Variable angle placement trajectory design of non-uniform rational B-splines curve and buckling property of cylindrical shell

-

摘要: 基于三次非均匀有理B样条(NURBS)曲线,开展纤维变角度圆柱壳设计及其屈曲特性研究。首先,以三次NURBS曲线定义纤维变角度铺放参考轨迹,确定了变角度铺层的表示方式。其次,以纤维变角度铺层±<25(0.4)(0.8)75>和±<65(0.4)(0.8)10>为例,展示了三次NURBS曲线轴向平移铺层和周向平移铺层在圆柱壳上的纤维角度分布情况。然后,用纤维变角度铺层代替定刚度圆柱壳中的±45°铺层,对变刚度圆柱壳进行线性屈曲分析,对轴向平移圆柱壳、周向平移圆柱壳和定刚度圆柱壳进行对比。最后,在曲率半径约束下,研究权因子对圆柱壳屈曲性能的影响。结果表明:周向平移圆柱壳有着更好的屈曲性能;在曲率半径约束下,通过确定起始角、终止角和控制点参数得到屈曲性能优异的变刚度圆柱壳,而改变权因子能使变刚度圆柱壳的屈曲载荷再次提高。

-

关键词:

- 三次非均匀有理B样条(NURBS)曲线 /

- 圆柱壳 /

- 变角度 /

- 轨迹规划 /

- 屈曲特性

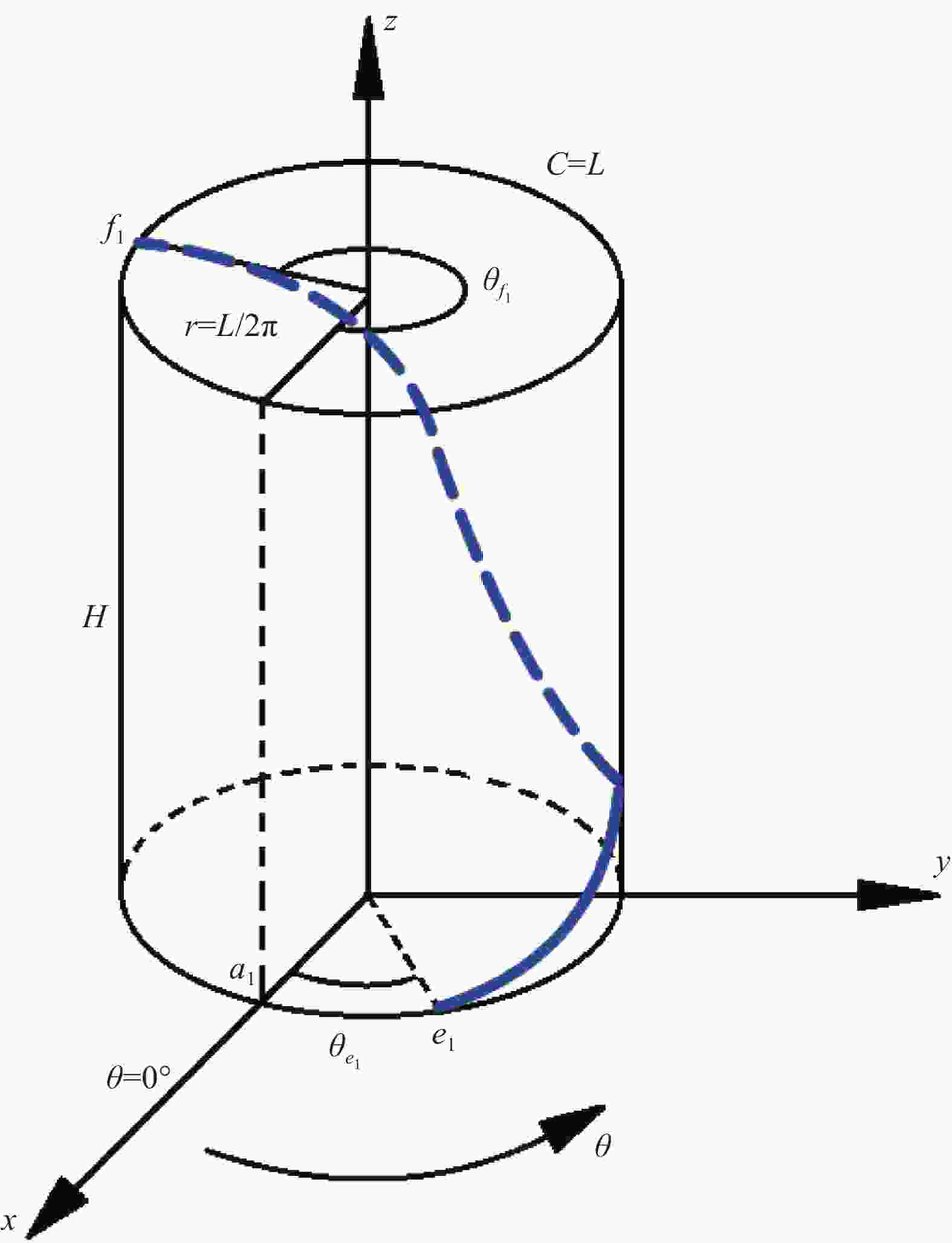

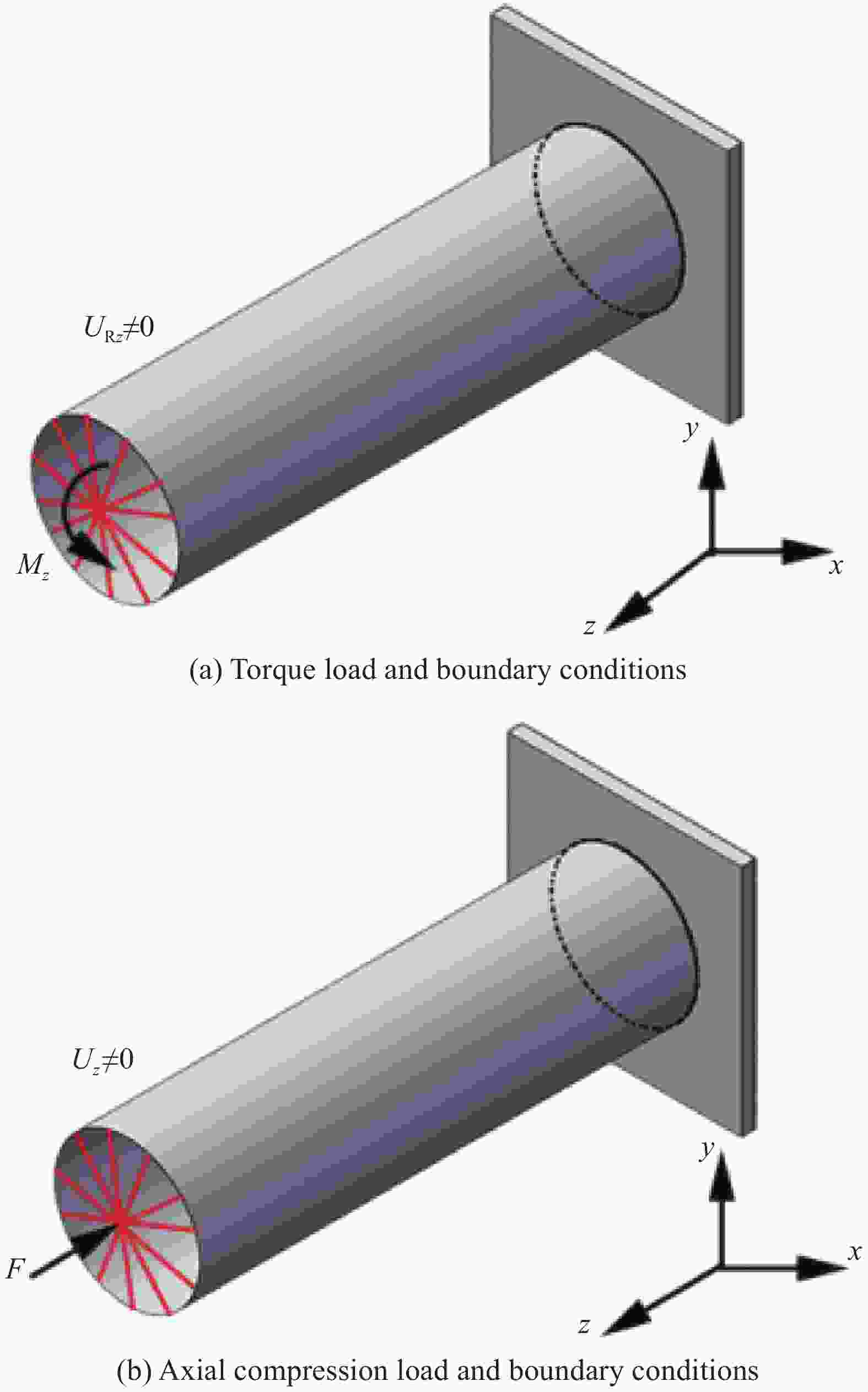

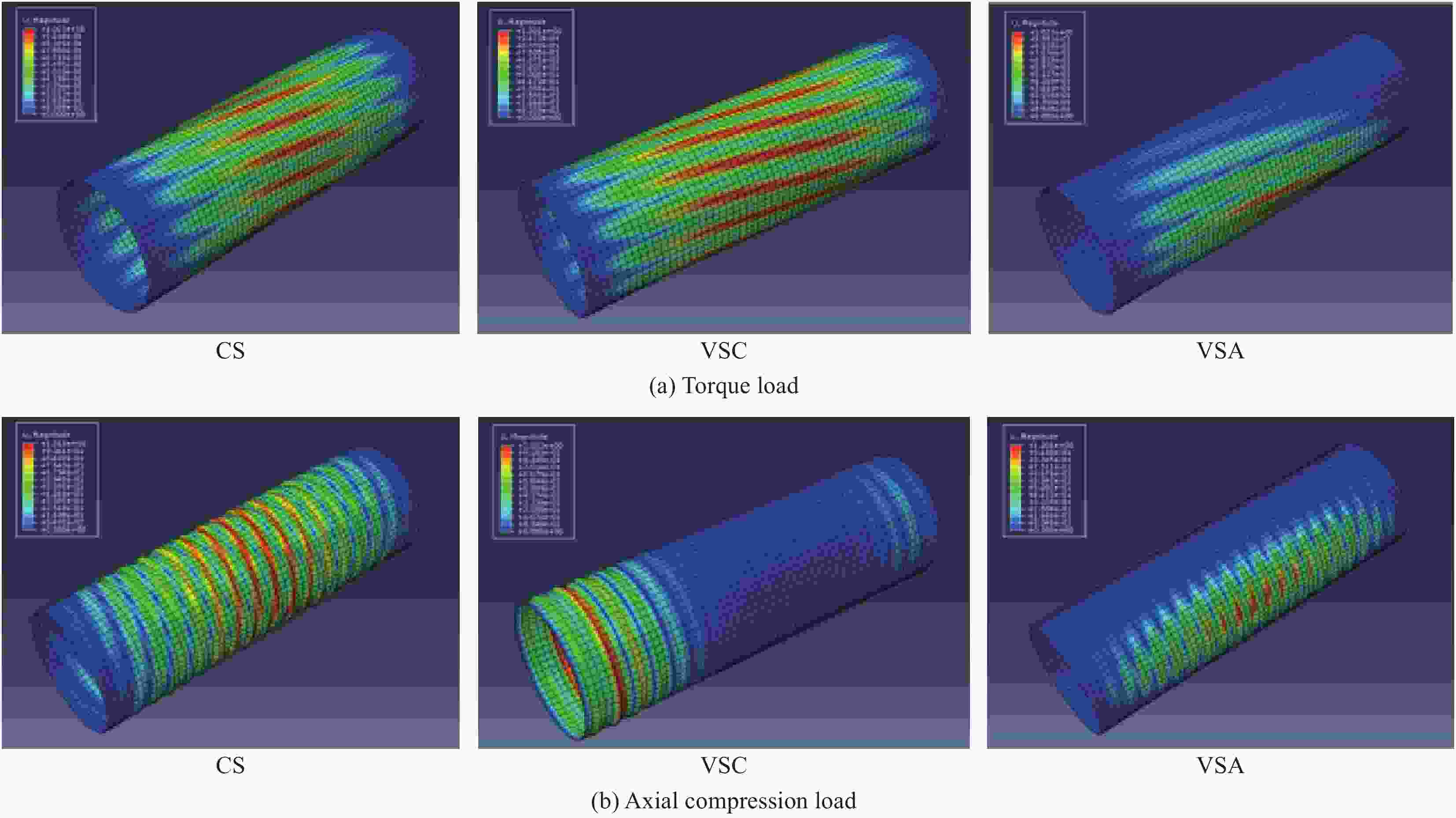

Abstract: Based on cubic non-uniform rational B-splines (NURBS) curve, the design and bucking property of cylindrical shell produced by fiber variable angle placement were studied. Firstly, the reference trajectory of fiber variable angle placement was defined by cubic NURBS curve, and the parameterized expression of fiber variable angle placement was determine. Secondly, taking the fiber variable angle placements ±<25(0.4)(0.8)75> and ±<65(0.4)(0.8)10> as examples, the fiber angle distributions of the axial and circumferential shift placements of the cubic NURBS curve on the cylindrical shell were demonstrated. Then, the ±45° placement of constant stiffness cylindrical shell was replaced by the fiber variable angle placements. The linear buckling analysis of the variable stiffness cylindrical shell was carried out, and the axial translation cylindrical shell, circumferential translation cylindrical shell and constant stiffness cylindrical shell were compared. Finally, the influence of weight factors on the buckling property was studied under the constraint of curvature radius. The results show that the circumferential translation cylindrical shell has better buckling performance. Under the constraint of curvature radius, the variable stiffness cylindrical shell with excellent buckling performance can be obtained by determining initial angle, termination angle and control point parameter, and the buckling load of the variable stiffness cylindrical shell can be increased again by changing the weight factor. -

表 1 圆柱壳的铺层结构

Table 1. Laminate structure of cylindrical shell

Name Layer structure CS [±45/0/90]2s VSC [±φ/0/90]2s VSA [±φ/0/90]2s Notes: CS—Constant stiffness; VSC—Variable stiffness circumferential translation; VSA—Variable stiffness axial translation. 表 3 定刚度(CS)圆柱壳线性屈曲分析结果

Table 3. Linear buckling results of constant stiffness (CS) cylindrical shel

Load type Buckling load coefficient Axial compression load 1515 Torque load 83892 表 4 扭矩载荷下的变刚度(VS)圆柱壳线性屈曲分析结果

Table 4. Linear buckling results of variable stiffness (VS) cylindrical shell under torque load

Variable stiffness layer Curvature radius R/mm Buckling load coefficient of VSC Buckling load coefficient of VSA <25(0.1)(0.8)75> ≥700 97430 75501 <25(0.2)(0.8)75> 97895 75407 <25(0.3)(0.8)75> 98324 75414 <25(0.4)(0.8)75> 98748 75524 <25(0.4)(0.9)75> 95811 78504 <25(0.5)(0.8)75> 99179 75763 <25(0.5)(0.9)75> 96501 78160 <25(0.6)(0.8)75> 99621 76165 <25(0.6)(0.9)75> 97188 77939 <25(0.7)(0.9)75> 97868 77888 <25(0.8)(0.9)75> 98533 78058 表 5 轴压载荷下的VS圆柱壳线性屈曲分析结果

Table 5. Linear buckling results of VS cylindrical shell under axial compression load

Variable stiffness layer Curvature radius R/mm Buckling load coefficient of VSC Buckling load coefficient of VSA <65(0.1)(0.2)10> ≥700 1558 1316.8 <65(0.1)(0.3)10> 1565.2 1343.5 <65(0.1)(0.4)10> 1571.9 1363.1 <65(0.1)(0.5)10> 1577.4 1375.9 <65(0.2)(0.3)10> 1598.9 1354.9 <65(0.2)(0.4)10> 1598.7 1367.8 <65(0.2)(0.5)10> 1596.6 1374 <65(0.2)(0.6)10> 1591.9 1375.4 <65(0.2)(0.9)10> 1553.4 1367.7 <65(0.3)(0.4)10> 1642.7 1378.1 <65(0.3)(0.5)10> 1631.6 1380.6 <65(0.3)(0.6)10> 1617.8 1379.1 <65(0.3)(0.7)10> 1601.8 1375.1 <65(0.4)(0.6)10> 1671.6 1390.9 <65(0.4)(0.7)10> 1647.4 1386 <65(0.4)(0.8)10> 1623 1380.1 表 2 T300碳纤维增强环氧树脂复合材料参数

Table 2. Parameters of T300 carbon fiber reinforced epoxy composite materials

E1/MPa E2/MPa v12 G12/MPa G13/MPa G23/MPa 121000 8600 0.3 5100 5100 3100 Notes: E1, E2—Elastic modulus; G12, G13, G23—Shear modulus of elasticity; v12—Poisson's ratio. -

[1] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU Shanyi. Advanced composite material and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [2] 韩振宇, 李玥华, 富宏亚, 等. 热塑性复合材料纤维铺放工艺的研究进展[J]. 材料工程, 2012(2):91-96. doi: 10.3969/j.issn.1001-4381.2012.02.020HAN Zhenyu, LI Yuehua, FU Hongya, et al. Thermoplastic composites fiber placement process research[J]. Journal of Materials Engineering,2012(2):91-96(in Chinese). doi: 10.3969/j.issn.1001-4381.2012.02.020 [3] 赵欣, 朱健健, 李梦, 等. 复合材料应用研究与产业发展建议[J]. 材料导报, 2016, 30(S1):525-530.ZHAO Xin, ZHU Jianjian, LI Meng, et al. Research on composites application and industrial development suggestion[J]. Materials Reports,2016,30(S1):525-530(in Chinese). [4] 陈绍杰. 大型飞机与复合材料[J]. 航空制造技术, 2008(15):32-37. doi: 10.3969/j.issn.1671-833X.2008.15.003CHEN Shaojie. Large aircraft and composite[J]. Aeronautical Manufacturing Technology,2008(15):32-37(in Chinese). doi: 10.3969/j.issn.1671-833X.2008.15.003 [5] 张小辉, 朱玉祥, 张少秋, 等. 先进复合材料自动铺丝技术研究进展[J]. 航空制造技术, 2018, 61(7):54-58.ZHANG Xiaohui, ZHU Yuxiang, ZHANG Shaoqiu, et al. Research progress on automated fiber placement technol-ogy[J]. Aeronautical Manufacturing Technology,2018,61(7):54-58(in Chinese). [6] GÜRDAL Z, OLMEDO R. In-plane response of laminates with spatially varying fiber orientations: variable stiffness concept[J]. AIAA Journal,1993,31(4):751-758. doi: 10.2514/3.11613 [7] GÜRDAL Z, TATTING B, WU K. Tow-placement technol-ogy and fabrication issues for laminated composite structures[C]//Proceedings of the 46th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference. Austin, Texas: AIAA, 2005: 1-18. [8] WU Z, WEAVER P M, RAJU G, et al. Buckling analysis and optimisation of variable angle tow composite plates[J]. Thin-Walled Structures,2012,60:163-172. doi: 10.1016/j.tws.2012.07.008 [9] ALHAJAHMAD A, ABDALLA M M, GÜRDAL Z. Design tailor-ing for pressure pillowing using tow-placed steered fibers[J]. Journal of Aircraft,2008,45(2):630-640. doi: 10.2514/1.32676 [10] ALHAJAHMAD A, ABDALLA M M, GÜRDAL Z. Optimal design of tow-placed fuselage panels for maximum strength with buckling considerations[J]. Journal of Aircraft,2010,47(3):775-782. doi: 10.2514/1.40357 [11] MAROUENE A, BOUKHILI R, CHEN J, et al. Effects of gaps and overlaps on the buckling behavior of an optimally designed variable-stiffness composite laminates-A numerical and experimental study[J]. Composite Structures,2016,140:556-566. doi: 10.1016/j.compstruct.2016.01.012 [12] BLOM A W, STICKLER P B, GÜRDAL Z. Optimization of a composite cylinder under bending by tailoring stiffness properties in circumferential direction[J]. Composites Part B: Engineering,2010,41(2):157-165. doi: 10.1016/j.compositesb.2009.10.004 [13] ROUHI M, GHAYOOR H, HOA S V, et al. Multi-objective design optimization of variable stiffness composite cylinders[J]. Composites Part B: Engineering,2015,69(69):249-255. [14] ROUHI M, GHAYOOR H, HOA S V, et al. Effect of structural parameters on design of variable-stiffness composite cylinders made by fiber steering[J]. Composite Structures,2014,118:472-481. doi: 10.1016/j.compstruct.2014.08.021 [15] ROUHI M, GHAYOOR H, FORTIN-SIMPSON J, et al. Design, manufacturing, and testing of a variable stiffness composite cylinder[J]. Composite Structures,2018,184:146-152. doi: 10.1016/j.compstruct.2017.09.090 [16] KHANI A, ABDALLA M M, GÜRDAL Z. Circumferential stiffness tailoring of general cross section cylinders for maximum buckling load with strength constraints[J]. Composite Structures,2012,94(9):2851-2860. doi: 10.1016/j.compstruct.2012.04.018 [17] 吴尘瑾, 祖磊, 李书欣, 等. 变刚度复合材料层合板的纤维铺放路径设计及屈曲分析[J]. 玻璃钢/复合材料, 2018(4):5-10.WU Chenjin, ZU Lei, LI Shuxin, et al. Desigh of fiber placement path and buckling analysis of variable-stiffness composite laminates[J]. Fiber Reinforcement Fiber/Compo-sites,2018(4):5-10(in Chinese). [18] 闫光, 韩小进, 阎楚良, 等. 复合材料圆柱壳轴压屈曲性能分析[J]. 复合材料学报, 2014, 31(3):781-787.YAN Guang, HAN Xiaojin, YAN Chuliang, et al. Buckling analysis of composite cylindrical shell under axial compression load[J]. Acta Materiae Compositae Sinica,2014,31(3):781-787(in Chinese). [19] 孙士平, 张冰, 邓同强, 等. 复合载荷作用变刚度复合材料回转壳屈曲优化[J]. 复合材料学报, 2019, 36(4):1052-1061.SUN Shiping, ZHANG Bing, DENG Tongqiang, et al. Buckling optimization of variable stiffness composite rotary shell under combined loads[J]. Acta Materiae Compositae Sinica,2019,36(4):1052-1061(in Chinese). [20] 吴双华, 尹冠生, 陈童, 等. 变刚度圆柱壳屈曲分析及铺丝路径优化[J]. 复合材料科学与工程, 2020(3):37-43. doi: 10.3969/j.issn.1003-0999.2020.03.006WU Shuanghua, YIN Guansheng, CHEN Tong, et al. Buckling analysis of variable stiffness cylindrical shell and optimization of laying path[J]. Composites Science and Engineering,2020(3):37-43(in Chinese). doi: 10.3969/j.issn.1003-0999.2020.03.006 [21] 邓同强. 变刚度复合材料层合板壳的分析与优化[D]. 南昌: 南昌航空大学, 2017.DENG Tongqiang. Analysis and optimization of laminated composite shells with variable stiffness[D]. Nanchang: Nanchang Hangkong University, 2017(in Chinese). [22] 赵志远. 基于机器人的热塑性复合材料铺放装备及工艺仿真研究[D]. 哈尔滨: 哈尔滨工业大学, 2020.ZHAO Zhiyuan. Research on robot-based placement equipment and process simulation of thermoplastic composite[D]. Harbin: Harbin Institute of Technology, 2020(in Chinese). -

下载:

下载: