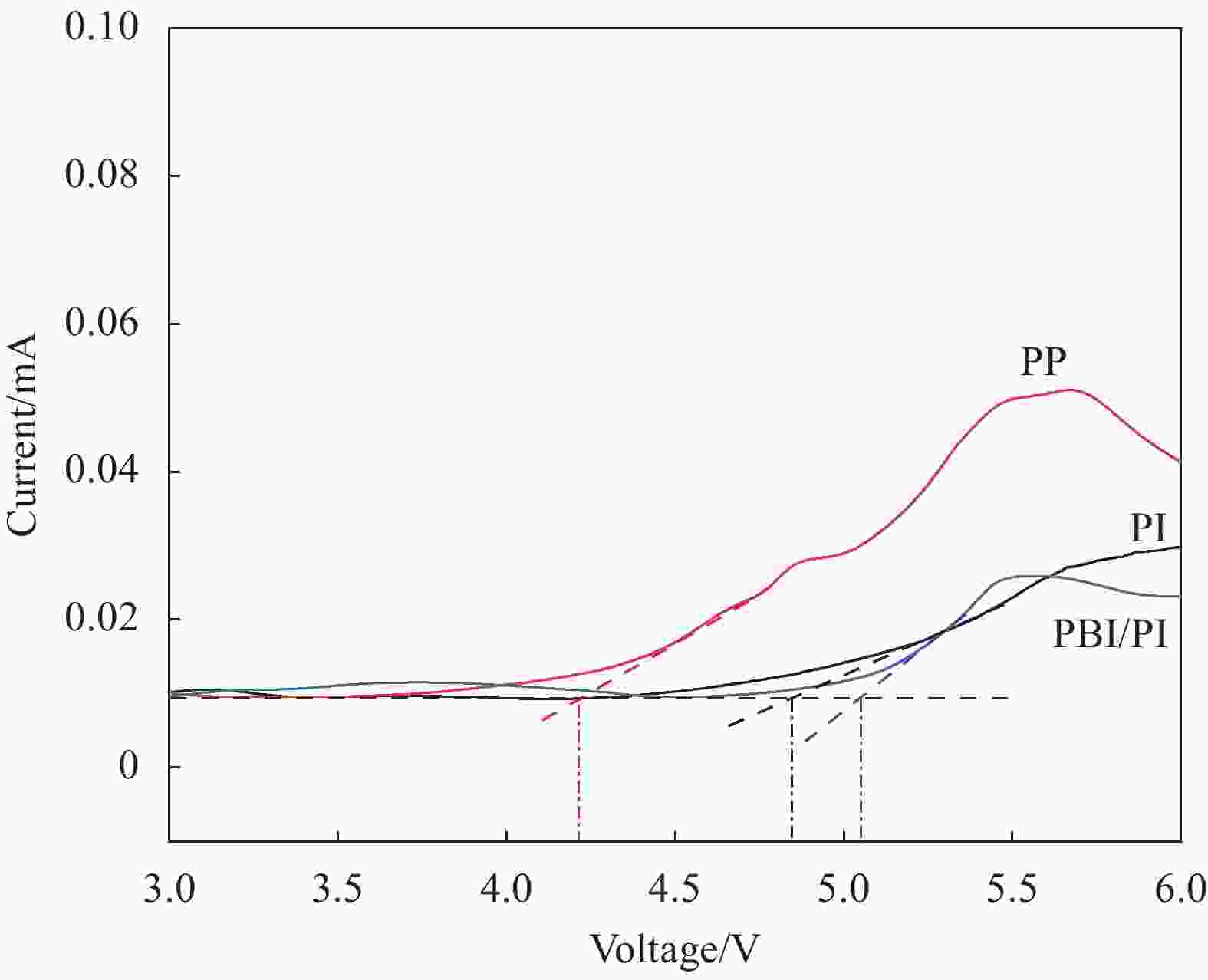

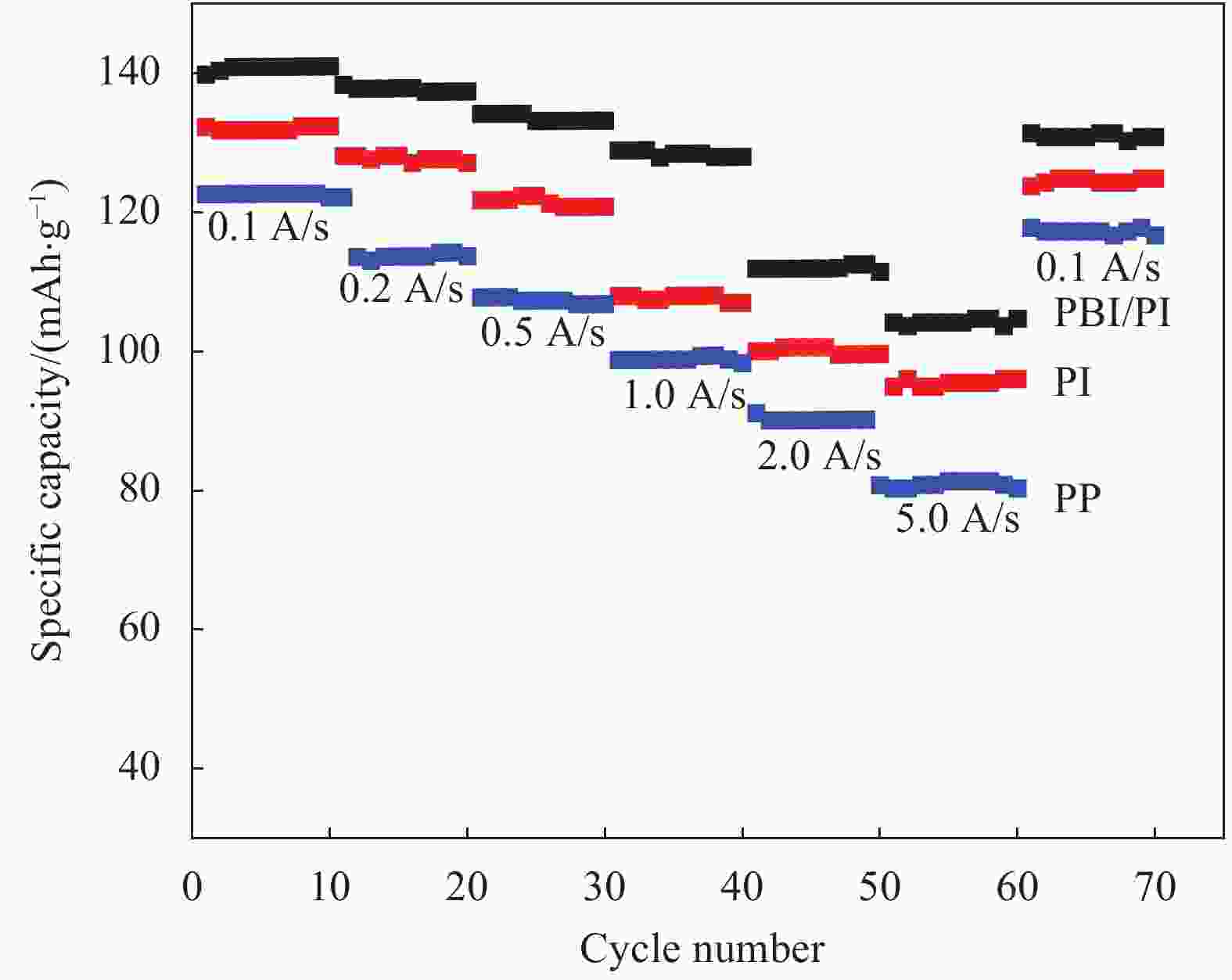

摘要: 为了改善商业隔膜孔隙率和吸液率不高、耐热性和热尺寸稳定性不佳的问题,通过选用聚苯并咪唑(PBI)预聚体对聚酰亚胺(PI)进行改性,采用高压静电纺丝法制备了质量比PBI∶PI=0.3∶1.0的复合纤维隔膜。研究了复合纤维隔膜的微观形貌、孔隙率、吸液率、热性能、电化学性能及电池性能,并将PBI∶PI=0.3∶1.0的复合纤维隔膜、PI纤维隔膜及聚丙烯(Celgard 2400,PP)隔膜进行了性能对比。结果表明,PBI∶PI=0.3∶1.0的PBI/PI复合纤维隔膜孔隙率达82%,吸液率达618%;在空气气氛中,300℃无尺寸收缩,在N2气氛中,分解温度在400℃以上,800℃时残重大于50%;离子电导率达1.29×10−3 S/cm,较PP隔膜几乎提高了1个数量级;界面阻抗为489.34 Ω,较PP隔膜降低了17%;电化学稳定窗口提高到5.05 V,为PP隔膜的119%;以PBI∶PI=0.3∶1.0的复合纤维隔膜组装的CR 2032型电池表现出优异的电池性能,经大电流放电后电池性能稳定,初始放电容量达130.01 mA·h/g,在1 A/s循环100次后容量保持率高达98.91%,均优于Celgard 2400隔膜电池。Abstract: In order to improve the problems of low porosity, low electrolyte uptake of commercial separators, poor heat resistance and thermal dimensional stability, Polybenzimidazole (PBI) was used to modify polyimide (PI). The PBI∶PI=0.3∶1.0 (mass ratio) composite fiber separator was prepared by the method of high-voltage electrostatic spinning. The microscopic morphology, porosity, electrolyte uptake, thermal performance, electrochemical performance and battery performance of the composite fiber separator were studied. The performance of composite fiber separator with mass ratio of PBI∶PI=0.3∶1.0, PI fiber separator and polypropylene (Celgard 2400, PP) separator were compared. The results show that the composite fiber separator with PBI∶PI=0.3∶1.0 has a porosity of 82% and electrolyte uptake of 618%; in an air atmosphere, there is no size shrinkage at 300℃; in a nitrogen atmosphere, the decomposition temperature is above 400℃, and the residual mass at 800℃ is more than 50%. The ionic conductivity reaches 1.29×10−3 S/cm, which is almost an order of magnitude higher than PP separatos; the interface impedance is 489.34 Ω, which is 17% lower than PP separator; the electrochemical stability window is increased to 5.05 V, which is 19% of the PP separator; CR 2032 battery assembled with PBI∶PI=0.3∶1.0 composite fiber separator shows excellent battery performance. After high current discharged, cells properties remain stable, initial discharge capacity is 130.01 mA·h/g, capacity retention rate is 98.91% after 100 cycles of 1 A/s, which is better than PP separator cells.

-

Key words:

- electrospinning /

- polybenzimidazole /

- biphenyl type polyimide /

- lithium-ion cells /

- separator

-

表 1 PBI/PI复合纤维隔膜、PI纤维隔膜、聚丙烯(PP)隔膜的孔隙率和吸液率

Table 1. Porosity and electrolyte uptake of PBI/PI composite fiber separators, PI and polypropylene (PP) separators

Sample Porosity/% Electrolyte uptake/% PBI/PI 82 618 PI 76 565 PP (Celgard 2400) 42 150 Note: Celgard 2400 is a single-layer PP separator with a thickness of 25 μm. -

[1] SHEN Chen, WANG Huaiguo. Research on the technological development of lithium-ion battery industry in China[J]. Journal of Physics: Conference Series,2019,1347(1):012087. [2] CANO Z P, BANHAM D, YE S, et al. Batteries and fuel cells for emerging electric vehicle markets[J]. Nature Energy,2018,3(4):279-289. doi: 10.1038/s41560-018-0108-1 [3] LIU Zhifang, JIANG Yingjun, HU Qiaomei, et al. Safer lithium-ion batteries from the separator aspect: Development and future perspectives[J]. Energy & Environmental Materials,2020,4(3):336-362. [4] MUHAMMAD W, SHAMSHAD A, FENG Chao, et al. Recent development in separators for high-temperature lithium-ion batteries[J]. Small,2019,15(33):1901689. [5] PARIKH D, CHRISTENSEN T, HSIEH C T, et al. Elucidation of separator effect on energy density of Li-ion batteries[J]. Journal of The Electrochemical Society,2019,166(14):3377-3383. doi: 10.1149/2.0571914jes [6] HEIDARI AA, Mahdavi H. Recent development of polyolefin-based microporous separators for liion batteries: A review[J]. The Chemical Record,2020,20(6):570-595. doi: 10.1002/tcr.201900054 [7] LAGADEC M F, ZAHN R, WOOD V. Characterization and performance evaluation of lithium-ion battery separators[J]. Nature Energy,2019,4:16-25. doi: 10.1038/s41560-018-0295-9 [8] LI Yaqian, YU Le, HU Weiren, et al. Thermotolerant separators for safe lithium-ion batteries under extreme conditions[J]. Journal of Materials Chemistry A,2020,8(39):20294-20317. doi: 10.1039/D0TA07511F [9] 巩桂芬, 邹明贵, 崔巍巍, 等. 锂离子电池隔膜材料EVOLi-OMMT的制备及其性能[J]. 复合材料学报, 2022, 39(3): 1186-1193.GONG Guifen, ZOU Minggui, CUI Weiwei, et al. preparation and performance of EVOLi-OMMT separator material for lithium ion battery[J]. Acta Materiae Compositae Sinica, 2022, 39(3): 1186-1193(in Chinese). [10] LI Xiaoyan, CHEN Weichen, QIAN Qingrong, et al. Electrospinning-based strategies for battery materials[J]. Advanced Energy Materials,2021,11(2):2000845. doi: 10.1002/aenm.202000845 [11] XUE Jiajia, WU Tong, DAI Yunqian, et al. Electrospinning and electrospun nanofibers: Methods, materials, and applications[J]. Chemical Reviews,2019,119(8):5298-5415. doi: 10.1021/acs.chemrev.8b00593 [12] 崔巍巍, 孟庆朋, 王振宇, 等. 大倍率高耐热聚醚酰亚胺-聚偏氟乙烯芯壳纳米纤维锂离子电池隔膜[J]. 复合材料学报, 2019, 36(1):69-76.CUI Weiwei, MENG Qingpeng, WANG Zhenyu, et al. Large-rate, high-heat-resistant poly-etherimide-polyvinylidene fluoride core-shell nanofiber lithium ion battery separator[J]. Acta Materiae Compositae Sinica,2019,36(1):69-76(in Chinese). [13] HE Lei, CAO Jianhua, LIANG Tian, et al. Effect of monomer structure on properties of polyimide as LIB separator and its mechanism study[J]. Electrochimica Acta,2020,337:135838. [14] YU Haibin, SHI Yake, YUAN Biao, et al. Recent developments of polyimide materials for lithium-ion battery separators[J]. Ionics,2021,27(3):907-923. doi: 10.1007/s11581-020-03865-2 [15] 巩桂芬, 王磊, 李泽. 静电纺聚乙烯-乙烯醇磺酸锂/聚酰亚胺锂离子电池隔膜复合材料的电化学性能[J]. 复合材料学报, 2018, 35(10):2632-2639.GONG Guifen, WANG Lei, LI Ze. Electro-chemical performance of electrospun polyethylene-lithium vinyl alcohol sulfo-nate/polyimide lithium-ion battery diaphragm composite[J]. Acta Materiae Compositae Sinica,2018,35(10):2632-2639(in Chinese). [16] ZHOLOBKO O, WU X F, ZHOU Z P, et al. A comparative experimental study of the hygroscopic and mechanical behaviors of electrospun nanofiber membranes and solution-cast films of polybenzimidazole[J]. Journal of Applied Polymer Science,2020,137(39):49639. [17] CHO S J, CHOI H, JI H Y. Evaluation of PBI nanofiber membranes as a high-temperature resistance separator for lithium-ion batteries[J]. Fibers and Polymers,2020,21(5):993-998. doi: 10.1007/s12221-020-9955-z [18] SUN Guohua, KONG lushi, LIU Bingxue, et al. Ultrahigh-strength, nonflammable and high-wettability separators based on novel polyimide-core@polybenzimidazole-sheath nanofibers for advanced and safe lithium-ion batteries[J]. Journal of Membrane Science,2019,582:132-139. doi: 10.1016/j.memsci.2019.04.005 [19] SUN Guohua, LIU Bingxue, NIU Hongqing, et al. In situ welding: Superb strength, good wettability and fire resistance tri-layer separator with shutdown function for high-safety lithium-ion battery[J]. Journal of Membrane Science,2020,595:117509. [20] MAEYOSHI Y, DONG D, KUBOTA M, et al. Long-term stable lithium metal anode in highly concentrated sulfolane-based electrolytes with ultrafine porous polyimide separator[J]. ACS Applied Materials & Interfaces,2019,11(29):25833-25843. [21] 孙国华. 基于芳杂环聚合物纤维的制备、微结构调控及其性能研究[D]. 北京: 北京化工大学, 2020.SUN Guohua. Study on preparation, microstructure control and performance of aromatic heterocyclic polymer fibers[D]. Beijing: Beijing University of Chemical Technology, 2020(in Chinese). [22] 梁乃强. 锂离子电池用聚苯并咪唑隔膜的制备及其性能研究[D]. 上海: 上海交通大学, 2017.LIANG Naiqiang. Study on preparation and performance of polybenzimidazole separator for lithium ion batteries[D]. Shanghai: Shanghai Jiaotong University, 2017(in Chinese). [23] 巩桂芬, 王磊, 兰健. EVOH-SO3Li/PET电纺锂离子电池隔膜电化学性能[J]. 材料工程, 2018, 46(3):7-12.GONG Guifen, WANG Lei, LAN Jian. Electrochemical performance of electrospun lithium-ion battery separator[J]. Journal of Materials Engineering,2018,46(3):7-12(in Chinese). [24] LIU Xiaoting, ZHANG Bin, WU Yingnan, et al. The effects of polybenzimidazole nanofiber separator on the safety and performance of lithium-ion batteries: Characterization and analysis from the perspective of mechanism[J]. Jour-nal of Power Sources,2020,475:228624. doi: 10.1016/j.jpowsour.2020.228624 -

下载:

下载: