Thermal conductivity and electrical properties of Al2O3-Sn57Bi43/epoxy composites

-

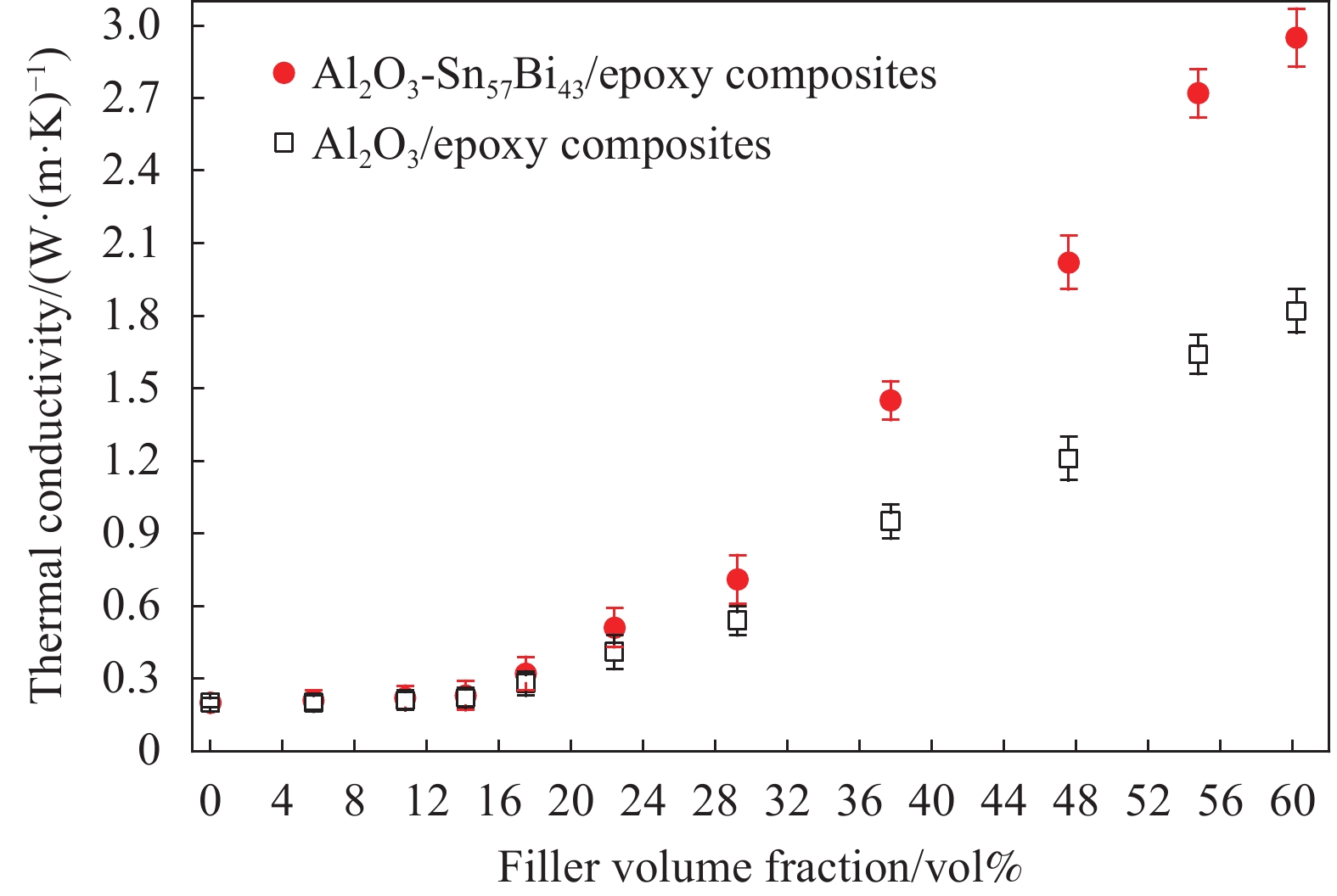

摘要: 在聚合物基体中构建由高导热填料相互连接而成的导热通路是提高复合材料导热性能的有效策略。本文采用共还原法,在Al2O3微球表面沉积低熔点纳米锡铋合金颗粒(Sn57Bi43),制备杂化材料(Al2O3-Sn57Bi43),用于环氧树脂的导热绝缘填料。当环氧树脂受热固化时,Al2O3-Sn57Bi43表面Sn57Bi43纳米颗粒熔融,将填料相互连接而形成有效的导热通路,提高复合体系导热性能。当填料体积含量为60vol%时,Al2O3-Sn57Bi43/环氧树脂复合材料的导热系数为2.95 W·(m·K)−1,比Al2O3/环氧树脂复合材料的导热系数(1.82 W·(m·K)−1)提高了62.1%。Fogyel及Agari模型分析表明,Al2O3表面沉积Sn57Bi43有利于降低填料间接触热阻,形成导热通路。与Al2O3/环氧树脂复合材料相比,Al2O3-Sn57Bi43/环氧树脂复合材料的介质损耗增加,介电强度及体积电阻率降低,但仍具有电绝缘性能。由于填料-基体间界面性能改善及Al2O3-Sn57Bi43形成的网链结构能起到传递应力,阻止裂纹扩张的作用,Al2O3-Sn57Bi43/环氧树脂复合材料的拉伸断裂强度提高。Abstract: Constructing thermal conductive pathways in polymer matrix with interconnected high conductive thermal fillers is an effective strategy to enhance the thermal conductivity of the composites. In this paper, eutectic Sn-Bi alloy (Sn57Bi43) nanoparticles are deposited on the surface of Al2O3 microspheres by coreduction method to prepare Al2O3-Sn57Bi43 hybrids as thermal conductive and electrical insulating fillers for epoxy resin. During the heat curing of epoxy resin, Sn57Bi43 nanoparticles on the Al2O3 surface melt and bridge the separate fillers together to form effective thermal conductive pathway, and thus enhance the thermal conductivity of the composites. When filler volume fraction is 60vol%, the thermal conductivity of Al2O3-Sn57Bi43/epoxy composites is 2.95 W·(m·K)−1, 62.1% higher than that of Al2O3/epoxy composites (1.82 W·(m·K)−1). The results of Fogyel and Agari simulation demonstrate that the deposition of Sn57Bi43 on Al2O3 surface reduces the thermal contact resistance between fillers and forms thermally conductive networks more easily. The Al2O3-Sn57Bi43/epoxy composites exhibit higher dielectric loss, lower dielectric strength and volume resistivity than Al2O3/epoxy composites, still with electrical insulating properties. What is more, the tensile strength of the Al2O3-Sn57Bi43/epoxy composites is improved, because the improved interfacial properties of filler-matrix and the formed networks could transfer stress and prevent crack expansion.

-

Keywords:

- epoxy resin /

- Al2O3 /

- eutectic Sn-Bi alloy /

- hybrid materials /

- thermal conductivity /

- electrical insulation

-

现代电气电子设备趋于向大功率、小体积及高密高频、集成化、微型化方向发展,其直接后果便是在更小的体积内产生了更多的热量,如果这些热量无法及时向外传递,将加速绝缘老化,严重影响设备的运行效率和可靠性,甚至发生故障或事故[1-3]。提高绝缘封装材料的导热性能是解决电气电子设备热管理问题的最有效途径[4-6]。环氧树脂是应用最为广泛的绝缘封装材料之一,但纯环氧树脂的导热系数低(0.20 W·(m·K)−1),极大限制了其在现代电气电子设备中的应用。为了提高环氧树脂材料的导热性能,将高导热绝缘填料,如Al2O3、MgO、ZnO、BN、氮化铝(AlN)等,添加到基体中,获得填充型导热复合材料是一种简单有效的解决方法[7-12]。其中,球形Al2O3因其导热系数较高、成本低、介电性能优良,且在聚合物基体中剪切阻力小、黏度低,而得到广泛应用[13-14]。然而,采用常规共混制备的Al2O3/环氧树脂复合材料,由于填料在基体中随机分布,不易相互连接形成导热通路,复合材料导热系数的提高有限[15-16]。

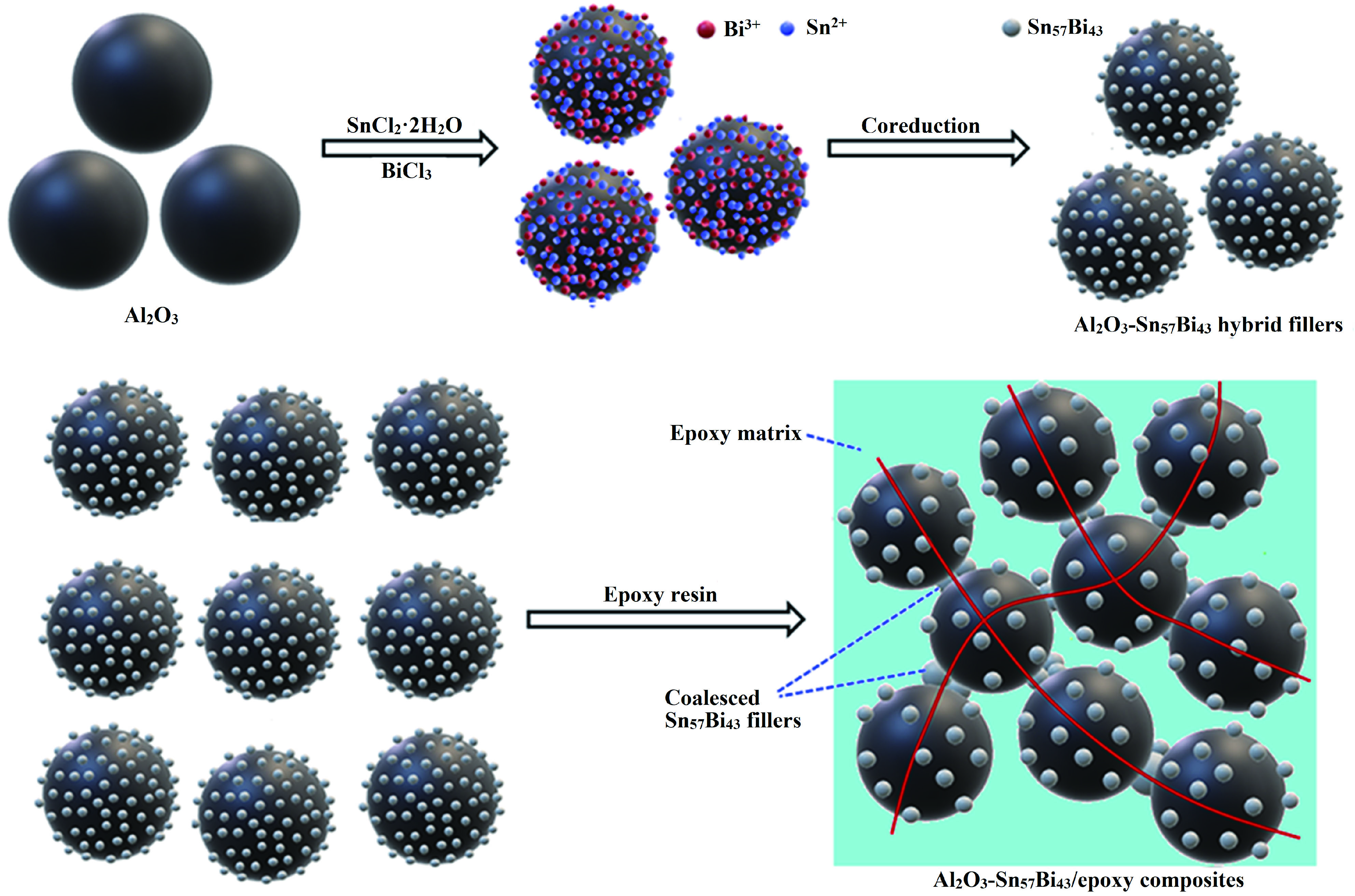

在聚合物基体中构建由高导热填料相互连接而形成的导热通路是提高复合材料导热性能的有效策略。如吴加雪等[17]采用四针状氧化锌晶须(T-ZnOw)和片状氮化硼(BN)混杂填充环氧树脂,使填料间更容易相互搭接形成导热通路。Chen等[18]在氮化硼纳米片(BNNS)表面沉积纳米Ag后与环氧树脂复合,然后经300℃热处理,使纳米Ag熔融烧结而将BNNS相互连接形成导热通路。Yu等[19]在三聚氰胺甲醛海绵表面吸附BNNSs,并进一步经多巴胺修饰后,浸渍BN/环氧树脂,制备叶脉结构的二级可调网络导热通路。Ren等[20]将Al2O3采用偶联剂修饰后,沉积纳米银,然后与环氧树脂复合,利用纳米银颗粒的桥联作用,以促进热传导,降低填料间接触热阻。Hao等[21]及Hu等[22]分别采用双轴压缩和凝胶注模成型,然后高温烧结,预先制备3D多孔结构Al2O3骨架,再真空浸渍环氧树脂,构建3D互联结构导热通路。这些方法通常需要较高的固化或处理温度,且工艺复杂,成本高。本文采用共还原法,在Al2O3微球表面沉积低熔点纳米锡铋合金颗粒(Sn57Bi43),制备Al2O3-Sn57Bi43杂化材料,用于环氧树脂的导热绝缘填料。当环氧树脂受热固化时,填料表面Sn57Bi43颗粒熔融,将填料相互连接而形成有效的导热通路,提高复合材料导热率。同时,由于Sn57Bi43被绝缘性Al2O3及树脂基体隔离,Al2O3-Sn57Bi43/环氧树脂复合材料仍具有电绝缘性能。

1. 实验材料及方法

1.1 原材料

环氧树脂:工业级,牌号CYD-128,环氧值0.51~0.54,岳阳巴陵华兴石化有限公司;594固化剂:β, β'-二甲氨基乙氧基-1, 3, 6, 2-三恶硼杂八环,工业级,无锡钱广化工原料有限公司;球形Al2O3导热绝缘填料:上海瑀锐新材料科技有限公司;BiCl3和SnCl2·2H2O:分析纯,上海麦克林生化科技有限公司;36%~38%的HCl水溶液及KBH4:化学纯,国药集团化学试剂有限公司。

1.2 Al2O3-Sn57Bi43杂化材料的制备

参照文献[23]所述方法制备Al2O3-Sn57Bi43杂化材料。具体过程如下:第一步,将20.53 g (0.091 mol) SnCl2·2H2O、21.44 g (0.068 mol) BiCl3溶于500 mL HCl水溶液;第二步,在氮气保护,冰浴条件下,将78.18 g (1.45 mol) KBH4溶于1000 mL水,然后加入100 g Al2O3;第三步,在氮气保护、冰浴条件下,将第一步所得溶液滴加到第二步所得溶液中,3~4 h滴加完毕,然后继续反应1 h;第四步,离心分离,倒出上层清液,然后再加入适量水、离心分离,如此反复3~4次,以去除未反应的BiCl3、SnCl2·2H2O、HCl等杂质;第五步,将沉淀物经80℃真空干燥24 h,得灰色Al2O3-Sn57Bi43杂化材料。

1.3 Al2O3-Sn57Bi43/环氧树脂复合材料的制备

将环氧树脂和594固化剂按质量比10∶1室温搅拌混合均匀后,加入Al2O3-Sn57Bi43,初步搅拌混合后再将混合物进一步经行星式离心真空混合机混合、脱泡,再将混合物经150℃/4 h固化,即得Al2O3-Sn57Bi43/环氧树脂复合材料。按同样的方法,制备填料体积含量(Vf)相同的Al2O3/环氧树脂复合材料作为对比。计算复合材料的Vf值时,需预先测得基体及填料密度。环氧树脂基体材料(固化后)、Al2O3和Al2O3-Sn57Bi43的密度采用东莞市宏拓仪器有限公司DahoMeter DH-300固液两用比重计,阿基米德法测试,结果分别为1.19 g·cm−3、3.88 g·cm−3和4.36 g·cm−3。图1为Al2O3-Sn57Bi43杂化材料及Al2O3-Sn57Bi43/环氧树脂复合材料的制备过程示意图。

1.4 测试与表征

X-射线光电子能谱(XPS)采用美国Thermo Fisher Scientific公司ESCALAB250Xi,测试条件为铝靶(Kα,hν=1486.6 eV),阴极加速电压14.0 kV,功率250 W,真空度5×10−8 Pa。全谱扫描分辨率1 eV,窄普扫描分辨率0.1 eV。差示扫描量热分析(DSC)采用德国Netzsch204F1,扫描范围30~320℃,升温速率10℃/min。微观形貌观察采用日本JSM-5600LV场发射扫描电子显微镜,喷金后观察。复合材料的热扩散率(α)采用德国Netzsch公司LFA 467HT HyperFlash导热系数测量仪,激光闪射法室温测试,然后通过公式λ=αCpρ求出导热系数(λ)。Cp为材料的比热容,采用DSC蓝宝石法测试;ρ为材料密度,采用阿基米德排水法测试。材料拉伸断裂强度按GB/T 1040.1—2018[24]测试,体积电阻率和介电强度分别按GB/T 1410—2006[25]和GB/T 1408.1—2016[26]。介质损耗按GB/T 1409—2006[27]测试,频率50 Hz。

2. 结果与讨论

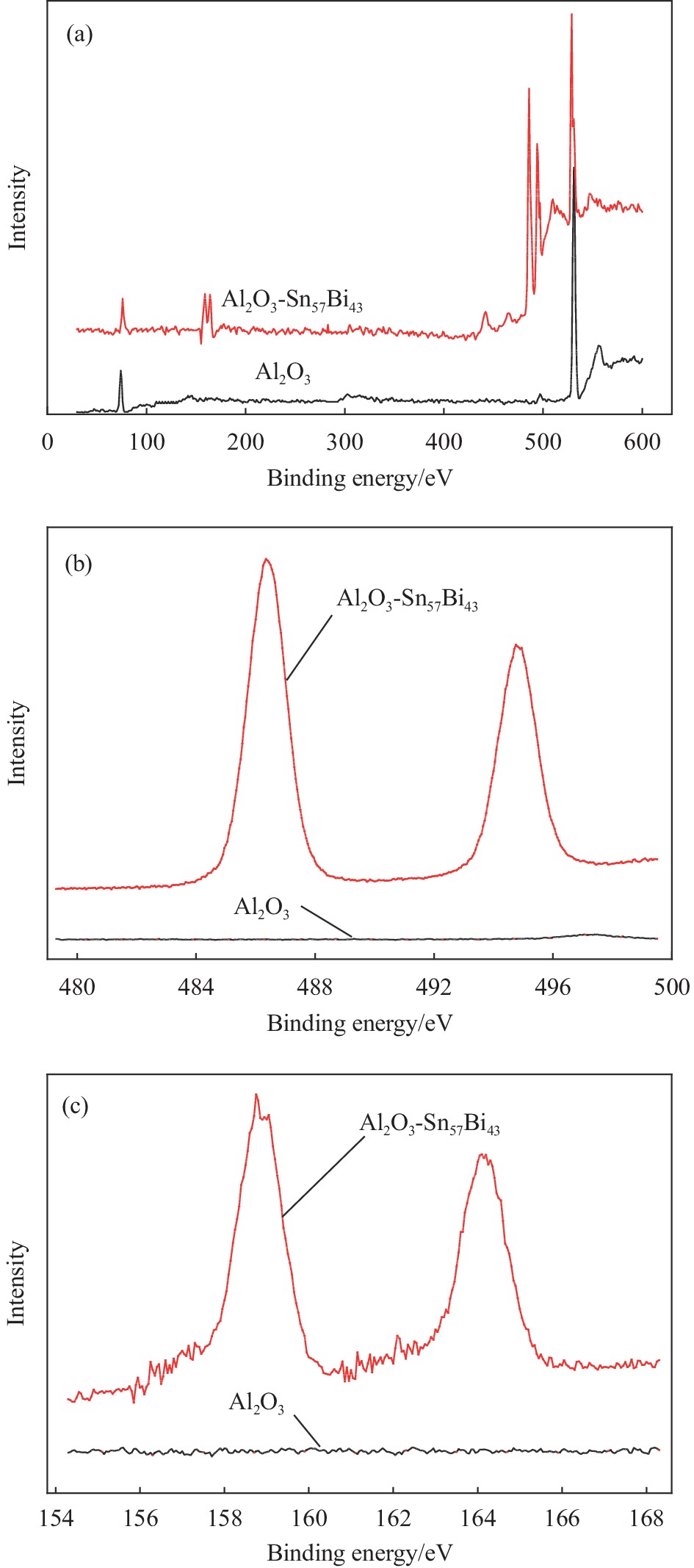

按1.2节所述的Al2O3-Sn57Bi43的制备工艺,由于还原剂过量,Sn2+和Bi3+全部被还原,因此杂化材料中Sn57Bi43的理论含量为20wt%。图2为Al2O3和所制备Al2O3-Sn57Bi43的XPS全谱及Sn3d、Bi4f的高分辨率窄谱。72.9 eV和529.5 eV处分别为Al2p和O1s的峰,与Al2O3相比,Al2O3-Sn57Bi4在484.9 eV和493.3 eV处检测出明显的Sn3d5/2和Sn3d3/2峰,在156.4 eV和161.7 eV处检测出明显的Bi4f7/2和Bi4f5/2峰。由XPS计算得到的样品元素质量含量见表1,与理论结果基本一致。

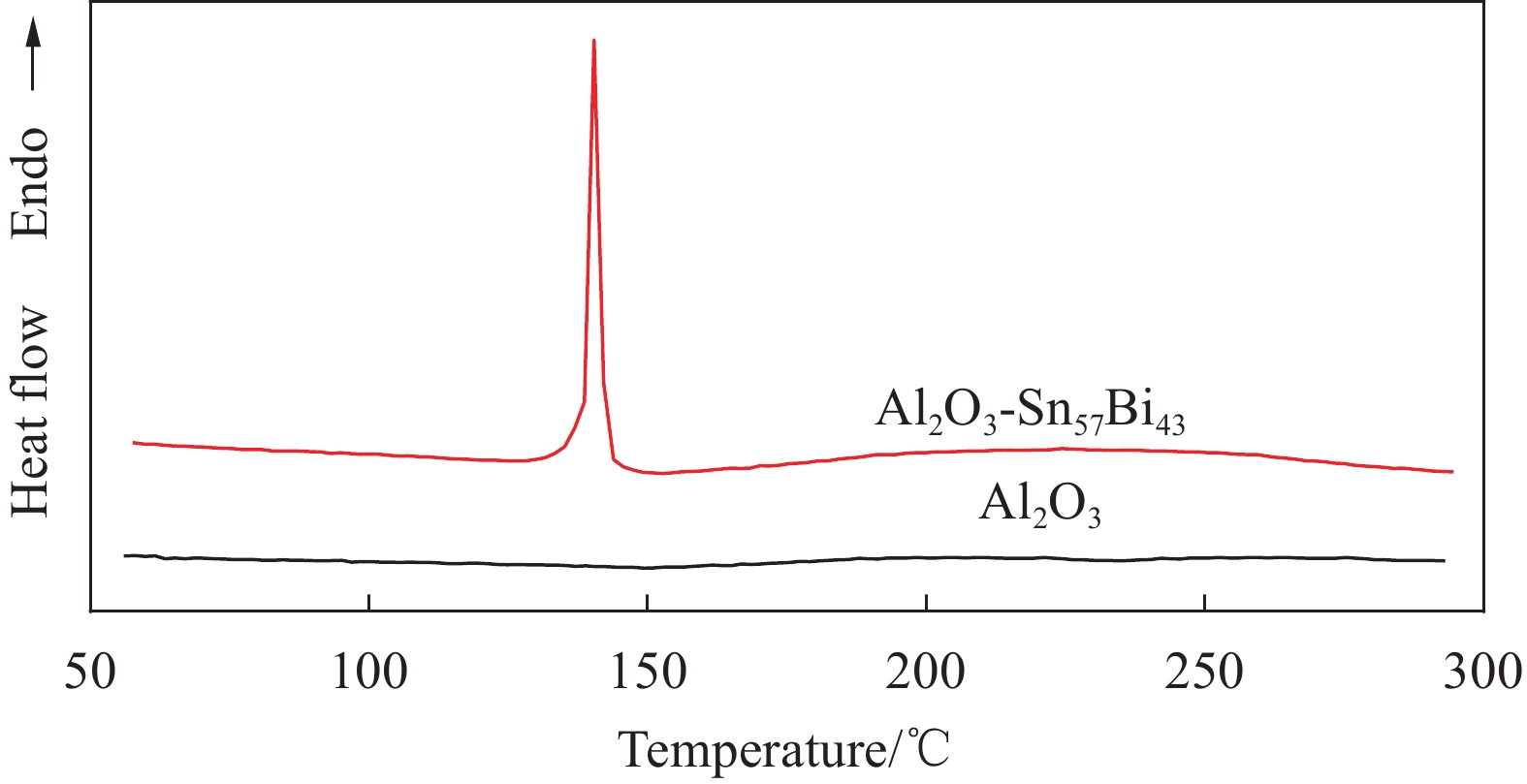

表 1 Al2O3和Al2O3-Sn57Bi43的元素组成Table 1. Element compositions of Al2O3 and Al2O3-Sn57Bi43wt% Sample Al O Sn Bi Al2O3 50.72 47.36 0.00 0.00 Al2O3-Sn57Bi43 40.25 37.98 8.51 11.38 图3为Al2O3和Al2O3-Sn57Bi43的DSC曲线。Al2O3-Sn57Bi43在140.3℃左右出现的峰为低熔点Sn57Bi43合金颗粒的熔融吸收峰[23]。

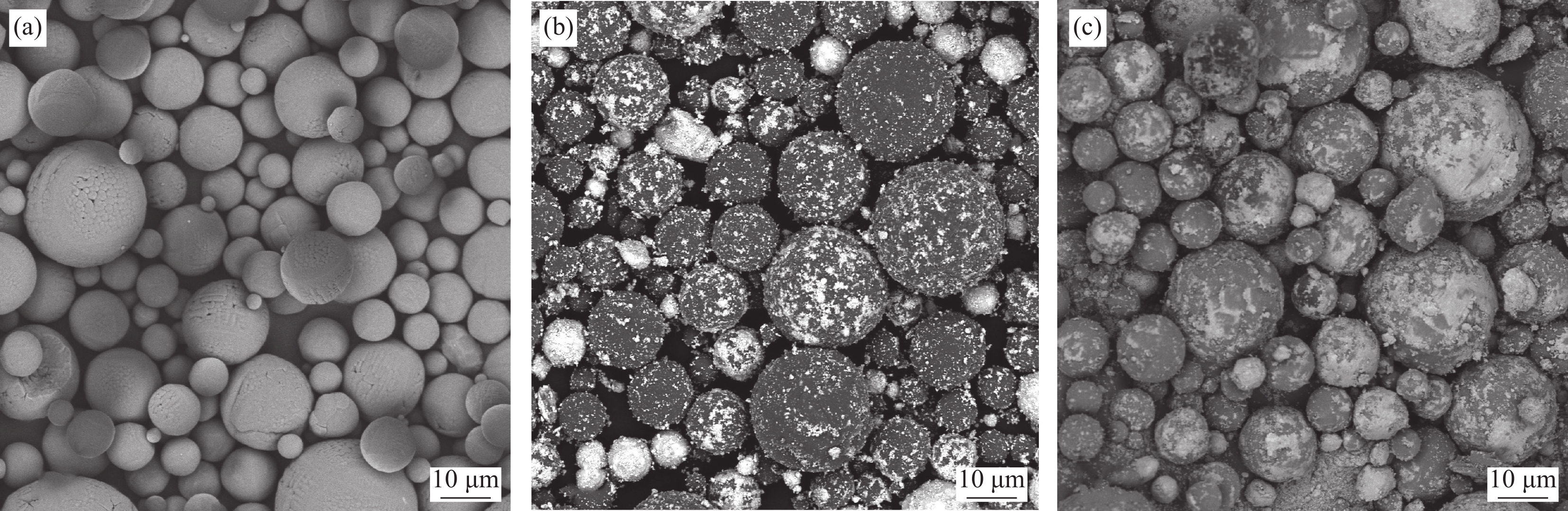

图4为Al2O3和Al2O3-Sn57Bi43杂化材料及经150℃/2 h处理后杂化材料的SEM图像。Al2O3的粒径为5~25 μm,杂化材料表面吸附有Sn57Bi43颗粒,其粒径约100~300 nm,经150℃/2 h处理后的杂化材料表面,Sn57Bi43颗粒发生明显的熔融团聚现象。

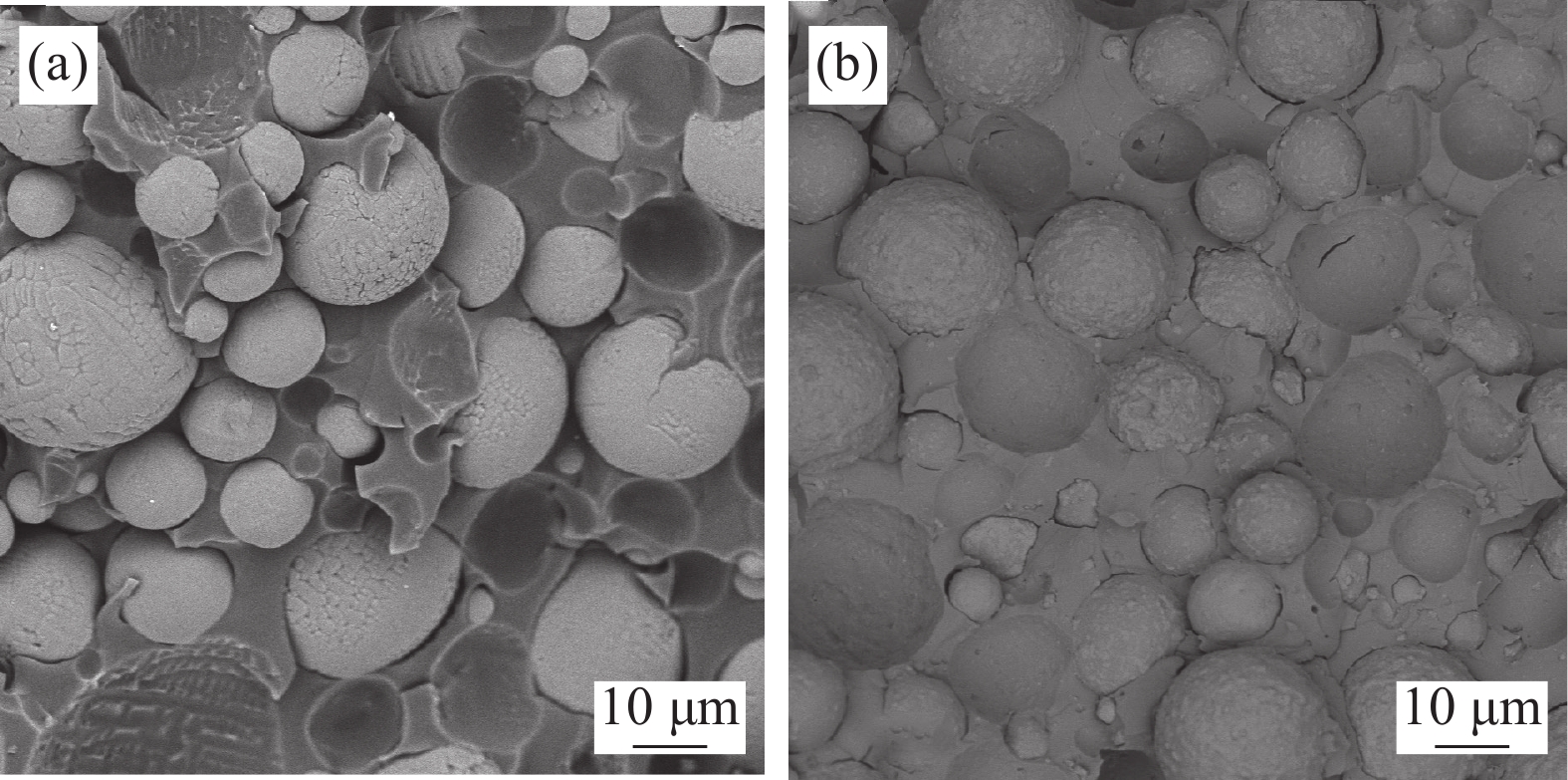

图5为填料体积含量Vf =60vol%的Al2O3/环氧树脂及Al2O3-Sn57Bi43/环氧树脂复合材料横截面的SEM图像。Al2O3/环氧树脂复合材料的填料-基体界面处存在明显空隙。Al2O3-Sn57Bi43/环氧树脂复合材料的填料-基体界面处空隙明显减少,说明界面性能改善。这一方面是由于Al2O3-Sn57Bi43表面的Sn57Bi43纳米颗粒使填料的粗糙度及比表面积增大,另一方面是由于Al2O3-Sn57Bi43杂化填料表面熔融而提高了环氧树脂基体对填料的浸润性。Al2O3-Sn57Bi43/环氧树脂复合材料界面性能的改善不仅可以降低基体-填料间界面热阻,提高材料导热系数,而且可以提高材料的力学性能。

表2为不同填料体积含量的Al2O3/环氧树脂和Al2O3-Sn57Bi43/环氧树脂复合材料的密度、比热容及热扩散系数。随着填料含量的增加,复合材料的密度及扩散系数增加,比热容下降。由材料的密度、比热容及热扩散系数,可计算出导热系数。

表 2 Al2O3/环氧树脂和Al2O3-Sn57Bi43/环氧树脂复合材料的密度、比热容及热扩散系数Table 2. Density, specific heat capacity and thermal diffusion coefficient of Al2O3/epoxy and Al2O3-Sn57Bi43/epoxy compositesVf/% Al2O3/epoxy Al2O3-Sn57Bi43/epoxy Density/

(kg·m−3)Specific heat

capacity/[J·(kg·K)−1]Thermal diffusion

coefficients/(m2·s−1)Density/

(kg·m−3)Specific heat

capacity/[J·(kg·K)−1]Thermal diffusion

coefficients/(m2·s−1)0 1.19×103 1106.43 1.52×10−7 1.19×103 1106.43 1.52×10−7 6 1.35×103 1045.03 1.42×10−7 1.38×103 1016.70 1.50×10−7 11 1.49×103 1004.05 1.41×10−7 1.54×103 958.87 1.49×10−7 14 1.57×103 982.84 1.43×10−7 1.63×103 929.55 1.51×10−7 17 1.65×103 963.71 1.76×10−7 1.73×103 903.46 2.05×10−7 22 1.78×103 935.68 2.46×10−7 1.89×103 865.83 3.12×10−7 29 1.97×103 902.86 3.04×10−7 2.11×103 822.64 4.09×10−7 38 2.21×103 868.87 4.94×10−7 2.39×103 778.87 7.77×10−7 48 2.48×103 838.89 5.81×10−7 2.71×103 741.04 10.05×10−7 55 2.67×103 821.50 7.48×10−7 2.93×103 719.42 12.90×10−7 60 2.80×103 810.51 8.03×10−7 3.09×103 705.88 13.51×10−7 图6为填料体积含量(Vf)对Al2O3/环氧树脂及Al2O3-Sn57Bi43/环氧树脂复合材料导热系数的影响。当Vf 较低时,随Vf增加,复合材料导热系数的增加非常缓慢。这是由于当Vf较低时,填料呈“孤岛”状分布在基体中,相互之间基本无接触,不能形成导热通路。当Vf增加到某一程度,填料间相互接触的概率增加,导热通路亦开始形成,这时随Vf增加,材料导热系数明显增加。该Vf值(约20vol%)即为填料的临界体积含量(Vc)。在Vf相等条件下,Al2O3-Sn57Bi43/环氧树脂复合材料的导热系数明显大于Al2O3/环氧树脂复合材料的导热系数。当Vf =60vol%时,Al2O3-Sn57Bi43/环氧树脂复合材料的导热系数为2.95 W·(m·K)−1,比Al2O3/环氧树脂复合材料的导热系数(1.82 W·(m·K)−1)提高了62.1%。

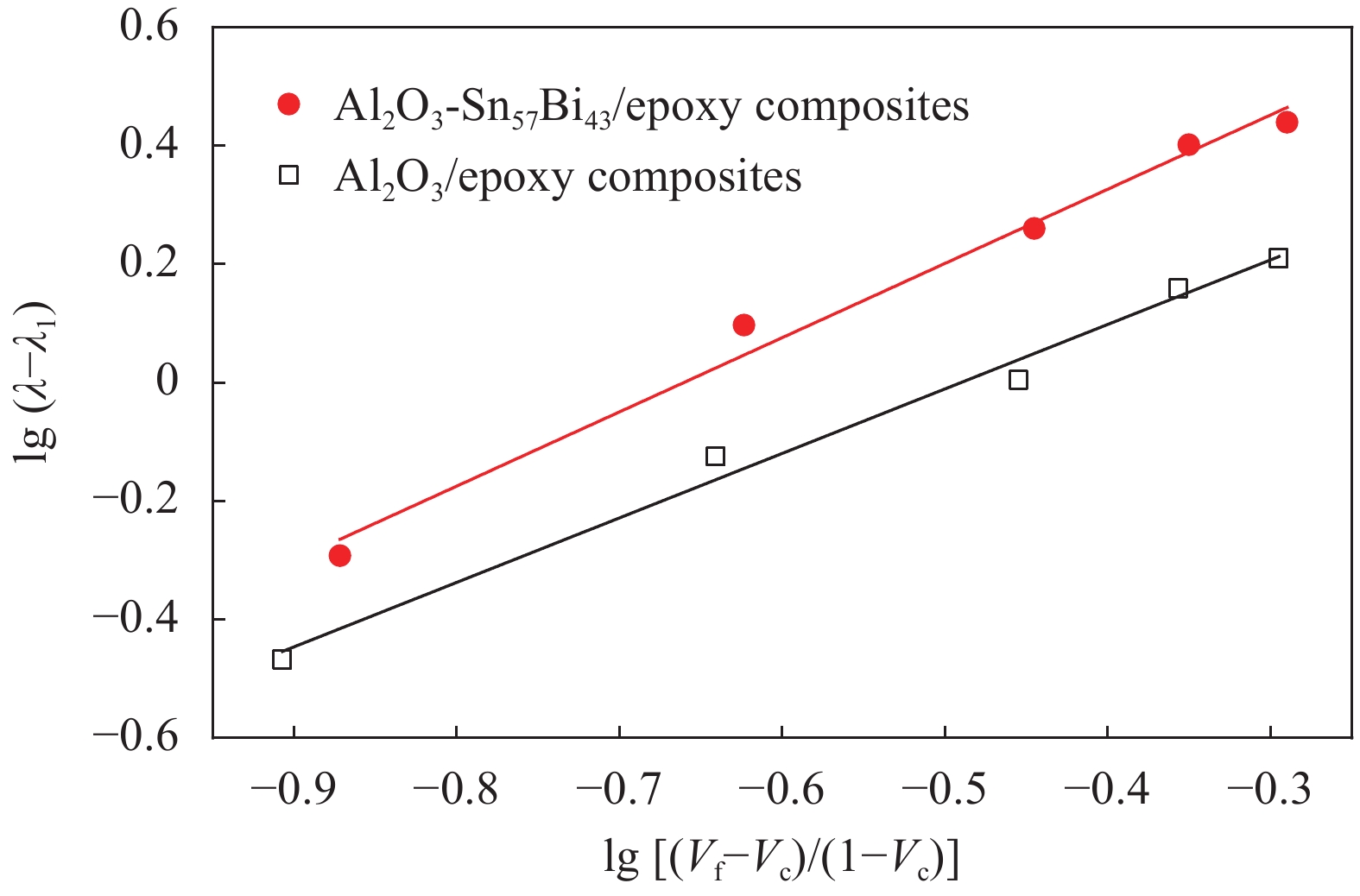

采用非线性Foygel模型考察Al2O3表面沉积Sn57Bi43对填料间接触热阻(Rc)的影响,其公式如下[28-29]:

λ−λ1=λ0(Vf−Vc1−Vc)β (1) 式中:λ、λ1分别为复合材料、聚合物基体的导热系数;λ0为指前因子;Vf为填料体积含量;Vc为填料的临界体积含量,超过该值,填料间开始发生接触,形成导热通路,材料导热系数明显增加;β为与导热系数有关的幂指数。

由图6可知,Vc约为20%,小于或大于该值,两种材料的λ-Vf均呈良好的线性相关。将Vf大于或小于20%时的λ-Vf分别进行线性拟合,两直线的交点所对应的Vf值即为Vc,结果见表3。将式(1)取对数,得如下公式:

表 3 Al2O3/环氧树脂和Al2O3-Sn57Bi43/环氧树脂复合材料导热系数的非线性Foygel模拟结果Table 3. Simulation results of nonlinear Foygel model for the thermal conductivity of Al2O3/epoxy and Al2O3-Sn57Bi43/epoxy compositesSample Vc/% λ0/(W·(m·K)−1) β Rc/(K·W−1) Al2O3 19.23 3.42 1.088 1.17×105 Al2O3-Sn57Bi43 18.25 6.73 1.253 8.35×104 Notes: Vc—Critical volume fraction of filler; λ0—Pre-exponential factor; β—Conductivity exponent that depends on the aspect of filler; Rc—Interface thermal resistance. lg(λ−λ1)=lgλ0+βlg(Vf−Vc1−Vc) (2) 图7为式(2)的线性拟合结果,与实验结果基本一致。由图7可以得到λ0、β,根据下式:

Rc=1λ0LVβc (3) 可以得到复合材料中填料间接触热阻Rc,L为填料直径,取平均值15 μm。表3为两种复合材料导热系数的模拟分析结果。Al2O3-Sn57Bi43/环氧树脂复合材料的Rc=8.35×104 K·W−1,明显小于Al2O3/环氧树脂复合材料的Rc=1.17×105 K·W−1。

基于热传导的串并联模型,并考虑到填料间发生相互接触对填充型复合材料导热系数的影响,Agari等[30]提出了如下公式:

lgλ=Vf[C2lgλ2−lg(C1λ1)]+lg(C1λ1) (4) 式中:λ2为填料的导热系数;C1表示影响聚合物结晶度和结晶尺寸的因子;C2表示填料形成导热链难易程度的因子,C2值越大,表示填料越容易相互聚集形成导热通路。

图8为复合材料的lgλ-Vf关系曲线。可知,在低Vf(<20vol%)时,两种复合材料的lgλ-Vf关系曲线的线性程度较差,而在高Vf时,两种复合材料的lgλ-Vf关系曲线呈良好的线性相关。这是由于在低填充量下,填料呈“孤岛”状分布在基体中,相互接触形成导热链的概率极低,此时,填料-基体间界面热阻对材料导热性能的影响较大,但在公式中未能体现该因素的影响,因此,lgλ-Vf关系曲线的线性程度较差。在高Vf时,填料相互接触概率增大,此时,填料间相互连接形成导热通路的难易程度对材料导热性能影响也随之变大,因此,lgλ-Vf关系曲线的线性程度较好。

![]() 图 7 Al2O3/环氧树脂和Al2O3-Sn57Bi43/环氧树脂复合材料的lg(λ-λ1)-lg[(Vf-Vc)/(1-Vc)]曲线λ1 and λ2—Thermal conductivity of polymer and fillers respectively; Vf—Volume fraction of fillers; Vc—Critical volume fraction of fillersFigure 7. lg(λ-λ1)-lg[(Vf-Vc)/(1-Vc)] curves of Al2O3/epoxy and Al2O3-Sn57Bi43/epoxy composites

图 7 Al2O3/环氧树脂和Al2O3-Sn57Bi43/环氧树脂复合材料的lg(λ-λ1)-lg[(Vf-Vc)/(1-Vc)]曲线λ1 and λ2—Thermal conductivity of polymer and fillers respectively; Vf—Volume fraction of fillers; Vc—Critical volume fraction of fillersFigure 7. lg(λ-λ1)-lg[(Vf-Vc)/(1-Vc)] curves of Al2O3/epoxy and Al2O3-Sn57Bi43/epoxy composites表4为两种复合材料的C1和C2模拟结果。Al2O3/环氧树脂及Al2O3-Sn57Bi43/环氧树脂复合材料的C1值非常接近。这是由于环氧树脂是交联型非结晶材料,加入填料后对环氧树脂的聚集态结构无实质性影响。Al2O3-Sn57Bi43/环氧树脂复合材料的C2值明显大于Al2O3/环氧树脂复合材料的C2值,说明Al2O3-Sn57Bi43比Al2O3更容易在环氧基体中相互连接形成导热链。这可能是由于Al2O3-Sn57Bi43表面Sn57Bi43熔融而将填料相互连接的缘故。

表 4 Al2O3/环氧树脂和Al2O3-Sn57Bi43/环氧树脂复合材料导热系数的Agari模拟结果Table 4. Agari simulation results for the thermal conductivity of Al2O3/epoxy and Al2O3-Sn57Bi43/epoxy compositesSample C1 C2 Al2O3 0.7661 0.8991 Al2O3-Sn57Bi43 0.7495 1.1465 Notes: C1—Factor affecting crystallinity and crystal size of polymer; C2—Factor of ease in forming conductive chains of fillers. 表5为填料体积含量Vf对Al2O3/环氧树脂和Al2O3-Sn57Bi43/环氧树脂复合材料拉伸性能的影响。随Vf增加,Al2O3/环氧树脂复合材料的拉伸断裂强度及断裂伸长率均下降,这是由于填料与基体的界面性能差。随Vf增加,Al2O3-Sn57Bi43/环氧树脂复合材料的拉伸断裂强度及断裂伸长率提高,这是由于填料-基体间界面性能改善及Al2O3-Sn57Bi43形成的网链结构能起到传递应力,阻止裂纹扩张的作用。

表6为填料体积含量对Al2O3/环氧树脂和Al2O3-Sn57Bi43/环氧树脂复合材料电性能的影响。Al2O3/环氧树脂复合材料的体积电阻率、介质损耗角正切(tanδ)和介电强度和分别为1013 Ω·m、10−3和25 MV·m−1左右,基本不受Vf的影响。随Vf增加,Al2O3-Sn57Bi43/环氧树脂复合材料的tanδ增加,介电强度和体积电阻率下降。这可能是由于复合材料中的Sn57Bi43金属导体导致漏导损耗和极化损耗的原因。当Vf =60vol%时,Al2O3-Sn57Bi43/环氧树脂复合材料的体积电阻率为8.6×1011 Ω·m,仍具有电绝缘性(体积电阻率≥1011 Ω·m)。通常,在导电粒子填充树脂基复合材料中,当粒子之间开始相互接触,形成逾渗网络时,体系的电阻率将急剧下降,甚至由绝缘体向半导体或导体转变。在本文中,Sn57Bi43的含量很低,不足以形成导电逾渗网络。另外,电绝缘性基体及Al2O3产生的隧穿势垒也阻碍了电子传递。

表 5 填料体积含量对Al2O3/环氧树脂和Al2O3-Sn57Bi43/环氧树脂复合材料拉伸断裂强度的影响Table 5. Effects of filler volume fraction on tensile properties of Al2O3/epoxy and Al2O3-Sn57Bi43/epoxy compositesVf/vol% Al2O3/epoxy Al2O3-Sn57Bi43/epoxy Tensile strength/MPa Elongation at break/% Tensile strength/MPa Elongation at break/% 0 44.56±1.83 4.47±0.17 44.56±1.83 4.47±0.17 20 40.31±1.20 4.06±0.14 46.84±2.04 4.75±0.21 40 37.41±1.15 3.54±0.15 49.65±2.16 5.09±0.19 60 32.28±1.09 3.21±0.11 51.62±2.62 5.36±0.24 表 6 填料体积含量对Al2O3/环氧树脂和Al2O3-Sn57Bi43/环氧树脂复合材料电性能的影响Table 6. Effects of filler volume fraction on electric properties of Al2O3/epoxy and Al2O3-Sn57Bi43/epoxy compositesVf/vol% Al2O3/epoxy Al2O3-Sn57Bi43/epoxy Volume resistivity/

(1013 Ω·m)Dielectric strength/

(MV·m−1)Dielectric loss tanδ/

10−3Volume resistivity/

(1013 Ω·m)Dielectric strength/

(MV·m−1)Dielectric loss tanδ/

10−30 2.67±0.68 25.8±1.6 4.75±0.08 2.670±0.680 25.8±1.6 4.75±0.08 20 2.79±0.51 25.2±2.1 3.98±0.06 0.921±0.106 22.1±1.4 11.02±0.22 40 2.81±0.62 24.5±1.9 5.22±0.07 0.264±0.096 19.6±1.2 15.46±0.97 60 2.87±0.75 24.3±1.3 4.75±0.07 0.086±0.034 18.5±1.3 19.43±1.46 3. 结 论

(1) 采用共还原法,在Al2O3表面沉积低熔点纳米锡铋合金颗粒(Sn57Bi43),制备了杂化材料(Al2O3-Sn57Bi43),用于环氧树脂的导热绝缘填料。当环氧树脂受热固化时,Al2O3-Sn57Bi43表面Sn57Bi43熔融,将填料相互连接而形成有效的导热通路,提高复合体系导热性能。当填料体积含量为60vol%时,Al2O3-Sn57Bi43/环氧树脂复合材料的导热系数为2.95 W·(m·K)−1,比Al2O3/环氧树脂复合材料的导热系数(1.82 W·(m·K)−1)提高了62.1%。

(2) Fogyel模型分析表明,Al2O3-Sn57Bi43/环氧树脂复合材料的填料间接触热阻(Rc)为8.35×104 K·W−1,明显小于Al2O3/环氧树脂复合材料的Rc=1.17×105 K·W−1;Agari模型分析表明,Al2O3-Sn57Bi43比Al2O3更容易在环氧树脂基体中相互连接形成导热链。

(3) 随填料体积含量增加,Al2O3/环氧树脂复合材料的拉伸断裂强度及拉伸断裂伸长率下降,而Al2O3-Sn57Bi43/环氧树脂复合材料的拉伸断裂强度及拉伸断裂伸长率提高。与Al2O3/环氧树脂复合材料相比,Al2O3-Sn57Bi43/环氧树脂复合材料的介质损耗增加,介电强度和体积电阻率下降。当填料体积含量为60vol%时,Al2O3-Sn57Bi43/环氧树脂复合材料的体积电阻率为1011 Ω·m,低于Al2O3/环氧树脂复合材料的体积电阻率(1013 Ω·m),但仍具有电绝缘性能。

-

图 7 Al2O3/环氧树脂和Al2O3-Sn57Bi43/环氧树脂复合材料的lg(λ-λ1)-lg[(Vf-Vc)/(1-Vc)]曲线

λ1 and λ2—Thermal conductivity of polymer and fillers respectively; Vf—Volume fraction of fillers; Vc—Critical volume fraction of fillers

Figure 7. lg(λ-λ1)-lg[(Vf-Vc)/(1-Vc)] curves of Al2O3/epoxy and Al2O3-Sn57Bi43/epoxy composites

表 1 Al2O3和Al2O3-Sn57Bi43的元素组成

Table 1 Element compositions of Al2O3 and Al2O3-Sn57Bi43

wt% Sample Al O Sn Bi Al2O3 50.72 47.36 0.00 0.00 Al2O3-Sn57Bi43 40.25 37.98 8.51 11.38 表 2 Al2O3/环氧树脂和Al2O3-Sn57Bi43/环氧树脂复合材料的密度、比热容及热扩散系数

Table 2 Density, specific heat capacity and thermal diffusion coefficient of Al2O3/epoxy and Al2O3-Sn57Bi43/epoxy composites

Vf/% Al2O3/epoxy Al2O3-Sn57Bi43/epoxy Density/

(kg·m−3)Specific heat

capacity/[J·(kg·K)−1]Thermal diffusion

coefficients/(m2·s−1)Density/

(kg·m−3)Specific heat

capacity/[J·(kg·K)−1]Thermal diffusion

coefficients/(m2·s−1)0 1.19×103 1106.43 1.52×10−7 1.19×103 1106.43 1.52×10−7 6 1.35×103 1045.03 1.42×10−7 1.38×103 1016.70 1.50×10−7 11 1.49×103 1004.05 1.41×10−7 1.54×103 958.87 1.49×10−7 14 1.57×103 982.84 1.43×10−7 1.63×103 929.55 1.51×10−7 17 1.65×103 963.71 1.76×10−7 1.73×103 903.46 2.05×10−7 22 1.78×103 935.68 2.46×10−7 1.89×103 865.83 3.12×10−7 29 1.97×103 902.86 3.04×10−7 2.11×103 822.64 4.09×10−7 38 2.21×103 868.87 4.94×10−7 2.39×103 778.87 7.77×10−7 48 2.48×103 838.89 5.81×10−7 2.71×103 741.04 10.05×10−7 55 2.67×103 821.50 7.48×10−7 2.93×103 719.42 12.90×10−7 60 2.80×103 810.51 8.03×10−7 3.09×103 705.88 13.51×10−7 表 3 Al2O3/环氧树脂和Al2O3-Sn57Bi43/环氧树脂复合材料导热系数的非线性Foygel模拟结果

Table 3 Simulation results of nonlinear Foygel model for the thermal conductivity of Al2O3/epoxy and Al2O3-Sn57Bi43/epoxy composites

Sample Vc/% λ0/(W·(m·K)−1) β Rc/(K·W−1) Al2O3 19.23 3.42 1.088 1.17×105 Al2O3-Sn57Bi43 18.25 6.73 1.253 8.35×104 Notes: Vc—Critical volume fraction of filler; λ0—Pre-exponential factor; β—Conductivity exponent that depends on the aspect of filler; Rc—Interface thermal resistance. 表 4 Al2O3/环氧树脂和Al2O3-Sn57Bi43/环氧树脂复合材料导热系数的Agari模拟结果

Table 4 Agari simulation results for the thermal conductivity of Al2O3/epoxy and Al2O3-Sn57Bi43/epoxy composites

Sample C1 C2 Al2O3 0.7661 0.8991 Al2O3-Sn57Bi43 0.7495 1.1465 Notes: C1—Factor affecting crystallinity and crystal size of polymer; C2—Factor of ease in forming conductive chains of fillers. 表 5 填料体积含量对Al2O3/环氧树脂和Al2O3-Sn57Bi43/环氧树脂复合材料拉伸断裂强度的影响

Table 5 Effects of filler volume fraction on tensile properties of Al2O3/epoxy and Al2O3-Sn57Bi43/epoxy composites

Vf/vol% Al2O3/epoxy Al2O3-Sn57Bi43/epoxy Tensile strength/MPa Elongation at break/% Tensile strength/MPa Elongation at break/% 0 44.56±1.83 4.47±0.17 44.56±1.83 4.47±0.17 20 40.31±1.20 4.06±0.14 46.84±2.04 4.75±0.21 40 37.41±1.15 3.54±0.15 49.65±2.16 5.09±0.19 60 32.28±1.09 3.21±0.11 51.62±2.62 5.36±0.24 表 6 填料体积含量对Al2O3/环氧树脂和Al2O3-Sn57Bi43/环氧树脂复合材料电性能的影响

Table 6 Effects of filler volume fraction on electric properties of Al2O3/epoxy and Al2O3-Sn57Bi43/epoxy composites

Vf/vol% Al2O3/epoxy Al2O3-Sn57Bi43/epoxy Volume resistivity/

(1013 Ω·m)Dielectric strength/

(MV·m−1)Dielectric loss tanδ/

10−3Volume resistivity/

(1013 Ω·m)Dielectric strength/

(MV·m−1)Dielectric loss tanδ/

10−30 2.67±0.68 25.8±1.6 4.75±0.08 2.670±0.680 25.8±1.6 4.75±0.08 20 2.79±0.51 25.2±2.1 3.98±0.06 0.921±0.106 22.1±1.4 11.02±0.22 40 2.81±0.62 24.5±1.9 5.22±0.07 0.264±0.096 19.6±1.2 15.46±0.97 60 2.87±0.75 24.3±1.3 4.75±0.07 0.086±0.034 18.5±1.3 19.43±1.46 -

[1] LI Q, CHEN L, GADINSKI M R, et al. Flexible high-temperature dielectric materials from polymer nanocomposites[J]. Nature,2015,523(7562):576-579. DOI: 10.1038/nature14647

[2] HARUKI M, TANAKA K. Controlling thermal conductivities and electrical insulation properties of carbon nanofiber/polyimide composites using surface coating techniques[J]. Polymer Composites,2020,41(8):2990-2997. DOI: 10.1002/pc.25591

[3] LIU J C, GUO Y F, WENG C X, et al. High thermal conductive epoxy based composites fabricated by multi-material direct ink writing[J]. Composites Part A: Applied Science and Manufacturing,2020,129:105684. DOI: 10.1016/j.compositesa.2019.105684

[4] CHEN J, HUANG X Y, SUN B, et al. Highly thermally conductive yet electrically insulating polymer/boron nitride nanosheets nanocomposite films for improved thermal management capability[J]. ACS Nano,2019,13(1):337-345. DOI: 10.1021/acsnano.8b06290

[5] CHEN J, HUANG X Y, ZHU Y K, et al. Cellulose nanofiber supported 3D interconnected BN nanosheets for epoxy nanocomposites with ultrahigh thermal management capability[J]. Advanced Functional Materials,2017,27(5):1604754. DOI: 10.1002/adfm.201604754

[6] CAMILLERI R, HOWEY D A, MCCULLOCH M D. Predicting the temperature and flow distribution in a direct oil-cooled electrical machine with segmented stator[J]. IEEE Transactions on Industrial Electronics,2016,63(1):82-91. DOI: 10.1109/TIE.2015.2465902

[7] OUYANG Y G, DING F, BAI L Y, et al. Design of network Al2O3 spheres for significantly enhanced thermal conduc-tivity of polymer composites[J]. Composites Part A: Applied Science and Manufacturing,2020,128:105673. DOI: 10.1016/j.compositesa.2019.105673

[8] AKHTAR M W, KIM J S, MEMON M A, et al. Surface modification of magnesium oxide/epoxy composites with signifi-cantly improved mechanical and thermal properties[J]. Journal of Materials Science: Materials in Electronics,2021,32(11):15307-15316. DOI: 10.1007/s10854-021-06080-5

[9] 吴宇明, 虞锦洪, 曹勇, 等. 高导热低填量聚合物基复合材料研究进展[J]. 复合材料学报, 2018, 35(4):760-766. DOI: 10.13801/j.cnki.fhclxb.20170607.001 WU Yuming, YU Jinhong, CAO Yong, et al. Review of polymer-based composites with high thermal conductivity and low filler loading[J]. Acta Materiae Compositae Sinica,2018,35(4):760-766(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20170607.001

[10] 高利达, 李祥, 张效重, 等. 六方氮化硼-立方氮化硼/环氧树脂复合材料的制备与热物性能[J]. 复合材料学报, 2022, 39(6):2599-2606. DOI: 10.13801/j.cnki.fhclxb.20210819.005 GAO Lida, LI Xiang, ZHANG Xiaochong, et al. Preparation and thermophysical properties of hexagonal boron nitride-cubic boron nitride/epoxy composites[J]. Acta Materiae Compositae Sinica,2022,39(6):2599-2606(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20210819.005

[11] HUTCHINSON J M, MORADI S. Thermal conductivity and cure kinetics of epoxy-boron nitride composites-A review[J]. Materials, 2020, 13(16): 3634

[12] WEI Z L, XIE W Q, GE B Z, et al. Enhanced thermal conductivity of epoxy composites by constructing aluminum nitride honeycomb reinforcements[J]. Composites Science and Technology,2020,199:108304. DOI: 10.1016/j.compscitech.2020.108304

[13] 周文英, 丁小卫. 导热高分子材料[M]. 北京: 国防工业出版社, 2014: 187-188. ZHOU Wenying, DING Xiaowei. Thermal conductive polymer materials[M]. Beijing: National Defense Industry Press, 2014: 187-188.

[14] LEE W, WIE J, KIM J. Enhancement of thermal conducti-vity of alumina/epoxy composite using poly(glycidyl methacrylate) grafting and crosslinking[J]. Ceramics International,2021,47(13):18662-18668. DOI: 10.1016/j.ceramint.2021.03.198

[15] WANG W, YANG L Y, ZHENG M M, et al. Enhanced thermal conductivity of epoxy composites via bridged Al2O3 network with in situ formed silver nanoparticles[J]. Polymer Composites,2022,43(1):330-338. DOI: 10.1002/pc.26377

[16] PAN Z H, LIU Y H, WANG F, et al. Al2O3 dispersion-induced micropapillae in an epoxy composite coating and implications in thermal conductivity[J]. ACS Omega,2021,6(28):17870-17879. DOI: 10.1021/acsomega.1c01282

[17] 吴加雪, 唐超, 张天栋, 等. 氮化硼和氧化锌晶须共掺杂环氧树脂复合材料的导热与绝缘性能[J]. 复合材料学报, 2022, 39(5):2183-2191. DOI: 10.13801/j.cnki.fhclxb.20210903.003 WU Jiaxue, TANG Chao, ZHANG Tiandong, et al. Thermal conductivity and electrical insulating properties of epoxy composites mixed with boron nitride and zinc oxide whisker[J]. Acta Materiae Compositae Sinica,2022,39(5):2183-2191(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20210903.003

[18] CHEN C, XUE Y, LI Z, et al. Construction of 3D boron nitride nanosheets/silver networks in epoxy-based composites with high thermal conductivity via in-situ sintering of silver nanoparticles[J]. Chemical Engineering Journal,2019,369:1150-1160. DOI: 10.1016/j.cej.2019.03.150

[19] YU H T, GUO P L, QIN M M, et al. Highly thermally conductive polymer composite enhanced by two-level adjustable boron nitride network with leaf venation structure[J]. Composites Science and Technology,2022,222:109406. DOI: 10.1016/j.compscitech.2022.109406

[20] REN L L, LI Q, LU J B, et al. Enhanced thermal conductivity for Ag-deposited alumina sphere/epoxy resin composites through manipulating interfacial thermal resistance[J]. Composites Part A: Applied Science and Manufacturing,2018,107:561-569. DOI: 10.1016/j.compositesa.2018.02.010

[21] HAO L C, LI Z X, SUN F, et al. High-performance epoxy composites reinforced with three-dimensional Al2O3 ceramic framework[J]. Composites Part A: Applied Science and Manufacturing,2019,127:105648. DOI: 10.1016/j.compositesa.2019.105648

[22] HU Y, DU G P, CHEN N. A novel approach for Al2O3/epoxy composites with high strength and thermal conductivity[J]. Composites Science and Technology,2016,124:36-43. DOI: 10.1016/j.compscitech.2016.01.010

[23] FRONGIA F, PILLONI M, SCANO A, et al. Synthesis and melting behaviour of Bi, Sn and Sn-Bi nanostructured alloy[J]. Journal of Alloys and Compounds,2015,623:7-14. DOI: 10.1016/j.jallcom.2014.08.122

[24] 中国国家标准化管理委员会. 塑料-拉伸性能的测定: GB/T 1040.1—2018[S]. 北京: 中国标准出版社, 2018. Standardization Administration of the People's Republic of China. Plastics-Determination of tensile properties: GB/T 1040.1—2018[S]. Beijing: China Standards Press, 2018(in Chinese).

[25] 中国国家标准化管理委员会. 固体绝缘材料体积电阻率和表面电阻率试验方法: GB/T 1410—2006[S]. 北京: 中国标准出版社, 2006. Standardization Administration of the People's Republic of China. Methods of test for volume resistivity and surface resistivity of solid electrical insulating materials: GB/T 1410—2006[S]. Beijing: China Standards Press, 2006(in Chinese).

[26] 中国国家标准化管理委员会. 绝缘材料电气强度试验方法 第1部分: 工频下试验: GB/T 1408.1—2016[S]. 北京: 中国标准出版社, 2016. Standardization Administration of the People's Republic of China. Insulating materials: Test methods for electric strength Part 1: Test at power frequencies: GB/T 1408.1—2016[S]. Beijing: China Standards Press, 2016(in Chinese).

[27] 中国国家标准化管理委员会. 测量电气绝缘材料在工频、音频、高频(包括米波波长在内)下电容率和介质损耗因数的推荐方法: GB/T 1409—2006[S]. 北京: 中国标准出版社, 2006. Standardization Administration of the People's Republic of China. Recommended methods for the determination of the permittivity and dielectric dissipation factor of electrical insulating materials at power, audio and radio frequencies including meter wavelengths: GB/T 1409—2006[S]. Beijing: China Standards Press, 2006(in Chinese).

[28] 王绪彬, 张昌海, 张天栋, 等. 三维多孔氮化铝/环氧树脂复合材料的导热与电性能[J]. 复合材料学报, 2023, 40(6):3341-3349. DOI: 10.13801/j.cnki.fhclxb.20220905.002 WANG Xubin, ZHANG Changhai, ZHANG Tiandong, et al. Thermal conductivity and electrical properties of three-dimensional porous aluminum nitride/epoxy composites[J]. Acta Materiae Compositae Sinica,2023,40(6):3341-3349(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20220905.002

[29] HU J T, HUANG Y, YAO Y M, et al. Polymer composite with improved thermal conductivity by constructing a hierarchically ordered three-dimensional interconnected network of BN[J]. ACS Applied Materials and Interfaces,2017,9(15):13544-13553. DOI: 10.1021/acsami.7b02410

[30] AGARI Y, UNO T. Estimation on thermal conductivities of filled polymers[J]. Journal of Applied Polymer Science,1986,32(7):5705-5712. DOI: 10.1002/app.1986.070320702

-

目的

现代电气电子设备的主要发展趋势是大功率、小体积及高密化,从而导致设备在有限的体积内产生了更多的热量。为了满足设备及时高效的散热需求,高导热绝缘聚合物材料的研发与应用引起了极大关注。根据制备技术,可分为本征型和填充型两类。其中,填充型导热绝缘聚合物材料加工成型方便、易于工业化生产,是目前制备高导热绝缘聚合物材料的主要方法。然而,与填料的本征导热性能相比,复合材料导热系数的提高十分有限。这主要是由于高导热填料被聚合物基体所包围,难以形成有效的导热通路。在聚合物基体中构建由高导热填料相互连接而成的导热通路是提高复合材料导热性能的有效策略。

方法采用共还原法,在AlO微球表面沉积低熔点纳米锡铋合金颗粒(SnBi),制备AlO-SnBi杂化材料,用于环氧树脂的导热绝缘填料。当环氧树脂受热固化时,填料表面SnBi颗粒熔融,将填料相互连接而形成有效的导热通路,提高复合材料导热率。同时,由于SnBi被绝缘性AlO及树脂基体隔离,AlO-SnBi/环氧树脂复合材料仍具有电绝缘性能。采用Fogyel及Agari模型分析了AlO/环氧树脂及AlO-SnBi/环氧树脂复合材料的填料间接触热阻及填料相互连接形成导热链的难易程度。

结果当填料体积含量()较低时,随增加,复合材料导热系数的增加非常缓慢。这是由于当较低时,填料呈“孤岛”状分布在基体中,相互之间基本无接触,不能形成导热通路。当增加到某一程度,填料间相互接触的概率增加,导热通路亦开始形成,这时随增加,材料导热系数明显增加。该值即为填料的临界体积含量()。在相等条件下,AlOSnBi/环氧树脂复合材料的导热系数明显大于AlO/环氧树脂复合材料的导热系数。当=60%时,AlO-SnBi/环氧树脂复合材料的导热系数为2.95 W·(m·K),比AlO/环氧树脂复合材料的导热系数(1.82 W·(m·K))提高了62.1%。Fogyel模型分析表明,AlO-SnBi/环氧树脂和AlO/环氧树脂复合材料的值分别为18.25%和19.23%,AlO-SnBi/环氧树脂复合材料的填料间接触热阻()为 8.35×10 K·W,明显小于AlO/环氧树脂复合材料的1.17×10 K·W。Agari模型分析表明,AlO-SnBi/环氧树脂复合材料的(填料形成导热链难易程度的因子,值越大,表示填料越容易相互聚集形成导热通路)为1.1465,大于AlO-SnBi/环氧树脂复合材料的=0.8991。随增加,AlO/环氧树脂复合材料的拉伸断裂强度及拉伸断裂伸长率下降,而AlO-SnBi/环氧树脂复合材料的拉伸断裂强度及拉伸断裂伸长率提高。与AlO/环氧树脂复合材料相比,AlO-SnBi/环氧树脂复合材料的介质损耗增加,介电强度和体积电阻率下降。当=60%时,AlO-SnBi/环氧树脂复合材料的体积电阻率为10 Ω•m,低于AlO/环氧树脂复合材料的体积电阻率(10 Ω•m),但仍具有电绝缘性能。

结论采用共还原法,制备了AlO-SnBi杂化填料。当填料体积含量为60%时,AlO-SnBi/环氧树脂复合材料的导热系数为2.95 W·(m·K),比AlO/环氧树脂复合材料的导热系数(1.82 W·(m·K))提高了62.1%。Fogyel及Agari模型分析表明,表面沉积SnBi有利于降低填料间接触热阻,形成导热通路。与AlO/环氧树脂复合材料相比,AlO-SnBi/环氧树脂复合材料的拉伸断裂强度提高、介质损耗增加、介电强度及体积电阻率降低,但仍具有电绝缘性能。

-

随着现代电气电子设备趋于向大功率、小体积、轻量化,以及高密高频、集成化、微型化方向发展,热管理问题已经成为制约设备性能和可靠性提高的主要技术瓶颈之一,需研制高导热绝缘封装材料解决结构散热问题。常规填充型导热绝缘材料,填料之间接触热阻大,不易相互连接形成有效的导热通路,导热性能提高十分有限。

本文采用共还原法,在氧化铝(Al2O3)表面沉积低熔点纳米锡铋合金颗粒(Sn57Bi43),制备杂化材料(Al2O3-Sn57Bi43),用于环氧树脂的导热绝缘填料。当环氧树脂受热固化时,杂化材料表面Sn57Bi43熔融,将填料相互连接而形成导热通路,提高复合体系导热性能。当填料体积含量为60%时,Al2O3-Sn57Bi43/环氧树脂复合材料的导热系数为2.95 W·(m·K)-1,比Al2O3/环氧树脂复合材料的导热系数(1.82 W·(m·K)-1)提高了62.1%。Fogyel及Agari模型分析表明,Al2O3表面沉积Sn57Bi43有利于降低填料间接触热阻,形成导热通路。与Al2O3/环氧树脂复合材料相比,Al2O3-Sn57Bi43/环氧树脂复合材料的介质损耗增加,介电强度及体积电阻率降低,但仍具有电绝缘性能。由于填料-基体间界面性能改善,以及Al2O3-Sn57Bi43形成的网链结构能起到传递应力,阻止裂纹扩张的作用,Al2O3-Sn57Bi43/环氧树脂复合材料的拉伸断裂强度提高。

Al2O3-Sn57Bi43杂化材料及Al2O3-Sn57Bi43/环氧树脂复合材料的制备过程示意图

下载:

下载: