Interlaminar mechanical properties and heat resistance of silicone modified epoxy resin composites

-

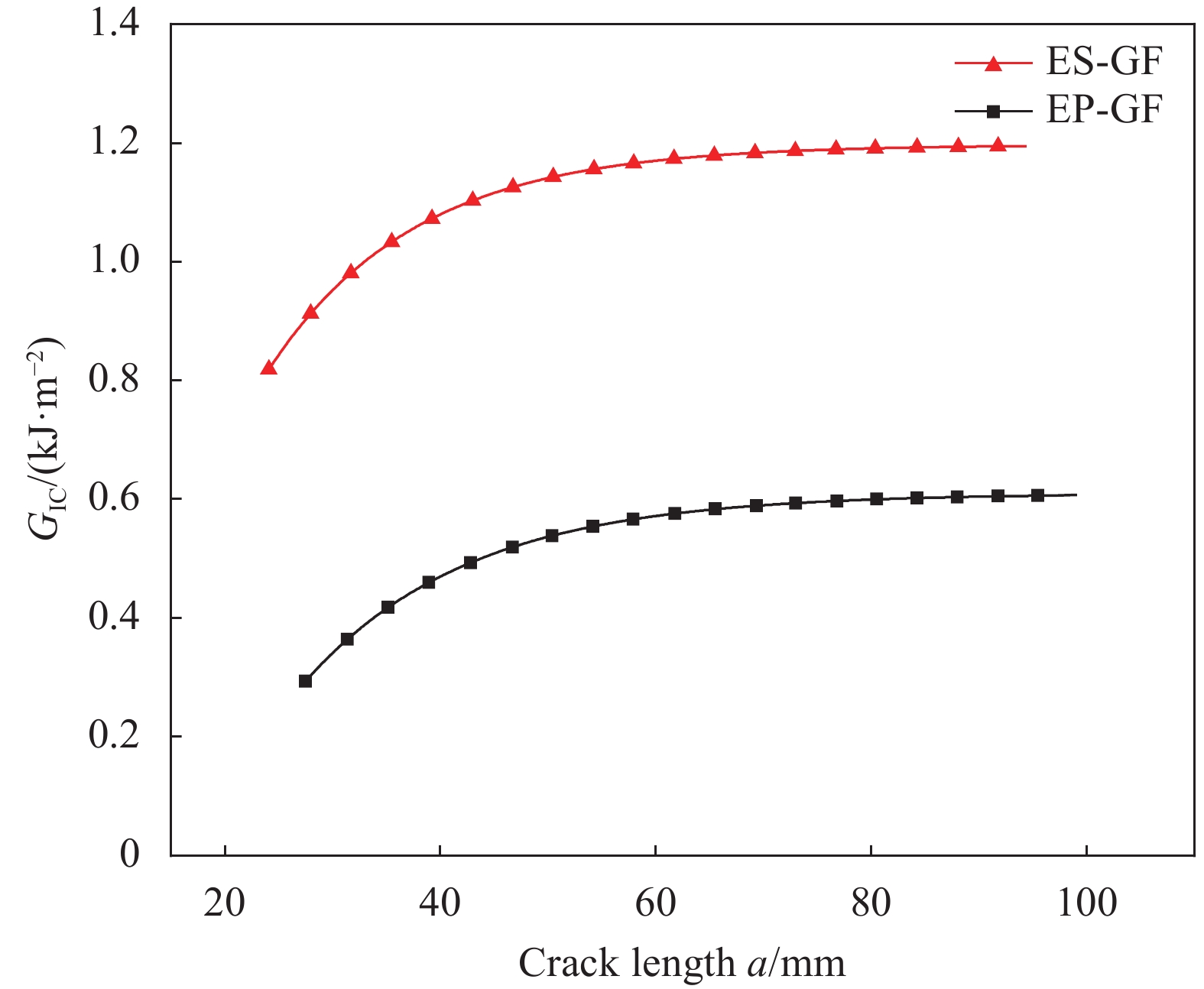

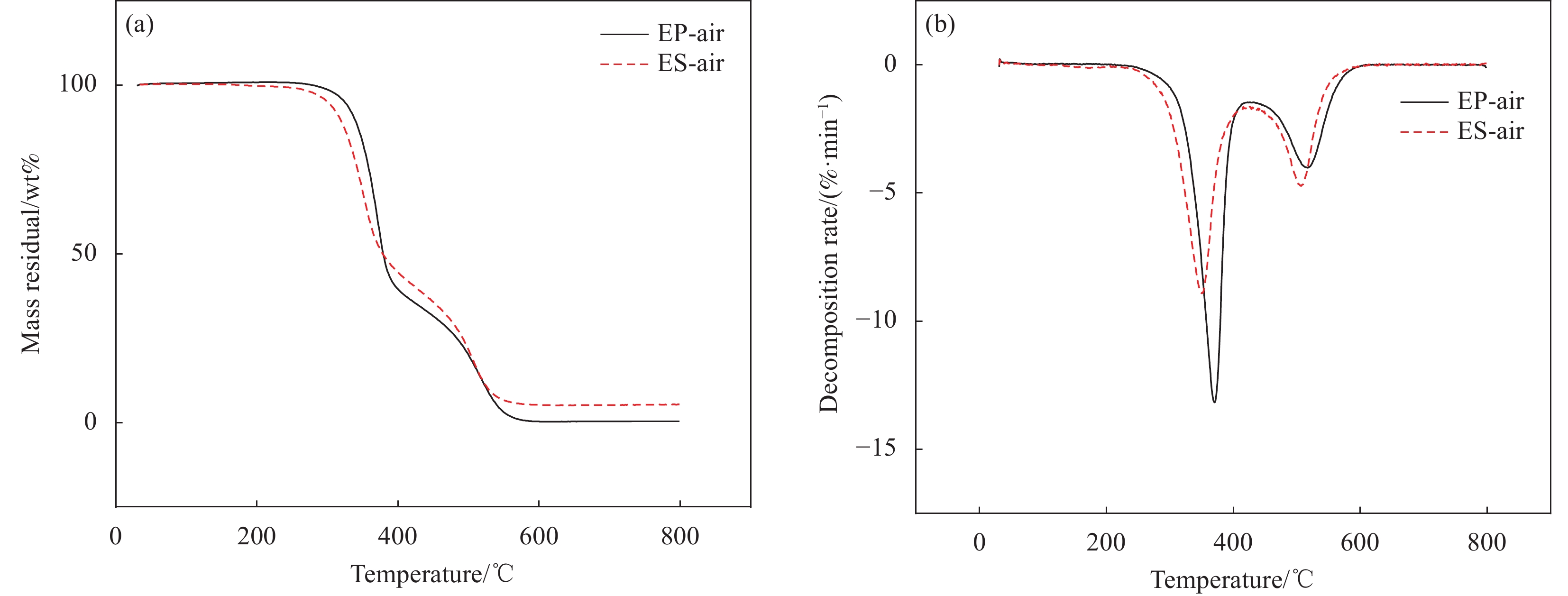

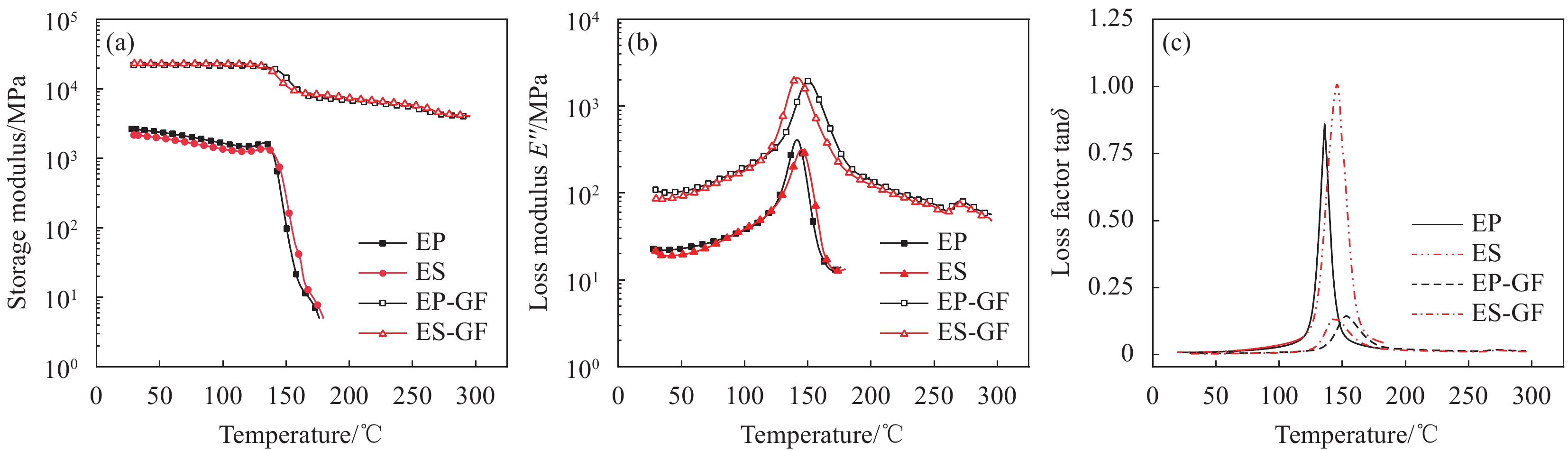

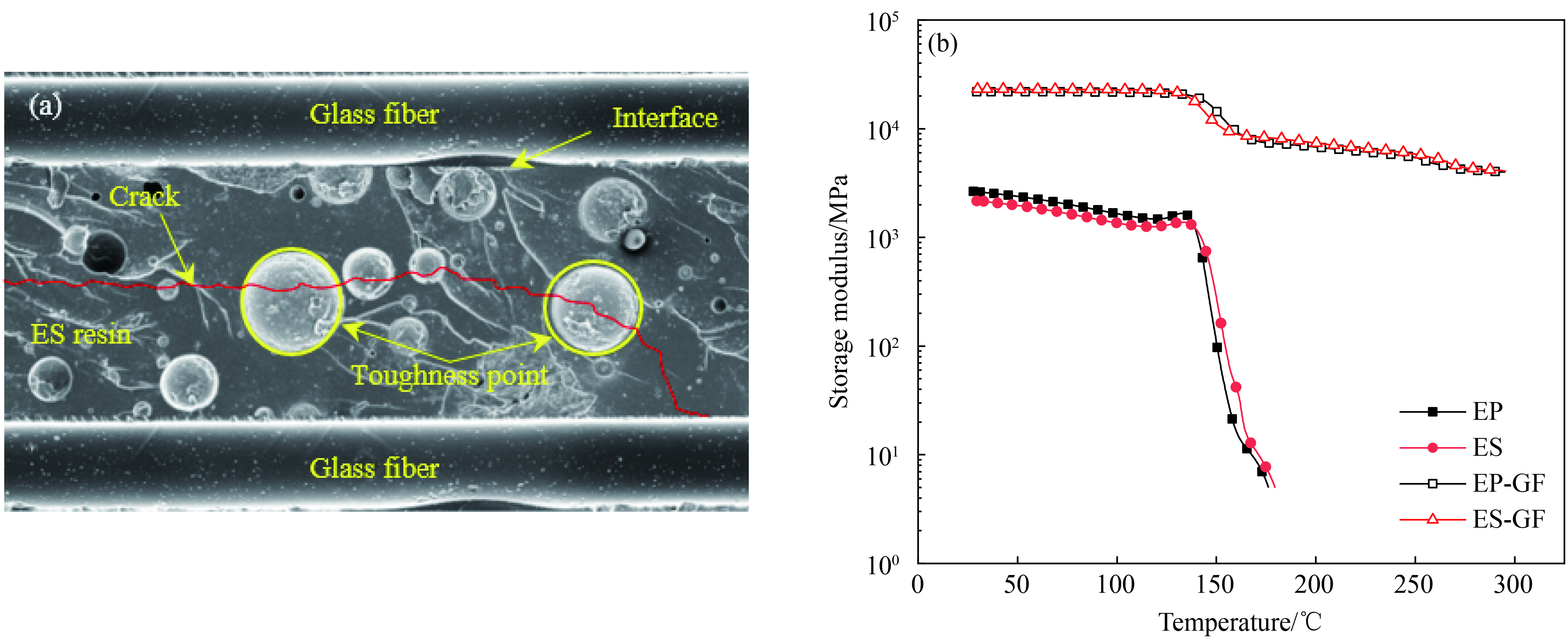

摘要: 通过环氧树脂基体增韧改性同时提升环氧树脂基复合材料层间力学性能和耐热性能的研究具有重要工程应用价值。对端羟基聚二甲基硅氧烷与环氧树脂进行缩合反应制备改性树脂(ES),采用真空导入方法制备玻璃纤维增强改性环氧树脂基复合材料(ES-GF)。通过双悬臂梁和短梁剪切等实验对复合材料的层间力学性能进行测量,通过热失重和动态机械热测试对复合材料的耐热性能进行评价,相应的玻璃纤维增强未改性环氧基复合材料(EP-GF)的层间力学性能和耐热性能也被测试用于对比分析。为了对复合材料层间力学性能强化和耐热性提升的物理机制进行解析,改性前后的环氧树脂的拉伸强度、拉伸模量、弯曲强度、弯曲模量、拉伸断裂延伸率、摆锤冲击强度和微观结构特征等也被测量和表征。实验结果表明:相比EP-GF,ES-GF的I型临界应变能释放率(断裂韧性)提升了98.1%,层间剪切强度提升13.3%,层间力学性能的强化归因于Si—O键柔性链段、“韧性点”发挥“钉锚”及纤维/基体浸润性提高的综合作用,其层间破坏模式由纤维基体脱粘转变为基体内聚破坏。ES的最大热失重速率降低了33.1%,800℃最终残余增加了13.5倍。在玻璃化转变温度Tg之前ES-GF的储能模量比EP-GF提高1.3 GPa,在Tg之后ES-GF的储能模量比EP-GF提高0.8 GPa左右,硅氧烷改性环氧树脂的玻璃化转变温度略有提高。

-

关键词:

- 端羟基聚二甲基硅氧烷(HTPDMS) /

- 改性 /

- 环氧树脂基复合材料 /

- 层间性能 /

- 耐热性能

Abstract: The research on improving the interlayer mechanical properties and heat resistance of epoxy resin matrix composites through toughening modification of epoxy resin matrix has important engineering application value. Modified resin (ES) was prepared by condensation reaction of hydroxyl terminated polydimethylsiloxane and epoxy resin, and glass fiber reinforced modified epoxy resin matrix composite (ES-GF) was prepared by vacuum introduction method. The interlaminar mechanical properties of the composite were measured by double cantilever beam and short beam shear tests. The thermal resistance of the composite was evaluated by thermogravimetry and dynamic mechanical thermal testing. The interlaminar mechanical properties and thermal resistance of the corresponding glass fiber reinforced unmodified epoxy matrix composites (EP-GF) were also tested for compara-tive analysis. In order to analyze the physical mechanism of strengthening the interlaminar mechanical properties and improving the heat resistance of the composite, the tensile strength, tensile modulus, flexural strength, flexural modulus, tensile elongation at break, pendulum impact strength and microstructure characteristics of the epoxy resin before and after modification were also measured and characterized. The experimental results show that, compared with EP-GF, the release rate of type I critical strain energy (fracture toughness) of ES-GF is increased by 98.1%, and the interlaminar shear strength is increased by 13.3%. The strengthening of interlaminar mechanical properties is attributed to the comprehensive effect of Si—O bond flexible chain segment, "ductile points" playing a "nail anchor" role and improvement of fiber/matrix wettability. The maximum thermal weight loss rate of ES is decreased by 33.1%, and the final residue at 800℃ is increased by 13.5 times. Before glass transition temperature Tg, the storage modulus of ES-GF is 1.3 GPa higher than that of EP-GF, and after Tg, the storage modulus of ES-GF is nearly 1.3 GPa higher than that of EP-GF, and the glass transition temperature of siloxane modified epoxy resin is slightly increased. -

铬(Cr)作为一种重要的生产原材料被广泛应用于制革、冶金、电镀、纺织印刷、电池等行业中[1- 2],也相应产生了含铬废水,如果处理不当,会对生态环境造成危害[3]。水中的铬(Cr)主要以Cr(VI)和Cr(III)两种形式存在,其中Cr(VI)具有溶解度高、迁移能力强、危害大的特点[4]。目前,含Cr(VI)废水的处理方法有沉淀法、光催化法、吸附还原法、离子交换法等[5],其中吸附还原法运行成本低、操作简单、效率高,受到研究者广泛关注。

纳米零价铁(nZVI)比表面积大、还原性强、表面活性高,对重金属具有良好的去除效果,在环境污染方面受到重视。秦泽敏等[6]对比了还原性铁粉、活性炭及nZVI对Cr(VI)的去除效果,发现nZVI对Cr(VI)的去除率达到了80%以上,远大于还原性铁粉(2%)和活性炭(5%)。然而,由于nZVI粒径小、表面能大及自身磁性,容易产生团聚,导致比表面积和还原能力降低,限制了其在水处理中的应用[7]。为了克服这个缺点,研究人员尝试使用不同的材料作为nZVI载体,以减少颗粒团聚,如膨润土[8]、介孔二氧化硅[9]、活性炭[10]、生物炭[11]等。Shi等[8]采用膨润土作为载体,制备膨润土负载nZVI复合材料,对含Cr(VI)电镀废水的去除率大于90%。Petala等[9]采用介孔二氧化硅负载零价铁纳米,有效地抑制了nZVI的团聚,对Cr(VI)去除能力比nZVI更高。刘剑等[12]通过液相还原法制备了活性炭负载nZVI复合材料,在Cr(VI) 初始浓度50 mg/L、温度40℃、初始pH=2.0、投加量3.0 g/L条件下反应5 min,Cr(VI)去除率为99.4%。生物炭具有较大的比表面积、发达的孔隙结构及丰富的官能团,对重金属具有良好的吸附性能[13-14]。生物炭负载零价纳米铁,能有效降低nZVI的团聚效应[15],而且生物炭良好的导电性,能够增强nZVI的电子转移能力,从而提高nZVI的反应活性[16]。生物炭负载nZVI在重金属废水处理中能发挥协同作用。但目前鲜有通过污泥基生物炭(SB)负载nZVI处理含Cr(VI)废水的报道。

因此,本文以市政污泥为原料制备SB负载nZVI复合材料(nZVI-SB),探讨其对废水中Cr(VI)的去除性能、Cr(VI)去除的机制,为nZVI-SB应用于含Cr(VI)废水处理提供借鉴。

1. 实验材料及方法

1.1 nZVI-SB的制备

脱水污泥取自湖南某污水处理厂,其含水率为50.83%。脱水污泥经研磨、干燥后,通过0.18 μm筛收集过筛粉末污泥,干燥后的粉末污泥挥发分含量为37.94wt%,灰分含量为61.03wt%[14]。

SB制备:称取一定量干燥的粉末污泥填满坩埚并压实,盖紧坩埚盖,制造一个无氧环境。将坩埚置于450℃的马弗炉中热解2 h,得到黑色固体物质即为SB。

nZVI制备[17]:向装有70 mL超纯水和30 mL乙醇的三颈烧瓶中加入7.4464 g FeSO4·7H2O,在搅拌器上匀速搅拌(150 r/min),直至FeSO4·7H2O完全溶解。然后充入氮气排出空气,持续搅拌,以2.5 mL/min匀速加入适量的硼氢化钠,直至无气泡产生,反应完成。取出沉淀,迅速用超纯水洗涤3次,无水乙醇洗涤2次,得到的黑色固体放入60℃真空干燥箱中干燥8 h,干燥后的黑色固体即为nZVI。

nZVI-SB制备:将适量的SB加入不同量的FeSO4·7H2O溶液中,使nZVI-SB 中Fe∶C的质量比分别为 1∶4、1∶2、1∶1和2∶1。然后按照上述合成nZVI的方法制备nZVI-SB,分别记为nZVI-SB(1∶4)、nZVI-SB(1∶2)、nZVI-SB(1∶1)和nZVI-SB(2∶1),见表1。

表 1 样品名称缩写Table 1. Abbreviation name of samplesSample Fe/wt% SB/wt% nZVI-SB(1∶4) 20.0 80.0 nZVI-SB(1∶2) 33.3 66.7 nZVI-SB(1∶1) 50.0 50.0 nZVI-SB(2∶1) 66.7 33.3 Notes: nZVI—Nanoscale zero-valent iron; SB—Sludge-based biochar. 1.2 重金属含量分析

将1 g污泥和SB分别加入50 mL的逆王水(浓硝酸∶浓盐酸=3∶1)中,在微波消解仪(ETHOS 1,意大利)中消解处理2 h,测定过滤液中重金属浓度。采用电感耦合等离子发射光谱法测定重金属浓度。

1.3 批量吸附实验

1.3.1 Fe∶C质量比的影响

为了研究Fe∶C质量比对Cr(VI)去除效果的影响,将不同质量比(1∶4、1∶2、1∶1和2∶1) nZVI-SB样品0.025 g和50 mL的Cr(VI)溶液(50 mg/L)加入到150 mL锥形瓶中,调节初始pH值为2.0,温度为30℃,在150 r/min的恒温振荡器(IS-RDD3,美国精骐)中反应4 h后取上清液,测量剩余Cr(VI)浓度。

1.3.2 初始pH的影响

反应初始pH设置为2、3、4、5、6、7、8、9,Cr(VI)溶液初始浓度为50 mg/L,温度为30℃,准确吸取50 mL该溶液于150 mL锥形瓶中,加入0.025 g nZVI-SB(1∶1),恒温振荡4 h后取上清液,测量Cr(VI)的浓度,以考察初始pH对Cr(VI)去除效果的影响。

1.3.3 nZVI-SB投加量的影响

配制Cr(VI)溶液初始浓度为50 mg/L,分别准确吸取50 mL该溶液加入一系列150 mL锥形瓶中,再分别加入0.005 g、0.0125 g、0.025 g、0.035 g、0.05 g、0.065 g nZVI-SB(1∶1),以设置nZVI-SB投加量分别为0.1、0.25、0.5、0.7、1.0和1.3 g/L,在初始pH为2、30℃条件下恒温振荡4 h后取上清液,测量Cr(VI)的浓度。

采用二苯碳酰二肼分光光度法测定溶液中Cr(VI)的吸光度,重复3次计算剩余Cr(VI)的平均值。Cr(VI)的去除率和吸附量计算如下式所示:

R=C0−CeC0×100\% (1) q=(C0−Ce)Vm (2) 式中:R为去除率(%);C0为溶液中初始Cr(VI)质量浓度(mg/L);Ce为反应结束后溶液中Cr(VI)质量浓度(mg/L);q为Cr(VI)的吸附容量(mg/g);V为溶液体积(L);m为nZVI-SB质量(g)。

1.4 吸附模型

将500 mL的Cr(VI)溶液(50 mg/L)加入1000 mL锥形瓶中,调节溶液pH为2,再加入0.5 g/L nZVI-SB(1∶1),在30℃的恒温振荡器中吸附0~720 min,采用准一级动力学模型、准二级动力学模型和颗粒内扩散模型对吸附过程进行拟合,方程式如下式:

ln(qe−qt)=lnqe−K1t (3) tqt=1K2q2e+tqe (4) qt=Kdt12+Ci (5) 式中:qe为平衡吸附量(mg/g);qt为t时刻的吸附量(mg/g);K1为准一级吸附速率常数(min−1);K2为准二级吸附速率常数(g/(mg·min)−1);Kd为颗粒内扩散速率常数(mg/(m·min1/2));Ci为边界层常数。

将不同浓度的Cr(VI)溶液(40~110 mg/L)50 mL分别加入150 mL锥形瓶中,调节初始 pH值为2,加入0.5 g/L nZVI-SB(1∶1),分别在20℃、30℃和 40℃的恒温振荡器中吸附4 h,考察温度对Cr(VI)去除效果的影响,并用Langmuir吸附等温线模型和Freundlich吸附等温线模型进行拟合,方程式如下所示:

Ceqe=Ceqm+1qmKL (6) lnqe=(1/n)lnCe+lnKF (7) 式中:qm为吸附质在单位质量吸附剂的最大吸附容量(mg/g);KL为Langmuir模型的吸附平衡常数;KF为Freundlich模型的吸附平衡常数;1/n为与吸附强度有关的经验参数。

1.5 材料表征

采用SEM (Inspect F50,美国FEI)观察nZVI-SB微观形貌,对比nZVI-SB去除Cr(VI)前后的形态变化;采用TEM (HT7700,日本日立公司)来观察nZVI在生物炭表面的分布情况及是否生成纳米颗粒;同时采用比表面积分析仪(3Flex 5.02,美国麦克)分析nZVI-SB孔隙结构;通过能量色散X射线光谱(EDS) (X-Max,英国牛津)对nZVI-SB表面的元素组成进行分析;使用XRD (Bruker D8,德国布鲁克)分析样品晶型结构及物象组成,XRD数据通过Jade 6.5软件处理;采用XPS (Escalab 250Xi,美国Thermo Fisher Scientific)分析样品元素组成与价态变化,原始数据采用Avantage软件进行分峰拟合。综合表征结果探讨Cr(VI)去除机制。

1.6 nZVI-SB再生试验

过滤、收集与Cr(VI)反应后的nZVI-SB(1∶1),并将其加入到0.2 mol/L的HCl中振荡脱附2 h。之后将溶液过滤,沉淀用去离子水洗涤至中性,60℃真空干燥12 h后重复Cr(VI)去除试验,计算nZVI-SB再生后对Cr(VI)的去除效果。

2. 结果和讨论

2.1 重金属含量分析

污泥和SB消解液中重金属浓度如表2所示,热解制备成生物炭之后Zn、Pb、Cu、Ba和Cd的浓度有一定程度的富集,这与污泥热解过程中有机质不断分解有关。两者的重金属浓度值都远低于《危险废物鉴别标准浸出毒性鉴别》(GB/T 5085.3—2007)规定值(不超过1/6)[18],说明SB中重金属含量符合规范要求。

表 2 污泥及污泥基生物炭(SB)消解液中重金属浓度Table 2. Heavy metal concentrations in digestion solution of sludge and sludge-based biochar (SB)(mg·L−1) Sample Zn Pb Cu Ba Cd Cr Sludge 5.28 0.34 2.37 7.32 0.06 0.14 SB 7.81 0.51 3.01 8.67 0.09 0.13 Specified value

in GB/T

5085.3—2007[18]100.00 5.00 100.00 100.00 1.00 15.00 2.2 材料表征分析

图1为SB和nZVI-SB(1∶1)处理Cr(VI)前、后的SEM-EDS图像。从图1(a)可看出,SB存在大量的块状结构,表面更加光滑。而nZVI-SB(1∶1)(图1(b))的表面存在大量链状聚集的颗粒物[19],这说明零价铁被负载在SB表面。图1(b)的EDS结果显示有Fe峰,进一步验证nZVI-SB复合材料制备成功。吸附Cr(VI)后,SEM变化不大,而EDS出现了Cr元素,证明nZVI-SB(1∶1)成功固定了铬(图1(c))。EDS分析得出nZVI-SB(1∶4)、nZVI-SB(1∶2)、nZVI-SB(1∶1)和nZVI-SB(2∶1)中Fe的质量百分数分别约为19.87wt%、33.31wt%、49.92wt%和66.63wt%(表3),符合预期比例。

图2为nZVI-SB(1∶1)处理含Cr(VI)废水前、后的TEM图像。处理含Cr(VI)废水前nZVI颗粒均匀分散并固定在SB表面(图2(a))。结果表明,在SB中引入nZVI颗粒提高了nZVI的分散和稳定性,从而增加了nZVI-SB(1∶1)还原或吸附Cr(VI)的活性位点[20]。吸附Cr(VI)后,nZVI-SB(1∶1)表面纳米颗粒减少,且相应的颗粒物变大(图2(b)),推测这可能是生成了Cr(III)-Fe(III)氢氧化物沉淀;结合图1(c)的EDS图中Cr 峰的出现,表明溶液中的Cr(VI)能够被nZVI-SB(1∶1)去除。

表 3 SB和nZVI-SB的元素组成Table 3. Elemental composition of SB and nZVI-SBwt% Sample C N O Na Mg Al Si K Ca Cr Fe SB 40.48 8.46 34.94 0.19 0.39 3.26 6.43 0.88 3.05 0.33 1.59 nZVI-SB(1∶4) 36.63 7.56 33.05 0.22 0.48 0.63 0.76 0.28 0.30 0.22 19.87 nZVI-SB(1∶2) 30.41 6.41 27.55 0.18 0.36 0.51 0.62 0.23 0.24 0.18 33.31 nZVI-SB(1∶1) 23.92 3.11 21.45 0.14 0.27 0.28 0.35 0.19 0.21 0.16 49.92 nZVI-SB(2∶1) 16.48 1.76 14.45 0.06 0.13 0.11 0.16 0.08 0.08 0.06 66.63 通过N2吸脱附比表面积测量仪测定SB及nZVI-SB(1∶1)比表面积和孔径,结果图3所示。SB和nZVI-SB(1∶1)的比表面积分别为47.07 m2/g和116.32 m2/g(图3(a)),孔径分别为14.34 nm和11.56 nm(图3(b))。nZVI-SB(1∶1)的比表面积远远大于SB,说明SB经过nZVI改性后所得的复合材料具有更大的吸附Cr(VI)潜力。nZVI-SB(1∶1)孔径比SB小,是由于SB具有多孔性结构,nZVI颗粒在制备过程中一部分球状颗粒嵌入生物炭的孔隙中[21],造成孔径减小。

SB和nZVI-SB(1∶1)去除Cr(VI)前、去除Cr(VI)后的XRD图谱如图4(a)所示。SB的XRD图谱中,2θ=20.9°、26.79°、35.01°、50.6°、60.01°及68.62°对应的主要物质为SiO2,而2θ=29.37°、39.4°对应的物质为CaCO3[22]。负载nZVI后,nZVI-SB(1∶1)的XRD特征峰发生变化,SiO2和CaCO3的相关峰减弱,甚至消失,检测到与α-Fe0相关的44.7°的特征峰,证明Fe0的存在[23-24],这表明nZVI在SB上负载成功[15]。2θ=35.65°处为Fe2O3 峰[25],可能是nZVI-SB复合材料制备过程中,部分nZVI被氧化。去除Cr(VI)后,nZVI 峰显著减弱,2θ=35.5°处为Cr2FeO4峰,证明nZVI和Cr(VI)之间发生了氧化还原反应,形成了混合铬铁氧化物Cr2FeO4[26]。图4(b)为nZVI-SB(1∶1)去除Cr(VI)前、去除Cr(VI)后的XPS全谱,处理前没有Cr(VI)的特征峰,去除Cr(VI)后可观察到Cr2p特征峰,表明复合材料可吸附固定Cr(VI)。

2.3 不同Fe∶C质量比对Cr(VI)去除的影响

图5显示了不同吸附剂类型对Cr(VI)的去除效果,SB、nZVI、nZVI-SB(1∶4、1∶2、1∶1、2∶1)对Cr(VI)的平衡吸附量分别为8.13、88.80、50.00、85.33、99.13和91.33 mg/g。SB的吸附量最低,主要是通过吸附作用固定Cr(VI)[13],而nZVI具有很强的还原性,可通过还原、吸附和共沉淀作用去除水中的Cr(VI)[27]。从图5可知,nZVI-SB中的Fe∶C质量比会对去除效果产生明显的影响。随着Fe/C从0.25增加到1.0,吸附量从50.00 mg/g显著增加到99.13 mg/g,进一步证实nZVI的负载增强了SB对Cr(VI)的去除能力。nZVI的去除性能优于nZVI-SB(1∶4)和nZVI-SB(1∶2),这可能是在nZVI-SB(1∶4)和nZVI-SB(1∶2)中,过量的生物炭占据nZVI的表面活性位点[28],从而影响了nZVI与Cr(VI)的反应。另外,与nZVI-SB(1∶1)相比,nZVI-SB(2∶1)对Cr(VI)的吸附量出现了降低,这可能是过量的nZVI在SB表面出现团聚,从而导致吸附量的下降。结果表明,Fe∶C质量比为1∶1的nZVI-SB去除Cr(VI)的能力最高。因此,选择nZVI-SB(1∶1)进行后续试验。

2.4 溶液初始pH对Cr(VI)去除的影响

初始pH值对Cr(VI)去除的影响如图6所示。随着溶液pH从2增加到9,nZVI-SB(1∶1)对Cr(VI)吸附量从99.13 mg/g下降至37.07 mg/g,原因可能是在酸性条件下存在大量的H+,促进nZVI-SB(1∶1)表面上氧化铁的溶解,暴露出更多的反应位点[29]。图7是用Visual MINTEQ软件模拟了Cr(VI)在不同pH值(2~12)的存在形态分布曲线图。在高pH值下,复合材料容易去质子化带负电[14, 30],Cr(VI)在溶液中主要以阴离子

CrO2−4 形式存在,两者同性相斥,从而造成吸附量下降。当pH>7时,溶液中存在大量的OH−,这有利于nZVI-SB(1∶1)表面形成Cr(III)-Fe(III)氢氧化物沉淀,阻碍了nZVI内部的电子向外转移[31],妨碍了Cr(VI)与活性位点的接触,从而抑制反应的进行。2.5 投加量对Cr(VI)去除的影响

nZVI-SB(1∶1)投加量对Cr(VI)去除效果见图8。当nZVI-SB(1∶1)的投加量从0.1 g/L增加到0.5 g/L时,nZVI-SB(1∶1)对Cr(VI)的去除率从27.48%快速增加到99.13%;当投加量大于0.5 g/L后,去除率基本保持不变。分析原因是,反应初期随着nZVI-SB(1∶1)投加量的增加,活性位点迅速增多[15],导致nZVI-SB(1∶1)对Cr(VI)的去除率迅速增加;但随着投加量的继续增加,而溶液中的Cr(VI)离子有限,对Cr(VI)的去除率增加变缓并趋于稳定。总体上吸附容量随着投加量的增加而减少,从最初的137.33 mg/g减少到38.41 mg/g。原因是随着投加量增加,单位质量nZVI-SB(1∶1)对Cr(VI)的吸附量下降[32]。

2.6 吸附动力学

在温度30℃、nZVI-SB(1∶1)投加量为0.5 g/L、Cr(VI)浓度为50 mg/L和溶液初始pH为2的条件下,Cr(VI)在720 min内的去除情况如图9(a)所示。随着反应时间的增加,nZVI-SB(1∶1)对Cr(VI)的吸附容量逐渐增加,前5~180 min吸附量增加较快,之后增加较缓慢,在240 min时基本达到吸附平衡。在初始阶段,吸附容量的迅速增加主要是由于有大量的结合位点可供吸附;随着吸附的继续,吸附位点接近饱和状态,吸附速率减慢,直至达到平衡[33]。

为了探究nZVI-SB(1∶1)对Cr(VI)的吸附过程和控速步骤,选用准一级动力学模型、准二级动力学模型和颗粒内扩散模型对实验数据进行分析,结果及相应的拟合参数如图9(b)~9(d)和表4所示。结果发现,t/qt与t呈明显的直线关系,准二级吸附动力学方程的线性相关系数(R2=0.999)大于其准一级动力学方程的线性相关系数(R2=0.855)。而准一级动力学模型拟合的qe(38.57 mg/g)与实际吸附量(99.13 mg/g)相差较大,而准二级动力学模型拟合的qe(103.07 mg/g)与实际值相当,说明准二级动力学方程能够更好地描述nZVI-SB(1∶1)对Cr(VI)的吸附过程。因此,吸附过程以化学吸附为主[34]。颗粒内扩散模型拟合分析发现,吸附分为吸附剂表面吸附和孔道内缓慢扩散两个阶段。直线都不经过原点,说明孔道内扩散不是控制吸附过程的关键步骤[19]。而粒子扩散常数Kd1>Kd2,表明表面吸附是Cr(VI)吸附去除的限速步骤[25]。

2.7 吸附等温线

在pH为2、投加量0.5 g/L、吸附时间4 h条件下,探讨Cr(VI)初始质量浓度(40~110 mg/L)和吸附温度(20℃、30℃及40℃)对Cr(VI)去除的影响,结果如图10(a)所示。随着Cr(VI)初始质量浓度的增加,吸附量呈上升趋势,这可能与传质驱动力有关,较高的Cr(VI)浓度使液相和nZVI-SB(1∶1)表面之间的浓度梯度更大,导致更多的Cr(VI)转移到nZVI-SB(1∶1)表面[35]。在相同Cr(VI)初始质量浓度下,40℃下Cr(VI)吸附量最大,说明升高温度能够促进nZVI-SB(1∶1)对Cr(VI)的去除。原因是较高的温度有利于增加金属离子的迁移率,从而增加Cr(VI)与吸附位点的接触概率[36]。

表 4 nZVI-SB(1∶1)对Cr(VI)的吸附动力学参数Table 4. Adsorption kinetic parameters of Cr(VI) adsorption by nZVI-SB(1∶1)Intraparticle diffusion model qe/(mg·g−1) K/(min−1) R2 Kd/(mg·(m·min0.5)−1) C R2 Quasi-first order dynamics model 38.57 0.0113 0.855 5.858 22.731 0.971 Quasi-second-stage dynamics model 103.07 0.0005 0.999 0.038 98.551 0.946 Notes: qe—Equilibrium adsorption capacity; K—Adsorption rate constant; R2—Linear correlation coefficient; Kd—Particle diffusion constants; C—Constant. 通过Langmuir和Freundlich吸附等温线模型对Cr(VI)去除过程进行拟合,拟合曲线和拟合参数分别如图10(b)、10(c)和表5所示。结果表明,Langmuir方程模拟所得的最大吸附量(151.23 mg/g)和实际吸附容量(150.60 mg/g)相当。Langmuir吸附等温线的相关系数均高于Freundlich吸附等温线的相关系数。这表明Langmuir吸附等温模型更适合描述nZVI-SB去除Cr(VI)的过程,即Cr(VI)在nZVI-SB表面的吸附是均匀的单分子层吸附[16]。与其他吸附剂相比,本文中的nZVI-SB(1∶1)对Cr(VI)的去除性能优于绝大部分吸附剂,见表6。

2.8 机制分析

为了更加深入的了解nZVI-SB(1∶1)对Cr(VI)的去除机制,对处理Cr(VI)前、处理Cr(VI)后的nZVI-SB(1∶1)进行XPS分析,结果如图11和表7所示。图11(a)为nZVI-SB(1∶1) C1s的高分辨精细图谱,吸附前主要峰有C—C(284.64 eV)、C—O(286.06 eV)和C=O(288.54 eV)。与Cr(VI)反应后,这3个峰的面积存在变化,表明这些基团参与了对Cr(VI)的吸附[16]。图11(b)中反应前O1s的主要峰有Fe—O(529.95 eV)、C—O(531.17 eV)和C=O(532.04 eV),吸附后C—O的峰面积增多,C=O的峰面积减少,表明生物炭可以作为电子传递介质,通过表面某些官能团得失电子参与反应[40]。吸附前nZVI-SB(1∶1)的Fe2p光谱中(图11(c)),出现Fe0弱峰(706.70 eV),表明成功合成了nZVI。结合能为724.39 eV 和711.10 eV,对应于Fe(II)的氧化物(FeO);结合能为728.15 eV和714.41 eV对应于Fe(III)的氧化物(Fe2O3),这与XRD的结果一致。吸附后Fe0特征峰消失,Fe(II)峰面积下降,Fe(III)峰面积上升,表明nZVI和Fe(II)被Cr(VI)氧化[41]。图11(d)中580.40 eV和590.28 eV处的峰为Cr(VI)特征峰,说明Cr(VI)被nZVI-SB(1∶1)吸附[42]。577.01 eV和586.85 eV处的峰为Cr(III)特征峰,说明部分Cr(VI)能被nZVI-SB(1∶1)还原生成Cr(III)[25]。其中Cr(III)和Cr(VI)分别占元素Cr含量的84.39%和15.61%(表7),大部分Cr以Cr(III)的形式存在。

表 5 nZVI-SB(1∶1)对Cr(VI)的吸附等温线拟合参数Table 5. Adsorption isotherm fitting parameters of Cr(VI) by nZVI-SB(1∶1)Temperature/℃ Langmuir Freundlich qm/(mg·g−1) KL R2 KF n R2 20 141.55 0.457 0.999 98.48 8.93 0.821 30 143.84 0.338 0.999 104.73 9.99 0.744 40 151.23 0.433 0.999 106.38 9.07 0.766 Notes: qm—Maximum adsorption capacity; KL—Adsorption equilibrium constant of the Langmuir model; KF—Adsorption equilibrium constant of Freundlich model; n—Constants related to the adsorption intensity. 表 6 nZVI-SB(1∶1)和其他吸附剂对Cr(VI)的吸附能力比较Table 6. Comparison of the adsorption capacity of Cr(VI) by nZVI-SB(1∶1) and other adsorbentsAdsorbent pH Temperature/℃ Adsorption

capacity/(mg·g−1)Ref. Sludge biochar (500℃) 7 25 7.93 [13] Bentonite-supported nanoscale zero-valent iron (B-nZVI) 5 25 39.48 [23] Ficus carica biosorbent 3 30 19.68 [36] Magnetic nanoparticle-Phosphorene-Titanium nano tubes (MNP-PN-TNT) 9 25 35.00 [2] Nanoscale zero-valent iron grafted on acid-activated attapulgite (A-nZVI) 7 27 4.94 [31] HNO3 modified quinoa biochar 4 — 55.85 [37] ZnO modified hyacinth biochar — 25 43.48 [38] Halloysite nanotubes/ploy composites 2 25 855.66 [39] nZVI-SB(1∶1) 2 40 150.60 This study 综合2.2节SEM、TEM和XRD分析,推测nZVI-SB(1∶1)去除Cr(VI)的主要机制如图12所示。Cr(VI)首先被nZVI-SB(1∶1)吸附固定,此后部分Cr(VI)与nZVI提供的电子接触后被还原为Cr(III),nZVI被氧化为Fe2+,Fe2+仍具有还原性,可将Cr(VI)还原为Cr(III)。生成的Cr(III)、Fe(III)结合成为Cr(III)-Fe(III)氢氧化物沉淀[19],通过C—C、C—O和C=O等官能团吸附在nZVI-SB(1∶1)上,达到去除Cr(VI)的目的。

表 7 nZVI-SB(1∶1)去除Cr(VI)前、去除Cr(VI)后的C1s、O1s、Fe2p和Cr2p XPS光谱的成分和相应的相对百分比Table 7. Composition and relative percents of C1s, O1s, Fe2p and Cr2p XPS spectra before and after Cr(VI) removal by nZVI-SB(1∶1)Components Relative percentage/% Binding energy/eV Before After Before After C1s C—C 58.99 59.78 284.64 284.69 C—O 26.24 24.00 286.06 286.27 C=O 14.77 16.22 288.54 288.72 O1s Fe—O 32.07 30.05 529.95 529.99 C—O 29.94 57.76 531.17 531.40 C=O 37.99 12.19 532.04 532.58 Fe2p Fe0 0.36 0.00 706.70 — Fe(II) 70.31 67.96 711.10/724.39 711.11/724.45 Fe(III) 29.33 32.04 714.41/728.15 714.44/728.55 Cr2p Cr(III) — 84.39 — 577.01/586.85 Cr(VI) — 15.61 — 580.40/590.28 2.9 洗脱再生试验

nZVI-SB(1∶1)的洗脱再生试验如图13所示。经过3次循环,nZVI-SB(1∶1)对Cr(VI)的去除率逐次降低,第3次能够保持在74.34%。随着洗脱次数的增加,Cr(VI)去除率逐渐下降。这可能是复合材料上的nZVI被洗脱及nZVI-SB(1∶1)表面上Fe0和Fe2+逐渐消耗造成的[32]。但对于SB而言,成本低廉,可以很容易制备,因此后续nZVI-SB再生主要考虑如何保持nZVI活性方面。

3. 结 论

(1) 以污泥基生物炭(SB)作为载体,通过液相还原法成功制备了纳米零价铁(nZVI)-SB材料,Fe∶C质量比为1∶1时,nZVI-SB(1∶1)对Cr(VI)的去除效果最好。

(2) 在初始pH值为2、投加量为0.5 g/L、温度为40℃条件下,nZVI-SB(1∶1)对Cr(VI)的最大去除量为150.60 mg/g。Cr(VI)去除过程符合Langmuir吸附等温模型和准二级吸附动力学模型,说明Cr(VI)吸附属于均匀的化学吸附过程。

(3) nZVI-SB(1∶1)对Cr(VI)的吸附机制主要为Cr(VI)首先被吸附到nZVI-SB(1∶1)表面,随后大部分与nZVI、Fe(II)反生氧化还原反应,生成Cr(III);最后与Fe(III)形成Cr(III)-Fe(III)氢氧化物沉淀。

(4) 以市政污泥为原料,制备SB负载nZVI,可高效处理含Cr(VI)废水。生物炭有效的解决了nZVI易团聚问题,提高nZVI的活性,生物炭负载nZVI在含Cr(VI)废水处理中能发挥协同作用。

-

表 1 环氧树脂(EP)与HTPDMS改性环氧树脂(ES)固化配比表 (质量比)

Table 1 Epoxy resin (EP) and HTPDMS modified epoxy resin (ES) curing ratio table (Mass ratio)

Name E51/% HTPDMS/% MeHHPA/% DMP-30/% EP 100 0 85.68 0.5 ES 80 20 68.54 0.5 Notes: MeHHPA—Tetramethylhexahydrophthalic anhydride; DMP-30—2, 4, 6-tri(dimethylaminomethyl) phenol. 表 2 EP和ES在空气气氛下的热失重数据

Table 2 Thermogravimetric data of EP and ES in air

Atmosphere Sample T−5%/℃ T−10%/℃ Tmax1/℃ Tmax2/℃ Char residue in

800℃/wt%Air EP 323.0 337.0 369.9 517.3 0.37 ES 299.9 317.9 351.0 507.4 5.38 Notes: T−5%—Onset degradation temperature at 5.0wt% mass loss; T−10%—Temperature at 10wt% mass loss; Tmax1 and Tmax2—Maximum decomposition temperature in the first and second stage. -

[1] JIN F L, LI X, PARK S J. Synthesis and application of epoxy resins: A review[J]. Journal of Industrial and Engineering Chemistry,2015,29:1-11. DOI: 10.1016/j.jiec.2015.03.026

[2] GU H B, MA C, GU J W, et al. An overview of multifunctional epoxy nanocomposites[J]. Journal of Materials Chemistry C,2016,4(25):5890-5906.

[3] DOMUN N, HADAVINIA H, ZHANG T, et al. Improving the fracture toughness and the strength of epoxy using nanomaterials—A review of the current status[J]. Nanoscale,2015,7(23):10294-10329. DOI: 10.1039/C5NR01354B

[4] 董慧民, 益小苏, 安学锋, 等. 纤维增强热固性聚合物基复合材料层间增韧研究进展[J]. 复合材料学报, 2014, 31(2):273-285. DONG Huimin, YI Xiaosu, AN Xuefeng, et al. Development of interleaved fibre-reinforced thermoset polymer matrix composites[J]. Acta Materiae Compositae Sinica,2014,31(2):273-285(in Chinese).

[5] ZUCCHELLI A, FOCARETE M L, GUALANDI C, et al. Electrospun nanofibers for enhancing structural performance of composite materials[J]. Polymers for Advanced Technologies,2011,22(3):339-349. DOI: 10.1002/pat.1837

[6] 杨瑞瑞. PEI纳米纤维层间增韧碳纤维环氧复合材料性能研究[J]. 材料开发与应用, 2015, 30(5):57-62. YANG Ruirui. Performance of carbon fiber/epoxy compo-site interfacial toughened by PEI nanofiber membranes[J]. Development and Application of Materials,2015,30(5):57-62(in Chinese).

[7] KOMAROV V A, PAVLOV A A, PAVLOVA S A, et al. Reinforcement of aerospace structural elements made of layered composite materials[J]. Procedia Engineering,2017,185:126-130. DOI: 10.1016/j.proeng.2017.03.329

[8] 莫正才, 胡程耀, 霍冀川, 等. 苎麻短纤维层间增韧碳纤维/环氧树脂复合材料[J]. 复合材料学报, 2017, 34(6):1237-1244. MO Zhengcai, HU Chengyao, HUO Jichuan, et al. Interlayer-toughening carbon fiber/epoxy composites with short ramie fiber[J]. Acta Materiae Compositae Sinica,2017,34(6):1237-1244(in Chinese).

[9] YAO H C, ZHOU G D, WANG W T, et al. Effect of polymer-grafted carbon nanofibers and nanotubes on the interlaminar shear strength and flexural strength of carbon fiber/epoxy multiscale composites[J]. Composite Structures,2018,195:288-296. DOI: 10.1016/j.compstruct.2018.04.082

[10] GUZMAN DE VILLORIA R, HALLANDER P, YDREFORS L, et al. In-plane strength enhancement of laminated composites via aligned carbon nanotube interlaminar reinforcement[J]. Composites Science and Technology,2016,133:33-39. DOI: 10.1016/j.compscitech.2016.07.006

[11] 于妍妍, 张远, 高丽敏, 等. 基于碳纳米管薄膜的复合材料层间增韧[J]. 航空学报, 2019, 40(10):307-314. YU Yanyan, ZHANG Yuan, GAO Limin, et al. Toughness enhancement for interlaminar fracture composite based on carbon nanotube films[J]. Acta Aeronautica et Astronautica Sinica,2019,40(10):307-314(in Chinese).

[12] ALSAADI M, UGLA A A, ERKLIG A. A comparative study on the interlaminar shear strength of carbon, glass, and Kevlar fabric/epoxy laminates filled with SiC particles[J]. Journal of Composite Materials,2017,51(20):2835-2844. DOI: 10.1177/0021998317701559

[13] 张兴迪, 刘刚, 党国栋, 等. 含磷聚芳醚酮颗粒层间增韧碳纤维/双马树脂RTM复合材料[J]. 高分子学报, 2016(9):1254-1262. ZHANG Xingdi, LIU Gang, DANG Guodong, et al. Properties of interlaminar toughened CF/BMI composites by phosphorus-containing PAEK particles[J]. Acta Polymerica Sinica,2016(9):1254-1262(in Chinese).

[14] 姚佳伟, 刘梦瑶, 牛一凡. PEK-C膜层间增韧碳纤维/环氧树脂复合材料的力学性能[J]. 复合材料学报, 2019, 36(5):1083-1091. YAO Jiawei, LIU Mengyao, NIU Yifan. Mechanical properties of PEK-C interlayer toughened carbon fiber/epoxy composites[J]. Acta Materiae Compositae Sinica,2019,36(5):1083-1091(in Chinese).

[15] NAFFAKH M, DUMON M, GÉRARD J F. Study of a reactive epoxy-amine resin enabling in situ dissolution of thermoplastic films during resin transfer moulding for toughening composites[J]. Composites Science and Technology,2006,66(10):1376-1384. DOI: 10.1016/j.compscitech.2005.09.007

[16] 谭珏, 邓火英, 谭朝元. 丁腈橡胶增韧环氧树脂基烧蚀防热材料性能[J]. 宇航材料工艺, 2018, 48(1):54-57. TAN Jue, DENG Huoying, TAN Zhaoyuan. Properties of ablative material based on epoxy resin modified by CTBN[J]. Aerospace Materials & Technology,2018,48(1):54-57(in Chinese).

[17] BACH Q V, VU C M, VU H T, et al. Significant enhancement of fracture toughness and mechanical properties of epoxy resin using CTBN-grafted epoxidized linseed oil[J]. Journal of Applied Polymer Science,2020,137(2):48276. DOI: 10.1002/app.48276

[18] JIANG M Q, LIU Y, CHENG C, et al. Enhanced mechanical and thermal properties of monocomponent high performance epoxy resin by blending with hydroxyl terminated polyethersulfone[J]. Polymer Testing,2018,69:302-309. DOI: 10.1016/j.polymertesting.2018.05.039

[19] DRAGAN E S. Design and applications of interpenetrating polymer network hydrogels: A review[J]. Chemical Engi-neering Journal,2014,243:572-590. DOI: 10.1016/j.cej.2014.01.065

[20] SALIMIAN S, MALFAIT W J, ZADHOUSH A, et al. Fabrication and evaluation of silica aerogel-epoxy nanocompo-sites: Fracture and toughening mechanisms[J]. Theoretical and Applied Fracture Mechanics,2018,97:156-164. DOI: 10.1016/j.tafmec.2018.08.007

[21] GU H B, ZHANG H Y, MA C, et al. Trace electrosprayed nanopolystyrene facilitated dispersion of multiwalled carbon nanotubes: Simultaneously strengthening and toughening epoxy[J]. Carbon,2019,142:131-140. DOI: 10.1016/j.carbon.2018.10.029

[22] 孔志祥, 邹路丝, 张洋, 等. 含柔性链段环氧树脂的合成与性能[J]. 粘接, 2015, 36(11):44-47. KONG Zhixiang, ZOU Lusi, ZHANG Yang, et al. Synthesis and properties of epoxy resin containing flexible segments[J]. Adhesion,2015,36(11):44-47(in Chinese).

[23] BAO Q R, WANG B W, LIU Y, et al. Epoxy resin flame retarded and toughed via flexible siloxane chain containing phosphaphenanthrene[J]. Polymer Degradation and Stability,2020,172:109055. DOI: 10.1016/j.polymdegradstab.2019.109055

[24] Composites Group. Rubber-toughened GFRCs optimised by nanoparticles[J]. Composites,2005,42(21):72-75.

[25] 朱德智. 增强增韧的环氧树脂/二氧化硅纳米复合材料的制备与研究[J]. 塑料工业, 2017, 45(6):66-69. ZHU Dezhi. Preparation and study of reinforced and toughened epoxy/nanosilica nanocomposites[J]. China Plastics Industry,2017,45(6):66-69(in Chinese).

[26] HU K, BAO L X, CHEN X F, et al. Synthesis of castor oil-derived decanediamide as a novel flexible asphalt-modified epoxy resin curing agent[J]. Advances in Polymer Technology,2018,37(4):1092-1098. DOI: 10.1002/adv.21760

[27] 魏波, 周金堂, 姚正军, 等. 环氧树脂基体的原位增韧技术研究进展[J]. 材料导报, 2019, 33(17):2976-2988. WEI Bo, ZHOU Jintang, YAO Zhengjun, et al. Research progress in toughening epoxy resin matrix by in-situ technique[J]. Materials Reports,2019,33(17):2976-2988(in Chinese).

[28] VERREY J, WINKLER Y, MICHAUD V, et al. Interlaminar fracture toughness improvement in composites with hyperbranched polymer modified resin[J]. Composites Science and Technology,2005,65(10):1527-1536. DOI: 10.1016/j.compscitech.2005.01.005

[29] 文钦, 刘博伟, 冀运东. 端羟基聚二甲基硅氧烷改性环氧树脂研究[J]. 热固性树脂, 2020, 35(1):25-28. WEN Qin, LIU Bowei, JI Yundong. Study on the hydroxyl-terminated polydimethylsiloxane modified epoxy resins[J]. Thermosetting Resin,2020,35(1):25-28(in Chinese).

[30] ASTM International. Stand test method for matrix solids content and matrix content of composites prepreg: ASTM D3529—16[S]. West Conshohocken: ASTM International, 2016.

[31] International Organization for Standarization. Plastics— Determination of tensile properties—Part 1: General principles: ISO 527-1: 2012[S]. Geneva: ISO, 2012.

[32] ASTM International. Standard test methods for flexural properties of unreinforced and reforced plastics and electrical insulating materials: ASTM D790—17[S]. West Conshohocken: ASTM International, 2017.

[33] 全国塑料标准化技术委员会. 塑料简支梁冲击性能的测定: GB/T 1043.1—2008[S]. 北京: 中国标准出版社, 2008. National Plastic Standardization Technical Committee. Determination of charpy impact properties: GB/T 1043.1—2008[S]. Beijing: Standards Press of China, 2008(in Chinese).

[34] ASTM International. Standard test method for short-beam strength of polymer matrix composite materials and their laminates: ASTM D2344/D2344 M—16[S]. West Conshohochen: ASTM International, 2016.

[35] ASTM International. Standard test method for mode I interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: ASTM D5528/D5528 M—21[S]. West Conshohocken: ASTM International, 2021.

[36] OCHI M, TAKEMIYA K, KIYOHARA O, et al. Effect of the addition of aramid-silicone block copolymer on phase structure and toughness of cured epoxy resins modified with silicone[J]. Polymer,1998,39(3):725-731.

[37] HENG Z G, ZENG Z, CHEN Y, et al. Silicone modified epoxy resins with good toughness, damping properties and high thermal residual weight[J]. Journal of Polymer Research,2015,22(11):203.

[38] HOU S S, CHUNG Y P, CHAN C K, et al. Function and performance of silicone copolymer. Part IV. Curing behavior and characterization of epoxy-siloxane copolymers blended with diglycidyl ether of bisphenol-A[J]. Polymer,2000,41(9):3263-3272. DOI: 10.1016/S0032-3861(99)00525-X

[39] WANG W J, PERNG L H, HSIUE G H, et al. Characterization and properties of new silicone-containing epoxy resin[J]. Polymer,2000,41(16):6113-6122.

[40] HUANG X N, HULL D. Effects of fibre bridging on GIC of a unidirectional glass/epoxy composite[J]. Composites Science and Technology,1989,35(3):283-299. DOI: 10.1016/0266-3538(89)90040-7

[41] ZHANG H, LIU Y, KUWATA M, et al. Improved fracture toughness and integrated damage sensing capability by spray coated CNTs on carbon fibre prepreg[J]. Compo-sites Part A: Applied Science and Manufacturing,2015,70:102-110. DOI: 10.1016/j.compositesa.2014.11.029

[42] CECH V, KNOB A, HOSEIN H A, et al. Enhanced interfacial adhesion of glass fibers by tetravinylsilane plasma modification[J]. Composites Part A: Applied Science and Manufacturing,2014,58:84-89. DOI: 10.1016/j.compositesa.2013.12.003

[43] CHEN J H, SCHULZ E, BOHSE J, et al. Effect of fibre content on the interlaminar fracture toughness of unidirectional glass-fibre/polyamide composite[J]. Composites Part A: Applied Science and Manufacturing,1999,30(6):747-755. DOI: 10.1016/S1359-835X(98)00188-2

[44] BIAN D K, TSUI J C, KYDD R R, et al. Interlaminar toughening of fiber-reinforced polymers by synergistic modification of resin and fiber[J]. Journal of Manufacturing Science and Engineering,2019,141(8):1-12.

[45] CHONG H M, TAYLOR A C. The microstructure and fracture performance of styrene-butadiene-methylmethacrylate block copolymer-modified epoxy polymers[J]. Journal of Materials Science,2013,48(19):6762-6777. DOI: 10.1007/s10853-013-7481-8

[46] CHENOWETH K, CHEUNG S, VAN DUIN A C T, et al. Simulations on the thermal decomposition of a poly(dimethylsiloxane) polymer using the ReaxFF reactive force field[J]. Journal of the American Chemical Society,2005,127(19):7192-7202. DOI: 10.1021/ja050980t

[47] CHEN K, SUSNER M A, VYAZOVKIN S. Effect of the brush structure on the degradation mechanism of polystyrene-clay nanocomposites[J]. Macromolecular Rapid Communications,2005,26(9):690-695. DOI: 10.1002/marc.200500043

[48] JIA P, LIU H C, LIU Q, et al. Thermal degradation mechanism and flame retardancy of MQ silicone/epoxy resin composites[J]. Polymer Degradation and Stability,2016,134:144-150. DOI: 10.1016/j.polymdegradstab.2016.09.029

[49] HAMDANI S, LONGUET C, PERRIN D, et al. Flame retardancy of silicone-based materials[J]. Polymer Degradation and Stability,2009,94(4):465-495. DOI: 10.1016/j.polymdegradstab.2008.11.019

[50] ANANDA KUMAR S, SANKARA NARAYANAN T S N. Thermal properties of siliconized epoxy interpenetrating coatings[J]. Progress in Organic Coatings,2002,45(4):323-330. DOI: 10.1016/S0300-9440(02)00062-0

[51] CRISTEA M, IBANESCU S, CASCAVAL C N, et al. Dynamic mechanical analysis of polyurethane-epoxy interpenetrating polymer networks[J]. High Performance Polymers,2009,21(5):608-623. DOI: 10.1177/0954008309339940

-

期刊类型引用(10)

1. 陈然,贾红斌,李奕莹,李双洋,周建飞,石碧. 胶原生物炭/g-C_3N_4/WO_3复合材料光催化去除水体中Cr(Ⅵ). 皮革科学与工程. 2025(01): 1-7+28 .  百度学术

百度学术

2. 孙志勇,张宇辰,吴喜军. 聚乙烯亚胺交联膨润土对水中Cr(Ⅵ)的吸附性能与机制. 复合材料学报. 2025(02): 949-960 .  本站查看

本站查看

3. 赵啟超,白红娟,韩群英,孙竹梅,刘鹏霄,王子豪,叶宇晗,王瑶. 低温热解磷酸改性花生壳生物炭的制备及对水中Cr(Ⅵ)的去除. 中北大学学报(自然科学版). 2024(04): 503-512 .  百度学术

百度学术

4. 李然,纪丽丽,何前锐,夏晓月,王亚宁. 贻贝壳负载纳米零价铁去除钒(Ⅴ)的性能与机制. 工业水处理. 2024(09): 127-135 .  百度学术

百度学术

5. 张潇宇. 试分析钢铁厂含铬废水污泥处理工艺. 冶金与材料. 2024(11): 71-73 .  百度学术

百度学术

6. 郜飞,董良飞,葛玉龙,唐园园,李芬. 污泥生物炭/凹凸棒土的制备及其吸附性能研究. 无机盐工业. 2023(05): 91-99 .  百度学术

百度学术

7. 王阳,高衍浩,孔凡今. 生物炭负载纳米零价铁修复重金属污染土壤的研究进展. 山东化工. 2023(10): 98-101 .  百度学术

百度学术

8. 吴培,刘子璇,雷明婧,余意,刘家豪,聂芳,朱健,王平. 葡萄籽提取液还原制备生物炭负载纳米铁对水中As(Ⅲ)的去除性能及机理. 环境工程学报. 2023(08): 2596-2605 .  百度学术

百度学术

9. 李佳璇,王平,万斯,陈润华. 高孔隙率生物炭研制及其处理废水中磷酸盐. 复合材料学报. 2023(11): 6395-6406 .  本站查看

本站查看

10. 农海杜,毛悦梅,沙海超,谢水波,陈胜兵,曾涛涛. 污泥基生物炭负载纳米零价铁除U(Ⅵ)性能及机理. 环境科学与技术. 2023(11): 195-202 .  百度学术

百度学术

其他类型引用(7)

-

目的

环氧树脂基复合材料层合结构面法向力学性能较弱,其损伤和断裂行为主要由树脂的性能决定,再加上航空和船舶等行业的发展,热和烧蚀环境对复合材料的要求越来越苛刻。各行业逐渐意识到同时具有较强层间力学性能和耐热性的复合材料的重要性。本文通过聚硅氧烷对环氧树脂基体进行共聚改性,极大的提高了玻璃纤维增强树脂基复合材料层间断裂韧性及耐热性。

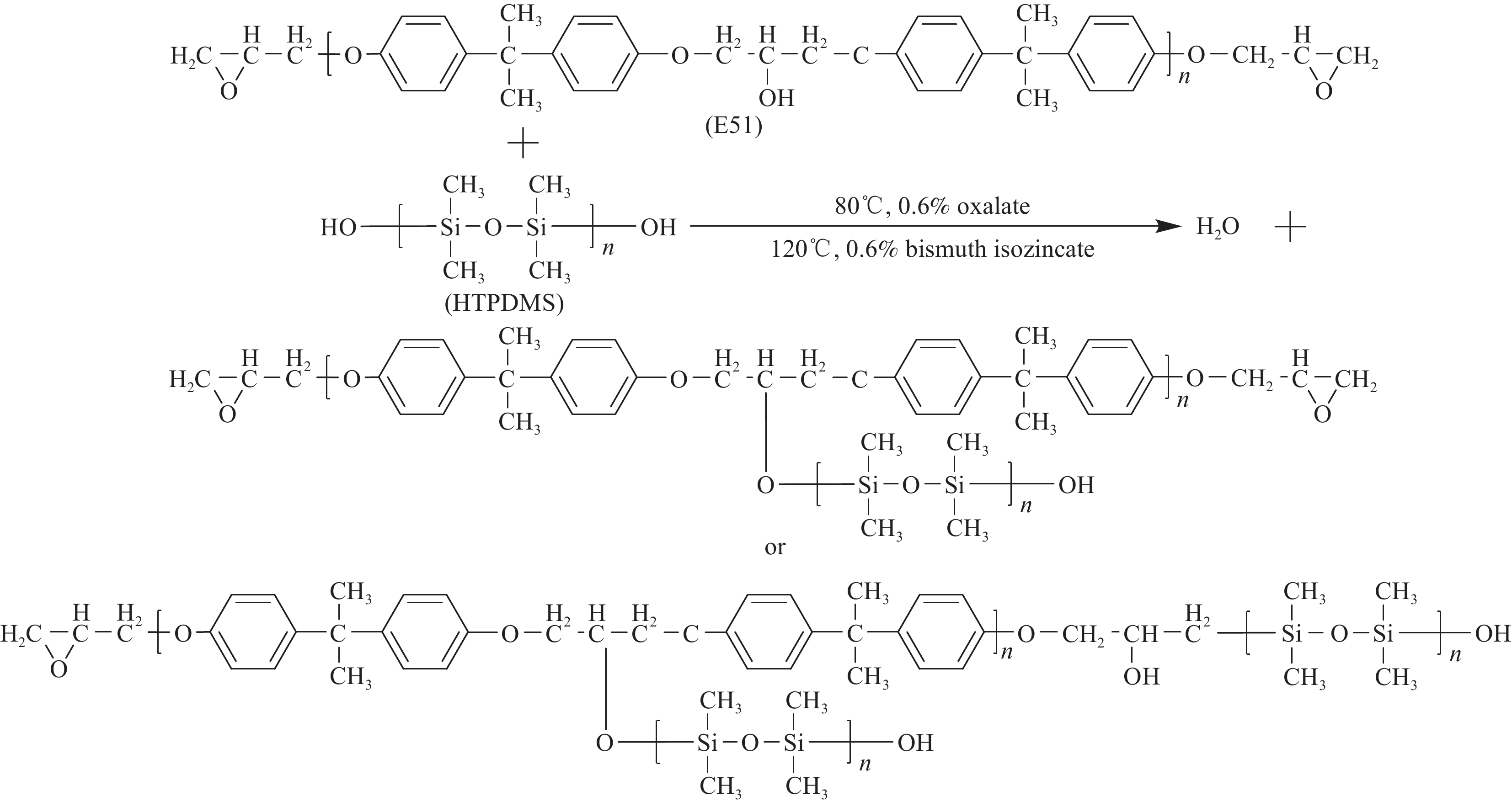

方法将改性后的环氧树脂与未改性的环氧树脂制备成玻璃纤维增强树脂基复合材料,分别测试其层间力学性能和耐热性能的优劣。首先,将E51环氧树脂(EP)和端羟基聚二甲基硅氧烷(HTPDMS)按照8:2的比例放入三颈瓶中,按照文中描述方法使得HTPDMS与EP发生缩合反应得到改性树脂(ES)。其次,将两种树脂与固化剂和促进剂混合后,采用真空导入的方法将其导入预先铺叠好的单轴向玻璃纤维机织布中,随后放入模压机中100℃固化2 h,150℃固化5 h进行固化,得到玻璃纤维增强环氧树脂基复合材料(EP-GF)和玻璃纤维增强环氧树脂基复合材料(ES-GF)。最后,将制备好的复合材料层压板雕刻成为预定尺寸试样。为验证基体改性对复合材料层间力学性能的影响,对两种复合材料进行了短梁剪切测试和DCB测试。为验证基体改性对复合材料耐热性能的影响,对ES和EP进行热失重测试和差示扫描量热测试,对两种复合材料进行动态热机械分析测试。为探究ES-GF层间力学性能提高的原因,使用扫描电镜对树脂浇铸体断面和复合材料层间开裂断面进行观察,测试浇铸体的断裂延伸率和摆锤冲击强度,测试两种树脂对玻璃板的润湿角,并得出ES-GF层间破坏模型。

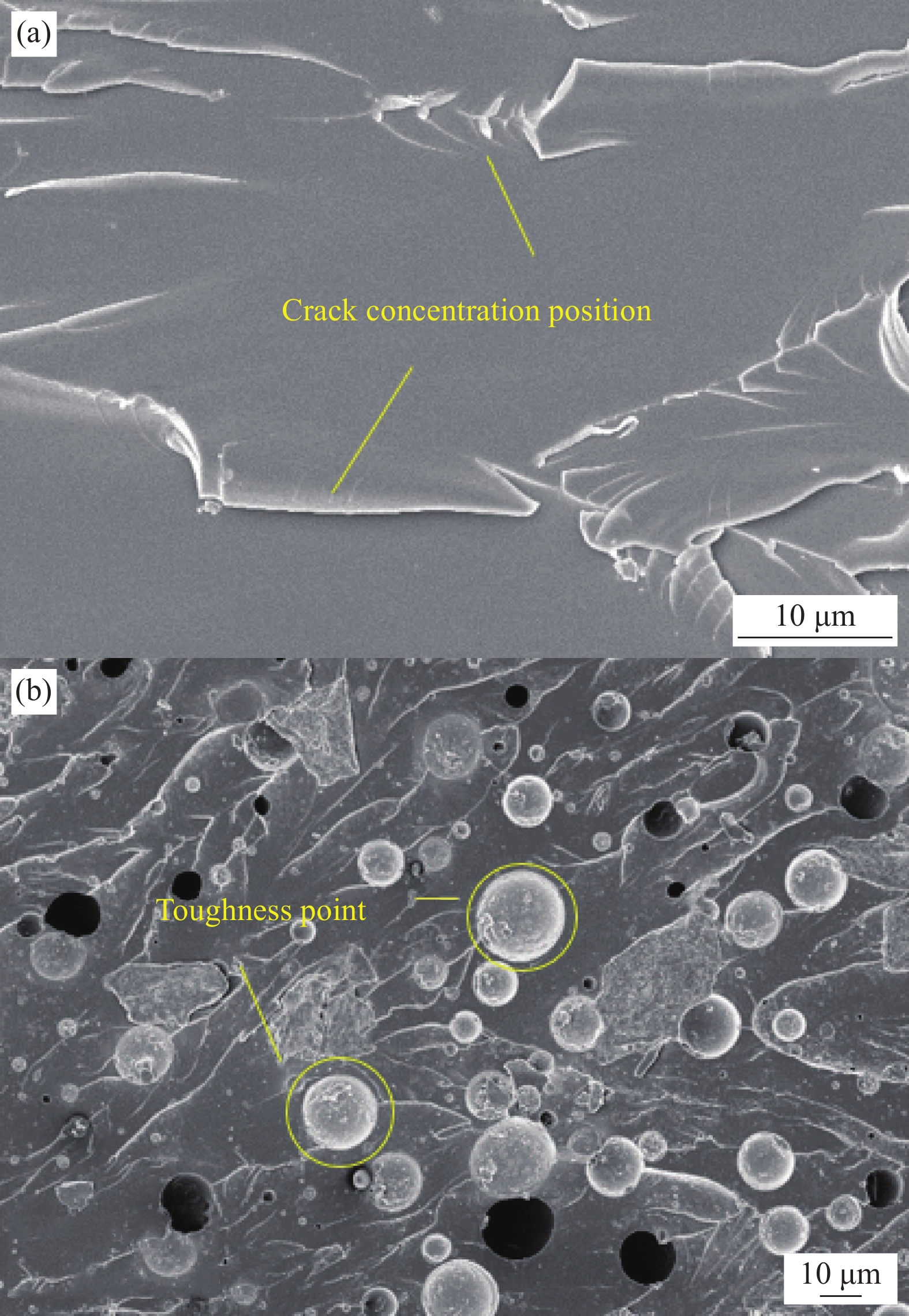

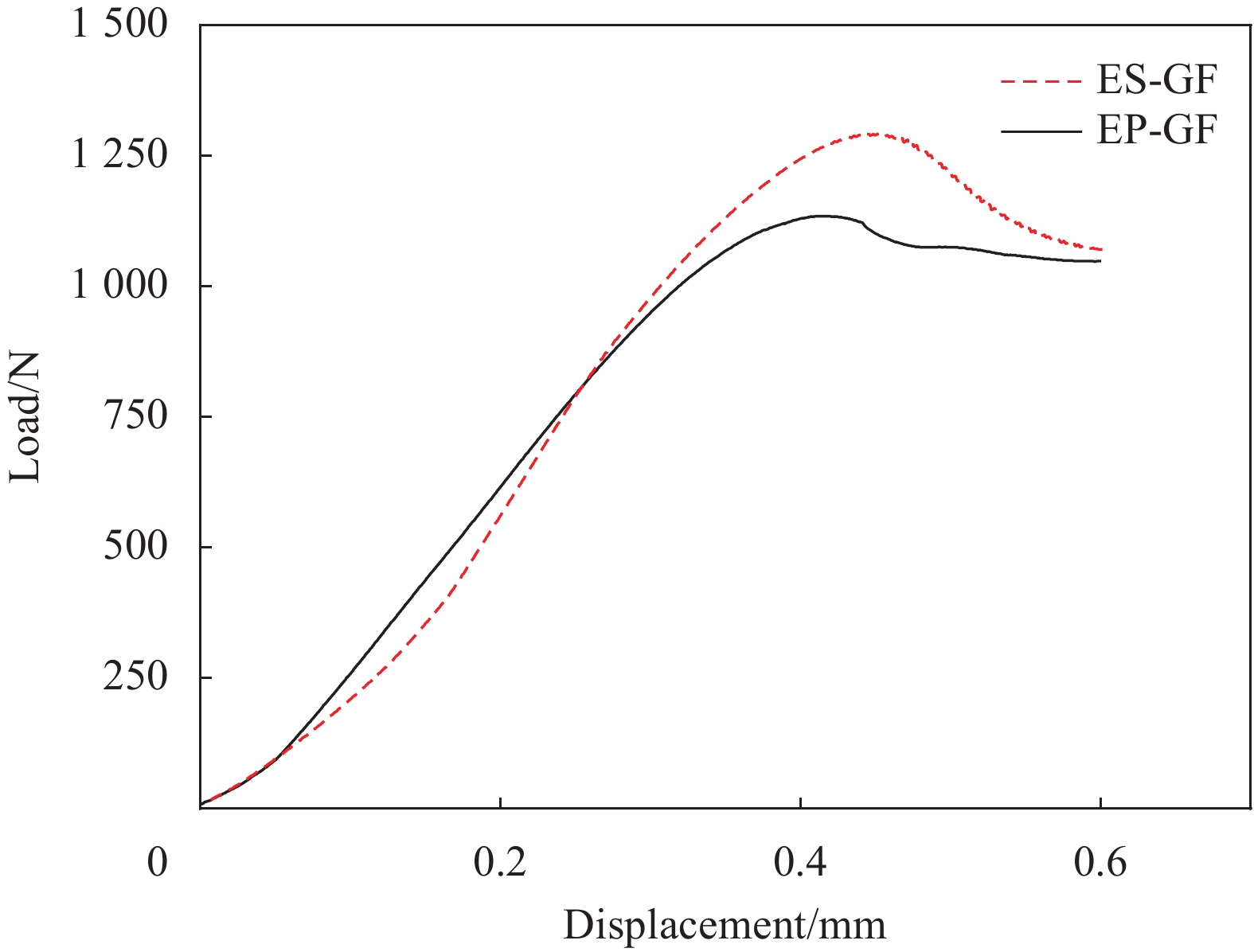

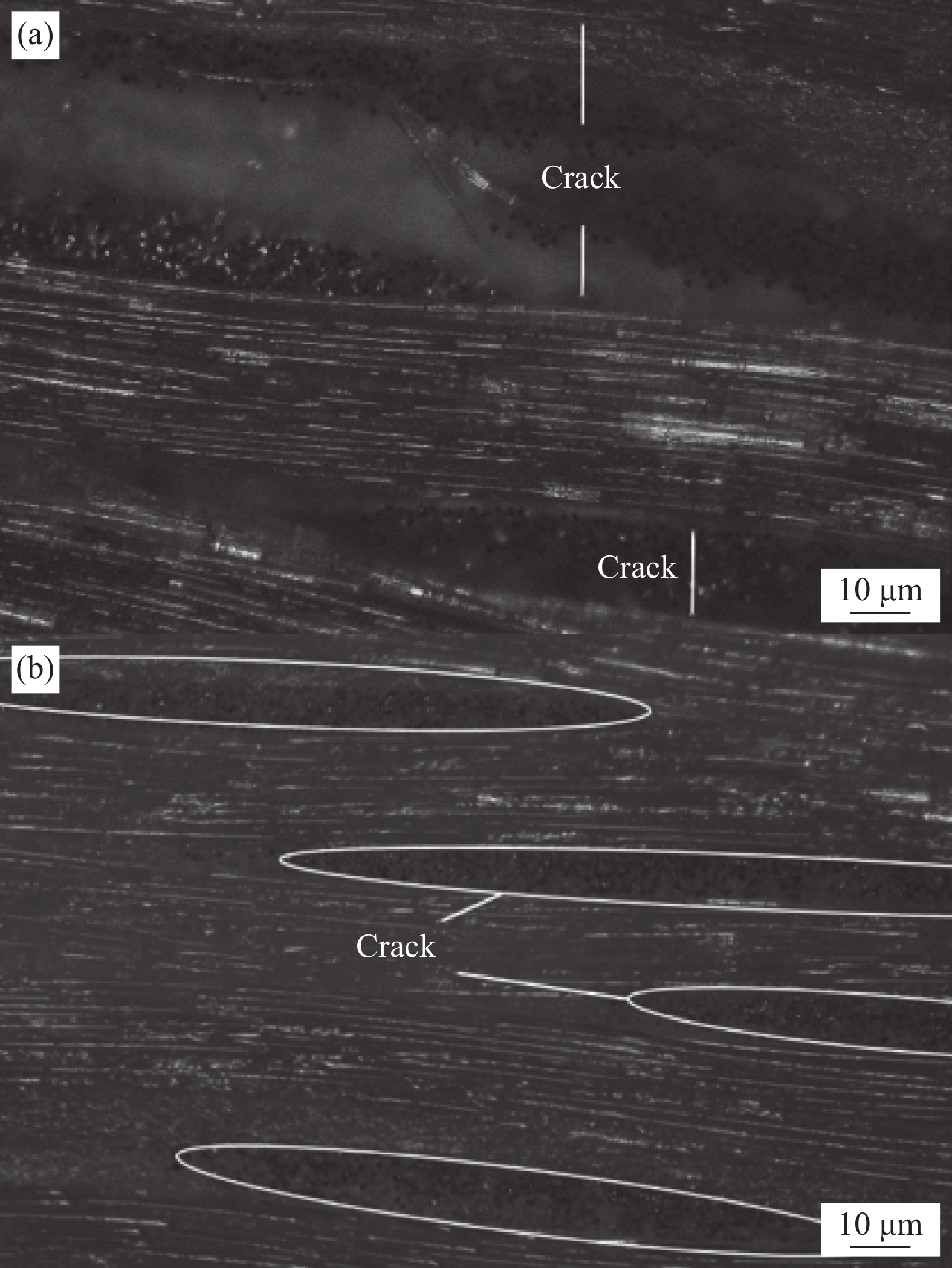

结果测试结果显示,ES树脂断裂延伸率提高98.1%,摆锤冲击强度提高72.5%,说明ES树脂具有较好的韧性。这对于其复合材料层间力学性能的提高发挥了重要作用。ES-GF裂纹稳定扩展的Ⅰ型层间断裂韧性提高98%,短梁剪切强度提高13%,表明由改性树脂制备成的复合材料具有较好层间力学性能。ES热失重速率降低了33.1%,最终热残余量提高13.5倍,ES-GF高温下的储能模量提高10.8%,DSC与DMA测试结果均表明ES树脂的玻璃化转变温度略有提高,表明,通过硅氧烷进行改性能够提高其复合材料的耐热性。另外,ES对玻璃板的润湿角降低了5°。扫描电镜观察发现,ES树脂断面粗糙而且存在“韧性点”,ES-GF断面的玻璃纤维中粘连树脂较多。

结论通过对树脂浇铸体常温力学性能的测试表明:相对于EP,ES在韧性提高的同时其拉伸强度和弯曲强度并未出现较大幅度的降低,符合基体韧性提高可以导致其复合材料层间断裂韧性提高这一公认观点。热失重数据和DMA数据均表明ES-GF具有较好的热稳定性。ES的玻璃化转变温度提高10℃是对耐热性提高的一个补充。耐热性提高的原因在于ES-GF中存在Si—O,相对于C—C和C—O有更大的键能和键角。根据测试与观察结果,推断ES-GF层间力学性能提高的原因有:①硅氧烷改性环氧树脂引入了具有柔性的Si—O键,ES树脂浇铸体及其复合材料的韧性均有提高。②ES中存在“韧性点”,在ES-GF层间开裂时起到了钉锚作用。③ES与玻璃纤维的浸润性更好,是的其破坏模式由脱粘转变为内聚力破坏。最后总结得出ES-GF层间破坏的模型图。

-

纤维增强环氧树脂基复合材料在航空、航天、船舶以及电子封装等领域扮演着重要的角色,人们希望纤维增强环氧树脂基复合材料在具有更好的力学性能的同时也兼具更佳的环境适用能力(比如耐热和阻燃性能)。聚硅氧烷具有优良的柔韧性和热稳定性、高介电强度、低表面能等特点,在环氧树脂结构中引入具有柔韧性的Si—O键后,可降低固化物内应力从而提高韧性,同时还可以提升体系的热稳定性,聚硅氧烷对环氧树脂的增韧耐热改性成为相关领域的研究热点。

本文通过端羟基聚二甲基硅氧烷与环氧树脂(EP)的缩合反应对纤维增强树脂基复合材料的基体进行改性,采用双悬臂梁和短梁剪切等实验对复合材料的层间力学性能进行测量,通过热失重和动态机械热测试对复合材料的耐热性能进行评价。实验结果表明:硅氧烷改性后复合材料的I型临界应变能释放率(断裂韧性)提升了98.1%,层间剪切强度提升13.3%,层间力学性能的强化归因于Si—O键柔性链段、“韧性点”发挥“钉锚”作用以及纤维/基体界面强化的综合作用,其层间破坏模式由纤维基体脱粘转变为基体内聚破坏。硅氧烷改性后复合材料耐热性能也得到了明显提升,最大热失重速率降低了33.1%,800℃最终残余增加了13.5倍。在Tg之前ES-GF的储能模量比EP-GF提高1.3 GPa,在Tg之后ES-GF的储能模量比EP-GF提高近10.8%,硅氧烷增韧改性并未降低环氧树脂的玻璃化转变温度,甚至略有提高。

Interlaminar failure model of composite, storage modulus of resin and their composites

下载:

下载: