Ballistic mechanism of the hybrid panels with UHMWPE woven fabrics and UD laminates

-

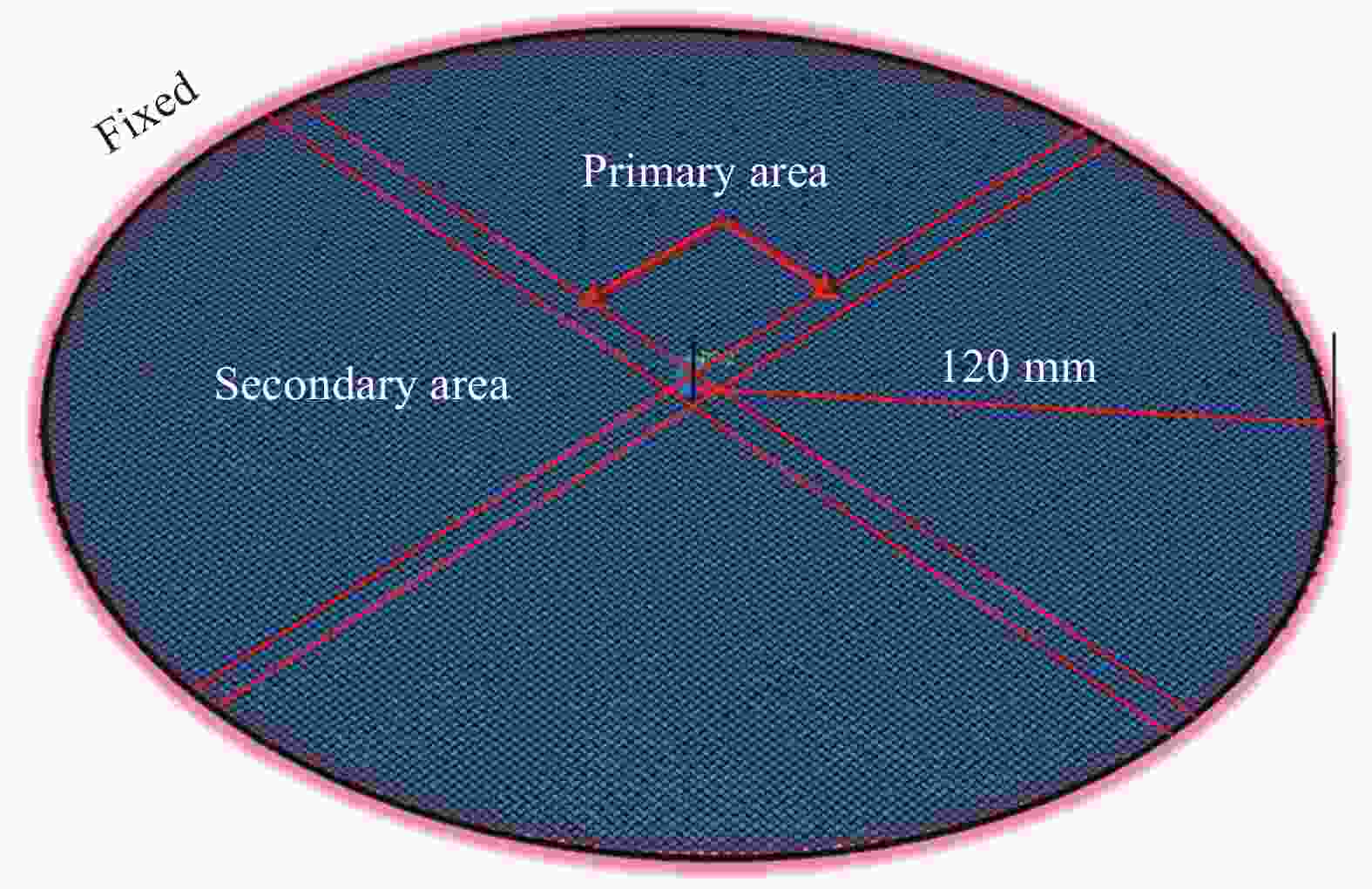

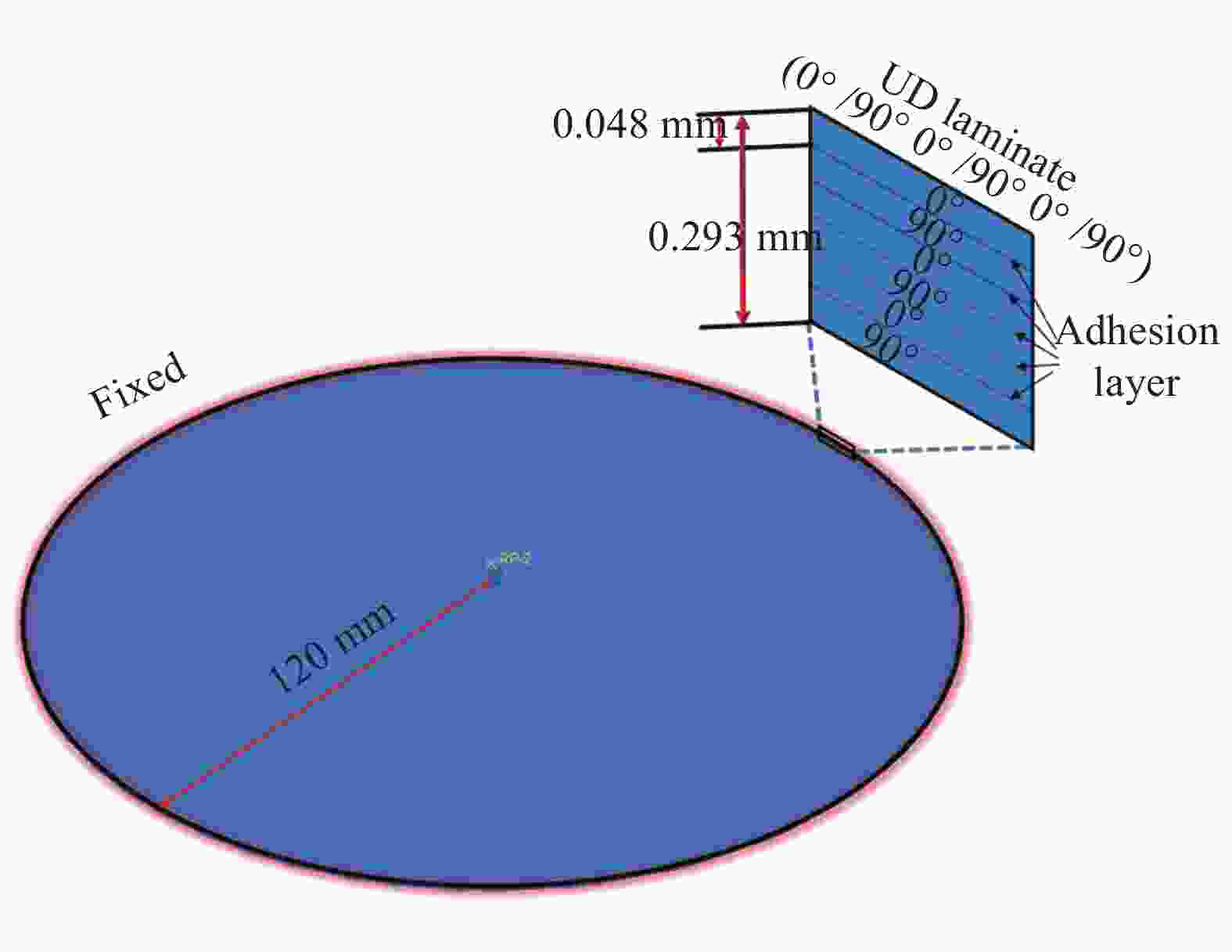

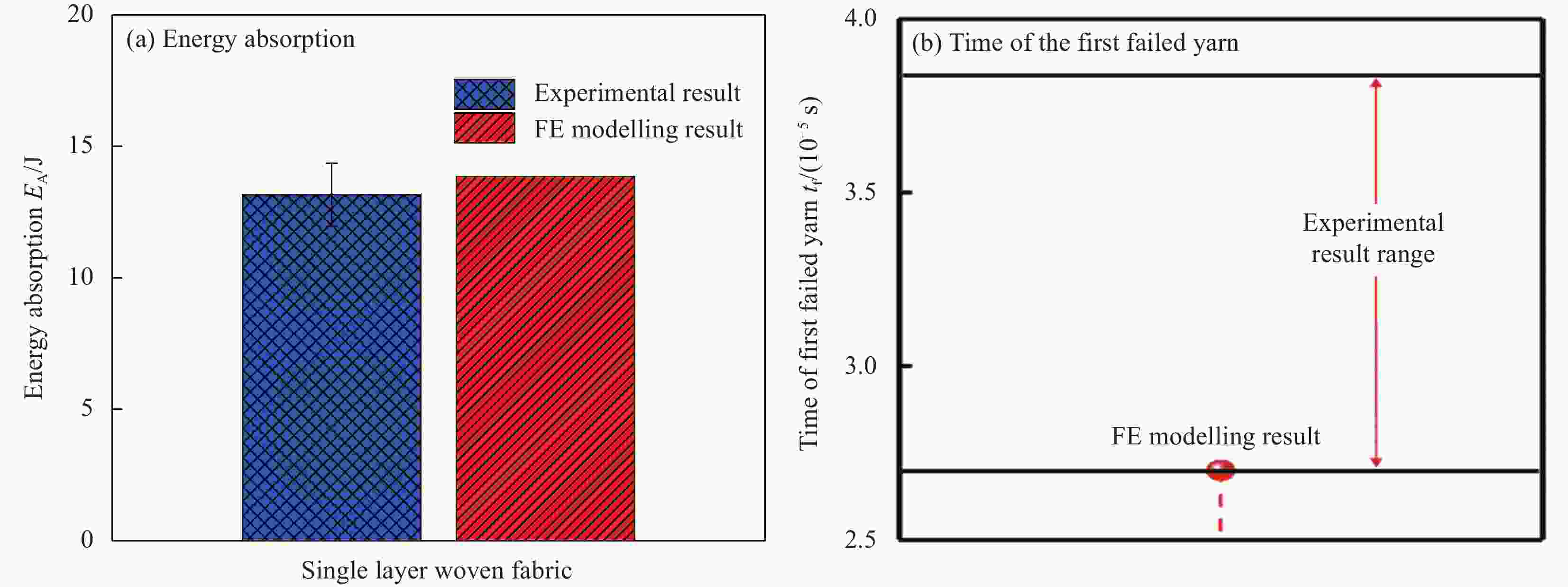

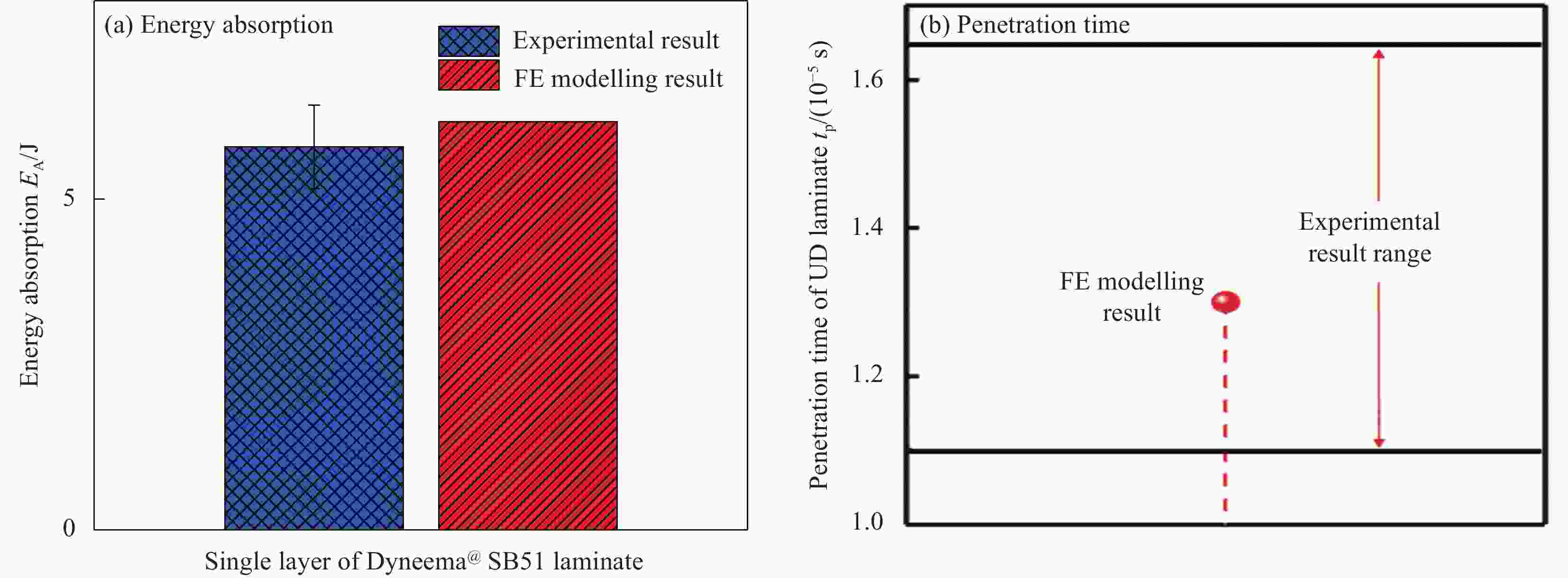

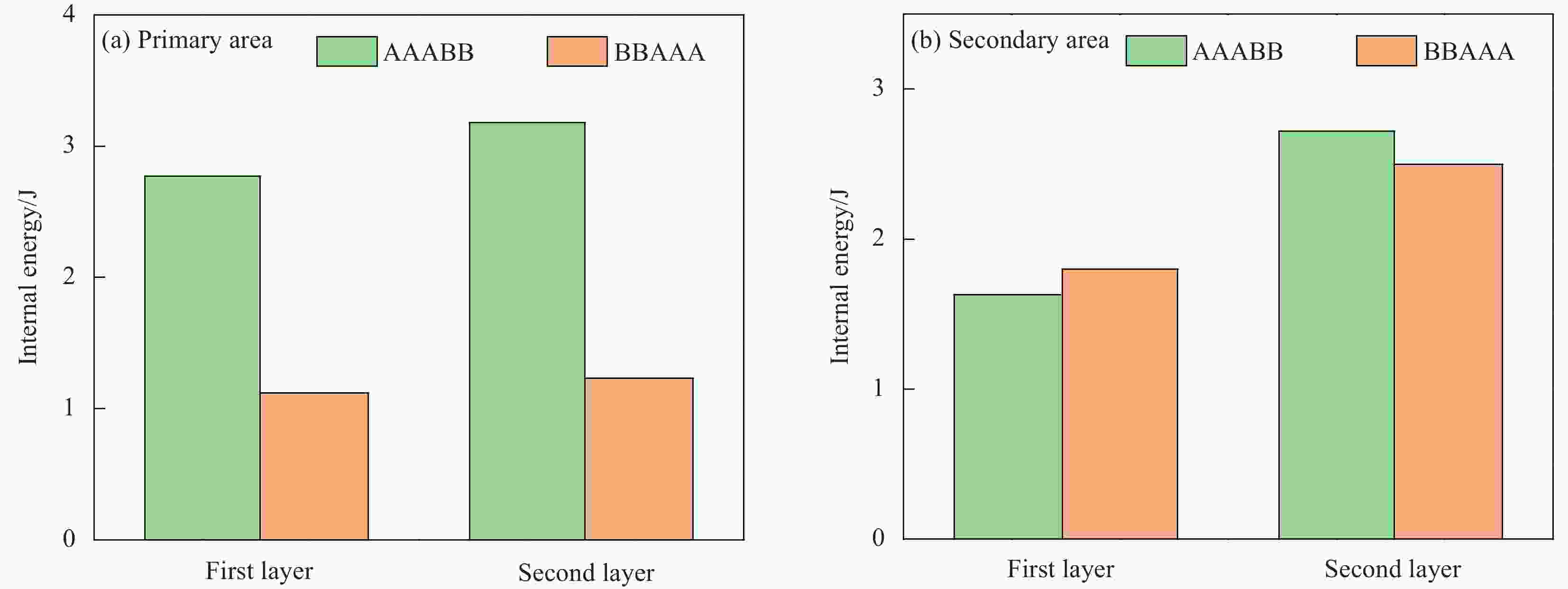

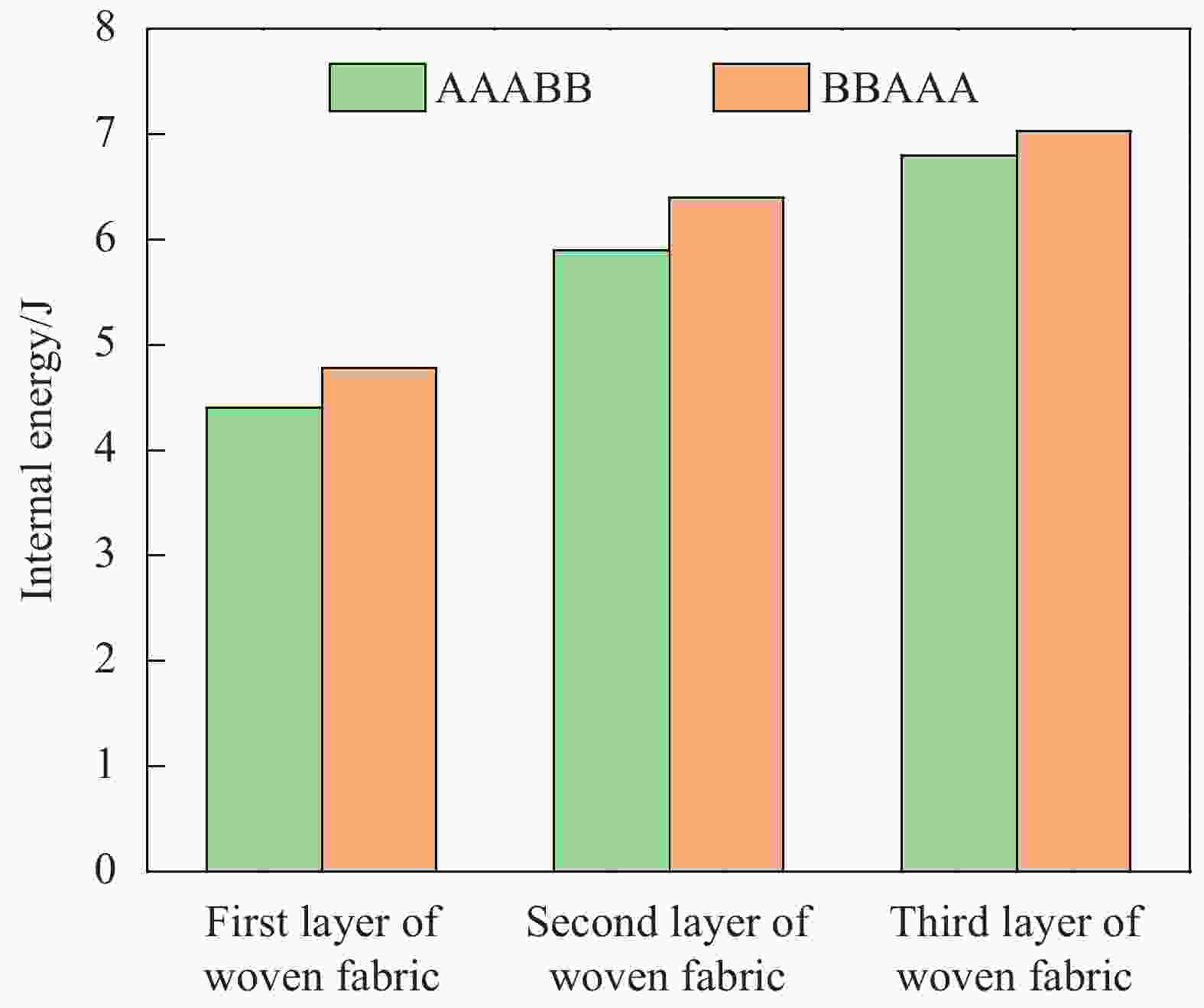

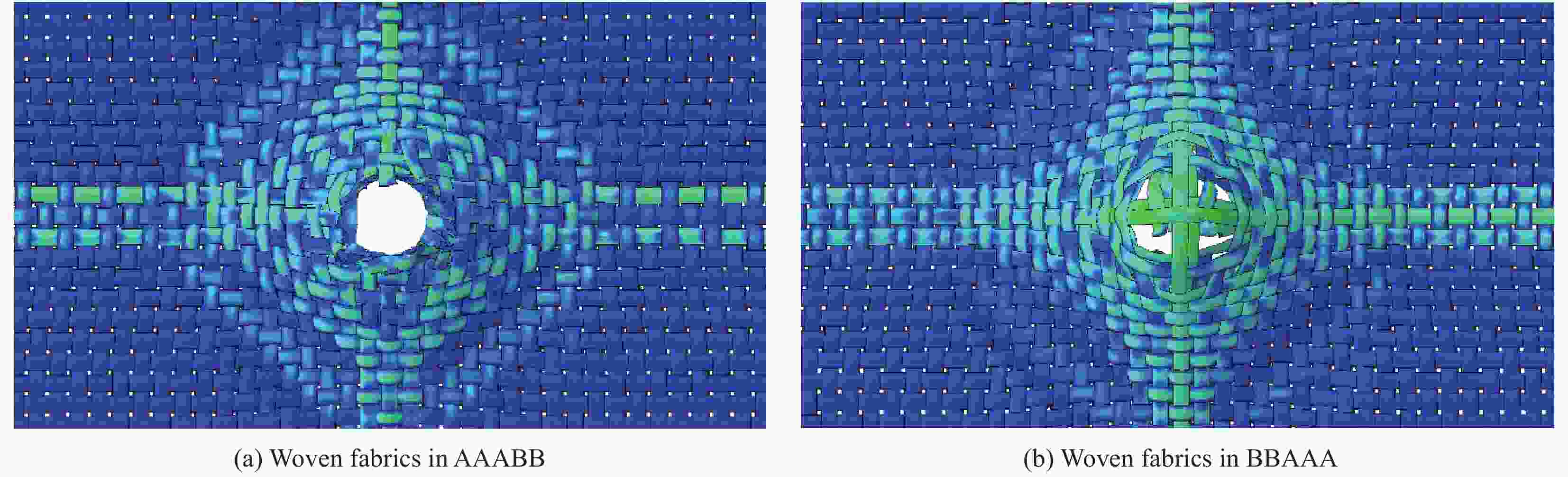

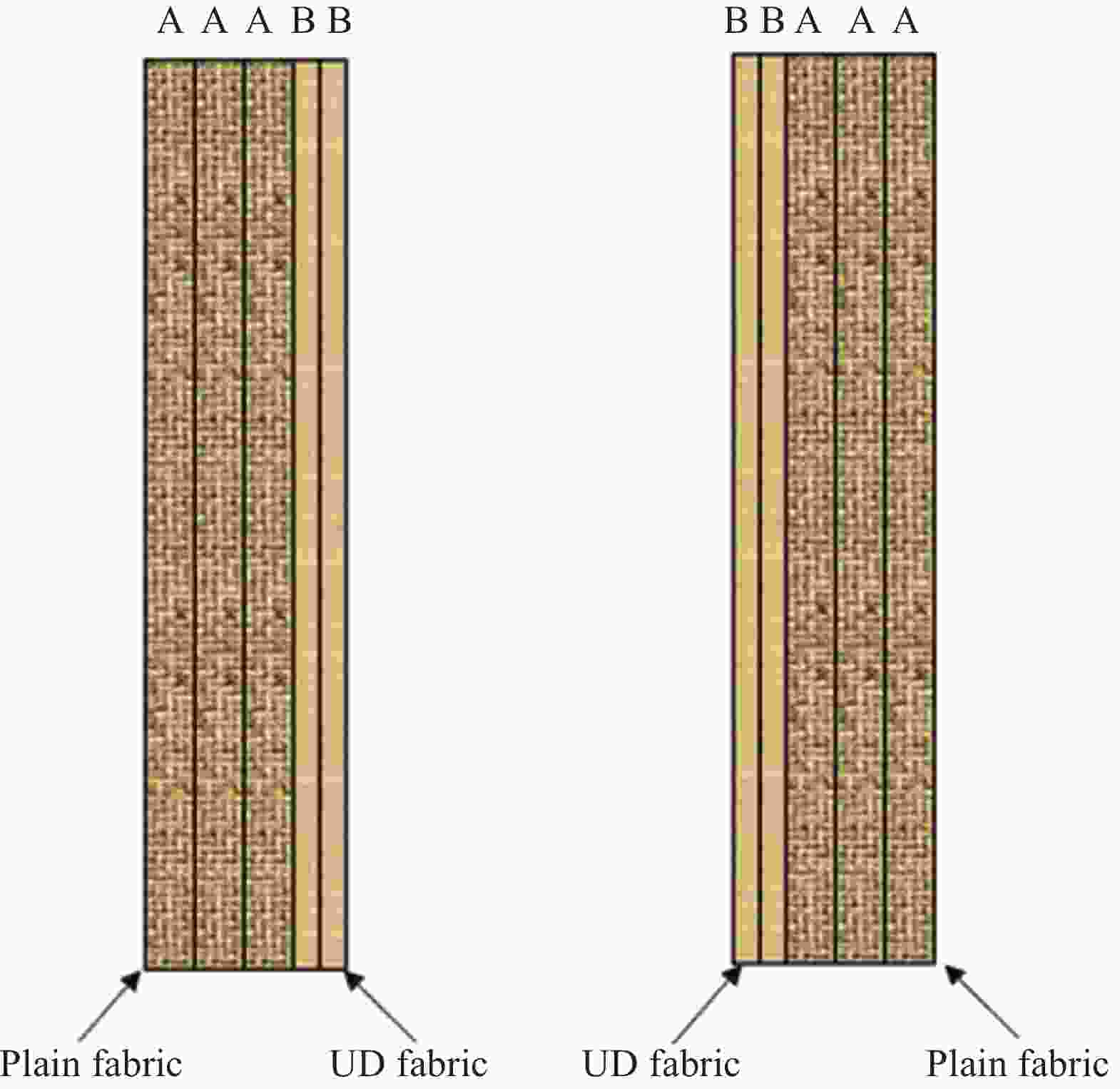

摘要: 柔性防弹衣具有隐蔽性好、穿着舒适的优点,而采用平纹与单向(UD)布杂化结构具有更好的防护效果。本文采用三层超高分子量聚乙烯(UHMWPE)纤维平纹织物(A)和两层Dyneema® SB51 UD布(B)组成AAABB和BBAAA两种混合靶板,通过弹道实验比较两种排列方式的防弹性能差异。结果表明,将平纹织物在前UD布在后能大幅提升整块板的防弹性能,能量吸收比后者高约20%。进一步采用有限元模拟来阐明其防弹机制,模拟结果表明将平纹织物放在面层不易被切断,使得平纹织物层发生更大的形变,也使后面的UD布发生大面积形变,吸收大量能量。而UD布放在前面层易产生的切力破坏,失去对后面层的作用。而平纹织物在后层容易发生滑移,且形变纵深过大,不利于防弹保护。该研究结果阐明了平纹织物和UD布不同顺序堆叠时的防弹机制,为进一步优化设计该类柔性防弹衣提供了坚实的理论基础。Abstract: Soft body amour has the advantages of good concealment and high comfortability. Recent studies demonstrate that soft body amours made up of layers of woven fabrics and unidirectional (UD) laminates show better ballistic performance. However, the mechanism behind has not been clarified. This work utilized three layers of woven fabrics (A) made by ultrahigh molecular weight polyethylene (UHMWPE) yarns and two layers of Dyneema® SB51 UD laminates (B) to compose two types of hybrid panels, viz. AAABB and BBAAA. Ballistic tests were carried out to evaluate their performance. The results show that the first type panel absorbs around 20% more energy than the second counterpart does. The finite element modelling is used to clarify the ballistic mechanism. The results illustrate that when the woven fabrics in front, they are not easier to be failed by shear, which results in more deformation of the fabric and therefore more deformation of the UD laminates behind, thereby giving rise to higher energy absorption. In contrast, when the UD laminates in front, they are easier to be damaged by the shear stress, failing to act on the followed layers. Moreover, when the woven fabrics at the rear, they tend to slip and meanwhile bring about more deformation in depth, which is detrimental to the protection. This study sheds light on the ballistic mechanism of hybrid panels with laying woven fabrics and UD laminates in different sequences. Such results, theoretically, pave the way for the design of the hybrid soft body amours.

-

Key words:

- UHMWPE fiber /

- woven fabric /

- unidirectional (UD) laminate /

- hybrid panel /

- finite element analysis /

- ballistic impact

-

表 1 UHMWPE纱线模型弹性性质

Table 1. Elastic properties of UHMWPE yarn in modelling

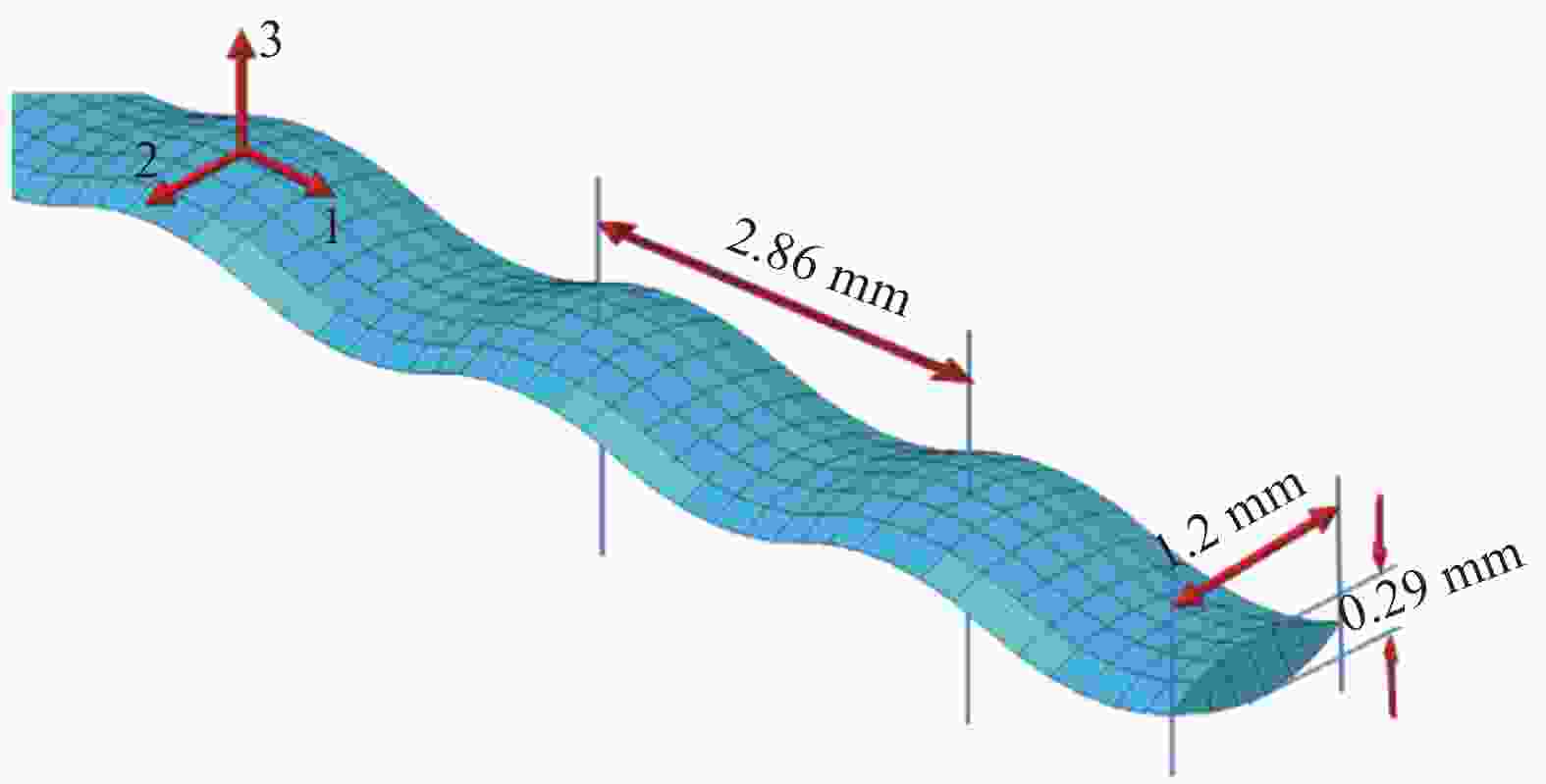

E1/MPa E2/MPa E3/MPa ν12 ν13 ν23 G12/MPa G13/MPa G23/MPa 88000 1210 1210 0.2 0.2 0.4 370 370 1500 Notes: E1, E2, E3—Young’s modulus in the 1, 2, 3-directions of the UHMWPE yarn model, respectively; ν12—Poisson’s ratio that characterizes the transverse strain in the 2-direction, when the yarn model is stressed in the 1-direction; ν13—Poisson’s ratio that characterizes the transverse strain in the 3-direction, when the yarn model is stressed in the 1-direction; ν23—Poisson’s ratio that characterizes the transverse strain in the 3-direction, when the yarn model is stressed in the 2-direction; G12, G13, G23—Shear modulus in 12, 13, 23-directions of the yarn model. 表 2 UD布模型弹性性质

Table 2. Elastic properties of a UD ply

E1/MPa E2/MPa E3/MPa ν12 ν13 ν23 G12/MPa G13/MPa G23/MPa 110000 3600 3600 0.07 0.07 0.07 420 420 420 表 3 粘结层的弹性性质

Table 3. Elastic properties of the adhesive ply

E/Enn/MPa G1/Ess/MPa G2/Ett/MPa 850 850 850 Notes: E/Enn—Nominal traction in the normal direction; G1/Ess and G2/Ett—Nominal tractions in the two local shear directions. -

[1] CHEESEMAN B A, BOGETTI T A. Ballistic impact into fabric and compliant composite laminates[J]. Composite Structures,2003,61(1-2):161-173. doi: 10.1016/S0263-8223(03)00029-1 [2] 顾伯洪. 织物弹道贯穿性能分析计算[J]. 复合材料学报, 2002, 19(6):92-96. doi: 10.3321/j.issn:1000-3851.2002.06.017GU Bohong. Analytical modelling of woven fabric under ballistic perforation[J]. Acta Materiae Compositae Sinica,2002,19(6):92-96(in Chinese). doi: 10.3321/j.issn:1000-3851.2002.06.017 [3] 朱德举, 彭恋. SiC-超高分子量聚乙烯仿生柔性叠层结构防弹性能关键影响因素的仿真与试验[J]. 复合材料学报, 2020, 37(11):2928-2940.ZHU Deju, PENG Lian. Simulation and experiment of key influencing factors on ballistic performance of SiC-ultra-high molecular weight polyethylene biomimetic flexible laminated structure[J]. Acta Materiae Compositae Sinica,2020,37(11):2928-2940(in Chinese). [4] GU B. Analytical modeling for the ballistic perforation of planar plain-woven fabric target by projectile[J]. Compo-sites Part B: Engineering,2003,34(4):361-371. doi: 10.1016/S1359-8368(02)00137-3 [5] 何业茂, 焦亚男, 周庆, 等. 弹道防护用先进复合材料弹道响应的研究进展[J]. 复合材料学报, 2021, 38(5):1331-1348.HE Yemao, JIAO Ya'nan, ZHOU Qing, et al. Research progress on ballistic response of advanced composite for ballistic protection[J]. Acta Materiae Compositae Sinica,2021,38(5):1331-1348(in Chinese). [6] 陈晓钢. 纺织基防弹防穿刺材料的研究回顾[J]. 纺织学报, 2019, 40(6):158-164.CHEN Xiaogang. Trend of research in textile-based protective materials against ballistic and stabbing[J]. Journal of Textile Research,2019,40(6):158-164(in Chinese). [7] 周熠, 陈晓钢, 张尚勇, 等. 超高分子量聚乙烯平纹织物在柔性防弹服中的应用[J]. 纺织学报, 2016, 37(4):60-64.ZHOU Yi, CHEN Xiaogang, ZHANG Shangyong, et al. Application of ultra-high molecular-weight polyethylene plain weave on soft body armour[J]. Journal of Textile Research,2016,37(4):60-64(in Chinese). [8] TABIEI A, NILAKANTAN G. Ballistic impact of dry woven fabric composites: A Review[J]. Applied Mechanics Reviews,2008,61(1):1-13. [9] NILAKANTAN G, GILLESPIE J W. Ballistic impact modeling of woven fabrics considering yarn strength, friction, projectile impact location, and fabric boundary condition effects[J]. Composite Structures,2012,94(12):3624-3634. doi: 10.1016/j.compstruct.2012.05.030 [10] CHEN X, ZHU F, WELL G. An analytical model for ballistic impact on textile based body armour[J]. Composites Part B: Engineering,2013,45(1):1508-1514. doi: 10.1016/j.compositesb.2012.08.005 [11] YANG Y, CHEN X. Study of energy absorption and failure modes of constituent layers in body armour panels[J]. Composites Part B: Engineering,2016,98:250-259. doi: 10.1016/j.compositesb.2016.04.071 [12] YANG Y, CHEN X. Determination of materials for hybrid design of 3D soft body armour panels[J]. Applied Compo-site Materials,2018,25(4):861-875. doi: 10.1007/s10443-018-9716-y [13] CHEN X, ZHOU Y, WELL G. Numerical and experimental investigations into ballistic performance of hybrid fabric panels[J]. Composites Part B: Engineering,2014,58:35-42. doi: 10.1016/j.compositesb.2013.10.019 [14] BAJYA M, MAJUMDAR A, BUTOLA B, et al. Ballistic performance and failure modes of woven and unidirectional fabric based soft armour panels[J]. Composite Structures,2021,255:112941. doi: 10.1016/j.compstruct.2020.112941 [15] GUO Z, CHEN W. A merit parameter to determine the stacking order of heterogeneous diphasic soft armor systems[J]. Composite Structures,2020,241:112086. doi: 10.1016/j.compstruct.2020.112086 [16] WANG Y, CHEN X, YOUNG R, et al. An experimental study of the effect of ply orientation on ballistic impact perfor-mance of multi-ply fabric panels[J]. Textile Research Jour-nal,2016,86(1):34-43. doi: 10.1177/0040517514566110 [17] LU Z, YUAN Z, CHEN X, et al. Evaluation of ballistic performance of STF impregnated fabrics under high velocity impact[J]. Composite Structures,2019,227:111208. doi: 10.1016/j.compstruct.2019.111208 [18] YUAN Z, CHEN X, ZENG H, et al. Identification of the elastic constant values for numerical simulation of high velocity impact on dyneema® woven fabrics using orthogonal experiments[J]. Composite Structures,2018,204:178-191. doi: 10.1016/j.compstruct.2018.07.024 [19] WANG Y, CHEN X, YOUNG R, et al. A numerical and experimental analysis of the influence of crimp on ballistic impact response of woven fabrics[J]. Composite Structures,2016,140:44-52. doi: 10.1016/j.compstruct.2015.12.055 [20] HUANG W, WANG Y, XIA Y. Statistical dynamic tensile strength of UHMWPE-fibers[J]. Polymer,2004,45(11):3729-3734. doi: 10.1016/j.polymer.2004.03.062 [21] PISANOVA E, ZHANDAROV S, MÄDER E. How can adhesion be determined from micromechanical tests?[J]. Composites Part A: Applied Science and Manufacturing,2001,32(3):425-434. [22] GRUJICIC M, ARAKERE G, HE T, et al. A ballistic material model for cross-plied unidirectional ultra-high molecular-weight polyethylene fiber-reinforced armor-grade compo-sites[J]. Materials Science & Engineering A,2008,498(1-2):231-241. [23] YUAN Z, WANG K, QIU J, et al. A numerical study on the mechanisms of Dyneema® quasi-isotropic woven panels under ballistic impact[J]. Composite Structures,2020,236:111855. doi: 10.1016/j.compstruct.2020.111855 [24] MIN S, CHU Y, CHEN X. Numerical study on mechanisms of angle-plied panels for ballistic protection[J]. Materials & Design,2016,90:896-905. [25] VAN DINGENEN J L J. High performance dyneema fibres in composites[J]. Materials & Design,1989,10(2):101-104. [26] ONG CW, BOEY CW, HIXSON R S, et al. Advanced layered personnel armor[J]. International Journal of Impact Engineering,2011,38(5):369-383. doi: 10.1016/j.ijimpeng.2010.12.003 [27] ATTWOOD J P, FLECK N A, WADLEY H N G, et al. The compressive response of ultra-high molecular weight polyethylene fibres and composites[J]. International Journal of Solids and Structures,2015,71:141-155. doi: 10.1016/j.ijsolstr.2015.06.015 -

下载:

下载: