Flexural strength enhancement study of aluminum-CFRP at liquid nitrogen temperature

-

摘要: 随着铝合金-碳纤维增强树脂复合材料(CFRP)逐渐应用到火箭推进器,其低温环境下的粘结性能强化已引起广泛关注。针对环氧接头潜在的粘接界面缺陷,采用阳极氧化和砂化分别处理铝合金和CFRP板表面制得多孔表面。采用树脂预涂(RPC)技术消除铝合金孔道根部原有的大分子环氧树脂空穴缺陷,也可通过RPC技术将增强纤维碳纳米管浸渍到铝合金表面的孔道中,形成准Z方向的纤维桥联,进一步提高环氧接头的粘结强度。三点弯曲试验(3-P-B)结果表明,室温下处理后的铝合金-CFRP弯曲强度提高了14.6%,液氮温度下弯曲强度提高了27.6%。经过表面处理后,CFRP在室温和液氮温度下的破坏模式均由较弱的界面脱胶破坏转变为主体结构的断裂破坏。总之,系列有效的处理方法可为低温液体燃料箱的工业应用提供另一种参考。Abstract: The adhesive bonding strength enhancement of aluminum substrate and carbon fiber reinforced polymer (CFRP) at cryogenic temperature has attracted far-ranging attention with their application expanding to rocket booster. Aiming at the potential bonding interface defect of epoxy joint, we adopted the anodizing and sanding treatments to modify surface performance of Al substrate and CFRP panel respectively. The resin pre-coating (RPC) technique was used to eliminate the originally existing defect caused by macromolecular epoxy at the root of porous Al substrate. The carbon nanotubes were applied as additives to be impregnated into channels on Al substrate surface via RPC technique and construct the quasi-Z directional fiber bridging, which can further improve the adhesive bonding strength of epoxy joint. The three-point bending (3-P-B) results show the flexural strength of aluminum substrate-CFRP after treated has been enhanced by 14.6% at room temperature, and even higher 27.6% at liquid nitrogen temperature based on that of the one only cleaned by acetone. Failure mode exhibits the weaker adhesive failure on bonding interface has been transformed into main structure fracture failure of CFRP after combined surface treatments at both room temperature and liquid nitrogen temperature. Overall, the effective treatment methods can offer an alternative reference in industrial application of cryogenic liquid fuel tank.

-

火箭推进器的轻量化设计不仅能提高运载能力和降低制造成本,而且有效地促进了火箭推进器的循环利用。碳纤维增强树脂基复合材料(CFRP)作为一种轻质高强度材料,已被用作传统金属替代材料,实现轻量化设计[1-4]。胶接技术能有效地连接金属和CFRP复合材料,避免了CFRP复合材料的加工损伤、局部应力集中及金属-CFRP粘结界面处潜在的电化学腐蚀,该技术也被应用于制造高性能结构件的工业生产[5-7]。

火箭推进剂贮箱[8-9]常用于盛装液态燃料,如液氧。箱内温度低至−183℃, 潜在的热冷交变应力会导致应用树脂粘结的非相似基体界面失效,主要是由于胶粘剂脆性随温度的下降而继续增大[10-11],基体材料与胶粘剂之间的粘结界面较弱。通常,室温下的力学性能强化仍是非相似基体粘结性能的主要研究方向,除了航空航天工业外,关于结构强度在实际应用温度下的演变规律的研究较少。目前针对粘结界面问题,普通的金属与CFRP板的表面改性,如砂磨[12-14]、喷砂[15-17]和NaOH刻蚀[5,18-19]等,可提高环氧树脂的润湿性,增强粘结界面[20]的扩散和相容性,从而加强机械咬合。基于渗透和机械咬合理论,以刻蚀或喷射处理在基体表面形成垂直通道,能有效促进粘结[21-23]。

在机械和化学处理工艺中,阳极氧化[24-26]已被证实是一种更有效的处理方法,通过电解液、电解电压与电流、电解槽温度等[27] 多因素的联动调控,能刻蚀形成利于粘结的多孔表面。同时,将高性能界面增强粒子引入多孔氧化膜中,构建准Z方向纤维集团,可增韧环氧树脂胶体,也能强化树脂与基体的粘结界面[4,15,28]。低温环境下,纯环氧树脂的硬度和强度会增加,但其脆性也会增加[10],而添加增强粒子可以改善脆性[29-31]。此外,粘结界面也存在树脂脆性问题,且不同基体的不相容性也影响粘结界面的稳定性。基于此,准Z方向的纤维分布模型可以消除胶体和基体的潜在的弱界面结构,构建一种结构更稳定、性能更强且断裂阻抗更优的复合结构体,为低温液体燃料贮箱的应用提供了更可靠的复合材料。

本文创新性地设计了一种有效的铝合金和CFRP板表面改性处理系统,采用树脂预涂层(RPC)技术进一步提高改性表面与固化环氧树脂的相容性,引导碳纳米管嵌入或竖直分布于多孔氧化膜内。采用砂纸打磨和RPC处理CFRP板表面,形成更牢固的CFRP板/环氧树脂粘结界面。通过三点弯曲(3-P-B)试验测试了弯曲强度,确定了不同表面处理方法的破坏模式演变规律;此外,表征了铝合金多孔氧化膜的微观形貌、内部微纳米孔道形貌、化学成分及阳极氧化前后的粗糙度等性能。

1. 材料设计、制备与表征

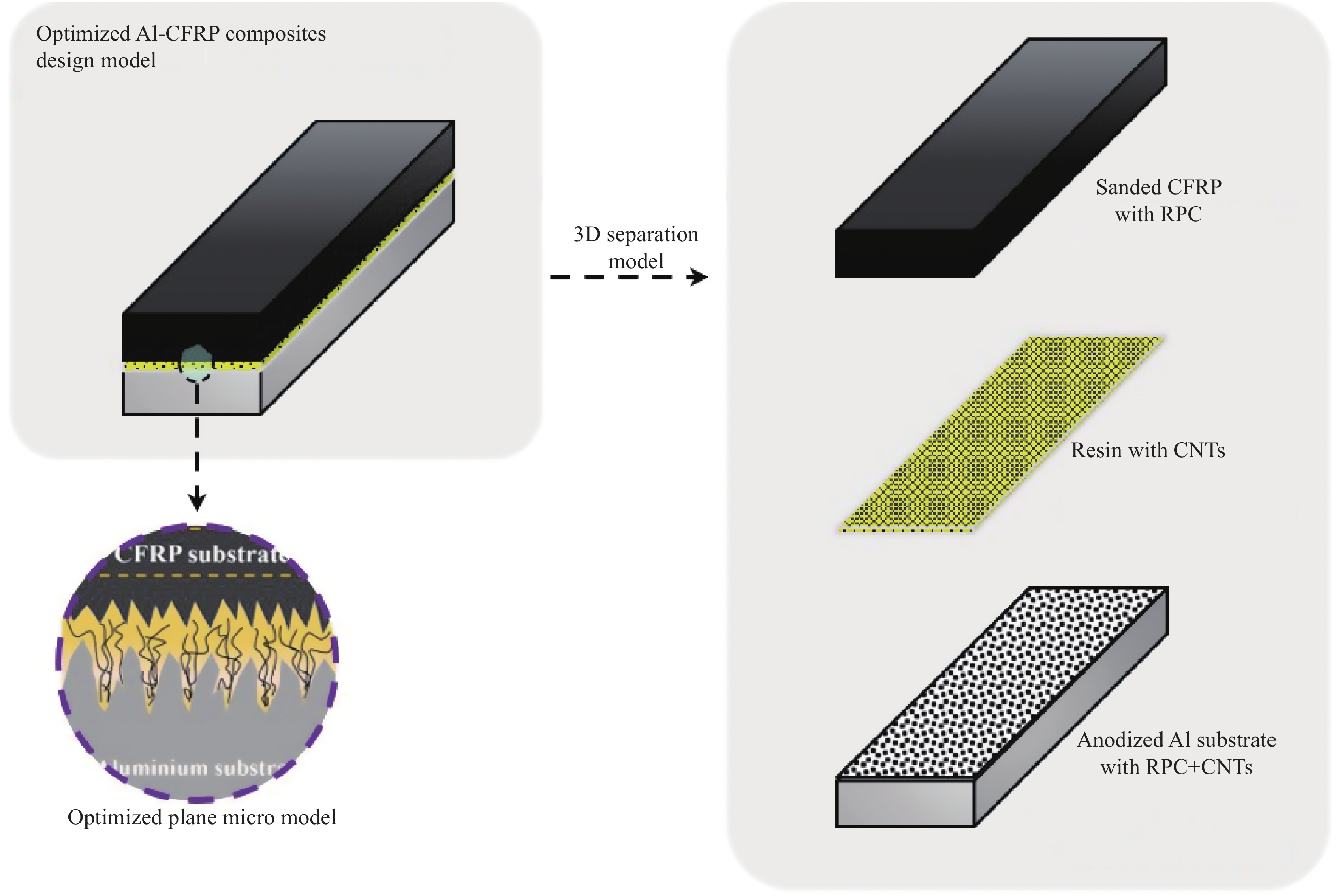

1.1 复合材料设计概念

润湿性、相容性和机械咬合性更佳的粘接界面,有助于形成更稳定的复合材料结构。为了提高界面粘接性能,因而需对粘接基体进行表面改性。采用阳极氧化处理铝合金表面,将相对平整且不易润湿的表面刻蚀形成孔道准Z方向分布的多孔膜,该多孔膜对环氧树脂有较好润湿性,也为RPC技术负载碳纳米管提供垂直空间,利于消除孔道根部的空穴缺陷。同样,采用RPC技术优化CFRP/环氧树脂胶接界面,能使其具备更高的机械咬合性能。图1显示了经过不同的处理方法的粘结工艺设计模型,对于各种复杂服役环境下Al-CFRP复合材料的结构强化发挥了关键作用。低温环境下,该胶接界面对提高机械咬合性能的作用尤为明显。由于冷缩作用,环氧树脂与基体(包括铝合金和CFRP板)间的粘结界面会产生不可逆的潜在裂纹并沿其扩展,准Z方向分布的纤维能减少或消除潜在的界面裂纹,从而改变复合材料在室温或低温下的结构失效模式,进一步提高粘结强度。

1.2 复合材料制备

通过预处理、阳极氧化处理或磨砂处理、RPC处理及粘结等工艺制备了最终的Al-CFRP复合材料。

首先,铝合金和CFRP板的预处理阶段。阳极氧化处理前,用丙酮超声清洗6060 T5铝合金(澳大利亚Midalia Steel Pty 公司,厚度3 mm,宽度25 mm)约30 min,去除污垢、灰尘和油等一些表面污渍。放入10wt%的NaOH溶液中浸泡10 min,去除难溶性物质[26],然后用去离子水洗掉表面的NaOH。然后放入10wt%的HNO3溶液中浸泡5 min,反应残余的NaOH,防止碱性粒子带入电解槽,再用去离子水清除残留的HNO3溶液获得电解用铝合金。用P240氧化铝砂纸打磨3K斜纹编织CFRP板(深圳市领航者新材料科技有限公司,厚度2 mm,宽度25 mm),再用丙酮超声清洗已磨的CFRP板10 min,去除表面污渍获得粘结用CFRP板。

其次,铝合金阳极氧化处理阶段。称取定量的硫酸(澳大利亚Chem supply集团有限公司;H2SO4,AR,98%,密度1.84 g/cm3)和草酸(澳大利亚Merck 集团有限公司;C2H2O4·2H2O,M=126.07 g/mol),制备质量分别为20wt%和0.5wt%的最终电解质溶液。在阳极氧化槽中,铝合金为阳极,碳棒为阴极。电解液温度为室温,电解电压为12 V,阳极氧化过程为1 h[5]。

然后,铝合金和CFRP板的RPC工艺处理阶段。配置铝合金碳纳米管RPC处理液,其中树脂∶碳纳米管∶丙酮=10wt%∶1wt%∶89wt%,并对阳极氧化后的铝合金进行处理。配置CFRP板RPC处理液,其中树脂∶丙酮=10wt%∶90wt%,并对磨砂后的CFRP板进行处理。

最后,铝合金和CFRP板的粘结阶段。采用1∶1的质量比均匀混合普通树脂(澳大利亚Dulux 集团有限公司,双酚A氯丙烷环氧树脂)和固化剂(澳大利亚Dulux 集团有限公司,三乙烯四胺固化剂)制得粘结胶体,采用不同表面条件组合的铝合金和CFRP板制备了四组Al-CFRP复合材料:(1) 铝合金和CFRP板均仅采用丙酮超声清洗;(2) 铝合金阳极氧化,CFRP板丙酮超声清洗;(3) 铝合金阳极氧化,CFRP板磨砂处理和RPC处理;(4) 铝合金阳极氧化和RPC (添加碳纳米管)处理,CFRP板磨砂处理和RPC处理。

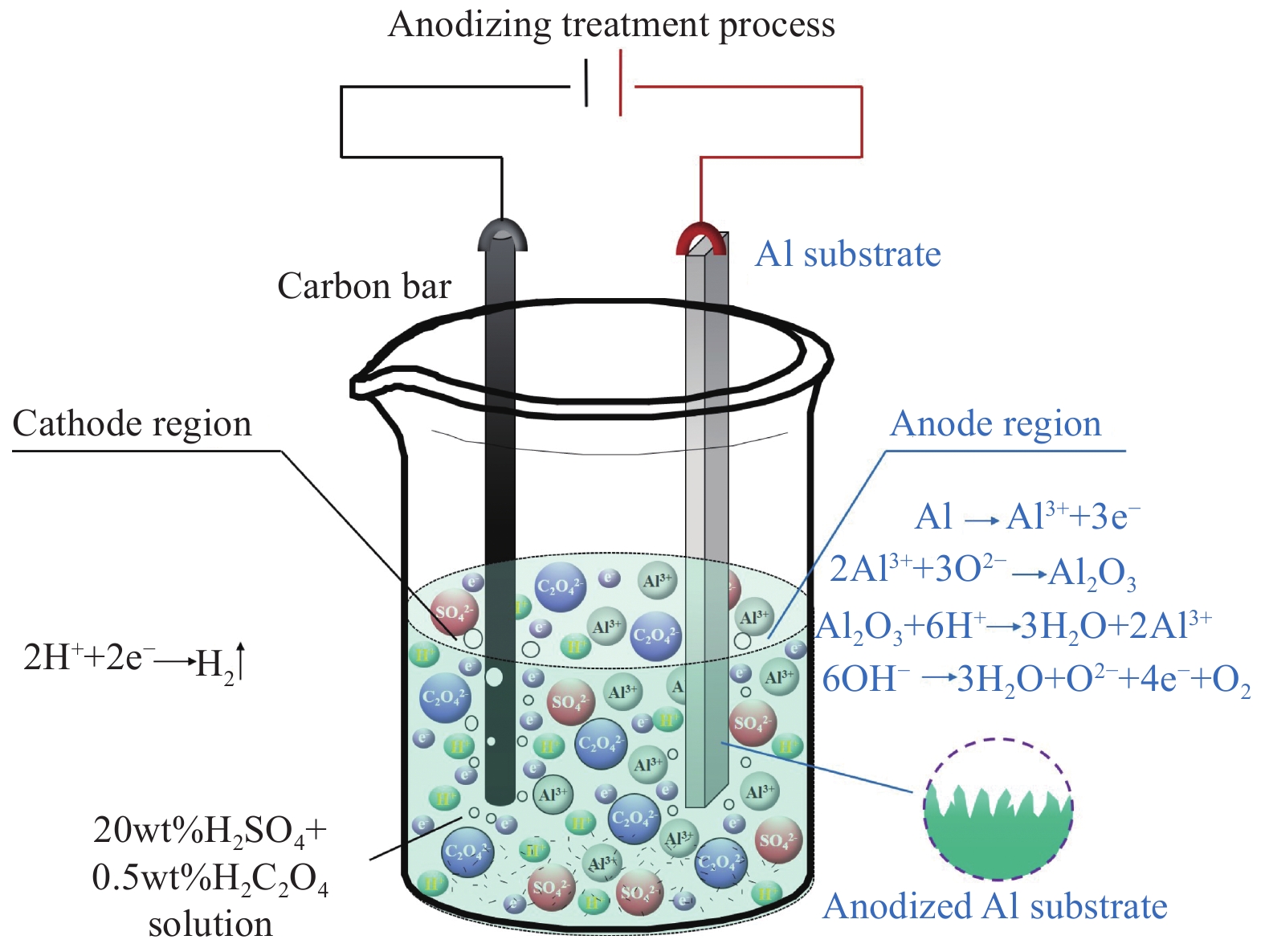

1.3 化学刻蚀原理

铝合金表面的电化学腐蚀实际上是多孔膜的生成和分解反应,取决于在电化学环境中进行的一系列阳极氧化反应[32]。图2显示了阳极区发生的多孔膜的产生和分解,铝合金失去电子变成Al3+离子,与O2−反应从而生成稳定的Al2O3薄膜。整个薄膜生长过程中,薄膜生长速度并不完全相同,因此,生成的薄膜在微观上是不均匀的。处于电解槽的酸性环境中,生成的薄膜也会发生分解反应,Al2O3与活性H+反应再次生成Al3+,并分解回溶液。该分解反应主要集中在较薄的多孔膜区域,而非整个Al2O3多孔膜。薄膜区由于电阻小、电流大,在电场作用下更易被穿透。铝合金表面Al2O3薄膜的形成和分解过程是同时发生的,并形成了硬质的Al2O3多孔薄膜层和垂直通道区。最后,达到Al2O3多孔薄膜生成与分解的平衡条件,整个薄膜结构趋于稳定。

1.4 复合材料性能表征

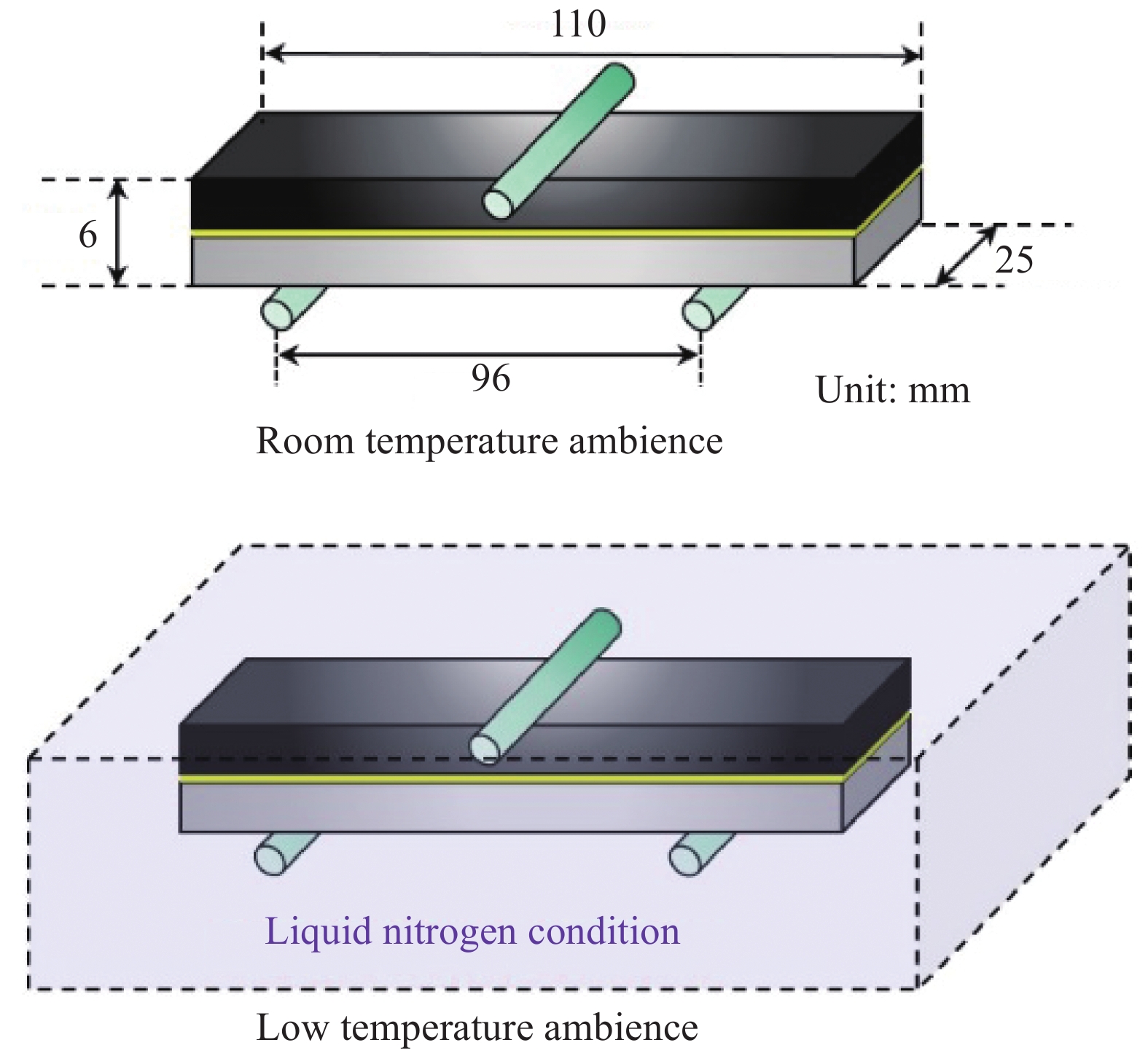

室温下,采用Instron 5982万能试验机(100 kN)对复合材料的进行三点弯曲试验。液氮温度下,复合材料的弯曲试验通过Instron 5982万能试验机和液氮储存装置进行,复合材料浸泡于液氮约10 min,降温到−196℃。图3展示试样的特征参数,测试样品的尺寸为110 mm×25 mm×6 mm,被放置在上压头两侧等距约48 mm处,分布于两个下支点中间。位移控制速度为2 mm/min,负载力骤降后停止试验,加载过程中未观察到滑动和整体屈曲。每组共5个样品用于三点弯曲试验。

采用扫描电子显微镜(FEI Verios XHR SEM,Thermo Fisher Scientific Inc.,USA)和Everhart-Thornley探测器在10 kV/0.4 nA下观察了阳极氧化前后铝合金的表面形貌。通过聚焦离子束(Focus ion beam,FIB)对阳极氧化后的铝合金切槽,采用Ga离子束完成深度为30 μm的孔道切割和抛光,并用扫描电子显微镜(FEI-Helios 650,Thermo Fisher Scientific Inc.,USA)在5.0 kV的高压和0.34 nA的电流下观察了内孔结构。

利用原子力显微镜(AFM,Bruker,Germany)测量三维表面粗糙度。使用纳米镜分析对数据进行分析,以获得区域粗糙度参数和三维表面形貌。

使用AlKα (hv=1846.6 eV)正常起飞角的单色辐射源的ESCALAB 250Xi(Thermo Scientific K-Alpha,Thermo Fisher Scientific Inc.,USA)获得X射线光电子能谱(XPS)光谱。记录了Al2p和C1s峰的高分辨光谱,光斑尺寸为400 μm,使用通过能量50 eV和步长0.1 eV。在曲线拟合之前,结合能标度相对于结合能为284.8 eV的不定烃进行了校准。利用XPS PEAK软件对Al2p的高分辨率扫描进行分析。

2. 结果与讨论

2.1 铝合金表面微观形貌

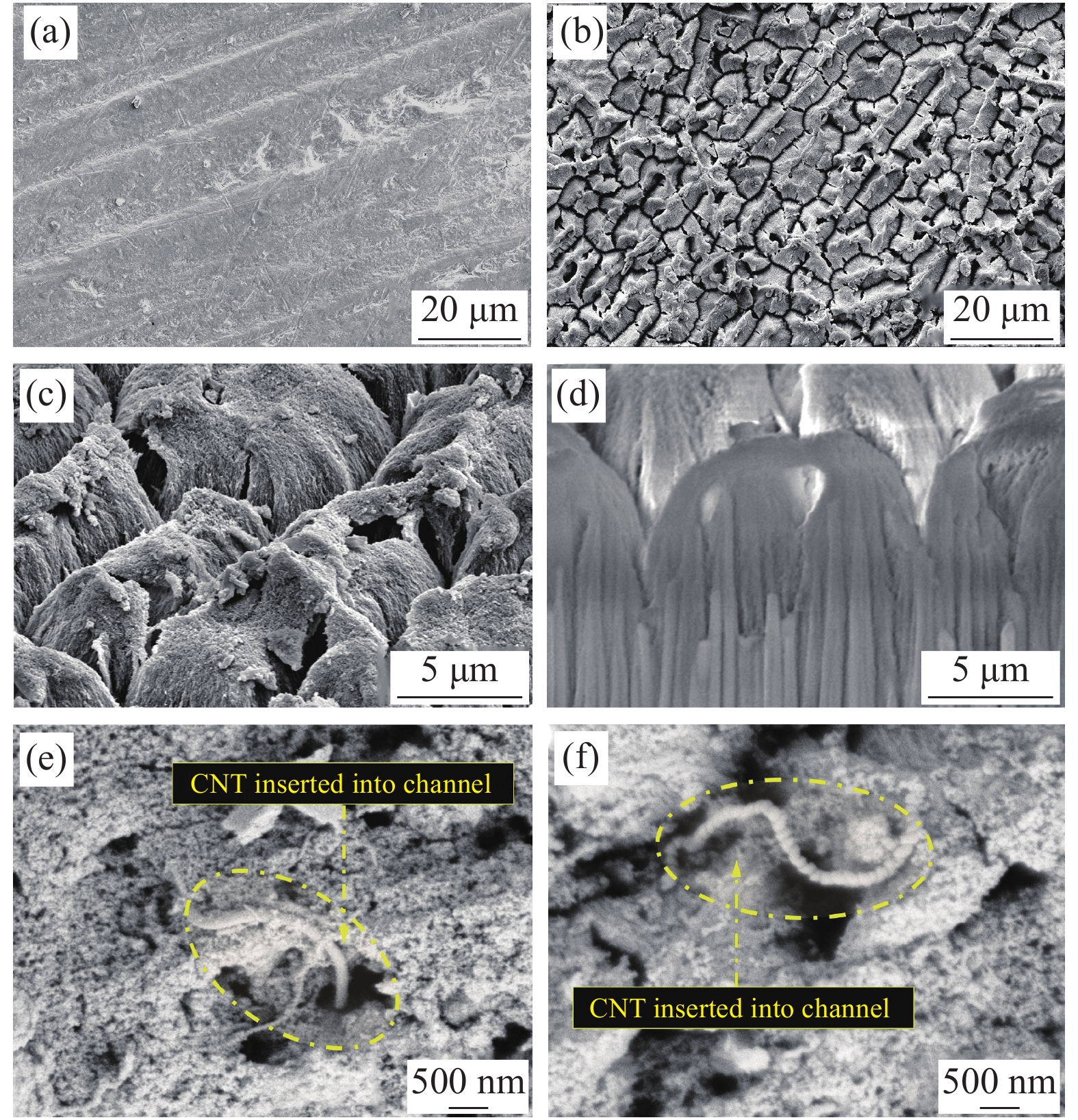

图4为经过丙酮清洗和阳极氧化处理后铝合金表面的SEM图像。如图4(a)所示,能观察到挤压成型过程中产生的平行沟壑结构及在搬运、储存和运输过程中产生的一些细小划痕。图4(b)~4(d)显示了铝合金独特的微孔结构,主要是由于硫酸/草酸混合物在不同区域进行不同程度的刻蚀和氧化行为,这也造成阳极氧化膜的不同生成和溶解速率。通过图4(b)的90°俯视角可以看到峰谷状结构,根据图4(c)的52°俯视角图像显示,该峰谷状结构更加立体清晰。图4(d)为FIB处理后多孔铝合金表面切口壁的正面图。据测算,该孔径宽度约为200~800 nm,孔径深度约为3~5 nm。图4(e)和图4(f)呈现了经过RPC处理后铝合金表面形貌。观察可知,碳纳米管已嵌入多孔氧化层的孔道结构。随着RPC溶液中丙酮的挥发,碳纳米管被残留的树脂溶液拽入到孔道结构,形成半嵌入式结构,该结构能促进准Z方向的纤维桥联行为的形成[5,32]。

![]() 图 4 6060 T5铝合金的SEM图像:(a) 铝合金表面丙酮超声清洗;(b) 阳极氧化后的铝合金表面具有较深的微/纳米结构通道;(c) 阳极氧化后的铝合金52°视角图像;(d) 聚焦离子束(FIB)处理后多孔铝合金表面切口壁的正面图;(e)、(f) RPC处理后CNTs嵌入到铝合金表面孔道结构[32]Figure 4. SEM images of 6060 T5 Al substrate: (a) Al substrate surface with acetone ultrasonic cleaning; (b) Al substrate surface with deep micro-/nano-structured channels after anodizing treatment; (c) 52° view image of the Al substrate after anodized corresponding to (b); (d) Frontal view of the notched wall on porous Al substrate surface after focus ion beam (FIB); (e),(f) CNTs inserted into the channel of Al substrate surface after RPC technique[32]

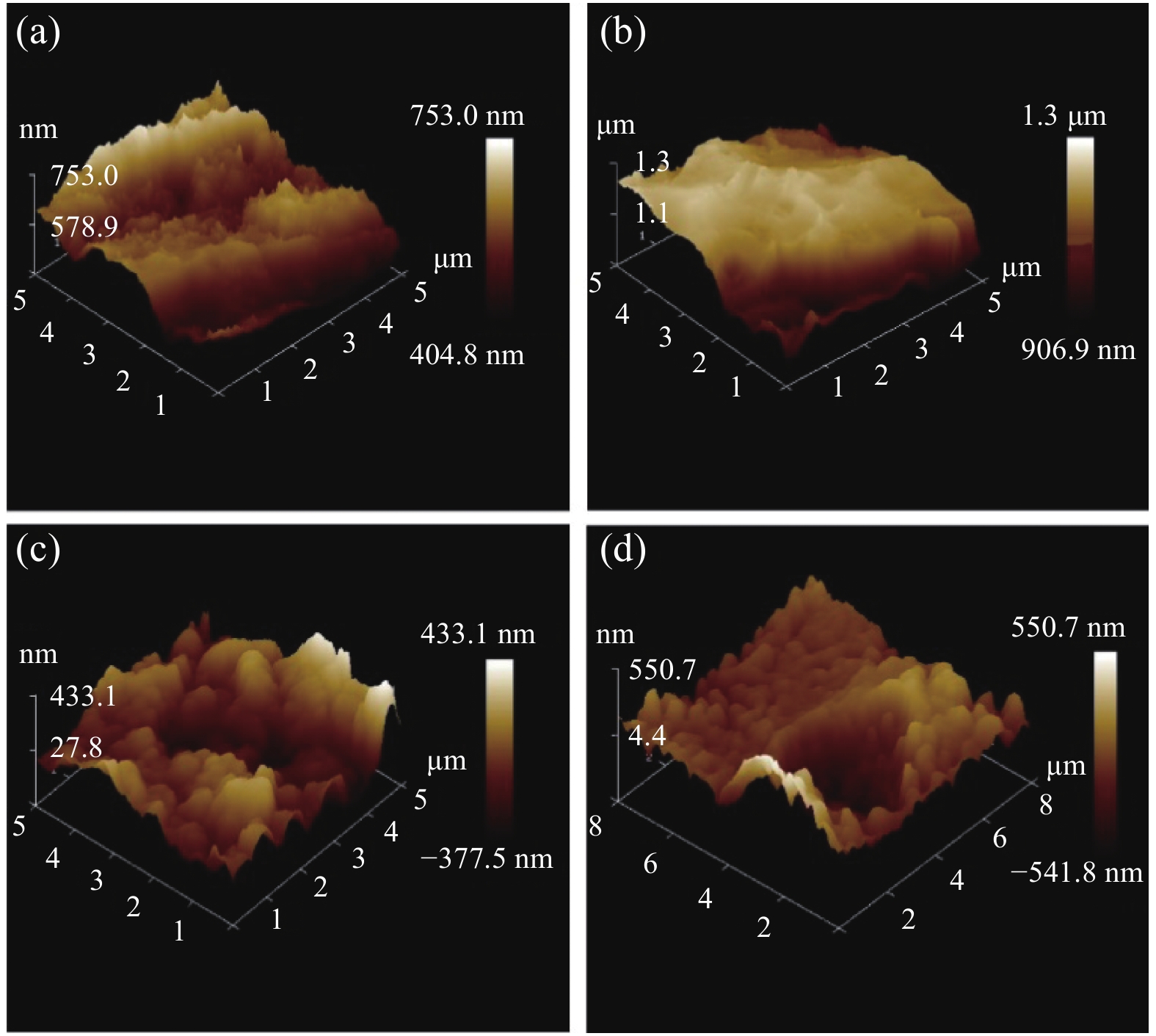

图 4 6060 T5铝合金的SEM图像:(a) 铝合金表面丙酮超声清洗;(b) 阳极氧化后的铝合金表面具有较深的微/纳米结构通道;(c) 阳极氧化后的铝合金52°视角图像;(d) 聚焦离子束(FIB)处理后多孔铝合金表面切口壁的正面图;(e)、(f) RPC处理后CNTs嵌入到铝合金表面孔道结构[32]Figure 4. SEM images of 6060 T5 Al substrate: (a) Al substrate surface with acetone ultrasonic cleaning; (b) Al substrate surface with deep micro-/nano-structured channels after anodizing treatment; (c) 52° view image of the Al substrate after anodized corresponding to (b); (d) Frontal view of the notched wall on porous Al substrate surface after focus ion beam (FIB); (e),(f) CNTs inserted into the channel of Al substrate surface after RPC technique[32]图5是阳极氧化处理前后铝合金表面的AFM图像。图5(a)和图5(b)显示了仅用丙酮清洗的铝合金试样在两个不同的典型区域的三维高度图案轮廓,除了挤压过程导致的不均匀表面形态外,几乎没有观察到多孔结构,与图4(a)所示的形貌吻合。图5(c)和图5(d)显示了经过阳极氧化的铝合金的表面多孔形貌,在两个区域均能观察到明显的峰谷状结构。根据表1中铝合金阳极氧化前后的表面粗糙度值,经阳极氧化后表面粗糙度主要特征值表面算术平均粗糙度Sa和表面均方根粗糙度Sq都明显增大。因此,阳极氧化处理可以通过改变表面形貌来优化表面性能。

表 1 经丙酮超声清洗和阳极氧化处理后6060 T5铝合金的表面粗糙度参数Table 1. Surface roughness measurements of the 6060 T5 Al substrate treated by acetone ultrasonic cleaning and anodizingTreatment method Sample number Sa/nm Sq/nm Rmax/nm Acetone ultrasonic cleaning Fig.5(a) 53.4 62.5 353 Fig.5(b) 36.5 42.9 238 Anodizing surface treatment Fig.5(c) 91.3 114 785 Fig.5(d) 95.4 134 1037 Notes: Sa—Surface arithmetical mean roughness; Sq—Surface root mean square roughness; Rmax—Maximum roughness depth. 2.2 铝合金表面元素组成

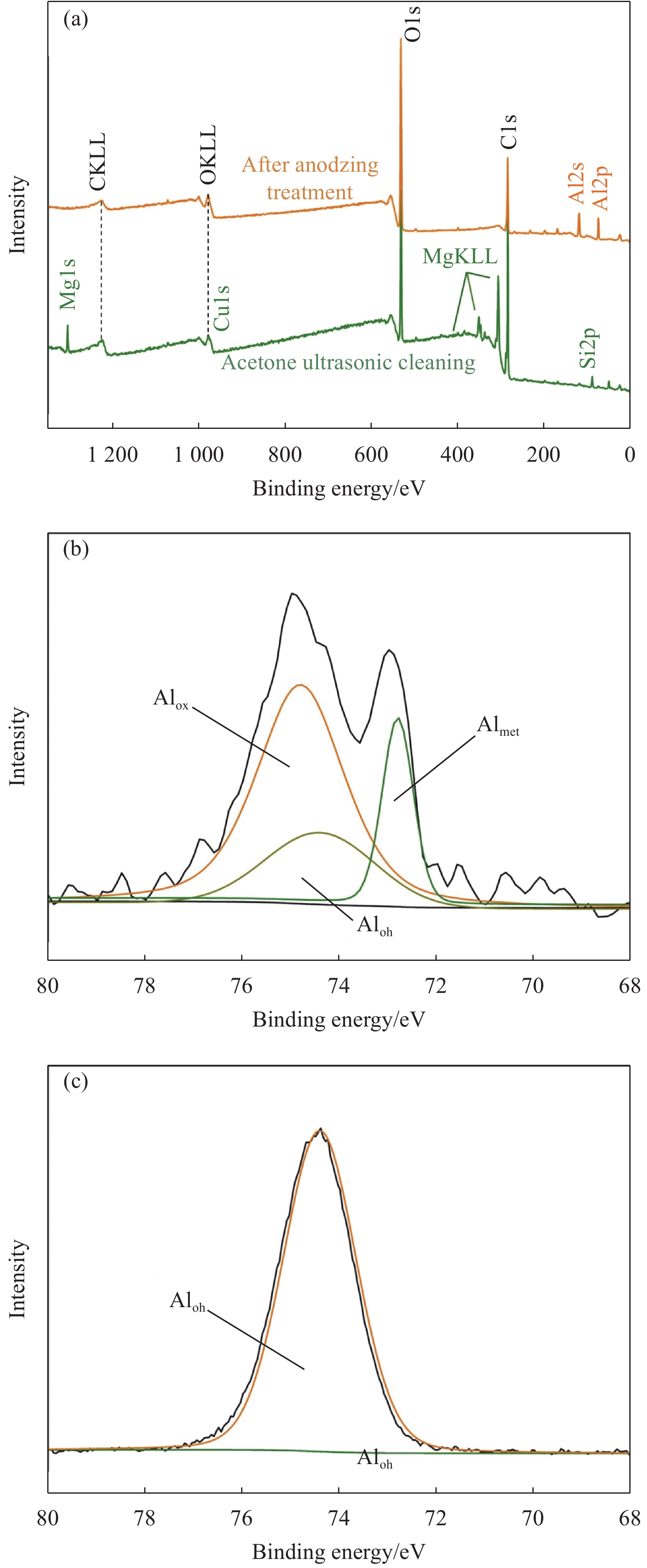

图6为经丙酮超声清洗和硫酸-草酸溶液阳极氧化的铝合金XPS图谱。仅丙酮清洗后的铝合金XPS图谱表明,6060 T5铝合金的基本成分为Al、O、Mg、Si和Cu[6]。然而,经阳极氧化的铝合金曲线上仅剩下Al和O,原本存在的Mg、Si、Cu消失了,这是由于阳极氧化反应生成了一种新的多孔超薄氧化膜。同时在该曲线上,某些不定烃类污染物的表面出现一个C1s峰,其强度曲线明显降低。

![]() 图 6 丙酮超声清洗和阳极氧化的铝合金表面的光谱分析 (a) ;丙酮超声清洗 (b) 和阳极氧化处理后铝合金表面 (c) 的高分辨Al2p核心级光谱Figure 6. Survey spectra of Al substrate surfaces cleaned ultrasonically by acetone and anodized (a); high resolution Al2p core-level spectra for Al substrate surfaces after acetone ultrasonic cleaning (b) andanodizing treatment (c)Aloh—Aluminium hydroxide hydroxide; Almet—Metallic aluminium; Alox—Aluminium oxide

图 6 丙酮超声清洗和阳极氧化的铝合金表面的光谱分析 (a) ;丙酮超声清洗 (b) 和阳极氧化处理后铝合金表面 (c) 的高分辨Al2p核心级光谱Figure 6. Survey spectra of Al substrate surfaces cleaned ultrasonically by acetone and anodized (a); high resolution Al2p core-level spectra for Al substrate surfaces after acetone ultrasonic cleaning (b) andanodizing treatment (c)Aloh—Aluminium hydroxide hydroxide; Almet—Metallic aluminium; Alox—Aluminium oxide通过分析两种衬底的高分辨Al2p光谱,进一步研究了阳极氧化前后铝合金表面的变化。如图7(a)所示,丙酮清洗的铝合金的Al2p光谱由3个不同的峰组成:(1) 72.8 eV[33]处的金属铝(Almet);(2) 74.4 eV[34]处的氢氧化铝和羟基氢氧化铝(Aloh);(3) 74.8 eV[35]处的氧化铝(Alox)。氢氧化铝的产生归因于大气中的水蒸气。这些颗粒结合不良,会削弱黏附力。由于氧化薄膜厚度小于XPS的取样深度,因此仍能检测到铝合金的信号。图7(b)显示了阳极氧化后的铝合金,由于经过NaOH溶液和HNO3溶液的预处理,因此表面层上没有Alox。而经过阳极氧化的铝合金表面,金属铝的峰消失了,表明该峰与基体表面的金属间化合物有关。根据表2中表面层的Almet、Alox和Aloh的原子百分比份额可以发现,取样深度内的金属铝含量下降到0%,并完全转变为Aloh。最终元素组分由Aloh组成,主要是由于刚经过阳极氧化处理的铝合金用去离子水清洗,以去除残留的硫酸-草酸溶液,导致形成的Alox再次与H2O反应生成最终的Aloh。

2.3 Al-CFRP复合材料弯曲强度

表3为4组不同处理方式下Al-CFRP复合材料的弯曲强度,随着铝合金阳极氧化、CFRP板表面磨砂及RPC技术等处理方式的叠加运用,复合材料的峰值载荷Pmax和弯曲强度均得到持续提升。图7(a)显示了仅丙酮清洗和铝合金阳极氧化+RPC(碳纳米管)与CFRP板磨砂+RPC两组试样的典型力-位移曲线,由于非相似粘结基体的接头变形,在峰值载荷前呈现出非线性行为[13]。液氮温度和室温下测得的两个峰值载荷Pmax明显处于不同的值域内,说明低温有助于提升粘结强度。对比同一温度的对照组试样和实验组试样,也能观察到峰值载荷Pmax的增强。根据图7(b)和表3的弯曲强度值,通过铝合金阳极氧化+RPC(碳纳米管)与CFRP板磨砂+RPC的联合处理,室温下强度比丙酮清洗提高14.6%,液氮温度下强度提高27.6%。液氮温度下增强27.6%,可能是由于准Z方向的碳纳米管,随着温度的降低,相较于纯环氧胶接接头,位于粘结界面的碳纳米管纤维桥联行为对于环氧接头的增强效果会更佳。

表 2 丙酮清洗和阳极氧化后铝合金上超薄表面层的表面元素组成Table 2. Surface elemental composition of the ultra-thin surface layer on both acetone-cleaned and anodized Al substratesSample Almet Alox Aloh Acetone-cleaned Al substrate 21.0% 62.7% 17.5% Anodized Al substrate − − 100.0% 表 3 室温(RT)和液氮温度(LNT)下对照组和实验组Al-CFRP复合材料的3-P-B试验结果Table 3. 3-P-B test results of control and treated Al-CFRP composites at room temperature (RT) and liquid nitrogen temperature (LNT)Sample Treatment process Test

conditionAverage

Pmax/NStandard

deviation/NShear

strength/MPaStandard

deviation/MPaControl Acetone ultrasonic cleaning for both RT 2564.21 136.87 269.97 48.14 LNT 2915.79 591.69 532.92 60.51 T1 Anodizing for Al and Acetone ultrasonic cleaning for CFRP RT 2690.45 142.53 285.76 23.42 LNT 5364.05 514.17 569.73 49.64 T2 Anodizing for Al and sanding +

RPC for CFRPRT 2760.61 121.31 290.15 17.75 LNT 5541.01 531.58 582.38 42.73 T3 Anodizing for Al and RPC (CNTs) sanding + RPC for CFRP RT 5015.57 109.55 309.31 13.05 LNT 6374.42 545.44 680.01 48.14 Note: Pmax—Maximum peak load. 2.4 Al-CFRP复合材料失效模式

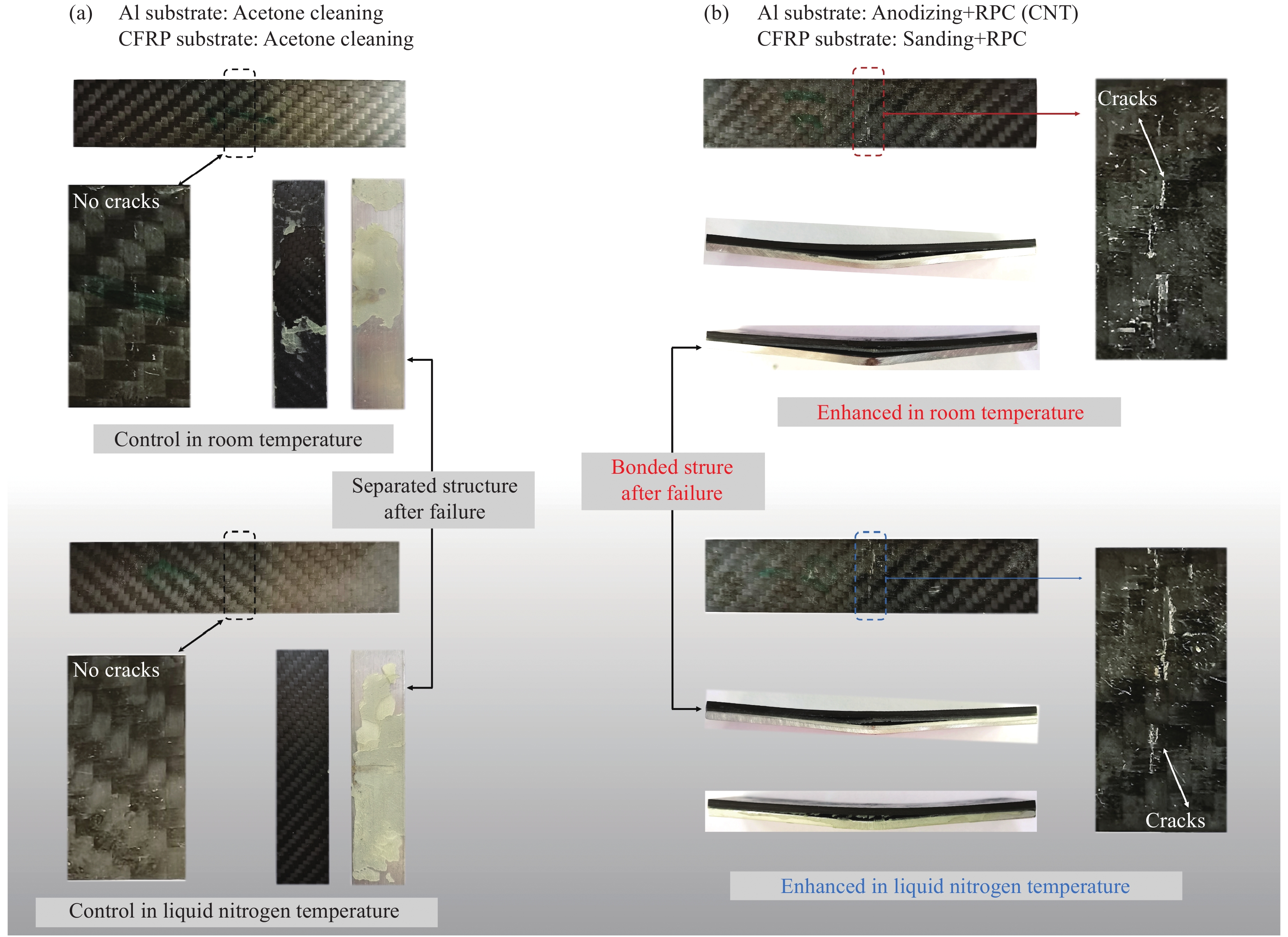

图8为Al-CFRP复合材料经过弯曲测试后的失效表面,能更清晰地解释图7所示的弯曲强度变化。仅用丙酮清洗铝合金和CFRP板的Al-CFRP复合材料,无论在室温下还是在液氮温度下,铝合金与环氧胶体的胶接界面都发生了典型脱胶失效(图8(a))。当材料结构发生明显变形时,很容易导致粘结界面失效,但低温可以增强胶接接头,提高铝合金的刚度,延缓潜在的粘结失效,从而提高弯曲强度。整个负载过程中,上表面压力负载区域(即上部CFRP板)没有损坏,下部铝合金逐渐弯曲。然而,仅丙酮清洗的Al-CFRP复合材料的粘结破坏模式可以通过阳极氧化、磨砂和RPC技术等方法实现转变。如图8(b)所示,在室温和液氮温度下完成弯曲试验后,受损的Al-CFRP复合材料仍保持结构半粘合状态,铝合金和CFRP板结构未分离,即使从侧面观察也未观察到明显的粘结破坏。与仅丙酮清洗的复合材料相比,在加载过程中,除铝合金发生弯曲变形外,CFRP板也发生了弯曲断裂破坏,同时经联合处理的Al-CFRP复合材料的弯曲变形量比仅丙酮清洗的复合材料大,这也解释复合材料的弯曲强度增强。对于联合处理后的Al-CFRP复合材料,液氮温度下的抗弯强度高于室温下的抗弯强度的原因与仅丙酮清洗的复合材料相似,在液氮中,主要归因于CFRP板与铝合金更强的粘结界面和结构刚度。

![]() 图 8 Al-CFRP复合材料三点弯曲试验后的部分粘合及分离的失效表面:(a) 丙酮超声清洗后的铝合金和CFRP板;(b) 铝合金经过阳极氧化和RPC(添加碳纳米管),CFRP板经过砂纸打磨和RPCFigure 8. Failure surfaces of adhesive bonded Al-CFRP composite and the separated pieces: (a) Acetone ultrasonic cleaning for Al substrate and CFRP; (b) Anodized Al substrate with RPC + CNTs and sanding and RPC for CFRP

图 8 Al-CFRP复合材料三点弯曲试验后的部分粘合及分离的失效表面:(a) 丙酮超声清洗后的铝合金和CFRP板;(b) 铝合金经过阳极氧化和RPC(添加碳纳米管),CFRP板经过砂纸打磨和RPCFigure 8. Failure surfaces of adhesive bonded Al-CFRP composite and the separated pieces: (a) Acetone ultrasonic cleaning for Al substrate and CFRP; (b) Anodized Al substrate with RPC + CNTs and sanding and RPC for CFRP2.5 增强机制

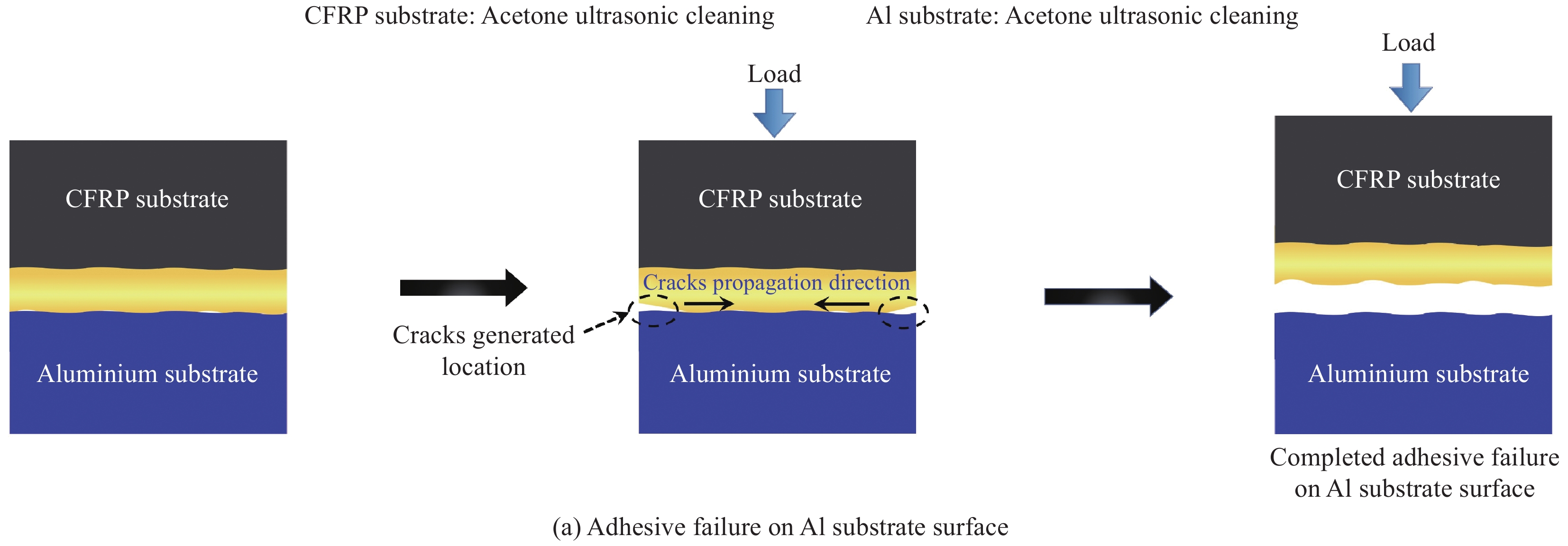

裂纹总是产生于较弱的区域并沿粘结界面扩展,最终导致Al-CFRP复合材料的结构破坏[13]。如图9所示,阳极氧化处理前后不同的表面条件可以改变弯曲破坏模式。对于仅丙酮超声清洗的铝合金,完全脱胶失效发生在铝基体与环氧树脂的粘结界面(图9(a)),随着变形量的增加,裂纹沿铝合金/环氧树脂粘结界面扩展,这是由于铝合金与环氧树脂粘结界面较差的相容性,几乎没有机械咬合行为[5-6]。在液氮条件下,即使铝合金的刚度获得提高并减小弯曲变形量,但也不能改变这种现象。然而,良好的粘结界面有助于改变这种弱界面失效模式。垂直分布的多孔结构不仅可以优化与环氧树脂的相容性,增加接触面积,加强机械咬合,还能为碳纳米管的嵌入创造纵向孔道空间,形成准Z方向分布的纤维桥联[32]。它们的共同作用提升了胶接接头性能,促进了CFRP板的断裂失效代替胶接界面的部分脱胶失效。

![]() 9 Al-CFRP复合材料的粘接表面失效模式示意图:(a) 仅经过丙酮超声清洗的铝合金与CFRP板呈现出典型的脱胶失效;(b) 经过阳极氧化和RPC(添加碳纳米管)的铝合金与经过砂纸打磨和RPC的CFRP板呈现出碳纤维基体的断裂失效9. Schematic diagram of failure mode on Al substrate and CFRP adhesive surface: (a) Typical adhesive failure only with acetone ultrasonic cleaning for Al substrate and CFRP; (b) CFRP fracture failure with anodizing + RPC with carbon nanotubes for Al substrate and sanding + RPC for CFRPCFRP—Carbon fiber reinforced polymer; CNTs—Carbon nanotubes

9 Al-CFRP复合材料的粘接表面失效模式示意图:(a) 仅经过丙酮超声清洗的铝合金与CFRP板呈现出典型的脱胶失效;(b) 经过阳极氧化和RPC(添加碳纳米管)的铝合金与经过砂纸打磨和RPC的CFRP板呈现出碳纤维基体的断裂失效9. Schematic diagram of failure mode on Al substrate and CFRP adhesive surface: (a) Typical adhesive failure only with acetone ultrasonic cleaning for Al substrate and CFRP; (b) CFRP fracture failure with anodizing + RPC with carbon nanotubes for Al substrate and sanding + RPC for CFRPCFRP—Carbon fiber reinforced polymer; CNTs—Carbon nanotubes3. 结 论

本工作成功增强了铝合金-碳纤维增强树脂基复合材料(CFRP)复合材料在室温和液氮温度下的粘接性能。通过阳极氧化表面处理和树脂预涂层(RPC)技术有效的应用,在铝合金表面刻蚀形成一层具有垂直孔道的多孔氧化薄膜,为碳纳米管的嵌入提供了纵向空间,从而在环氧树脂/铝合金粘接界面上构筑准

Z方向的碳纳米管桥联。同时CFRP板表面磨砂与RPC处理提高了环氧树脂/CFRP界面的粘结性能。通过铝合金与CFRP板表面的联合处理,室温下复合材料的抗弯强度比仅丙酮清洗处理增强了14.6%,液氮温度下,增强效果进一步提升到27.6%。基于碳纳米管桥联对裂纹产生和扩展的抑制作用,Al-CFRP复合材料的失效模式由原本较弱的脱胶失效转变为CFRP板的断裂失效。因此,“铝合金阳极氧化+RPC(添加碳纳米管)与CFRP板磨砂+RPC”的联合处理是一种有效的Al-CFRP复合材料环氧胶接接头强化方法,为低温液体燃料箱的工业化生产提供了一项可参照的技术方案,促进了航空航天工业的发展。 -

图 4 6060 T5铝合金的SEM图像:(a) 铝合金表面丙酮超声清洗;(b) 阳极氧化后的铝合金表面具有较深的微/纳米结构通道;(c) 阳极氧化后的铝合金52°视角图像;(d) 聚焦离子束(FIB)处理后多孔铝合金表面切口壁的正面图;(e)、(f) RPC处理后CNTs嵌入到铝合金表面孔道结构[32]

Figure 4. SEM images of 6060 T5 Al substrate: (a) Al substrate surface with acetone ultrasonic cleaning; (b) Al substrate surface with deep micro-/nano-structured channels after anodizing treatment; (c) 52° view image of the Al substrate after anodized corresponding to (b); (d) Frontal view of the notched wall on porous Al substrate surface after focus ion beam (FIB); (e),(f) CNTs inserted into the channel of Al substrate surface after RPC technique[32]

图 6 丙酮超声清洗和阳极氧化的铝合金表面的光谱分析 (a) ;丙酮超声清洗 (b) 和阳极氧化处理后铝合金表面 (c) 的高分辨Al2p核心级光谱

Figure 6. Survey spectra of Al substrate surfaces cleaned ultrasonically by acetone and anodized (a); high resolution Al2p core-level spectra for Al substrate surfaces after acetone ultrasonic cleaning (b) andanodizing treatment (c)

Aloh—Aluminium hydroxide hydroxide; Almet—Metallic aluminium; Alox—Aluminium oxide

图 8 Al-CFRP复合材料三点弯曲试验后的部分粘合及分离的失效表面:(a) 丙酮超声清洗后的铝合金和CFRP板;(b) 铝合金经过阳极氧化和RPC(添加碳纳米管),CFRP板经过砂纸打磨和RPC

Figure 8. Failure surfaces of adhesive bonded Al-CFRP composite and the separated pieces: (a) Acetone ultrasonic cleaning for Al substrate and CFRP; (b) Anodized Al substrate with RPC + CNTs and sanding and RPC for CFRP

9 Al-CFRP复合材料的粘接表面失效模式示意图:(a) 仅经过丙酮超声清洗的铝合金与CFRP板呈现出典型的脱胶失效;(b) 经过阳极氧化和RPC(添加碳纳米管)的铝合金与经过砂纸打磨和RPC的CFRP板呈现出碳纤维基体的断裂失效

9. Schematic diagram of failure mode on Al substrate and CFRP adhesive surface: (a) Typical adhesive failure only with acetone ultrasonic cleaning for Al substrate and CFRP; (b) CFRP fracture failure with anodizing + RPC with carbon nanotubes for Al substrate and sanding + RPC for CFRP

CFRP—Carbon fiber reinforced polymer; CNTs—Carbon nanotubes

表 1 经丙酮超声清洗和阳极氧化处理后6060 T5铝合金的表面粗糙度参数

Table 1 Surface roughness measurements of the 6060 T5 Al substrate treated by acetone ultrasonic cleaning and anodizing

Treatment method Sample number Sa/nm Sq/nm Rmax/nm Acetone ultrasonic cleaning Fig.5(a) 53.4 62.5 353 Fig.5(b) 36.5 42.9 238 Anodizing surface treatment Fig.5(c) 91.3 114 785 Fig.5(d) 95.4 134 1037 Notes: Sa—Surface arithmetical mean roughness; Sq—Surface root mean square roughness; Rmax—Maximum roughness depth. 表 2 丙酮清洗和阳极氧化后铝合金上超薄表面层的表面元素组成

Table 2 Surface elemental composition of the ultra-thin surface layer on both acetone-cleaned and anodized Al substrates

Sample Almet Alox Aloh Acetone-cleaned Al substrate 21.0% 62.7% 17.5% Anodized Al substrate − − 100.0% 表 3 室温(RT)和液氮温度(LNT)下对照组和实验组Al-CFRP复合材料的3-P-B试验结果

Table 3 3-P-B test results of control and treated Al-CFRP composites at room temperature (RT) and liquid nitrogen temperature (LNT)

Sample Treatment process Test

conditionAverage

Pmax/NStandard

deviation/NShear

strength/MPaStandard

deviation/MPaControl Acetone ultrasonic cleaning for both RT 2564.21 136.87 269.97 48.14 LNT 2915.79 591.69 532.92 60.51 T1 Anodizing for Al and Acetone ultrasonic cleaning for CFRP RT 2690.45 142.53 285.76 23.42 LNT 5364.05 514.17 569.73 49.64 T2 Anodizing for Al and sanding +

RPC for CFRPRT 2760.61 121.31 290.15 17.75 LNT 5541.01 531.58 582.38 42.73 T3 Anodizing for Al and RPC (CNTs) sanding + RPC for CFRP RT 5015.57 109.55 309.31 13.05 LNT 6374.42 545.44 680.01 48.14 Note: Pmax—Maximum peak load. -

[1] 李游, 李传习, 郑辉, 等. 固化剂混掺对高温下CFRP板-钢板界面黏结性能的影响[J]. 复合材料学报, 2021, 38(12):4073-4089. LI Y, LI C X, ZHENG H, et al. Effect of curing agent mixing on interfacial bond behavior of glued CFRP plate-steel plate at elevated temperature[J]. Acta Materiae Compositae Sinica,2021,38(12):4073-4089(in Chinese).

[2] 任明伟, 洪治国, 周玉敬, 等. 复合材料防撞梁低速碰撞优化设计[J]. 复合材料学报, 2022, 39(2):854-862. REN M W, HONG Z G, ZHOU Y J. Low-speed collision optimization design of composite bumper[J]. Acta Materiae Compositae Sinica,2022,39(2):854-862(in Chinese).

[3] 刘洋, 庄蔚敏. 碳纤维增强树脂复合材料和铝合金温热自冲铆接工艺及接头力学性能[J]. 复合材料学报, 2021, 38(11):3563-3577. LIU Y, ZHUANG W M. Joining process and mechanical properties of warm self-piercing riveting for carbon fiber reinforced polymer and aluminum alloy[J]. Acta Materiae Compositae Sinica,2021,38(11):3563-3577(in Chinese).

[4] 包建文, 蒋诗才, 张代军. 航空碳纤维树脂基复合材料的发展现状和趋势[J]. 科技导报, 2018, 36(9):52-63. BAO J W, JIANG S C, ZHANG D J. Current status and trends of aeronautical resin matrix composites reinforced by carbon fiber[J]. Science & Technology Review,2018,36(9):52-63(in Chinese).

[5] CHENG F, HU YS, LV ZF, et al. Directing helical CNT into chemically-etched micro-channels on aluminum substrate for strong adhesive bonding with carbon fiber composites[J]. Composites Part A: Applied Science and Manufacture,2020,135:105952. DOI: 10.1016/j.compositesa.2020.105952

[6] HU Y S, YUAN B Y, CHENG F, et al. NaOH etching and re-sin pre-coating treatments for stronger adhesive bonding between CFRP and aluminium alloy[J]. Composites Part B: Engineering,2019,178:107478. DOI: 10.1016/j.compositesb.2019.107478

[7] FIORE V, CALABRESE L, PROVERBIO E, et al. Salt spray fog ageing of hybrid composite/metal rivet joints for automo-tive applications[J]. Composites Part B: Engineering,2017,108:65-74. DOI: 10.1016/j.compositesb.2016.09.096

[8] MURRAY B R, DOULE A, FEERICK P J, et al. Rotational moulding of PEEK polymer liners with carbon fibre/PEEK over tape-placement for space cryogenic fuel tanks[J]. Material Design,2017,132:567-581. DOI: 10.1016/j.matdes.2017.07.026

[9] RAMOLA L, SANKARESWARAN N. Design and modal analy-sis of cryogenic rocket propellant tank[J]. International Journal of Scientific Research in Science, Engineering and Technology, 2016, 2: 614-620.

[10] HU Y S, CHENG F, JI Y, et al. Effect of aramid pulp on low temperature flexural properties of carbon fibre reinforced plastics[J]. Composites Science and Technology,2020,192:108095. DOI: 10.1016/j.compscitech.2020.108095

[11] SETHI S, RAY B C. Experimental study on the mechanical behavior and microstructural assessment of Kevlar/epoxy composites at liquid nitrogen temperature[J]. Journal of the Mechanical Behavior of Materials,2014,23:95-100. DOI: 10.1515/jmbm-2014-0011

[12] SUN Z, SHI S, HU X Z, et al. Short-aramid-fiber toughening of epoxy adhesive joint between carbon fiber composites and metal substrates with different surface morphology[J]. Composites Part B: Engineering,2015,77:38-45. DOI: 10.1016/j.compositesb.2015.03.010

[13] SUN G, LIU X, ZHENG G, et al. On fracture characteristics of adhesive joints with dissimilar materials-An experimen-tal study using digital image correlation (DIC) technique[J]. Composites Structure,2018,201:1056-1075. DOI: 10.1016/j.compstruct.2018.06.018

[14] PARK S Y, CHOI W J, CHOI H S, et al. Recent trends in surface treatment technologies for airframe adhesive bonding processing: A review (1995-2008)[J]. The Journal of Adhesion,2010,86:192-221. DOI: 10.1080/00218460903418345

[15] WANG B, HU X, HUI J, et al. CNT-reinforced adhesive joint between grit-blasted steel substrates fabricated by simple resin pre-coating method[J]. The Journal of Adhesion,2018,94:529-540. DOI: 10.1080/00218464.2017.1301255

[16] 段瑛涛, 武肖鹏, 王智文, 等. 碳纤维增强树脂复合材料-热成型钢超混杂层合板层间力学性能[J]. 复合材料学报, 2020, 37(10):2418-2427. DUAN Y T, WU X P, WANG Zhiwen, et al. Interlaminar mechanical properties of carbon fiber reinforced plastics-thermoformed steel super-hybrid laminates[J]. Acta Materiae Compositae Sinica,2020,37(10):2418-2427(in Chinese).

[17] LIU W, ZHENG Y, HU X, et al. Interfacial bonding enhancement on the epoxy adhesive joint between engineered bamboo and steel substrates with resin pre-coating surface treatment[J]. Wood Science and Technology,2019,53:785-799. DOI: 10.1007/s00226-019-01109-9

[18] SALEEMA N, SARKER DK, PAYNTER R W, et al. A simple surface treatment and characterization of AA 6061 aluminum alloy surface for adhesive bonding applications[J]. Applied Surface Science,2012,261:742-748. DOI: 10.1016/j.apsusc.2012.08.091

[19] ZAIN N M, AHMAD S H, ALI E S. Effect of surface treatments on the durability of green polyurethane adhesive bonded aluminium alloy[J]. International Journal of Adhesion and Adhesives,2014,55:43-55. DOI: 10.1016/j.ijadhadh.2014.07.007

[20] TAN B, JI Y, HU Y, et al. Pretreatment using diluted epoxy adhesive resin solution for improving bond strength between steel and wood surfaces[J]. International Journal of Adhesion and Adhesives,2019,98:102502.

[21] WANG B, BAI Y, HU X, et al. Enhanced epoxy adhesion between steel plates by surface treatment and CNT/short-fibre reinforcement[J]. Composites Science and Technol-ogy,2016,127:149-157. DOI: 10.1016/j.compscitech.2016.03.008

[22] SHI S, SUN Z, HU X, et al. Carbon-fiber and aluminum-honeycomb sandwich composites with and without Kevlar-fiber interfacial toughening[J]. Composites Part A: Applied Science and Manufacture,2014,67:102-110. DOI: 10.1016/j.compositesa.2014.08.017

[23] SUN Z, HU X, CHEN H. Effects of aramid-fibre toughening on interfacial fracture toughness of epoxy adhesive joint between carbon-fibre face sheet and aluminium substrate[J]. International Journal of Adhesion and Adhe-sives,2014,48:288-294. DOI: 10.1016/j.ijadhadh.2013.09.023

[24] ZHANG Z, SHAN J G, TAN X H, et al. Effect of anodizing pretreatment on laser joining CFRP to aluminum alloy A6061[J]. International Journal of Adhesion and Adhe-sives,2016,70:142-151. DOI: 10.1016/j.ijadhadh.2016.06.007

[25] ALIASGHARI S, SKELDON P, ZHOU X, et al. Effect of an anodizing pre-treatment on AA 5052 alloy/polypropylene joining by friction stir spot welding[J]. Materials Science and Engineering: B,2019,245:107-112. DOI: 10.1016/j.mseb.2019.05.018

[26] XU Y, LI H, SHEN Y, et al. Improvement of adhesion performance between aluminum alloy sheet and epoxy based on anodizing technique[J]. International Journal of Adhesion and Adhesives,2016,70:74-80. DOI: 10.1016/j.ijadhadh.2016.05.007

[27] SAEEDIKHANI M, JAYIDI M, YAZDANI A. Anodizing of 2024-T3 aluminum alloy in sulfuric-boric-phosphoric acids and its corrosion behavior[J]. Transactions of Nonferrous Metals Society of China,2013,23:2551-2559. DOI: 10.1016/S1003-6326(13)62767-3

[28] 程飞, 蒋宏勇. 基于芳纶pulp优化的碳纤维增强树脂基复合材料的抗损伤性能及残余抗压强度研究[J]. 复合材料学报, 2021, 38(11):3610-3619. CHENG F, JIANG H Y. Research on damage resistance and residual compressive strength of carbon fiber reinforced plastic optimized by aramid pulp[J]. Acta Materiae Compositae Sinica,2021,38(11):3610-3619(in Chinese).

[29] JIN K, WANG H, TAO J, et al. Interface strengthening mechanisms of Ti/CFRP fiber metal laminate after adding MWCNTs to resin matrix[J]. Composites Part B: Engineering,2019,171:254-263. DOI: 10.1016/j.compositesb.2019.05.005

[30] HUNG P, LAU K, QIAO K, et al. Property enhancement of CFRP composites with different graphene oxide employment methods at a cryogenic temperature[J]. Composites Part A: Applied Science and Manufacture,2019,120:56-63. DOI: 10.1016/j.compositesa.2019.02.012

[31] KARA M, KIRICI M, TATER A C, et al. Impact behavior of carbon fiber/epoxy composite tubes reinforced with multi-walled carbon nanotubes at cryogenic environment[J]. Composites Part B: Engineering,2018,145:145-154. DOI: 10.1016/j.compositesb.2018.03.027

[32] CHENG F, HU Y, ZHANG X, et al. Adhesive bond strength enhancing between carbon fiber reinforced polymer and aluminum substrates with different surface morphologies created by three sulfuric acid solutions[J]. Composites Part A: Applied Science and Manufacture,2021,146:106427. DOI: 10.1016/j.compositesa.2021.106427

[33] GOUSHEGIR S M, SCHARNAGL N, SANTOS J F, et al. XPS analysis of the interface between AA2024-T3/CF-PPS friction spot joints[J]. Surface and Interface Analysis,2016,48:706-711. DOI: 10.1002/sia.5816

[34] LI X, HUFNAGEL S, XU H Y, et al. Aluminum (oxy)hydroxide nanosticks synthesized in bicontinuous reverse microemulsion have potent vaccine adjuvant activity[J]. ACS Applied Materials & Interfaces,2017,9:22893-22901.

[35] UHART A, LEDEUIL J B, GONBEAU D, et al. An auger and XPS survey of cerium active corrosion protection for AA2024-T3 aluminum alloy[J]. Applied Surface Science,2016,390:751-759. DOI: 10.1016/j.apsusc.2016.08.170

-

期刊类型引用(0)

其他类型引用(1)

-

下载:

下载: