Flexural strength enhancement study of aluminum-CFRP at liquid nitrogen temperature

-

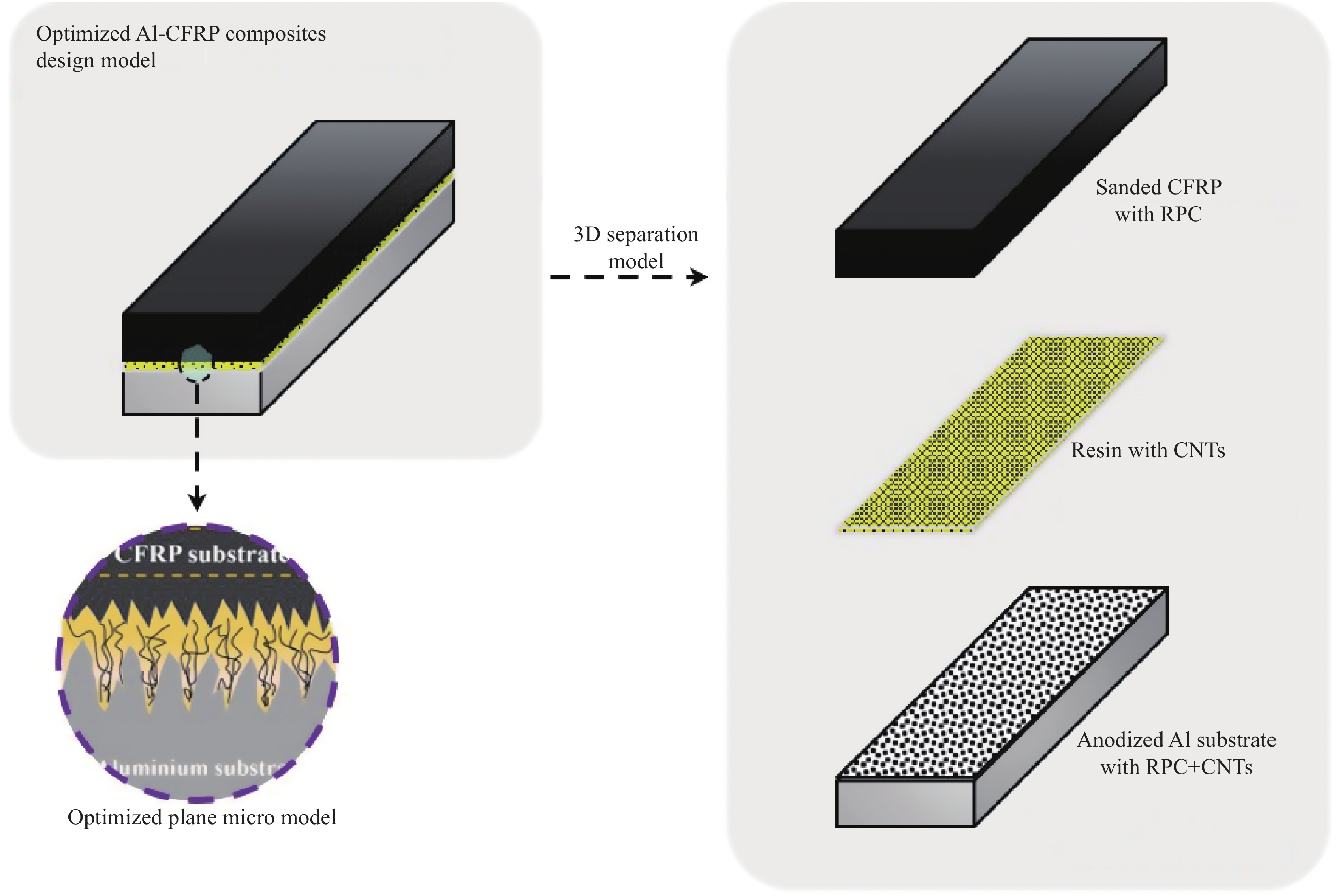

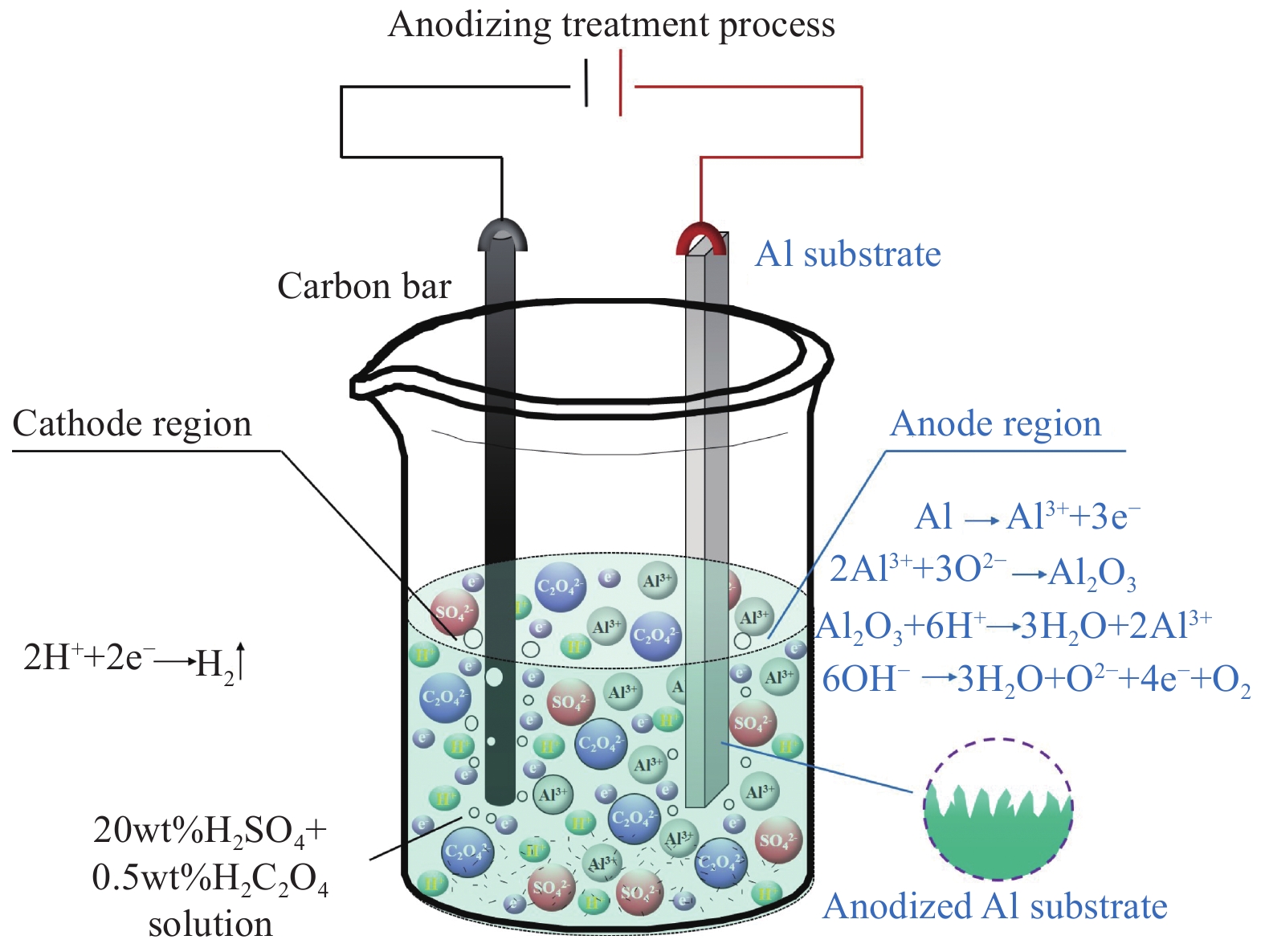

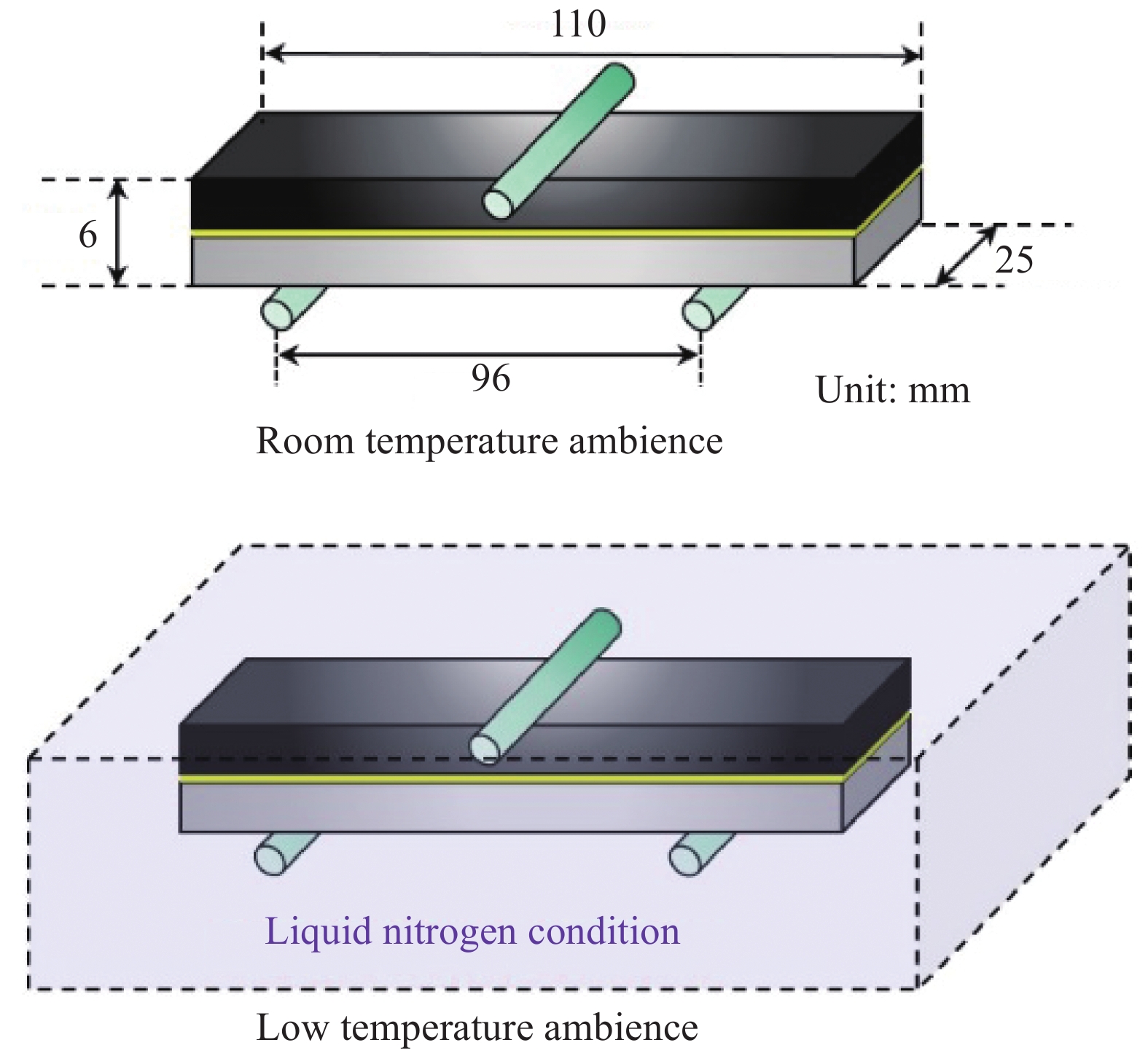

摘要: 随着铝合金-碳纤维增强树脂复合材料(CFRP)逐渐应用到火箭推进器,其低温环境下的粘结性能强化已引起广泛关注。针对环氧接头潜在的粘接界面缺陷,采用阳极氧化和砂化分别处理铝合金和CFRP板表面制得多孔表面。采用树脂预涂(RPC)技术消除铝合金孔道根部原有的大分子环氧树脂空穴缺陷,也可通过RPC技术将增强纤维碳纳米管浸渍到铝合金表面的孔道中,形成准Z方向的纤维桥联,进一步提高环氧接头的粘结强度。三点弯曲试验(3-P-B)结果表明,室温下处理后的铝合金-CFRP弯曲强度提高了14.6%,液氮温度下弯曲强度提高了27.6%。经过表面处理后,CFRP在室温和液氮温度下的破坏模式均由较弱的界面脱胶破坏转变为主体结构的断裂破坏。总之,系列有效的处理方法可为低温液体燃料箱的工业应用提供另一种参考。Abstract: The adhesive bonding strength enhancement of aluminum substrate and carbon fiber reinforced polymer (CFRP) at cryogenic temperature has attracted far-ranging attention with their application expanding to rocket booster. Aiming at the potential bonding interface defect of epoxy joint, we adopted the anodizing and sanding treatments to modify surface performance of Al substrate and CFRP panel respectively. The resin pre-coating (RPC) technique was used to eliminate the originally existing defect caused by macromolecular epoxy at the root of porous Al substrate. The carbon nanotubes were applied as additives to be impregnated into channels on Al substrate surface via RPC technique and construct the quasi-Z directional fiber bridging, which can further improve the adhesive bonding strength of epoxy joint. The three-point bending (3-P-B) results show the flexural strength of aluminum substrate-CFRP after treated has been enhanced by 14.6% at room temperature, and even higher 27.6% at liquid nitrogen temperature based on that of the one only cleaned by acetone. Failure mode exhibits the weaker adhesive failure on bonding interface has been transformed into main structure fracture failure of CFRP after combined surface treatments at both room temperature and liquid nitrogen temperature. Overall, the effective treatment methods can offer an alternative reference in industrial application of cryogenic liquid fuel tank.

-

具有轻质、高强、免锈蚀及抗疲劳性能良好等诸多优点的碳纤维增强聚合物复合材料(Carbon fiber reinforced polymer,CFRP)筋有望成为传统钢制筋材的替代品,特别是对于在恶劣环境下工作的预应力结构[1-3]。相较于易导致CFRP筋出现“切口效应”而过早发生横向破坏的夹持型锚固系统,粘结型锚固系统通过CFRP筋-粘结介质界面的化学胶着力、摩擦力及机械咬合力可实现对CFRP筋更可靠、有效的锚固[4-5]。活性粉末混凝土(Reactive powder concrete,RPC)以其优异的力学性能和耐久性能可成为有效锚固CFRP筋的粘结介质[6]。RPC灌注的CFRP筋粘结型锚固系统已在实际工程中得以成功应用,并表现出优异的锚固性能[7-8]。然而,CFRP筋及其粘结型锚固系统在建造和运营过程中可能遭受火灾作用[9-12]。火灾下CFRP筋及CFRP筋-粘结介质界面因树脂基体较弱的耐高温性能而易成为受力薄弱环节,则高温下CFRP筋及其粘结型锚固系统的力学性能值得关注。因此,对CFRP筋及其粘结型锚固系统的高温力学性能进行研究是十分必要的。

国内外部分学者对高温下CFRP筋的力学性能开展了研究。Wang等[13]试验研究了20~600℃作用下CFRP筋力学性能退化规律,结果表明:高温下CFRP筋应力-应变始终呈线性关系;CFRP筋抗拉强度随处理温度升高而近似线性衰减,并在500℃时完全丧失;处理温度高于350℃时,CFRP筋弹性模量急剧下降。杨桢楠[14]试验研究了100~500℃作用下CFRP筋的力学性能,结果表明:处理温度大于200℃时,CFRP筋的抗拉强度与弹性模量均大幅下降。周飞[15]对20~500℃作用下CFRP筋力学性能进行了试验研究,提出了适于表征高温下CFRP筋轴拉性能退化规律的指数函数模型。上述研究所采用CFRP筋的树脂玻璃化转变温度Tg均小于200℃。

另有部分学者对高温下纤维增强塑料(Fiber reinforce plastic,FRP)筋-混凝土界面的粘结性能进行了试验研究。吕西林等[16]研究了处理温度、混凝土强度与粗骨料粒径等参数对20~250℃作用下玻璃纤维增强聚合物复合材料(Glass fiber reinforced polymer,GFRP)筋-混凝土界面粘结性能的影响规律,结果表明处理温度高于110℃时,界面粘结强度相较于常温下降低了85%~90%。Katz等[17-18]对20~250℃作用下GFRP筋-混凝土界面粘结性能进行了研究,给出了适于表征界面粘结强度衰减规律的半经验模型,结果表明处理温度为250℃时,界面粘结强度仅为常温时的10%~20%;筋材表面处理方式是影响界面粘结强度的重要因素。王晓璐等[19]研究了20~350℃作用下FRP (GFRP、玄武岩纤维增强聚合物复合材料(Basalt fiber reinforced polymer,BFRP))筋-混凝土界面的粘结性能,提出了高温下界面粘结强度衰减模型与粘结-滑移本构模型,结果表明处理温度由60℃增至120℃时,界面粘结强度的衰减幅度最大;200℃时界面粘结强度仅为常温时的15%。鞠竹等[20]对20~190℃作用下GFRP筋-混凝土界面的粘结性能进行了研究,并提出了适用于表征高温下界面粘结-滑移行为的双折线模型。

综上所述,现有研究侧重于高温下具有较低Tg (Tg<200℃) FRP筋材轴拉性能及FRP筋-混凝土界面粘结性能,鲜见关于高温下CFRP筋(Tg>200℃)及其粘结型锚固系统力学性能研究的报道。为此,本文将在方志等[21]的研究(侧重于研究高温后CFRP筋及其粘结型锚固系统的残余力学性能,是开展火灾后相应评估工作的依据)的基础上,对高温下一种抗火性能优良的CFRP筋(Tg>200℃)及其粘结型锚固系统的静力性能进行试验研究,以揭示处理温度对高温下CFRP筋轴拉性能及其锚固性能的影响规律,提出适于表征高温下CFRP筋轴拉性能及其锚固性能的实用计算公式,为评估CFRP筋及其锚固系统的抗火性能提供依据。本文与前期研究的成果将共同为高性能CFRP筋材的工程应用提供理论基础。

1. 试验概况

1.1 试件设计

参照《纤维增强复合材料筋基本力学性能试验方法》(GB/T 30022—2013)[22]设计CFRP筋轴拉试件,以筋材处理温度T(分别为25℃、100℃、210℃和300℃)为试验参数,设计4组试件,每组3个试件,共计12个试件。

CFRP筋轴拉试件由长为680 mm的自由段及其两端长为360 mm的粘结型锚固系统组成,总长共计1400 mm,如图1所示。其中,锚固CFRP筋的粘结型锚固系统通过在外径为42 mm、内径为36 mm的钢套筒内灌注RPC形成,筋材周围RPC保护层厚度为12 mm。

选取试验锚的处理温度T (分别为25℃、100℃、210℃、300℃)为锚固性能试验的参数,设计4组试件,每组2个试件,共计8个试件。锚固性能试件的粘结长度l均设置为5d,其中d为CFRP筋的公称直径,d=12 mm。

CFRP筋-RPC锚固性能试件由CFRP筋材自由段及其位于左右两侧的工具锚与试验锚组成,如图2所示。以CFRP筋轴拉试件的粘结型锚固系统作为锚固性能试件的工具锚。为便于测定CFRP筋-RPC界面粘结-滑移性能,锚固性能试件右侧的试验锚通过在外径为76 mm、内径为72 mm的钢套筒内灌注RPC形成。试验锚长度设置为420 mm,以与高温炉炉腔长度380 mm相匹配。为获取试验预设的粘结长度l=5d,试验锚加载端与自由端的CFRP筋外侧均预埋长度为180 mm的耐高温陶瓷套管。利用耐高温胶密封陶瓷套管与CFRP筋间的孔隙,以防止灌注粘结介质时RPC进入陶瓷套管内。此外,利用耐高温胶带将K型热电偶的较少部分金属探头固定于CFRP筋-RPC界面,以实时监测试验过程中粘结界面的温度。

利用设置在锚筒两端的聚乙烯封盖中心处圆孔精确定位轴拉试件或锚固系统性能试件的CFRP筋。浇筑钢锚筒的粘结介质RPC形成粘结型锚固系统,将其静置24 h后再采用90℃蒸汽养护48 h。

1.2 试验材料

轴拉与锚固性能试验所用的CFRP筋材均由江苏连云港中复碳芯电缆科技有限公司提供,其外观尺寸及Tg如图3和表1所示。CFRP筋由体积含量为66.3vol%的T700SC连续碳纤维丝束与TP224环氧树脂拉挤而成。

CFRP筋粘结型锚固系统的粘结介质-RPC由不含钢纤维的商品预混料加水拌制而成,其设计强度等级为RPC150。边长100 mm的立方体实测抗压强度为158 MPa,RPC配合比(单方质量比)如表2所示。

表 1 CFRP筋外观尺寸及玻璃化转变温度TgTable 1. Dimensions and glass transition temperatureTg of CFRP barNominal

diameter/mmRib

width/mmRib

height/mmEmbossing

space/mmTg/℃ 12 9.26 0.27 14.8 210 表 2 RPC配合比及抗压强度Table 2. Mix proportion and compressive strength of RPCStrength grade Cement Silica fume Quartz flour Quartz sand Water reducer Water binder ratio RPC150 1 0.25 0.25 1.1 0.02 0.16 1.3 温升加载方式与测点布置

轴拉与锚固性能试验的温升加载及测量装置分别如图4、图5所示。试验中采用的温升加载方式参考金属材料高温拉伸试验方法(GB/T 4338—2006)[23],如图6所示。将轴拉试件的筋材自由段或锚固性能试件的试验锚放置于高温试验炉(尺寸为380 mm (长)×410 mm (宽)×650 mm (高)) 中,以3℃/min的温升速率温升至目标温度,恒温一定时间(对于轴拉试件,通常恒温20 min;对于锚固性能试件,恒温至CFRP筋-RPC界面温度达到目标温度)后再进行单调加载。高温炉由长沙科辉炉业科技有限公司提供,其升温区间和最大升温速率分别为100~1200℃和100℃/min。利用设置在CFRP筋表面与CFRP筋-RPC界面的K型热电偶分别监测轴拉与锚固性能试件的实时温度。

当试件温度达到目标温度且稳定时,利用600 kN液压伺服试验机(南京诺尔泰设备制造有限公司)以1 mm/min的位移加载速率对试件施加轴向拉力或拉拔力。其中,锚固性能试件的拉拔力需借助固定于液压伺服试验机夹具上的工具锚,对放置在反力架上的试验锚进行施加,如图5所示。为使锚固性能试件始终处于铅直受力状态,在反力架与试验锚之间设置了可转动的开孔球铰。利用液压伺服试验机的力传感器采集试件拉拔力。采用与CFRP筋表面紧密接触的高温引伸计测量轴拉试件筋材自由段中部的应变。锚固性能试件加载端CFRP筋-RPC界面滑移通过固定于CFRP筋上的位移传感器获取。

2. CFRP筋轴拉试验结果及分析

2.1 CFRP筋轴拉试件的破坏形态

高温下各CFRP筋轴拉试件的典型破坏形态均为拉断破坏,破断位置均分布于筋材自由段区域内;随着处理温度逐渐升高,拉断破坏形态由筋材断口破坏与少量丝束分离的片状形态转变为纤维丝“蓬松”的形态,如图7所示。

常温下,试件的轴拉应力超过80%极限抗拉强度后,少量纤维丝破断而发出细小声响;当轴拉应力达到极限抗拉强度时,试件会突然破坏而形成位于自由段中部的断口,并伴随有轻微的炸裂现象。但文中常温试件炸裂程度较轻,且筋材自由段左侧区域因炸裂形成的碳纤维细条未能及时收集而丢失,导致图7中所示常温试件的破坏形态与典型的纤维束爆裂形态(纤维束炸开的扫帚状)存在一定的差别。

对于处理温度为100~210℃的轴拉试件,其轴拉应力接近极限抗拉强度时因少量纤维丝破断而发出细小声响。由于树脂性能退化较轻微,少量破断的纤维丝呈丝束分离的片状形态。筋材轴拉应力达到极限抗拉强度后突然发生伴有清脆响声的破断,其断口位置靠近筋材自由段中间区域。

对于处理温度不低于Tg=210℃的轴拉试件,其自由段中部树脂因高温作用而逐渐软化、甚至部分分解(厂家提供的树脂基体5wt%质量损失相应温度为318℃),导致树脂-纤维界面粘结性能快速衰减、部分纤维丝间无树脂而裸露。筋材轴拉应力达到极限抗拉强度后,其自由段中部裸露的纤维丝发生破断而呈现“蓬松”的状态。

2.2 CFRP筋轴拉试验结果

各轴拉试件的主要试验结果、应力-应变曲线如表3与图8所示。可见,高温下轴拉试件破断前的应力-应变基本呈线性关系。利用应力-应变曲线中0.2~0.5倍极限抗拉强度范围内的割线模量确定筋材轴向试件的弹性模量[24]。高温下CFRP筋轴拉性能的衰减规律如图9所示。

表 3 CFRP筋轴向拉伸试验结果Table 3. Results of axial tensile test for CFRP barSpecimen Pu/kN fu/MPa ¯fu/MPa E/GPa ¯E/GPa εu/10−6 ¯εu/10−6 AT-T25-1 280.8 2631 2650 162.2 159.9 15627 15513 AT-T25-2 283.1 2653 161.8 15464 AT-T25-3 284.5 2666 155.6 15448 AT-T100-1 274.2 2569 2588 133.0 141.6 18506 18387 AT-T100-2 278.0 2605 143.5 18343 AT-T100-3 276.3 2589 148.3 18312 AT-T210-1 198.9 1864 1861 98.7 102.9 18298 18201 AT-T210-2 192.7 1806 105.5 18254 AT-T210-3 204.3 1914 104.4 18051 AT-T300-1 176.0 1649 1566 82.6 87.9 17963 17816 AT-T300-2 157.0 1471 92.4 17762 AT-T300-3 168.3 1577 88.8 17723 Notes: In the specimen code, AT is axial tensile, T indicates the treatment temperature, the last number indicates the same specimen number; Pu—Ultimate bearing capacity; fu—Tensile strength; ¯fu—Average value; E—Elastic modulus; ¯E—Average value; εu—Ultimate tensile strain; ¯εu—Average value. 相较于常温试件,100℃下轴拉试件的抗拉强度、弹性模量分别减小了2.3%、11.4%,而极限拉应变增大了18.5%;210℃和300℃下轴拉试件的抗拉强度、弹性模量分别减小了(29.8%、40.9%)和(35.6%、45%),而极限拉应变分别增大了17.3%和14.8%。可见,高温下筋材弹性模量较抗拉强度受处理温度的影响更为显著,两者的衰减幅度在处理温度由100℃增至210℃时达到最大。高温下筋材的极限拉应变较常温下有所增大,并随处理温度升高而呈先增大后减小的变化趋势。究其原因,处理温度为Tg时,筋材自由段区域的树脂逐渐软化,导致筋材整体性退化明显,各纤维间的受力更趋不均,使筋材抗拉强度与弹性模量退化显著。此外,高温下筋材的弹性模量(或轴拉刚度)较抗拉强度更依赖于树脂基体的力学性能。高温下树脂基体的力学性能因其较差的耐高温性能而快速衰减,其退化幅度远大于碳纤维,进而导致高温下筋材弹性模量的衰减幅度较抗拉强度更大、极限拉应变较常温下有所增加。

![]() 图 9 高温下CFRP筋轴拉性能衰减规律fu(T)/fu—Reduction coefficient of tensile strength under high-temperature; Eu(T)/Eu—Reduction coefficient of elastic modulus under high-temperature; εu(T)/εu—Reduction coefficient of ultimate tensile strain under high-temperatureFigure 9. Decay law of axial tensile performance of CFRP bar exposed to elevated temperature

图 9 高温下CFRP筋轴拉性能衰减规律fu(T)/fu—Reduction coefficient of tensile strength under high-temperature; Eu(T)/Eu—Reduction coefficient of elastic modulus under high-temperature; εu(T)/εu—Reduction coefficient of ultimate tensile strain under high-temperatureFigure 9. Decay law of axial tensile performance of CFRP bar exposed to elevated temperature3. CFRP筋-RPC锚固性能试验结果及分析

3.1 CFRP筋-RPC锚固性能试件的破坏形态

图10为CFRP 筋-RPC 锚固性能试件破坏形态。将锚固性能试件破坏后的试验锚加载端含陶瓷套管区域切除,以便观察CFRP筋-RPC界面的破坏形态,如图10(a)所示。高温下锚固性能试件的破坏形态均为滑移破坏,具体表现为筋材表面压纹肋发生剪切破坏,其核心部分从锚固区被拔出,筋材肋间RPC未被拔出。随着处理温度升高,筋材压纹肋及肋间表面树脂逐渐软化、甚至部分分解,而高温下RPC的剩余剪切性能远高于树脂;导致压纹肋更易发生剪切破坏、从锚固区拔出的筋材核心部分表面压纹肋残留的痕迹越发模糊,无树脂包裹而裸露的部分纤维丝因与肋间RPC发生摩擦而破坏,如图10(b)所示。因此,高温下CFRP筋-RPC界面粘结性能主要取决于树脂的剩余剪切性能。

3.2 CFRP筋-RPC锚固性能试件的粘结-滑移曲线

各锚固性能试件的试验结果、高温下的粘结-滑移曲线分别如表4和图11所示。可见,各锚固性能试件的粘结-滑移曲线均可分为以下四个阶段:(1) 线性段。粘结-滑移基本呈线性关系,加载端的粘结界面滑移较小,均在0~1 mm之间。粘结界面的切应力主要由筋材与RPC间化学胶着力抵抗。粘结界面的化学胶着力随处理温度升高而逐渐减小,导致加载端的初期滑移逐渐增大;(2) 非线性上升段。粘结-滑移呈明显的非线性关系,筋材与粘结介质间化学胶着力丧失,粘结界面的切应力主要由筋材与RPC间摩擦力、筋材表面凸起的压纹肋及肋间RPC形成的机械咬合力共同抵抗。筋材表面的压纹肋树脂抗剪性能逐渐衰减,导致粘结强度逐渐降低;(3) 下降段。筋材表面的部分压纹肋发生剪切破坏,其与肋间RPC的机械咬合力丧失。抵抗粘结界面切应力的机械咬合力逐渐减小,导致CFRP筋-RPC界面滑移继续增大;(4) 残余段。界面的切应力主要由未拔出的筋材核心部分与RPC界面间摩擦力抵抗。随着滑移增大,试验锚陶瓷管内的带肋筋材进入锚固区,其表面压纹肋与RPC间机械咬合力参与抵抗粘结界面切应力,进而导致残余段可承担的粘结界面切应力逐渐增加。

采用下式计算试件锚固区CFRP筋-RPC界面的平均粘结强度τu,并将计算结果示于表4:

τu=Puπdl (1) 式中:Pu为极限荷载值;d为筋材公称直径;l为粘结长度。

表 4 CFRP筋-RPC锚固性能试验结果Table 4. Results of CFRP bar-RPC anchorage performance testSpecimen T/℃ Pu/kN ¯Pu/kN τu/MPa s/mm ¯su/mm A-T25-L5d-1 25 66.74 66.38 29.36 6.74 6.67 A-T25-L5d-2 66.02 6.60 A-T100-L5d-1 100 50.58 52.84 23.37 6.44 6.53 A-T100-L5d-2 55.10 6.62 A-T210-L5d-1 210 34.30 31.47 13.92 5.88 6.01 A-T210-L5d-2 28.64 6.14 A-T300-L5d-1 300 11.85 9.85 4.36 5.69 5.63 A-T300-L5d-2 7.85 5.57 Notes: In the specimen code, A is anchorage, T indicates the treatment temperature, the last number indicates the same specimen number; T—Treatment temperature; L—Bond length; τu—Average bond strength; s—Slip of loading end corresponding to Pu; d—Diameter of CFRP bar; ˉPu—Average value of ultimate bearing capacity for anchorage system; ˉsu—Average value of the slip of loading end corresponding to Pu。 3.3 温度对CFRP筋-RPC锚固性能试件粘结强度的影响

锚固性能试件粘结强度随温度的变化规律如表4与图12所示。可见,试件粘结强度随处理温度升高而线性退化。相较于常温下的锚固性能试件,100℃、210℃和300℃下试件粘结强度分别减小了20.4%、52.6%和85.1%。究其原因为随着处理温度逐渐升至210℃和300℃,筋材表面的压纹肋树脂逐渐软化、甚至部分分解,导致用于抵抗粘结界面切应力的主要抗力—筋材压纹肋与肋间RPC的机械咬合力大幅退化。

4. 公式建立

4.1 高温下CFRP筋轴拉性能

对本文高温下轴拉试验结果进行回归分析,构建适于表征高温下(25℃

⩽ T\leqslant 300℃) CFRP筋轴拉性能退化规律的计算模型,如以下两式及图9(a)、图9(b)所示:\frac{{{f_{\rm{u}}} \left( T \right)}}{{{f_{\rm{u}}}}} = 0.387 \exp \left[ { - 3 {{\left( {\frac{{T - {T_0}}}{{{T_{\rm{g}}}}}} \right)}^4}} \right] + 0.613 (2) \frac{{{E_{\rm{u}}} \left( T \right)}}{{{E_{\rm{u}}}}} = 0.47 \exp \left[ { - 3 {{\left( {\frac{{T - {T_0}}}{{{T_{\rm{g}}}}}} \right)}^2}} \right] + 0.53 (3) 将式(2)除以式(3),可得高温下CFRP筋极限拉应变退化规律的计算公式为

\frac{{{\varepsilon _{\rm{u}}} \left( T \right)}}{{{\varepsilon _{\rm{u}}}}} = \frac{{0.387 \exp \left[ { - 3 {{\left( {\dfrac{{T - {T_0}}}{{{T_{\rm{g}}}}}} \right)}^4}} \right] + 0.613}}{{0.47 \exp \left[ { - 3 {{\left( {\dfrac{{T - {T_0}}}{{{T_{\rm{g}}}}}} \right)}^2}} \right] + 0.53}} (4) 式中:fu(T)、Eu(T)、εu(T)分别为高温下CFRP筋的抗拉强度、弹性模量及极限拉应变;fu、Eu、εu为常温下CFRP筋的抗拉强度、弹性模量及极限拉应变;T0为常温25℃;25℃

\leqslant T\leqslant 300℃。利用式(4)计算本文各轴拉试件的极限拉应变,并将其与试验值进行对比分析,结果如表5与图9(c)所示。试验值/计算值的平均值及变异系数分别为1.010与0.01,表明式(4)可较准确地表征高温下(25℃

\leqslant T\leqslant 300℃) CFRP筋极限拉应变的退化规律,亦表明式(2)、式(3)均具有较高计算精度。为明确Tg对高温下CFRP筋轴拉性能的影响规律,将本文CFRP筋(Tg=210℃)轴拉性能退化规律与文献[15]中CFRP筋(Tg=126℃)相应结果进行对比分析,如图9(a)、图9(b)及图13所示。可见本文CFRP筋极限抗拉强度和弹性模量随温度的衰减规律与文献[15]试验结果基本相似;相较于文献[15]选用的CFRP筋(Tg=126℃),本文筋材(Tg=210℃)的高温轴拉性能更优,300℃下本文筋材的轴拉性能较常温试件仅退化46%~50%,如图9(a)与图9(b)所示;但本文筋材轴拉性能受(T−T0)/Tg的影响更显著,如图13所示。

表 5 CFRP筋轴拉试件极限拉应变试验值与计算值对比Table 5. Comparison of measured and predicted ultimate tensile strain of CFRP bar axial tensile specimensSpecimen εu,t/10−6 εu,c/10−6 εu,t/εu,c AT-T25 15513 15513 1.000 AT-T100 18387 17902 1.030 AT-T210 18201 18227 0.999 AT-T300 17816 17852 0.998 Average 1.010 Variation coefficient 0.01 Note: εu,t, εu,c—Experimental and calculated values of ultimate tensile strain of axial tensile specimen respectively. 4.2 高温下CFRP筋-RPC锚固性能试件界面粘结强度

基于ACI 440.1R-15[24]中FRP筋-普通混凝土界面粘结强度的理论模型,对表4中的实测数据进行回归分析,构建适于表征高温下CFRP筋-RPC界面粘结强度退化规律的计算公式,如下式所示:

\frac{{{\tau _{\rm{u}}}(T)}}{{\sqrt {{f_{{\rm{cu}}}}} }} = \left[ {1 - \frac{{0.64(T - {T_0})}}{{{T_{\rm{g}}}}}} \right]\left( {2 + 1.89\frac{d}{l}} \right) (5) 式中:fcu为RPC的立方体抗压强度;T0为室温,25℃;25℃

\leqslant T\leqslant 300℃。利用式(5)预测各试件的平均粘结强度,结果如表6所示,实测值/预测值的平均值及变异系数分别为0.99与0.06,表明式(5)可较准确地表征高温下(25℃

\leqslant T\leqslant 300℃) CFRP筋-RPC界面粘结强度的退化规律。表 6 CFRP筋-RPC界面粘结强度试验值与计算值对比Table 6. Comparison between measured and predicted bond strength of CFRP bar-RPC interfaceSpecimen fcu/MPa τu,t/MPa τu,c/MPa τu,t/τu,c A-T25-L5d 158 29.36 29.89 0.98 A-T100-L5d 158 23.37 23.06 1.01 A-T210-L5d 158 13.92 13.04 1.07 A-T300-L5d 158 4.36 4.84 0.90 Average 0.99 Variation coefficient 0.06 Notes: fcu—Cube compressive strength of RPC; τu,t, τu,c—Experimental and calculated values of interfacial bond strength between CFRP bars and RPC, respectively. 4.3 高温下CFRP筋-RPC锚固性能试件临界锚固长度

将温升处理下CFRP筋的拉断破坏与高温下锚固区滑移破坏同时发生时所对应的筋材锚固长度定义为高温下筋材的临界锚固长度lcr(T),则由临界破坏时的平衡条件可知:

{\tau _{\text{u}}}(T){\text{π}}d{l_{{\text{cr}}}}(T) = {f_{\text{u}}}(T)({\text{π}}{d^2} /4) (6) 将式(5)代入式(6),可得高温下CFRP筋的临界锚固长度(25℃

\leqslant T\leqslant 300℃)为{l_{{\rm{cr}}}}(T) = \frac{{{f_{\rm{u}}}(T)d}}{{8\sqrt {{f_{{\rm{cu}}}}} \left( {1 - \dfrac{{0.64(T - {T_0})}}{{{T_{\rm{g}}}}}} \right)}} - 0.945d (7) 利用式(7)计算本文中各试件的临界锚固长度,并将其与试件实际锚固长度进行比较,以预测试件发生的破坏形态,结果如表7所示。可见,基于式(7)预测的破坏形态与实际情况吻合。

表 7 CFRP筋-RPC锚固性能试件临界锚固长度计算值及预测的破坏形态Table 7. Critical anchorage length determined by formula and predicted failure mode of CFRP bar-RPC anchorage performance testSpecimen T/℃ Anchorage

length/mmActual

failure

modeCritical

anchorage

length/mmPredicted

failure

modeA-T25-L5d 25 60 Slip 304.9 Slip A-T100-L5d 100 389.0 A-T210-L5d 210 497.8 A-T300-L5d 300 1142.9 5. 结 论

(1) 相较于常温试件,100℃、210℃和300℃下轴拉试件的抗拉强度、弹性模量分别下降了(2.3%、11.4%)、(29.8%、40.9%)和(35.6%、45%);而极限拉应变分别增大了18.5%、17.3%和14.8%。高温下筋材的弹性模量较抗拉强度受处理温度的影响更为显著;筋材的极限拉应变随处理温度升高而先增大后减小。

(2) 锚固性能试件碳纤维增强聚合物复合材料(CFRP)筋-活性粉末混凝土(RPC)界面的粘结强度随处理温度升高而线性退化。100℃、210℃和300℃下CFRP筋-RPC界面的粘结强度较常温试件分别下降20.4%、52.6%与85.1%。

(3) 构建了适于表征高温下CFRP筋及其粘结型锚固系统力学性能退化规律的实用计算公式,均具有较高计算精度。

(4) 高温下文中所用筋材轴拉性能较玻璃化转变温度Tg<200℃的CFRP筋更优良,但本文筋材轴拉性能受(T−T0)/Tg (T为处理温度,T0为室温)的影响更显著。

(5) 文中针对CFRP筋及其锚固系统高温力学性能的研究均未考虑筋材初应力的影响,与预应力结构中CFRP筋的实际受力情形存在一定偏差。但本文研究可视为后续含初应力的CFRP预应力筋及其锚固系统高温力学性能研究的基础,有必要先行开展。

-

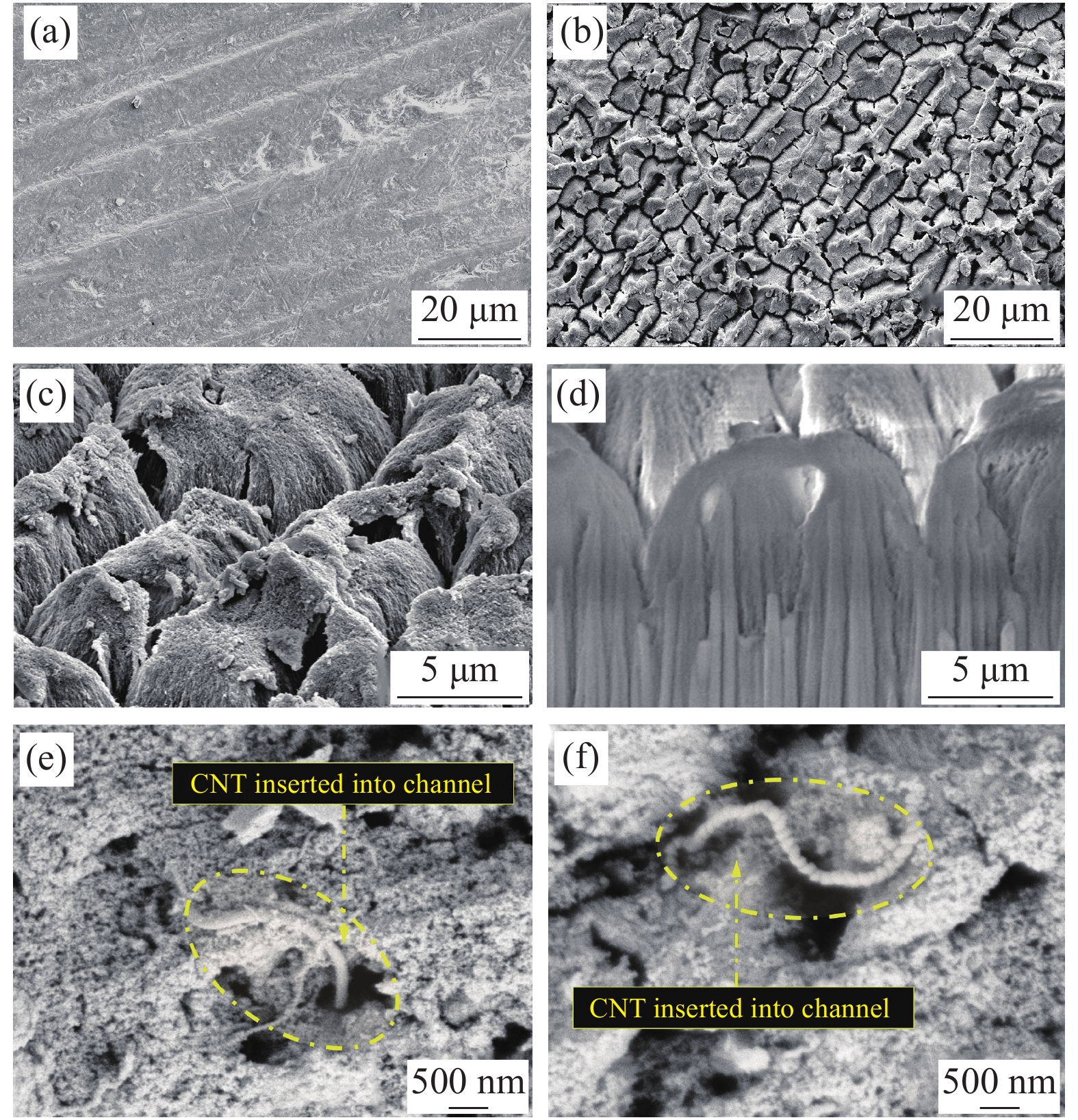

图 4 6060 T5铝合金的SEM图像:(a) 铝合金表面丙酮超声清洗;(b) 阳极氧化后的铝合金表面具有较深的微/纳米结构通道;(c) 阳极氧化后的铝合金52°视角图像;(d) 聚焦离子束(FIB)处理后多孔铝合金表面切口壁的正面图;(e)、(f) RPC处理后CNTs嵌入到铝合金表面孔道结构[32]

Figure 4. SEM images of 6060 T5 Al substrate: (a) Al substrate surface with acetone ultrasonic cleaning; (b) Al substrate surface with deep micro-/nano-structured channels after anodizing treatment; (c) 52° view image of the Al substrate after anodized corresponding to (b); (d) Frontal view of the notched wall on porous Al substrate surface after focus ion beam (FIB); (e),(f) CNTs inserted into the channel of Al substrate surface after RPC technique[32]

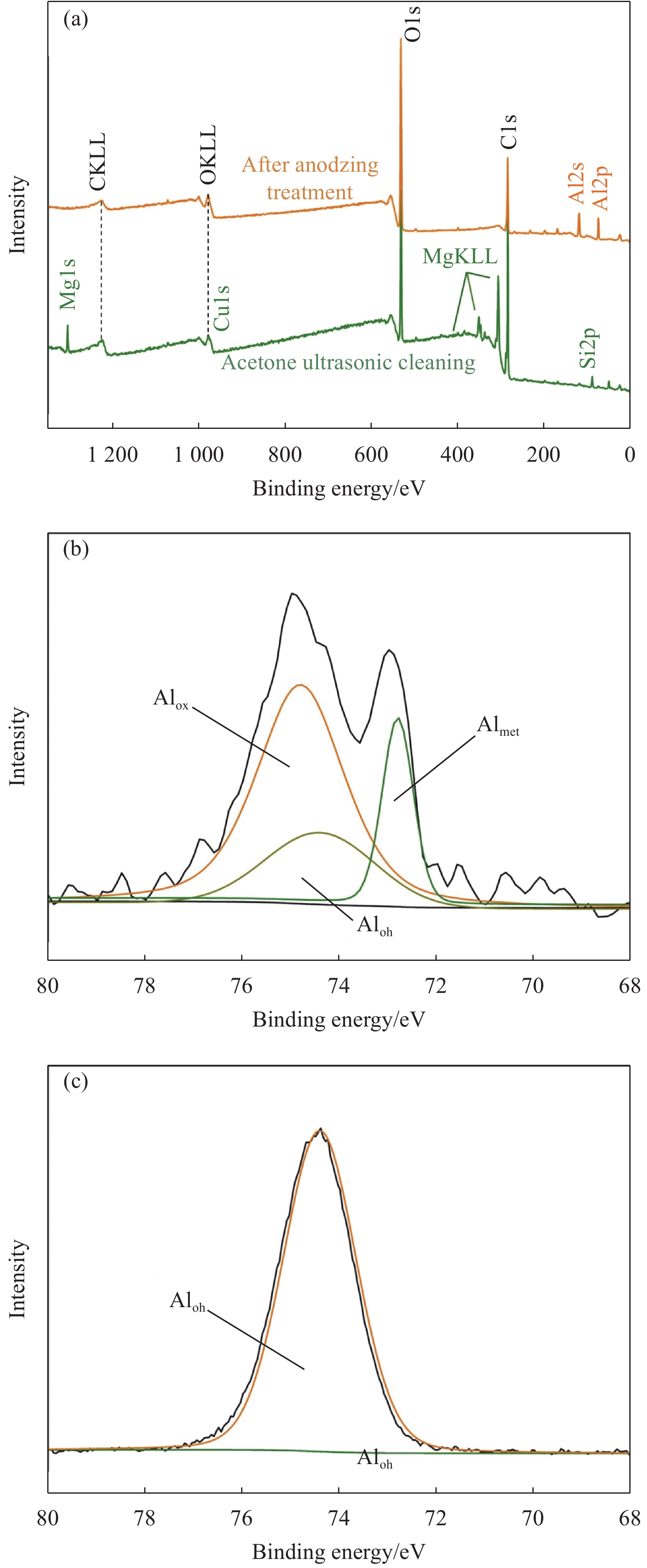

图 6 丙酮超声清洗和阳极氧化的铝合金表面的光谱分析 (a) ;丙酮超声清洗 (b) 和阳极氧化处理后铝合金表面 (c) 的高分辨Al2p核心级光谱

Figure 6. Survey spectra of Al substrate surfaces cleaned ultrasonically by acetone and anodized (a); high resolution Al2p core-level spectra for Al substrate surfaces after acetone ultrasonic cleaning (b) andanodizing treatment (c)

Aloh—Aluminium hydroxide hydroxide; Almet—Metallic aluminium; Alox—Aluminium oxide

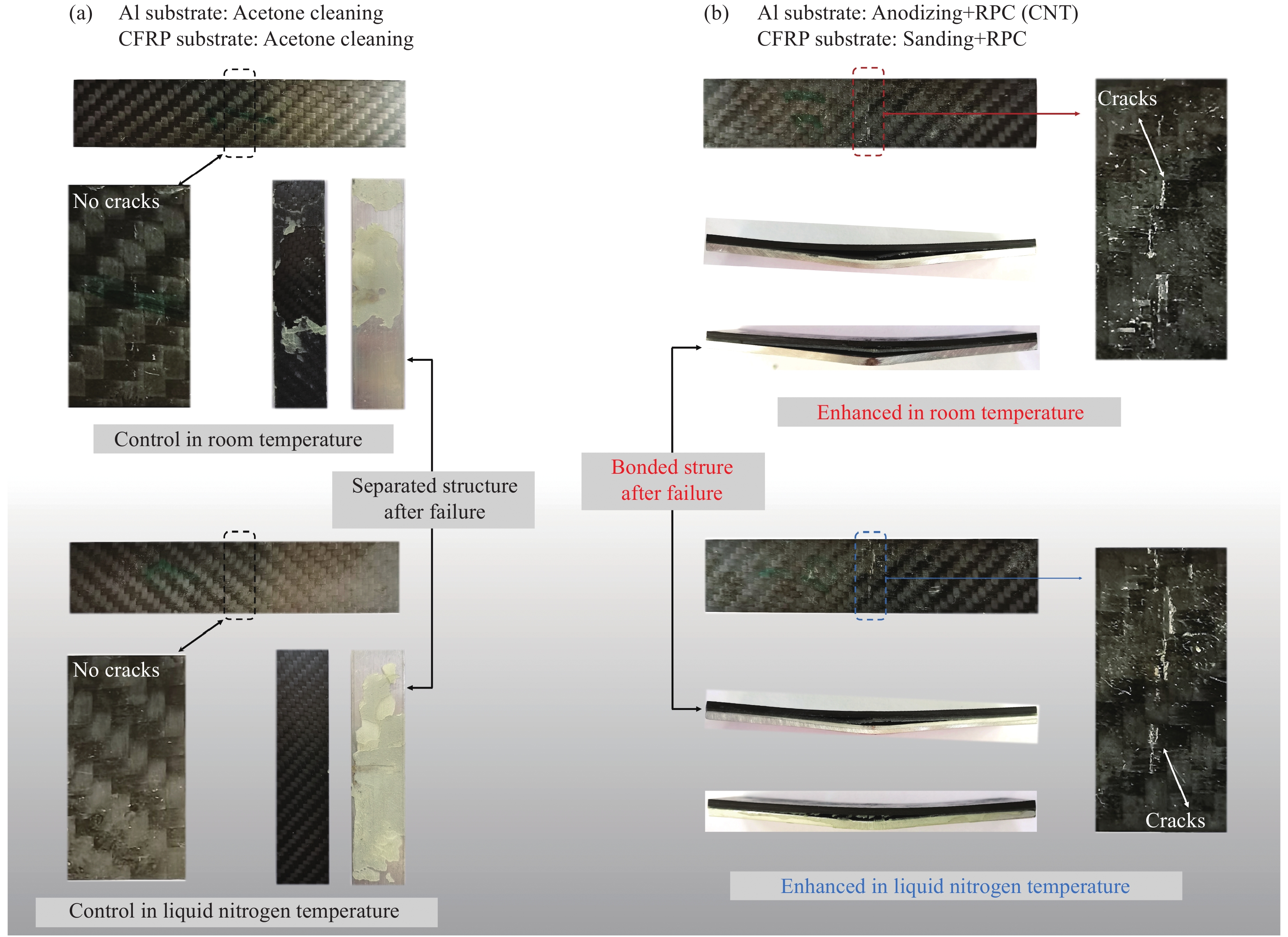

图 8 Al-CFRP复合材料三点弯曲试验后的部分粘合及分离的失效表面:(a) 丙酮超声清洗后的铝合金和CFRP板;(b) 铝合金经过阳极氧化和RPC(添加碳纳米管),CFRP板经过砂纸打磨和RPC

Figure 8. Failure surfaces of adhesive bonded Al-CFRP composite and the separated pieces: (a) Acetone ultrasonic cleaning for Al substrate and CFRP; (b) Anodized Al substrate with RPC + CNTs and sanding and RPC for CFRP

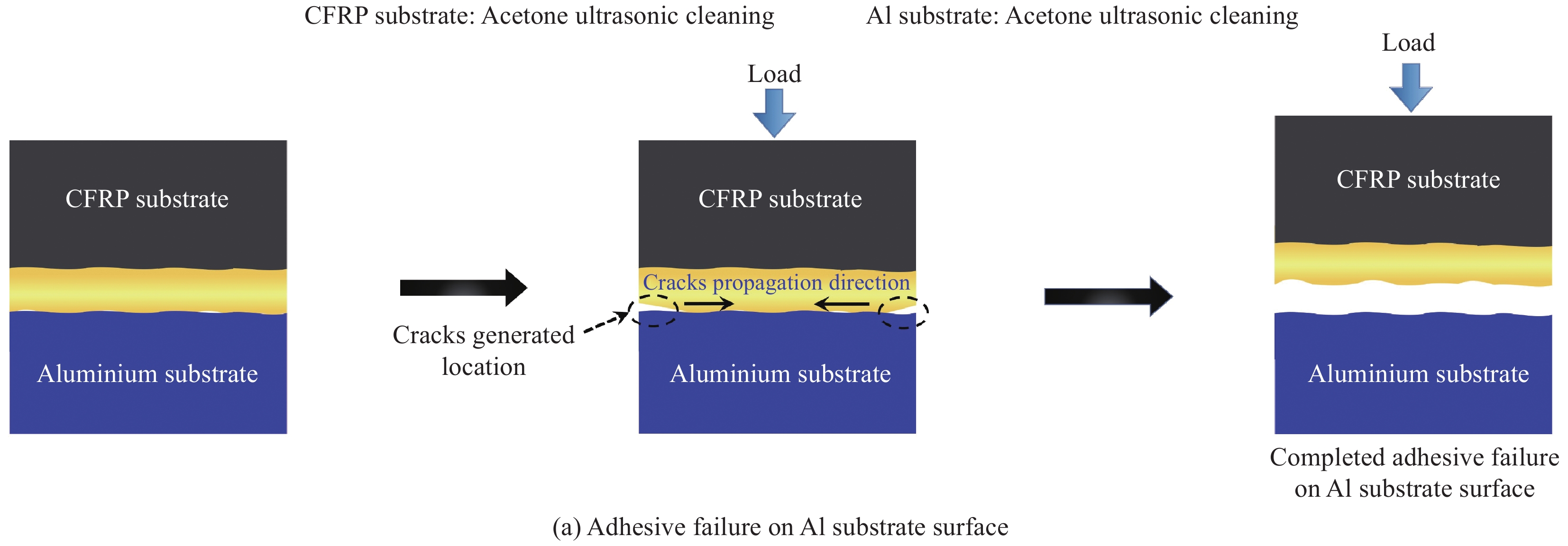

9 Al-CFRP复合材料的粘接表面失效模式示意图:(a) 仅经过丙酮超声清洗的铝合金与CFRP板呈现出典型的脱胶失效;(b) 经过阳极氧化和RPC(添加碳纳米管)的铝合金与经过砂纸打磨和RPC的CFRP板呈现出碳纤维基体的断裂失效

9. Schematic diagram of failure mode on Al substrate and CFRP adhesive surface: (a) Typical adhesive failure only with acetone ultrasonic cleaning for Al substrate and CFRP; (b) CFRP fracture failure with anodizing + RPC with carbon nanotubes for Al substrate and sanding + RPC for CFRP

CFRP—Carbon fiber reinforced polymer; CNTs—Carbon nanotubes

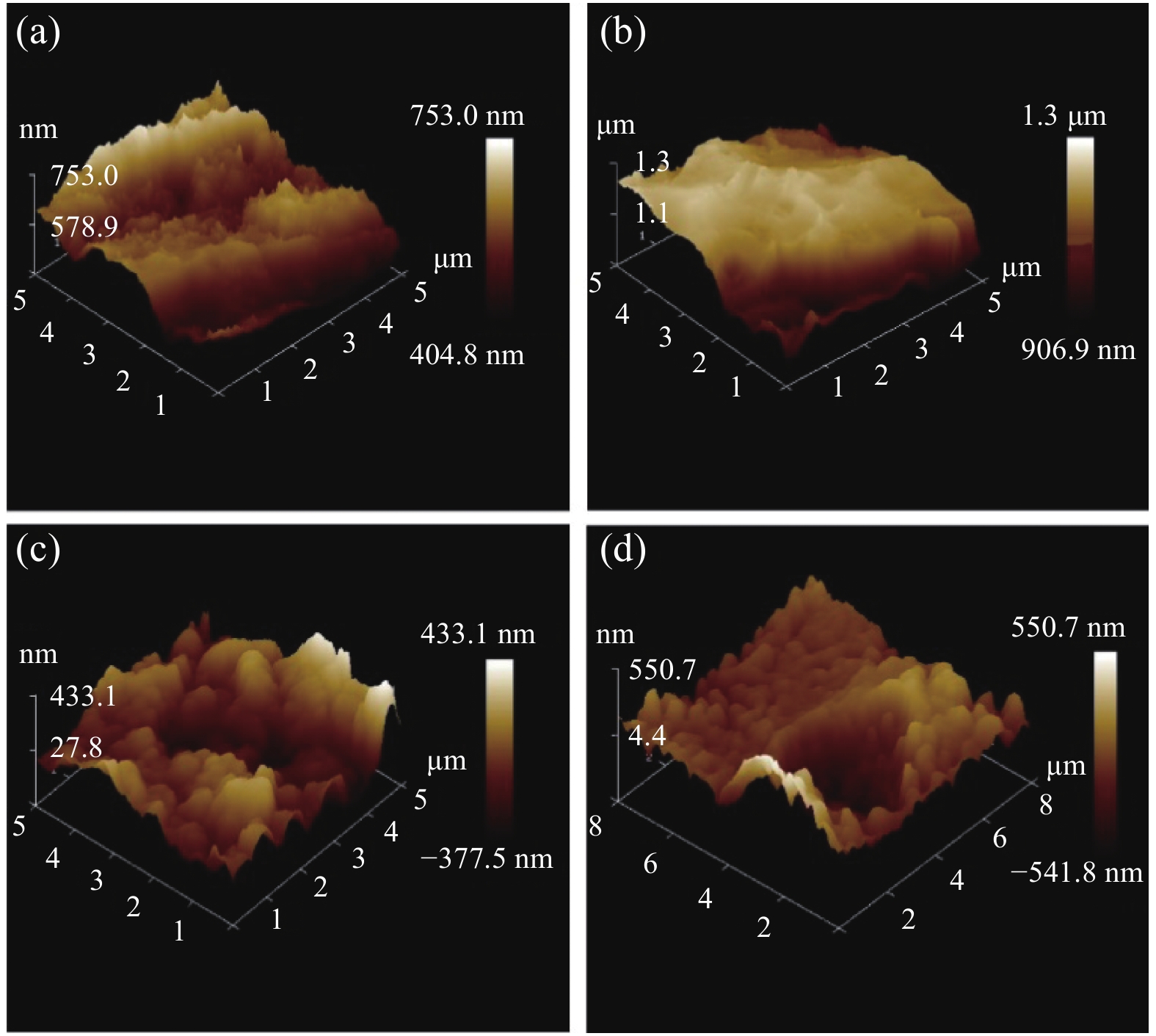

表 1 经丙酮超声清洗和阳极氧化处理后6060 T5铝合金的表面粗糙度参数

Table 1 Surface roughness measurements of the 6060 T5 Al substrate treated by acetone ultrasonic cleaning and anodizing

Treatment method Sample number Sa/nm Sq/nm Rmax/nm Acetone ultrasonic cleaning Fig.5(a) 53.4 62.5 353 Fig.5(b) 36.5 42.9 238 Anodizing surface treatment Fig.5(c) 91.3 114 785 Fig.5(d) 95.4 134 1037 Notes: Sa—Surface arithmetical mean roughness; Sq—Surface root mean square roughness; Rmax—Maximum roughness depth. 表 2 丙酮清洗和阳极氧化后铝合金上超薄表面层的表面元素组成

Table 2 Surface elemental composition of the ultra-thin surface layer on both acetone-cleaned and anodized Al substrates

Sample Almet Alox Aloh Acetone-cleaned Al substrate 21.0% 62.7% 17.5% Anodized Al substrate − − 100.0% 表 3 室温(RT)和液氮温度(LNT)下对照组和实验组Al-CFRP复合材料的3-P-B试验结果

Table 3 3-P-B test results of control and treated Al-CFRP composites at room temperature (RT) and liquid nitrogen temperature (LNT)

Sample Treatment process Test

conditionAverage

Pmax/NStandard

deviation/NShear

strength/MPaStandard

deviation/MPaControl Acetone ultrasonic cleaning for both RT 2564.21 136.87 269.97 48.14 LNT 2915.79 591.69 532.92 60.51 T1 Anodizing for Al and Acetone ultrasonic cleaning for CFRP RT 2690.45 142.53 285.76 23.42 LNT 5364.05 514.17 569.73 49.64 T2 Anodizing for Al and sanding +

RPC for CFRPRT 2760.61 121.31 290.15 17.75 LNT 5541.01 531.58 582.38 42.73 T3 Anodizing for Al and RPC (CNTs) sanding + RPC for CFRP RT 5015.57 109.55 309.31 13.05 LNT 6374.42 545.44 680.01 48.14 Note: Pmax—Maximum peak load. -

[1] 李游, 李传习, 郑辉, 等. 固化剂混掺对高温下CFRP板-钢板界面黏结性能的影响[J]. 复合材料学报, 2021, 38(12):4073-4089. LI Y, LI C X, ZHENG H, et al. Effect of curing agent mixing on interfacial bond behavior of glued CFRP plate-steel plate at elevated temperature[J]. Acta Materiae Compositae Sinica,2021,38(12):4073-4089(in Chinese).

[2] 任明伟, 洪治国, 周玉敬, 等. 复合材料防撞梁低速碰撞优化设计[J]. 复合材料学报, 2022, 39(2):854-862. REN M W, HONG Z G, ZHOU Y J. Low-speed collision optimization design of composite bumper[J]. Acta Materiae Compositae Sinica,2022,39(2):854-862(in Chinese).

[3] 刘洋, 庄蔚敏. 碳纤维增强树脂复合材料和铝合金温热自冲铆接工艺及接头力学性能[J]. 复合材料学报, 2021, 38(11):3563-3577. LIU Y, ZHUANG W M. Joining process and mechanical properties of warm self-piercing riveting for carbon fiber reinforced polymer and aluminum alloy[J]. Acta Materiae Compositae Sinica,2021,38(11):3563-3577(in Chinese).

[4] 包建文, 蒋诗才, 张代军. 航空碳纤维树脂基复合材料的发展现状和趋势[J]. 科技导报, 2018, 36(9):52-63. BAO J W, JIANG S C, ZHANG D J. Current status and trends of aeronautical resin matrix composites reinforced by carbon fiber[J]. Science & Technology Review,2018,36(9):52-63(in Chinese).

[5] CHENG F, HU YS, LV ZF, et al. Directing helical CNT into chemically-etched micro-channels on aluminum substrate for strong adhesive bonding with carbon fiber composites[J]. Composites Part A: Applied Science and Manufacture,2020,135:105952. DOI: 10.1016/j.compositesa.2020.105952

[6] HU Y S, YUAN B Y, CHENG F, et al. NaOH etching and re-sin pre-coating treatments for stronger adhesive bonding between CFRP and aluminium alloy[J]. Composites Part B: Engineering,2019,178:107478. DOI: 10.1016/j.compositesb.2019.107478

[7] FIORE V, CALABRESE L, PROVERBIO E, et al. Salt spray fog ageing of hybrid composite/metal rivet joints for automo-tive applications[J]. Composites Part B: Engineering,2017,108:65-74. DOI: 10.1016/j.compositesb.2016.09.096

[8] MURRAY B R, DOULE A, FEERICK P J, et al. Rotational moulding of PEEK polymer liners with carbon fibre/PEEK over tape-placement for space cryogenic fuel tanks[J]. Material Design,2017,132:567-581. DOI: 10.1016/j.matdes.2017.07.026

[9] RAMOLA L, SANKARESWARAN N. Design and modal analy-sis of cryogenic rocket propellant tank[J]. International Journal of Scientific Research in Science, Engineering and Technology, 2016, 2: 614-620.

[10] HU Y S, CHENG F, JI Y, et al. Effect of aramid pulp on low temperature flexural properties of carbon fibre reinforced plastics[J]. Composites Science and Technology,2020,192:108095. DOI: 10.1016/j.compscitech.2020.108095

[11] SETHI S, RAY B C. Experimental study on the mechanical behavior and microstructural assessment of Kevlar/epoxy composites at liquid nitrogen temperature[J]. Journal of the Mechanical Behavior of Materials,2014,23:95-100. DOI: 10.1515/jmbm-2014-0011

[12] SUN Z, SHI S, HU X Z, et al. Short-aramid-fiber toughening of epoxy adhesive joint between carbon fiber composites and metal substrates with different surface morphology[J]. Composites Part B: Engineering,2015,77:38-45. DOI: 10.1016/j.compositesb.2015.03.010

[13] SUN G, LIU X, ZHENG G, et al. On fracture characteristics of adhesive joints with dissimilar materials-An experimen-tal study using digital image correlation (DIC) technique[J]. Composites Structure,2018,201:1056-1075. DOI: 10.1016/j.compstruct.2018.06.018

[14] PARK S Y, CHOI W J, CHOI H S, et al. Recent trends in surface treatment technologies for airframe adhesive bonding processing: A review (1995-2008)[J]. The Journal of Adhesion,2010,86:192-221. DOI: 10.1080/00218460903418345

[15] WANG B, HU X, HUI J, et al. CNT-reinforced adhesive joint between grit-blasted steel substrates fabricated by simple resin pre-coating method[J]. The Journal of Adhesion,2018,94:529-540. DOI: 10.1080/00218464.2017.1301255

[16] 段瑛涛, 武肖鹏, 王智文, 等. 碳纤维增强树脂复合材料-热成型钢超混杂层合板层间力学性能[J]. 复合材料学报, 2020, 37(10):2418-2427. DUAN Y T, WU X P, WANG Zhiwen, et al. Interlaminar mechanical properties of carbon fiber reinforced plastics-thermoformed steel super-hybrid laminates[J]. Acta Materiae Compositae Sinica,2020,37(10):2418-2427(in Chinese).

[17] LIU W, ZHENG Y, HU X, et al. Interfacial bonding enhancement on the epoxy adhesive joint between engineered bamboo and steel substrates with resin pre-coating surface treatment[J]. Wood Science and Technology,2019,53:785-799. DOI: 10.1007/s00226-019-01109-9

[18] SALEEMA N, SARKER DK, PAYNTER R W, et al. A simple surface treatment and characterization of AA 6061 aluminum alloy surface for adhesive bonding applications[J]. Applied Surface Science,2012,261:742-748. DOI: 10.1016/j.apsusc.2012.08.091

[19] ZAIN N M, AHMAD S H, ALI E S. Effect of surface treatments on the durability of green polyurethane adhesive bonded aluminium alloy[J]. International Journal of Adhesion and Adhesives,2014,55:43-55. DOI: 10.1016/j.ijadhadh.2014.07.007

[20] TAN B, JI Y, HU Y, et al. Pretreatment using diluted epoxy adhesive resin solution for improving bond strength between steel and wood surfaces[J]. International Journal of Adhesion and Adhesives,2019,98:102502.

[21] WANG B, BAI Y, HU X, et al. Enhanced epoxy adhesion between steel plates by surface treatment and CNT/short-fibre reinforcement[J]. Composites Science and Technol-ogy,2016,127:149-157. DOI: 10.1016/j.compscitech.2016.03.008

[22] SHI S, SUN Z, HU X, et al. Carbon-fiber and aluminum-honeycomb sandwich composites with and without Kevlar-fiber interfacial toughening[J]. Composites Part A: Applied Science and Manufacture,2014,67:102-110. DOI: 10.1016/j.compositesa.2014.08.017

[23] SUN Z, HU X, CHEN H. Effects of aramid-fibre toughening on interfacial fracture toughness of epoxy adhesive joint between carbon-fibre face sheet and aluminium substrate[J]. International Journal of Adhesion and Adhe-sives,2014,48:288-294. DOI: 10.1016/j.ijadhadh.2013.09.023

[24] ZHANG Z, SHAN J G, TAN X H, et al. Effect of anodizing pretreatment on laser joining CFRP to aluminum alloy A6061[J]. International Journal of Adhesion and Adhe-sives,2016,70:142-151. DOI: 10.1016/j.ijadhadh.2016.06.007

[25] ALIASGHARI S, SKELDON P, ZHOU X, et al. Effect of an anodizing pre-treatment on AA 5052 alloy/polypropylene joining by friction stir spot welding[J]. Materials Science and Engineering: B,2019,245:107-112. DOI: 10.1016/j.mseb.2019.05.018

[26] XU Y, LI H, SHEN Y, et al. Improvement of adhesion performance between aluminum alloy sheet and epoxy based on anodizing technique[J]. International Journal of Adhesion and Adhesives,2016,70:74-80. DOI: 10.1016/j.ijadhadh.2016.05.007

[27] SAEEDIKHANI M, JAYIDI M, YAZDANI A. Anodizing of 2024-T3 aluminum alloy in sulfuric-boric-phosphoric acids and its corrosion behavior[J]. Transactions of Nonferrous Metals Society of China,2013,23:2551-2559. DOI: 10.1016/S1003-6326(13)62767-3

[28] 程飞, 蒋宏勇. 基于芳纶pulp优化的碳纤维增强树脂基复合材料的抗损伤性能及残余抗压强度研究[J]. 复合材料学报, 2021, 38(11):3610-3619. CHENG F, JIANG H Y. Research on damage resistance and residual compressive strength of carbon fiber reinforced plastic optimized by aramid pulp[J]. Acta Materiae Compositae Sinica,2021,38(11):3610-3619(in Chinese).

[29] JIN K, WANG H, TAO J, et al. Interface strengthening mechanisms of Ti/CFRP fiber metal laminate after adding MWCNTs to resin matrix[J]. Composites Part B: Engineering,2019,171:254-263. DOI: 10.1016/j.compositesb.2019.05.005

[30] HUNG P, LAU K, QIAO K, et al. Property enhancement of CFRP composites with different graphene oxide employment methods at a cryogenic temperature[J]. Composites Part A: Applied Science and Manufacture,2019,120:56-63. DOI: 10.1016/j.compositesa.2019.02.012

[31] KARA M, KIRICI M, TATER A C, et al. Impact behavior of carbon fiber/epoxy composite tubes reinforced with multi-walled carbon nanotubes at cryogenic environment[J]. Composites Part B: Engineering,2018,145:145-154. DOI: 10.1016/j.compositesb.2018.03.027

[32] CHENG F, HU Y, ZHANG X, et al. Adhesive bond strength enhancing between carbon fiber reinforced polymer and aluminum substrates with different surface morphologies created by three sulfuric acid solutions[J]. Composites Part A: Applied Science and Manufacture,2021,146:106427. DOI: 10.1016/j.compositesa.2021.106427

[33] GOUSHEGIR S M, SCHARNAGL N, SANTOS J F, et al. XPS analysis of the interface between AA2024-T3/CF-PPS friction spot joints[J]. Surface and Interface Analysis,2016,48:706-711. DOI: 10.1002/sia.5816

[34] LI X, HUFNAGEL S, XU H Y, et al. Aluminum (oxy)hydroxide nanosticks synthesized in bicontinuous reverse microemulsion have potent vaccine adjuvant activity[J]. ACS Applied Materials & Interfaces,2017,9:22893-22901.

[35] UHART A, LEDEUIL J B, GONBEAU D, et al. An auger and XPS survey of cerium active corrosion protection for AA2024-T3 aluminum alloy[J]. Applied Surface Science,2016,390:751-759. DOI: 10.1016/j.apsusc.2016.08.170

-

期刊类型引用(6)

1. 辛雨柯,邓庆田,宋学力,李新波. 加筋曲板结构抗弯承载能力分析. 塑性工程学报. 2024(02): 189-198 .  百度学术

百度学术

2. 梁永廷,于文学,熊芯,乔珂. 碳纤维复合材料超大开度门结构设计与仿真. 北京交通大学学报. 2024(06): 144-153 .  百度学术

百度学术

3. 吴菁,章向明,胡明勇,朱子旭,王安稳. 复合材料船体帽型加筋板弯曲应力. 船舶力学. 2023(07): 1084-1095 .  百度学术

百度学术

4. 吴菁,章向明,朱子旭,胡明勇,王安稳. 复合材料船体帽型加筋板面内刚度. 海军工程大学学报. 2023(04): 1-6+28 .  百度学术

百度学术

5. 刘宸宇,骆烜赫,刘康翔,孟增,肖山. 基于平铺刚度法的弧形加筋板的轻量化设计. 应用数学和力学. 2023(08): 953-964 .  百度学术

百度学术

6. 邱家波. 复合材料加筋壁板的弯曲计算和刚度优化. 中国造船. 2023(05): 119-129 .  百度学术

百度学术

其他类型引用(1)

-

下载:

下载: